- 1Department of Computing Science, University of East Anglia, Norwich, United Kingdom

- 2School of Engineering and Physical Science, University of Lincoln, Lincoln, United Kingdom

Climate change and environmental challenges make traditional horticulture methods less reliable for future global food production. Urban horticulture offers environmental, health and social benefits, and a route to future food security, but cities provide limited access to affordable land and residents lack expertise and available time. Automation can address these challenges, but current solutions are generally prohibitive due to their scale and cost, and are focused on generating produce for premium markets. This paper explores the potential for affordable, scalable, open source autonomous robotics as a solution for automating urban environments. We specify the tasks urban horticulture robots must be able to perform and establish criteria for their scale, functions and cost. By reviewing existing robotic technologies across different domains, we explore which formats could be adapted to meet the tasks demanded by urban growers. Our focus is on small-scale vertical hydroponic farming, offering high productivity and resource savings compared to soil growing. Robots to automate these soil-free growing setups are proposed as a natural starting point for the development of urban horticulture as a future mitigation for food supply shortages amid changes to Earth’s climate and ecosystems. Finally, we identify the Open Source Hardware community as an viable route for driving the development of cost-effective, adaptable robotic solutions for urban horticulture, promoting wider adoption in capital-poor regions.

1 Introduction

1.1 Food production challenges

Global food production is under threat as climate change causes more frequent and severe droughts, floods and extreme temperatures; each of which can significantly impact crop yields (Miron et al., 2023), particularly near the equator (Zandalinas et al., 2021; Joshi et al., 2024; Jagermeyr et al., 2021). Additional stressors to successful cultivation include habitat loss, pollution and the spread of pests and diseases, which can lead to greater reliance on chemicals that further harm the environment (Skendžić et al., 2021). Soil quality and degradation caused by intensive farming practices poses a threat to long-term crop productivity since, when disturbed beyond critical thresholds, their slow or sometimes irreversible restoration can erode essential ecosystem functions required for plant growth (Lal, 2009; Kraamwinkel et al., 2021).

1.2 Challenges and limitations of soil-based horticulture

Open field growing is currently the most accessible format for farmers, but is also vulnerable to climate shocks. In 2024, the UK suffered a 20% drop in wheat yield and other crops due to climatic conditions (Department for Environment, Food and Rural Affairs, (DEFRA), 2025) and given predictions that by mid-century, global temperatures will regularly surpass the Paris Climate Agreement threshold of 1.5 degrees Celsius, this will result in more frequent and severe weather events (Diffenbaugh and Barnes, 2023). The World Meteorological Organization (World Meteorological Organization, 2024) and NASA (Bardan, 2025) confirmed that 2023 and 2024, respectively, were already the warmest years on record, exceeding 1.5 degrees Celsius. Since this trend is predicted to accelerate (Hansen et al., 2023) new thinking around food resilience must be a priority.

To use more land may seem an obvious solution. Over the next 40 years, it is anticipated that climate change will convert approximately 2.7 million km2 of previously untouched wilderness into land suitable for farming (Gardner et al., 2023). While appearing as an opportunity to expand agricultural production, the transformation would come at immense and irreversible ecological cost, threatening critical ecosystem services and accelerating biodiversity loss—on which outdoor food production relies. Combined with a looming land crunch, where demand for usable land for different purposes is outstripping supply (King et al., 2023), food security solutions must favor the use of existing, or reduced land use.

Productivity per unit area can be improved through interventions, including chemical use, designed to lessen stress on the plants (Miron et al., 2023; Jones et al., 2023). However, the use of chemical pesticides’ are associated with human health issues (Dhankhar and Kumar, 2023) and fertilizer is costly and vulnerable to global political events (Vos et al., 2025).

Regenerative and conservation farming, including organic approaches, that avoid synthetic inputs also offer valuable environmental benefits (Connor, 2024). However, organic practices tend to require greater land inputs (Park and Williams, 2024) or incur additional costs, with only mild yield improvements. For instance, zero tillage in South Asia cut production costs by 15–16% and stabilized yields for wheat and maize (Malhi et al., 2021), yet its yield per unit area remains lower than that of large-scale mechanized conventional farming. Hence, despite their promise for improving climate change resilience and ecological regeneration, these approaches may not directly improve short or medium-term food security.

Any outdoor cultivation is subject to unpredictable weather which can lead to catastrophic crop failures, in turn, placing additional strain—particularly for poorer nations—on remaining food resources (Mirzabaev et al., 2023). The entrenched effects of climate change may also outpace the time-scales in which restorative farming methods will reap their intended benefits (Ranganathan et al., 2020). The success of any new open field farming approach relies on the motivation and environmental understanding of farmers (Brown et al., 2022), which may be a barrier considering profit margins in farming are already small (Kuhmonen and Siltaoja, 2022).

The mounting challenges of soil-based horticulture, ranging from climate instability to land scarcity and input dependency, highlights a need for resilient alternatives. These pressures are increasingly steering innovation toward protected horticulture and agri-robotics, in particular vertical farming, where the protected environment and automation offer the potential to stabilize yields and adapt food production to a changing environmental and economic landscape (Lemay and Boggs, 2024).

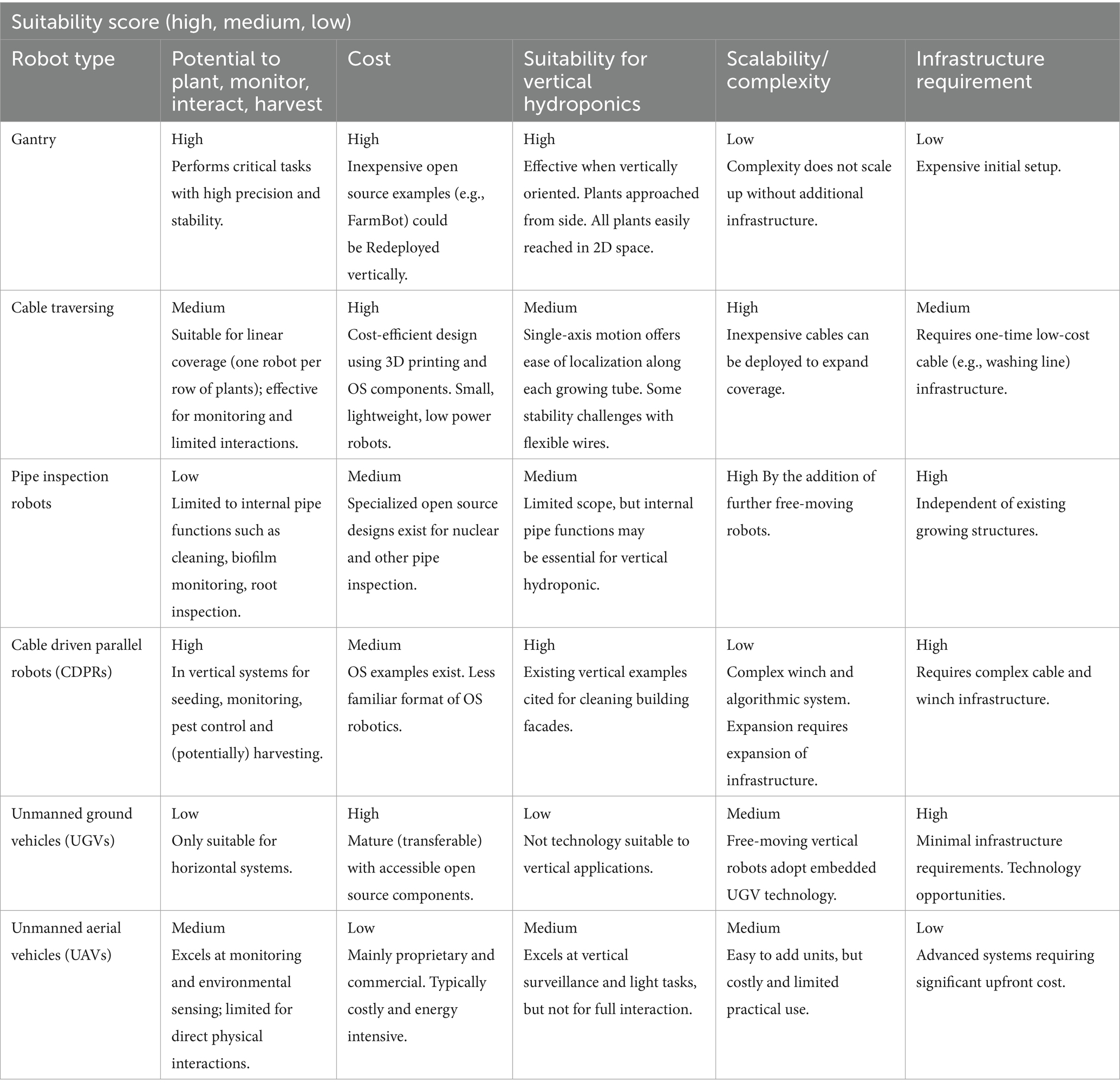

1.3 Protected horticulture

Indoor spaces can provide a stable growing environment, shielding crops from environmental extremes and pests, allowing for multiple or extended growing cycles throughout the year (Liao et al., 2020; Hanaka et al., 2023; Chimankare et al., 2023; Tsai and Lee, 2021). Greenhouses achieve higher yields, faster growth and better-quality produce compared to outdoor cultivation (Chacha et al., 2023; Jain et al., 2023; Dorr et al., 2021; Ramasamy et al., 2021). Vertical farming maximizes production from the compact footprints typical of greenhouses or indoor spaces, and when combined with hydroponics can enable denser planting and greater resource control by the elimination of soil (Table 1).

While protected horticulture offers a highly effective buffer against environmental stressors and may be regarded as the gold standard for commercial cultivation, it comes with substantial infrastructure and energy costs. In an urban context, such as growing against building facades, on rooftops or within shared public spaces, glasshouses may be impractical or inaccessible. For low-resource growers, the capital investment required for even non-automated greenhouses can present a significant barrier. In such cases, comparable yields to soil based cultivation have been demonstrate using hydroponic systems operating in the open air, avoiding factors such as soil degradation and offering the advantage of multiple crop cycles within a year (Bostanci and Ulger, 2022).

1.4 Hydroponic cultivation

Given its ability to deliver high yields in compact spaces with minimal resource input, hydroponic cultivation is poised to play a central role in shaping the future of urban horticulture. Particularly when deployed within controlled environments, it offers a means to optimize yield by precisely managing water and nutrient inputs, pest and diseases, thereby improving efficiency and reducing costs (Villagran et al., 2024). Numerous examples of advanced indoor vertical farming exist, including installations on urban brownfield sites and subterranean facilities (Oh and Lu, 2023). A comparative study in India (Mishra et al., 2024) found that hydroponic systems consistently outperformed conventional soil-based agriculture in terms of productivity, with lettuce yields reaching 31.2 kg/m2 compared to 21.8 kg/m2 in traditional methods, demonstrating the potential for higher output within a reduced spatial footprint. However, horticultural practices vary globally, and climatic conditions may influence the relative advantages of different cultivation methods. A separate study (Verdoliva et al., 2021), which controlled for environmental and fertilization variables, determined that hydroponic techniques are capable of producing yields and crop quality equivalent to or exceeding those of soil-based cultivation. While hydroponics presents clear agronomic advantages, successful implementation necessitates specialized equipment, technical expertise, and active management to ensure consistent performance and adoption at scale.

As such, large-scale automated vertical farms capable of offering comparable yields to in-field growing are financially prohibitive for small-scale growers due to high startup costs and ongoing energy requirements, particularly for LED lighting, heating and ventilation (Maureira et al., 2022; Chacha et al., 2023; Gil et al., 2023). To recoup high running costs, commercial vertical farms have focused on niche, high profit products destined for premium distributors, suggesting that commercial hydroponics would be an unlikely route for improving food security by the provision of staple crops, particularly as this model is also associated with high rates of commercial failure (de Baumont Oliveira et al., 2022). This focus of commercial hydroponics toward high-cost premium crops in favor of staple crops, excludes marginalized and low-income communities from reaping the food security benefits of commercial urban hydroponics.

2 The importance of urban horticulture

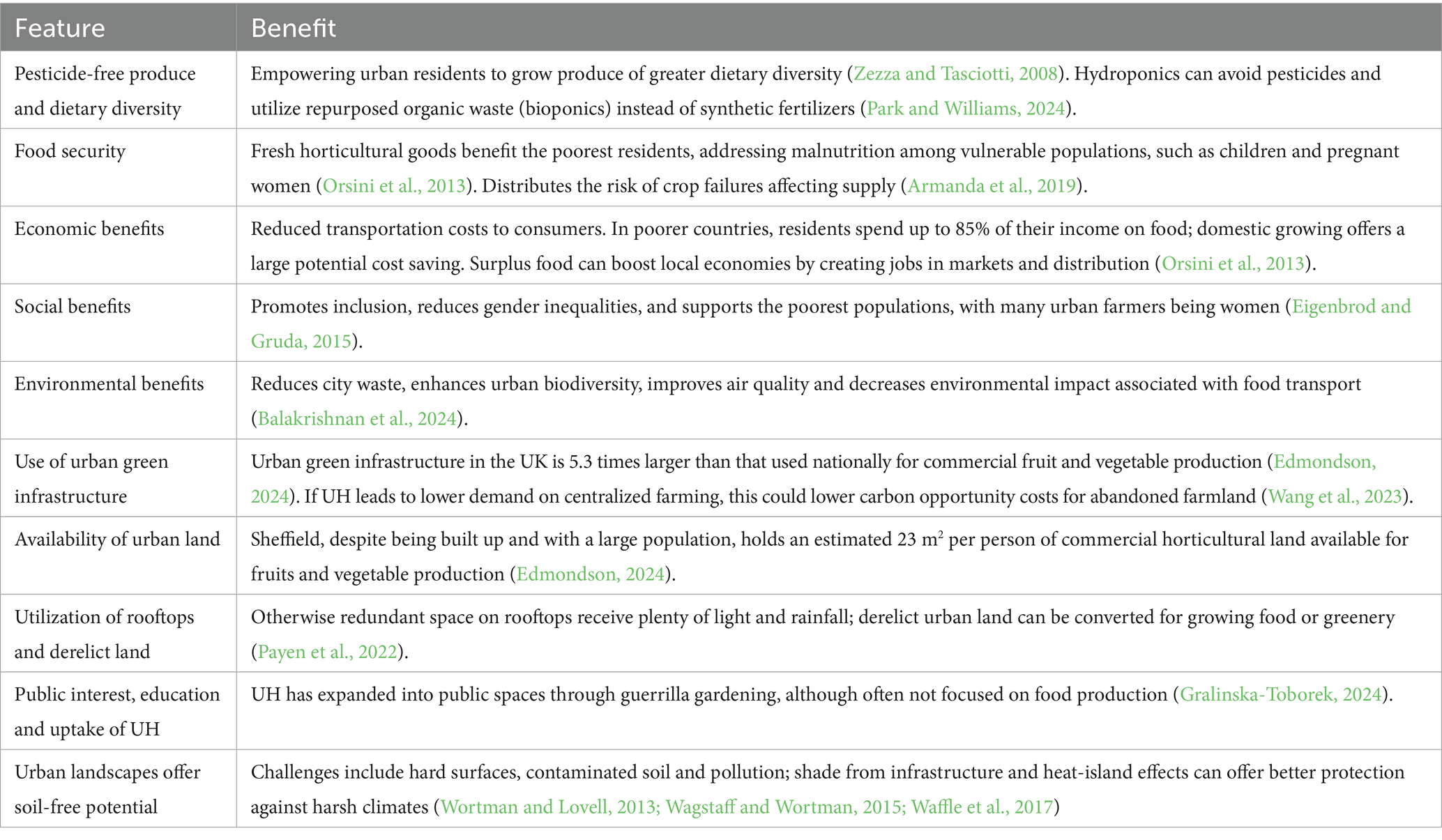

Urban agriculture is the production of crops and livestock within cities and towns (Zezza and Tasciotti, 2010); urban horticulture (UH) specifically focuses on the cultivation of edible plants such as fruits and vegetables (Congreves, 2022). Utilizing the unique, structural constraints of urban environments, particularly when adopting soil-free growing, may encourage the repurposing of derelict, hard-standing and underutilized spaces such as rooftops, building facades and balconies (Beacham et al., 2019). Efficient use of otherwise redundant space, and a growing awareness of the benefits of UH (summarized in Table 2) provides an incentive for exploring automation to accelerate UH uptake, such that it becomes a mainstream contributor to food security in line with the UN’s Sustainable Development Goal 2 (United Nations Department of Economic and Social Affairs, 2024). Once a niche concept, the importance of UH is now recognized at a global, strategic level for addressing food security (Figueres and Rivett-Carnac, 2020; Armanda et al., 2019).

Urban horticulture holds particular promise in rapidly urbanizing regions, such as parts of Sub-Saharan Africa, and Latin America. In South Asia, where land scarcity, rural-to-urban migration, and unmet food security needs are intensifying, urban horticulture is emerging as a vital solution for securing food sources, strengthening urban resilience and supporting community wellbeing (Balakrishnan et al., 2024). In these contexts, compact and efficient cultivation systems can provide critical support for nutritional access and local resilience. Yet, the need to increase yield from minimal footprints is increasingly global, as climate change places pressure on even land-abundant or affluent regions. Embedding flexible, resource-efficient growing models into cities now offers an important strategy for future-proofing food systems across diverse geographic and socioeconomic settings.

2.1 Challenges to urban horticulture adoption

Despite the measurable benefits of urban horticulture, its widespread adoption is constrained by several economic, technical and logistical hurdles. Traditional rural farming provides economies of scale with high productivity, whereas domestic urban horticulture is typically a secondary activity, for home consumption, and so generally less productive (Zezza and Tasciotti, 2010). Maintaining a garden or greenhouse can also be daunting for novices, and even experienced growers lack the time required for upkeep (Edmondson, 2024). The high cost of urban land (Gallent et al., 2024) compounded by the additional expenses of soil-based cultivation, such as seeds, equipment, fertilizer, topsoil and compost (Dobson et al., 2021) further limits its appeal compared to the convenience of shop-bought produce. The ready availability of rooftops in some urban settings offer opportunities for urban space utilization, yet their use remains constrained by the costs of providing clean water, filtering pollution, ensuring accessibility and navigating complex planning regulations (Zambrano-Prado et al., 2021). Some of these energy and water barriers, for outdoor hydroponics, have been met with innovative solutions (James Adams et al., 2021), however, despite its potential to maximize yields from limited spaces (Beacham et al., 2019), other barriers remain, related to motivation, technical knowledge and the time commitment required. The economic, technical and logistical constraints of urban horticulture may strengthen the case for automation, not through commercial-scale farm factories, but via a now-ubiquitous model of open-source robotics that lowers barriers to entry and promotes accessible, community-driven innovation tailored to local needs.

2.2 Smart technology for boosting urban horticulture

The use of hydroponics in an urban setting may only gain widespread support where it reliably delivers significantly higher-quality yields from compact growing spaces, while saving growers time, effort and money compared to equivalent shop bought produce. The use of smart sensors, actuators and internet of things (IoT) technologies has demonstrated improved consistency and predictability around plant growth and health (Soheli et al., 2022). In addition, gardening apps—often free to use—offer practical support for both domestic and commercial growers (Netthikumarage et al., 2022).

Indoor and outdoor hydroponic systems have demonstrated nutritionally rich yields under variable conditions (Rajaseger et al., 2023; Gumisiriza et al., 2020) which, when combined with smart technologies, provide measurable advantages for smart urban horticulture, including app-based monitoring (Shin et al., 2024). By combining IoT smart hydroponics within protected environments, built using consumer-level components, this has been demonstrated to achieve yet further improvements in quality and resource efficiency (S H et al., 2024). Automating irrigation, ventilation, lighting and nutrient delivery into hydroponic and soil based growing, often referred to as smart farming (Yepez-Ponce et al., 2023), can remove time-consuming tasks from the grower and improves yield reliability (Chakraborty et al., 2022).

The real and current challenges facing centralized soil-based horticulture will help drive innovation in food production methods and although commercial protected vertical farming will continue to play an important role through environmental control and higher productivity, its high start-up and operational costs makes it impractical for small-scale and staple crop production. Urban horticulture, already widely practiced in private gardens and allotments, may service those individuals and communities sufficiently motivated and available to undertake the activity. However, for urban horticulture to be a serious contributor to global food security will require the adoption of the most productive growing practices, such as hydroponics, in combination with affordable (non-commercial), scalable automation.

2.3 The limitations of commercial downscaling

2.3.1 Complexity and cost

Commercial vertical farms are built using significant capital investment, proprietary mechanization and advanced software controls that incur high maintenance overheads and technical expertise, most likely beyond the skill sets of domestic or subsistence growers. These set-ups can demand investments of tens, or hundreds of millions of dollars to build and run (Adenauer, 2014).

For small-scale or subsistence growers, attempting to replicate commercial hydroponic systems through the purchase or construction of automated kits (Shin et al., 2024) often proves impractical. While these setups may emulate aspects of high-end automation, they typically lack the protective infrastructure of controlled environments, yet still incur substantial costs and technical complexity—particularly if components fail—thus outweighing the modest yields achievable at this scale.

To scale up a pre-existing embedded automated small-scale system rapidly encounters escalating costs due to the need for additional embedded, multi-element sensors (Dennison et al., 2025), heightening the risk of failure from multiple component breakdowns; a well-documented issue in even well-resourced commercial settings (de Baumont Oliveira et al., 2022).

While creating small-scale versions of commercial automation to meet local needs seems attractive, it is often difficult and expensive to replicate the complex intelligence of those systems. Without the economic and infrastructural support of larger operations, maintaining these automated systems can be challenging for vulnerable growers in low-resource environments.

In contrast, non-automated systems using basic resin tubing and low-voltage pumps, readily obtainable to the public, offer a low-cost, low-maintenance option capable of supporting hundreds of plants; however, crucially, they provide no automated oversight or intervention.

We propose a more promising approach: decoupling automation from the hydroponic infrastructure itself. Rather than embedding sensors and control elements within the growing system, our suggested model maintains a simple, modular hydroponic setup, enhancing robustness and accessibility—while deploying mobile, low-cost robots to perform monitoring and intervention tasks. These robots would be designed to traverse and interact with the planted environment, enabling greater flexibility, scalability and resilience across diverse urban contexts. The remainder of this paper explores the functional requirements and design considerations for such robotic systems.

2.3.2 Energy advantages of small-scale urban growing

Commercial vertical farms—sometimes referred to as “plant factories” (Lee and Lin, 2024)—depend heavily on artificial lighting and tightly controlled climate systems to achieve year-round, high-yield cultivation. While effective in output, the approach incurs substantial energy costs, ties operations to grid infrastructure and increases vulnerability to fluctuations in energy supply and pricing (Panotra et al., 2024).

By contrast, miniature hydroponic systems designed for small-scale urban growing offer a significantly lower energy alternative. By prioritizing natural daylight, particularly abundant in Global South regions such as Asia, Africa, and South America, where urban horticulture is particularly promising (Balakrishnan et al., 2024), these systems mitigate the high energy costs typically associated with artificial lighting.

The compact scale of urban hydroponic growing makes it well suited to low-power technologies. Akin to domestic robotic lawnmowers whose power capacity would be inefficient for large fields but ideal for private gardens, miniature horticultural robots can be constructed using low-voltage batteries, efficient motors, and lightweight, biodegradable materials. Their slower, low-energy operation, exemplified by systems such as SlothBot (Notomista et al., 2019), mirrors the gradual growth cycles of non-commercial crops, using energy only as needed.

While a single miniature robot may be sufficient for routine hydroponic tasks of the smallest scale, their true advantage lies in their scalability, when deployed in modular swarms, utilizing IoT approaches to coordinate, adapt and collectively deliver performance (Dennison et al., 2025).

3 Managing hydroponics with robots

3.1 A prospective look at urban horticulture robots

Through a technology review, we explore which existing robotic technologies could be adapted, using Open Source technology, for urban horticultural tasks—and what these tasks need to be. The review examines a diverse array of robotic technologies, some of which are well known and others, more specialized, however all of which may have the potential to be adapted and miniaturized for urban hydroponic applications.

Robotic urban horticulture, a potential new branch of smart urban horticulture (Rey et al., 2024), offers advantages over small-scale fixed, embedded hydroponic technology. Internet of Things (IoT) solutions for domestic hydroponic systems, which we briefly explore conceptually, offers some affordable mechanization, however, small scale mobile robots operating autonomously or possibly as cobots in collaboration with human growers (Benos et al., 2023) may take different forms, but would operate independently of the plant-growing structure.

Vertical growing can involve the inaccessible positioning of plants for humans (Zambrano-Prado et al., 2021; Javaid et al., 2022). Due to the small scale potential of domestic systems, lightweight—slow-moving robots would operate at height with relatively low power demands, also making solar a potential power option. Different formats may carry payloads, monitor plants for disease and pests, or interact with plants through integrated manipulators and grippers, delivering tailored care that is hard to achieve with static, embedded technologies.

From this conceptualization, it is expected that robots would be more cost-effective to build and scalable, both in terms of numbers, and of functionality, with existing units able to autonomously move into new planted areas as the systems expands. Out of the box, a robot may be able to perform at a baseline of required plant care functionality, or, with IoT connectivity, units possessing swarm-enabled functionality would be capable of sharing data of the entire set-up. Unlike commercial automation (including field robots) that involve proprietary design and components, (Zhang, 2024), small mobile robots built from consumer-grade motors and sensors could remain affordable. Should a unit fail, it could be swapped out—without incurring system downtime, ensuring better overall system reliability.

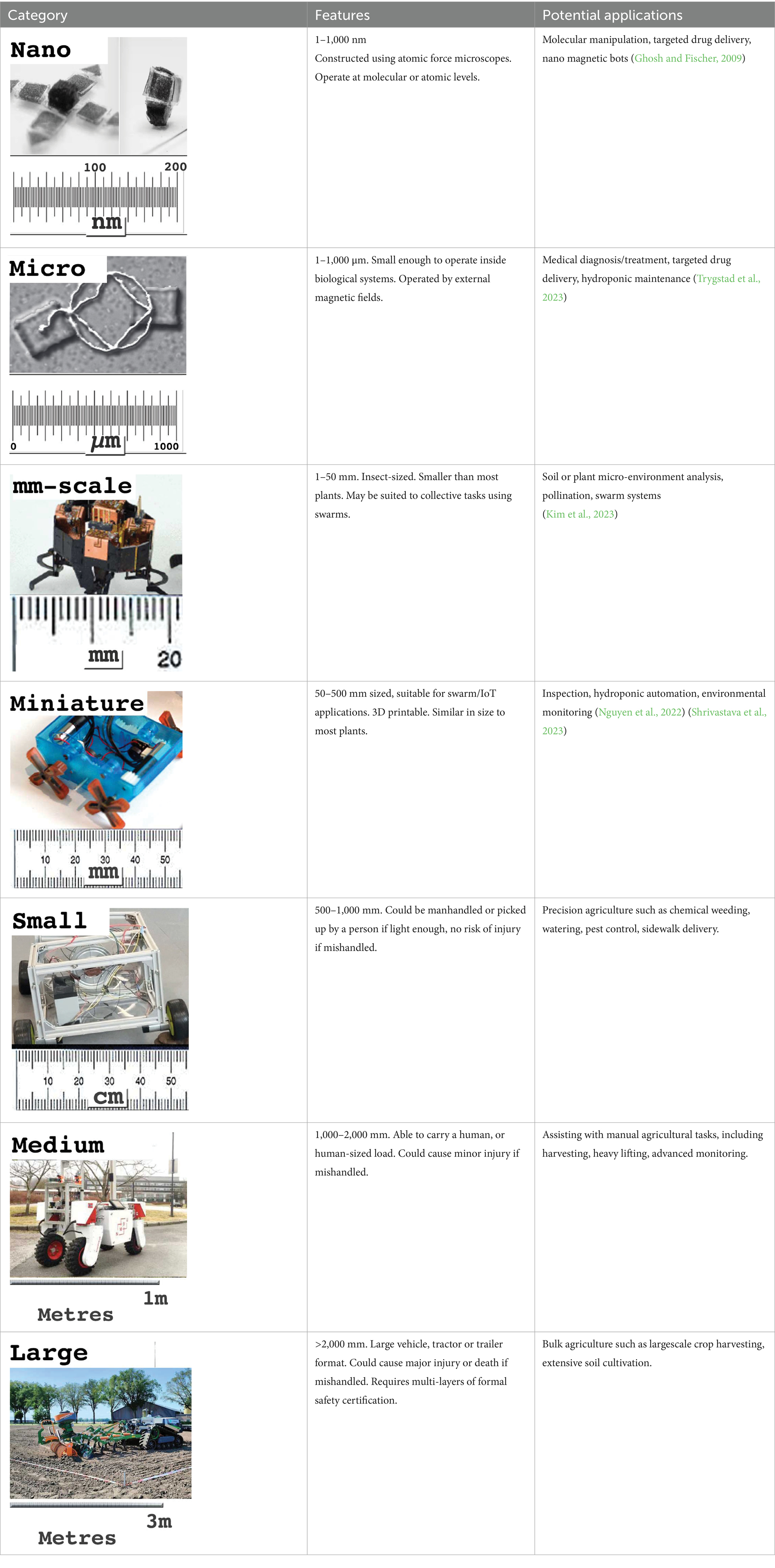

3.2 Characterizing robots by size

Robots are typically classified by mobility, interaction method, or intended function (Jahn et al., 2020), yet these taxonomies often overlook key physical attributes such as shape, size or weight. The U. S. Navy classifies unmanned vehicles primarily by weight; small (less than 400 lb), lightweight (400 lb. up to 1 ton), medium (1–15 tons), and large (greater than 15 tons)—demonstrating that weight, regardless of physical form, in some domains serves as a more helpful criterion (Turner, 2019). In urban horticulture, where space can be constrained and large, heavy robots could be impractical or pose a danger to humans, a robot’s physical dimensions become a priority. For example, research of seed-sowing robots may initially appear promising until their tractor-size dimensions discount them. For reviewing available technologies, we start with a categorization of robots of nano & micro, millimeter-scale, miniature, small, medium and large, which tend to align their capabilities with the diverse tasks and compact settings encountered in this field (Table 3).

3.2.1 Nano and micro

1–1,000 nm robots include molecular actuators such as rotating motors and walkers using methods based on chemistry and biology (Niu et al., 2023). Micro (1 μm–1 mm) robots can be made from non-biological materials using lithography (Miskin et al., 2020) and are typically controlled and powered through manipulation of external magnetic fields. Nano and micro robots have been researched primarily for human medical applications such as drug delivery, though have also been applied to horticulture including navigating through plant veins (Huan et al., 2023) and delivery of conventional agrochemical fertilizers, pesticides and herbicides (Huska et al., 2022). They currently have limited direct applications in urban horticulture, as building and controlling them requires highly specialized tools.

3.2.2 Millimeter-scale

Robots, ranging from 1 to 50 mm, represent the initial frontier of visible macro robotics. Their small dimensions enable capabilities that are more difficult to achieve at larger scales. For example, flying robots at the millimeter level (Chukewad et al., 2021) may offer novel approaches to insect-free pollination, while crawling variants could navigate and monitor crop areas between the stems of plants (Hutama et al., 2021). Currently though, these robots require niche or bespoke components for their construction, placing them outside the realm of mainstream open-source development.

3.2.3 Miniature

Robots in this category exist within a 50–500 mm size range. Unlike the neighboring categories, these robots can be constructed using non-specialized components and, unlike small and large robots, are less likely to pose a mechanical danger to people around them (Hutama et al., 2021). They can typically be fabricated with inexpensive 3D printing and off-the-shelf components, making them accessible to the open source (OS) community.

3.2.4 Small

Robots such as the pedestrian-friendly sidewalk delivery robots (Gehrke et al., 2023) or grass-cutting robots are generally light enough to pick up and be carried by humans, but can also carry similar loads to those carried by humans. Examples vary in size from 0.5 to 1 m and weigh between 20 and 50 kg, making most ground-based wheeled robots suitable for fields and warehouses.

3.2.5 Medium

Robots in this category range from 1 to 2 meters in size and are usually capable of transporting similar payloads as carried by humans. In agriculture, this size has been widely adopted for greenhouses and field operation, usually equipped with sensors, manipulators or platforms for transporting produce. They are typically too heavy for a human to pick up and although often slow moving, could inflict minor injuries should they collide with humans, so require some safety consideration.

3.2.6 Large

Robots in this category are substantial machines, of sizes above 2 m. They including self-driving tractors, bulldozers and cars (Spykman et al., 2021), all of which incorporate extensive sensor suites and sophisticated control algorithms to navigate complex environments. Due to their scale, these robots have the capacity for high performance and operational efficiency, however strict safety protocols are necessary to avoid harm to humans or damage to property.

3.2.7 Miniature: optimum scale for urban robotic horticulture

Given the space constraints and safety considerations of urban horticulture, miniature robots—ranging from 50 to 500 mm—offer the most practical scale for general deployment. Smaller, and larger robots may find a place too—however the more specialized components, construction, power requirements, build costs and maintenance makes them less appealing than those built from Commercial Off-The Shelf Components (COTS), the use of which has gained traction in many fields of engineering (O’Halloran et al., 2017), and even the space industry (Hodson et al., 2022).

Unlike nano, or micro-scale devices, which require specialized fabrication, or larger robots that can be costly or hazardous, miniature systems strike a balance between capability, accessibility, and safety. Their compatibility with off-the-shelf components and 3D-printable designs makes them ideally suited to open-source development, enabling broad community engagement and rapid iteration in the pursuit of equitable, locally adaptable automation.

3.3 The essential role of open source in urban robotic horticulture

Since reliance on commercial systems is often cost-prohibitive and insufficiently adaptable for small-scale or experimental growers, developing miniature robotics for urban hydroponics faces a key challenge. Commissioning bespoke designs from private firms remains inaccessible for most subsistence or domestic users, particularly where iteration and system flexibility are essential. In contrast, open-source hardware (OSH)—physical devices made freely available under permissive licenses—offers a more inclusive model for community-driven innovation and end-user customization, especially in contexts where standardized commercial options fall short (Ruiz-Larrea et al., 2016).

Unlike open-source software (OSS), which is virtually cost-free to replicate, OSH involves tangible production and fabrication costs that can affect scalability and accessibility (Katz, 2012). Despite this, OSH invites a wealth of global design input, encourages peer-validated improvements and enables adaptation to local needs; qualities increasingly recognized by some industries who are turning to OSH to accelerate development and redefine conventional commercialization pathways (Li et al., 2021).

For the lifecycle of miniature hydroponic robots, OSH enables the use of standardized, easily sourced components—often mass-produced or 3D printed—and transparency and reproducibility through OS licensing terms (Mies et al., 2022). Certification schemes and open publishing protocols help assure reliability, while an understanding around reciprocal obligations would ensure that community contributions continue to grow the shared design ecosystem.

However, OSH is not without its limitations since disparate documentation standards, inconsistent license frameworks and ambiguities in safety responsibility—particularly concerning harmful materials or electromagnetic emissions—remain real challenges (Carpentier, 2021). Such concerns are more important when addressing food security in low-income contexts, where financial risk associated with unreliable technology can translate into real harm, as can a lack of oversight around potentially harmful materials used for robot construction.

Nevertheless, OSH offers a promising path to sustainable, modular robotics development where affordability, adaptability and long-term availability are paramount. Academic–industry collaborations can help bridge the gap between high-spec research environments and grassroots users, ensuring solutions are ambitious yet appropriately scaled and safe (Gupta et al., 2016; Andersen-Gott et al., 2012). While OSH may not have fully mirrored the virtuous cycle seen in OSS—where high levels of trust have led to collaboration and positive reciprocal behavior (Edgeman et al., 2018), as OSH becomes easier to use and access—the barriers may be lower for small-scale urban robots, where design simplicity and local fabrication are viable. For miniature urban hydroponic robotics, open source is not simply a strategy it is an enabler of accessible, future-ready innovation that aligns with both sustainability and food equity goals (European Commission. Directorate General for Research and Innovation, Elsevier, ESADE, CWTS, and Lisbon Council, 2019).

3.4 Urban horticulture robot tasks: desiderata

If urban hydroponic robots were to be developed through commercial channels, creating functional reliability at scale would be relatively straightforward, albeit at a cost that could place them beyond the reach for many who would be set to benefit most. However, in an open source paradigm, where systems are developed iteratively by diverse contributors using commercial off-the-shelf (COTS) components, achieving comparable functionality becomes a more complex and collaborative challenge.

Like household robots such as robotic vacuums and lawnmowers, the success of miniature horticultural robots depends on their ability to consistently and effectively replicate human tasks. Urban horticulture (UH) robots must prove they can automate critical food production activities, but with tighter affordability. Their design must anticipate off-grid operation, long-term adaptability and the realities of a globally distributed development community; ensuring utility, inclusivity and resilience across the varied urban contexts they are meant to serve.

Soil-based horticulture presents major obstacles for urban robots with unpredictable planting, high land costs and crop localization challenges that complicates mobility and data processing (Gil et al., 2023). Hydroponic growing solves two of these challenges since hydroponic crops are planted in precise locations within a rigid structure allowing a robot to be able to localize the plants by their positions; secondly, a robot can utilize the hydroponic tubing for support and locomotion. Although the maximized yields of hydroponics makes it an attractive choice for urban horticulture, open source innovations in this area may also drive the development of robotic solutions in soil-based farming, a practice likely to remain dominant in the foreseeable future while hydroponics gains wider acceptance.

Horticulture is a process that arguably begins with the selection of suitable seeds, followed by their germination and subsequent cultivation into mature plants for consumption. These stages represent the most promising areas for full robotic automation to benefit urban growers, as human involvement at any point could compromise the technology’s perceived worthiness. The aspiration should therefore be for a full automated set of stages resulting in plants for consumption and ideally, the process should be interruptible, such that certain plants can be removed and new plants added at any time without affecting other plants within the system.

3.4.1 Planting and seeding

This first stage, the accurate placement of seeds or seedlings (seeds that have sprouted with small stems or leaves) is fundamental, but can be time-consuming for a human grower (Kumar et al., 2022). Urban hydroponic systems may be located in inaccessible areas, such as dense greenhouses or on building exteriors, making autonomous robotic operation a valuable function. Precision is also crucial to achieve optimal results (Kumar et al., 2024), since errors in seed placement may only become evident at germination. Automation reduces the need for specialized knowledge in setting optimal planting times and configurations (Cerda et al., 2022), and automated seed or seedling selection, mirroring a similar soil-based open source system (Farmbot) (Mahajan et al., 2019), may help to boost urban grower adoption. Once a seed or seedling has been placed in a basket—containing a growing medium like rock-wool, or without, it must be placed within the hydroponic tube where its roots reach down into the solution, enabling the plant to develop.

3.4.2 Weeding

For soil-based agriculture, weeds are often a problem, competing for nutrients and light. While hydroponic systems located within greenhouses are largely immune to weeds, open-air setups which are likely to be more commonplace in urban settings, face a higher risk of weed and fungal spore intrusion, potentially obstructing light and imposing additional structural loads on the growing tubes. Given the limited data for open-air hydroponics (James Adams et al., 2021), early robotic detection and eradication of weeds would be a sensible predictive mitigation of a potential problem of open air growing that is likely to benefit the crops as they mature (Coleman et al., 2022).

3.4.3 Watering

As the seedlings develop and become more established, reliable irrigation is fundamental to plant growth and health (Zheng et al., 2023). Hydroponic growing systems, using a continuously circulating nutrient solutions, largely eliminate traditional irrigation challenges. However, when seeds, that lack established roots, are planted directly into a hydroponic substrate like rock-wool, they require moisture to trigger germination and to sustain early growth until their roots connect with the nutrient solution. Even after plants are established, research on foliar irrigation (Kagawa, 2022; Corriveau et al., 2012) suggests that targeted spraying can enhance nutrient delivery and improve water uptake. In an urban setting, spraying may also help clear dust from leaves to aid photosynthesis (Thompson et al., 1984).

3.4.4 Pest control

Urban horticulture is vulnerable to pest infestations. While indoor hydroponic systems are by their nature a non-chemical approach to pest control (Tavares et al., 2015), outdoor setups expose plants to a variety of insects, arachnids and mollusks. Future urban hydroponics may involve growing plants at height or in inaccessible locations, where monitoring and interventions would be difficult for humans. Integrating pest control capabilities into horticultural robots, such as monitoring, early intervention, targeted chemical applications, ultraviolet light (UV) application (Meyer et al., 2021), or humane physical removal techniques, would enhance their ability to protect crops effectively to achieve better yields.

3.4.5 Monitoring and surveillance

Hydroponic systems, unlike soil growing, depend on precise and continuous monitoring of plant health and environmental conditions due to their reliance on recirculating nutrient solutions. Soil provides a natural buffer against environmental fluctuations, however, most forms of hydroponics are sensitive to sudden failures, such as pump malfunctions (Bhujel et al., 2020; Bunyuth and Serey, 2024). Apart from some formats, such as drip-feed systems (Rajendran et al., 2024), failure resulting in a lack of water can have immediate and severe consequences, since plants deprived for even a short time may be unrecoverable (Zheng et al., 2023). Monitoring should be a routine and necessary function, using cameras and sensors capable of providing detailed data around growth, nutrient uptake, pest presence and disease onset, allowing for real-time adjustments and for predicting harvest readiness. Plant species will place different demands on shared hydroponic solutions (Sharma et al., 2019) so monitoring can help determine when the composition needs adjusting, or if foliar feeding of particular plants is appropriate.

3.4.6 Harvesting

Automating the final stage of the growing process, harvesting, would bring significant advantages around system efficiency. With crops like lettuce ready for harvest in as little as 35 days (Sharma et al., 2019), robots capable of retrieving produce as they become ready, from inaccessible locations would ensure optimal utilization of space by allowing immediate re-seeding and involving minimize human intervention.

3.4.7 Cleaning

Cleaning of the hydroponic systems forms an essential function of a robot workforce, to maintain the hydroponic infrastructure, preventing debris and nutrient build-up that can encourage algae growth. The level of cleaning is likely to vary depending on where in the world the urban hydroponic system is. Cleaning robots are likely to promote greater uptime and consistent productivity, leading to more dependable systems.

4 Adaptable robot technologies

The automation of urban horticulture can draw upon advancements in established robotics to develop reliable, scalable and adaptable platforms that support open-source innovation. This review selects existing robotic examples from across different categories of application, yet which still align with the expected functional requirements of urban hydroponic horticulture. Software solutions such as localization, image detection and decision-making algorithms for robot behaviors fall outside the scope of this review, with an abundance of literature on such systems readily available. The robots considered here, are assumed to possess programming appropriate to their intended use, and therefore, potentially extendable or replicable to achieve specific urban horticulture functions.

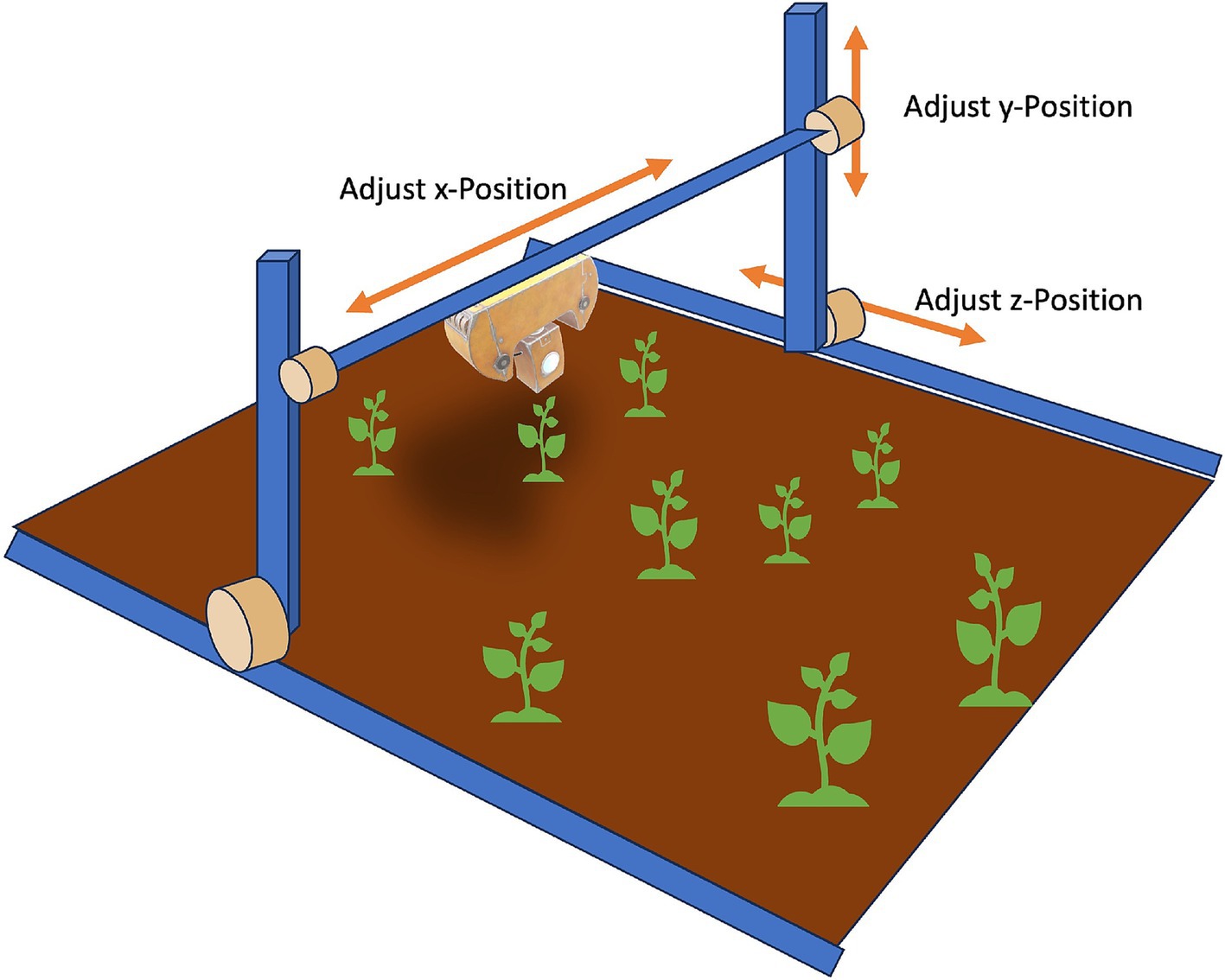

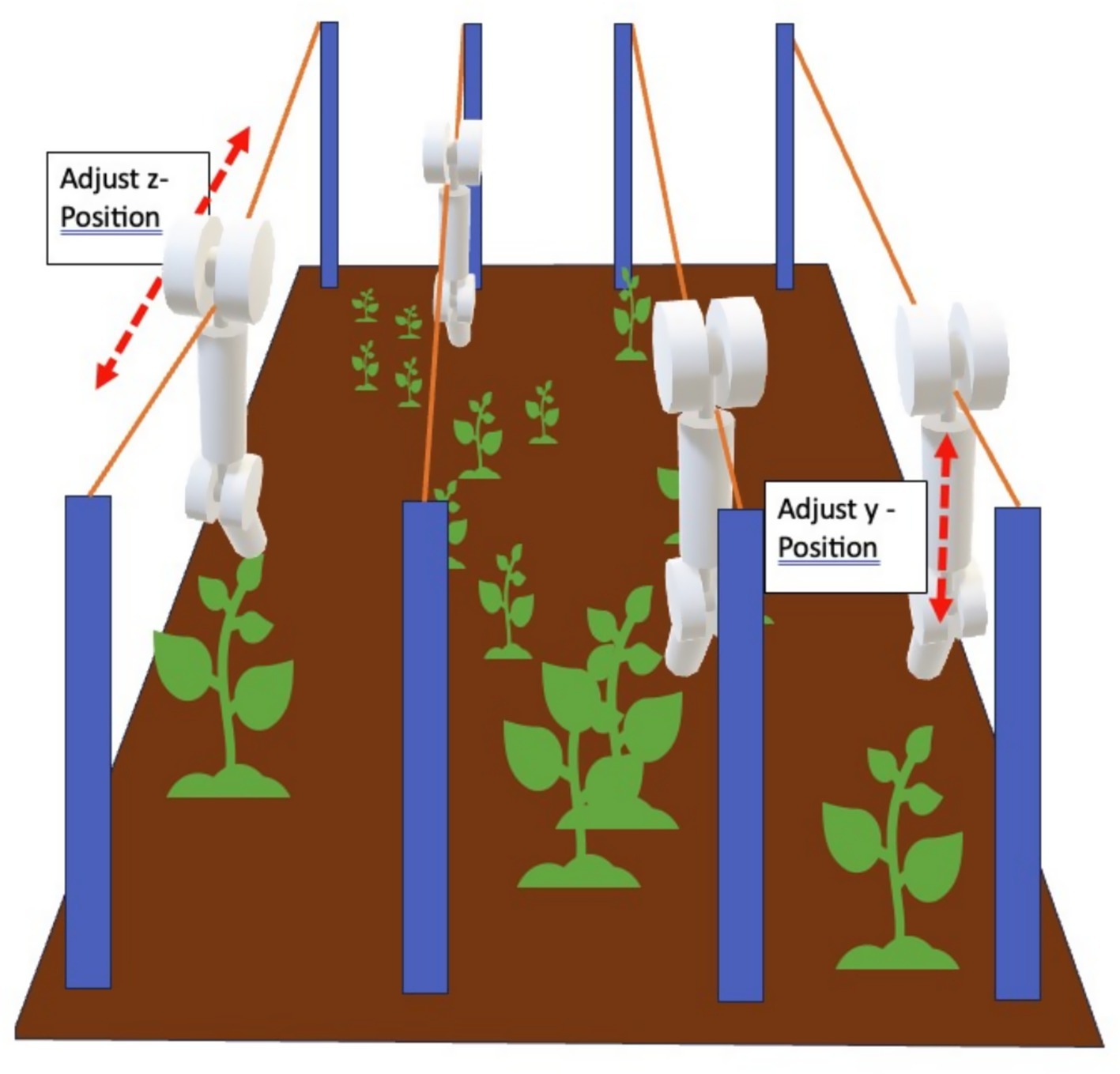

4.1 Gantry and Cartesian robots

Gantry robots are an established technology in commercial hydroponic vertical farming for automating large-scale processes, such as moving plant trays and positioning irrigation systems. A gantry, as depicted in Figure 1 typically consists of a mobile platform and crane system that traverses a space below using parallel tracks, allowing it precise robotic functionality, akin to technologies like 3D printers or Computer Numerical Control (CNC) machining (Jamaludin et al., 2015; Bp, 2019). Gantries are also used in everyday settings, including some types of vending machines which operate on a vertically-orientated gantry that can pick bottles of water and drop them into a dispenser. The relatively small size of a gantry robot head (for example on a 3D printer) might place it into the “miniature” category, despite their reliance on rails to move (Jamaludin et al., 2015).

4.1.1 Horizontal gantry robots

Commercial urban vertical farms optimize space through gantry-mounted sensors and effectors (Duckett et al., 2018), while enhancing efficiency and scalability through automation technologies like IoT and advanced lighting systems (Dennison et al., 2025). Gantries are used for plant handling and manipulator positioning in hydroponic setups with some gantry systems designed to operate overhead of the horizontally-aligned hydroponic plants (Luna-Maldonado et al., 2019). FarmBot, a commercially-available open-source gantry system for domestic, educational and research use, is a Cartesian gantry robot capable of managing plant life cycles from seeding to pre-harvest for soil-based growing (Mahajan et al., 2019). The manipulator, mounted on the gantry moves horizontally and vertically, interacting with soil and foliage and is able to switch tools for tasks like seeding or weeding. A similar experimental open source gantry system (Bhogavalli and Tech, 2021) with which the researcher aims to address food quality issues in India, is designed for outdoor raised beds and powered by solar energy for automating seeding and irrigation. A large scale working greenhouse gantry system (Palli et al., 2019) utilizes mainly commercial-off-the-shelf (COTS) components, enabling advanced features such as imaging, plant mapping and precision application of fertilizer. The system incorporates Internet-of-Things (IoT) functionality, enhanced with cloud-based machine learning algorithms for autonomous monitoring and reporting of greenhouse conditions, enabling targeted plant-level intervention.

The potential of different styles of Cartesian and gantry systems for traditional protected horticulture has been explored (Belforte et al., 2006), identifying that gantries can allow for precise plant positioning without complex kinematics. An experimental, Open Source system (Takara et al., 2021), uses a single gantry to move two separate manipulators both above and below plants to monitor and weigh soil-grown vertically-farmed plants.

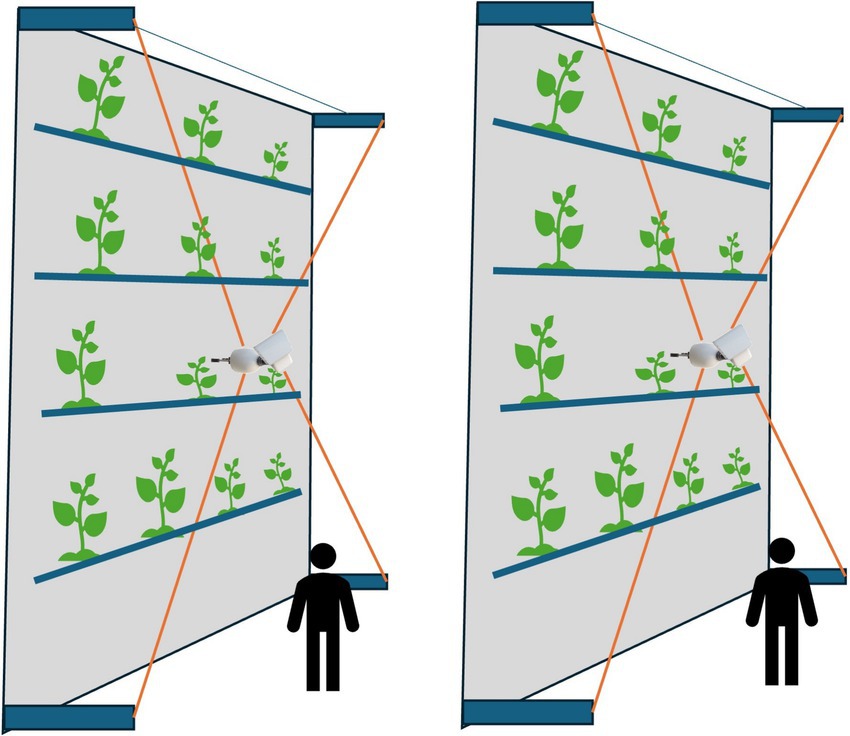

4.1.2 Vertical gantry robots

Vertical hydroponics requires a corresponding vertically-mounted gantry to provide access to plants. Hospital pharmacies (Ghadeer Faisal, 2023) have started to installed vertical gantry robots that use a gripper mounted on the gantry to load or pick medicines requested by the pharmacists. This format, of a gantry-mounted manipulator approaching plants from the side, may offer an advantage for vertical growing. through reducing the risk of damage to the plant canopy. Industrial storage picking systems utilize gantry robots on a larger scale, for pick and placement of warehouse goods (He et al., 2024).

4.1.3 Upwards-facing gantry

A kiwi fruit harvesting robot (Au et al., 2020) mounted on an outdoor Unmanned Ground Vehicle (UGV) platform—thus employing dual localization methods—uses an upward-facing Cartesian manipulator that is able to identify, then harvest kiwis from a densely populated canopy.

4.1.4 Platform gantry

The Modular Automated Crop Array Online System (MACARONS), describes an open hardware gantry platform for automating soil-based plant transport and monitoring within a vertical horticulture systems (Wichitwechkarn and Fox, 2023). Adapting this open hardware system for hydroponics offers a departure from considering the plants as static entities within the growing system, instead moving them to the robot or sensors, akin to large scale vertical farms.

4.1.5 Summary

This review finds horizontal gantry systems to be more frequently reported in the literature, likely reflecting their use in traditional horizontal, soil-based agriculture. However, their spatial inefficiency makes them ill-suited to dense urban contexts. In contrast, vertical gantry systems offer potential advantages for urban hydroponics, including side-access to plants and the possibility of using rigid hydroponic racks as dual-purpose gantry rails, reducing infrastructure requirements. Yet, vertical systems face scalability constraints: expanding growing racks typically demands additional rail extensions, and plant mobility on platforms may conflict with efficient hydroponic water circulation, especially where gravity-fed systems are used.

Commercial vertical farms demonstrate that gantry robots can achieve high precision, localization and reliability, attributes that could be valuable in small-scale urban agriculture. While the complexity and cost of these systems often hinder scaling-down, Open Source implementations such as Farmbot suggest a more accessible path, particularly if redesigned for vertical hydroponic setups. Such robots could automate core hydroponic tasks like planting, monitoring and harvesting within compact footprints. However, these existing examples are limited by scalability being restricted to fixed areas of operation. Nevertheless, their modularity, low power demands and clear alignment with Open Source development make them promising candidates for adaptable, space-efficient urban hydroponic robotics.

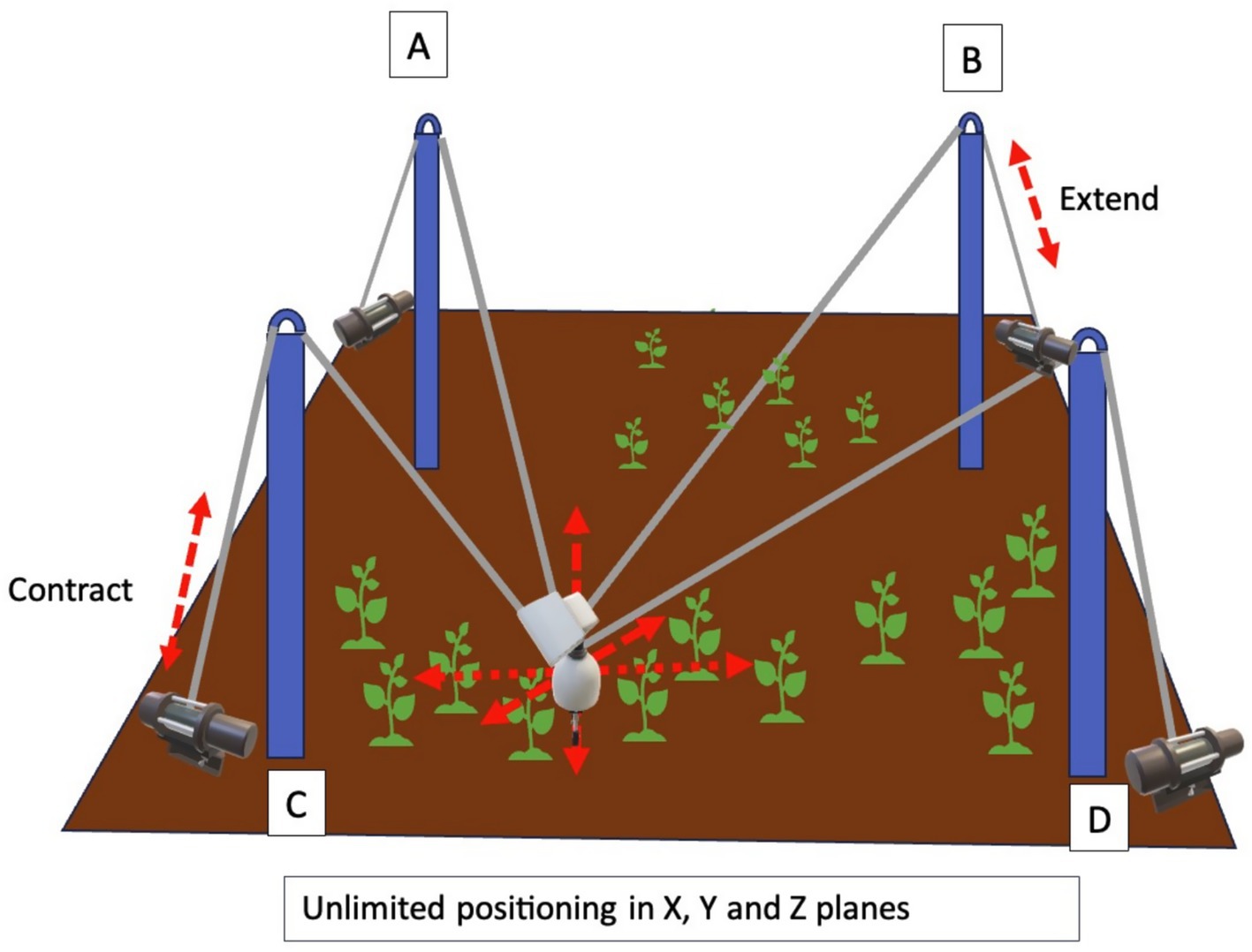

4.2 Cable-traversing robots

Robots that move on wires, as depicted in Figure 2 may offer a cost-efficient alternative to the rigid construction of gantry systems, offering some stability and guided movement along taut cables for accessing plants for surveillance (Thomopoulos et al., 2021) or manipulation. While traditionally limited to one-dimensional movement per cable, requiring multiple cables for expanded coverage, some methods of cable traversing overcome this limitation (Figure 2).

4.2.1 Wheel-driven cable propulsion

Cable-traversing is particularly suited to plants being grown horizontally since it is generally easier for a robot to hang from a horizontal cable than to climb vertical. Early wheeled cable-traversing robot designs were motivated by a need to safely inspect and repair high-voltage power cables (Sawada et al., 1991; Toussaint et al., 2009). Despite limitations of the technology at the time, the robots were able to move autonomously at 100 mm/s on wheels engaged with the wires, and by using arms and bridges to pull themselves across obstacles such as brackets (Pouliot and Montambault, 2008). One usual limitation of line-traversing with wheels is that each robot must be tethered to a single wire and transferring between wires through decoupling and recoupling, is generally a slow and risky process. Wire-traversing generally limits the function of a robot to whatever it can reach or view from its position on the wire. Through algorithmic coverage control (Notomista and Egerstedt, 2018), this limitation has been diminished algorithmically through projecting two-dimensional motion onto one-dimensional wires, creating a Continuous Onto Wires (COW) map for optimizing monitoring and spraying. SlothBot, a solar-powered cable robot, conserves energy through slow movement, making it ideal for plant care tasks like harvesting in low-speed environments. Its two-body structure with an actuated decoupling mechanism allows it to switch wires, enabling network traversal rather than single-track operation (Notomista et al., 2019).

4.2.2 Brachiation

Brachiation, describes locomotion generated by alternating reaching and grasping motions, as observed in primates navigating forest branches and vines (Reda et al., 2022), and requiring rapid decoupling and recoupling combined with pendulous dynamics to facilitate movement across unpredictable overhead botanical structures. Brachiation can be used to move horizontally—both along and between adjacent wires, or vertically—as on a wall (Rosa et al., 2012). Robotic brachiation, within two-dimensional spaces (Davies et al., 2018), when applied to a cable grid instead of single cables, can achieve similar functionality to that of a tethered robot gantry system, but where the brachiating robot is free to roam. Brachiation robots have been developed for traversing ledges (Lin and Tian, 2022), which could inspire a cable-free means for navigating by grasping hydroponic tubing directly, rather than utilizing separate cables. Brachiation also provides robots enhanced 2D maneuverability where they are able to reliably switch between “rope” and “ladder” modes (Davies et al., 2018). An artifact of brachiation is the unpredictable movements generated on flexible wires compared to smooth wheeled motion. A two-link under-actuated robot uses dynamic modeling to safely execute grasping manoeuvrers by predicting the likely cable motion generated by its own brachiation (Farzan et al., 2018, 2019).

4.2.3 Cable crawling

Pneumatic artificial muscles provide a novel approach to cable-based locomotion, that could offer a high power-to-weight ratio suiting heavier payloads like water or harvested plants. Despite operating at a slow pace, their efficiency could align with horticultural tasks that do not demand real-time performance (Mendoza et al., 2023).

4.2.4 Cable climbing

Repair robots designed for vertical steel support cables on suspension bridges demonstrate an alternative traction and locomotion method (Xu et al., 2021; Cho et al., 2013), involving the robot encircling the support cable to apply inward pressure to generate the necessary traction for vertical or semi-vertical locomotion. A similar technique is employed by climbing robots used for servicing street lamps, which grip the post entirely (Noohi et al., 2010) and require a fully unobstructed 360-degree path for movement. However, in hydroponic systems, plants extend outward from the pipes, thus occupying part of the circumference. A hydroponic robot using this method would need to be modified to generate sufficient traction without completely surrounding the pipe, to leave space for the plants.

4.2.5 Robots on rails

An approach currently used in some hydroponic greenhouses utilizes robots located on rails located between rows of plants. This represents a locomotion approach, as observed in tomato monitoring (Seo et al., 2021) and greenhouse spraying (Moreno et al., 2024) that crosses between a gantry and line traversing since although movement is restricted to one dimension, the robot itself, rather than the gantry it is fixed to, is able to move vertically to some degree to reach different parts of the plants.

4.2.6 Summary

Cable-traversing robots, ranging from wheel-driven and brachiation-inspired mechanisms, to cable crawling and pipe-climbing formats, present an effective propulsion method suited to the linear, structured layouts typical of miniaturized urban hydroponic systems. These platforms could navigate along preinstalled cables or pipes, requiring a one-time infrastructure investment that supports long-term growing setups. While this introduces upfront cost, it also removes complex localization requirements: movement is confined to predefined linear paths, reducing navigational demands and computational overhead.

Despite their promise, such systems are constrained by their mechanical dependencies, including the need for stable, fixed cables to ensure precision. Flexible wires, while inexpensive, lack the rigidity for accurate plant interaction, especially in outdoor environments where wind or physical contact can destabilize movement. The risk of full detachment during reattachment-based traversal strategies seen in some examples, poses further reliability and safety concerns in densely built environments. Thicker cable or pipe formats, as used in bridge inspection robotics, offer greater stability but would require adapted gripping mechanisms to avoid clashing with plants growing along those surfaces.

Modern algorithmic coverage enhancements and cable-switching techniques do allow for 2D scalability, making cable-based robots potentially viable for urban horticulture in constrained spaces. Their small form factor also makes them ideal candidates for 3D printing and integration of low-power, Open Source components. This aligns closely with the goals of sustainable, inclusive design and cost-efficiency. Compared to ground-based motion systems or gantries, these robots trade off stability for simplicity and scalability, yet may serve as an effective platform in contexts where gantry infrastructure is impractical or cost-prohibitive or where tasks are limited to monitoring or spraying.

4.3 Pipe inspection robots

Pipe inspection robots represent an active area of interest for industry and critical safety systems, such as nuclear power plants (He et al., 2024). The potential role of pipe inspection robots in hydroponics for maintaining system uptime could be of high importance, since hydroponic pipes are prone to biofilm build-up Lee et al. (2015) which either require chemical or manual elimination. A useful role of urban hydroponic robots, in addition to supporting the cultivation of crops, would be to maintain the health of the growing infrastructure. A secondary role may be plant root inspection, since plants share the same nutrient solution, enabling disease to spread, so early detection is likely to be beneficial. It may be easier for a robot traveling within the tubes to undertake a cleaning or monitoring task compared to an externally-positioned robot.

4.3.1 Miniaturized in-tube robots

Miniaturization of robotic technologies to the millimeter-scale as reported in minimally invasive medical treatments (Li et al., 2022), may hold possibilities for internal pipe inspection or cleaning for hydroponic systems. Miniature and millimeter-scale, robots incorporating smart materials could enhance motility, particularly on uneven terrains (Ng et al., 2021). Miniature monitoring platforms (Ruiz-Larrea et al., 2016), work well in narrow spaces and undergrowth, which may translate to root spaces within pipes. Soft robotics research (Chi et al., 2024), may provide potential solutions for pollination, pruning, pest detection and environmental monitoring through the harnessing of smart materials, such as stimuli-responsive and bio-hybrid designs, using AI-driven control systems to help generate sufficient precision and responsive performance. A review of pipe inspection robots (John and Mubarak, 2022) found that three out of four reported wheel module configurations positioned wheels across three or more locations around the pipe’s internal circumference to achieve suitable traction. An alternative design, a miniature pipe exploration robot designed for sewer pipes (Nguyen et al., 2022) travels along the bottom of the pipe, which could enable the robot to avoid plant baskets and roots. Miniature robots designed for internal pipe inspection using peristaltic motion (McDaniel and Aravelli, 2022) show promise for fully-automated hydroponic set-ups in smart urban horticulture; the robot, although not specified as waterproof in the research, could provide regular cleaning to maintain a healthy environment. Earthworm-inspired research (Kernbaum et al., 2012) that was able to generate peristaltic robot movement with a braided mesh exterior could offer a method of locomotion through constrained spaces within hydroponic pipes, potentially avoiding the protruding baskets and roots. Bio-inspired snake-like motion is discussed separately, however, an amphibious snake design (Yu et al., 2009) may provide easy access to the long, narrow root spaces of hydroponic tubes, lessening the challenge of obstructions caused by baskets and roots.

4.3.2 Summary

Pipe-inspection robots are uniquely suited to operate within the enclosed, linear confines of hydroponic growing tubes, where their primary functions could include biofilm monitoring, internal root inspection and cleaning—all critical (currently manual) roles within hydroponics. Their in-pipe configuration would enable reliable traction and localization through contact with the pipe’s internal surface, reducing the need for complex navigation algorithms. This single-axis mode of traversal simplifies motion control but inherently limits their operational scope to maintenance tasks within the pipe interior—possible requiring one robot per tube.

While traveling inside the tubes offers protection from falling, or external disturbances such as wind, their functionality is constrained by the physical structure of hydroponic systems, particularly the presence of baskets and protruding root masses, which could obstruct movement and significantly limit the size of viable robot designs. In large installations, retrieving a robot that has experienced a mechanical failure could prove challenging. Nevertheless, their ability to manage root overgrowth, especially in preventing clogs that impede water flow, positions them as valuable allies for improving system resilience and uptime.

These robots are best seen as specialist tools rather than comprehensive horticultural solutions. Their configuration excludes them from roles such as planting, canopy monitoring or harvest operations, but their potential simplicity—which may require only simple rule-based operation, slow-paced energy efficiency and maintenance focus make them well-aligned with urban hydroponics systems that prioritize internal hygiene and sustainability. As with other low-power, compact robotic platforms, they are amenable to Open Source adaptation and modular production, potentially offering an accessible and reliable maintenance companion within the broader automation ecosystem.

4.4 Cable driven parallel robots

Cable-driven parallel robots (CDPR) feature a robot head Figure 3 designed to hold an end-effector such as a camera or gripper, and maneuvered via three or more cables (usually four) anchored to winding mechanisms situated outside of the robot’s zone of operation. The end-effector’s movement and positioning depends on synchronized pulling or releasing by the attached wrenches, combining forces and moments across the cables, functioning similarly to joint control in traditional robotic manipulators (Bosscher and Ebert-Uphoff, 2004). Cable-driven parallel robot manipulators, due to their small scale, offer the advantages of limiting shade and ventilation that can be caused by larger standard greenhouse robots (Newman et al., 2018).

4.4.1 Horizontally orientated CDPR

For normal operation, cable-driven parallel robots (CDPR) rely on tension for movement control, which limits the amount of downward exertion to the weight, under gravity, of the end-effector (Qian et al., 2018). Soil-based operations that require downward force are therefore limited by the mass of the robot head/end effector, rendering them suitable mainly for monitoring, spraying or lifting operations. Spidercam (Bai et al., 2019), a cable-driven phenotyping system, uses integrated sensors for detailed plant measurements over a 0.4 ha field. While its 27 metre poles exceed typical greenhouse heights, its reliable outdoor performance with drip irrigation demonstrates impressive performance (García-Vanegas et al., 2023) as a compact parallel cable robot capable of reaching the edges of the growing area while maintaining a stable end-effector; it achieves this using two cables attached to the upper and lower corners of the end-effector, alongside independently adjustable winches, to ensures uniform positioning. If applied to vertical systems, this design could enable precise access to all plants within an optimized growing space. A hybrid cable based robot (Chen et al., 2022), equipped with a manipulator and camera, enables non-destructive plant mass estimation in vertical hydroponic farms. This system combining the scalability of a cable-driven parallel robot (CDPR) with the dexterity of a multi-degree-of-freedom robotic arm to capture plant images from various angles (Figures 3, 4).

4.4.2 Vertically-orientated

When operated in the vertical plane, as depicted in Figure 4, cable-driven parallel robot systems may offer a cost effective solution for vertical hydroponic growing, since by the use of only four cables—in contrast with multiple cables associated with cable traversing robots, or a more complex rigid gantry, the robot head is able to reach any coordinate within a potentially large two-dimensional vertical growing area, for example, the side of a building. A vertical configuration also allows the robot to approach plants from the side, reducing the risk of collision with plant foliage and allowing monitoring of the visible plant. To reach and manipulate plants is more challenging than for horizontal systems, since gravity cannot be utilised to move the head towards the plants, as with a horizontal configuration, although dynamically adjusting the length of each corner pole that support the cables, as in Agrocablebot, could provide this third-dimension control. A CDPR for cleaning the walls of high-rise buildings presents a potential example for vertical hydroponic growing on buildings. The research (Shao et al., 2021) also establishes working force parameters—including suggested height to width ratios of areas it can operate within and cable tensions—offering insights into the application of miniature robots operating at height in built-up areas. A hybrid cable-based robot, combining a cable-driven parallel robot with a 4 degree-of-freedom arm (Chen et al., 2022) reports high-accuracy and medium-throughput plant monitoring in vertical hydroponics.

4.4.3 Summary

Cable-driven parallel robots (CDPRs) offer a precise method of end-effector positioning by adjusting the tension and length of cables anchored around a workspace, and have seen success in horizontal configurations for two-dimensional horticultural operations such as monitoring and watering. When scaled down and and developed under an Open Source methodology, such platforms could offer accurate, low-power automation within urban hydroponic systems. However, as they rely on long, variably tensioned cables to control motion in three dimensions, their capacity to exert meaningful force for tasks such as seedling placement or harvesting remains unclear.

When reoriented vertically, CDPRs present an intriguing proposition for servicing inaccessible growing spaces such as walls or facades. This side-on approach allows access to plant canopies while reducing the risk of collision. In theory, vertical CDPRs could support a broader horticultural role; planting, monitoring, pest control and harvesting, while maintaining a compact, scalable presence in space-constrained urban environments. Unlike cable-traversing robots, CDPRs typically require only three or four cables to control the end-effector within the entire 2D growing area, simplifying positional computation.

CDPRs however have serious infrastructure demands and mechanical limitations. As noted in phenotype monitoring applications (Newman et al., 2018), end-effector tilting occurs when extended far from a central axis, affecting precision. Moreover, cable anchor points must usually extend beyond the cultivation zone to access crops at the outer edges, creating margins of inaccessibility. Scalability would require winch repositioning and full system recalibration to ensure cable alignment and tension, introducing setup complexity uncommon to simpler robotic platforms. These factors suggest that while vertical CDPRs offer potential advantages in terms of flexibility and access, their real-world utility in urban hydroponics will depend on effective mitigation of structural and calibration constraints.

4.5 Unmanned aerial vehicle/drone

Drones are already widely used in outdoor agriculture to provide cost-effective crop monitoring through aerial imagery (Reinecke and Prinsloo, 2017). Recent advancements in real-time obstacle avoidance, navigation and stabilization technologies have expanded their utility to indoor environments, addressing challenges from limited GPS access and vertical height constraints (Kangunde et al., 2021; Dinelli et al., 2023). Plant-inspired millimeter-scale robots, such as wind-dispersed drones, enable precision tasks such as pollen delivery, offering potential solutions for insect-free flowering crop cultivation (Yang et al., 2023).

Insect-sized flapping-wing drones equipped with solar cells and piezoelectric actuators permit continuous plant health monitoring, although their suitability for outdoor settings—including strong air currents remains uncertain (Jafferis et al., 2019; Kondoyanni et al., 2022; Tu et al., 2020). Quadrotors or miniature Unmanned Aerial Vehicles (UAVs) specifically developed for horticulture, provide practical payload capacity and capabilities for measuring environmental parameters like temperature, humidity, luminosity and carbon dioxide concentration for supporting climate control, crop monitoring, and failure detection (Roldan et al., 2015). However, these technologies are costly and flight is energy intensive, hence battery longevity may be a key consideration for their use in urban horticulture.

4.5.1 Summary

Unmanned Aerial Vehicles (UAVs) may offer benefits for urban horticulture by their rapid, 360-degree movement for crop monitoring and environmental sensing tasks. Their ability to capture high-resolution aerial imagery and measure critical parameters, such as temperature, humidity, luminosity, infestation, plant diseases as well as environmental factors, makes them effective for monitoring plant health and supporting climate control in both indoor and outdoor settings. The incorporation of advanced real-time obstacle avoidance and stabilization technologies extends their utility to confined urban environments, where GPS limitations and vertical constraints often challenge traditional monitoring systems. However, UAVs also face some limitations with regard to the range of horticultural tasks required in urban hydroponics. Their energy-intensive flight operations and limited battery longevity restrict sustained performance. While open-source developments are emerging, capable UAVs tend to be costly and of limited practical use for small-scale urban growers compared to gantry or cable-driven robot. Despite their precision in monitoring, UAVs are less capable at performing direct physical interactions, such as planting, harvesting or detailed manipulation tasks, making them best suited as a complementary tool for aerial surveillance rather than a stand-alone solution for full-spectrum urban hydroponic automation.

4.6 Unmanned ground vehicles

Unmanned Ground Vehicles (UGVs) and Automated Guided Vehicles (AGVs), are well-established robotic formats (Gonzalez-De-Santos et al., 2020), contributing significantly to advancements across sectors, including agriculture, automotive, military and domestic robotics. A common characteristic is movement along the ground, often using wheels—a feature perhaps less relevant to hydroponic robots that access plants grown in tubes. Unmanned Ground Vehicles robots though also incorporate technologies for localization, vision and manipulation, functions that are generally useful within the agricultural sector. While soil-based and soil-less cultivation have clear differences, UGV innovations offer transformative potential for hydroponic systems through observable technology transfer in the farming sector (Esposti, 2002), where features, for example navigation, path planning, power management and precision monitoring are common to both formats.

Several research examples illustrate UGV capabilities, other than locomotion, likely to be shared with hydroponic robots. The Roomba vacuum cleaner (Coggins, 2022) and open source examples (Asafa et al., 2018; Rashid et al., 2016) employ moderately effective levels of AI for room navigation, with efficient power management (Sahin and Guvenc, 2007). An open source miniature seeding robot employs a modular high-end Global Navigation Satellite System (GNSS) and also accommodates a lower-cost GNSS system to record the geo-spatial position of seeds—which could be adapted to identify hydroponic plant placement, enabling precise revisits (Rogers and Fox, 2020). Wildlife monitoring robots utilize open source microprocessors for constant surveillance and live activity streaming via Wi-Fi modules (Krishnan et al., 2022), monitoring functions transferable to swarm hydroponic robotics. The Robotnik Summit XL collects greenhouse data autonomously using infrared temperature and soil moisture sensors to optimize crop care (Ruiz-Larrea et al., 2016). Agrobot Lala, performs soil analysis and advanced navigation for weed management (Kitic et al., 2022; Slaughter et al., 2008), both functions mappable to hydroponic growing.

Unmanned Ground Vehicles (UGVs) have been developed for a wide range of ground based activities, and therefore embody a great deal of understanding around current robotic technology. Many examples offer well-established capabilities, such as precise localization in two and three dimensional space, vision, path planning and power management, making them accessible and cost-effective for many existing commercial agricultural applications. Although UGVs are in themselves inherently less suited to vertical urban hydroponic systems, some of the component technologies they host are transferable to horizontal hydroponic growing environments, such as localization, power management, path planning and vision. It is also worth considering that some commercial and consumer hydroponic systems are horizontally-orientated, so certain formats of ground-based vehicle (included legged locomotion motion) may offer solutions in such set ups.

5 Discussion

In the search for sustainable solutions to food insecurity, amid accelerating climate change and urbanization, hydroponics is emerging as a promising format for urban food production, due to its high productivity and efficient use of space and resources. Wider adoption of hydroponics by small-scale and domestic growers, to augment or replace grocery bought food, would depend on how financially and technically accessible the method of growing is. Whereas automation is proven to be effective—if not essential in commercial vertical farming, it does not down-scale economically and would not eliminate system complexity, which would likely be a barrier. Mobile robotic automation presents a preferable, affordable and scalable alternative, with lightweight, easily configurable mobile robot platforms suiting the layout of vertically structured hydroponic setups, by capitalizing on the structured placement of plants, removing several challenges facing soil-based robots; including navigation and plant identification.

Miniature robotics, usually less than 50 cm in size, represent an optimal scale for urban hydroponic management since they can incorporate low-cost, off-the-shelf parts and 3D printable bodies. Compared to large, or millimeter-scale robots, miniature robots are more easily produced. Lightweight designs and low power requirements of miniature robots, not only promote safe operation in densely populated urban areas, including on building facades or rooftops, but matches them well to the spatial confines of vertical farming. Larger—usually heavier—robots pose both safety risks and impracticalities within constrained spaces typical of urban environments, while millimeter-scale robots, though promising in other contexts, lack the physical work capacity needed for an urban horticulture domain.

The evolution of open source robotics is not proposed as a technical preference, but a strategic one. By decoupling innovation from large commercial investments, the open source model supports a community driven, rapid iteration process that has the capacity to call on local knowledge to create robotic functions to suit specific global needs, for example different climates or crop types. This, in turn, paves the way for a swifter functional evolution of robotic systems, from gantry-mounted and cable-guided formats to pipe-traversing designs that could automate the different stages of the hydroponic growing cycle. Open source hardware is especially well suited to the miniature robotics scale in terms of costs, tools, and construction techniques, including 3D printing.

Mobile, miniature, open source robotic platforms therefore represent a viable avenue for scaling hydroponic systems used in urban settings. They hold the potential to unlock previously inaccessible growing spaces, thus helping democratize sustainable food production for domestic and small-scale growers where space is limited. By integrating these innovations into vertical, soil-less farming, urban horticulture can contribute, in a sustainable and scalable way, to future food security.

Author contributions

AS: Conceptualization, Formal analysis, Investigation, Methodology, Resources, Visualization, Writing – original draft, Writing – review & editing. RH: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – review & editing. CF: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was supported by the EPSRC (grant EP/S023917/1).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Adenauer, L. (2014). Up, up and away! The economics of vertical farming. J. Agric. Stud. 2, 40–60. doi: 10.5296/jas.v2i1.4526

Andersen-Gott, M., Ghinea, G., and Bygstad, B. (2012). Why do commercial companies contribute to open source software? Int. J. Inf. Manag. 32, 106–117. doi: 10.1016/j.ijinfomgt.2011.10.003

Armanda, D. T., Guinee, J. B., and Tukker, A. (2019). The second green revolution: innovative urban´ agriculture’s contribution to food security and sustainability – a review. Glob. Food Secur. 22, 13–24. doi: 10.1016/j.gfs.2019.08.002

Asafa, T. B., Afonja, T. M., Olaniyan, E. A., and Alade, H. O. (2018). Development of a vacuum cleaner robot. Alex. Eng. J. 57, 2911–2920. doi: 10.1016/j.aej.2018.07.005

Au, C., Barnett, J., Lim, S. H., and Duke, M. (2020). Workspace analysis of Cartesian robot system for kiwifruit harvesting. Ind. Robot. 47, 503–510. doi: 10.1108/IR-12-2019-0255

Bai, G., Ge, Y., Scoby, D., Leavitt, B., Stoerger, V., Kirchgessner, N., et al. (2019). Nu-spidercam: a large-scale, cable-driven, integrated sensing and robotic system for advanced phenotyping, remote sensing, and agronomic research. Comput. Electron. Agric. 160, 71–81. doi: 10.1016/j.compag.2019.03.009

Balakrishnan, S., Devi, H., and Kumar, K. (2024). Urban horticulture: a cutting-edge strategy and essential for the future. Int. J. Environ. Clim. Change 14, 227–238. doi: 10.9734/ijecc/2024/v14i34035

Bardan, R. (2025). Temperatures rising: NASA confirms 2024 warmest year on record NASA. Running Time: 69 Section: Goddard Institute for Space Studies.

Beacham, A. M., Laura, V., and Monaghan, J. M. (2019). Vertical farming: a summary of approaches to growing skywards. J. Hortic. Sci. Biotechnol. 94, 277–283. doi: 10.1080/14620316.2019.1574214

Belforte, G., Gay, P., Aimonino, D. R., Belforte, G., Gay, P., and Aimonino, D. R. (2006). “Robotics for improving quality, safety and productivity in intensive agriculture: challenges and opportunities” in IntechOpen industrial robotics: programming, simulation and applications. Torino.

Benos, L., Moysiadis, V., Kateris, D., Tagarakis, A. C., Busato, P., Pearson, S., et al. (2023). Human–robot interaction in agriculture: a systematic review. Sensors 23:6776. doi: 10.3390/s23156776

Bhogavalli, R., and Tech, B. (2021). Automated farming using gantry robot. Int. Res. J. Eng. Technol. 8, 3547–3553.

Bhujel, A., Basak, J. K., Khan, F., Arulmozhi, E., Jaihuni, M., Sihalath, T., et al. (2020). Sensor systems for greenhouse microclimate monitoring and control: a review. J. Biosyst. Eng. 45, 341–361. doi: 10.1007/s42853-020-00075-6

Bosscher, P., and Ebert-Uphoff, I. (2004). “Wrench-based analysis of cable-driven robots” in IEEE International Conference on Robotics and Automation, 2004. Proceedings. ICRA ‘04. 2004, 4950–4955.

Bostanci, K., and Ulger, S. (2022). Comparison of spinach cultivation in floating hydroponic system and soil in glasshouse and open field conditions. Medit. Agric. Sci. 35, 7–14. doi: 10.29136/mediterranean.1061475

Bp, R. (2019). Control of gantry system in production line. J. Emerg. Technol. Innov. Res. 6, 262–267.

Brown, K., Schirmer, J., and Upton, P. (2022). Can regenerative agriculture support successful adaptation to climate change and improved landscape health through building farmer self-efficacy and wellbeing? Curr. Res. Environ. Sustainab. 4:100170. doi: 10.1016/j.crsust.2022.100170