- 1School of Food Science and Nutrition, University of Leeds, Leeds, United Kingdom

- 2Department of Food Science, Faculty of Food and Consumer Sciences, Ladoke Akintola University of Technology, Ogbomosho, Nigeria

- 3Department of Food Engineering, Faculty of Engineering and Technology, Ladoke Akintola University of Technology, Ogbomosho, Nigeria

- 4Department of Biosciences, Durham University, Durham, United Kingdom

Global concerns over the depletion of fossil fuels and their impact on the environment have resulted in the development of bio-based materials with more sustainable approaches. The need for a more sustainable economy and a reduction of fossil fuel dependency is driving research in this field. Biopolymers are chain-like molecular structures made of covalently attached monomeric units derived from renewable resources, microorganisms, or synthetic and biodegradable sources. Although biopolymer-based coatings have promising applications in postharvest preservation, they are often limited by their inherent properties when applied alone to fresh produce. This review focuses on assessing the efficacy and potential of biopolymer-based edible coatings in postharvest preservation, with a specific emphasis on the role of functional additives in enhancing performance. Furthermore, it explores how natural additives like essential oils, antioxidants, and antimicrobials interact with biopolymer matrixes in synergy, evaluating their enhanced functional properties in extending the shelf life of produce as well as their environmental impact and biodegradability. By analyzing interactions, release mechanisms, and comparative effectiveness of additives, the role and future of active ingredients in creating multifunctional preservation systems that meet food safety and sustainability requirements is presented.

1 Introduction

Biopolymers are naturally occurring, biodegradable compounds composed of covalently bound monomeric units, synthesized by organisms including plants, animals, bacteria, and fungi. Structurally diverse, biopolymers encompass polysaccharides like cellulose and starch, proteins, and microbial products such as polyhydroxyalkanoates (PHAs), each with unique functional properties. Unlike synthetic polymers, which are largely derived from fossil fuels, biopolymers are typically sourced from renewable origins, though biodegradability is not an inherent trait. Instead, biodegradability depends on factors such as polymer composition and environmental conditions a crucial distinction since the environmental impact of biopolymers is tied to both their sourcing and their capacity to decompose. This versatility positions biopolymers as highly suitable for sustainable postharvest applications, especially in the development of consumable coatings that offer effective protection for perishable items like fruits and vegetables (Kocira et al., 2021; Das et al., 2023).

The rising interest in biopolymer-based edible coatings (ECs) is fueled by growing environmental concerns over synthetic packaging. Conventional plastic-based packaging materials, predominantly derived from petrochemicals, provide effective food preservation but are resistant to degradation. This leads to significant environmental pollution and waste management challenges, as these materials persist in ecosystems long after disposal (Ncube et al., 2020). By contrast, biopolymer coatings, such as those based on polysaccharides, proteins, and lipids, present a sustainable alternative with an inherent capacity to biodegrade under diverse environmental conditions. Studies have shown that biopolymer-based coatings serve as effective barriers to moisture, oxygen, and carbon dioxide, helping to maintain freshness and extend the shelf life of fresh produce. This shift from synthetic to biodegradable packaging aligns with global sustainability initiatives focused on reducing waste and promoting eco-friendly materials, making biopolymers an ideal solution for postharvest preservation in the agricultural sector (Hoque et al., 2011; Shaikh et al., 2019). Scaling production for commercial use further complicates the adoption of biopolymers as viable packaging solutions. Biopolymers sourced from natural materials can exhibit variability in composition, leading to inconsistencies in film properties. For large-scale production, achieving uniformity and long-term stability in functional performance is essential, as fluctuations in mechanical or barrier qualities could undermine consumer trust and regulatory compliance. Standardization of biopolymer sources and processing techniques is thus crucial for ensuring reliable quality, particularly when integrating diverse functional additives (Umaraw et al., 2020).

A key advancement in biopolymer-based coatings is their functionalization with active additives. The integration of essential oils (EOs), antioxidants, and antimicrobial agents into biopolymer matrices has been transformative, as these additives enhance the coatings’ protective qualities by inhibiting microbial growth, slowing oxidation, and reinforcing barriers to gases and moisture. Research has demonstrated that the inclusion of EOs in biopolymers like chitosan not only prolong the shelf life of fresh produce but also improves the mechanical and barrier properties of the films themselves (Nogueira et al., 2021; Díaz-Montes and Castro-Muñoz, 2021; Hossen et al., 2024). For instance, cinnamon and thyme essential oils, known for their potent antimicrobial properties, have been shown to be highly effective in preserving fresh-cut fruits and vegetables when integrated into biopolymer coatings. These additives act through mechanisms that disrupt microbial cell membranes and provide antioxidant protection against lipid peroxidation (Bibow and Oleszek, 2024).

This review focuses on assessing the efficacy and potential of biopolymer-based edible coatings in postharvest preservation, with a specific emphasis on the role of functional additives in enhancing performance. By exploring how natural additives such as essential oils, antioxidants, and antimicrobials synergistically interact with biopolymer matrices, this review aims to evaluate not only the environmental impact and biodegradability of these coatings but also their enhanced functional properties in prolonging produce shelf life. Through an in-depth analysis of the interactions, release mechanisms, and comparative effectiveness of various additives, this article underscores the transformative role of active ingredients in converting biopolymer films into multifunctional preservation systems that address both food safety and sustainability demands.

2 Background and concept of biopolymers

Biopolymers are naturally occurring macromolecules composed of covalently bonded monomeric units, forming larger, functional biomolecules. Synthesized by living organisms, these polymers are typically biodegradable and renewable, with sources ranging from bacteria, fungi, and plants to crustaceans and shrubs. Biopolymers can be broadly classified into protein-based and polysaccharide-based compounds, each possessing distinct physicochemical properties that enable diverse applications, particularly in sustainable packaging and preservation. Common examples include protein-based biopolymers such as silk and wool, as well as polysaccharide-based biopolymers like cellulose and starch. Additionally, complex natural polymers, including collagen and natural rubber, contribute to various industrial and biomedical applications. While biopolymers are bio-based, not all exhibit inherent biodegradability. The distinction between bio-based materials, which originate from renewable sources, and biodegradable materials, which decompose under environmental conditions, is crucial. Therefore, biodegradability must be explicitly assessed for each biopolymer, as it is not an intrinsic property solely derived from renewable sourcing (Das et al., 2023).

Biopolymers exhibit unique physicochemical properties that contribute to their broad applicability. Polysaccharides, characterized by high molecular weight and extensive hydrogen-bonding potential, form structured matrices that serve as effective barriers against gases and moisture. Proteins, composed of complex amino acid sequences, provide flexibility in film formation while offering enhanced mechanical properties, making them viable candidates for packaging applications. These biopolymers are sourced from diverse natural origins. For instance, polysaccharides such as cellulose, derived from plant biomass, possess excellent mechanical strength and barrier properties, making them suitable for coating applications. Likewise, proteins obtained from milk, collagen, and eggs demonstrate intrinsic film-forming capabilities, which can be further optimized through cross-linking. This modification enhances their structural integrity and barrier performance, rendering them particularly beneficial for food packaging applications (Dutta and Sit, 2024).

Biopolymers can be synthesized using organic resources such as vegetable oils, carbohydrates, proteins, and resins, with production techniques tailored to optimize their structural and functional properties. For instance, synthetic biology has advanced microbial synthesis methods, enabling the production of polyhydroxyalkanoates (PHAs) directly by bacteria or other microorganisms. Genetically modified organisms are increasingly employed to produce bio-monomers, which can be polymerized to form biopolymers like PHAs, which offer strong, biodegradable alternatives to conventional plastics. Chemical processes are also used, as seen in the production of polylactic acid (PLA) from microorganisms like Escherichia coli. Such processes enable the formation of biopolymers with specific properties, such as high tensile strength or improved barrier qualities, which are desirable in food preservation applications (Anderson et al., 2018).

One of the primary applications of biopolymers is in edible coatings for agricultural products, where they serve as protective layers for fresh produce. These coatings form a thin, edible barrier on the surface of fruits and vegetables, reducing oxidation, moisture loss, and microbial contamination. By functioning as gas and moisture barriers, edible biopolymer coatings help regulate respiration rates and delay spoilage, thereby extending shelf life. Moreover, these coatings can be infused with active agents like antioxidants and antimicrobials, which further enhance their preservation effects (Priya et al., 2023). Bioactive compounds, including essential oils and other natural preservatives, can be incorporated within the biopolymer matrix, allowing controlled release and sustained protection against microbial growth. This combination of barrier and active protective qualities positions biopolymers as viable alternatives to synthetic packaging, especially as consumer demand grows for natural, non-toxic food preservation methods (Duong et al., 2024).

The effectiveness of biopolymer-based edible coatings is influenced by the specific material properties of each biopolymer group, which includes lipids, proteins, and polysaccharides. Each category offers unique attributes relevant to food preservation. Lipids, for instance, provide hydrophobic barriers, reducing moisture loss in high-water-content foods (Devi et al., 2024). Proteins are valued for their film strength and flexibility, making them suitable for perishable goods that require resilient packaging. Polysaccharides, with their inherent film-forming capabilities and gas barrier qualities, play a key role in the preservation of high-respiration produce. Together, these biopolymers support a range of applications, from extending shelf life to enhancing food quality by controlling moisture and oxygen levels (Bhaskar et al., 2023).

While biopolymers offer promising eco-friendly alternatives for food preservation, challenges remain in optimizing their properties to match those of synthetic materials. Issues such as mechanical strength, water vapor permeability, and cost-effectiveness must be addressed to make biopolymers viable for large-scale, commercial applications. However, the versatility and environmental benefits of biopolymers continue to drive research into their development, particularly in the integration of functional additives to enhance their antimicrobial and antioxidative properties. Further advancements in biopolymer technology and synthetic biology are expected to expand the scope of biopolymers, making them essential in the shift toward sustainable packaging solutions and environmentally friendly food preservation systems (Moeini et al., 2020; Guo et al., 2022).

2.1 Biopolymers as edible coatings

Biopolymers have garnered significant interest for their role as edible coatings, particularly in postharvest preservation, due to their potential to serve as biodegradable, consumable layers that extend the shelf life of fresh produce. These coatings act as a physical barrier against oxidative degradation, moisture loss, and microbial contamination, effectively reducing spoilage and enhancing food safety. Unlike synthetic preservatives, biopolymer-based coatings are generally safe for human consumption, appealing to consumer demand for chemical-free preservation options. This demand has driven the exploration of biopolymers such as chitosan, starch, alginate, and cellulose, which exhibit favorable film-forming properties and can be applied directly to the surface of fruits and vegetables (Kocira et al., 2021).

Studies reveal that biopolymer-based coatings can be tailored to address specific preservation needs, reflecting a high degree of adaptability in the food industry. For example, starch-based coatings, when combined with lipid additives, exhibit improved water resistance, making them suitable for high-moisture products like cut fruits. Research shows that adding beeswax to starch coatings reduces water vapor permeability, effectively slowing down moisture loss and extending shelf life (Vakili-Ghartavol et al., 2024). Alginate, another biopolymer derived from brown seaweed, is known for its gel-forming properties and compatibility with various active agents. Alginate coatings enriched with calcium ions exhibit robust structural stability, improving the physical barrier effect and reducing moisture transfer between the produce and the environment (Shaikh et al., 2019).

The functional versatility of biopolymers also allows for the incorporation of antioxidants, which counteract oxidative reactions that degrade color, flavor, and nutritional content in fruits and vegetables. Ascorbic acid and other natural antioxidants integrated into biopolymer matrices help preserve the sensory and nutritional qualities of coated produce. Studies on cellulose-based coatings with antioxidant additives have demonstrated that these coatings maintain the visual appeal and vitamin content of produce over extended storage periods, appealing to consumers and reducing food waste (Choeybundit et al., 2024). Additionally, biopolymers can act as carriers for probiotics and other beneficial microorganisms, offering a multifunctional solution that contributes to food safety and quality.

In terms of economic and environmental sustainability, biopolymer-based coatings hold several advantages. They are typically derived from renewable resources such as agricultural waste or marine by-products, reducing dependency on petrochemical-based packaging and contributing to circular bio-economies (Devi et al., 2022). Moreover, these coatings are compostable and do not introduce non-degradable waste into the environment, unlike conventional plastic packaging. For instance, cellulose-based coatings derived from agricultural residues decompose naturally, minimizing the environmental footprint associated with food preservation. As biopolymer coating technologies advance, the scalability and cost-effectiveness of these coatings continue to improve, making them increasingly viable for large-scale commercial use (Versino et al., 2023).

2.2 Role of biopolymers in sustainable postharvest management

Postharvest management is essential for reducing losses in fresh fruits and vegetables, which are valuable for their rich nutrient profiles, including vitamins, minerals, and organic acids critical to human health (Imahori and Bai, 2024). Over recent decades, increased global demand for fresh produce has driven growth in the fruit and vegetable industry, fueled by rising living standards and shifts in dietary preferences toward more plant-based foods. However, significant challenges persist, particularly in low-resource regions, where up to one-third of the produce is lost at various stages of the supply chain. These losses arise from a combination of intrinsic factors, such as physiological senescence, and extrinsic factors, notably pathogenic infections caused by fungi and bacteria that can accelerate spoilage and degrade quality (Tian et al., 2016). Such postharvest deterioration not only reduces marketable yield but also undermines food security and economic gains for smallholder farmers.

Traditional postharvest preservation strategies primarily rely on synthetic chemicals to control spoilage and extend shelf life. Pesticides and fungicides, though effective in the short term, pose significant health and environmental concerns due to their potential to accumulate as residues on produce and enter surrounding ecosystems, raising risks of toxicity for both consumers and wildlife. In addition, fungal pathogens produce toxic secondary metabolites, which may accumulate in stored produce, increasing food safety risks and threatening consumer health. The urgent need for safer and more sustainable alternatives has catalyzed research into natural preservation techniques, particularly those based on biopolymer technology, which aims to limit synthetic inputs while safeguarding food quality and safety (Mensitieri et al., 2011). Biopolymer-based edible coatings, made from renewable materials such as polysaccharides and proteins, provide a promising solution by forming a protective barrier that reduces exposure to contaminants and mitigates pathogen-induced spoilage without reliance on synthetic chemicals.

Modern postharvest management incorporates a combination of physical storage techniques to maximize the quality and longevity of both intact and fresh-cut produce (Yousuf et al., 2021). Core practices include cold storage, controlled atmospheric conditions, and humidity regulation, which collectively slow metabolic processes and delay senescence. Cold storage remains one of the most widely used methods, effectively reducing respiration rates and extending shelf life for a variety of fruits and vegetables. However, temperature control alone may not be sufficient for all produce, as some fruits are prone to chilling injuries that compromise quality (Ziv and Fallik, 2021). Modified Atmosphere Packaging (MAP) is another widely adopted technique that adjusts the gaseous composition around the produce, typically reducing oxygen and elevating carbon dioxide levels, to slow respiration and microbial growth. MAP has proven particularly effective for high-respiration items like leafy greens, but the costs associated with the specialized materials and infrastructure can limit its accessibility, especially in developing regions (Ma et al., 2017). Gamma irradiation is yet another approach that effectively reduces microbial load by damaging the DNA of spoilage organisms; however, concerns over consumer perception and regulatory hurdles continue to limit its widespread adoption in some markets.

Recent innovations in biopolymer-based edible coatings offer a sustainable and health-conscious approach to postharvest management. Derived from natural sources, food-grade biopolymers, such as chitosan, cellulose, and alginate, provide a protective layer that enhances shelf life by reducing respiration and water loss while acting as a barrier against pathogens. These coatings are often supplemented with bioactive additives, such as essential oils, antioxidants, and antimicrobial agents, which provide additional defense against microbial contamination and oxidation, thereby preserving the nutritional and sensory quality of the produce (Kocira et al., 2021). Unlike synthetic coatings, biopolymers are biodegradable and generally recognized as safe (GRAS), minimizing the risk of harmful residues. The application of these biopolymer coatings is particularly relevant in scenarios where cold storage and MAP may be unavailable or economically unfeasible, offering an accessible and effective preservation strategy for small-scale producers and markets lacking advanced storage facilities.

In addition to extending shelf life, biopolymer coatings align with consumer demand for clean-label and environmentally friendly preservation methods. As interest in sustainable agriculture and food safety grows, biopolymer-based coatings represent an innovative intersection of renewable material science and food technology, allowing for improved produce quality without the trade-offs associated with synthetic chemicals. These coatings not only contribute to reduced pesticide dependency but also support environmental objectives by offering compostable packaging solutions, contributing to a circular economy in the food sector (Mensitieri et al., 2011). As research continues to advance, biopolymer coatings are anticipated to play a significant role in postharvest management, addressing both preservation and sustainability goals essential for global food systems.

2.3 Types and sources of food-grade biopolymers

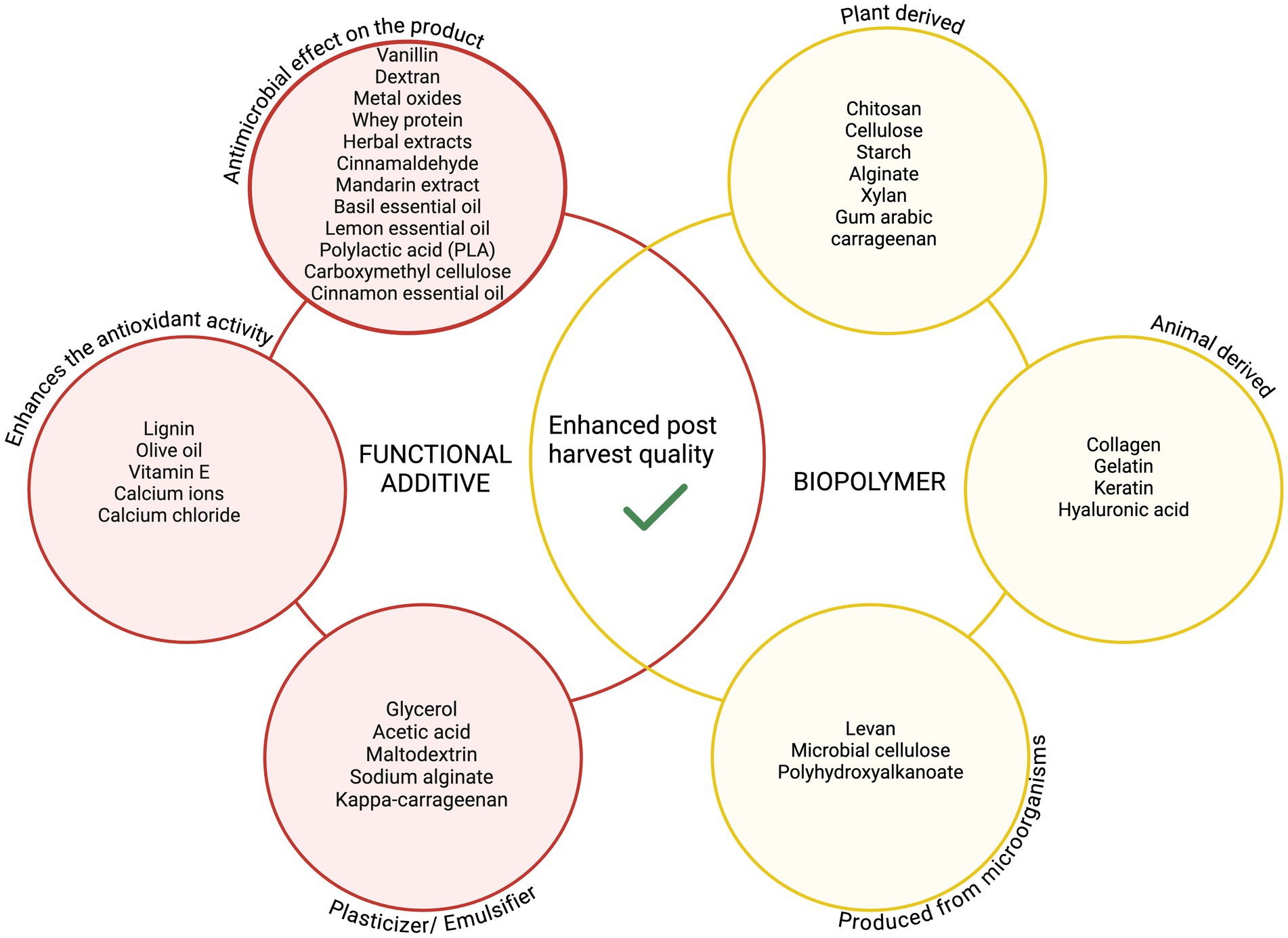

Biopolymers, given their sustainable origin and biodegradability, are increasingly recognized as critical components in food packaging and preservation. Classified primarily by source (Figure 1), biopolymers can be derived from plants, animals, and microbes, each offering distinct structural and functional properties. This versatility enables them to serve as effective barriers in edible coatings, enhancing shelf life, maintaining sensory quality, and aligning with growing consumer demand for chemical-free food preservation solutions.

Figure 1. Classification and examples of biopolymers according to their origin and functional additives according to their mode of operation.

2.3.1 Plant-derived biopolymers

2.3.1.1 Chitosan

Chitosan, a deacetylated derivative of chitin, stands out for its versatility and bioactivity. As the second most abundant polysaccharide in nature, chitosan is sourced primarily from crustacean shells, fungi, and insect exoskeletons. The polymer’s cationic nature, arising from its amino groups, imparts unique properties, including antimicrobial, antioxidant, and film-forming capabilities, making it highly effective for food preservation (Duan et al., 2021). Research highlights that chitosan exhibits potent antimicrobial efficacy against a broad spectrum of pathogens, including fungi, bacteria, and yeasts, due to its ability to disrupt microbial cell membranes (Doan et al., 2025). This disruption is enhanced by chitosan’s chelation properties, which bind essential nutrients and further impede microbial growth. When combined with essential oils or plant extracts, chitosan coatings have shown a marked increase in gas barrier properties and moisture resistance, making them especially suitable for high-moisture produce (Sánchez-González et al., 2011a,b).

2.3.1.2 Starch

Starch, a polysaccharide composed of amylose and amylopectin chains, is the most abundant renewable carbohydrate source, obtained from crops like maize, potatoes, and rice (Apriyanto et al., 2022). Due to its low cost and biodegradability, starch is widely utilized as a base for bioplastics and edible coatings. However, its hydrophilic nature limits its water barrier properties, a drawback that has spurred research into modified starch blends. Studies demonstrate that thermoplastic starch (TPS) can be processed under specific conditions to enhance its compatibility with other materials, allowing for improved film strength and barrier properties (Chatkitanan and Harnkarnsujarit, 2021). Additives such as lipids or essential oils, which exhibit hydrophobic properties, are often incorporated to offset starch’s moisture sensitivity, enabling starch-based films to function effectively in food preservation by reducing water vapor transmission and extending shelf life (Tavassoli-Kafrani et al., 2016).

2.3.1.3 Xylan

Xylan, a hemicellulose found in plant cell walls, is a promising alternative for food-grade biopolymers. Extracted from agricultural residues like corn stalks and wheat straw, xylan provides an eco-friendly, non-toxic coating material with inherent barrier properties against moisture and gases. Xylan-based films have been used effectively to protect perishable items by reducing water loss and extending freshness. For instance, studies show that xylan-based coatings on apples significantly reduced weight loss over a month, highlighting their potential in moisture-sensitive applications (Ali et al., 2019). Xylan’s biocompatibility also allows it to be combined with bioactive compounds, further enhancing its preservation properties and offering a dietary fiber component when consumed with fruits, underscoring its multifunctional role in edible coatings.

2.3.1.4 Cellulose

Cellulose, an abundant polysaccharide in plant cell walls, is a linear polymer of glucose molecules, renowned for its robustness and structural integrity. It is highly regarded in packaging for its film-forming ability, mechanical stability, and oxygen barrier properties, which help delay oxidative degradation in packaged foods (Thakur et al., 2012). Recent advancements in cellulose modification, particularly through nanocellulose, have expanded its potential, enabling cellulose to form stable films with enhanced mechanical and barrier properties. Bacterial cellulose, synthesized by organisms like Gluconacetobacter spp., offers even greater purity and uniformity, forming hydrophilic, porous structures that can be functionalized with antimicrobial agents. This application of bacterial cellulose in edible coatings provides controlled release of bioactive substances, enhancing microbial stability and extending product shelf life (Rajwade et al., 2015).

2.3.1.5 Gum Arabic

Derived from Acacia senegal and Acacia seyal, gum Arabic is a complex polysaccharide rich in soluble fibers, valued for its emulsifying, stabilizing, and encapsulation capabilities in food applications. The polysaccharide’s high solubility and ability to form stable emulsions make it a valuable carrier for bioactive ingredients, protecting flavors and essential oils within a matrix that stabilizes against oxidation and microbial growth (Williams et al., 2009). Studies demonstrate gum Arabic’s efficacy in preserving sensory qualities, as evidenced by its application on fruits and vegetables, where it maintained flavor and appearance postharvest (Tiamiyu et al., 2023). Additionally, gum Arabic’s film-forming properties allow it to function as a protective barrier, applicable in both fresh produce coatings and confectionery, enhancing gloss and maintaining structural integrity.

2.3.1.6 Alginate

Alginate, an anionic polysaccharide derived from brown seaweeds, exhibits remarkable gelling and film-forming abilities due to its linear structure of mannuronic and guluronic acids. This characteristic makes it ideal for encapsulating bioactive compounds in food preservation (Abdul Khalil et al., 2018). Alginate films, cross-linked with calcium ions, demonstrate excellent mechanical properties and moisture barrier performance, making them suitable for fresh-cut fruits and vegetables. Studies have shown that alginate coatings, particularly those reinforced with calcium, can significantly reduce respiration rates and delay browning, thereby preserving the appearance and nutritional quality of fresh produce (Paques et al., 2014).

2.3.2 Marine-derived biopolymers

2.3.2.1 Carrageenan

Carrageenan, a sulphated polysaccharide extracted from red algae, is known for its excellent gelling, stabilizing, and film-forming properties. Its unique molecular structure, composed of alternating galactose and 3,6-anhydrogalactose, allows it to form strong, flexible films that can encapsulate and stabilize various bioactive compounds (Zia et al., 2016). Carrageenan has been used to coat berries and other soft fruits, forming an antiviral and antimicrobial layer that prolongs shelf life and maintains nutritional quality (Falcó et al., 2019). When combined with antioxidants or plant extracts, carrageenan coatings exhibit enhanced preservation qualities, helping to maintain moisture content and visual appeal while inhibiting microbial growth during storage (Giannakourou and Tsironi, 2021).

2.3.3 Synthetic and biodegradable polymers

2.3.3.1 Polylactic acid (PLA)

Polylactic Acid (PLA), a bio-based polymer derived from lactic acid fermentation of agricultural products like corn and sugarcane, is widely used in bioplastic packaging. PLA’s compostability, approved by the FDA for food contact, makes it an environmentally favorable alternative to petrochemical-based plastics (Swetha et al., 2023). PLA’s use in coating fresh produce is particularly advantageous for high-respiration fruits, as it provides a selective gas barrier, maintaining oxygen and carbon dioxide exchange that delays ripening. Enhanced with antimicrobial agents like oregano or garlic extracts, PLA coatings reduce microbial growth effectively, as demonstrated in salad and vegetable storage studies, highlighting PLA’s potential as an active packaging material (Llana-Ruiz-Cabello et al., 2015).

2.3.4 Animal-derived biopolymers

2.3.4.1 Gelatine

Gelatine, a partially hydrolyzed form of collagen, is widely used for edible films due to its film-forming, oxygen barrier, and protective properties. Derived from sources like bovine and fish collagen, gelatine-based coatings are hygroscopic and highly biocompatible, making them suitable for coating perishable items like meat and dairy. However, gelatine’s hydrophilic nature limits its water resistance, necessitating blending with hydrophobic agents or crosslinkers to enhance durability (Alfaro et al., 2014). Studies have demonstrated that gelatine’s film strength can be optimized with plant extracts or other polymers, forming composite films that maintain structural integrity while reducing oxidative degradation (Zhao et al., 2016).

2.3.4.2 Keratin

Keratin, a fibrous protein high in cysteine, offers robust barrier properties due to its dense, cross-linked structure, making it a promising material for packaging applications requiring high durability. Keratin-based films exhibit resistance to enzymatic and microbial degradation, which is beneficial for high-protein foods vulnerable to spoilage. Research has shown that keratin’s incorporation into biopolymer matrices can improve tensile strength and moisture resistance, enhancing its suitability for food packaging (Saha et al., 2019). Its high disulfide bond content offers additional stability, making it a potential solution for long-term storage applications where mechanical durability is required.

2.3.5 Microbial-derived biopolymers

2.3.5.1 Levan

Produced by various microbial strains, including Bacillus subtilis and Zymomonas mobilis, levan is a fructan with significant potential as a thickener and stabilizer. Known for its biocompatibility and biodegradability, levan forms strong films that can be used in both food and pharmaceutical applications. Studies emphasize its scalability, with microbial production offering a sustainable approach to sourcing this polymer (Domżał-Kędzia et al., 2023). Levan’s inherent viscosity and resistance to degradation make it suitable for extending the shelf life of perishable items when used in coating applications.

2.3.5.2 Polyhydroxyalkanoate (PHA)

PHA, a biopolymer synthesized by various microorganisms under nutrient-limited conditions, is a fully biodegradable alternative to traditional plastics. The thermoplastic properties of PHA, coupled with its biocompatibility, allow it to form films with physical characteristics ranging from flexible to rigid, depending on the monomer composition (Mannina et al., 2019). Given its natural origin and ability to degrade without producing toxic residues, PHA is especially suited for eco-friendly food packaging applications, demonstrating excellent barrier properties when reinforced with bioactive compounds.

2.3.5.3 Microbial cellulose

Microbial cellulose, synthesized by bacteria like Gluconacetobacter xylinus, exhibits a highly crystalline structure devoid of lignin and hemicellulose, resulting in superior purity and strength. Unlike plant-derived cellulose, microbial cellulose offers unique advantages in film-forming capacity due to its high water-holding ability and moldability. Research indicates that microbial cellulose films, when impregnated with antimicrobial agents, can serve as an effective barrier in fresh produce packaging, enhancing shelf life and microbial stability (Azeredo et al., 2019). The material’s versatility in biopolymer applications has positioned it as a promising candidate for sustainable, high-performance food packaging.

3 Food-grade functional additives in biopolymer coatings for postharvest preservation

Food-grade functional additives (FAs) are bioactive compounds integrated into biopolymer coatings to enhance their mechanical properties, barrier functions, and bioactivity. These additives play a pivotal role in preventing spoilage and preserving the nutritional and sensory qualities of horticultural crops by providing antioxidative, antimicrobial, and moisture-regulating properties. Such additives, derived from natural sources, include antioxidants, antimicrobial agents, plasticizers, and moisture regulators as presented in Figure 1 (Dai et al., 2024). Their integration into biopolymers like chitosan, starch, and alginate has created sustainable alternatives to synthetic coatings and preservatives. However, the efficacy of these additives depends on their compatibility with the biopolymer matrix and their stability during storage and application (Moghadas et al., 2024). While their advantages in enhancing biopolymers are evident (Marturano et al., 2014; Sutharsan et al., 2023; Moghadas et al., 2024; Revutskaya et al., 2024), challenges related to cost, regulatory approval, and large-scale production persist at present.

3.1 Types of functional additives

3.1.1 Antioxidants

Antioxidants play a pivotal role in enhancing food-grade biopolymer coatings by preventing oxidative degradation, a major contributor to spoilage and nutrient loss in fresh produce and processed foods. Natural antioxidants such as tocopherols, ascorbic acid, and polyphenols are particularly valuable for their ability to neutralize free radicals, thereby preserving the sensory and nutritional quality of food products. These antioxidants are frequently incorporated into biopolymer matrices like chitosan, starch, or alginate, where they act as stabilizing agents that mitigate oxidative reactions on food surfaces.

Tocopherols, often derived from natural sources like vegetable oils, act as lipid-soluble radical scavengers, making them effective in preventing lipid peroxidation. This function is especially beneficial for fatty foods or those prone to rancidity, such as nuts, meat products, and dairy. For instance, chitosan-based coatings enriched with tocopherols have been shown to extend the shelf life of fresh fish filets by inhibiting oxidation and maintaining sensory attributes like texture and color (Hernández-Muñoz et al., 2008). Similarly, ascorbic acid, a water-soluble antioxidant commonly known as Vitamin C, works as a reducing agent. It not only scavenges reactive oxygen species but also regenerates other antioxidants within the system, enhancing overall efficacy. Starch-based coatings infused with ascorbic acid have been particularly effective in preserving the visual and nutritional quality of fresh-cut tropical fruits like mangoes and pineapples (Dai et al., 2024). Polyphenols, sourced from plant extracts such as green tea, grape seeds, or pomegranate peel, provide dual benefits of radical scavenging and metal ion chelation. By reducing the pro-oxidative activity of metal ions, polyphenols enhance the stability of food products that are prone to oxidative damage. For instance, gelatine-based coatings containing green tea extract have been shown to preserve the freshness and antioxidant capacity of fresh fish fillets, delaying discoloration and lipid oxidation (Siripatrawan and Harte, 2010). Another example includes chitosan coatings infused with grape seed extract, which have been demonstrated to reduce browning and firmness loss in strawberries during extended storage (Gupta et al., 2020).

Despite their benefits, the incorporation of antioxidants into biopolymer coatings presents several challenges. Stability is a primary concern, as many antioxidants are sensitive to environmental conditions such as light, heat, and oxygen. This instability can lead to diminished efficacy during processing and storage. For instance, ascorbic acid is prone to oxidative degradation in high-temperature or oxygen-rich environments, limiting its effectiveness in coatings for products requiring long-term storage (Dhall, 2013). Similarly, polyphenols can lose their bioactivity due to interactions with other components in the biopolymer matrix, potentially affecting their radical-scavenging abilities. Addressing these limitations often involves encapsulation techniques to protect antioxidants and ensure their controlled release, though such technologies can increase production complexity and cost.

3.1.2 Antimicrobial agents

Natural antimicrobial agents such as essential oils (EOs) and organic acids are integral to enhancing the microbial barrier properties of biopolymer coatings. These additives effectively combat a wide range of spoilage microorganisms and foodborne pathogens, including Salmonella and E. coli, thereby extending the shelf life and safety of food products. Their incorporation into biopolymer matrices like pectin, cellulose, and chitosan provides an active layer of protection, ensuring food remains fresher for longer durations while reducing the reliance on synthetic chemical preservatives.

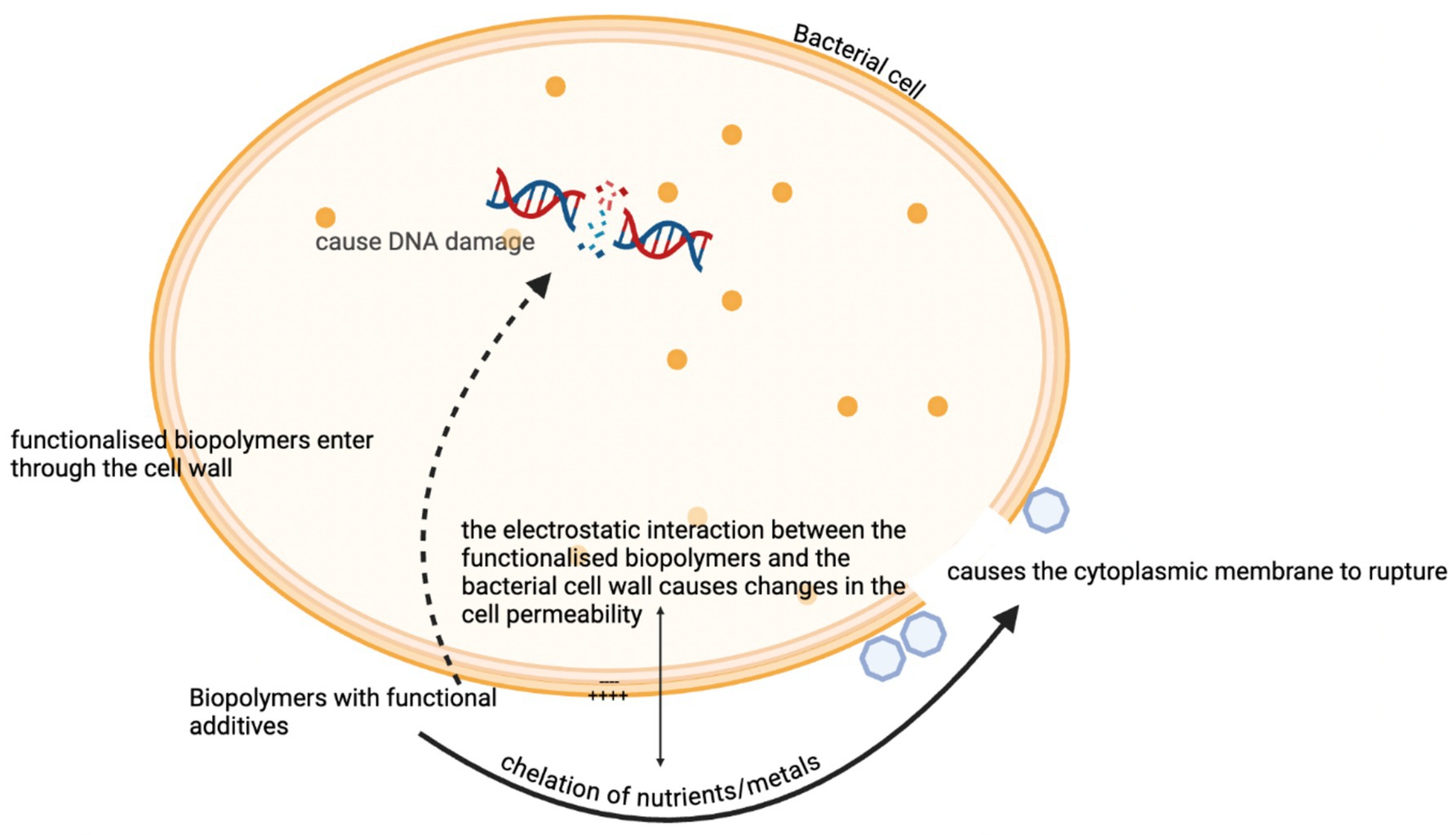

Essential oils, derived from plants such as thyme, oregano, and cinnamon, are particularly effective antimicrobial agents due to their high content of bioactive compounds like thymol, carvacrol, and eugenol. These compounds exert antimicrobial action by disrupting microbial cell membranes, penetrating the lipid bilayer, increasing permeability, and causing leakage of cellular contents. The denaturation of membrane proteins further contributes to microbial cell death. For instance, pectin-based films containing oregano EO have been shown to inhibit the growth of Listeria monocytogenes on fresh-cut fruits, effectively preserving their quality and preventing spoilage (Burt, 2004; Adiletta et al., 2021). Similarly, organic acids such as citric acid and lactic acid are widely utilized as antimicrobial additives in biopolymer coatings. These acids create an acidic microenvironment unfavorable for microbial growth, particularly against pathogens like Salmonella and E. coli. Chitosan films enriched with citric acid have demonstrated enhanced microbial inhibition, making them ideal for use in packaging fresh produce, poultry, and seafood (Sutharsan et al., 2023).

Despite their efficacy, challenges exist in maintaining the stability and functionality of antimicrobial agents over extended storage periods. Essential oils, for example, are highly volatile, which can result in rapid evaporation and diminished effectiveness. Encapsulation technologies, such as microencapsulation and nanoencapsulation, are being developed to address these limitations by providing a controlled-release mechanism. For instance, encapsulated cinnamon oil in alginate beads ensures sustained antimicrobial action throughout the storage period of fresh dairy products, thereby maintaining quality without overwhelming the sensory attributes (Dhall, 2013). Another challenge lies in the high production costs and regulatory barriers associated with the use of natural antimicrobials in food packaging. Regulatory frameworks often require comprehensive safety assessments for each additive and its interaction within biopolymer matrices, significantly delaying market approval. Moreover, the sensory impacts of some essential oils, such as strong flavors and aromas, can limit their application in certain food categories. Balancing efficacy with sensory neutrality and regulatory compliance remains a critical area for future research and innovation (Revutskaya et al., 2024).

3.1.3 Plasticizers and emulsifiers

Plasticizers and emulsifiers play critical roles in enhancing the mechanical, structural, and functional properties of biopolymer coatings, making them more versatile and effective for food preservation applications. These additives address key limitations of biopolymer films, such as brittleness, rigidity, and inconsistent dispersion of hydrophobic compounds, thereby expanding their applicability across diverse food products.

Plasticizers, such as glycerol and sorbitol, are indispensable in improving the flexibility and durability of biopolymer films. By reducing brittleness and enhancing elasticity, these compounds facilitate the formation of coatings that can conform to the irregular surfaces of fruits and vegetables without cracking. Plasticizers achieve this by interacting with polymer chains and decreasing intermolecular forces, which in turn increases the mobility of the polymer network. For example, glycerol has been shown to significantly improve the mechanical properties of chitosan films, enabling their application on highly perishable produce such as strawberries and tomatoes. These flexible coatings provide a protective barrier that reduces moisture loss and microbial contamination while maintaining the structural integrity of the film (Sánchez-González et al., 2011a, 2011b). Sorbitol, another widely used plasticizer, enhances the stability and transparency of biopolymer coatings, making it particularly suitable for starch-based films. Studies have demonstrated that the incorporation of sorbitol into starch films improves their tensile strength and elongation capacity, rendering them effective for wrapping fresh-cut fruits and bakery items (Tavassoli-Kafrani et al., 2015). However, the selection and concentration of plasticizers are crucial, as excessive amounts can compromise the water vapor barrier properties of the films, potentially reducing their effectiveness in high-humidity environments.

Emulsifiers, on the other hand, address the challenge of uniformly dispersing hydrophobic additives like essential oils within hydrophilic biopolymer matrices. These compounds enhance the stability and functionality of the coatings by preventing phase separation and ensuring a consistent distribution of bioactive agents. Lecithin, a phospholipid commonly used as an emulsifier, has proven effective in incorporating essential oils into starch-based films. By improving the homogeneity of the oil-polymer mixture, lecithin enhances the antimicrobial activity of the coatings, ensuring that the protective effects are evenly distributed across the food surface (Pérez-Gago and Krochta, 2001; Revutskaya et al., 2024). The inclusion of emulsifiers also improves the sensory properties of biopolymer coatings, as they mitigate the intense aromas or flavors often associated with essential oils. For example, emulsifiers allow for the gradual release of essential oils in coatings, maintaining antimicrobial efficacy while minimizing sensory alterations that might affect consumer acceptance. This balance is critical for applications in products like fresh-cut fruits, dairy items, and minimally processed vegetables, where maintaining sensory quality is paramount.

Despite their benefits, the use of plasticizers and emulsifiers in biopolymer coatings is not without challenges. Excessive plasticizer content can lead to undesirable stickiness or decreased barrier performance, while some emulsifiers may interact unfavorably with other functional additives, reducing their bioactivity or stability. Additionally, regulatory hurdles regarding the approval of certain additives for food contact applications and cost considerations can limit their adoption in commercial settings.

4 Mechanisms and efficacy of functional additives in food-grade polymers in enhancing preservation properties

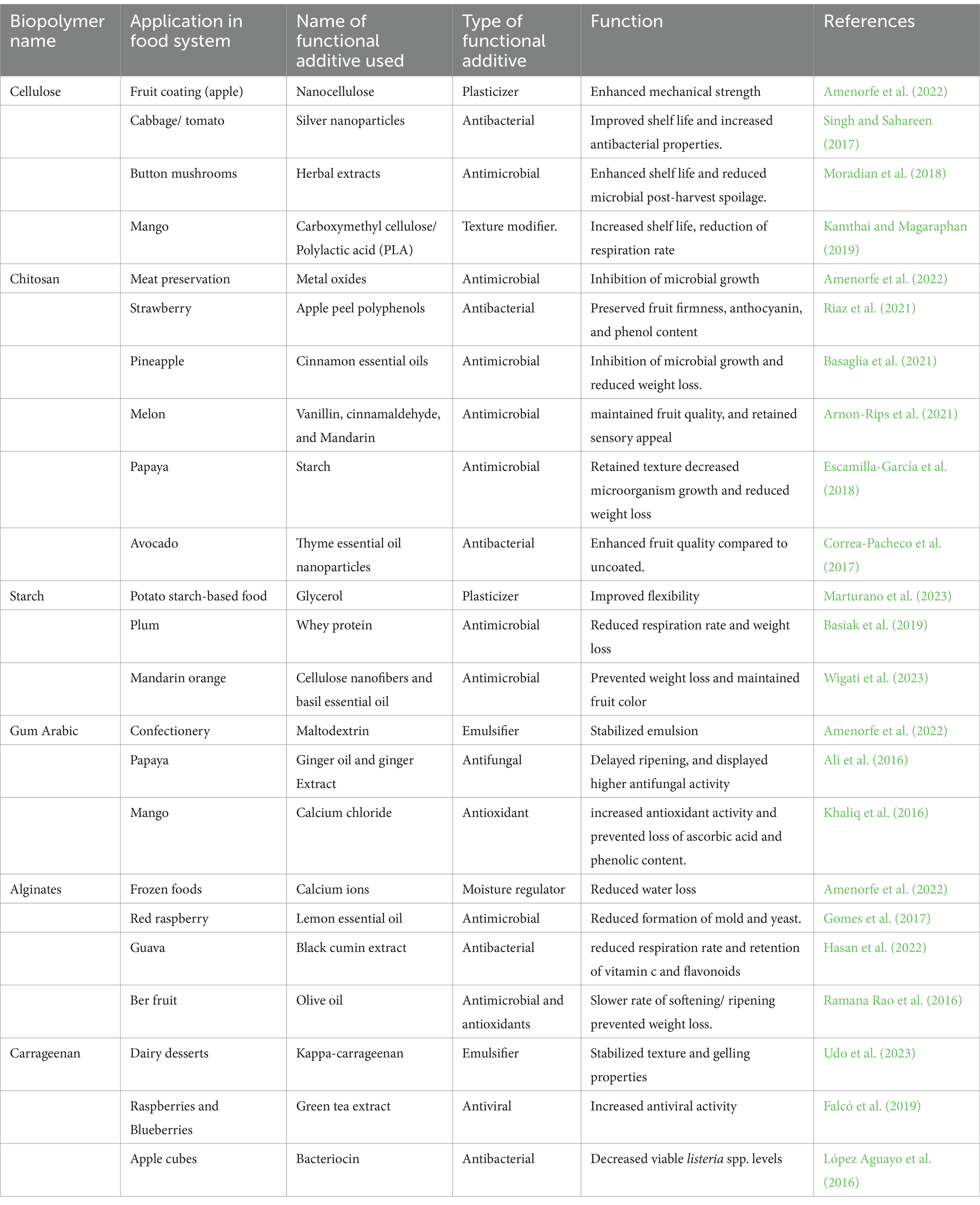

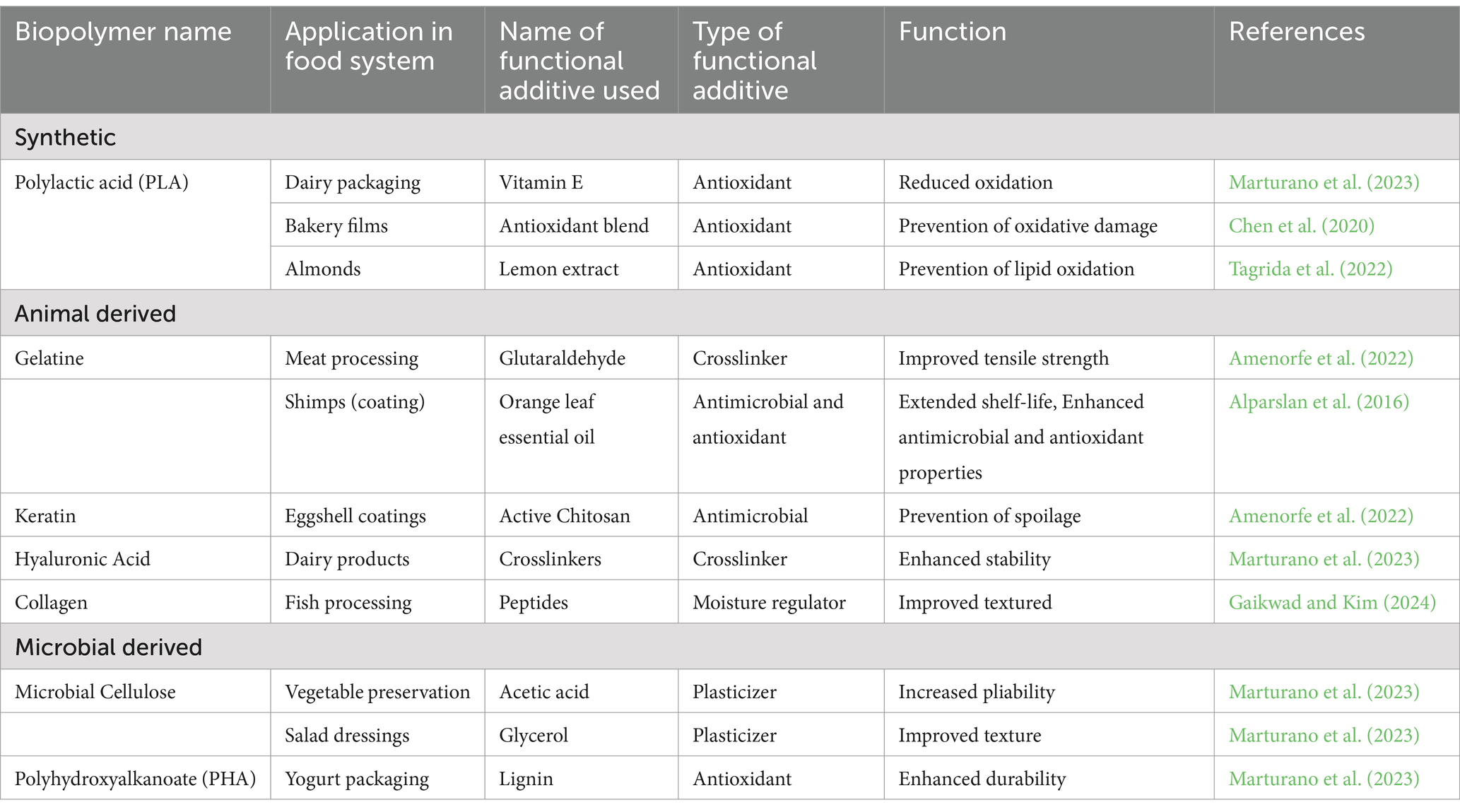

Functional additives are instrumental in elevating the effectiveness of food-grade biopolymers as edible coatings and packaging solutions as displayed in Tables 1, 2. Through their bioactive properties, additives such as essential oils, antioxidants, and nanoparticles address critical challenges in food preservation by enhancing antimicrobial, antioxidant, and barrier functionalities. These improvements are essential for extending shelf life, maintaining sensory quality, and aligning with the demand for natural and sustainable preservation methods. This section critically examines the mechanisms and effects of various functional additives in enhancing food-grade polymers, supported by findings from recent academic literature as reflected in Figure 2.

Table 1. Plant derived biopolymers and functional additives in food systems: applications, types, and enhancements.

Table 2. Synthetic, microbial, and animal derived biopolymers and functional additives in food systems: applications, types, and enhancements.

4.1 Essential oils: mechanisms and application in biopolymer matrices

Essential oils (EOs) are highly effective as natural antimicrobial and antioxidant agents due to their rich composition of terpenoids, phenols, and other volatile compounds. Studies have shown that EOs such as thyme, oregano, and rosemary oils disrupt microbial cell membranes, causing cell lysis and reducing microbial load in food products (Abers et al., 2021). In food-grade polymers like chitosan, the incorporation of EOs not only extends the shelf life of fruits and vegetables but also enhances antimicrobial efficacy. For example, Sánchez-González et al. (2011a,b) demonstrated that chitosan films infused with thyme oil significantly inhibited E. coli and Staphylococcus aureus, enhancing produce safety during storage.

EOs face limitations, however, due to their volatility, strong odor, and potential for rapid degradation. Recent studies address these challenges by encapsulating EOs in nanoparticles, which help to control the release and stabilize the active compounds. For instance, Ellboudy et al. (2023) reported that cinnamon oil encapsulated in chitosan nanoparticles not only minimized sensory impact but also provided a controlled release of antimicrobial compounds, proving effective in extending cheese shelf life without compromising flavor. This encapsulation technique optimizes EO functionality, allowing for targeted microbial inhibition over prolonged storage periods, which is particularly beneficial for products with longer shelf-life requirements.

4.2 Antioxidants: enhancing nutrient retention and sensory qualities

Natural antioxidants, including ascorbic acid, tocopherols, and polyphenolic extracts, play a pivotal role in preventing oxidative spoilage, which can otherwise lead to nutrient loss, off-flavors, and discoloration in food. When integrated into biopolymer films, antioxidants protect perishable foods by scavenging free radicals that initiate oxidation. Siripatrawan and Harte (2010) highlighted that alginate films embedded with green tea extract effectively delayed oxidative spoilage in fish products, preserving freshness and sensory appeal. Furthermore, chitosan-based films with antioxidants like ascorbic acid have been shown to reduce browning in fruits, such as apples, thereby maintaining visual quality and extending the appeal for consumers (Özdemir and Gökmen, 2019).

The incorporation of polyphenol-rich plant extracts, such as those from grape seeds, has proven to be particularly effective in both antimicrobial and antioxidant roles. For instance, Gupta et al. (2020) demonstrated that grape seed extract in starch films protected strawberries from microbial spoilage and oxidative damage, thereby extending both their esthetic and nutritional quality. Such applications of antioxidants are especially relevant for fruits with high susceptibility to oxidation, where antioxidant-laden coatings can provide dual benefits in quality retention and shelf-life extension.

4.3 Nanoparticles: enhancing mechanical strength and barrier properties

Nanoparticles, particularly silver (AgNPs), zinc oxide (ZnO-NPs), and titanium dioxide (TiO2-NPs), provide significant structural and functional benefits when incorporated into biopolymers. Due to their high surface area-to-volume ratio, nanoparticles interact efficiently with microbial cells and strengthen the biopolymer matrix, enhancing both antimicrobial properties and mechanical stability. Studies demonstrate that embedding AgNPs into chitosan films results in substantial antimicrobial effects, reducing contamination risks from pathogens such as L. monocytogenes and Salmonella typhimurium (Emamifar, 2011). Furthermore, ZnO nanoparticles in starch films have been shown to improve tensile strength and reduce permeability, making them ideal for moisture-sensitive applications (Ghasemlou et al., 2011).

Safety concerns regarding nanoparticle migration into food matrices have led to innovations in immobilization techniques. For instance, Hosseinzadeh et al. (2020) developed chitosan-cellulose nanocomposites with immobilized TiO2 nanoparticles, demonstrating effective antimicrobial performance in meat preservation with minimal migration, thereby meeting food safety standards. This immobilization approach allows nanoparticles to retain antimicrobial efficacy while ensuring consumer safety, which is critical for biopolymer applications in direct food contact scenarios.

4.4 Plant extracts: multi-functional additives for enhanced preservation

Plant extracts rich in polyphenols and flavonoids, such as pomegranate and green tea, are gaining attention for their multi-functional roles in biopolymer films. These extracts not only serve as antioxidants but also offer antimicrobial benefits, extending the preservation capabilities of biopolymers. Rodrigues et al. (2022) reported that cellulose films infused with green tea extract effectively reduced microbial load and oxidative degradation in packaged fruits, demonstrating their dual-action benefits. Furthermore, gelatine films containing oregano extract have been shown to effectively inhibit microbial growth in meat products, enhancing both water vapor barrier properties and extending shelf life (Ma et al., 2023).

Souza et al. (2020) explored the use of clove and cinnamon extracts in carboxymethylcellulose films, finding that the films offered strong antimicrobial and antioxidant protection for high-respiration fruits. These studies suggest that plant extracts provide not only preservation benefits but also improve the sensory quality of packaged foods by maintaining freshness and natural flavors, catering to the consumer demand for clean-label ingredients.

4.5 Advanced antimicrobials: nisin, lysozyme, and chitosan oligomers

In addition to essential oils and plant extracts, other bioactive antimicrobials like nisin, lysozyme, and chitosan oligomers have proven effective in controlling foodborne pathogens when incorporated into biopolymers. Nisin, a bacteriocin commonly used in dairy preservation, has been incorporated into PLA films, where it demonstrated efficacy in controlling L. monocytogenes in cheese products (Da Silva Malheiros et al., 2010). Lysozyme, an enzyme targeting Gram-positive bacterial cell walls, has also shown promise in biopolymer matrices like alginate and carrageenan, providing enhanced preservation for fresh produce through effective microbial inhibition (Syngai and Ahmed, 2019).

Synergistic combinations of antimicrobials are being studied to extend the functional range of biopolymers. For instance, a starch matrix infused with chitosan and nisin exhibited a dual-action antimicrobial effect against S. aureus, enhancing both film stability and antimicrobial longevity (Tang et al., 2024). Such combinations allow for a broader spectrum of protection, addressing diverse spoilage organisms and foodborne pathogens while reducing reliance on chemical preservatives.

4.6 Lipid-based additives and plasticizers: improvement of physical properties

Plasticizers such as glycerol and sorbitol are commonly added to biopolymer films to improve flexibility and reduce brittleness. However, these plasticizers can adversely affect water vapor permeability, necessitating additional modifications to maintain barrier integrity. Tavassoli-Kafrani et al. (2015) demonstrated that blending glycerol-plasticized starch films with lipids like beeswax significantly improved water resistance, resulting in a more effective barrier for moisture-sensitive foods. These findings suggest that combining plasticizers with hydrophobic additives can enhance the versatility of starch-based films, making them more adaptable for a wide range of food applications.

Lipid-based additives such as carnauba wax and beeswax have proven beneficial in enhancing the hydrophobicity of cellulose-based films, reducing both water vapor and oxygen permeability. Sanyang et al. (2016) found that beeswax-incorporated starch films exhibited lower permeability and greater tensile strength, which are desirable characteristics for food packaging where moisture control is critical. In addition, combining these lipid additives with essential oils or antioxidants creates multifunctional films that offer both physical and bioactive protection for food products.

5 Commercially available functional additives used in food-grade biopolymer coatings and their applications

Functional additives have become integral components of food-grade biopolymer coatings, enhancing their barrier, mechanical, antimicrobial, and antioxidative properties. Commercially available additives, including essential oils, plant extracts, nanoparticles, and bioactive compounds, are specifically formulated for applications in the food industry to meet regulatory standards for safety and efficacy. Below is a detailed discussion of key functional additives available on the market and their specific use cases in biopolymer coatings.

5.1 Essential oils

Essential oils (EOs) such as thyme, oregano, cinnamon, and clove are widely available as natural preservatives. Companies like Berjé and Albert Vieille specialize in producing high-purity essential oils tailored for food-grade applications (Research and Markets Ltd, 2025). Essential oils are incorporated into coatings made from chitosan, starch, or alginate to provide antimicrobial and antioxidant effects. For example, oregano and thyme oils are used in biopolymer films for fresh-cut fruits and vegetables, preventing spoilage caused by bacteria and fungi (Yammine et al., 2022). In another study, Hashemi and Khaneghah developed basil seed gum films with oregano essential oil (2–6%), exhibiting antibacterial and antioxidant properties for food product packaging (Hashemi and Khaneghah, 2017). Chitosan films infused with commercial thyme EO have demonstrated strong inhibitory effects against E. coli and S. aureus, prolonging the shelf life of fresh strawberries by reducing microbial contamination and maintaining sensory quality (Hoque et al., 2011). Additionally, cinnamon oil incorporated into alginate films protects bakery products from mold growth during storage, improving safety without altering the flavor profile (Lim et al., 2022).

5.2 Antioxidants

Natural antioxidants such as ascorbic acid, tocopherols, and plant-based polyphenols are manufactured by companies like BASF (Vitamin E) and Naturex (plant extracts) (Research and Markets Ltd, 2025). These compounds are used in biopolymer coatings to prevent oxidative damage in packaged foods, extending shelf life by delaying lipid oxidation and color degradation. Ascorbic acid incorporated into chitosan-based coatings has been shown to prevent browning in fresh-cut apples and maintain the visual and nutritional quality of the fruit over extended storage (Özdemir and Gökmen, 2019). Choi et al. (2017) developed biopolymeric coatings composed of apple skin powder and carboxymethylcellulose, incorporating apple skin extract and tartaric acid. These coatings, designed for food packaging applications, exhibited notable antioxidant properties and demonstrated enhanced antimicrobial activity against gram-negative bacteria compared to gram-positive bacteria. Similarly, green tea extract, rich in catechins, has been used in gelatine-based coatings to protect fresh fish filets from oxidative spoilage, preserving texture, flavor, and color (Siripatrawan and Harte, 2010).

5.3 Plant extracts

Plant-based additives such as pomegranate, green tea, and grape seed extracts are commercially produced by companies like Frutarom and DuPont. These extracts are incorporated into polysaccharide-based biopolymer films to provide antimicrobial and antioxidant benefits. Pomegranate peel extract incorporated into alginate coatings has shown strong antibacterial effects against Salmonella and L. monocytogenes, making it suitable for poultry and fresh produce applications (Kumar et al., 2022). Similarly, grape seed extract in starch coatings effectively inhibited microbial growth in strawberries while enhancing their antioxidant capacity and overall freshness during storage.

5.4 Nanoparticles

Nanoparticles such as silver (AgNPs), zinc oxide (ZnO-NPs), and titanium dioxide (TiO2-NPs) are produced by companies like Sigma-Aldrich and Nanocyl for incorporation into biopolymer coatings. These additives improve the mechanical strength, antimicrobial activity, and water vapor barrier properties of biopolymer films. Silver nanoparticles embedded in chitosan coatings have been used to reduce microbial contamination in ready-to-eat salads by targeting foodborne pathogens such as L. monocytogenes (Emamifar, 2011). Additionally, ZnO nanoparticles in starch-based coatings enhance the tensile strength of films and reduce moisture permeability, making them suitable for moisture-sensitive products like baked goods and dairy (Ghasemlou et al., 2011).

5.5 Bioactive peptides

Bioactive peptides such as nisin and lysozyme are widely available from manufacturers like Chr. Hansen and DSM. These peptides are incorporated into biopolymer coatings to target spoilage microorganisms, particularly Gram-positive bacteria. Nisin, a bacteriocin approved for use in food, has been incorporated into PLA films to control L. monocytogenes in cheese products, extending their shelf life without altering sensory qualities (Da Silva Malheiros et al., 2010). Lysozyme, an enzyme that degrades bacterial cell walls, has been used in carrageenan-based coatings to protect fresh produce like melons and leafy greens, reducing microbial load during storage (Syngai and Ahmed, 2019).

5.6 Lipid-based additives

Lipid-based additives, including beeswax, carnauba wax, and shellac, are manufactured by companies like Strahl and Pitsch and Koster Keunen for use in food coatings. These additives are incorporated into polysaccharide films to improve hydrophobicity and reduce water vapor permeability. Beeswax incorporated into starch coatings has been shown to improve water resistance and extend the shelf life of fresh-cut mangoes, preserving their texture and reducing moisture loss during storage (Sanyang et al., 2016). Carnauba wax in cellulose coatings has been applied to fresh citrus fruits to maintain their glossy appearance and reduce dehydration (Tavassoli-Kafrani et al., 2015).

5.7 Controlled-release systems

Encapsulation technologies using cyclodextrins or lipid nanoparticles are offered by companies like Encapsys and Aveka for the controlled release of functional additives. These systems are designed to stabilize volatile compounds and ensure sustained release during storage. Essential oils encapsulated in chitosan nanoparticles have been used in coatings for cheese to provide gradual antimicrobial protection while minimizing flavor impact. For instance, cinnamon oil encapsulated in lipid nanocarriers extended the microbial safety of soft cheese without altering its sensory profile (Ellboudy et al., 2023). Similarly, curcumin encapsulated in alginate matrices provided long-term antioxidant protection for acidic fruits like berries (Wiratantri et al., 2024).

The availability and application of functional additives in food-grade biopolymer coatings represent a critical advancement in food preservation technologies. From essential oils and antioxidants to nanoparticles and bioactive peptides, these additives address diverse challenges in maintaining food quality and extending shelf life. Continued research and development, particularly in encapsulation and controlled-release technologies, will further enhance the efficacy and commercial viability of these additives, driving their adoption in sustainable packaging solutions.

6 Prospects of functionally active biopolymers and limitations of biopolymers

Recent advancements in nanoencapsulation technology have substantially enhanced the functional efficacy of essential oils (EOs) and other bioactive additives within biopolymeric matrices. Encapsulation at the nanoscale facilitates a controlled and sustained release of these bioactive compounds, ensuring prolonged antimicrobial and antioxidant activity throughout storage. This technique addresses critical limitations associated with EOs, including their volatility and pronounced sensory attributes, which can adversely affect food flavor and aroma upon rapid release (Pierozan et al., 2024). The integration of nanoencapsulation into biopolymeric films signifies a paradigm shift from passive to active packaging solutions, enabling coatings to actively mitigate microbial spoilage and oxidative degradation while preserving product freshness and sensory integrity. This innovation aligns with the increasing demand for intelligent and sustainable food packaging systems.

Despite these advancements, persistent challenges exist in optimizing the mechanical and barrier properties of biopolymer-based films. Polysaccharide-based films, although effective, typically exhibit elevated water permeability, thereby limiting their efficacy in high-humidity environments. Recent investigations have concentrated on incorporating nanoparticles or nanocomposites into biopolymeric matrices to ameliorate these deficiencies. For instance, silver nanoparticles have demonstrated promising enhancements in durability and antimicrobial performance; however, their widespread application remains constrained due to regulatory barriers and high production costs (Umaraw et al., 2020; Moeini et al., 2020). Overcoming these challenges through scalable and economically viable innovations will be imperative for advancing the commercial feasibility of biopolymer-based coatings.

The incorporation of functional additives such as EOs, antioxidants, and antimicrobials continues to revolutionize biopolymer-based coatings by significantly augmenting their preservative capabilities. Essential oils, including those derived from thyme, oregano, and cinnamon, possess high phenolic content and exhibit potent antimicrobial properties by disrupting microbial cell membranes (Yammine et al., 2022). When integrated into biopolymers such as chitosan, these oils enhance the antimicrobial efficacy of coatings, effectively extending the shelf life and safety of perishable commodities. Notably, chitosan-based coatings infused with EOs have exhibited substantial inhibitory effects on microbial proliferation, reducing spoilage and preserving the quality of fruits and vegetables over extended storage periods (Hoque et al., 2011). These developments not only improve food preservation but also align with consumer preferences for natural, clean-label preservation methodologies.

Essential oils, as complex mixtures of volatile compounds with robust antimicrobial and antioxidant properties, encounter challenges related to volatility and their potential to impart overpowering sensory attributes. Encapsulation within biopolymeric matrices mitigates these limitations by offering controlled-release mechanisms that stabilize EO activity while preserving their gradual bioactive effects. Additionally, EO-infused films impart an aromatic dimension to coatings, potentially enhancing consumer acceptance. Controlled-release formulations, as demonstrated by Lim et al. (2022), mitigate excessive sensory impacts while ensuring consistent antimicrobial activity over extended storage durations, thereby expanding their applicability in food-grade formulations.

The synergistic combination of multiple functional additives within a single biopolymeric matrix has been shown to enhance preservative properties and broaden the functional spectrum of coatings. The co-integration of antioxidants with antimicrobial agents has yielded multifunctional coatings capable of simultaneously mitigating oxidative spoilage and microbial contamination, significantly prolonging the shelf life of perishable horticultural commodities (Adiletta et al., 2021). In a recent study, a starch-based coating incorporating thyme EO and ascorbic acid effectively preserved strawberries for 14 days, maintaining their nutritional and sensory attributes while exhibiting superior antimicrobial efficacy compared to coatings containing a single additive (Sutharsan et al., 2023). These findings underscore the potential of synergistic formulations in achieving comprehensive food protection, although further investigations are warranted to optimize additive concentrations and interactions for maximal efficacy (Moghadas et al., 2024).

A promising alternative involves the co-utilization of EOs with nanoparticles to develop multifunctional biopolymeric films. Nanocomposites comprising silver nanoparticles and EOs have demonstrated enhanced antimicrobial efficacy, leveraging the membrane-disrupting activity of EOs alongside the broad-spectrum antimicrobial properties of nanoparticles. This combinatory approach has exhibited efficacy against both Gram-positive and Gram-negative bacteria, rendering it suitable for diverse food preservation applications (Kumar et al., 2022). However, these formulations raise safety and regulatory concerns, particularly regarding the potential migration of nanoparticles into food products. Addressing these challenges through advanced immobilization techniques and stringent adherence to regulatory safety standards will be critical for future commercialization.

Controlled-release systems represent a pivotal advancement in food-grade biopolymeric coatings by optimizing the functionality of bioactive additives and ensuring their sustained efficacy over extended storage durations. These systems employ techniques such as microencapsulation and nanotechnology to achieve targeted and prolonged delivery of functional additives. Microencapsulation involves encapsulating bioactive compounds within protective biopolymer shells such as chitosan, alginate, or starch which serve as barriers against external factors such as light, oxygen, and moisture, facilitating gradual release modulated by environmental stimuli such as pH, temperature, or enzymatic activity. For instance, EO encapsulated alginate beads exhibit humidity-triggered release, thereby providing antimicrobial protection for fresh produce packaging.

Nanotechnology further refines controlled-release capabilities by encapsulating bioactive agents at the molecular level. Nanocarriers, such as chitosan nanoparticles loaded with curcumin, enhance the stability and bioavailability of functional compounds. Wiratantri et al. (2024) demonstrated that these nanoparticles exhibited pH-responsive release, rendering them highly effective for applications requiring sustained antioxidant and antimicrobial protection. Such technological advancements are particularly beneficial for acidic food products, bakery goods, and perishable dairy and meat items, where sustained release mitigates spoilage while preserving sensory and nutritional integrity.

7 Conclusion

This review has established that a constantly growing number of substances derived from natural sources offer a sustainable alternative to polymer formulations for the preservation of post-harvest quality in horticultural crops. Nevertheless, food-grade biopolymers, while effective in forming protective barriers, typically lack sufficient antimicrobial, antioxidant, and mechanical properties to fully prevent spoilage and deterioration over extended storage periods. To overcome these limitations, functional additives such as essential oils, natural antioxidants, and antimicrobial agents are increasingly being integrated into biopolymer matrices. These additives enhance the coatings’ performance by improving moisture and gas barrier properties, providing controlled-release antimicrobial action, and preventing oxidative degradation. Functionalized biopolymer films have been shown to significantly extend the shelf life and preserve the nutritional quality of fresh produce, aligning with consumer preferences for safer, chemical-free food preservation solutions. The continuous evolution of biopolymer-based coatings, driven by advancements in nanotechnology and functional ingredient integration, holds substantial potential for sustainable and effective food preservation strategies, reinforcing their role as a viable alternative to conventional synthetic packaging materials.

Author contributions

RK: Writing – original draft. AO: Writing – original draft. KP: Writing – original draft. IB: Conceptualization, Funding acquisition, Project administration, Resources, Writing – review & editing. MO: Conceptualization, Funding acquisition, Writing – review & editing. CO: Writing – review & editing. CN: Conceptualization, Funding acquisition, Writing – review & editing. II: Conceptualization, Funding acquisition, Project administration, Resources, Supervision, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. II reports financial support was provided by Innovate UK KTP 22–23 R3ME [Project Number 10048462] and ISFP ODA funding from University of Leeds.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Gen AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdul Khalil, H. P. S., Banerjee, A., Saurabh, C. K., Tye, Y. Y., Suriani, A. B., Mohamed, A., et al. (2018). Biodegradable films for fruits and vegetables packaging application: preparation and properties. Food Eng. Rev. 10, 139–153. doi: 10.1007/s12393-018-9180-3

Abers, M., Schroeder, S., Goelz, L., Sulser, A., St. Rose, T., Puchalski, K., et al. (2021). Antimicrobial activity of the volatile substances from essential oils. BMC Complement. Med. Therap. 21:124. doi: 10.1186/s12906-021-03285-3

Adiletta, G., Di Matteo, M., and Petriccione, M. (2021). Multifunctional role of chitosan edible coatings on antioxidant Systems in Fruit Crops: a review. Int. J. Mol. Sci. 22:2633. doi: 10.3390/ijms22052633

Alfaro, A. D. T., Balbinot, E., Weber, C. I., Tonial, I. B., and Machado-Lunkes, A. (2014). Fish gelatin: characteristics, functional properties, applications and future potentials. Food Eng. Rev. 7, 33–44. doi: 10.1007/s12393-014-9096-5

Ali, A., Hei, G. K., and Keat, Y. W. (2016). Efficacy of ginger oil and extract combined with gum Arabic on anthracnose and quality of papaya fruit during cold storage. J. Food Sci. Technol. 53, 1435–1444. doi: 10.1007/s13197-015-2124-5

Ali, U., Kanwar, S., Yadav, K., Basu, S., and Mazumder, K. (2019). Effect of arabinoxylan and β-glucan stearic acid ester coatings on post-harvest quality of apple (Royal Delicious). Carbohydr. Polym. 209, 338–349. doi: 10.1016/j.carbpol.2019.01.002

Alparslan, Y., Yapıcı, H. H., Metin, C., Baygar, T., Günlü, A., and Baygar, T. (2016). Quality assessment of shrimps preserved with orange leaf essential oil incorporated gelatin. LWT Food Sci. Technol. 72, 457–466. doi: 10.1016/j.lwt.2016.04.066

Amenorfe, L. P., Agorku, E. S., Sarpong, F., and Voegborlo, R. B. (2022). Innovative exploration of additive incorporated biopolymer-based composites. Sci. African 17:e01359. doi: 10.1016/j.sciaf.2022.e01359

Anderson, L. A., Islam, M. A., and Prather, K. L. J. (2018). Synthetic biology strategies for improving microbial synthesis of "green" biopolymers. J. Biol. Chem. 293, 5053–5061. doi: 10.1074/jbc.TM117.000368

Apriyanto, A., Compart, J., and Fettke, J. (2022). A review of starch, a unique biopolymer – structure, metabolism and in planta modifications. Plant Sci. 318:111223. doi: 10.1016/j.plantsci.2022.111223

Arnon-Rips, H., Cohen, Y., Saidi, L., Porat, R., and Poverenov, E. (2021). Covalent linkage of bioactive volatiles to a polysaccharide support as a potential approach for preparing active edible coatings and delivery systems for food products. Food Chem. 338:127822. doi: 10.1016/j.foodchem.2020.127822

Azeredo, H. M. C., Barud, H., Farinas, C. S., Vasconcellos, V. M., and Claro, A. M. (2019). Bacterial cellulose as a raw material for food and food packaging applications. Front. Sustain. Food Syst. 3:7. doi: 10.3389/fsufs.2019.00007

Basaglia, R. R., Pizato, S., Santiago, N. G., Maciel De Almeida, M. M., Pinedo, R. A., and Cortez-Vega, W. R. (2021). Effect of edible chitosan and cinnamon essential oil coatings on the shelf life of minimally processed pineapple (smooth cayenne). Food Biosci. 41:100966. doi: 10.1016/j.fbio.2021.100966

Basiak, E., Geyer, M., Debeaufort, F., Lenart, A., and Linke, M. (2019). Relevance of interactions between starch-based coatings and plum fruit surfaces: a physical-chemical analysis. Int. J. Mol. Sci. 20:2220. doi: 10.3390/ijms20092220

Bhaskar, R., Zo, S. M., Narayanan, K. B., Purohit, S. D., Gupta, M. K., and Han, S. S. (2023). Recent development of protein-based biopolymers in food packaging applications: a review. Polym. Test. 124:108097. doi: 10.1016/j.polymertesting.2023.108097

Bibow, A., and Oleszek, W. (2024). Essential oils as potential natural antioxidants, antimicrobial, and antifungal agents in active food packaging. Antibiotics (Basel, Switzerland) 13:1168. doi: 10.3390/antibiotics13121168

Burt, S. (2004). Essential oils: their antibacterial properties and potential applications in foods a review. Int. J. Food Microbiol. 94, 223–253. doi: 10.1016/j.ijfoodmicro.2004.03.022

Chatkitanan, T., and Harnkarnsujarit, N. (2021). Effects of nitrite incorporated active films on quality of pork. Meat Sci. 172:108367. doi: 10.1016/j.meatsci.2020.108367

Chen, C., Liu, F., Yu, Z., Ma, Y., Goff, H. D., and Zhong, F. (2020). Improvement in physicochemical properties of collagen casings by glutaraldehyde cross-linking and drying temperature regulating. Food Chem. 318:126404. doi: 10.1016/j.foodchem.2020.126404

Choeybundit, W., Karbowiak, T., Lagorce, A., Ngiwngam, K., Auras, R., Rachtanapun, P., et al. (2024). Eco-friendly straws: a fusion of soy protein isolate and cassava starch coated with beeswax and shellac wax. Polymers 16:1887. doi: 10.3390/polym16131887

Choi, I., Chang, Y., Shin, S.-H., Joo, E., Song, H. J., Eom, H., et al. (2017). Development of biopolymer composite films using a microfluidization technique for carboxymethylcellulose and apple skin particles. Int. J. Mol. Sci. 18:1278. doi: 10.3390/ijms18061278

Correa-Pacheco, Z. N., Bautista-Baños, S., Valle-Marquina, M. Á., and Hernández-López, M. (2017). The effect of nanostructured chitosan and chitosan-thyme essential oil coatings on Colletotrichum gloeosporioides growth in vitro and on cv Hass avocado and fruit quality. J. Phytopathol. 165, 297–305. doi: 10.1111/jph.12562

Dai, L., Wang, X., Mao, X., He, L., Li, C., Zhang, J., et al. (2024). Recent advances in starch-based coatings for the postharvest preservation of fruits and vegetables. Carbohydr. Polym. 328:121736. doi: 10.1016/j.carbpol.2023.121736

Das, A., Ringu, T., Ghosh, S., and Pramanik, N. (2023). A comprehensive review on recent advances in preparation, physicochemical characterization, and bioengineering applications of biopolymers. Polym. Bull. 80, 7247–7312. doi: 10.1007/s00289-022-04443-4

Da Silva Malheiros, P., Daroit, D. J., and Brandelli, A. (2010). Food applications of liposome-encapsulated antimicrobial peptides. Trends Food Sci. Technol. 21, 284–292. doi: 10.1016/j.tifs.2010.03.003

Devi, A., Bajar, S., Kour, H., Kothari, R., Pant, D., and Singh, A. (2022). Lignocellulosic biomass valorization for bioethanol production: a circular bioeconomy approach. Bioenergy Res. 15, 1820–1841. doi: 10.1007/s12155-022-10401-9

Devi, L. S., Jaiswal, A. K., and Jaiswal, S. (2024). Lipid incorporated biopolymer based edible films and coatings in food packaging: a review. Curr. Res. Food Sci. 8:100720. doi: 10.1016/j.crfs.2024.100720

Dhall, R. K. (2013). Advances in edible coatings for fresh fruits and vegetables: a review. Crit. Rev. Food Sci. Nutr. 53, 435–450. doi: 10.1080/10408398.2010.541568

Díaz-Montes, E., and Castro-Muñoz, R. (2021). Edible films and coatings as food-quality preservers: an overview. Food Secur. 10:249. doi: 10.3390/foods10020249

Doan, N. T., Quan, N. V., Anh, L. H., Duc, N. D., and Xuan, T. D. (2025). Exploring the potential of chitosan-phytochemical composites in preventing the contamination of antibiotic-resistant bacteria on food surfaces: a review. Molecules 30:455. doi: 10.3390/molecules30030455

Domżał-Kędzia, M., Ostrowska, M., Lewińska, A., and Łukaszewicz, M. (2023). Recent developments and applications of microbial Levan, a versatile polysaccharide-based biopolymer. Molecules 28:5407. doi: 10.3390/molecules28145407