- 1Bioeconomy Office Hohenheim, University of Hohenheim, Stuttgart, Germany

- 2Department of Plant-Based Foods, Institute of Food Science and Biotechnology, University of Hohenheim, Stuttgart, Germany

Background/Introduction: Biointelligence in the approach of food additive manufacturing represents a significant advancement, enabling the reverse engineering and design of foods. Legislation restricting trans-fats has accelerated research into alternatives, but ingredients like saturated and trans fats play key roles in food quality and functionality. Oleogels are a promising replacement. Food additive manufacturing introduces a biointelligent approach, combining biological and technical components with information technology to optimize food design. This study investigates 3D printing of oleogel and bigel systems using apricot seed oil, aiming to assess their significance, applicability, and printability as sustainable alternatives to trans fats for innovative, resource-efficient food production.

Methods: Apricot seed oil, rich in antioxidants and polyunsaturated fatty acids, was processed into plant-based oleogels and bigels. The material systems were incorporated into 3D printed food structures. Material characterization and techno-functional analysis were conducted to evaluate the suitability of apricot seed oil for structuring 3D printed foods and controlling food texture.

Results: Adjusting the type and concentration of oil-gelator mixtures enabled tailored texture and lipid distribution to fit consumer preferences. Sustainability impacts were assessed at intermediate processing steps, demonstrating the value of holistic evaluations beyond technical factors.

Discussion: Biointelligent 3D printing offers a platform to optimize sensory and sustainability qualities in food design. The integration of apricot seed oil into novel food matrices enables versatile nutritional product development, supporting researchers and industry stakeholders in advancing consumer-centric, sustainable production and consumption practices.

1 Introduction

The demand for healthier foods worldwide has been on the rise in recent years due to an increased awareness of the prevention of the so-called Noncommunicable Diseases (NCDs) such as heart disease, stroke, cancer, diabetes or chronic lung disease, which are responsible for 74% of all deaths worldwide (WHO, 2025). One of these foods associated with having a negative effect on human health is saturated fats. Saturated solid fats occur naturally in animal- and dairy-based products but for the creation of solid fats using plant-based oils, hydrogenation is used to convert unsaturated fatty acids into saturated fats. This processing prevents those manufactured trans-fats from becoming rancid and keeps them solid at room temperature, which is why they are also called solid fats (EU-Commission, 2011). High intakes of trans and saturated fats can cause adverse health effects such as an increase in the risk of cardiovascular disease (CVD). Consumers find such trans-fats in confectionary and bakery products, but also in meat products. The percentage share of trans-fats varies between food groups and amount from 1 to 37% for some confectionary for example (Dingel and Matissek, 2013). Research for alternatives to such fats has been increasing because legislation is banning trans-fats and demands a reduction in their consumption. Therefore, concerning the reduction of trans-fats through the research for alternatives, it was shown that replacing 5% of trans-fat with polyunsaturated fats can reduce CVD risk by up to 37% (Roche, 2005).

However, replacing trans-fats represents a challenge for the food industry because of their high technological values for the food industry (Silva et al., 2023). A challenge for any alternative is the high stability against oxidation processes and long validity of existing saturated fats from palm oil, which is additionally associated with a long list of environmental problems. Replacing these fats requires a solution that provides similar technological and functional properties such as they can prolong the shelf life of foods, positive impact on the overall flavor and contribute also to crispiness. At this stage, product quality is highly depended on trans and saturated fat and is negatively affected if replaced (Manzoor et al., 2022).

A promising approach to replace trans-fats apart from polysaccharides or proteins are oleogels (Puscas et al., 2020). They are being created by converting liquid vegetable oil into a solid-like gel. Oleogels are finding profound applications in many areas of food industry such as bakery, meat, confectionary, and dairy as a healthier alternative to saturated fat and trans-fat (Manzoor et al., 2022). Vegetable oil composition influences oleogel formation. Research shows carbon chain length, fatty acid saturation and other factors affect the oleogels properties and behavior in food, which is why oleogels are limited in fully replacing physical and functional properties in food products (Puscas et al., 2020).

These limitations between processing characteristics and technological or sensory qualities can be overcome if they are applied beyond drop-in solutions in existing food industry recipes by using biointelligent approaches and new technologies for food production. One of these new technologies is 3D food printing. As an additive manufacturing technique, 3D printing processes food structures through a layer-by-layer principle which allows for precise and layer-based control over the food properties (Derossi et al., 2024). Its principle of operation enables the processing of pre-defined and complex structures and textures with customizable sensory properties and tailored nutrition (Derossi et al., 2020; Fahmy et al., 2023). This can be used to create personalized foods for people with specific health conditions but also create food designs that can create the exact mouthfeel that satisfies consumer preferences, which is essential for the success of any food product (Giura et al., 2021; Tan et al., 2018). From a biointelligence perspective, 3D printing combines the approach of integrating and processing of new biomaterials (food or non-food) with a technological autonomous structuring approach. Furthermore, the biointelligence in the approach of food additive manufacturing represents a significant advancement, enabling the reverse engineering and design of foods to gain deeper insights into the performance of individual components. This is accomplished by integrating digital CAD modeling—subsequently realized through 3D printing—with a detailed assessment of the biological properties of food ingredients. The system created through is to be described as a biointelligent system because it is based on the combination of a biological component with a technical component and it is combined with information technology (Miehe et al., 2023). However, the full transformative potential of this deep-tech approach extends beyond what can be captured by conventional techno-functional analysis alone. This research aims to explore the broader significance, applicability and printability for using 3D food printing to process oleo- and bigel material systems as a sustainable alternative to trans fats. In doing so, we not only address the technical challenges involved such as the influence of integrating apricot seed oil on the printing behavior and texture properties but also consider how this approach can contribute to the transition towards a more sustainable food system. Specifically, we aim to understand the actual value created by incorporating by-product based oleogels into a food matrix. The replacement of existing fats in food matrices needs to be benchmarked against the properties of the “old” fat source.

Using 3D food printing could enable us to define quality parameters that can be translated into a market value for the by-product, thus upgrading it to an official food resource that can be produced on a large scale according to industry requirements. This assessment goes beyond a “simple” input–output relationship, being equivalent to the understanding that emerged from the relationship between wheat’s protein content and its effect on baking quality, creating a market value for wheat with a certain protein content. In the case of sidestreams, we hypothesize that we can gain more than just a market value for a new food resource. The digital food design and food matrix-building processes using additive manufacturing technology could also be considered valuable products in their own right. This could generate additional value with implications for different business concepts or supply chains, leading to new value webs (Vargas-Carpintero et al., 2022).

To address this complexity, the paper is structured as follows: first, we outline the context of the circular bioeconomy; then, review the current state of research into biointelligent food component design, with a particular focus on the 3D printing of oleogels and bigels. Building on this foundation, the methods section details the technical case study addressing the assessment of material behavior, within the scope of 3D printing, dependent on oil concentration using rheological analysis to characterize the viscoelastic response of the material system. Printing performance and behavior were assessed using an in-line, camera-based morphological approach developed in our previously published paper (Fahmy et al., 2020). In addition, a comparison of the resulting textural properties of both material systems (oleo and bigels) between apricot seed and sunflower oil was carried out. The results section presents an overview over the effect of integration of the apricot seed oil (in oleo- and bigel systems) on the material and texture properties as well as the processing behavior in the scope of 3D printing. Finally, the discussion section evaluates the level value proposition of these new textural properties from a systems perspective, highlighting the broader implications of integrating oleogels using biointelligent food additive manufacturing.

2 Circular bioeconomy and state-of-the-art technology design background

2.1 Oleogels

Based on the use of oleogelators, an oleogel is a three-dimensional network of either solid particles or gelling agents where an oil phase is immobilized within. The oleogelators, such as polymers, serve as the primary structuring component for the oil-trapping network formation. Moreover, this structuring or oleogelation process can be performed and achieved through different methods such as homogenization, solvent evaporation, and melt blending (Pawar et al., 2024). Oleogels can have different sources, such as classical vegetable oils, but also camellia oil. Novel oleogels have been produced based on fermentation involving residues from food industry by-products, namely sugar cane molasses and soya bean processing by-products. But also tomato peels, spent coffee ground have been used to derive oleogels (Puscas et al., 2020). Stone fruits are a widely available by-product of food processing such as juice or jam production which produces fruit stones in large quantities. These pits are very rich in oils that can be extracted and used for oleogel production, thus providing a new alternative source of unsaturated fats, valorizing biomass streams that have long been discarded, improving the environmental footprint and providing health effects for foods of the future that can make a difference in future food production at various levels. One of those stone fruits are apricots, which are produced worldwide, with the highest production volumes in Turkey. The oil content of apricot seeds varies between 40 and 50% (Pawar and Nema, 2023). The fatty acid composition resembles oil obtained from peaches and is similar favorable for human consumption as compared to other seed oils such as blackcurrant, raspberry or strawberry seed oil, all of which have a low content of saturated fatty acids (Stryjecka et al., 2019). and are underutilized by-products from food processing. Oil yield is dependent on the region, variety or processing technology for oil extraction (Pawar and Nema, 2023). The stone of an apricot represents between 12.7–22.2% over overall fruit weight and within the stone seed weight, which contains the oil, is about 30.7–33.7% (Pawar and Nema, 2023). The stone can be used as much for gardens or parks or for sandpaper. All these valorization options represent and pay into the concept of a sustainable and circular bioeconomy, which focusses on the holistic valorization of the total existing biomass in the form of a material use with the aim to create the highest possible value while achieving environmental and social sustainability (Iorgulescu, 2023; Reinmuth and Scheurich, 2026).

2.2 3D printing of oleo- and bigel material systems

Additive manufacturing or 3D printing is defined as a layer-based manufacturing approach and compared to mass production methods, it is a technique suitable for the customization, personalization and on-demand processing of food structures (Sun et al., 2015). Material extrusion and hot melt extrusion are the most common 3D printing techniques used in the integration of oleogels in food structures as they rely on extrusion and deposition principle which is suitable for processing of wide range of food materials with viscoelastic properties in the form of doughs, gels and pastes. While 3D printing of different food materials is used for specific applications such as sensory design and texture modulation (Fahmy et al., 2021; Fahmy et al., 2022b; Fribus et al., 2024), recently more published research is focusing on the applicability and 3D printing behavior of lipid-based materials as fat phases for altering mechanical properties of printed materials, for personalized foods and for nutraceutical applications (Andriotis et al., 2024; De Salvo et al., 2023, 2025; Fernandes et al., 2023; Miao et al., 2024). This approach is adapted as 3D printing offers the innovative possibility of integrating and localization of lipid-based materials into more complex food structures which is not possible using other processing technologies. The lipid-based materials are mostly in the form of oleo- and bigels under the category of semi-solid material systems. Moreover, the structure of oleogels is formed by structuring an oil phase with gelling agents (oleogelators) where the oil phase is physically entrapped in the three-dimensional network of gelator molecules resulting in a viscoelastic gel (Shakeel et al., 2018). Bigels are formulated by combining an oleogel and a hydrogel which gives them the ability to deliver lipophilic and hydrophilic agents. Regarding the current research in 3D printing of oleo- and bigel material systems, the focus is mainly on the development of edible inks while elucidating the printability and printing behavior relative to the oil content (Miao et al., 2024; Wen et al., 2021). Other research includes the development of plant-based fat phases for meat analogues and the processing of enriched oleo- and bigel systems for nutraceutical design (De Salvo et al., 2023, 2025; Wen et al., 2021).

As an overview for the development of plant-based oleo- and bigel material systems for 3D printing applications, and regarding the material-process interactions, several studies were conducted to investigate the parameter-dependent printing behavior of newly developed material systems in relation to their material properties (Andriotis et al., 2024; De Salvo et al., 2023, 2025; Kavimughil et al., 2022; Miao et al., 2024; Qiu et al., 2022). As an example, studies by Miao et al. and kang et al. investigated the applicability and printing behavior of two different types of oleogels (Kang et al., 2022). The two mentioned studies used different types of gelling mechanisms and oleogelators for the development of the 3D printable oleogels to analyze the influence of oil content and oleogelators on the printing behavior and post-printing geometrical quality of printed structures. Presenting a typical method for the development of oleogels for 3D printing applications, the study by Kang et al. developed an approach for the printing and texture optimization of beeswax-based oleogel material systems using high oleic sunflower oil. The approach of using beeswax as an oleogelator is a quite common technique to induce oleogelation through the induction of a three-dimensional viscoelastic network by which the liquid oil becomes trapped. The objective of their optimization method was focused on 3D texturing of structures imitating the texture properties of lard. Using a similar oleogelation approach, other studies used Hydroxypropyl Methylcellulose (HPMC), monoglyceride and triglyceride (MCT) for investigating the printing behavior and using the oleogel systems as a carrier of bioactive compounds (De Salvo et al., 2023, 2025; Kavimughil et al., 2022). Considering a non-typical method, Miao et al. presented an approach for increasing the oil content (namely soybean oil) within 3D printable starch-based oleogel systems (with tunable properties) through the creation of space-spanning particle network driven by capillary forces. Also, the authors investigated the influence of adding xanthan gum as a polysaccharide thickener on the material properties and printing behavior. Finally, while main published literature in relation to 3D printing of oleogels focuses on either the development and investigation of fat phases for solid fat replacement or as a carrier of bioactive compounds, other studies used oleogel systems as an additive or a substitute for 3D printing of fat containing material systems (Huang et al., 2023). For example, Huang et al. used an HPMC and MCT based oleogels to enhance the solidification of white chocolate after extrusion. For the mentioned objective, the authors investigated the influence of oleogel concentration (using hydrogenated palm oil) on the material and printing behavior.

Similar to the published research focusing on oleogels, literature focused on 3D printing of bigels are aimed towards the development and investigation of different bigel material systems in term of mechanical, rheological and printing behavior (Andriotis et al., 2024; Fernandes et al., 2023; Qiu et al., 2022). With the main focus on analyzing the applicability and behavior during 3D printing, Qiu et al. investigated the rheological response, microstructure and printability of bigel systems based on corn oil (Qiu et al., 2022). The bigel systems were composed of a hydrogel phase based on a combination of carrageenan and xanthan gum and an oleogel phase structured by beeswax as an oleogelator. In this study, the authors performed analyzes of varying fractions of the oleogel, highlighting an improvement in post-printing quality and geometric stability as the oleogel fraction increased. A similar study by Frenandes et al. focused also on elucidating the effect of increasing the oleogel fraction on the physical properties and printability of bigels (Fernandes et al., 2023). The authors also used beeswax-based oleogel (based on sunflower oil), as Qiu et al. however, this study compared the material and printing behavior of the bigels with respect to two different hydrogel phases. For the hydrogel phases, Fernandes et al. used one phase based on agar and xanthan gum and another phase based on gelatin and xanthan gum. The study produced similar results, showing that a higher oleogel fraction achieved better printing quality for both hydrogel phases. Also, the results showed significant differences depending on the used hydrogel phase regarding material properties and printing behavior, highlighting the influence of the used hydrogel phase on the overall 3D printing performance. Generally, from the published articles focusing on 3D printing of oleo- and bigel systems, it can be observed that with increasing oil content in oleogels, the geometrical accuracy and stability of printed structures decreased. On the other hand, accuracy and stability increased with the increase in oleogel fractions in bigel systems. Finally, in the following sections, this study explores the applicability of integrating apricot seed oil in oleo- and bigel material systems. The material, texture and processing behavior are systematically analyzed within the scope of 3D food printing.

3 Materials and methods

3.1 Raw materials

For the starch-based oleogels, native wheat starch was provided by Kröner Stärke (Ibbenbrünen, Germany). In this study, the used sunflower oil is a commercially available oil that was procured locally from the supermarket. The apricot seed oil was purchased from Circular Store (Felde, Germany). The Beeswax was purchased from Romeru Innovations (Kornwestheim, Germany).

3.2 Material preparation

For material characterization and 3D printing, a total of 5 starch-based oleo- and 5 bigels were prepared. Based on a capillary bridge method for the preparation of oleogels (Miao et al., 2024), the ratio of starch to apricot oil (S-O) was varied to simulate different gel networks and their corresponding rheological responses. The hydration was kept constant for all oleogel systems at 2 mL/g (v/w) based on the dry weight of starch (native starch). Moreover, the different S-O ratios were prepared using different fractions of starch to oil corresponding to 34:66 (S34-O66), 38:62 (S38-O62), 42:58 (S42-O58), 46:54 (S46-O54) and 50:50 (S50-O50). The different fractions of starch and oil (S-O) were mixed using a stator-rotor disperser ULTRA-TURRAX T25 (Ika-Werke GmbH, Staufen im Breisgau, Germany) for 3 min at 10000 rpm. Then, water was added, and the formed capillary suspension was additionally mixed for 3 min at 8000 rpm to initiate the transition from a liquid to a gel state.

3.3 3D printing setup

For printing of the oleogel and bigel material systems, a custom built cartesian-based 3D printer was used. The 3D printer was constructed using an XYZ gantry system (igus GmbH, Köln, Germany) equipped with toothed belt linear actuators. A Vipro-Head3 progressive cavity pump PCP (ViscoTec GmbH, Tögingen, Germany) was used for the deposition of the materials. Depending on the viscoelastic response of the materials and the printing settings, the PCP extruder had a flow rate of 0.30–3.30 mL/min. A conical nozzle of 0.84 mm diameter was used for all 3D printing trials. For constant and stable feed of the materials, air pressure of 3 bar was used to transport the materials from the cartridge to the pumping/extrusion unit. A borosilicate glass plate was used as the printing plate where all material systems were deposited at room temperature. Using a set of four setscrews, the printing plate was leveled before the printing trials to ensure no uncertainties propagate in the printed structures due to inclinations. The Repetier-Host software (Hot-World GmbH, Willich, Germany) was used. The software contained the CuraEngine slicer (Ulitmaker B.V., Ulrecht, Netherlands) which was used to define the printing parameters. Furthermore, other calibration and selection of printing settings was performed according to our previous study (Fahmy et al., 2020). The 3D printer was equipped with an on-board automatic camera-based morphology analysis system (Fahmy et al., 2020) utilizing a MATLAB-based image analysis algorithm (Mathworks Inc. Massachusetts, United States).

3.4 Printing quality analysis using a camera-based approach

To control the material flow during extrusion and deposition, 3 printing settings required determination and standardization which are the filament diameter [mm], the flow rate [%] and the extrusion speed [mm/s]. For the determination of the printing parameters such as the filament diameter [mm], the flow rate multiplier [%] and the extrusion speed [mm/s], single lines with an arbitrary length l of 50 mm were printed perpendicular to the attached side-view camera. With fixed parameters, tests were carried out by varying one of the parameters. The tests indicated the following optimum parameters for obtaining a clean line (no line breakage, no extruded filament winding, correct average line height): a filament diameter of 0.45 mm, a flow rate multiplier of 130% and a speed of 12 mm/s.

To evaluate the dimensions of the line using the image analysis algorithm, a reference object of the LEGO® cube type (lateral dimensions: h = 11.40 mm, l = 31.80 mm) to convert the pixel size into spatial dimensions. Each sample was printed in triplicate and a photograph was taken for each print. Similarly, the behavior of multi-layer printing was assessed by geometric analyzes of 3D printed hollow cubic structures (3D model dimensions: h = 15 mm, l = 15 mm). Front and top view images were taken, and the image-based dimensional analysis was performed (Fahmy et al., 2020). All printing behavior analyzes were conducted in triplicates (n = 3).

3.5 Rheological characterization

The rheological response is a determinant of the deposition and post-printing behavior of viscoelastic food materials during 3D printing (Fahmy et al., 2020). The viscoelastic properties of all oleo- and bigels material systems were characterized using oscillatory measurements on a compact controlled strain rheometer MCR302a (Anton Paar, Ostfildern, German). The rheometer was equipped with a cross-hatched plate-plate geometry with a diameter of 14 mm. All rheological trails were performed at a set clearance of 1 mm. For the characterization of all material systems, the sample was placed, the gap was adjusted, and the material was trimmed. A constant temperature of 21 °C was maintained through a Peltier plate system. For determining the linear viscoelastic region (LVER) and the concentration-dependent flow points and yield stresses, amplitude sweeps at a constant frequence of 1 Hz and shear strain range of 0.01 to 100% were performed. The strain-dependent behavior of the storage (G`) and loss (G``) moduli was characterized. Moreover, frequency sweeps were performed in a frequency range of 1 to 10 Hz at 0.01% to characterize the viscoelastic responses of all material systems. All rheological measurements were performed in triplicates (n = 3).

3.6 Texture profile analysis

The textural properties of the oleo- and bigels were characterized using a TA.XTplusC texture analyzer (Stable Micro Systems, Godalming, United Kingdom). Investigations were carried out through double compression tests under quasi-static conditions. Moreover, texture measurements were performed at room temperature directly after the preparation of the material systems. To standardize the samples for the double compression measurements, the material systems were prepared in 3D printed cylinders of 15 mm in diameter. The preparation of the samples was performed according to the same method mentioned in section 3.2. For all measurements, a cylindrical probe with a diameter of 10 mm was used. With a test speed of 1 mm/s, all samples were compressed to 10% of their original height. All compressions were initiated after a trigger force of 0.05 N was reached. The hardness and cohesiveness of the oleo- and bigel systems were characterized and compared to the same material systems formulated with sunflower oil. The mentioned comparison was performed to characterize the influence of oil composition on the mechanical and deformation properties of oleo- and bigel systems, which influences the flow properties during extrusion and deposition. All textural characterizations were performed at room temperature and in triplicate.

3.7 Data analysis and processing

Data processing and statistical analysis were carried out using OriginPro 2024 (Northampton, Massachusetts, United States). Unless otherwise indicated, measurements were performed in triplicates. Values are presented as mean value ± standard deviation.

4 Results and discussion

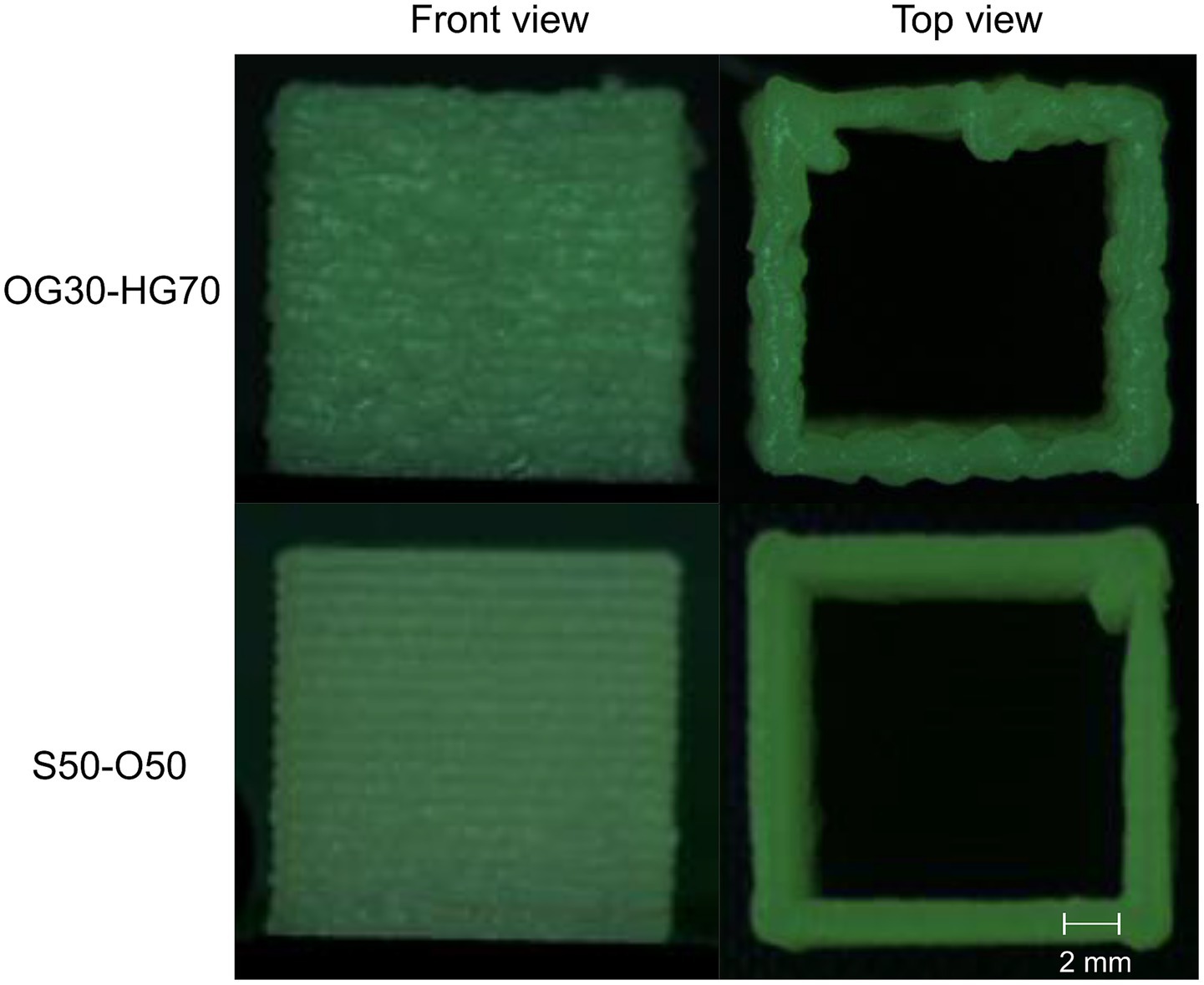

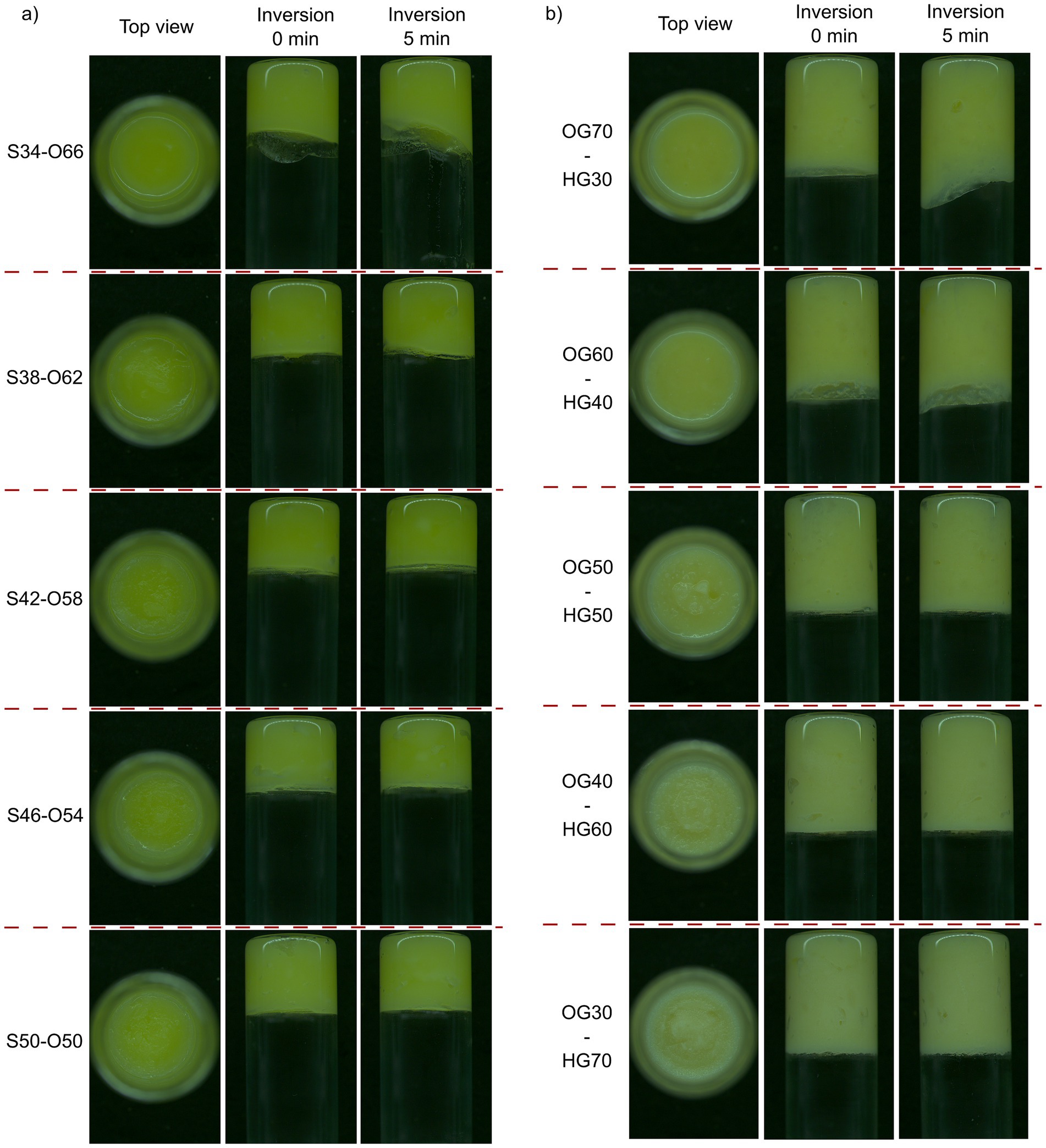

To characterize the oil concentration-dependent rheological response and viscoelastic properties, both material systems were prepared as mentioned section 2.2 and visual inversion tests were performed. This qualitative approach was conducted to obtain a preliminary relationship between the oil content and the stability of the formulated material systems. As shown in Figure 1, the inversion tests indicated that both material systems possess adequate gelling properties and stability under applied gravity with respect to time. For the S34-O66, OG70-HG30 and OG60-HG40, limited material flow was observed indicating a weaker capillary suspension in the case of the oleogels and a weaker gel network in the case of the bigels.

Figure 1. Appearance (top- and side-views) and inversion stability of the prepared material systems directly after preparation and after 5 min: (a) the oleogel material systems at different starch to apricot oil (S-O) ratios with a descending concentration of apricot oil; (b) the bigel material systems at different oleogel to hydrogel (OG-HG) ratios with a descending concentration of apricot oil.

The extrusion/deposition behavior during 3D printing and the post-printing geometric stability are highly dependent on the flow and mechanical properties as well as on the viscoelastic response of the material systems. To enumerate, the structure of a 3D printable material system must indicate structural deformation and shear thinning behavior with the application of shear forces during extrusion while processing rapid structural regeneration after deposition (Chen et al., 2019; Dankar et al., 2020; Fahmy et al., 2021). Certainly, the required order of magnitude of such behavior is highly dependent on the material’s structure, extruder’s principle of operation, and the shear forces developed during extrusion. The applied shear forces during extrusion are highly dependent on the selected printing and flow settings during slicing as well as the applied geometric effect applied inside the extruder. Thus, the flow and deposition behavior differ for the same material system when comparing different extruders or extrusion principles such as direct extrusion, screw extrusion or progressive cavity pumping. Characterizing and modulating the rheological response of 3D printable materials to ensure high printing quality cannot be generalized for general 3D printing but rather for the used and tested printing setup and applied flow settings. This is typically not mentioned by published articles focused on developing and characterizing new 3D food printing material systems (Fahmy et al., 2020). Therefore, the obtained printing results of the oleo- and bigel material systems in relation to the fundamental rheological characteristics is relevant to the described 3D printing setup and settings selection.

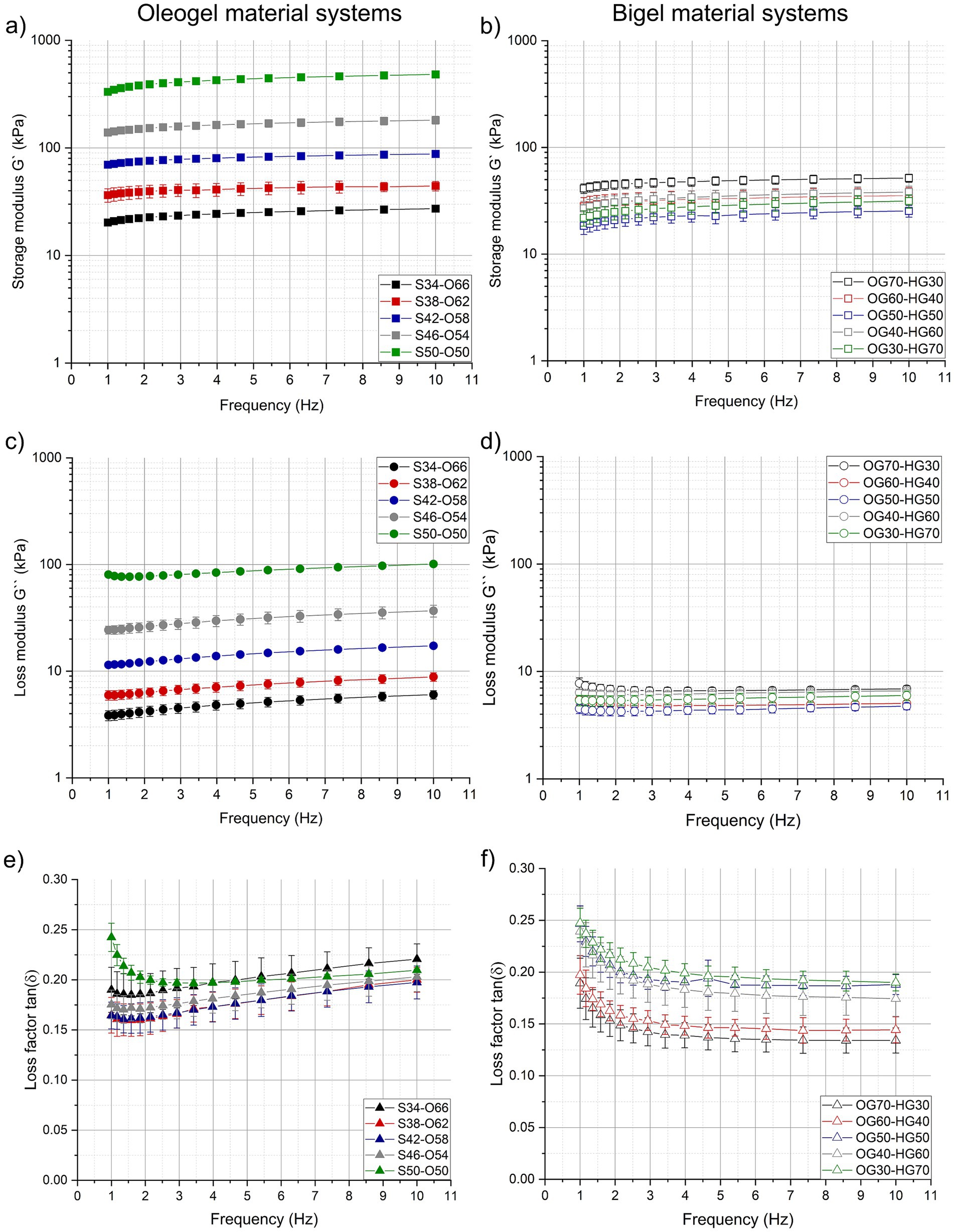

The rheological responses of the material systems were mainly characterized through both amplitude and frequency sweeps. Shows the storage G` and loss G`` moduli of the oleo- and bigel material systems with respect to the S-O and OG-HG ratios, respectively. For all material systems, even with the increase in oil concentration, elastic and viscous responses indicate a solid-like behavior where the G` is higher than the G``, as shown in Figure 2. The same behavior is also indicated in the G` and G`` response to the increase in strain amplitude. To illustrate, the characterized solid-like behavior is indicative of the time-dependent behavior of the inversion tests. Moreover, shown in Figures 2a,c, the increase behavior of the elastic and viscous responses of the oleogels with respect to the decrease in oil concentration and to the increase in starch concentration. With the increase in starch concentration in the capillary suspension, more granules are incorporated into the network formed by the space-spanning particles resulting in a starch-dependent modulation of the viscoelastic response (Domenech and Velankar, 2015; Miao et al., 2024). Therefore, the modulation of the order of magnitude of the solid-like behavior of such a material system (oleogels formed through starch-based capillary bridges) is performed by increasing the starch concentration. In general, from the perspective of 3D printing, an increase in the yield stress, viscous and elastic response increases the post-printing geometric stability and decreases collapse/slumping behavior due to the increased resistance to the forces developed from surface tension and layer-dependent hydrostatic pressure (M’Barki et al., 2017). On the other hand, such an increase poses a challenge during extrusion and deposition where higher forces are required to reach yielding of the material and to sustain continuous deposition. Also, highly dependent on the material’s structure, the increase in viscoelasticity leads to delays in the initiation of extrusion/deposition typically leading to under-extrusion at the beginning of the printing process and requires high applied retraction to avoid over-extrusion and nozzle drag effects (Fahmy et al., 2020; Liu et al., 2019).

Figure 2. Frequency sweep of the oleo- and bigel material systems in the range of 1–10 Hz at 21 °C: (a) storage modulus or elastic component of the different oleogel starch-oil (S-O) concentrations; (b) storage modulus or elastic component of the different bigel oleogel-hydrogel (OG-HG) concentrations; (c) loss modulus or viscous component of the different oleogel S-O concentrations; (d) loss modulus or viscous component of the different bigel OG-HG concentrations; (e) loss factor of the different oleogel S-O concentrations; (f) loss factor of the different bigel OG-HG concentrations. Values are presented as mean ± standard deviation (n = 3).

Considering the rheological response of the bigel material systems, similar behavior was observed to the starch-based oleogels when comparing the storage and loss moduli. For all oleogel OG to hydrogel HG ratios, the elastic component G` is higher than viscous component G`` indicating a viscoelastic solid-like behavior. This is also indicative of the time-dependent visual assessment during the inversion tests. However, as shown in Figures 2b,d, the increase or decrease behavior of the G` and G`` with respect to the change in OG to HG ratio is not as prominent as the starch-based oleogels. Unlike the starch-based oleogels where a clear decrease in the network strength was observed with increasing the oil concentration, the bigel materials did not exhibit the same clear decrease behavior in the elastic and viscous components. Such behavior can be attributed to the catastrophic phase inversion (from oil–water to water–oil or vice versa) in emulsions and bigels (Bouchama et al., 2003; Jiang et al., 2022). The catastrophic phase inversion in such material systems is defined and induced by changes in the emulsion water-to-oil ratio by increasing the volume fraction of the dispersed phase where divergence, hysteresis and bimodality occur (Tadros, 2013). Furthermore, the critical inversion point of the bigel material systems was not determined within the scope of the study as the main objective was to investigate the applicability of the oleo- and bigel material systems within the valorization scope of apricot oil as a lipid source for 3D printed fat phases.

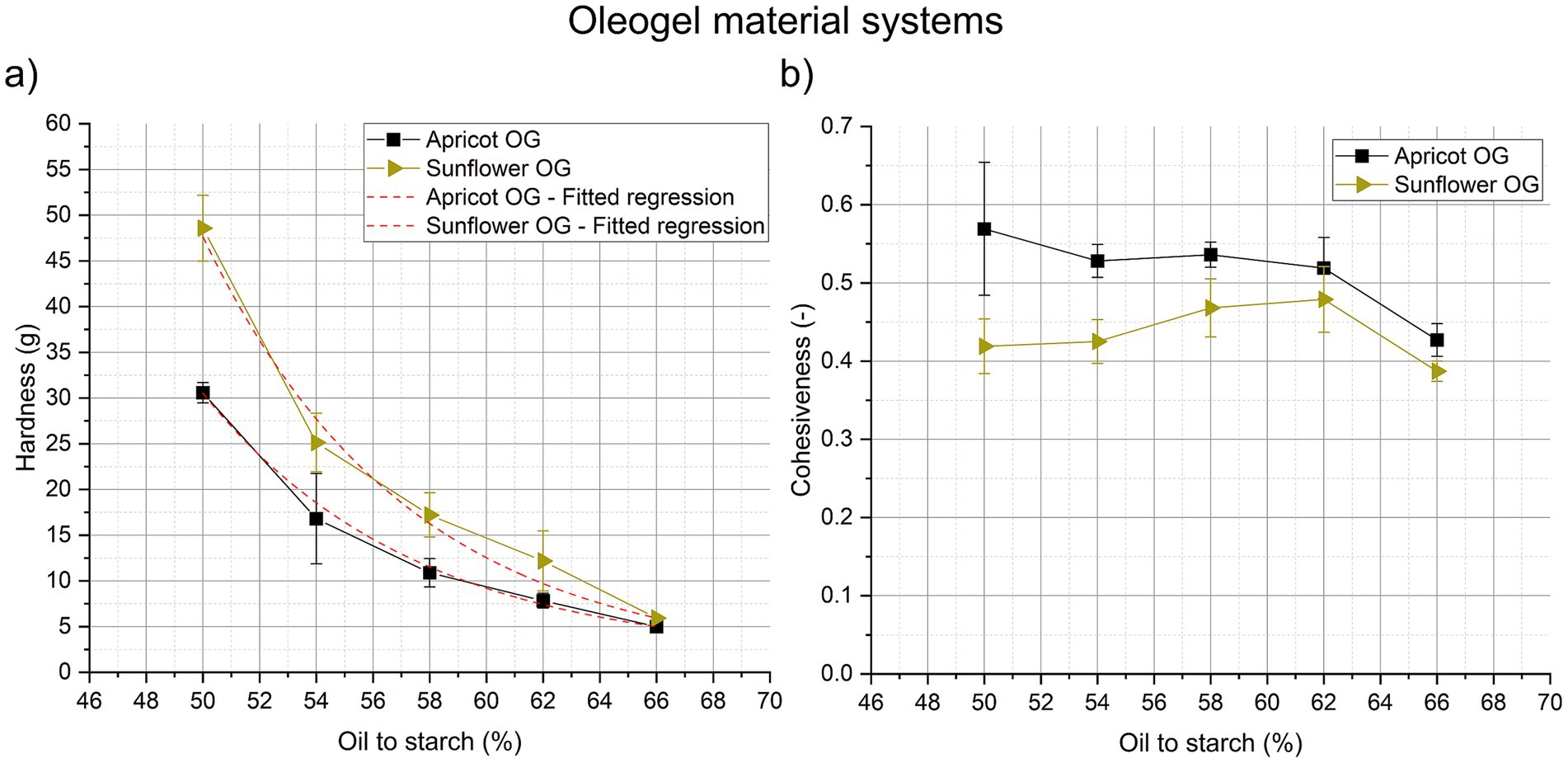

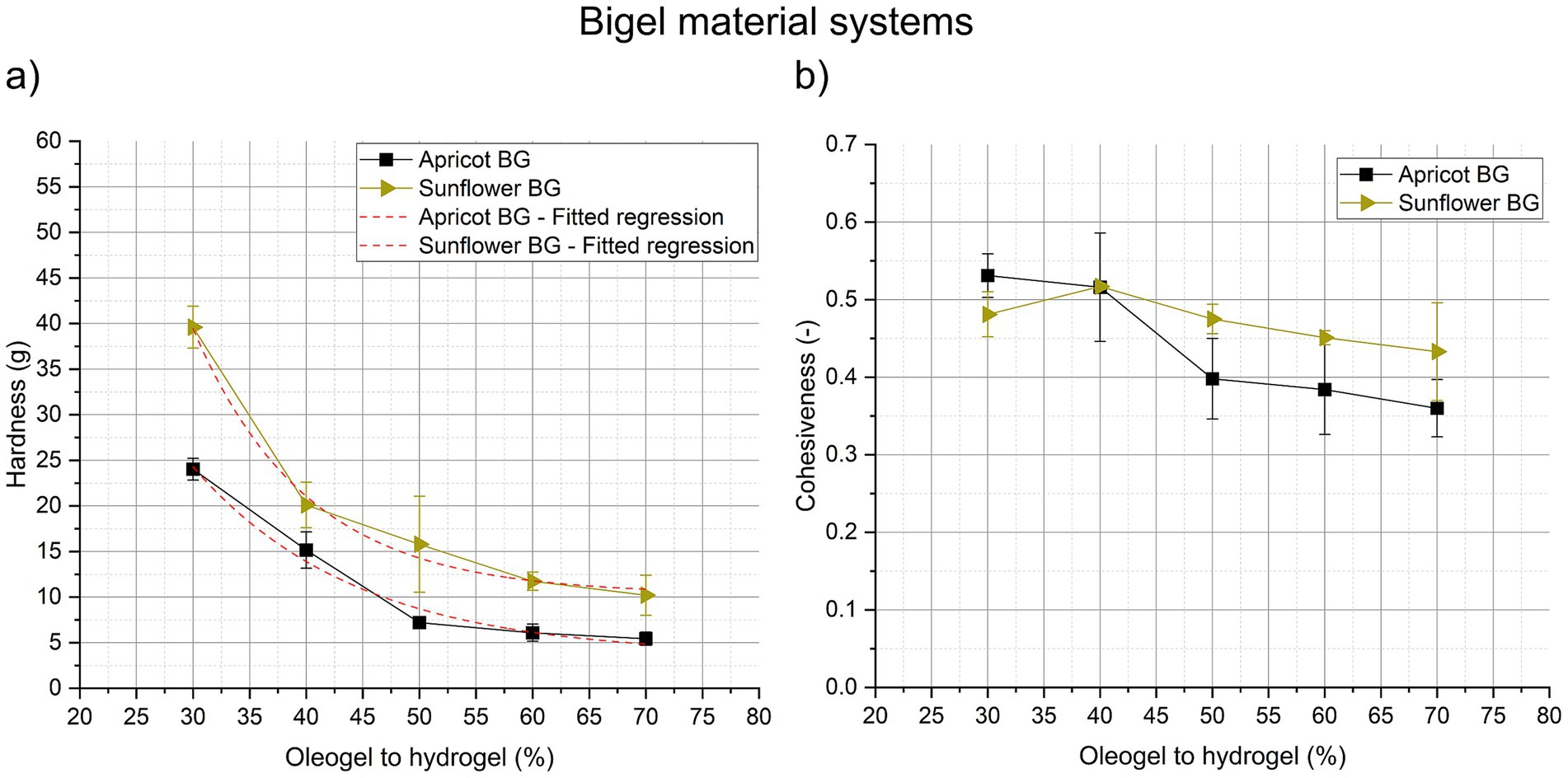

The texture properties of oleo- and bigels are one of the main determinants for the printing behavior as well as the resultant texture of 3D printed structures. Moreover, the texture properties of such material systems are highly dependent on the oil content, oil composition, type, and concentration of the oleogelator. To investigate the effect mentioned variables on the texture properties, as mentioned in section 3.6, the texture properties, namely the hardness and cohesiveness, were characterized using a double compression test under quasi-static conditions. For a qualitative overview over the effect of oil type and composition on the texture properties, both material systems containing the apricot oil were compared to the same systems (with same concentrations) containing sunflower oil. For both oleo- and bigel systems, as shown in Figures 3a, 4a, and for all oil concentrations, it was observed that the inclusion of sunflower oil produced significantly higher hardness compared to the apricot oil. Such significant observation can be directly related to the differences in minor components and fatty acid composition present in both oils (Frolova et al., 2022; Manzoor et al., 2022; Patel, 2015). Within the scope of this study, the fatty acid composition of both oils wasn’t characterized. However, from previously published studies, it is stated that higher saturation in oil leads to stronger gels (Patel, 2015). Overall, with respect to the increase in oil content, both material systems (oleo- and bigels) for both oil types showed the same exponential decay behavior of hardness. This behavior for both material systems and for both types of oils were fitted with regressions. The hardness behavior was fitted for all systems for the mathematical determination of resultant hardness for other oil fractions.

Figure 3. Texture behavior of apricot- and sunflower-based oleogel material systems: (a) hardness decrease behavior with respect to the increase in oil to starch ratio. Exponential decrease regression of both material systems (apricot oil BG R2 = 0.99 and sunflower oil BG R2 = 0.98); (b) decrease behavior of cohesiveness with respect to the increase in oil to starch ratio. Values are presented as mean ± standard deviation (n = 3).

Figure 4. Texture behavior of apricot- and sunflower-based bigel material systems: (a) hardness decrease behavior with respect to the increase in oleogel to hydrogel ratio. Exponential decrease regression of both material systems (apricot oil BG R2 = 0.98 and sunflower oil BG R2 = 0.99); (b) decrease behavior of cohesiveness with respect to the increase in oleogel to hydrogel ratio. Values are presented as mean ± standard deviation (n = 3).

From a structural point of view, the cohesiveness can describe the intermolecular attraction of a material which defines the shape retention of structures under a defined deformation. It is characterized by how well the structure withstands the second deformation (in a double compression test) compared to the first deformation cycle. From this explanation, it can be inferred that the cohesiveness can provide an indicator for the strength of the internal bonds of the materials. From the perspective of 3D printing, materials possessing shear thinning qualities while showing high cohesiveness are desirable. High cohesiveness (also yield strength) represents materials with structural and geometrical stability that can withstand an increasing number of deposited layers during 3D structuring while low cohesiveness can be an indicator for phase separation and slumping or structural collapse. For both material systems (oleo- and bigels) as well as for both oil types, the cohesiveness ranged from approximately 0.55 to 0.35 which could be lower than standard 3D food printing materials (fiber-based, starch-based and protein-based) (Addo et al., 2025; Fahmy et al., 2022a). While the oil type showed significant influence on the hardness or the overall strength of the gels, such influence was not observed in the cohesiveness of the gels. Furthermore, the increase in hardness of the material systems containing sunflower oil compared to apricot oil can be assumed for the rheological response in terms of both the viscos and elastic components. However, the rheological response of the sunflower oil containing systems was not characterized as within the scope of this study, the sunflower oil containing systems were not processed or 3D printed. The comparison was performed using the texture analysis to highlight the influence of the oil type on the overall stiffness of the material systems.

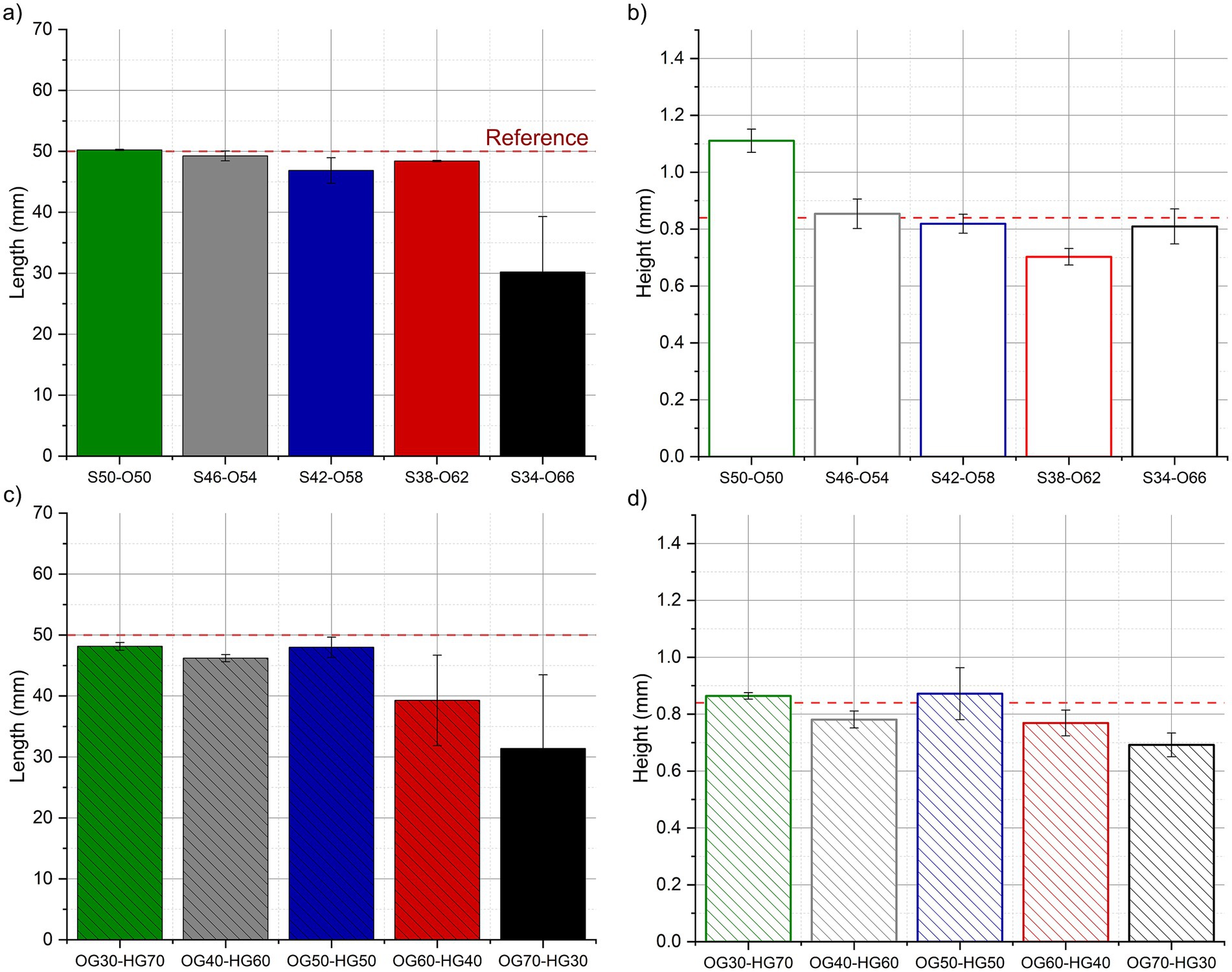

As oleo- and bigel material systems represent promising candidates for the structuring of fat phases in 3D printed meat analogues, maintaining a relatively high oil content while ensuring a high printing quality is of outmost importance. By varying the oil content and maintaining accuracy and reproducibility, different and modular fat phase distributions can be 3D structures within anisotropic protein phases depending on the required texture and sensory perception of the meat analogue. Thus, the printing behavior was characterized by using the mentioned camera-based morphological method in section 3.4. The main objective of the characterization was to assess the applicability of 3D structuring of the oleo- and bigel material systems with respect to the increase in the apricot oil concentration. On the other hand, comprehensive analysis of the oil content-dependent viscoelastic induced defects such as under- and over-extrusion, liquid rope coiling, and drag effects were not quantified for the purpose of this study.

For investigating the printing behavior of the oleo- and bigel material systems, the length and height of single lines were autonomously quantified from a front-view camera. As shown in Figure 5, the red lines (reference) represent the design and target values for the printed oleo- and bigel lines. For the length, the reference is 50 mm as selected by the designed line model while the reference for the height is 0.84 mm which corresponds to the used nozzle diameter. Figure 5 shows the quantified extruded length and height of the oleo- and bigel material systems at the different apricot oil concentrations. For the highest oil content oleogel S32-O66 and bigel OG70-HG30 (also for the OG60-HG40), as shown in Figures 5a,c, the average height of the printed lines was observed to be 30.20 ± 9.10 mm (39.6% deviation from reference) and 31.40 ± 12.00 mm (37.2% deviation from reference). Also, both materials showed high standard deviation compared to the other printed material systems. This deviation from the reference and high standard deviation can be attributed to phase separation due to the high extrusion forces applied on a weak network at such high oil concentration. The high forces generated overtime throughout the extrusion and deposition processes cause the oil phase to separate from the formed network as such a process is denoted by high variability which was observed in the high uncertainty in the printed length. Moreover, both materials with the highest oil content (from the oleo- and bigel material systems) showed slumping behavior even in printing one layer as can be seen in Figures 5b,d. The slumping behavior is denoted by the reduction in the printing height where the materials tend to flow after deposition as they do not possess a high enough yield strength to resist the applied gravitational force and surface tension (Fahmy et al., 2020; M’Barki et al., 2017). For the other material systems (both oleo- and bigels) with lower oil concentrations, the printability assessment through the characterization of length and width showed relatively adequate accuracy. The accuracy is marked by the absence of high deviation from the reference dimensions (referring to the design line length and nozzle diameter). Furthermore, over-extrusion was observed in the S50-O50 oleogel material system as shown in Figure 5b where the height of the extruded lines exceeded the nozzle diameter. The increase in height of this material can be explained by the high overall elastic and viscous response and hardness of the mentioned material compared to the other materials, as shown in Figures 3, 4.

Figure 5. Extruded length and height of the oleo- and bigel material systems: (a) extruded length with respect to the different oleogel S-O concentrations; (b) extruded height with respect to the different oleogel S-O concentrations; (c) extruded length with respect to the different bigel OG-HG concentrations; (d) extruded height with respect to the different bigel OG-HG concentrations. Values are presented as mean ± standard deviation (n = 3).

From the printability analysis, it can be deduced that the 3D processing of both material systems yielded higher printing accuracy at low oil concentrations. It can be further specified to three starch-based oleogel systems (O50-S50, S46-O54 and S42-O58) and three bigel systems (OG30-HG70, OG40-HG60 and OG50-HG50). Of course, this is highly dependent on the used oil and its lipid composition and gelator type as well as dependent on the employed printing process (extrusion type, printing settings, etc.) (Frolova et al., 2022; Guénard-Lampron et al., 2021). Moreover, to qualitatively and quantitively assess the geometrical and structural quality for 3D printed oleo- and bigel structures, 15x15x15 mm3 cube structures with no infill were printed and assessed using the same camera-based approach. As an example, the front and side views of the 3D printed oleo- and bigels cubes with the lowest oil concentration are shown in Figure 6. Results showed that for both materials, only a 10% deviation in the length, width and height of the cubes occurred. However, visually and qualitatively, it can be seen that the bigel material system exhibits high surface roughness and non-homogeneity (not quantified) compared to the oleogel system. This behavior can be seen in other published literature investigating the printing behavior of bigel systems (Fernandes et al., 2023; Qiu et al., 2022).

Finally, the performance of Oleogels in 3D food printing applications depends on the oil concentration. Gels with low oil content showed good printability and structural properties. Bigels and oleogels containing a lot of oil require adjustments to improve their deposition behavior and post-printing stability. These results pave the way for new opportunities in the use of food inks for innovative 3D applications, contributing to the personalization of food products. On top of this, as opposed to existing industry solutions, a reduction in oil content can present further opportunities for health and reduce the amount of energy dense inputs for food production. Through the use of 3D food printing in food applications that can replace saturated fats, it can be concluded that this technology does not create one but three advantages in total, reduction in input use, new food structures reducing the limitations existing for oleogels in traditional food designs and on top a reduced amount of oleogels in the overall food formulation, which may have a positive effect on the calorie intake.

5 Discussion and impact

5.1 Challenges in valorizing oil from stone fruits using 3D printed oleo- and bigels

Despite the recent exponential growth in the oleogel field, the use of oleogels is still in the early stages of development due to a number of challenges. These challenges include the food regulations that not only require food grade gelators but also impose restrictions on gelator concentrations in food products (Younes et al., 2018). Other limitations include the lack of knowledge of and uncertainties about their interaction with other food ingredients, how they behave under different processing conditions for different food products, and the need for inexpensive and easily accessible food grade gelators (Park and Maleky, 2020). Concerning other stone fruits, not all have the same oil content and composition. As seen in the results section, the texture and mechanical behavior is highly dependent on the oil composition which possesses a challenge in valorizing other types of oil where more printability studies have to be performed to determine the printing behavior and the optimum gelator to oil ratio.

5.2 Product and technical innovations

The value proposition in terms of product innovation lies in two main aspects which are the development of fat phases using valorized plant-based oils from food processing by-products through the two possible pathways namely oleo- and bigels and subsequently, the possible integration of such fat phases in direct food applications using 3D printing techniques. From the techno-functional properties point of view, oleo- and bigel systems (considering valorized oils from by-products) can be used in other 3D printing materials containing fat phases to improve the geometrical and structural stability of 3D printed structures (Drewnowski, 1997; Scott and Downey, 2007). Such materials can be used in 3D printing of cereal-based materials and products as a replacement for solid fats such as butter, margarine and shortening which are typically used in the printing of cake and cookie formulations (Piovesan et al., 2020; Pulatsu et al., 2020, 2022; Varghese et al., 2020). Considering the sensory perception of foods, it is comprehensively studied and proven that textures and texture properties which manifest as texture perception (mouthfeel) are a significant determinant and influence consumer preferences regarding any food product (Stribiţcaia et al., 2020). While using oleo- and bigels within material formulations, the texture properties can be tuned (using either the oil-gelator type and concentration) thus influencing the overall sensory properties of the 3D printed structures without varying the concentration of other material constituents, post-processing or even the cellular parameters in the case of 3D printing of cellular/foam structures. Coupling this approach with established 3D texture modulation/control techniques and the on-demand processing of 3D printing, increases the possibility of customization, in terms of textural preferences, and decreases the possibility of time- or storage-dependent effects and thus, increasing the possibility of consumer acceptance. Recent studies show that 72% of consumers enjoy trying foods with different textures, and nearly half (especially millennials) may prioritize texture over ingredients when making purchasing decisions (Riesco et al., 2019). Going from a general texture perspective to the texture of meat analogues, the successful 3D printing of oleo- and bigel systems presents an opportunity for the improvement (in comparison to animal-based products) of the texture properties of plant-based meat analogues. Currently, 3D printed meat analogues are mainly processed using either structured (fibrillated) or unstructured protein phases with no spatial localization of fat phases within the structure which of course is not highly regarded as normal meat from a texture and also flavor perspective (Ko et al., 2021; Miller et al., 2024; Shahbazi et al., 2021; Wen et al., 2023). Oleo- and bigel fat phases can be used in combination with dual and co-axial extrusion 3D printing to spatially localize fibrillated protein phases and fat phases to create plant-based meat analogues with possibly improved overall sensory qualities. This approach can be then considered and highlighted as artificial muscle fibers combined with variable and controllable artificial fat marbling.

5.3 Nutritional value of apricot seed oil

In terms of its composition, apricot seed oil is rich in antioxidants and polyphenolic compounds. The only saturated fatty acid (SFA) present in the apricot seed oil is palmitic acid, while the monounsaturated (MUFA) and polyunsaturated (PUFA) fatty acids are oleic acid (the main fatty acid in the oil) and linoleic acid, respectively (Aydin, 2024). Stryjecka et al. (2019) compared apricot oil with other vegetable and sidestreams-based oils and shows the low levels of SFA and high levels of PUFA, making apricot seed oil an oil of high nutritional quality (Stryjecka et al., 2019).

5.4 Bioeconomy value proposition

The value proposition brings together two key elements: the evaluation of the unique textural properties of 3D-printed foods and assessing food inks made from by-products. From a product and technical innovation perspective, the results of the techno-functional analysis of introducing new plant-based sources derived from food processing by-products using 3D printing technologies were shown. The overall resource efficiency of utilizing by-products adds value, but this depends heavily on the processing steps required to manipulate the by-product stream so that it can be integrated into a food matrix (Ali et al., 2025; Choe et al., 2023). Apricot seed oil was used for the printing performance test based on the fact that there were no specific pre-processing requirements during oil production, and it had already achieved good printability results.

The valorization of apricot seed oil provides an additional valorization pathway for a by-product that is available in high volumes, thus creating added value for the biomass stream, which is already valuable to the cosmetic and food industries (Brahmi et al., 2023). However, it only plays a minor role in the food industry (according to the literature). Recent advancements have converted apricot oil into new plant-based milk alternatives and used it to create plant-based spreads for breakfast (kern-tec, 2025). Adding additional value-added products can in the long term lead to the creation of a new commodity-like food source. That way the main product, apricot flesh, is decoupled in the valuation of the fruit stone. That means the market value of the stone can increase independently of the main fruit and enter new market segments. Innovation and product diversification can create market value and increase resilience of agricultural systems through the establishment of new sustainable value chains.

Texturing agents such as emulsifiers, stabilizers, thickeners, and bulking agents, modify the texture of processed foods (Iriondo-Dehond et al., 2018). In 3D food printing, however, the CAD design utilizes these agents’ biological properties as a basis for embedding quality attributes into each food layer, shaping the overall texture for specific fabrication goals. This food sustainability assessment stands out by evaluating not the finished product, but an intermediate, transformable food matrix and its properties regarding sustainability (Hassoun et al., 2024).

By merging valorization with advanced 3D texture modulation, a customizable platform emerges for consumer studies during product development. On-demand printing allows precise control over texture preferences, meeting individual tastes, reducing costs, and improving study efficiency—often ranging from thousands to hundreds of thousands of dollars depending on complexity, sample size, and methodology (Food-Reaserch-Lab, 2024).

Because printability tests link directly to the printing design, products can be quickly adjusted during studies based on participant feedback, with new samples printed instantly to match individual preferences. This approach enables future consumer studies to directly estimate the texture’s value in product development, also considering health benefits.

6 Conclusion

In the techno-functional case study presented in this study, the applicability of integration of apricot seed oil in 3D structured oleo- and bigel material systems was investigated. To summarize, for both material systems, higher geometrical accuracy and structural stability were observed at lower oil concentrations (for the oleogels) and at lower oleogel fractions (for the bigels). An increase in the oil concentration or the oleogel fraction led to higher collapse or slumping of both the printed lines and cubes. Of course, further analysis is required to investigate the influence of the used oleogelator as well as the hydrogel phase. From a textural perspective, both material systems with apricot seed oil showed lower hardness compared to the systems incorporating sunflower oil, showing the influence of the oil composition on the texture properties. Finally, to maximize the amount of valorized oil, other gelator types or hydrogel phases must be investigated in the future.

In this study, oleo- and bigels were used as a singular focus of study; however, they could also be integrated into more comprehensive food formulation. While oleo- and bigels significantly influence the texture properties of a product, which is better achieved with higher oil concentrations, the modular, customizable and personalized textures of a food could possibly be achieved by combining different layers with different food formulations, thus keeping a low oil concentration and thus saturated fat fraction in the overall food formulation. From a bioeconomy point of view, smart texture design that not only takes the macronutrients but also the effect of texture design on the overall texture properties, can increase resource efficiency in two ways and beyond the existing recipes of the food industry.

Other studies have used oleogels to create adipose tissue mimetics, which is the primary fat store in animal-based meat (Czapalay and Marangoni, 2024), and found that unlike emulsion gels, which could also be used to create such fat replacers, oleogels often used non-label-friendly ethylcellulose to achieve the tissue mimetics. This is another important aspect to consider when using oleogels in food formulations, as the way the materials are combined to create the food formulation will affect the overall sustainability of the original biomass streams and therefore the suitability of the by-product as an alternative recipe component. Additive manufacturing can replace ethylcellulose through intelligent structural design, helping to resolve the otherwise trade-off between functionality and food sustainability (Hassoun et al., 2024), which will need to be more fully considered in the future when designing new food formulations.

Additionally, ethical considerations can be included in the overall sustainability assessment of food formulations that replace animal fat high in saturated fat for religious reasons (Nicholson and Marangoni, 2023). Beyond health effects, this aspect contributes to a more inclusive society that recognizes social and religious beliefs in addition to the mere functionality of food. This is a dimension of food that will become increasingly important in the future, especially if 3D-printed plant-based food is designed specifically for the elderly, who can fully benefit from the added value of additive manufacturing and who are often completely dependent on the food provided by care institutions.

And finally, the technical settings, such as nozzle sizes or adjustments to printer settings, are variable (Qiu et al., 2024). However, these technical aspects, which strongly influence the printing performance, should be summarized in any sustainability assessment under the concept of site-specific process adaptation, which is incremental to any technology that is also used in other contexts. As an example, any technology provided for primary production in agriculture has default settings and a basic technology setup. Rarely will these settings be sufficient for use in a real-world environment, where site specifics and necessary interoperability requirements with other tools force adjustments to the factory settings. In industry, standard processing plant system components are optimized based on the overall industry plant set-up, and economic values can be optimized at the fourth decimal place. However, in the evaluation of the food processing industry, such technologies are still comparable and integrated into the overall assessment of results and performance.

The overall bioeconomic value of new oleogel formulations arises from the integration of oil derived from food industry by-products and the combination of various sustainability aspects, such as circular design, with technological functionality. By using oleogels in 3D-printed food solutions that are based on these by-products, the food industry is presented with a multidimensional value proposition for the future. This approach generates economic wealth in a sustainable manner, giving equal consideration to ethical and environmental concerns alongside economic factors.

However, achieving this balance requires that the sustainability of future food systems be evaluated within broader system boundaries, rather than focusing solely on techno-economic aspects—a challenge that is frequently encountered in current assessments (Crossland et al., 2025; Lemanna et al., 2024). Therefore, further research should concentrate on developing new holistic frameworks for assessing and valuing food sustainability within circular bioeconomy systems. 3D food printing, as a biointelligent technology, can facilitate the creation of essential data sets through reverse engineering. It also enables the measurement of contributions to a sustainable food system, for example, by evaluating the structuring potential of plant-based materials.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

ER: Writing – original draft, Conceptualization, Visualization, Investigation, Methodology, Writing – review & editing, Formal analysis. AF: Investigation, Validation, Conceptualization, Writing – review & editing, Formal analysis, Writing – original draft, Methodology, Visualization. OR: Formal analysis, Writing – original draft, Data curation, Methodology, Validation, Investigation. MJ: Resources, Investigation, Conceptualization, Supervision, Methodology, Project administration, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. Publishing fees supported by Funding Programme Open Access Publishing of University of Hohenheim.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Addo, E. O., Wild, S., Yousefi, A., Fahmy, A. R., and Jekle, M. (2025). Insights into the material and 3D printing behaviour of fiber-enriched protein gels. Food Res. Int. 203:115873. doi: 10.1016/j.foodres.2025.115873

Ali, E. A., Mohammed, D. M., El Gawad, F. A., Orabi, M. A., Gupta, R. K., and Srivastav, P. P. (2025). Valorization of food processing waste byproducts for essential oil production and their application in food system. Waste Manag. Bull. 3:100200. doi: 10.1016/j.wmb.2025.100200

Andriotis, E. G., Paraskevopoulou, A., Fatouros, D. G., Zhang, H., and Ritzoulis, C. (2024). Design of Aerated Oleogel–Hydrogel Mixtures for 3D printing of personalized Cannabis edibles. Gels 10, 1–15. doi: 10.3390/gels10100654

Aydin, Ç. M. (2024). Characteristics of Hozat apricot seed oil as a new source of oilseed. Appl. Food Res. 4. doi: 10.1016/j.afres.2024.100396

Bouchama, F., Van Aken, G. A., Autin, A. J. E., and Koper, G. J. M. (2003). On the mechanism of catastrophic phase inversion in emulsions. Colloids Surf. A Physicochem. Eng. Asp. 231, 11–17. doi: 10.1016/j.colsurfa.2003.08.011

Brahmi, F., Chennit, B., Batrouni, H., Benallaoua, K., Madani, K., and Boulekbache-Makhlouf, L. (2023). Valorization of apricot, melon, and watermelon by-products by extracting vegetable oils from their seeds and formulating margarine. OCL 30:11. doi: 10.1051/ocl/2023009

Chen, H., Xie, F., Chen, L., and Zheng, B. (2019). Effect of rheological properties of potato, rice and corn starches on their hot-extrusion 3D printing behaviors. J. Food Eng. 244, 150–158. doi: 10.1016/j.jfoodeng.2018.09.011

Choe, U., Childs, H., Zeng, M., Zheng, W., Zhu, H., Zhu, L., et al. (2023). Value-added utilization of fruit seed oils for improving human health: a Progress review. ACS Food Sci. Technol. 3, 528–538. doi: 10.1021/acsfoodscitech.2c00120

Crossland, M., Coe, R., Lamanna, C., Chiputwa, B., Orero, L., Adoyo, B., et al. (2025). Measuring the holistic performance of food and agricultural systems: a systematic review. Front. Sustain. Food Syst. 9:1472109. doi: 10.3389/fsufs.2025.1472109

Czapalay, E., and Marangoni, A. (2024). Functional properties of oleogels and emulsion gels as adipose tissue mimetics. Trends Food Sci. Technol. 153:104753. doi: 10.1016/j.tifs.2024.104753

Dankar, I., Haddarah, A., Sepulcre, F., and Pujolà, M. (2020). Assessing mechanical and rheological properties of potato puree: Effect of different ingredient combinations and cooking methods on the feasibility of 3d printing. Foods 9, 1–12. doi: 10.3390/foods9010021

De Salvo, M. I., Palla, C. A., and Cotabarren, I. M. (2023). Effect of printing parameters on the extrusion 3D printing of oleogel-based nutraceuticals. J. Food Eng. 349:111459. doi: 10.1016/j.jfoodeng.2023.111459

De Salvo, M. I., Palla, C., and Cotabarren, I. M. (2025). Development of an operational map for the 3D printing of Phytosterol-enriched Oleogels: rheological insights and applications in nutraceutical design. Foods 14, 1–16. doi: 10.3390/foods14020200

Derossi, A., Caporizzi, R., Paolillo, M., and Severini, C. (2020). Programmable texture properties of cereal-based snack mediated by 3D printing technology. J. Food Eng. 289:110160. doi: 10.1016/j.jfoodeng.2020.110160

Derossi, A., Spence, C., Corradini, M. G., Jekle, M., Fahmy, A. R., Caporizzi, R., et al. (2024). Personalized, digitally designed 3D printed food towards the reshaping of food manufacturing and consumption. NPJ Sci. Food 8, 1–10. doi: 10.1038/s41538-024-00296-5

Dingel, A., and Matissek, R. (2013). trans-Fettsäuren, Gehalte in vielen Lebensmitteln erfolgreich minimiert. Dtsch. Lebensmitt. Rundsch., 109, 580–583. Available online at: https://www.dge.de/wissenschaft/fachinformationen/trans-fettsaeuren-und-die-gesundheit/#:~:text=Auffällig%20ist%2C (dass die Gehalte, 2012). (Accessed September 25, 2025).

Domenech, T., and Velankar, S. S. (2015). On the rheology of pendular gels and morphological developments in paste-like ternary systems based on capillary attraction. Soft Matter 11, 1500–1516. doi: 10.1039/c4sm02053g

Drewnowski, A. (1997). Taste preferences and food intake. Annu. Rev. Nutr. 17, 237–253. doi: 10.1146/annurev.nutr.17.1.237

EU-Commission. (2011). Trans fat in food. Available online at: https://food.ec.europa.eu/food-safety/labelling-and-nutrition/trans-fat-food_en. (Accessed September 25, 2025).

Fahmy, A. R., Amann, L. S., Dunkel, A., Frank, O., Dawid, C., Hofmann, T., et al. (2021). Sensory design in food 3D printing – structuring, texture modulation, taste localization, and thermal stabilization. Innov. Food Sci. Emerg. Technol. 72:102743. doi: 10.1016/j.ifset.2021.102743

Fahmy, A. R., Becker, T., and Jekle, M. (2020). 3D printing and additive manufacturing of cereal-based materials: quality analysis of starch-based systems using a camera-based morphological approach. Innov. Food Sci. Emerg. Technol. 63:102384. doi: 10.1016/j.ifset.2020.102384

Fahmy, A. R., Derossi, A., and Jekle, M. (2023). Four-dimensional (4D) printing of dynamic foods—definitions, considerations, and current scientific status. Foods 12:3410. doi: 10.3390/foods12183410

Fahmy, A. R., Jekle, M., and Becker, T. (2022a). Texture modulation of starch-based closed-cell foams using 3D printing: Deformation behavior beyond the elastic regime. J. Texture Stud. 54, 153–169. doi: 10.1111/jtxs.12729

Fahmy, A. R., Vogt, U. T., Jekle, M., and Becker, T. (2022b). Hardness targeted design and modulation of food textures in the elastic-regime using 3D printing of closed-cell foams in point lattice systems. J. Food Eng. 320:110942. doi: 10.1016/j.jfoodeng.2022.110942

Fernandes, A. S., Neves, B. V., Mazzo, T. M., Longo, E., Jacob-Lopez, E., Zepka, L. Q., et al. (2023). Bigels as potential inks for extrusion-based 3d food printing: effect of oleogel fraction on physical characterization and printability. Food Hydrocoll. 144:108986. doi: 10.1016/j.foodhyd.2023.108986

Food-Reaserch-Lab. (2024). A comprehensive guide of the costs involved in new product development. Available online at: https://www.foodresearchlab.com/blog/new-product-development/costs-involved-in-new-product-development/. (Accessed September 25, 2025).

Fribus, R., Kant, J., Fahmy, A. R., and Jekle, M. (2024). Texture modulation of starch-based materials using microfoaming-assisted 3D printing. Future Foods 9:100311. doi: 10.1016/j.fufo.2024.100311

Frolova, Y., Sarkisyan, V., Sobolev, R., Makarenko, M., Semin, M., and Kochetkova, A. (2022). The influence of edible oils’ composition on the properties of beeswax-based Oleogels. Gels 8:48. doi: 10.3390/gels8010048

Giura, L., Urtasun, L., Belarra, A., Ansorena, D., and Astiasarán, I. (2021). Exploring tools for designing dysphagia-friendly foods: a review. Foods 10, 1–16. doi: 10.3390/foods10061334

Guénard-Lampron, V., Masson, M., Leichtnam, O., and Blumenthal, D. (2021). Impact of 3D printing and post-processing parameters on shape, texture and microstructure of carrot appetizer cake. Innov. Food Sci. Emerg. Technol. 72, 1–11. doi: 10.1016/j.ifset.2021.102738

Hassoun, A., Boukid, F., and Ozogul, F. (2024). Food sustainability and food industry 4.0: unveiling the relationship. Front. Sustain. Food Syst. 8:1440023. doi: 10.3389/fsufs.2024.1440023

Huang, J. H. R., Lim, G. G. C. W., Su, C. H., and Ciou, J. Y. (2023). Improvement of 3D white chocolate printing molding effect with oleogels. Heliyon 9:e19165. doi: 10.1016/j.heliyon.2023.e19165

Iorgulescu, R. I. (2023). Bioeconomy. In Dictionary of Ecological Economics: Terms for the New Millennium. EE Elgar online. 35–36. doi: 10.4337/9781788974912.B.22

Iriondo-Dehond, M., Miguel, E., and Del Castillo, M. D. (2018). Food byproducts as sustainable ingredients for innovative and healthy dairy foods. Nutrients 10, 1–24. doi: 10.3390/nu10101358

Jiang, Q., Wang, Y., Du, L., Li, S., Liu, Y., and Meng, Z. (2022). Catastrophic phase inversion of bigels characterized by fluorescence intensity-based 3D modeling and the formability for decorating and 3D printing. Food Hydrocoll. 126:107461. doi: 10.1016/j.foodhyd.2021.107461

Kang, H., Oh, Y., Lee, N. K., and Rhee, J. K. (2022). Printing optimization of 3D structure with lard-like texture using a beeswax-based Oleogels. J. Microbiol. Biotechnol. 32, 1573–1582. doi: 10.4014/jmb.2209.09052

Kavimughil, M., Leena, M. M., Moses, J. A., and Anandharamakrishnan, C. (2022). 3D printed MCT oleogel as a co-delivery carrier for curcumin and resveratrol. Biomaterials 287:121616. doi: 10.1016/j.biomaterials.2022.121616

kern-tec. (2025). Kern tec. Available online at: https://www.kern-tec.com/. (Accessed September 25, 2025).

Ko, H. J., Wen, Y., Choi, J. H., Park, B. R., Kim, H. W., and Park, H. J. (2021). Meat analog production through artificial muscle fiber insertion using coaxial nozzle-assisted three-dimensional food printing. Food Hydrocoll. 120:106898. doi: 10.1016/j.foodhyd.2021.106898

Lemanna, C., Coe, R., Crossland, M., Fuchs, L., Barahona, C., Chiputawa, B., et al. (2024). Developing holistic assessments of food and agricultural systems a meta-framework for metrics users. Bogor, Indonesia and Nairobi, Kenya: CIFOR-ICRAF. doi: 10.17528/cifor-icraf/009081

Liu, Z., Bhandari, B., Prakash, S., Mantihal, S., and Zhang, M. (2019). Linking rheology and printability of a multicomponent gel system of carrageenan-xanthan-starch in extrusion based additive manufacturing. Food Hydrocoll. 87, 413–424. doi: 10.1016/j.foodhyd.2018.08.026

M’Barki, A., Bocquet, L., and Stevenson, A. (2017). Linking rheology and printability for dense and strong ceramics by direct ink writing. Sci. Rep. 7:6017. doi: 10.1038/s41598-017-06115-0

Manzoor, S., Masoodi, F. A., Naqash, F., and Rashid, R. (2022). Oleogels: promising alternatives to solid fats for food applications. Food Hydrocoll. Health 2:100058. doi: 10.1016/j.fhfh.2022.100058

Miao, W., Fu, Y., Zhang, Z., Lin, Q., Li, X., Sang, S., et al. (2024). Fabrication of starch-based oleogels using capillary bridges: potential for application as edible inks in 3D food printing. Food Hydrocoll. 150:109647. doi: 10.1016/j.foodhyd.2023.109647

Miehe, R., Baumgarten, Y., and Bauernhansl, T. (2023). Towards a common understanding of the biointelligence concept. Procedia CIRP 120, 1416–1421. doi: 10.1016/j.procir.2023.09.186

Miller, O., Scarlett, C. J., and Akanbi, T. O. (2024). Plant-based meat analogues and consumer interest in 3D-printed products: a Mini-review. Foods 13:2314. doi: 10.3390/foods13152314

Nicholson, R. A., and Marangoni, A. G. (2023). Overview of the structure-property relationship in fat mimetics. In M. A. P. R. Cerqueira and L. M. P. Castro (Eds.), Fat mimetics for food applications. Wiley. doi: 10.1002/9781119780045.ch2

Park, C., and Maleky, F. (2020). A critical review of the last 10 years of Oleogels in food. Front. Sustain. Food Syst. 4, 1–8. doi: 10.3389/fsufs.2020.00139

Pawar, V. U., Dessai, A. D., and Nayak, U. Y. (2024). Oleogels: versatile novel semi-solid system for pharmaceuticals. AAPS PharmSciTech 25, 1–21. doi: 10.1208/s12249-024-02854-2

Pawar, K. R., and Nema, P. K. (2023). Apricot kernel characterization, oil extraction, and its utilization: a review. Food Sci. Biotechnol. 32, 249–263. doi: 10.1007/s10068-022-01228-3

Piovesan, A., Vancauwenberghe, V., Aregawi, W., Delele, M. A., Bongaers, E., de Schipper, M., et al. (2020). Designing mechanical properties of 3d printed cookies through computer aided engineering. Foods 9:1804. doi: 10.3390/foods9121804

Pulatsu, E., Su, J. W., Kenderes, S. M., Lin, J., Vardhanabhuti, B., and Lin, M. (2022). Restructuring cookie dough with 3D printing: relationships between the mechanical properties, baking conditions, and structural changes. J. Food Eng. 319:110911. doi: 10.1016/j.jfoodeng.2021.110911

Pulatsu, E., Su, J. W., Lin, J., and Lin, M. (2020). Factors affecting 3D printing and post-processing capacity of cookie dough. Innov. Food Sci. Emerg. Technol. 61:102316. doi: 10.1016/j.ifset.2020.102316

Puscas, A., Muresan, V., Socaciu, C., and Muste, S. (2020). Oleogels in food: a review of current and potential applications. Foods 9, 1–27. doi: 10.3390/foods9010070

Qiu, R., Wang, K., Tian, H., Liu, X., Liu, G., Hu, Z., et al. (2022). Analysis on the printability and rheological characteristics of bigel inks: potential in 3D food printing. Food Hydrocoll. 129:107675. doi: 10.1016/j.foodhyd.2022.107675

Qiu, R., Wang, G., Zhao, P., Liu, L., Awais, M., Fan, B., et al. (2024). Modification of the texture of 3D printing soy protein isolate-based foods with proper nozzle sizes: a swallowing oriented strategy for dysphagia diet. Int. J. Biol. Macromol. 282:136694. doi: 10.1016/j.ijbiomac.2024.136694

Reinmuth, E., and Scheurich, P. (2026). “Residual biomass characteristics” in Bioeconomy - an interactive textbook on sustainability and social change. eds. I. Lewandowski, L. Mayorga-Duarte, P. Scheurich, R. Vargas Carpintero, V. Schlecht, and J. Weik (Switzerland AG: Springer Nature).

Riesco, S., Picaza, N., and Cruz, E. S. (2019). EATrends: trends with highest impact for food innovation. AZTI-Tecnalia. Available online at: https://www.azti.es/wp-content/uploads/2020/11/EATrends_Report2019_FINAL.pdf. (Accessed September 25, 2025).

Roche, H. M. (2005). Fatty acids and the metabolic syndrome. Proc. Nutr. Soc. 64, 23–29. doi: 10.1079/pns2004405

Scott, C. L., and Downey, R. G. (2007). Types of food aversions: animal, vegetable, and texture. J. Psychol. 141, 127–134. doi: 10.3200/JRLP.141.2.127-134

Shahbazi, M., Jäger, H., Ettelaie, R., and Chen, J. (2021). Construction of 3D printed reduced-fat meat analogue by emulsion gels. Part I: flow behavior, thixotropic feature, and network structure of soy protein-based inks. Food Hydrocoll. 120:106967. doi: 10.1016/j.foodhyd.2021.106967

Shakeel, A., Lupi, F. R., Gabriele, D., Baldino, N., and De Cindio, B. (2018). Bigels: a unique class of materials for drug delivery applications. Soft Mater. 16, 77–93. doi: 10.1080/1539445X.2018.1424638

Silva, R. C. D., Ferdaus, M. J., Foguel, A., and da Silva, T. L. T. (2023). Oleogels as a fat substitute in food: a current review. Gels 9:180. doi: 10.3390/gels9030180

Stribiţcaia, E., Evans, C. E. L., Gibbons, C., Blundell, J., and Sarkar, A. (2020). Food texture influences on satiety: systematic review and meta-analysis. Sci. Rep. 10, 1–18. doi: 10.1038/s41598-020-69504-y

Stryjecka, M., Kiełtyka-Dadasiewicz, A., Michalak, M., Rachoń, L., and Głowacka, A. (2019). Chemical composition and antioxidant properties of oils from the seeds of five apricot (Prunus armeniaca L.) cultivars. Journal of oleo. Science 68, 729–738. doi: 10.5650/jos.ess19121

Sun, J., Peng, Z., Zhou, W., Fuh, J. Y. H., Hong, G. S., and Chiu, A. (2015). A review on 3D printing for customized food fabrication. Procedia Manuf. 1, 308–319. doi: 10.1016/j.promfg.2015.09.057

Tadros, T. (2013). Elasticity. In Encyclopedia of colloid and Interface science (341–342). Springer Berlin Heidelberg. Available online at: https://link.springer.com/rwe/10.1007/978-3-642-20665-8_74. (Accessed September 25, 2025).

Tan, C., Toh, W. Y., Wong, G., and Li, L. (2018). Extrusion-based 3d food printing - materials and machines. Int. J. Bioprint. 4:2. doi: 10.18063/IJB.v4i2.143

Vargas-Carpintero, R., Hilger, T., Tiede, K., Callenius, C., Mössinger, J., Souza, R. F., et al. (2022). A Collaborative, systems approach for the development of biomass-based value webs: the case of the acrocomia palm. Land 11. doi: 10.3390/land11101748

Varghese, C., Wolodko, J., Chen, L., Doschak, M., Srivastav, P. P., and Roopesh, M. S. (2020). Influence of selected product and process parameters on microstructure, rheological, and textural properties of 3D printed cookies. Foods 9:907. doi: 10.3390/foods9070907

Wen, Y., Chao, C., Che, Q. T., Kim, H. W., and Park, H. J. (2023). Development of plant-based meat analogs using 3D printing: status and opportunities. Trends Food Sci. Technol. 132, 76–92. doi: 10.1016/j.tifs.2022.12.010

Wen, Y., Che, Q. T., Kim, H. W., and Park, H. J. (2021). Potato starch altered the rheological, printing, and melting properties of 3D-printable fat analogs based on inulin emulsion-filled gels. Carbohydr. Polym. 269:118285. doi: 10.1016/j.carbpol.2021.118285

Keywords: food sustainability, bioeconomy, circularity, biointelligence, 3D food printing, oleogels, bigels

Citation: Reinmuth E, Fahmy AR, Ribette O and Jekle M (2025) Towards sustainable biointelligent food design: structuring potential of plant-based materials exemplified using apricot seed oil oleogels and bigels through 3D food printing. Front. Sustain. Food Syst. 9:1651027. doi: 10.3389/fsufs.2025.1651027