- Department of Food Production, Faculty of Food and Agriculture, The University of the West Indies - St. Augustine Campus, St. Augustine, Trinidad and Tobago

Yogurt enriched with underutilized fruits and probiotics offer a promising solution for sustainable food systems. In this study, milk produced locally was fermented with a consortium of active cultures of lactic acid bacteria (LAB) probiotics (Lactobacillus bulgaricus, Lactobacillus acidophilus, and Streptococcus thermophilus) and infused with four levels of local green papaya nectar- 0% (YP0), 5% (YP5), 10% (YP10) and 15% (YP15) to produce four yogurts. The study employed a 4 × 3 complete randomized design giving 12 treatments. The main objectives were: to formulate yogurt incorporating lactic acid bacteria (LAB) probiotics and varying concentrations of green papaya nectar and to evaluate the sensory acceptability and physicochemical characteristics of probiotic yogurt produced with different inclusion levels of green papaya nectar. The LAB count ranged from 6.34–6.36 log10 CFU while pH increased significantly (p < 0.05) during storage. The °Brix value increased significantly (p < 0.05) with higher papaya nectar inclusion levels, which is reflective of the higher total soluble solid content of the green papaya that was incorporated at various concentrations. The color L* value of the yogurts became significantly higher (p < 0.05) during storage indicating they became lighter in color. Sensory acceptability scores revealed that yogurts with higher papaya nectar inclusion were significantly (p < 0.05) more preferred than the control in overall acceptability. At day 7, consistency was significant (p < 0.05) for Y10 and Y15, where consistency improved from 4.33 cm/s to 7.67 cm/s in Y3 and from 5.00 cm/s to 9.83 cm/s in Y4. The results suggest that papaya nectar can be a promising natural additive to improve the sensory appeal of yogurt for sustainable food systems.

1 Introduction

Yogurt is considered one of the most popular fermented dairy foods globally (Wang et al., 2025) since it is renowned for its nutritional value and functional properties, especially as a medium of probiotics. It is rich in bioactive proteins, hydrolyzed proteins, vitamins, and minerals, thus contributing to its.

Popularity among consumers (Shishir et al., 2024). The probiotics which are live cultures of lactic acid bacteria (LAB) namely, Streptococcus thermophilus, Lactobacillus delbrueckii subsp. bulgaricus and Lactobacillus acidophilus play multifaceted roles in gut health, immune modulation, and metabolic regulation. They are producers of organic acids and metabolites, such as lactic acid and bacteriocins, which lower gut pH and promote mineral absorption and have shown to inhibit pathogen growth. Furthermore, probiotics enhance the body’s immune response by stimulating dendritic and innate immune cells, causing better regulation of cytokine production and antibody secretion. Optimum levels of probiotics, ranging from 106 to 109 cfu/mL, are vital for maintaining these benefits throughout the shelf life of the yogurt (Codex Alimentarius Commission, 2022; Wang et al., 2025). Cow’s milk is considered the chief source for yogurt production due to its rich nutritional composition, including proteins, lactose, fats, calcium, phosphorus, and vitamins (Li et al., 2022) but it extends beyond cow’s milk, encompassing dairy from small ruminants and plant-based ingredients as well. The choice of milk source plays an important role in the physicochemical and organoleptic properties of yogurt. It has been reported that, the consistency, texture and shelf life of yogurts are desirable by high quality cow’s milk but plant-based alternative usually requires specific fermentation strains and processes to achieve similar quality standards (McClements and Grossmann, 2021).

Due to a growing awareness of the health benefits of functional foods, there has been a progressive interest in enhancing the nutritional and functional properties of yogurt by incorporating plant- based value-added ingredients (Wang et al., 2025; Wajs et al., 2023) such as fruits. Moreover, a diverse and healthier gut microbiome is achieved as a result of yogurt produced with plant-based materials (Sarıtaş et al., 2024). Studies have enhanced the nutritional value, sensory profile and functional properties of yogurts with commonly used tropical fruits such as passion fruit (De Toledo et al., 2018; Ning et al., 2021; Priyashantha et al., 2025), mango (Anjum et al., 2025; Minj and Vij, 2025; Lastra-Ripoll et al., 2023; Teshome et al., 2017), pineapple (Lou et al., 2024; Sah et al., 2016), banana (Dutta Roy et al., 2015; Mahomud et al., 2024; Vicent, 2024). There have also been reports about the use of papaya in yogurt production but they are limited. One study reported that the use of green papaya powder and banana, enhanced the nutritional and functional value of yogurts (Sarker et al., 2023) while another study revealed that a combination of ripened papaya and mango improved sensory acceptability (Teshome et al., 2017).

The Caribbean region is endowed with a wide variety of nutrient-rich fruits that do not only impart distinctive tropical flavors to fermented dairy products like yogurt but also present opportunities to support sustainable food systems. However, the high perishability of these fruits at full ripeness underscores the need for innovative processing and preservation strategies that reduce food waste, enhance value addition, and contribute to climate-resilient agricultural practices. Among these fruits is Papaya (Carica papaya L.) which is widely cultivated and readily available across the Caribbean region, where it serves as a key tropical fruit with both nutritional and economic significance. According to the FAO, Trinidad and Tobago produced approximately 1,228 metric tons of papaya in 2022, contributing to the nation’s agricultural diversity and food security and ranking 55th globally and accounting for about 0.01% of the world’s total papaya production (Food and Agriculture Organization of the United Nations, 2023).

Papaya in its unripe form has a longer shelf life that its ripe stage, is rich in dietary fiber, polyphenols, enzymes such as papain and prebiotic compounds that can enhance gut health (Ali et al., 2012). Green papaya’s potential to serve as a functional additive in fermented products stems from its antioxidant activity, antimicrobial properties, nutraceutical adjuvant in combined therapies against Alzheimer’s disease, allergic reaction, anticancer activity, anemias (Leitao et al., 2022) and ability to modulate the gut microbiota (do Prado et al., 2021). Furthermore, the valorization of underutilized tropical fruits like green papaya aligns with sustainable food system goals, promoting biodiversity and reducing food waste (Aschemann-Witzel et al., 2023). Hence, the integration of green papaya into probiotic yogurt offers an approach to developing functional dairy products with enhanced nutritional profiles and potential health benefits. However, limited research exists on the effects of green papaya on the sensory attributes and quality characteristics of probiotic yogurt internationally and there are no known studies in the Caribbean region. Thus, the main focus of this present study was primarily on conducting a preliminary evaluation of the final yogurt formulations produced with green papaya nectar on sensory acceptability and quality characteristics.

1.1 Objectives

To conduct an exploratory study on basic physicochemical, microbiological and sensory characteristics of probiotic yogurts with varying concentrations of green papaya nectar.

1.2 Experimental design

The experimental design followed a completely 4 × 3 randomized design in which, each yogurt treatment was replicated three times with 12 yogurt samples overall. Four variations of the probiotic yogurts were produced according to the various levels of papaya nectar: 0, 5, 10 and 15%.

2 Materials and methods

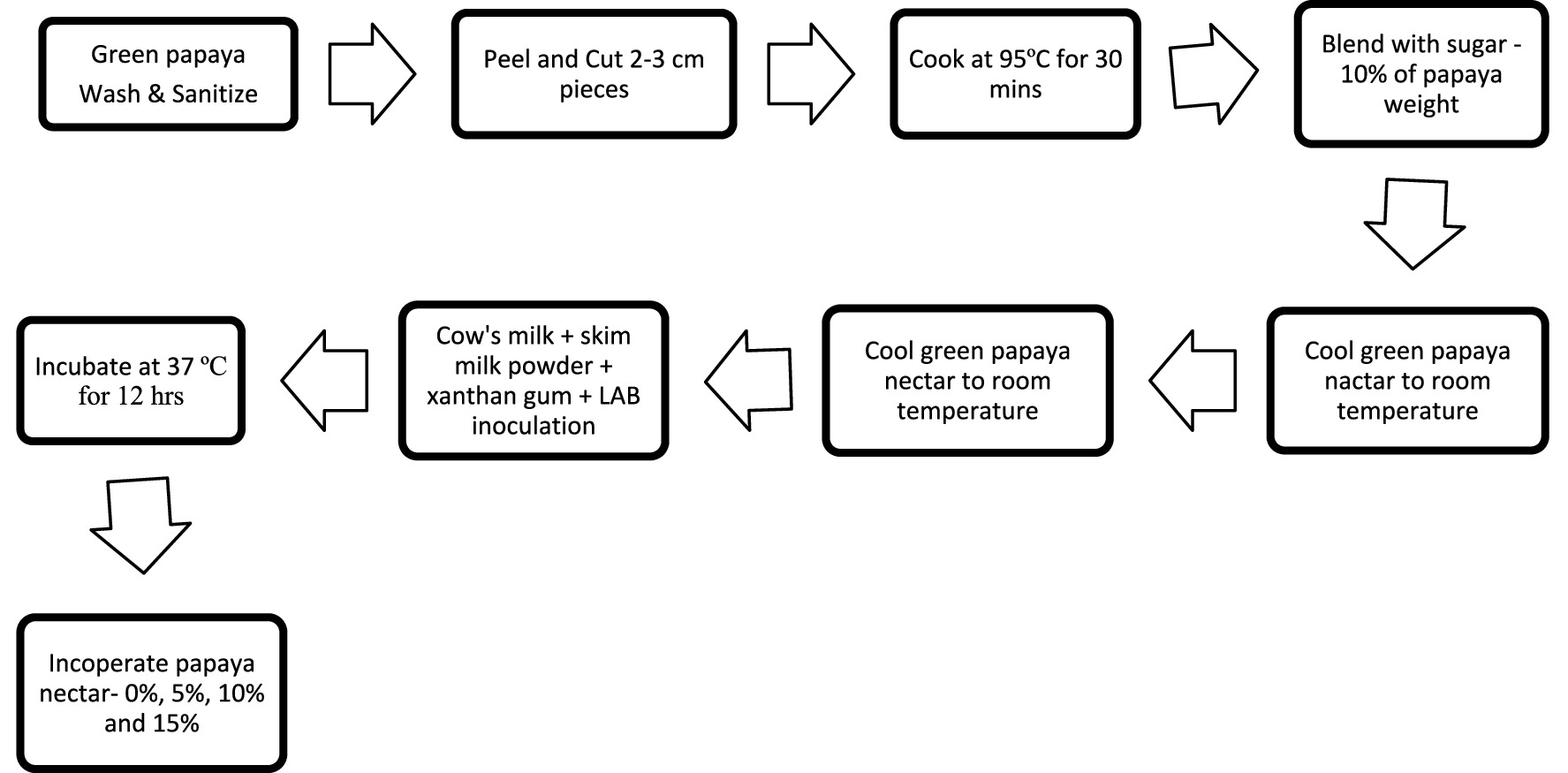

2.1 Preparation of green papaya nectar

For the purposes of this study, green papaya was used from a single, uniform batch harvested at the mature green stage to minimize variability such as in management and soil type. The mature green papaya was obtained from the Field Station at the University of the West Indies, St. Augustine Campus, Trinidad, W.I. where standard agronomic practices were followed. The papaya was washed in a sanitizing solution of tap water with chlorine bleach by diluting 500 mL of household bleach in 200 mL of water. Thereafter, it was cut into 2–3 cm pieces using a knife sterilized with 70% ethanol and blended using a sterile blender (Proctor Silex model, 58,130, North Carolina, USA) at a speed of #8 for 15 min. No filtration was applied, and the entire puree was utilized. To produce papaya nectar, the prepared fruit was cooked in a pot at 95°C for 30 min and blended with sugar (Sweet Cane Granulated Sugar, Gopaul and Company Ltd. Trinidad and Tobago, W.I.) at a weight of 10% of the raw papaya (Othman et al., 2019). The sugar used in this study is mainly composed of sucrose, a disaccharide. After heating, the papaya puree nectar was kept to cool to room temperature before incorporating in the yogurts.

2.1.1 Production of yogurt with green papaya nectar

Pasteurized cow’s milk sourced from the Field Station at the University of the West Indies, St. Augustine Campus (Trinidad, W.I.), was used to produce yogurts following a changed version of the method described by Othman et al. (2019). Skimmed milk powder (6% w/w) and xanthan gum (0.2% w/w, Now Foods, Bloomingdale, IL, USA) were incorporated into the milk. The blend was then inoculated with a probiotic culture (0.5% w/w) comprising Lactobacillus bulgaricus, Lactobacillus acidophilus, and Streptococcus thermophilus (Yogourmet, Canada) according to manufacturer’s instructions The inoculated milk was incubated at 37°C for 12 h until complete curd formation (Dutta Roy et al., 2015). After fermentation, four yogurt formulations were prepared using varying concentrations of papaya nectar by weight: 0% (no papaya, control), 5, 10, and 15%, corresponding to the labels YP0, YP5, YP10, and YP15, respectively, following Othman et al. (2019). Each formulation was then assessed for sensory acceptability, physicochemical characteristics, microbiological stability, and proximate nutrient composition. Evaluations were conducted immediately after production (day 0), and the physicochemical analyses were repeated after 7 days of storage (Figure 1).

2.2 Physicochemical analyses

The chromaticity of each yogurt sample was analysed in triplicate using a Konica Minolta Chroma Meter CR-400 (Tokyo, Japan), following standard protocol. Before measurements, the device was calibrated with its black and white reference plates to establish a zero baseline. Approximately 50 mL of yogurt was placed into glass beakers, and three readings were taken from different areas of the surface using the L*, a*, and b* coordinate system. In this system, L* ranges from 0 (black) to 100 (white) to indicate lightness, a* denotes the red-to-green axis, and b* is the yellow-to-blue axis. In addition, the psychometric parameters, Hue, Chroma and whiteness index were obtained using the Equations 1–3 below (Purohit et al., 2023; Castillo et al., 2025).

2.2.1 Yogurt pH analysis

The measurement of pH analysis was performed using a pH tester HI198103 Hanna Instruments (Rhode Island, USA). The pH tester was standardized before measurements using pH 4 and 7 buffers. The pH measurement was replicated three times for each yogurt.

2.2.2 Yogurt Brix analysis

The °Brix value (sugar content) of the yogurt samples was measured by using a refractometer (Pocket Refractometer Pal1 Atago, Tokyo, Japan). The sample plate was cleaned and dried. Approximately 1 mL of the yogurt was placed on the plate, which was then closed and the reading was taken. Three readings were taken for each sample (Kamal-Eldin et al., 2020).

2.2.3 Yogurt Bostwick consistency

Yogurt samples were stirred for 1 min and then placed into the small containment chamber of the bench-top Bostwick consistometer (24925-000 CSC Scientific, Virginia USA). The releasing gate was then released, and the consistency was determined by measuring the distance (cm) over which the yogurts flowed for 30 s (Kamal-Eldin et al., 2020).

2.2.4 Yogurt water activity analysis

The water activity of each yogurt was determined using a PawKit Aqualab water activity meter (Washington, USA) according to the manufacturer’s instructions.

2.3 Measurement of proximate analysis

2.3.1 Moisture content determination

Proximate analysis was carried out to determine total solids, moisture, and crude protein in accordance with AOAC International (2002) standard procedures. Moisture content was measured by drying a 1–2 g sample at 102 ± 2°C using a Thermo Scientific UT-6200 hot air oven (ANKOM dryer) for 3–5 h, then cooling the sample in a desiccator for approximately 15 min before weighing and moisture content was calculated as difference in weight and expressed in percentage.

2.3.2 Crude protein

The crude protein content was estimated using the Kjeldahl method (KjelFlex K360 system), following the AOAC International (2002) protocol. Briefly, a liquid sample was placed in a Kjeldahl digestion flask, to which 25 mL of concentrated sulfuric acid and catalyst tablets were added. The mixture was heated on a digestion rack until it became clear. After cooling, 100 mL of distilled water was added, the digest was transferred to a 250 mL volumetric flask, and topped up to volume before thorough mixing. For nitrogen recovery, the Markham distillation unit was employed. A 5 mL aliquot of the diluted digest was transferred into the distillation chamber, mixed with 5 mL of concentrated sulfuric acid, and distilled into 25 mL of boric acid contained in a 100 mL Erlenmeyer flask until the distillate reached 25 mL. The ammonia-trapped solution was then titrated with 0.01 N hydrochloric acid. Finally, crude protein content was calculated based on the nitrogen content using the standard conversion factor.

Calculations:

Calculation of protein on dry mass % crude Protein = % Nitrogen × 6.25, where 6.25 is the protein-nitrogen conversion factor.

2.3.3 Total solids

Total solids in yogurt were determined using the AOAC Official Method 925.23. Approximately 3–5 g of thoroughly mixed yogurt was weighed into a pre-weighed, flat-bottomed glass dish. The sample was preheated on a water bath for 10–15 min to remove free moisture, then dried in a hot air oven at 102 ± 2°C until constant weight was achieved, typically within 2–3 h, as verified when successive weighing differed by ≤1 mg. After drying, the dish was cooled in a desiccator before reweighing. Total solids content was calculated based on the weight difference between the dried sample and the initial wet sample, calculated as a percentage of the initial wet weight (AOAC International, 2006).

2.4 Microbial analysis

The yogurt samples underwent microbiological evaluation immediately after production. These analyses aimed to quantify colony-forming units (CFU) of LAB (probiotic strains) and yeasts and molds. Enumeration was performed on Tomato Juice Agar (TJA; Oxoid, UK) for LAB (Das et al., 2023), and Potato Dextrose Agar (PDA; Oxoid, UK) for yeasts and molds. All media and equipment were sterilized at 121°C, 15 psi for 15 min using a Tuttnauer steam autoclave, and all procedures took place within an Envirco laminar flow hood under aseptic conditions. Each yogurt sample (10 g) was aseptically weighed and homogenized in a sterile stomacher for 60 s. Subsequently, 90 mL of sterile peptone water was added. Serial 10-fold dilutions were prepared up to 10−7. Aliquots were plated onto TJA and incubated aerobically at 35°C for 48 h, while PDA plates were incubated at 25°C for the same duration. After incubation, plates containing 30–300 colonies were counted as per AOAC International (1999) guidelines. Results were expressed as CFU/g.

2.5 Sensory evaluation

The yogurts with varying amounts of papaya nectar were subjected to sensory evaluation and compared to control yogurt treatments made without papaya nectar. A sensory panel consisting of panelists (n = 30, Females = 17, Males = 13) from the Department of Food Production, The University of the West Indies was randomly selected to determine the sensory attributes of the yogurts with various levels of the papaya nectar. The panelists ages ranged from 18 to 47 years. The sensory scores were based on the degree of preference of organoleptic qualities of appearance, color, taste, mouthfeel, aroma and overall acceptability using a 9-point hedonic scale in the range of 9 = like extremely, 8 = like very much, 7 = like moderately, 6 = like slightly, 5 = neither like nor dislike, 4 = dislike slightly, 3 = dislike moderately, 2 = dislike very much and 1 = dislike extremely. The yogurts were presented in a random manner, labeled with three digits random code and a structured scoring sheet was used to record the scores. Panelists were provided with plain crackers and water for palate cleansing between samples.

2.6 Statistical analyses

All statistical analyses were done using SPSS (Version 21.4), for Microsoft Windows. The results were analysed for variance among treatments and between time (day 0 and 7) by ANOVA and the significant means separated by Tukey Pairwise Comparisons (p < 0.05).

3 Results and discussion

3.1 Physicochemical characteristics

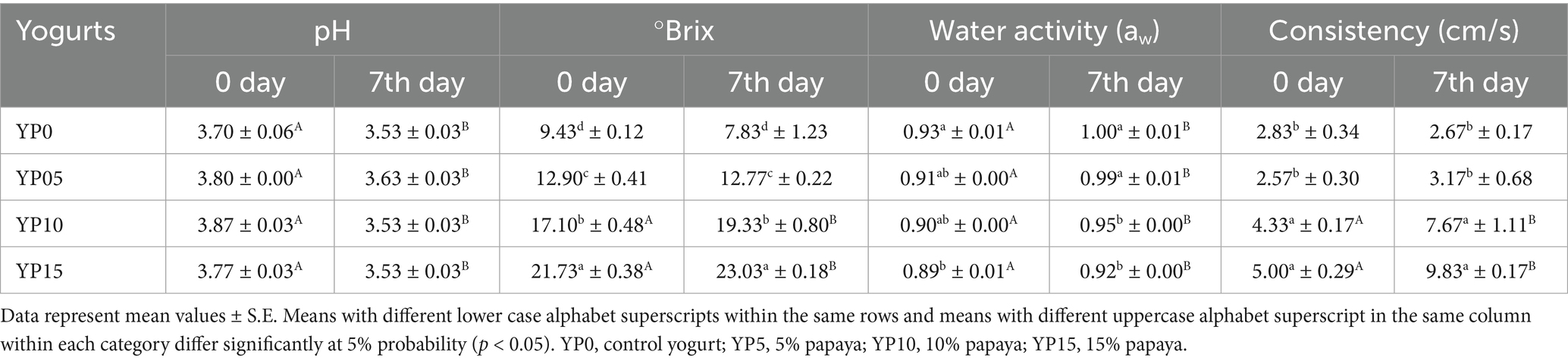

The pH of the yogurt remained acidic across all treatments (Table 1) and different inclusion levels of papaya nectar did not cause significant changes in pH among yogurts at the beginning or at day 7. However, a notable significant (p < 0.05) reduction in pH was noticed with the yogurts at days 0 and seven, indicating increased acidity over time. Even though no titratable acidity measurements or organic acid profiling were conducted to quantify this acid development, the significant pH reduction is most likely attributed to LAB metabolism during shelf life. In this study, the inclusion of varying levels of green papaya nectar had no significant effect on the initial pH of yogurts. This finding is supported by the lack of significant variation in pH among yogurts right after production and up to the storage period of 7 days. However, a notable reduction in pH was observed across all treatments after storage, which is the expected trend of increased acidification over time due to increased LAB activity. Previous studies have reported similar post-storage pH reductions in yogurts enriched with tropical fruits. For example, Anjum et al. (2025) and Tefera et al. (2016) reported pH declines in mango and papaya pulp yogurts, respectively, during storage. Additionally, Othman et al. (2019) documented acidification trends in papaya-supplemented yogurts. These reports therefore support the current findings despite differences in fruit variety and type may influence outcomes.

Table 1. Effect of different levels of papaya nectar inclusion and storage on the physicochemical properties (pH, °Brix, water activity and consistency of yogurt).

The final pH values ranging from 3.53 to 3.63 after 7 days demonstrate a highly acidic environment that is characteristic of stored yogurt. According to Codex Alimentarius Commission (2003) standard for fermented milk, the typical range for final pH is 4.0–4.6. Though the pH values for this current study falls on the lower end of this typical range it is still considered acceptable. The role of green papaya nectar in modulating acidification cannot be confirmed without further biochemical analysis, but the results demonstrate acceptable pH stability across treatments within the observed storage period. The amount of sugar in the yogurt is measured in °Brix (Table 1). The control yogurt (YPO) exhibited the lowest °Brix value of 9.43, while YP15 had the highest value of 21.73. As the green papaya nectar inclusion increases, a statistically significant (p < 0.05) increase in °Brix was observed across yogurts. This is however, consistent with the naturally higher total soluble solid content of the green papaya that was incorporated at various concentrations. These results align with studies that revealed proportional increases in °Brix after sweetened fruits were included into yogurt formulations (Othman et al., 2019; Teshome et al., 2017). Storage had minimal impact on °Brix values for YP0 and YP5, but for higher inclusion levels YP10 and YP15, a significant increase (p < 0.05) was observed. Thus, indicating that at higher fruit inclusion levels, sugar concentration may continue to rise over time. For future studies, there is a need to profile the sources of additional sugar solutes over and above the added sucrose levels.

Water activity (aw), a critical factor influencing microbial stability and shelf life, exhibited a decreasing trend as papaya nectar inclusion increased (Table 1). However, the difference was not statistically significant among YP0, YP5, and YP10. In contrast, YP15 had a significantly lower (p < 0.05) water activity value compared to the other treatments. After storage, the declining trend in water activity persisted. While YP0 and YP05 showed no significant difference, YP10 and YP15 had significantly lower (p < 0.05) water activity compared to the other yogurts. The storage period had a highly significant impact on water activity, as yogurt samples after 7 days exhibited increased values across all treatments. This increase may be attributed to moisture redistribution within the yogurt matrix, potentially affecting its textural and microbial properties.

Water activity is a critical parameter governing the microbial stability and shelf life of food products, including yogurt, as it quantifies the availability of free water necessary for microbial proliferation (Brodziak et al., 2020; Sarker et al., 2023). In this study, a decreasing trend in water activity was observed with increasing papaya nectar inclusion, with the highest fortification level (YP15) showing a statistically significant reduction (p < 0.05) compared to lower levels at day 0. This decline may be attributed to the increased concentration of soluble solids from papaya nectar, which binds free water and thereby reduces Water activity. After 7 days of storage, a significant increase in water activity was recorded across all treatments which may be explained by moisture migration or redistribution within the yogurt matrix during storage. Such changes can influence texture and microbial susceptibility, as water becomes more available despite the presence of soluble solids. The observed initial reduction in water activity aligns with findings by Sarker et al. (2023), who reported a similar decrease in water activity following fortification of yogurt with papaya powder, although their study noted water activity remained below 0.99 and relatively stable over storage. In contrast, our results indicate a significant rise in water activity after 1 week, albeit remaining below 0.99 in fortified samples, suggesting that while moisture availability increases, it remains at levels limiting extensive microbial growth. Importantly, despite increased water activity over storage, the yogurt samples retained a low pH, which likely inhibited microbial proliferation and ensured safety for consumption (Sarker et al., 2023; Sarker and Siddiqui, 2023). Although there is no Codex-mandated water activity standard for yogurt, prior report indicates that, most stirred yogurts maintain a water activity of 0.97 to 0.99 (Shah, 2007) similar to our study thus supporting microbial stability and texture. Thus, papaya nectar fortification influences yogurt’s physicochemical properties by modulating water activity and consistency, with implications for shelf life and quality.

The consistency of the yogurts is presented in Figure 2 and Table 1. Consistency of yogurts was significantly (p < 0.05) influenced by the inclusion levels of papaya nectar between YP0 (0%) and YP5 (5%) and with YP10 (10%) and YP15 (15%) as well as at day 7 (Table 2). At the beginning of the study (day 0), yogurts with higher papaya nectar inclusion (YP10 and YP15) exhibited significantly greater consistency values compared to YP0 and YP5. The yogurt, YP15 had the highest consistency value followed by YP10 YP0 and YP5. Thus, indicating that papaya nectar enhanced the viscosity and structural integrity of the yogurt matrix. At 7 days of storage, a general increase in consistency was observed across all yogurts. The increase was statistically significant (p < 0.05) for YP10 and YP15. In contrast, the consistency of YP0 and YP5 did not change significantly during storage (p > 0.05), suggesting that lower papaya nectar inclusion levels did not impact the yogurts textural properties over time.

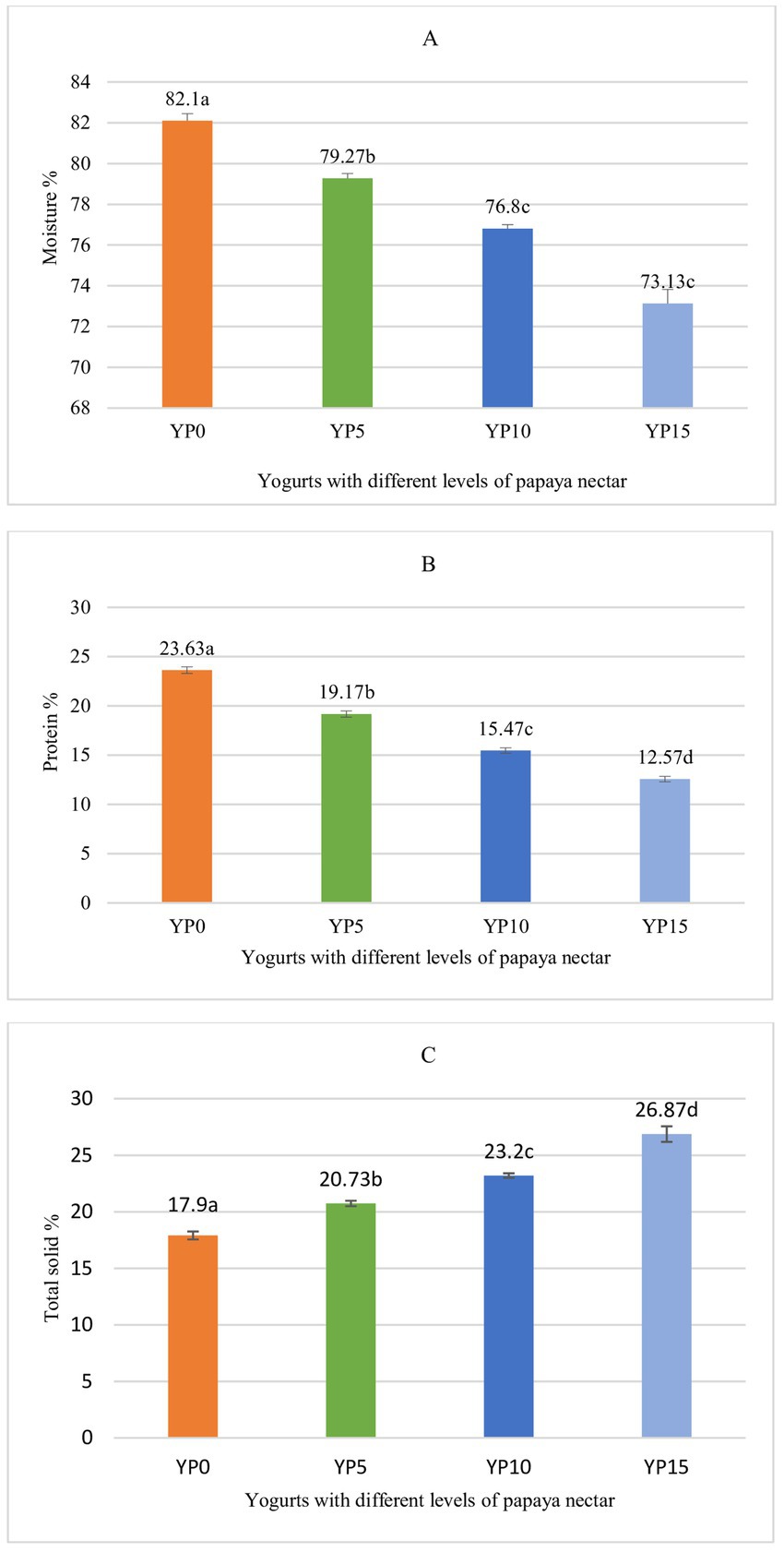

Figure 2. (A–C) Proximate moisture, protein and total solids of green papaya yogurt. Data represent mean values ± standard error. Means with different alphabet differ significantly at 5% probability (p<0.05). YPO, control yogurt; YP5, 5% papaya; YP10, 10% papaya; YP15, 15% papaya.

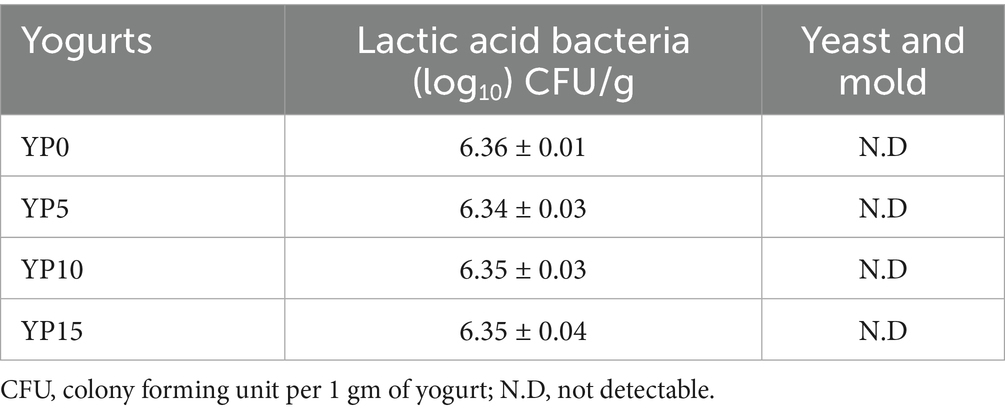

Table 2. Lactic acid bacteria (Lactobacillus bulgaricus, Lactobacillus acidophilus, and Streptococcus thermophilus) and yeast and mold counts of papaya-nectar yogurts.

The general increase in consistency values in this study indicate that the yogurts became less viscous as the levels of papaya nectar pulp increased and even during storage at day 7. This finding was also supported by other yogurt studies with the inclusion of fruits (Anjum et al., 2025; Ranadheera et al., 2012). The reduction in consistency of the yogurts is attributed to enzymatic degradation of pectin from the fruit, dilution effect from water content in the fruit pulp and the disruption of protein gel network (Cho et al., 2020).

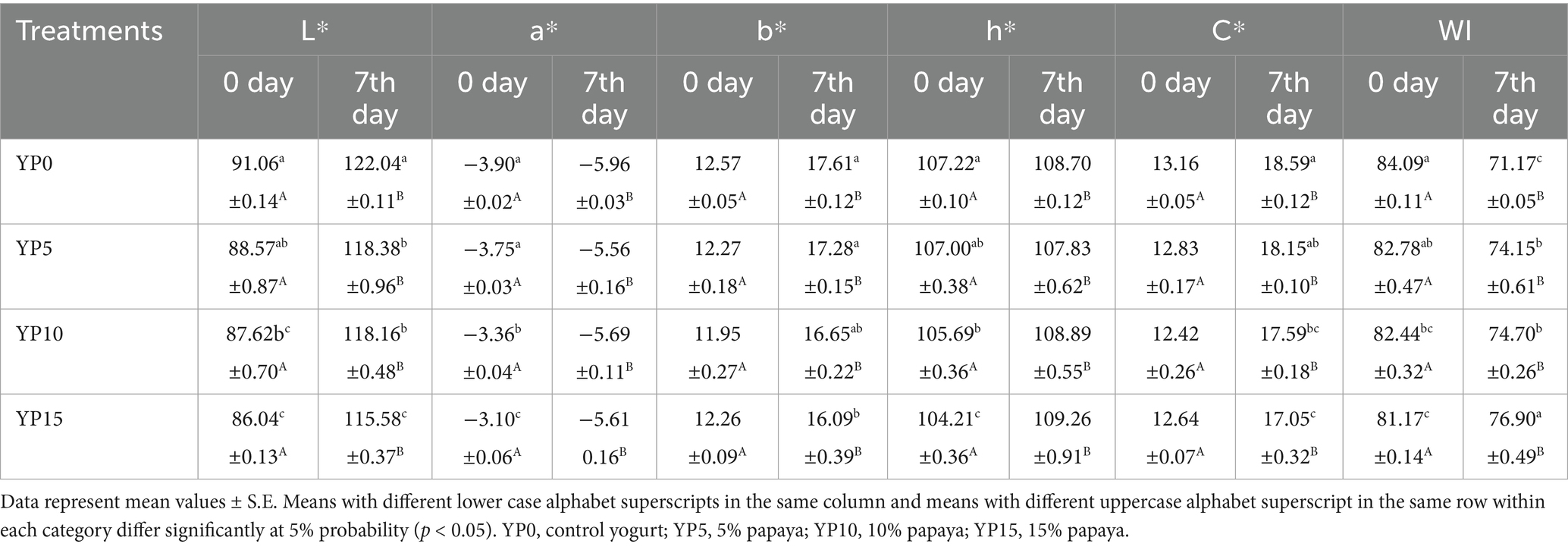

The color L* a* b* values for the green papaya-nectar yogurts are represented in Table 3. The L* values represent the lightness of a color, ranging from 0 (black) to 100 (white), where higher values indicate lighter shades. In the present study, the L* value was highest in yogurt without papaya nectar (YP0), indicating a lighter color. However, with the progressive incorporation of papaya nectar, the L* value decreased significantly (p < 0.05), resulting in a darker appearance. The lowest lightness (L* = 86.04) was exhibited by YP15. A similar trend was observed after 7 days of storage, where the differences between treatments remained significant but the L* value increased significantly (p < 0.05) indicating that yogurt samples became lighter after 7 days.

The a* value quantifies color along the red-green axis, where positive values indicate red tones, and negative values represent green tones. A higher positive a* value corresponds to a stronger red hue, while a lower (negative) value denotes an increased green intensity. In the present study, YP0 exhibited the lowest a* value, whereas YP15 recorded the highest, indicating that the inclusion of papaya nectar significantly increased the red hue of yogurt (p < 0.05, Table 3). This trend was consistent after the seven-day storage period, with the a* values ranging from −5.96 (YP0) to −5.15 (YP15). However, the observed increase in a* values across different treatments during storage was not statistically significant, suggesting a numerical but not biologically significant shift in color intensity. When comparing the a* values before and after storage, a significant (p < 0.05) decline was observed across all treatments. For instance, YP0 decreased from −3.90 to −5.96, while YP15 declined from −3.10 to −5.61, indicating a shift toward a lighter and less intense red tone over time. This suggests that storage duration influenced the stability of red pigments, potentially due to oxidation or pigment degradation.

He b* value indicates a color’s position on the yellow–blue spectrum: positive b* signifies a shift toward yellow, while negative b* denotes a shift toward blue. A larger positive b* corresponds to a more vivid yellow hue, whereas a more negative b* reflects a deeper blue tint. In the present study, the b* values remained positive at day 0, confirming the dominance of yellow tones in all yogurt samples. The inclusion of papaya nectar levels did not cause a statistically significant (p > 0.05) increase in b* values; however, a numerical decline was observed as the papaya nectar concentration increased. This suggests that higher levels of papaya nectar slightly reduced the yellow intensity, though the effect was not statistically substantial. After 7 days of storage, a significant (p < 0.05) increase in b* values were observed across all treatments, indicating an enhanced yellow intensity over time. The highest b* value (17.61) was recorded in YP0, while the lowest (16.09) was observed in YP15. The decline in b* values with increasing papaya nectar concentration followed a linear trend, and the difference among treatments was significant.

The Hue value indicates the type of color (red, yellow, blue) based on its position in the color wheel and it is calculated using the a* and b* value. Higher h* values indicate colors shifting toward yellow (90°) or green (180°). Lower h* values indicate colors closer toward red (0°) or blue (270°). In yogurt analysis, an increase in hue angle suggests a shift toward a lighter color. In the present study, the h* ranged between 107.22 (YP0) and 104.20 (YP15) indicating that color shifting toward yellow. The h* value decreased when percentage of papaya nectar increased, YP0 and YP10 did not differ significantly. Similarly, YP10 and YP15 did not differ significantly but YP15 differ significantly (p < 0.05). At 7 days of storage, the h* value among yogurts also did not differ significantly but they increased significantly (p < 0.05) from the time of production to day 7.

Chroma, also called color purity or saturation, measures the vividness or dullness of a color. Higher C* values indicate more intense, saturated colors. Lower C* values mean duller, faded colors. In this study, the C* value ranged between 13.16 and 12.42 and there was no significant difference in C* value despite various inclusion levels of papaya nectar to yogurt. However, the C* value increased significantly (p < 0.05) after a storage period of 7 days which ranged between 18.89 and 17.05. The control yogurt (YP0) exhibited the highest C* value compared to the other yogurts with the inclusion of the papaya nectar which is indicative of a more intense color.

Whiteness index quantifies how close a sample is to pure white, considering L*, a*, and b* values. Higher WI values denote a whiter appearance. A WI value closer to white will be high, typically approaching 100. The WI value decreased when papaya nectar inclusion level increased. The highest WI value was exhibited by the control YP0 being 84.09 and the lowest was shown by YP15 being 81.17. However, there was no significant difference in these values among yogurts after production but a significant reduction (p < 0.05) occurred in all yogurts from the time of production and at day seven during storage.

Color can be considered as a most important factor used by consumers to judge food quality and influence purchasing of a food product (Castillo et al., 2025; Ramsaran et al., 2024). The significant differences exhibited by the L* a* b* values among the papaya nectar yogurt can be attributed to the progressive increase in the inclusion of the green papaya nectar in the yogurts. The L* value of the yogurts became significantly darker as the inclusion level of papaya increased due to increasing levels of the chlorophyll pigment (Khurnpoon et al., 2014). The changes exhibited by the L* value, becoming lighter during the storage period can be due to degradation of the green chlorophyll pigment influenced by factors such as pH as the acidic environment during fermentation and the LAB activity. When comparing the a* values before and after storage, the decline across all treatments suggests that storage duration also influenced the stability of red pigments, potentially due to oxidation or pigment degradation. In the present study, the b* values remained positive at day 0, confirming the dominance of yellow tones in all yogurt samples. The numerical decline observed as the papaya nectar concentration increased, suggests that higher levels of papaya nectar though the effect was not statistically substantial, slightly reduced the yellow intensity. Similar findings The transformation of the color of yogurts becoming lighter during storage in this study, can be more acceptable to consumers as they show a higher preference for such color intensities in dairy related products (Manzoor et al., 2019). When comparing the a* values before and after storage, a significant (p < 0.05) decline was observed across all treatments. This suggests that storage duration influenced the stability of red pigments, potentially due to oxidation or pigment degradation. In the present study, the b* values remained positive at day 0, confirming the dominance of yellow tones in all yogurt samples. However, a numerical decline was observed as the papaya nectar concentration increased. This suggests that higher levels of papaya nectar slightly reduced the yellow intensity, though the effect was not statistically significant. The changes in the h*, C* and WI values of the yogurts while storing is also attributed to alteration of the papaya pigments.

3.2 Microbial analysis

The mean lactic acid bacteria (LAB) count (log10 CFU/g) for papaya-nectar yogurts ranged from 6.34 to 6.36 log10 CFU/g as displayed in Table 2. The LAB counts among yogurts was not significant (p > 0.05). Additionally, yeasts and mold counts were undetectable. The LAB counts ranged from 6.35–6.36 log10 CFU/g across all treatments, indicating active LAB growth. However, the various inclusion levels of green papaya nectar did not significantly influence LAB counts among yogurts. These findings align with those of Sarker et al. (2023), who reported that the addition of functional ingredients did not impact LAB counts during fermentation. However, their study on yogurt fortified with green papaya powder and banana resistant starch showed higher LAB counts ranging from 8.30 to 8.43 log10 CFU/g. Similarly, Hoxha et al. (2023) observed LAB counts above 8 log10 CFU/g while Tefera et al. (2016) reported a significant increase in LAB counts with increasing levels of papaya juice in yogurt formulations. Moreover, yogurt samples supplemented with 20% papaya juice exhibited the highest LAB count (8.15 ± 0.13 log10 CFU/g), while the control (without papaya juice) recorded the lowest count (7.81 ± 0.07 log10 CFU/g). Additionally, Teshome et al. (2017) reported LAB counts of 7.14 log10 CFU/g in control yogurt and 7.03 log10 CFU/g in yogurt supplemented with 25% papaya juice. Similar findings were reported in various plant-based yogurts, including Dovyalis caffra fruit yogurt (Waweru et al., 2024), papaya pulp yogurt (Waweru et al., 2021), papaya juice yogurt (Tefera et al., 2016; Teshome et al., 2017), and papaya-cactus blended yogurt (Matter et al., 2016). Despite the LAB counts in our study, was less than these previous yogurt studies, they exceeded 106 CFU/g, thereby complying with Codex Alimentarius Commission (2022) standards, which stipulate a minimum of 106 CFU/g of labeled microorganisms in fermented milk products. Additionally, yeast, and mold were not detectable in any of the samples suggesting that the pasteurization process was highly effective in eliminating microbial contaminants. This also reflects compliance with food safety standards outlined by the Codex Alimentarius Commission (2022).

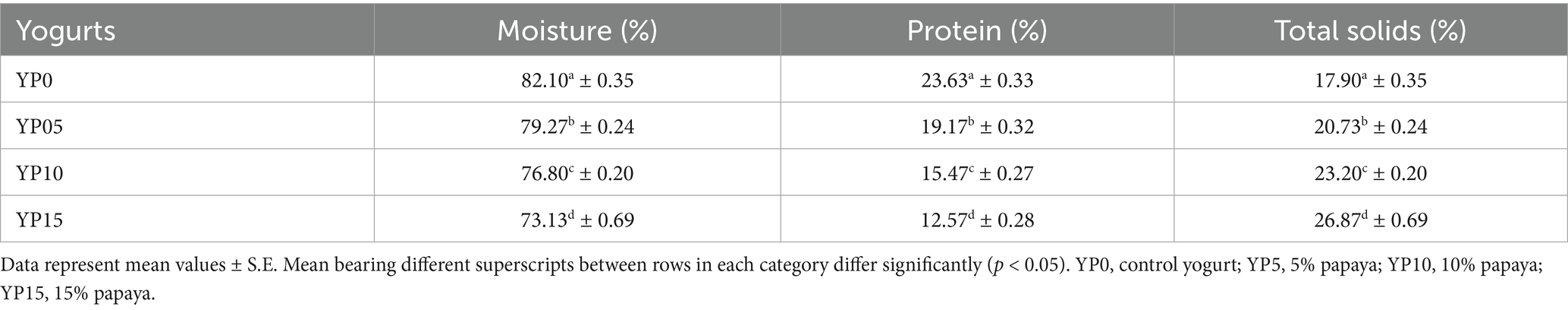

3.3 Proximate composition – moisture, protein and total solids of papaya yogurt

The proximate composition of freeze-dried yogurt with different percentages of papaya nectar is presented in Table 4. The moisture content of freeze-dried yogurt showed a significant decline (p < 0.05) from 82.10 to 73.13% as the inclusion level of papaya nectar increased. This reduction in moisture was accompanied by a corresponding increase in total solids from 17.90% in YP0 to 26.87% in YP15. The differences between the different inclusion levels of papaya nectar were highly significant. Furthermore, the results revealed a significant linear decline in proximate protein but a significant linear increase as the level of papaya nectar increased. The inclusion of green papaya nectar linearly altered the proximate composition of the yogurt. In this study, the proximate analysis was conducted post freeze-drying, and to date, no direct comparable reports have been found that specifically address green papaya nectar inclusion in cow milk yogurt. However, the observed values in this study are broadly comparable to those reported by Ismail et al. (2020), who documented protein concentrations in whole milk yogurt supplemented with 0.5% whey protein concentrate, 0.5% spirulina, 0.5% modified starch, and a control (without additives) as 25.65, 27.35, 26.29, and 25.44%, respectively. In the current experiment, protein content decreased linearly with increasing levels of green papaya nectar. Compared to the control yogurt (YP0), the protein content was reduced by 19.12, 34.52, and 46.79% in YP5, YP10, and YP15, respectively. This reduction is likely due to the low protein content of green papaya nectar, which contains less than 1% protein (1.46% in unripe, 0.64% in hard ripe, and 0.29% in very ripe stages) as reported by Chukwuka et al. (2013). Concurrently, the linear increase in total solids approximately 50% higher in YP15 compared to YP0 may be attributed to the higher dry matter content of green papaya (18.61% in unripe, 13.32% in hard ripe, and 10.79% in very ripe fruit). These findings suggest that papaya nectar inclusion significantly modifies the nutritional structure of the final yogurt product, particularly by increasing total solids while decreasing protein concentration. Further studies are required with optimizing the protein, fat and other nutrients in the finished product.

3.4 Sensory attributes

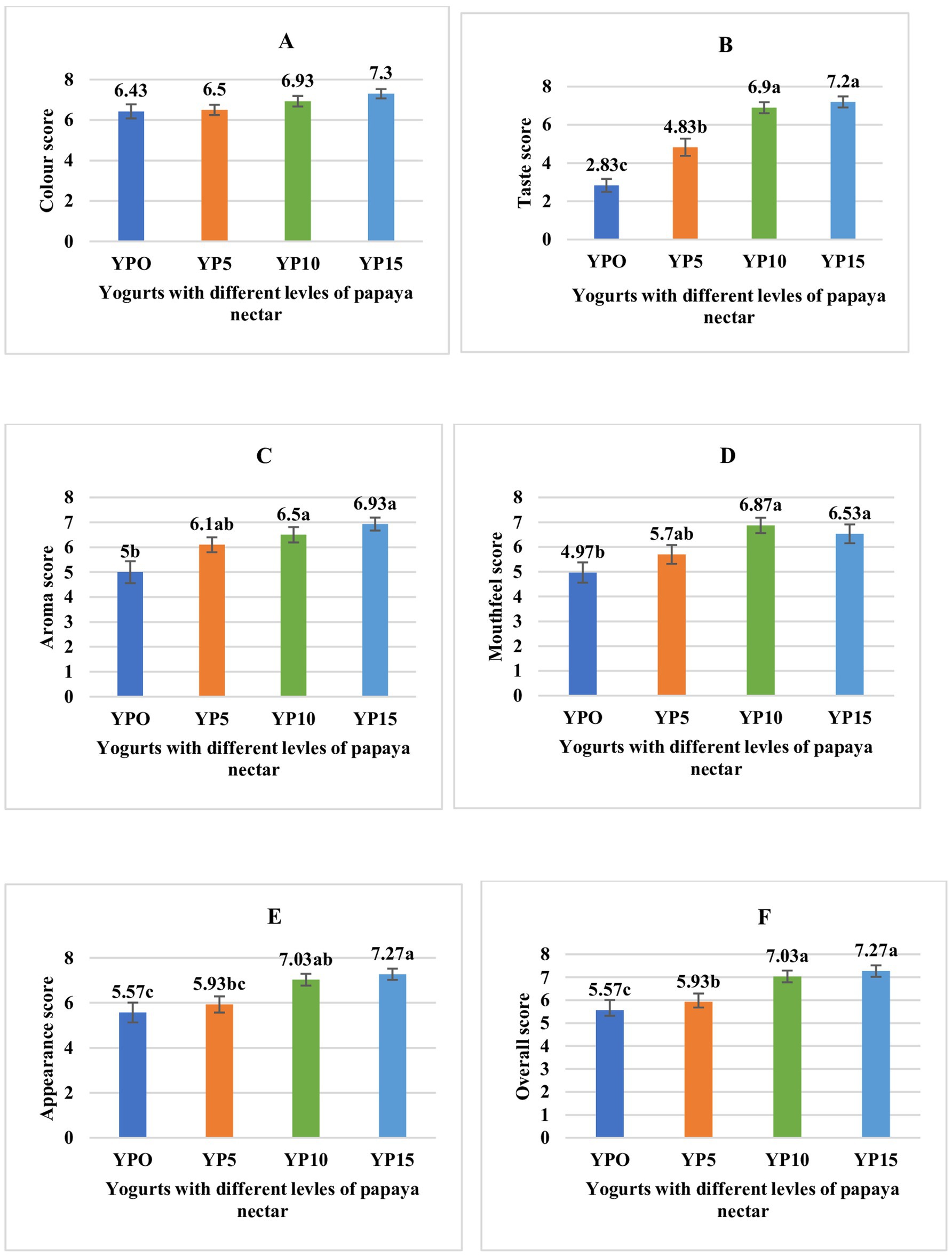

The sensory attributes, color, taste, aroma, appearance, mouthfeel and overall acceptability of yogurts with varying levels of papaya nectar inclusion are presented in Figures 3A–F. The color scores (Figure 3A) ranged from 6.43 (like slightly, YP0) to 7.30 (like moderately, YP15) and did not exhibit any significant differences (p > 0.05) among yogurts. This suggests that while papaya nectar contributed to some enhancement in color perception, the changes were not distinct enough to be perceptibly different among the yogurts by the sensory panelists.

Figure 3. (A–F) Sensory attributes – color, taste, aroma, mouthfeel, appearance, overall acceptability. Data represent mean values ± standard error. Means with different alphabet differ significantly at 5% probability (p<0.05). YPO, control yogurt; YP5, 5% papaya; YP10, 10% papaya; YP15, 15% papaya.

The taste scores (Figure 3B) exhibited a significant increasing trend with higher papaya nectar inclusion. The control yogurt, YP0 had the lowest taste score (2.83, dislike very much), whereas YP15 recorded the highest score (7.20; like moderately), followed by Y10 with a like slightly score of 6.9 indicating that papaya nectar enhanced the flavor complexity of the yogurt. Statistical analysis revealed that YP10 (6.90) and YP15 (7.20) did not differ significantly from each other but were significantly higher (p < 0.05) than scores for YP0 (2.83, dislike very much) and YP5 (4.83, dislike slightly). This suggests that a higher level of papaya nectar incorporation positively influenced taste perception.

A similar trend was noticed for aroma (Figure 3C), where YP0 exhibited the lowest score (5.00, neither like nor dislike). The inclusion of papaya nectar significantly increased aroma intensity (p < 0.05) among the control yogurt YP0, YP10 and YP15. The mouthfeel scores (Figure 3D) progressively increased with higher papaya nectar inclusion. YP0 recorded the lowest score (4.97, dislike slightly), while YP10 exhibited the highest (6.87, like slightly). Although there was a numerical increase across treatments, significant differences were revealed only among the control yogurt YP0 and the papaya nectar-enriched formulations of YP10, and YP15 suggesting that the textural improvements were primarily due to the presence of the papaya levels. For appearance (Figure 3E), the lowest score was recorded also for YP0 (5.57, neither like nor dislike), while YP15 (7.27, like moderately) demonstrated the highest score. Furthermore, YP15 had a significantly higher (p < 0.05) appearance score than YP0 and YP05, suggesting that the fruit’s natural pigments and consistency contributed positively to visual appeal.

The overall sensory acceptability (Figure 3F) scores revealed that yogurts with higher papaya nectar inclusion (YP10 and YP15) were significantly more preferred (p < 0.05) than YP10. YP0 recorded the lowest overall score (3.83), reinforcing that the added papaya nectar enhanced the sensory perception of yogurt. These findings indicate that papaya nectar positively influenced key sensory attributes. The results suggest that papaya nectar can serve as a functional ingredient to improve the sensory score of yogurt, making it a promising natural additive for enhancing consumer acceptability of yogurt as an underutilized fruit crop.

The mean color score was numerically highest at the 15% green papaya nectar inclusion level (7.3) and lowest at the 0% inclusion level (6.43); however, these differences were not statistically significant. This finding is consistent with the results of Aguirre et al. (2019), who reported no significant differences in color scores when papaya extract was added up to a 20% level, with scores ranging from 7.01 to 7.59. Similarly, Waweru et al. (2024) observed a mean color score of 7 in Dovyalis caffra fruit yogurt, with no significant differences between treatments, indicating moderate consumer acceptance across all formulations. However, in an earlier study, Waweru et al. (2021) reported a significant increase in color score when papaya was used as a fortifying ingredient in yogurt preparation. In contrast, Sarker et al. (2023) found that fortification with green papaya powder and banana-resistant starch significantly reduced the color score. Tefera et al. (2016) reported that increasing the inclusion level of papaya juice up to 15% improved the color score, but a further increase to 20% resulted in a significantly lower score. Additionally, studies by Matter et al. (2016) and Waweru et al. (2021, 2024) concluded that storage had no significant impact on color scores. In the present study, sensory evaluation was conducted after 1 week of storage. The green papaya used was white to moderately creamy in color, which may explain the limited impact on color scores, even at higher inclusion levels.

The taste score of the yogurt significantly increased with the progressive inclusion of green papaya nectar, rising from 2.83 at 0% to 7.20 at the 15% inclusion level. This trend indicates that papaya fortification markedly improved the taste acceptability of the yogurt. These findings are in agreement with those of Aguirre et al. (2019), who reported a significantly higher taste score of 7.6 at a 10% inclusion level of papaya juice compared to plain yogurt. However, they also noted that further increases in papaya concentration did not result in a statistically significant improvement in taste. Similarly, Dutta Roy et al. (2015) observed significant improvement in taste score when inclusion of papaya pulp was increased from 05 to 15%. In contrast, Sarker et al. (2023) reported that fortification with green papaya powder and banana-resistant starch significantly reduced the taste score of yogurts. The present study indicated that the green papaya nectar inclusion up to 15% level significantly enhanced the taste and consumer preference. This is supported by the aroma score where in higher inclusion level (10 and 15%) exerted significantly higher aroma score (6.5 and 6.93 respectively) than non-fortified yoghurt (5.00). The progressive and significant improvement in mouthfeel may be due to the solid and fiber content in the added green papaya nectar.

The progression in scores across treatments suggests that increasing papaya nectar levels contributed positively to yogurt quality, particularly in terms of visual appeal and flavor perception. The natural pigments and fiber content in papaya likely enhanced the color and consistency, thereby improving appearance and mouthfeel. Statistically, YP15 differed significantly from YP0 and YP05 in terms of appearance (p < 0.05), denoting a clear visual preference for yogurts with higher papaya content.

These findings agree with the report by Othman et al. (2019), who observed improved sensory ratings in yogurts with 15–25% papaya inclusion, with the plain control sample receiving the lowest scores. Similar trends were also noted by Dutta Roy et al. (2015) and Aguirre et al. (2019), who reported that increasing levels of papaya juice improved certain sensory attributes without significantly altering overall acceptance. However, contrary findings were reported by Sarker et al. (2023), where the addition of green papaya peel at increasing levels led to a decline in consumer preference. This discrepancy may be attributed to differences in the form of papaya used nectar versus peel as the peel may impart undesirable textural or bitter notes, whereas nectar offers a smoother texture and sweeter flavor profile.

It is important to note that while YP10 and YP15 were both statistically superior to the control (p < 0.05), there were no statistically significant differences between YP10 and YP15 in many attributes, suggesting that papaya nectar inclusion beyond 10% may not result in proportionally higher sensory improvements. This indicates that the optimal inclusion level likely lies between 10 and 15%, balancing sensory enhancement with product stability and consumer preference.

Overall, the results support the potential use of papaya nectar as a functional natural additive in yogurt production. Its positive impact on key sensory attributes, particularly taste, aroma, mouthfeel, and appearance position it as a promising candidate for improving consumer acceptability in fruit-based dairy products.

4 Conclusion

Underutilized fruit crops such as papaya hold significant potential for integration into value-added food products that support sustainable food systems. In this exploratory study, green papaya, an underutilized but readily available fruit crop was incorporated into probiotic yogurt formulations at varying concentrations to develop four types of yogurts. The control yogurt (YP0), which lacked green papaya nectar, received the lowest sensory scores and was least preferred. In contrast, yogurts containing green papaya nectar (YP5, YP10, and YP15) demonstrated significantly higher sensory acceptance across all evaluated parameters, including color, taste, aroma, mouthfeel, appearance, and overall acceptability. Furthermore, all yogurt samples maintained lactic acid bacteria (LAB) counts exceeding 106 CFU/g, meeting the probiotic viability standards set by the Codex Alimentarius Commission. These findings highlight green papaya’s potential not only to enhance the sensory and functional qualities of yogurt but also to serve as a strategic ingredient in promoting dietary diversity, reducing food waste, and fostering agri-food innovation. Thus, the valorization of green papaya in probiotic yogurt production exemplifies a practical and scalable approach to advancing resilient and sustainable food systems in the Caribbean and similar contexts.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

VG: Writing – review & editing, Project administration, Funding acquisition, Investigation, Supervision, Writing – original draft, Validation, Visualization, Formal analysis, Methodology, Conceptualization. SK: Writing – review & editing, Writing – original draft, Formal analysis, Visualization, Data curation, Validation. AS: Data curation, Methodology, Writing – original draft, Writing – review & editing. W-AI: Writing – review & editing, Validation, Writing – original draft.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. The financial support was received from the Department of Food Production, Faculty of Food and Agriculture, St. Augustine Campus, The University of the West Indies.

Acknowledgments

Gratitude is expressed to Mr. Nirvahn Maharaj and Ms. Kriya Narine for their technical assistance.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Reference

Aguirre, M. A. S., Diego, R. A., Marave, S. J. D., Valderrama, D. L., and De Jose, A. C. (2019). Utilization of papaya (Carica papaya L.) extracts in the production of yoghurt drink. Antorcha 7, 21–30.

Ali, A., Devarajan, S., Waly, M., Essa, M. M., and Rahman, M. S. (2012). “Nutritional and medicinal value of papaya (Carica papaya L.)” in Natural products and bioactive compounds in disease prevention. eds. M. E. Mustafa, A. Manickasavagan, and E. Sukumar (Hauppauge, New York: Nova Science Pub Inc.), 34–42.

Anjum, N., Islam, M. N., Roy, J., and Mahomud, M. S. (2025). Enhancing soy yogurt: the impact of mango pulp and alkali blanching on physico-chemical, nutritional and sensory qualities. Appl. Food Res. 5:100983. doi: 10.1016/j.afres.2025.100983

AOAC International (1999). Official method 999.08: Aerobic plate count in foods. Official methods of analysis. 14th Edn. Washington, DC: Association of Official Analytical Chemists.

AOAC International (2002). Official methods of analysis of AOAC international. 17th Edn. Washington, DC: Association of Official Analytical Chemists.

AOAC International (2006). Official methods of analysis of AOAC International. 18th Edn. Washington, DC: Association of Official Analytical Chemists.

Aschemann-Witzel, J., Bizzo, H. R., Chaves, A. C. S. D., Faria-Machado, A. F., Soares, A. G., Fonseca, M. J. O., et al. (2023). Sustainable use of tropical fruits? Challenges and opportunities of applying the waste-to-value concept to international value chains. Crit. Rev. Food Sci. Nutr. 63, 1339–1351. doi: 10.1080/10408398.2021.1963665

Brodziak, J., Król, J., Barłowska, A., Teter, M., and Florek, M. (2020). Changes in the physicochemical parameters of yoghurts with added whey protein in relation to the starter bacteria strains and storage time. Animals 10:1350. doi: 10.3390/ani10081350

Castillo, C., de Gannes, V., Eudoxie, G., Isaac, W. A. P., and Karuppusamy, S. (2025). Production and physicochemical and microbiological evaluation of orange flesh sweet potato flatbread infused with spinach as a healthy food option. PRO 13:427. doi: 10.3390/pr13020427

Cho, W. Y., Kim, D. H., Lee, H. J., Yeon, S. J., and Lee, C. H. (2020). Quality characteristic and antioxidant activity of yogurt containing olive leaf hot water extract. CyTA - J. Food 18, 43–50. doi: 10.1080/19476337.2019.1640797

Chukwuka, K. S., Iwuagwu, M., and Uka, U. N. (2013). Evaluation of nutritional components of Carica papaya L. At different stages of ripening. IOSR Journal of Pharmacy and Biological Sciences. 6, 13–16. Available online at: www.iosrjournals.or

Codex Alimentarius Commission (2022). Standard for fermented milks: CXS 243–2003. Codex Alimentarius: International food standards. Rome: FAO/WHO.

Das, T., Bhattacharyya, S., Datta, S., and Banik, A. (2023). Study of normal and pathogenic bacteria and yeasts in curd samples. IP Int. J. Med. Microbiol. Trop. Dis. 9, 57–65. doi: 10.18231/j.ijmmtd.2023.011

De Toledo, N. M. V., Camargo, A. C., Ramos, P. B. M., Button, D. C., Granato, D., and Canniatti-Brazaca, S. G. (2018). Potentials and pitfalls on the use of passion fruit by-products in drinkable yogurt: physicochemical, technological, microbiological, and sensory aspects. Beverages 4:47. doi: 10.3390/beverages4030047

do Prado, S. B. R., Minguzzi, B. T., Hoffmann, C., and Fabi, J. P. (2021). Modulation of human gut microbiota by dietary fibers from unripe and ripe papayas: distinct polysaccharide degradation using a colonic in vitro fermentation model. Food Chem. 348:129071. doi: 10.1016/j.foodchem.2021.129071

Dutta Roy, D. K., Saha, T., Akter, M., Hosain, M., Khatun, H., and Roy, M. C. (2015). Quality evaluation of yogurt supplemented with fruit pulp (banana, papaya, and watermelon). Int. J. Nutr. Food Sci. 4, 695–699. doi: 10.11648/j.ijnfs.20150406.25

Food and Agriculture Organization of the United Nations. (2023). FAOSTAT Statistical Database: Crops and livestock products [Data set]. Available online at: https://www.fao.org/faostat/en/#data/QCL.fao.org (Accessed May 12, 2025).

Hoxha, R., Evstatieva, Y., and Nikolova, D. (2023). Physicochemical, rheological, and sensory characteristics of yogurt fermented by lactic acid bacteria with probiotic potential and bioprotective properties. Foods 12:2552. doi: 10.3390/foods12132552

Ismail, E. A., Aly, A. A., and Atallah, A. A. (2020). Quality and microstructure of freeze-dried yoghurt fortified with additives as protective agents. Heliyon 6:e05196. doi: 10.1016/j.heliyon.2020.e05196

Kamal-Eldin, A. A., Gharsallaoui, A., Hamed, F., and Ghnimi, S. (2020). Physicochemical, rheological, and micro-structural properties of yogurts produced from mixtures of camel and bovine milks. NSF Journal. 19, 26–33. doi: 10.1016/j.nfs.2020.05.001

Khurnpoon, L., Sirivejabandhu, K., and Sangwanangkul, P. (2014). Changes in pigments and fruit quality in papaya from different harvesting seasons. J. Agric. Technol. 10, 1039–1049.

Lastra-Ripoll, S. E., Quintana, S. E., and García-Zapateiro, L. A. (2023). Yogurt enriched with mango peel extracts (Mangifera indica) in chitosan–xanthan gum dispersions: physicochemical, rheological, stability, and antioxidant activity. Fluids 8:259. doi: 10.3390/fluids8100259

Leitao, M., Ribeiro, T., García, P. A., Barreiros, L., and Correia, P. (2022). Benefits of fermented papaya in human health. Foods. 11:563. doi: 10.3390/foods11040563

Li, Y., Yu, Y., Wu, X., Liu, B., Ma, H., Zhao, X., et al. (2022). Specially designed yogurt supplemented with a combination of pro- and prebiotics relieved constipation in mice and humans. Nutrition 103:111802. doi: 10.1016/j.nut.2022.111802

Lou, K., Zheng, Y., Tan, X., Wang, L., Tong, C., Huang, S., et al. (2024). Influence of sonication-assisted fermentation on the physicochemical features and antioxidant activities of yogurts fortified by polyphenol-rich pineapple peel powder with varied chemical profiling. Food Res. Int. 198:115333. doi: 10.1016/j.foodres.2024.115333

Mahomud, M. S., Islam, M. N., Hossen, D., Wazed, M. A., Yasmin, S., and Sarker, M. S. H. (2024). Innovative probiotic yogurt: leveraging green banana peel for enhanced quality, functionality, and sensory attributes. Heliyon 10:e38781. doi: 10.1016/j.heliyon.2024.e38781

Manzoor, S., Yusof, Y. A., Chin, N. L., Tawakkal, I. S. M., Fikry, M., and Chang, L. S. (2019). Quality characteristics and sensory profile of stirred yogurt enriched with papaya peel powder. Pertanika J. Trop. Agric. Sci. 42, 519–533. doi: 10.47836/pjtas.42.2.09

Matter, A. A., Mahmoud, E. A. M., and Zidan, N. S. (2016). Fruit flavored yoghurt: chemical, functional and rheological properties. Int J Environ Agric Res 2, 57–66.

McClements, D. J., and Grossmann, L. (2021). A brief review of the science behind the design of healthy and sustainable plant-based foods. NPJ Sci Food 5:17. doi: 10.1038/s41538-021-00099-y

Minj, J., and Vij, S. (2025). Determination of synbiotic mango fruit yogurt and its bioactive peptides for biofunctional properties. Front. Chem. 12:1470704. doi: 10.3389/fchem.2024.1470704

Ning, X., Luo, Z., Chen, Z., Zhou, C., Xie, C., Du, W., et al. (2021). Fortification of set yogurt with passion fruit juice: effects on fermentation kinetics, physicochemical properties, and functionality. J. Dairy Sci. 104, 4084–4093. doi: 10.3168/jds.2020-19261

Othman, N., Hamid, H. A., and Suleiman, N. (2019). Physicochemical properties and sensory evaluation of yogurt nutritionally enriched with papaya. Food Research, 3, 791–797. doi: 10.26656/fr.2017.3(6).199

Priyashantha, H., Madushan, R., Pelpolage, S. W., Wijesekara, A., and Jayarathna, S. (2025). Incorporation of fruits or fruit pulp into yoghurts: recent developments, challenges, and opportunities. Front. Food Sci. Technol. 5:1581877. doi: 10.3389/frfst.2025.1581877

Purohit, A., Jain, M., Sarkhel, S., Roy, A., and Mohan, A. (2023). Determination of quality kinetics, microbiology, and sensory properties of shelf-stable chicken-wing sauce. Front. Food Sci. Technol. 3:1204804. doi: 10.3389/frfst.2023.1204804

Ramsaran, R., de Gannes, V., and Eudoxie, G. (2024). Quality evaluation of innovative buttermilk biscuits produced from orange-flesh sweet potato flour infused with coconut. Front. Food Sci. Technol. 4:1467839. doi: 10.3389/frfst.2024.1467839

Ranadheera, C. S., Evans, C. A., Adams, M. C., and Baines, S. K. (2012). Probiotic viability and physico-chemical and sensory properties of plain and stirred fruit yogurts made from goat’s milk. Food Chem. 135, 1411–1418. doi: 10.1016/j.foodchem.2012.06.025

Sah, B. N. P., Vasiljevic, T., McKechnie, S., and Donkor, O. N. (2016). Physicochemical, textural, and rheological properties of probiotic yogurt fortified with fiber-rich pineapple peel powder during refrigerated storage. LWT Food Sci. Technol. 65, 978–986. doi: 10.1016/j.lwt.2015.09.027

Sarıtaş, S., Mondragon Portocarrero, A. C., Miranda, J. M., Witkowska, A. M., and Karav, S. (2024). Functional yogurt: types and health benefits. Appl. Sci. 14:1798. doi: 10.3390/app142411798

Sarker, A., Jung, Y., and Siddiqui, R. (2023). Yoghurt fortification with green papaya powder and banana resistant starch: effects on the physicochemical and bioactive properties. Int. J. Food Sci. Technol. 58, 5745–5756. doi: 10.1111/ijfs.16672

Sarker, A., and Siddiqui, R. A. (2023). Effects of ultrasonic processing on the quality properties of fortified yogurt. Ultrason. Sonochem., 98, 106533. doi: 10.1016/j.ultsonch.2023.106533

Shah, N. P. (2007). Functional cultures and health benefits of fermented dairy products. J. Dairy Sci. 90, 834–850. doi: 10.1016/j.idairyj.2007.01.014

Shishir, M. R. I., Saifullah, M., Hashim, S. B. H., Aalim, H., Bilal, M., Khan, S., et al. (2024). Micro- and nano-encapsulated natural products in yogurt: an emerging trend to achieve multifunctional benefits in product quality and human health. Food Hydrocoll. 154:110124. doi: 10.1016/j.foodhyd.2024.110124

Tefera, T., Bussa, N., Abera, S., and Bultosa, G. (2016). Effect of papaya juice, stabilizer and storage duration on physical, microbiological, and acceptability of yoghurt. J. Sci. Sustain. Dev. 4, 41–56. doi: 10.20372/au.jssd.4.2.2016.059

Teshome, G., Keba, A., Assefa, Z., Agza, B., and Kassa, F. (2017). Development of fruit-flavored yoghurt with mango (Mangifera indica L.) and papaya (Carica papaya L.) fruit juices. Food Sci. Qual. Manag. 67, 40–45.

Vicent, V. (2024). Influence of banana powder on proximate composition, physicochemical and rheological properties of soy yoghurt. Appl. Food Res. 4:100450. doi: 10.1016/j.afres.2024.100450

Wajs, J., Brodziak, A., and Król, J. (2023). Shaping the physicochemical, functional, microbiological, and sensory properties of yoghurts using plant additives. Foods 12:1275. doi: 10.3390/foods12061275

Wang, X., Wang, L., Wei, X., Xu, C., Cavender, G., Lin, W., et al. (2025). Invited review: advances in yogurt development—microbiological safety, quality, functionality, sensory evaluation, and consumer perceptions across different dairy and plant-based alternative sources. J. Dairy Sci. 108, 33–58. doi: 10.3168/jds.2024-25322

Waweru, D. M., Arimi, J. M., Marete, E., Harbourne, N., and Jacquier, J.-C. (2024). Effect of different formulations and storage on the physicochemical, microbiological, and organoleptic characteristics of Dovyalis caffra fruit yogurt. Foods 13:4102. doi: 10.3390/foods13244102

Keywords: papaya, yogurt, underutilized fruit crop, sustainability, lactic acid bacteria

Citation: de Gannes V, Karuppusamy S, Sealey A and Isaac W-AP (2025) An exploratory study on the sensory acceptability and quality characteristics of probiotic yogurt with green papaya (Carica papaya L.): promoting underutilized fruit crops. Front. Sustain. Food Syst. 9:1644804. doi: 10.3389/fsufs.2025.1644804

Edited by:

Henry Awika, University of the Virgin Islands, US Virgin IslandsReviewed by:

Juni Sumarmono, Jenderal Soedirman University, IndonesiaDewi Yunita, Syiah Kuala University, Indonesia

Copyright © 2025 de Gannes, Karuppusamy, Sealey and Isaac. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Vidya de Gannes, dmlkeWEuZGVnYW5uZXNAdXdpLmVkdQ==; Sivakumar Karuppusamy, c2l2YWt1bWFyLmthcnVwcHVzYW15QHV3aS5lZHU=

Vidya de Gannes

Vidya de Gannes Sivakumar Karuppusamy*

Sivakumar Karuppusamy* Wendy-Ann P. Isaac

Wendy-Ann P. Isaac