- 1Department of Food Science and Nutrition, Avinashilingam Institute for Home Science and Higher Education for Women, Coimbatore, India

- 2Department of Chemical Science, Faculty of Science, UniversitiTunku Abdul Rahman, Kampar, Malaysia

- 3Faculty of Technology, Goce Delcev University Shtip, Skopje, North Macedonia

- 4Faculty of Technology and Technical Sciences, University St. Kliment Ohridski-Bitola, Veles, North Macedonia

- 5Department of Mechanical Engineering, Faculty of Engineering, Taif University, Taif, Saudi Arabia

- 6Department of Food Science and Nutrition, College of Sciences, Taif University, Taif, Saudi Arabia

- 7Department of Food and Nutrition, Faculty of Human Sciences and Design, King Abdulaziz University, Jeddah, Saudi Arabia

- 8Department of Food Science and Nutrition, College of Agriculture and Food Sciences, King Faisal University, Al-Ahsa, Saudi Arabia

- 9Department of Materials Science and Engineering, Korea University, Seoul, Republic of Korea

- 10Department of Biology, Aljumum University College, Umm Al-Qura University, Makkah, Saudi Arabia

The study investigated the potential of tapioca starch (Manihot esculenta) as a raw material for food packaging enhanced with basil leaf oil, citric acid, and carboxymethyl cellulose. The objective of this study was to standardize active edible tapioca films and evaluate their physicochemical, textural, and barrier properties (oxygen and water vapor transmission rates), microbial load, brine shrimp lethality assay (BSLA), and biodegradability. Films were produced using a casting technique with tapioca starch (10 g), dried using a film-making machine, and enhanced with 0.1 g citric acid as a crosslinker, 0.5 g carboxymethyl cellulose as a filler, and 1 ml basil leaf oil as an additive. Tapioca film (30 × 21 cm, 0.25 mm thickness) exhibited 3%−5% moisture, 1%−2% ash, and a pH of 5–6, with tensile strengths ranging from 2.48 to 6.28 MPa and elongation at break between 10.36% and 16.75% oxygen transmission rate was 690.05 to 811.14 cc/m2/day, and water vapor transmission rate was 0.73 to 1.21 cm3/m2/24h/0.1 MPa. The inclusion of citric acid, carboxymethyl cellulose, and basil leaf oil improved the tensile strength and barrier properties, making the films suitable for packaging a variety of food products (cereals, legumes, spices, condiments, extruded products, and sugar candies) for up to 120 days. The microbial load remained below 5.7 × 101 CFU/g, with low toxicity (7% in BSLA), and the films degraded completely in moist topsoil within 24 days. This study highlights the tapioca starch films enhanced with carboxymethyl cellulose, citric acid and basil oilas a sustainable alternative to single-use plastics. It provides an effective packaging solution for non-perishable commodities and sugar candies with improved functional properties and environment sustainability.

1 Introduction

Packaging is essential for preserving food quality and safety, and extending the shelf life of food items in the food industry. In addition to preserving and nourishing packaged food, it fosters interaction with consumers and convenience (Putri et al., 2023). Increased consumer awareness of food safety and quality has driven innovations in food packaging toward the development of smart (intelligent and active) packaging, with edible materials suitable for extending the shelf life of food products (Khandeparkar et al., 2024; Amin et al., 2022). The non-biodegradability of synthetic polymers exhibited difficulty in disposal and ends in landfills that leads to numerous health hazards. The films degrade faster than synthetic or other non-biodegradable materials and eliminate the need for conventional garbage disposal management (Ibrahim et al., 2022; Cruz et al., 2024; Dörnyei et al., 2023; Kumar et al., 2023; Prasad et al., 2024; Khandeparkar et al., 2024). Biopolymers, particularly starch films, have significant advantages owing to their low cost, extensive availability, edibility, and biodegradability (Trajkovska Petkoska et al., 2021a,b).

Tapioca (Manihot esculenta) is a widely grown crop in tropical and subtropical regions. It is the third-largest source of carbohydrates worldwide. Tapioca plays a vital role in food security for over one billion people. It isan ideal source of starch, that can beutilized in standardization of eco-friendly and edible films. Tapioca starch-based films are colorless, odorless, tasteless; andresistant to moisture and oxygen (Ansori et al., 2023; Shah et al., 2024; Martins et al., 2024). The films made fromcarbohydrate rich sources like tubers and cereals are cost-effective, biodegradable, and consumable (Navasingh et al., 2023; Fu et al., 2022; Izzi et al., 2023; Linares-Castañeda et al., 2023; Rahmadhia et al., 2023). Including glycerol as a plasticizer significantly improves the film's flexibility, water and gas barrier properties. It is commonly used in food packaging due to its neutral taste, odorless, and does not affect the color of the end product (Tarique et al., 2021; Navasingh et al., 2023; Rahmadhia et al., 2023). Gabriel et al. (2021) found that starch films with glycerol, exhibited better tensile strength, flexiblility and stretchablility. In contrast, the starch films without glycerol are often brittle and stiff due to the uneven structure of amylose and amylopectin.

Starch properties can be altered by changing the pH and ionic strength. Citric acid, a natural and cost-effective polycarboxylic acid found in fruits, is an effective crosslinking agent. It improves the strength and durability of starch films, which is more suitable for packaging (Chi et al., 2024). Othman et al. (2019) found that adding microcrystalline cellulose (MCC) to starch films significantly enhanced their physical, mechanical, barrier, and thermal properties; enhancing the usage of films in food packaging. Essential oils, which are generally recognized as safe (GRAS) for food use, are also gaining attention for their antioxidant and antibacterial properties, making it ideal for producing biodegradable active films (Song et al., 2025).

The study aimes to standardize tapioca starch edile films by incorporating cross-linkers, filllers and additives such as citric acid, carboxymethyl cellulose, and basil leaf oil. The films were systamatically characterized for its physical, mechanical and barrier properties. Further, thetoxicity, suitability, and biodegradability of the standardized active edible tapioca films were also analyzed. These findings of tapioca starch films show potential for commercial use particularly for packaging non-perishable commodities, candies and confectionary products.

2 Materials

2.1 Procurement of raw materials

Fresh tapioca was procured from the local market in Coimbatore, Tamil Nadu, India, for starch extraction. Basil leaves were collected from nearby farmsin and around Coimbatore.

Glycerol, carboxy methyl cellulose (CMC; with sodium salt), and food-grade citric acid (CA; 95%−97% purity) were sourced from Sigma-Aldrich in Coimbatore for the formulationof edible films. Glycerol was used as the plasticizer, CMC as filler and CA as crosslinker to enhance the functional properties of the tapioca film as active edible film.

2.2 Extraction of starch from tapioca

Tapioca starch was extracted using a wet extraction technique according to the procedure demonstrated by Shao et al. (2023) and Amaraweera et al. (2021). The fresh tapioca was peeled, chopped into pieces and ground in industrial wet blender. Then, washed with 10 times of water to the quantity of pulp, stirred it for 5 min and then, filtered through triple-layered sieve (0.03 mm mesh). Again, the filtrate was allowed to settle down by adding five times of water (to the quantity of filtrate), and the white mass was collected carefully by decanting. The collected starch was dried at 65°C for 5 h in hot air oven (Technico) and the moisture content was below 12%.

2.3 Extraction of essential oil from basil leaves (BO)

Basil leaves were cleaned, shade-dried, and pulverized in a blender. Powdered basil leaves (50 g) were soaked overnight in 250 ml ethanol (99.9% analytical grade ethanol, China Make) in a beaker. Extraction was performed using a Soxhlet apparatus with ethanol as the solvent. The extraction process was conducted at 80°C for 2 h and repeated four times. The extracts were collected and allowed to stand at room temperature to facilitate the evaporation of the residual solvent. The beaker was then weighed to determine the final weight of the extract. The extract was filtered through Whatman No. 1 filter paper, and the filtrate was stored in dark bottles at 4°C for preservation (Romano et al., 2022). The extracted basil oil (BO) is used in tapioca starch films as additive to enhance the properties.

2.4 Standardization of tapioca film

Tapioca-based edible films were standardized using a patented film-making machine (patent no. 480705, Indian Patent, dated 12th December 2023), designed by the Avinashilingam Institute for Home Science and Higher Education for Women, Coimbatore, Tamil Nadu, India. Initially, 10 g of tapioca starchand 2 ml of glycerol, serving as the matrix and plasticizer, respectively, were dissolved in 290 ml of water and heated to 100°C for 10–12 min to form a clear, transparent casting solution. To enhance and optimize the active film composition, various concentrations of citric acid (0.1–1 g), carboxymethyl cellulose (0.1–1 g), and extracted basil oil (1–5 ml) were tried and the best proportion was selected (based on visual appearance, stretchability, thickness, seal-ability and surface smoothness) and evaluated for its sensory attributes, structural integrity, and barrier properties. The standardized formulaton was: 0.1 g of food-grade citric acid as a cross-linker, carboxymethyl cellulose (0.5 g) as a filler, and 1 ml of extracted oil from shade-dried basil leaves as an additive. The film casting solution was then kept undisturbed for 15 min to remove air bubbles, and the solution was casted onto the conveyor belt of the film-making machine, where an adjustable thickness scale ensured the uniform spreading of the solution. The film was passed through three heating coils set at controlled temperatures of 70, 65, and 55°C, moving at a speed of 0.5–1.5 rpm in a closed chamber for 4 h. Then, the dried film was kept undisturbed for 7 min in the end of conveyor belt (out of heating coils), to reach ambient room temperature, allowing for easy peeling (from the conveyor belt) without cracking. Attemptingto peel the film while it was still at 55°C, leads to cracking of film.

The tapioca starch film (TSF) refers to filmsstandardized withtapioca starch and glycerol. Subsequently, to improve the film properties, carboxymethyl cellulose (CMC) was added to TSF resultng in TSF-CMC formulation. Further, the incorporation of citric acid (CA) to TSF-CMC to standardizethe TSF-CMC-CA film. To further enhance the propeerties, basil oil extract (BO) to TSF-CMC-CA was added to form TSF-CMC-CA-BO film.

2.5 Physical and chemical properties of tapioca starch and film

2.5.1 Starch yield

The total yield of starch was calculated as a percentage by measuring the initial weight of the fresh and finely ground tapioca to the dried extracted starch divided by 100 as stated by Lazim et al. (2021).

2.5.2 Moisture and ash content

The moisture content of tapioca starch and standardized films were analyzed using a Shimadzu Moisture Balance (MOC 120). Five gram of tapioca starch or 2 cm × 2 cm tapioca starch film were placed in a aluminum plate of the moisture balance analyzer at 120°C for 2–5 min. It was done in triplicates and the obtained results were noted. Ash contentwas measured using a Laboratory scale Muffle Furnace (P-LAB). Two gram of starch or film were first charred for 30 min and then incinerated at 600°C for 4 h. After incineration, the crucibles were cooled in a dessicator for 50 min before mesuring the ash residue (Lazim et al., 2021).

2.5.3 pH value

The pH of tapioca starch or films were measured using a digital pH meter calibrated with pH 5 and pH 9 standards. The optimum room temperature 28°C and 55% humidity was maintained. Two gram of tapioca starch or film was thoroughly mixed in 100 ml of water to assess its acidity (Lazim et al., 2021).

2.5.4 Thickness of the film

The thickness of the film was measured using a screw gauge with ±0.01 mm sensitivity to ensure consistency and functionality. The measurements were taken at 28°C and the moisture content of the film ranging from 3 to 5%.

2.6. Textural and barrier properties of tapioca films

2.6.1. Textural properties of tapioca film

The tensile strength of the tapioca film was analyzed using a Universal Tensile Tester (Deepak Polyplast, Gujarat, India) according to the ASTM D412-16 standard (ASTM International, 2021). The standardizedtapioca film enhanced with cross-linkers, fillers and additives with the dimension of 50 mm × 25 mm × 0.25 mm was taken to analyze the tensile strength (MPa), break strain (%), elongation at break (%), and ultimate strain and force. The films was stretched until break, and the force applied was measured in triplicates at room temperature (28°C) and 50% relative humidity.

2.6.2. Oxygen transmission rate of tapioca film

Oxygen Transmission Rate of Tapioca Film was measured byASTM D 3985-17 standards (ASTM International, 2017) using an N500 Oxygen Transmission Rate Analyzer (GBPI, Guangzhou, China). It calculates the steady-state rate of oxygen gas transfer through films. The thickness of the film was measured and the test was conducted at 28°C with zero percent huidity. The oxygen pressure was mainted at 1 atm and niitrogen as the carrier gas.

2.6.3. Water vapor transmission rate of tapioca film

A Water Vapor Transmission Rate Permeation Analyzer (C303H Labthink, China) was used to assess the water vapor transmission rate according to the ASTM E96/E96M-16 standard (ASTM International, 2016). The test techniques encompassed the determination of water vapor transmission through the tested samples (the sample thickness was < 0.32 mm).

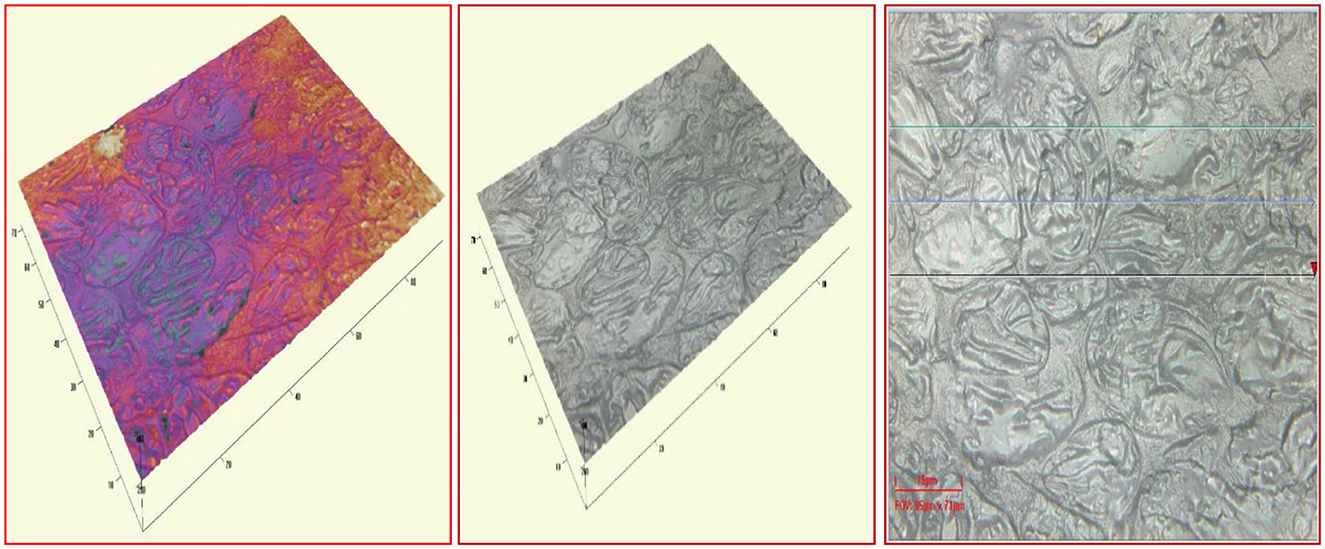

2.7 3D optical profilometer

Smooth, dry starch films were analyzed using a 3D Optical Profilometer at a Z range of 404 μm, 200 steps, and a step size of 2.08 μm. The analysis, conducted at a resolution of 95 μm × 71 μm, revealed the surface patterns and trends critical for film characterization.

2.8 Exposure test of tapioca film

Non-perishable food products were packed in edible films, and weight changes were monitored for 120 days at 5-day intervals and stored at room temperature (28°C). The ingredients selected for the studyincludes non-perishable food items from each category, such as cereals, pulses, spices, condiments, and extruded products. Weight change refers to the moisture and oxygen absorption by the standardized filmsfrom the environment. For the study, 10 g of rice, ragi, bengal gram dhal, salt, sugar, spiral pasta were taken in 10 g and 5 g of ragi flour, chili powder, cumin seeds, tea powder, marshmellows, and candies (sweetened and flavored candies, cumin candies) wereweighed. Then the weighed food items were sealed (a single press) at 80–90°C using a sealing machine (Ekavir home scale sealing machine).

2.9 In vivo brine shrimp lethality analysis (BSLA) of tapioca films

The toxicitywas determined using brine shrimp lethality assay (BSLA) for all the four standardized films (TSF, TSF-CMC, TSF-CMC-CA, and TSF-CMC-CA-BO). For each film, a stock solution was prepared by weighing 1 mg of the film that was dissolved in 1 ml of distilled water. Stock solutions were prepared at a concentrations of 100, 250, 500, 1,000, and 1,500 μl by adding saline solution. Thirty shrimps were introduced in 25 ml of saline solution and the mortality rate was observed at 2, 4, 6, and 24 h. Potassium dichromate (K2Cr2O7) (1 mg/ml) was used as a positive control, and a brine solution without sample was used as the blank. The mortality rate of brine shrimp was estimated using the number of dead shrimp during a set period.

2.10 Total microbial load analysis of tapioca films

The colony-forming units for standardized films were measured using IS 5402 procedures on days 1, 30, 60, 90, and 120 as shelf-life indicators for standardized edible tapioca films (IS 5402, 2012; Makawi et al., 2019) by dissolving one gram of the sample in 9 ml of sterile peptone water (0.1%). Serial dilutions from 101 to 109 in duplicate were made using homogenate water with 0.1% peptone and poured into plate count agar. The dilutions were incubated at 35°C for 48 h, and the colonies were counted.

2.11 Biodegradability of tapioca films

A soil burial test was employed to assess the biodegradability of the films (Ferreira-Filipe et al., 2022). Square-shaped standardized tapioca films, 5 cm in size, weighing 2 g (approx.) were buried in a beaker which contains 100 g of soil which was wetted with 20 ml of waterand stored at room temperature (28°C with 55% humidity) for 24 days to check their biodegradability. Weight changes were recorded every 3 days until the samples were completely degraded. The weight loss percentage was computed by dividing the change in the initial and final weights (g) by the initial weight, multiplied by 100.

2.12 Statistical analysis

All experiments were performed in triplicate, and the results were expressed as the mean value (standard deviation). One-way Analysis of Variance (ANOVA) and Duncan's Multiple-Range Test (p ≤ 0.05) were performed using the Statistical Package for Social Sciences (SPSS) software version 25. Graph was plotted using Microsoft Office Excel, version 2021.

3 Results and discussions

3.1 Physical and chemical properties of tapioca starch and film

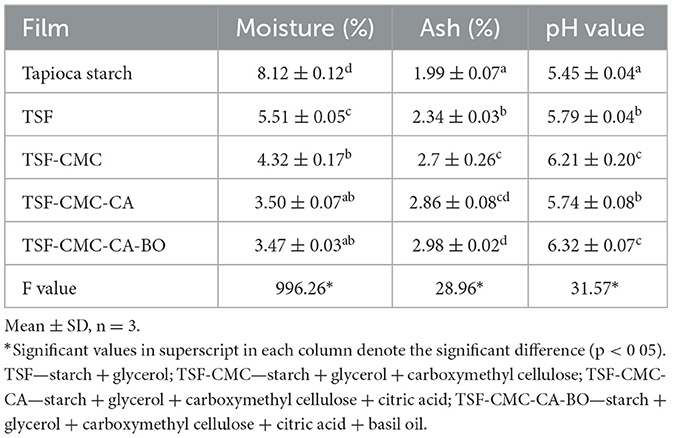

One hundred gram of fresh tapioca resulted in the extraction of 62 g of starch through a decanting technique, leading to a total starch yield of 62%. The physical and chemical properties of tapioca starch andactive films, highlighting asignificant difference (p < 0.05) in moisture, ash content, and pH values are shown in Table 1. Tapioca starch exhibited the highest moisture content (8.12%), the lowest ash content (1.99%), and a mildly acidic pH of 5.45. The edible tapioca film, measuring, 30 cm × 21 cm × 0.25 mm (length × breadth × thickness) was standardized and optimized from the standardized proportions. The tapioca starch film (TSF) showed a reduced moisture content of 5.51%, an increased ash content of 2.34%, and a slight increase in pH to 5.79 compared to the raw starch. Incorporating carboxymethyl cellulose (CMC) further decreased the moisture content to 4.32%, increased the ash content to 2.7%, and brought the pH closer to neutrality at 6.21. The addition of citric acid (TSF-CMC-CA) lowered moisture to 3.50%, raised ash to 2.86%, and resulted in a pH of 5.74. The combination of basil oil, citric acid, and CMC in the starch film (TSF-CMC-CA-BO) achieved the lowest moisture content (3.47%), the highest ash content (2.98%), and the most neutral pH of 6.32. Increasing the concentration of cross-linker, filler and additive resulted in a poor physical properties and deformed films. Supporting these findings, Ratnaduhita et al. (2021) reported that tapioca starch contains 9.32% moisture and 0.09% ash content. In contrast, Kaur et al. (2023) found that starch extracted from Curcuma angustifolia rhizomes had moisture and ash contents of 5.9 and 0.5%, respectively. Furthermore, Pérez-Vergara et al. (2020) indicated that the moisture content of native cassava starch used in beeswax and plasticizer-based films ranged between 8.60 and 20%, with corresponding ash percentages.

3.2. Textural and barrier properties of tapioca films

3.2.1. Textural properties of tapioca film

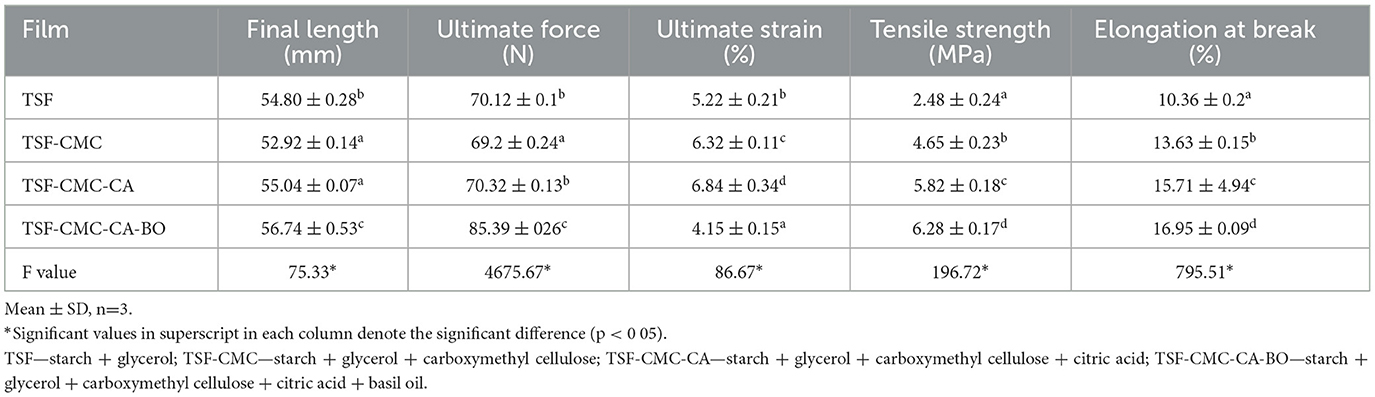

Textural properties of the four standardized films were analyzed in triplicates, revealing significant differences among the formulations (p < 0.05) as shown in Table 2. The TSF film (starch + glycerol), exhibited the lowest tensile strength (2.48 MPa) and a breaking elongation of 10.36%, with an ultimate strain of 5.22%. Incorporation ofcarboxymethyl cellulose (CMC) as a filler in TSF-CMC film, exhibited an improvedtensile strength (4.65 MPa) and elongation to 13.63%, with a greater ultimate strain, 6.32% as compared with TSF. Further enhancement was observed by adding both the fillers and crosslinkers (CMC and citric acid) in TSF-CMC-CA film, which increased the tensile strength to 5.82 MPa and elongation to 15.71%, with an ultimate strain of 6.84%. The TSF-CMC-CA-BO filmincorporated with basil leaf oil as an additive along with a filler and crosslinker, showed the highest tensile strength at 6.28 MPa, an elongation at a break of 16.95%, and an ultimate force of 85.39 N. However, its ultimate strain of 4.15% was slightly lower than the other formulations. TSF-CMC-CA-BO was the strongest and most flexible, making it ideal for advanced food packaging applications. The tensile properties of the standardized films arewell-suited for sachet packaging. Functional enhancements in the standardized filmshave higher tensile strength and better elongation, expanding its potential uses.

The study results support the findings from Ratnaduhita et al. (2021) also observed tensile strengths ranging from 2.14 to 3.00 N/mm2 in tapioca starch films that contained glycerol and carrageenan. In contrast with the findings of, Pak et al. (2020), found that a tapioca film with 3.5% Persian gum and 35% glycerol reached a tensile strength of 40.3 MPa and an elongation at break of 59.95%. Crosslinked starch films became stronger, but their elongation decreased with higher citric acid concentrations as the crosslinking process formed larger molecular structures (Chi et al., 2024). Additionally, Rahmadhia et al. (2023) discovered that tapioca starch films enhanced with anthocyanin extract showed improved tensile strength and elongation at break.

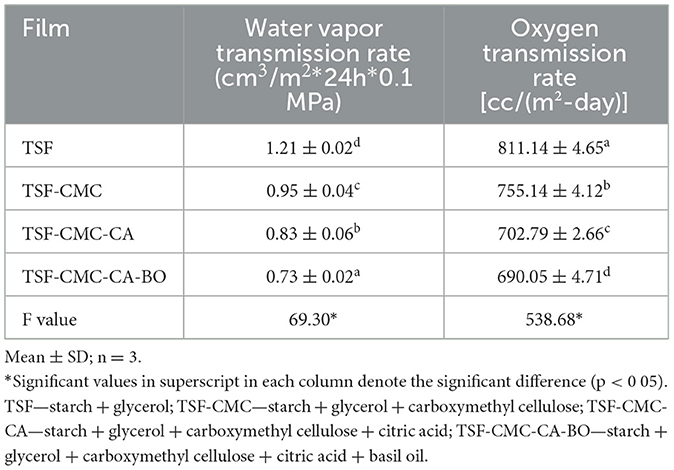

3.2.2. Water vaporand oxygentransmission rate of tapioca film

The Water Vapor Transmission Rate (WVTR) and the Oxygen Transmission Rate (OTR) of active tapioca starch films are significantly influenced by the incorporation of fillers, cross-linkers, and additivesas given in Table 3. The starch-glycerol film (TSF) had the highest WVTR (1.21 ± 0.02 cm3/m2·24 h·0.1 MPa) and OTR (811.14 ± 3.02 cc/m2·day), indicating a weaker barrier property. The film withcarboxymethyl cellulose, TSF-CMC, both WVTR and OTR showed improved barrier properties as compared to TSF. Further addition of citric acid in the TSF-CMC-CA film, showed better barrier properties. The TSF-CMC-CA-BO included with basil oil, showed the lowest WVTR (0.73 ± 0.02 cm3/m2·24 h·0.1 MPa) and OTR (690.05 ± 4.71 cc/m2·day), indicating excellent moisture and oxygen barrier performance.

Previous studies found that, oxygen permeability is an important in food packaging as too much oxygen can cause oxidative reactions, lipid rancidity, and browning. It reduces the product quality and shelf life (Amaraweera et al., 2021). The OTR values of the tapioca films in this study are similar to those of pea protein-enhanced tapioca starch films, which had oxygen permeability values between 0.12 and 0.27 cc/m2/day·kPa (Huntrakul et al., 2020). The developed films are suitable for packaging foods moderately sensitive to oxygen, like whole grains, extruded snacks, spices, dried fruits, vegetables, nuts, seeds, and baked goods. Previous studies reported WVP values of tapioca starch films between 5.42 and 6.99 g/m2/day with glycerol and carrageenan (Ratnaduhita et al., 2021); higher beeswax concentrations improved moisture resistance, with WVP ranging from 3.27 to 15.70 × 10−12 g·m−1 ·Pa−1·s−1 (Gabriel et al., 2021). Similarly, tapioca starch films with anthocyanin extract had WVP values between 1.32 to 1.78 × 10−14 kg·m/m2·s·Pa (Rahmadhia et al., 2023). The findings highlight the effect of combining CMC, citric acid, and basil oil to improve the barrier properties of edible films, and a promising option for sustainable food packaging solutions.

3.3 3D optical profilometer

Figure 1 shows the surface morphology of tapioca starch film through a 3D optical profilometer. The grayscale variations indicate differences in height or depth across the surface. Lighter areas represent higher elevations, and darker areas indicate lower elevations. It shows an uneven and textured surface with peaks and valleys, highlighting the topographical features of the starch film. The microscopic view illustrates the composition and structure of the film, allowing for an analysis of its properties and characteristics. The surface roughness of the tapioca film is observable through the differences in color intensity. The imaging was conducted at a field of view measuring 95 μm × 71 μm with a step size of 1.37 μm. The 3D imaging reveals that the film has a slight roughness, and the bonding of all the compounds is visible. The average roughness and Z-range value for the tapioca film was 404 μm. The present study aligns with the results of Biswal et al. (2024) reported that the film formulated with starch, carboxymethylcellulose, and glycerol exhibited a uniform microstructure, showing no signs of phase separation among its components. Similarly, Kaur et al. (2023) found that the starch film displayed an ordered, compact, and homogeneous structure.

3.4 Exposure test of tapioca film

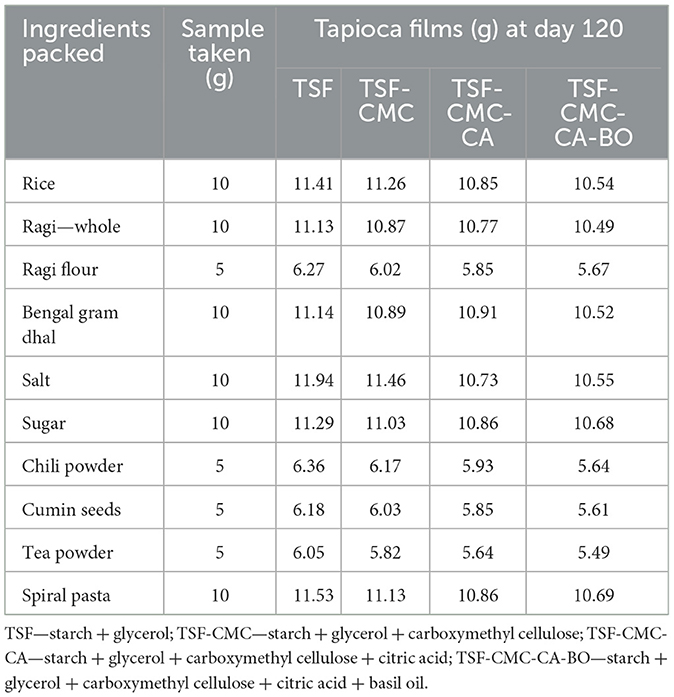

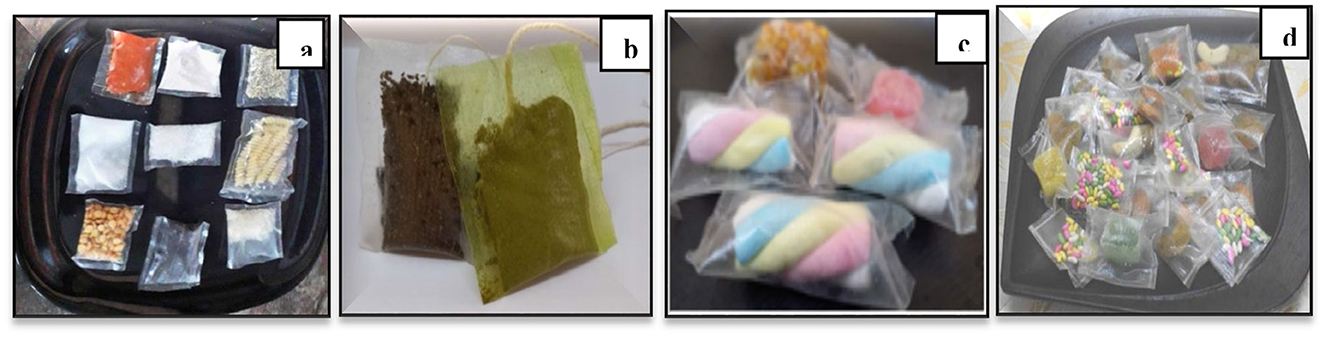

The exposure test of the tapioca film for packaging various dry food ingredients was assessed over a 120-day storage period, and the results are tabulated in Table 4 and Figure 2. Across all samples, the films retained slightly higher weights than their initial values, suggesting minimal moisture absorption. Films containing basil oil (TSF-CMC-CA-BO) exhibited slightly lower weights, likely due to the volatile nature of essential oils. Among the packed ingredients, rice and pasta showed high weight retention, while whole and ground ragi exhibited moderate interaction with the films. Salt and sugar resulted in notable variations, with salt contributing to higher weight retention, possibly due to moisture absorption. Spices such as chili powder, cumin, and tea powder exhibited the lowest weight retention, indicating stronger interactions with the films.

Tapioca starch films, particularly those enhanced with fillers, crosslinkers, and additives such as carboxymethylcellulose, citric acid, and basil oil, demonstrated good stability and strong potential for eco-friendly, biodegradable, and edible packaging. The films proved suitable for packing a variety of dry food products, including cereals, pulses, spices, sugar, and salt in both whole and powdered forms. Additionally, candies, marshmallows, and sugar confectioneries wrapped in these edible films showed minimal weight gain, remaining within a 0.3 g increase over 120 days. The 120-day exposure test confirmed that tapioca starch films are effective for packaging non-perishable foods, including cereals, pulses, spices, condiments, extruded products, and sugar-based confectioneries, making them a promising eco-friendly alternative to conventional packaging materials. The findings of the present study were supported by the studies, Otero-Herrera et al. (2025) found that, sweet potato starch films were suitable for packing candies. Roidoung et al. (2025) stated that, tapioca starch was heat sealable and suitable for sachet packaging.

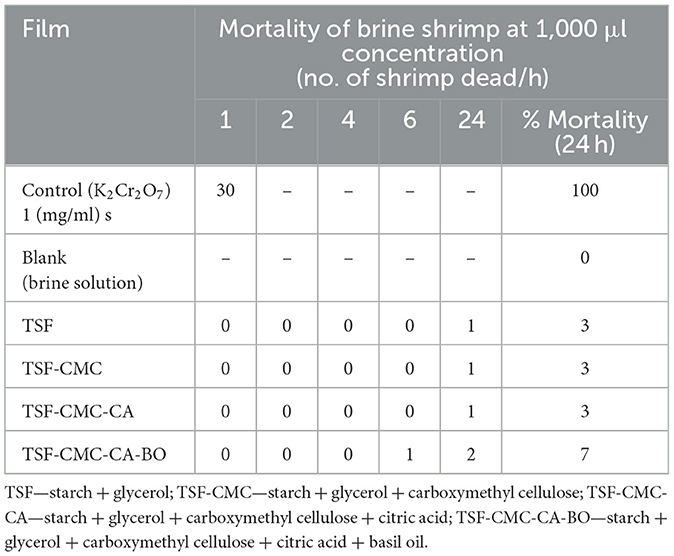

3.5. In vivo brine shrimp lethality analysis of tapioca films

The Brine Shrimp Lethality Assay was conducted to assess the toxicity of standardized active tapioca films with fillers, additives, and crosslinkers (Table 5). The findings showed that all tested film formulations displayed low toxicity when compared to potassium dichromate (K2Cr2O7) and the blank (brine solution) has not exhibited any mortality till 24 h. At a concentration of 1,000 μl, the mortality rate of brine shrimp remained low across all samples, with a maximum of two deaths recorded in the formulation containing starch, glycerol, carboxymethyl cellulose, citric acid, and basil oil (TSF-CMC-CA-BO). After 24 h, the highest recorded mortality rate was only 7%, indicating that the films are largely non-toxic. The low lethality rate of the developed tapioca films indicates their non-toxic nature, reinforcing their suitability as biodegradable and eco-friendly alternatives to conventional plastic-based food packaging. This aligns with the findings of Lazim et al. (2021), which state that D. pentaphylla starch is non-toxic and biocompatible, as its LC50 value is below the toxicity threshold of 29.27 mg/ml in a zebrafish embryo study.

3.6 Total microbial load analysis of tapioca films

The microbial growth assessment of tapioca starch-based films over a period of 120 days revealed that the incorporation of crosslinkers (such as citric acid) and additives (like basil oil) effectively reduced microbial proliferation. On the first day, no colony-forming units (CFUs) were detected in any of the four standardized films. By day 120, the CFU counts varied among the formulations: the tapioca starch film (TSF) exhibited 5.7 × 101 CFU/g, TSF with carboxymethyl cellulose (TSF–CMC) had 4.1 × 101 CFU/g, TSF combined with citric acid (TSF-CMC-CA) recorded 3.7 × 101 CFU/g, and the formula with both citric acid and basil oil (TSF-CMC-CA-BO) showed the lowest count, 3.1 × 101 CFU/g. The findings of the present study are consistent with previous research, Pérez-Vergara et al. (2020), which showed that tapioca starch films containing beeswax and ethanolic propolis extract had strong antifungal activity against Aspergillus niger, creating an inhibition zone of about 25 mm. It confirms that adding bioactive compounds to starch films can improve their antimicrobial properties. Kaur et al. (2023) found that crosslinking with organic acids led to stronger antimicrobial activity than films without these acids. On the other hand, Lazim et al. (2021) reported that Dioscorea pentaphylla starch did not show significant antibacterial activity against E. coli, S. aureus, S. cerevisiae, and S. typhi within 24 h. And also suggests that the antimicrobial effectiveness of starch films depends on the specific additives used. Combining citric acid and Basil leaf oil is important in reducing microbial count in tapioca films.

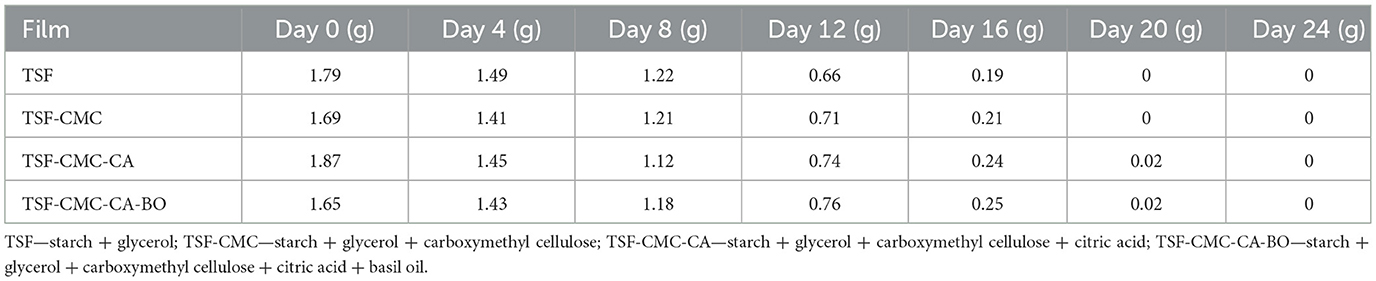

3.7 Biodegradability of tapioca film

The biodegradability study, using a soil burial test, shows that all the tapioca films break down effectively over time. Their weight decreases gradually, with complete degradation occurring by Day 24 as shown in Table 6. The tapioca starch film (TSF) degraded the fastest, leaving no residue by Day 20. The TSF with carboxymethylcellulose (TSF-CMC) followed a similar pattern but took slightly longer to degrade. Films containing citric acid (TSF-CMC-CA) and basil oil (TSF-CMC-CA-BO) were more stable at first, leaving small residues (0.02 g) by Day 20, but they fully degraded by Day 24. The enhanced structural stability of the films with citric acid and basil oil can be attributed to crosslinking, which delays the degradation process. The biodegradability of tapioca films fortified with fillers, crosslinkers, and additives shows complete degradation within 24 days, confirming their status as environmentally friendly and suitable for sustainable packaging applications. An earlier study by Amaraweera et al. (2021) noted that 58% of the total weight loss occurred by the 15 day in native tapioca starch thin films. Meanwhile, Biswal et al. (2024) reported that a film standardized with starch, carboxymethylcellulose, and glycerol degraded by 32% within seven days. Additionally, Kaur et al. (2023) indicated that weight loss during film degradation is due to soil bacteria breaking down starch, resulting in the production of ethanol and methane through fermentation. They also noted that water sorption and crosslinking modify the water absorption properties, which delays degradation.

5 Conclusions

The research findings emphasize the enormous potential of tapioca starch films as eco-friendly and practical packaging solutions for a wide range of food items. Tapioca starch films are a viable alternative to traditional Single-Use Plastics in the food industry and address the rising concern about plastic pollution and environmental deterioration. They are colorless, odorless, tasteless, and nontoxic, which possess barriers to oxygen, gas, and moisture. Tapioca films with active compounds exhibited reduced moisture and increased ash percentage with neutral pH. Ten grams of extracted tapioca starch can yield a 30 cm × 21 cm film with 0.25 mm thickness. The addition of crosslinker (citric acid), filler (carboxymethyl cellulose), and additive (basil oil) enhances tensile strength and elongation at break, improving mechanical durability. It enhances the barrier properties against gas permeation—an essential improvement for bio-based tapioca films, which are generally more prone to moisture permeability than petroleum-based alternatives.

Edible tapioca starch films with active compounds are versatile and adaptable, making them ideal for packaging a wide range of food items, such as cereals and legumes, spices, condiments, tea or coffee powder, extruded goods, and sugar sweets, indicating their potential use in non-perishable food packaging industries in commercial and households particularly in food, entertainment and hospitality sector. It degraded within 24 days and the brine shrimp lethality assay exhibited non-toxic at higher concentrations. Further research can be carried out with semi-perishable and perishable foods in different environmental settings. Tapioca starch films are a realistic and ethical solution for sustainable packaging potentials due to their ability to preserve food freshness and integrity while reducing negative environmental impact.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

PR: Methodology, Writing – review & editing. DM: Methodology, Writing – original draft. AD: Data curation, Writing – review & editing. MM: Supervision, Writing – review & editing. GP: Supervision, Writing – original draft. MH: Software, Writing – original draft. RS: Writing – original draft. WA: Data curation, Writing – review & editing. FA: Validation, Writing – review & editing. AT: Supervision, Writing – review & editing. SQ: Project administration, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by Taif University, Saudi Arabia, Project No. (TU-DSPP-2024-79).

Acknowledgments

The authors extend their appreciation to Department of Science and Technology-Science and Engineering Research Board (DST-SERB), Project no. (EEQ/2018/001013) and Technology Development Program (DST-TDP, Project no. DST/TDT/TDP-60/2022), Avinashilingam Institute for Home Science and Higher Education for Women, Coimbatore, Tamil Nadu, India. The authors extend their appreciation to Taif University, Saudi Arabia, for supporting this work through project number (TU-DSPP-2024-79).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Gen AI was used in the creation of this manuscript.

Correction note

This article has been corrected with minor changes. These changes do not impact the scientific content of the article.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Amaraweera, S. M., Gunathilake, C., Gunawardene, O. H., Fernando, N. M., Wanninayaka, D. B., Manamperi, A., et al. (2021). Preparation and characterization of biodegradable cassava starch thin films for potential food packaging applications. Cellulose 28, 10531–10548. doi: 10.1007/s10570-021-04199-6

Amin, U., Khan, M. K. I., Maan, A. A., Nazir, A., Riaz, S., Khan, M. U., et al. (2022). Biodegradable active, intelligent, and smart packaging materials for food applications. Food Packaging Shelf Life 33:100903. doi: 10.1016/j.fpsl.2022.100903

Ansori, A., Soeparman, S., Widhiyanuriyawan, D., and Widodo, T. D. (2023). Enhanced mechanical and water resistance properties of cassava starch-PVA composites with TiO2 nanofillers for triboelectric nanogenerators films. EUREKA Phys. Eng. 2, 184–201. doi: 10.21303/2461-4262.2023.002647

ASTM International (2016). ASTME96/E96M-16 Standard Test Methods for Water Vapor Transmission of Materials. West Conshohocken, PA: ASTM International.

ASTM International (2017). ASTM D3985-17. Standard Test Method for Oxygen Gas Transmission Rate Through Plastic Film and Sheeting Using a Coulometric Sensor. West Conshohocken, PA: ASTM International.

ASTM International (2021). ASTM D412-16 Standard Test Method for tensile strength through Vulcanized Rubber and Thermoplastic Elastomers. West Conshohocken, PA: ASTM International. Available online at: https://www.astm.org/standards/d412 (accessed August 8, 2024).

Biswal, A. K., Chakraborty, S., Saha, J., Panda, P. K., Pradhan, S. K., Behera, P. K., et al. (2024). Process optimization, fabrication, and characterization of a starch-based biodegradable film derived from an underutilized crop. ACS Food Sci. Technol. 4, 1844–1863. doi: 10.1021/acsfoodscitech.4c00149

Chi, Y., Maitland, E., and Pascall, M. A. (2024). The effect of citric acid concentrations on the mechanical, thermal, and structural properties of starch edible films. Int. J. Food Sci. Technol. 59, 1801–1813. doi: 10.1111/ijfs.16933

Cruz, R. M., Albertos, I., Romero, J., Agriopoulou, S., and Varzakas, T. (2024). Innovations in food packaging for a sustainable and circular economy. Adv. Food Nutr. Res. 108, 135–177. doi: 10.1016/bs.afnr.2023.10.003

Dörnyei, K. R., Uysal-Unalan, I., Krauter, V., Weinrich, R., Incarnato, L., Karlovits, I., et al. (2023). Sustainable food packaging: an updated definition following a holistic approach. Front. Sustain. Food Syst. 7:1119052. doi: 10.3389/fsufs.2023.1119052

Ferreira-Filipe, D. A., Paço, A., Natal-da-Luz, T., Sousa, J. P., Saraiva, J. A., Duarte, A. C., et al. (2022). Are mulch biofilms used in agriculture an environmentally friendly solution?-an insight into their biodegradability and ecotoxicity using key organisms in soil ecosystems. Sci. Total Environ. 828:154269. doi: 10.1016/j.scitotenv.2022.154269

Fu, J., Alee, M., Yang, M., Liu, H., Li, Y., Li, Z., et al. (2022). Synergizing multi-plasticizers for a starch-based edible film. Foods 11:3254. doi: 10.3390/foods11203254

Gabriel, A. A., Solikhah, A. F., and Rahmawati, A. Y. (2021). Tensile strength and elongation testing for starch-based bioplastics using melt intercalation method: a review. J. Phys. Conf. Ser. 1858:012028. doi: 10.1088/1742-6596/1858/1/012028

Huntrakul, K., Yoksan, R., Sane, A., and Harnkarnsujarit, N. (2020). Effects of pea protein on properties of cassava starch edible films produced by blown-film extrusion for oil packaging. Food Packaging Shelf Life 24:100480. doi: 10.1016/j.fpsl.2020.100480

Ibrahim, I. D., Hamam, Y., Sadiku, E. R., Ndambuki, J. M., Kupolati, W. K., Jamiru, T., et al. (2022). Need for sustainable packaging: an overview. Polymers 14:4430. doi: 10.3390/polym14204430

IS 5402 (2012). Microbiology of Food and Animal Feeding Stuffs - Horizontal Method for the Enumeration of Microorganisms – Colony Count Technique at 30°C. Available online at: https://law.resource.org/pub/in/bis/S06/is.5402.2012.pdf (accessed August 14, 2024).

Izzi, Y. S., Gerschenson, L. N., Jagus, R. J., and Ollé Resa, C. P. (2023). Edible films based on tapioca starch and WPC or gelatine plasticized with glycerol: potential food applications based on their mechanical and heat-sealing properties. Food Bioprocess Technol. 16, 2559–2569. doi: 10.1007/s11947-023-03089-y

Kaur, P., Alam, T., Singh, H., Jain, J., Singh, G., Broadway, A. A., et al. (2023). Organic acids modified starch–cmc based biodegradable film: antibacterial activity, morphological, structural, thermal, and crystalline properties. J. Pure Appl. Microbiol. 17, 241–257. doi: 10.22207/JPAM.17.1.14

Khandeparkar, A. S., Paul, R., Sridhar, A., Lakshmaiah, V. V., and Nagella, P. (2024). Eco-friendly innovations in food packaging: a sustainable revolution. Sustain. Chem. Pharm. 39:101579. doi: 10.1016/j.scp.2024.101579

Kumar, N., Pratibha, Prasad, J., Yadav, A., Upadhyay, A., Neeraj, et al. (2023). Recent trends in edible packaging for food applications—perspective for the future. Food Eng. Rev. 15, 718–747. doi: 10.1007/s12393-023-09358-y

Lazim, A. M., Sharlina, M. E., Azfaralariff, A., Yaacob, W. A., Lim, S. J., Fazry, S., et al. (2021). Structure, physicochemical and toxicity properties of underused malaysian native Tuber's starch (Dioscorea Pentaphylla). J. King Saud Univ. Sci. 33:101501. doi: 10.1016/j.jksus.2021.101501

Linares-Castañeda, A., Sánchez-Chino, X. M., Gómez y Gómez, Y. M., Jiménez-Martínez, C., Martínez Herrera, J., Cid-Gallegos, M. S., et al. (2023). Cereal and legume protein edible films: a sustainable alternative to conventional food packaging. Int. J. Food Prop. 26, 3197–3213. doi: 10.1080/10942912.2023.2267785

Makawi, A. B., Mustafa, A. I., Adiamo, O. Q., and Mohamed Ahmed, I. A. (2019). Physicochemical, nutritional, functional, rheological, and microbiological properties of sorghum flour fermented with baobab fruit pulp flour as starter. Food Sci. Nutr. 7, 689–699. doi: 10.1002/fsn3.913

Martins, V. F., Pintado, M. E., Morais, R. M., and Morais, A. M. (2024). Recent highlights in sustainable bio-based edible films and coatings for fruit and vegetable applications. Foods 13:318. doi: 10.3390/foods13020318

Navasingh, R. J. H., Gurunathan, M. K., Nikolova, M. P., and Królczyk, J. B. (2023). Sustainable bioplastics for food packaging produced from renewable natural sources. Polymers 15:3760. doi: 10.3390/polym15183760

Otero-Herrera, A., Fuentes-Gaviria, L., Pérez-Cervera, C., and Andrade-Pizarro, R. (2025). Development of edible films based on sweet potato (Ipomoea batatas) starch and their application in candy packaging. Int. J. Biol. Macromol. 299:140031. doi: 10.1016/j.ijbiomac.2025.140031

Othman, S. H., Majid, N. A., Tawakkal, I. S. M. A., Basha, R. K., Nordin, N., and Shapi'i, R. A. (2019). Tapioca starch films reinforced with microcrystalline cellulose for potential food packaging application. Food Sci. Technol. 39, 605–612. doi: 10.1590/fst.36017

Pak, E. S., Ghaghelestani, S. N., and Najafi, M. A. (2020). Preparation and characterization of a new edible film based on Persian gum with glycerol plasticizer. J. Food Sci. Technol. 57, 3284–3294. doi: 10.1007/s13197-020-04361-1

Pérez-Vergara, L. D., Cifuentes, M. T., Franco, A. P., Pérez-Cervera, C. E., and Andrade-Pizarro, R. D. (2020). Development and characterization of edible films based on native cassava starch, beeswax, and propolis. NFS J. 21, 39–49. doi: 10.1016/j.nfs.2020.09.002

Prasad, J., Dixit, A., Sharma, S. P., Mwakosya, A. W., Petkoska, A. T., Upadhyay, A., et al. (2024). Nanoemulsion-based active packaging for food products. Foods Raw Mater. 12, 22–36. doi: 10.21603/2308-4057-2024-1-585

Putri, T. R., Adhitasari, A., Paramita, V., Yulianto, M. E., and Ariyanto, H. D. (2023). Effect of different starch on the characteristics of edible film as functional packaging in fresh meat or meat products: a review. Mater. Today Proc. 87, 192–199. doi: 10.1016/j.matpr.2023.02.396

Rahmadhia, S. N., Sidqi, A. A., and Saputra, Y. A. (2023). Physical properties of tapioca starch-based film indicators with anthocyanin extract from purple sweet potato (Ipomea batatas L.) and response to pH Changes. Sains Malays. 52, 1685–1697. doi: 10.17576/jsm-2023-5206-06

Ratnaduhita, A., Nuhriawangsa, A. M. P., and Kartikasari, L. R. (2021). Physico-chemical properties of gathot (fermented cassava) flour applied on edible film. IOP Conf. Ser. Earth Environ. Sci. 888:012035. doi: 10.1088/1755-1315/888/1/012035

Roidoung, S., Sonyiam, S., and Fugthong, S. (2025). Development of heat sealable film from tapioca and potato starch for application in edible packaging. J. Food Sci. Technol. 62, 389–395. doi: 10.1007/s13197-024-06041-w

Romano, R., De Luca, L., Aiello, A., Pagano, R., Di Pierro, P., Pizzolongo, F., et al. (2022). Basil (Ocimum basilicum L.) leaves as a source of bioactive compounds. Foods 11:3212. foods11203212 doi: 10.3390/foods11203212

Shah, Y. A., Bhatia, S., Al-Harrasi, A., and Khan, T. S. (2024). Advancements in the biopolymer films for food packaging applications: a short review. Biotechnol. Sustain. Mater. 1:2. doi: 10.1186/s44316-024-00002-1

Shao, Y., Jiao, R., Wu, Y., Xu, F., Li, Y., Jiang, Q., et al. (2023). Physicochemical and functional properties of the protein–starch interaction in Chinese yam. Food Sci. Nutr. 11, 1499–1506. doi: 10.1002/fsn3.3189

Song, Z., Zang, Z., Cao, Y., Ma, Y., Li, B., Han, L., et al. (2025). Tapioca starch/konjac gum-based composite film incorporated with nanoliposomes encapsulated grape seed oil: structure, functionality, controlled release and its preservation role for chilled mutton. Food Chem. 463:141081. doi: 10.1016/j.foodchem.2024.141081

Tarique, J. S. M. S., Sapuan, S. M., and Khalina, A. (2021). Effect of glycerol plasticizer loading on the physical, mechanical, thermal, and barrier properties of arrowroot (Maranta arundinacea) starch biopolymers. Sci. Rep. 11:13900. doi: 10.1038/s41598-021-93094-y

Trajkovska Petkoska, A., Anka, D., Davor, K., Nishant, P., and Broach, A. T. (2021a). “Biobased materials as a sustainable potential for edible packaging,” in Sustainable Packaging, ed. S. S. Muthu (Cham: Springer), 111–135. doi: 10.1007/978-981-16-4609-6_5

Keywords: tapioca starch film, textural analysis, exposure test, non-toxic, biodegradability, barrier properties

Citation: Raajeswari P, Manivel D, Dhanapal ACTA, Menkinoska M, Pavlovska G, Helal M, Sami R, Alsanei WA, Alessa FM, Trajkovska Petkoska A and Qari SH (2025) Sustainable biodegradable tapioca starch films enhanced with basil oil, carboxymethyl cellulose, and citric acid for functional food packaging applications. Front. Sustain. Food Syst. 9:1610769. doi: 10.3389/fsufs.2025.1610769

Received: 12 April 2025; Accepted: 02 June 2025;

Published: 25 June 2025; Corrected: 24 July 2025.

Edited by:

Saiful Irwan Zubairi, National University of Malaysia, MalaysiaReviewed by:

José Armando Ulloa, Autonomous University of Nayarit, MexicoEddie Ti Tjih Tan, MARA University of Technology, Malaysia

Copyright © 2025 Raajeswari, Manivel, Dhanapal, Menkinoska, Pavlovska, Helal, Sami, Alsanei, Alessa, Trajkovska Petkoska and Qari. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Paramasivam Raajeswari, cmFhamVzd2FyaV9mc25AYXZpbnV0eS5hYy5pbg==; Rokayya Sami, cm9rYXl5YS5kQHR1LmVkdS5zYQ==

†ORCID: Paramasivam Raajeswari orcid.org/0000-0002-5311-0823

Paramasivam Raajeswari1*†

Paramasivam Raajeswari1*† Devatha Manivel

Devatha Manivel Anto Cordelia Tanislaus Antony Dhanapal

Anto Cordelia Tanislaus Antony Dhanapal Rokayya Sami

Rokayya Sami Woroud A. Alsanei

Woroud A. Alsanei Fatima M. Alessa

Fatima M. Alessa Anka Trajkovska Petkoska

Anka Trajkovska Petkoska Sameer H. Qari

Sameer H. Qari