- 1Civil Engineering Department, Istanbul Arel University, Istanbul, Türkiye

- 2Mechanical Engineering Department, Istanbul Arel University, Istanbul, Türkiye

- 3Chemical Engineering Department, Marmara University, Istanbul, Türkiye

This study examines the impact of thermal loading on the structural integrity of two types of potato storage facility: naturally cooled underground warehouses and steel-constructed refrigerated warehouses. Cold storage facilities are widely used for long-term storage of agricultural produce such as potatoes under varying indoor/outdoor temperature conditions. The finite element method (FEM) using SAP2000® was employed to model and evaluate the structural responses of these storage systems to thermal loading. The research focuses on the deformation, displacement and bending moments experienced by these structures. The findings reveal significant differences in the durability and performance of the two storage types. These results highlight important considerations for their design and structural optimisation. Based on these insights, recommendations are proposed to enhance the efficiency and longevity of cold storage facilities. This study contributes to the existing body of knowledge on the thermal behavior of storage infrastructures, offering valuable guidance on improving the design and operational effectiveness of agricultural cold storage systems.

1 Introduction

The agricultural sector plays a pivotal role in meeting the ever-increasing global demand for food, leveraging its extensive production capacity to ensure food security. However, the sustainability of agricultural production and the preservation of food quality depend on the effective storage of harvested products to prevent spoilage and extend their shelf life. Cold storage facilities are essential for maintaining the long-term viability of perishable agricultural produce. Potatoes, in particular, are one of the most widely consumed staple foods worldwide and require optimal storage conditions to prevent deterioration and maintain their nutritional and economic value (Etejere and Bhat, 1986).

Storing potatoes is a complex process that requires precise control of environmental factors such as temperature, humidity, ventilation and light exposure. Maintaining these conditions is essential for preventing quality degradation, sprouting and microbial decay (Mahmood et al., 2019). Various storage techniques and structural designs offer distinct advantages in preserving potatoes over extended periods. The selection of an appropriate storage system is influenced by factors such as economic feasibility, energy efficiency, environmental conditions and storage capacity.

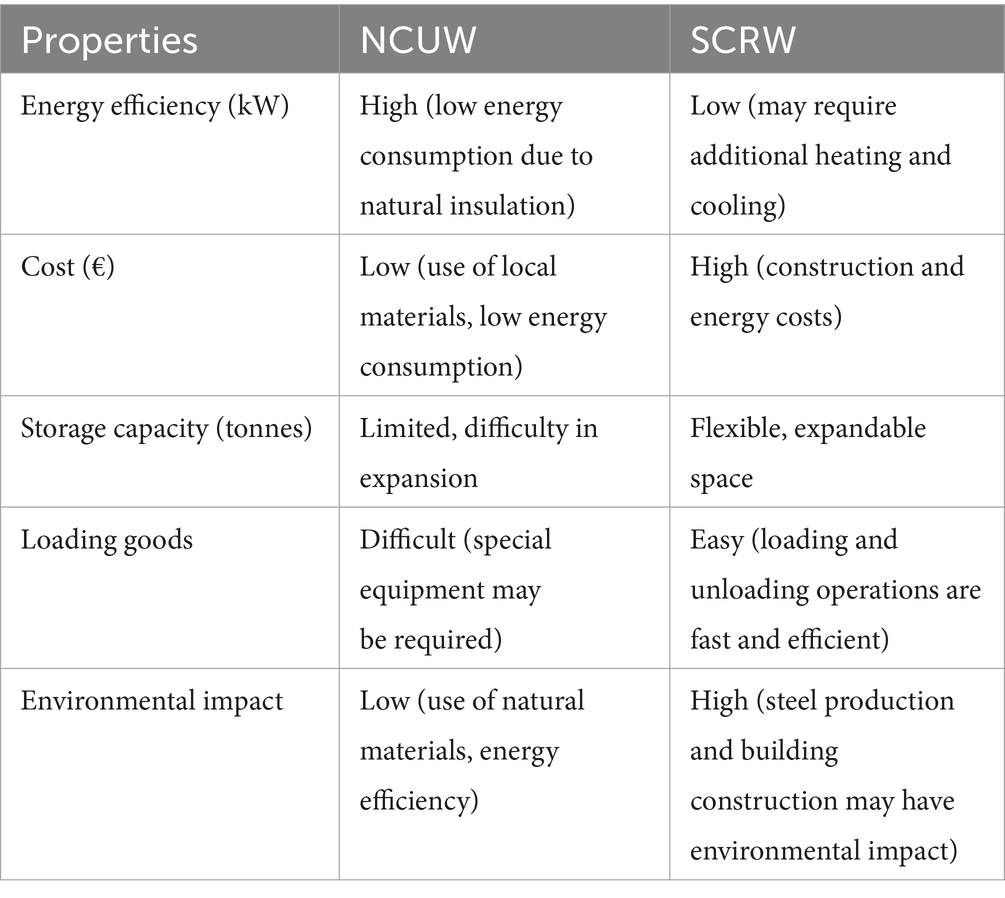

Potato storage infrastructure is typically constructed from a variety of materials, with two predominant design paradigms emerging: naturally cooled underground warehouses (NCUWs), which are carved from materials such as ignimbrite rock; and steel-constructed refrigerated warehouses (SCRWs), which are engineered for large-scale agricultural operations. NCUWs use the insulating properties of natural materials to maintain stable internal climates with minimal energy input. This makes them particularly advantageous in rural regions where traditional agricultural practices are commonplace. Key benefits include low operational energy consumption and the ability to naturally regulate humidity levels. However, these structures present challenges such as high initial construction costs, spatial limitations, and complex maintenance issues related to waterproofing and exposure to the elements.

Conversely, SCRWs embody modern engineering advancements and offer flexible, scalable storage solutions for industrial agricultural enterprises. The modular nature of steel structures allows for expansion and adaptability, and their design enables efficient loading, unloading and logistical operations. Despite their functional advantages, SCRWs typically incur higher construction costs and operational energy demands, necessitating artificial climate control systems to maintain optimal storage conditions. Furthermore, the carbon footprint associated with steel production and refrigeration-based storage raises sustainability concerns, especially compared to underground alternatives.

Understanding the structural responses of NCUWs and SCRWs to temperature fluctuations is paramount, given the substantial influence of thermal loads on storage facility integrity. Variations in external and internal thermal conditions can induce structural deformations, displacements and bending moments, which may compromise long-term durability. Although extensive research has been conducted on the thermal performance of various structural materials (Saetta et al., 1995; Owen et al., 1983; Szyszkowski and King, 1995), few studies have specifically addressed potato storage facilities. The existing literature emphasises the thermophysical properties of ignimbrite as a construction material (Sapcı et al., 2014; Gündüz, 2008; Yıldız et al., 2014), highlighting its low thermal conductivity and stability under fluctuating temperatures. Furthermore, studies have emphasised the sustainability and energy efficiency benefits of NCUWs in agricultural applications (Capoğlu and Ozden, 2023; Aydan and Ulusay, 2003; Balls, 2001; Baba et al., 2005; Mehta and Eezekiel, 2010).

A comparative analysis of NCUWs and SCRWs is essential for developing cost-effective and environmentally sustainable storage solutions for the agricultural sector. While both storage types demonstrate efficiency under specific conditions, a comprehensive evaluation of their respective advantages and limitations is necessary to optimise storage strategies. This study aims to assess the structural performance of NCUWs and SCRWs under thermal loading by reviewing literature, conducting field research and using SAP2000® software for numerical modelling. By examining the durability of these storage systems and their implications for long-term agricultural productivity, the research will provide recommendations on how to enhance cold storage designs. Ultimately, the findings will inform decisions regarding investments in storage infrastructure, ensuring the preservation of potato quality while promoting economic and environmental sustainability.

2 Types of potato storage facilities

2.1 Naturally cooled underground warehouse (NCUW)

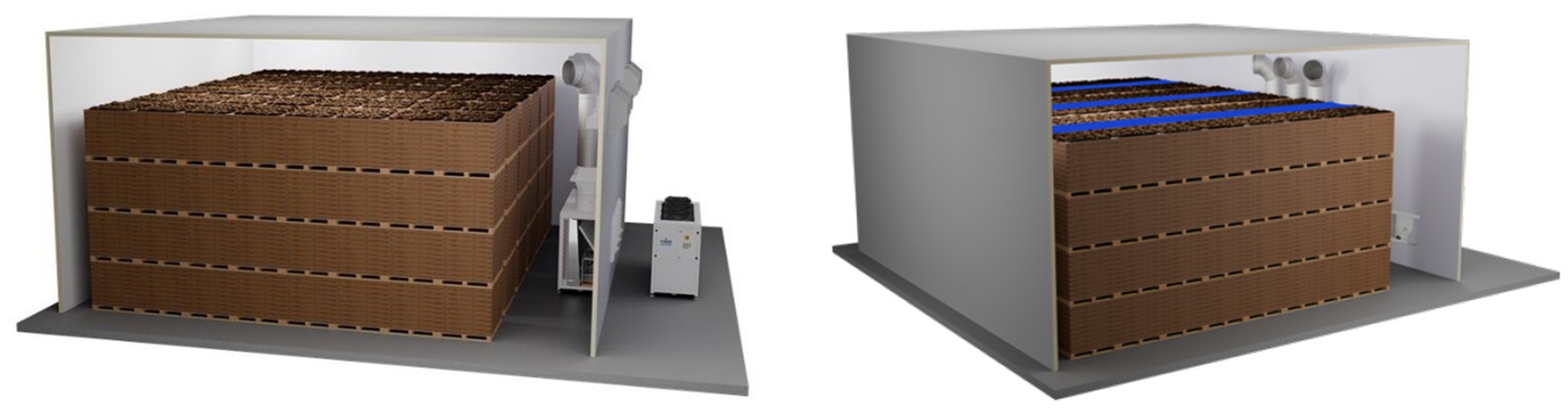

NCUW refers to spaces that have been naturally excavated beneath the Earth’s crust (see Figure 1). This type of storage minimises energy consumption thanks to the ground’s natural insulating properties, while maintaining stable temperature and humidity levels inside. NCUW is particularly prevalent in areas where traditional farming methods are still used.

Underground storage facilities are insulated from environmental temperature fluctuations, enabling potatoes to be stored at a consistent temperature. In this environment, the temperature usually remains between 5 and 10°C. This helps to maintain the quality of the potatoes. No extra energy is spent on heating or cooling in the natural environment. This increases energy efficiency and reduces operating costs. Underground storage naturally regulates humidity, preventing potatoes from drying out and ensuring they are stored properly. Maintaining a balanced moisture content slows down the spoilage process and increases yield.

However, the construction of underground storage can be challenging depending on the geological nature of the location. They are also susceptible to natural disasters such as water seepage or landslides. Access to underground storage areas can be more difficult than to conventional storage areas. Specialised equipment may be required for loading and unloading. Furthermore, underground warehouses usually offer limited space and expansion opportunities (Ozturk, 2010).

2.2 Steel-constructed refrigerated warehouse (SCRW)

Steel-constructed refrigerated warehouses are storage areas usually built using prefabricated steel materials, offering large spaces (see Figure 2). Designed using modern engineering techniques, these structures are especially used in large-scale agricultural enterprises.

Thanks to their modular design, steel structures can be easily expanded. This allows warehouse capacity to be increased as required. Easy Access and Industrial Warehouses are designed to be easily accessible by vehicles. This makes loading and unloading operations quicker and more efficient. Steel structures are built using durable, robust materials to ensure the safety of storage areas. In addition, systems that comply with fire safety standards can be incorporated.

In addition to these advantages, the following disadvantages should be noted: steel structures can consume more energy than underground warehouses. Heating or cooling systems are often required, which can increase operating costs. Construction costs for steel warehouses can be higher than for underground warehouses. This can pose an economic barrier, particularly for small businesses. The production of steel materials can have an environmental impact. Additionally, large structures may be less energy efficient than underground storage. Table 1 shows a comparison of the two types of warehouse.

3 Methodology

This study employs a comparative analysis approach to investigate the mechanical and physical alterations induced by thermal loads resulting from temperature differentials in two distinct types of potato storage facility.

The physical and thermal properties of the ignimbrite rock in the Naturally Cooled Underground Warehouse (NCUW) were determined based on data obtained from the literature. Due to its inherent insulating properties, this type of storage is generally less affected by external temperature fluctuations.

Steel-Constructed Refrigerated Warehouse (SCRW): The analysis considered the thermal expansion properties and structural behavior of steel. This type of facility is more flexible and resilient, but more susceptible to thermal deformation.

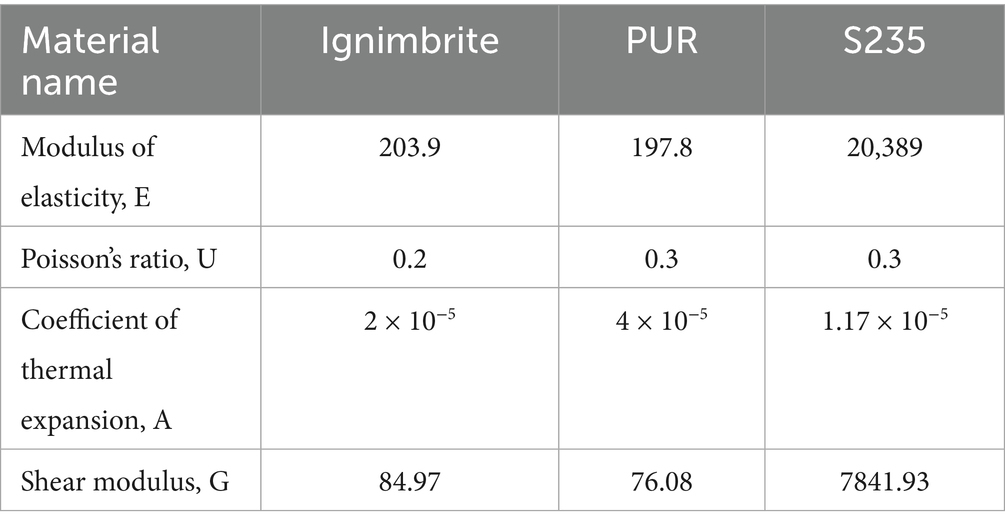

To enable a rigorous comparative analysis, case studies representing both storage types were examined first. To ensure the validity of the finite element analysis, two facilities of comparable scale and exposure to similar thermal loads and environmental conditions were selected. The first case study focuses on a naturally excavated ignimbrite rock storage unit, while the second focuses on a modern industrial cold storage warehouse constructed using prefabricated steel sections and insulated with polyurethane panels. Table 2 shows the material properties used in the modelling.

Both storage facilities are designed to maintain an internal temperature of +4°C, which is optimal for preserving potatoes. This temperature stability naturally creates a thermal gradient between the interior of the storage facility and the external atmosphere. The outdoor temperature dataset was derived from 84 years of average seasonal temperature records for Nevşehir, Turkey, as documented by the Turkish State Meteorological Service (TSMS) (2025). Consequently, the structural materials in both facilities experience thermal stresses, resulting in deformations, displacements and stress distributions within their structural components. These mechanical and physical phenomena were analysed systematically using finite element modelling techniques.

For this study, SAP2000® v.15, widely used software in structural engineering, was employed for the modelling and analysis. Such finite element software is widely used to simulate structural responses under thermal loads, offering a robust methodology for evaluating deformations and stress distributions across varying thermal conditions (Werkle, 2021). The structural behavior of both warehouse types under thermal loading conditions was assessed in order to gain insight into their performance and long-term durability.

The following key parameters were computed for both storage structures as a result of the numerical simulations:

- Structural deformations: Expansion and contraction resulting from thermal loads.

- Displacements: Movements observed within the structural elements.

- Bending moments: Internal moment effects acting upon structural components in both storage types.

These parameters were systematically analysed for both warehouse types using the finite element method within SAP2000®. After modelling each structure and defining the applied thermal loads, a computational analysis was conducted.

4 Results

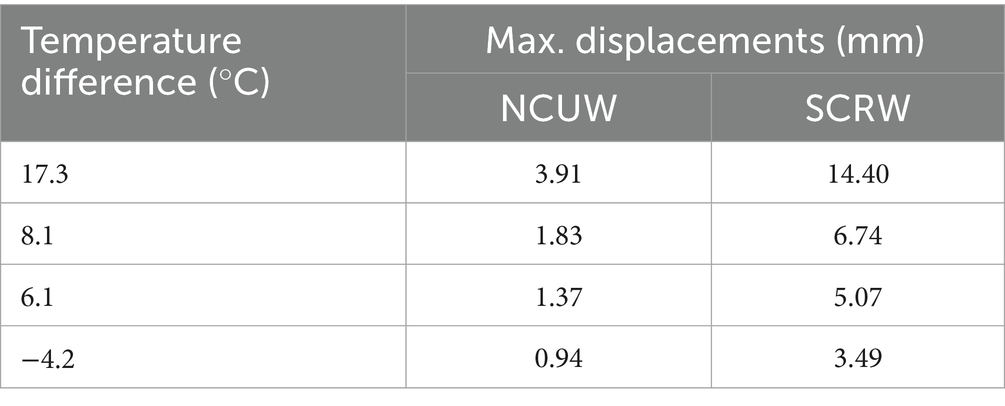

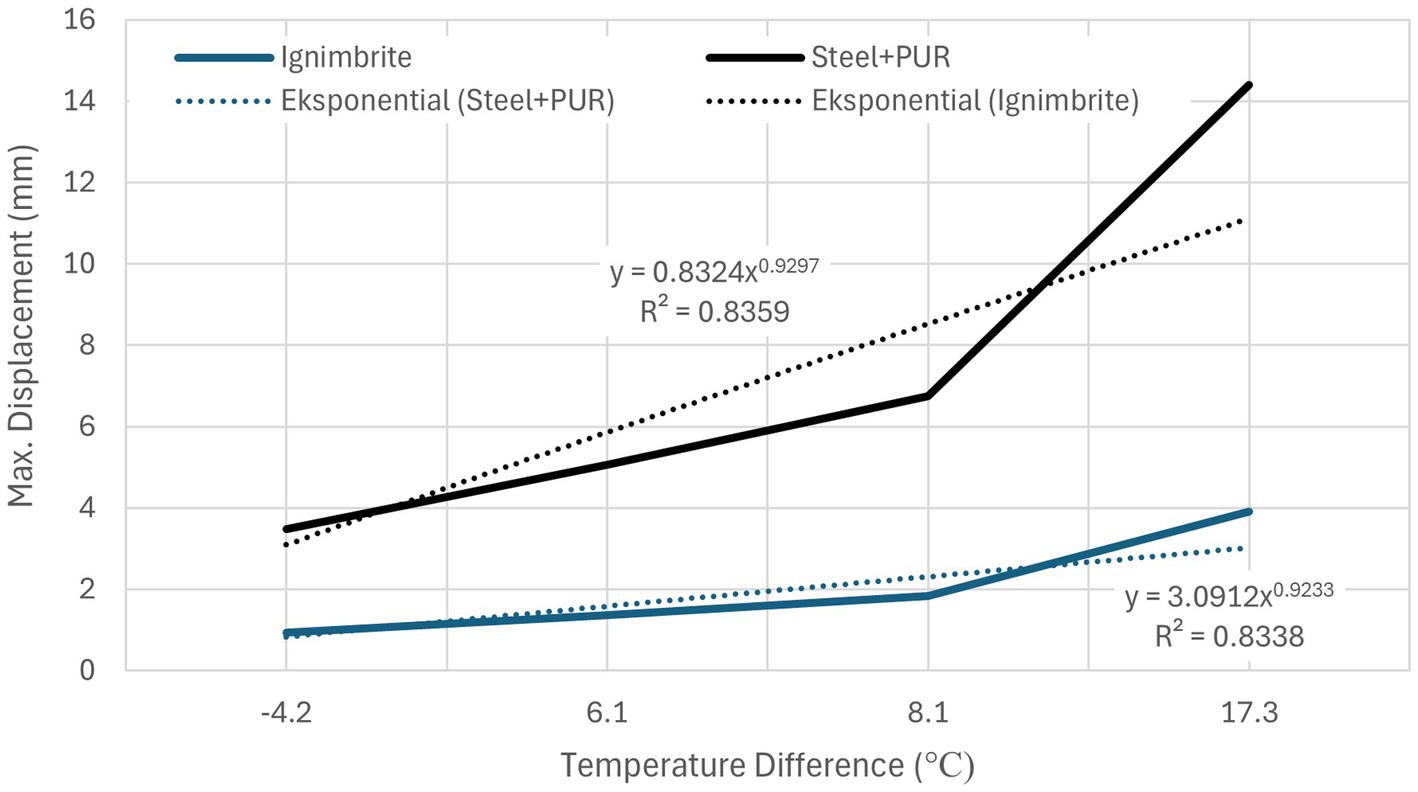

The mechanical response of NCUW and SCRW under varying thermal conditions was evaluated through numerical analyses conducted following the structural modeling process. Table 3 presents a comparative assessment of the maximum displacement values observed in both storage types. At a temperature differential of 17.3°C, the maximum displacement recorded at the frame joint points of the NCUW was 3.91 mm, whereas the corresponding displacement in the SCRW reached 14.40 mm. Furthermore, at temperature differentials of 8.1°C, 6.1°C, and−4.2°C, the NCUW exhibited displacements of 1.83 mm, 1.37 mm, and 0.94 mm, respectively, while the SCRW demonstrated significantly higher displacement values of 6.74 mm, 5.07 mm, and 3.49 mm under the same thermal conditions. These findings indicate that SCRW experience greater structural deformations under thermal loads compared to NCUW, highlighting the critical influence of material properties and thermal expansion characteristics on the overall stability of these storage facilities.

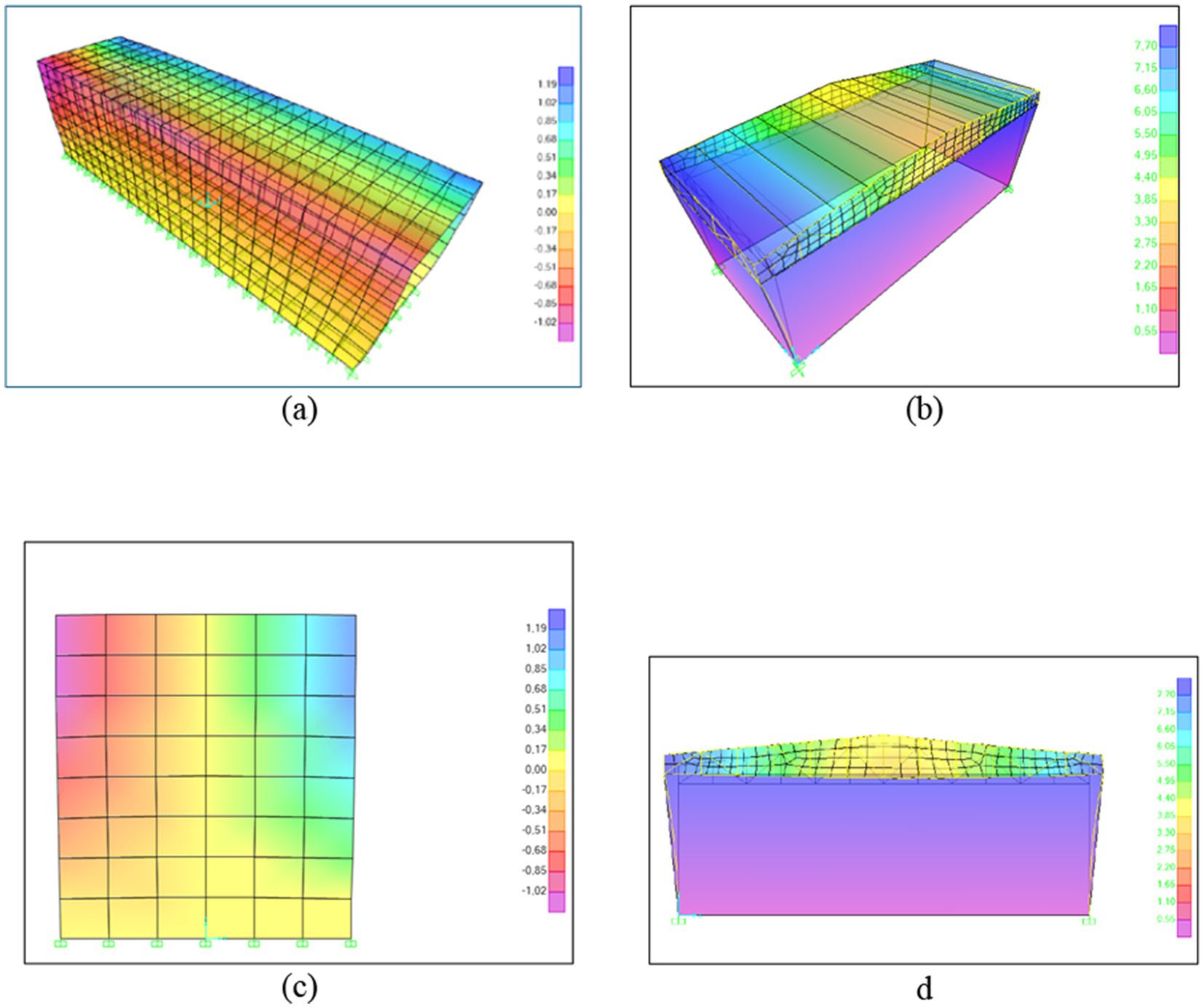

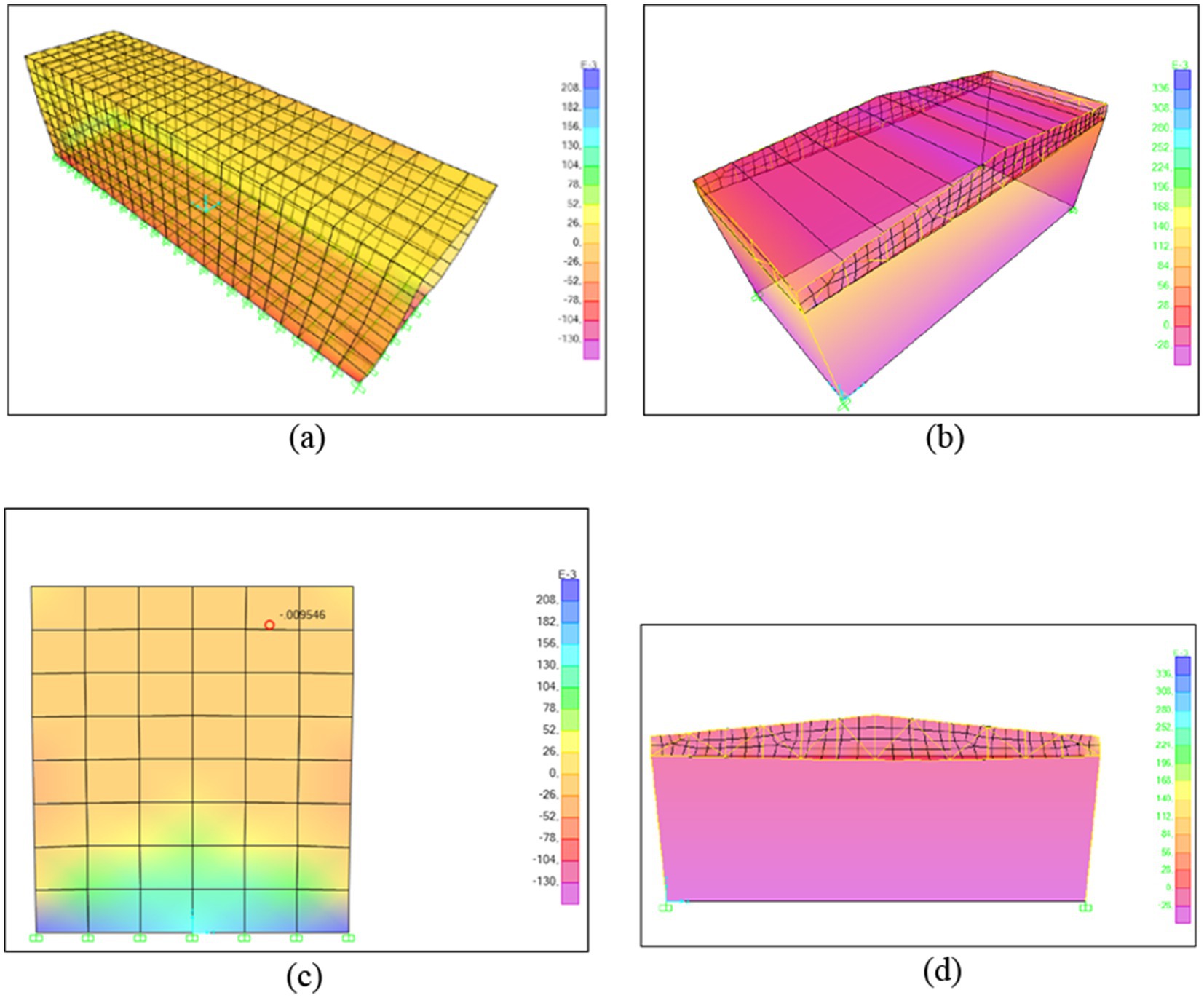

To provide a comprehensive visualization of the structural deformations, Figure 3 illustrates the three-dimensional (3D) displacement distributions across all sections of the storage structures under a temperature differential of 17.3°C. Additionally, the deformed configurations of the front-section regions are highlighted to facilitate a clearer understanding of the structural responses to thermal loads.

Figure 3. (a) 3D View of deformed shape of NCUW at 17.3°C difference. (b) 3D View of deformed shape of SCRW at 17.3°C difference. (c) Front section view of deformed shape of NCUW at 17.3°C difference. (d) Front section view of deformed shape of SCRW at 17.3°C difference.

The variations in displacement magnitudes corresponding to different temperature differentials are illustrated in Figure 4, where the distinct structural responses of NCUW and SCRW are clearly observed. The displacement values for SCRW exhibit a significantly higher sensitivity to temperature fluctuations, as evidenced by the steeper slope of the graph. This indicates that SCRW undergo considerably greater deformations in response to thermal loads compared to NCUW, emphasizing the critical role of material properties and thermal expansion characteristics in structural performance.

The stress distributions resulting from a temperature differential of 17.3°C across all surfaces of the structures are depicted as three-dimensional (3D) visualizations in Figures 5a,b. Additionally, to provide a more detailed examination of stress concentrations, Figures 5c,d illustrate the stress values specifically observed in the front-section regions of the structures. These visual representations offer valuable insights into the thermal stress behavior of both NCUW and SCRW, facilitating a comparative analysis of their structural responses under thermal loads.

Figure 5. (a) 3D View of maximum stresses of NCUW at 17.3°C difference. (b) 3D View of maximum stresses of SCRW at 17.3°C difference. (c) Front section view of maximum stresses of NCUW at 17.3°C difference. (d) Front section view of maximum stresses of SCRW at 17.3°C difference.

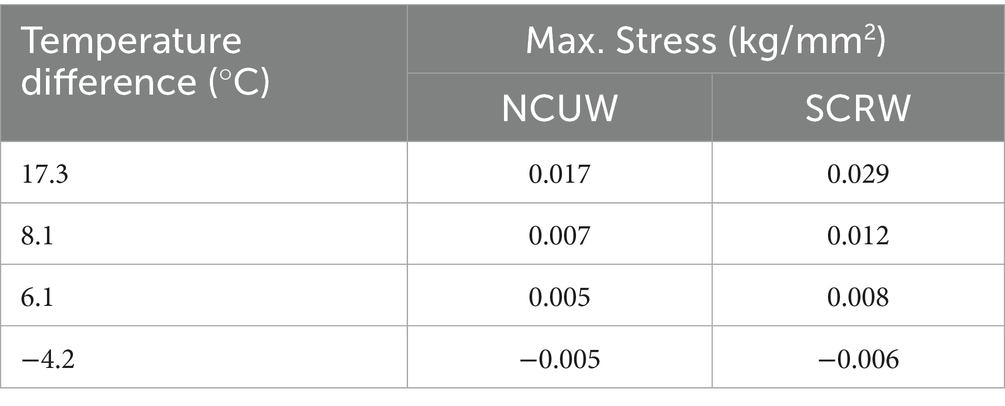

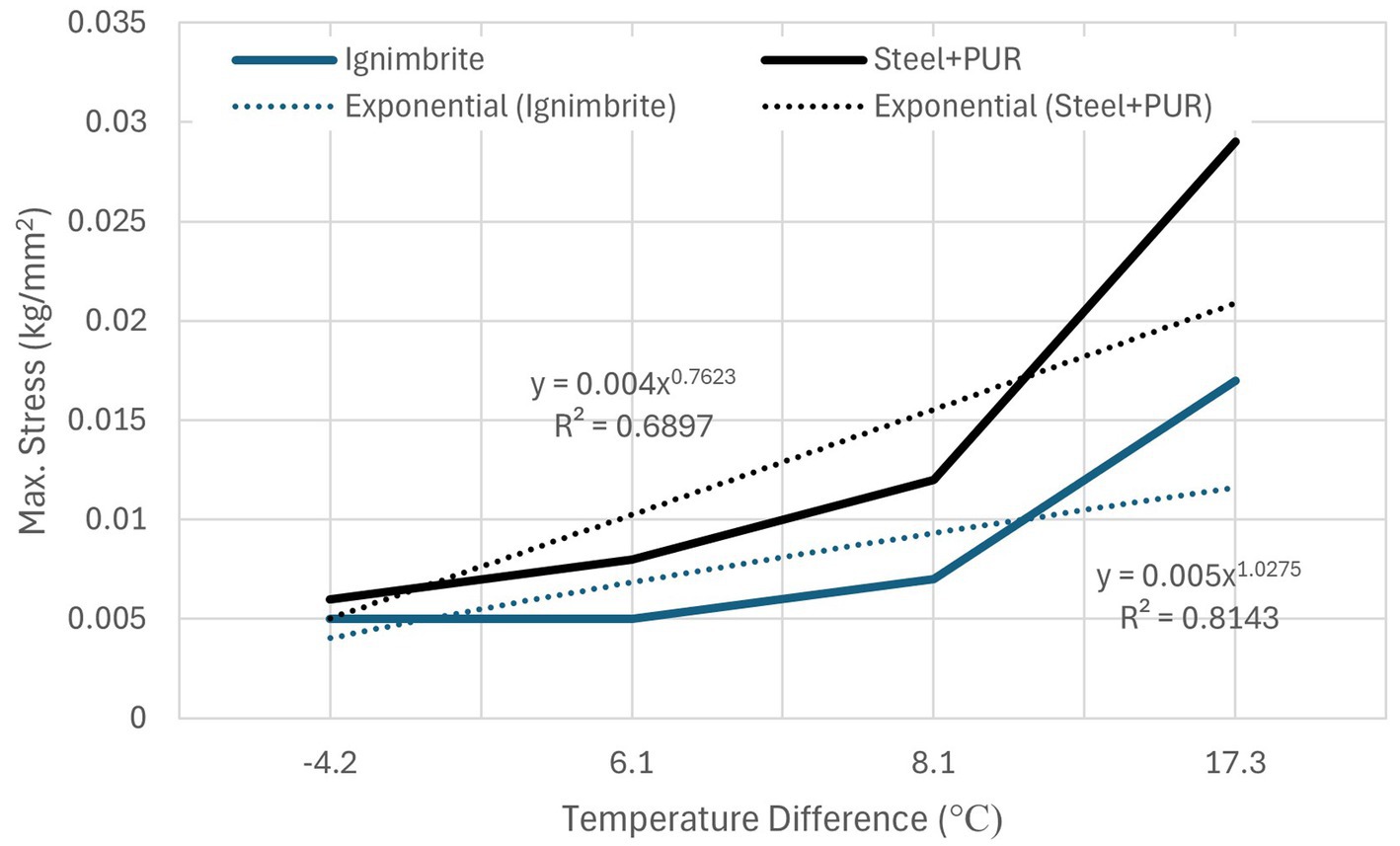

Table 4 presents a comparative analysis of the maximum stress values observed on the surfaces of both the NCUW and SCRW structures. At a temperature differential of 17.3°C, the NCUW exhibited a maximum stress of 0.017 kg/mm2, whereas the SCRW experienced a higher stress value of 0.029 kg/mm2. Furthermore, at temperature differences of 8.1°C, 6.1°C, and −4.2°C, the NCUW demonstrated stresses of 0.007 kg/mm2, 0.005 kg/mm2, and 0.005 kg/mm2, respectively. In contrast, the SCRW showed corresponding stresses of 0.012 kg/mm2, 0.008 kg/mm2, and 0.06 kg/mm2 under the same temperature conditions.

Figure 6 illustrates the relationship between stress values and temperature differentials, highlighting a distinct contrast between the NCUW and SCRW structures. Notably, the stress values in the steel storage (SCRW) exhibit a significantly greater sensitivity to temperature variations, as evidenced by the pronounced slope of the graph. This indicates a much sharper increase in stress with respect to temperature changes in the SCRW compared to the NCUW, underscoring the heightened susceptibility of the steel structure to thermal fluctuations.

5 Discussion

This study reveals that steel-constructed refrigerated warehouses (SCRWs) are significantly more susceptible to thermal-induced structural challenges than naturally cooled underground warehouses (NCUWs). Finite element analysis demonstrated that SCRWs exhibit greater displacements, bending moments, and stress concentrations under temperature fluctuations. These effects are especially pronounced at structural corners, where thermal expansion and contraction lead to higher localized deformation. Such behavior stems from the material properties of steel and polyurethane insulation, which possess high modulus of elasticity and shear modulus, amplifying the deformation capacity under thermal loads.

In contrast, NCUWs constructed from ignimbrite rock exhibit superior thermal stability. Owing to their low thermal conductivity and the buffering capacity of the surrounding earth, these structures maintain consistent interior temperatures and experience minimal deformation. The natural insulation provided by underground placement significantly mitigates external thermal effects, reducing structural stress and enhancing long-term durability.

Material characteristics strongly influence structural performance. In SCRWs, polyurethane’s high coefficient of thermal expansion, combined with steel’s rigidity, results in notable strain under thermal gradients. Numerical modeling confirms that displacement and stress values are primarily governed by the elastic and shear moduli, followed by thermal expansion coefficients. These insights underline the importance of material selection in thermally sensitive storage environments.

Beyond structural performance, this analysis highlights the broader implications for energy consumption and environmental impact. SCRWs, reliant on mechanical cooling, typically consume 25–40 kWh/m2 annually, whereas NCUWs require less than 5 kWh/m2, mostly for minimal ventilation and lighting (Mehta and Eezekiel, 2010; Yilmaz and Yilmaz, 2020). Furthermore, the embodied carbon of steel construction—estimated at 1.8 to 2.5 tons CO₂-equivalent per ton, significantly exceeds that of natural materials like ignimbrite, which require minimal processing and transport (Zhou et al., 2022). Life cycle assessment (LCA) data support the notion that NCUWs offer considerable reductions in greenhouse gas emissions over time due to passive thermal regulation and the absence of synthetic refrigerants.

Despite their environmental and structural benefits, NCUWs are not without challenges. High initial construction costs, limited scalability, and logistical difficulties in loading and unloading can hinder widespread adoption. Conversely, SCRWs are favored for their modularity, faster construction, and adaptability to industrial operations, albeit with higher long-term operational and environmental costs.

Ultimately, both NCUWs and SCRWs present distinct trade-offs. NCUWs offer long-term sustainability and structural resilience, making them attractive for regions with suitable geology and traditional farming contexts. SCRWs, while structurally less stable under thermal loads, remain a practical solution where scalability and logistics are prioritized. Moving forward, strategies such as hybrid storage models, advanced insulation materials, and refined thermal management systems may help bridge the gap between structural efficiency and environmental responsibility.

6 Conclusion

This study underscores the significant influence of thermal loading on the structural performance and sustainability of potato cold storage facilities. Finite element analysis revealed that steel-constructed refrigerated warehouses (SCRWs) are highly sensitive to temperature differentials, exhibiting substantial displacement and stress concentrations. In contrast, naturally cooled underground warehouses (NCUWs) demonstrated superior thermal stability and structural resilience due to their insulating geological composition.

Beyond structural behavior, the findings emphasize the critical role of design choices in shaping energy efficiency and environmental impact. While SCRWs offer scalability and operational convenience, they incur higher embodied carbon and long-term energy costs. NCUWs, though more complex to construct, represent a low-energy, low-emission alternative aligned with sustainable agricultural practices.

Optimizing storage infrastructure for both mechanical durability and environmental performance requires a holistic approach. Material selection, insulation strategy, and site-specific conditions must be carefully integrated into the design process. As global agriculture seeks resilient and sustainable solutions, NCUWs offer a compelling model where geological and economic conditions permit.

Future research should focus on hybrid systems and advanced material applications to enhance the thermal performance of steel structures. Additionally, empirical data should be collected through field observation or controlled experiments to validate numerical findings. While the current analysis is largely based on simulations under thermal gradients, real-world factors such as soil moisture in naturally cooled underground storages (NCUWs) and fluctuating mechanical loads in steel-constructed refrigerated storages (SCRWs) can also be modelled, particularly during loading operations. As a result, informed decision-making in cold storage design could improve food safety, reduce carbon emissions, and support long-term agricultural sustainability.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

IY: Data curation, Investigation, Methodology, Project administration, Software, Supervision, Writing – original draft. DY: Data curation, Investigation, Methodology, Writing – original draft, Writing – review & editing. EM: Project administration, Supervision, Writing – review & editing. II: Investigation, Methodology, Writing – original draft.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aydan, O., and Ulusay, R. (2003). Geotechnical and geoenvironmental characteristics of man-made underground structures in Cappadocia, Turkey. Eng. Geol. 69, 245–272. doi: 10.1016/S0013-7952(02)00285-5

Baba, A., Kaya, A., and Turk, N. (2005). Fairy chimneys of Cappadocia and their engineering properties. J. Appl. Sci. 5, 800–805. doi: 10.3923/jas.2005.800.805

Balls, R. (2001). Store design and operations. In: National potato conference proceedings. Bedfordshire, UK

Capoğlu, O. F., and Ozden, M. (2023). Sustainable use of tuff storage facilities for potato (Solanum tuberosum L.) tubers in Central Anatolia, Turkey. Potato Res. 66, 873–887. doi: 10.1007/s11540-022-09579-4

Etejere, E. O., and Bhat, R. B. (1986). Traditional and modern storage methods of underground root and stem crops in Nigeria. Turrialba 36, 33–37.

Gündüz, L. (2008). Use of quartet blends containing fly ash, scoria, perlitic pumice and cement to produce cellular hollow lightweight masonry blocks for non-load bearing walls. Constr. Build. Mater. 22, 747–754. doi: 10.1016/j.conbuildmat.2007.01.008

Mahmood, M. H., Sultan, M., and Miyazaki, T. (2019). Significance of temperature and humidity control for agricultural products storage: overview of conventional and advanced options. Int. J. Food Eng. 15:20190063. doi: 10.1515/ijfe-2019-0063

Owen, D. R. J., Figueiras, J. A., and Damjanic, F. (1983). Finite element analysis of reinforced and prestressed concrete structures including thermal loading. Comput. Methods Appl. Mech. Eng. 41, 323–366. doi: 10.1016/0045-7825(83)90012-9

Ozturk, T. (2010). The potato storage in the volcanic tuff storages in Turkey. GOU, Ziraat Fakültesi Dergisi 27, 113–120.

Saetta, A., Scotta, R., and Vitaliani, R. (1995). Stress analysis of concrete structures subjected to variable thermal loads. J. Struct. Eng. 121, 446–457. doi: 10.1061/(ASCE)0733-9445(1995)121:3(446)

Sapcı, N., Gündüz, L., and Yağmurlu, F. (2014). Usage of Aksaray ignimbrites as natural lightweight aggregate and evaluation of the production for lightweight hollow masonry units. Pamukkale Univ. J. Eng. Sci. 20, 63–69.

Szyszkowski, W., and King, J. (1995). Stress concentrations due to thermal loads in composite materials. Comput. Struct. 56, 345–355. doi: 10.1016/0045-7949(95)00027-E

Turkish State Meteorological Service (TSMS) (2025). Available at: https://www.mgm.gov.tr

Werkle, H. (2021). Finite elements in structural analysis: Theoretical concepts and modeling procedures in statics and dynamics of structures. Switzerland: Springer International Publishing.

Yıldız, M., Yıldız, A., Kahya, A., and Gurcan, S. (2014). Geology of Kızılkaya (Sevinçli/Aksaray), ignimbrite and investigation of the usage as building stone. Erciyes Üniv. Fen Bilim. Enstitüsü Derg. 30, 1–8.

Yilmaz, D., and Yilmaz, I. C. (2020). Comparative cost assessment of cold storage plants and natural storage structures for potato. Potato Res. 63, 497–505. doi: 10.1007/s11540-020-09454-0

Keywords: thermal loads, potato cold storage, structural deformation, steel structure, refrigerated warehouses

Citation: Yilmaz IC, Yilmaz D, Mancuhan E and Ince IT (2025) Evaluating the thermal behavior and structural integrity of potato cold storage facilities: insights for design optimization. Front. Sustain. Food Syst. 9:1596969. doi: 10.3389/fsufs.2025.1596969

Edited by:

Qingli Dong, University of Shanghai for Science and Technology, ChinaCopyright © 2025 Yilmaz, Yilmaz, Mancuhan and Ince. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Deniz Yilmaz, ZGVuaXp5aWxtYXpAYXJlbC5lZHUudHI=

Ismail Cengiz Yilmaz1

Ismail Cengiz Yilmaz1 Deniz Yilmaz

Deniz Yilmaz