Abstract

In automated production and processing technologies in the food industry, artificial intelligence (AI) plays a key role. The use of intelligent automation technology in multiple production processes not only greatly improves production efficiency, but also ensures the safety and quality of food products, which has great potential for the innovative revolution in the food industry. This paper provides an overview of AI technology and its potential applications in food industry automation, focusing on its use in food safety testing, production processing, production data analysis and prediction, and demonstrating the benefits of increased efficiency, reduced costs and improved product quality. However, the power of AI technology for the food industry has also prompted consideration of the possibilities and limitations of introducing intelligent food automation processing equipment or systems into food business applications. The aim of this paper is to provide ideas and guidance to governments, researches and food industry personnels in the hope of encouraging and accelerating the development of AI technology in food production and processing.

1 Introduction

As a consequence of the continuous growth of the global population and the improvement of living standards, food demand has exhibited an unprecedented growth trajectory. Mavani et al. (2022) posited that global food demand would increase by 59–98% by 2050. The growth of food demand has put higher demands on agricultural production, but also brings unprecedented challenges to food processing and supply chain management. The food industry therefore needs to seek innovative solutions to meet the growing demand for food under the premise of ensuring food quality and safety.

Since the manual processing operation in the production process of substitute food, automation technology has become a key factor recognized by the public to improve production efficiency and ensure product quality (Buljo and Gjerstad, 2013). Automation technology can make the production line more intelligent, and the entire production process can be completed without manual intervention, not only reducing the error of manual operation, but also making the production process more stable and accurate (Iqbal et al., 2017; Konur et al., 2023). At the same time, a variety of sensor equipment and machines equipped on the production line can be real-time monitoring and data analysis, and can also achieve accurate control of temperature, pressure, humidity and other parameters in the production process. When faced with rapid changes in market demand, automation technology can also help enterprises quickly and better adjust production plans to meet the diversified needs of consumers (Onwude et al., 2020).

In recent years, the emergence of artificial intelligence (AI) technology is not only changing various industries, but also rapidly affecting the food industry, bringing revolutionary changes to the food industry once again (Jadhav et al., 2025). With the continuous breakthrough of AI technology in image recognition, natural language processing (NLP), machine learning (ML) and other fields, it provides strong technical support for the intelligent automated production process of the food industry (Ferryman, 2020; Li et al., 2024; van Erp et al., 2021). The introduction of AI technology into operating equipment in the food processing process can enable enterprises to carry out intelligent management in food quality control, equipment predictive maintenance, supply chain optimization, etc., which not only greatly improves production efficiency but also reduces production costs (Chhetri, 2024; Thibault et al., 2024).

Given the immense potential that AI has demonstrated in the automation of the food industry, this paper reviews the application potential of AI technology in the automation of the food industry, focusing on the description of the application of AI in the automation of various processes in the food industry. Secondly, it discusses the technical and ethical challenges faced by AI in the automation of the food industry and proposes corresponding research prospects. It is hoped that this review can provide valuable references and insights for the automation and innovation of the food industry.

2 The potential of AI in the automation of the food industry

2.1 Overview of key AI technologies and their application potential

The definition of AI as an interdisciplinary field of study has evolved over time. The first understanding of AI began with the study of computers performing tasks that would normally require human intelligence. With the rapid development of AI technology, it has become a comprehensive technology system including ML, DL, NLP and other sub-fields. ML, as one of the cores of AI, enables computer systems to learn rules from data and use these rules to make predictions about new data without the need to write explicit instructions for every possible situation. ML includes three aspects, supervised learning, unsupervised learning and reinforcement learning, which play an important role in different application scenarios. Supervised learning is usually used for prediction and classification tasks, unsupervised learning is suitable for data mining and cluster analysis, and reinforcement learning performs well in decision-making processes and control tasks. DL, as a branch of ML, uses multi-layer neural networks to simulate the human brain to identify and extract features from data, and conducts complex mathematical modeling to achieve the purpose of processing information. In DL models, convolutional neural networks (CNNs) and recurrent neural networks (RNNs) typically perform well in areas such as image and speech recognition and NLP (Janiesch et al., 2021; Qian et al., 2023; Zhao et al., 2025). NLP is another key area of AI, which enables computers to understand, interpret and generate human language in terms of language recognition, semantic understanding, machine translation and other functions, and has a wide range of applications in daily life involving information extraction, sentiment analysis and dialogue systems (Cambria and White, 2014). By simulating and expanding human learning, reasoning, perception and other abilities, these technologies have shown extensive application potential in many fields such as medical care, agriculture and education. Current research published in Nature proposes a foundational model for general medical AI, an AI model capable of performing multiple tasks, flexibly interpreting different medical data patterns, including images, electronic health records, laboratory results, genomics, charts, or medical text, and producing outputs that demonstrate advanced medical reasoning capabilities, such as free-text explanations, verbal advice, or image annotations. It can support clinical doctors in completing a series of important tasks and reduce the administrative burden on clinical doctors (Moor et al., 2023). In agriculture, Benameur et al. (2024) propose that AI has been utilized in research projects to implement smart agricultural irrigation and robotic grape cultivation technologies (Ang Minn et al., 2017). These applications allow for the collection of higher-quality agricultural data with reduced labor input, ultimately enhancing the precision and efficiency of agricultural processes. Additionally, studies have shown that the attention and memory parameters of children with autism have significantly improved based on AI software, and AI-driven personalized learning programs are effective in teaching skills and promoting social integration for children with autism (Atturu and Naraganti, 2024). The application of AI technology in different fields has not only improved the operational efficiency of industries but also provided new solutions for solving complex problems.

2.2 The application and potential of AI technology in the automation of the food industry

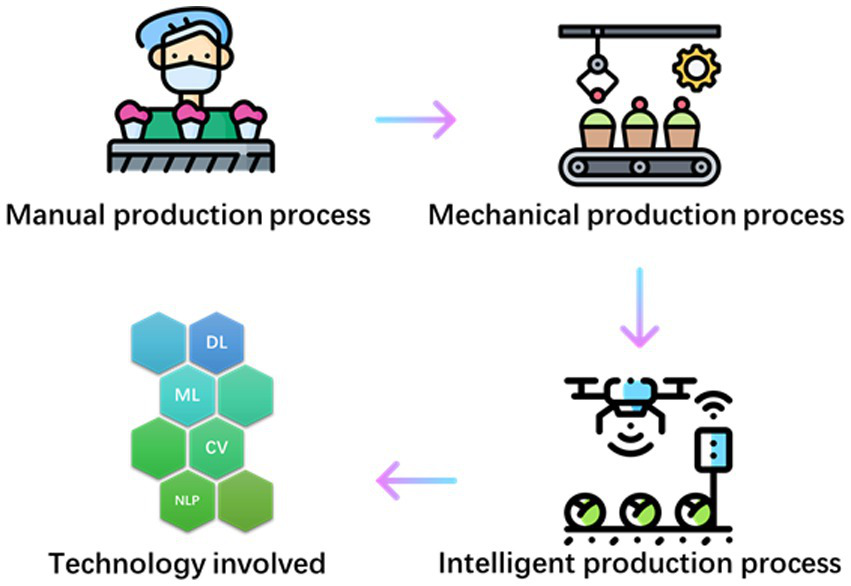

With the successful application and in-depth development of AI technology in a number of industries, its powerful data processing capabilities, pattern recognition and predictive analysis benefits are increasingly recognized by the public and have gradually been introduced into the food industry, bringing about a revolutionary change in the food industry (Hassoun et al., 2023). Since the beginning of the industrial revolution, mechanized production and processing in the food industry began to replace manual labor, greatly improving the production efficiency of the food industry. So far, with the rapid development of electronic technology and computer science, automation in the food industry has entered a new stage of development, involving more complex processing and quality control (Wang et al., 2022). However, automation in the food industry still faces many challenges, such as the diversity of food raw materials and the complexity of their production processes, the consistency of food safety and quality, and the need to meet the diversity of changing market demands (Çakmakçı et al., 2024). In order to address cope with these challenges, the introduction of AI technology provides new ideas and tools for the development and change of the food industry, among which the core technology of AI to simulate human intelligent activities are particularly important, including ML, DL, computer vision, NLP and expert systems (Bidyalakshmi et al., 2024). These technologies can imitate human learning, reasoning, perception and decision-making, and realize the autonomous learning and decision-making ability of machines, providing new impetus and possibilities for the automation of the food industry (Li and Liu, 2019; Qiu et al., 2023) (Figure 1).

Figure 1

Technological evolution of food industry.

ML enables machines to continuously optimize their performance through data learning and experience accumulation. In food industry automation, this technology can be applied not only to predict market demand, optimize inventory management, but also to analyze historical data to predict equipment maintenance needs, thereby reducing downtime and maintenance costs (Albayrak Ünal et al., 2023; Kumar et al., 2021). DL can also enable machines to handle complex pattern recognition tasks by modelling the neural network structure of the human brain. In automated food safety inspection, food defects and contaminants can be identified after training through DL to improve inspection speed and accuracy (Banús et al., 2021; Goyal et al., 2024). NLP technology enables machines to understand and generate human language, which can be used in food industry automation to analyze consumer feedback and extract suggestions for product improvements, automate customer service, and make faster and more personalized responses (Nunes et al., 2023; Taneja et al., 2023). Computer Vision technology can make the machine “see” and understand the ability of visual information, in the automated production of food can quickly identify the color, shape and size of food, automatically eliminate unqualified products, greatly improving production efficiency and product consistency (Kim et al., 2024). The comprehensive application of AI technology can not only improve the automation ability of food industry production, but also reflect its future core value and potential in food industry automation (Cavallo et al., 2019; Wang et al., 2022).

3 The application of AI in food industry automation

In contemporary food production and processing, the integration of automated production lines greatly improves efficiency and ensures the stability and consistency of food quality. The application of AI technology has promoted the development of these production lines in the direction of automation and intelligence, so that the factory can achieve intelligent management, and provide enterprises with the ability to control costs, optimize resources and quickly respond to market demands.

3.1 Application of AI in food safety automation detection

AI has gradually become a key technology in the automated quality control process in the field of food inspection to ensure food safety and quality. The core of AI technology is to simulate human learning and cognitive processes. Through ML and DL technologies, a large number of data sets from different sources are analyzed, and a model is constructed and trained to identify the rule of specific features of food raw materials and detect deviations from quality standards, efficient and accurate detection of food raw materials can be achieved (Table 1) (Nayak et al., 2020; Singh et al., 2024). The EU has reportedly adopted Bayesian network models for predicting food fraud. In addition to this, the US Food and Drug Administration (FDA) has also been working on developing ML-based screening tool to identify high and low risk seafood shipments since 2019 (Qian et al., 2023). DL is often good at processing high and complex data and has important applications in the field of computer vision. In the context of food safety inspection and quality classification, product quality can be assessed automatically, accurately and effectively (Zhang et al., 2023; Chhetri, 2024). For example, through DL models, image data of food raw materials can be identified, visual features such as color, shape and texture of food can be detected, or its chemical composition can be identified through spectral analysis. NLP technology can also analyze inspection reports and historical data to predict potential quality issues (Makridis et al., 2023). The application of these technologies makes the testing process of food raw materials more intelligent and automated.

Table 1

| Application | ML method | Important outcome | References |

|---|---|---|---|

| Figs | Computer vision | Based on computer vision detection 99.5% of spoiled figs were correctly classified and 89% of light colored quality figs were correctly classified. | Benalia et al. (2016) |

| Meat | Convolutional neural network | Thermal imaging combined with CNN detection method with 99.99% accuracy. | Zheng et al. (2021) |

| Tomatoes | Convolutional neural network | Detection accuracy of 94.6% for external defects in tomatoes. | da Costa et al. (2020) |

| Mangoes | Convolutional neural network | Mango’s automatic defect detection is 98% accurate | Nithya et al. (2022) |

| Tomatoes | Back-propagation neural network | Accuracy of 99.31% for classification of tomato ripeness based on color features and BPNN approach. | Wan et al. (2018) |

| Fruits | Convolutional neural network | Detects fruit rot with 99.93% accuracy. | Afsharpour et al. (2024) |

| Potatoes | deep convolutional neural network | The optimal detection accuracy of RFCN ResNet101 in the DCNN model was 95.6%. | C. Wang and Xiao (2021) |

| Juglans | Convolutional neural network | The two-stage convolutional network completed image segmentation with a 99.4% correct test rate, and pecan classification verified 96.5% of foreign objects in the image. | Rong et al. (2020) |

| Pistachio | Convolutional neural network | The classification accuracy using convolutional neural network is over 90% and the VGGNet-19 architecture achieves 100% success rate in classifying the LAB color space. In addition, the YUV/ResNet-50 and HSV/VGGNet-19 combinations achieved over 98% success in detecting peanut adulteration. | Çinarer et al. (2024) |

| Chilli | Support vector machine | The classification model developed for chilli peppers had an accuracy of 98%. | Jiang et al. (2018) |

Application of artificial intelligence technology in food inspection.

With the continuous upgrading of people’s demand for real-time detection information of food quality, non-destructive testing has gradually replaced the traditional artificial sensory detection and chemical analysis methods. The traditional artificial sensory detection and chemical analysis methods are often delayed and destructive, causing certain losses to human, material and financial resources (Kang et al., 2022). The appearance of nondestructive testing has a satisfactory application potential in the food supply chain. The combination of hyperspectral imaging technology and DL can significantly improve the quantitative analysis of food ingredients. Hyperspectral images can provide rich spectral information beyond traditional RGB images, so that DL models can extract complex component characteristics for non-destructive testing of chemical composition and pesticide residue identification in food. This technology not only improves the detection accuracy, but also reduces the detection cost, and meets the needs of modern food safety monitoring. AI-driven computer vision systems, which enable automated safety inspections and quality control, are one of the ways to replace traditional manual sensory inspection and chemical analysis with non-destructive testing. They can analyze food image or video data to identify food defects, contamination or irregularities, and achieve real-time monitoring of food raw material physical properties. Automatic identification and elimination of non-conforming material targets (Shen et al., 2024). Fruit quality classification is a key standard for enterprises to expand the market, and automatic sorting of fruit after harvest has become a key challenge for quality control (Nithya et al., 2022). It is reported that CNN has been widely used in food image classification and defect detection. By training a large amount of labeled data, CNN can learn and identify the surface features of food, and automatically identify the defects on the surface of fruits through algorithms, such as appearance defects such as deformed fruit, spots, cracked fruit, discoloration or surface damage. In the detection of apples, bananas and other fruits, AI algorithms can accurately identify and automatically eliminate unqualified products on the production line, achieve sorting and grading to improve fruit quality, and greatly improve the efficiency and accuracy of the detection process. Nithya et al. (2022) used CNN to automatically detect and grade appearance defects such as spots, discoloration or surface damage in mangoes, with an accuracy of 98%. The use of AI-based CVS and ML algorithms can complete the classification and grading of fruits and vegetables, ensuring that high-quality fruits and vegetables are consumed by the market or used for raw material processing. Benalia et al. (2016) reported that the accuracy of CVS in classifying spoiled figs could reach 99.5%. As one of the important indicators to evaluate the freshness and maturity of fruits and vegetables, computer vision can also determine the maturity of food by analyzing the color distribution in the image. For example, in tomato ripen assessment, the AI device system can dynamically adjust the harvest time based on color changes to ensure the optimal picking time, thereby increasing the market value of the product. Wan et al. (2018) proposed a method that combines feature color values with the Backpropagation Neural Network (BPNN) classification technique to detect the ripeness (green, orange, and red) of fresh market tomatoes (Roma and pear varieties). Additionally, specialized robots combined with multiple cameras have been realized in the product inspection and testing phase, which, in conjunction with deep learning algorithms, can inspect various food labels and quality, achieving low-cost and high-performance real-time monitoring of various food qualities (Khan et al., 2018; Pan et al., 2017; Pierson and Gashler, 2017). In addition, AI systems can continuously learn and adapt to new data, constantly optimizing detection algorithms to improve accuracy and efficiency. This automation not only reduces the need for manual testing, reduces costs, but also increases testing speed, ensuring that food raw materials meet safety and quality standards before entering the production process (Barthwal et al., 2024).

3.2 Application of AI in automated food production and processing

The integration of AI technology into automated production lines during processing and manufacturing enables food processing lines to achieve a higher level of autonomous operation, marking a significant shift toward intelligence and precision in the food industry. At present, intelligent robots are undoubtedly a key element for food processing production lines. These robots have exceptional capabilities and high precision in performing tasks such as sorting and cutting. Taking fruit processing as an example, berries are subjected to modern intelligent detection technologies and methods that include various detection devices during sorting, drying, disinfection and decontamination, and freezing processes, and use AI to process data from detection devices, followed by classification or regression modelling prediction (Wang et al., 2022). In the seafood industry, it has been demonstrated that after scanning fish fillets, computer algorithms determine the best trimming pattern, and then waterjet knives (powered by focused high-pressure water jets) automatically trim the unnecessary fish skin from the fillets (Barbut, 2020). According to Wang and Li (2024), automation and intelligence in meat processing have been widely used in primary processing, with meat cutting equipment systems combining machine vision and computer science capable of 700 cuts per minute with an accuracy of up to ±5%. De Medeiros Esper et al. (2021) described the transport of pigs or poultry from farms to slaughterhouses to final chilling, where the slaughtering process is largely automated, and discussed several meat processing systems that integrate vision technology, such as AiRA robotics and beef carcass separation. AI robots are not only capable of performing many tedious and repetitive tasks such as food assembly, packaging and palletizing (Kumar et al., 2021; Vasudevan et al., 2024), but are also able to work in harsh environments, ensuring the continuity and stability of the production process. In addition to intelligent automation of production operations, AI-assisted data analysis and prediction during production and processing will directly affect production efficiency, resource utilization and product quality (Liakos et al., 2018).

3.3 Role of AI in automated production data analysis and forecasting

In the process of food production and processing, a large amount of data will be generated, involving raw materials procurement, production operations and product quality testing and other key production links from sensors, databases and other data. Through the establishment of data acquisition system, data integration and data cleaning, effective data can be analyzed to obtain data characteristics, trends, distribution and other relations, which will directly affect the production efficiency, resource utilization and product quality. The application of AI technology makes the analysis and prediction of production data more efficient and accurate (Zhou et al., 2019). Enterprises can achieve more accurate production scheduling, demand forecasting and quality management, thereby gaining a competitive advantage in a fierce market environment.

3.3.1 Real-time monitoring and analysis of production data

Food production is a complex and uncertain process, the fluctuation of output and the randomness of market demand, the variability of raw materials and ingredients will lead to the difference between the planned output and the actual production (Keong et al., 2024). At the same time, the environmental and hygienic conditions of food factories can have a crucial impact on food quality and safety, putting pressure on companies in terms of economic costs and environmental impacts (Garre et al., 2020). Common machine learning algorithms, such as decision trees, random forests, and support vector machines, often show unique advantages when dealing with large and complex data sets (Table 2). For example, ML models can predict production requirements in the coming weeks based on historical sales and production data to optimize production plans. DL, especially RNN and long short-term memory networks (LSTMs), excel at handling time-series data. They can capture time dependencies in production data, making them suitable for demand forecasting and equipment failure alerts. For example, LSTMs can analyze historical operation data of production lines, to predict equipment failures, enable pre-emptive maintenance, and reduce downtime. Nunes et al. (2023) presented a tool to help visualize and identify trends in antenna test systems. The tool focuses on the ability to predict end-of-life (EOL) failures by exploring the data provided by the tests, allowing users to view graphs showing data progression and predict future data using AI models. By monitoring and analysing various data in the production process in real time, AI models can identify metrics that deviate from the normal range and warn of potential safety hazards. This quality prediction can help companies adjust production parameters in a timely manner to ensure the stability of product quality. In dairy production, modern intelligent detection systems often combine ML algorithms to analyse key parameters such as temperature, pH and total bacteria count. Once these parameters exceed the preset range, the system will automatically notify operators and take corresponding corrective measures promptly. Early knowledge of batch quality can save costs associated with recalls, packaging, and transportation, not only preventing non-compliant products from entering the market but also effectively reducing production losses and improving production efficiency (Sankhye and Hu, 2020). For example, by analyzing environmental data such as temperature and humidity, combined with quality indicators, ML models can monitor product quality in real-time and alert potential issues.

Table 2

| Application | ML method | Important outcome | References |

|---|---|---|---|

| Food freshness | Convolutional neural network | The accuracy of meat freshness prediction was 96.2%. | Gong et al. (2023) |

| Potato wastage | Convolutional neural network | Accuracy of 94.6% for real-time monitoring of potato waste based on the Internet of Things using load cells and image-processing technology. | Jagtap et al. (2019) |

| Food freshness | Deep convolutional neural networks | DCNN predicts meat freshness with 98.5% accuracy. | Guo et al. (2020) |

| Food freshness | YOLO deep learning algorithm models | Development of triple-emitting probe-loaded hydrogel labels for real-time visual differentiation of food freshness. | Wu et al. (2024) |

| Meat freshness | Convolutional neural network | CMS using CNN algorithm for meat freshness monitoring has an accuracy of 95.3%. | Wang et al. (2024) |

Application of AI technology in food production data monitoring and analysis.

3.3.2 Application of forecasting models in demand planning and inventory management

Traditional approaches to food demand forecasting rely primarily on historical sales data, seasonal trends and a number of qualitative factors such as market activity, economic conditions and consumer preferences. However, these approaches have limitations such as limited reliance on data or may not fully capture the complex and variable factors that affect demand. For example, lack of real-time data analysis capabilities that limit rapid response to market changes or inventory overhangs or shortages that may result from poor forecasting accuracy; And the difficulty of handling large amounts of data and complex models at scale. Therefore, to improve the accuracy and responsiveness of forecasting, many food companies have begun to turn to advanced data analytics technologies, such as ML and DL, to overcome these limitations. In recent years, the rise of AI technologies, such as DL, has attracted many researchers to the field of demand forecasting. AI-driven demand forecasting technologies can identify and analyse complex relationships and patterns in large data sets, such as historical sales records, market trends, weather patterns, social media sentiment and competitor activity. This technology is capable of overcoming the challenges confronted by traditional approaches when explaining and capturing numerous factors that affect consumer behavior (Reddy et al., 2021). For example, in the dairy industry, Delaney et al. (2022) applied the K-Nearest Neighbors (K-NN) algorithm, using data from nearby farms to augment the data of the target farm, to improve the interpretability of the results and increase the possibility of the increasing milk production and profitability. Goli et al. (2018) developed a multi-stage model, which combined Multi-Layer Perceptron (MLP), Adaptive Neuro-Fuzzy Inference System (ANFIS) and Support Vector Regression (SVR), to achieve accurate dairy demand forecasting. They concluded that population behavior and inflation have the most significant impact on dairy consumption in Iran. In the food industry, Nassibi et al. (2023) highlighted the need to use ML capabilities to efficiently process and evaluate large data sets to help food companies adapt to market changes and manage the supply chain more effectively. Specifically, they used Support Vector Machine (SVM) and LSTM algorithms to improve the demand forecasting capabilities of a large distribution company in Saudi Arabia.

In the domain of inventory management, the principal issues typically are overstock and the risk of stockout (Abu et al., 2021). Excessive inventory will entail the occupation of a considerable amount of funds and augment the risks of product deterioration and waste. Perishable dairy products are prone to be affected by such issues. Whereas the occurrence of stockout problems will exert a negative influence on customer satisfaction and diminish the market competitiveness of the company (Ali and Asif, 2012). These problems are further influenced by factors like the limited shelf life, the restricted transportation time and the high transportation frequency, thereby resulting in the augmentation of operational and transportation costs (Shafiee et al., 2021). To address the challenges in inventory management of perishable products, researchers have developed various methods. For example, Rana et al. (2022) put forward two inventory planning strategies, namely First-In-First-Out and Last-In-First-Out, for optimizing product pricing and batch size, enabling the maximization of profits in the backdrop of perishable products. Their approach focuses on maximizing profits. They believe that demand should be determined by price and freshness, and under such circumstances, stockouts are permitted. Rout et al. (2019) developed a production inventory model within the classical Economic Production Quantity framework, focusing on handling changes in customer demand during stockout periods, taking into account product deterioration over time. The model uses a piecewise constant function to approximate the backorder changes during the stockout period, and has demonstrated the accuracy of this approximation in practice. Today, the advent of AI has brought new solutions to inventory management (Sharma et al., 2022). For example, Şimşek (2024) found through case studies of Coles, Walmart, and Migros that AI has already been successful in reducing waste, optimizing inventory, and enhancing customer satisfaction. By integrating AI into inventory management systems, companies can improve the efficiency and accuracy of the decision-making process (Singh and Adhikari, 2023). Praveen et al. (2019) found that the greatest waste in the supply chain occurs in inventory management due to inaccurate demand forecasting. To address this problem, they developed a back-propagation model based on a multi-layer feed-forward neural network that can accurately predict demand and solve the costly inventory problems caused by mismatched supply and demand. Islam et al. (2024) outlined ML methods that can be used for dynamic inventory management and proposed a neural network-based Sequence to Quantity algorithm for demand forecasting.

4 Application of AI in food industry automation: challenges and prospects

4.1 Technical implementation cost

Although AI-related research has seen considerable application in areas such as computer vision and NLP, the technology’s widespread use in the food industry is still in the exploratory stage. As AI technology involves multiple levels of technological inputs, such as basic sensors, robotics, complex algorithms, and large amounts of data and efficient computing power, it is evident that this must necessitate a high initial capital investment in automation equipment, software systems, and infrastructure. Secondly, there is still a need for funds to be constantly invested in day-to-day production operations, maintenance and upgrading in order to remain sufficiently competitive. For many capital-strapped small and medium-sized enterprises, this often discourages them from building and upgrading their factories intelligently. In addition, the introduction of AI automation technology needs to be accompanied by the introduction or education and training of technicians with the relevant knowledge and skills to ensure that there are appropriate technicians who are able to operate and maintain the new equipment and technology, which adds an additional human resource cost to the organization. In order to solve the problems faced above, enterprises can combine their own needs through the phased implementation of intelligent automation strategy, for example, enterprise can be the first to start using intelligent automation equipment or technology in key production links or work sections with high labor costs, and then gradually expand, which can effectively reduce the financial pressure of the initial investment. At the same time, government departments can help enterprises reduce the implementation cost of intelligent automation technology through policy support and assistance. Through the above methods, the technical implementation cost of AI automation in the food industry can be effectively reduced to promote the application and development of AI automation technology.

4.2 Data authenticity and integrity

The use of AI is driving digital transformation across industries, and the food industry needs a lot of consumer data and business data to train AI models when using AI to help transform the industry. This data covers all aspects of the food supply chain, involving different business sectors, or confidential information within organizations. For part of the data cannot be complete or real access, this missing or inaccurate data will directly affect the performance of the automation system, leading to decision-making errors and reduced productivity. In addition, some enterprises or institutions of food safety testing according to the actual situation only contains sampling data, but not all the food testing data, therefore, there is also a lack of food product data under the same batch, the same time period and other limited conditions, the incompleteness of these data makes the enterprise in the optimization of AI technology cannot achieve the expected results, which in turn affects the efficiency of the entire production process and cost control. In order to address the above challenges, multiple parties need to be involved to maintain security and privacy in the use of data. For the development and application of AI tools, they need to be supported by reliable privacy-preserving techniques, and differential privacy and federated learning are considered as promising approaches. Guaranteeing compliance and better management of data security and privacy of AI tools is inevitably bound by relevant laws and regulations. Countries or governments need to respond to the development of AI technology and introduce regulations as soon as possible to ensure that the food supply chain and regulators are comfortable with the use of AI technology, leading to the development of AI in the food industry. In addition, encouraging interdisciplinary exchanges and cooperation among multidisciplinary and multi-disciplinary personnel to help food professionals and enterprises solve special industry needs and technologies will help to solve the difficulties faced in the development of AI in the food industry faster.

5 Conclusion

The development of the food industry from the initial manual production and processing of manpower to the improvement of mechanized equipment, and then today’s AI technology to help, it is not difficult to see that AI technology in the automated production and processing of the food industry has an inseparable role and revolutionary role. In all sections of the food industry, it has shown the advantages of improved efficiency and safer food security. Although there are deficiencies in the cost of technology implementation, data authenticity and integrity, the potential of AI in food industry applications will be more explored and widely used as the technology matures and costs are reduced, and the data management process is improved.

Statements

Author contributions

XS: Funding acquisition, Supervision, Writing – original draft. XZ: Writing – review & editing. GD: Formal analysis, Writing – review & editing. HD: Funding acquisition, Writing – original draft, Writing – review & editing. XC: Funding acquisition, Investigation, Writing – review & editing. YH: Writing – review & editing. HH: Investigation, Writing – original draft. LW: Writing – original draft.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by the National Key Research and Development Program of China (2024YFE0199500).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1

Abu Z. Tarek C. P. Beauregard Y. (2021). Optimization of inventory management to prevent drug shortages in the hospital supply chain. Appl. Sci.11:2726. doi: 10.3390/app11062726

2

Afsharpour P. Zoughi T. Deypir M. Zoqi M. J. (2024). Robust deep learning method for fruit decay detection and plant identification: enhancing food security and quality control. Front. Plant Sci.15:1366395. doi: 10.3389/fpls.2024.1366395

3

Ali M. Asif M. (2012). Inventory management and its effects on customer satisfaction. Oeconomics Knowledge4:11.

4

Ang Minn L. P Seng K. P. Ge F. L. (2017). Natural Inspired Intelligent Visual Computing and Its Application to Viticulture. Sensors17:1186.

5

Atturu H. Naraganti S. (2024). Effectiveness of AI-driven Individualized Learning Approach for Children with Autism Spectrum Disorder (ASD). Europ. Psych, 67, S77. doi: 10.1192/j.eurpsy.2024.205

6

Albayrak Ünal Ö. Erkayman B. Usanmaz B. (2023). Applications of Artificial Intelligence in Inventory Management: A Systematic Review of the Literature. Archives of Computational Methods in Engineering, 30, 2605–2625. doi: 10.1007/s11831-022-09879-5

7

Banús N. Boada I. Xiberta P. Toldrà P. Bustins N. (2021). Deep learning for the quality control of thermoforming food packages. Scientific Reports11:21887. doi: 10.1038/s41598-021-01254-x

8

Barbut S. (2020). Meat industry 4.0: a distant future?Anim. Front.10, 38–47. doi: 10.1093/af/vfaa038

9

Barthwal R. Kathuria D. Joshi S. Kaler R. S. S. Singh N. (2024). New trends in the development and application of artificial intelligence in food processing. Innovative Food Sci. Emerg. Technol.92:103600. doi: 10.1016/j.ifset.2024.103600

10

Benalia S. Cubero S. Prats-Montalbán J. M. Bernardi B. Zimbalatti G. Blasco J. (2016). Computer vision for automatic quality inspection of dried figs (Ficus carica L.) in real-time. Comput. Electron. Agric.120, 17–25. doi: 10.1016/j.compag.2015.11.002

11

Benameur R. Dahane A. Kechar B. Benyamina A. E. H. (2024). An Innovative Smart and Sustainable Low-Cost Irrigation System for Anomaly Detection Using Deep Learning. Sensors24:1162.

12

Bidyalakshmi T. Jyoti B. Mansuri S. M. Srivastava A. Mohapatra D. Kalnar Y. B. et al . (2024). Application of Artificial Intelligence in Food Processing: Current Status and Future Prospects. Food Eng. Rev. doi: 10.1007/s12393-024-09386-2

13

Buljo J. O. Gjerstad T. B. (2013). “15 - Robotics and automation in seafood processing” in Robotics and Automation in the Food Industry. ed. CaldwellD. G. (Woodhead Publishing), 354–384.

14

Cambria E. White B. (2014). Jumping NLP Curves: A Review of Natural Language Processing Research [Review Article]. IEEE Comput. Intellig. Magazine9, 48–57. doi: 10.1109/MCI.2014.2307227

15

Çakmakçı S. Polatoğlu B. Çakmakçı R. (2024). Foods of the Future: Challenges, Opportunities, Trends, and Expectations. Foods13:2663.

16

Cavallo D. P. Cefola M. Pace B. Logrieco A. F. Attolico G. (2019). Non-destructive and contactless quality evaluation of table grapes by a computer vision system. Computers and lectronics in Agriculture156, 558–564. doi: 10.1016/j.compag.2018.12.019

17

Chhetri K. B. (2024). Applications of artificial intelligence and machine learning in food quality control and safety assessment. Food Eng. Rev.16, 1–21. doi: 10.1007/s12393-023-09363-1

18

Çinarer G. Doğan N. Kılıç K. Doğan C. (2024). Rapid detection of adulteration in pistachio based on deep learning methodologies and affordable system. Multimed. Tools Appl.83, 14797–14820. doi: 10.1007/s11042-023-16172-5

19

da Costa A. Z. Figueroa H. E. H. Fracarolli J. A. (2020). Computer vision based detection of external defects on tomatoes using deep learning. Biosyst. Eng.190, 131–144. doi: 10.1016/j.biosystemseng.2019.12.003

20

De Medeiros Esper I. From P. J. Mason A. (2021). Robotisation and intelligent systems in abattoirs. Trends Food Sci. Technol.108, 214–222. doi: 10.1016/j.tifs.2020.11.005

21

Delaney E. Greene D. Shalloo L. Lynch M. Keane M. T. (2022). Forecasting for sustainable dairy produce: Enhanced long-term, Milk-supply forecasting using k-NN for data augmentation, with Prefactual explanations for XAI. Cham: Case-Based Reasoning Research and Development.

22

Ferryman K. (2020). Addressing health disparities in the Food and Drug Administration’s artificial intelligence and machine learning regulatory framework. J. American Med. Inform. Assoc, 27, 2016–2019. doi: 10.1093/jamia/ocaa133

23

Garre A. Ruiz M. C. Hontoria E. (2020). Application of machine learning to support production planning of a food industry in the context of waste generation under uncertainty. Oper. Res. Perspectives7:100147. doi: 10.1016/j.orp.2020.100147

24

Goli A. Zareh H. K. Tavakkoli-Moghaddam R. Sadeghieh A. (2018). A comprehensive model of demand prediction based on hybrid artificial intelligence and metaheuristic algorithms: a case study in dairy industry. J. Ind. Syst. Eng.11, 190–203.

25

Gong W. Yao H.-B. Tao Chen Y. X. Fang Y. Zhang H.-Y. Li B.-W. et al . (2023). Smartphone platform based on gelatin methacryloyl (GelMA)combined with deep learning models for real-time monitoring of food freshness. Talanta253:124057. doi: 10.1016/j.talanta.2022.124057

26

Goyal R. Singha P. Singh S. K. (2024). Spectroscopic food adulteration detection using machine learning: Current challenges and future prospects. Trends in Food Science & Technology146:104377. doi: 10.1016/j.tifs.2024.104377

27

Guo L. Wang T. Zhonghua W. Wang J. Wang M. Cui Z. et al . (2020). Portable food-freshness prediction platform based on colorimetric barcode Combinatorics and deep convolutional neural networks. Adv. Mater.32:e2004805. doi: 10.1002/adma.202004805

28

Hassoun A. Aït-Kaddour A. Abu-Mahfouz A. M. Rathod F. B. et al . (2023). The fourth industrial revolution in the food industryPart I: Industry 4.0 technologies. Critical Rev. Food Sci Nutri.63, 6547–6563. doi: 10.1080/10408398.2022.2034735

29

Islam Z. Nisha Gurung M. Md Rokibul H. (2024). Novel AI-powered dynamic inventory management algorithm in the USA: machine learning dimension. J. Econ. Financ. Account. Studies6, 156–168. doi: 10.32996/jefas.2024.6.2.12

30

Iqbal J. Khan Z. H. Khalid A. (2017). Prospects of robotics in food industry. Food Sci. Technol, 37. doi: 10.1590/1678-457X.14616

31

Jadhav H. B. Alaskar K. Desai V. Sane A. Choudhary P. et al . (2025). Transformative impact: Artificial intelligence in the evolving landscape of processed food - A concise review focusing on some food processing sectors. Food Cont, 167:110803. doi: 10.1016/j.foodcont.2024.110803

32

Jagtap S. Bhatt C. Thik J. Rahimifard S. (2019). Monitoring potato waste in food manufacturing using image processing and internet of things approach. Sustain. For.11:3173. doi: 10.3390/su11113173

33

Janiesch C. Zschech P. Heinrich K. (2021). Machine learning and deep learning. Elect. Mark, 31, 685–695. doi: 10.1007/s12525-021-00475-2

34

Jiang J. Cen H. Zhang C. Lyu X. Weng H. Haixia X. et al . (2018). Nondestructive quality assessment of chili peppers using near-infrared hyperspectral imaging combined with multivariate analysis. Postharvest Biol. Technol.146, 147–154. doi: 10.1016/j.postharvbio.2018.09.003

35

Kang Z. Zhao Y. Chen L. Guo Y. Qingshuang M. Wang S. (2022). Advances in machine learning and hyperspectral imaging in the food supply chain. Food Eng. Rev.14, 596–616. doi: 10.1007/s12393-022-09322-2

36

Keong T. W. Husin Z. Ismail M. A. H. Yasruddin M. L. (2024). Stacked ensemble learning based on deep transfer learning models for food ingredient classification and food quality determination. Neural Comput. & Applic.36, 18705–18725. doi: 10.1007/s00521-024-10233-y

37

Khan Z. H. Khalid A. Iqbal J. (2018). Towards realizing robotic potential in future intelligent food manufacturing systems. Innovative Food Sci. Emerg. Technol.48, 11–24. doi: 10.1016/j.ifset.2018.05.011

38

Kim Y. Lee J. Kim S. (2024). Study of active food processing technology using computer vision and AI in coffee roasting. Food Science and Biotechnology33, 2543–2550. doi: 10.1007/s10068-023-01507-7

39

Konur S. Lan Y. Thakker D. Morkyani G. Polovina N. et al . (2023). Towards design and implementation of Industry 4.0 for food manufacturing. Neural Comput Appli.35, 23753–23765. doi: 10.1007/s00521-021-05726-z

40

Kumar I. Rawat J. Mohd N. Husain S. (2021). Opportunities of artificial intelligence and machine learning in the food industry. J. Food Qual.2021, 1–10. doi: 10.1155/2021/4535567

41

Liakos K. G. Busato P. Moshou D. Pearson S. Bochtis D. (2018). Machine learning in agriculture: a review. Sensors18:2674. doi: 10.3390/s18082674

42

Li X. Yin A. Choi H. Y. Chan V. Allman-Farinelli M. et al . (2024). Evaluating the Quality and Comparative Validity of Manual Food Logging and Artificial Intelligence-Enabled Food Image Recognition in Apps for Nutrition Care. Nutri.16:2573.

43

Li P. Liu X. (2019). Common Sensors in Industrial Robots: A Review. J. Physics: Conference Series, 1267:012036. doi: 10.1088/1742-6596/1267/1/012036

44

Makridis G. Mavrepis P. Kyriazis D. (2023). A deep learning approach using natural language processing and time-series forecasting towards enhanced food safety. Mach. Learn.112, 1287–1313. doi: 10.1007/s10994-022-06151-6

45

Mavani N. R. Ali J. M. Suhaili Othman M. A. Hussain H. H. Rahman N. A. (2022). Application of Artificial Intelligence in Food Industrya Guideline. Food Eng. Rev.1, 134–175. doi: 10.1007/s12393-021-09290-z

46

Moor M. Banerjee O. Abad Z. S. H. Krumholz H. M. Leskovec J. et al . (2023). Foundation models for generalist medical artificial intelligence. Nature616, 259–265. doi: 10.1038/s41586-023-05881-4

47

Nassibi N. Fasihuddin H. A. Hsairi L. (2023). Demand forecasting models for food industry by utilizing machine learning approaches. Int. J. Adv. Comput. Sci. Appl.14:3101. doi: 10.14569/IJACSA.2023.01403101

48

Nayak J. Vakula K. Dinesh P. Naik B. Pelusi D. (2020). Intelligent food processing: journey from artificial neural network to deep learning. Comput Sci Rev38:100297. doi: 10.1016/j.cosrev.2020.100297

49

Nithya R. Santhi B. Manikandan R. Rahimi M. Gandomi A. H. (2022). Computer vision system for mango fruit defect detection using deep convolutional neural network. Food Secur.11:3483. doi: 10.3390/foods11213483

50

Nunes C. Ricardo Nunes E. J. Pires S. Barroso J. Reis A. (2023). A machine learning tool to monitor and forecast results from testing products in end-of-line systems. Appl. Sci.13:2263. doi: 10.3390/app13042263

51

Onwude D. I. Chen G. Eke-emezie N. Kabutey A. Khaled A. Y. et al . (2020). Recent Advances in Reducing Food Losses in the Supply Chain of Fresh Agricultural Produce. Process, 8:1431.

52

Pan L. Pouyanfar S. Chen H. Qin J. Chen S. C. (2017). “DeepFood: automatic multi-class classification of food ingredients using deep learning,” in 2017 IEEE 3rd international conference on collaboration and internet computing (CIC) 2017.

53

Pierson H. A. Gashler M. S. (2017). Deep learning in robotics: a review of recent research. Adv. Robot.31, 821–835. doi: 10.1080/01691864.2017.1365009

54

Praveen U. Farnaz G. Hatim G. (2019). Inventory management and cost reduction of supply chain processes using AI based time-series forecasting and ANN modeling. Procedia Manufacturing38, 256–263. doi: 10.1016/j.promfg.2020.01.034

55

Qian C. Murphy S. I. Orsi R. H. Wiedmann M. (2023). “how can AI help improve food safety?” annual review of. Food Sci. Technol.14, 517–538. doi: 10.1146/annurev-food-060721-013815

56

Qiu Z. Paul H. Wang Z. Hirai S. Kawamura S. (2023). An Evaluation Systemof Robotic End-Effectors for Food Handling. Foods12, 4062.

57

Rana R. S. Kumar D. Prasad K. (2022). Two warehouse dispatching policies for perishable items with freshness efforts, inflationary conditions and partial backlogging. Oper. Manag. Res.15, 28–45. doi: 10.1007/s12063-020-00168-7

58

Reddy G. Ramswaroop S. Yellu R. Thuniki P. (2021). Optimizing supply chain management through artificial intelligence: techniques for predictive maintenance, demand forecasting, and inventory optimization. J. AI-Assisted Sci. Discovery1, 129–144.

59

Rong D. Wang H. Xie L. Ying Y. Zhang Y. (2020). Impurity detection of juglans using deep learning and machine vision. Comput. Electron. Agric.178:105764. doi: 10.1016/j.compag.2020.105764

60

Rout C. Chakraborty D. Goswami A. (2019). A production inventory model for deteriorating items with backlog-dependent demand. RAIRO Oper. Res.55, S549–S570. doi: 10.1051/ro/2019076

61

Sankhye S. Hu G. (2020). Machine learning methods for quality prediction in production. Logistics4:35. doi: 10.3390/logistics4040035

62

Shafiee F. Kazemi A. Chaghooshi A. J. Sazvar Z. Mahdiraji H. A. (2021). A robust multi-objective optimization model for inventory and production management with environmental and social consideration: a real case of dairy industry. J. Clean. Prod.294:126230. doi: 10.1016/j.jclepro.2021.126230

63

Sharma R. Shishodia A. Gunasekaran A. Min H. Munim Z. H. (2022). The role of artificial intelligence in supply chain management: mapping the territory. Int. J. Prod. Res.60, 7527–7550. doi: 10.1080/00207543.2022.2029611

64

Shen C. Wang R. Nawazish H. Wang B. Cai K. Baocai X. (2024). Machine vision combined with deep learning–based approaches for food authentication: an integrative review and new insights. Compr. Rev. Food Sci. Food Saf.23:e70054. doi: 10.1111/1541-4337.70054

65

Şimşek A. (2024). AI in managing perishable goods inventory. London: IGI Global, 29–70.

66

Singh N. Adhikari D. (2023). AI in inventory management: applications, challenges, and opportunities. Int. J. Res. Appl. Sci. Eng. Technol.11, 2049–2053. doi: 10.22214/ijraset.2023.57010

67

Singh R. Nickhil C. Nisha R. Upendar K. Jithender B. Deka S. C. (2024). A comprehensive review of advanced deep learning approaches for food freshness detection. Food Eng. Rev.17, 127–160. doi: 10.1007/s12393-024-09385-3

68

Taneja A. Nair G. Joshi M. Sharma S. Sharma S. Jambrak A. R. et al . (2023). Artificial Intelligence: Implications for the Agri-Food Sector. Agronomy13:1397.

69

Thibault B. Zeynoddin M. Bonakdari H. Ratti C. Khalloufi S. (2024). Assessment of artificial intelligence for predicting porosity of dehydrated food products. Compu. Elec. Agricul, 221:108934. doi: 10.1016/j.compag.2024.108934

70

Vasudevan S. Lamine Mekhalfi M. Blanes C. Lecca M. Poiesi F. Ian Chippendale P. et al . (2024). Machine vision and robotics for primary food manipulation and packaging: a survey. IEEE Access12, 152579–152613. doi: 10.1109/ACCESS.2024.3479781

71

van Erp M. Reynolds C. Maynard D. Starke A. Martín R. I. et al . (2021). Using Natural Language Processing and Artificial Intelligence to Explore the Nutrition and Sustainability of Recipes and Food. Front. Artificial Intelligence3. doi: 10.3389/frai.2020.621577

72

Wan P. Toudeshki A. Tan H. Ehsani R. (2018). A methodology for fresh tomato maturity detection using computer vision. Comput. Electron. Agric.146, 43–50. doi: 10.1016/j.compag.2018.01.011

73

Wang M. Li X. (2024). Application of artificial intelligence techniques in meat processing: a review. J. Food Process Eng.47:e14590. doi: 10.1111/jfpe.14590

74

Wang J. Xia L. Liu H. Zhao C. Ming S. Jingyi W. (2024). Colorimetric microneedle sensor using deep learning algorithm for meat freshness monitoring. Chem. Eng. J.481:148474. doi: 10.1016/j.cej.2023.148474

75

Wang C. Xiao Z. (2021). Potato surface defect detection based on deep transfer learning. Agriculture11:863. doi: 10.3390/agriculture11090863

76

Wang D. Zhang M. Mujumdar A. S. Dongxing Y. (2022). Advanced detection techniques using artificial intelligence in processing of berries. Food Eng. Rev.14, 176–199. doi: 10.1007/s12393-021-09298-5

77

Wu C. Chang H. Chen X. Yang S. Dai Y. Tan P. et al . (2024). Deep learning-assisted rapid assessment of food freshness using an anti-interfering triple-emission Ratiometric fluorescent sensor. ACS Sustain. Chem. Eng.12, 2465–2475. doi: 10.1021/acssuschemeng.3c07765

78

Zhang Y. Deng L. Zhu H. Wang W. Ren Z. Zhou Q. et al . (2023). Deep learning in food category recognition. Inf. Fusion98:101859. doi: 10.1016/j.inffus.2023.101859

79

Zhao Z. Wang R. Liu M. Bai L. Sun Y. (2025). Application of machine vision in food computing: A review. Food Chem.463:141238. doi: 10.1016/j.foodchem.2024.141238

80

Zheng M. Zhang Y. Jianfeng G. Bai Z. Zhu R. (2021). Classification and quantification of minced mutton adulteration with pork using thermal imaging and convolutional neural network. Food Control126:108044. doi: 10.1016/j.foodcont.2021.108044

81

Zhou L. Zhang C. Liu F. Qiu Z. He Y. (2019). Application of deep learning in food: a review. Compr. Rev. Food Sci. Food Saf.18, 1793–1811. doi: 10.1111/1541-4337.12492

Summary

Keywords

artificial intelligence, automation, machine learning, food industry, industrial intelligence

Citation

Song X, Zhang X, Dong G, Ding H, Cui X, Han Y, Huang H and Wang L (2025) AI in food industry automation: applications and challenges. Front. Sustain. Food Syst. 9:1575430. doi: 10.3389/fsufs.2025.1575430

Received

12 February 2025

Accepted

02 April 2025

Published

25 April 2025

Volume

9 - 2025

Edited by

Qingli Dong, University of Shanghai for Science and Technology, China

Reviewed by

Zhiyao Zhao, Beijing Technology and Business University, China

Mazen Alharbi, King Abdulaziz City for Science and Technology, Saudi Arabia

Updates

Copyright

© 2025 Song, Zhang, Dong, Ding, Cui, Han, Huang and Wang.

This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Haohan Ding, dinghaohan@jiangnan.edu.cn

Disclaimer

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.