- 1Department of Integrative Agriculture, College of Agriculture and Veterinary Medicine, United Arab Emirates University, Al Ain, United Arab Emirates

- 2ASPIRE Research Institute for Food Security in the Drylands (ARIFSID), United Arab Emirates University, Al Ain, United Arab Emirates

- 3Department of Food Science, College of Agriculture and Veterinary Medicine, United Arab Emirates University, Al Ain, United Arab Emirates

Aquaponic systems are integrated food production systems that recycle nutrients through the combination of aquaculture and hydroponics. Nutrient recovery in aquaponic systems faces major challenges such as imbalances in nutrients, inefficiencies in nutrient extraction, and scalability constraints. Various methods have been investigated to address these challenges, including physical approaches (e.g., filtration and sedimentation), chemical strategies (e.g., struvite precipitation), and biological techniques (e.g., microbial digestion and nutrient mineralization). Additionally, hybrid strategies that are a combination of these methods are also reviewed for their potential to improve nutrient recovery and system performance in aquaponic systems. Emerging technologies such as hybrid biofilters and phototrophic bioconversion show promise in addressing these challenges, though they require further research for full-scale implementation. This review comprehensively examines the sources and composition of aquaponic sludge, the role of macro- and micronutrients, and critically analyses various physical, chemical, and biological nutrient recovery strategies. It also highlights innovative approaches and their integration potential. By synthesizing the strengths and limitations of these methods, this review provides a roadmap for optimizing nutrient recovery to advance low-waste, circular aquaponic models.

1 Introduction

The increase in global food demand due to population growth, urbanization and climate change has intensified the need for sustainable food production systems. There is a growing pressure on the sustainability of agricultural systems due to these factors (FAO et al., 2024). If the current trends persist, it may lead to increased food crises in the future. In 2024, more than 295 million people in 53 countries faced acute hunger, a 14% increase from 2023, with record-high numbers experiencing catastrophic levels of hunger (FSIN and GNAFC, 2025). If these trends persist, food crises are likely to worsen, particularly in vulnerable arid and semi-arid regions. In 2023, approximately 66.1 million people in the Arab region (≈approximately 14% of the population) experienced hunger, while nearly 186.5 million suffered from moderate or severe food insecurity (FAO et al., 2024). Countries in the Middle East and North Africa, already facing extreme water stress, are expected to experience further declines in agricultural yields due to prolonged droughts, land degradation, and limited freshwater availability (Murphy et al., 2024). These challenges highlight the urgent need for water-efficient, climate-resilient farming systems, such as aquaponics. Aquaponics, which integrates fish rearing with plant cultivation, is now being studied and supported by scientists as a sustainable way to reuse water and nutrients in food production (Ibáñez Otazua et al., 2022; Nair et al., 2025).

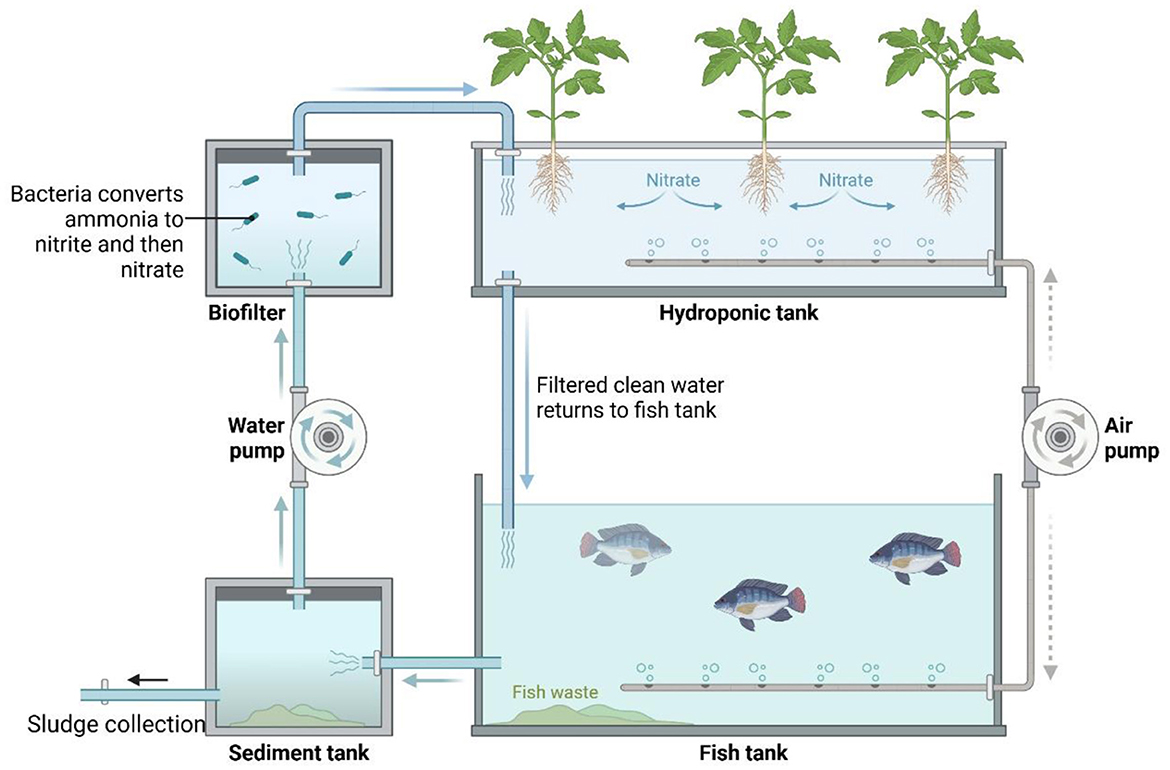

Aquaponics can be defined as the co-cultivation of fish (aquaculture) and plants (hydroponics) where the nutrient-rich effluent water from aquaculture is used as biofertilizer for the hydroponically cultivated plants (Farrant et al., 2021; David et al., 2022). In a typical aquaponic system (Figure 1), the fish waste effluents from aquaculture undergo biodegradation by microbial communities, converting them into essential nutrients for plant growth. Water leaving the hydroponic system is recycled back into the aquaculture tanks, maximizing nutrient and water reuse in a closed-loop system (Colt et al., 2024). Coupled aquaponics (CAP) integrates recirculating aquaculture systems (RAS) with hydroponic cropping systems (HCS) and shared water treatment units, further improving efficiency and scalability (Tetreault et al., 2023a). In contrast, decoupled aquaponics (DAP) features a multi-loop system wherein the aquaculture and hydroponic units operate as independent systems (Aslanidou et al., 2024). A standard aquaponic system consists of three main components: (1) the aquaculture tank (fish rearing), (2) the biofilter, where microbes convert fish waste into plant-usable nutrients, and (3) the hydroponic system (grow bed) for plant cultivation. The integration of these components helps to minimize the need for chemical fertilizers, reduces water contamination, and provides an organic, efficient method of production of both fish and plants (Memon et al., 2022; Tetreault et al., 2023a). This symbiotic relationship not only conserves water but is also a sustainable food production system (Verma et al., 2023). These systems are thus particularly suitable in regions facing water scarcity (Nishanth et al., 2024). The scalability of aquaponic systems ranges from small-scale units such as those in households to large commercial establishments. This makes it especially useful in cities or locations that have very little land for cultivation. Aquaponic systems can produce a diverse range of fish and crops in small areas (Proksch and Baganz, 2020). It also has the benefit of producing food close to the direct consumers. There has been an upsurge in global food demand due to increased population density, movement into urban areas and degradation of the environment. Aquaponics seeks to address this increase in food demand in the context of Sustainable Development Goal 2 (Zero Hunger). Aquaponics is a sustainable alternative to conventional agriculture as it helps in achieving a balance between water and nutrient usage (Ibrahim et al., 2023). Recent analyses of global aquaponic systems highlight emerging trends in system design, scalability, and operational strategies, with particular emphasis on the role of microbial communities in nutrient transformation and plant growth (Kushwaha et al., 2025). These insights demonstrate that optimizing microbial activity is critical for improving nutrient recovery efficiency in both small- and large-scale systems.

Despite these advantages, one major drawback of existing aquaponic systems is related to waste and nutrient management. While soluble fish waste is mineralized by microbial communities and made available to plants (Eck et al., 2019), solid aquaculture sludge that is composed of fish excrement and leftover feed is often removed and discarded (Yep and Zheng, 2019; Xia et al., 2022). This sludge is a valuable source of nutrients for plant growth (Xia et al., 2022). A study by Rafiee and Saad (2005) found that fish sludge contains significant amounts of nutrients from accumulated aqua feed. It consists of 24% of iron (Fe), 86% of manganese (Mn), 47% of zinc (Zn), 22% of copper (Cu), 16% of calcium (Ca), 89% of magnesium (Mg), 6% of nitrogen (N), 6% of potassium (K), and 18% of the phosphorus (P) from the fish feed, indicating its potential as a nutrient source if properly processed and utilized. Another study revealed that fish sludge contains 40% of nutrients from fish feed, which can be recycled further to support plant growth, indicating potential for recovering the nutrients from fish waste and its utilization as a nutrient-rich source for plant growth (Yogev et al., 2016). Recovering nutrients from sludge could offer significant environmental and economic benefits by eliminating solid waste and enhancing nutrient supply to the hydroponic plants (Zhang et al., 2021). Nutrient recovery in aquaponics relies on microbial processes that transform fish waste into plant-available forms. Total Ammonia Nitrogen (TAN) is the major component in fish waste and is excreted through fish gills and found in solid waste. TAN, excreted through fish gills and present in solid waste, is converted into nitrates via nitrification. Earlier, this was understood to be a two-step process involving the bacteria Nitrosomonas and Nitrobacter/Nitrospira (Heise et al., 2021). This long-term understanding of the nitrification process was revised with the discovery of comammox Nitrospira, capable of complete ammonia oxidation and enhanced nitrogen cycling efficiency in RAS (Daims et al., 2015; Van Kessel et al., 2015; Heise et al., 2021). TAN concentration in aquaponic systems is generally lower than in conventional aquaculture, ranging from 0.350 to 5.946 milligrams per liter (mg/L) compared to 0.350–9.353 mg/L (Deviona et al., 2020). However, Febriani et al. (2018) report that TAN levels can still exceed the recommended thresholds, reaching 3.231–8.989 mg/L making system management and monitoring very crucial. TAN is harmful to both fish and plants beyond the threshold levels. Imbalances in nitrification, coupled with sludge accumulation and low dissolved oxygen can inhibit microbial activity (Banu et al., 2023). This leads to elevated TAN levels that are harmful to both fish and plants and reduce the overall efficiency of nutrient transformation and recovery for plant use (Banu et al., 2023). Microbial biofilters, aerobic/anaerobic mineralization, and phototrophic bioconversion are among the strategies used to optimize nutrient recovery (Krueger et al., 2021; Amin et al., 2023). Advanced biological systems, such as Down-flow Hanging Sponge—Upflow Sludge Blanket (DHS-USB) bioreactors, have been demonstrated to efficiently remove nitrogenous wastes in closed freshwater recirculating aquaculture systems, further improving water quality and nutrient recovery (Watari et al., 2021; Obondo et al., 2025). These microbial processes are critical in soil-less systems, enabling plants to utilize recovered nutrients for root development, photosynthesis, and overall growth (Eck et al., 2019; Gabr et al., 2024).

The significance of nutrient recovery in aquaponics extends to both environmental and economic dimensions. Efficient nutrient recycling prevents nitrogen and phosphorus runoff, reducing eutrophication, dead zones, and groundwater contamination observed in conventional agriculture (Shukla and Saxena, 2019; Craswell, 2021). By converting fish waste into plant-available nutrients, aquaponics systems maintain consistent plant growth, enhance crop yields, and reduce the need for external fertilizers, making production more cost-effective (Memon et al., 2022; Zhang et al., 2021). Aquaponics offer additional advantages such as low pollutant discharge, reduced input costs, and improved resource efficiency, particularly in water-scarce or resource-constrained regions. However, optimizing nutrient availability requires careful management of water quality, microbial activity, feed composition, and sludge accumulation, as high ammonia levels or inefficient nutrient transformations can negatively affect both fish and plant health (Banu et al., 2023). The integration of microbial nutrient recovery with fish and plant production positions aquaponics as a promising technology for sustainable urban and small-scale agriculture.

Recent reviews of aquaponic systems have highlighted ongoing challenges in nutrient recovery, system scalability, and operational efficiency (Lopchan Lama et al., 2025). However, few studies have comprehensively compared physical, chemical, biological, hybrid, and emerging nutrient recovery strategies while evaluating their integration potential, scalability, and efficiency. This review addresses these gaps by critically examining nutrient recovery approaches in aquaponics, with a focus on enhancing sustainability, nutrient use efficiency, and overall system performance. Key challenges considered include nutrient imbalances, inadequate uptake by plants and fish, design limitations, and management of organic waste and nutrient-rich effluents. By comparing the strengths, limitations, costs, and scalability of each method, this review provides insights to optimize nutrient transformation pathways, improve recovery efficiency, and guide future innovations for sustainable and commercially scalable aquaponic systems.

2 Problems and challenges in nutrient recovery

2.1 Nutrient composition and imbalances

The difference in the amount of fish waste generated and the nutrient requirements of the plants leads to nutrient imbalances in aquaponic systems. Aquaponic sludge contains almost all the essential macronutrients and micronutrients. Goddek et al. (2019b) observed that from the total nutrient input via fish feed, 6% nitrogen, 18% phosphorus, 16% calcium, and 89% magnesium accumulated in the solid sludge fraction. On dry matter basis, 24% iron, 86% manganese, 47% zinc, and 22% copper were retained in the sludge showing that a good proportion of micronutrients and some number of macronutrients remain in the solid waste. Sludge contains more phosphorus as about 30–65% of phosphorus input accumulates and is removed via filtration (Delaide et al., 2017). Fu et al. (2018) observed that the aquaculture residue contains 17%, 3%, and 62% of protein, fat and carbohydrates (based on dry matter), respectively, suggesting that fish residue can be utilized for microbial conversion and nutrient recovery. Fish convert only a portion of the nitrogen and phosphorus in their feed into biomass, with a significant fraction remaining unassimilated and released into the water as waste, reflecting the inefficiency of nutrient utilization (Yang and Kim, 2020; Dalbem Barbosa et al., 2024). For example, studies report that fish may assimilate approximately 25–45% of nitrogen and 40–60% of phosphorus from feed, indicating that a substantial proportion of these nutrients enters the aquatic system and underscores the need for effective nutrient recovery strategies.

Research indicates that nutrient levels in aquaponics are considerably lower than those found in conventional hydroponic solutions, particularly concerning potassium, calcium, and iron (Bittsanszky et al., 2016; Pineda-Pineda et al., 2017). Studies show that while certain nutrients, such as phosphate, sulfate, sodium, and magnesium, tend to accumulate, others, like potassium and nitrate, often remain at suboptimal levels (Maneepong, 2019). The primary source of nutrients in aquaponic systems is fish feed, leading to complexities in the availability and balance of essential nutrients (Eck et al., 2019). Factors like fish feeding rate, hydraulic loading rate and pH affect the aquaponic solution, implying that system-level adjustments are necessary for consistent nutrient availability (Chu et al., 2022).

The solution pH in aquaponics is a compromise between the pH required by microbes and plants (da Silva Cerozi and Fitzsimmons, 2016). The microbial conversion of ammonia into nitrites and then nitrates takes place at a pH of 8.5, while plants require a pH of around 6.0 for optimum nutrient uptake. In most aquaponic systems, a pH near 7.0 is maintained to balance all three organisms (Wortman, 2015; Wongkiew et al., 2017). Maintaining optimal pH is crucial for the health of fish, plants, and nitrifying bacteria, with an ideal range of 6.4–7.4 (Mori et al., 2021). The pH fluctuations in aquaponic systems are influenced by factors such as fish waste, temperature, nitrification process, and microbial activity (Defa et al., 2019). The availability of phosphorus for plants depends on the pH, with most P becoming unavailable at a pH above 7.0 as it gets converted to insoluble complexes (Asao, 2012). Also, 30–65% of the P remains in solid fish sludge, which is unavailable to plants (Wang et al., 2023).

Leafy greens generally perform well with minimal supplementation, while fruiting vegetables such as tomatoes, peppers, cucumbers, and zucchini often exhibit deficiencies in potassium, calcium, and iron. Foliar application can alleviate deficiencies, improving crop quality and preventing disorders like blossom end rot and tip burn (Roosta and Hamidpour, 2013; Bittsanszky et al., 2016; Pineda-Pineda et al., 2017). Species-specific nutrient requirements necessitate tailored management strategies (Zhang et al., 2021; Goddek and Keesman, 2020). Iron deficiency is common due to low iron in commercial fish feeds (Kasozi et al., 2019).

CAP typically exhibits greater nutrient use efficiency but can result in nutrient deficiencies, especially in fruiting vegetables that require higher nutrient levels (Aslanidou et al., 2024; Tetreault et al., 2023a; Monsees et al., 2017). In contrast, DAP allows for enhanced control over nutrient concentrations, aligning more closely with hydroponic methods but requires partial effluent discharge to maintain water quality (Zhu et al., 2024; Aslanidou et al., 2024).

2.2 Nutrient loss pathways and water quality constraints

In aquaponics, several nutrient loss pathways exist and these limit the availability of essential elements to plants. A significant proportion of nutrients, particularly phosphorus and potassium, is lost via solid sludge, as filtration systems are often unable to capture fine particulate matter containing these elements (Goddek et al., 2019b; Cohen et al., 2018; Khiari et al., 2019; Monsees et al., 2019). In DAP systems, partial discharge of fish effluent (about 10–40%) to maintain water quality further removes dissolved nutrients, reducing their availability for plant uptake (Zhu et al., 2024).

Not all nutrients in fish feed are assimilated by the fish; approximately 45–75% of nitrogen and phosphorus can be excreted into the water or retained in solid waste (Yang and Kim, 2020; Dalbem Barbosa et al., 2024). Fish excrete ammonia, which must be converted to nitrate by microbial activity before it is available to plants. Losses can occur if this conversion is incomplete or inefficient (Wortman, 2015; Wongkiew et al., 2017). Microorganisms play a key role in mineralizing organic nutrients from fish waste and uneaten feed, releasing essential macronutrients and micronutrients into the water for plant uptake (Eck et al., 2019; da Silva Cerozi and Fitzsimmons, 2016). Insufficient microbial activity can temporarily immobilize nutrients in microbial biomass, further limiting availability.

Nutrient losses also occur through volatilization of nitrogen as ammonia, particularly at high pH levels (>7.5), and through adsorption or precipitation of elements such as phosphorus, calcium, magnesium, and trace metals onto tank surfaces, pipes, or media substrates (Wortman, 2015; Wongkiew et al., 2017; Asao, 2012; Wang et al., 2023). Plant uptake represents another pathway, with nutrients accumulating in leaves, stems, or fruits, potentially creating localized depletion if not continuously replenished (Bittsanszky et al., 2016; Maneepong, 2019). Evaporation and plant transpiration can concentrate salts and certain nutrients in solution, indirectly affecting nutrient balance and availability (Tetreault et al., 2023a).

Water quality constraints further influence nutrient availability. Fluctuations in pH, temperature, and dissolved oxygen levels can inhibit microbial nitrification, nutrient solubility, and plant uptake efficiency (Defa et al., 2019; da Silva Cerozi and Fitzsimmons, 2016). High pH can reduce the solubility of phosphorus, iron, and other micronutrients, while low dissolved oxygen can create anaerobic zones that limit nutrient transformation (Wortman, 2015; Wongkiew et al., 2017). Accumulation of metabolites such as ammonia, nitrites, or sulfides due to poor water circulation or inadequate filtration can further stress fish and reduce the overall nutrient availability to plants (Goddek et al., 2019b; Eck et al., 2019).

Finally, routine system discharge, flushing, or cleaning operations remove nutrients from the system, further reducing the efficiency of nutrient recycling (Zhu et al., 2024). Collectively, these nutrient loss pathways and water quality constraints highlight the inefficiencies of aquaponic systems in fully recycling fish-derived nutrients and underscore the need for improved recovery and management strategies.

2.3 System design and operational limitations

Aquaponic system design is a critical factor influencing nutrient recovery and overall operational efficiency. However, several design-related limitations hinder optimal nutrient retention and reuse. One major challenge is the inefficiency of filtration systems. Many aquaponic setups rely on solid filtration methods—such as drum filters or mesh filters—that are not capable of capturing fine particulate matter. These finer solids often contain essential nutrients, particularly macronutrients like phosphorus and potassium, and are typically lost as waste (Goddek et al., 2019b; Cohen et al., 2018; Khiari et al., 2019; Montanhini Neto and Ostrensky, 2015; Monsees et al., 2019). Loss of nutrients directly reduces the nutrient availability for plants, limiting crop yield and forcing reliance on external fertilizers, which undermines the sustainability of the system. CAP design limits independent nutrient adjustment, while DAP improves nutrient control but requires effluent discharge (Aslanidou et al., 2024; Tetreault et al., 2023a; Zhu et al., 2024; Eck et al., 2019). System type selection thus affects nutrient recovery efficiency and must align with the target crop and operational goals.

Spatial constraints further worsen these issues. Compact system designs frequently lack the space required to incorporate advanced nutrient recovery technologies, such as biofilters or sludge processing units (Zhang et al., 2021; Goddek and Keesman, 2020). Limited space can lead to uneven nutrient distribution, localized deficiencies, and suboptimal plant growth, highlighting the need for careful layout planning. This limits the retention and recycling of nutrients and leads to rapid nutrient depletion, adversely affecting plant growth (Aslanidou et al., 2024; Eck et al., 2019). The nutrient availability from an aquaponic system depends on its size and influences the number of fish and plants it can support (Lobanov et al., 2021). Larger systems generate more waste and in turn supports more plants. However, certain essential nutrients like iron (Fe), manganese (Mn), zinc (Zn), boron (B), molybdenum (Mo), and copper (Cu) are often present in low amounts in the water from RAS. External addition of these nutrients may be required, limiting the ability to meet plant nutritional needs solely through fish waste (Lobanov et al., 2021). In addition, poor layout and suboptimal water flow dynamics can cause uneven nutrient distribution, resulting in localized deficiencies that impede plant development (Yang and Kim, 2020; Kasozi et al., 2019). Hydraulic optimization is essential for effective nutrient cycling and plant health.

Tetreault et al. (2023b) emphasized the importance of optimizing key parameters such as hydraulic retention time (HRT) to ensure nutrient contact time and water quality. According to his study, space-related challenges and nutrient accessibility issues can be addressed through the use of modular and scalable designs such as vertical farming designs. Adopting such scalable designs allows for improved nutrient retention and system expansion without compromising operational efficiency. Sustainability and operational efficiency can be further enhanced through renewable energy systems such as solar-powered water circulation units. According to Colt et al. (2024) many aquaponic systems fail due to the lack of engineering principles applied to them. This is particularly in the sizing and positioning of components like clarifiers, degassers, and sump tanks. System hydraulics, dissolved oxygen control, and proper sizing of biofiltration units are important to avoid oxygen stress in fish and anaerobic zones in plant beds. Failure to address these factors can result in poor nutrient transformation, lower plant growth, and increased operational risk.

Colt et al. (2024) also stressed the importance of designing systems with redundancy and fail-safe mechanisms to reduce the risk of catastrophic failures such as power outages or pump malfunctions. Implementing these measures ensures continuity of nutrient cycling and prevents abrupt losses in plant productivity. Better integration of data-driven monitoring and control technologies is also necessary to optimize water quality and nutrient recycling in real-time. Research suggests that optimizing system design—particularly through improvements in water circulation and spatial configuration—can significantly enhance nutrient use efficiency and crop productivity (Adhikari et al., 2020; Bittsanszky et al., 2016). Belmeskine et al. (2023) demonstrated that integrating vertical farming with aquaponics not only improves space utilization but also enhances nutrient accessibility. Overall, thoughtful system design directly affects nutrient retention, operational efficiency, and the ability to sustainably scale aquaponic operations.

2.4 Challenges in waste management and nutrient recovery practices

Organic waste and nutrient-rich effluents pose the biggest challenge to aquaponic systems and must be managed efficiently to maintain a balance between fish growth, plants, and beneficial microbes (Tyson et al., 2011). Aquaponics faces economic and technological challenges such as scaling operations, energy consumption management, and securing organic certification despite its high water use efficiency and increased crop yields (Ibrahim et al., 2023). While various recovery approaches have been explored, limitations in solid waste removal, sludge processing, and nutrient reutilization often reduce system efficiency and sustainability. In a conventional aquaponic setup, solid fish waste gets accumulated as uneaten aquafeed. Efficient removal and treatment are necessary to prevent water quality deterioration (Cohen et al., 2018). If left unaddressed, the decomposition of organic matter can lead to the buildup of harmful metabolites, such as ammonia and nitrites, which can adversely affect fish health and increase their mortality rates (Goddek et al., 2019b). Based on factors such as fish species and feeding practices, effective solid waste management is further complicated by the physical and biological properties of the waste generated. Many systems rely on mechanical filtration methods, such as drum or mesh filters, which may not adequately remove all solid waste, particularly fine particulates. This inadequacy can result in nutrient imbalances and potential anaerobic conditions that hinder plant growth and development (Khiari et al., 2019). Untreated nutrient-rich effluents generated from aquaponic systems if discharged into local water bodies can pose risks to environmental health. Eutrophication can be caused by high nutrient effluents causing more algal blooms that deteriorates water quality and negatively impacts aquatic ecosystems (Bittsanszky et al., 2016). Phosphorus is the primary limiting factor, with phosphate concentration as low as 0.02 mg/L in water leading to the formation of algal blooms (Chen et al., 2018).

Recovering nutrients from aquaculture sludge in aquaponics provides both environmental and economic benefits by preventing solid waste discharge and supplying additional nutrients for the hydroponic system (Zhang et al., 2021). Sludge should be collected, labeled and stored in designated containers to prevent potential contamination. The use of covered storage systems has been shown to reduce environmental impacts such as global warming and eutrophication (Willén et al., 2017). After collection, key parameters such as pH, nutrient concentrations, organic matter content, and microbial activity must be assessed to gain information about its nutrient composition and potential applications (Cernica et al., 2023).

The characteristics of aquaponic sludge varies considerably based on the fish species involved. Aquaponic sludge has low content of total solids (1.5–3.0%) but a high volatile solid fraction ranging from 17% to 92% (Wu and Song, 2021). While nutrients in aquaculture effluents alone may be insufficient compared to standard hydroponic solutions (Nozzi et al., 2018), recovering and mineralizing sludge can significantly enhance nutrient availability, reducing the need for external fertilizers and supporting more diverse crop production (Montanhini Neto and Ostrensky, 2015; Zhang et al., 2021). Untreated nutrient-rich effluents discharged into the environment can cause eutrophication and algal blooms, deteriorating water quality and harming aquatic ecosystems (Bittsanszky et al., 2016; Chen et al., 2018).

2.5 Microbial community dynamics

Microbial communities play an important role in the conversion of ammonia to nitrates and the maintenance of system stability in aquaponic systems. Recent studies using 16S rRNA gene amplicon sequencing and metataxonomic analyses have revealed that these communities are highly diverse and compartmentalized across fish tanks, biofilters, hydroponic units, and plant roots (Eck et al., 2019; Schmautz et al., 2022; Rogge et al., 2024; Kasozi et al., 2021; Ruiz et al., 2023). Proteobacteria is the most dominant bacterial phylum and comprise nitrifying bacteria such as Nitrosomonas and Nitrobacter, critical for the nitrogen cycle (Kasozi et al., 2021; Eck et al., 2019; Ruiz et al., 2023). Bacteroidetes is another dominant phylum and includes bacteria that facilitate the degradation of organic matter and nutrient recycling (Kasozi et al., 2021; Schmautz et al., 2022; Ruiz et al., 2023). Actinobacteria decompose complex organic compounds and support mineralization processes (Kasozi et al., 2021; Ruiz et al., 2023). Minor phyla, including Firmicutes, Planctomycetes, Verrucomicrobia, and Chloroflexi, have also been reported at lower abundances and are associated with specific functional roles such as organic matter degradation and nitrogen transformations (Schmautz et al., 2022; Rogge et al., 2024; Ruiz et al., 2023). Microbial communities vary between the different compartments in aquaponic systems. The concentration of nitrifying bacteria is highest in the biofilter and hydroponic tank. The aquaculture conditions influence the microbes in the fish tank and harbor distinct assemblages (Rogge et al., 2024). Factors such as system design, water quality parameters (pH, temperature, dissolved oxygen), and organic loading strongly influence microbial composition and function (Kasozi et al., 2021; Ruiz et al., 2023). The independence and compartment-specific distribution of bacterial communities highlight their adaptability and functional specialization, which is essential for optimizing nutrient availability, reducing external fertilizer requirements, and maintaining system health (Ruiz et al., 2023; Eck et al., 2019). Understanding these microbial dynamics allows for informed operational decisions, including managing feeding regimes, water circulation, and system configuration to enhance nutrient cycling and ensure sustainable aquaponic production (Schmautz et al., 2022; Rogge et al., 2024).

3 Current methods and technologies for nutrient recovery

Nutrient recovery from aquaponic systems play an important role in maximizing sustainability, minimizing waste, and enhancing system efficiency. Fish sludge from aquaculture contains valuable nutrients that can be extracted and reused, addressing waste management issues and resource scarcity (Zhang et al., 2021). Different methods, including physical, chemical, and biological processes, have been developed to extract and recycle essential nutrients, contributing to improved plant and fish production. In many cases, hybrid approaches that combine more than one method offer the most efficient solutions for nutrient recovery.

3.1 Physical methods

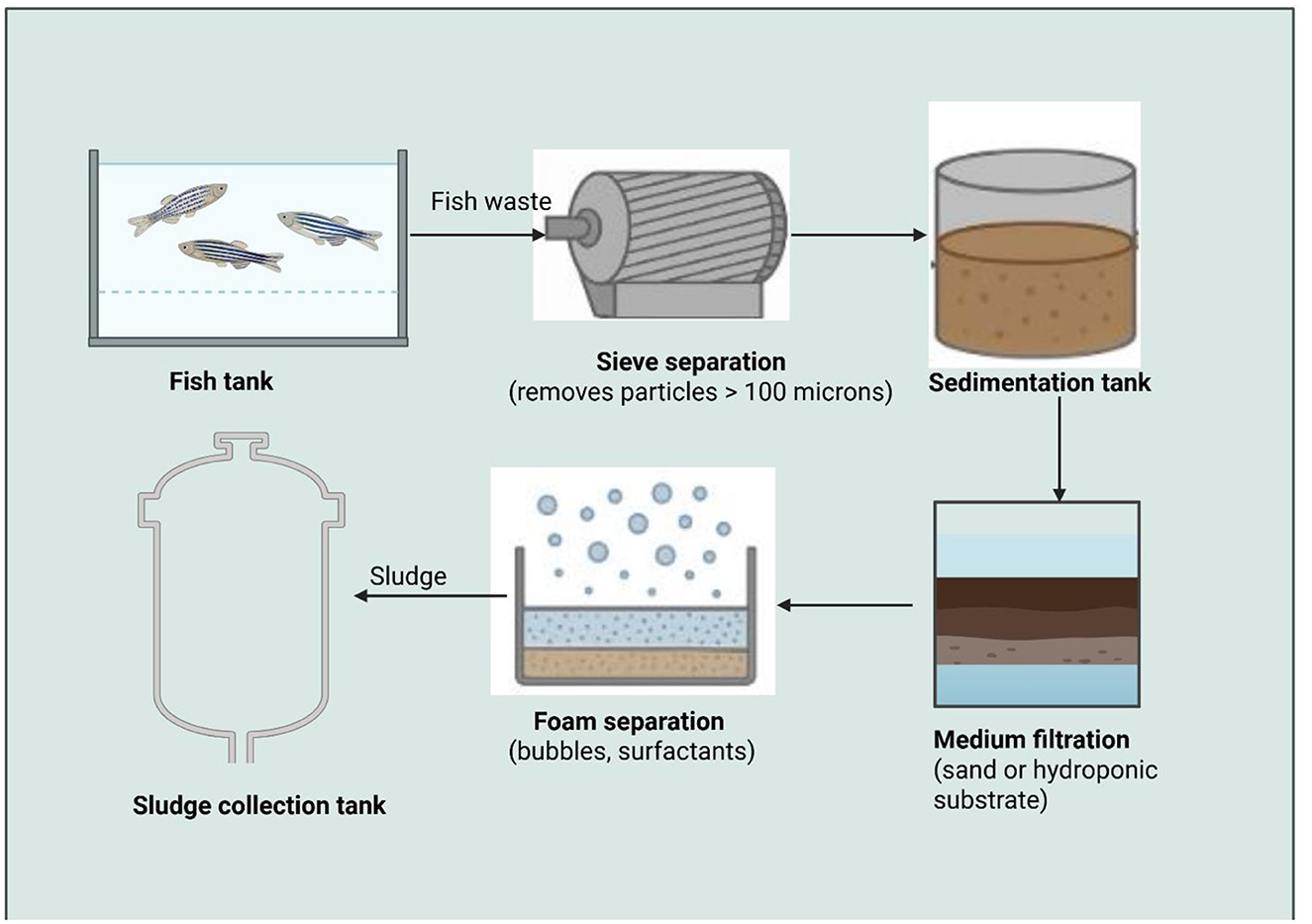

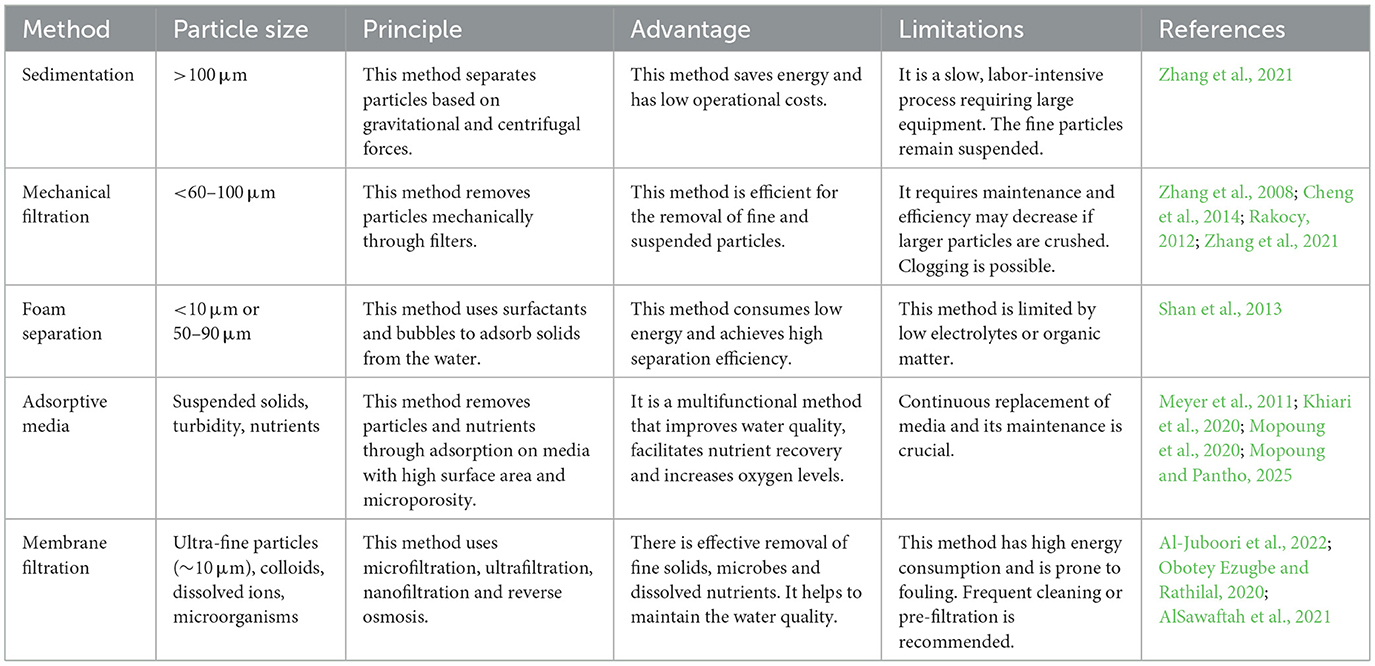

Physical separation methods set the precursor for all other methods of sludge separation. These methods focus on the separation and removal of solid waste from the water, which is the first step in managing sludge. Once sludge collection is completed, other processes, including chemical or biological methods, can be used to further process or recover nutrients from the sludge. Physical methods are thus central to sludge collection and management, forming the foundation for subsequent nutrient recovery techniques. Particle size and density are the two essential factors when selecting suitable separation technology for fish sludge. Particles larger than 100 microns are considered suspended sediments, which can be efficiently removed through gravity sedimentation or hydro cyclones. Suspended sediments, particularly those smaller than 100 microns, may disperse into fine particles under the influence of aquatic organisms and water movement (Fu et al., 2018). Currently, the solid removal methods used in aquaponics are primarily those employed in RAS. These methods include sedimentation, sieve separation, medium filtration, and foam separation (Zhanga et al., 2021). Other approaches include adsorptive media and membrane separation.

Sedimentation depends on gravitational forces acting on particles and centrifugal forces created by water flow or secondary retention methods. This gravitational force along with the centrifugal force of water flow rotation or secondary retention, helps in the sedimentation of solids. Sedimentation has lower operating costs and consumes less energy, but its large size makes it time-consuming and labor intensive (Zhanga et al., 2021). Sedimentation helps to remove particles of size larger thab 100 μm while finer particles may remain suspended and require additional treatment. Settling basins, tube or plate separators, centrifugal separators, and swirl separators are some of the common devices used in this process. Sedimentation is a power-saving and economical process, but it tends to be labor-intensive and can be slow due to the size of the equipment.

Mechanical filtration helps in the removal of particles of size less than 60 μm. Sieve separation uses a sieve with a specific aperture size to capture solids based on particle size, removing them through back washing. Sieve separators help to separate solid particles based on particle size. The solids are then removed by backwashing. Rotary drum filters are frequently employed in this method, achieving removal rates of 68–94% for suspended solids with particle sizes ranging from 60 to 100 microns when inlet concentrations exceed 50 mg/L (Cheng et al., 2014). Drum filters can be expensive, but the crushing of larger particles during the process may decrease their efficiency (Cheng et al., 2014; Zhang et al., 2021). Medium filtration captures suspended solids using porous materials such as quartz sand, ceramsite, anthracite, and polystyrene. Hydroponic substrates like sand and gravel can also effectively remove solid waste by intercepting solids as aquaculture effluent passes through the hydroponic bed while decomposing leftover organic matter (Rakocy, 2012). However, to sustain system efficiency, regular bed tillage or replacement is necessary to prevent the clogging of media (Rakocy, 2012).

Foam separation utilizes surfactants and bubbles to adsorb solids, demonstrating low energy consumption and high efficiency in removing particles smaller than 10 microns or within the 50–90-micron range. However, this method may be limited by low concentrations of electrolytes and organic matter (Shan et al., 2013). Figure 2 is a representation of a system integrating all physical methods.

Adsorptive media (biochar) have gained recent popularity as an effective method for physical separation of sludge in aquaponics. Biochar, also known as charcoal, is a carbonaceous material obtained from the pyrolysis of organic feedstock (Meyer et al., 2011). Biochar-based filtration can remove suspended solids and turbidity and act as a polishing step before the water reaches the plants in the aquaponic systems (Khiari et al., 2020). A study by Mopoung et al. (2020) demonstrated that the use of rice husk biochar in water treatment increased the concentration of dissolved oxygen in the aquaculture water. Activated biochar prepared via partial air oxidation efficiently adsorbs ammonia, nitrite, nitrate, phosphate, and suspended solids due to its high surface area and microporosity (Mopoung and Pantho, 2025). Biochar thus represents a multifunctional tool that enhances water quality, nutrient cycling, and aquaponic efficiency.

Membrane separation technologies such as microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO) are commonly used when ultra-fine particles (~10 μm), colloids, dissolved ions, or microbial contaminants need to be removed. Suspended solids and microorganisms can be effectively removed through MF and UF while NF and RO can target dissolved ions and concentrate nutrients such as nitrogen and phosphorus for reuse (Al-Juboori et al., 2022; Obotey Ezugbe and Rathilal, 2020). Membrane separation also plays a key role in maintaining water quality in close-loop systems by effectively recovering nutrients from sludge leachates. Fouling from suspended solids is a major disadvantage and this increases energy consumption along with frequent cleaning or maintenance (AlSawaftah et al., 2021). Pre-filtration through other methods is often necessary to minimize fouling and prolong membrane lifespan. Strategies such as backwashing, chemical cleaning, and antifouling coatings are critical for sustainable operation in aquaponics.

Collectively these physical methods can help to adopt an integrative approach for the effective management of sludge from aquaponics. Zhang et al. (2020) proposed an innovative approach that integrates the collection and transformation of solid sludge within a single device. This equipment enables the mineralization of collected sludge into soluble nutrients through microbial activities, significantly minimizing nutrient loss, and is highly efficient in nutrient utilization. Table 1 is an outline of the various physical methods.

3.2 Chemical methods

Chemical methods are important in nutrient recovery from aquaponics and wastewater treatment systems. These methods involve chemical additives, precipitating agents, and selective reactions to convert dissolved nutrients into solid or extractable forms. These nutrients, once recovered, are valuable products and can be used as fertilizers. Chemical methods are often integrated with biological and physical recovery techniques to enhance overall efficiency (Urbanowska and Polowczyk, 2024). Recent advancements include techniques such as hydrogel-based nutrient capture, which allows selective adsorption of phosphate, nitrate, and ammonium ions (Li et al., 2023a). Thus, chemical methods of nutrient recovery improve nutrient efficiency and support sustainable agricultural practices.

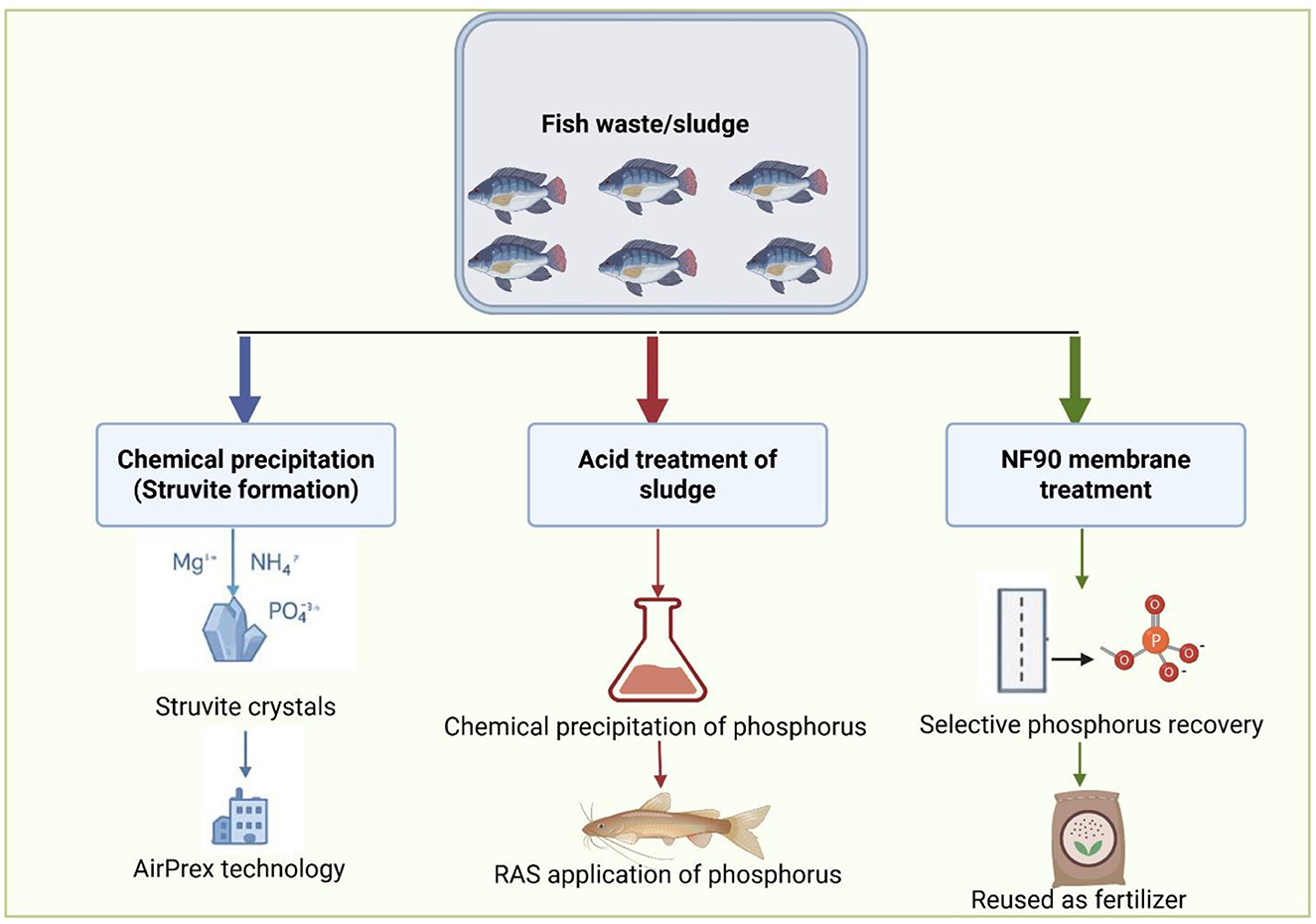

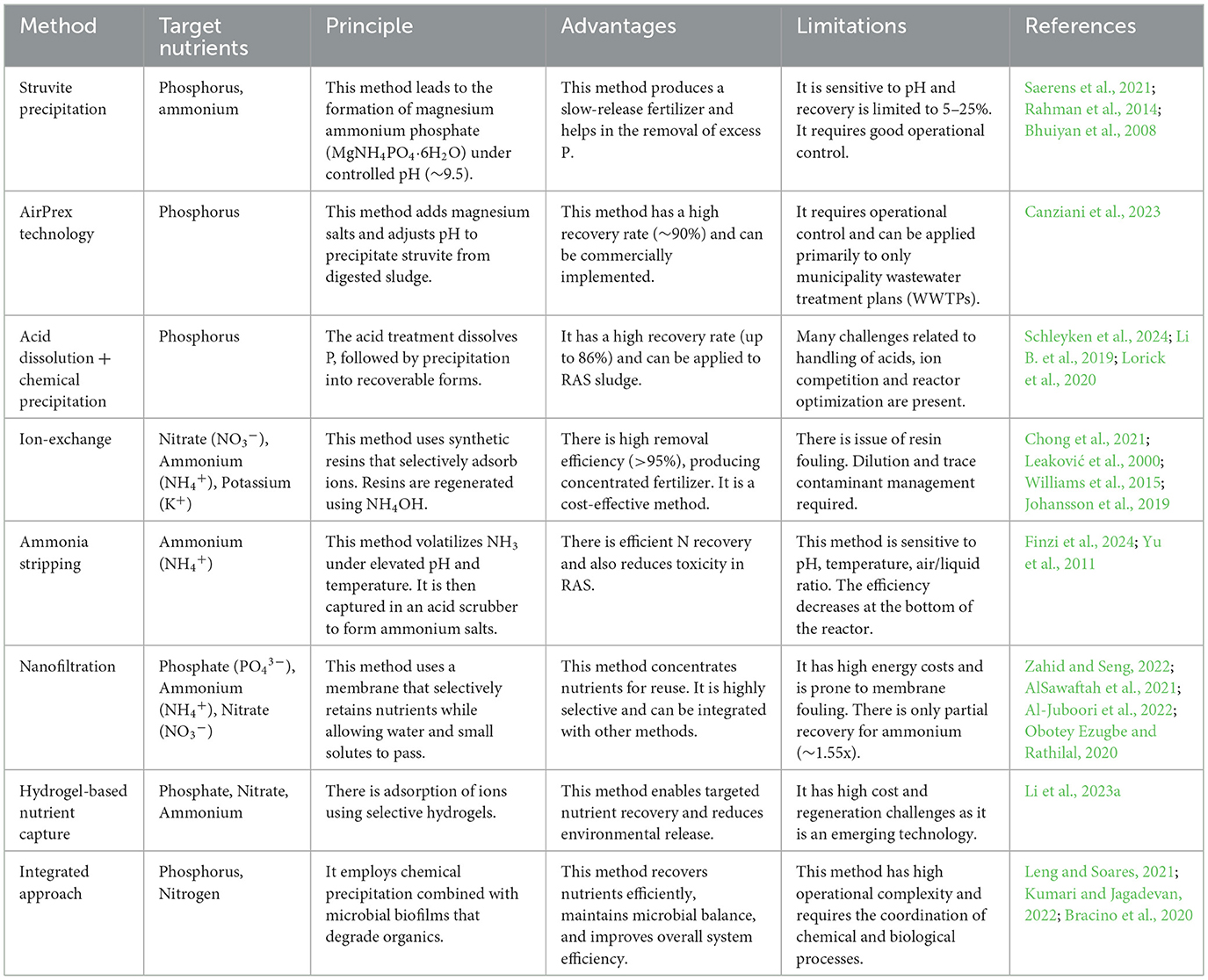

Chemical precipitation techniques are widely used in recovery of nutrients from wastewater, particularly phosphorus. One of the most studied and applied methods is struvite precipitation, which involves the formation of magnesium ammonium phosphate (MgNH4PO4·6H2O; Saerens et al., 2021). This crystalline compound precipitates when magnesium, ammonium, and orthophosphate ions are present in the aqueous sludge phase in suitable ratios and under controlled pH conditions. Struvite is a phosphorus source and can replace phosphate rock as a fertilizer (Rahman et al., 2014; Saerens et al., 2021). Struvite precipitation offers benefits such as removal of excess phosphorus from effluents, prevention of pipe clogging due to struvite scaling, and production of slow-release fertilizers (Bhuiyan et al., 2008; Desmidt et al., 2015). This method of phosphorus recovery was mainly developed to prevent struvite crystallization in wastewater treatment plants, leading to incrustation of reactors and clogging of pipes (Schleyken et al., 2024). In aquaponic systems, where phosphorus can be limiting, struvite precipitation provides a way to recycle this nutrient from fish waste into plant-available forms. However, this process is sensitive to pH with optimal precipitation happening around a pH of 9.5 (Lorick et al., 2020). A higher pH leads to the formation of alternate compounds. The recovery potential of this method is limited to 5–25% of the phosphorus in the wastewater (Saerens et al., 2021).

The AirPrex technology developed in 2010 by the company CNP—Technology Water and Biosystems GmbH, based in Munich (Canziani et al., 2023). This method was originally developed to recover phosphorus in the form of struvite from digested sludge in municipal wastewater treatment plants. It is commercially implemented in multiple plants across Europe and North America. In this method, struvite is precipitated by the addition of magnesium salts and the increase in pH, recovering up to 90% of soluble P (Canziani et al., 2023). While originally developed for the recovery of phosphorus from municipal wastewater, these methods have great potential for use in the aquaculture and aquaponic industries.

A study by Schleyken et al. (2024) investigated the efficiency of an enhanced chemical method for the recovery of phosphorus from sludge generated in RAS cultivating African catfish (Clarias gariepinus). Phosphorus extraction and recovery were done through acid dissolution followed by chemical precipitation. The findings of the study showed that the acid treatment increased the dissolved phosphorus by 53% in extensive and 61% in intensive fish rearing systems. Phosphorus recovery was as high as 86% when combined with chemical precipitation. Future designs must address challenges by considering factors such as reactor operation, ion competition, and crystal growth dynamics to improve process efficiency and product quality for wider implementation (Li B. et al., 2019; Lorick et al., 2020). Figure 3 outlines the different chemical methods for phosphorus recovery.

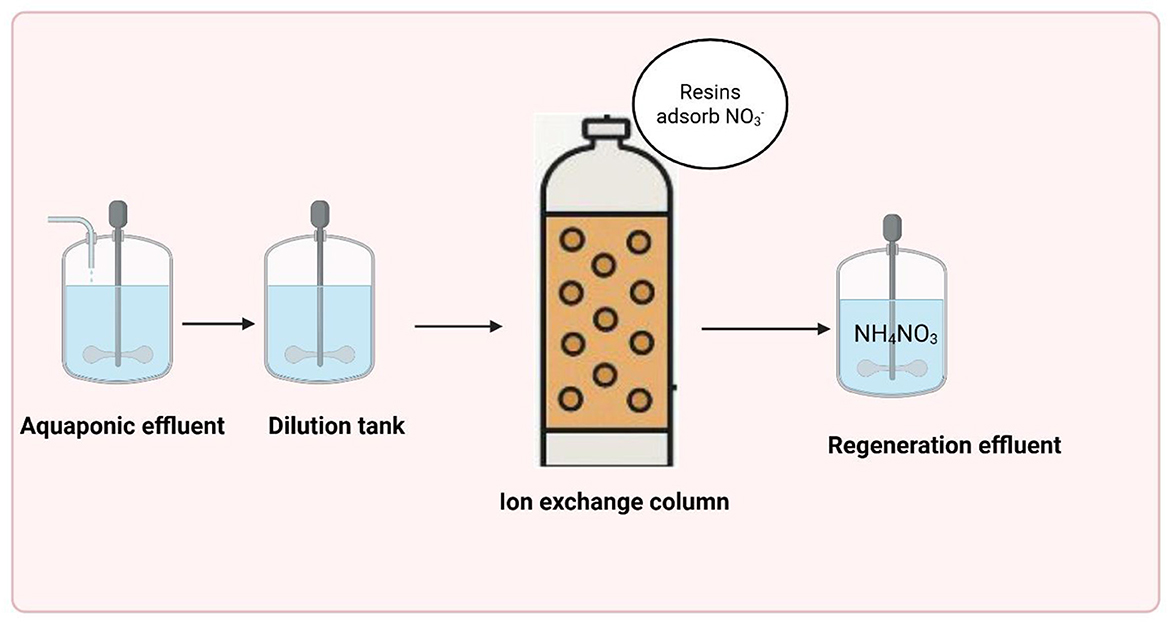

Ion-exchange uses synthetic resins for selective adsorption of nitrogen compounds from aqueous solutions (Chong et al., 2021; Figure 4). Strong-base anion exchangers are employed for nitrate recovery. Resins regeneration is done using ammonium hydroxide (NH4OH), releasing the bound nitrate and reusing the resin (Chong et al., 2021). Dilution of the aquaponic effluent is a precursor to the ion-exchange process as this reduces the salinity and prevents resin fouling (Leaković et al., 2000). Williams et al. (2015) reported that this process has high removal efficiency for nutrients (>95% for nitrogen and phosphorus) and produces highly concentrated fertilizer products. This method is relatively cost-effective and efficient for recovering nitrate from aquaponic water streams. However, the management of trace contaminants is necessary to improve the recovery efficiencies for certain nutrients (Tarpeh et al., 2018).

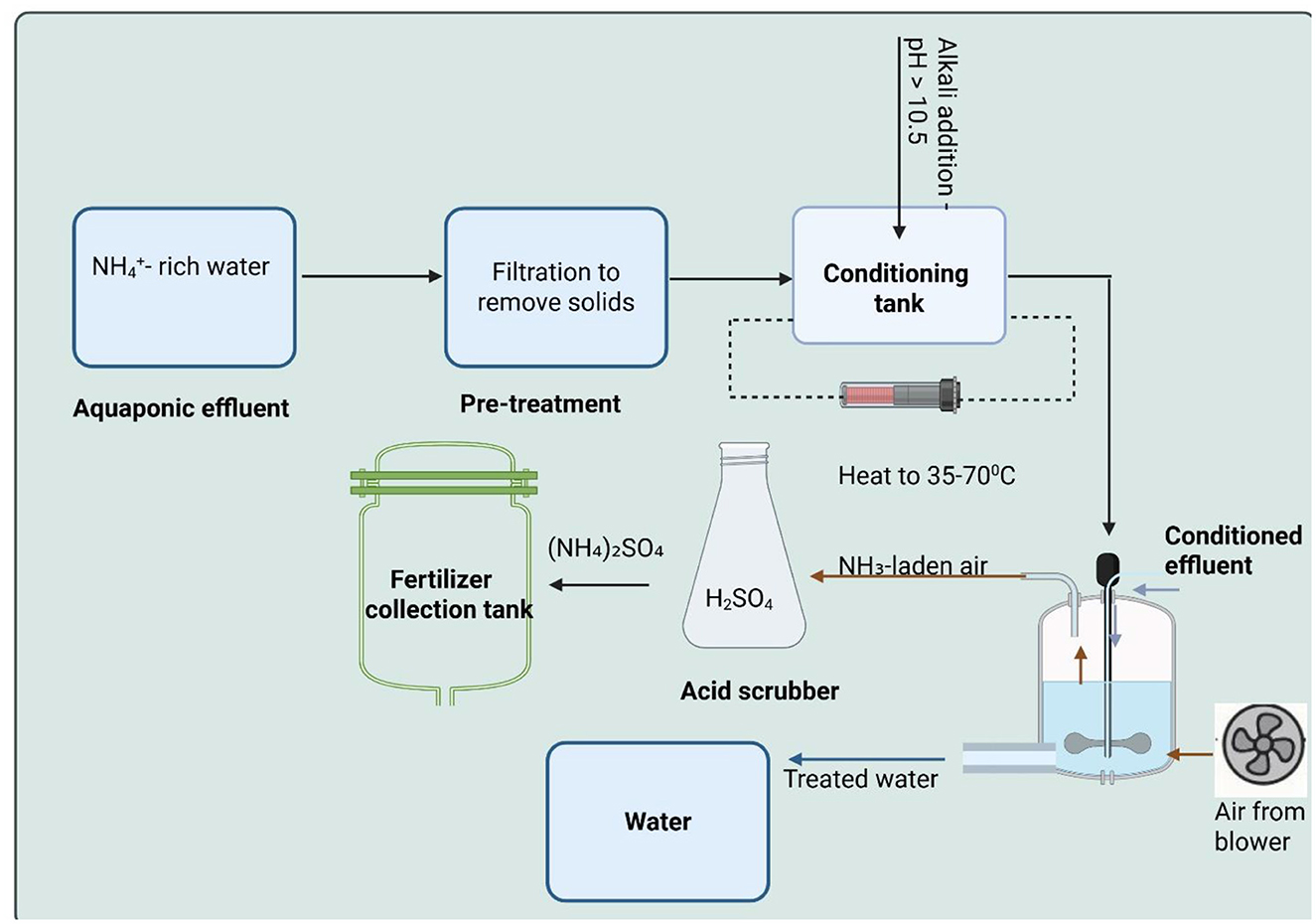

Ammonia Stripping uses a closed reactor is used for the volatilization of ammonia under elevated pH and temperature (Figure 5). The volatilized through ammonia is carried through the reactor's headspace when a stream of air passes it. This ammonia-laden air is subsequently purified in an acid scrubber, typically using sulfuric acid (H2SO4), forming ammonium sulfate [(NH4) 2SO4], a nitrogen-rich fertilizer (Finzi et al., 2024). This method not only recovers ammonia efficiently but also contributes to reducing nitrogen toxicity in recirculating systems. Since the efficiency of this method is influenced by pH, temperature, and air/liquid ratio, lower efficiency is observed at the bottom of packed bed reactors due to decreased liquid volume fraction and temperature (Yu et al., 2011).

Membrane technologies, including nanofiltration (NF) and reverse osmosis (RO), are increasingly used for nutrient recovery in aquaponics. NF membranes (e.g., NF90) can selectively retain phosphate, ammonium, and nitrate ions while allowing water and small solutes to pass, concentrating nutrients for reuse as fertilizers (Zahid and Seng, 2022). Membrane separation offers high selectivity and potential integration with other chemical methods, but challenges include fouling, energy costs, and maintenance (AlSawaftah et al., 2021; Al-Juboori et al., 2022; Obotey Ezugbe and Rathilal, 2020).

Chemical methods are integrated with physical and biological methods to enhance overall efficiency. For instance, the simultaneous application of struvite precipitation and biofiltration enables both phosphorus recovery and organic matter breakdown (Leng and Soares, 2021; Kumari and Jagadevan, 2022). In such systems, aquaponic waste is directed through biofilters containing immobilized microbial cultures. These microbes form biofilms on the filter medium, degrade organic compounds, and produce nutrient-rich effluents (Bracino et al., 2020). The addition of chemical precipitating agents ensures efficient recovery of specific nutrients while maintaining microbial balance. Ongoing research aims to refine chemical recovery processes to align with circular economy and sustainable agriculture principles. Innovations focus on improving reaction efficiency, optimizing reagent use, and reducing operational costs. The development of selective sorbents, eco-friendly precipitants, and hybrid reactor systems hold promises for enhancing nutrient recovery rates while minimizing environmental impact. These advancements are essential for ensuring the long-term viability of aquaponics and other integrated food production systems. Table 2 summarizes all the chemical nutrient recovery methods.

3.3 Biological methods

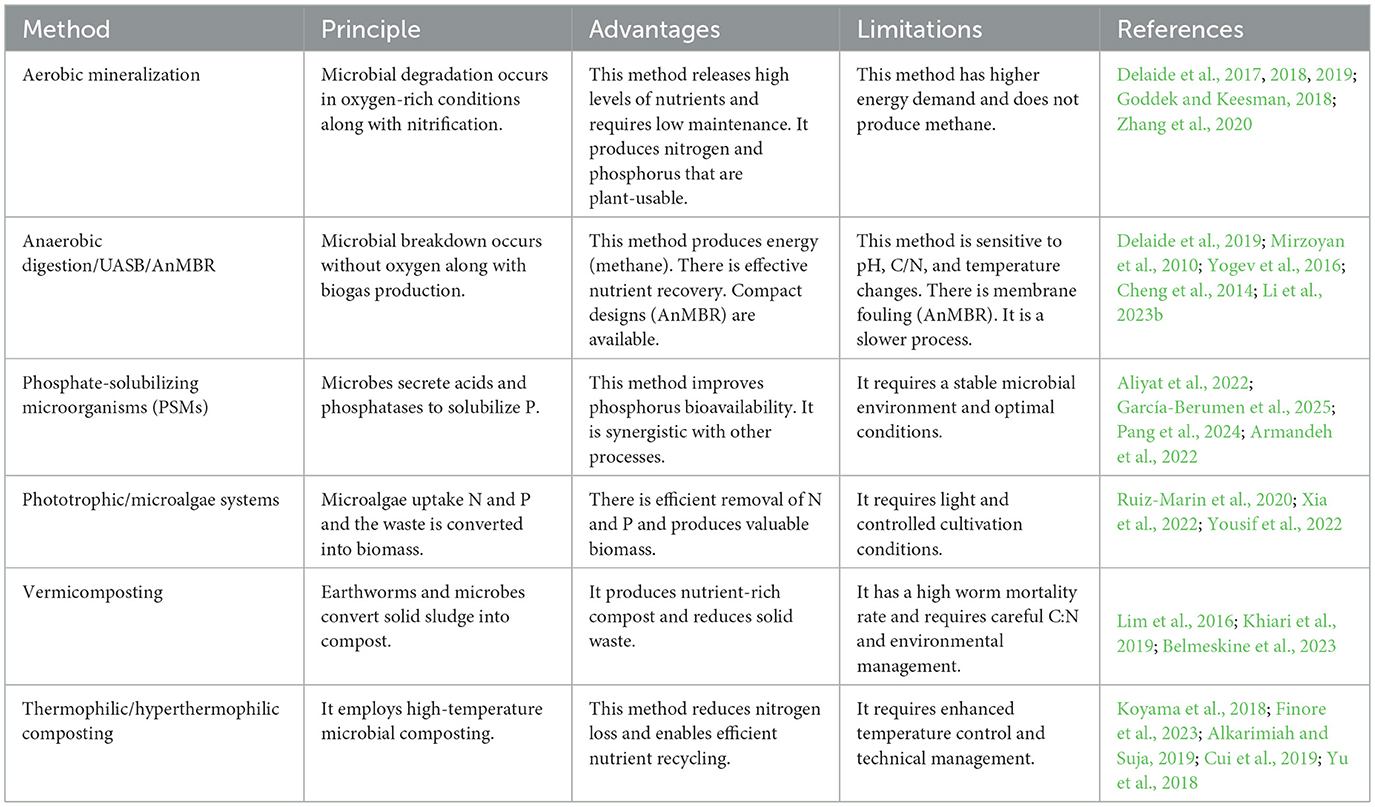

Biological methods for nutrient recovery from fish sludge involve the microbial degradation and transformation of organic matter. Biological methods can be broadly categorized into microbial mineralization and nitrification, phosphate-solubilizing microorganisms (PSMs), algal and phototrophic systems, and vermicomposting. Nutrient mineralization of fish sludge can occur under both aerobic and anaerobic conditions through microbial degradation (Zhang et al., 2021). Both aerobic and anaerobic processes are effective in decreasing organic matter levels, achieving removal rates of at least 50% for total suspended solids and chemical oxygen demand (Delaide et al., 2018). Delaide et al. (2018) also reported that the nutrient mineralization rates for macro and micronutrients range between 10% and 60% (Delaide et al., 2018). Microorganisms break down organic solids into soluble nutrients that plants can utilize (Zhang et al., 2020).

Microbial mineralization represents the fundamental mechanism of nutrient release from aquaponic sludge, achieved either in oxygen-rich (aerobic) or oxygen-limited (anaerobic) environments. These biological reactions decompose organic matter and convert nitrogenous compounds into plant-available nitrate through nitrification. Aerobic methods involve microbial reduction of organic matter in the presence of oxygen. Aerobic reactors are superior with higher reduction rates (Delaide et al., 2019). In aerobic reactors, air is injected into the sludge-water mixture through air blowers connected to diffusers and propellers. This injection provides oxygen supply and ensures the adequate mixing of the sludge (Delaide et al., 2017). Aerobic mineralization helps in the release of macro and micro-nutrients bound to the organic matter. Biogenic CO2 released during aerobic digestion is part of the carbon cycle and can be absorbed by plants for growth.

The mineralization of organic matter collected from solid removal units, clarifiers, or drum filters in RAS represents an effective method for recycling nutrients. Throughout aerobic digestion, a drop in pH promotes the mineralization of bound minerals within the sludge. Previous research indicates that this pH change results in the release of phosphorus from RAS sludge (Delaide et al., 2017). The consistent supply of oxygen and presence of organic matter create optimal conditions for heterotrophic microorganisms. The dissolved carbon dioxide forms carbonic acid, contributing to the decrease in pH. The ideal pH of RAS is between 6.8 and 7.0 to ensure effective microbial conversion of ammonium to nitrite and subsequently to nitrate within the biofilters (Goddek et al., 2019b). Although nitrification may slow down or halt when pH drops below 6, this does not adversely affect mineralization (Ebeling et al., 2006). The decline in pH helps release nutrients in the form of precipitated minerals like calcium phosphates. Research has shown that a major portion of phosphate in sludge is acid-soluble, highlighting the need for more efficient mineralization units for aquaponic applications (Zhang et al., 2020). Aerobic mineralization offers benefits such as low maintenance requirements. The nutrient-rich effluent produced can be used directly for plant fertilization.

Ezziddine et al. (2020) developed a method that included nutrient mobilization using aerobic digestion followed by solids precipitation using chitosan as the flocculant. Over the 4-week experimental period, soluble nitrogen increased significantly from 181.0 to 903.0 mg/L, while soluble phosphorus rose from 8.2 to 160.0 mg/L. Other essential macro- and micronutrients also reached levels suitable for hydroponic use. Importantly, the use of chitosan flocculation (15 mg/L) reduced turbidity by 96%, allowing 80% of the sludge to be reclaimed as a nutrient-rich, low-TSS liquid phase. Thus, natural flocculants such as chitosan can be incorporated in aerobic digestion to improve nutrient recovery efficiency.

Anaerobic methods use microorganisms that live without oxygen to decompose organic waste, produce biogas and reduce the volume of solids while releasing nutrients. The digestion depends on specific conditions such as pH, temperature, salinity, mineral composition, carbon/nitrogen ratio (C/N), volatile fatty acids (VFAs) content, and HRT making it more challenging (Mirzoyan et al., 2010). A study by Strauch et al. (2018) found that the Total Organic Carbon (TOC) in aquaculture sludge (366–416 g/kg dm) is 36–42% lower than that in a typical matrix, and the C/N ratio is 1.1–3.8 times lower than the required value for anaerobic digestion. It has several advantages, including simple operational steps, low costs, and the potential to produce a byproduct such as biogas, a renewable energy source (Delaide et al., 2019). pH, salinity, mineral composition, temperature, HRT, and the carbon-to-nitrogen (C/N) ratio are some of the factors that determine the digestion of sludge and biogas production potential (Khalid et al., 2011). Anaerobic digestion methods for the treatment of RAS sludge are conventional methods and have been in use for more than three decades. While early studies mostly focused on freshwater systems, subsequent research increasingly focused on marine and brackish water environments as well (Klas et al., 2006; McDermott et al., 2001; Kotcharoen et al., 2023; Mirzoyan et al., 2008).

The Upflow Anaerobic Sludge Blanket (UASB) reactor is an anaerobic digestion system where a microbial blanket is used for the upward flow of sludge containing microorganisms. along with its low operational costs and simplicity of operation. The solid-removal efficiency of the system is very high (>92%) for waste with low total suspended solids (TSS; 1–3%). The low operational costs and simplicity of operations are among the advantages. Studies of marine and saline RAS have demonstrated their potential in aquaponics. In a previous study, of the 25% carbon introduced into the UASB, 12.5% was converted to methane, 7.5% to carbon dioxide, and the remaining 5.0% remained as non-degradable carbon (Yogev et al., 2016). This configuration resulted in improved energy recovery, accounting for about 12% of the overall energy demand of RAS.

The Anaerobic Membrane Bioreactor (AnMBR) is a more advanced technology for treating sludge. While the UASB uses a settling process, the AnMBR utilizes membranes to separate solids from liquids. A membrane pore size of 0.1–0.5 μm can even retain microorganisms for better biomass concentration and treatment efficiency (Li et al., 2023b). The AnMBR has two design options: side-stream (where the membrane is external to the tank) and submerged (where the membrane is within the tank). The AnMBR offers unique advantages, such as the separation of sludge retention time (SRT) from the HRT and allowing for a faster degradation of sludge. It also provides high-quality effluent, retains most nutrients, removes pathogens, and has a smaller carbon footprint (Judd, 2010). The higher organic loading and longer SRT enhance the biogas production in AnMBR, thereby improving energy recovery and contributing to a net-positive energy balance in some systems (Li et al., 2023b). Regular membrane maintenance is still a concern and should be done to prevent biofouling, which in turn increases the operational cost. The integration of UASB with a membrane reactor to filter UASB effluent has been promising in effectively removing both organic carbon and nitrogen (Li et al., 2020). This hybrid approach is a safer and cleaner way for the use of UASB effluents in aquaponics.

Phosphate-solubilizing microorganisms (PSMs) are key agents that enhance the bioavailability of phosphorus to plants by converting insoluble phosphorus in fish sludge into soluble orthophosphates. These organisms include bacterial genera such as Bacillus, Pseudomonas, and Acinetobacter, and fungal genera such as Aspergillus and Penicillium, which secrete organic acids (e.g., gluconic, oxalic, citric) and express phosphatases to mobilize both inorganic and organic phosphorus (Aliyat et al., 2022; García-Berumen et al., 2025). Armandeh et al. (2022) isolated phosphate-solubilizing bacteria from fishpond sediments belonging to Pseudomonas and Acinetobacter and showed that one strain (Persian10) significantly increased soluble phosphorus levels in sediment microcosms and aquarium conditions (by releasing 48–170 mg P L−1). Thus, integrating PSMs into sludge treatment bioreactors or vermicomposting substrates can substantially enhance phosphorus release while maintaining microbial stability and synergizing with other mineralization processes.

Phototrophic microorganisms which also include certain microalgae species have proven to be successful in the treatment of aquaculture sludge, particularly in systems focusing on nutrient recovery. These microalgae help in the conversion of waste into valuable biomass and are useful in aquaponic systems (Xia et al., 2022). Common species such as Chlorella vulgaris and Scenedesmus obliquus effectively remove nitrogen and phosphorus, while mixotrophic cultivation (using both organic and inorganic carbon) enhances nutrient uptake efficiency (Ruiz-Marin et al., 2020; Yousif et al., 2022). Biofloc systems also offer sustainable options for managing excess nutrients in recirculating aquaculture and aquaponic systems by creating an ideal environment for the growth and multiplication of beneficial microbes. These microbes help to degrade organic matter, improve water quality, and reduce the need for external waste treatment (Martinez-Córdova et al., 2015). Vermicomposting of sludge from recirculating aquaponic systems is a promising approach to sustainably managing aquaponics sludge and producing valuable end-products (Lim et al., 2016). In the aquaponic system, vermicomposting of sludge can be done separately in a designed system as only the solid phase of the sludge will be used in the composting process. This nutrient rich solution can be effectively utilized in the hydroponic systems that help to improve plant growth and balance nutrient deficiencies (Khiari et al., 2019). The vermicomposting process involves several steps, and the first is the collection of aquaponic sludges from solid filtration devices in the system, such as mesh filters or drum filters. Clarifiers and settling tanks are also useful in the collection of sludges as the solid particles naturally settle and accumulate at the bottom. The clarified water is then returned to the system. Pumps and other manual devices can be used to remove the accumulated sludge from filtration devices and settling tanks. A study by Boruszko (2020) found that the addition of sawdust improved the C: N ratio of sludge. Sawdust can be added to the aquaponics sludge to improve the C: N ratio, as sludge is low in dry matter. Another study found that the addition of shredded cardboard improved the C: N ratio of the RAS sludge (Marsh et al., 2005). The C:N ratio of sludge can be further improved by the addition of dry carbonaceous material like wheat straw (Kouba et al., 2018).

In vermicomposting, the earthworms are released over the aquaponic sludge mixture. Earthworms have a very fast growth rate and double every 60–90 days (Jawaher, 2020). A stocking density of 1.60 kg-worms/m2 (≈3,200 worms) weighing 0.5 g each resulted in the highest bioconversion of the aquaponic sludge substrate (Ndegwa and Thompson, 2000). A recent study reported that aquaponic sludge stabilization was reflected in a 22.36% increase in earthworm weight and a 27.51% increase in length after 21 days of vermicomposting (Belmeskine et al., 2023). At this stage, the vermicompost was harvested by separating the earthworms. The collected vermicompost was further sieved to remove any earthworms or other debris. The collected vermicompost can then be used as a biofertilizer or soil amendment. Though vermicomposting remains a viable option for nutrient recovery, a high mortality rate is one of its major drawbacks. Birch et al. (2010) reported a mortality rate of 28–77% while processing aquaculture sludge. Vermicomposting requires careful management of stocking density and other environmental conditions to ensure optimum results (Hait and Tare, 2011).

Thermophilic composting is a type of composting done at a temperature of 60–70 °C. This system creates an optimal environment for the growth of thermophilic microbial communities, thereby facilitating the improved recovery of total ammonia nitrogen (TAN) from aquaponic systems (Koyama et al., 2018). There is better aquaculture sludge volume reduction and helps in the recycling of valuable nutrients for use in agriculture. Thermophilic bacteria, particularly from the genera Bacillus and Thermus produce thermostable enzymes such as proteases, cellulases, and lignin-modifying enzymes during the process (Finore et al., 2023). Nitrogen loss and poor efficiency are few of the drawbacks of the system. Alkarimiah and Suja (2019) compared the conventional pile method with closed reactor systems. The closed reactor system is more efficient, with technical factors like rotation frequency, aeration rates, and initial moisture content significantly influencing the thermophilic temperature achievement (Alkarimiah and Suja, 2019).

Hyperthermophilic composting is a type of thermophilic composting that reduces nitrogen losses up to 40.9% as compared to the conventional method (Cui et al., 2019). This is achieved through reduced ammonia volatilization and inhibited enzymatic activities (Cui et al., 2019). This method operates at even higher temperatures. The increased formation of humic acid further reduces nitrogen loss. A higher composting efficiency is achieved by the presence of distinct microbial communities belonging to the families Thermaceae and Thermoactinomycetaceae (Yu et al., 2018). Each method contributes distinct ecological and agronomic benefits, and their integration holds potential for maximizing nutrient recovery while minimizing waste in aquaponic systems (Table 3).

3.4 Hybrid and integrated methods

Nutrient loss and excessive biomass generation are some of the challenges in conventional methods like anaerobic and aerobic mineralization (Xia et al., 2022). Hybrid and innovative methods integrate various methods to overcome these challenges for enhanced nutrient recovery. These approaches combine the advantages of physical, chemical, and biological methods, improving nutrient solubilization, reducing environmental impacts, and increasing the economic feasibility of aquaponic operations.

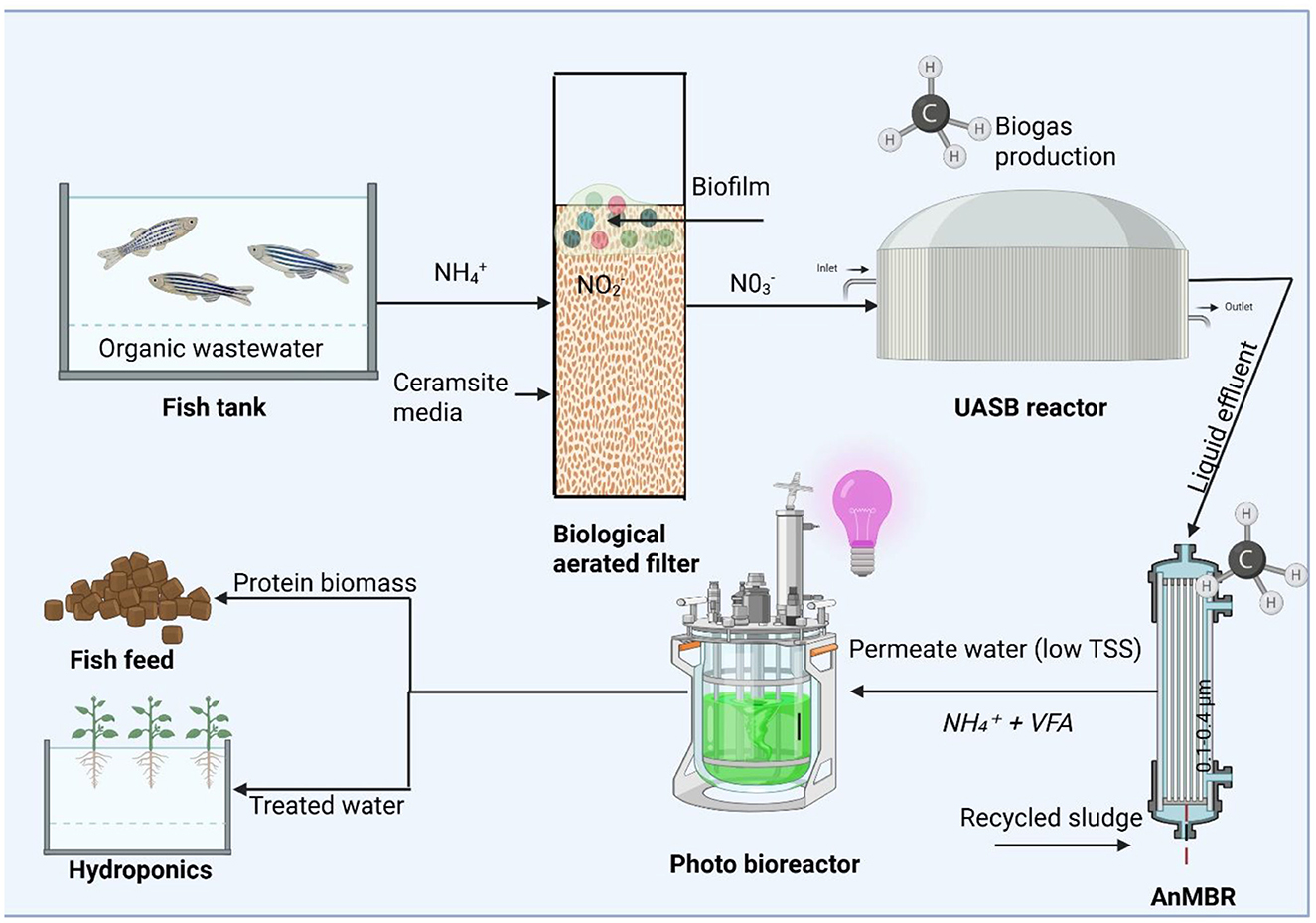

The integration of the Upflow Anaerobic Sludge Blanket (UASB) reactor and Anaerobic Membrane Bioreactor (AnMBR) is considered a hybrid system because it combines the advantages of two distinct wastewater treatment processes (Li et al., 2020). The UASB reactor and AnMBR are complementary technologies for the efficient treatment and reuse of organic wastewater in sustainable systems like aquaponics (Judd, 2010). In a UASB reactor, anaerobic microbial granules help to degrade organic matter into biogas as wastewater flows through it. A three-phase separator operating at the top allows for gas collection, effluent discharge, and sludge retention. This system has a high organic load capacity with minimum energy demand and sludge production. However, it has limitations such as retention of fine particles and removal of nutrients. The AnMBR addresses these limitations by combining anaerobic digestion and membrane filtration. The UASB reactor anaerobically treats organic waste, converting sludge into biogas and removing solids and organic matter cost-effectively while the AnMBR uses membrane filtration to produce high-quality effluent with minimal suspended solids and enhanced nutrient retention (Judd, 2010). This integrated method allows for enhanced removal of organic carbon and nitrogen, cleaner effluent suitable for reuse in aquaponics, reduced sludge production, and higher biogas recovery, thereby ensuring the safe and efficient operation of aquaponic systems.

Physical separation technologies are increasingly applied in nutrient recovery, as they remove solids while retaining soluble compounds. Membrane-based methods including microfiltration, ultrafiltration, and nanofiltration can concentrate nutrients from aquaculture effluent for plant reuse (Loh et al., 2022; Coque et al., 2023; Ltaief et al., 2025). Other physical methods, such as sedimentation and screening techniques (Ion Exchange, 2023; Genesis Water Technologies, 2023), can reduce sludge loads prior to biological treatment, improving downstream nutrient conversion efficiency. By integrating UASB and AnMBR with these physical separation strategies, it is possible to enhance organic carbon and nitrogen removal, recover soluble nutrients effectively, reduce sludge production, and generate biogas, supporting the safe and efficient operation of aquaponic systems (Delaide et al., 2019).

Additionally, forward osmosis and selective nanofiltration membranes (New) have been tested to selectively recover ammonium, phosphate, and potassium from fish effluents. These techniques can concentrate nutrients to levels suitable for direct use as hydroponic fertilizers, minimizing water and energy usage in aquaponic systems (Zhang et al., 2021). Physical methods often serve as a preliminary step in hybrid systems, reducing the burden on biological or chemical recovery units and improving overall nutrient recovery efficiency.

The integration of fish sludge separation and nutrient conversion into a single unit enhances efficiency while minimizing the adverse impacts of aquaponic systems. Biological aerated filters (BAF) incorporating ceramsite and lignocellulosic materials effectively recover macro- and micronutrients from fish sludge (Zhang et al., 2020). Originally developed from biological filters in Europe during the late 1980s (Wu et al., 2015), BAFs use granular media to support biofilm formation, filtering suspended solids and fine particles through microbial filtration and flocculation, maintaining effluent suspended matter below 10 mg/L. The large surface area promotes nitrifying and heterotrophic bacterial growth, facilitating ammonium nitrogen removal (>90%) and organic matter breakdown (Dong et al., 2020; Ma and Qiu, 2002). BAFs have been widely applied in secondary wastewater treatment for municipal and industrial purposes (Farabegoli et al., 2009) and in recirculating mariculture systems (Dong et al., 2020). Using Kaldness plastic media, Wongkiew et al. (2018) achieved NH3-N removal >90% and TN removal >85%, though fouling necessitated regular backwashing (Yang et al., 2010; Wongkiew et al., 2018; Dong et al., 2020). Experiments integrating ceramsite with lignocellulosic materials (corn straw, wheat straw, sawdust) improved physical filtration and microbial nutrient conversion, achieving high mineralization through nitrification and phosphorus dissolution (Zhang et al., 2020). The effluent exhibited nutrient concentrations of 12.3% N, 11.8% P, 4.5% K, 26.4% Ca, 22.6% Mg, and 46.0% S. Notably, the micronutrients Cu, Zn, and Mo exceeded 100% of the concentrations observed in the standard Hoagland solution 2020.

Anaerobic solubilization process involves the conversion of insoluble organic matter into low-molecular-weight fatty acids and alcohols using heterotrophic bacteria in absence of oxygen (Xia et al., 2022). Hydrolysis and fermentation phases are some of the anaerobic solubilization process that minimizes acetogenesis and avoids methanogenesis while complete anaerobic digestion, includes hydrolysis, fermentation, acetogenesis, and methanogenesis, this approach leads to a shorter conversion period and fewer biomass by-products. Hydrolysis breaks down organic solids into soluble compounds like sugars and amino acids, while fermentation further degrades these into volatile fatty acids (VFAs), alcohols, ammonia, CO, and H2S. The process does not complete the fermentation phase since acidogenic bacteria can directly utilize short-chain fatty acids. In Acetogenesis and methanogenesis process the conversion of VFAs into acetic acid, H2, CO2, and methane, occurs that leads to the carbon loss. This process has challenges such as nitrogen loss due to anaerobic ammonium oxidation or denitrification. Critical measures of the process include VFA, total ammonium nitrogen (TAN), and soluble chemical oxygen demand (SCOD). Research shows that over 60% of biodegradable solids can be converted to soluble organic matter within 2 days, with pH and nutrient concentrations reflecting the extent of solubilization (Conroy and Couturier, 2010; Monsees et al., 2017).

Aerobic solubilization is more efficient than anaerobic solubilization due to higher microbial activity and faster reaction kinetics in the presence of oxygen (Xia et al., 2022). Maintaining optimal dissolved oxygen (DO > 2 mg/L) supports microbial efficiency and promotes nitrifying bacteria that oxidize ammonia to nitrate. The process begins with Aerobic Hydrolysis (AH), where extracellular enzymes break down complex organic matter into simpler substrates for heterotrophic, ammonia-oxidizing, and nitrite-oxidizing bacteria (Qu et al., 2021). Aerobic phototrophic bacteria (APB), particularly purple non-sulfur bacteria, assimilate ammonia directly, minimizing nitrogen loss and enhancing nutrient retention (Delaide et al., 2019). Under suitable light, APB perform both photoheterotrophic and photoautotrophic metabolism, fixing CO2 and assimilating nitrogen and phosphorus. Aerobic solubilization generates more bioavailable organic matter compared to anaerobic processes (Xia et al., 2022). Efficiency can be further improved using modified biological aerated filters (MBAF) with sponge media and biofilms, which enhance nutrient conversion from fish sludge (Gao et al., 2021).

Phototrophic bioconversion using anoxygenic phototrophic bacteria (APB) is another alternative that helps reduce nutrient loss while producing protein-rich biomass for aquaculture (Xia et al., 2022). These advancements could greatly improve the sustainability of aquaponic systems by reducing environmental impacts and boosting economic feasibility (Adhikari et al., 2020). The synergistic use of multiple recovery techniques—for example, combining aerobic digestion with struvite precipitation—can significantly enhance nutrient solubilization while simultaneously stabilizing sludge and recovering phosphorus in a plant-available form (Delaide et al., 2018). Such combinations can reduce the load on individual treatment units and optimize system-wide nutrient availability, particularly in large-scale systems where single-method approaches may fall short (Zhang et al., 2021). Moreover, integrating biological and chemical methods have shown to improve cost-effectiveness by reducing the frequency of chemical inputs while increasing nutrient recovery rates (Goddek et al., 2019a).

Hybrid biofilter systems combine two or more biological processes to enhance nutrient removal efficiency. These systems often integrate aerobic and anaerobic microbial processes or combine different reactor designs to optimize nitrogen and organic matter removal. Obondo et al. (2025) demonstrated effective nitrogenous waste removal in a closed freshwater recirculating aquaculture system using DHS–USB, which combines aerobic nitrification in the sponge phase and organic matter degradation in the sludge blanket phase. Similarly, Watari et al. (2021) applied the DHS–USB system in a closed Epinephelus bruneus aquaculture setup, achieving efficient nitrogen removal. Kagali et al. (2025) evaluated combined medium culture and raft systems for enhanced waste removal, demonstrating that integrating different biological setups can improve overall nutrient recovery in aquaponic systems. These hybrid approaches leverage the synergistic effects of multiple biological processes, offering higher efficiency and stability compared to single-method systems.

Despite these benefits, further research is needed to model and quantify the economic trade-offs and scalability potential of such hybrid strategies under commercial operating conditions (Turnšek et al., 2019). Figure 6 is a representation of a system integrating all the hybrid methods.

4 Conclusion

This review aimed to critically evaluate nutrient recovery strategies in aquaponic systems, highlighting the strengths, limitations, and potential integration of physical, chemical, and biological approaches. The analysis demonstrates that no single method is sufficient. Physical methods are essential for initial sludge separation but they are insufficient alone. Biological methods offer a pathway for mineralization but can be slow. Chemical methods provide targeted recovery but may introduce costs and complexities.

Hybrid systems, which integrate physical, biological, and chemical approaches emerge as the most promising avenue for sustainable and efficient nutrient recovery in aquaponic systems. Future research should focus on optimizing hybrid systems that integrate physical, chemical, and biological approaches for scalable applications. Pilot-to-commercial-scale studies are needed to evaluate operational feasibility, space-efficient designs, and modular system configurations. Enhancing recovery of limiting nutrients, such as potassium and phosphorus, through complementary strategies like biofloc systems, vermicomposting, and microbial consortia is essential. Long-term field studies are required to assess sustained system performance, including nutrient balance, plant growth, water quality, and operational stability. Integration of AI-based sensing and control systems can facilitate real-time nutrient monitoring and predictive management. Standardization of nutrient recovery protocols and exploration of microbial-mediated mineralization could improve efficiency and reduce variability across systems. Additionally, economic feasibility, energy efficiency, and environmental sustainability assessments should guide the adoption of nutrient recovery methods in commercial aquaponics.

Further research should focus on scaling hybrid systems, improving cost-effectiveness, and developing real-time nutrient monitoring to maintain optimal nutrient balance. Such efforts will be essential to fully realize the sustainability and commercial viability of aquaponic systems in the face of increasing resource constraints.

Author contributions

DN: Conceptualization, Data curation, Visualization, Writing – original draft. CS: Data curation, Visualization, Writing – review & editing. RM: Data curation, Visualization, Writing – review & editing. RS: Writing – review & editing. IS: Writing – review & editing. SM: Supervision, Writing – review & editing. AJ: Funding acquisition, Supervision, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was supported by ASPIRE, the technology program management pillar of Abu Dhabi's Advanced Technology Research Council (ATRC), via the ASPIRE “ASPIRE Research Institute for Food Security in the Drylands – ARIFSID” (Fund Code: 21R097).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Generative AI statement

The author(s) declare that no Gen AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Adhikari, R., Rauniyar, S., Pokhrel, N., Wagle, A., Komai, T., and Paudel, S. R. (2020). Nitrogen recovery via aquaponics in Nepal: current status, prospects, and challenges. SN Appl. Sci. 2, 1–15. doi: 10.1007/s42452-020-2996-5

Aliyat, F. Z., Maldani, M., El Guilli, M., Nassiri, L., and Ibijbijen, J. (2022). Phosphate-solubilizing bacteria isolated from phosphate solid sludge and their ability to solubilize three inorganic phosphate forms: calcium, iron, and aluminum phosphates. Microorganisms 10:980. doi: 10.3390/microorganisms10050980

Al-Juboori, R. A., Al-Shaeli, M., Aani, S. A., Johnson, D., and Hilal, N. (2022). Membrane technologies for nitrogen recovery from waste streams: scientometrics and technical analysis. Membranes 13:15. doi: 10.3390/membranes13010015

Alkarimiah, R., and Suja, F. (2019). Effects of technical factors towards achieving the thermophilic temperature stage in composting process and the benefits of closed rector system compared to conventional method–a mini review. Appl. Ecol. Environ. Res. 17, 9979–9996. doi: 10.15666/aeer/1704_99799996

AlSawaftah, N., Abuwatfa, W., Darwish, N., and Husseini, G. (2021). A comprehensive review on membrane fouling: mathematical modelling, prediction, diagnosis, and mitigation. Water 13:1327. doi: 10.3390/w13091327

Amin, M., Agustono, A., Ali, M., Prayugo, P., and Hum, N. N. M. F. (2023). Isolation and screening of indigenous nitrifying bacteria to enhance nutrient recovery in an aquaponics system. J. World Aquac. Soc. 54, 1607–1623. doi: 10.1111/jwas.12970

Armandeh, M., Mahmoudi, N., and Fallah Nosratabad, A. R. (2022). Screening and evaluation of phosphate-solubilizing bacteria isolated from aquaculture ponds in a step-by-step strategy as potential biofertilizer. J. Appl. Microbiol. 133, 1581–1596. doi: 10.1111/jam.15660

Asao, T. (ed.)., (2012). Hydroponics: A Standard Methodology for Plant Biological Researches. Rijeka: BoD–Books on Demand. doi: 10.5772/2215

Aslanidou, M., Elvanidi, A., Mourantian, A., Levizou, E., Mente, E., and Katsoulas, N. (2024). Evaluation of productivity and efficiency of a large-scale coupled or decoupled aquaponic system. Sci. Hortic. 337:113552. doi: 10.1016/j.scienta.2024.113552

Banu, S., Rahman, M. S., and Haque, M. J. (2023). Assessing the performance of a pond sludge remover set and sludge composition. J. Sci. Technol. 43:50. doi: 10.59125/JST.21205

Belmeskine, H., Dilmi, N., and Tsagadirts, Z. (2023). Aquacultural sludge recovery and vermicomposting for soil amendment: a useful strategy for sustainable agriculture. Int. J. Recycl. Organic Waste Agric. 12, 111–121. doi: 10.30486/IJROWA.2022.1944998.1372

Bhuiyan, M. I. H., Mavinic, D. S., and Koch, F. A. (2008). Phosphorus recovery from wastewater through struvite formation in fluidized bed reactors: a sustainable approach. Water Sci. Technol. 57, 175–181. doi: 10.2166/wst.2008.002

Birch, S., Bell, R., Nair, J., and Cao, P. V. (2010). “Feasibility of vermicomposting of aquaculture solid waste on the Mekong Delta, Vietnam: a pilot study,” in Vermitechnology II. Dynamic Soil, Dynamic Plant, ed. N. Karmegam (Ikenobe; Kagawa: Global Science Books, Ltd), 127–134.

Bittsanszky, A., Uzinger, N., Gyulai, G., Mathis, A., Junge, R., Villarroel, M., et al. (2016). Nutrient supply of plants in aquaponic systems. Ecocycles 2, 17–20. doi: 10.19040/ecocycles.v2i2.57

Boruszko, D. (2020). Vermicomposting as an alternative method of sludge treatment. J. Ecol. Eng. 21, 22–28. doi: 10.12911/22998993/116352

Bracino, A. A., Concepcion, R. S., Dadios, E. P., and Vicerra, R. R. P. (2020). “Biofiltration for recirculating aquaponic systems: a review,” in Proceedings of the 2020 IEEE 12th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM) (Piscataway, NJ: IEEE), 1–6. doi: 10.1109/HNICEM51456.2020.9400136

Canziani, R., Boniardi, G., and Turolla, A. (2023). “Phosphorus recovery—recent developments and case studies,” in Sustainable and Circular Management of Resources and Waste Towards a Green Deal, eds. M. N. V. Prasad and M. Smol (Amsterdam: Elsevier), 269–281. doi: 10.1016/B978-0-323-95278-1.00007-3

Cernica, G., Constantin, M. A., Dumitrescu, I., and Codreanu, A. M. (2023). “Research on the possibilities of evaluation and recovery of sludge from sewage treatment plants from the perspective of circular economy,” in Proceedings of the 18th International Conference on Environmental Science and Technology, Athens, Greece.

Chen, M., Ding, S., Chen, X., Sun, Q., Fan, X., Lin, J., et al. (2018). Mechanisms driving phosphorus release during algal blooms based on hourly changes in iron and phosphorus concentrations in sediments. Water Res. 133, 153–164. doi: 10.1016/j.watres.2018.01.040

Cheng, Q., Han, S., Cao, G., Jiang, S., and Chen, Z. (2014). Techniques on suspended solid removal in a recirculating system in aquaculture: a review. Chinese J. Fish. 27, 61–67.

Chong, M. M., Tan, L. S., Jusoh, N. W. C., Goto, M., and Tsuji, T. (2021). “Natural cellulosic adsorbent for recovery of nitrate from aquaculture effluent,” in Proceedings of the 5th International Conference on Advanced Technology and Applied Sciences 2020 (ICATAS 2020) in Conjunction With the 6th Malaysia-Japan Joint International Conference 2020 (MJJIC 2020), Vol. 1051 (Bristol: IOP Publishing Ltd). doi: 10.1088/1757-899X/1051/1/012063