- 1Department of Mechanical Engineering, Sarala Birla University, Ranchi, India

- 2Department of Machining, Assembly and Engineering Metrology, Faculty of Mechanical Engineering, VSB-Technical University of Ostrava, Ostrava, Czechia

- 3Research and Development Cell, Department of Mechanical Engineering, School of Engineering, Manav Rachna International Institute of Research and studies, Faridabad, India

- 4Department of Mechanical Engineering, Amity University, Ranchi, India

- 5University of Jeddah, Jeddah, Saudi Arabia

- 6Department of Orthodontics, Faculty of Dental Sciences, SGT University, Gurugram, Haryana, India

- 7Department of Mechanical Engineering, School of Core Engineering, Faculty of Science, Technology & Architecture, Manipal University, Jaipur, India

- 8Department of Mechanical Engineering, IIMT University, Meerut, India

- 9Department of Biosciences, Saveetha School of Engineering. Saveetha Institute of Medical and Technical Sciences, Chennai, India

The objective of this review paper is to provide a comprehensive and systematic analysis of the various aspects of vibration-assisted welding (VAW), focusing on its applications, limitations, future potential, and critical evaluations. This review examines welding processes where vibrations serve as a primary mechanism driving the process. It also explores cases where vibrations act as an auxiliary method to enhance operational efficiency and weld quality. A detailed examination is conducted on the physical mechanisms underlying VAW, along with state-of-the-art developments, experimental studies, technological advancements, and diverse applications across relevant fields such as aerospace, automotive, shipbuilding, and biomedical industries. The analysis highlights the benefits of VAW over conventional welding techniques, including enhanced mechanical properties, refined microstructures, and improved overall weld quality. Given these advantages, vibrations have emerged as a transformative technology in welding, leading to notable advancements in productivity and product performance in the twenty-first century. This paper aims to assess the current state of VAW and outline prospective directions for future research and industrial adoption. Further research is needed to standardize VAW methodologies and optimize process parameters for industrial use.

1 Introduction

The mechanical strength of different welded connections influences the reliability and service performance of welded structures. Recent years have seen a rise in the use of the vibratory approach as a feasible alternative to the traditional heat treatment procedure, which involves some costly and time-consuming processes but effectively enhances weld quality. (Krajewski, 2009; Krajewski, 2010; Krajewski, 2011). Regardless of the parent metal or the welding procedure, the vibrations modify the structures of the melted and heat-affected zones (HAZ). Using a variety of vibratory settings, the vibratory welding process transfers external energy to the weld zone during or after the welding operation in the form of vibration. Vibratory welding techniques have less influence on the environment; less time spent producing, and reduced operating expenses. Mechanical and electric arc vibrations are two methods for introducing vibration into the welding zone to enhance process efficiency. There are essentially two ways to use vibration to the various industrial processes: vibration of the tool (Gunawan Setia Prihandana, 2009; Xu, 2009; Jimma, 1998; Qi, 2008; Mousavi, 2007; Huang, 2002; Weber, 1984; Babitsky, 2003; Skelton, 1968) and vibration of the workpiece (Shen, 2008; Pilyushenko, 1992; Nie, 2011; Abramov, 1995; Wu, 2005; Tewar S., 1999; Kim, 2008).

Vibrations of dielectric fluid (Gunawan Setia Prihandana, 2009), tool electrodes (Xu, 2009), blank holders in deep drawing processes (Jimma, 1998), vibrating wire drawing dies, vibrating extrusion dies (Mousavi, 2007), and vibrating die during upsetting (Huang, 2002), are a few examples of specific cases within the first group. The vibration of flowing melt during extrusion, melt vibration, and vibrating work components during welding (Wu, 2005; Tewar, 1999) fall under the second category. External vibrations in the processes above lead to less cutting or drawing force and improved surface quality. Mechanical vibrations have been proven in studies to alter the properties and structure of welded joints (Krajewski, 2012).

When mechanical vibrations are used during welding, the structure and qualities of the welded connections improve. (Balasubramanian, 2011). Mechanical or electric arc vibrations can be used to inject vibration into the welding zone to boost welding process efficiency. The vibrations produced by the tool and the workpiece are the two main vibrations used in industrial operations (Prihandana, 2009). Several impacts of the vibration contribute to the weld’s quality improvement. In order to improve the quality of the weld, it might be helpful first to break up any oxide or other impurities that may be present on the materials’ surface that is being fused. Second, the vibration aids in mixing the molten metal, lowering the possibility of porosity and other flaws (Ranjan, 2022). Regardless of the parent metal or the welding procedure, the vibrations alter the structures of the melted and heat-impacted zones (HAZ). Using a variety of vibratory settings, the vibratory welding method transfers external energy in the form of vibration to the weld zone during or after the welding procedure (Kalpana, 2017). Vibrations can be imparted to a workpiece in a variety of ways, including longitudinal, transverse, vertical, and random vibrations. The impact of longitudinal vibration on mechanical characteristics, including hardness, yield strength, and ultimate tensile strength.

The article presents a detailed review of various vibration assisted welding techniques that are used for improving the mechanical properties of welded joints. It also gives us an idea about how microstructure refined plays an important role for enhancing mechanical properties of welded joints.

2 Different vibration assisted welding technique

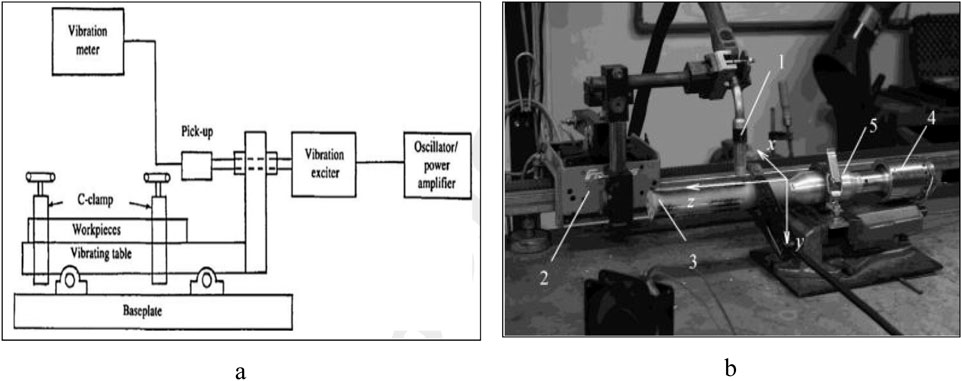

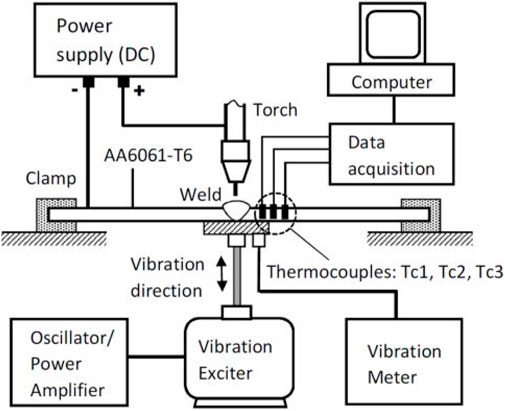

Figure 1a shows a schematic representation of the experimental setup. Using a manual metal arc welder, the workpieces were secured to a table that was longitudinally vibrating with the aid of an electrodynamic vibrator (Yunhao Xia, 2024). The experimental setup as shown in Figure 1b included a waveguide coupled through a concentrator with a ceramic transducer powered by a GUZ202500W ultrasonic generator. The setup also comprised an ARISTOTIG 200 AC/DC TIG welding machine (ESAB Co.), a Fronius ALU Edition MIG welding source, and a mechanized system for straight-line welding (Fronius Co.). In TIG welding, a 2.4 mm WC 20 Grey tungsten electrode with a spherical tip was used, and the molten pool was shielded by argon at a flow rate of 11 L/min. Welding was performed with an AC or DC supply at 150 A and 30 Hz, with a welding speed of 0.0025 m/s, and the torch was fixed for flat welding.

Figure 1. (A). Schematic diagram of experimental setup (Yunhao Xia, 2024). Reprinted with permission from Copyright (1993) Sage Publications. (B) Experimental set-up: 1 – welding torch, 2 – linear manipulator, 3 – waveguide, 4 – ultrasonic transducer, 5 – concentrator (KRAJEWSKI, 2012). Reprinted with permission from Copyright (2012) Polish Academy of Sciences.

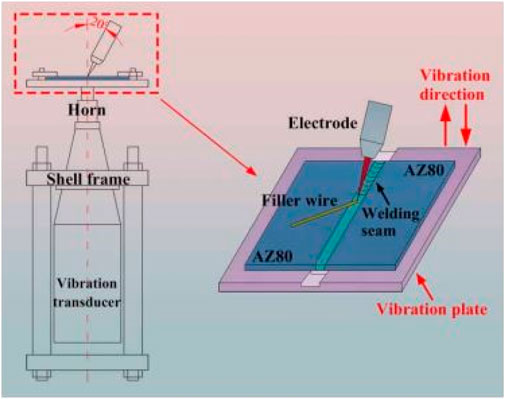

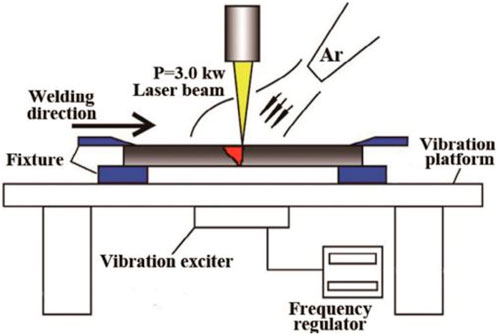

The waveguide was coupled through a concentrator with a ceramic transducer supplied by a GUZ 20 2500 W ultrasonic generator made by the Tele-Radio technical Institute (KRAJEWSKI, 2012). During the welding process, only the workpiece is subjected to vibration, as seen in Figure 2, while the vibration transducer, shell frame, and horn remain motionless. During the welding process, a high-frequency ultrasonic vibration generator with a 20 kHz output frequency was employed to drive ultrasonic vibration into the molten pool in a direction perpendicular to the base plates (Hui Lia, 2017). Figure 3 depicts a schematic of the vibration-assisted GMAW process. Before welding, a vibration exciter vibrated the plates at various frequencies in a vertical direction that was parallel to the plates.

Figure 2. Schematic diagrams of ultrasonic vibration enhanced TIG welding set-up (Hui Lia, 2017). Reprinted with permission from Copyright (2017) Taylor and Francis.

Figure 3. Schematic of vibration-assisted GMAW process (M.N. Ilman, 2022). Reprinted with permission from Copyright (2022) Elsevier.

A vibration meter fastened to the underside of a backing plate simultaneously recorded the response amplitudes. The vibration exciter was situated at one-half the backing plate’s length (Ilman, 2022).

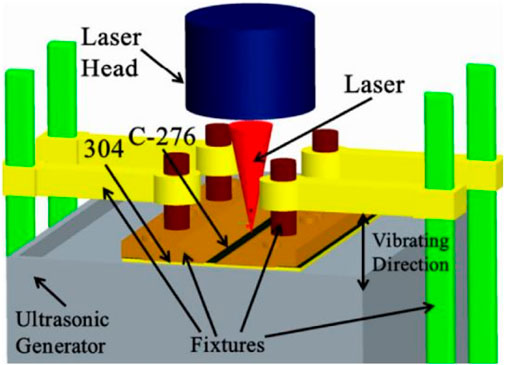

Figure 4 shows a schematic of the ultrasonic vibration-assisted pulsed laser welding setup. The setup consisted of an ultrasonic vibration platform and welding fixtures, with fixtures used to secure the workpiece to the ultrasonic vibration board. At a fixed frequency of 20 kHz, the ultrasonic generator produced a maximum output of 500W. Three distinct ultrasonic output powers of 0W, 250W, and 500W were used for laser welding. The ultrasonic output power was used to regulate the amplitude of the ultrasonic vibration board (Siyu Zhoua, 2018).

Figure 4. Set-up for ultrasonic vibration-assisted pulsed laser dissimilar welding (Siyu Zhoua, 2018). Reprinted with permission from Copyright (2018) Elsevier.

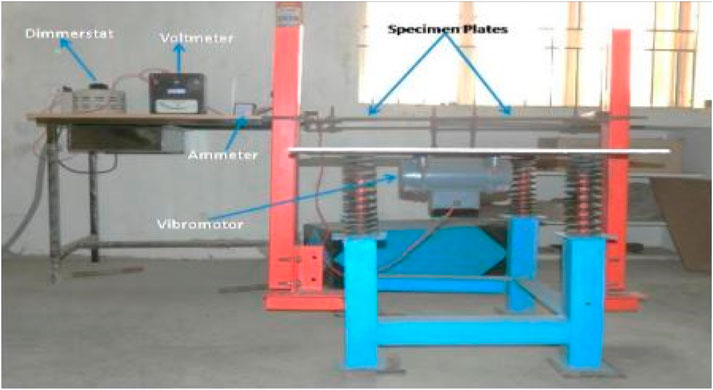

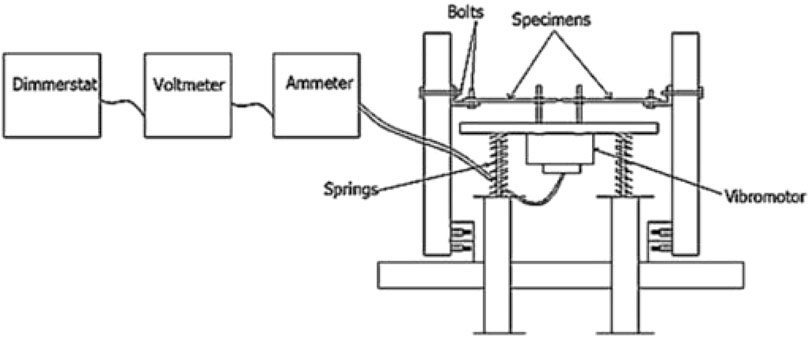

The specimen may be placed on a platform with four springs at each corner. The vibratory table setup was completed by attaching a vibromotor to form the vibration platform. The vibrations were generated by connecting an ammeter, voltmeter, and dimmerstat to the vibromotor. Figure 5 shows the experimental setup.

Figure 5. Experimental setup of vibration assisted welding (Muvvala Chinnam Naidu, 2021). Reprinted with permission from Copyright (2021) ACCENTS Journals.

To enhance the mechanical characteristics of the weldment by introducing beneficial changes in the weld region’s microstructure, a supplemental vibratory setup that is adept at delivering mechanical excitations to the weld pool for “manual metal arc welding” is designed (Muvvala Chinnam Naidu, 2021).

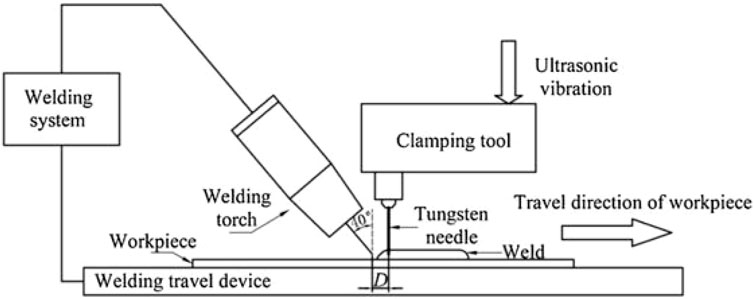

Figure 6 shows the intended configuration for vibrations and an external magnetic field. Mild steel is employed as the workpiece material in the current research project. By changing the motor’s speed from 721 rpm to 923 rpm and the external magnetic field by changing currents from 0.2 amp to 0.3-amp, welding was done on the workpieces while modulating the magnitude of vibrations (Suresh Chitturi, 2020). In order to introduce vibration into the molten pool, a high-melting-point tungsten needle with applied ultrasonic vibration was inserted directly from the front side of the arc-welded weld pool, as illustrated in Figure 7.

Figure 6. Vibration assisted welding set up (Suresh Chitturi, 2020). Reprinted with permission from Copyright (2020) IOP Publishing.

Figure 7. Schematic of the experimental process with the ultrasonic vibration of weld pool (Guancheng Zhaoa, 2020). Reprinted with permission from Copyright (2020) Elsevier.

The output amplitude of the ultrasonic device was 105 µm and the frequency was 20 kHz (Guancheng Zhaoa, 2020).

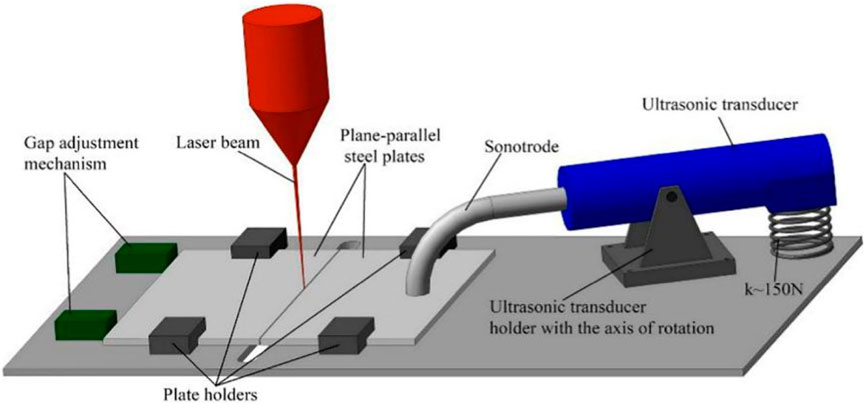

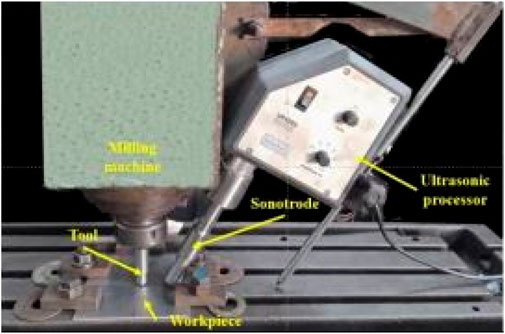

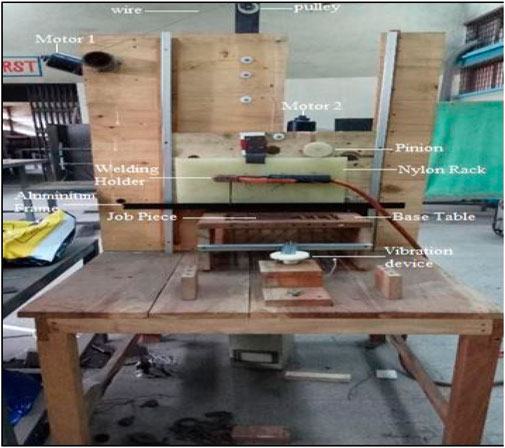

A custom-made ultrasonic transducer assembly was used to treat the weld using ultrasound. The assembly shown in Figure 8 included a generator that produced and transferred ultrasonic vibrations to a magnetostrictive transducer. The sonotrode was linked to the transducer, which was housed in a case with liquid cooling. In order to transmit ultrasonic vibrations, the sonotrode was attached and fastened to the workpiece (A.V. Kolubaev, 2020). The pure iron and vibration platform were solidly attached during the welding operation is shown in Figure 9. When the maximum value of the vibration acceleration was attained, the vibration. The resonance frequency was frequency (Jiewen Jin, 2019). The aluminium sheet was cut to the desired size for the sample using an abrasive water jet machine. The FSW tool was made from H13 hot work tool steel rod with a shoulder diameter and pin diameter of 14 mm and 5mm, respectively. The requisite ultrasonic vibration waves were obtained using an ultrasonic processor. A titanium sonotrode with a tip diameter of 22 mm and a length of 100 mm was utilised to produce ultrasonic vibration waves with a 24 kHz frequency, an 85-W power output, and an adjustable amplitude up to 100 µm (EL-Wazery, 2022) as shown in Figure 10. The experiment’s wooden framework is depicted in Figure 11.

Figure 8. Schematic of the setup for ultrasonic-assisted laser welding of steel sheets (Kolubaev, 2020). Reprinted with permission from Copyright (2020) Elsevier.

Figure 9. Micro vibration laser welding platform (Jiewen Jin, 2019). Reprinted with permission from Copyright (2019) Wiley.

Figure 10. Experimental setup for UAFSW process (M. S. EL-Wazery, 2022). Reprinted with permission from copyright (2022) Materials and Energy Research Center.

Figure 11. Experimental setup for ultrasonic vibration assisted welding (Mahmudul and Pavel, 2018). Reprinted with permission from copyright (2018).

Large wooden table, base table, large wooden plate for vertical up and down movement, nylon rack, pinion, pulley, and motors are all mounted on top of the large table that is part of the wooden frame. With its four wheels, the small base table can travel along two rail lines. There’s one vibration device in front of that small base plate. This configuration enables the workpiece and the base table to bounce back and forth (Mahmudul and Pavel, 2018).

A vibration platform and an imbalanced vibrometer make up the configuration is shown in Figure 12. A circulating vibrometer, the surface plate, and the springs on which the surface plate is mounted vibrate the specimen (Vykunta Rao, 2022).

Figure 12. Line diagram of experimental set up (M. Vykunta Rao, 2022). Reprinted with permission from copyright (2022) Springer Nature.

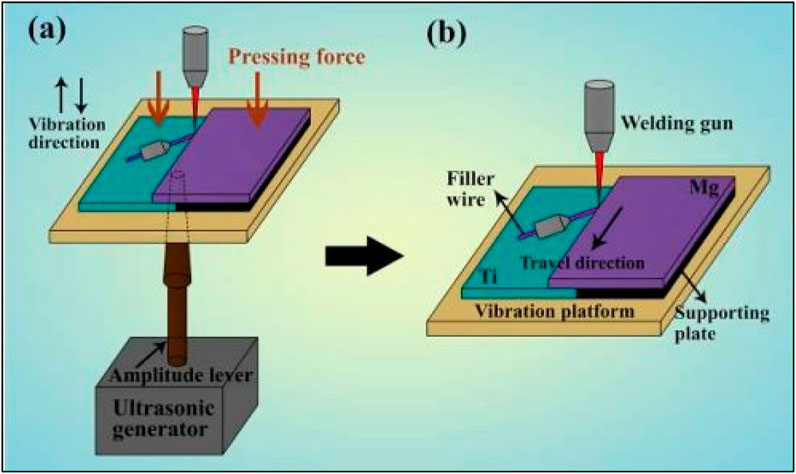

Figure 13 shows the schematic representation of the experimental setup for ultrasonic vibration. To refine coarse columnar-Mg grains of Mg/Ti joints through cavitation and acoustic streaming effects, ultrasonic vibration was introduced into the welding pool using a system with a maximum output amplitude of 30 m, a maximum output power of 1.6 kW, and a maximum output frequency of 20 kHz. The vibration’s path was parallel to the welding plate (Chuan Xu, 2016).

Figure 13. Schematic illustration of the experimental setup (Chuan Xu, 2016). Reprinted with permission from Copyright (2016) Elsevier.

3 Effect of vibration assisted welding on mechanical properties

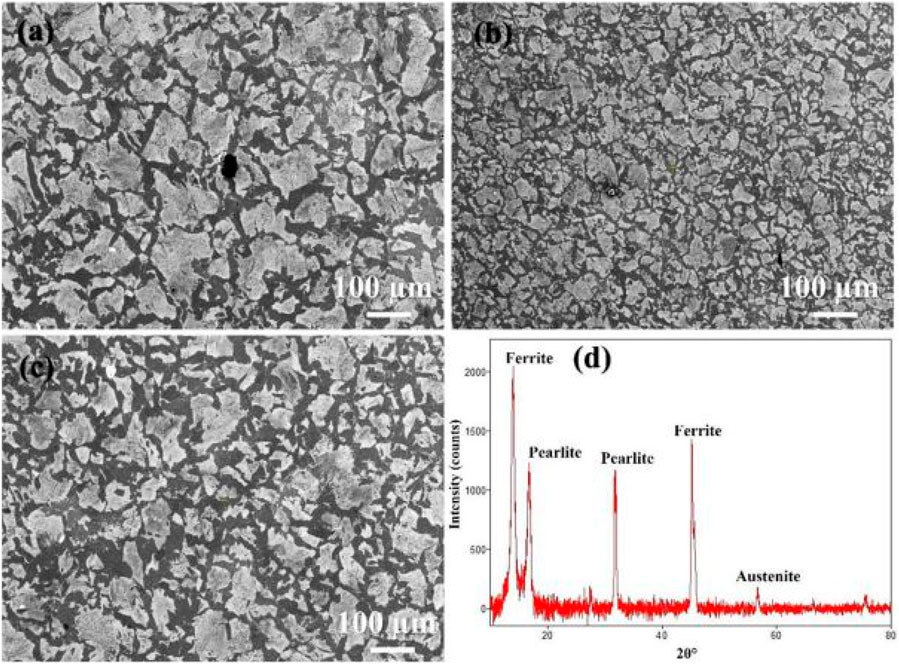

The Scanning electron micrograph images following post weld heat treatment (PWHT) at various temperatures are displayed in Figure 16, which highlights the notable microstructural alterations with a fine grain structure. Upon close inspection, welded joints exhibit a ferrite-pearlite structure with distinct white and dark regions. Scanning electron micrograph (SEM) images of the welded joints following PWHT at 600°C, 650°C, and 700°C are displayed in Figure 14. The test specimen is depicted in detail by the SEM analysis. It is demonstrated that the grain structure eventually becomes more regular after PWHT at 650o C, increasing the tensile strength (Rajeev Ranjan, 2024).

Figure 14. (a) SEM image after PWHT at 600o C (b) SEM image after PWHT at 650 C, (c) SEM image after PWHT at 700 C, (d) XRD pattern (Rajeev Ranjan, 2024). Reprinted with permission from Copyright (2024) Springer nature.

The tensile fractures of the welded joints GTA and UA-GTA are displayed in Figure 15. The fracture surfaces of both samples show characteristic dimples that indicate ductile fractures. There are both small and large dimples visible in the tensile fracture of the welded joint between the GTA and the UA-GTA. However, compared to the normal GTAW, the UA-GTAW fracture has somewhat bigger dimples (Yunhao Xia, 2024).

Figure 15. The fracture of samples after the tensile test: (a), (b), (c) and (d): GTA welded joint; (e), (f), (g) and (h) UA-GTA welded joint. (Yunhao Xia, 2024). Reprinted with permission from Copyright (2024) Elsevier Publications.

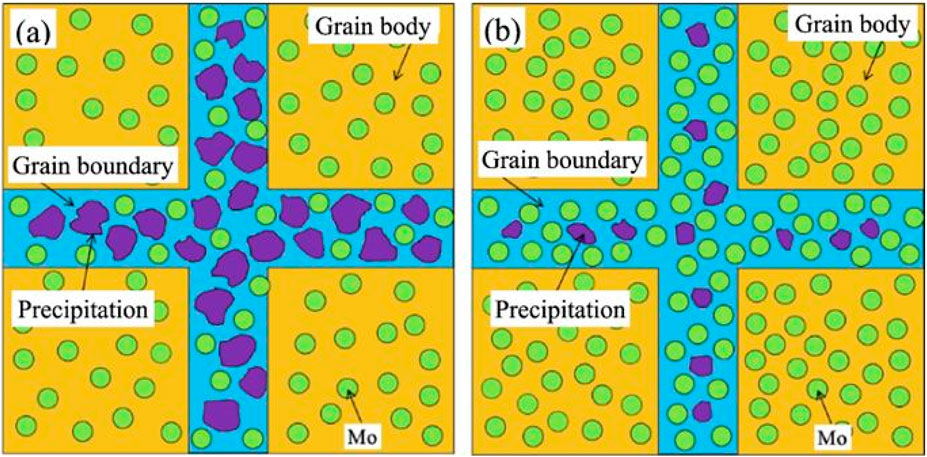

As illustrated in Figure 16, the nickel-based weld’s intergranular corrosion can be explained by the poor Mo theory, which is comparable to the poor Cr theory in the intergranular corrosion of stainless steel. The TCP phases are enriched in Mo element, and the formation of these TCP phases will consume the Mo close to the grain boundary, per the microstructure analysis. The majority of the Mo element in precipitated phases originates from the grain boundary because the diffused activation of Mo in the grain body is significantly lower than that of Mo within the grain boundary, resulting in a lower diffused rate of Mo in the grain body than that of the grain boundary (Siyu Zhou, 2021).

Figure 16. Influence mechanism of ultrasonic vibration on intergranular corrosion: (a) Laser welding without ultrasonic; (b) Ultrasonic assisted laser welding. (Siyu Zhou, 2021). Reprinted with permission from Copyright (2021) Elsevier Publications.

With mechanical vibrations of the workpieces during FCAW, the fatigue strength of weldments formed of weldable-grade SM 490A steel was only marginally enhanced. The experiment employed mechanical vibration equipment consisting of a rotary vibrator, sensor, analyser, and programmable logic controller.

The experiment was run at 60 Hz, which is the resonance frequency. The vibration caused the grain to become more refined, and the specimen’s mechanical qualities, including tensile strength, impact strength, and hardness, were enhanced (Lee, 2007).

The superior mechanical properties and weld formation in friction stir welding can be attributed to the softening effect of ultrasonic vibration. The base metal used for the butt-welding process was commercial 2024Al-T4 rolled plates with a thickness of 3 mm. Both localised ultrasonic vibration and none were used. The vibration tool head, which was connected to an ultrasonic amplitude transformer, projected vibration into the material 20 mm in front of the tool. The operating parameters of the ultrasonic vibration system were 20 kHz, 300 W of output power, and 40 µm of amplitude. According to reports, these vibrations might speed up the butt-welding process. Welded joint’s tensile strength and the weld nugget zone’s microhardness were enhanced (Liu, 2015). Due to the grain refinement brought on by arc oscillation, the mechanical parameters of the weld, including as yield strength, UTS, and % elongation, were enhanced (Raman, 2012).

After using ultrasonic vibration assisted laser welding to weld SUS301 stainless steel sheet with a thickness of 0.6 mm, the effects of fixed-point ultrasonic vibration and trailing ultrasonic vibration on the macrostructure, microstructure, and mechanical characteristics of the joints were examined. The outcomes showed that ultrasonic aided laser welding, particularly T-ULW, allows for improvements in both ductility and tensile strength of the welds (Zuguo Liu, 2022a).

Using ultrasonic vibrations in manufacturing improves the structural effectiveness of produced goods. It provides a noticeable benefit for the mechanical and microstructural characteristics of items. In this study, the AISI 304 stainless steel was joined using the Ultrasonic Assist Cold Metal Transfer (U-CMT) process. With the use of optical microscopy, SEM, and XRD, the welded joints are examined. The U-CMT welded joint’s microhardness, tensile strength, and residual tests are analysed and contrasted with CMT welded joint. The U-CMT welded joint’s microhardness and tensile findings demonstrate a significant increase in their mechanical characteristics as a result of the grain refinement caused by ultrasonic vibrations in the fusion area (Yuvaraj J. G., 2022).

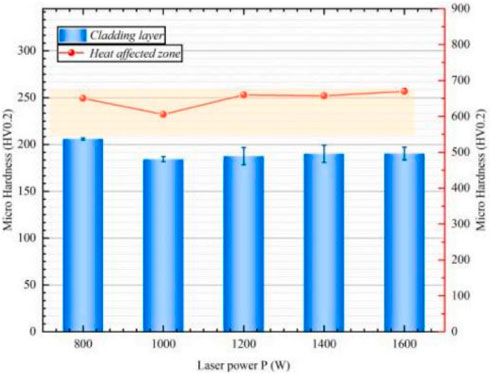

In order to enhance the functionality of the produced pieces, ultrasonic and laser cladding technology were used. The experimental results demonstrate that the ultrasonic vibration-induced grain size was finer than the traditional laser cladding-induced grain size. The average grain size was 0.522 times that of non-vibration when the amplitude was 25 m. Figure 17 shows the effect of laser power on microhardness and it is also observed that high-frequency vibration application may reduce porosity while enhancing microhardness and wear resistance (Lida Zhu, 2021). These two distinct welding techniques’ weld formations features and material flow behaviour were investigated and contrasted. The welding instrument supplied axial ultrasonic vibration directly to the weld. Results indicate that ultrasonic vibration can significantly speed up the welding process for joints with no defects. The UAFSW can create defect-free welded connections at a welding speed that is 50% faster than that of the traditional FSW at a rotational speed of 1,200 rpm. Additionally, axial force may be reduced by 9%, and ultrasonic vibrations can improve joint surface quality.

Additionally, ultrasonic vibrations noticeably increase both the volume of the pin-driven zone (PDZ) and the thickness of the transition zone (TZ) (Zhiqiang Zhang, 2020).

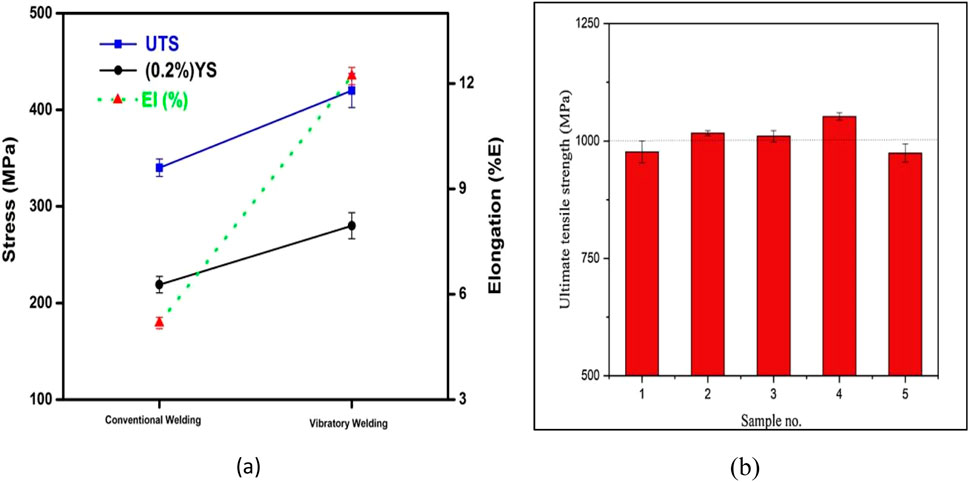

Experimental research on impact strength is conducted after the unique vibratory technique is established for mechanically vibrating the specimens. Comparing the experimental input process parameters’ effects on impact strength to the standard welding method. Results showed that when compared to standard arc-welded specimens, impact strength with excitations increased by 17%, and a voltage at 190 V mostly influences enhanced flexural strength for the vibrating motor and 18 V for the D.C.-motor linked to the electrode (Bade Venkata Suresh, 2022). The yield strength increased by 61 MPa (from 219 to 280 MPa), and the UTS value increased by 80 MPa (from 340 to 420 MPa). The term “ductility,” the gain in value, expressed as a percentage elongation, was approximately two times as great from 5.71% to 12.9% This rise in the UTS value and welded yield strength favourable micro-structural characteristics of joints (vibratory weld specimen) alterations that hindered grain formation led to the dendrites in the grain having comparatively shorter pools weld (Pravin SINGH, 2017). Under the circumstances of the molten pool’s ultrasonic vibration, the UTS of the butt joint rose. The sample with the highest UTS was subjected to molten pool ultrasonic vibration. (Guancheng Zhaoa, 2020), (Figures 18a, b).

Figure 18. (a) Tensile graph for welded specimen (Pravin SINGH, 2017). Reprinted with permission from Copyright (2017) The Scientific Bulletin (b) Results of tensile tests (Guancheng Zhaoa, 2020). Reprinted with permission from Copyright (2020) Elsevier.

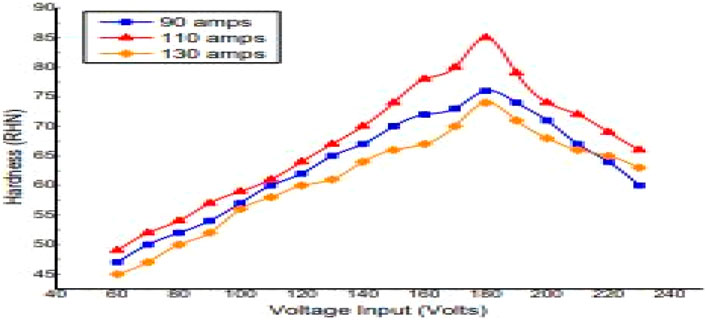

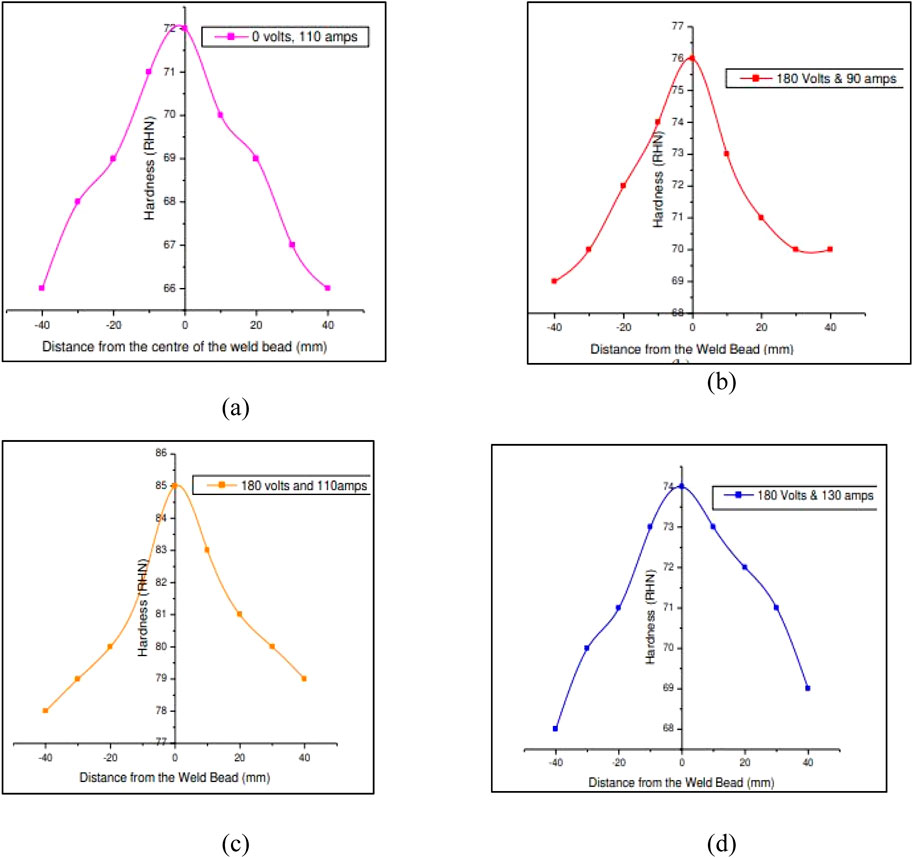

The examples are welded using vibro-motor voltage ranges between 60 and 230 V at intervals of 20 V at 90 amps, 20 V at 110 amps, and 20 V at 130 amps (Figure 19). The specimens’ initial hardness is minimal, but it steadily rises when vibrations are increased for 90 amps, 110 amps, and 130 amps from 60 V to 180 V and then again from 180 V to 230 V. The peak value of hardness is recognised at 180 V of vibromotor and 110 amps of welding current for 90 amps, 110 amps, and 130 amps because the material grade changes from austenitic stainless steel to martensitic, which makes the HAZ of metal as weaker. The welding current here, along with the vibration parameter, also affects the weldment’s hardness quality. Following the results, 180 V and 110 amps yield the highest hardness rating (Figure 20). Large dendrites break down into smaller ones due to molten pool stimulation during welding, and the grain size decreases with vibration. For stainless steel type 304 L materials, the hardness values are raised due to vibrations that reduce grain size (Muvvala Chinnam Naidu, 2021).

Figure 20. Hardness values of vibratory assisted weld joints at (a) 0 V and 110 amps (b) 180 and 90 amps (c) 180 and 110 amps (d) 180 and 130 amps (Muvvala Chinnam Naidu, 2021). Reprinted with permission from Copyright (2021) ACCENTS Journals.

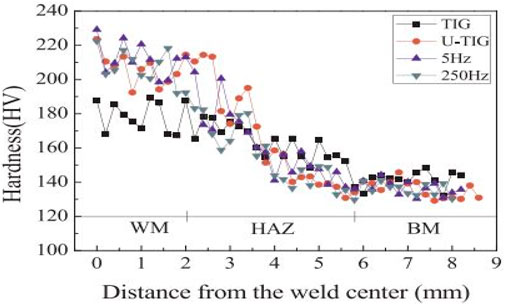

For four welding procedures, the base metal (BM) and heat effect zone (HAZ) hardness values were essentially the same. Weld metal (WM) has a harder surface than BM and HAZ. The standard GTAW has a WM hardness of roughly 180 HV (Figure 21). Three ultrasonic aided welding processes have around 210 HV WM hardness, which is virtually the same. The microstructure refinement is what caused the WM hardness in three ultrasonic aided welding procedures to increase by roughly 30 HV in comparison to the traditional GTAW (Chao Chen, 2020). The UMZ has a lesser hardness than the BM, as can be seen. The development of austenite grains in the UMZ is the cause.

Figure 21. Micro-hardness distribution profile (Chao Chen, 2020). Reprinted with permission from Copyright (2020) Elsevier.

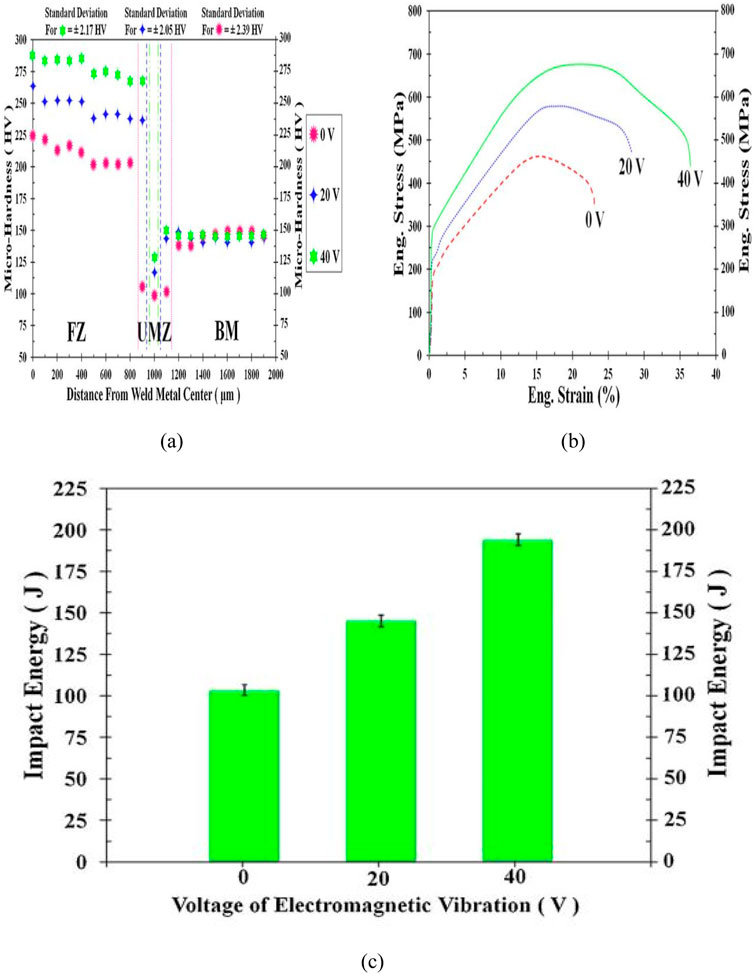

The degree of loss in hardness in the UMZ is modest due to the use of electromagnetic vibration during GTAW, and as a result, the UMZ is not regarded as a weak zone in the weld joint. On the other hand, it can be seen that the WM’s centre zones have a harder composition than its side zones and zones near the fusion line (Figure 22a). For 316L stainless steel GTAW joints, engineering stress-strain curves have been published. As shown in the figure, the yield strength, tensile strength, and toughness of 316L stainless steel joints intensify as the density of electromagnetic vibration during the GTAW process increases (Figure 22b). For 316L stainless steel GTAW joints, the Charpy impact test results have been provided. This image shows how the impact resistance and fracture energy of 316L stainless steel GTAW joints intensely increase by increasing the intensity of electromagnetic vibration during the GTAW process. According to the Charpy impact test results, the impact energy increased from 106 J for weld joints that did not use electromagnetic vibration to 189 J for those that did when 40 V of electromagnetic vibration was applied (Figure 22c) (Masoud Sabzia, 2018).

Figure 22. Mechanical testing (a) Micro-hardness test, (b) Tensile test, (c) Charpy impact test (Masoud Sabzia, 2018). Reprinted with permission from Copyright (2018) Elsevier.

4 Effect of vibration assisted welding on microstructure

A recently created welding technique is ultrasonic assisted laser welding (ULW). A high-speed camera monitoring system monitors the shapes of the molten pools during trailing ultrasonic assisted laser welding (T-ULW) and conventional laser welding (LW), and the welding temperature fields and weld pool temperature evolution are numerically simulated. The findings of the macro morphology study demonstrate that ultrasonic vibration not only lengthens the molten pool but also alters the cross-sectional morphologies of the welds by narrowing the top and widening the bottom. The findings of the microstructure study show that the fusion zone of the T-ULW welds is consistently distributed and mostly made up of refined equiaxed grains (Zuguo Liu, 2022a).

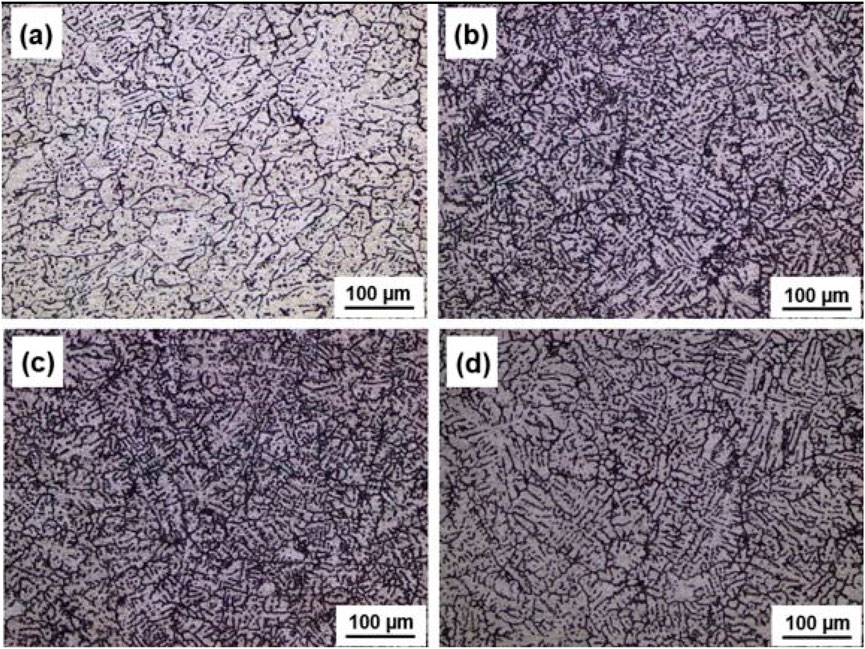

Under the influence of mechanical vibration during welding, the microstructure, mechanical characteristics, and corrosion performance of gas metal arc AA6061-T6 aluminum alloy welded joints have been studied. The study’s vibration frequencies, f, fell between 0 and 500 Hz. Following that, a number of experiments were conducted in a 3.5% NaCl solution, including microstructural inspection, microhardness measurements, tensile testing, fatigue crack growth tests coupled with fractography studies and electrochemical polarisation tests. It was discovered that the grain refinement of columnar dendritic and equiaxed dendritic microstructures in the weld metal area was the primary cause of the strengthening mechanisms in the vibrated weld joints as shown in Figure 23. These microstructures may prevent the emergence of fatigue cracks in the metal used for welding (Ilman, 2022). Using ultrasonic vibrations in manufacturing improves the structural effectiveness of produced goods. It provides a noticeable benefit for the mechanical and microstructural characteristics of items. With the use of optical microscopy, SEM, and XRD, the welded joints are examined. The U-CMT welded joint’s microhardness, tensile strength, and residual tests are analysed and contrasted with CMT welded joint. The U-CMT welded joint’s microhardness and tensile findings demonstrate a significant increase in their mechanical characteristics due to the grain refinement caused by ultrasonic vibrations in the fusion area (Yuvaraj J. G., 2022). The tendency for micro-segregation in the weld was reduced, and the ultrasonic vibration enhanced the uniform distribution of the components. The average tensile strength and elongation of the joint increased from 613 to 650 MPa and from 16.15% to 31.54%, respectively, using ultrasonic vibration.

Figure 23. Weld metal microstructures in: (a) as-welded condition and (b), (c), (d) vibration assisted welding at 100 Hz, 300 Hz and 500 Hz, respectively (Ilman, 2022). Reprinted with permission from Copyright (2022) Elsevier.

In Figure 24, the weld profile is displayed. There is penetration of the weld in both processes. The width of the weld on the top surface decreases to 0.578 mm upon the addition of ultrasonic vibration, while the width of the weld on the bottom surface increases to 0.406 mm from 0.3437 mm. The weld’s geometric size is smaller than it would be in the absence of ultrasonography. Figure 24a illustrates the typical wine-glass weld morphology in case A. But in the case that ultrasonic vibration is exerted, the weld morphology changes obviously, and the weld morphology is a cone, as shown in Figure 24b. In case B, the weld fusion zone (FZ) (Figures 24d, f) sees a more homogeneous and refined grain structure (Zuguo Liu, 2022b). The high temperature strength and oxidation resistance of nickel-based alloys are outstanding, but due to the coarse grains and severe segregation in their welding joints, these alloys are more prone to hot cracking. Sodium thiosulfate was utilised to model crystallisation, allowing researchers to understand the nucleation mechanism under mechanical vibration better and increase the hot-cracking resistance and mechanical qualities of nickel-based alloy welded joints. The findings demonstrate the method by which the Inconel 601H alloy’s grains are refined during gas tungsten arc welding (GTAW) under varied vibration modes and parameters. The low-frequency mechanical vibration operations produced significant grain refining effects in the welds as compared to the GTAW process; as a result, a greater hardness distribution was also accomplished under the vibration circumstances (Ze-long Wang, 2018). Through the welding instrument, ultrasonic vibration was directly delivered in an axial direction to the weld. The transition zone’s thickness is greatly reduced, and ultrasonic vibrations significantly increase the pin-driven zone’s volume. The UAFSW results in more sub grains and malformed grains than the FSW.

Figure 24. Microstructure of weld. (a) Weld morphology of case A; (b) Weld morphology of case B; (c) Fusion zone of case A; (d) Fusion zone of case B; (e) Heat affected zone of case A; (F) Heat affected zone of case (B) (Zuguo Liu, 2022a). Reprinted with permission from Copyright (2022) Elsevier.

The majority of the research indicated that those dark fringes were IGA’s core. However, according to multiple reports (backed up by direct TEM diffraction evidence), those were Cr2 N precipitates that were forming on dislocations. The current work’s TEM/EDX result, which is shown in the Supplementary Materials, shows a high degree of Cr enrichment in the precipitate, which is most likely Cr2 N. The precipitate with a tangled dislocation morphology is referred to as Cr2 N dislocation bundles from this point on. The following precipitation behaviour of Cr2 N seems appropriate (Tsai et al., 2018). Using the bead on plate technique, vibration welding is carried out on mild steel plates that are 6 mm thick with various material combinations. The effectiveness of the vibratory welding process is compared to traditional welding. Induced vibration during welding enhanced the nucleation rate, and steeper temperature gradients were discovered across the heat-affected zone (HAZ), according to metallographic investigations. In the case of vibratory welding, comparably finer grain microstructures are seen (Singh, 2017).

One of the most popular processes, shielded metal arc welding (SMAW), has been utilised to prepare weld specimens. A novel vibratory arrangement has been developed that stirs the weld-pool’s molten metal before the welding process causes it to solidify. The vibratory setup has a maximum amplitude of 0.5 mm and a resonance frequency of 300 Hz. When compared to traditional welded connections, the microstructure analysis of vibratory welded joints reveals smaller grain sizes (Pravin Kumar Singh, 2016).

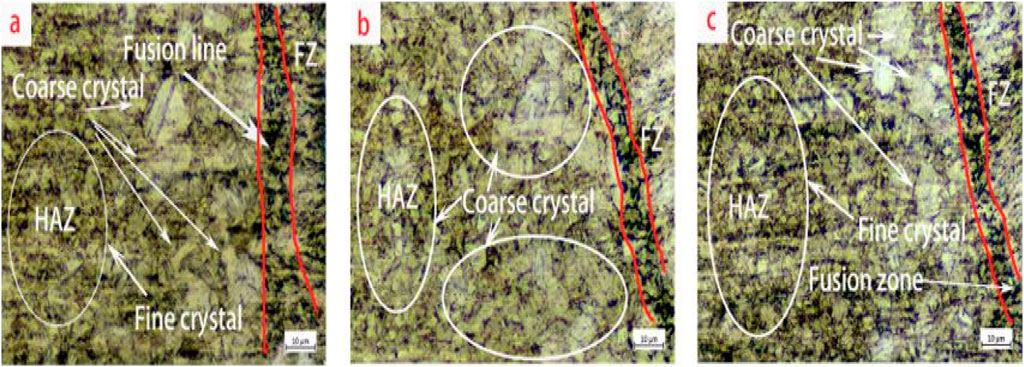

The OM images of the welds in the heat-affected zone are displayed in Figure 25, and they accurately depict the grain microstructure there. While the heat-affected zone of the weld in Case B (Figure 25b) distributes with a significant amount of coarse grain, the microstructure of the grains in HAZ in Cases A and C (Fig. 29(a) and (c), respectively), is primarily composed of fine grains. Stated differently, ultrasonic can efficiently smooth the grain. Naturally, there are differences in the refinement effect depending on how the ultrasound is applied. Figure 25a, c make this difference in the refinement effect very evident. Figures 25a, c were compared (Zuguo Liu, 2022b).

Figure 25. Microstructure of weld in heat affected zone. (a) Case A, (b) Case B, (c) Case C (Zuguo Liu, 2022b). Reprinted with permission from Copyright (2022) Elsevier.

A brand-new technique called Ultrasonic-Magnetic field Coaxial Hybrid GTAW (U-M-GTAW) was put forth to enhance the characteristics of the joints by coaxial connection of magnetic field and ultrasonic vibration to the welding arc. The grain size of the U-M-GTAW joint centre was lowered by 12.4% compared to GTAW when ultrasonic and magnetic fields were combined with GTAW, and the joint centre nearly entirely changed into equiaxed crystals. The mechanical qualities of the joints were all enhanced by the external energy fields (Chao Chen, 2023).

5 Optimization of welding process parameters

To provide the intended and valuable outcomes, process factors must be assessed, regulated, and optimized. Common process variables that affect the desired outcome of a welding process include welding speed, arc voltage, welding current, etc. Depending on the type of welding method chosen, different welding process parameters apply. For this reason, achieving a high-quality weld necessitates managing the input welding parameters. One of the most important welding output characteristics in this process is weld dilution, which has an impact on welding productivity as well as quality. Using Taguchi’s design of experiments technique, the effects of variables like wire feed rate (W), welding voltage (V), nozzle-to-plate distance (N), welding speed (S), and gas flow rate (G) on weld dilution were mathematically studied. Signal-to-noise ratios (S/N) were determined after the data was gathered and used to determine the ideal levels for each input parameter (Aghakhani, 2011).

The gas metal arc welding (GMAW) process parameters of an AISI 410 martensitic stainless steel work piece were optimised using the Taguchi technique. Based on the orthogonal array Taguchi approach, sixteen experimental runs (L16) were carried out. The impact of welding factors including welding speed, welding current, and wire diameter on penetration is discussed in this study. The most important factor and projected ideal parameter setting are determined using the ANOVA and signal to noise ratio (S/N ratio) (AMBEKAR, 2015).

The experiments are carried out using a Taguchi orthogonal matrix. Tool pin profile geometry, tool rotating speed, and welding speed are all input factors. The joint’s tensile strength and the weld’s microhardness are included in the response. The experimental findings are analysed using the Taguchi technique. Taguchi steps are a special optimisation method for estimating the best process parameter choices. The experiment results indicated that the square tool pin profile increased tensile strength and microhardness (Niranjan, 2023).

In order to combine plastics, a technique known as ultrasonic welding (UW) uses heat produced by high-frequency mechanical motion. This method is recognised to be effective in numerous industries, including textile, packaging, and automotive. The best UW process parameters for producing a plastic power box with a high weld strength are studied using Taguchi techniques. Weld amplitude is the most crucial control element affecting weld strength, followed by weld pressure, hold duration, and trigger location (Kuo, Tsai, Li, Lin and Chen, 2022). The Taguchi technique was used to optimise input parameters using the L9 orthogonal array. Nine trial runs were made in MINITAB software to create the L9 orthogonal array table. The feed rate, tool pin shape, and tool rotation speed were selected as the input parameters for optimisation. At the same time, the optimised hardness, tensile strength, and impact strength were the output parameters (Anil Raj, 2021).

The L9 (34) orthogonal table was used to create the micro-vibration-assisted laser welding experiment for the 6082-aluminum alloy. The results revealed that the dendritic grains were dispersed across the fine, uniform, and equiaxed crystal areas in the weld centre (Qinghua Lu, 2021). The welded samples underwent shear strength tests, and the results were analysed using Taguchi’s S/N ratio analysis with the supposition that a higher ratio indicates better performance. The regression model’s analysis of variance reveals that the significant components with p-values less than 0.5 are penetration depth and tool rotational speed. Confirmation tests reveal an acceptable discrepancy of 2.06% between the estimated and expected shear strength. The model’s R2 and adjusted R2 values with a standard error of 0.076 indicate that it is statistically significant (Veerendra Chitturi, 2022).

The critical vibratory welding process parameters welding current, welding speed, and frequency of the vibrations produced in the molten weld pool were optimised through the application of Taguchi’s analysis and Response surface methodology (RSM). The effect of process variables on tensile strength and hardness was evaluated using optimisation techniques. Two different regression models were employed with RSM to ascertain how vibratory welding settings affected hardness and tensile strength. The frequency at its resonance value, or 300 Hz, has the greatest impact on achieving the ideal tensile strength and hardness (Pravin Kumar Singh, 2017).

6 Low frequency vibration assisted welding

A recent study examined the effects of low-frequency vibration welding on the microstructure and mechanical properties of mild steel butt-welded joints with a 4 mm thickness. The study discovered that LFVW welding greatly improves the joint’s mechanical characteristics. Tensile strength, elongation, area reduction, and hardness of the welded junction all improved by as much as 33%, 147%, 102%, and 42%, respectively. In addition, the distribution and consistency of mechanical characteristics throughout the joint were observed to have improved, and there were less microstructural flaws than with traditional welding, according to the research. The voltage value of two peaks with frequencies ranging from 22 Hz to 400 Hz was thought to represent the opposing amplitude of vibration. Next, a spectrum map was made with the vibration frequency (Y-axis) and opposite vibration amplitude (X-axis) as reference points. The low (67 Hz), medium (250 Hz), and high (375 Hz and 390 Hz) vibration frequencies were selected using the spectrum map, and then the simultaneous vibration welding process began. Also, the effects of LFVW on the microstructure and mechanical characteristics of friction stir welded joints in mild steel have also been investigated. The study discovered that LFVW welding enhanced the joints’ mechanical characteristics by an astonishing 18%, 70%, and 28%, respectively, in terms of Charpy impact energy, microhardness, and tensile strength. Additionally, the study revealed that LFVW welding resulted in a refined microstructure with consistent grain size, finer particle dispersion, and less defects (Kumar, 2017). The impact of LFVW on the mechanical properties and microstructure of mild steel forgings was investigated. According to the study, LFVW significantly increased the welded joint’s elongation and tensile yield strength. The vibration’s impact resulted in a significant reduction in the grain size of the weld zone and a decrease in the number of cavities (Tewar S. P., 1999). Another investigation compares the mechanical characteristics of traditional welding techniques versus low frequency vibration assisted welding in mild steel plates.

According to the study, compared to conventional welding, low-frequency vibration aided welding created materials with greater yield and tensile strengths as well as reduced hardness. The authors concluded that using this technique might greatly enhance the mechanical characteristics of mild steel welded joints (Ingram, 2019). Another inquiry has been conducted into the impact of low-frequency vibration on the welding of mild steel. The use of low-frequency vibration, according to the authors, might assist in decreasing deformation and distortion in the welded joint by increasing the depth of fusion and lowering the welding temperature. The study also showed that the use of low-frequency vibration might enhance the weld zone’s microstructure, leading to an increase in the toughness and hardness of the welded connection (Yamamoto, 1993).

The research investigated the effects of low-frequency vibration on the mechanical characteristics and microstructure of mild steel welded joints. The findings showed that porosity, fractures, and other problems in the welded junction may be successfully avoided by using low-frequency vibration. The study also discovered that this technique considerably increased the welded joint’s tensile strength, hardness, and toughness. (Ilman, Metallurgical, mechanical and corrosion characteristics of vibration assisted gas metal arc AA6061-T6 welded joints, 2022).

Low-frequency vibration assisted welding (LFVW) is a solid-state welding technique that combines low frequency vibrations and pressure to join two materials. Given its ability to create robust and long-lasting bonds between a variety of materials, it has found widespread application in a number of industries, most notably the automotive and aerospace sectors. One of the most commonly used materials in the industry, mild steel, can be welded using a novel technique called LFVW, which is becoming more and more popular. The material’s surface characteristics are enhanced by applying mechanical vibrations to the welding tool, speeding up the welding process (Rao, 2014). Compared to traditional welding methods, it offers several advantages, such as improved mechanical qualities, a quicker welding process, and better weld quality. However, there are few investigations on welding mild steel with low-frequency vibration (Victor, 2020).

7 Post weld heat treatment

Fusion welding is a dependable and effective joining technique that produces metal coalescence by means of fusion. Many industries, including aerospace, shipbuilding, nuclear, bridge, and equipment, use this kind of welding extensively. Welding causes a nonuniform temperature distribution, thermal stresses, and localized plastic deformation (Chang, 2004). The majority of discussions on the process of welding structural steel connections emphasise the significance of heat input. Low-carbon steels are generally preferred in the automotive industry because of their better weldability, penetration, and lower investment. These steels have excellent weldability in comparison to other steels; most of the time, all welding techniques can be used to join them. Welding a thicker piece of low-carbon steel requires using the right heat treatment conditions. Fusion welding methods such as metal (or) gas metal arc welding (MIG/GMAW) and tungsten inert gas welding (TIG) have gained popularity over time because of their superior weld characteristics. GMAW is especially helpful when joining plates with varying thicknesses (Rajakumar, 2020). Fusion welding requires heat in order to melt the filler material and the workpiece’s surface, enabling coalescence and the formation of a solid, long-lasting connection after solidification. As a result, when fusion welding, the amount of heat applied is vital. Again, the welding current, voltage, and torch travel speed all affect the amount of heat input. To supply a specific heat input, these three parameters must be chosen (Saha, 2019). The process of applying a controlled heating and cooling cycle to a particular metal or alloy produces the required microstructures and mechanical properties, including hardness, elongation, tensile strength, yield strength, and toughness. Among the many different structural types of steel are austenite, ferrite, pearlite, bainite, and martensite. When steel is heated, many phase transitions take place (Blaoui, 2018). Heat input during welding causes a range of structural, thermal, and mechanical impacts into the heat-affected zone (HAZ), including expansion and contraction, metallurgical changes, and compositional changes (Zhao, 2016). AISI 4140 alloy steel’s hardness value as determined by the HAZ was lower than that of the base material. This variation resulted from an increase in martensitic structure. As the AISI 4140 steel cooled from high temperatures, a martensite transition happened near the weld interaction. On AISI 1050 steel, a pearlitic structure was found in the heat-affected zone (Celik, 2009). Several variables influence submerged arc welding (SAW) process output response. These include Marangoni convection, temperature-dependent thermo-physical properties, applied forces such as electromagnetic and gravity forces, surface tension’s capacity to keep objects in place, metal transfer during welding, and input parameters (Bahrami, 2014). The microstructural analysis is crucial for determining the heat input’s shape and the weld’s quality (Lan, 2016). Because of the high temperatures, the fusion zone (FZ) and the heat-affected zone (HAZ) frequently have an uneven ratio of ferrite to austenite. The fast cooling rates and high temperatures that characterize the welding process (Cervo, 2010). Welding different metals is known to cause some problems, particularly since it's harder to join dissimilar metals than identical ones. It has been discovered that the heat treatment temperature has the largest influence on the reduction of residual stress and deformation and that the reduction of residual stress is also affected by the material’s flexibility (Bensheng Huang, 2020). The effects of post-annealing and post-tempering on the mechanical, microstructural, and corrosion properties of gas metal arc welding of AISI 304 stainless steel have been investigated. As a result, compared to the post-tempered and post-annealed joints, the as-welded junction was harder. This was due to the stress-relieving action of annealing and eliminating Cr-rich precipitates in the post-tempering weld joint (Taiwo Ebenezer Abioye, 2020). Each specimen underwent post-weld heat treatments for the same amount of time and at different temperatures following welding. Temperatures for post-weld heat treatment at 150, 300, and 450°C were established. After the treatment, cross sections were taken from the area that was exposed to post-weld heat. The specimens were subjected to microscopic examination, hardness testing, and nondestructive testing. As a result, it was discovered that increasing post weld hardness lowered hardness values in heat affected zones of tempered martensite steel (Uzunali, 2015).

Vibration-assisted welding (VAW) is the process of combining mechanical vibration and traditional welding techniques. This method will improve the weld quality and decrease the chance of defects such as porosity, lack of fusion, and cracking (Vivès, 1993). The vibratory method has gained popularity recently as a feasible alternative to the conventional heat treatment procedure, which entails multiple expensive and time-consuming processes but significantly improves weld quality (Krajewski A., 2016). Compared to other vibration-assisted welding techniques, low-frequency vibration-assisted welding is better suited for mild steel. Low-frequency vibration-assisted welding (LFVW) has been demonstrated to alter the microstructure of the weld, which may alter the mechanical characteristics of joints that have been butt-welded. (Ilman, Metallurgical, mechanical and corrosion characteristics of vibration assisted gas metal arc AA6061-T6 welded joints, 2022). The molten pool was disturbed and the welded joints’ grain size was decreased by mechanical vibration, but the welded specimens’ microhardness and ductility were enhanced. As vibration research has progressed, the effects of vibration on grain refinement, hardness characteristics, and the metallurgical characteristics of welded joints have become more evident. The impact of vibration on mechanical properties as well as the optimum ways to weld by determining the appropriate values for amplitude, frequency, and speed, have also been studied (Zhang, 2021). The mechanical properties of the welded joints and any possible defects arising from deposition are intimately linked to their microstructure. The Fusion Zone (FZ), Heat Affected Zone (HAZ), and Base Metal areas are typically employed to divide the microstructure. (Khamari, 2018).

Future research can look into how vibration and heat treatment affect different materials, such as aluminum, high-carbon steels, and alloy steels. Although the shielded metal arc welding process is the focus of this work, TIG and MIG welding techniques may also be covered in future studies. Furthermore, research into the use of vibration-assisted welding for fusing disparate materials could be beneficial. Future studies could also look into how to combine robotic systems and vibration-assisted welding to improve automated manufacturing.

8 Conclusion

By conducting a quantitative literature review, this review article seeks to provide a state-of-the-art review for various vibration assisted welding process parameters that have a significant impact on the mechanical properties of welded joints. Additionally, guidelines and critical evaluation have been established for the researchers regarding the best methods, parameters, equipment, materials, instruments, etc. to choose in order to improve the mechanical properties of the welded components that are formed.

Following are the concluding remarks:

1. The detailed review of various vibration assisted welding methods suggest that mechanical properties of welded joints of different materials can be improved by providing vibration during welding.

2. Various experimental setups used by researchers have been analysed to provide insights for designing an optimized experimental setup for vibration-assisted welding.

3. The present study also gives us idea that how microstructure analysis plays a very important role in improving mechanical properties of welded joints.

4. The presence of fine grain structure was found by microstructural analysis, which may enhance the mechanical properties of welded joints because to a reduction in dendritic size connected with being near a weld pool excited.

5. The present literature review also suggests the desired frequency range of vibration for different welding processes, categorizing them into high frequency, medium frequency, and low frequency.

6. Induced vibration also helps in mixing the molten metal in the weld melt pool.

7. PWHT enhances microhardness by refining martensite and ferrite, while LFVW with low heat input further increases hardness; impact strength improvement is attributed to stress relief through recrystallization during annealing.

8. The regression equation, which was developed by RSM, has been demonstrated to be a useful tool for the vibration assisted welding parameters and to have a significant impact on the responses. The best parameters for vibration-assisted welding have also been determined using the RSM and TAGUCHI methodologies.

Future research on vibration-assisted welding (VAW) should focus on optimizing process parameters, developing standardized guidelines, and integrating with Industry 4.0 technologies for enhanced efficiency. Advanced numerical modeling and cost-benefit analyses will aid in industrial adoption. Further studies on critical applications in aerospace, automotive, and biomedical industries are essential for validation. Exploring hybrid approaches with other welding techniques can lead to improved weld strength and defect reduction.

Author contributions

RR: Methodology, Resources, Writing – original draft, Writing – review and editing. RC: Funding acquisition, Investigation, Methodology, Resources, Writing – review and editing. AsK: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review and editing. MS: Investigation, Methodology, Resources, Writing – review and editing. FA: Conceptualization, Formal Analysis, Investigation, Methodology, Resources, Writing – review and editing. ND: Investigation, Methodology, Resources, Writing – review and editing. AjK: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review and editing. SC: Investigation, Methodology, Project administration, Resources, Visualization, Writing – review and editing. SS: Investigation, Methodology, Project administration, Resources, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article.

Acknowledgments

The authors extend their acknowledgment to the financial support of the European Union under the REFRESH-Research Excellence For REgion Sustainability and High-tech Industries project number CZ.10.03.01/00/22_003/0000048 via the Operational Programme Just Transition and has been done in connection with project Students Grant Competition SP2025/062 “Specific research on progressive and sustainable production technologies” and SP2025/063 “Specific research on innovative and progressive manufacturing technologies” financed by the Ministry of Education, Youth and Sports and Faculty of Mechanical Engineering VŠB-TUO.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abramov, V. O., Sommer, F., and Orlov, D. (1995). Properties of Al-Pb base alloys applying electromagnetic forces and ultrasonic vibration during casting. Mater. Lett. 23 (1-3), 17–20. doi:10.1016/0167-577x(95)00275-8

Aghakhani, M. (2011). Parametric optimization of gas metal arc welding process by Taguchi method on weld dilution. Int. J. Model. Optim. 1 (3), 216–220. doi:10.7763/ijmo.2011.v1.38

Ambekar, S. D. (2015). Parametric Optimization of Gas metal arc welding process byusing Taguchi method on stainless steel AISI 410. Int. J. Res. Mod. Eng. Emerg. Technol. 4 (1), 1–9.

Anil Raj, J. P., Pratap Kumar, J., Melwin Rego, A., and Sunit Rout, I. (2021). Optimization of friction stir welding parameters during joining of AA3103 and AA7075 aluminium alloys using Taguchi method. Mater. Today Proc. 46 (17), 7733–7739. doi:10.1016/j.matpr.2021.02.246

Babitsky, A. N., Kalashnikov, A., Meadows, A., and Wijesundara, A. (2003). Ultrasonically assisted turning of aviation materials. J. Mater. Process. Technol. 132, 157–167. doi:10.1016/s0924-0136(02)00844-0

Bade Venkata Suresh, Y. S. (2022). “Influence of mechanical vibrations on impact strength of 1018 mild steel butt-weld-joints,” in Recent trends in product design and intelligent manufacturing systems, 633–644.

Balasubramanian, K. (2011). Studies on the effect of vibration on hot cracking and grain size in AA7075 aluminum alloy welding. Int. J. Eng. Sci. Technol., 681–686.

Bensheng Huang, J. L., Liu, J., Zhang, S., Chen, Q., and Chen, L. (2020). Effect of post-weld heat treatment on the residual stress and deformation of 20/0Cr18Ni9 dissimilar metal welded joint by experiments and simulations. J. Mater. Res. Technol. 9 (3), 6186–6200. doi:10.1016/j.jmrt.2020.04.022

Blaoui, M. M., Zemri, M., and Brahami, A. (2018). Effect of heat treatment parameters on mechanical properties of medium carbon steel. Mech. Mech. Eng. 22 (4), 909–918. doi:10.2478/mme-2018-0071

Celik, S., and Ersozlu, I. (2009). Investigation of the mechanical properties and microstructure of friction welded joints between AISI 4140 and AISI 1050 steels. Mater. Des. 30, 970–976. doi:10.1016/j.matdes.2008.06.070

Cervo, R., Ferro, P., and Tiziani, A. (2010). Annealing temperature effects on super duplex stainless steel UNS s32750 welded joints. I: microstructure and partitioning of elements. J. Mater Sci. 45, 4369–4377. doi:10.1007/s10853-010-4310-1

Chang, P.-H., and Teng, T. L. (2004). Numerical and experimental investigations on the residual stresses of the butt-welded joints. Comput. Mater. Sci. 29 (4), 511–522. doi:10.1016/j.commatsci.2003.12.005

Chao Chen, C. F., Fan, C., Cai, X., Lin, S., Yang, C., and Zhuo, Y. (2020). Microstructure and mechanical properties of Q235 steel welded joint in pulsed and un-pulsed ultrasonic assisted gas tungsten arc welding. J. Mater. Process. Technol. 275, 116335. doi:10.1016/j.jmatprotec.2019.116335

Chao Chen, W. L., Li, W., Sun, X., Feng, T., Du, W., and Zhao, X. (2023). Ultrasonic-Magnetic field coaxial hybrid controlling the microstructure and mechanical properties of 304 stainless steel GTAW joints. J. Mater. Res. Technol. 25, 5807–5819. doi:10.1016/j.jmrt.2023.07.055

Chuan Xu, G. S., Sheng, G., Cao, X., and Yuan, X. (2016). Evolution of microstructure, mechanical properties and corrosion resistance of ultrasonic assisted welded-brazedMg/Ti joint. J. Mater. Sci. and Technol. 32 (12), 1253–1259. doi:10.1016/j.jmst.2016.08.029

Edwin Raja Dhas, J., and Dhas, S. J. H. (2012). A review on optimization of welding process. Procedia Eng. 38, 544–554. doi:10.1016/j.proeng.2012.06.068

EL-Wazery, M. S., Mabrouk, O. M., Khafagy, S. M., and El-sissy, A. R. (2022). Mechanical and microstructural evaluation of aa6082-T61 joints produced byUltrasonic vibration assisted friction stir welding process. Int. J. Eng. 35 (12), 2297–2304. doi:10.5829/ije.2022.35.12c.04

Guancheng Zhaoa, Z. W., Wang, Z., Hu, S., Duan, S., and Chen, Y. (2020). Effect of ultrasonic vibration of molten pool on microstructure andmechanical properties of Ti-6Al-4V joints prepared via CMT + P welding. J. Manuf. Process. 52, 193–202. doi:10.1016/j.jmapro.2020.01.045

Gunawan Setia Prihandana, M. M., Mahardika, M., Hamdi, M., Wong, Y., and Mitsui, K. (2009). Effect of micro-powder suspension and ultrasonic vibration of dielectric fluid in micro-EDM processes-Taguchi approach. Int. J. Mach. Tools Manuf. 49 (12), 1035–1041. doi:10.1016/j.ijmachtools.2009.06.014

Huang, M. L., Lucas, M., and Adams, M. J. (2002). Influence of ultrasonics on upsetting of a model paste. Ultrasonics 40 (1-8), 43–48. doi:10.1016/s0041-624x(02)00245-7

Hui Lia, J. Z. (2017). Enhancement of AZ80 joints using ultrasonic vibration-assisted welding process. Sci. Technol. Weld. Join. 24 (4), 308–315.

Ilman, M. N., Widodo, A., and Triwibowo, N. (2022). Metallurgical, mechanical and corrosion characteristics of vibration assisted gas metal arc AA6061-T6 welded joints. J. Adv. Join. Process. 6, 100129. doi:10.1016/j.jajp.2022.100129

Ingram, E., Golan, O., Haj-Ali, R., and Eliaz, N. (2019). The effect of localized vibration during welding onthe microstructure and mechanical behavior ofSteel welds. Materials 12 (16), 2553. doi:10.3390/ma12162553

Jiewen Jin, Q. L., Lu, Q., Zhang, P., Li, C., and Yan, H. (2019). A study on the microstructure and fatigue properties of welding joints in vibration-assisted laser welding process. Steel Res. Inteenational 91 (4), 1900548. doi:10.1002/srin.201900548

Jimma, Y. K., Kasuga, Y., Iwaki, N., Miyazawa, O., Mori, E., Ito, K., et al. (1998). An application of ultrasonic vibration to the deep drawing process. J. Mater. Process. Technol. 80-81, 406–412. doi:10.1016/s0924-0136(98)00195-2

Kalpana, J., Rao, P. S., and Rao, P. G. (2017). Effect of vibratory welding process on hardness of dissimilar welded joints. Eng. Solid Mech. 5 (2), 133–138. doi:10.5267/j.esm.2017.2.003

Khamari, B. K., Kumar Sahu, P., and Biswal, B. B. (2018). Microstructure analysis of arc welded mild steel plates. Int. Conf. Mech. Mater. Renew. Energy 377, 012049. doi:10.1088/1757-899x/377/1/012049

Kim, B. J., Son, Y., Yun, J., and Lee, J. S. (2008). Residual stress relief and redistribution of welded metals by vibratory stress relaxation. Mater. Sci. Forum 580–582, 419–423. doi:10.4028/www.scientific.net/msf.580-582.419

Kolubaev, A. V., Sizova, O., Fortuna, S., Vorontsov, A., Ivanov, A., and Kolubaev, E. (2020). Weld structure of low-carbon structural steel formedby ultrasonic-assisted laser welding. J. Constr. Steel Res. 172, 106190. doi:10.1016/j.jcsr.2020.106190

Krajewski, A. (2009). Welding processes supported by mechanical vibration. Sci. Bull. Mech. Ser. Innovations Join. Tech. 229, 33–51.

Krajewski, A. (2010). The investigation of the effect of ultrasound field on the weld structure and properties. Sci. Bull. Mech. Ser. 230, 71–82.

Krajewski, A. (2016). Mechanical vibrations in welding processes. Weld. Int. 30 (1), 27–32. doi:10.1080/09507116.2014.937606

Krajewski, A., Włosiński, W., Chmielewski, T., and Kołodziejczak, P. (2012). Ultrasonic-vibration assisted arc-welding of aluminum alloys. Bull. Pol. Acad. Sci. 60, 841–852. doi:10.2478/v10175-012-0098-2

Kumar, S., Wu, C., and Padhy, G. (2017). Application of ultrasonic vibrations in welding and metal processing:A status review. J. Manuf. Process. 26, 295–322. doi:10.1016/j.jmapro.2017.02.027

Kuo, C.-C., Tsai, Q.-Z., Li, D.-Y., Lin, Y.-X., and Chen, W.-X. (2022). Optimization of ultrasonic welding process parameters to enhance weld strength of 3C power cases using a design of experiments approach. Polymers 14 (12), 2388. doi:10.3390/polym14122388

Lan, L., Kong, X., Qiu, C., and Zhao, D. (2016). Influence of microstructural aspects on impact toughness of multi-pass submerged arc welded HSLA steel joints. Mater. and Des. 90, 488–498. doi:10.1016/j.matdes.2015.10.158

Lee, C. H., Jang, G. C., Park, H. C., and Chang, K. H. (2007). Effect of vibration during welding on the fatigue strength of structural steel weldments. Solid State Phenom. 124-126, 1329–1332. doi:10.4028/3-908451-31-0.1329

Lida Zhu, Z. Y., Yang, Z., Xin, B., Wang, S., Meng, G., Ning, J., et al. (2021). Microstructure and mechanical properties of parts formed by ultrasonic vibration-assisted laser cladding of Inconel 718. Surf. Coatings Technol. 410, 126964. doi:10.1016/j.surfcoat.2021.126964

Liu, X. C., Wu, C. S., and Padhy, G. K. (2015). Improved weld macrosection, microstructure and mechanical properties of 2024Al-T4butt joints in ultrasonic vibration enhanced friction stir welding. Sci. Technol. Weld. Join. 20 (4), 345–352. doi:10.1179/1362171815y.0000000021

Mahmudul, H., Pavel, N. R., Habib, M. A., Sanin, A. Y., and Salman, A. (2018). A study of mechanical properties of vibration assisted arc welding joint. Eur. J. Eng. Res. Sci. 3 (3), 46–52. doi:10.24018/ejeng.2018.3.3.631

Masoud Sabzia, S. M., and Dezfuli, S. M. (2018). Drastic improvement in mechanical properties and weldability of 316L stainless steel weld joints by using electromagnetic vibration during GTAW process. J. Manuf. Process. 33, 74–85. doi:10.1016/j.jmapro.2018.05.002

Mousavi, H. F., Feizi, H., and Madoliat, R. (2007). Investigations on the effects of ultrasonic vibrations in the extrusion process. J. Mater. Process. Technol. 187-188, 657–661. doi:10.1016/j.jmatprotec.2006.11.168

Muvvala Chinnam Naidu, a. K., and Padal, K. T. B. (2021). The effect of post-weld heat-treatment (PWHT) and vibratory assisted welding (VAW) on hardness of 304L stainless steels material. Int. J. Adv. Technol. Eng. Explor. 8 (84), 1514–1523. doi:10.19101/ijatee.2021.874450

Nie, K. B., Wang, X., Wu, K., Hu, X., Zheng, M., and Xu, L. (2011). Microstructure and tensile properties of micro-SiC particles reinforced magnesium matrix composites produced by semisolid stirring assisted ultrasonic vibration. Mater. Sci. Eng. A 528 (29-30), 8709–8714. doi:10.1016/j.msea.2011.08.035

Niranjan, T., Singaravel, B., Chakradhar, B., and Srinivasulu Raju, S. (2023). Process parameter optimization in friction stir welding process using Taguchi method. Mater. Today Proc. doi:10.1016/j.matpr.2023.04.426

Pilyushenko, V. L., Belevitin, V. A., Pettik, Y. V., Klimenko, E. S., and Degtyarenko, I. P. (1992). The influence of vibration treatment on the structure and properties of iron and steel castings. Chem. Petroleum Eng. 28 (6), 401–402. doi:10.1007/bf01148990

Pravin Kumar Singh, D. P., Patel, D., and Prasad, S. B. (2016). Development of vibratory welding technique and tensile properties investigation of shielded MetalArc welded joints. Indian J. Sci. Technol. 9 (35), 1–6. doi:10.17485/ijst/2016/v9i35/92846

Pravin Kumar Singh, S. D., Patel, D., and Prasad, S. B. (2017). Optimization of vibratory welding process parameters using response surface methodology. J. Mech. Sci. Technol. 31, 2487–2495. doi:10.1007/s12206-017-0446-0

Pravin Singh, D. (2017). Investigation on the effect of vibrations on cooling behavior and mechanical propertiesof smaw butt welded joints. U.P.B. Sci. Bull. Ser. D. 79 (2), 137–146.

Prihandana, M. M., Mahardika, M., Hamdi, M., Wong, Y., and Mitsui, K. (2009). Effect of micro-powder suspension and ultrasonic vibration of dielectric fluid in micro-EDM processes-Taguchi approach. Int. J. Mach. Tools Manuf. 49, 1035–1041. doi:10.1016/j.ijmachtools.2009.06.014

Qi, J. Y. (2008). Investigations on the effects of ultrasonic vibrations in the wire. IEEE Ultrason. Symp., 2134–2137.

Qinghua Lu, J. J., Jin, J., Zhang, P., Yan, H., Shi, H., and Zhao, J. (2021). Performance of vibration-assisted laser welded joints based on orthogonal experiment design. J. Mater. Eng. Perform. 31, 2147–2158. doi:10.1007/s11665-021-06362-3

Rajakumar, S., Vimal Kumar, P., Kavitha, S., and Balasubramanian, V. (2020). Mechanical and microstructural characteristics of conventional and robotic gas metal arc welded low carbon steel joints: a comparative study. Metallogr. Microstruct. Analysis 9, 337–344. doi:10.1007/s13632-020-00645-2

Rajeev Ranjan, S. K., Jha, S. K., Mouria, P. K., and Mishra, S. (2024). Investigation of post weld heat treatment on mechanical properties of low frequency vibration assisted SMAW mild steel welded joints. Int. J. Interact. Des. Manuf. (IJIDeM) 18, 5489–5500. doi:10.1007/s12008-024-01793-3

Raman, N. S., and Raman, R. (2012). Grain refinement in Al–Mg–Si alloy TIG welds using transverse mechanical arc oscillation. J. Mater. Eng. Perform. 21 (11), 2495–2502. doi:10.1007/s11665-012-0207-2

Ranjan, R. (2022). Effect of vibration on weld quality and properties in vibration assisted welding: a review. Int. J. Mech. Handl. Automation 8, 1–10.

Rao, P. G., and Krishna, A. G. (2014). Mechanical properties improvement of weldments using vibratory welding system. Proc. Institution Mech. Eng. Part B J. Eng. Manuf. 229, 776–784. doi:10.1177/0954405414531248

Saha, M. K., Hazra, R., Mondal, A., and Das, S. (2019). Effect of heat input on geometry of austenitic stainless steel weld bead on low carbon steel. J. Institution Eng. (India) Ser. C 100, 607–615. doi:10.1007/s40032-018-0461-7

Shen, Y. L., and Shen, K. (2008). The effect of melt vibration on polystyrene melt flowing behavior during extrusion. J. Macromol. Sci. Part B 47 (6), 1228–1235. doi:10.1080/00222340802403453

Singh, P. K. (2017). Investigation on the effect of auxiliary vibrations on microstructure and mechanical properties of SMAW butt welded joints. Int. J. Eng. Material Sci. 25, 155–162.

Siyu Zhou, B. W., Wang, B., Wu, D., Ma, G., Yang, G., and Wei, W. (2021). Follow-up ultrasonic vibration assisted laser welding dissimilar metals for nuclear reactor pump can end sealing. Nucl. Mater. Energy 27, 100975. doi:10.1016/j.nme.2021.100975

Siyu Zhoua, G. M., Ma, G., Dongjiang, W., Chai, D., and Lei, M. (2018). Ultrasonic vibration assisted laser welding of nickel-based alloy and Austenite stainless steel. J. Manuf. Process. 31, 759–767. doi:10.1016/j.jmapro.2017.12.023

Skelton, R. C. (1968). Turning with an oscillating tool. Int. J. Mach. Tool Des. Res. 8 (4), 239–259. doi:10.1016/0020-7357(68)90014-0

Suresh Chitturi, C. K., Mohana Krishna, C. K., Bhaumik, M., and Ammisetti, D. K. (2020). Improvement of weld joint strength by applying random vibrations along with external magnetic field. IOP Conf. Ser. Mater. Sci. Eng. 998, 012035. doi:10.1088/1757-899x/998/1/012035

Taiwo Ebenezer Abioye, I. S., Omotehinse, I. S., Oladele, I. O., Olugbade, T. O., and Ogedengbe, T. I. (2020). Effects of post-weld heat treatments on the microstructure, mechanical and corrosion properties of gas metal arc welded 304 stainless steel. World J. Eng. 17 (1), 87–96. doi:10.1108/wje-11-2019-0323

Tewar, S. (1999a). Effects of transverse oscillation on tensile properties of mild steel weldments. Iron Steel Inst. Jpn. 39 (6), 570–574.

Tewar, S. P. (1999b). Effects of oscillation on impact property of weldments. ISIJ Int. 39 (8), 809–812. doi:10.2355/isijinternational.39.809

Tsai, Y.-T, Lin, P.-C., Chen, Y.-W., Wang, S.-H., and Yang, J.-R. (2018). Fatigue behavior and microstructural characteristics of a duplex stainless steel weld metal under vibration-assisted welding. Mater. Sci. Eng. A. 720, 319–327. doi:10.1016/j.msea.2018.02.096

Uzunali, U. Y. (2015). The effects of post weld heat treatment on the mechanical properties of tempered martensite and high strength steel welded joints. Adv. Struct. Eng. Mech.

Veerendra Chitturi, S. R., Pedapati, S. R., and Awang, M. (2022). MATHEMATICAL MODEL FOR FRICTION STIR LAP WELDED AA5052 AND SS304 JOINTS AND PROCESS PARAMETERS OPTIMIZATIONFOR HIGH JOINT STRENGTH. Adv. Mater. Sci. 22 (1), 5–22. doi:10.2478/adms-2022-0001

Victor, A. D. (2020). Impact of low frequency vibration during welding and annealing on microstructure of mild steel butt-welded joints. Mod. APPROACHES MATERIAL Sci., 366–373.

Vivès, C. (1993). Effects of electromagnetic vibrations on the microstructure of continuously cast aluminium alloys. Mater. Sci. Eng. A 173 (1-2), 169–172. doi:10.1016/0921-5093(93)90209-w

Vykunta Rao, M. (2022). Genaral regression neural network based frame work for the evaluation of ultimate tensile strength of vibratory assisted welded joints. Recents Adv. Manuf. Automation, Des. Energy Technol., 173–180.

Weber, H., Herberger, J., and Pilz, R. (1984). Turning of machinable glass ceramics with an ultrasonically vibrated tool. CIRP Ann. - Manuf. Technol. 33 (1), 85–87. doi:10.1016/s0007-8506(07)61385-7

Wu, W. (2005). Mechanical behavior of the precision component after synchronous vibratory joining. 5650, 438, doi:10.1117/12.582408

Xu, M. G., Zhang, J., Li, Y., Zhang, Q., and Ren, S. (2009). Material removal mechanisms of cemented carbides machined by ultrasonic vibration assisted EDM in gas medium. J. Mater. Process. Technol. 209 (4), 1742–1746. doi:10.1016/j.jmatprotec.2008.04.031

Yamamoto, H., Harada, S., Ueyama, T., Ogawa, S., Matsuda, F., and Nakata, K. (1993). Beneficial effect of low frequency pulsed MIG welding on grain refinement of weld metal and improvementof solidification crack susceptibility for aluminiumalloy. Weld. Int. 7 (8), 593–598. doi:10.1080/09507119309548453

Yunhao Xia, B. D., Dong, B., Cai, X., and Lin, S. (2024). Ultrasonic vibration assisted gas tungsten arc welding of Inconel 690 alloy: ultrasonic effect to refine grains and improve mechanical properties. Ultrason. Sonochemistry 108, 106950. doi:10.1016/j.ultsonch.2024.106950

Yuvaraj, N., Roy, J. G., and Vipin, (2022). Enhancement of microstructural and mechanical properties of ultrasonic vibration-assisted Cold metal transfer welding of 304 stainless steel. J. Mater. Eng. Perform. 31, 8497–8511. doi:10.1007/s11665-022-06877-3

Ze-long Wang, Z.-t. Z.-b.-f., Zheng, Z. t., Zhao, L. b., Lei, Y. f., and Yang, K. (2018). Microstructure evolution and nucleation mechanism of Inconel 601H alloy welds by vibration-assisted GTAW. Int. J. Minerals, Metallurgy, Mater. 25, 788–799. doi:10.1007/s12613-018-1627-2

Zhang, P., Jin, J., Yan, H., Shi, H., and Zhao, J. (2021). Performance of vibration-assisted laser welded joints based on orthogonal experiment design. J. Mater. Eng. Perform. 31, 2147–2158. doi:10.1007/s11665-021-06362-3

Zhao, M., Chiew, S., and Lee, C. (2016). Post weld heat treatment for high strength steel welded connections. J. Constr. Steel Res. 122, 167–177. doi:10.1016/j.jcsr.2016.03.015

Zhiqiang Zhang, C. H., He, C., Li, Y., Yu, L., Zhao, S., and Zhao, X. (2020). Effects of ultrasonic assisted friction stir welding on flow behavior, microstructure and mechanical properties of 7N01-T4 aluminum alloy joints. J. Mater. Sci. and Technol. 43, 1–13. doi:10.1016/j.jmst.2019.12.007

Zuguo Liu, X. J., Jin, X., Li, J., Hao, Z., and Zhang, J. (2022b). Numerical simulation and experimental analysis on the deformation and residual stress in trailing ultrasonic vibration assisted laser welding. Adv. Eng. Softw. 172, 103200. doi:10.1016/j.advengsoft.2022.103200

Keywords: vibration assisted welding, ultrasonic vibration, mechanical properties, microstructure, TIG, MIG, SMAW

Citation: Ranjan R, Cep R, Kumar A, Srivastava M, Altarazi F, Dogra N, Kumar A, Chand S and Samal SP (2025) Comprehensive review of vibration-assisted welding processes: Mechanisms, applications, and future directions. Front. Mech. Eng. 11:1550928. doi: 10.3389/fmech.2025.1550928

Received: 24 December 2024; Accepted: 28 February 2025;

Published: 09 June 2025.

Edited by:

Kanak Kalita, Vel Tech Dr. RR and Dr. SR Technical University, IndiaReviewed by:

Akash Nag, Institute of Geonics (ASCR), CzechiaGulshan Kumar, Birla Institute of Technology and Science, United Arab Emirates

Copyright © 2025 Ranjan, Cep, Kumar, Srivastava, Altarazi, Dogra, Kumar, Chand and Samal. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ajay Kumar, YWpheS5rdW1hcjMwODg2QGdtYWlsLmNvbQ==; Ashwini Kumar, YWtuaXRqc3IwOEBnbWFpbC5jb20=

Rajeev Ranjan

Rajeev Ranjan Robert Cep

Robert Cep Ashwini Kumar

Ashwini Kumar Mayank Srivastava4

Mayank Srivastava4 Ajay Kumar

Ajay Kumar