- 1University of Life Sciences in Lublin, Lublin, Poland

- 2Department of Machinery Exploitation and Management of Production Processes, University of Life Sciences in Lublin, Lublin, Poland

This literature review examines the problems associated with ash deposition and deposit formation in low-power heating devices and identifies possible solutions. The combustion of herbaceous biomass, especially that from waste from the agri-food industry, causes a large increase in the amount of mineral deposits in heating devices at a low melting point of the compounds they are composed of (particularly due to the presence of potassium (K), sodium (Na), and sulfur (S) compounds). They affect not only the formation of deposits and sediments but also the emission of fly ash, its handling, and the possibilities for its use and disposal. Problems related to ash depend on the content of alkaline oxides, which vary in proportion across different types of biomass. A dominant percentage of silicon dioxide (SiO2) is characteristic of ash from grass, rice husks, miscanthus, and straw pellets. Grass ash also contains a significant amount of potassium oxide (K2O), while ash from poplar wood, willow, and soy pellets is notable for its high calcium oxide (CaO) content. The deposition of ash volatiles and aerosols on boiler surfaces reduces heat exchange efficiency. The solution to the ash problems during combustion is the use of mineral additives, with kaolin being the most promising because of its very good ability to capture problematic alkali-containing compounds during combustion and convert them into potassium aluminium silicates with a high melting point. In addition, kaolin exhibits certain catalytic properties and can act as a carrier for active catalytic components that can be used in the processes of reducing nitrogen oxides (NOx) and particulate matter (PM). Natural carrier materials, such as kaolin clays, are of considerable practical importance as acidic catalysts. Methods for measuring the surface acidity of solids - including Brønsted and Lewis acid centres - which play a key role in catalysis are therefore of significant interest. The introduction of such additives increases the heating efficiency of the plant and at the same time reduces carbon monoxide (CO) and NOx emissions (which is inconsistently confirmed in the literature).

1 Introduction

Biomass as an energy source contributes to reducing dependence on imported fossil fuels (coal, gas), while at the same time bringing benefits to countries where biomass fuels are an emerging source of renewable energy. Understanding the combustion behaviour of fuels is essential for the efficient and safe design and operation of equipment. Similarly, understanding the mineral content is crucial, as it significantly impacts the dynamics of the power generation system. The energetic use of biomass has many benefits, including social, economic and energy security. The considerable diversity of plant species useful in the energy sector is associated with a large diversity in terms of physical properties (hardness, specific gravity, moisture, porosity) and chemical composition of the raw materials obtained from them. This has a significant impact on the calorific value of the biomass but also on the combustion process and the condition of the heating equipment in which it is carried out. Although biomass is environmentally friendly, its use can create many problems that can lead to a sudden interruption of boiler operation, for example, as a result of the complex process of ash deposition on the convection surfaces of heat exchange. This process occurs in a wide range of flue gas temperatures, surfaces and depends on the properties of the ash as well as the design and operating conditions of the boiler. Problems associated with the presence of ash in biomass combustion systems (such as grate boilers and drop-in or retort burners) are linked to the formation of agglomerates from partially molten ash at high temperatures, as well as the deposition of ash in low-temperature zones of the boiler’s heat exchange surfaces, particularly in convective sections. These phenomena contribute to accelerated metal corrosion, increased emissions, and complications in the utilization and disposal of ash waste from such biomass-fired systems. Some negative effects of increased ash deposition as a result of biomass combustion on the efficiency and operation of the combustion system can be presented as follows:

1. Decrease in boiler efficiency. Increased ash deposition, along with changes in the properties of ash deposits containing low-melting compounds [K, Na, S, and calcium (Ca)], leads to the formation of a coating on the particles of bottom ash. This coating is partially molten, which at a later stage results in the sticking and adhesion of particles, ultimately leading to ash agglomeration in the combustion chamber. In addition, the deposition of melted or partially melted ash deposits on the heat exchange surfaces slows down the heat exchange in the boiler, which is manifested by a decrease in the thermal efficiency of the combustion chamber and its performance.

2. Boiler damage. The process of deposit formation may occur to such an extent that the flow of flue gases may be restricted. This may lead to mechanical damage to boiler components, which is also associated with the formation of corrosion. The accumulation and subsequent shedding of large ash deposits in the upper parts of the boiler and the surfaces of the steam pipes may restrict the flow of gas, causing damage to the combustion system components.

3. Maintenance problems. Very large deposits would require premature shutdown for maintenance. To remove ash deposits, shutdowns (often unplanned) are required to clean the accumulated deposits.

4. Furthermore, the accumulation of ash deposits on the heat exchange surfaces also leads to an increase in the temperature of the boiler exhaust gases, which results in a decrease in the efficiency of the combustion device and an increase in CO and NOx emissions.

Thanks to the knowledge of the chemical composition and physical properties of ash, it is possible to predict the tendency to form deposits on boiler elements and their potential for corrosion, erosion or abrasion. The behavior of ash in the system depends to a large extent on the fuel used. To achieve a stable energy generation system, it is essential to thoroughly understand the requirements of the fuel used in order to adapt the combustion technology — especially when it comes to biomass derived from industrial waste or energy crops, which due to their chemical composition exhibit different behavior during combustion than other types of biomass (Nunes et al., 2016; Wei et al., 2022).

The aim of this study is therefore to analyze and synthesize information related to the quantity and chemical composition of ash from various types of herbaceous biomass, as well as to examine the issues associated with deposit formation and ash deposition in heating systems that burn such biomass, based on the current state of knowledge in the relevant literature. These issues are related not only to the sintering and slagging of bottom ash, but also to the chemical composition of solid biofuels, which is of great importance in the case of using various types of biomass. This study may help to systematize knowledge regarding the impact of ash on the combustion process and emissions in heating systems, while also indicating solutions aimed at minimizing problems related to bed agglomeration and fouling of heat exchangers in heating equipment.

2 Characteristics of the chemical composition of ash

Ash is a solid residue resulting from the complete oxidation of fuel. It is formed from inorganic (mineral) components during combustion. Inorganic material contained in biomass can be divided into two fractions: by-products that are added to fuels during its processing (sand or clay from harvesting, storage) and inherent material that acts as nutrients fulfilling basic biological functions for plants and is more finely distributed in the fuel (atomically dispersed). The elements that make up ash include: aluminum (Al), Ca, iron (Fe), K, magnesium (Mg), Na, phosphorus (P), silicon (Si), copper (Cu). In the literature on the subject, the components of ash have been divided into macroelements: Ca, K, Si, Mg, P, Na, S and microelements: Al, Fe, manganese (Mn), lithium (Li), barium (Ba), boron (Br). These elements in ash occur in the form of oxide compounds: SiO2, aluminum oxide (Al2O3), iron oxide (Fe2O3), manganese oxide (Mn3O4), titanium oxide (TiO2), CaO, magnesium oxide (MgO), sulfur trioxide (SO3), phosphorus pentoxide (P2O5), sodium oxide (Na2O), K2O. Basic compounds of ash include: CaO, MgO, K2O, Na2O and Fe2O3. Examples of acidic components of ash are: SiO2, Al2O3, hydrochloric acid (HCl), S, sulfur suboxide (S2O), P2O5 and TiO2. When the acidic and basic components of ash react, a salt or mineral is formed. The chemical composition of ash is most commonly expressed as the percentage content of these oxides. The content of ash-forming elements in biomass fuels varies greatly depending on the fuel and its type. The presence and percentages of the above-mentioned oxides and elements in the ash are important in terms of their behavior in the combustion process of the biofuel in which they occur in the ash, which results in an impact on the operation of heating devices and pollutant emissions (Lokare, 2008; Odzijewicz et al., 2023; Tortosa-Masiá, 2010). In ash, we distinguish eutectic compounds, which are a mixture of two or more salts that together have a lower melting point than the compounds themselves. The molten alkali salt (KCl, potassium sulfate (K2SO4) is deposited on the heat exchanger surface and can transfer the metal oxide to the salt. They are characterized by the eutectic number, which quantitatively expresses how the alkali metals and alkaline earth metals present are related to each other (Stauber-Alfredsson, 2018). In the characterization of ash, it is also important that the alkali metals (responsible for the emission of fine particles) or alkaline earth metals (responsible for the increase in the melting temperature of the ash) (AAEMs-Alkali and Alkaline Earth Metals) form zeolites. This is a group of hydrated aluminosilicates of alkali or alkaline earth metals (mainly Na, K, Mg and Ca) with pores of uniform diameter, regular internal cavities and channels of discrete sizes and shapes. The Ca and Mg group is the strongest in bottom ash, constituting more than 50% in all fractions and fuels. Alkali metal and alkaline earth metal species (AAEMs) are the main components of biomass ash and can positively influence biomass combustion by acting as a catalyst. On the other hand, high concentrations of ash and alkali metals (K, Na, Ca, magnesium (Mg), etc.) in biomass cause ash-related problems through condensation and reactions, such as slagging (mainly related to alkali chlorides and sulfates), agglomeration (mainly dependent on the chemical and melting properties of the coating, which are sensitive to the relative amount of calcium and potassium in the fuel), corrosion (mainly related to flue gases containing chlorine (Cl2), HCl, NaCl (aerosol), KCl (aerosol) and other species that accelerate the oxidation of metal alloys) and contamination. Alkali metals such as K and Na together with Cl are the most important elements in biomass ash that affect undesirable processes. During fuel combustion, reactive compounds evaporate and alkali metals can form aerosols (potassium hydroxide (KOH), KCl, K2SO4, NaCl, sodium sulfate (Na2SO4) in the gas phase. Alkali metal aerosols can react with each other or other ash components (SiO2, Fe2O3) to form eutectic mixtures. Alkali metals can also occur in the solid phase in the form of silicates (potassium silicate (K2Si2O5), sodium metasilicate (Na2SiO3) and aluminosilicates (potassium aluminum silicate (KAISi3O8), nepheline (KAISiO4), albite (NaSi3AlO8) (Yu et al., 2021; Zhang et al., 2018; Royo R. et al., 2022; Jiao et al., 2023; Oladejo et al., 2020; Mlonka-Mędrala et al., 2020).

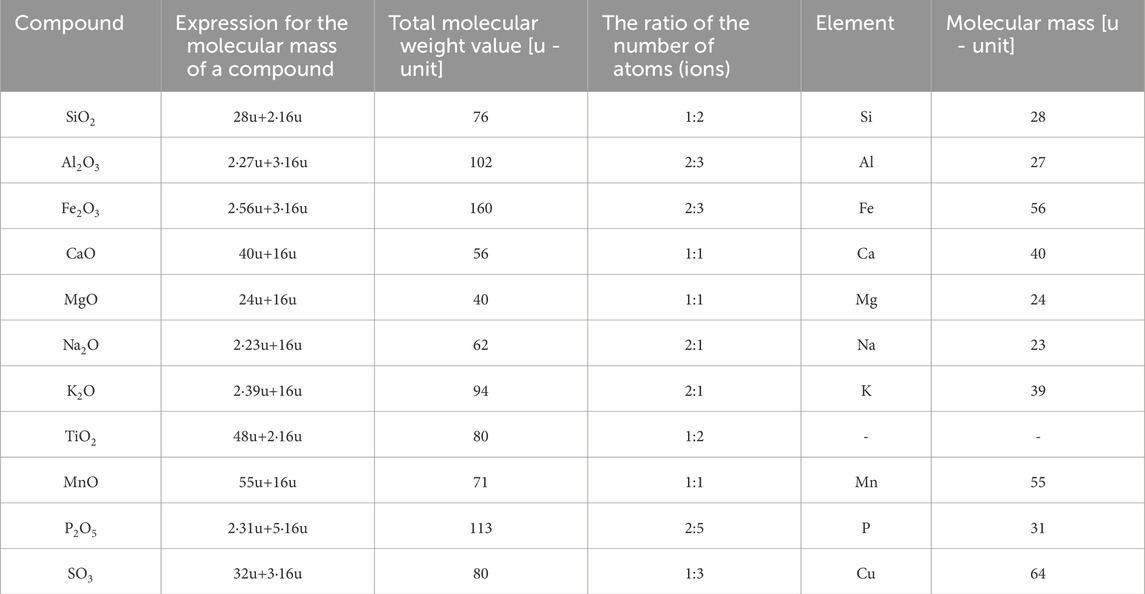

Ashes resulting from biomass combustion are classified into bottom ash and fly ash. Bottom ash captures evaporated potassium, which combines with silica present in the bed material, causing its agglomeration. Agglomeration occurs when ash particles form layers around the bed material particles (mainly quartz sand, which consists of silica, potassium and calcium). It occurs as a result of chemical reactions, the presence of a liquid phase and sintering in the solid state. Fly ash from biomass combustion, on the other hand, is very diverse in terms of chemical composition and the type of material from which it was obtained. In addition, the formation of SO3 also depends on its chemical composition. During combustion, inorganic compounds of biomass undergo chemical and physical changes. Volatile compounds (K and Na are volatile elements but Cl, carbon dioxide (CO2) and S are considered to be particularly volatile) are released into the gas phase (released ash is formed) while non-volatile (Al, Ca, Fe, Mg and Si) ash particles (these are usually large ash particles) remain on the furnace grate forming bottom ash or forming a coarse fraction of fly ash (Laxminarayan, 2018; Kowalczyk-Juśko, 2017). Elements contained in ash can also cause problems during combustion in the boiler. Despite the fact that the ash content in biomass is much lower than in coal, their different origins and differences in chemical composition affect the operation of heating devices causing increased slag and ash deposition in the furnace or increased wear of metal boiler elements due to corrosion. Therefore, it is a very important issue to assess the content of individual mineral components in the ashes resulting from the combustion of biomass (Zając et al., 2018). The characteristics of chemical compounds present in the ash are presented in Table 1.

Table 1. Molecular weights of chemical compounds/elements present in biomass ash [Source: own study: Lide (2005)].

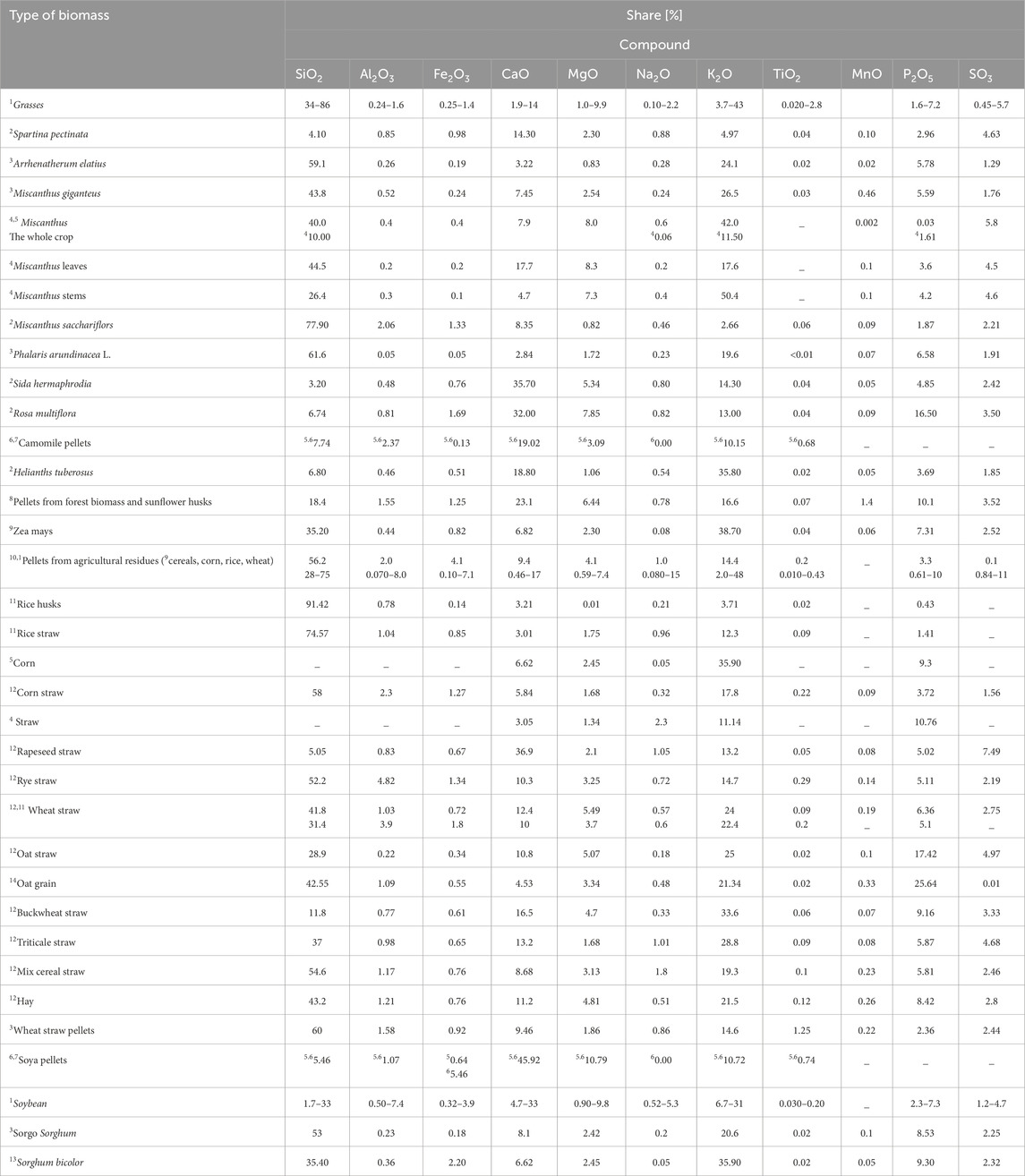

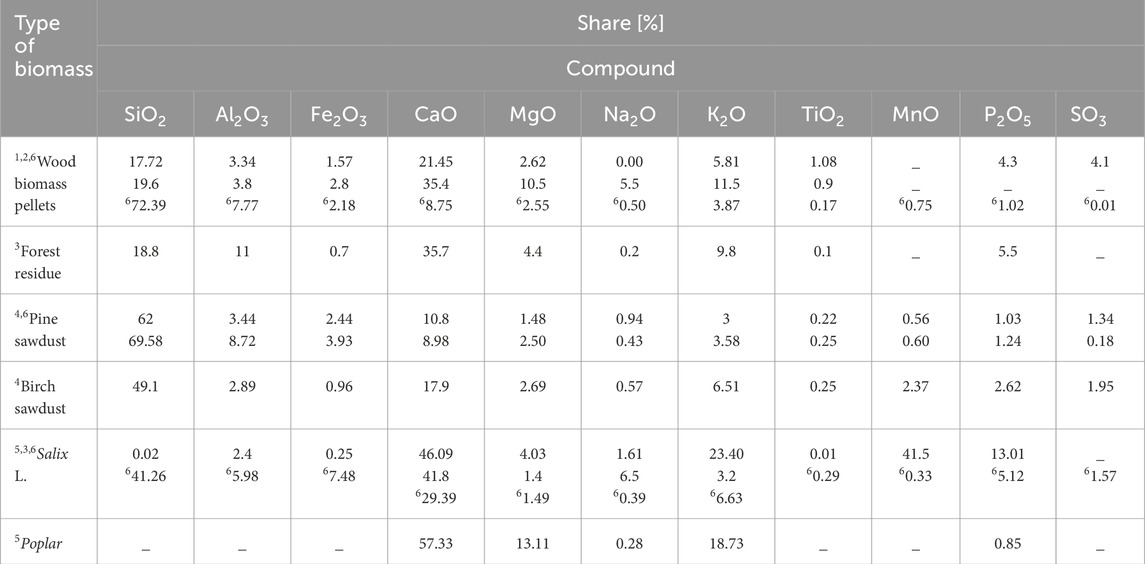

The sum of basic oxides is an important parameter for ash assessment. Based on the literature review, Tables 2, 3 present the % share of chemical compounds for different types of biomass.

Table 2. % share of chemical compounds in herbaceous biomass [Source: own study: 1Zhai et al. (2021); 2Kowalczyk-Juśko (2009); 3Lalak et al. (2016); 4Baxter et al. (2014); 5Odzijewicz et al. (2023); 6Gvero et al. (2020); 7Botić et al. (2022); 8Kalisz et al. (2015); 9Kowalczyk-Juśko et al. (2015a); 10Sato et al. (2022); 11Dyjakon (2012); 12Kraszkiewicz et al. (2017); 13Kowalczyk-Juśko et al. (2015b); 14Kalisz (2023)].

Table 3. % share of chemical compounds in wood biomass [Source: own study: 1Botić et al. (2022); 2Sato et al. (2022); 3Dyjakon (2012); 4Kraszkiewicz et al. (2017); 5Odzijewicz et al. (2023), 6Kalisz (2023)].

Based on the data presented in Tables 2, 3, it can be concluded that the chemical composition of biomass ash varies significantly. The composition of grass ash has the highest content of SiO2 (34%–86%) and K2O (50.4%) with moderate amounts of CaO (1.9%–17.7%) and P2O5 (0.03%–7.2%) and small amounts (<8%) of other elements. Rice husk ash has a similar content of SiO2 (91.42%) and rice straw (74.57%) to grass ash but a lower content of K2O (3.71%) and other chemical compounds. In addition, the lowest content of K2O is shown by miscanthus (2.66%), pine sawdust (3%) and woody biomass pellets (3.87%).

Willow, Virginia mallow, rapeseed straw, soybean pellets, multiflora rose, chamomile pellets contain much less SiO2 (respectively: 0.02%, 3.20%, 5.05%, 5.46%, 6.74%, 7.74%) than grasses, rice husks (91.42%), rice straw (74.57%), wheat straw pellets (60%) and agricultural residue pellets (28%–75%), but more CaO (45.92% - soybean pellets). However, the highest CaO content is found in poplar (57.33%) and willow (46.09%).

The intense internal reactions occurring in biomass ash at elevated temperatures generate a large amount of eutectic compounds, which significantly reduce the melting point of the ash resulting in an increased possibility of ash particles adhering from the gas flow. Additionally, ash formed from herbaceous biomass sinters at low temperatures (below 850 °C) and causes the formation of slags. Hence, wood-based products are the most commonly used biomass fuels, containing up to 40% less ash compared to other agricultural biomass raw materials, e.g., straw (Laxminarayan, 2018; Li et al., 2023; Generowicz et al., 2023; Rodriguez et al., 2020; Repić et al., 2019; Ion et al., 2023; Zapata et al., 2023; Dyjakon, 2012; Vaniyambadi, 2015; Yongtie et al., 2018; Zeng et al., 2018; Odzijewicz et al., 2023; Nzihou and Stanmore, 2013; Royo J. et al., 2022; Sarbassov et al., 2017; Schulze et al., 2020; Laxminarayan et al., 2017; Meka et al., 2022; Lalak et al., 2016; Xu et al., 2021; Thomas et al., 2018; Tesfaye et al., 2022; Niu et al., 2016; Zhai et al., 2021). The PN-EN ISO 21404:2020–08 standard (update of the CEN/TS 15370-1:2006 standard) is a document presenting a method for determining characteristic temperatures during the melting of complex inorganic components of solid biofuel ash at high temperatures. The characteristic temperatures defined in this standard are used to compare the tendency of ashes of different types and qualities of solid biofuels to form molten deposits or in assessing the susceptibility of the bed to agglomeration during heating (Stałe, 2025).

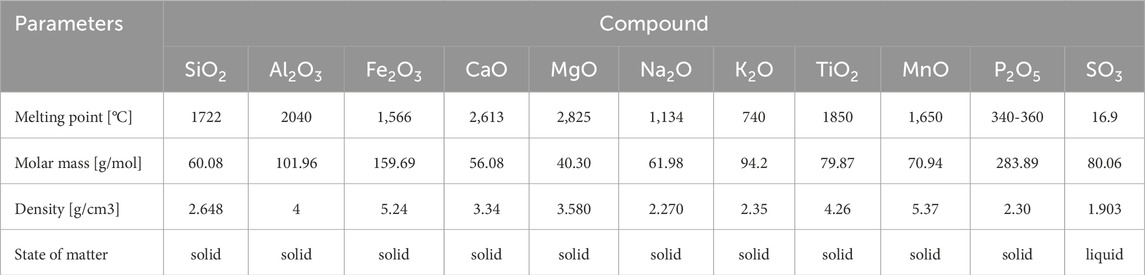

The composition of ash affects its softening and melting temperatures. The melting characteristics of the ash (Table 4) are an important factor in determining the propensity of fuels to form molten or partially melted slag deposits on the furnace wall surfaces of all combustion systems and can influence the nature of fouling deposits that occur on heat exchangers and other surfaces of biomass-fired boilers. The melting of most fuel ashes is a complex phenomenon that is best described by a melting curve, which shows the mass percentage of molten ash as a function of temperature. Two temperatures are considered in the ash melting curves and are used to describe the behavior of the ash:

- T15 temperature, at which 15% of the ash material melts. This is the temperature at which the surfaces of the particles or slag deposits begin to become sticky and susceptible to incoming particles,

- T70 temperature, at which 70% of the ash melts. This is the level from which the outer surface of the ash deposit on the vertical boiler tube will begin to flow.

Table 4. Selected characteristics of ash components [Source: own study: Lide (2005)].

There are a number of complex thermodynamic models that can accurately predict the ash melting curve of a given fuel. For coal combustion, slagging and fouling indices have been developed to obtain and indicate the propensity of fuel ash to form deposits during combustion based on its chemical composition. When biomass is co-fired with coal, all the components of most biomass ash, mainly alkali metals and alkaline earth metals, are strong fluxing agents for aluminosilicate systems. The introduction of biomass can result in a lower melting point and therefore an increased slagging potential (Loo and Koppejan, 2008).

One of the very important parameters during each biomass combustion process is the temperature at which ash shrinkage (sintering) begins. This is the temperature at which ash shrinks, i.e., the temperature at which ash begins to show a tendency to slagging. The ash sintering temperature for different types of biomass varies as follows: wheat straw 840 °C, rapeseed straw 640 °C, sunflower husk pellets 810 °C, rye straw 730 °C, oat straw 770 °C, mustard straw 630 °C, corn straw 650 °C, hemp straw 640 °C, sorghum stalks 760 °C, tobacco stalks 570 °C (Zhu et al., 2014; Cichy, 2013; Chen et al., 2022).

The alkali content of biomass creates potential problems related to bed agglomeration as well as fouling and corrosion of heat exchangers. An example is herbaceous fuels, which contain silicon and potassium, the main components in fly ash formation. Compared to other biomass fuels, they are also rich in chlorine (Cl). These properties create problems with ash deposition and formation at high or moderate combustion temperatures. The main sources of these problems are:

1. Reaction of alkali with silica to form alkali silicates, which melt or soften at low temperatures (below 700 °C) depending on composition.

2. Reaction of alkali with sulfur to form alkali metal sulfates on the heat exchange surfaces of the combustion chamber.

The sintering and softening temperatures can differ significantly for the same type of herbaceous biomass, depending on the chemical composition of the ash, which is related to the plant species, cultivation method and soil type. Characteristic ash softening temperatures for some types of biomass are: rye straw 1,002 °C, wheat straw 998 °C, barley straw 980 °C. Alkaline material plays a major role in both processes. The mobility of the alkali material is defined as its ability to contact other materials and is measured using chemical extraction techniques. The presence of alkali metals and alkaline earth metals (AAEMs) in biomass has been found to have a significant effect on ash deposition, sintering, agglomeration, contamination, slagging and corrosion (Gogolev et al., 2021; Biedermann and Obernberger, 2005; Xu et al., 2020; Vassiliev et al., 2013a; Vassiliev et al., 2013b; Wang et al., 2020; Garba et al., 2012; Horvat and Dović, 2018; Hartmann et al., 2013; Baxter et al., 1998; Oladejo et al., 2020; Nzihou and Stanmore, 2013). Herbaceous biomass (straw, nut husks, fruit pits, grasses) causes more problems during combustion than wood. Compounds such as potassium, sodium, whether in the form of oxides, hydroxides or organometallic compounds, tend to lower the melting point of ash mixtures containing various minerals such as SiO2. Also, high chlorine content in the fuel increases the release of potassium in the gas phase at relatively low temperatures. This causes serious problems related to slagging, contamination and agglomeration of the bed in the boiler, which can lead to switching off the heating device (Dyjakon, 2012). In connection with the above, the chemical composition of the fuel affects the rate of ash deposition from biomass fuels. It was also found that the process of deposit formation from herbaceous grass or miscanthus is about six times faster than from wood. Woody biomass is rich in Ca, Si and K compounds. Determining the melting behavior and release to the gas phase of biomass fuel ash is of great importance, therefore it is important to study herbaceous biomass fuels in order to characterize the ash composition. From the point of view of biomass combustion, a high content of K and Ca is unfavorable, because they easily react with other elements (e.g., Si) to form alkalis with very low melting points (approx. 700 °C). In turn, an increased content of K can increase the slagging potential. In contrast, ashes with lower alkali and higher Ca content exhibit easier to manage slagging and contamination problems.

3 Ash in the operation of heating devices

During the operation of heating devices, the main problem is their contamination with ash during the process in which a deposit forms on the colder areas of the device as a result of the condensation of particles transferred from warmer to colder areas. Fouling means the process of deposit formation on convective heat exchange surfaces. The formation of large ash deposits is caused by a relatively large amount of compounds containing alkalis such as KCl and K2SO4 and the low melting point of many ash components. These deposits reduce the overall heat transfer coefficient, which leads to corrosion of metal surfaces. Additionally, the behavior of ash in the combustion chamber and furnace is problematic, as it forms slag and sinter due to the effects of high temperaturę. The mechanism of slag formation consists in the melting of ash, agglomeration of ash particles (also with fuel) and sintering. Slagging is a process during which deposits form on the heat exchange surfaces of the boiler and the refractory material as a result of adhesion of viscous particles. Slag deposits consist of an inner powder layer containing silicates and alkali compounds (Repić et al., 2019; Blondeau, 2013; Rodriguez et al., 2020; Ion et al., 2023; Wnorowska et al., 2020; Vega-Nieva et al., 2015).

Slagging is a very complex phenomenon, which is not only a physical and chemical reaction but also a serious problem in the use of biomass, which affects the operation of biomass combustion devices. Slagging and deposition reduce the efficiency of biomass combustion, which can lead to damage to the boiler, reducing its output, resulting in repair costs and, above all, difficulties in the daily use of biomass fuels (Yongtie et al., 2017; Rodríguez et al., 2021; Kowalczyk-Juśko, 2017). The parameter that determines the ability of ash to slagging is the content of iron oxides. The viscosity of particles is a key parameter in the case of ashes rich in silicates. High iron content causes a decrease in ash viscosity, which is manifested by a greater tendency to form deposits. Ashes with a Fe203 content of <6% are considered to be low-slagging (Kalisz et al., 2015; Kleinhans et al., 2018; Wu et al., 2018). Slag deposits on the boiler or furnace wall are formed as a result of the action of fine ash particles containing K and Cl. Chlorine promotes the release of potassium in the biomass, causing the formation of troublesome KCl, which condenses on the heating surfaces of the boiler. Problems with ash deposition depend on the presence of elements such as Na, K, Cl and Si and Al.

Potassium present in biomass as a result of oxidation processes during combustion leads to the formation of impermeable deposits on the surface of heating devices as well as agglomeration and corrosion (Deng et al., 2019; Miccio et al., 2019; Niu et al., 2016; Wang et al., 2018c). The more alkali metals and chlorides present in biomass, the lower the ash melting temperature and therefore the greater the tendency to form slag. The formation of slag in the furnace limits the access of air to the fuel, resulting in a decrease in temperature and an increase in the concentration of carbon monoxide in the exhaust gases. It is therefore necessary to ensure that the temperature in the furnace and combustion chamber in the case of grate furnaces exceeds 650 °C when burning agricultural biomass and, at the same time, is below the ash sintering temperature in the case of retort and horizontal-feed boilers or the ash softening temperature (in the case of heating appliances with a moving grate) (Pałaszyńska and Juszczak, 2018; Arvelakis et al., 2001; Livingston, 2016). Soluble potassium, which occurs in ionic form, is released during combustion as KOH, KCl and other forms, as a result of which it is easily available for further reaction with other flue gas compounds (Niu et al., 2016; Xu et al., 2021). According to Wang L. et al. (2012) and Kassman (2012), the main components of particulate matter present in the generated flue gases are potassium chloride (KCl) and potassium sulfate (K2SO4), whose melting points are 750 °C and 850 °C. Systems consisting of KCl and K2SO4 salts can melt at a low temperature of 550 °C or even lower (Lindberg et al., 2013; Funcia et al., 2020). Potassium and chlorine are the main components causing undesirable deposits and corrosion of superheater tubes in boilers fired with solid fuels (Ǻmand et al., 2006).

During co-combustion, leaching or the use of additives, an increase in the K + Cl and Si + Al ratio in the fuel can lead to an increase in the KCl concentration, which will manifest itself in greater slag formation. On the other hand, a decrease in the K + Cl and Si + Al ratio will lead to the capture of K by Si and Al, which will result in less slagging during combustion (Baxter et al., 1998; Kassman et al., 2013; Zhu et al., 2014). Ash deposition on the heating surface takes place as a result of four mechanisms: inertial collision, condensation of evaporated inorganic compounds, thermophoresis and chemical reactions (Veijonen et al., 2003; Hernik and Wnorowska, 2022; Jensen et al., 2019; Garba et al., 2012; Yongtie et al., 2018; Shao et al., 2012; Jensen et al., 2016; Stam, 2020; Yang et al., 2017; Livingston, 2016; Laxminarayan, 2018; Vaniyambadi, 2015).

In the initial stage of deposition, submicron ash particles are transferred to the cool surface under the influence of gas temperature, regardless of inertial impact. This process is known as thermophoresis. As a result of combustion, chemical reactions such as chlorination, oxidation and sulphation occur between solid and gaseous compounds and the deposition layer. An example is silica, which reacts with volatile alkali metal, i.e., potassium, to form low-melting compounds causing slagging and fouling at normal biomass boiler temperature (800 °C–900 °C). The produced alkali silicates or calcium chlorides tend to deposit on the boiler wall causing fouling or corrosion at low melting temperature 700 °C–750 °C (Veijonen et al., 2003; Baxter et al., 1998; Kleinhans et al., 2018; Shao et al., 2012; Funcia et al., 2020).

The main operational problem of biomass-fired boilers is the deposition of fly ash on the boiler surface. Alkalis, chlorine and silicates are the main fractions of ash deposits regardless of the type of fuel. Fouling and slagging are complex phenomena dependent on:

- Transformation of inorganic ash components in fuels,

- Chemical reactions between gas, liquid and solid phases in suspension and on surfaces,

- Reaction kinetics and species transport rates,

- Attachment of ash particles to surfaces and release of deposited liquids and solids.

The removal of deposits can occur by several mechanisms, namely,:

- Erosion,

- Detachment,

- Flow of molten slag,

- Thermal and mechanical stress in the deposits.

Erosion occurs when sharp-edged fly ash particles collide with unfused deposits, resulting in the removal of deposits by spalling or repeated deformation. Two main mechanisms are distinguished: brittle erosion and plastic erosion. The equivalence of both sub-mechanisms depends on the material properties of the particle and the wall material, the angle of impact, and the kinetic energy of the particle (Schulze et al., 2020; Stauber Alfredsson 2018; Livingston, 2016; Laxminarayan, 2018).

Debonding occurs when the stress generated (e.g., due to soot blowing or the weight of the deposit) exceeds the adhesion force at the interface of the depositing tube, causing the deposit to be removed from the tube surface. If the temperature of the outer layer of the bed is high enough to form low-viscosity slags, molten phases can flow out of the bed. Thermal shocks caused by temperature changes in the boiler can cause deposits to form due to differences in the thermal expansion coefficients of the tube, the corrosion layer, and the deposit (Laxminarayan, 2018).

It was also found that biomass with herbaceous raw materials causes increased agglomeration due to the high content of alkaline compounds. In turn, a small share of biomass in fuel ash (coal) has a significant effect on the microstructure and chemical composition of the sediments, increasing the rate at which the sediments consolidate and strengthen with increasing temperature. Alkali metals contained in biomass, i.e., K, which reacts with other ash-forming elements, while chlorine forms compounds containing alkalis, KCl causing problems related to fouling and slagging, corrosion and agglomeration on the superheater or boilers (Guo et al., 2020; Miccio et al., 2019; Shao et al., 2012; Loo and Koppejan, 2008; Kassman, 2012; Tortosa Masiá, 2010; Balint et al., 2024; Niu et al., 2016; Oladejo et al., 2020), which hinder heat transfer and thus reduce the thermal efficiency of the boiler (Guo et al., 2020; Mlonka-Mędrala et al., 2020). Excess alkali in biomass-based fuels can be released into KOH. The presence of KOH on heat exchange surfaces can be an important factor in the corrosion mechanisms of biomass combustion devices (Berlanga and Ruiz, 2013).

The influence of boiler design, operating conditions and fuel properties on ash deposit behaviour is seen by emphasizing or limiting the role of one or more of these mechanisms, thereby changing the composition, phase and properties of the deposit. Surfaces exposed to particle impact can accumulate both silica and alkali silicates at a very rapid rate. In contrast, surfaces exposed to flue gases and less to particle impact show signs of deposit accumulation, vapour condensation and sulphation of condensed vapours containing alkali. These processes lead to the formation of deposits with different properties, high reflectivity, low thickness and growth rate. Fuels containing little alkali or silica show less growth of deposits.

Studies of deposits on the heating surface of biomass boilers are most often carried out by analyzing mature deposits collected during boiler maintenance. The composition of the deposits varies depending on the distance from the boiler superheater surface. The innermost layer of deposits usually contains iron oxide, KCl and K2SO4. The intermediate layer contains molten KCl and other ash particles. In some deposits, a reaction between KCl and captured ash particles can occur, leading to the release of chlorine-containing gases. However, it is difficult to study the dynamic deposition process in detail by analyzing mature deposits (Zhang et al., 2020; Sandy Sharp, 2010).

The chemistry of inorganic transformations in boilers is quite complex and involves many physicochemical pathways between alkalis, alkaline earth and other inorganic and organic compounds in the fuel. Inorganic substances derived from biomass fuels are deposited in various forms on the boiler surface (Veijonen et al., 2003; Shao et al., 2012; Capablo, 2016; Repić et al., 2019; Rabaçal and Costa, 2015).

Studies indicate that the major release of alkaline material occurs as a result of combustion during the charring phase. The original form of the alkaline waste gases corresponds to thermodynamic estimates of product stability and vapor pressure. Deposits enriched in potassium, sulfur, and chlorine indicate that condensation and chemical reaction mechanisms play a significant role in deposit formation. The condensation mechanism enriches the deposit with condensable vapors such as chlorides. The chemical reaction mechanism converts alkali and alkaline earth metals to sulfates. Both mechanisms are dependent on the mass transfer rate. Differences between the boiler wall and convection channel deposits are evident and indicate different mechanisms responsible for ash deposition in different areas of the boiler.

4 Slagging and pollution indicators

In the literature on the subject, slagging and contamination indicators have been defined to determine the risk of deposits and agglomeration of biomass ash during combustion and co-combustion of biofuel in a boiler.

One of the most popular indices used as an indicator of the tendency for fuel ash contamination is the ratio of base to acid B/A to acid oxides in the ash:

If: B/A ratio <0.75 – contamination may occur; B/A < 0.4 or B/A > 0.7 – the tendency to sedimentation is low, but if 0.7 > B/A>0.4 – high (Bapat et al., 1997; Dyjakon, 2012).

In the case of biomass, the importance of potassium is also justified. Therefore, biomass of agricultural and herbaceous origin - straw, nutshells, fruit pits, weeds and grasses cause more problems than wood. The metals potassium and sodium, whether in the form of oxides, hydroxides or organometallic compounds, tend to lower the melting point of ash mixtures containing other various minerals, such as silica (SiO2). As a result, serious problems with slagging, fouling or agglomeration of the bed in the boiler arise, which can lead to its shutdown. Therefore, it is justified to introduce a new indicator based on the melting and sintering coefficient of SI oxides:

If: SI index >2 – the risk of slagging is low, SI < 2 – high (Bapat et al., 1997; Basu et al., 2000) and the Cm index, which expresses the ratio of basic to acidic oxides:

The SR slag viscosity index is also used to determine the tendency to deposition. Viscosity is one of the basic properties of liquid slags and is a key parameter for many industrial processes. It plays an important role in slag adhesion, ash fusion, viscous flow and other phenomena:

A high value of the index means a high content of slag viscosity. If: SR > 72 – the slag has a low tendency to slagging, 72 ≥ SR > 65 – medium, SR ≤ 65 – low, SR is 72–80 – the tendency to form impurities is low, SR is 65–73 – medium and 50-65 – very high (Bryers, 1996).

The dependence of melting temperatures on basic compounds (Fe2O3+CaO + MgO) shows a similar character for different fuels (coals, biomass and municipal waste).

Biomass is burned in various heating devices (pulverized fuel, grate, fluidized bed boilers) where particle agglomeration may occur. In order to estimate this risk, the bed agglomeration index BAI was developed, relating the ash composition to agglomeration (fluidized bed reactors):

If: BAI <0.15, then agglomerates are formed (Capablo et al., 2009).

Another IC index is based on the ratio of iron oxide and calcium oxide as a parameter to assess contamination:

If: IC < 0.3 or IC > 3.0 then the tendency to create pollutants is low, 0.3 < IC < 3.0 – high (Ściążko et al., 2006).

A similar tendency to form deposits is described by the quotient (SA) of silicon oxide and aluminum oxide (Bapat et al., 1997).

Another indicator is the sum of Fe and Ca oxides:

If the sum of Fe2O3+CaO does not exceed 10% then the fuel has a low tendency to form pollutants.

The final parameter is the Fu fouling index, which takes into account in particular the alkaline elements (sodium and potassium). This index is presented by the following equation:

The Fu index determines the tendency of the fuel to form and then sinter contaminants on heating surfaces and shows the tendency to form deposits that initiate slagging.

If: Fu ≤ 0.6 – the fuel is not susceptible to contamination, 0.6 < Fu ≤ 40 – it has a high tendency, Fu > 40 – very high tendency to the formation and sintering of contaminants (Bapat et al., 1997; Dyjakon, 2012; Kowalczyk-Juśko, 2017).

On the other hand, Miles et al. (1996) presented the alkali index in the following equation in order to monitor the amount of alkali in fuels and minimize the occurrence of slagging and contamination:

where: HHV (Higher Heating Value) is the higher calorific value (MJ/kg) at H = 0% and K2O and nitrous oxide (N2O) are expressed as a percentage of these components in the fuel composition in dry mass according to the index:

- Alkaline index >0.17 kg alkali/MJ – probable contamination.

- Alkaline index >0.34 kg alkali/MJ – contamination will definitely occur.

Whereas (Pronobis, 2005) presents the following values to reduce slagging and Cl based contamination in biomass fuels, where Cl is the chlorine content (%) in the dry mass of the sample:

- Cl < 0.2 – low tendency to slagging,

- 0.2 < Cl < 0.3 – moderate tendency to slagging,

- 0.3 < Cl < 0.5 – high tendency to slagging,

- Cl > 0.5 – very high tendency to slagging.

In the study conducted by Kowalczyk-Juśko (2017) for herbaceous biomass, the ratio of alkaline to acidic components, showing a tendency to ash deposition, was the lowest in the case of perennial grasses (Miscanthus sacchariflorus) and prairie knotweed (Spartina pectinata Boscex Link), and many times higher in the case of Virginia mallow. Ashes from the biomass of Chinese miscanthus (Miscanthus sacchariflorus) and Japanese knotweed (S. pectinata) were characterized by a low tendency to form impurities and sediments (Table 5). At the same time, in the case of ash from Virginia mallow (Sida hermaphrodita Rusby) and Jerusalem artichoke (Helianthus Tuberosus L.), a very high tendency to sintering, slagging and sedimentation was observed, which is evidenced by significantly higher Fu, SI, BAI values.

Table 5. Slagging and contamination indicators for ashes from the tested biomass [Source: Kowalczyk-Juśko (2017)].

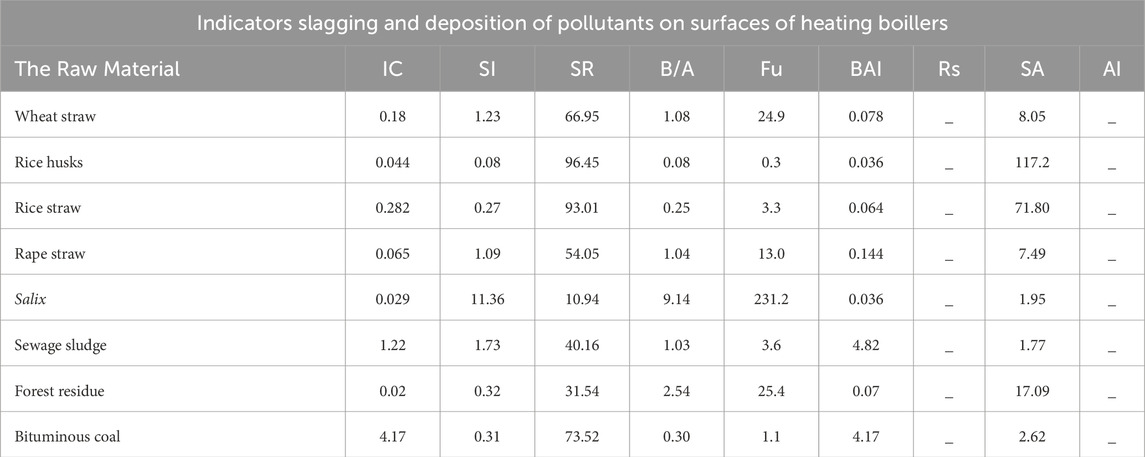

In turn, the research conducted by Dyjakon (2012) for the slagging and contamination indicators of the boiler heating surfaces showed significant differences in the tested plant biomass, which is presented in Table 6.

Table 6. Results of indicators slagging and deposition of pollutants on surfaces of heating boilers [Source: own study: Dyjakon (2012)].

In turn, in the study by Baxter et al. (2014) it was shown that the ratio of alkaline to acidic components in the leaves of Miscanthus giganteus ranged from 0.7 to 1.3, while in the stems these proportions were different. The B/A ratio was 1.3–3.2.

There are many empirical correlations that allow the assessment of ash behavior and its effect on deposition both on boiler walls (slagging) and on the edges of convection tubes (fouling). A number of slagging and fouling indices have been developed for coal fuels to obtain and indicate the tendency of fuel ash to form deposits in combustion chambers or boilers based on chemical composition, which exhibit a different behavior than biomass fuels. For example, the slagging indices for Serbian coal, which consists of 88% brown ash coals, their application to biomass fuels containing brown ash should confirm the tendency of this fuel to form deposits on boiler heating surfaces. Since most slagging indices are therefore based on the assessment of the melting properties of aluminosilicate ash from coal, their application to biomass ash systems, which are very different in chemical terms, may be problematic. In case of low-level biomass co-firing, the mixed ash still consists mainly of the aluminosilicate system, so that typical methods for assessing coal slagging can be applied. If biomass is co-fired with coal in larger quantities, all important components of most biomass ash, mainly alkali metals and alkaline earth metals, are strong fluxing agents for aluminosilicate systems. The introduction of biomass can result in a lower melting point and therefore an increase in the slagging potential. Pollution indicators of biomass ash are based on the total alkali content of the fuel. The main driving force for conventional pollutant formation in boilers is considered to be the deposition of Na and K compounds by oxidation/condensation mechanism (Loo and Koppejan, 2008; Repić et al., 2019).

5 Assessment of the possibilities of improving the thermal properties of ash in terms of their impact on exhaust gas emissions

Slagging, deposit formation and surface corrosion are ash-related problems that should be investigated when using fuel blends, as they can lead to reduced efficiency and availability of facilities, which results in increased energy costs. Proper selection of biomass fuels based on the chemical composition of the ash and mixing them in the right proportions can reduce the rate of ash deposition and corrosion. The mechanisms of release of inorganic compounds depend on the boiler operating conditions and staged combustion can cause local reducing conditions, which poses a risk of boiler corrosion. Corrosion is the process of dissolving metal into a more stable compound. This process occurs as a result of electrochemical reactions, oxidation and reduction reactions, involving ions and electrons, forming an oxide. The mechanism of the corrosion process caused by chlorine, HCl, Cl2, NaCl, KCl and alkali compounds (K, Na) is the process of steel oxidation accelerated by the presence of chlorine in the flue gases, called active oxidation. The corrosion rate is temperature dependent and depends on the volatilization of the metal chloride (Lokare, 2008; Stauber Alfredsson, 2018).

In the research conducted by Royo J. et al. (2022), it was shown that in order to compensate (at least partially) the negative impact of plant components in the mixtures, it is interesting to use a higher value of excess air (λ), because it allows to lower the combustion temperature (at λ > 1), which means reducing the degree of sintering and deposition, thus improving the ash behavior during pellet combustion.

In the study conducted by Naganuma et al. (2013) the mechanism of fouling formation was investigated and it was found that alkali sulfates play an important role in increasing the adhesion force. One possible solution to the fouling problem is to reduce the adhesion force. Therefore, thermal spraying of a nickel alloy onto the heating device pipes may help achieve this.

In turn, Pałaszyńska and Juszczak (2018) examined the effect of selected biomass types (coffee husk pellets or pellets combined with wheat straw pellets and cherry stones, sewage sludge pellets, rye and corn straw briquettes, and miscanthus briquettes) on the slag formation process. The studies showed that the boiler operated correctly during the combustion of the above-mentioned types of biomass. For all types of fuel, only brittle, porous slag was formed, which was easily fragmented by the reciprocating movement of the grate pushers and then removed from the furnace. This means that the temperature in the boiler was above the ash sintering temperature and below the ash softening temperature. In addition, a significant amount of brittle deposits was observed in the combustion chamber and on the heat exchange surfaces, which required cleaning the boiler after 40 h of operation. However, most of the deposits were created by burning coffee husk pellets.

On the other hand, herbaceous biomass fuel in the form of pellets from rice husks and corn stalks was commonly used in studies (He et al., 2022) on pollutant emissions and slag properties. The studies indicate opposite trends in the change of CO and NOx concentrations in exhaust gases. NOx emissions generated during the combustion of corn stalks as a result of multi-layer secondary air distribution are comparable to the combustion of rice husks. The obtained research results can contribute to efficient combustion and low pollutant emissions. Therefore, NOx emissions and ash slagging rates at the exhaust gas outlet are used as an assessment indicator to study the operating conditions for low NOx emissions and slagging rates during the combustion of corn stalks under air distribution conditions. On the other hand, slagging does not occur during the combustion of rice husks, therefore, NOx and CO emission concentrations serve as an assessment indicator when selecting optimal operating conditions.

5.1 Methods of modifying thermal properties of ash

One of the solutions to the problems related to the formation of ash during biomass combustion is the use of additives that reduce the negative impact on biomass ash and boiler operation. The additives are environmentally friendly and easy to use, which change the chemical composition of the ash, transforming it into a safe form and improve the ash melting temperature. To achieve better additive efficiency, it is required that the additive has a smaller particle size, which facilitates physical adsorption and chemical reactions. In biomass boilers, additives can be used that reduce the negative impact of biomass ash on boiler operation. The additive can act in two different ways by reacting with alkali metals such as KCl and KOH and binding the base into less aggressive compounds or by diluting it so that critical alkali forms occur in lower concentrations in fly ash (Vamvuka and Kakaras, 2011; Plaza et al., 2019; Jensen et al., 2016; Shao et al., 2012; Vamvuka et al., 2009; Kubica et al., 2016; Mroczek et al., 2011). Reagents are classified into: aluminosilicates (Al-Si), S, P and Ca, e.g., magnesite. Addition of sulfur-based additives (ammonium sulfate (NH)2SO4) to the combustion chamber reduces the rate of corrosion. Additives changing the physicochemical properties of ash, facilitate its removal by means of soot blowers, e.g., copper oxychloride (3CuO∙CuCl2∙4H2O), which through its action reduces slagging as a result of causing ash deposits to disintegrate and become brittle. However, repeated soot blowing leads to rapid erosion of the pipe surface. Additives based on aluminosilicates are used to transform evaporated inorganic substances into less harmful forms or to retain hazardous compounds in specific ash fractions, for example, by binding potassium. It has also been shown that aluminosilicate or SiO2 based additives react with gaseous alkali species (KCl, KOH, NaCl, sodium hydroxide (NaOH) and reduce the degree of fouling in the superheater area. Of all the types, Al-Si based additives are the best at capturing K present in biomass during combustion, coal fly ash, forming aluminosilicates with higher melting points. Coal fly ash with higher Si content and lower melting point captures KCl more effectively than fly ash from reference coal. This additive has been commercially used in full-scale biomass boilers for K capture (Jensen et al., 2019; Shao et al., 2012; Zhou et al., 2017; Wang et al., 2018a; Wang et al., 2018b; Wang et al., 2018c; Wang et al., 2019; Chen et al., 2022). Among the above-mentioned additives, Al-Si is the most effective Kaolin is preferred due to its availability and ability to capture K to form high-melting potassium aluminosilicates and thus better cope with the problems associated with biomass combustion and the relatively high content of alkali metals in the biomass ash, which leads to high contents of salts such as KCl, KOH and K2SO4 in the flue gases. Al-Si based additives are kaolin (Al2O3∙2SiO2), kaolinite (a component of kaolin), bentonite, bauxite, zeolite, halloysite, olivine, feldspar, mica Equation 11:

where Al2Si2O5(OH)4-halloysite, KAISiO4-kalsilite

More stable and high-melting forms can be created using monocalcium phosphate Equations 11, 12:

where CaK2P2O7-calcium dipotassium diphosphate.

On the other hand, alkali metal chlorides can be converted to the gas phase into alkali metal sulfates, which are characterized by a higher melting point and lower corrosive activity (Equations 11, 13) (Madhiyanon et al., 2020; Nørskov et al., 2010; Maj and Matus, 2023; Wang et al., 2018b; Wang et al., 2018c; Sandy Sharp, 2010; Wang et al., 2019; Li et al., 2023; Blomberg, 2007; Meng et al., 2017; Kassman, 2012; Plaza et al., 2019; Zhou et al., 2016).

As reported by Batir et al. (2019) and Wang et al. (2013), kaolin raises the melting temperature of biomass ash and is considered the most effective additive. Its main component is kaolinite, Al2Si2O5(OH)4, which, when heated to 450 °C, transforms into metakaolinite. Metakaolinite then reacts with potassium (K) to form crystalline products such as KAlSiO4 and leucite (KAlSi2O6), characterized by high melting points of approximately 1,600 °C and 1,500 °C, respectively. Kaolin can reduce the concentration of potassium chloride, which results in a reduction of the agglomeration process. The use of Al-Si-based additives has been considered the most appropriate additive to eliminate problems associated with biomass combustion (Wang X. et al., 2012; Davidsson et al., 2008; Jensen et al., 2019; Khalil et al., 2012; Zhu et al., 2014). The addition of kaolin plays a significant role in reducing the emission of fine particles. K and Na are believed to be released from the biomass particle in the form of volatile chloride vapors (KCl and NaCl) and hydroxide vapors (KOH and NaOH). The release of alkali in the form of chlorides is related to the rate of release of highly reactive HCl, which can act as a limiting or promoting factor. The addition of HCl to biomass combustion has been shown to increase the release of alkali metals.

On the other hand, under low HCl conditions, alkaline compounds tend to react with silicates (Rabaçal and Costa, 2015).

In contrast, the addition of mica showed the highest inhibition efficiency (90%) for both corn straw and poplar (Sandberg, 2011; Abioye et al., 2023). It has also been shown (Escobar and Műller, 2007) that clay minerals rich in SiO2, e.g., kaolinite irreversibly capture alkali. Clay minerals with different SiO2 and Al2O3 compositions were tested and it was found that the capture efficiency is influenced by the ratio of both components.

The addition of halloysite to biomass combustion causes:

- An increase in the characteristic temperatures of biomass ash, which has a positive effect on reducing the process of fly ash deposition on heat exchange surfaces,

- Reduction of contamination and slagging of the boiler heating surfaces,

- Reduction of bed agglomeration,

- Reduction of high-temperature corrosion,

- Extension of the boiler operation inter-repair periods,

- Change in the quality and composition of ash, expanding the possibilities of its economic use,

- Reduces the average height of sediment formation (39% decrease), sediment mass (37% decrease) and sedimentation rate (37% decrease) (Hernik and Wnorowska, 2022; Plaza et al., 2019).

In addition, halloysite in its raw form has additional layers of water molecules Al2Si2O5(OH)4∙2H2O, which distinguishes it from kaolin Al2Si2O5(OH)4. Differences also occur in the structure, as the halloysite structure reveals the presence of nanotubes, whereas kaolin forms a lamellar structure. While kaolin is an almost pure mineral (99.9% purity) in the form in which it is commercially available on the market, halloysite is a raw ore containing numerous impurities and trace amounts of other elements. Both aluminosilicates have an extensive specific surface area, thanks to which they are considered very good sorbents (Sobieraj and Kalisz, 2021).

Other sorbents, such as dolomite and clay, can also be used, which prevent the reaction between potassium and silica. There are many studies on the properties of sand and rock ilmenites, showing their ability to transport oxygen and interact with ash components derived from fuel. Other additives consisting mainly of iron ore are hematite (FeO) and titanium-iron ore - ilmenite (FeTiO3). Hematite has the ability to remove Hg from fly ash with a wide temperature range. In turn, ilmenite has the advantage of absorbing potassium molecules from ash, thus reducing agglomeration with the sand bed material used. Studies have shown that the addition of KCl, K2CO3 or K2SO4 increases the reactivity of ilmenite, while alkaline compounds such as potassium (III) phosphate (KPO3) have a negative effect on reactivity. Moreover, potassium salts: KCl, potassium carbonate (K2CO3) or K2SO4 as the main forms of potassium present in biomass ash, can catalytically affect biomass combustion (Corcoran et al., 2014; Corcoran et al., 2018; Sun et al., 2018; Zhou et al., 2017; Yang et al., 2017; Izquierdo et al., 2017; Gogolev et al., 2021; Andersson et al., 2024; Kaniowski et al., 2022). However, the use of bauxite (consists mainly of aluminium hydroxides – hydrargillite (Al2O3∙3H2O), boehmite (aluminium hydroxide Al(OH)3 or diaspore (aluminium hydroxide AlO(OH), contains clay minerals, silica, iron oxides and hydroxides) as an additive enriching bottom ash (ash from agricultural residues with an admixture of brown coal) with calcium compounds can capture K. Under combustion conditions no signs of ash deposition or bed agglomeration were observed (Vamvuka et al., 2009; Wolf et al., 2004).

In the case of materials used in a reactor, an ash layer may form on the bed particles due to the deposition of AAEM compounds released from the fuel (Marinkovic et al., 2015).

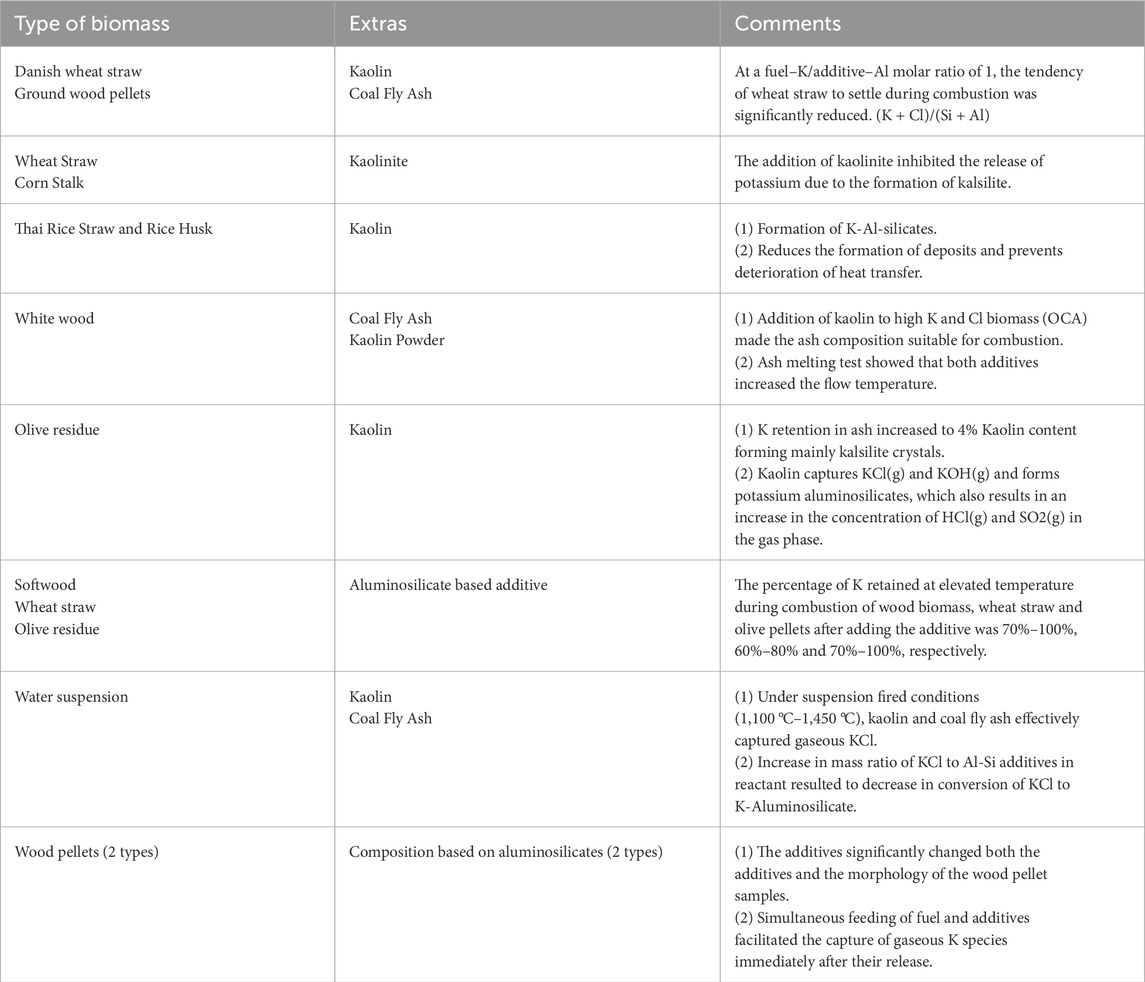

Table 7 summarizes the different cases of using aluminosilicate-based additives to reduce ash deposition by capturing K.

Table 7. List of additives based on aluminosilicates that capture potassium (K) during biomass combustion [Source: own study: Wang et al. (2022); Li et al. (2020); Madhiyanon et al. (2020); Roberts et al. (2019); Batir et al. (2019); Clery et al. (2018); Arendt et al. (2016); Paneru et al. (2016)].

5.2 The impact of modified biofuel with anti-caking additives on exhaust gas emissions – environmental and technological aspects

Sintering of biomass ash on heat exchangers reduces heat exchange efficiency and makes it difficult to clean the accumulated ash. In the case of heat exchangers, the ash deposits contain elements such as K, S and Cl (Dell’Antonia et al., 2013). Based on the research conducted (Botić et al., 2022) using herbaceous biomass (soy straw pellets and camomile processing waste) burned in a low-power heating device (<50 kW), the results show that the gas emission values (permissible values for: CO -750 mg/m3 and NOx - 200 mg/m3) during the combustion of biomass containing a higher percentage of nitrogen significantly exceed the recommended values. All types of additives (clay, kaolinite, bentonite) led to a reduction of CO emissions by about 50% during the combustion of wood pellets and pellets from camomile waste, while soy straw pellets increased their emissions. NOx emission values after the use of ash anti-caking additives did not change significantly in wood pellets (<200 mg/m3 compared to pellets from camomile waste). In turn, the study (Gehrig et al., 2019) focused on the use of energy willow (instead of forest biomass) and the additive - kaolin during combustion in a small boiler of 12 kW. The observed emission of particulate matter shows a clear decrease for fuel mixtures mixed with kaolin. The addition of kaolin reduces the K content in the tested particles regardless of the fuels used and confirms the K retention in the bottom ash. In addition, gaseous NOx emissions correlate with the N content of fuel blends and show an increase in NOx emissions with the increase in the share of energy willow, where kaolin has no major effect on NOx emissions. On the other hand, a study conducted (Gollmer et al., 2023) in a small-scale biomass combustion plant (33 kW) showed that the addition of 0.5% by weight of kaolin (especially the Kaolin III type with the smallest particle size) to wood chips significantly reduced CO emissions - from 96 mg/Nm3 (without addition) to 26 mg/Nm3. This reduction was greater than in the case of the use of an electrostatic precipitator (ESP), which reduced CO emissions to 96 mg/Nm3. The authors suggest that kaolin may act catalytically, although this mechanism has not yet been fully explained. In turn, in the experiment conducted (Nguyen et al., 2019) using a 0.1 MWth fluidized bed boiler (CFB) in an oxygen atmosphere, replacing quartz sand with kaolin as a bed material contributed to the stabilization of the combustion process and reduced CO and NOx emissions. Additionally, kaolin improved the fluidization properties and prevented particle agglomeration. Another study (Xu et al., 2018) conducted in a 1000 MW coal-fired power plant found that adding kaolin to the combustion chamber reduced the emission of fine PM2.5 particles by 36.72% after passing through an electrostatic precipitator. Although the main goal was to reduce particulate matter emissions, changes in ash composition were also observed, which may affect gaseous emissions, including CO and NOx. Similar studies were conducted (Norizam et al., 2024) investigating the effect of kaolin addition on the partitioning of chemical elements in particulate matter (PM) during the combustion of primary and waste wood biomass fuels in a 250 kW grate boiler. The results showed that the PM emission levels were significantly reduced by about 70%–76% and 60%–66% after the addition of kaolin for the primary and waste woody biomass, respectively, which inhibited the partitioning of alkaline species into fine and ultrafine PM. On the other hand, the concentration of non-volatile elements (SiO2 and Al2O3) significantly increased in the PM emissions after the addition of kaolin due to the adhesion and aggregation of particulate matter between airborne kaolin and fine and ultrafine PM. Moreover, the addition of 1.55 wt. % kaolin showed comparable effects with the addition of 2.5 wt. % on the chemical composition of PM emissions. KCl salts were also reduced after the addition of kaolin. The conducted computer simulations (Chen et al., 2021) showed that the addition of 3 wt. % kaolin during coal combustion reduced the emission of PM0.3 particles by 33.35%. Although the study focused on particulate matter, the authors suggest that kaolin may also affect gaseous emissions by adsorption of mineral precursors. In the study (Sommersacher et al., 2013) biomass fuels, i.e., spruce and straw and an additive (kaolin), were investigated. In the case of spruce, the addition of 0.2 wt. % kaolin was sufficient to reduce aerosol emissions by 87%. In addition, the melting point of the ash increased by 40 °C. The ash content of this mixture increased slightly and the increase in sulfur dioxide (SO2) and HCl emissions was also negligible. The addition of kaolin seems to be of particular interest for small (residential) pellet applications to significantly reduce particulate emissions, as these systems are not usually equipped with dust collectors. In the case of straw, the addition of kaolin in an amount of about 4 wt. % can be recommended to significantly reduce aerosol emissions and significantly improve the ash melting properties. The ash content of this fuel/kaolin mixture increases by about 69%. The addition of kaolin to straw is also applicable on a medium (>100 kW) and large scale, where an appropriate flue gas cleaning system is usually used. In the study (Huelsmann et al., 2019), an 8.6 kW pellet stove and a 12 kW pellet boiler were used to burn wood pellets with 0.5% and 1 wt. % kaolinite. The results show a similar particulate emission reduction effect for both combustion devices of 46% (pellet stove) and 48% (pellet boiler) using 0.5 wt. % kaolinite. However, the use of 1 wt. % kaolinite indicates different results. The total particulate emissions from the pellet boiler were reduced by approximately 69%, while emissions from the pellet boiler were only slightly reduced, by approximately 5%.

In turn, in the study (Wang et al., 2022), the results of combustion of wheat straw and wood with kaolin addition showed that at a dose of 3.13% of this additive, the tendency of wheat straw to sedimentation significantly decreased from 86% to 29%. It was also found that kaolin has a relatively higher Al content and the Al/Si molar ratio of 0.89 may indicate a higher K capture capacity of kaolin. Similar studies (Tissari et al., 2008) showed (combustion of oats and wood in a 20 kW pellet boiler) that K release during combustion was reduced in the case of oats, while it was increased in the case of wood. In addition, the role of kaolin in the formation of sediments during wood combustion was also investigated, where the addition of kaolin changed the fractionation of Cl so that it occurred mainly in the flue gases and not in the PM fraction. The corrosion potential was also found to be reduced by the addition of kaolin (Khalil et al., 2012). In contrast, in (Morris et al., 2022) pellets of miscanthus and wheat straw were used and tested in a 65 kW fluidized bed combustion chamber with different doses of dolomite and kaolin on a bed of quartz sand. The use of kaolin and dolomite at doses of 50%–150% by weight of ash prevented defluidization of the bed in the case of miscanthus. Dolomite released Ca content along with some Mg content into the ash, facilitating the formation of high melting Ca and Mg silicates. In contrast, kaolin absorbed potassium from the ash, facilitating the formation of high melting aluminosilicates. This absorption occurred to a depth of about 60 mm in the kaolin, although the typical depth was about 20 mm. In another study (Madhiyanon et al., 2013) it was shown that the addition of kaolin during combustion of empty fruit bunches allowed to maintain high temperature. Ӧhman et al. (2004) also showed how the addition of kaolin affects the tendency to slagging in case of combustion of pollutant-free and problematic (contaminated stem wood) wood fuel. It was observed that kaolin slightly reduced slagging in case of contaminated wood but significantly increased it in case of uncontaminated fuel. Increased slagging was associated with the formation of low-temperature Ca-Al-K silicates. In another study (Xiong et al., 2008) the effect of kaolin on the tendency to slagging during combustion of corn in a 50 kW boiler was assessed. It was observed that the addition of kaolin increased the concentration of KAISi2O6 in both slag and ash. In similar studies (Boström et al., 2009) oat grains mixed with kaolin were used for combustion. Several different ash fractions were characterized and it was found that in the unsintered bottom ash the emission of fine particulate matter was reduced and K was captured in the KAISiO4 and KAISi2O6 phases. Therefore, the main effects of ash transformation were attributed to the formation of two high melting point compounds KAISiO4 and KAISi2O6. It can therefore be concluded that kaolin reduces the amount of fine particles and substances forming deposits and thus prevents slag formation.

Another study Zhao et al. (2006) analyzed the effect of Na and Ca on NOx emission during coal combustion. The results showed that these minerals can significantly affect NOx emission, suggesting that the presence of various minerals, including kaolin, may have a significant effect on gaseous emissions. A similar study Xu et al. (2014) investigated the mechanism of alkali metal capture by kaolin by burning high-sodium lignite (a component of brown coal with relatively well-preserved wood structure) in a tube furnace, and the effects of kaolin content, reaction temperature, and kaolin and fuel particle sizes on the Na capture efficiency by kaolin. It was found that kaolin could chemically adsorb NaCl, the main sodium species in flue gas, to form high-melting sodium aluminosilicates such as nepheline (NaAlSiO4) and albite (NaAlSi3O8), and the nepheline formation reaction dominated the sorption mechanism. The larger addition of kaolin resulted in greater sodium binding in ash. The sodium capture efficiency decreased with the increase of temperature or the injection of larger kaolin particles. The sodium retention with 6 wt. % kaolin addition to fuel at 1,200 °C could reach 70% of the total sodium in the burning coal, which could greatly reduce the ash issues and facilitate the safe burning of high-alkali coal in boilers.

In addition, calcium additives containing CaO, calcium carbonate (CaCO3) and calcium hydroxide (Ca(OH)2) are more active during the combustion of biomass rich in K and P, helping to convert K vapours into high melting potassium silicates/phosphates. Accordingly, when biomass fuels contain high levels of K, Si and Ca, P-based additives can be used to reduce ash caking and bed agglomeration. A commonly used additive in Denmark is limestone (CaCO3) in an amount of 1%–2% to avoid caking and thus prevent deposits in biomass-fired heating devices. It has also been found that limestone addition can cause a shift from alkali chlorides to alkali sulphates in fly ash fines (Shao et al., 2012; Ronnback et al., 2008). Wolf et al. (2005) used Ca-based additives including limestone for the combustion of high-alkaline biomass, finding that the emission of gaseous SO2 could be reduced by up to 25%. It has been shown Bäfver et al. (2009) that the combustion of cereal grains (rye and wheat) with CaO in low-power heating devices reduces slagging by forming high-melting Ca-Mg-K phosphates, which may prevent the formation of fly ash particles due to the incorporation of potassium into calcium compounds that remain in the bottom ash. Furthermore, Bäfver et al. (2009) also found that the addition of limestone can cause a shift from alkali chlorides to alkali sulphates in the fine fly ash particles. He also observed that particle emissions could be reduced by adding kaolin to the combustion of oat grain in residential buildings (2% kaolin added to the fuel reduced particle emissions by 31% and 4% reduced emissions by 57%).

Composite additives containing 20%–50% of purge air, 25%–65% of kaolin, 20%–60% of MgO and 15%–30% of activated alumina may prove to be effective additives. These additives reduced the potassium content, which also reduced the sedimentation process. With the increase in combustion temperature, the additives showed better performance and the addition of CaO reduced the HCl emission (Liao et al., 2015).

In the studies Kalisz (2023) a mixture of halloysite and dry urea was used in a ratio of 1:3 using fuels (coal, biomass). The use of the urea-halloysite mixture ensured NOx reduction at an average level of 52%, which corresponds to emissions of 175 mg/m3. This result indicates the correctness of the stoichiometric excess coefficient of the additive SR = 2 used in the studies, along with maintaining the ammonia (NH3) level at a low level (<2 ppm).

In another work, Skodras et al. (2007) investigated the co-combustion of brown coal with olive stones, sawdust, almond shells, municipal sewage sludge and investigated the ability of urea to reduce the formation of toxic gases (polychlorinated dibenzo-p-dioxins (PCDD) and dibenzofurans (PCDF). In all cases, the addition of urea (CH4N2O) resulted in a reduction of emissions and it therefore can be used to prevent the formation of PCDD/F.

In order for the additive to be used in biomass burning devices, it should be inexpensive, non-damaging to the boiler or flue gas cleaning systems, and the use of product residues should be taken into account. Some additives that increase the sintering and ash softening temperature, e.g., halloysite, zeolite or kaolinite, can slightly reduce the amount of slag formed in the furnace and the amount of deposits in the boiler (Kubica et al., 2016; Mroczek et al., 2011).

NOx emission reduction systems are an integral part of the environmental protection system in the power unit. Among the operated installations, there are technologies that reduce NOx emissions at the combustion stage (primary methods) and their secondary reduction by the action of an additive such as urea on the exhaust gases in the appropriate temperature range. In secondary methods, two main reducing agents are used: aqueous solutions of ammonia or urea for which the reduction occurs according to the following reaction (Kuropka, 2001; KOBIZE, 2017):

where CO(NH2)2-urea, NO-nitrogen oxide, N2-nitrogen.

Natural silicates are an interesting raw material for the synthesis of catalysts and adsorbents. Catalysis is a phenomenon of changing the rate of chemical reactions as a result of the action of substances called catalysts on the reactants. A catalyst, on the other hand, is a substance that increases the rate at which a chemical reaction reaches equilibrium, while not being consumed in the process. Adsorption, on the other hand, consists in the separation and retention of gas components on the external and internal surface (in the pores) of a solid body called an adsorbent. The retention of molecules on the surface occurs as a result of the action of short-range physical and chemical forces. Catalysts are applied onto ceramic carriers, known as adsorbents. The carriers are characterized by a highly developed internal surface (channels) and often have a honeycomb structure and their task is to increase the surface of the active phase and increase the mechanical and thermal durability of the catalyst. It can also be a source of active centers of a different type than the active phase, or significantly modify its electronic structure. Examples of heterogeneous catalyst supports are: SiO2, Al2O3, chromium (III) oxide-Cr2O3, MgO, CaO. A heterogeneous catalyst consists of an active phase dispersed on a support and additionally consists of one or more promoters. Promoters are compounds that modify the physical and electronic structure of the active substance, are responsible for inhibiting its unfavorable phase transformations and facilitate regeneration. Promoters include: K, P, Mg, Ca, titanium (Ti), vanadium (V). Catalysis plays an important role in preventing and removing the effects of pollution resulting from the combustion of biomass, including herbaceous biomass. Catalytic reactions usually result in reduced energy demand and increased selectivity. Catalysis and catalytic processes are the basis for many industries. The use of natural material as a catalyst or substrate for the production of a catalyst not only reduces the costs associated with their production, but also makes the process used environmentally friendly and can make a significant contribution to sustainable development. Typically, the support materials must have strong adhesion to the catalytic material and provide an increase in surface area and adsorption capacity. Support materials for the ceramic industry, i.e., kaolin clays, have been recognized as useful materials for the preparation of TiO2 composites that enhance the removal of pollutants due to their adsorption properties and large surface area. TiO2 is a semiconducting oxide, known as one of the most commonly used photocatalysts due to its low cost, stability, high reactivity, and ability to react with a large number of pollutants (NOx) (Kuropka, 2000; Maia et al., 2025; Książek et al., 2017). Kaolin exhibits some catalytic properties and can act as a carrier for active catalytic components (metals, metal oxides) that can be used in NOx reduction processes. Like other aluminosilicates, kaolin can be modified to increase its adsorption capacity (NOx molecules are adsorbed on the kaolin surface, where adsorption is a key step that allows further chemical reactions) and catalytic capacity. The acidic nature of the catalyst surface includes issues related to both the nature (Lewis, Brønsted centers), concentration and strength of the acid centers. Acids are substances capable of donating a proton (Brønsted acids). According to the Lewis theory, an acid is a substance capable of accepting an electron pair. These definitions apply to liquids, but they also apply to solids, on the surface of which acid centers are present. The role of Lewis acid centers is played by coordinatively unsaturated cations. Anions containing hydrogen can dissociate to form protons - we then obtain Brønsted acid centers. Basic centers, which are surface anions, can also be present on the surface of the solid. Acid catalysts belong to one of the most important categories of heterogeneous catalysts, which consist of an active phase dispersed on a support. The support itself not only provides physical properties to facilitate high dispersion of active sites but also interacts with the active component, thus becoming an essential part of the catalytic material (Najbar, 2000).

Methods of reducing NOx emissions into the atmosphere using urea and aluminosilicates are divided into

1. Methods of reducing NOx emissions from combustion processes. This group of methods is referred to as primary or clean.

2. Methods of removing NOx from waste gases. This group includes secondary or cleaning methods, which in turn are divided into dry and wet.

Dry methods include: selective catalytic reduction, non-selective catalytic reduction, catalytic decomposition, adsorption. Adsorption involves binding gas phase molecules (adsorbate) to atoms on the surface of a solid (adsorbent) before the reaction that produces more desirable products. In catalysis, the reactants are adsorbates and the catalyst is the adsorbent. Wet methods, on the other hand, are absorption methods (absorption means uptake and refers to the process of receiving or taking in).

Among the dry methods, the selective catalytic reduction (SCR) method is particularly important. Its main principle is the reduction of particulate matter (PM) emissions and the decreased emission of nitrogen oxides (NOx) in the exhaust gases (Warych, 1994). SCR NOx catalysts are platinum group metals (Pt, rhodium (Rh), Pd) and transition metal oxides (V205, TiO2, MoO3), which have the advantage of being cheaper and less sensitive to poisoning than platinum group metals. Particularly interesting are catalysts containing V205 deposited on TiO2 and on a mixed oxide carrier TiO2-SiO2. The vanadium-titanium catalyst is characterized by high activity at low temperatures and high resistance to SO2 poisoning (Parvulesku et al., 1998).

The SCR mechanism involving Brønsted sites, using aluminosilicates (e.g., kaolin) as an example, is as follows:

1. Ammonia adsorption

The introduction of aluminum atoms into the SiO4 structure leads to the formation of acidic centers. Each trivalent aluminum atom introduced into the silicon-oxygen tetrahedra (SiO4) network is bound to four oxygen anions, the AlO4 tetrahedron has a charge of (−1). In order to maintain the electroneutrality of the aluminosilicate network, the presence of cations is necessary, compensating the negative charge. The simplest way to balance the charge is to introduce a proton, which leads to the formation of surface hydroxyl groups (OH) with the character of strong Brønsted acid centers. Their formation can be explained by assuming dissociative adsorption of a water molecule, occurring on the Al ion. The aluminum ion on the surface, surrounded by three tetravalent Si atoms, has an electrophilic character due to the shift of the charge from the Al3+ ion to the Si4+ ions. It can therefore accept a hydroxyl group, formed by donating a proton from a water molecule. This proton is bound to the neighboring oxide ion. The resulting Si-OH-Al group is strongly polarized and has the character of a strong acid. When aluminosilicates are heated above about 700 K, the surface dehydrates. Removing a water molecule from the Brønsted acid center leads to the exposure of an aluminum ion with the properties of an electron pair acceptor, i.e., to the formation of a Lewis acid center. On the surface of aluminosilicate catalysts at the temperature of catalytic reactions, we deal with both Brønsted and Lewis type centers. The ammonia molecule, reacting with Brønsted acid centers, forms ammonium ions (NH4+), and reacting with Lewis acid centers, forms complexes in which the ammonia electron pair forms a coordination bond with the Lewis electron acceptor center (NH3 L). At the Brønsted acid site (i.e., the–OH group in the kaolin structure), ammonia protonation occurs:

As a result, an adsorbed form of ammonia (ammonium ion) is created, ready to participate in subsequent reactions (Najbar, 2000).

2. Adsorption of NO and O2

The method of catalytic decomposition of NOx according to the reaction is: