- 1School of Management, Jiangsu University, Zhenjiang, China

- 2School of Agricultural Equipment Engineering, Jiangsu University, Zhenjiang, China

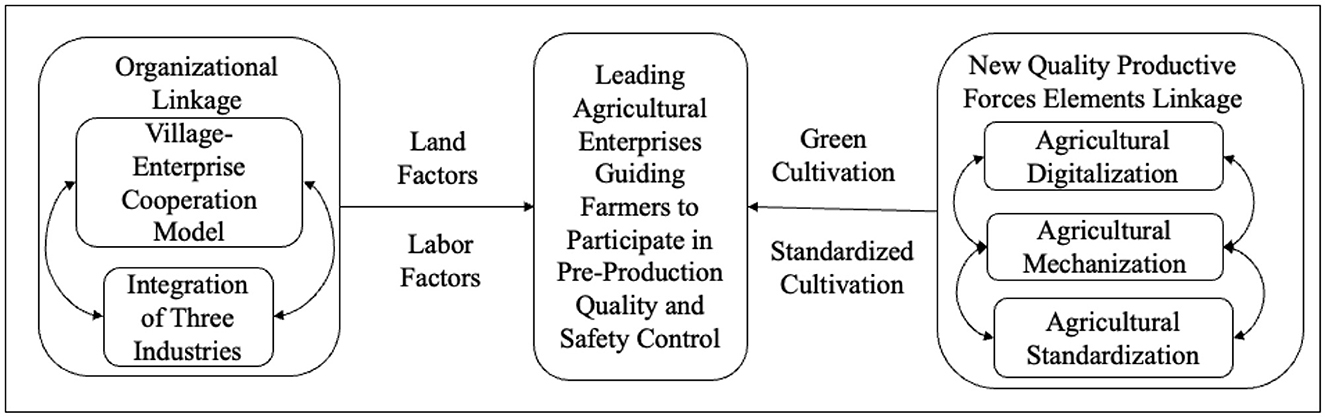

The leadership of agricultural enterprises in guiding farmers to participate in pre-production quality and safety control not only helps promote high-quality agricultural development and drives the industrialization process of agriculture, but also provides important support for achieving the goal of building a strong agricultural nation. The re-search employs a grounded theory approach to conduct a multi-case study, following the general logic of “Motivations-Behaviors-Outcomes.” Relevant data from case companies were extracted, analyzed, and coded to construct a theoretical interpretation, revealing the intrinsic mechanisms of agricultural leading enterprises in pre-production quality and safety control and identifying key influencing factors. Additionally, using fuzzy-set qualitative comparative analysis, the study explores how five enterprise control behaviors—village-enterprise cooperation, integration of primary, secondary, and tertiary industries, agricultural mechanization, agricultural digitalization, and agricultural technology promotion—collaborate to guide farmers' involvement in pre-production quality and safety control from a configurational perspective. The results indicate that agricultural leading enterprises guide farmers' participation in pre-production quality and safety control through organizational linkage mechanisms and new quality productive forces elements linkage mechanism, and based on this, six configurational paths are summarized, leading to the identification of three constructs: Industry Integration-driven, Digital Intelligence-driven, and Land Trusteeship-driven. This paper focuses on agricultural leading enterprises and farmers in the Yangtze River Delta region of China. The study does not limit itself to exploring the independent influence of enterprise-led actions in guiding farmers' participation in pre-production quality and safety control, but rather investigates how multiple factors work together to lead farmers' participation under various interacting elements.

1 Introduction

China has proposed accelerating the construction of a new development pattern and achieving the strategic goal of modernizing with high-quality development, with a particular emphasis on the priority development of agriculture and rural areas. High-quality agricultural development is not only the core path to promoting rural re-vitalization and building a strong agricultural nation but also an inevitable choice for realizing the goal of Chinese-style modernization. In this process, China has introduced the concept of “New quality productivity,” aiming to guide economic transformation and upgrading, promote the cultivation of strategic emerging industries and future industries, and foster the formation of new forms of productivity with new attributes, functions, and characteristics (Ma Juan, 2024; Zhou and Xu, 2023; Xu et al., 2023).

New quality productivity is essentially a form of productivity driven by innovation, distinct from traditional economic growth models. It emphasizes technological progress, optimized resource allocation, and highly efficient production methods. Specifically, new quality productivity is jointly fostered by technological breakthroughs, innovative al-location of production factors, and deep transformation and upgrading of industrial chains. The core feature of this concept is the optimized combination of labor, labor materials, and labor objects, which drives productivity improvement (Headley, 1972; Luo and Geng, 2024). A significant increase in total factor productivity becomes a core indicator of new quality productivity development, and its key driving force is innovation, fundamentally reflecting advanced productivity (Li et al., 2024). In the context of Chinese-style modernization, agricultural productivity upgrading is not only the result of technological innovation but also a systematic improvement supported by multiple dimensions, including technology, factors, systems, and the environment (Xu et al., 2025; Huang et al., 2024). New quality productivity emphasizes transforming agricultural productivity through technological innovation, especially in terms of increasing agricultural total factor productivity and achieving low-carbon, green, and sustainable development, which is of great significance (Agrawal et al., 2022; Shen et al., 2022). This process not only focuses on improving production efficiency but also aims to meet the growing demand for high-quality agricultural products, thereby enhancing the overall quality of life for the people (Liu et al., 2022; Zheng et al., 2025).

In the context of agricultural industrialization, agricultural industrial organization models, based on industrial organization theory, play a vital role as institutional carriers in agricultural development, serving as bridges, links, and carriers in the agricultural industry (Liang et al., 2024; Zhong and Kong, 2012). Therefore, promoting close connections between farmers and other entities in the industrial chain, establishing stable industrial organization models, may become an effective path for enterprise-led farmer participation in pre-production quality and safety control (Chen et al., 2024). Existing research suggests that the primary organizational model is “agricultural leading enterprises + cooperatives + farmers” (Zheng, 2024; Wu, 2023). This organizational model not only helps implement various quality control measures effectively in agricultural production but also enhances the production capacity and quality safety control efficiency of agricultural leading enterprises (Liu, 2022). Agricultural leading enterprises, with their modern production capabilities, refined management mechanisms, and extensive market channels, play a leading role in quality and safety control in the agricultural product supply chain (Zeng, 2021). Since 2018, multiple departments, such as the Ministry of Commerce and the Ministry of Agriculture Rural Affairs1, have jointly promoted the “Supply Chain Innovation and Application Pilot” project, aiming to promote the deep integration of farmers and the agricultural industry chain, thereby forming a full industrial chain cooperation model centered on agricultural leading enterprises and benefiting farmers (Jin et al., 2024; Liu and Qin, 2021; Gao et al., 2024; Zeng, 2021). In this model, cooperatives serve as a bridge between enterprises and farmers, helping agricultural leading enterprises influence farmers' production behaviors, promoting green planting, and achieving carbon reduction in agriculture (Ren, 2024; Wang and Qiu, 2024). Cooperatives also facilitate the organic connection of smallholder farmers with modern agriculture through organizational operations, standardized production, green production, financial credit, and the extension of the industrial chain (Wang et al., 2025).

With the improvement of China's economic development level and agricultural labor productivity, as well as the diversification of agricultural industrial structure and rural employment structure, urbanization's absorption of rural population, and other factors, traditional farmers are being impacted from various angles and levels, leading to a diversity of economic perspectives and planting scales. This has resulted in a diversified classification of farmers, including individual farmers, contract farmers, mixed farmers, and large-scale farmers (Pei et al., 2024; Peng and Xu, 2023; Lin et al., 2024; Liao, 2024; Chen, 2007; Zhang and Zhao, 2013).

Previous research has recognized the importance of strengthening quality and safety control during the agricultural production phase (Li H. et al., 2022; Elbeltagi et al., 2023; Li et al., 2023; Cui et al., 2024). Liu et al. (2021) and others pro-posed using blockchain technology to supervise key data, such as production conditions, agricultural input usage, and processing materials, to achieve effective pre-production quality safety control of agricultural products. Pan and Luo (2021) suggested building an “Internet+” integrated monitoring platform to improve the current instability in agricultural product production quality. Li B. et al. (2022) researched the impact of digital promotion services via smartphones on farmers' adoption of sustainable agricultural technologies, finding that farmers using these services could improve the effectiveness of quality and safety control actions, such as precision fertilization, technical learning, and soil testing. Lu and Zhang (2022), while exploring how cooperatives promote green production among farmers, indicated that cooperatives significantly boost farmers' adoption of green production behaviors, with an overall increase of 25.57%. Chen and Ma (2023) argued that cooperative support significantly enhances farmers' cognitive and behavioral abilities, serving as an important external factor in agricultural product quality and safety control. Cai et al. (2019) used the example of reduced fertilizer and pesticide use to illustrate the positive role cooperatives play in improving agricultural product quality and safety. Zhang et al. (2022) found that cooperatives could improve farmers' quality control behaviors, with cooperatives owning independent agricultural product brands placing more emphasis on product quality control. Li et al. (2021) suggested that brand premiums have a positive effect on preproduction quality safety control, particularly when brand-specific assets constrain farmers' production behaviors, maximizing the impact of brand premiums on enhancing product quality and safety. Under the background of supply-side structural reform in agriculture, agricultural mechanization has not only promoted largescale production but also facilitated the integration of primary, secondary, and tertiary industries, thereby contributing to improved agricultural product quality (Guo, 2023; Li W. et al., 2022; Li et al., 2025; Jin et al., 2021). Liu (2024) proposed that chemical weeding has a negative impact on product quality, and the introduction of mechanized physical weeding robots provides technical support for the production of high-quality agricultural products. Yin et al. (2022) developed a high-end equipment manufacturing system framework aimed at satisfying the green quality requirements of agricultural products, providing a technological path for high-quality agricultural development. Yang and Li (2022) suggested that agricultural machinery services should be tailored to local conditions to better meet farmers' needs for producing high-quality agricultural products. Yu et al. (2022) found through heterogeneity analysis that farmers involved in managed economic crops achieve the highest ecological and economic benefits, with service organizations in land trusteeship using environmentally friendly agricultural technologies such as green pest control, integrated water and fertilizer management, and soil testing-based fertilization, significantly reducing pesticide and fertilizer application intensity and improving agricultural product quality and safety. The innovation of this study lies in its significant shift and deepening of the research perspective on agricultural product quality and safety control. Previous research predominantly focused on specific methods and technical pathways for agricultural product quality and safety management, often tending toward the independent effect analysis of single factors. These studies, however, paid limited attention to the role of multiple stakeholders, particularly leading agricultural enterprises, in guiding farmers' proactive safe production behaviors. In contrast, this study's core focus is on the context of leading agricultural enterprises' dominance, investigating which agricultural product quality control measures are more effectively accepted and adopted by farmers.

Based on the existing literature, current research primarily focuses on specific methods and technological pathways for agricultural product quality and safety control. However, there is relatively limited attention to the factors influencing farmers' proactive safety production behaviors under the guidance of leading enterprises in a multifactor context. Therefore, this study aims to explore which agricultural product quality control measures are more effectively accepted and adopted by farmers in the context of agricultural leading enterprises taking the lead. At present, research on preproduction quality and safety control of agricultural products has covered various aspects, including cooperative participation, industrial integration, mechanization levels, and digital technologies. However, most studies tend to focus on the independent effects of single factors on quality control. As research methods continue to improve, the interactive effects among multiple factors and their complex impacts on quality control effectiveness have gradually emerged as a new research direction.

Based on this, this paper uses data from agricultural leading enterprises and farmers in the Yangtze River Delta region of China, applying configurational theory to analyze the multidimensional combination of measures that guide farmer behavior and their multiple interactive effects on preproduction quality control of agricultural products. By exploring the mechanisms of multifactor dynamic combinations in agricultural product quality and safety, this paper aims to provide a theoretical basis and empirical support for optimizing quality control strategies and practical pathways.

2 Identification of mechanisms and influencing factors

2.1 The grounded theory methodology

Grounded theory, established by Glaser and Strauss (2017), is a qualitative research methodology aimed at inductively generating provisional theories from empirically observed social phenomena through systematic data analysis and coding. It requires researchers to continuously compare and synthesize concepts through ongoing interaction with data, embodying a constructivist research paradigm. Given its essential characteristic of theory generation from data, Grounded Theory is well-suited for tasks such as extracting perceived quality attributes, effectively compensating for the shortcomings of traditional attribute extraction methods. This study seeks to explore the intrinsic mechanisms of pre-production quality and safety control by agricultural leading enterprises, focusing not only on how these enterprises participate in control themselves but also on how they lead farmers' participation. Given the exploratory nature of this research, this study employs the Grounded Theory approach for rigorous qualitative inquiry. By systematically analyzing and coding data from multiple representative case enterprises, and ensuring the data's sufficient representativeness and mutual corroboration, the aim is to reduce subjective conjecture and enhance the validity of theoretical construction.

2.2 Mechanisms analysis

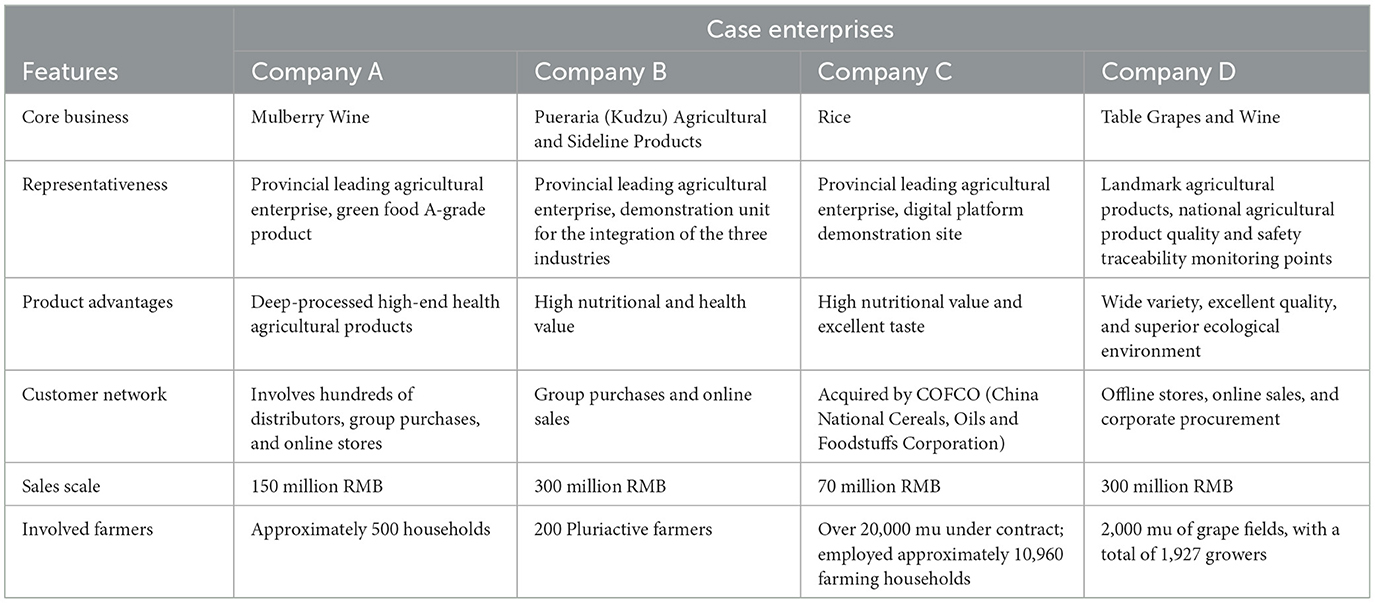

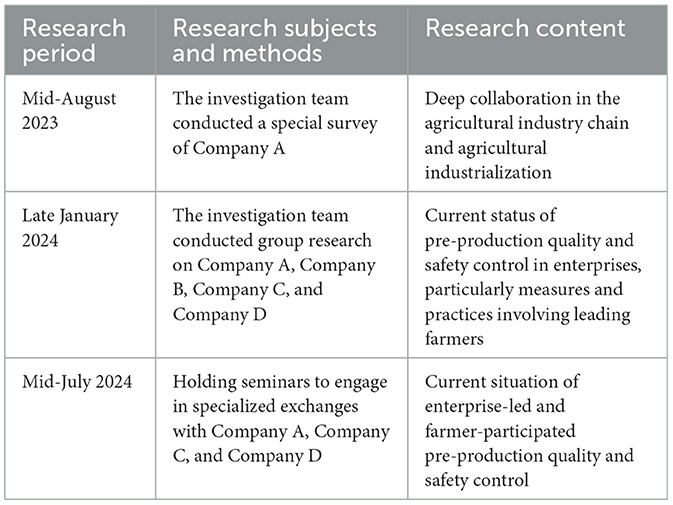

This study selects four leading agricultural enterprises in the Yangtze River Delta region of China, which guide farmers in producing high-quality agricultural products, as research samples (see Tables 1, 2). A multiple-case study is conducted using the grounded theory method. Following the analytical logic of “motivation–behavior–outcome,” interview data from these enterprises are systematically extracted, thoroughly analyzed, and coded at multiple levels. Ultimately, a theoretical interpretation is constructed to reveal the internal mechanism of agricultural leading enterprises in pre-production raw material quality control (He and You, 2022).

This study employs open coding to systematically analyze the interview data of the four case enterprises, thoroughly reading and accurately understanding the text to identify the main mechanisms and key events related to the motivations, behaviors, and outcomes of agricultural leading enterprises guiding farmers in pre-production quality and safety control. The key interviewees for this study will be internal personnel directly influencing or managing pre-production quality control of agricultural products. Given the research's emphasis on deeply understanding the internal mechanisms of raw material quality control within enterprises, the most critical respondents will include: senior enterprise management, managers of quality control departments, and heads of procurement. During the second-level coding process, relevant content from the case data was conceptually summarized, integrating the latest advancements in theoretical research. The motivation section focuses on the roles, functions, and effects of farmers in pre-production quality and safety control; the behavior section examines the response measures under different mechanisms; and the outcome section analyzes the changes and impacts on both farmers and pilot enterprises after implementing action strategies under different mechanisms. This process then distills secondary coding entries. Based on this, axial coding is applied to integrate and abstract the open coding concepts, further summarizing them into higher-level categories, ultimately forming the primary coding.

A grounded theory analysis is conducted to explore the pathways and mechanisms through which leading agricultural enterprises engaged in high-quality agricultural product production guide farmers to participate in pre-production quality and safety control. The primary focus is to address the issue of linkage, specifically by examining the linkage establishment process and performing a processual analysis. This aims to elucidate the linkage mechanisms and pathways through which agricultural leading enterprises orchestrate farmer involvement in pre-production quality and safety control.

2.2.1 Mechanism 1: organizational connection mechanism

Pre-production quality and safety control is a critical link in the entire agricultural product value chain, where the guiding and standardizing role of agricultural leading enterprises on farmers' behavior is paramount. This paper analyzes the internal logic of how agricultural leading enterprises guide farmers' behavior in pre-production quality and safety control through organizational linkage mechanisms, from the perspective of industrial organization theory (Plott, 1982; Yuan et al., 2024). Within the organizational linkage mechanism, labor force elements constitute the foundation for leading agricultural enterprises to implement pre-production quality and safety control. However, a primary challenge currently faced is the heterogeneity of farmer types, encompassing contract farmers, part-time farmers, large-scale farmers, and individual smallholders, each exhibiting significantly divergent demands. The inability of leading agricultural enterprises to effectively discern the specific roles and needs of these diverse farmer types in pre-production quality and safety control leads to a lack of targeted quality control measures, consequently resulting in agricultural product quality and safety issues.

In response, case enterprises have adopted a series of countermeasures. Agricultural cooperatives play a pivotal intermediary role between leading agricultural enterprises and farmers. Utilizing village-enterprise collaboration as a bridge, leading agricultural enterprises, through contracting with cooperatives, enhance the awareness and behaviors of various farmer types regarding agricultural product quality and safety control. Co-operatives disseminate the economic and social value of quality control to farmers through policy dissemination and organized training, thereby reinforcing farmers' behavioral cognition of quality control. Simultaneously, a mechanism combining rewards and penalties is employed to ensure the equivalent conversion of agricultural product value, gradually shifting agricultural product prices from a pooling equilibrium to a separating equilibrium. This breaks the economic cycle of “bad money driving out good,” thereby enhancing farmers' willingness to implement quality control. Building upon the cultivation and enhancement of farmers' quality control behavioral capabilities, leading agricultural enterprises provide support tools such as production factors, technical training, and low-interest loans. By promoting the establishment of industry-university-research groups and conducting targeted technical training, farmers' capacity to implement quality control is augmented. From the perspective of industrial organization theory, this can be viewed as agricultural leading enterprises overcoming market failures, particularly issues of information asymmetry and transaction costs, by constructing effective “vertical integration” and “quasi-integration” models. Through cooperative organizations acting as intermediaries, enterprises can effectively transmit information, reduce the costs of transacting with dispersed farmers, and utilize incentive mechanisms to guide farmers' behavior toward desired quality standards. This aligns with transaction cost economics theory, which posits that organizational arrangements can reduce transaction costs and enhance efficiency.

Leading agricultural enterprises, through promoting land trusteeship or transfer, improve the efficiency of idle resource element utilization and further stimulate farmers' enthusiasm for producing high-quality agricultural products. For part-time farmers facing household labor shortages or seasonal employment, idle land is entrusted or transferred to cooperatives, enterprises, or small farmers, forming a more efficient intensive management model. This production model not only facilitates specialized management and enhances production management efficiency but also integrates agricultural materials, technology, and human resources required for high-quality agricultural product pro-duction, enabling dynamic management of breeding, production management, and post-harvest storage processes. Concurrently, enterprises leverage big data, cloud computing, and Internet of Things technologies to predict extreme climate and natural disaster changes, enabling proactive scientific production decisions. Government subsidies for large-scale production of high-quality agricultural products further incentivize the contiguous production model of land trusteeship or transfer, allowing farmers to benefit from policy dividends and promoting the effective implementation of pro-farmer policies. This reflects industrial organization theory's perspective on how enterprises enhance competitiveness through resource integration and economies of scale. By promoting land trusteeship or transfer, enterprises can optimize the allocation of production factors and elevate the professionalization and intensification of agricultural production. This aligns with the theory of firm boundaries, which posits that enterprises internalize production activities to reduce market transaction costs and thereby achieve efficiency gains.

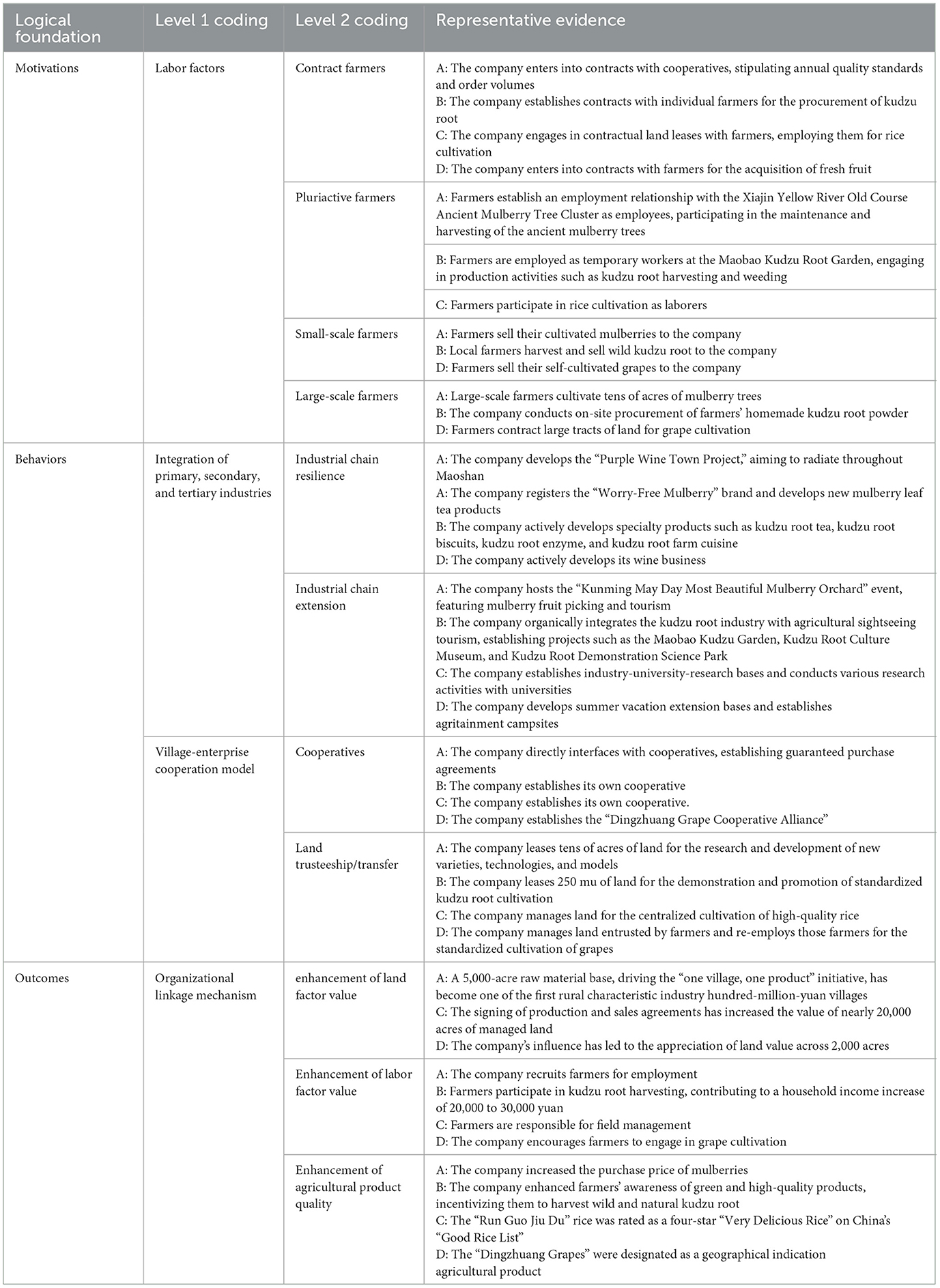

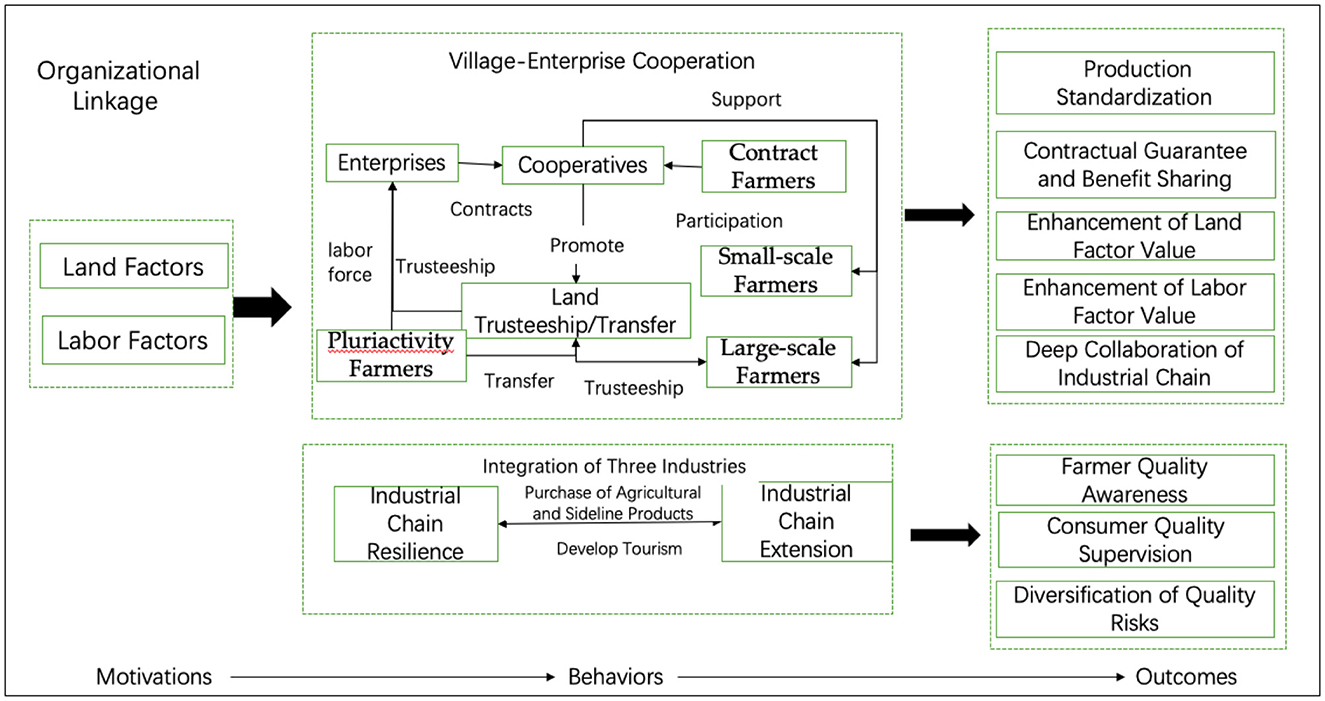

Leading agricultural enterprises, through the deep integration of primary, secondary, and tertiary industries, enhance farmers' awareness of pre-production agricultural product quality and safety control. The extension of the industrial chain not only lengthens the agricultural product value chain but also propels farmers toward high-quality production transformation. In forward extension, the order contract model directly links farmers' production behaviors with market demands, unifying quality standards and brand requirements, thereby standardizing farmers' production behaviors. By enhancing industrial chain resilience and developing new products and brands, leading enterprises enable farmers to more directly perceive the premium benefits of high-quality agricultural products, thereby further enhancing their quality control awareness. The grounded theory analysis results and pathways of leading agricultural enterprises guiding farmers to participate in pre-production quality and safety control based on the organizational linkage mechanism are presented in Table 3 and Figure 1, respectively.

Table 3. Grounded theory analysis results of leading agricultural enterprises guiding farmers' participation in pre-production quality and safety control based on the organizational linkage mechanism (Selected Representative Evidence).

Figure 1. Pathways for leading agricultural enterprises to guide farmers in pre-production quality and safety control through the organizational linkage mechanism.

2.2.2 Mechanism 2: new quality productive forces elements linkage mechanism

The current proposition of new quality productive forces elements highlights that producing high-quality agricultural products is pivotal, with advanced productivity being the essence. This entails focusing on new types of laborers, labor materials, and labor objects, along with their optimized combinations, and taking the substantial enhancement of total factor productivity as the core marker. Consequently, standardized and green planting have become new driving forces for leading agricultural enterprises to guide farmers in promoting pre-production agricultural product quality and safety control. The efficacy of the new quality productive forces linkage mechanism can be thoroughly analyzed from the perspective of agricultural value chain collaboration theory. This theory focuses on the interaction, division of labor, and cooperation among various actors within the agricultural value chain, and how collaboration can optimize resource allocation and enhance value. It provides a theoretical framework for understanding how agricultural leading enterprises leverage new quality productive forces to improve overall value chain efficiency and quality (Mishra et al., 2024; Despoudi et al., 2018).

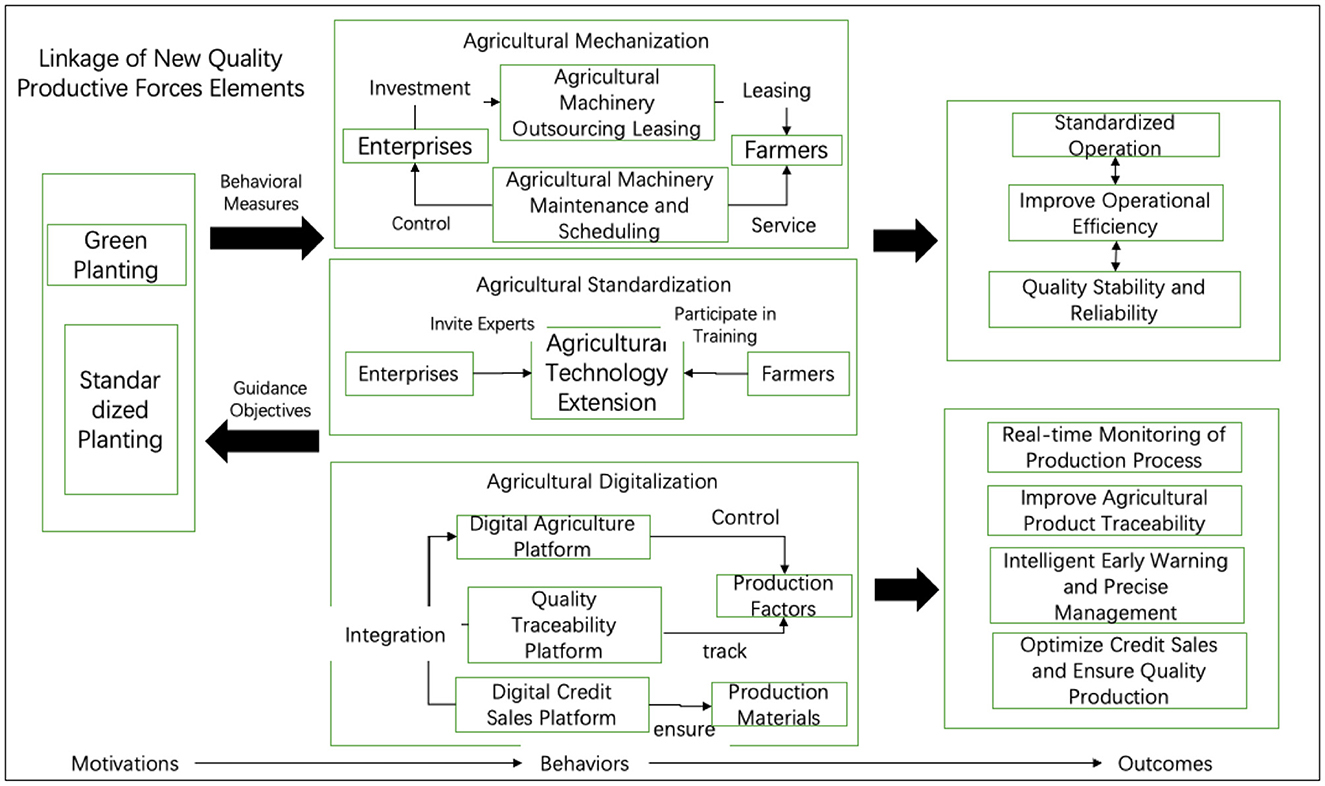

To realize standardized and green planting, leading agricultural enterprises cultivate and develop new types of agricultural laborers, tools, and objects. Through agricultural technology extension and industry-university-research cooperation, leading agricultural enterprises enhance farmers' quality control capabilities. Enterprises invite agricultural experts to provide full-cycle production technical guidance to farmers in the fields and collaborate with research institutions to develop patented technologies and promote standardized planting models. Agricultural value chain collaboration theory posits that knowledge sharing and technical assistance can compensate for smallholder farmers' disadvantages in acquiring technology and information, thereby enhancing their production skills and management capabilities, and ultimately strengthening their participation and competitiveness within the value chain. This collaborative approach helps dismantle traditional agricultural production barriers, facilitates the dissemination and application of advanced production techniques, and consequently improves the quality of agricultural products. New labor objects, centered on data elements, enable leading agricultural enterprises to establish digital platforms for digital and in-formation-based monitoring of field management. By leveraging big data, cloud computing, and Internet of Things technologies, enterprises construct intelligent farmland management systems to achieve real-time monitoring of crop growth environments and optimize planting strategies through intelligent decision-making systems. In terms of financial credit, enterprises launch agricultural credit platforms to provide farmers with financial support such as agricultural material credit sales, reducing farmers' production input pressure and enhancing their enthusiasm for participating in high-quality planting. For quality traceability, enterprises establish a full-process traceability system from production to market, including product QR code traceability and government food safety electronic traceability systems, ensuring that the sources of agricultural products are traceable, destinations are trackable, and responsibilities are accountable, thereby enhancing consumer trust in product quality. Within agricultural value chain collaboration, effective information flow can mitigate information asymmetry, enhance decision-making efficiency, and facilitate coordinated actions among various stakeholders. Concurrently, establishing a comprehensive farm-to-fork traceability system not only bolsters consumer trust in product quality but, more critically, constructs a robust risk management mechanism ensuring verifiable origins, traceable destinations, and assignable accountability for agricultural products. This contributes to clarifying responsibilities across all stages of the value chain, thereby reducing quality and safety risks, consistent with the agricultural value chain collaboration theory's emphasis on leveraging information sharing and traceability mechanisms to reduce uncertainty and enhance trust. New types of labor tools in agricultural mechanization are crucial for improving agricultural product quality. Addressing the issues of insufficient farm machinery and low mechanization levels among farmers, leading agricultural enterprises reduce farmers' production costs and improve mechanized operation efficiency through agricultural machinery outsourcing leasing and maintenance scheduling mechanisms. Enterprises or cooperatives provide farm machinery leasing services and conduct pilot demonstrations in areas suitable for farm machinery promotion to enhance farmers' awareness and application capabilities of mechanized planting. Furthermore, for complex terrains such as hills and mountains, enterprises establish farm machinery adaptation and scheduling systems to ensure that farmers can access suitable agricultural machinery and maintenance services, thereby improving the precision and stability of agricultural production. Agricultural value chain collaboration theory posits that through cross-actor resource integration and specialized division of labor, the strengths of all parties can be fully leveraged to achieve overall production efficiency improvements. Particularly in complex geographical environments, the establishment of an agricultural machinery adaptation and dispatch system further ensures production precision and stability, thereby enhancing the quality of agricultural products.

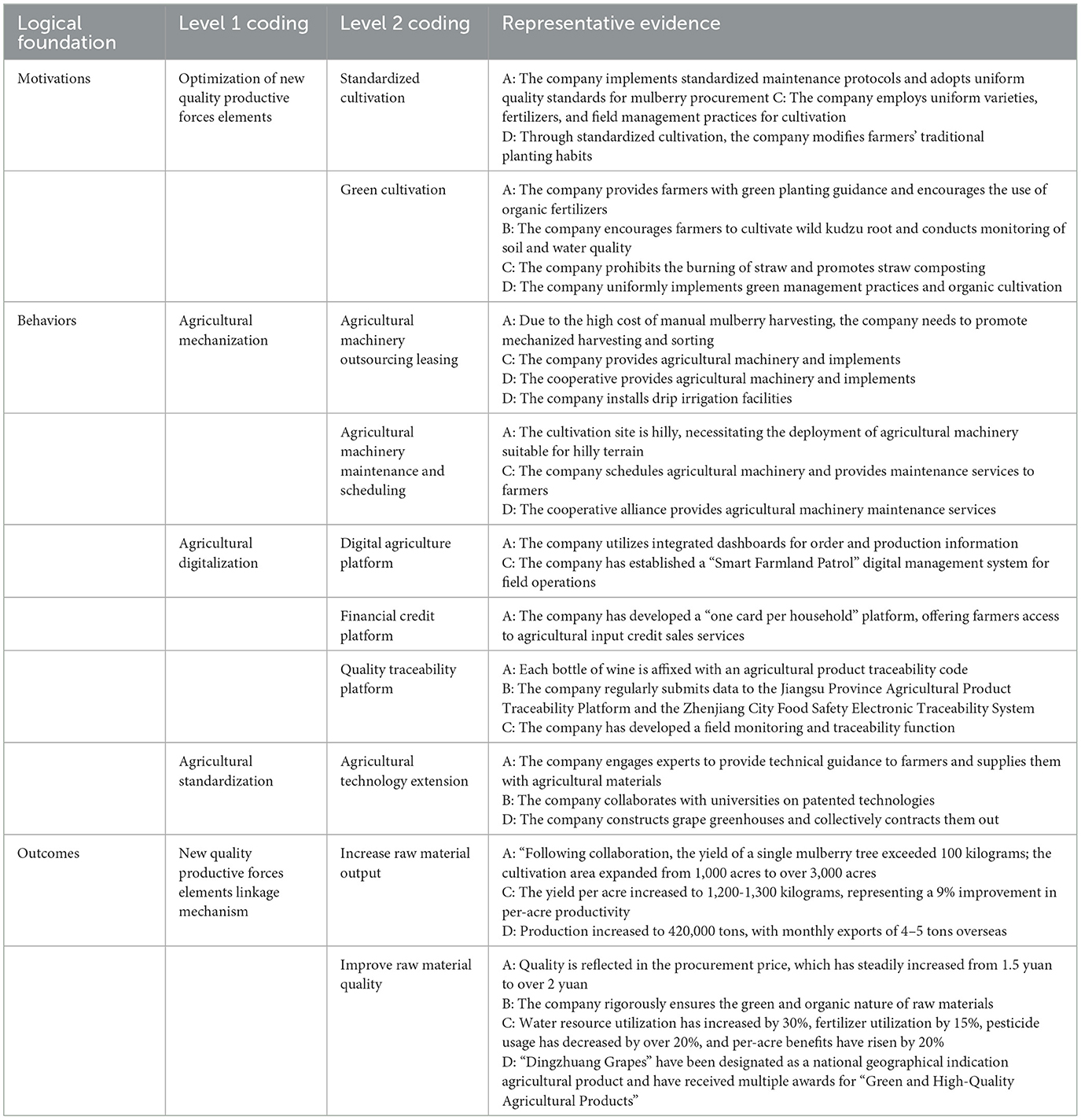

Leveraging the new quality productive forces linkage mechanism, agricultural leading enterprises guide farmers' participation in pre-production agricultural product quality and safety control through practices informed by agricultural value chain collaboration theory. By employing key collaborative approaches such as knowledge sharing, information flow optimization, risk management, resource integration, and efficiency enhancement, these enterprises effectively integrate new types of laborers, labor tools, and labor objects. This integration drives innovation in agricultural production models, achieves deep synergy between enterprises and farmers within the value chain, and ultimately accomplishes the objectives of elevating agricultural product quality and yield. The grounded theory analysis results and pathways of leading agricultural enterprises guiding farmers in pre-production agricultural product quality and safety control based on the linkage mechanism of new quality productive forces elements are presented in Table 4 and Figure 2, respectively.

Table 4. Grounded theory analysis results of leading agricultural enterprises guiding farmers' participation in pre-production quality and safety control based on the organizational linkage mechanism (selected representative evidence).

Figure 2. Pathways for leading agricultural enterprises to guide farmers in pre-production quality and safety control through the new quality productive forces elements linkage mechanism.

This study, taking four representative leading agricultural enterprises as examples, analyzes the cyclical mechanisms through which enterprises guide farmers to participate in pre-production quality and safety control. By exploring the inherent logic of “motivations-behaviors-outcomes,” it is found that the linkage mechanisms involve two dimensions: organizational and new quality productive forces elements. These are multi-dimensional linkage mechanisms that collaboratively ensure and facilitate farmers' participation in the quality and safety control of the industrial chain. The organizational linkage mechanism serves as a necessary foundation for enterprises to guide farmers in pre-production quality and safety control. It addresses the effective integration of farmers' production factors, such as land and labor, into the agricultural industrial chain by organizing contract and large-scale farmers through cooperative organizational management and absorbing individual smallholders and part-time farmers through land transfer/trusteeship. This enables various types of farmers to become the first link in the agricultural industrial chain and a necessary component of vertical collaboration. The linkage mechanism of new quality productive forces elements acts as a catalyst for enterprises to guide farmers in pre-production quality and safety control. Starting from green and standardized planting, leading agricultural enterprises optimize the combi-nation of technological innovation, labor materials, and labor objects, enabling farmers to participate in agricultural production activities conveniently and efficiently. This drives farmers to achieve self-accumulation cycles, innovation, and transformation, ensuring high-quality and high-yield outcomes.

In the quality and safety control of the entire agricultural industrial chain, leading agricultural enterprises promote farmers' active participation in pre-production quality and safety control through the synergistic effect of organizational linkage mechanisms and new quality productive forces elements linkage mechanisms, thereby improving the quality and yield of agricultural products. This mechanism provides an effective path for deep cooperation between leading agricultural enterprises and farmers, promotes the modernization and high-quality development of agricultural production, and supports the innovation and sustainable development of the agricultural industrial chain. The mechanisms through which leading agricultural enterprises guide farmers in pre-production quality and safety control are illustrated in Figure 3.

Figure 3. The mechanism of leading agricultural enterprises guiding farmers to participate in pre-production quality and safety control.

2.3 Identification of influencing factors

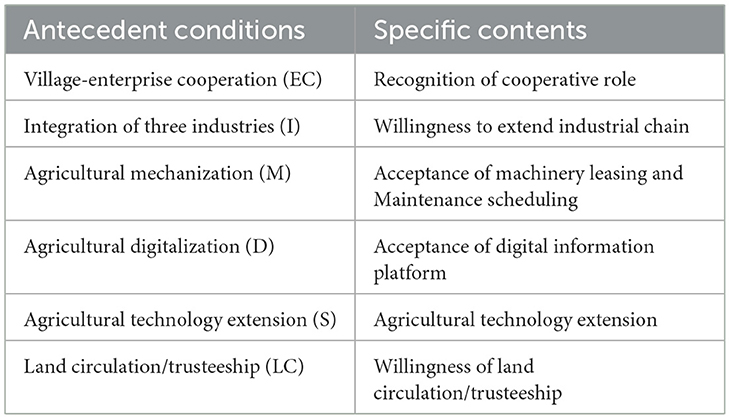

A grounded analysis of the preceding text reveals that pre-production quality and safety control in agriculture is a multi-pathed, complex collaborative behavior between agricultural leading enterprises and farmers. The integration of three industries, village-enterprise cooperation, agricultural mechanization, agricultural digitalization, and agricultural standardization have, to varying degrees, promoted farmers' participation in pre-production quality and safety control. However, the complexity of this combined pathway poses challenges to traditional regression analysis methods. Therefore, it is necessary to select key behavioral elements based on the actual needs of leading agricultural enterprises and farmers, and to explore the configurational structures under multiple behavioral interactions, in order to accurately identify the core and peripheral factors influencing farmers' participation in pre-production quality and safety control. In light of this, this paper selects five key elements—the integration of three industries, village-enterprise cooperation, agricultural mechanization, agricultural digitalization, and agricultural technology extension—as antecedent conditions for guiding farmers' deep participation in pre-production quality and safety control. The specifics are shown in Table 5.

3 Data and methods

3.1 Fuzzy set qualitative comparative analysis method

Fuzzy-set Qualitative Comparative Analysis is a research method that combines qualitative and quantitative approaches. It builds upon the theory and methods of Qualitative Comparative Analysis (QCA), integrating Boolean algebra and set theory to provide a novel research perspective for addressing complex causal relationships. By leveraging the advantages of both quantitative and qualitative analysis, fsQCA analyzes and synthesizes concurrent causal relationships among different sets through the com-parison of a certain number of cases. This means that various combinations of variables may influence multiple cases to produce the same phenomenon. From a holistic per-spective, fsQCA explores the process of complex social problems arising from multiple concurrent causes (Glaser and Strauss, 2017; Leppänen et al., 2023). Compared to crisp-set Qualitative Comparative Analysis (csQCA) and multi-value Qualitative Comparative Analysis (mvQCA), fsQCA better prevents information loss during data conversion and enhances data precision, thereby more accurately detecting the effects caused by changes in antecedent conditions (Rubinson, 2019). Due to its ability to transform causal relationships into complex causalities characterized by fuzziness, asymmetry, and equivalence, fsQCA can address partial membership issues of sets, precisely capturing the impact of conditional variable changes on outcome variables (Ong and Johnson, 2023).

This paper employs the fsQCA method, primarily considering that existing research indicates that exploring the pathways for leading agricultural enterprises to guide farmers in pre-production quality and safety control requires more than just analyzing the in-dependent effects of individual behaviors. It necessitates a holistic approach to investigate the outcomes of multiple complex variables interacting with each other. By transforming fuzzy sets into truth tables, fsQCA retains the advantages of truth table analysis in processing qualitative data, limited diversity, and simplifying configurations, thereby endowing the research with dual attributes of qualitative and quantitative analysis (Du et al., 2022). Furthermore, this paper utilizes fsQCA 3.0 software to set qualitative anchors and employs program operations to finely calibrate the variable membership and outcome membership of cases within the sets. Necessity analysis of individual conditional variables is conducted, and truth tables are constructed to explore the impact of conditional variable combinations on outcome variables. Finally, the conditional configurations are analyzed to examine the sufficiency of different conditional variable configurations on the outcome variables (Du et al., 2024).

3.2 Data source

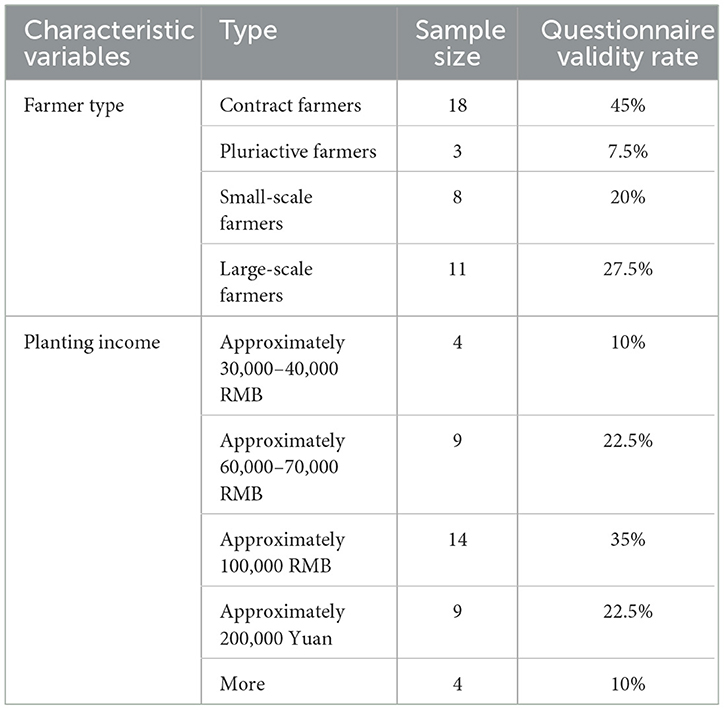

Given that the fsQCA method has different sample size requirements compared to traditional quantitative analytical methods—being suitable for small to medium-sized samples, typically considering 20–50 cases as appropriate—this study employed purposive sampling to select 40 farmer households in China's Yangtze River Delta region as the research sample. According to the research needs, the sample selection criteria included: farmers must be within the industrial radiation range of enterprise A and cover four types: contract farmers, part-time farmers, individual small-holders, and large-scale farmers. The design of the questionnaire was closely aligned with behaviors related to organizational linkage mechanisms and new quality productive forces elements linkage mechanisms. A total of 40 questionnaires were distributed, and 33 valid questionnaires were returned, meeting the standards for medium-sized sample research. The basic characteristics of the sample are detailed in Table 6.

4 Empirical analysis and results

4.1 Reliability and validity test

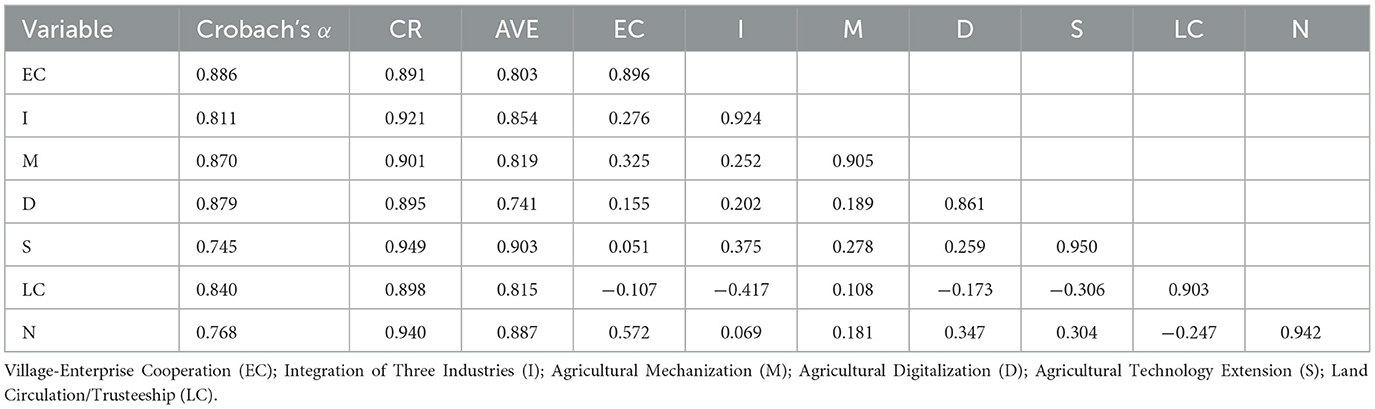

This study utilizes SPSS 20.0 software to analyze the reliability and validity of the scales. The reliability of the scales is assessed using Cronbach's alpha coefficient and CR value. The closer the alpha and CR values are to 1, the better the reliability. Generally, a value above 0.7 indicates good reliability of the scale. Validity represents the degree to which results approximate the intended targets. The convergent validity of the scales is typically measured using the average variance extracted (AVE) of all variables. An AVE value above 0.5 indicates good convergent validity. The discriminant validity is optimal when the AVE is higher than the correlation coefficients of other variables. The test results are shown in Table 7.

4.2 Data calibration

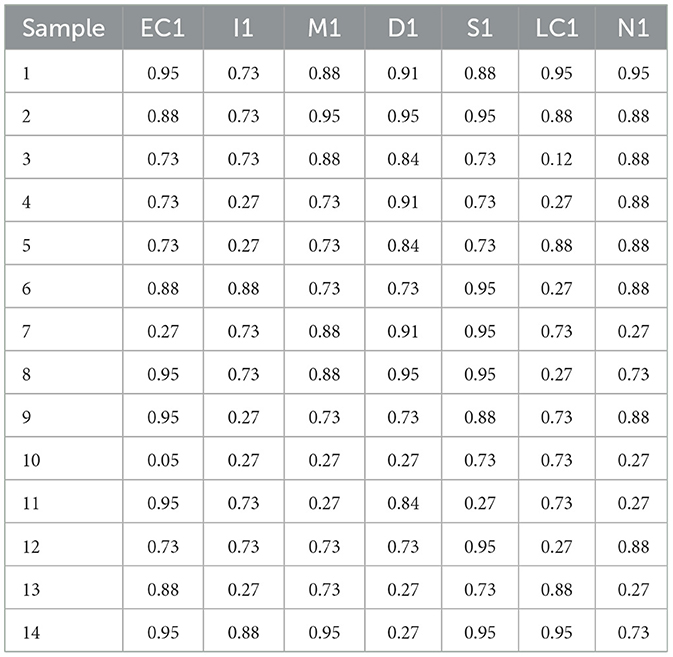

Data calibration is the process of converting variables into sets and calculating membership scores. In fsQCA software, the membership relationships of each instance within the sets and the outcome membership relationships are calibrated. 1 indicates absolute membership, 0 indicates absolute non-membership, and 0.5 is the maximum ambiguity point for assessing whether an instance belongs to a set. Since the variables “Village-Enterprise Cooperation,” “Integration of Three Industries,” “Agricultural Mechanization,” “Agricultural Digitalization,” “Agricultural Technology Extension,” and “Pre-Production Quality and Safety Control Level” in this study were obtained through a four-point Likert scale, the original data must be transformed into values between 0 and 1 before fsQCA analysis. To calibrate the variables in each sample, this paper selects three anchor points: 4, 2.5, and 1. Consequently, the membership scores of each variable in the samples are shown in Table 8.

During the analysis, sensitivity checks were conducted by subtly adjusting the calibration anchor points. While these adjustments led to minor fluctuations in membership scores, the core configurational pathways identified in this study, along with their explanatory power, remained substantially robust. Due to space constraints, a detailed report of these sensitivity analyses is omitted from the main text.

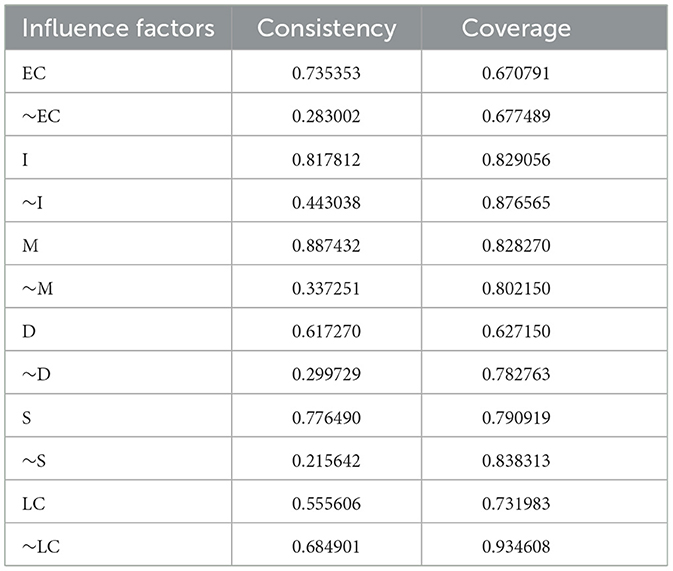

4.3 Single condition necessity analysis

For the needs of fsQCA analysis, a necessity analysis must first be performed, where necessity refers to the explanatory power of a single conditional variable on the outcome variable. Before truth table analysis, a consistency threshold of 0.9 must be met for the conditional variable to be considered necessary. If the consistency is 1, this condition is essential, and the subset relationship between the conditional variable and the outcome variable is optimal. The analysis results are shown in Table 9.

4.4 Results

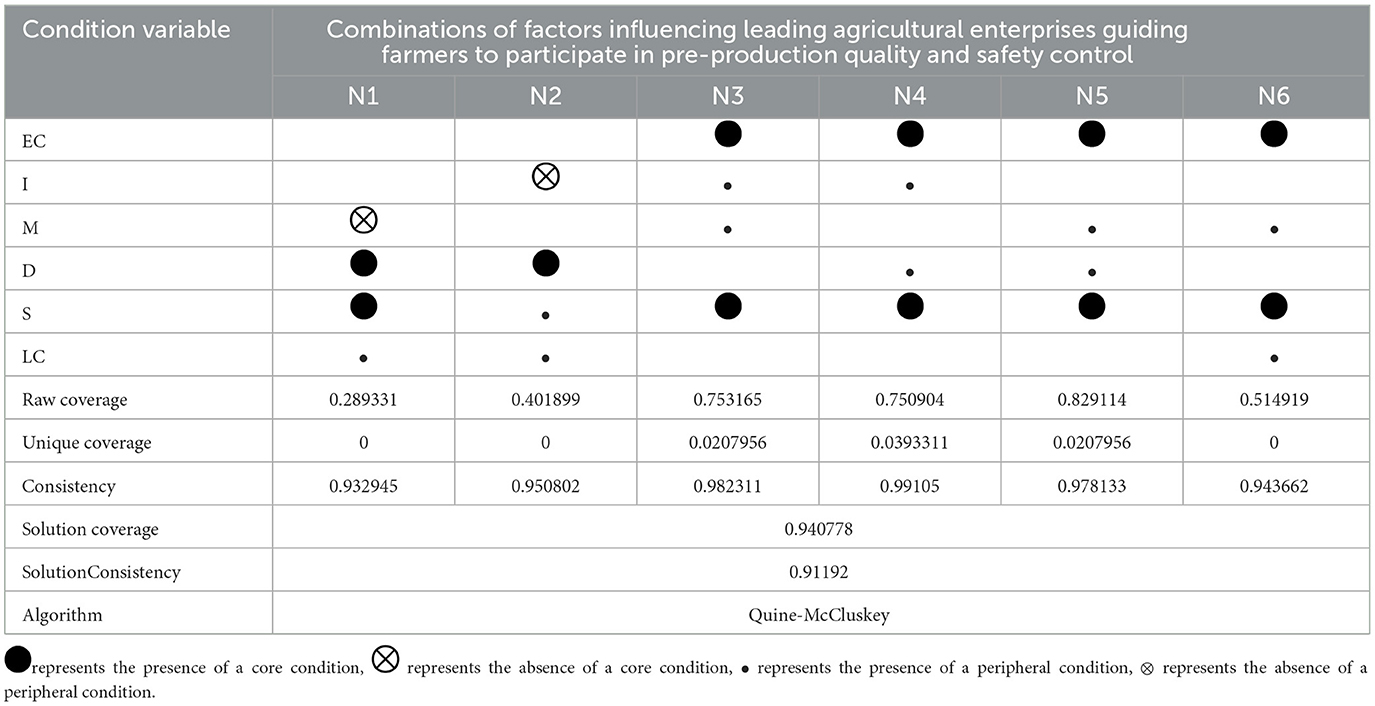

After conducting necessity analysis on individual conditional variables, this paper analyzes the sufficiency of configurations composed of different combinations of conditional variables on the outcome variable. Intermediate solutions are used to determine the number of configurations and the included conditions, and these are combined with parsimonious solutions to distinguish between core conditions and peripheral conditions. A solid circle indicates the presence of a conditional variable, a hollow circle indicates the absence of a conditional variable, a large circle represents a core condition, a small circle represents a peripheral condition, and a blank indicates that the conditional variable can be either present or absent. Standardized analysis is performed using fsQCA 4.0 software, and the configuration analysis results of the combinations of influencing factors for farmers' participation in vertical collaboration in the industrial chain are shown in Table 10.

As shown in Table 10, the overall consistency of the configurations in this study is 0.912, indicating that the six configurations explain 0.912 of the extent to which leading agricultural enterprises guide farmers to participate in pre-production quality and safety control. The overall coverage rate is 0.941, indicating that the research results ultimately cover 94.1% of the case scenarios. The consistency of all configurations in this paper is higher than the acceptance standard of 0.8. These configurations and the willingness of farmers to participate in vertical collaboration in the industrial chain have a good subset relationship, demonstrating that the antecedent conditions have a good explanatory power for the outcome variable (pre-production quality and safety control level of agricultural products). Based on the above research, this paper has derived a total of six configurations with high levels of pre-production quality and safety control for agricultural products.

Configuration N1 (~M*D*S*LC) indicates that a low level of agricultural mechanization, a high level of agricultural digitalization, a strong agricultural technology extension effort, and a high willingness for land trusteeship can result in high control over pre-production quality of agricultural products.

Configuration N2 (~I*D*S*LC) indicates that a low level of integration of three industries, a high level of agricultural digitalization, adequate agricultural technology extension, and a high willingness for land trusteeship can result in a high level of control over pre-production quality of agricultural products.

Configuration N3 (EC*I*M*S) indicates that participation in cooperatives, a high level of integration of three industries, agricultural mechanization, and a strong agricultural technology extension effort can result in high control over pre-production quality of agricultural products.

Configuration N4 (EC*I*D*S) indicates that participation in cooperatives, a high level of integration of three industries, a high degree of digitalization, and a strong agricultural technology extension effort can result in high control over pre-production quality of agricultural products. This configuration has the highest consistency index and the strongest explanatory power.

Configuration N5 (EC*M*D*S) indicates that participation in cooperatives, high levels of agricultural mechanization and digitalization, and a strong agricultural technology extension effort can result in high control over pre-production quality of agricultural products.

Configuration N6 (EC*M*S*LC) indicates that participation in cooperatives, a high level of agricultural mechanization, a strong agricultural technology extension effort, and a high willingness for land trusteeship can result in high control over pre-production quality of agricultural products.

Through the interpretation of the above six configurations, it can be seen that all six configurations significantly affect the level of pre-production quality and safety control of agricultural products. The explanatory power ranking is: N4 > N3 > N5 > N2 > N6 > N1.

4.5 Robustness check

Robustness checks are used to ensure that research findings are not accidental phenomena resulting from specific data or methodological choices. By altering certain parameters or conditions, if the results remain consistent, then these results can be considered reliable. Common robustness check methods include: adjusting calibration values, changing case frequency thresholds, varying consistency thresholds, and adding other conditions related to the outcome. This paper employs the method of changing case consistency thresholds to analyze whether the original results are robust by comparing the state of the set relationships and parameter differences before and after the change. By adjusting the case consistency threshold from 0.8 to 0.85, the generated configurations remain consistent with the original configurations, and the consistency and coverage of the solutions do not change. The robustness check shows that the configuration results are robust.

4.6. Result discussion

Based on the six configurations, three overarching configurational types can be summarized regarding how leading agricultural enterprises guide farmers to participate in pre-production quality and safety control.

4.6.1 Configuration 1: three-industry integration driven

This configuration includes configurations N3 and N4, characterized by the deep participation of cooperatives and the enhancement of three-industry integration levels, combined with the integrated application of agricultural mechanization, agricultural technology extension, and digital technologies. In configuration N3, the active involvement of cooperatives, high levels of three-industry integration, and the synergistic effect of agricultural mechanization and agricultural technology extension significantly enhance pre-production quality control capabilities of agricultural products. Configuration N4 further introduces higher levels of digital technology, strengthening the refined management of agricultural production, and demonstrating higher consistency indices and explanatory power in fsQCA analysis. This configuration is suitable for leading agricultural enterprises that promote industrial chain collaboration through modern agricultural production and deep industrial integration. By leading three-industry integration and modern technologies, these enterprises can stimulate farmers' willingness to participate and improve their behavioral performance in pre-production quality control. Therefore, the three-industry integration driven configuration not only helps to promote the coordinated development of agriculture, industry, and service sectors but also pro-vides continuous momentum for high-quality agricultural production, enhancing the overall quality control level of the agricultural industrial chain by encouraging active farmer participation.

Under this configuration, leading agricultural enterprises should collaborate with large-scale farmers to transfer and manage idle land to form large-scale planting, while also purchasing mechanized equipment and providing agricultural technology extension to part-time farmers and contract farmers to establish standardized production. Leading agricultural enterprises should further strengthen cooperation with cooperatives, promote the integrated development of agriculture with secondary and tertiary industries through the organized management of cooperatives, and facilitate the development of primary agricultural products toward processed agricultural products, branded products, and agricultural tourism, thereby upgrading products and increasing added value. Various types of farmers should participate in the integrated development of rural primary, secondary, and tertiary industries, forming a complete “production-sales-tourism” industrial chain, which enhances farmers' subjective awareness of pre-production quality and safety control through industrial chain extension. This aligns well with traditional agricultural supply chain theories that emphasize enhancing agricultural product value-added and quality through industrial extension and value chain integration. Numerous prior studies have indicated that developing secondary and tertiary industries such as agricultural product processing, warehousing and logistics, and agritourism contributes to the formation of a complete industrial chain, which in turn imposes higher demands on the quality of primary agricultural products and prompts producers to strengthen quality control. However, the unique contribution of this study lies in its explicit revelation of the crucial organizational role of cooperatives in the integration of primary, secondary, and tertiary industries, and how agricultural leading enterprises, by spearheading this integration and technological modernization, can significantly stimulate farmers' willingness to participate, thereby improving their performance in pre-production quality control.

4.6.2 Configuration 2: digital intelligence driven

This configuration encompasses configuration N5, emphasizing the core role of digital technologies and intelligent means in agricultural production, especially in the context of deep integration of agricultural mechanization and digital technologies. Con-figuration N5 indicates that, based on cooperative participation, the enhancement of agricultural mechanization levels, the widespread application of digital technologies, and the strengthening of agricultural technology extension jointly build an efficient pre-production quality control system. The digital intelligence driven configuration is particularly suitable for agricultural production environments with high digital technology penetration and advanced information levels. Under this configuration, relying on advanced digital and intelligent means can achieve precise monitoring and quality assurance of the entire agricultural production process, thereby promoting the trans-formation of agricultural production toward efficiency, greenness, and intelligence.

This configuration emphasizes the leading role of agricultural enterprises in promoting and applying digital technologies to encourage farmers to actively participate in pre-production quality control, ensuring that agricultural products are produced more accurately and efficiently. The leading role of agricultural enterprises provides farmers with technical support and management tools to help them overcome the limitations of traditional production methods, thereby improving the overall quality control capabilities of the industrial chain. In this model, it is recommended that agricultural enterprises provide more comprehensive technical support to various types of farmers. For contract farmers and large-scale farmers, enterprises should use digital platforms and intelligent equipment to help farmers monitor the entire agricultural production process. Enterprises should improve information flow capabilities and socialized services such as agricultural machinery and technology for individual smallholders and part-time farmers, enhancing their initiative to participate in pre-production quality and safety control. This aligns perfectly with current research hotspots in the fields of smart agriculture and digital agriculture. Extensive prior research has already demonstrated the technical effectiveness of digital technologies in quality control. However, this study's unique contribution lies in its not only confirming this technical efficacy but also emphasizing the leading role of agricultural enterprises in the promotion and application of digital technologies. It further elucidates how these enterprises, by providing comprehensive technical support and management tools, can effectively incentivize various types of farmers to actively participate in pre-production quality control, thereby overcoming the limitations of traditional production methods and achieving overall supply chain quality improvement. This significantly enriches the practical pathways for empowering smallholder farmers with digital technologies, revealing the crucial role of leading enterprises in driving agricultural digital transformation and bridging the “digital divide,” thus offering a new perspective for enhancing the modernization of smallholder farming in our country.

4.6.3 Configuration 3: land trusteeship driven

This configuration includes configurations N1, N2, and N6, characterized by the high manifestation of land trusteeship willingness, supplemented by the support of agricultural mechanization and agricultural technology extension. The implementation of land trusteeship significantly reduces the presence of individual smallholders and promotes the increase of contract farmers, part-time farmers, and large-scale farmers, driving the intensive management model of farmers. In configurations N1 and N2, the combination of the strength of land trusteeship willingness, the level of agricultural digitalization, and effective agricultural technology extension plays a crucial role. Especially in the context of strong land trusteeship willingness, enterprises can improve farmers' willingness and ability to participate in pre-production quality control by optimizing land resource al-location and strengthening technical support. The land trusteeship model helps to reduce the dispersion among farmers, increase production scale, and thereby enhance their enthusiasm and efficiency in participating in quality control. In configuration N6, the synergistic application of land trusteeship and agricultural mechanization further enhances farmers' production capacity and quality control levels.

The land trusteeship model helps farmers improve production efficiency and strengthen quality and safety control through centralized management, large-scale production, and technical support. The guidance and support of agricultural enterprises enable farmers, especially contract farmers, part-time farmers, and large-scale farmers, to better participate in the quality control process of agricultural products, thereby im-proving the quality and safety level of the entire industrial chain. The land trusteeship driven configuration highlights the positive role of land trusteeship in enhancing farmers' initiative to participate in pre-production quality control. This model is particularly suitable for areas where land trusteeship obligations and agricultural mechanization levels are at a medium to low stage. Agricultural enterprises should further improve land trusteeship and transfer mechanisms, optimize resource allocation, and strengthen co-operation with cooperatives. Through the organized management of cooperatives, they should promote the implementation of land trusteeship models and provide land trusteeship support for part-time farmers and individual smallholders. For contract farmers and large-scale farmers, enterprises should continuously promote the synergistic application of land trusteeship models and agricultural mechanization, improve farmers' production efficiency through advanced management systems, and strengthen quality monitoring to promote the quality improvement of the entire industrial chain. This aligns highly with existing research on appropriate scale farming and the agricultural socialized service system in China. Numerous studies have argued that land transfer and trusteeship are crucial pathways to achieving large-scale and intensive agricultural production, enhancing agricultural efficiency and market competitiveness. Moreover, large-scale operations often imply more standardized production management and higher quality standards. Building upon existing findings, this study more deeply reveals the indirect yet profound mechanisms through which the land trusteeship model impacts pre-production quality control of agricultural products. Specifically, this research emphasizes the synergistic effect of land trusteeship and agricultural mechanization in enhancing farmers' production capabilities and quality control levels. This moves beyond the traditional perspective that solely focuses on the economic benefits of land trusteeship, instead delving into its potential in reshaping farmers' production behaviors and stimulating their proactive engagement in quality control. These findings offer new practical insights for improving land trusteeship and transfer mechanisms, optimizing agricultural resource allocation, and constructing a more effective agricultural socialized service system.

Through the summarization and analysis of the six configurations, it can be seen that under the combined effect of village-enterprise cooperation, three-industry integration, agricultural mechanization, digitalization, and agricultural technology extension, farmers show a strong willingness to participate in pre-production quality and safety control of agricultural products. These configurations not only effectively enhance the quality and safety control capabilities of agricultural product raw materials by leading agricultural enterprises but also reduce quality risks in the mid- and post-production stages, thereby improving the quality and safety control efficiency of the entire industrial chain. Furthermore, the research results indicate that the leading role of agricultural enterprises on farmers is the result of multi-factor synergy, which further verifies the complexity of the configurations and increases the credibility of problem analysis based on a configurational perspective.

5 Conclusions

This study, focusing on leading agricultural enterprises and farmers in the Yangtze River Delta region of China, explores the configurational pathways of leading agricultural enterprises guiding farmers to participate in pre-production quality and safety control, combining grounded theory and fuzzy-set Qualitative Comparative Analysis. The research provides constructive suggestions for leading agricultural enterprises to guide farmers in participating in vertical collaboration within the industrial chain to a certain extent, but it still has some limitations. In the configuration analysis process, this paper selected five conditional variables—village-enterprise cooperation, integration of three industries, agricultural mechanization, agricultural digitalization, and agricultural technology extension—to study their configurational effects on farmers' participation in pre-production quality and safety control. Considering that enterprise quality control behaviors in grounded analysis can be further subdivided, future research could further refine the configurational effects of specific enterprise behaviors in quality control on guiding farmers' participation in pre-production quality control.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Ethics statement

Ethical approval was not required for the studies involving humans. The studies were conducted in accordance with the local legislation and institutional requirements. Written informed consent for participation was not required from the participants or the participants' legal guardians/next of kin in accordance with the national legislation and institutional requirements.

Author contributions

CL: Validation, Software, Conceptualization, Methodology, Writing – original draft. WL: Writing – review & editing, Funding acquisition, Supervision, Project administration. YY: Conceptualization, Software, Writing – original draft, Validation. QY: Writing – review & editing, Funding acquisition, Supervision. ML: Writing – original draft, Data curation.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by the National Natural Science Foundation of China (32472013); Jiangsu University Philosophy and Social Sciences Research Major Project (2024SJZD045); Zhen-jiang City Soft Science Project (RK2024009); the Major Basic Science (Natural Science) Foundation of the Jiangsu Higher Education Institutions of China (24KJA210001); the Independent Innovation Fund of Agricultural Science and Technology in Jiangsu Province (CX(21)1007); Zhenjiang Social Science Joint Research Project (2024YBL061); and College Students' Innovation and Entrepreneurship Projects (202410299146).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Gen AI was used in the creation of this manuscript.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Footnotes

1. ^Ministry of Agriculture and Rural Affairs. Opinions on Promoting the Growth and Strengthening of Agricultural Industrialization Leading Enterprises. Available online: http://www.moa.gov.cn/govpublic/XZQYJ/202110/t20211026_6380529.htm (Accessed 22 October 2021).

References

Agrawal, S., Kumar, V., Kumar, S., and Shahi, S. K. (2022). Plant development and crop protection using phytonanotechnology: a new window for sustainable agriculture. Chemosphere 299:134465. doi: 10.1016/j.chemosphere.2022.134465

Cai, R., Wang, Z. Y., and Qian, L. (2019). Does joining a cooperative promote family farms to choose environmentally friendly production methods? — a case study of reducing fertilizer and pesticide use. China Rural Obs. 51−65. doi: 10.20074/j.cnki.11-3586/f.2019.01.004

Chen, C. S. (2007). Evolutionary logic and classification of Chinese farmers. Agric. Econ. Issues 79−84, 112. doi: 10.3969/j.issn.1000-6389.2007.11.016

Chen, J., Han, Q., and Yang, R. (2024). The impact of industrial organization models on the quality certification behavior of large-scale farmers: an empirical analysis based on data from China's third agricultural census. Agric. Technol. Econ. 43−58. doi: 10.13246/j.cnki.jae.20230620.002

Chen, W. Q., and Ma, P. C. (2023). Cooperative support and small farmers' quality control behavior: theoretical perspectives and empirical testing. J. Huazhong Agric. Univ. 82−92. doi: 10.13300/j.cnki.hnwkxb.2023.01.008

Cui, Y., Zhao, C., and Zhang, Q. (2024). Impact of digital transformation in agribusinesses on total factor productivity. Int. Food Agribus. Manag. Rev. 27, 843–857. doi: 10.22434/ifamr1064

Despoudi, S., Papaioannou, G., Saridakis, G., and Dani, S. (2018). Does collaboration pay in agricultural supply chain? An empirical approach. Int. J. Prod. Res. 56, 4396–4417. doi: 10.1080/00207543.2018.1440654

Du, Y. Z., Liu, Q. C., and Chen, K. W. (2022). Ecological business environment, total factor productivity, and the multidimensional models of urban high-quality development: A configurational analysis from a complex systems perspective. Manag. World 38, 127–145. doi: 10.19744/j.cnki.11-1235/f.2022.0123

Du, Y. Z., Sun, N., and Liu, Q. C. (2024). Using mixed methods to develop and analyze complex mediation models: a case study of business environment promoting innovation vitality, coordinating new productive forces, and “employment priority”. Manag. World 40, 217–237. doi: 10.19744/j.cnki.11-1235/f.2024.0071

Elbeltagi, A., Srivastava, A., Deng, J., Li, Z., Raza, A., Khadke, L., et al. (2023). Forecasting vapor pressure deficit for agricultural water management using machine learning in semi-arid environments. Agric. Water Manag. 283:108302. doi: 10.1016/j.agwat.2023.108302

Gao, Q., Cui, W., and Han, G. (2024). The income growth and catch-up effect of rural specialty industries under the high-quality development of agricultural industries: evidence from China's characteristic agricultural product advantage areas. Macroecon. Qual. Res. 12, 76–89. doi: 10.13948/j.cnki.hgzlyj.2024.06.006

Glaser, B., and Strauss, A. (2017). Discovery of Grounded Theory: Strategies for Qualitative Research. New York, NY: Routledge. doi: 10.4324/9780203793206

Guo, Q. (2023). The role of agricultural mechanization in agricultural supply-side structural reform. Hebei Agric. Mach. 6, 15−17. doi: 10.15989/j.cnki.hbnjzzs.2023.06.046

He, M. Z., and You, M. H. (2022). Mechanism of small farmers entering the agricultural full-industry chain cycle: a case study of four agricultural supply chain innovation and application pilot enterprises in Hubei. China Circ. Econ. 36, 23–35. doi: 10.14089/j.cnki.cn11-3664/f.2022.02.003

Headley, J. C. (1972). Agricultural productivity, technology, and environmental quality. Am. J. Agric. Econ. 54, 749–756. doi: 10.2307/1239209

Huang, Q., Guo, W., and Wang, Y. (2024). A study of the impact of new quality productive forces on agricultural modernization: empirical evidence from China. Agriculture 14:1935. doi: 10.3390/agriculture14111935

Jin, Q., Dang, H., Wang, H., and Zhang, Z. (2024). Exploring cooperative mechanisms in the Chinese agricultural value chain: a game model analysis based on leading enterprises and small farmers. Agriculture 14:437. doi: 10.3390/agriculture14030437

Jin, Y., Liu, J., Xu, Z., Yuan, S., Li, P., Wang, J., et al. (2021). Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 14, 1–19. doi: 10.25165/j.ijabe.20211404.6821

Leppänen, P., George, G., and Alexy, O. (2023). When do novel business models lead to high performance? A configurational approach to value drivers, competitive strategy, and firm environment. Acad. Manag. J. 66, 164–194. doi: 10.5465/amj.2020.0969

Li, B., Zhuo, N., Ji, C., and Zhu, Q. (2022). Influence of smartphone-based digital extension service on farmers' sustainable agricultural technology adoption in China. Int. J. Environ. Res. Public Health 19:9639. doi: 10.3390/ijerph19159639

Li, D., Zhou, H., and Zhou, L. (2021). Brand premium and agricultural product quality safety: evidence from rice cultivation in Jiangsu. Financ. Res. 47, 34–48. doi: 10.16538/j.cnki.jfe.20200918.402

Li, H., Chen, L., and Zhang, Z. (2022). A study on the utilization rate and influencing factors of small agricultural machinery: evidence from 10 hilly and mountainous Provinces in China. Agriculture 13:51. doi: 10.3390/agriculture13010051

Li, L., Gu, T., and Shi, Y. (2024). The influence of new quality productive forces on high-quality agricultural development in China: mechanisms and empirical testing. Agriculture 14:1022. doi: 10.3390/agriculture14071022

Li, W., Li, Y. C., and Yang, Q. Z. (2025). Research on agricultural machinery maintenance scheduling strategy considering fault classification. J. Agric. Mechanization Res. 48, 1−8. Available online at: http://kns.cnki.net/kcms/detail/23.1233.S.20250519.1644.010.html

Li, W., Liu, C., Yang, Q., and Zhang, X. (2023). Factors influencing farmers' vertical collaboration in the agri-chain guided by leading enterprises: a study of the table grape industry in China. Agriculture 13:1915. doi: 10.3390/agriculture13101915

Li, W., Ni, X., Zuo, X., Liu, S., and Mei, Q. (2022). Study on influencing factors of micro and small enterprises' work safety behavior in chinese high-risk industries. Front. Psychol. 13:880205. doi: 10.3389/fpsyg.2022.880205

Liang, Y., Bi, W., and Zhang, Y. (2024). A review and outlook on agricultural industrial organization models. Chin. J. Agric. Mach. Chem. 45, 317–324.

Liao, Y. H. (2024). Configuration analysis of factors influencing farmers' planting structure: a comparison between small and large-scale farmers. Arid Zone Resour. Environ. 38, 51–60. doi: 10.13448/j.cnki.jalre.2024.118

Lin, J., Zheng, Q., and Benitez, J. (2024). Impact of digital orientation and corporate social responsibility activities on the alliance relationship stability in contract farming. Inf. Manag. 61:103958. doi: 10.1016/j.im.2024.103958

Liu, H. C., Wang, X. W., and Chen, W. H. (2021). Research on agricultural product safety production mechanisms based on blockchain technology. Agric. Econ. Issues 66−76. doi: 10.13246/j.cnki.iae.2021.11.007

Liu, L. S. (2024). Empowering the development of high-quality and high-end agricultural products through weeding robots. China Agric. Reclam. 45. doi: 10.16342/j.cnki.11-1157/s.2024.06.025

Liu, S., and Qin, Q. (2021). Research on the path of geographical indication agricultural products promoting rural revitalization. Agric. Econ. 141−142. doi: 10.3969/j.issn.1001-6139.2021.04.052

Liu, X., Li, W., Zhao, C., et al. (2022). Research on the development strategy for modern smart ecological agriculture in China toward 2050. Chin. J. Eng. Sci. 24, 38–45. doi: 10.15302/J-SSCAE-2022.01.006

Liu, Y. (2022). Research on the development path of China's green food industry supply chain under the belt and road initiative. Yunnan Soc. Sci. 122−130. Available online at: https://link.cnki.net/urlid/53.1001.c.20220711.1806.004

Lu, Q. Z., and Zhang, Y. F. (2022). How cooperatives promote farmers' green production. J. For. Econ. Manag. 21, 707–715. doi: 10.16195/j.cnki.cn36-1328/f.2022.06.76

Luo, B., and Geng, P. (2024). New productivity in agriculture: theoretical framework, core concepts, and pathways for improvement. Agric. Econ. Issues 13−26. doi: 10.13246/j.cnki.iae.2024.04.010

Ma Juan (2024). Opinions of the CPC Central Committee and the State Council on Effectively Promoting Rural Revitalization by Learning and Applying the Experience of the “Thousand Villages Demonstration, Ten Thousand Villages Renovation” Project. No. 6 State Council Bulletin, China Government Website. Available online at: https://www.gov.cn/gongbao/2024/issue_11186/202402/content_6934551.html (Accessed January 1, 2024).

Mishra, V., Ishdorj, A., Tabares Villarreal, E., and Norton, R. (2024). Collaboration in agricultural value chains: a scoping review of the evidence from developing countries. J. Agribus. Dev. Emerg. Econ. doi: 10.1108/JADEE-12-2023-0311

Ong, W. J., and Johnson, M. D. (2023). Toward a configural theory of job demands and resources. Acad. Manag. J. 66, 195–221. doi: 10.5465/amj.2020.0493

Pan, S. Q., and Luo, F. (2021). Research on the Shaoguan “Internet +” high-end agricultural product integrated monitoring platform. Coop. Econ. Technol. 96−97. doi: 10.13665/j.cnki.hzjjykj.2021.06.040

Pei, X., Zheng, X., and Wu, C. (2024). How part-time farming affects cultivated land use sustainability: survey-based assessment in China. Land 13:1242. doi: 10.3390/land13081242

Peng, P., and Xu, Z. (2023). Subjective preferences, liquidity constraints, and price risk management under large-scale farm management. China Agric. Econ. Rev. 16, 76–96. doi: 10.1108/CAER-12-2022-0287

Plott, C. R. (1982). Industrial organization theory and experimental economics. J. Econ. Lit. 20, 1485–1527.

Ren, D. P. (2024). Promoting the overall quality improvement of farmers' cooperatives through unions. China Farmers Coop. 14−15. doi: 10.3969/j.issn.1674-5914.2024.12.zgnmhzc202412005

Rubinson, C. (2019). Presenting qualitative comparative analysis: notation, tabular layout, and visualization. Methodol. Innov. 12:2059799119862110. doi: 10.1177/2059799119862110

Shen, Z., Wang, S., Boussemart, J. P., et al. (2022). Digital transition and green growth in Chinese agriculture. Technol. Forecast. Soc. Change 181:121742. doi: 10.1016/j.techfore.2022.121742

Wang, H., and Qiu, T. (2024). The effects of farmer cooperatives on agricultural carbon emissions reduction: evidence from rural China. J. Clean. Prod. 450:141881. doi: 10.1016/j.jclepro.2024.141881

Wang, J., Zhou, H., and Hu, X. (2025). The mechanism of fruit and vegetable industry alliances promoting the connection between small farmers and modern agriculture. China Circ. Econ. 39, 33–44. doi: 10.14089/j.cnki.cn11-3664/f.2025.03.004

Wu, C. (2023). Embedded governance of agricultural leading enterprises over cooperative farmers: a case study of donghua sugar factory. J. China Agric. Univ. 40, 82–100. doi: 10.13240/j.cnki.caujsse.2023.01.002

Xu, Y., Liu, S., and Jiang, Y. (2025). Research on the pathways for high-quality development of China's agricultural product export trade empowered by new productive forces. North. Hortic. 140−146. doi: 10.11937/bfyy.20242936

Xu, Z., Zheng, L., and Cheng, M. (2023). New productivity drives high-quality development: advantageous conditions, key issues, and pathways for selection. J. Southwest Univ. 49, 12–22. doi: 10.13718/j.cnki.xdsk.2023.06.002

Yang, S., and Li, W. (2022). The impact of socialized agricultural machinery services on land productivity: evidence from China. Agriculture 12:2072. doi: 10.3390/agriculture12122072

Yin, S., Wang, Y., and Xu, J. (2022). Developing a conceptual partner matching framework for digital green innovation of agricultural high-end equipment manufacturing system toward Agriculture 5.0: a novel niche field model combined with fuzzy VIKOR. Front. Psychol. 13:103958. doi: 10.3389/fpsyg.2022.924109

Yu, L. H., Gao, Q., and Jiang, Z. (2022). The impact of land trusteeship on farmers' ecological and economic benefits and its boundaries. Agric. Technol. Econ. 22−36. doi: 10.13246/j.cnki.jae.20210913.001

Yuan, L., Wentai, B., and Yuejie, Z. (2024). Review and prospect of agricultural industry organization model research. J. Chin. Agric. Mechanization 45:317. doi: 10.13733/j.jcam.issn.2095-5553.2024.08.046

Zeng, M. L. (2021). An empirical study on enterprises' willingness to control quality and safety in the agricultural product supply chain: based on a survey of 42 enterprises in Hubei. South. Agric. Mach. 52, 21–23. doi: 10.3969/j.issn.1672-3872.2021.20.006

Zeng, M. L. (2021). Quality coordination control mechanism and optimization path of agricultural product supply chain. Bus. Econ. Res. 145−149. doi: 10.3969/j.issn.1002-5863.2021.16.035

Zhang, Y. F., Lü, C. C., and Lu, Q. Z. (2022). Branding of vegetable and fruit cooperatives and farmers' agricultural product quality control behavior — influence mechanisms and effect measurement. J. China Agric. Univ. 27, 283–298. doi: 10.11841/j.issn.1007-4333.2022.07.25

Zhang, Z. X., and Zhao, H. (2013). The predicaments of new agricultural operating entities and their system and mechanism innovations. Reform 78−87. doi: 10.3969/j.issn.2095-5286.2023.01.007

Zheng, L. (2024). Big hands holding small hands: the role of new agricultural operating entities in farmland abandonment. Food Policy 123:102605. doi: 10.1016/j.foodpol.2024.102605

Zheng, M., Yan, S., and Xu, S. (2025). Digital economy, industry–academia–research collaborative innovation, and the development of new-quality productive forces. Sustainability 17:318. doi: 10.3390/su17010318

Zhong, Z., and Kong, X. (2012). The impact of industrial organization models on agricultural product quality and safety: evidence from the dairy industry. Manag. World 79−92. doi: 10.19744/j.cnki.11-1235/f.2012.01.009

Zhou, W., and Xu, L. (2023). On new quality productivity: connotative characteristics and key focus areas. Gaige 1−13. Available online at: https://kns.cnki.net/kcms2/article/abstract?v=7HNy6Ze5ODGuztoEH20dzIhFX2xVE-0k_EX-IcMbqEVmkfXweMt-i6EMTHkLk3U8YrBS6vEOOcGuEhnKHW22HN_lIZPkL-l9a7t_8U7nXH6wpi2MnSAw5p-kXfAubzFiIXUe4CAAi78mlIxssASl864L8z0zq3SgpNh7-y-hkzykH0v4MEjht55stl7SVjOXLGuFQSka6Xw=&uniplatform=NZKPT&language=CHS

Keywords: agricultural leading enterprises, farmers, agricultural product quality, grounded theory, qualitative comparative analysis

Citation: Liu C, Li W, You Y, Yang Q and Li M (2025) Research on leading agricultural enterprises guiding farmers' participation in pre-production quality and safety control: evidence from the Yangtze River Delta Region of China. Front. Sustain. Food Syst. 9:1615223. doi: 10.3389/fsufs.2025.1615223

Received: 20 April 2025; Accepted: 05 June 2025;

Published: 02 July 2025.

Edited by:

Francesco Bozzo, University of Bari Aldo Moro, ItalyReviewed by:

Muhamad Nurdin Yusuf, Universitas Galuh, IndonesiaYang Shen, Xiamen University, China

Xiaofeng Fan, Hainan University, China