- Johann Heinrich von Thünen Institute, Institute of Sea Fisheries, Bremerhaven, Germany

Maximizing resource efficiency and reducing waste in fish processing are key to enhancing economic productivity, conserving resources, and ensuring nutritional security. However, publicly accessible data on seafood processing residues in Germany remain unavailable, making it difficult to accurately assess resource efficiency. Considerable quantities of salmon are processed in the country, generating residues, co-products or by-products, herein summarized under rest raw material (RRM). To address this data gap, volumes, utilization, and applications of salmon RRM for 2020 were systematically collected, mapped, and analysed using material flow analysis (MFA). Results highlight the quantities available at each step along the value chain and the current utilizations of this biomass. The applied mixed-methods approach, incorporating industry reports, surveys, expert interviews, and official statistics, revealed that salmon processing generates around 19,500 tonnes of RRM in Germany. When factoring in imports, nearly 40,000 tonnes of RRM are processed in total. Of all salmon raw material processed in Germany, ~98% is utilized for food and feed and only about 2% go into disposal. Less than 1% of produced food-grade salmon oil and meal is used for domestic human consumption. In light of these results, the potential for transforming salmon rest raw material into high-value products, making use of its valuable bioactive compounds, is discussed, considering current challenges, such as their confinement to niche markets or procedural difficulties in need of resolution. These findings provide actionable insights that underscore the potential for strategic RRM management to enhance the economic and ecological sustainability of aquatic biomass processing, supporting global food security efforts.

1 Introduction

“Waste is the symbol of inefficiency of any modern society and a representation of misallocated resources” (Song et al., 2015).

Sustainable food production has become a critical global challenge of the 21st century, driven by the need to feed a growing population while minimizing environmental impact. Central to this challenge is the efficient use of existing natural resources, a key objective outlined in the United Nations Sustainable Development Goals (SDGs) (United Nations, 2024), with SDG 2 focused on ending hunger and achieving food security and SDG 12 emphasising sustainable consumption and production patterns, including responsible waste management (United Nations, 2024). In response, resource efficiency has been integrated into Germany’s national sustainability strategy (Bundesregierung Deutschland, 2021), and the sustainable use of biological resources is promoted through the German Biomass Strategy.

A significant focus of sustainable food production is aquatic biomass, which is rich in essential nutrients such as protein and healthy fats. Harnessing this resource efficiently plays a crucial role in strengthening global food security (Food and Agriculture Organization of the United Nations (FAO), 2022). The aquatic species consumed most in Germany in 2020 is farmed Atlantic salmon (Salmo salar), with a share of 18.8% it accounts for the major portion of the market volume (Fisch Informationszentrum e.V. (FIZ), 2023). Also globally, Atlantic salmon was among the most significant farmed aquatic species in 2020, with a total sales volume of 2,721,000 tonnes and a market value of 15 billion USD, ranking third in value among all farmed aquatic biomass (Food and Agriculture Organization of the United Nations (FAO), 2022). That year, Norway, the leading producer in Northern Europe, exported 1.1 million tonnes of cage-farmed salmon for further processing (Aandahl, 2021).

During processing, substantial amounts of residues or rest raw material (RRM)1 are produced, including heads, viscera, skins and frames. These have the potential to be transformed into valuable products, such as food items, pharmaceuticals, and animal feed or other value-added products, thereby contributing to both economic and environmental sustainability (Shahidi et al., 2019). Despite advances in understanding the nutritional and economic potential of salmon RRM (Ramírez, 2013; Hjellnes et al., 2020; Myhre et al., 2023), the specific practices and efficiencies involved in its utilization, particularly within the German context, remain insufficiently explored. A key unresolved question is how much of these materials emerge, how are they processed and utilized within the German industry. This gap in understanding hinders efforts to maximize the value of these resources and reduce waste, two essential components of sustainable production.

Grasping the utilization of RRM could significantly enhance the economic and environmental performance of the German fish processing industry (Song et al., 2015). Previous studies have primarily focused on the potential applications of RRM (Gildberg et al., 2000; Jaczynski, 2008; Rustad et al., 2011; Ramírez, 2013; Kestin, 2017; Le Gouic et al., 2017; Stevens et al., 2018; Liu and Dave, 2022). These studies indicate that salmonid RRM is an excellent source of potent bioactive molecules such as proteins, omega-3 oil, collagen, gelatine, peptides, enzymes, hydroxyapatite, and minerals. Biomolecules like bioactive peptides exhibit powerful antioxidant, antihypertensive, antimicrobial, anticoagulant, and antidiabetic activities (Ramakrishnan et al., 2024).

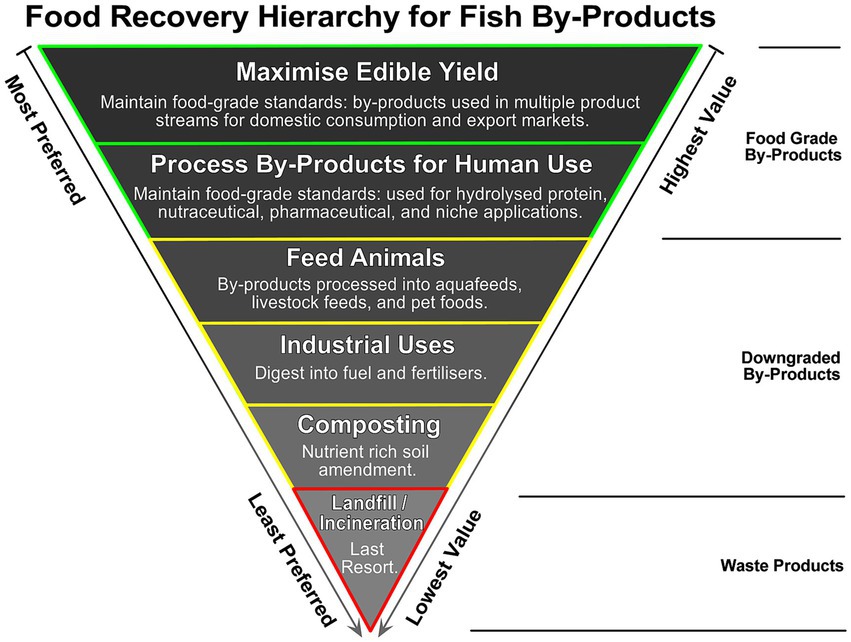

The preferred use of these RRM has been outlined in the “Food recovery hierarchy for fish by-products,” adapted from the US EPA Food Recovery Hierarchy and the EU food waste hierarchy by Stevens et al. (2018), based on scenarios evaluating value-added for fish RRM in Scotland (Figure 1). This hierarchy suggests that the most environmentally and economically beneficial use of RRM is to maintain its food-grade quality and maximize edible yield, prioritizing domestic use over export. The next tier involves processing RRM into high-value consumables for human use, such as protein powders, hydrolysates, salmon oil supplements, collagen supplements, and further niche products. The following tier recommends using RRM for animal feed, if used strategically resulting in more food for human consumption, or as pet food, substituting higher-grade products. Lower tiers include using RRM for industrial fuels, fertilizers, and composting. Options that, while downgrading the value, are still preferable to landfilling, the least desirable option (Stevens et al., 2018).

Figure 1. Stevens et al. (2018)—the rise of aquaculture by-products.

Only few studies have investigated the actual practices employed by processors or assessed the efficiency of these practices (Stevens et al., 2018; Myhre et al., 2023; Love et al., 2024). Tangible examples for good practices are Iceland, where the Iceland Ocean Cluster has improved and monitored the efficiency of RRM use (Sigfusson et al., 2013). Norway recognized seafood RRM as a resource for further production since the beginning of the 20th century, producing products like fertilizers, animal feed, and fish oil (Rustad et al., 2011). Currently, approximately 90% of the Norwegian salmon industry’s RRM is utilized, with the data being well-documented through national statistics (Ytrestøyl et al., 2015; Myhre et al., 2023). In contrast, Germany, despite being one of Europe’s major salmon processors (European Market Observatory for Fisheries and Aquaculture Products (EUMOFA), 2024), lacks publicly available documentation on the quantities and utilization of RRM from salmon processing, creating a gap in transparency and knowledge about the industry’s resource efficiency.

To address this, a comprehensive investigation into the quantities, current practices, and challenges associated with salmon RRM utilization in Germany was conducted. This study involved original data collection and a Material Flow Analysis (MFA), supplemented by qualitative expert interviews, to gain a thorough understanding of the German salmon industry. By identifying best practices and areas for improvement, this research aims to provide actionable insights that can enhance resource efficiency in the industry. By closing the identified gaps valuable information is provided that can inform policy decisions and industry practices, ultimately supporting the broader goal of economic and environmental sustainability and enhancing sustainable food production.

2 Materials and methods

This study employs data from 2020 to quantify RRM occurrence and availability, assess current utilization practices, and identify opportunities for improving resource efficiency in Germany.

The term rest raw material (RRM) is subdivided according to its intended use, following the terminology established by Ulleberg et al. (2023) and Aspevik et al. (2017), based on definitions set by the European Parliament: main products are those the industry produces for direct sale, such as fillets or whole fish. The remaining biomass is classified as rest raw material or residual raw material. RRM that is suitable for human consumption is referred to as co-products and forms one RRM fraction, while RRM unsuitable for human consumption is termed by-products. Co-products are susceptible to microbial and chemical deterioration, especially in fatty portions, necessitating proper handling to prevent degradation to by-products (European Market Observatory for Fisheries and Aquaculture Products (EUMOFA), 2024). By-products are further classified into three risk categories following European regulation (EC) No 1069/2009 (European Union, 2009). Category 3 by-products can be used for animal feed under strict conditions (Regulation (EC) No. 999/2001 and Regulation (EC) No 1069/2009) (European Union, 2001; European Union, 2009). Category 1 and 2 by-products are prohibited from use in food or feed (with rarely applied exceptions for feed) and are typically utilized for biofuels, fertilizers, or disposed of as waste.

2.1 Data collection

To accurately quantify and assess the utilization of materials in each category, a dual data collection approach was applied: Secondary data was gathered from official sources and primary data from direct industry observations. Secondary data included official trade and production statistics from the Federal Statistics Office (Destatis) and fisheries landings data from the Federal Institute for Food and Agriculture (BLE). Primary data were collected through both quantitative and qualitative methods, ensuring a robust and comprehensive dataset by combining official statistics with direct industry insights. This approach was particularly valuable given the lack of prior data on salmon RRM streams in Germany. The integration of empirical qualitative data from industry stakeholders provided a detailed perspective on the current state of RRM management, highlighting potential areas for improvement and innovation in resource utilization.

2.1.1 Primary data sources

2.1.1.1 Questionnaires

Structured questionnaires were distributed to all major processing companies in Germany involved in the production of salmon main products, co-products, by-products, oil and meal. The questionnaires focused on obtaining detailed information about the quantities of salmon processed, the volumes and types of RRM generated, and their uses or disposal. The data collected were instrumental in determining the flow of materials from the processing plants to various end uses or disposal pathways. Primary quantitative data were obtained in 2023 through structured questionnaires with closed-ended questions (see Appendix 1). Responding companies covered 23% of the primary salmon processing activity and full coverage (100%) of industrial rendering facilities involved in secondary processing in Germany in 2020. Small-scale or non-industrial processing activities, if present, were not included.

2.1.1.2 Expert interviews

Additional qualitative data were gathered in 2023 and 2024, in person, through four semi-structured expert interviews, with a total of seven interviewees, each lasting between forty minutes and two and a half hours. Interview participants were selected using purposive sampling, across Germany, to ensure a broad representation of the industry. Criteria for selection included the level of industry overview, the size of the company, geographic location, and the type of processing activity. This ensured that the insights gathered were representative of the relevant industry segments. Interviews were conducted with industry professionals, including representatives and managers of fish processing and rendering plants, a sustainability officer, a research & development manager as well as an operator of a small family-run processing company. The interviews aimed to explore factors influencing the supply, utilization and application of RRM, including logistical and technological constraints, market dynamics, regulatory compliance, and environmental conditions. The semi-structured interview format (Flick, 2021), guided by predefined guidelines (see Appendix 2), allowed for in-depth exploration of key themes while providing flexibility for interviewees to discuss additional relevant topics. To reflect sector-specific perspectives, interview guides were adapted for primary processors, RRM processors, and industry representatives, while maintaining common thematic blocks (e.g., input forms, residual flows, valorisation routes, efficiency and innovation potentials, and practical challenges) to ensure analytical comparability. The qualitative insights obtained served multiple purposes: they added depth to the study by providing context to the quantitative findings, verified and refuted quantitative data, and highlighted emerging trends and challenges within the industry. Interviews were analysed employing qualitative content analysis, which comprises systematic interpretation and coding of textual data to identify patterns, themes, and categories, emphasizing an iterative analysis by continually refining codes and categories as deeper understanding of the data emerges (Mayring, 2014). This approach emphasizes a transparent, and replicable analysis, with the software MAXQDA 24 (VERBI Software, Berlin, Germany) providing the tools to manage, code, and analyse qualitative data in alignment with these principles.

The integration of qualitative data with quantitative findings aligns with the mixed-methods approach advocated by Barclay et al. (2017), particularly in fisheries science and management. This approach was crucial for capturing the complex interactions between economic, environmental, and social factors that influence the use of RRM in the German salmon industry.

2.1.2 Secondary data sources

2.1.2.1 Official statistics

Secondary datasets were used to extrapolate the obtained volumes of RRM, their utilization, and disposal across the industry. These secondary datasets included import/export records, production and landings statistics. Trade data were sourced from the GENESIS-Online database of the German Federal Statistical Office (Destatis) (German Federal Statistical Office, 2025) and the official fishery landings data from the German Federal Office for Agriculture and Food (BLE). These statistics were essential for quantifying the total supply of raw salmon in the German market, including imports of whole salmon, fillets, and convenience products.

2.1.2.2 Industry reports

Additional data were obtained from industry reports, which provided context and supplementary information on the quantities and types of fish products, as well as the prevailing market conditions (Ramírez, 2013).

2.1.3 Data quality

The primary quantitative data were collected and concurrently verified through qualitative interviews conducted with key informants from relevant industry sectors. These interviews served a dual purpose: they provided essential primary data and enabled cross-validation and clarification of reported quantitative figures.

To mitigate potential bias inherent in industry self-reporting, the following strategies were employed: (1) Triangulation of data sources, (2) Probing questions during interviews to uncover inconsistencies, and (3) outlier exclusion. Such outliers were critically examined and excluded from the analysis when deemed unreliable. For each transfer coefficient directly derived from primary quantitative data, the corresponding 95% confidence interval (CI, upper and lower bounds) was calculated and reported.

While this mixed-methods approach enhanced data quality by leveraging the strengths of both methods to produce a more robust and reliable dataset, it also posed challenges, particularly due to the subjective nature of interview data. The study’s limitations and data uncertainty are addressed further in a dedicated subsection of the Results and Discussion.

2.1.4 Material flow analysis

The applied MFA is an analytical approach designed to quantify the flow of materials, tracing their path from harvest through various processing stages to ultimate utilization, final disposal or recycling. This method provides a systematic overview of the quantities of a specific material within a given system, enhancing comprehension of the associated transformation processes (Huang et al., 2012; Lenglet et al., 2017; Schweinle et al., 2020), enabling the identification of inefficiencies and opportunities for improvement. In this study, the MFA was visualized using the software e! Sankey calc, version 5.2.1, to model the flow of salmon raw materials through the German processing chain, from the point of import or catch to the final disposition of resulting products. This study does not fully follow the EU Economy-Wide MFA standard due to data availability and focus on specific flows. While key output streams relevant to environmental impact, such as waste and process water, were included, the full Domestic Processed Output (DPO) indicator, including gaseous emissions, was not computed.

2.1.5 Scope and system definition

This MFA covers material flows associated with domestic Atlantic salmon (Salmo Salar) production and imports of both Atlantic and Pacific salmon (Oncorhynchus spp., excluding Oncorhynchus mykiss) in Germany. Salmon was selected for three methodological reasons: (1) its central role in consumption, processing and rest raw material (RRM) generation in Germany, (2) high data availability from secondary processors, and (3) its high year-round supply through Norwegian aquaculture, which causes relatively consistent processing volumes. Restricting the analysis to salmon allowed for more robust mass balance calculations, clearer transfer coefficient estimation, and reduced seasonal or species-specific variability in RRM composition.

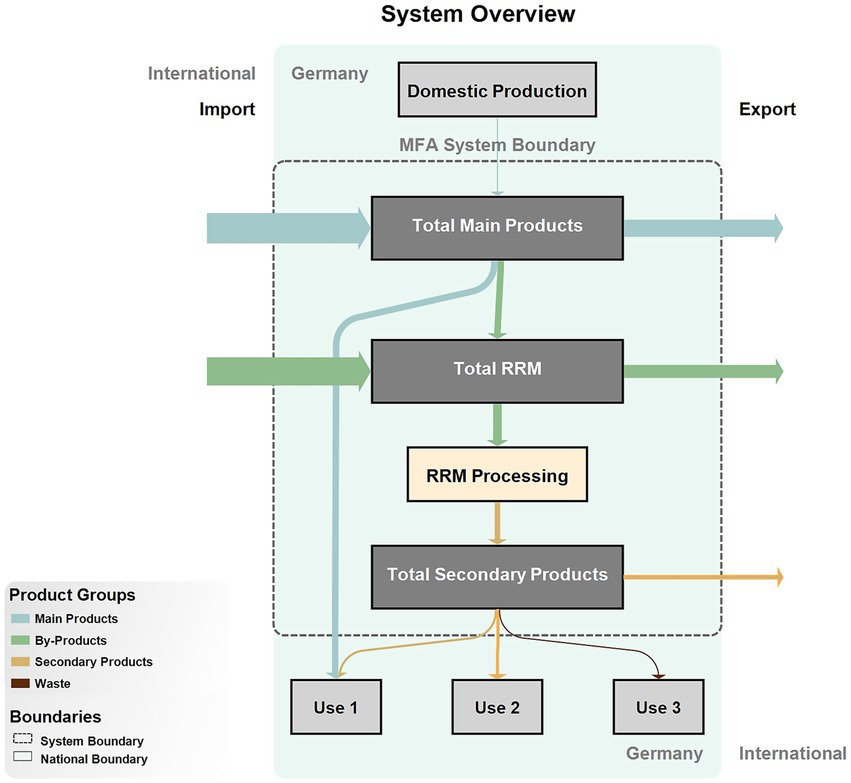

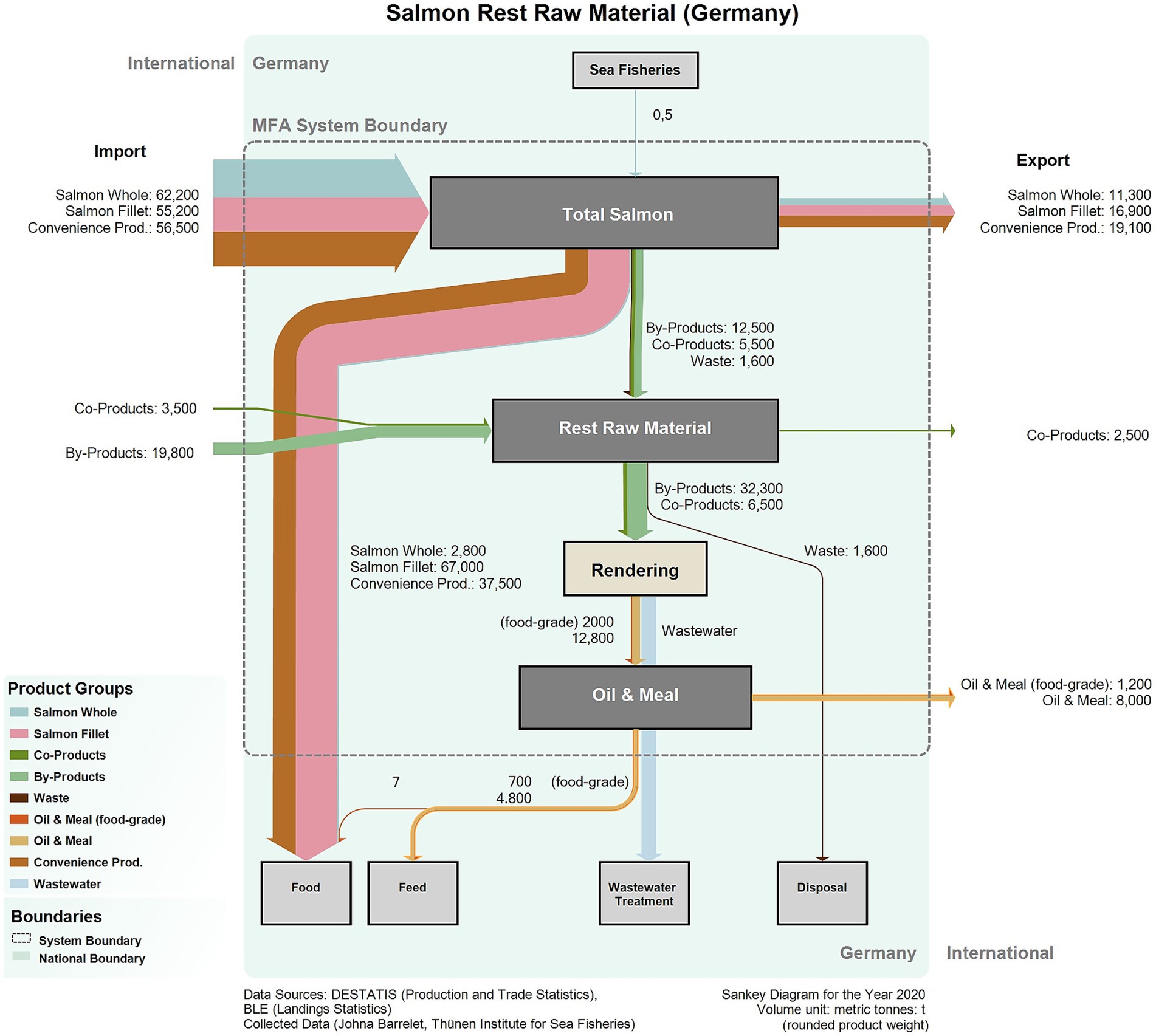

The analysis covers the salmon supply chain within Germany, from input (domestic production and imports) to output (exports, consumption, and utilization of salmon main products and salmon RRM). In Figures 2 and 3, all in-country end-uses (e.g., food, feed, wastewater treatment, and disposal) are shown within the light blue “Germany” boundary to reflect the national scope of flows (Figure 2). While visually located inside the boundary for clarity, these stages do not contribute to further technical transformation and are not included in the mass balance calculations of processing stages. Instead, they fall outside the MFA system boundary (grey dashed outline). A simplified system overview illustrating these boundaries is provided in Figure 2.

Figure 2. Simplified System Overview, visualized in a Sankey Diagram. The thickness of the arrows corresponds to the amount of material flowing, the color of the arrows signifies the product group. The darkgrey boxes show total products, the beige box secondary processing, while the lightgrey boxes show salmon sources and destinations. The light green background marks the flows ocurring within Germany, while the dashed grey line outlines the MFA system boundary.

Figure 3. Salmon rest raw material flow for Germany (year 2020) visualized in Sankey diagram. The thickness of the arrows corresponds to the amount of material flowing, the color of the arrows signifies the product group. The darkgrey boxes show total main and secondary products, the beige box secondary processing, while the lightgrey boxes show salmon sources and destinations. The light green background marks the flows ocurring within Germany, while the dashed grey line outlines the MFA system boundary. All numbers refer to the product weight (rounded metric tonnes).

The predominant form of salmon entering Germany is head-on, gutted (HOG); in this study, this form is referred to as whole salmon. Whole salmon is either sold directly to end-users or enters further processing to produce fillets and convenience products such as smoked salmon, salads, or ready-to-eat meals.

All salmon entering the system—through production or import—is collectively referred to as total salmon. From this total salmon, a portion is exported, while the remaining volume is sold domestically either whole or further processed. Processing yields directly edible main products (whole salmon, fillets, convenience products) and RRM (co-products, by-products, waste). The RRM is either exported, disposed of, or further processed through rendering, producing salmon oil, meal, and wastewater. Residual material sent to disposal is typically used for energy recovery (e.g., in biogas plants or incineration) and/or as fertilizer in accordance with waste management regulations. Wastewater from rendering is treated in wastewater facilities. Mass balance checks were applied only to processing stages within the MFA system boundary (dashed outline). Slight imbalances occurred due to rounding all flow values for better readability. Further utilization of wastewater and solid waste was not traced and is therefore not considered part of the system.

The following section describes the calculation steps used to quantify each major flow within the system.

2.1.6 Calculations

2.1.6.1 Balance calculations

These calculations determined the flow of materials through each stage, from the total salmon (Equations 1–4) supply through processing to the final products, considering imports, exports, and waste generation, providing insights into the efficiency of all processing stages and the utilization of RRM.

The balance of total salmon remaining in Germany ( ) was calculated as follows:

= whole salmon

= salmon fillet

= salmon convenience products

= domestically caught salmon

Whole salmon exports were deducted from whole salmon imports, while exported salmon fillet was deducted from imported salmon fillets and exported convenience products from imported convenience products (Equation 1). The resulting balances were added to the domestically caught salmon to estimate the total salmon available in Germany.

2.1.6.2 RRM calculation

Transfer coefficients for RRM generated from the processing of whole salmon and fillets were calculated as the median of values derived from primary quantitative data collected from the primary processing industry. Subsequently, these factors were applied to the volumes derived from the secondary data to compute the total salmon RRM available in Germany. Determining the quantities of RRM was a crucial aspect, and the application of transfer coefficients was highly relevant in this context (Myhre et al., 2023). The following transfer coefficients (TC) were used for determining RRM shares:

RRM from processing head-on gutted salmon:

= 0.33 (95% CI, lower/upper: 0.31–0.42)

RRM from processing salmon fillets:

= 0.05 (95% CI, lower/upper: 0–0.17)

In addition, the share of whole salmon sold without further processing was determined:

Whole salmon sales: = 0.06 (95% CI, lower/upper: 0–0.33)

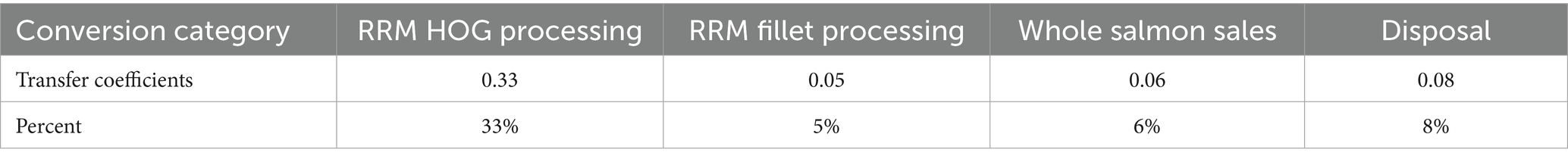

These factors were derived from industry data and validated through expert interviews to ensure accuracy (see Table 1).

Table 1. Conversion Categories, the respective transfer coefficients and percentages, extracted from primary data to determine material flows of salmon in Germany.

The RRM resulting from salmon processing ( ) was then determined by applying these transfer coefficients:

From the balance of whole salmon (imports, production and exports), whole salmon sold without further processing was subtracted (6%), as all RRM of these salmon accrue at the final consumers and are not available for further processing. The remaining volume was multiplied with the RRM transfer coefficient for whole salmon (33%) extracted from the questionnaires. Next, the available volume of salmon fillet in Germany was multiplied by the RRM transfer coefficient of salmon fillet processing (5%) and added to the RRM from whole salmon processed in Germany to account for RRM coming from fillet trimming. This calculation yielded the total RRM available from German processing (Equation 2).

Primary data from rendering plants on domestic inputs (full data coverage) were subtracted from this total, with the remainder representing material not further processed, which was divided into exports and waste.

2.1.6.3 Disposal calculation

Information on the distribution of RRM sold for human consumption, sold for other purposes and amounts that were disposed could also be extracted from primary data, a transfer coefficient for disposal of RRM was determined by summarizing all primary data on disposal amounts and calculating its share from the summarized rest raw material amount:

= 0.08

The share of RRM declared as waste comprised 8%. Thus, the disposal quantity ( ) was calculated as:

2.1.6.4 Export Calculation

The remaining RRM not intended for further processing ( ) or disposal ( ) was assumed to be exported ( ).

3 Results and discussion

This chapter first presents the results of the MFA for salmon based on quantitative data. It then integrates findings from both quantitative and qualitative analyses to provide additional insights into the pathways and processes involved in salmon utilization and explores key obstacles and opportunities for rest raw material (RRM) management in Germany. Building on this, the broader implications for overall resource efficiency are discussed. The chapter concludes with a reflection on data quality and study limitations.

3.1 Salmon rest raw material flow analysis

3.1.1 Raw material supply

With only 5–10% of wild-caught Pacific salmon (Oncorhynchus spp.), which was imported headed and gutted (HG), an estimated 90–95% of all salmon consumed in Germany in 2020 originated from aquacultural production of Atlantic salmon (Salmo salar) in Norway (80–90%), Scotland, Ireland, Iceland and the Faroes. As salmon were typically slaughtered at or close to the production facility, their viscera, and blood remained in the country of origin and were utilized as fertilizer and feed according to industry experts. The overwhelming majority of resulting head-on-gutted salmon (HOG) was transported to European processing plants by truck. This condition of raw material was preferred by industrial processors due to its traceability and lower degree of spoilage (Interview, 2024). The German HOG salmon imports amounted to over 60,000 t (Figure 3, top section, product group: Salmon Whole), adding the negligible German inland production of 0.5 t, and deducting exports of over 10,000 t, around 50,000 t of HOG salmon remained in Germany. Approximately, 6% (95% CI, lower/upper: 0–0.33) or 2,800 t rounded product weight of these were sold directly as an end-product without further processing (Figure 3, left, product group: Salmon Whole).

3.1.2 Generated fillet and RRM

Collected data showed that, on average, the fillet yield of salmon processing was 67% (from HOG to fillet). After processing, the remaining volumes, along with imports of almost 40,000 t fillets and 37,500 t convenience products, amounted to over 100,000 t of salmon main products (fillets and convenience products) for human consumption in Germany (Figure 3, left). The processing of HOG salmon generated considerable amounts of RRM, including trimmings, heads, frames, skins, and belly flaps. Based on the applied transfer coefficients, approximately 33% (95% CI, lower/upper: 0.31–0.42) of this processed biomass was classified as RRM. The total RRM generated from HOG salmon in 2020 amounted to almost 16,000 tonnes. Additionally, the processing of imported fillets produced another 5% of RRM (95% CI, lower/upper: 0–0.17) in the form of trimmings or skin, contributing a further 3,500 tonnes, bringing the total RRM generated from salmon processing in Germany to approximately 19,500 tonnes.

3.1.3 RRM destinations

The data analysis showed that larger domestic companies predominantly directed all RRM to foreign markets or to fish meal and oil production, while smaller companies, dealing with smaller amounts of residues, often opted for disposal. A fraction of co-products (~2,500 t) was exported for direct human consumption (Figure 3, right), i.e., frozen salmon heads to Asian markets, where there was demand for such products in traditional cuisines, or fresh frames to European processors specialized in mechanically deboned meat production (MDM), a processing technique of mechanically separating edible muscle tissue from bones and skin (Froning, 1981; Palmeira et al., 2016).

RRM intended for meal and oil production was collected in large tubs, sorted by co-products, by-products, and certification status (MSC/ASC). This process resulted in 12,500 tonnes of Category 3 by-products and 5,500 tonnes of co-products (Figure 3, top/centre). Notably, co-products were treated according to the same hygiene regulations as conventional food production (appropriate cold chain, storage, transport, quality inspections etc.). According to industry experts in Germany, these products were exclusively obtained from a small number of medium to larger companies across Europe, specializing in salmon processing, thereby enabling stable, high-quality production of single-origin products (Interview, 2023). Category 3 by-products were collected from primary processing plants by truck, partly within a regular collection service offered by the RRM processors, and stored in underground bunkers. Only about a third of these were sorted by species (Interview, 2023). Approximately 1,500 tonnes of co-products were downgraded to category 3 by-products at the rendering plant due to quality issues upon arrival and redirected to category 3 by-product rendering.

Both imported and domestically produced salmon co- and by-products, totalling nearly 40,000 tonnes, were rendered (wet) using a combination of thermal and mechanical treatment. This process yielded almost 15,000 tonnes of salmon oil and meal, of which 2,000 tonnes were food-grade oil and meal, suitable for human consumption (Figure 3, mid-section).

3.1.4 Utilization

The current utilization of RRM and RRM products could be divided into four primary pathways: (1) food for human consumption, (2) animal feed, (3) wastewater treatment and (4) disposal/energy use (Figure 3, bottom section). Oil and meal products found usage both domestically and abroad, with 63% exported and 37% used in Germany. Overall, around 92% of the salmon RRM produced in Germany was used for food or feed, resulting in a RRM disposal rate of 8%, equivalent to 3.2% of whole salmon (HOG) supply in Germany. These approximately 1,600 t in product weight were disposed of at a charge and directed to biogas plants for energy recovery, with generated residues possibly used as agricultural fertilizer. Waste disposal typically involved materials that were unsuitable for further processing due to spoilage or contamination, or that could not be transported to rendering facilities economically (Interviews, 2023, 2024).

The RRM rendering of co- and by-products demonstrated full utilization nearly without any further residues apart from a small amount of fat content in the processing water. RRM that disqualified for human consumption at arrival in the rendering plant was redirected to category 3 processing.

The material flow underscored the marginal utilization of salmon oil and protein for human consumption. Of the 700 t of food grade salmon oil and protein remaining in Germany, only a fraction (~1%) was utilized as food. The vast majority of food grade co-products was used for petfood, along with most of the nearly 5,000 t of category 3 oil and meal remaining in Germany (Figure 3, bottom section). Over 9,000 t of domestically produced salmon oil and meal were exported (Figure 3 bottom right), mainly for utilization in aquafeed and petfood production.

3.2 Obstacles and potentials

The findings of this study highlight both opportunities and challenges associated with the utilization of salmon RRM in Germany. Although salmon occupies the lower end of the RRM spectrum for aquatic biomass, which ranges from about 30 to 85% of the total biomass weight (Rustad et al., 2011), the large volumes of Atlantic salmon processed in Germany still result in substantial amounts of RRM, underscoring its potential for efficient resource utilization. Its popularity among consumers (Fisch Informationszentrum e.V. (FIZ), 2023), the uniform size and year-round availability, make farmed salmon an appealing option for primary processing as well as RRM rendering (Interviews, 2023).

3.2.1 Obstacles and potentials in current utilization of RRM

Applying the fish by-product hierarchy established by Stevens et al. (2018), the utilization efficiency of salmon RRM can be further assessed. With no landfill and only 8% disposal (energy use), 92% utilization of RRM from salmon processing for food and feed (Figure 3) can be considered an exemplary use of resources, still 70% of RRM was downgraded directly after primary processing from co-product to category 3 by-product (Figure 3), mainly due to the absence of a continuous cold chain, limited storage capacity, and general handling practices at the primary processing plant. Of the remaining co-products another 25% was downgraded at the rendering plant, following additional checks regarding freshness and the absence of foreign materials in the RRM containers, before secondary processing.

Interview data revealed that the logistics and infrastructure required to keep RRM edible—such as cooled facilities, transportation, and economies of scale—pose a significant challenge for processors, particularly smaller ones, thereby restricting the supply of co-products. Notably, co-products are very susceptible to microbial and chemical degradation, likely due to the disruption of biological membranes during processing, and therefore require timely and careful handling (Ulleberg et al., 2023). Additionally, the process of sorting RRM by species often proves too costly for smaller processors, further constraining the availability of co-products and limiting their use across different applications. Similar findings were presented by Stevens et al. (2018) for Scottish salmon processors. The study suggests that establishing a network of medium- to small-scale processors for the collective management and storage of RRM could enhance revenue streams. By pooling resources and infrastructure, such a network would improve efficiency, reduce operational costs, and better capitalize on the value of RRM (Stevens et al., 2018).

Another reason for marginal human consumption, experts pointed out, is the lack of domestic markets for food-grade fish oil and meal in Germany. This is attributed to a lack of marketing and limited local demand for value-added products such as oil, protein, or co-products like salmon heads, based on cultural customs. Larger processors export specific co-products to well-established markets in Asia (Figure 3, right), where these products have a long-standing tradition of being used for human consumption.

While the fish by-product hierarchy indicates that the highest-value use of fish RRM is as food or food ingredients (Stevens et al., 2018), it can be argued that this is only valid if sufficient demand is generated and the process is economically sustainable. Currently, fish oil in the form of Omega-3 capsules as dietary supplement is often manufactured abroad at a more affordable price and lower quality according to industry experts. Meanwhile, pet food producers are willing to pay a high price for fish oil and meal, hampering the incentive to create a market for human consumption (Interview, 2023). Yet, the market for dietary supplements has grown considerably in the past years (Djaoudene et al., 2023) and might hold additional marked potential for RRM-based products.

The collected data indicates that salmon oil and protein from RRM currently find no application in German aquafeed production (Figure 3, bottom). This can be attributed to EU restrictions in salmonid breeding due to regulation (EU) No 142/2011 against intra-species feeding (European Union, 2011), which is intended to prevent the spread of disease. Although this officially only applies to protein, in practice it is extended to oil (Interview, 2023). Consequently, this disqualifies the use of salmon oil and meal in trout farming, the main carnivorous aquaculture species grown in Germany.

Additionally, qualitative insights suggest that fish meal derived from RRM exhibits lower protein levels compared to meal produced from reduction fisheries, where the entire fish, including meat and viscera, is processed. For fast-growing aquaculture species, like salmonids, high levels of protein are essential (72–75% raw protein), whereas lower levels (63–65% raw protein) are more suitable for slow-growing Mediterranean species.

Experts further indicate that the German rendering industry observed a decline in EPA and DHA2 levels in farmed salmon from 15 to 7% between 1995 and 2010, after which levels have stabilized (Interview, 2023). These findings align with Sprague et al. (2016), who observed a decline in EPA/DHA levels in farmed Scottish Atlantic salmon from 2006 to 2015, attributed to the increased use of vegetable oils in aquafeeds. Shepherd and Bachis (2014) reached a similar conclusion. While this decline poses a challenge for the industry’s omega-3 rich marketing, farmed salmon still offers more long-chain omega-3 fatty acids than most other fish species and all terrestrial livestock (Sprague et al., 2016). However, aquafeed producers increasingly consider algae oils as a substitute, due to its broad spectrum of fatty acids (Interview, 2023). While algae oil traditionally carried a higher price, experts have reported a notable reduction in costs over the past year, attributed to increasing investments in algae aquaculture. As a result, its price has reached parity with fish oil. This trend is expected to continue, potentially making algae oil a more economically viable option (Interview, 2024).

3.2.2 Obstacles and potentials in traditional RRM rendering

German rendering plants face several challenges that threaten their economic profitability. These include an inconsistent supply of RRM, driven by rising salmon prices, a growing, competitive market for RRM (e.g., pet food industry, mink feed, biogas production) and global crises (e.g., Covid-19). Maintaining a consistent supply is crucial for ensuring full capacity utilization, making these challenges particularly problematic. In the context of production for human consumption, the increasingly stringent regulations and food safety thresholds in Germany require processors to test for a growing number of contaminants, leading to higher costs. Consequently, maintaining traditional fish meal production from RRM in its current form will be difficult in the long term. According to experts, improvements and innovation are inevitable for continued existence. One approach to improve the quality of category 3 products is to upgrade RRM storage by replacing underground bunkers with silos, implementing a first-in, first-out system (RRM stored first is processed first), while allowing for effective cooling of the stored materials. Other approaches are more focussed on innovations making use of the numerous properties of RRM components.

3.2.3 Obstacles and potentials of innovative RRM utilization

Industry experts reported a general trend towards the use of RRM for more specialized, high-value products (Interview, 2023). Ongoing research explores various pathways for higher added-value and diverse applications of salmon RRM, recognizing its considerable potential. Through enzymatic or chemical hydrolysis this rich source of protein can be converted into bioactive peptides offering numerous health benefits (Ramakrishnan et al., 2024). Enzymatic hydrolysis of salmon skin, for instance, can produce bioactive and nutritious hydrolysates with antihypertensive antioxidant and antimicrobial properties (Abdollahi and Undeland, 2018; Vázquez et al., 2021). Notably, a peptide (TPEVHIAVDKF) from Atlantic salmon by-products showed anti-allergic activity by inhibiting β-hexosaminidase release (Wang et al., 2020). Further, the extraction of collagen from salmon skin and scales is one of the innovations, receiving increasing attention from numerous health-related industries, including biomedical, food, and cosmetic sectors, as well as wound healing in pharmaceuticals (Sae-leaw and Benjakul, 2018; Oslan et al., 2022; Gaikwad and Kim, 2024). Collagen from fish is considered advantageous due to high availability, biocompatibility, ease of absorption by the body system, no religious restraints and low zoonotic disease risk compared to terrestrial, mammalian sources (Magtaan et al., 2021; Oslan et al., 2022). Various extraction methods, including acid-soluble, enzyme-soluble, and advanced techniques like ultrasound and supercritical fluid extraction, have been developed to optimize collagen yield (Oslan et al., 2022; Gaikwad and Kim, 2024). Given the increasing demand for collagen, it is essential to identify sources that are both sustainable and economically feasible (Gaikwad and Kim, 2024).

However, key interviewees highlighted several challenges that need to be addressed if this is explored further, including the management of problematic side streams such as caustic soda and phosphoric acid, with pH levels exceeding eight or dropping below four. Also, the economic viability of these processes remains uncertain, as well as the acceptance by consumers in European countries. Another promising application of salmon RRM mentioned during the interviews is the production of functional proteins, which can serve as alternatives to soy-based emulsifiers and various other uses in the food additives industry, or help to reduce water loss during fish smoking processes. However, if enzymatic hydrolysis is employed, higher costs are incurred due to the use of enzymes in the production process (Interview, 2023). Overall, innovative products such as collagen, functional peptides or salmon leather remain niche products, with engineering challenges in their production process yet to be fully addressed.

3.3 Overall resource efficiency of salmon processing in Germany

Maximizing the use of rest raw materials (RRM) in fish processing is crucial not only for improving overall resource efficiency but also for reducing environmental impact and economic losses along the value chain. In the context of rising global protein demand and sustainability pressures, aiming for 100% utilization of side streams becomes a strategic priority for both industry and policy (Gill et al., 2025; Venslauskas et al., 2021).

Germany stands out as one of the largest processors and consumers of Atlantic salmon in Europe, alongside France and Poland (European Market Observatory for Fisheries and Aquaculture Products (EUMOFA), 2024). As an importer of head-on gutted (HOG) salmon, where blood and viscera remain in the country of origin, Germany becomes responsible for the downstream resource efficiency of the remaining edible and non-edible parts of this resource. The presented study shows that approximately 98% of salmon raw material (HOG salmon and fillets) processed in Germany is utilized either for food or pet food, with only ~2% going into waste treatment for energy recovery and/or fertilizer use. This level of utilization compares favourably with international benchmarks. Norway’s aquaculture sector, dominated by Atlantic salmon, reports about 90% RRM utilization, with blood, originating from slaughterhouses, remaining as the main underutilized component (Myhre et al., 2023). In contrast, utilization rates in Norway’s demersal fisheries remain significantly lower, ranging between 50–60% (Myhre et al., 2023). These differences highlight the salmon sector’s biological, technical, and economic advantages, which enable more efficient and comprehensive use of available biomass.

International visions point toward a “zero-waste” biorefinery approach, where 100% of fish co-streams are valorised into high-value products for food, feed, biomaterials, cosmetics, nutraceuticals, followed by utilisation of the remaining residue for co-generation of energy and soil fertilisers (Ekins et al., 2016).

From a sustainability perspective, resource efficiency contributes to reducing pressure on ecosystems, lowering greenhouse gas emissions, and improving the circularity of food systems (Ekins et al., 2016; Halpern et al., 2022). By maximizing value recovery from existing biomass rather than increasing primary production, the environmental footprint of the seafood sector can be significantly reduced (Areche et al., 2024; Cooney et al., 2023; Cadena et al., 2024). This aligns with Sustainable Development Goal 12.3, which aims to halve per capita global food waste at the retail and consumer levels, and reduce food losses along production and supply chains, including post-harvest losses, by 2030 (United Nations, 2024). Germany has committed to this goal through its National Food Waste Reduction Strategy (Federal Ministry of Food and Agriculture (BMEL), 2019) which emphasizes the valorisation of side streams in the food and agricultural sectors, including fish processing. In this context, resource efficiency is not just a technical or economic indicator, it becomes a key lever for achieving sustainability in food systems. Germany’s well-established infrastructure for rest raw material (RRM) collection and processing provides a strong foundation. However, the findings of this study indicate that there is still untapped potential to shift from rendering to produce low-value outputs such as fishmeal and oil for pet food and feed applications to higher-value applications, such as food ingredients, nutraceuticals, and bio-based materials. While high utilization rates are a positive indicator, they do not automatically translate into high sustainability performance. In line with broader sustainability goals, it is increasingly essential to consider not just how much is used, but also how it is used. Such a transition would not only enhance economic returns but also support national and international sustainability commitments.

Policy and industry can draw several conclusions from the results of this study. First, targeted investment in RRM upgrading technologies could help shift current outputs into higher-value applications. Second, collaborative networks among small processors could improve economies of scale for RRM handling of regionally caught species and imported fish products beyond salmon. The potential of integrating other species more in the existing, highly-efficient value chain should be examined further.

Lastly, the quantified RRM flows presented in this study provide an important empirical basis for future Life Cycle Assessments (LCAs) of salmon processing. Johansen et al. (2022) highlight that the degree of RRM utilization in the market (referred to as by-product utilization in market, BUiM) is crucial for appropriately allocating environmental impacts in LCA models (Johansen et al., 2022). Their model for Atlantic Salmon LCA uses utilization data primarily derived from Kontali Analyse AS, which compiles information from desktop studies, industry interviews, consumer trends, and trade statistics including EUMOFA (Johansen et al., 2022). However, for Germany, the salmon BUiM value applied in their model is approximately 60%, a figure that underestimates actual utilization significantly as this study’s detailed data demonstrates. This discrepancy underlines the importance of country-specific RRM utilization data, as proxy values can lead to inaccurate environmental impact allocations (Johansen et al., 2022). By providing detailed, empirical German data showing a utilization rate of about 98% of salmon raw material (HOG and fillet), this study enables more precise allocation in LCAs, reducing uncertainty and improving the accuracy of environmental assessments of salmon products in Germany and the wider European market.

3.4 Study limitations and data uncertainty

This study combines official statistics, industry-derived quantitative data, and expert interviews to model salmon processing flows in Germany. While this mixed-methods approach provides valuable insights, certain limitations must be acknowledged.

Domestic production, import, and export volumes of salmon raw material were obtained from official statistics, whereas data on subsequent processing stages relied on primary data collection. The extent of primary data coverage varied across these stages.

The quantitative survey was conducted as an additional module of a regular biennial industry study and was distributed in writing to all identified processing facilities in Germany, with one follow-up reminder. While the industrial RRM processing sector was fully represented, only 23% of raw material processed by primary salmon processors in Germany was covered. Incomplete responses were included if internally consistent variable pairs (e.g., input and output quantities) were fully reported; otherwise, they were excluded. No imputation was applied, ensuring methodological rigor but limiting completeness. The low response rate among primary processors highlights the need for improved incentives or mandatory reporting, particularly for large operators.

Building on this dataset, uncertainty in RRM estimation remains a notable limitation. Based on primary processor responses, approximately 33% of incoming head-on gutted (HOG) salmon resulted in RRM. This estimate, while derived from a limited sample, aligns reasonably well with international benchmarks. Winther et al. (2020) report edible yields of 71% for HOG salmon to B-trim and 54% for total edible product, corresponding to RRM shares of 29 and 46%, respectively. The estimate from this study falls within that range, particularly given differences in trimming specifications and processing technologies. The estimated 5% RRM share from fillet processing, based on questionnaire responses, aligns with values reported by Stevens et al. (2018), who identify skin and belly flaps as typical residual fractions in a similar magnitude, providing an additional benchmark for validation. To further verify the plausibility of these values, reported RRM volumes were cross-checked against data from RRM processors, for which full data coverage was achieved. The good agreement between the estimated supply of RRM from primary processing and the actual inflows into RRM rendering facilities supports the validity of the reported ratio. A deviation from the EU EW-MFA standard may affect the studies comparability but was necessary given the mentioned data constraints and study scope.

Qualitative data were collected via seven semi-structured interviews targeting key stakeholders across the value chain, including both small-scale and large-scale primary processors, RRM processors, and sector representatives. While the sample size is small, participants were selected for their central positions and broad operational insight, ensuring coverage of relevant perspectives. Triangulation with quantitative data helped mitigate self-reporting bias, though some degree of subjectivity remains, especially regarding efficiency and valorisation potentials.

Finally, this study focuses on the year 2020, during which the COVID-19 pandemic influenced consumption patterns and trade dynamics. While aggregate salmon exports were not significantly affected, firm-level analysis revealed that lockdown measures influenced trade patterns for specific product forms, with larger firms showing stronger reactions (Asche et al., 2022). Moreover, the availability of residual materials fluctuates due to short-term contracts between primary and secondary processors. These factors limit generalizability and underscore the need for multi-year datasets to capture long-term trends and improve robustness.

Despite these limitations, the combination of high-coverage official data, survey responses, and expert interviews provides a coherent and internally consistent depiction of salmon processing flows. Cross-checks against international yield factors further support the reliability of key estimates.

4 Conclusion

The lack of publicly available data on the quantities and utilization of RRM from salmon processing in Germany was addressed in this study. Through a comprehensive investigation of the amounts, current practices, challenges, and opportunities related to salmon RRM recovery, the findings offer actionable insights that enhance resource efficiency in the industry, inform policy decisions, and ultimately support the broader goals of economic and environmental sustainability in food production.

This study highlights the considerable potential for enhancing sustainable management of aquatic resources through the integration of RRM recovery strategies in aquatic biomass processing. Germany has a well-established infrastructure for managing RRM, including rendering facilities and transport networks. Presently, 98% of salmon raw material is utilized for food and animal feed and ~2% disposed as waste and used for energy production. While utilization of RRM products for the pet food market is currently well-established, there is substantial potential for higher-value applications in other markets. If the use of RRM for human consumption is deemed the most desirable approach, optimizing infrastructure post-primary processing is essential to maintain quality standards for human consumption.

The efficient utilization and strategic management of RRM can significantly enhance the economic and nutritional value of aquatic biomass. With a continuous growth of aquaculture production, ensuring the resulting biomass is used resource-efficiently is critical for future sustainability. While financial incentives are main drivers for the processing industry, considerations of food security and production are equally vital for optimizing the overall system’s efficiency.

This study offers valuable insights for policymakers and industry stakeholders, encouraging continuous advancements in responsible and sustainable practices, by providing new data and shedding light on an often-overlooked aspect of the industry.

However, further research is needed to evaluate resource efficiency and innovation potential across different regions and species. Results from this study could be used to fine tune environmental impact assessments of processed salmon fillets and convenience products, by considering more precise amounts going into RRM processing. Also, future studies should continue to explore the potential of emerging technologies, such as enzymatic hydrolysis, in improving the efficiency of RRM utilization.

Ultimately, advancing sustainable processing practices and maximizing the use of co-products throughout the sector can play a crucial role in enhancing food security and promoting more sustainable food production on a global scale.

Data availability statement

The raw data supporting the conclusions of this article are restricted due to confidentiality and sample size, in order to protect participant anonymity. Requests to the Corresponding Author for access can be considered on a case-by-case basis, subject to ethical approval.

Ethics statement

Ethical approval was not required for the studies involving humans because expert Interviews were conducted, following the signing of a consent form and all data extracted from interviews was anonymized. The studies were conducted in accordance with the local legislation and institutional requirements. The participants provided their written informed consent to participate in this study.

Author contributions

SB: Conceptualization, Data curation, Validation, Visualization, Writing – review & editing. SS: Supervision, Writing – review & editing. JB: Conceptualization, Data Curation, Formal Analysis, Investigation, Methodology, Validation, Visualization, Writing – original draft, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This publication was compiled within the project MoBi II: Bioeconomy Monitoring II, granted by the Agency of Renewable Resources (FNR) under the auspices of the German Federal Ministry of Food and Agriculture (grant number 2221NR062A).

Acknowledgments

The authors are grateful to the industry experts, for their collaboration, participation and willingness to provide valuable information.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that Gen AI was used in the creation of this manuscript. During the preparation of this work the authors used the AI tools ChatGPT and DeepL in order to improve language and readability of scientific writing. After using these tools, the authors reviewed and edited the content as needed and take full responsibility for the content of the published article.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2025.1633288/full#supplementary-material

Footnotes

1. ^RRM – Rest raw material also referred to as by- or co-products.

2. ^Eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) are essential omega-3 fatty acids primarily synthesized by microalgae in aquatic ecosystems (Gladyshev et al., 2013). These fatty acids are transferred through the food chain, accumulating in fish, which have been the main source for human consumption (Gladyshev et al., 2013; Salem and Eggersdorfer, 2015). However, with depleting fish stocks and increasing demand, alternative sources are being explored (Adarme-Vega et al., 2014). The body needs EPA & DHA omega-3 s to develop and function optimally in every stage of life (Food and Agriculture Organization of the United Nations (FAO), 2022; Salem and Eggersdorfer, 2015; Shepon et al., 2022).

References

Aandahl, P. T.. (2021). Stable Norwegian seafood exports in 2020 despite the corona pandemic; Available online at: https://en.seafood.no/news-and-media/news-archive/stable-norwegian-seafood-exports-in-2020-despite-the-corona-pandemic/.

Abdollahi, M., and Undeland, I. (2018). Structural, functional, and sensorial properties of protein isolate produced from salmon, cod, and herring by-products. Food Bioprocess Technol. 11, 1733–1749. doi: 10.1007/s11947-018-2138-x

Adarme-Vega, T. C., Thomas-Hall, S. R., and Schenk, P. M. (2014). Towards sustainable sources for omega-3 fatty acids production Curr. Opin. Biotechnol. 26, 14–18. doi: 10.1016/j.copbio.2013.08.003

Areche, F. O., Dominguez, J. A. J., Huaman, J. T., Yapias, R. J. M., Rivera, T. J. C., Perales, L. D. M., et al. (2024). Maximizing the potential of marine resources: a sustainable approach to high-value product development from seafood by-products and waste Curr. Res. Nutr. Food Sci. 12, 1074–1092. doi: 10.12944/CRNFSJ.12.3.7

Asche, F., Straume, H. M., Garlock, T., Johansen, U., Kvamsdal, S. F., Nygaard, R., et al. (2022). challenges and opportunities: impacts of COVID-19 on Norwegian seafood exports. Aquat. Living Resour. 35:15. doi: 10.1051/alr/2022017

Aspevik, T., Oterhals, Å., Rønning, S. B., Altintzoglou, T., Wubshet, S. G., Gildberg, A., et al. (2017). Valorization of proteins from co- and by-products from the fish and meat industry. Top Curr Chem (Cham) 375:53. doi: 10.1007/s41061-017-0143-6

Barclay, K., Voyer, M., Mazur, N., Payne, A. M., Mauli, S., Kinch, J., et al. (2017). The importance of qualitative social research for effective fisheries management fish. Res. 186, 426–438. doi: 10.1016/j.fishres.2016.08.007

Bundesregierung Deutschland. (2021). Deutsche Nachhaltigkeitsstrategie — Weiterentwicklung. Available online at: https://www.bundesregierung.de/resource/blob/975274/1873516/9d73d857a3f7f0f8df5ac1b4c349fa07/2021-03-10-dns-2021-finale-langfassung-barrierefrei-data.pdf (Accessed June 17, 2024).

Cadena, E., Kocak, O., Dewulf, J., Iñarra, B., Bald, C., Gutierrez, M., et al. (2024). Valorisation of seafood side-streams through the design of new holistic value chains: WaSeaBi project. Sustainability 16:1846. doi: 10.3390/su16051846

Cooney, R., de Sousa, D. B., Fernández-Ríos, A., Mellett, S., Rowan, N., Morse, A. P., et al. (2023). A circular economy framework for seafood waste valorisation to meet challenges and opportunities for intensive production and sustainability. J. Clean. Prod. 392:136283. doi: 10.1016/j.jclepro.2023.136283

Djaoudene, O., Romano, A., Bradai, Y. D., Zebiri, F., Ouchene, A., Yousfi, Y., et al. (2023). A global overview of dietary supplements: regulation, market trends, usage during the COVID-19 pandemic, and health effects. Nutrients 15:3320. doi: 10.3390/nu15153320

Ekins, P., Hughes, N., Brigenzu, S., Arden Clark, C., Fischer-Kowalski, M., Graedel, T., et al. Resource efficiency: potential and economic implications. Report of the international resource panel, United Nations environment program (UNEP), Paris; (2016). Available online at: https://pure.iiasa.ac.at/id/eprint/13813/

European Market Observatory for Fisheries and Aquaculture Products (EUMOFA). (2024). Case study: Smoked salmon in the EU: Price structure in the supply chain – Fokus on France, Germany and Poland. Luxembourg. Available at: https://eumofa.eu/documents/20124/152790/PTAT+Smoked+salmon+FR+DE+PL_EN.pdf (Accessed August 15, 2025).

European Union. (2001). Regulation (EC) No 999/2001 of the European Parliament and of the Council of 22 May 2001 laying down rules for the prevention, control and eradication of certain transmissible spongiform encephalopathies; (cited 2024 Sep 16). Available online at: https://eur-lex.europa.eu/eli/reg/2001/999/oj.

European Union. (2009). Regulation (EC) No 1069/2009 of the European Parliament and of the Council of 21 October 2009 laying down health rules as regards animal by-products and derived products not intended for human consumption and repealing Regulation (EC) No 1774/2002 (Animal by-products Regulation): Regulation (EC) No 1069/2009. (Accessed Nov 29, 2023). Available online at: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32009R1069.

European Union. (2011). Commission regulation (EU) no 142/2011 of 25 February 2011 implementing regulation (EC) no 1069/2009 of the European Parliament and of the council laying down health rules as regards animal by-products and derived products not intended for human consumption and implementing council directive 97/78/EC as regards certain samples and items exempt from veterinary checks at the border under that directive text with EEA relevance: EU regulation 142/2011; [cited 2024 Sep 13]. Available online at: https://eur-lex.europa.eu/eli/reg/2011/142/oj.

Federal Ministry of Food and Agriculture (BMEL). Germany (2019). National strategy for food waste reduction. Available online at: https://www.bmleh.de/SharedDocs/Downloads/EN/_Food-and-Nutrition/Strategy_FoodWasteReduction.pdf (Accessed August 15, 2025).

Food and Agriculture Organization of the United Nations (FAO) (2022). Towards blue transformation. Rome: FAO.

Fisch Informationszentrum e.V. (FIZ). (2023). Daten und Fakten 2023. Hamburg; (Accessed 2024 Sep 9). Available online at: https://www.fischinfo.de/images/broschueren/pdf/FIZ_DF_2023.pdf

Flick, U. (2021). Qualitative Sozialforschung: Eine Einführung. 10. Auflage, Originalausgabe. Reinbek bei Hamburg: Rowohlts enzyklopädie im Rowohlt Taschenbuch Verlag.

Froning, G. W. (1981). Mechanical deboning of poultry and fish. Adv. Food Nutr. Res. 27, 109–147. Elsevier.

Gaikwad, S., and Kim, M. J. (2024). Fish by-product collagen extraction Using different methods and their application. Mar. Drugs 22. doi: 10.3390/md22020060

German Federal Statistical Office. (2025) Imports and exports (foreign trade): Germany, years, commodity classification (8-digit), Table 51000–0013 (cited 2025 Aug 15). Available online at: https://www-genesis.destatis.de/genesis/online

Gildberg, A., Simpson, B. K., and Haard, N. F. (Eds.) (2000). Seafood enzymes: Utilization and influence on postharvest seafood quality. New York: Marcel Dekker.

Gill, J. M., Hussain, S. M., Ali, S., Ghafoor, A., Adrees, M., et al. (2025). Fish waste biorefinery: a novel approach to promote industrial sustainability. Bioresour. Technol. 419:132050. doi: 10.1016/j.biortech.2025.132050

Gladyshev, M. I., Sushchik, N. N., and Makhutova, O. N. (2013). Production of EPA and DHA in aquatic ecosystems and their transfer to the land. Prostaglandins Other Lipid Mediat. 107, 117–126. doi: 10.1016/j.prostaglandins.2013.03.002

Halpern, B. S., Frazier, M., Verstaen, J., Rayner, P.-E., Clawson, G., Blanchard, J. L., et al. (2022). The environmental footprint of global food production. Nat. Sustain 5, 1027–1039. doi: 10.1038/s41893-022-00965-x

Hjellnes, V., Rustad, T., and Falch, E. (2020). The value chain of the white fish industry in Norway: history, current status and possibilities for improvement – a review regional studies in marine science 36:101293. doi: 10.1016/j.rsma.2020.101293

Huang, C. L., Vause, J., Ma, H. W., and Yu, C. P. (2012). Using Material/substance flow analysis to support sustainable development assessment: a literature review and outlook. Resour. Conserv. Recycl. 68, 104–116. doi: 10.1016/j.resconrec.2012.08.012

Jaczynski, J. (2008). Protein and Lipid Recovery from Food Processing By-products Using Isoelectric Solubilization/Precipitation. In: K. N. Papadopoulos, ed. Food Chemistry Research Developments. Hauppauge: Nova Science Publishers. 167–198.

Johansen, U., Nistad, A. A., Ziegler, F., Mehta, S., Wocken, Y., Hognes, E. S., et al. (2022). Greenhouse gas emissions of Norwegian salmon products. Norway: SINTEF Ocean.

Kestin, S. (2017). Issues in fisheries and aquaculture: The meat crisis. 2nd Edn. Abingdon, Oxon, New York, NY: Routledge.

Le Gouic, A. V., Harnedy, P. A., and FitzGerald, R. J. (2017). “Bioactive peptides from fish protein by-products” in Sweeteners. eds. J.-M. Merillon and K. G. Ramawat (Cham: Springer International Publishing), 1–35.

Lenglet, J., Courtonne, J.-Y., and Caurla, S. (2017). Material flow analysis of the forest-wood supply chain: a consequential approach for log export policies in France. J. Clean. Prod. 165, 1296–1305. doi: 10.1016/j.jclepro.2017.07.177

Liu, Y., and Dave, D. (2022). Beyond processing waste: extraction of oil from Atlantic salmon (Salmo salar) by-products using immobilized Alcalase on chitosan-coated magnetic nanoparticles aquaculture 548:737546. doi: 10.1016/j.aquaculture.2021.737546

Love, D. C., Asche, F., Fry, J., Brown, M., Nguyen, L., Garlock, T. M., et al. (2024). Fisheries and aquaculture by-products: case studies in Norway, United States, and Vietnam mar. Policy 167:106276. doi: 10.1016/j.marpol.2024.106276

Magtaan, J. K., Fitzpatrick, B., and Murphy, R. (2021). Elucidating the biological activity of fish-derived collagen and gelatine hydrolysates using animal cell culture—a review Curr. Pharm. Des. 27, 1365–1381. doi: 10.2174/1381612826666201210112119

Mayring, P. (2014). Qualitative content analysis: Theoretical foundation, basic procedures and software solution. Klagenfurt. Available online at: https://www.researchgate.net/publication/266859800

Myhre, M. S., Skavang, P. K., Remme, J., Wolff, R., and Carvajal, A. (2023). Mapping of marine rest raw material in the Norwegian seafood industry: a decade of results. J. Aquat. Food Prod. Technol. 32, 554–569. doi: 10.1080/10498850.2023.2255179

Oslan, S. N. H., Li, C. X., Shapawi, R., Mokhtar, R. A. M., Noordin, W. N. M., and Huda, N. (2022). Extraction and characterization of bioactive fish by-product collagen as promising for potential wound healing agent in pharmaceutical applications: current trend and future perspective. Int. J. Food Sci. 1:10. doi: 10.1155/2022/9437878

Palmeira, K. R., Mársico, E. T., Monteiro, M. L. G., Lemos, M., and Conte Junior, C. A. (2016). Ready-to-eat products elaborated with mechanically separated fish meat from waste processing: challenges and chemical quality. CyTA 14, 227–238. doi: 10.1080/19476337.2015.1087050

Ramakrishnan, V. V., Hossain, A., Dave, D., and Shahidi, F. (2024). Salmon processing discards: a potential source of bioactive peptides – a review food prod. Process. Nutr. 6:1. doi: 10.1186/s43014-023-00197-2

Rustad, T., Storrø, I., and Slizyte, R. (2011). Possibilities for the utilisation of marine by-products. Int J of Food Sci Tech 46, 2001–2014. doi: 10.1111/j.1365-2621.2011.02736.x

Sae-leaw, T., and Benjakul, S. (2018). Antioxidant activities of hydrolysed collagen from salmon scale ossein prepared with the aid of ultrasound. Int J of Food Sci Tech 53, 2786–2795. doi: 10.1111/ijfs.13891

Salem, N., and Eggersdorfer, M. (2015). Is the world supply of omega-3 fatty acids adequate for optimal human nutrition? Curr. Opin. Clin. Nutr. Metab. Care 18, 147–154. doi: 10.1097/MCO.0000000000000145

Schweinle, J., Geng, N., Iost, S., Weimar, H., and Jochem, D.. Monitoring sustainability effects of the bioeconomy: a material flow based approach using the example of softwood lumber and its core product Epal 1 pallet. Sustainability (2020); 12:2444. Available online at: https://www.mdpi.com/2071-1050/12/6/2444/pdf.

Shahidi, F., Varatharajan, V., Peng, H., and Senadheera, R. (2019). Utilization of marine by-products for the recovery of value-added products. JFB. 6, 10–61. doi: 10.31665/JFB.2019.6184

Shepherd, J., and Bachis, E. (2014). Changing supply and demand for fish oil Aquacult. Econ. Manag. 18, 395–416. doi: 10.1080/13657305.2014.959212

Shepon, A., Makov, T., Hamilton, H. A., Müller, D. B., Gephart, J. A., Henriksson, P. J., et al. (2022). Sustainable optimization of global aquatic omega-3 supply chain could substantially narrow the nutrient gap Resour. Conserv. Recycl. 181:106260. doi: 10.1016/j.resconrec.2022.106260

Sigfusson, T., Arnason, R., and Morrissey, K. (2013). The economic importance of the Icelandic fisheries cluster—understanding the role of fisheries in a small economy mar. Policy 39, 154–161. doi: 10.1016/j.marpol.2012.10.015

Song, Q., Li, J., and Zeng, X. (2015). Minimizing the increasing solid waste through zero waste strategy. J. Clean. Prod. 104, 199–210. doi: 10.1016/j.jclepro.2014.08.027

Sprague, M., Dick, J. R., and Tocher, D. R. (2016). Impact of sustainable feeds on omega-3 long-chain fatty acid levels in farmed Atlantic salmon, 2006-2015. Sci. Rep. 6:21892. doi: 10.1038/srep21892

Stevens, J. R., Newton, R. W., Tlusty, M., and Little, D. C. (2018). The rise of aquaculture by-products: increasing food production, value, and sustainability through strategic utilisation mar. Policy 90, 115–124. doi: 10.1016/j.marpol.2017.12.027

Ulleberg, D., Sletten, I. B., Jakobsen, A. N., Svenning, J. B., and Lerfall, J. (2023). Co-products from the Atlantic salmon filleting industry – Their properties, stability and potential as human food ingredients. LWT 180:114673. doi: 10.1016/j.lwt.2023.114673

United Nations (2024). The Sustainable Development Goals Report 2024. Available online at: https://unstats.un.org/sdgs/report/2024/The-Sustainable-Development-Goals-Report-2024.pdf (Accessed October 3, 2025).

Vázquez, J. A., Hermida-Merino, C., Hermida-Merino, D., Piñeiro, M. M., Johansen, J., Sotelo, C. G., et al. (2021). Characterization of Gelatin and hydrolysates from valorization of farmed Salmon skin by-products. Polymers (Basel) 13:2828. doi: 10.3390/polym13162828

Venslauskas, K., Navickas, K., Nappa, M., Kangas, P., Mozūraitytė, R., Šližytė, R., et al. (2021). Energetic and economic evaluation of zero-waste fish co-stream processing. Int. J. Environ. Res. Public Health 18:5. doi: 10.3390/ijerph18052358

Wang, K., Siddanakoppalu, P. N., Ahmed, I., Pavase, T. R., Lin, H., and Li, Z. (2020). Purification and identification of anti-allergic peptide from Atlantic Salmon (Salmo salar) byproduct enzymatic hydrolysates. J. Funct. Foods 72:104084. doi: 10.1016/j.jff.2020.104084

Winther, U., Skontorp Hognes, E., Jafarzadeh, S., and Ziegler, F. Greenhouse gas emissions of Norwegian seafood products in 2017. SINTEF Ocean ; (2020). (Accessed August 15, 2025). Available online at https://sintef.brage.unit.no/sintef-xmlui/bitstream/handle/11250/3044084/Rapport_klimafotavtrykk.pdf?sequence=1

Keywords: by-product, resource efficiency, salmon processing, rest raw material, material flow analysis (MFA), co-product, sustainability, waste management

Citation: Barrelet J, Brüning S and Simons S (2025) Salmon rest raw material flow—without a trace? Assessing resource efficiency of salmon processing in Germany. Front. Sustain. Food Syst. 9:1633288. doi: 10.3389/fsufs.2025.1633288

Edited by:

Farook Abdullah Sultan, University of Gävle, SwedenReviewed by:

Avijit Pandit, Norwegian University of Science and Technology, NorwayShegufta Shetranjiwalla, Memorial University of Newfoundland, Canada

Copyright © 2025 Barrelet, Brüning and Simons. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Johna Barrelet, am9obmEuYmFycmVsZXRAdHJhZm8tYWdyYXIuZGU=

Johna Barrelet

Johna Barrelet Simone Brüning

Simone Brüning Sarah Simons

Sarah Simons