- 1School of Economics and Management, Harbin Normal University, Harbin, China

- 2Research Institute of Remote Sensing and Information, Heilongjiang Academy of Agricultural Sciences, Harbin, China

Heilongjiang Province is a major production base of commercial grain in China. Its rice output accounts for about half of the national total. During the rice harvesting stage carbon emissions account for approximately 15–20% of the entire rice planting process. This makes it necessary to enhance the efficiency of mechanical operations, reduce diesel consumption, lower carbon emissions, minimize the loss of rice yield at the same time, and to improve the mechanical harvesting effect of rice. Chinese scholars have conducted extensive researches on post-harvest grain loss reduction, mainly focusing on the safe storage of grain by farmers. Few scholars have conducted researches on rice harvesting and the yield loss after harvesting. Meanwhile, foreign scholars mostly considered the details from the perspective of producers’ behavior and the precision of the rice harvester. In Heilongjiang Province rice is mainly harvested by combine harvester, and the inappropriate harvest timing and excessive machine speed of harvest are easy to cause rice loss. Therefore, based on the reality of the main rice varieties, planting patterns and field management methods currently in the main production areas, this study conducts experiments on the rice loss during the rice harvesting stage for different influencing factors such as rice harvester models, harvester traveling speed, harvesting time, rice humidity, stubble height and storage methods. Then single factor ANOVA and correlation analysis are used in this article, using Duncan test method for multiple comparison and difference significance analysis. The results show that a relatively later harvest time, a rice moisture content of 20–22%, a lower traveling speed of the harvester (5–6 km/h), and an appropriate stubble height (14–18 cm) can effectively reduce the amount of rice grain shedding about 1–1.5%. In this study, the main focus was on examining the effects of moisture content during rice harvesting, the speed of the harvesting machine, and the height of stubble left on the field on the loss of rice. Apart from the aforementioned factors that will significantly affect the post-harvest loss level of rice, human factors will also have relevant impacts on it. But this will be carried out in the next stage of the research.

1 Introduction

With <9% of the world’s arable land and 6.5% of its freshwater resources, China contributes a quarter of the world’s grain, making outstanding contributions to ensuring world food security (Han, 2010). Heilongjiang Province, as the most important commercial grain production base in China, holds an irreplaceable strategic position for national food security. In particular, its rice output accounts for over 40% of the national total, ensuring the supply of high-quality rice from the north. Meanwhile, the agricultural mechanization rate in the province reached 98%, far higher than the national average of 73%. Among them, the number of large-scale agricultural machines in use accounted for one fifth of the national total. While mechanization improves efficiency, it also presents environmental challenges. While large-scale agricultural machinery brings about efficient agricultural production, the rapid increase in carbon emissions has caused many negative impacts on the agricultural environment in Heilongjiang Province, leading to problems such as the northward shift of the accumulation zone, accelerated degradation of black soil, and frequent extreme weather. Direct carbon emissions from agriculture account for 12%, mainly coming from methane in rice fields and the application of N2O in chemical fertilizers. The main source of carbon emissions is the consumption of diesel in agricultural machinery, with an annual consumption exceeding 2 million tons. The carbon emissions during the rice harvesting stage account for approximately 15–20% of the entire planting process. This makes it necessary to enhance the efficiency of mechanical operations, reduce diesel consumption, lower carbon emissions, and at the same time reduce rice losses and improve the mechanical harvesting effect of rice.

Over the world, various innovative techniques are deployed to increase the productivity of rice (Qumail et al., 2023). However, few scholars have paid attention to the loss of rice after ripening. In terms of increasing the supply of rice, reducing the loss of mature rice in the harvest can not be ignored.

Numerous studies have shown that the issue of post-harvest loss of food is becoming a potential threat to global food security. As a large grain-producing country, the loss of grain after harvest is also quite serious. In China, 7–11% of the grain output was lost in the post-harvest period due to the raw method of dry storage, poor facilities and outdated technology (Ministry of Agriculture, 2014). During the post-harvest period, the loss of grain storage was especially serious, with a loss rate of about 8% (National Development and Reform Commission, State Food Bureau, 2011). In addition to the loss of grain storage, there were different degrees of loss due to various reasons in the process of harvesting, transportation, drying and processing.

Scholars have carried out extensive researches on the reduction of grain after harvest, mainly focusing on the study of farmers’ safe grain storage. Zhu (2023) thought the proportion of farmers’ grain storage in the total grain production is still large, and the loss rate and loss amount are still at a high level in the post-production loss of grain. Study on grain storage and fittings indicated the performance of the different grain storage equipment was different, and it was found that the traditional grain storage equipment could not make effective use of the storage technology, the annual grain storage loss was more than 6%, and the new grain storage equipment could reduce the grain storage loss to <1%. Study on the effect of different grain storage equipments on rice quality. Compared with other equipments, colored steel bins could reduce the deterioration of rice quality effectively. The results of Wang (2021) showed that in the post-production of grain, the grain loss is high in the process of grain harvesting, drying, farmers’ grain storage, transportation, storage, processing and so on. And the loss rate of harvesting link was closely related to mechanical level, harvesting time and so on, and the experimental results showed that the loss rate of harvesting of wheat might exceed 5%. On the basis of “multifunctional” demonstration granaries, Gao (2016) expressed his opinion that there was great potential for post-production loss of grain crops in China, and the focus of the loss should be on farmers’ grain storage and crop harvest. Wei (1995) discussed the feasibility of carrying out scientific and technological grain storage in rural areas, and believed that “multifunctional” granaries saved labor, material and money, had low technical requirements, and had good performance of insect and mildew prevention, which was suitable for large-scale promotion. In addition, some studies have shown that the loss rate of grain harvest was the lowest in the timely harvest period (Wang et al., 2016), and the loss amount was obviously increased in the timely harvest period (Zhao, 2022). It can be seen that the effect of harvest time on harvest loss rate was significant.

When studying the factors affecting the quality of rice, Tang (2019) proposed that the water content of rice should be reasonably controlled before storage, and the storage technology such as low-temperature air conditioning should be used to strengthen ventilation and cooling during storage to slow down the aging of rice.

Problems in the processes such as mechanical harvesting of rice and storage of rice have also attracted the attention of foreign researchers. Regarding the aspect of losses in mechanical harvesting of rice, some researchers found that the loss rates during the harvesting, threshing, cleaning and transportation of rice were 0.40, 0.52, 0.20 and 0.50%, respectively, (Basavaraja et al., 2007). Then based on a survey of 966 farmers in Bangladesh, some scholars concluded that the loss rate of rice during the harvesting process was 1.60–1.91% (Bala, 2011). Appiah et al. (2020) calculated the field loss rate of rice in Ghana by combining questionnaire surveys with field experiments, and the result was 4.07–12.05%. In addition, some foreign scholars implemented drying chain based on climate and drying methods to minimize the accumulation of mycotoxins and insect infestation in during products, reducing food loss, and improving food quality and safety. Bradford et al. (2018) believed that higher humidity was the most important factor in long-term food storage that affected postpartum loss.

Although scholars have carried out extensive discussion and research on the post-harvest loss and reduction of grain, they have mainly focused on grain storage, and have less research on other aspects of post-harvest, such as grain harvest and processing.

The reason for conducting research on the issue of post-harvest losses in rice is that rice fields are an important source of methane (CH₄) emissions, and the global warming potential of methane is 28–36 times that of carbon dioxide (on a century scale). Reducing rice losses (such as optimizing harvesting and storage processes) can reduce the excessive demand for rice fields, thereby reducing methane emissions. Just as the International Rice Research Institute (IRRI) has pointed out, improving rice management can reduce methane emissions by 30% while increasing production by 20%.

In general, this study emphasizes the need to comprehensively consider multiple factors such as the harvesting time, the speed of the harvesting machine, the stubble height, and storage techniques, in order to jointly reduce the losses of rice after it reaches maturity. And by measuring the loss of grain under different driving speed, stubble height, and the moisture content of different rice grains, this study determined the suitable speed and time of harvest of all kinds of combine harvesters, and optimized the storage means of the storage link, and determined the relationship between the number of turnover and the loss of storage, with a view to providing data support and policy suggestions for the relevant departments to reduce the post-harvest loss of grain, so as to provide reference for China to promote the structural reform of grain supply-side and increase rice supply.

2 Materials and methods

2.1 Testing purpose

In order to improve the operation efficiency of the rice harvesters which are owned by farmers in the main rice-producing areas of Heilongjiang Province and to reduce the rice loss during the harvesting stage, combined with the main rice varieties, planting patterns and field management methods currently in the main production areas, experiments on the rice loss during the rice harvesting stage were carried out for different influencing factors such as the model of rice harvester, the traveling speed of the harvester, the harvesting time, the moisture content of rice, the stubble height, and the storage method. Among them, the traveling speed of the rice harvester, the moisture content of the rice and the stubble height are the key influencing factors. The reasons are as follows:

2.1.1 The traveling speed of the rice harvester

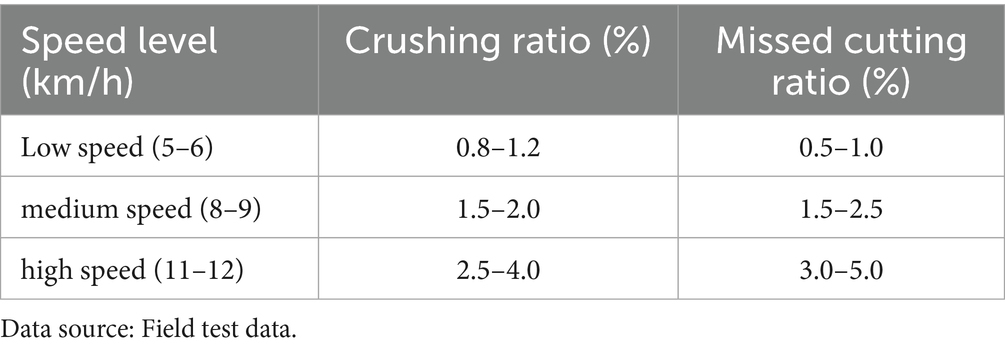

The traveling speed is a key parameter that affects the operational efficiency and yield loss. A balance needs to be struck between reducing losses quickly and ensuring stable harvest quality. Take the Kubota harvester as an example. The quantitative relationship between the traveling speed and the yield loss is as follows:

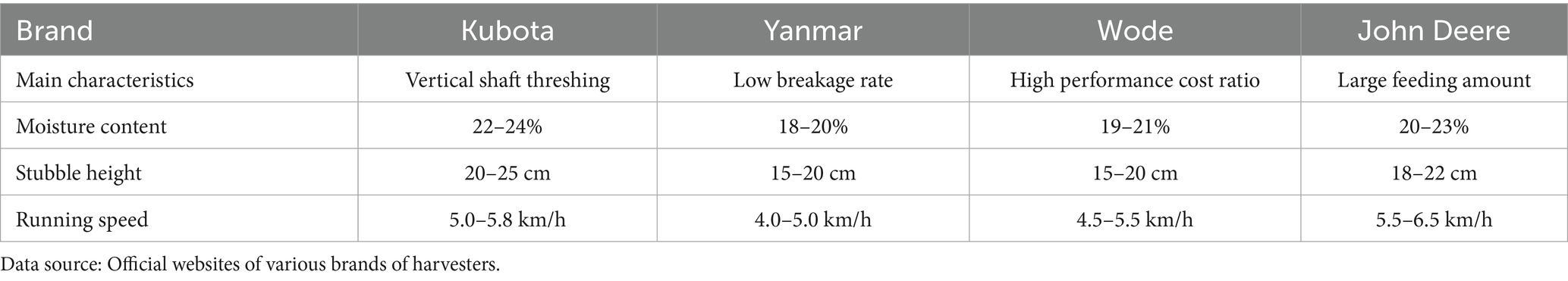

The higher the speed is, the more unbalanced the rotational speed of the harvester drum and the feeding amount will be. The grains will be subjected to greater mechanical impact force, and the crushing rate will also be higher, resulting in an increase in the loss rate. In addition, when the harvester’s grain divider deduces the rice plants too quickly, the proportion of uncut stems increases, and the rate of missed cuts also becomes higher (Table 1).

2.1.2 Rice moisture (water content)

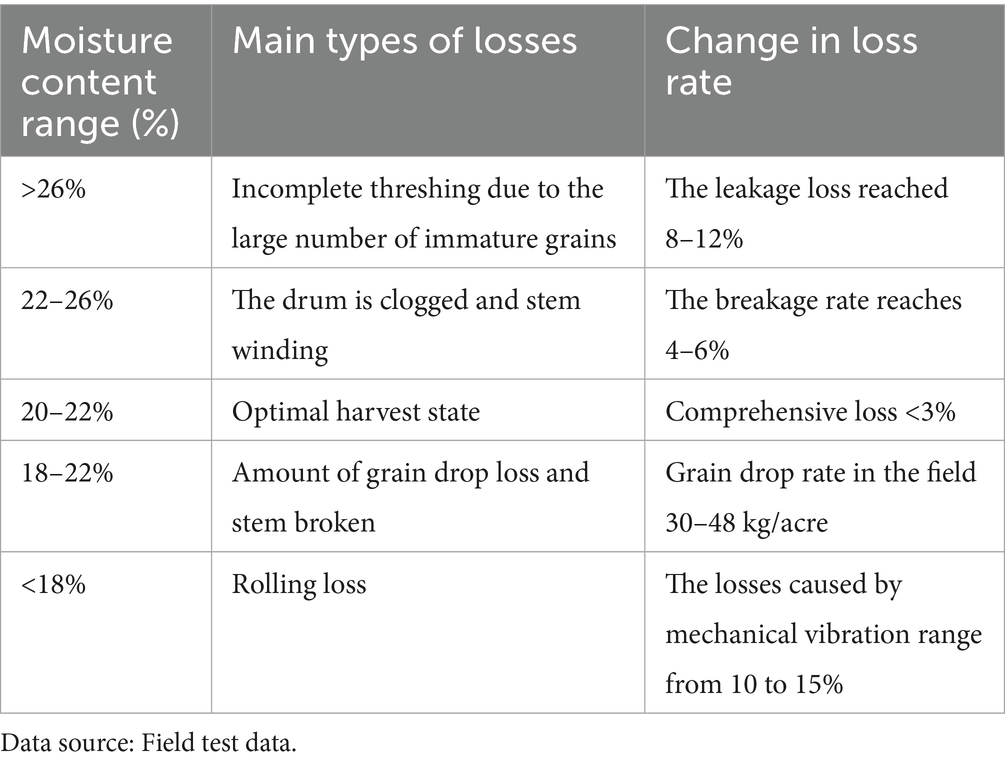

The humidity of rice is the core factor affecting the harvesting efficiency and yield loss. Because different humidity levels of rice have a significant correlation with the maturity of rice:

The vibration of the combine harvester has led to a threefold increase in the amount of grains dropped. In addition, the moisture content of rice also has a significant impact on storage losses. The higher the moisture content, the more likely it is to mold if stored improperly (Table 2).

2.1.3 Stubble height

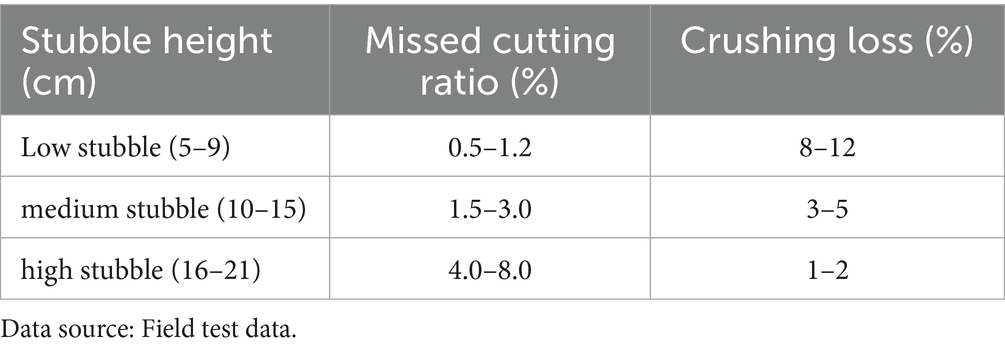

The stubble height of rice is a key parameter affecting the harvest yield. The quantitative relationship between stubble height and yield loss is as follows:

The high-stubble thresher failed to effectively gather the fallen rice plants, with a missed cutting rate of 3–5%. And when the crop is low, the tracks/tires of the harvester directly crush the rice stumps, causing the grains of adjacent uncut rice plants to fall off. The loss in the crushing area is three times that in the normal area (Table 3).

2.2 Testing materials

1. The trial, which was conducted from September 20th to 24th, 2023, was aimed at the pathway of loss during the harvest period, when all grains had turned yellow and more than 80 per cent of leaves had turned yellow. The test sites were Qiqihar Tailai County, Jiamusi Fuyuan City, which reason for choosing these areas is that both are located in the Songnen Plain and the Sanjiang Plain respectively, where have abundant water resources, flat terrain and fertile soil, and are typical representative areas for rice cultivation in Heilongjiang Province and are also model regions for mechanized rice harvesting. The area of the experimental plot is approximately 1–1.5 acres, and they were randomly selected from the plots in the main rice-growing areas. The tested rice varieties were Longyang 16 (Tailai) and Suijing 27 (Fuyuan), all of which were wide and narrow row planting patterns (line spacing 15 cm × 30 cm × 15 cm, column spacing 15 cm), and the field management was completely consistent (cultivated by Heilongjiang Academy of Agricultural Sciences). This study on plants is complied with relevant institutional, national, and international guidelines and legislation. The field studies on plants is approved by Harbin Normal University and Heilongjiang Academy of Agricultural Sciences. Harvesters were: Kubota, Yanmar, Wode and John Deere combine, according to the survey data, whose utilization rate in the local area is approximately 70%. Based on the flat terrain and soil conditions of the main rice-growing areas in Heilongjiang Province, the characteristics and optimal harvesting fields of the four main rice harvesters used in the experiment are shown in the Table 4.

2. The time of the experiment was November 18th, 2023, and the experiment were aimed at the storage link. The test sites were Acheng district and Wuchang county. The storage mode was mainly for farmers.

Table 4. Characteristics, moisture content, stubble height and running speed of the four types of harvesters.

2.3 Test methods

1. Mechanical harvesting was carried out in the test area. Four kinds of combine harvesters were sampled in the test area (Fuyuan) at a slow, constant speed and fast speed (5–6 km/h, 8–9 km/h, 11–12 km/h) and measured at 1 m2 using a scale (precision 0.01 m). In the area of size, the full rice in the test area was manually collected, the quantity was measured by electronic balance (precision 0.01 g), and the moisture content of rice was measured by moisture meter (precision 0.5%), repeated 3 times.

2. Mechanical harvesting was carried out in the test area, and the combined harvester took samples of the test area (Tailai) at different time points at a slow, constant and rapid speed (5–6 km/h, 8–9 km/h, 11–12 km/h), and measured 1 m2 using a scale (precision 0.01 m). In the area of size, the full rice in the test area was manually picked up, the quality was measured by electronic balance (precision 0.01 g), and the moisture content of rice was measured by moisture meter (precision 0.5%), repeated 3 times.

3. At the test site, three types of tests were conducted in the storage area: five daily flipping and stirring tests, three daily flipping and stirring tests, and no flipping and stirring tests.

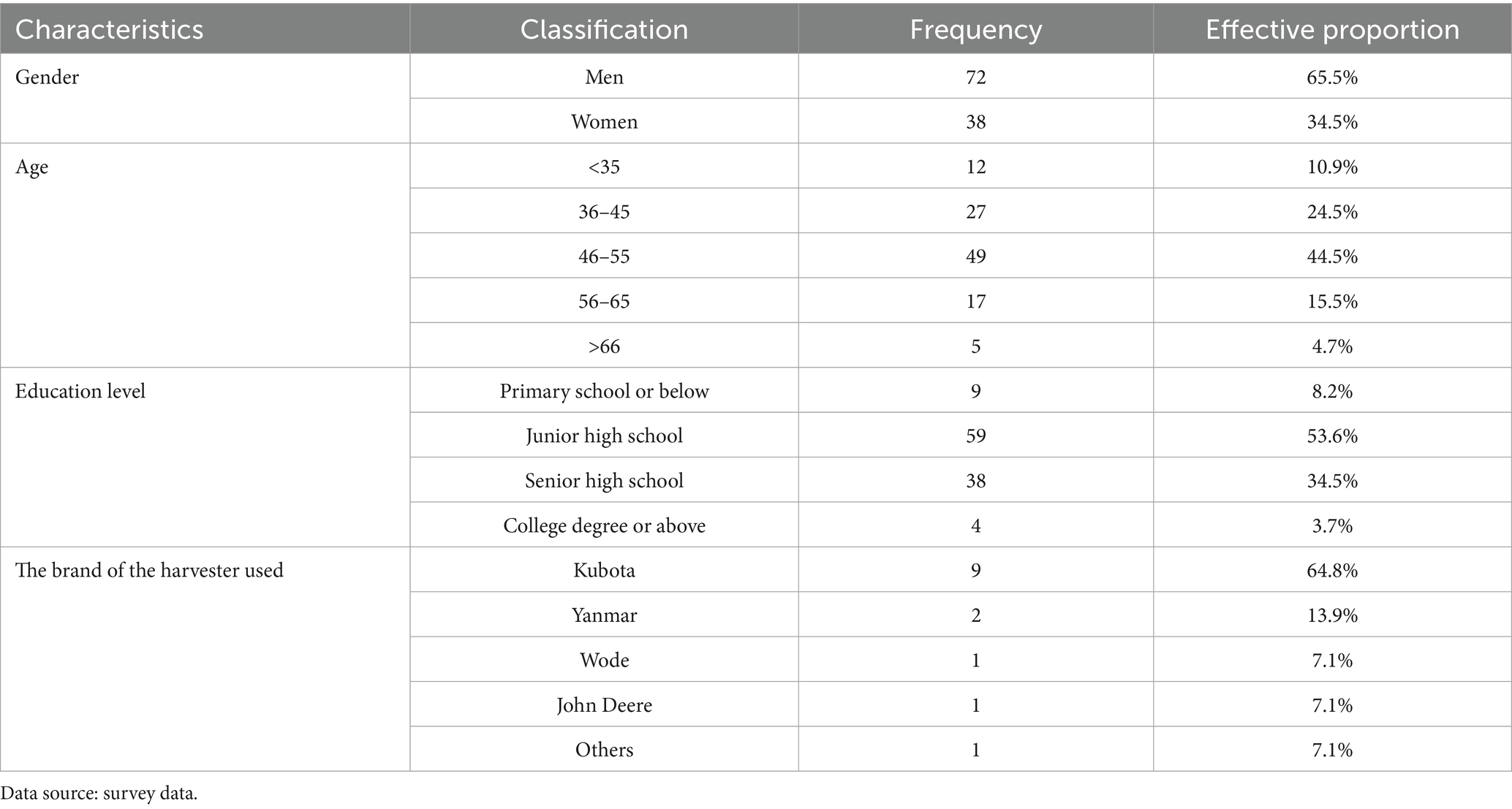

2.3.1 Household survey

A questionnaire survey was conducted among 110 farmers who planted rice at fixed observation points in Fuyuan City, Tailai County and Acheng District, Heilongjiang Province. The investigation mainly focused on the basic conditions of harvesting, transportation, drying and storage, and rice losses (Table 5).

2.4 Data analysis

Using Excel 2013 to sort out the data, SPSS 22.0 software for single factor ANOVA, correlation analysis, using Duncan test method for multiple comparison and difference significance analysis, the chart data in this paper are the average of three repetitions.

3 Results and discussion

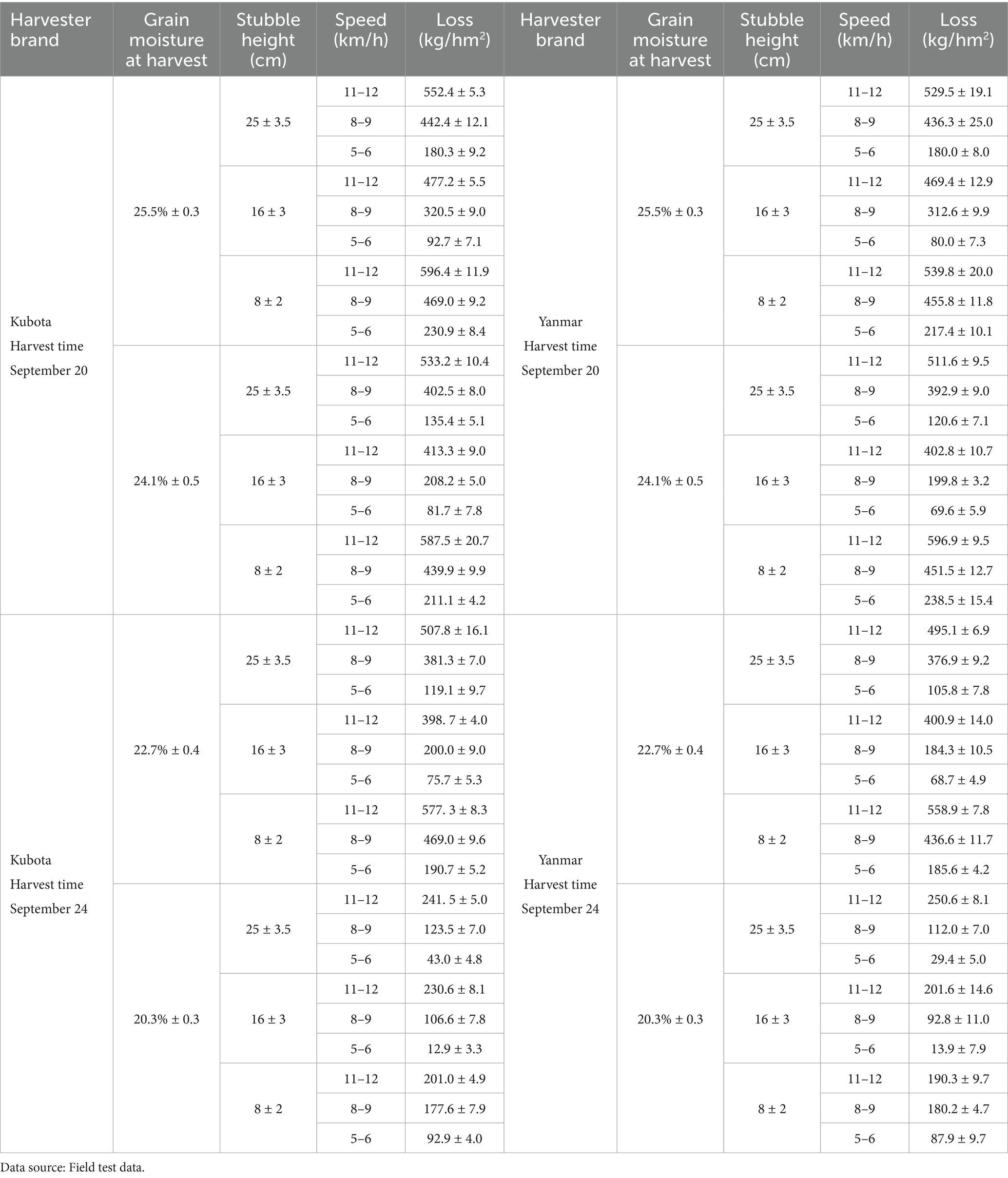

3.1 Effect of different grain moisture content on harvest

Due to the limitation of objective factors (meteorological conditions) and subjective factors (farmers’ will, etc.), the grain moisture content may be high when rice is harvested, which affects the harvesting efficiency of combine harvester. In this experiment, the rice was harvested on September 20th and September 24th respectively, and the rice varieties were all Longyang 16. As shown in Table 4, about 25.5% of the grain moisture content of different combine harvesters was a significant increase in the amount of loss, and the amount of loss of Kubota combine harvester was 180.3 kg/hm2 ~ 552.4 kg/hm2 on September 20th. Under the same conditions, the loss of the combined harvester was float between 230.9 kg/hm2 and 552.4 kg/hm2. When the stubble height rised from 8 cm to 25 cm. As we can see, the loss was the highest at high speed while stubble height was 8 cm. When the grain moisture content was about 20.3%, the loss of different combine harvesters decreased with drop in driving-speed. As you know, the loss of Kubota combine went down from 241.5 kg/hm2 to 12.9 kg/hm2 and the loss of the Yanmar combine decreased from 250.6 kg/hm2 to 13.9 kg/hm2 (Table 6). Furthermore, we can also observe the influence of stubble height on rice yield. When the humidity of rice and the traveling speed are constant, the loss of rice is the lowest when the stubble height is 16 cm.

There is a mutual influence relationship between the moisture content of rice grains, the stubble height and the loss of rice. This mainly involves aspects such as harvesting efficiency and grain loss. Keeping the stubble high reduces the proportion of stems entering the threshing device, thereby reducing the moisture transfer from the damp stems to the grains. However, it may cause some downcast ears to be missed during harvesting. A lower stubble height will allow more damp stems to be fed into the threshing machine. The moisture will be transferred to the grains through adhesion or friction of the broken stems and leaves, increasing the sorting burden of high-moisture rice and causing carry-over losses.

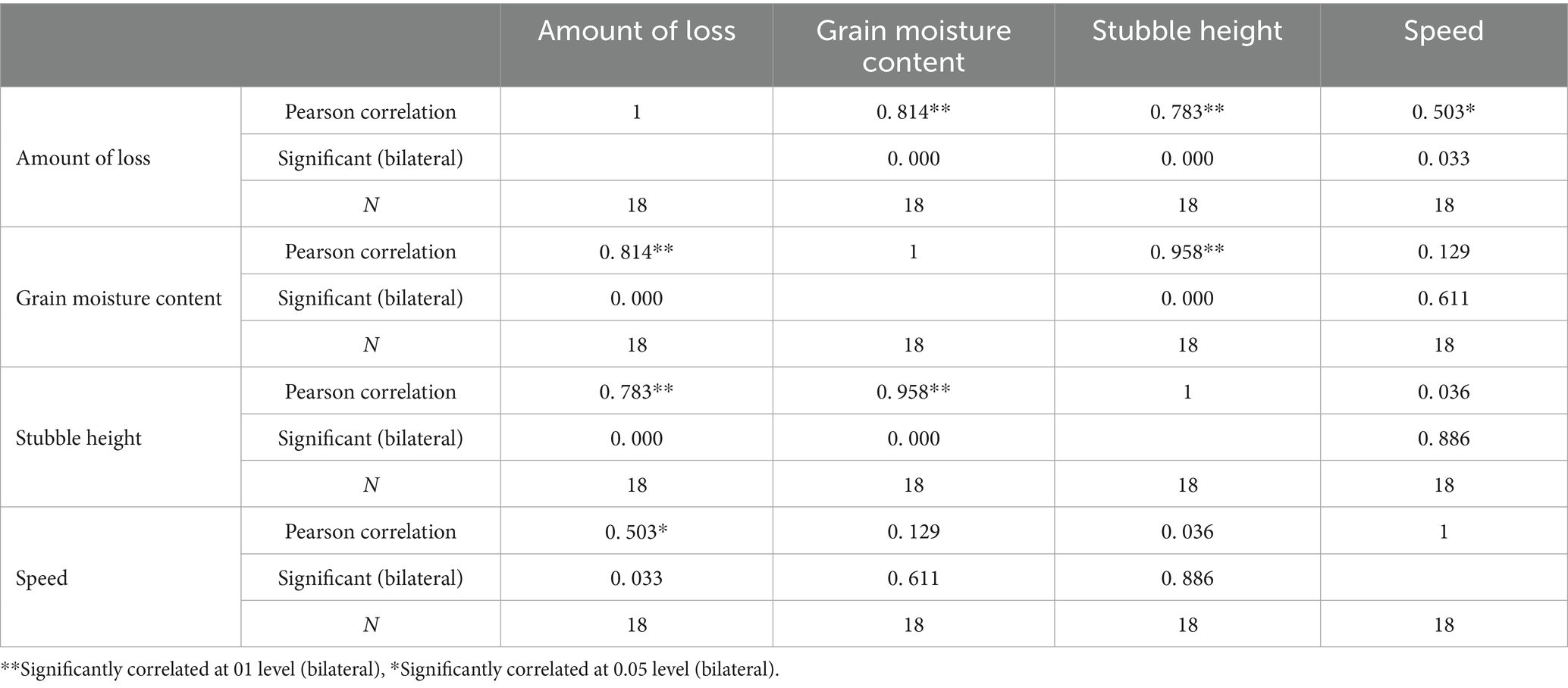

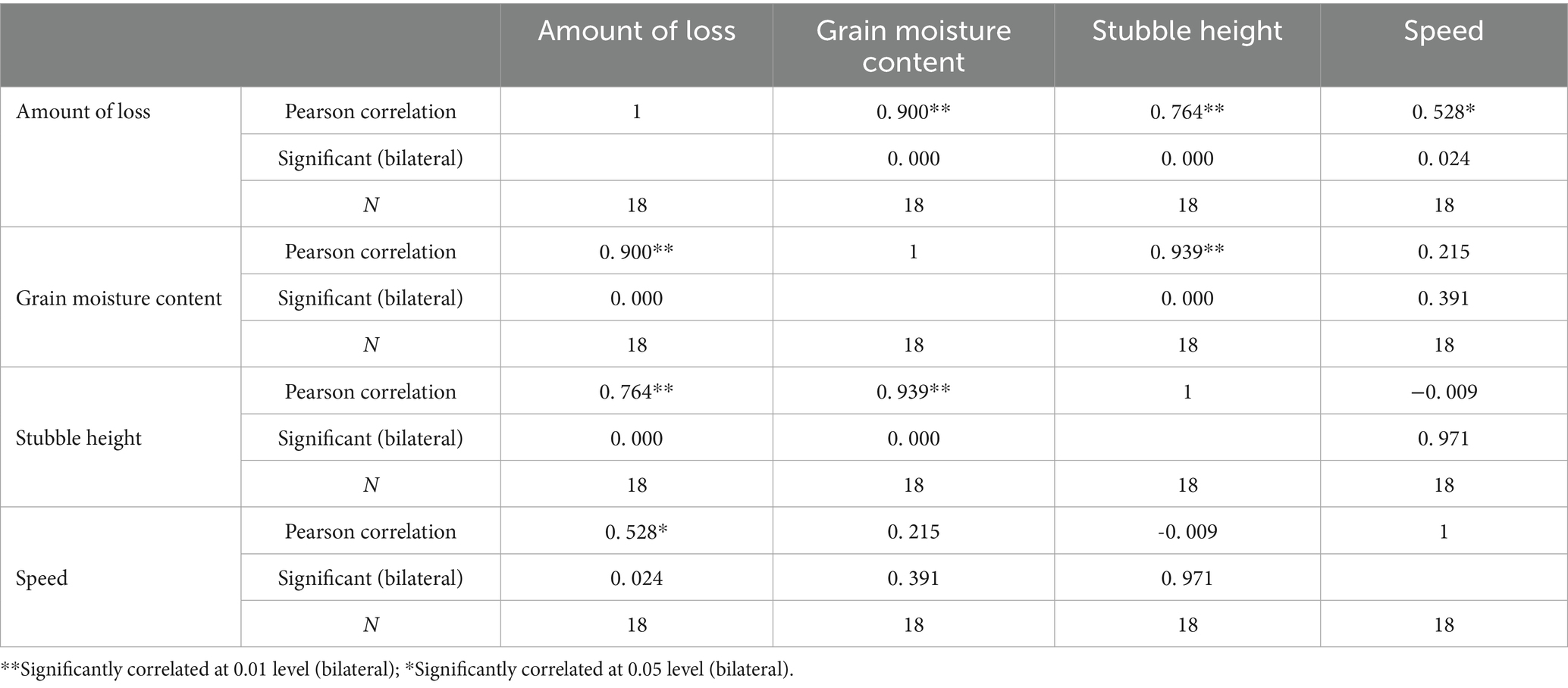

The correlation analysis between the factors of grain loss of the two kinds of combine harvesters is shown in Tables 7, 8. According to Table 6, the correlation between the amount of grain loss and grain water content of Kubota combine was the highest, the Pearson correlation coefficient was 0.814, followed by stubble height and driving speed, and the Pearson correlation coefficients were 0.783 and 0.503, respectively. It can be seen from Table 8 that the yield loss of Yanmar combine harvester was also the highest correlation with grain moisture content, the Pearson correlation coefficient was 0.900, followed by stubble height and driving speed, and its Pearson correlation coefficient was 0.764 and 0.528, respectively. The correlation analysis between the stubble height and the grain moisture content showed that the Pearson correlation coefficients of the two combine harvesters were the highest at 0.958 and 0.939, respectively, and this also indicates that when the moisture content of the grains is relatively high, appropriately increasing the stubble height can reduce the loss of grain drop.

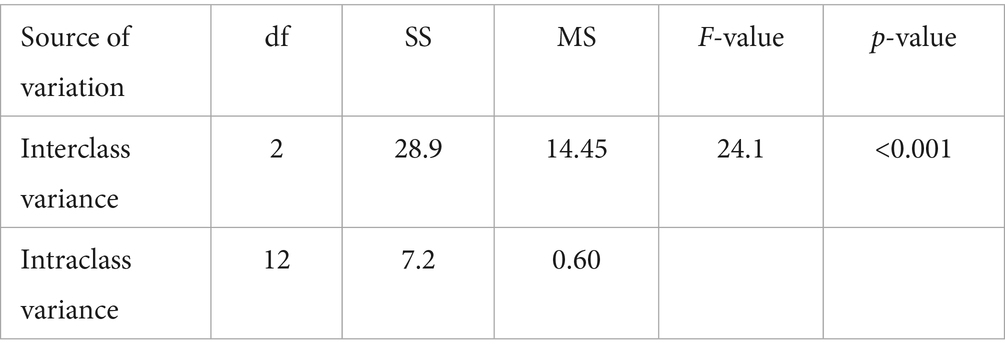

3.1.1 One-way analysis of variance for moisture content and Duncan’s test

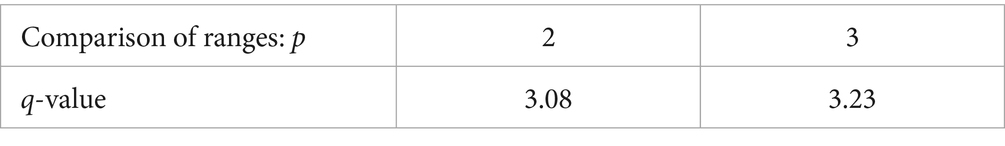

Chart 1. One-way analysis of variance-influence of water content in rice grains.

p < 0.001, Moisture content has a highly significant impact on the loss amount. Tukey test’s result: When the moisture content is between 26 and 18%, the loss rate increases by 4.3%, and when the moisture content is between 22 and 18%, the loss rate increases by 1.8%.

Calculate the standard error (SE) = 0.346.

Df = 12, α = 0.05, comparison of ranges and critical values are followed:

p = 2, LSR = 3.08 × 0.346 = 1.07.

p = 3, LSR = 3.23 × 0.346 = 1.12.

The test results show that there are significant differences in water content when comparing any two samples (p < 0.05).

3.1.2 One-way analysis of variance for driving speed and Duncan’s test

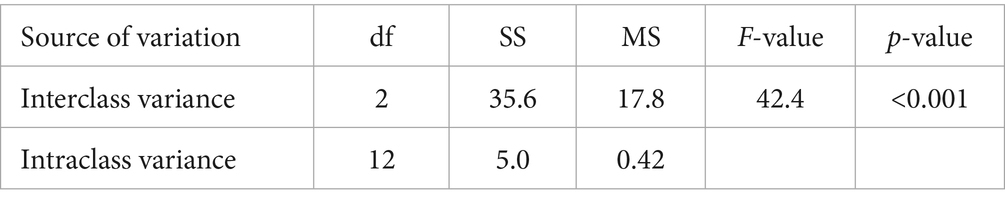

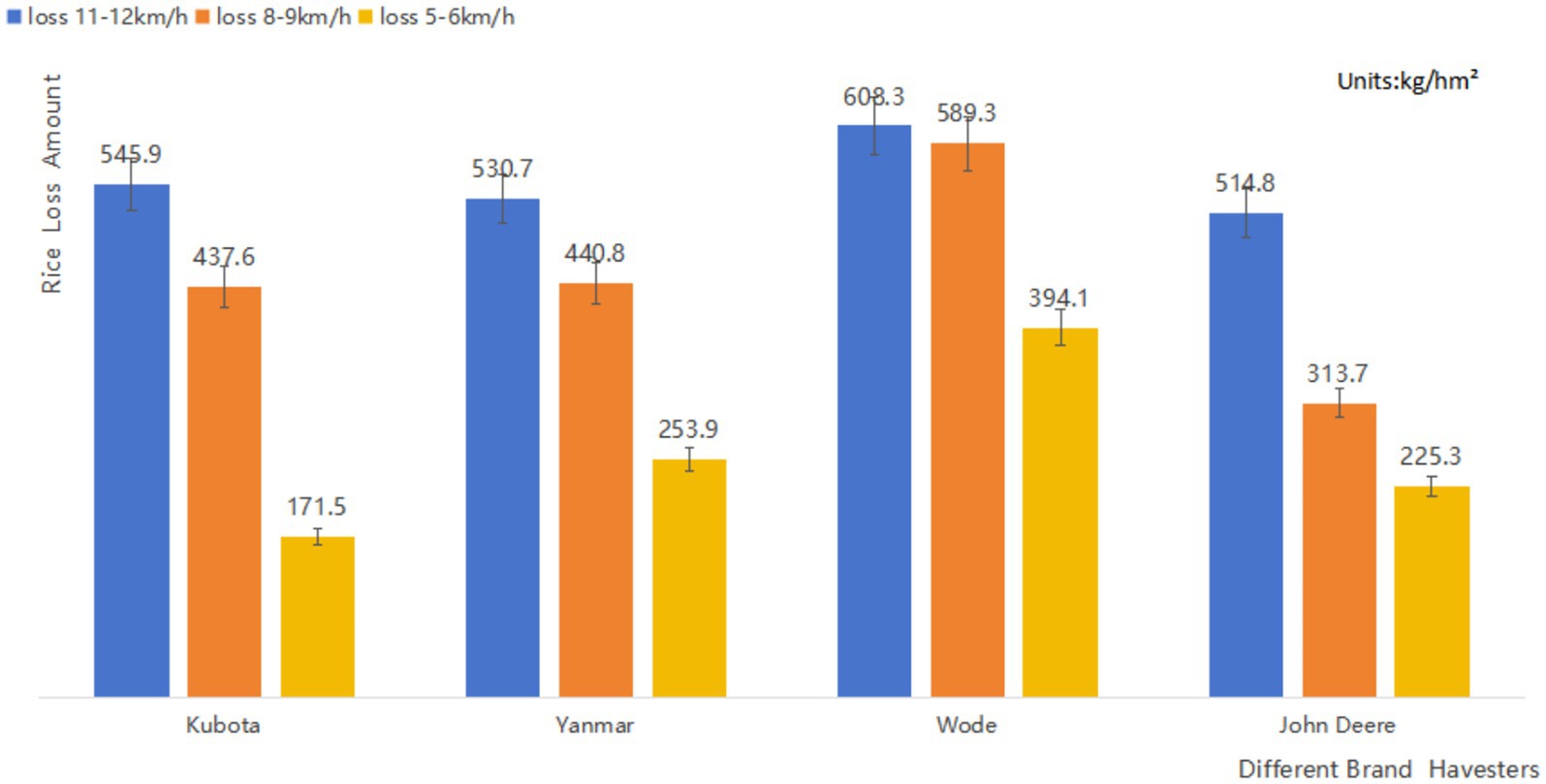

Chart 2. One-way analysis of variance-influence of driving speed in rice grains.

p < 0.001, driving speed has a highly significant impact on the loss amount.

SE = 0.29, p = 2, LSR = 3.08 × 0.29 = 0.89.

p = 3, LSR = 3.23 × 0.29 = 0.94.

The Duncan test results show that there are significant differences between all pairs of driving speeds (p < 0.05).

3.1.3 One-way analysis of variance for stubble height and Duncan’s test

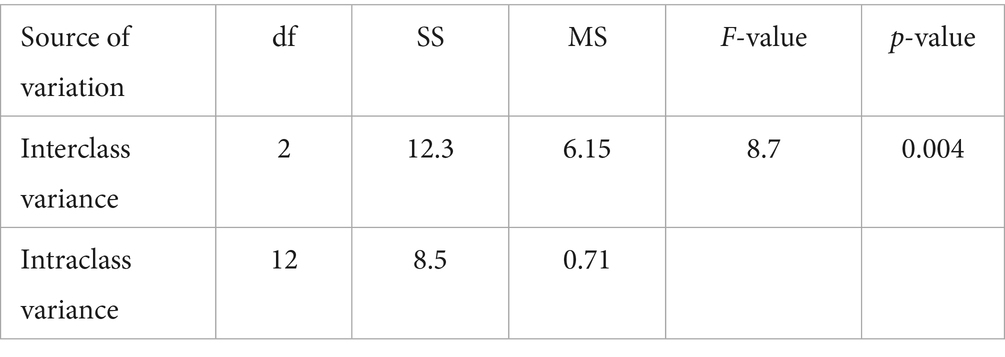

Chart 3. One-way analysis of variance-influence of stubble height in rice grains.

p = 0.004, driving speed has a significant impact on the loss amount.

SE = 0.24, p = 2, LSR = 3.08 × 0.24 = 0.74.

p = 3, LSR = 3.23 × 0.24 = 0.78.

The Duncan test results show that there are significant differences between all pairs of SE = 0.29, p = 2, LSR = 3.08 × 0.29 = 0.89.

p = 3, LSR = 3.23 × 0.29 = 0.94.

The Duncan test results show that there are significant differences between all pairs of driving speeds (p < 0.05).

3.2 Effect of different driving speeds on harvest

In the field, the loss of rice mainly includes the grain discharged from the outlet of the combine harvester and the loss of grain caused by the collision or natural drop of the cutting platform. The model of the combine harvester and different traveling speeds will both affect the proportion of grain drop loss. Figure 1 shows the loss of different combines at different speeds. It can be seen from the diagram that the four combines have the largest loss at fast speed, among which the loss of Wode combines was the highest at 608. 3 kg/hm2. All the four kinds of combine harvesters lost the least amount of damage when they were driving at a slow speed, and the lowest amount was 171.5 kg/hm2 for the Kubota harvester indicated that fast driving caused a large amount of loss. At the same time, the grain drop loss of the Wode combine harvester is 10–50% higher than that of other models under fast, normal and slow driving conditions. The John Deere combine harvester maintains a relatively good loss at the three driving speeds, which are 514.8 kg/hm2, 313.7 kg/hm2 and 225.3 kg/hm2, respectively. In addition, the significant analysis shows that there is no significant difference in the loss of the Kubota harvester and the Yanmar harvester in the constant speed driving, and the other are significant differences, indicating that the loss of the Kubota harvester and the Yanmar harvester is similar in the constant speed driving.

Figure 1. Loss of grain at different speeds for different combine harvesters. The moisture content of rice grain at sampling time is 25.8% and stubble height is 16 cm.

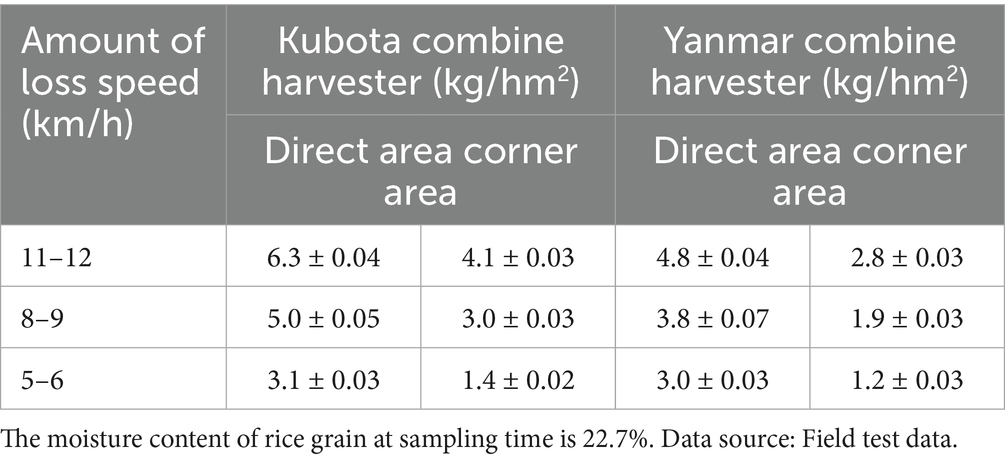

3.3 Effects of different harvest areas on harvest

In the process of harvesting, the combine harvester inevitably encountered the corner area, and the loss was also large in the turning area. The test data revealed comparative loss magnitudes between the two harvester types when they traveled at different speeds in the straight-through zone and the corner zone, as shown in Table 9. Data showed that the loss caused by Kubota harvesters was higher than that of Yanmar harvesters in both the straight-through area and the corner area.

And in the case of slow driving, the two kinds of combine harvesters in the corner of the harvest loss was less. In the case of rapid harvesting of the combine harvester, the loss amount of the Kubota combine harvesters was large in the corner area, and the loss amount was 6.3 kg/hm2, 2.2 kg/hm2 more than the direct-run area. When the Yanmar harvester was traveling at a moderate speed, the loss in the corner area was relatively small, with a loss of 3.8 kg/hm2, which was 1.9 kg/hm2 more than the direct area. When driving slowly, the loss of the two harvesters in two different regions was the lowest, of which the loss of the Kubota harvester was 3.1 kg/hm2 and 1.4 kg/hm2, respectively The loss of Yanmar combine harvester was 3.0 kg/hm2 and 1.7 kg/hm2, respectively.

3.4 Effect of different turnover on rice storage

The number of times the rice is turned during its storage period directly affects its weight and quality changes. Reasonable turning can prevent mold and pests, but excessive turning will lead to an increase in the rate of broken rice and the amount of fallen grains. Different flipping times caused changes in the amount of storage loss. The more times the rice was turned, the lower the mold rate was, but the number of dropped grains increased. When the stored rice is not turned over, the mold rate of the rice is relatively high, but the number of dropped grains decreases.

Taking into account the two indicators of mold rate and grain drop comprehensively, the proportion of storage loss of rice was the lowest, its average was 0.2%, the maximum value was 0.38%, and the minimum value was 0.12%. In the case of no turnover, the proportion of storage loss of rice was the largest, which was 0.36% more than that of five turnover. It can be seen that the number of turnover was also an important factor in determining the amount of storage loss.

3.5 Farmers’ questionnaire

A total of 110 questionnaires were collected. The questionnaire showed that the planting varieties in the survey area were more miscellaneous, including Longyang 16, Longyang 18, Suijing 18, Suijing 27 and so on, but the average yield was more consistent. There are losses in the post-harvest of rice, as follows:

Among the survey households, all were harvested using mechanical harvesting. The most used harvesters were the Kubota combine, accounting for 65 per cent, followed by the Yanmar harvesters, accounting for 15 per cent, and some farms and farmers used the John deere, Wode and Changfajialian combine, accounting for 20 per cent. The harvest time ranged from September 20th to October 15th, and the grain moisture content ranged from 18 to 26%.

From the perspective of the loss caused by the harvest time, the loss is relatively large when harvested too early, while the loss rate is slightly lower when harvested at the full maturity stage.

From the perspective of drying and storage, drying is a crucial step in the post-harvest processing of rice, and its effect directly affects the weight loss and quality changes during storage. 62% of the farmers directly transport the harvested rice to processing plants for sale without sun-drying it. Among the farmers who adopt sun-drying, 86% of them will dry the rice for 2 days. Generally, the moisture content of the rice can drop from 25 to 18%. During the drying process, the frequency of turning is relatively low. Usually, frequent turning causes grain loss of 18 to 30 kilograms per acre in the rice field. According to a survey, after the rice is dried, it is stored. 35% of farmers store the rice by themselves, and 65% of farmers transport the rice to rice processing plants for storage. When storing, if the moisture content of the rice is <15%, it can be stored directly. If the rice content exceeds 15%, the stored rice needs to be turned over or dried to prevent it from getting moldy.

4 Discussion

4.1 Effect of grain moisture on field harvest loss

A period of air humidity can help in reducing rice losses (Kishor et al., 2023). Field experiments showed that the grain moisture content directly affected the field harvest loss, and when the grain moisture content was about 21%, the field grain loss was the lowest. At the same time, the loss of the Yanmar combine harvester in the two kinds of combine harvesters involved in the experiment was lower than that in the Kubota combine harvester.

Previous studies have shown that the stage with the lowest post-harvest loss of rice was the best period to harvest, and the grain moisture content was lower at this time (Liu et al., 2011; Toro, 2005). This is also consistent with the results of this study. In addition, Wang’s (2004) research results showed that the optimal conditions for the harvest time merely included the loss of rice dry matte and did not calculate the loss caused by the mechanical operation of the rice harvester. Therefor his research conclusion had certain limitations. By comparing the mechanical harvesting losses of different combine harvesters, a correlation analysis was carried out in this experiment. The study shows that the correlation between the moisture content of rice and the loss amount is the greatest and most significant. According to the farmer survey data, the loss of rice during the rice harvesting process is approximately 3–5%, and this kind of loss is considered to be relatively large. The rice grains are closely combined with the stem. The threshing drum is unable to completely separate the grains, resulting in a large amount of residual grains. Moreover, the high-moisture grains have a soft texture and are prone to breakage or cracking when mechanically squeezed, which affects their storage and processing quality. Furthermore, this will also increase the risk of the rice ears getting tangled on the rollers or screens of the harvesting machine, causing the machine to get clogged. In fact, the results of the test data are much higher than the rough estimates of rice losses made by farmers. Comparing the experimental survey data, it can be seen that the loss estimated by farmers was low, the possible reason was that although farmers knew when the best time for harvesting was, they may not be able to find the harvester to start working at that point in time. Therefore, in the face of this objective situation, they did not pay attention to whether the harvesting time is the best time, nor did they care about the changes in the amount of loss.

4.2 Driving speed and driving area affect field harvest loss

Field experiments showed that the loss of rice in the corner area was large, and the loss of rice in the field could be reduced under the condition of slow driving. Field experiments showed that the speed of the combine harvester used in rice harvest directly affected the loss of harvest in the field, and when the driving speed was 5–6 km/h, the loss of grain in the field was the lowest. When the speed of the combine harvester was too fast, the speed of the harvester is out of balance with the feed volume. The greater the mechanical impact force on the grains, the higher the breakage rate of the rice, resulting in an increase in the loss rate. In addition, when the thresher of the harvester pushed down the rice plants too quickly, the proportion of uncut stems increased, and the rate of missed cutting also became higher. And when operating at high speed, the feeding volume of the harvester increases sharply, and the processing capacity of the threshing drum is overloaded. Some grains are discharged when being fully threshed, resulting in an increase in the number of residual grains on the ears. The loss rate that cannot be completely removed may rise from 2% to over 5%. Meanwhile, at high speeds, the rotational speed of the threshing drum does not match the forward speed of the machine. This can easily result in the rice plants being pushed over before being cut (especially for the fallen rice plants), or the cut plants not being promptly sent into the conveying device, causing grain spillage, thereby increasing the loss of the threshing platform. According to the survey data of farmers, the speed of driving affects the quantity of harvest, but the specific quantity is not clear. In this survey, this experiment enabled farmers to better understand the impact of different harvesting speeds on the loss of rice, allowing farmers to not only focus on the harvesting efficiency but also pay more attention to the loss of rice in the field during the harvest process.

4.3 Storage mode affects rice after-production loss

The loss amount during the storage of rice should comprehensively consider the changes in the number of turns, the moisture content of rice and the amount of grains dropped. When rice will be stored, if the moisture content is relatively high, it is necessary to increase the number of turns to prevent mold and the increase of loss. The surface of the stored rice grains will develop various kinds of mold. Molds are filamentous fungi. Under suitable conditions, the growth of molds will release a large amount of metabolic heat, causing the rice to heat up, thereby disrupting the normal temperature change pattern of the rice itself. If not dealt with in time, mold contamination will accelerate its spread, and microorganisms will multiply rapidly, producing toxins that can cause illness in humans and animals, resulting in huge economic losses. Since most of the farmers’ rice is in poor conditions, to prevent mold, they will turn over the rice to break the accumulation of local temperature and humidity, inhibit the growth of molds and pests, and avoid clumping or mold formation. Moreover, turning over the rice will promote the balance of moisture inside the rice, preventing the surface rice from being too dry (fragile) and the bottom rice from being too wet (moldy).

5 Conclusion

This study takes the combine harvester, which has the highest usage proportion in the main rice-producing areas of Heilongjiang Province, as an example. It analyzes the effects of these factors on the post-harvest yield loss of rice from the perspectives of the traveling speed of the harvester, the moisture content of rice, and the stubble height, and conducts relevant experiments.

Apart from the aforementioned factors that will significantly affect the post-harvest loss level of rice, human factors will also have relevant impacts on it. For instance: Some agricultural machinery operators have not received professional training and lack the operational skills to handle complex situations. They operate blindly, resulting in significant losses during mechanical harvesting. In the production process, some agricultural machinery operators lack the “loss reduction” awareness. Regardless of whether the rice harvest is abundant or insufficient, they always step on the accelerator all the way down and do not pay attention to the machinery harvesting losses. Some operators, in order to increase their income, exceed the normal operating speed range of the machinery during the harvesting process, resulting in a mismatch between the operation speed and the feed-in volume, and the loss rate also increases accordingly. Moreover, research on reducing post-production losses of rice from the perspectives of consumers and farmers has not yet been covered. This will be the key content of future research.

According to the experiments, in order to reduce post-harvest losses of rice, it is recommended that the harvest time be 10–15 days after the physical maturity of the rice. With moisture content as the core indicator, the rice with a moisture content of 20–22% should be harvested first. For example, in the Songnen Plain and Sanjiang Plain of Heilongjiang Province, the rice harvest days may be selected between September 20th and 30th, and the stubble height will be between 14 and 18 centimeters. The speed of the harvester should be adjusted according to the soil moisture, straight passage area and turning area. It can be observed that different speeds have some direct impact on costs. When the harvester travels at a high speed, fuel consumption increases by 10–15%, and the daily fuel consumption increases by 8–12 liters (60–90 yuan per day). Meanwhile, for every liter of diesel burned, a diesel engine emits approximately 2.68 kg of CO₂. If the daily fuel consumption increases by 10 liters (during high-speed operations), a single machine will emit an additional 536 kg of CO2 during the harvest season (20 days). Simultaneously, emissions of nitrogen oxides (NOx) and particulate matter (PM) also rise, exacerbating the formation of smog. When driving at a low speed, the operation time per unit area is prolonged, and the total fuel consumption may remain the same. For every 1 km/h increase in speed, the daily average operation area expands by 15–20%. For instance, if the speed goes from 3 km/h to 4 km/h, the daily harvest increases by 3.5–5 acres. If the charge per acre of harvested grain is 360 yuan, the daily income will increase by 1,200–1,800 yuan.

In a word, as the most widely grown rice in the world (Kamla et al., 2023), there is a long way to go to solve the problem of loss of rice, which is related to China’s food security and requires the attention and concerted efforts of the country, society and individuals in order to promote the better development of China’s grain industry.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Ethics statement

Ethical review and approval was not required for the study on human participants in accordance with the local legislation and institutional requirements. Written informed consent from the patients/participants or patients/participants' legal guardian/next of kin was not required to participate in this study in accordance with the national legislation and the institutional requirements.

Author contributions

HS: Writing – review & editing, Formal analysis, Writing – original draft, Methodology. YG: Validation, Writing – review & editing, Data curation, Formal analysis. YZ: Formal analysis, Writing – review & editing, Data curation, Validation. HZ: Visualization, Software, Writing – review & editing. XG: Software, Visualization, Writing – review & editing. JW: Resources, Data curation, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work is funded by Science and technology innovation project of gain high yield (2018YFD0300107-6); Doctoral fellowship program in Harbin Normal University (2021-KYYWF-0208); Open project of Heilongjiang Province Highend Think Tank-Modern Agricultural Development Research Center (ZKKF20220.050).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Appiah, F., Guisse, R., and Dartey, P. K. (2020). Postharvest losses of rice from harvesting to milling in Ghana. Journal of Stored Products and Postharvest Research, 2, 64–71.

Basavaraia, H., Mahajanashetti, S. B., and Udagatti, N. C. (2007). Economic analysis of post-harvest losses in food grains in India: A case study of Karnataka [J]. Agricultural Economics Research Review. 20, 117–126. doi: 10.115192/PS CP.S.A. 2007.1.2.5860

Bala, B. K. (2011). Postharvest loss and technical efficiency of rice,wheat and maize production system: assessment and measures for strengthening food security. Available at: http://fpmu.gov.bd/agridrupal/sites/default/files/CF-6_of_08_B_K_Bala.pdf,2011-10-19

Bradford, K. J., Dahal, P., Van Asbrouck, J., Kunusoth, K., Bello, P., Thompson, J., et al. (2018). The dry chain: reducing postharvest losses and improving food safety in humid climates. Trends Food Sci. Technol. 71, 84–93. doi: 10.1016/j.tifs.2017.11.002

Gao, L. W. (2016). Study on post-harvest loss characteristics and impairment potential of major grain crops in China. Trans. Chin. Soc. Agric. Eng. 32, 5–11. doi: 10.11975/j.issn.1002-6819.2016.23.001

Han, J. (2010). Study on the strategy of food production capacity and balance of supply and demand in China. Beijing: Capital University of Economics and Trade Press, 367.

Kamla, M., Vijaya, R., Nisha, A., Ajay, S., Shweta, M., Punesh, S., et al. (2023). Evaluation of non-structural carbohydrates of rice straw cultivars in agro-climatic zones of Haryana. Environ. Eng. Manag. J. 22, 1453–1459. doi: 10.3390/ijms23094864

Kishor, P. G., Sunil, K. R., Bhaskar, W. B., Ankita, V., and Nrusingh, C. P. (2023). Probably analysis of critical dry spells of Marathwada region of Maharashtra state for planning climate resilient cropping patterns. Environ. Eng. Manag. J. 22, 549–557. doi: 10.1016/j.engfailanal.2023.05012

Liu, D. J., Zhao, X. R., Gao, L. X., and Sφrensen, C. G. (2011). Effect of water content on logistics loss of rape harvest. J. Agric. Eng. 27, 339–342. doi: 10.19336/j.cnki.trtb.2011.03.038

Ministry of Agriculture, (2014). Ministry of agriculture circular on strengthening damage reduction in food processing. Available at: http://www.moa.gov.cn/zwllm/tzgg/tz/201407/t20140710_3964759.htm

National Development and Reform Commission, State Food Bureau, (2011). 12th five-year plan for special construction of scientific grain storage for farmers. Available at: http://www.chinagrain.gov.cn/n316640/n316903/c492333/content.Html (Accessed July 8, 2014).

Qumail, A., Hamza, F. G., Shakil, A., Zakir, H. D., Muhammad, S., Ubaid, U., et al. (2023). Conserving water: cost and productivity analysis of responsive drip and conventional irrigation. Environ. Eng. Manag. J. 22, 639–649. doi: 10.1016/j.agwat.2023.03.010

Tang, R. L. (2019). Study on the influencing factors of grain quality. Food Sci. Technol. Econ. 44, 108–109,129.

Toro, A. D. (2005). Influences on timeliness costs and their variability on arable farms. Biosyst. Eng. 92, 1–13. doi: 10.1016/j.biosystemseng.2005.06.007

Wang, J. W. (2004). Study on timely loss of rice harvest in Sanjiang plain. J. Agric. Mach. 35, 175–177.

Wang, P. Q. (2021). Overview of post-partum loss of grain in China. Modern Food 2021, 1–4. doi: 10.16736/j.cnki.cn41-1434/ts.2021.06.001

Wang, G. M., Yi, Z. Y., Chen, C., and Cao, G. Q. (2016). Effect of harvest period on loss composition of rice and wheat rotation. J. Agric. Eng. 32, 36–42.

Wei, M. R. (1995). To develop scientific and technological grain storage in rural areas. Grain Econ. Guangxi 1995, 32–33.

Zhao, X. (2022). Evaluation and analysis of post-production loss of grain in China. Arid Land Resour. Environ. 36, 3–7. doi: 10.13448/j.cnki.jalre.2022.140

Keywords: rice, post-harvest loss, harvest speed, grain moisture content, stubble height

Citation: Sun H, Gu Y, Zhang Y, Zhang H, Guan X and Wang J (2025) Loss of rice after ripening by mechanical harvest in Heilongjiang Province. Front. Sustain. Food Syst. 9:1652765. doi: 10.3389/fsufs.2025.1652765

Edited by:

Bradley George Ridoutt, Commonwealth Scientific and Industrial Research Organisation (CSIRO), AustraliaCopyright © 2025 Sun, Gu, Zhang, Zhang, Guan and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hongyan Sun, NDIyMDIxMTlAcXEuY29t

Hongyan Sun

Hongyan Sun Yingnan Gu2

Yingnan Gu2