- 1Department of Agronomy, Agricultural College and Research Institute (AC&RI), Tamil Nadu Agricultural University (TNAU), Madurai, Tamil Nadu, India

- 2ICAR-Krishi Vigyan Kendra, Tamil Nadu Agricultural University (TNAU), Madurai, Tamil Nadu, India

- 3Department of Food Policy and Public Health Nutrition, Community Science College and Research Institute (CSC&RI), Tamil Nadu Agricultural University (TNAU), Madurai, Tamil Nadu, India

- 4Department of Agricultural Microbiology, Agricultural College and Research Institute (AC&RI), Tamil Nadu Agricultural University (TNAU), Madurai, Tamil Nadu, India

- 5Agricultural Research Station, Tamil Nadu Agricultural University (TNAU), Kovilpatti, Tamil Nadu, India

- 6Department of Information Technology, Velammal College of Engineering and Technology, Madurai, Tamil Nadu, India

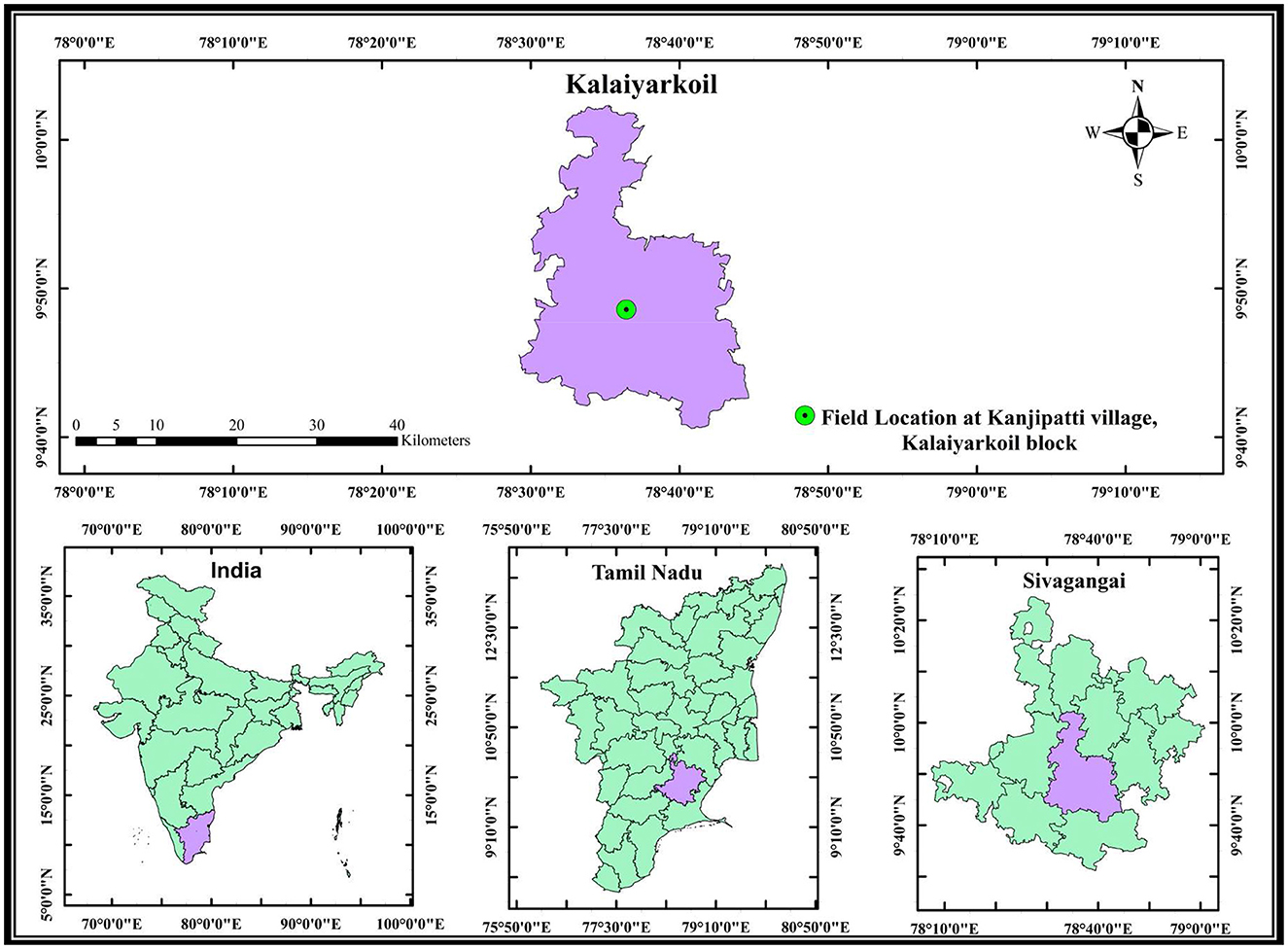

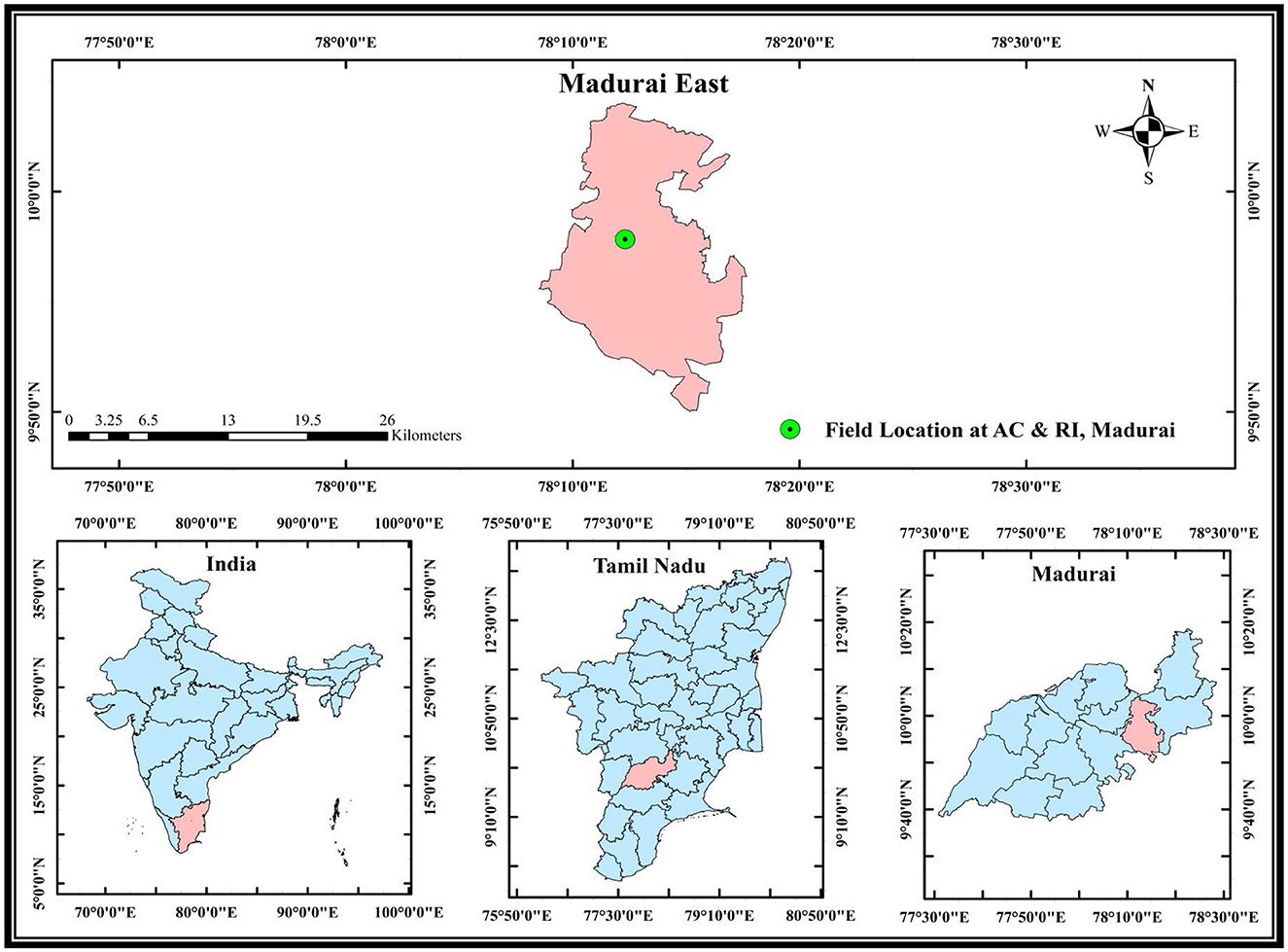

Precise application of nutrients and water in groundnut ensures optimal plant growth, enhances yield and quality and minimizes resource wastage. It promotes sustainable farming by improving nutrient use efficiency and saving water. Field experiments were conducted at two locations. This study addresses the need for efficient water and nutrient management in groundnut by evaluating the effects of automated drip irrigation and a low-cost smart drip fertigation system on its growth, physiology, root traits and yield. Location I was a farmer's field at Kanjipatti village of Kalaiyarkoil block, Sivagangai district (rabi 2023) and Location II was the central farm, Agricultural College and Research Institute in Madurai district (summer 2024) of Tamil Nadu. Field trials were laid out in split plot design with three replications. The main plot treatments consisted of three drip irrigation mrthods, namely; conventional drip irrigation (M1), time based automated drip irrigation (M2) and sensor based automated drip irrigation (M3); where as five drip fertigation treatments, viz., fertigation of 75% Recommended Dose of Fertilizers (RDF) (F1), fertigation of 100% RDF (F2), Soil Test Crop Response (STCR) based drip fertigation (F3), sensor based fertigation at 75% NPK level (F4), and sensor based fertigation at 100% NPK level (F5) were imposed in the sub plot. Significantly higher growth (plant height), physiological parameters (Crop Growth Rate [CGR], Leaf Area Index [LAI], Relative Water Content [RWC], Dry Matter Production [DMP], leaf temperature, Normalized Difference Vegetation Index [NDVI] and SPAD meter value), root characteristics (number of nodules, root length, volume, and dry weight) and ultimately yield (pod and haulm yield) of groundnut were recorded under sensor-based automated drip irrigation combined with sensor-based fertigation at 100% NPK level (M3F5). Sensor-based automated drip irrigation combined with sensor-based fertigation at 100% NPK level (M3F5) recorded 43.74% and 45.25% higher pod yield compared to conventional drip irrigation with fertigation at 75% RDF in both seasons, respectively. Practicing sensor-based automated drip fertigation in groundnut not only enhanced the yield but also reduced the input requirements, saving 7%−12% of water and 15%−25% of fertilizers in groundnut production.

1 Introduction

Groundnut (Arachis hypogaea L.), commonly referred to as the “King of oilseeds,” is an annual legume crop primarily grown for its edible seeds. India is a leading country in groundnut cultivation, holding the top position in terms of area under cultivation and ranking second in production, following China. In India, groundnut is cultivated in an area of 6.02 million hectares, producing 10.2 million tons annually with an average productivity of 1,703 kg/ha (Indiastat, 2022). A significant 82% of India's groundnut production is concentrated in five states. Gujarat leads with 34.8% of the total production, followed by Rajasthan (15.5%), Tamil Nadu (13%), Andhra Pradesh (11.8%), and Karnataka (7.1%). In Tamil Nadu, groundnut is cultivated over an area of 0.409 million hectares, producing 1.023 million tons annually with a higher average productivity of 2,500 kg/ha (Indiastat, 2022).

Groundnut requires approximately 500–700 mm of water to complete its life cycle. Optimizing the application of irrigation water and fertilizers is critical for efficient irrigation system design, water conservation, energy and cost savings and minimizing environmental hazards (Zafar et al., 2020). Drip irrigation supplies water directly to the root zone, significantly reducing water wastage (Kang et al., 2004; Ibragimov et al., 2007; Upadhyaya, 2015: Chtouki et al., 2024).

Currently, many farmers in India irrigate their fields through manual control, which can lead to inefficient water and nutrient use. These issues can be effectively addressed through smart irrigation and fertigation technologies such as automated drip irrigation systems, where irrigation occurs only when there is a critical need for water. The system uses valves that turn on or off automatically (Nagarajan et al., 2020). When integrated with fertigation, drip irrigation offers a more effective method of nutrient delivery, significantly improving crop yields (Jat et al., 2020). This method ensures precise and uniform nutrient application to the wetted area, where most active roots are concentrated, allowing for the right quantities and concentrations of nutrients throughout the growing season.

Sensor-based automated fertigation offers an advanced and intelligent approach by continuously adjusting irrigation and nutrient supply according to real-time data. These systems utilize inputs from moisture sensors, nutrient sensors (e.g., NPK sensors) and microcontrollers to manage the fertigation process effectively. Such smart systems are not only efficient but also essential for resource conservation and sustainability, especially in the context of climate change and resource depletion.

However, the high cost and complexity of commercial systems often limit access for small and marginal farmers in India. Therefore, the development and validation of low-cost, sensor-based automated drip irrigation and fertigation technologies tailored for smallholder farmers could offer a practical and scalable solution. This approach has the potential to increase groundnut productivity, reduce water and fertilizer use and enhance resource-use efficiency, contributing to improved farmer income and sustainable agriculture.

Despite advancements in irrigation technologies, limited efforts have been made to integrate sensor-based automation for both irrigation and fertigation under field conditions in groundnut. The present study aims to fill this gap by evaluating the effect of a low-cost sensor-based automated drip fertigation system on the growth, physiological parameters, root characteristics and yield of groundnut. It is hypothesized that this indigenous low-cost smart fertigat system will significantly improve groundnut productivity and resource-use efficiency compared to conventional methods, thereby providing a sustainable and scalable solution for small and marginal farmers.

2 Materials and methods

2.1 Experimental site description

Field experiments were conducted in two locations to evaluate the performance of automated drip irrigation and low cost smart drip fertigation system on growth, physiological parameters, root characters and yield of groundnut. Location I was a farmer's field at Kanjipatti village of Kalaiyarkoil block, Sivagangai district (rabi 2023) and Location II was the central farm, Agricultural College and Research Institute in Madurai district (summer 2024) of Tamil Nadu. The locations of the experimental sites are shown in Figures 1, 2. The soil texture of the experimental field in Kanjipatti village, Sivagangai district (Location I), is classified as red sandy clay loam. It is medium in available nitrogen (373 kg/ha), phosphorus (20.5 kg/ha), and potassium (275 kg/ha). In contrast, the soil texture of the experimental field at the Agricultural College and Research Institute, Madurai district (Location II), is sandy clay loam. It is low in available nitrogen (222 kg/ha) but medium in phosphorus (18.2 kg/ha) and potassium (190 kg/ha).

2.2 Weather

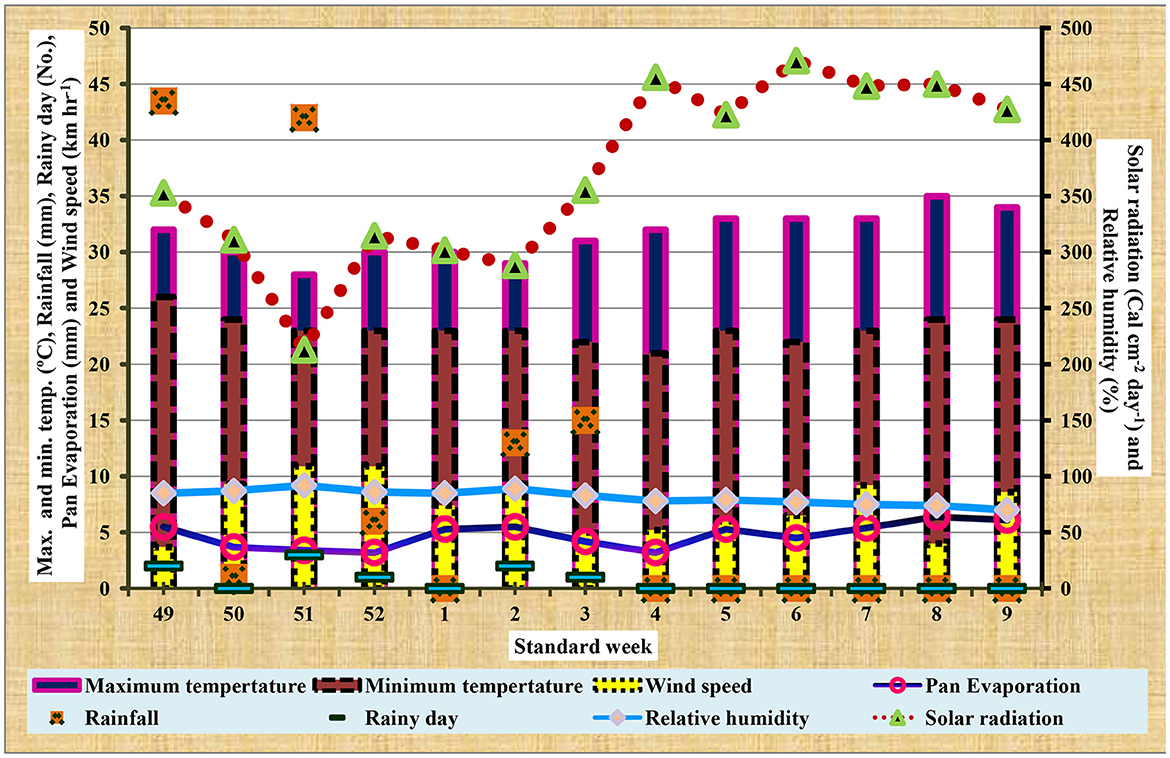

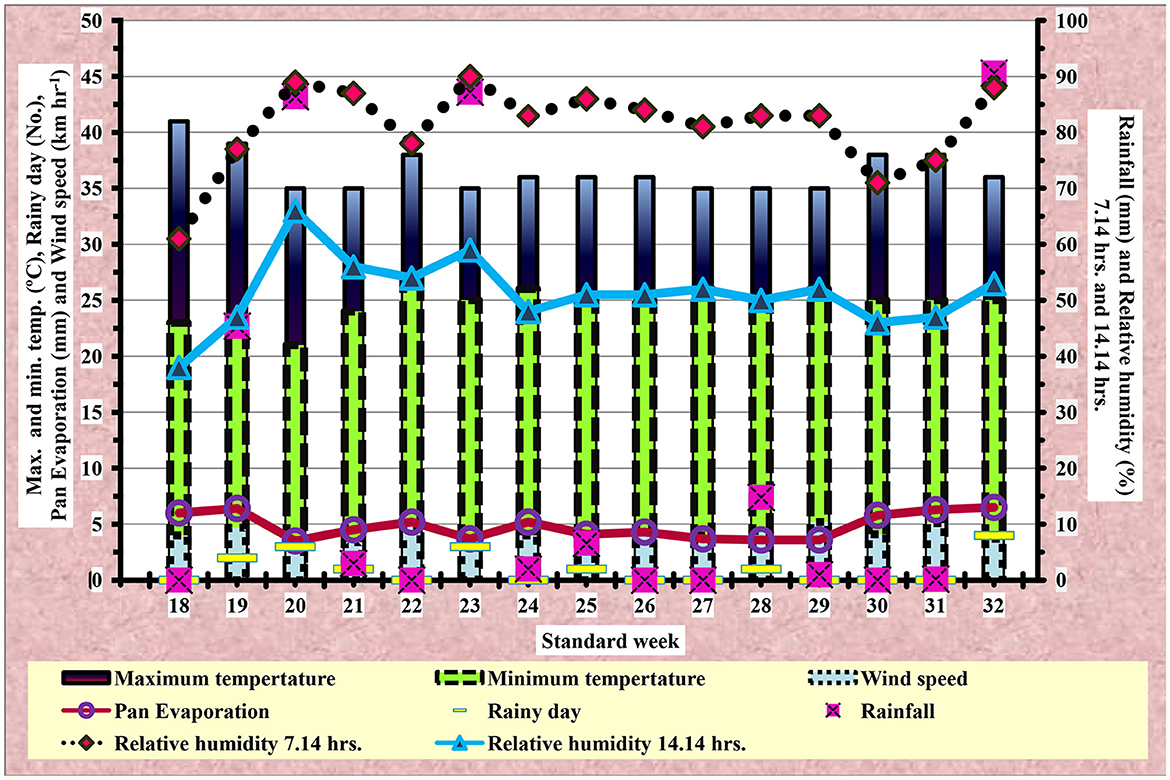

For Location I, data on maximum and minimum temperatures, relative humidity, pan evaporation, wind speed, rainfall and solar radiation were collected from the Agro Climatic Research Center in Coimbatore, Tamil Nadu. For Location II, measurements were taken at the Agro Meteorological Observatory, Agricultural College and Research Institute, Madurai district, Tamil Nadu. Maximum and minimum temperatures during the cropping period at Location I ranged from 28 °C to 35 °C and 21 °C to 26 °C, respectively. Location II prevailed temperatures ranging from 35 °C to 41 °C and 21 °C to 27 °C, respectively. Total rainfall of 120.5 mm and 337.2 mm was recorded with 9 and 15 rainy days in season I and II, respectively. For relative humidity, Location I recorded values between 70% and 92%, while Location II ranged from 61% to 90% at 7:14 h and 38% to 66% at 14:14 h. The weekly mean pan evaporation was 4.7 mm at Location I and 4.8 mm at Location II. The weekly mean wind speed was 7.4 km h−1 at Location I and 4.2 km h−1 at Location II. Location I recorded a weekly mean solar radiation of 370.2 Cal cm−2 day−1, while Location II recorded 6.3 h day−1 of weekly mean sunshine hours. The weather conditions during the crop growth period are depicted in Figures 3, 4.

Figure 3. Weekly trends of key weather parameters (maximum and minimum temperature, wind speed, rainfall, rainy day, pan evaporation, solar radiation and relative humidity) recorded during the groundnut cropping period (rabi, 2023).

Figure 4. Weekly trends of key weather parameters (maximum and minimum temperature, wind speed, rainfall, rainy day, pan evaporation and relative humidity) recorded during the groundnut cropping period (summer, 2024).

2.3 Treatment details

Field trials were laid out in split plot design with three replications. The main plot treatments consisted of three drip irrigation methods, namely; conventional drip irrigation (M1), time based automated drip irrigation (M2) and sensor based automated drip irrigation (M3); where as five drip fertigation treatments, viz., fertigation of 75% RDF (F1), fertigation of 100% RDF (F2), STCR based drip fertigation (F3), sensor based fertigation at 75% NPK level (F4), and sensor based fertigation at 100% NPK level (F5) were imposed in the sub plot.

M1 - Water is supplied through a drip irrigation system manually, without automation. The irrigation timing and quantity are based on crop evapotranspiration (ETc), M2 - Water is supplied through an automated drip irrigation system on a pre-set schedule. The system turns on and off at predetermined times, ensuring consistent water application based on fixed time intervals. M3 - Irrigation is controlled using soil moisture sensors. Water is applied only when sensors detect that the soil moisture has dropped below a certain threshold. This system ensures efficient water use, applying water only when needed based on real-time soil conditions. F1 - Fertilizer is applied through drip irrigation at 75% of the Recommended Dose of Fertilizers (RDF), as per CPG (2020), reducing fertilizer input by 25%, F2 - Fertilizer is applied through drip irrigation at the full 100% RDF, ensuring that crop nutrient requirements are fully met throughout the growing season, F3 - Fertilizer application is based on Soil Test Crop Response recommendations, with dosages adjusted according to soil test results. This approach optimizes fertilizer use according to the specific nutrient status of the soil and crop needs, F4–Water Soluble Fertilizers (WSF's) are applied when sensors detect that soil nutrient levels have fallen below the 75% NPK level threshold, automatically initiating fertigation to maintain the nutrient level at 75% NPK. This approach ensures fertigation is conducted based on real-time soil nutrient levels and F5–WSF's are applied when sensors detect that soil nutrient levels have fallen below the 100% NPK level threshold, automatically initiating fertigation to maintain the nutrient level at 100% NPK. This ensures precise and adequate fertilization based on real-time nutrient needs.

2.4 Crop and variety

Groundnut variety VRI 10 with duration of 90–95 days was used as test crop during both the seasons.

2.5 Seeds and sowing

Seeds were sown at a spacing of 30 cm × 10 cm. The seed rate was calculated at 125 kg per hectare, which is the recommended rate for irrigated groundnut. Gap filling was done on 15 DAS to maintain the optimum plant population across all plots.

2.6 Weed management

The spraying of pre-emergence herbicide Pendimethalin @ 2.5 liters ha−1 was done at 3 DAS. Subsequently, one hand weeding was employed at 30 DAS.

2.7 Nutrient management

Nutrient management was implemented according to the treatment schedule. The recommended dose of 25:50:75 kg NPK ha−1 as per the CPG (2020) was followed. P was applied as a basal through SSP @ 234.4 kg/ha for 75% RDF and 312.5 kg/ha for 100% RDF. Additionally, groundnut rich was applied @ 5 kg per hectare across all treatments. Gypsum was applied @ 400 kg ha−1 for all treatments, with 200 kg ha−1 as a basal and the remaining 200 kg ha−1 applied during earthing up at 45 DAS.

For this study, Urea, SSP, MOP, MAP, and potassium nitrate were used as sources of nutrients.

2.8 Innovation in the system

2.8.1 Cost effective design

The system is built using affordable and locally available components such as microcontroller boards (Arduino), sensors (soil moisture and EC), solenoid valves, relays, power supply units, PVC pipes and fittings, mobile applications, Wi-Fi modules, plastic barrels, and a low-pressure drip fertigation unit (using T-connectors and venturi). This design significantly reduces overall cost, making the technology accessible to small and marginal farmers.

2.8.2 Real time monitoring

Integration of soil moisture and EC sensors allows for continuous, real-time monitoring of soil and nutrient conditions. This enables precise and timely irrigation and fertigation decisions based on actual field requirements.

2.8.3 Automated control

The system is programmed to automatically initiate irrigation and fertigation when sensor values cross preset thresholds. This automation minimizes manual intervention, reduces labor requirements and prevent s the overuse of water and fertilizers.

2.8.4 User friendly interface

A simple mobile-based interface or display unit enables farmers to monitor system status and receive alerts, ensuring ease of use in rural settings without the need for advanced technical skills.

2.8.5 Improved nutrient use efficiency

By delivering water and fertilizers only when and where required, the system enhances nutrient use efficiency and minimizes environmental losses, contributing to sustainable agricultural practices.

2.9 Sensors

2.9.1 Moisture sensor

The irrometer sensor was used to assess soil moisture content in the field.

2.9.2 Nutrient sensors

The NPK sensors measured the levels of NPK in the soil by determining the concentration of N, P, and K ions in a specified volume of soil solution. Each sensor consisted of two probes: a reference electrode and an ion-selective electrode. The electrical potential difference between the probes was amplified into a data signal and transmitted to the microcontroller. The fertigation system automates the injection of nutrients by continuously monitoring soil nutrient levels using the NPK sensors.

2.10 Lay out of drip irrigation system

The water was pumped through 7.5 HP submersible motor from open well and it was conveyed to the field by using PVC pipes after filtering through sand and screen filters. From the main line water was taken to the field through sub mains of 63 mm and 40 mm diameter PVC pipes. In the sub main, 16 mm LLDPE inline laterals with 4 lph drippers spaced at 60 cm were fixed at a lateral spacing of 120 cm. And each laterals were laid on the center of the raised beds which were formed at 120 cm. A 16 mm tap was fixed at the head of each lateral in order to regulate the fertigation scheduling and the laterals were closed with end cap.

2.11 Seasons

The first crop was raised during rabi 2023 (Ayppasi pattam). The sowing was taken up on 03.12.2023 and harvesting was completed on 27.02.2024. Subsequently, the second crop was raised during summer 2024 (Chithirai pattam). Sowing was taken up on 06.05.2024 and harvesting was done on 13.08.2024.

2.12 Growth attributes

2.12.1 Plant population

Plant population was recorded from the net plot area by counting the number of plants in each treatment at at harvest and expressed in plants m−2.

2.12.2 Plant height

At harvest stage, plant height was measured from the ground to the tip of the topmost leaf. The average height of five different plants was calculated and expressed in cm.

2.13 Physiological parameters

2.13.1 Leaf area index

At the harvest stage, five tagged plants in each plot were used to measure the length and width of the third fully opened leaflet in the tetrafoliate leaves from the top of the main stem. LAI was calculated using the Palaniswamy and Gomez (1974) formula,

Where,

L - Mean leaf length (cm).

W - Mean leaf width (cm).

K - Constant factor (0.75).

N - Mean number of leaves per plant.

S - Plant spacing (cm2).

2.13.2 Dry matter production

For each treatment, dry matter production (DMP) was assessed at harvest stage of the crop. Five plants were randomly selected from the destructive sample row, uprooted and cleaned of dirt. The samples were shade-dried for 3 days, followed by oven-drying at 80 °C until they reached a constant weight. The dry weight was recorded and computed in kg ha−1.

2.13.3 Crop growth rate (CGR)

The crop growth rate was calculated from 25 to 50 DAS, 50 DAS to 75 DAS, and 75 DAS to harvest by using the formula given by Buttery (1970) and expressed in g m−2 day−1.

Where, W1 and W2 are the initial and final dry weight of the plant at time t1 and t2, ρ is the land area occupied by the plant in m2 and t1 and t2 are the initial and final day of a period of observation respectively.

2.13.4 SPAD meter value

Chlorophyll content of leaves was recorded as described by Peng et al. (1993) using the chlorophyll meter (SPAD-502, Soil Plant Analysis Development section, Minolta Camera Co. Ltd., Japan). The readings were recorded on the upper most fully expanded leaves in five randomly chosen plants at 50 DAS. The average values were worked out and expressed as SPAD meter value.

2.13.5 Normalized difference vegetation index

Green seekerTM (N-Tech Industries, Inc., Ukiah, CA, USA) is a portable hand-held optical sensor used to measure the NDVI values to determine the plant status. It is used to assess vegetation growth and biomass. The sensor was positioned around 60 cm above the plant canopy and measurements were taken at 50 DAS. The NDVI value was determined by measuring the light reflected from the green seeker sensor's active light source within a specific visible spectrum range. The light source emits light at wavelengths of 671 ± 6 nm and 780 ± 6 nm on the plant canopy.

2.13.6 Leaf temperature

Leaf temperature was measured at 50 DAS using an infrared thermometer to assess canopy temperature in the field. This device operates by detecting infrared radiation emitted from the plant surface, providing a non-contact, rapid and accurate method for temperature measurement. Temperature readings were recorded in degrees Celsius (°C).

2.13.7 Relative water content

At 50 DAS, fifty leaf discs were taken from the third leaf from the top, weighed and floated in water until fully rehydrated, weighed and then dried in the oven at 80 °C until a constant dry weight is obtained. Relative water content is determined with the formula suggested by Turner (1981) and expressed in per cent (%).

Where,

FW = Fresh weight of the leaf sample (g).

DW = Dry weight of the leaf sample (g).

TW = Turgid weight of the leaf sample (g).

2.14 Root growth characters

Root traits were assessed at harvest stage.

2.14.1 Number of root nodules per plant

The plants that are tagged were removed carefully and water was used to clean the roots which removes the soil sticking around without causing any damage to the nodules. Then the count of nodules were taken and stated as number of root nodules per plant.

2.14.2 Root length

The plants were removed carefully from the soil without damaging the roots by using digging fork. The root length of each plant was measured from the collar area down to the tip of the longest root. The mean value of the five root samples were recorded and expressed in cm.

2.14.3 Root volume

The sampled roots were separated and washed gently to remove the soil particles. Then roots are immersed in a measuring cylinder filled with known quantity of water. The difference between the initial and final reading after placing the root, gave the root volume as per water displacement method suggested by (Dewan and Subba Rao 1979) and expressed in cm3.

2.14.4 Root dry weight

Collected roots were initially shade dried and then oven-dried at 65 ± 5 °C until a constant weight was attained. Root dry weight was recorded and expressed as g plant−1.

2.15 Pod yield

The harvested pods from the net plot was sun dried to have a moisture content of 14 per cent and the pod yield is expressed in kg ha−1.

2.16 Haulm yield

After stripping off the pods, the haulms were sun dried and dry weight was recorded and expressed in kg ha−1.

2.17 Harvest index

Harvest index was determined by comparing the yield of the economically important plant portions (economic yield) to the overall biological yields in terms of dry matter.

2.18 Statistical analysis

To compare the difference among treatment combinations, data analyses was done with Agres software at 5% probability level as suggested by Gomez and Gomez (1984).

3 Results

3.1 Growth parameters

3.1.1 Plant population

Plant population was not influenced by drip irrigation and fertigation methods in both seasons (Table 1).

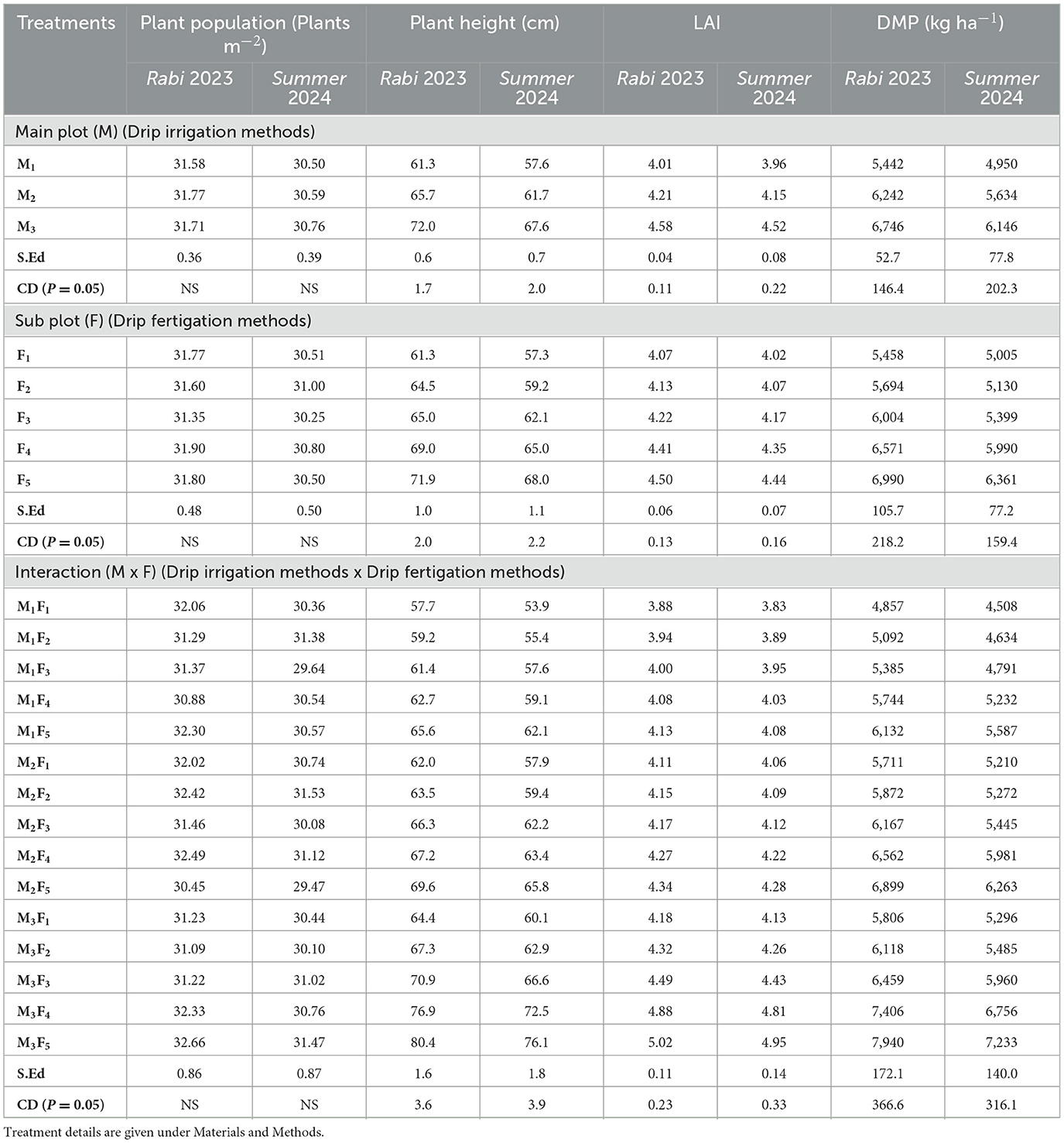

Table 1. Effect of drip irrigation and fertigation methods on growth and physiological parameters of groundnut (Arachis hypogaea L.).

3.1.2 Plant height

Drip irrigation and fertigation methods caused variations in plant height in both seasons (Table 1). Sensor based automated drip irrigation (M3) recorded significantly taller plants of 72.0 and 67.6 cm in the rabi (2023) and summer (2024) seasons, respectively. Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded significantly higher plant height of 71.9 and 68.0 cm in the rabi (2023) and summer (2024) seasons, respectively. On interaction, sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly taller plants of 80.4 and 76.1 cm in the rabi (2023) and summer (2024) seasons, respectively.

3.2 Physiological parameters

3.2.1 Leaf area index

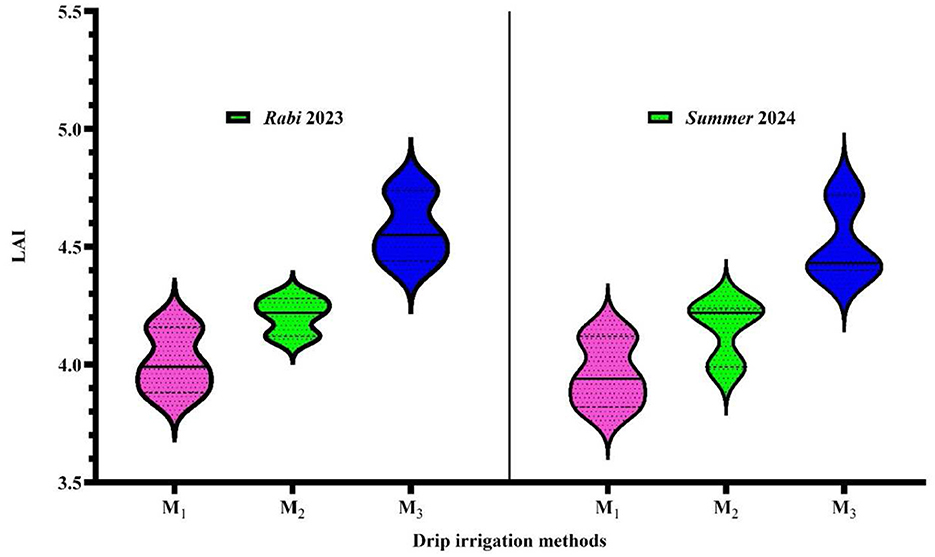

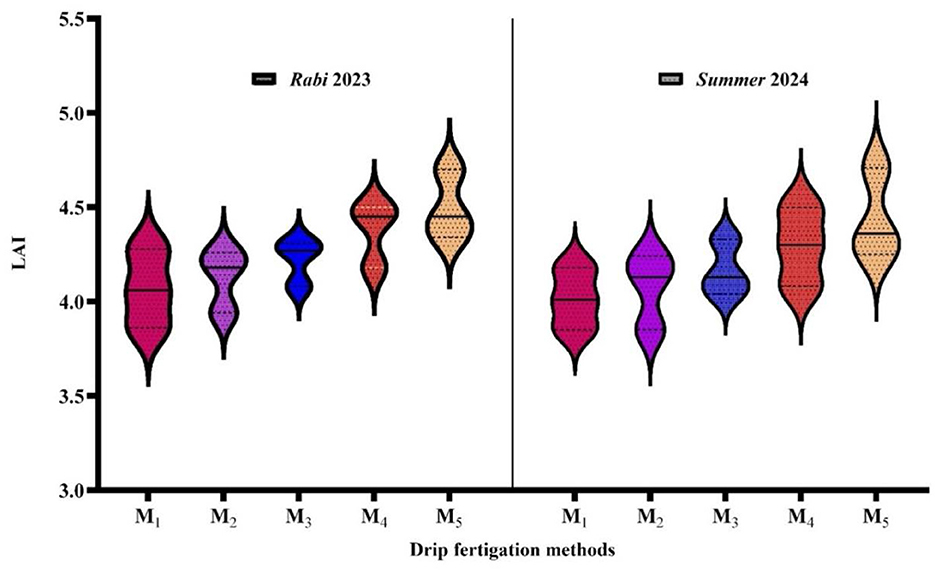

The leaf area index was significantly influenced bydrip irrigation and fertigation methods in both seasons (Table 1 and Figures 5, 6). Sensor based automated drip irrigation (M3) recorded significantly higher LAI of 4.58 and 4.52 in the rabi (2023) and summer (2024) seasons, respectively. Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded significantly higher LAI of 4.50 and 4.44 in the rabi (2023) and summer (2024) seasons, respectively. The interaction was significant. Sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly higher LAI of 5.02 and 4.95 in the rabi (2023) and summer (2024) seasons, respectively.

Figure 5. Effect of drip irrigation methods on LAI of of groundnut (Arachis hypogaea L.). LAI, Leaf Area Index; M1, Conventional drip irrigation; M2, Time based automated drip irrigation; M3, Sensor based automated drip irrigation.

Figure 6. Effect of drip fertigation methods on LAI of of groundnut (Arachis hypogaea L.). LAI, Leaf area index; M1, Drip fertigation of 75% RDF; M2, Drip fertigation of 100% RDF; M3, STCR based drip fertigation; M4, Sensor based fertigation at 75% NPK level; M5, Sensor based fertigation at 100% NPK level.

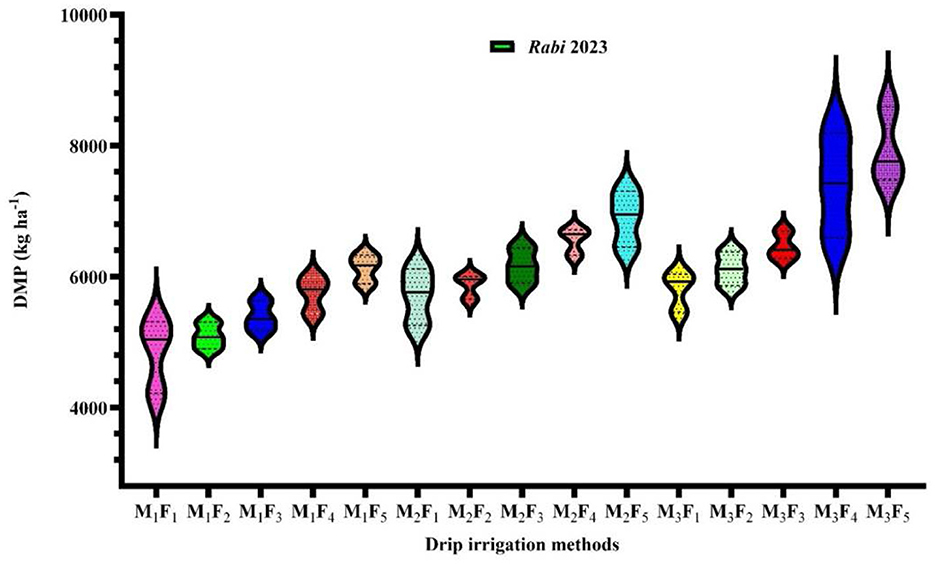

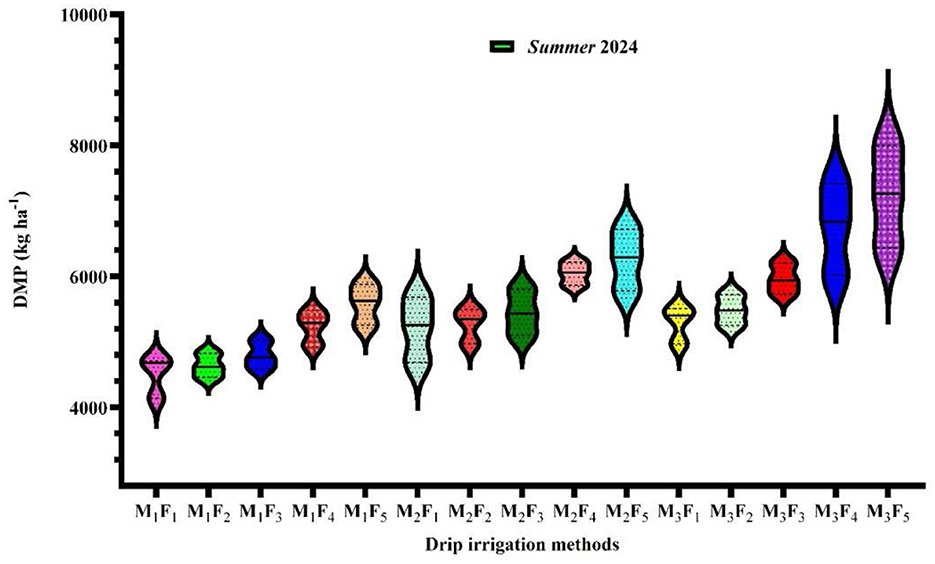

3.2.2 Dry matter production

The dry matter production was significantly influenced by drip irrigation and fertigation methods in both seasons (Table 1 and Figures 7, 8). Accumulation of significantly higher dry matter was noticed with sensor based automated drip irrigation (M3) with a weight of 6,746 and 6,146 kg ha−1 in the rabi (2023) and summer (2024) seasons, respectively. Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded significantly higher DMP of 6,990 and 6,361 kg ha−1 in the rabi (2023) and summer (2024) seasons, respectively. Interaction was found to be significant. Sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly higher DMP of 7,940 and 7,233 kg ha−1 in the rabi (2023) and summer (2024) seasons, respectively.

Figure 7. Effect of drip irrigation and fertigation methods on DMP of groundnut (Arachis hypogaea L.) during rabi 2023. DMP- Dry matter production; Kg ha−1, Kilogram hectare−1; M1, Conventional drip irrigation; M2, Time based automated drip irrigation; M3, Sensor based automated drip irrigation; F1, Drip fertigation of 75% RDF; F2, Drip fertigation of 100% RDF; F3, STCR based drip fertigation; F4, Sensor based fertigation at 75% NPK level; F5, Sensor based fertigation at 100% NPK level.

Figure 8. Effect of drip irrigation and fertigation methods on DMP of groundnut (Arachis hypogaea L.) during summer 2023. DMP, Dry matter production; Kg ha−1, Kilogram hectare−1; M1, Conventional drip irrigation; M2, Time based automated drip irrigation; M3, Sensor based automated drip irrigation; F1, Drip fertigation of 75% RDF; F2, Drip fertigation of 100% RDF; F3, STCR based drip fertigation; F4, Sensor based fertigation at 75% NPK level; F5, Sensor based fertigation at 100% NPK level.

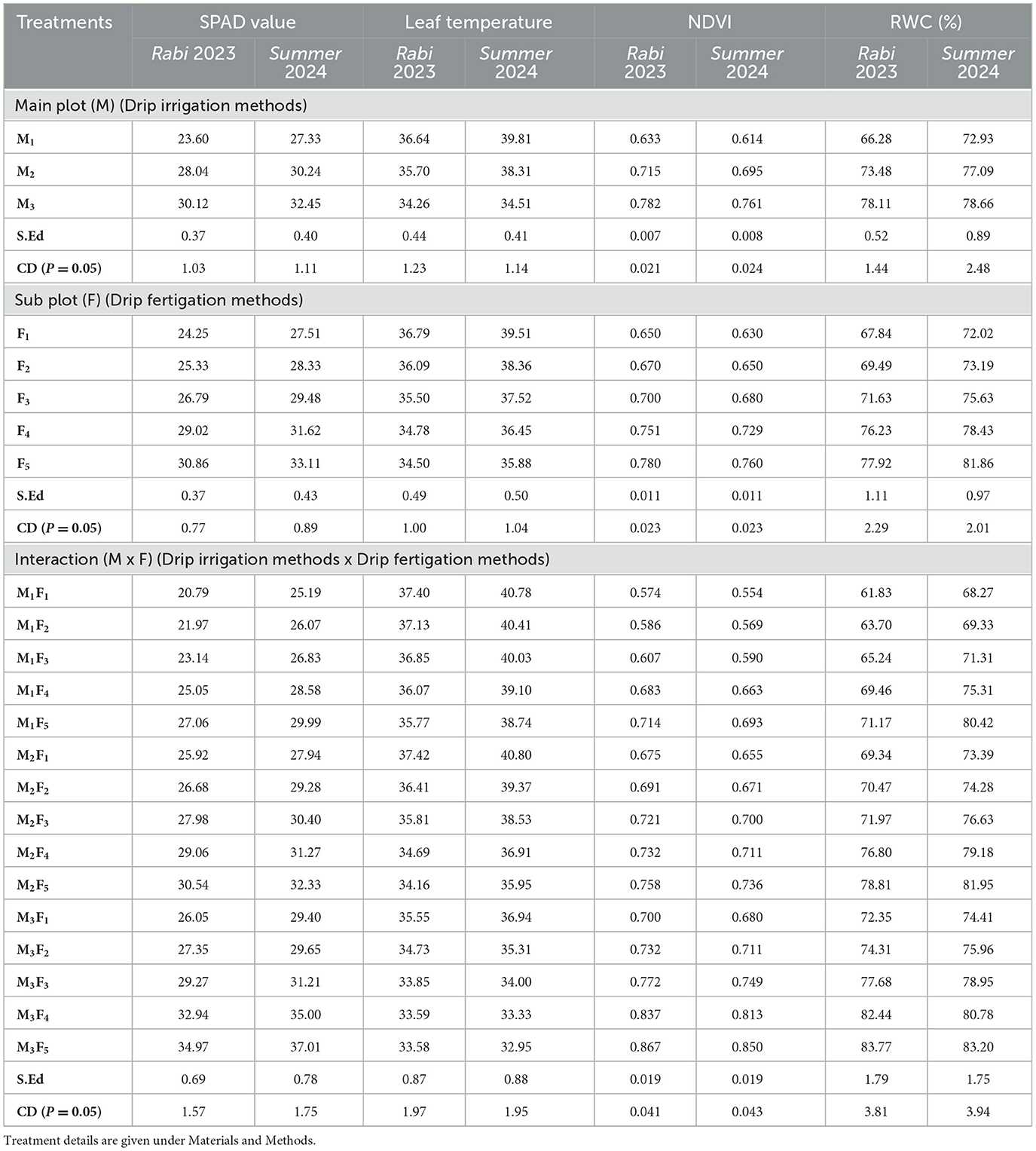

3.2.3 SPAD value

SPAD value was significantly influenced by drip irrigation and fertigation methods in both seasons (Table 2). Sensor based automated drip irrigation (M3) recorded maximum SPAD value of 30.12 and 32.45 in the rabi (2023) and summer (2024) seasons, respectively. Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded significantly higher SPAD value of 30.86 and 33.11 in the rabi (2023) and summer (2024) seasons, respectively. Interaction was significant. Sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly higher SPAD value of 34.97 and 37.01 in the rabi (2023) and summer (2024) seasons, respectively.

Table 2. Effect of drip irrigation and fertigation methods on physiological parameters of groundnut (Arachis hypogaea L.) at 50 DAS.

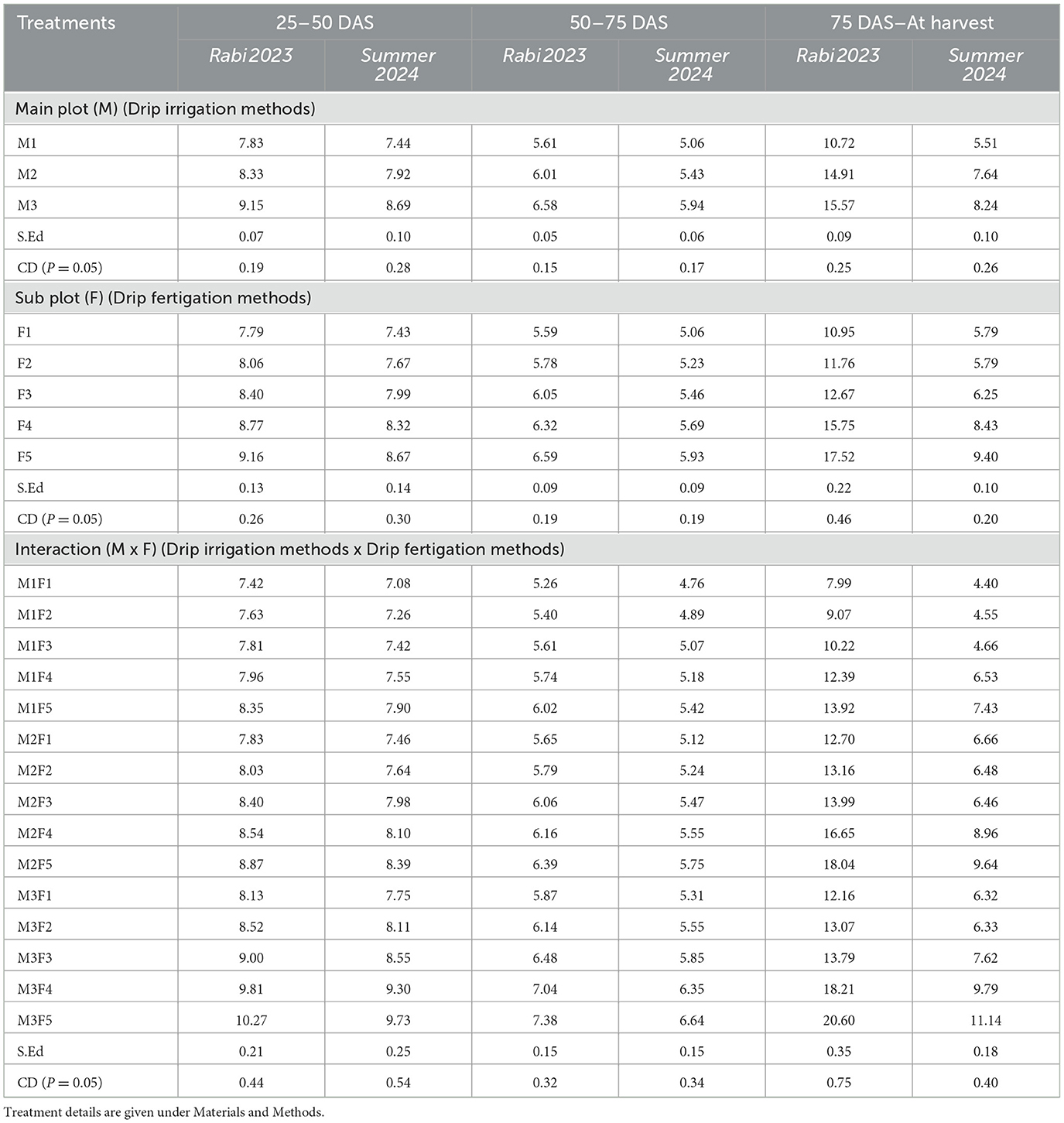

3.2.4 Crop growth rate

Crop growth rate was significantly influenced by drip irrigation and fertigation methods in both seasons (Table 3). Sensor based automated drip irrigation (M3) recorded significantly higher CGR during both seasons. In the rabi (2023) season, the CGR was 9.15 g m−2 day−1 from 25 to 50 DAS, 6.58 g m−2 day−1 from 50 to 75 DAS and 15.57 g m−2 day−1 from 75 DAS to harvest. Similarly, in the summer (2024) season, the CGR was 8.69 g m−2 day−1 from 25 to 50 DAS, 5.94 g m−2 day−1 from 50 to 75 DAS and 8.24 g m−2 day−1 from 75 DAS to harvest. Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded significantly higher CGR (9.16 g m−2 day−1 from 25 to 50 DAS, 6.59 g m−2 day−1 from 50 to 75 DAS and 17.52 g m−2 day−1 from 75 DAS to harvest during the rabi (2023) season and 8.67 g m−2 day−1 from 25 to 50 DAS, 5.93 g m−2 day−1 from 50 to 75 DAS and 9.40 g m−2 day−1 from 75 DAS to harvest during the summer (2024) season). On interaction, sensor based automated drip irrigation with sensor based fertigation at 100% NPK level (M3F5) resulted in the maximum CGR. In the rabi (2023) season, the CGR was 10.27 g m−2 day−1 from 25 to 50 DAS, 7.38 g m−2 day−1 from 50 to 75 DAS and 20.60 g m−2 day−1 from 75 DAS to harvest. During the summer (2024) season, the CGR was 9.73 g m−2 day−1 from 25 to 50 DAS, 6.64 g m−2 day−1 from 50 to 75 DAS and 11.14 g m−2 day−1 from 75 DAS to harvest.

Table 3. Effect of drip irrigation and fertigation methods on CGR (g m−2 day−1) of groundnut (Arachis hypogaea L.).

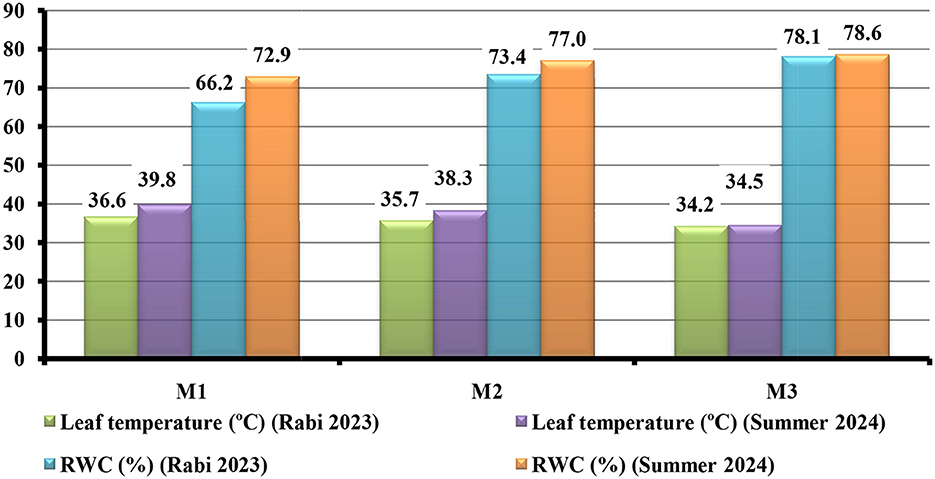

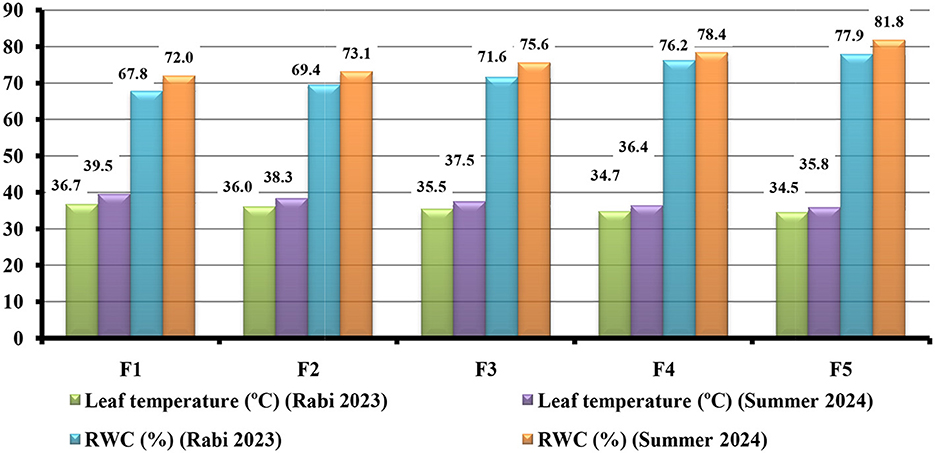

3.2.5 Leaf temperature

Leaf temperature was significantly influenced by drip irrigation and fertigation methods in both seasons (Table 2 and Figures 9, 10). Conventional drip irrigation (M3) recorded maximum leaf temperature of 36.64 and 39.81°C during rabi (2023) and summer (2024) seasons, respectively. Sensor based automated drip irrigation (M3) recorded lower leaf temperature of 34.26 and 34.51°C in the rabi (2023) and summer (2024) seasons, respectively. Among the drip fertigation methods, significantly higher leaf temperature registered with drip fertigation of 75% (F1) with 36.79 and 39.51°C in the rabi (2023) and summer (2024) seasons, respectively. Sensor based fertigation at 100% NPK level (F5) recorded significantly lower leaf temperature of 34.50 and 35.88°C during the rabi (2023) and summer (2024) seasons, respectively. Interaction was significant. Significantly higher leaf temperature were observed with combination of conventional drip irrigation and drip fertigation of 75% (M1F1) [37.40 and 40.78°C in the rabi (2023) and summer (2024) seasons, respectively] Sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly lower leaf temperature of 33.58 and 32.95°C in the rabi (2023) and summer (2024) seasons, respectively.

Figure 9. Effect of drip irrigation methods on leaf temperature and relative water content of groundnut (Arachis hypogaea L.). RWC, Relative Water Content; M1, Conventional drip irrigation; M2, Time based automated drip irrigation; M3, Sensor based automated drip irrigation.

Figure 10. Effect of drip fertigation methods on leaf temperature and relative water content of groundnut (Arachis hypogaea L.). RWC; Relative Water Content; F1, Drip fertigation of 75% RDF; F2, Drip fertigation of 100% RDF; F3, STCR based drip fertigation; F4, Sensor based fertigation at 75% NPK level; F5, Sensor based fertigation at 100% NPK level.

3.2.6 Normalized difference vegetation index

Normalized difference vegetation index was significantly influenced by drip irrigation and fertigation methods in both seasons (Table 2). Sensor based automated drip irrigation (M3) recorded maximum NDVI of 0.782 and 0.761 in the rabi (2023) and summer (2024) seasons, respectively. Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded significantly higher NDVI value of 0.780 and 0.760 in the rabi (2023) and summer (2024) seasons, respectively. Interaction was significant. Sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly higher NDVI value of 0.867 and 0.850 in the rabi (2023) and summer (2024) seasons, respectively.

3.2.7 Relative water content

Relative water content was significantly influenced by drip irrigation and fertigation methods in both seasons (Table 2 and Figures 9, 10). Sensor based automated drip irrigation (M3) recorded maximum RWC of 78.11 and 78.66% in the rabi (2023) and summer (2024) seasons, respectively. Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded significantly higher RWC of 77.92 and 81.86% in the rabi (2023) and summer (2024) seasons, respectively. Interaction was significant. Sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly higher RWC of 83.77 and 83.20% in the rabi (2023) and summer (2024) seasons, respectively.

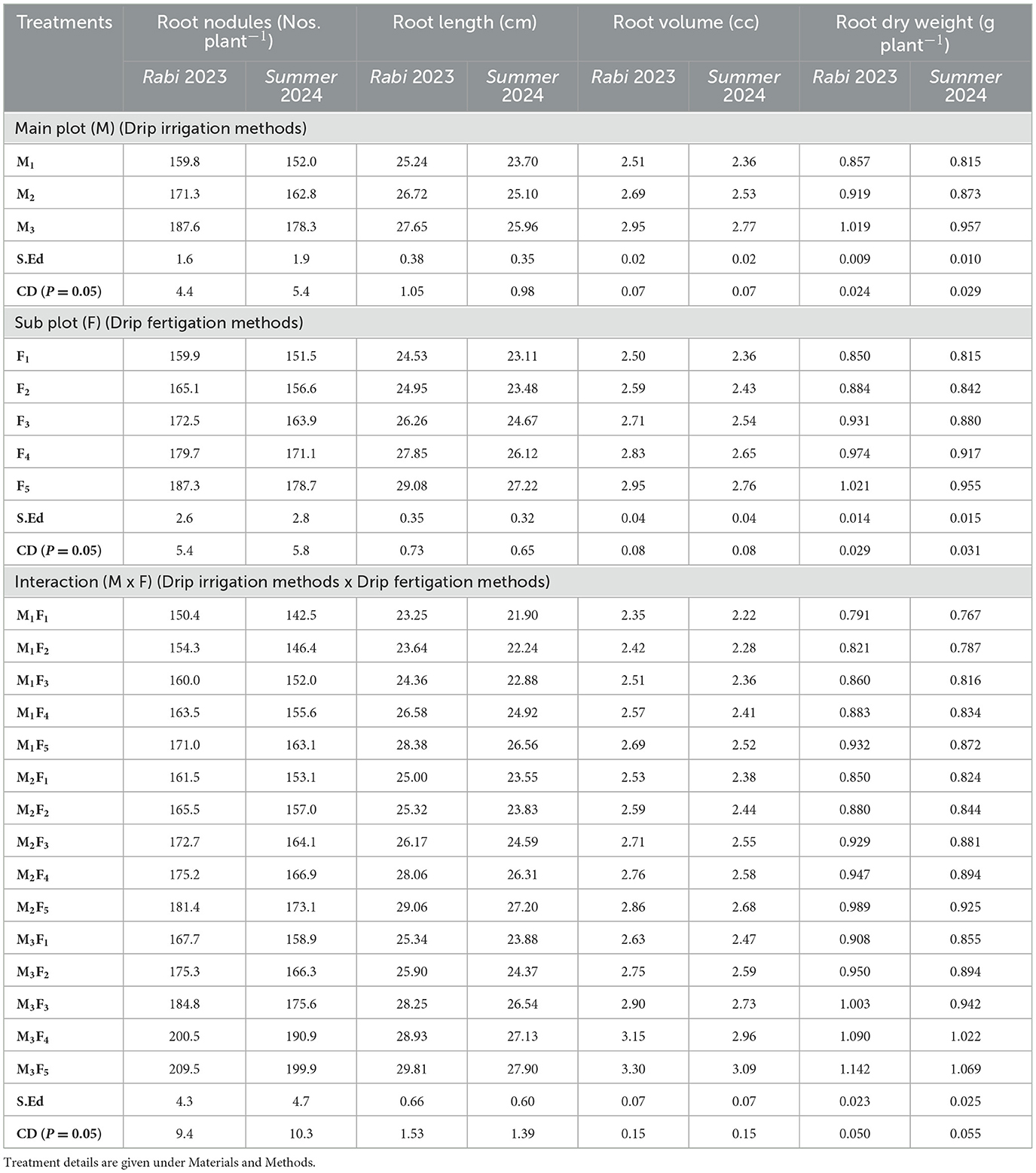

3.2.8 Root characters

Root characters were significantly influenced by drip irrigation and fertigation methods in both seasons (Table 4). Sensor based automated drip irrigation (M3) recorded higher values of root characters, viz.nodules (187.6 and 178.3 nos./plant), length (27.65 and 25.96 cm), volume (2.95 and 2.77 cc/plant), and dry weight (1.019 and 0.957 g) during rabi (2023) and summer (2024) seasons, respectively. With respect to drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded higher root characters, viz. nodules (187.3 and 178.7 nos./plant), length (29.08 and 27.22 cm), volume (2.95 and 2.76 cc/plant), and dry weight (1.021 and 0.955 g) in the rabi (2023) and summer (2024) seasons, respectively. On combination, sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded maximum root characters, viz. nodules (209.5 and 199.9 nos./plant), length (29.81 and 27.90 cm), volume (3.30 and 3.09 cc/plant), and dry weight (1.142 and 1.069 g) in the rabi (2023) and summer (2024) seasons, respectively.

Table 4. Effect of drip irrigation and fertigation methods on root characters of groundnut (Arachis hypogaea L.).

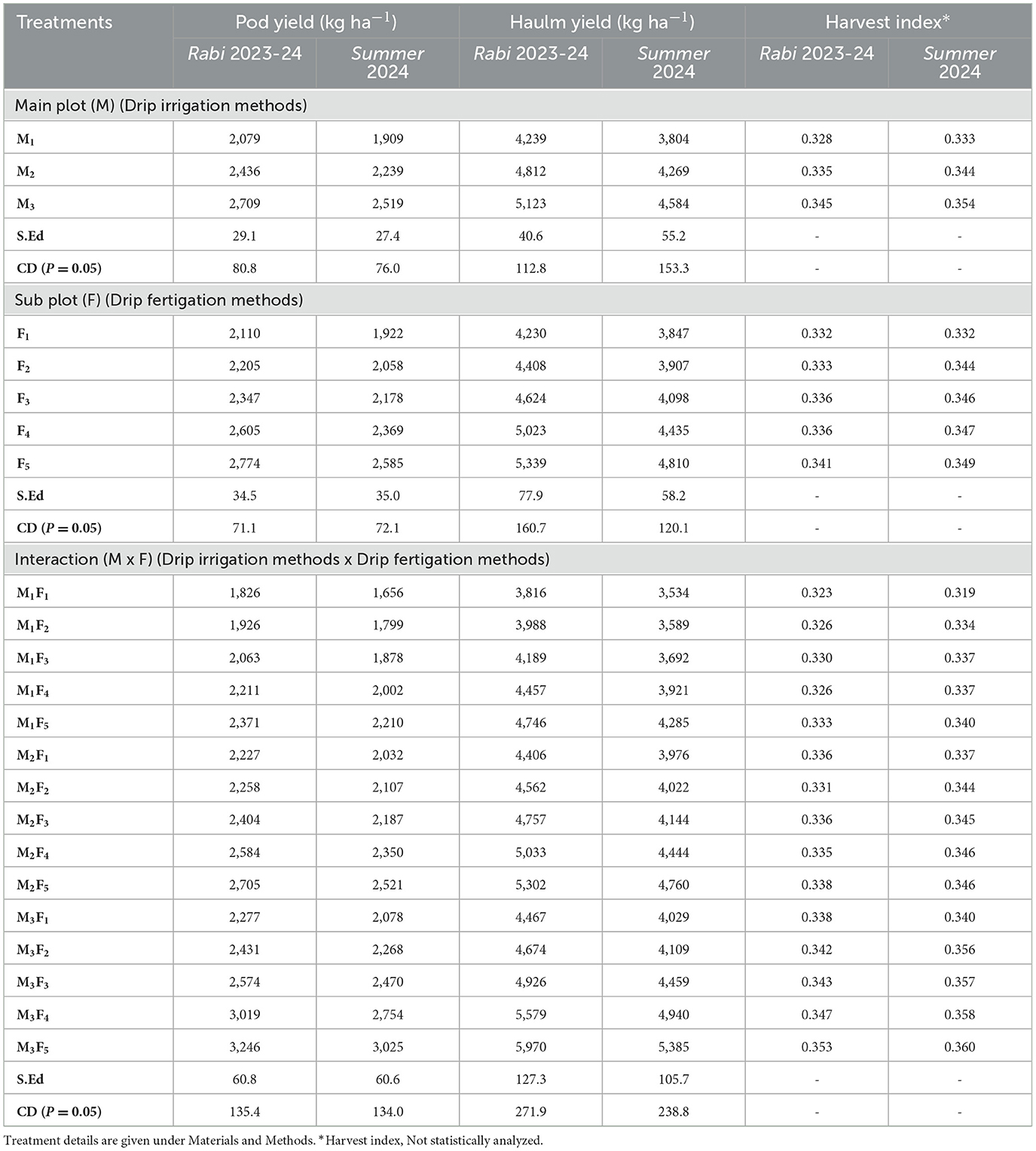

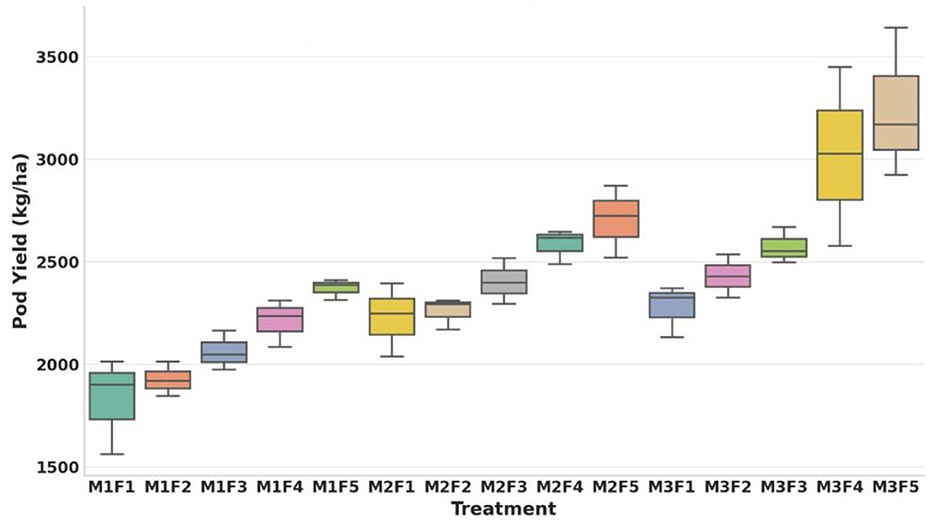

3.3 Yield

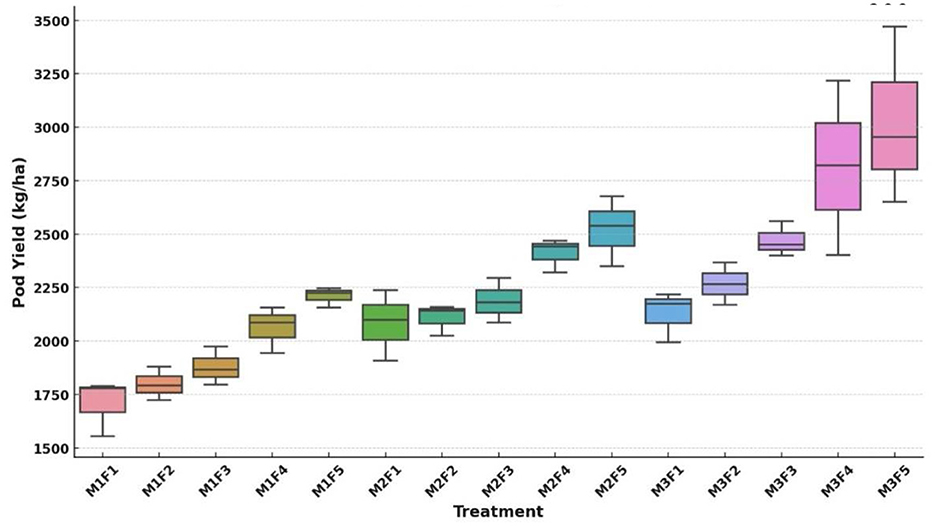

Drip irrigation and fertigation methods had significant impact on pod and haulm yield of groundnut in both seasons (Table 5 and Figures 11, 12). Sensor based automated drip irrigation (M3) recorded significantly higher pod yield (2,709 and 2,519 kg ha−1) and haulm yield (5,123 and 4,584 kg ha−1) in the rabi (2023) and summer (2024) seasons, respectively.

Table 5. Effect of drip irrigation and fertigation methods on yield of groundnut (Arachis hypogaea L.).

Figure 11. Effect of drip irrigation and fertigation methods on pod yield of groundnut (Arachis hypogaea L.) during rabi (2023). Kg/ha, Kilogram/hectare; M1, Conventional drip irrigation; M2, Time based automated drip irrigation; M3, Sensor based automated drip irrigation; F1, Drip fertigation of 75% RDF; F2, Drip fertigation of 100% RDF; F3, STCR based drip fertigation; F4, Sensor based fertigation at 75% NPK level; F5, Sensor based fertigation at 100% NPK level.

Figure 12. Effect of drip irrigation and fertigation methods on pod yield of groundnut (Arachis hypogaea L.) during summer (2024) season. Kg/ha, Kilogram/hectare; M1, Conventional drip irrigation; M2, Time based automated drip irrigation; M3, Sensor based automated drip irrigation; F1, Drip fertigation of 75% RDF; F2, Drip fertigation of 100% RDF; F3, STCR based drip fertigation; F4, Sensor based fertigation at 75% NPK level; F5, Sensor based fertigation at 100% NPK level.

Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded the maximum pod yield (2,774 and 2,585 kg ha−1) and haulm yield (5,339 and 4,810 kg ha−1) in both seasons, respectively. This was followed by sensor based fertigation at 75% NPK level (F4).

Pod and haulm yield were significantly influenced by a combination of various drip irrigation and fertigation methods. Combination with sensor based automated drip irrigation and sensor based fertigation at 100% NPK level (M3F5) recorded higher yield (3,246 kg ha−1 and 3,025 kg ha−1) and haulm yield (5,970 kg ha−1 and 5,385 kg ha−1) in both seasons, respectively.

Regarding harvest index, sensor based automated drip irrigation (M3) recorded higher harvest index (0.345 and 0.354) in both seasons, respectively. Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded harvest index (0.341 and 0.349) in both seasons, respectively. On interaction, sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded higher harvest index (0.353 and 0.360) in both seasons, respectively. None of the treatments had any perceptible variation on harvest index of groundnut.

4 Discussion

4.1 Growth parameters

Plant population was not influenced by drip irrigation and fertigation methods in both seasons, indicating that emergence and establishment were uniform across treatments. This is likely because all treatments received adequate initial moisture for germination and uniform sowing techniques were followed. Drip irrigation and fertigation methods caused variations in plant height in both seasons. Sensor based automated drip irrigation (M3) recorded significantly taller plants. Constant moisture availability near the crop root zone under higher irrigation scheduling levels likely created an optimal environment for root activity and water uptake. This consistent water supply minimized moisture stress and supported uninterrupted vegetative growth, resulting in enhanced plant height. Adequate moisture availability also facilitates better nutrient absorption, particularly nitrogen, which plays a crucial role in promoting cell division and elongation in the growing regions of the stem. As a result, plants grown under well-irrigated conditions tend to exhibit greater height due to enhanced physiological processes and sustained growth. The results were in agreement with the research conducted by Pushpa et al. (2007), Govindan and Grace (2012), Karthika and Ramanathan (2019), and Akshay et al. (2024). Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded significantly higher plant height. This may be attributed to the continuous supply and consequent availability of plant nutrients in the root zone till late stage of crop growth. This is in conformity with the findings of Venkadeswaran et al. (2014) and Sharma et al. (2019). On interaction, sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly taller plants. Drip fertigation, which applies water and nutrients at certain times to match the crop's need for each distinct stages, results in taller plants. This was attributed to the constant moisture availability near the root zone, promoting nutrient uptake and cell elongation. Additionally, the application of water-soluble fertilizers through fertigation contributed to improved growth qualities and increased plant height. Similar findings have been reported by Akshay et al. (2024).

4.2 Physiological parameters

The leaf area index was significantly influenced bydrip irrigation and fertigation methods in both seasons (Figures 5, 6). Sensor based automated drip irrigation (M3) recorded significantly higher LAI. The higher LAI might be due to the favorable soil moisture conditions created in the rhizosphere of groundnut, which promoted increased vegetative growth. This was reflected in the enhanced morphological characteristics such as the number of functional leaves per plant and leaf area (Shinde, 2020). Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded significantly higher LAI. This might be due to prolonged and steady availability of nutrients from WSF, which resulted in better translocation of photosynthates reflected in morphological characters viz., number of functional leaves plant−1 and leaf area. These results are in confirmation with the findings of Vijayalakshmi et al. (2011), Sanju (2013), Rathore et al. (2014), Soni and Raja (2017), Mouri et al. (2018), and Hasan et al. (2019). The interaction was significant. Sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly higher LAI. Higher LAI could be attributed to maintenance of higher soil water potential and constant availability of nutrients, which increased with higher irrigation levels and helped for better translocation of photosynthates and more carbohydrates synthesis contributing to maintaining plant water balance. Water play an important role in carbohydrate metabolism, protein synthesis, cell wall synthesis and cell enlargement. Similar results were reported by Sampathkumar et al. (2006) and Arif et al. (2016).

The dry matter production was significantly influenced by drip irrigation and fertigation methods in both seasons (Figures 7, 8). Accumulation of significantly higher dry matter was noticed with sensor based automated drip irrigation (M3). The higher growth parameters observed in the respective treatments can be attributed to the increased plant dry weight, which resulted from frequent irrigation and the use of water-soluble fertilizers. These practices ensured continuous availability of moisture and readily absorbable nutrients in the root zone, thereby enhancing nutrient uptake efficiency. Improved uptake supported active metabolic processes and biomass accumulation, ultimately leading to greater dry matter production and better expression of growth parameters. Vijaykumar (2009), Rekha et al. (2015), and Akshay et al. (2024) also found similar outcomes. Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded significantly higher DMP. The application of water-soluble fertilizers at higher concentrations enhanced nutrient absorption by the crop and facilitated more uniform nutrient distribution in the soil, leading to improved nutrient availability throughout the root zone. According to Jena and Aladakatti (2018), this may have led to increased nutrient intake and subsequent growth, which in turn produced more dry matter. Similar findings have been reported by Akshay et al. (2024). Interaction was found to be significant. Sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly higher DMP. The higher growth parameters were attributed to the increased plant dry weight observed in the respective treatment. Nutrients applied through drip fertigation ensured a continuous supply of nutrients while maintaining optimal water availability, leading to higher nutrient uptake. This in turn, resulted in greater dry matter accumulation by the plant. Similar results were documented by Jain et al. (2018) and Menda (2023). The frequent fertigation and application of water-soluble fertilizers likely promoted the uptake of both moisture and nutrients, further contributing to the increased buildup of dry matter (Akshay et al., 2024).

SPAD meter was used to determine leaf nitrogen status. SPAD value was significantly influenced by drip irrigation and fertigation methods in both seasons (Table 2). Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded significantly higher SPAD value. Adequate fertilization improved various physiological and metabolic processes in the plant system. The profound influence of water soluble fertilizer on crop growth seemed to be due to maintaining congenial nutritional environment of the plant rhizosphere on account of their increased availability which increased the nitrogenase activity of roots that resulted in higher physiological growth parameters, such as the SPAD value (Jain and Meena, 2015). Interaction was significant. Sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly higher SPAD value. This could be attributed to sufficient availability of moisture and the solubility of nutrients helped the crops to grow luxuriantly, which was reflected in higher SPAD value using sensor-based precision nutrient and irrigation management (Sachin et al., 2023).

Crop growth rate (CGR) is used as a character for estimating production efficiency of crop stand, which is influenced by LAI, photosynthetic rate, and leaf angle and is an index of amount of light interception. Crop growth rate was significantly influenced by drip irrigation and fertigation methods in both seasons. Sensor based automated drip irrigation with sensor based fertigation at 100% NPK level (M3F5) resulted in the maximum CGR. This may be attributed to the efficient utilization of water and nutrient resources, which supported active cell division and elongation during each stage of crop growth. This process contributed to an increase in leaf area, enhancing the plant's ability to intercept light and perform photosynthesis, which in turn resulted in a higher crop growth rate (Krishnamoorthy et al., 2013; Soni and Raja, 2017).

Leaf temperature serves as a critical indicator of both leaf water status and metabolic activity. The leaf temperature should be lower than the air temperature for getting higher productivity. Leaf temperature was significantly influenced by drip irrigation and fertigation methods in both seasons (Figures 9, 10). Conventional drip irrigation (M3) recorded maximum leaf temperature. Sensor based automated drip irrigation (M3) recorded lower leaf temperature. A lower numerical value of leaf temperature generally indicates better water availability, which promotes stomatal opening. This enhances transpiration and crop evapotranspiration, leading to cooling of the leaf surface. As a result, leaf water potential is maintained at a higher level, ultimately contributing to the observed reduction in leaf temperature.

Normalized difference vegetation index was significantly influenced by drip irrigation and fertigation methods in both seasons. Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded significantly higher NDVI value. This improvement in plant growth might be attributed to the higher chlorophyll content, which enhances the plant's photosynthetic efficiency, leading to better energy capture and assimilation. The timely application of inorganic fertilizers played a crucial role by ensuring that essential nutrients were available during critical growth stages, thereby minimizing nutrient losses due to leaching or volatilization. As a result, plants exhibited improved canopy development and greater biomass accumulation, contributing to better light interception and resource use efficiency. Furthermore, the increased nutrient availability, particularly nitrogen and phosphorus, is closely associated with protoplasm synthesis and protein formation in plant cells. These physiological processes are essential for cell division and expansion, ultimately promoting vigorous vegetative growth. Thus, the combination of timely nutrient supply, improved chlorophyll content, and enhanced canopy coverage contributed significantly to the overall growth performance of the crop. Interaction was significant. Sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly higher NDVI value. This could be attributed to the sufficient availability of moisture and the solubility of nutrients, which enabled the crops to grow luxuriantly. This was reflected in the higher NDVI values observed under sensor-based precision nutrient and irrigation management (Sachin et al., 2023).

Relative water content is the primary physiological gauge for assessing the water status of plant systems. Relative water content was significantly influenced by drip irrigation and fertigation methods in both seasons (Figures 9, 10). Sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded significantly higher RWC. This might be due to the positive effect of higher soil moisture content and effective utilization of water and nutrient sources which leads to increase in cell turgor cell expansion and solutes along with photosynthetic rate that helps in maintaining the optimum osmotic potential. The above results are in harmony with the findings of Nautiyal et al. (2002), Reddy et al. (2003), and Menda (2023).

4.3 Root characters

The root system is the major link between the plant and soil. Rooting depth and distribution are important traits for absorption of water and nutrients from the soil profile. Root length and volume reveals the root system's soil contact, aiding the absorption of water and nutrients, promoting shoot photosynthesis. Higher root dry weight enhances the resources availability fostering photosynthetic accumulation. Root characters were significantly influenced by drip irrigation and fertigation methods in both seasons. Sensor based automated drip irrigation (M3) recorded higher values of root characters. The significant increase in root length might be attributed to the creation of optimal soil moisture conditions, achieved through a balanced proportion of air and water in the crop's root zone (Soni et al., 2016; Shinde, 2020), which reflected in better growth of rhizobium and physiological activity of plant thus significantly higher root nodules, root volume and root dry wight were observed. Similar results were observed by Dabasree and Gunri (2014), Arif et al. (2016), and Shinde (2020). With respect to drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded higher root characters. This may be due to nodule development appeared to be source–sink relationship. The treatments might be produced and maintained more active photosynthesis are capable to well nodule formation due to availability of adequate photosynthesis (Shinde, 2020). On combination, sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded maximum root characters. This might be due to the higher availability of moisture. An adequate quantity of nutrients and moisture might have resulted in greater root proliferation. The provision of sufficient moisture, nutrients and soil aeration ultimately led to enhanced root growth. These results were in line with the findings of Kafkafi and Tarchitzky (2011), Abdzad Gohari et al. (2014), and Soni and Kumar (2016), who observed that root depth, volume and biomass contents vary due to differences in soil moisture and nutrient concentration in the root zone.

4.4 Yield

Drip irrigation and fertigation methods had significant impact on pod and haulm yield of groundnut in both seasons (Figures 11, 12). Sensor based automated drip irrigation (M3) recorded significantly higher pod yield and haulm yield. The higher yield observed under tensiometer sensor-based drip irrigation can be attributed to the precise and timely application of water, based on the actual moisture status of the root zone. This approach ensured that the crop received the required amount of water exactly when needed, thereby minimizing both water stress and water wastage. Consistent soil moisture availability supports optimal physiological processes such as nutrient uptake, photosynthesis, and cell expansion, which collectively contribute to improved plant growth and ultimately lead to higher yields. Similar results were reported by Kotadiya et al. (2024).

Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded the maximum pod yield and haulm yield. This was followed by sensor based fertigation at 75% NPK level (F4). The increased responses observed in the study can be primarily attributed to the higher solubility of water-soluble fertilizers. Because these fertilizers dissolve quickly and completely in water, they ensure that nutrients are readily available in the soil solution for root absorption. This enhanced availability facilitates greater nutrient uptake by the crop, especially during critical growth stages, supporting vital physiological processes such as photosynthesis, cell division, and elongation. Consequently, the improved nutrient nutrition positively influenced overall plant growth and development, which was ultimately reflected in higher yields. Similar results were obtained by Soni et al. (2019), Rank (2007), and Vijayalakshmi et al. (2011).

Pod and haulm yield were significantly influenced by a combination of various drip irrigation and fertigation methods. Combination with sensor based automated drip irrigation and sensor based fertigation at 100% NPK level (M3F5) recorded higher yield and haulm yield. Higher nutrient uptake might have been aided by the solubility and availability of sufficient quantities of nutrients with optimum soil moisture across the entire crop growth cycle. This helped to absorb more photosynthetically active radiation accompanied with increased yield attributes. The higher rate of photosynthate translocation from source to sink might have resulted in higher pod yield in peanut. Many reports indicated that fertigation with water soluble fertilizer can increase the yield of many crops besides saving 25% of the fertilizer (Martin, 1950; Kuster and Williams, 1964; Kumar et al., 2018; Jayakumar et al., 2021; Jain et al., 2021; Kumar et al., 2022; Hireholi et al., 2024).

Regarding harvest index, sensor based automated drip irrigation (M3) recorded higher harvest index. Among the drip fertigation methods, sensor based fertigation at 100% NPK level (F5) recorded harvest index. On interaction, sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) recorded higher harvest index. None of the treatments had any perceptible variation on harvest index of groundnut.

Based on the above results, it is concluded that sensor based automated drip irrigation combined with sensor based fertigation at 100% NPK level (M3F5) significantly enhanced the growth, physiological traits, root characteristics and yield of groundnut. This precision approach not only improved crop performance but also contributed to efficient utilization of water and fertilizers. The adoption of such smart irrigation and fertigation technologies in water scarce and input limited environments can substantially reduce input costs and enhance resource use efficiency. Consequently, this can lead to higher net returns for farmers through improved productivity and reduced input wastage. In addition, the sustainable use of natural resources, such as water and nutrients, aligns with climate-resilient farming practices. Future research should focus on scaling up these technologies across different agro-climatic regions and assessing their long-term impacts on soil health, farmer income and environmental sustainability.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding authors.

Author contributions

CA: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. AG: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. ES: Conceptualization, Data curation, Investigation, Methodology, Supervision, Writing – review & editing. GH: Data curation, Validation, Writing – review & editing. KK: Project administration, Validation, Writing – review & editing. BB: Writing – review & editing. SK: Writing – review & editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Acknowledgments

The authors express their gratitude to Tamil Nadu Agricultural University for providing the necessary facilities to conduct research on smart fertigation system in groundnut, which will culminate in this study. We also extend our thanks to the DST-FIST (Department of Science and Technology - Fund for Improvement of S&T Infrastructure) scheme for providing infrastructural support, which was instrumental in the successful completion.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Gen AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdzad Gohari, A., Jenabi Haghparast, R., and Khabbazkar, M. R. (2014). Peanut (Arachis hypogaea L.) response to irrigation different methods in north Iran. J. Novel Appl. Sci. 3, 1635–1637.

Akshay, D. V., Kumar, R. M., Sree, S. P., Sreedevi, B., Babu, M. B., and Sakhare, A. S. (2024). Optimizing growth and yield in aerobic rice through IoT-based drip irrigation and fertigation. Int. J. Plant Soil Sci. 36, 190–200. doi: 10.9734/ijpss/2024/v36i74720

Arif, M. B., Verma, I. M., and Khinchi, V. (2016). Effect of crop geometry and drip irrigation on growth, yield and economics of groundnut (Arachis hypogaea L.). Environ. Ecol. 34, 2274–2278.

Buttery, B. R. (1970). Effects of variation in leaf area index on growth of maize and soybeans. Crop Sci. 10, 9–13. doi: 10.2135/cropsci1970.0011183X001000010004x

Chtouki, M., Naciri, R., and Oukarroum, A. (2024). A review on phosphorus drip fertigation in the Mediterranean region: fundamentals, current situation, challenges, and perspectives. Heliyon 10:e25543. doi: 10.1016/j.heliyon.2024.e25543

CPG (2020). Crop Production Guide, Tamil Nadu Agricultural University. Available online at: https://tnau.ac.in/site/research/wp-content/uploads/sites/60/2020/02/Agriculture-CPG-2020.pdf (Accessed January 23, 2025).

Dabasree, S., and Gunri, S. K. (2014). Effect of polythene mulching, irrigation regimes and fertilizer doses on summer groundnut (Arachis hypogaea L.) nodulation, pod yield and nitrogen availability in soil. Environ. Ecol. 32, 1301–1303.

Dewan, G. I., and Subba Rao, N. S. (1979). Seed inoculation with Azospirillum brasilense and Azotobacter chroococcum and the root biomass of rice (Oryza sativa L.). Plant Soil 53, 295–302. doi: 10.1007/BF02277864

Gomez, K. A., and Gomez, A. A. (1984). Statistical Procedures for Agricultural Research. New York: John Wiley and Sons.

Govindan, R., and Grace, T. M. (2012). Influence of drip fertigation on growth and yield of rice varieties (Oryza sativa L.). Madras Agric. J. 99, 244–247. doi: 10.29321/MAJ.10.100056

Hasan, M., Uddin, K. Md, Mohammed, M., Tenguka, M., Zuan Ali Tan, K.ee, and Motmainna (2019). Impact on nitrogen and phosphorus fertilizer on growth, yield of Barbra groundnut. Plant Arch. 19, 501–504.

Hireholi, G., Patil, D. H., Rathod, P. S., Manjunatha, N., and Ananda, N. (2024). Optimizing irrigation scheduling to enhance nutrient uptake and soil microbial activity in linseed cultivation (Linum usitatissimum L.). Microbiol. Res. J. Int. 34, 29–37. doi: 10.9734/mrji/2024/v34i111496

Ibragimov, N., Evett, S. R., Esanbekov, Y., Kamilov, B. S., Mirzaev, L., and Lamers, J. P. (2007). Water use efficiency of irrigated cotton in Uzbekistan under drip and furrow irrigation. Agric. Water Manag. 90, 112–120. doi: 10.1016/j.agwat.2007.01.016

Indiastat (2022). Season-wise area, production and productivity of groundnut in India (1949–1950 to 2021–2022 - 3rd advance estimates). Available online at: https://www.indiastat.com/table/agriculture/season-wise-area-production-productivity-groundnut/17354# (Accessed January 23, 2025).

Jain, N. K., and Meena, H. N. (2015). Improving productivity of groundnut (Arachis hypogaea) by using water-soluble fertilizer through drip irrigation. Indian J. Agron. 60, 109–115. doi: 10.59797/ija.v60i1.4423

Jain, N. K., Meena, H. N., Bhaduri, D., and Yadav, R. S. (2018). Drip fertigation and irrigation interval effects on growth, productivity, nutrient, and water economy in summer peanut. Commun. Soil Sci. Plant Anal. 49, 2406–2417. doi: 10.1080/00103624.2018.1510951

Jain, N. K., Yadav, R. S., and Jat, R. A. (2021). Productivity, profitability, enzyme activities and nutrient balance in summer peanut (Arachis hypogaea L.) as influenced by NPK drip fertigation. Commun. Soil Sci. Plant Anal. 52, 443–455. doi: 10.1080/00103624.2020.1854287

Jat, R. A., Reddy, K. K., Solanki, R., Choudhary, R. R., and Sarkar, S. K. (2020). Optimum plant stand and nutrient doses for summer groundnut under check basin irrigation and drip fertigation in light black soils of peninsular Western India. J. Plant Nutr. 43, 1154–1174. doi: 10.1080/01904167.2020.1724303

Jayakumar, A., Solaimalai, A., and Baskar, K. (2021). A critical review on role of biofertilizers in enhancing the productivity of oilseed crops. J. Oilseeds Res. 38, 226–239. doi: 10.56739/jor.v38i3.137140

Jena, P., and Aladakatti, Y. R. (2018). Effect of conventional and water-soluble fertilizers through fertigation on growth, physiology, and yield of BT cotton. Int. J. Curr. Microbiol. Appl. Sci. Sp-7, 752–759.

Kafkafi, U., and Tarchitzky, J. (2011). “Fertigation: a tool for efficient fertilizer and water management,” in: International Fertilizer Industry Association (IFA), International Potash Institute (IPI) (Paris, France), 25–28.

Kang, Y., Wang, F., Liu, H., and Yuan, B. (2004). Potato evapotranspiration and yield under different drip irrigation regimes. Irrig. Sci. 23, 133–143. doi: 10.1007/s00271-004-0101-2

Karthika, N., and Ramanathan, S. P. (2019). Effect of drip fertigation on growth, physiological parameters and grain yield of rice grown in Cauvery new delta zone of Tamil Nadu. Int. J. Chem. Stud. 7, 2758–2761.

Kotadiya, R. H., Parmar, P. M., Poonia, T. C., Patel, D. J., and Kacchiyapatel, K. A. (2024). A comprehensive review of irrigation systems utilizing sensor technology. Int. J. Plant Soil Sci. 36, 334–343. doi: 10.9734/ijpss/2024/v36i94983

Krishnamoorthy, C., Rajamani, K., and Kumar, N. (2013). Effect of fertigation through drip and micro sprinkler on physiological parameters in cocoa (Theobroma cacao L.). Madras Agric. J. 100, 153–159. doi: 10.29321/MAJ.10.001261

Kumar, S., Singh, J., and Kumawat, P. (2022). Effect of irrigation schedule and fertigation level on soil microbial population of mandarin (Citrus reticulata Blanco) orchard cv. Nagpur Mandarin. Biol. Forum. 14, 350–354.

Kumar, V., Raha, P., and Ram, S. (2018). Effect of irrigation schedule and amino acids biostimulants on soil enzyme activities in potato (Solanum tuberosum L.) crop. Int. J. Curr. Microbiol. Appl. Sci. 7, 1912–1920. doi: 10.20546/ijcmas.2018.704.219

Kuster, E., and Williams, S. S. T. (1964). Selection of media for isolation of Streptomycetes. Nature 202, 928–929. doi: 10.1038/202928a0

Martin, J. P. (1950). Use of acid rose-bengal and streptomycin in plate method for estimating soil fungi. Soil Sci. 69, 215–232. doi: 10.1097/00010694-195003000-00006

Menda, M. K. (2023). Performance of groundnut (Arachis hypogaea L.) during rabi under cumulative influence of land configuration and fertigation. Doctoral dissertation, Acharya N.G. Ranga Agricultural University.

Mouri, S. J., Sarkar, M. A. R., Uddin, M. R., Sarker, U. K., Kaysar, M. S., and Hoque, M. M. I. (2018). Effect of variety and phosphorus on the yield components and yield of groundnut. Prog. Agric. 29, 117–126. doi: 10.3329/pa.v29i2.38295

Nagarajan, K., Ramanathan, S. P., Thiyagarajan, G., and Panneerselvam, S. (2020). Optimization of irrigation scheduling under different types of automated drip irrigation system for tomato. Int. J. Curr. Microbiol. Appl. Sci. 9, 3315–3319. doi: 10.20546/ijcmas.2020.907.387

Nautiyal, P. C., Ravindra, V., and Joshi, Y. C. (2002). Dry matter partitioning and water use efficiency under water deficit during various growth stages in groundnut. Indian J. Plant Physiol. 7, 135–139.

Palaniswamy, K. M., and Gomez, K. A. (1974). Length-width method for estimating leaf area of rice. Agron. J. 66, 430–433. doi: 10.2134/agronj1974.00021962006600030027x

Peng, S., Garcia, F. V., Laza, R. C., and Cassman, K. G. (1993). Adjustment for specific leaf weight improves chlorophyll meter's estimate of rice leaf nitrogen concentration. Agron. J. 85, 987–990. doi: 10.2134/agronj1993.00021962008500050005x

Pushpa, K., Devakumar, N., Murthy, R. K., and Nagaraju, Krishnamurthy. (2007). Yield and yield attributes of rice genotypes as influenced by methods of irrigation and nitrogen sources. Environ. Ecol. 25, 774–777.

Rank, H. D. (2007). Summer groundnut crop performance and economics under micro sprinkler irrigation at various water application levels. Legume Res. 30, 261–265.

Rathore, S. S., Shekhawat, K., Premi, O. P., Kandpal, B. K., and Chauhan, J. S. (2014). Comparative effect of irrigation systems and nitrogen fertigation on growth, productivity and water-use efficiency of Indian mustard (Brassica juncea) under semi-arid conditions of Rajasthan. Indian J. Agron. 59, 112–118. doi: 10.59797/ija.v59i1.4514

Reddy, T. Y., Reddy, V. R., and Anbumozhi, V. (2003). Physiological responses of groundnut (Arachis hypogea L.) to drought stress and its amelioration: a critical review. Plant Growth Regul. 41, 75–88. doi: 10.1023/A:1027353430164

Rekha, B., Jayadeva, H. M., Kombali, G., Nagaraju Mallikarjuna, G. B., and Geethakumari, A. (2015). Growth and yield of aerobic rice grown under drip fertigation. Ecoscan 9, 435–437.

Sachin, K. S., Dass, A., Dhar, S., Rajanna, G. A., Singh, T., Sudhishri, S., et al. (2023). Sensor-based precision nutrient and irrigation management enhances the physiological performance, water productivity, and yield of soybean under system of crop intensification. Front. Plant Sci. 14:1282217. doi: 10.3389/fpls.2023.1282217

Sampathkumar, T. S., Krishnasamy, S., Ramesh, K., and Shanmugasundaram. (2006). Effect of drip and surface irrigation methods with rice straw mulch on productivity and water use efficiency of summer cotton. Crop Res. 32, 141–144.

Sanju, H. R. (2013). Precision effect of precision water and nutrient management with different sources and levels of fertilizer on yield of groundnut. M.Sc. (Agri.) Thesis, University of Agricultural Sciences, Bengaluru.

Sharma, V., Singh, P. K., Yadav, K. K., Lakhawat, S. S., and Bhakar, S. R. (2019). Effects of chemical fertilizer scheduling on performance of okra (Abelmoschus esculentus L.) crop under soil moisture sensor-based automated drip and conventional drip irrigation system. Int. J. Chem. Stud. 7, 3189–3191.

Shinde, R. S. (2020). Effect of different levels of irrigation and fertilizers through drip irrigation coupled with different types of mulches on growth, yield, and quality of groundnut in Konkan region (Accession No. T06822). Doctoral dissertation, Dr. Balasaheb Sawant Konkan Krishi Vidyapeeth, Dapoli.

Soni, J. K., and Kumar, N. A. R. A. (2016). Effect of micro irrigation cum fertigation on root characteristics of groundnut (Arachis hypogaea L.). Adv. Life Sci. 5:20.

Soni, J. K., Raja, N. A., and Kumar, V. (2019). Improving productivity of groundnut (Arachis hypogaea L.) under drip and micro sprinkler fertigation system. Legume Res. 42, 90–95. doi: 10.18805/LR-3851

Soni, K. J., Ashok, R. N., and Ajaykumar, R. (2016). Response of physiological and yield attributing parameters of groundnut under drip and micro sprinkler fertigation. Bioscan 12, 373–376.

Soni, K. J., and Raja, N. A. (2017). Performance of groundnut (Arachis hypogaea L.) under drip and micro sprinkler fertigation system. Vehetos Int. J. Plant Res. 30, 2–6. doi: 10.5958/2229-4473.2017.00134.3

Turner, N. C. (1981). Techniques and experimental approaches for the measurement of plant water status. Plant Soil 58, 339–366. doi: 10.1007/BF02180062

Upadhyaya, A. (2015). Water management technologies in agriculture: challenges and opportunities. J. AgriSearch. 2:1.

Venkadeswaran, E., Sundaram, V., and Sankar, R. (2014). Influence of trickle fertigation on growth and physiological attributes of hybrid okra [Abelmoschus esculentus (L.) Moench]. Asian J. Hort. 2, 347–351. doi: 10.15740/HAS/TAJH/9.2/347-351

Vijayalakshmi, R., Veerabadran, V., Shanmugasundram, K., and Kumar, V. (2011). “Micro-sprinkler irrigation, fertigation, and land configuration as a best management technology package for groundnut,” in 8th International Micro Irrigation Congress Innovation Technology Management Micro-irrigation Crop Production Enhancement, Tehran, Iran, 200–207.

Vijaykumar, P. (2009). Optimization of water and nutrient requirement for yield maximization in hybrid rice under drip fertigation system (Oryza sativa L.). M.Sc. (Agri.) Thesis, Tamil Nadu Agricultural University, Coimbatore.

Keywords: groundnut, smart fertigation, sensors, growth, physiology, root characters, yield

Citation: Aathithyan C, Gurusamy A, Subramanian E, Hemalatha GG, Kumutha K, Bhakiyathu Saliha BA and Kamalesh S (2025) Response of indigenous low cost smart fertigation system on growth, physiology, root characters and yield of groundnut (Arachis hypogaea L.). Front. Sustain. Food Syst. 9:1566364. doi: 10.3389/fsufs.2025.1566364

Received: 24 January 2025; Accepted: 23 September 2025;

Published: 17 October 2025.

Edited by:

Anik Bhaduri, Australian National University, AustraliaReviewed by:

Mohamed Chtouki, Mohammed VI Polytechnic University, MoroccoP. N. Parmar, Navsari Agricultural University, India

Copyright © 2025 Aathithyan, Gurusamy, Subramanian, Hemalatha, Kumutha, Bhakiyathu Saliha and Kamalesh. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Arumugam Gurusamy, Z3VydXNhbXkuYUB0bmF1LmFjLmlu; Elangovan Subramanian, ZXN1YnJhbWFuaWFuQHRuYXUuYWMuaW4=

†Present address: Chellamani Aathithyan, College of Agricultural Technology (CAT), Kullapuram, Theni, Tamil Nadu, India

Chellamani Aathithyan

Chellamani Aathithyan Arumugam Gurusamy1*

Arumugam Gurusamy1* Elangovan Subramanian

Elangovan Subramanian G. Ganapathyswamy Hemalatha

G. Ganapathyswamy Hemalatha