- Department of Agricultural Sciences, University of Naples Federico II, Naples, Italy

The amount of agroindustrial waste, often rich in lignocellulosic components, has increased in recent years due to population growth and the resulting increase in food consumption. Improper disposal of food waste at the end of its life significantly impacts the environment by emitting greenhouse gases into the atmosphere. For this reason, Europe is mobilizing through the implementation of legislation that applies the circular economy model to the recovery of lignocellulosic rich food waste and its conversion into value-added products, such as bioplastics. Bioplastics have also been among the most discussed topics recently, as they could be an excellent alternative to conventional plastics. Therefore, companies have recently set out to give food waste a second life by converting it into bioplastics derived from cellulose and other lignocellulosic fractions. As far as the environmental impact is concerned, recycling seems to be the best way to handle food waste, as it fits into the concept of a circular bioeconomy leveraging lignocellulosic feedstocks and reducing greenhouse gas emissions. It is also important to compare European and non-European regulations on the application of the circular economy model. This review aims to categorize food waste and lignocellulosic biomass, identify related issues, and explore how it can be reused as a resource for producing value added products such as bioplastics. It also explores the potential of recycling as a means of reducing pollution from plastic and food waste. Finally, the concept of ecological sustainability and the application of circular economy models are examined.

1 Introduction

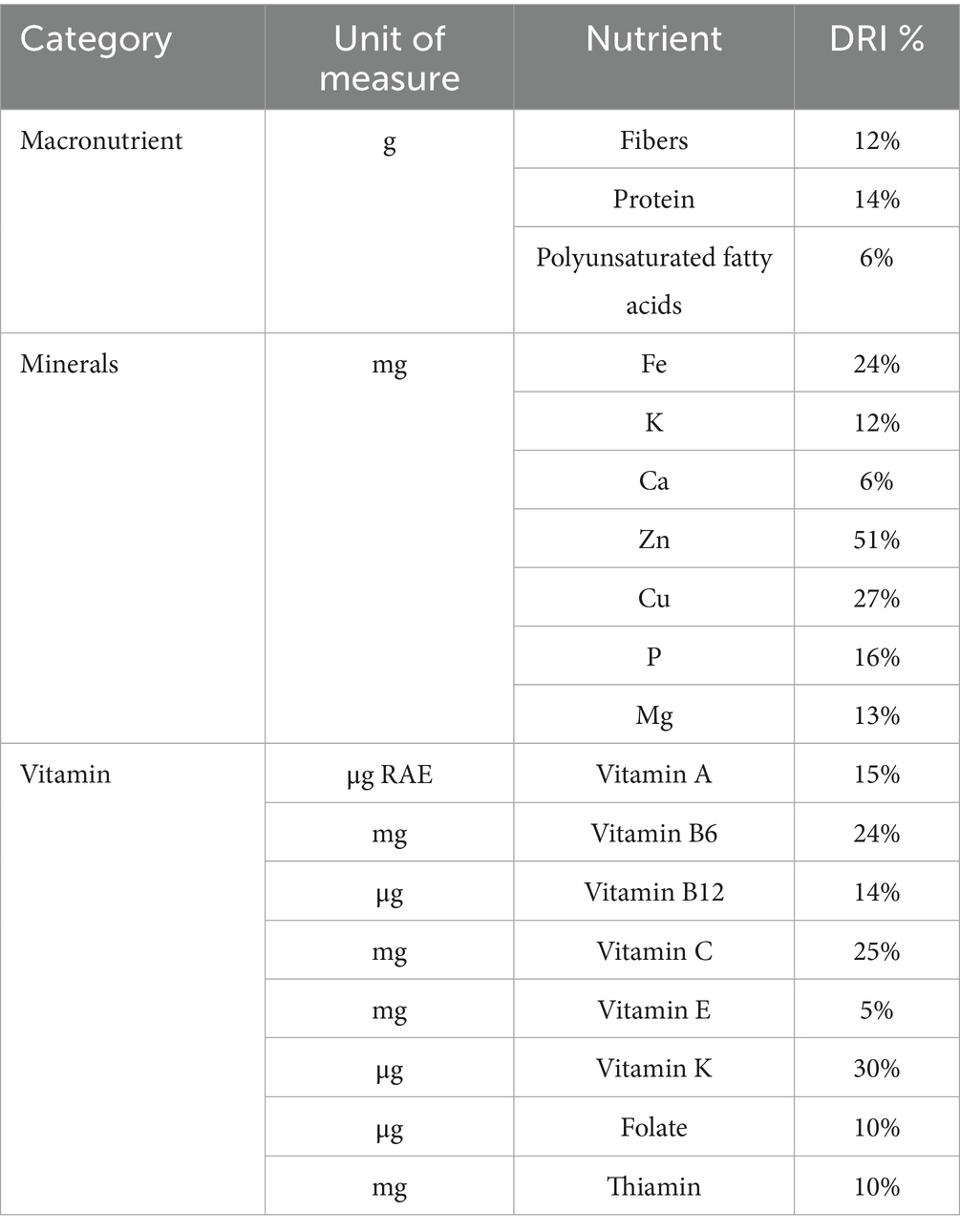

According to the FAO, around 1.3 billion tons wet of food waste are produced every year. As stated by the FAO, food waste (FW) is all waste generated during food production and can be categorized into different types depending on its origin and category: domestic, commercial, industrial, and agricultural waste (Xue et al., 2017), such as spoiled food, plant and animal waste and food scraps. A study conducted by Gustavsson et al. (2025) showed a quantitative analysis conducted on food waste generation across different categories and countries, with a particular focus on food waste patterns in the pre capitalist world. Quantitative data on food waste provides critical insights into the socio economic structures of different societies. A deeper insight into how economic systems influence food consumption, surplus, and loss is gained by comparing food waste in various countries and historical contexts, particularly in the period before the rise of capitalism. The huge amount of food waste poses a serious threat to the environment and the economy. Mismanagement and improper disposal of food waste have been shown to lead to different environmental problems, such as contamination of groundwater, generation of bad odors, and release of toxic gases into the environment, which in turn negatively impacts human health and the economy (Arun et al., 2020; Sharma et al., 2022). The phenomenon under discussion can be attributed to a number of factors: incorrect composting and storage, illegal dumping or disposal in fields and leaching from landfills from an economic perspective, the greatest impact is associated with disposal and production costs. In the last decade, many studies have been published in the literature showing the impact of FW in the world. The data presented by Skaf et al. (2021) show the impact of food waste in the world from an environmental perspective using different environmental indicators. In developing countries, the environmental impact is higher in almost all categories, especially in the USA, followed by the United Arab Emirates and Canada, compared to low income countries. According to Eurostat (2022), a large amount of food waste was produced in Europe in 2020, amounting to 57 million tons, with a corresponding environmental impact in the first phase of feed production (Scherhaufer et al., 2018). The data reported by Abbade (2020) suggest that the problem of FW is also a social problem. From a social perspective, this can lead to food safety, high consumption, and nutrient losses and thus health problems. In this case, Chen et al. (2020) compiled data from the literature on the average amount of each nutrient lost globally and the resulting environmental impact. The data showed that North America and Europe are the countries with the largest nutrient losses. They estimated an average loss of 273 calories, which, when related to daily dietary intake (DRI), equates to 15%. In addition, as shown in Table 1, nutrients and their most important values were selected based on the percentile value of the DRI.

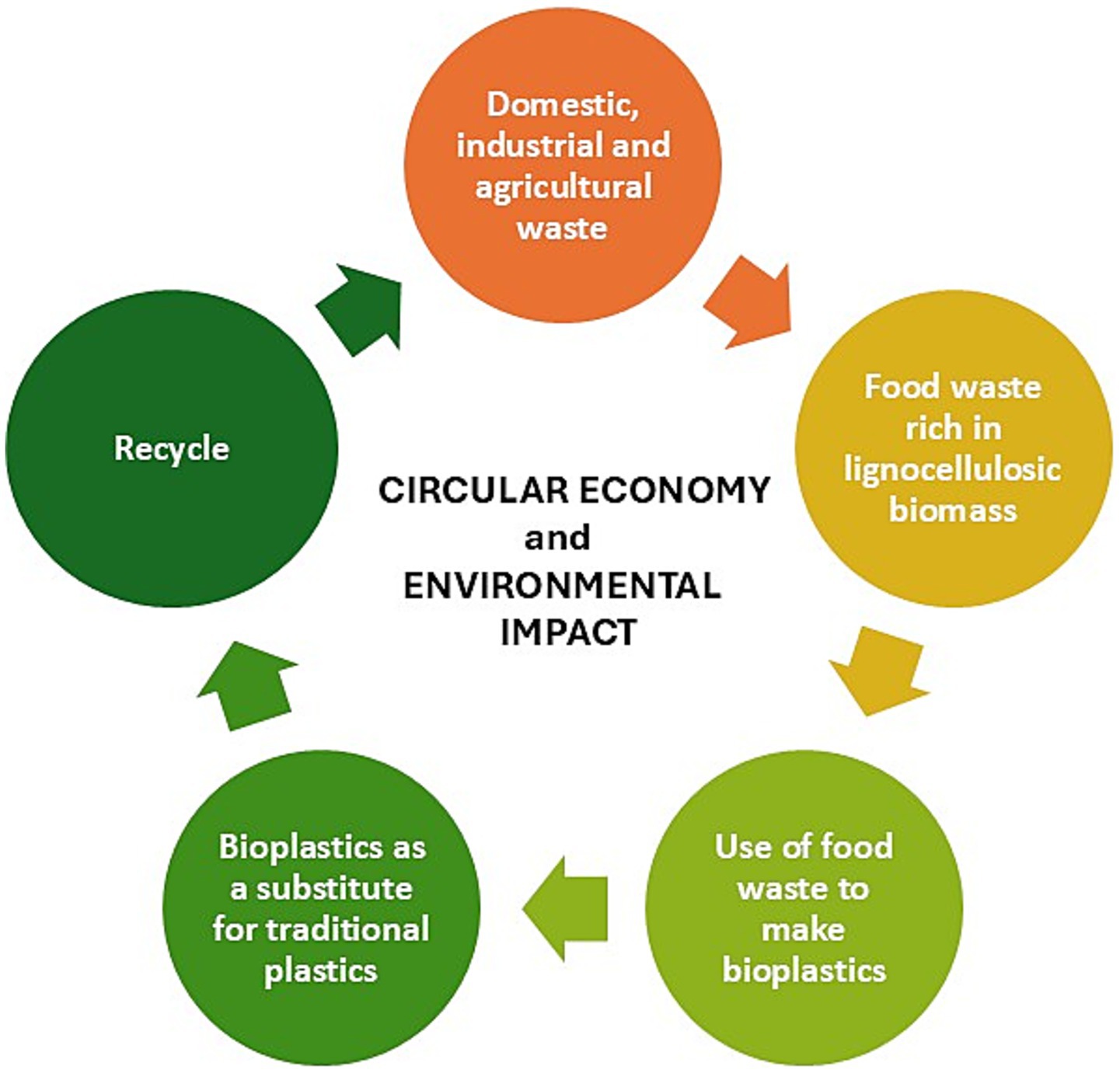

Based on the DRI values for the different categories of nutrients contained in FW, micronutrients appear to suffer the greatest loss at 50%. Achieving food sustainability is a crucial goal for safeguarding our planet and future generations. However, this path is complicated by two main problems that affect food handling, production and storage, resulting in food loss and waste (Eranda et al., 2024b). The concept of sustainable development is a global priority, requiring collaboration between different disciplines to address the complex issues related to climate change, the environment and efficient resource management. With this in mind, a crucial step in achieving the seventh pillar of the circular economy namely, the transition “from waste to consumption” consists in recovering and valorizing abundant organic waste, transforming it into high added-value products (Eranda et al., 2024b). Within the circular economy (CE) and bioeconomy (BCE) models, as well as in the context of increasing concerns about climate change, the focus is on giving a second life to agro-industrial waste by using it in bioplastic production processes. The importance of addressing bioplastics is evident from the significant increase in the production of synthetic plastics in recent years, which is expected to double in the coming decades (Mangal et al., 2023). Synthetic plastics have a major impact on society due to their ease of use and versatility (Silva et al., 2018) and other key properties such as light weight, flexibility, low cost, durability, and adaptability (Lee and Liew, 2020) However, synthetic plastics have many disadvantages, including significant environmental and human health impacts from plastic waste (Wright and Kelly, 2017) Over the last century, it has been found that these plastics can pollute various environmental areas and release micro and macroplastics that enter the food chain. Thus, research into the promotion of bioplastic use and production has been prompted by plastic pollution (Acquaviva et al., 2021). The most widely utilized by products for the synthesis of bioplastics at the moment are agricultural raw materials (Jayakumar et al., 2023). The production of plastic food packaging can benefit from the use of biomass waste as a substitute for fossil fuels. This transition is advantageous for two main reasons: it allows the food packaging sector to break away from fossil fuels and, at the same time, uses agricultural by-products to curb demand for petroleum-based plastics (Eranda et al., 2024b). The creation of sustainable, eco-friendly, and renewable goods from FWs is one of the largest issues that businesses are now confronting (Santana et al., 2021) Biomaterials are an intriguing alternative for recycling and environmental sustainability as they are non-toxic, biocompatible, biodegradable, and environmentally and economically sustainable (Sharma et al., 2020). One way to improve sustainability is to produce bioplastics from natural by-products of the food industry. This solution has the advantage of promoting material recycling, avoiding the need for incineration (Eranda et al., 2024b) Due to the high levels of chemical pollutants discharged into the environment from landfilled FW, research has focused on reusing FW from industrial waste so far, showing that using FW to make bioplastics can lower environmental pollution (Tsang et al., 2019) Furthermore, since bioplastics are biodegradable, replacing synthetic plastics can aid in lowering pollution (Figure 1).

Figure 1. The use of food waste in the pursuit of the circular economy concept entails the generation of value-added products, including bioplastics and recyclables. This approach is posited as a means of mitigating environmental impact.

This review aims to gather all the information from the current literature on how food waste can be valorized and transformed into value-added products such as bioplastics, which bring numerous environmental and economic benefits. It also analyzes the different types of bioplastics (biodegradable and compostable) and highlights their advantages and disadvantages. Finally, this review assesses the importance of moving from a linear economic model to a CE and bioeconomy model, examining the current regulations in the world.

2 Materials and methods

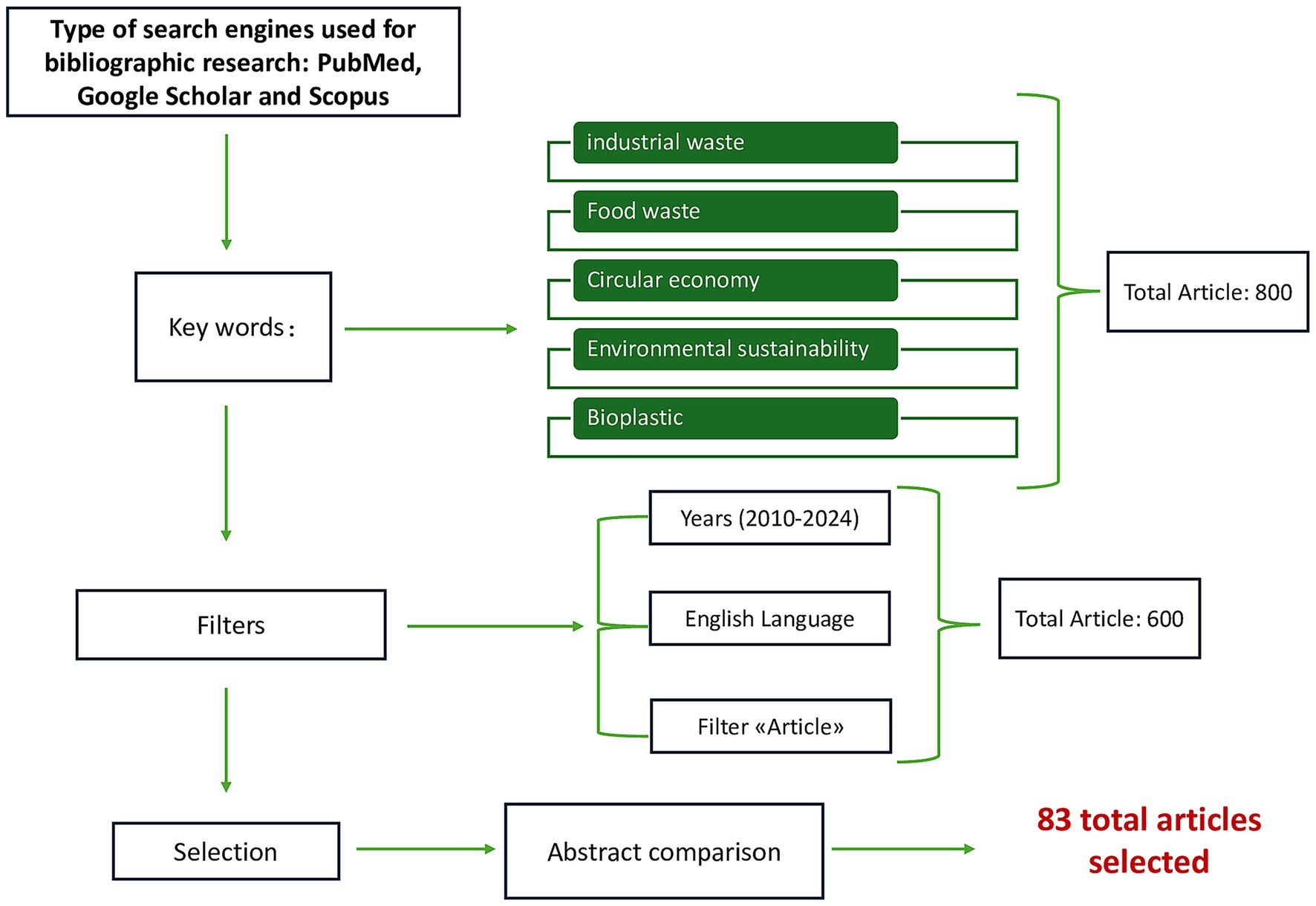

The search engines Google Scholar, Pubmed, and Scopus were used to conduct the literature search. The articles were chosen based on their congruence. Using keywords like agro-industrial waste, food waste, bioplastics, circular economy, and environmental sustainability, a selection of articles was initially produced based on the topic’s relevance. Filters were then applied to reduce the number of eligible articles. For this purpose, articles from the last 10 years (2010–2024) were evaluated, articles in English were selected and the selection filter “Article” was used. In the second step, the articles were selected based on the title and a brief reading of the abstract to determine whether they were related to the topic of research. Next, information about the topic was selected. In this case, the articles containing the same information were compared with each other. The selection was based on the year (the most recent considered) and whether it was an official definition of an institution. Accordingly, a total of 83 articles were selected. In addition, eight reports were included in the review, from which mainly definitions or regulations were extracted (Figure 2).

3 Development of the concept of FW

In recent years, the accumulation of FW has been driven by population growth and the high demand for processed food (Sharma et al., 2020). FW is quite heterogeneous but still consists of the three main macronutrients found in all foods: Proteins, carbohydrates, and lipids (Yin et al., 2016). Waste is generated at several stages of the supply chain, from production to processing and consumption (Bhattacharya et al., 2021). The amount of waste from production to consumption was calculated globally using some data from Gupta et al. (2022). It was found that the largest amount of waste is generated in the consumption phase, which accounts for 36%, followed by the production and storage phase at 24%, retail and distribution at 12% and finally packaging at 4%. Since 2008, new technological methods have been developed worldwide to reduce food waste (High-Level Panel on Food Security and Nutrition of the Committee on World Food Security, 2014; Food and Agricultural Organization, 2013; Food and Agricultural Organization, 2014). One of the most interesting factors being studied is the proper storage of food, as this has an impact on how much food is wasted. Many studies in the literature show results in this area. For example, Peña-Ortiz et al. (2023) use laurel extract for coating, and Peixoto et al. (2023) use potato crisps as a byproduct for food packaging. In this context, food companies and government agencies are working to implement plans to reduce food waste as much as possible and convert it into other products to promote global sustainability (Santana et al., 2021). A practical example is pollutants and organic residues generated during food processing, such as vegetable peelings, plant and animal waste, lignocellulosic material, and many others, from which bioethanol and biogas can be obtained (Wadhwa et al., 2015; Gowman et al., 2019; Kumar et al., 2021). In addition, FW has the potential for upcycling materials from monomeric, polymeric, and colloidal building blocks. These can be used without extensive purification or separation and serve as nutrient sources for biotechnological pathways. Many studies have been carried out on this topic in the past year. Teixeira et al. (2023) have shown how phenolic compounds with antioxidant activity, which are important for human health, can be obtained from the by-products of fruit processing, such as apple and pear peels and seeds. Jianu et al. (2024) investigated how the flowers of the Paulownia plant, which are considered a waste product, can be used to obtain bioactive compounds that have been shown to have an antioxidant effect and can be used in various fields.

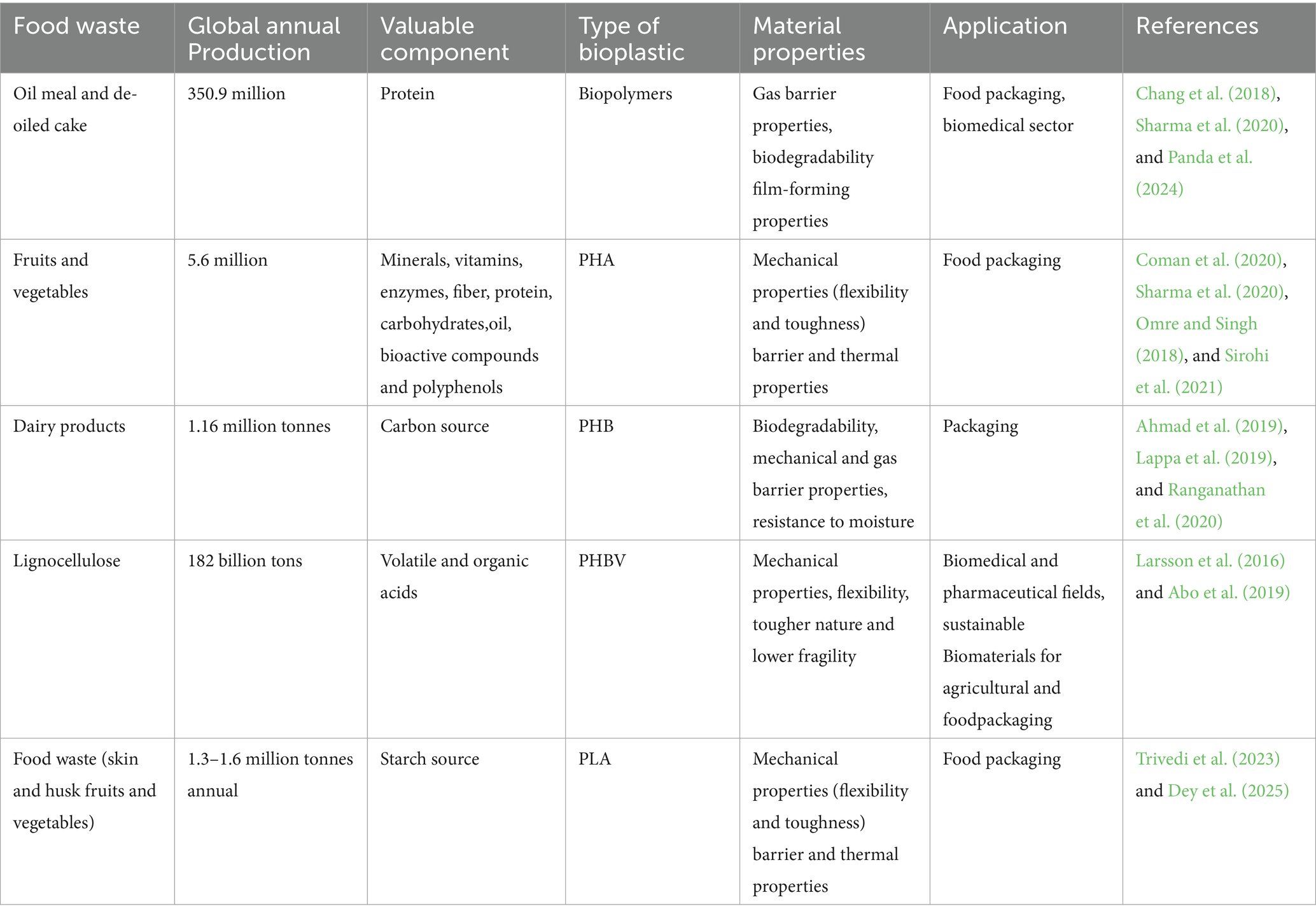

3.1 Sustainable production of high value products from lignocellulosic FW

The rapid expansion of the EU food processing industry, highlighted by a 3.1% turnover increase in 2012, has led to concerns about increased waste. Despite this growth, landfilling remains a prevalent and inexpensive method of waste disposal within the industry. The majority of food industry waste is primarily composed of lignocellulosic materials (Kiran et al., 2014; Yin et al., 2014). Lignocellulosic biomass, Earth’s most abundant renewable resource, is produced annually at a rate of 182 billion tons. Of this, 8 billion tons are currently utilized. This biomass, comprising plants and their processing residues, is rich in cellulose, lignin, and hemicellulose three of nature’s most prevalent polymers (Abo et al., 2019). Low solubility and processability hinder the effective and practical use of lignocellulose and its components, despite their availability, renewability, biodegradability, and biocompatibility which make them very useful for commercial application, instead (Mankar et al., 2021; Verardi et al., 2018). These elements may be converted into different chemical compounds and act as building blocks for bioplastics in both their native and chemically modified forms (Figure 3; Inyang et al., 2022). Therefore it could be not only a financial resource but also a great source of goods with added value and has potential uses in food additives, packaging, biomedicine, energy, and water treatment (Azeredo et al., 2019; Abdul Khalil et al., 2019; Ganguly et al., 2020). The use of lignocellulosic biomass from agricultural waste for the manufacturing of bioplastics has the potential to lower prices and related issues, according to studies by Lu et al. (2022) and Otoni et al. (2021). The use of lignin as a composite or as a raw material in the production of bioplastics has led to improvements in the mechanical and thermal properties of biomaterials. In fact, due to its chemical composition, lignin provides greater tensile strength and modulus, making it suitable for use in the automotive industry and for building materials (Wang et al., 2023). Among the bioplastics derived from lignocellulosic agricultural waste on the market are PHA and PLA. These are obtained through microbial fermentation processes due to the carbon component present in agricultural waste (Abedi and Hashemi, 2020; Chouhan and Tiwari, 2025). PLA is obtained from a microbial fermentation process, resulting from the polymerization of lactic acid, and is defined as a thermoplastic compound, while PHA is obtained from different microbial strains in the absence of nutrients (Montalbo-Lomboy, 2023; Naser et al., 2021). PLA and PHA offer advantages that make them suitable for use as substitutes for bioplastics in food packaging, including: mechanical properties such as flexibility and toughness, barrier and thermal properties, tensile strength and transparency (Bugnicourt et al., 2014; Mai et al., 2024; De Luca et al., 2023; Vayshbeyn et al., 2023). As demonstrated, the advantages of these two biopolymers are extensive for future use, but the main problem is related to the very high production costs. PHB is defined as another type of bioplastic derived from the microbial fermentation process starting from pre-treated lignocellulosic waste (Bhatia et al., 2021). PHB-based films are becoming increasingly popular, both for their biodegradability and for their mechanical and gas barrier properties, as well as their resistance to moisture (Memis Karabuga et al., 2025). The disadvantages of using PHB are due to its high production cost and the fragility of the material, which makes it unsuitable for use in food packaging. For this reason, PHB-based materials are designed in combination with other polymers in order to improve their properties for use in packaging (Memis Karabuga et al., 2025). In recent years, with regard to PHB, the synthesis of copolymers such as PHBV has been evolving. PHBV has proven to be an excellent material thanks to its biodegradability and easy electrical and thermal workability (Shaikh et al., 2021). Materials rich in lignocellulose are a promising source for producing poly(3-hydroxybutyrate-co-3-hydroxyvalerate), or PHBV, due to their ability to undergo processes that yield valuable volatile and organic acids. These acids are crucial precursors in the production of PHBV (Dey et al., 2024). Similar to other biopolymers, the production of PHBV [poly(3-hydroxybutyrate-co-3-hydroxyvalerate)] relies on microbial fermentation. This process employs specific microbial strains, which are selected based on the feedstock, to facilitate the synthesis of the necessary precursors for PHBV production. PHBV, also known as poly(3-hydroxybutyrate-co-3-hydroxyvalerate), has a wide range of applications across multiple industries. Its uses extend from biomedical and pharmaceutical fields, where its biocompatibility and biodegradability are highly valued, to the development of sustainable biomaterials for agricultural and food-contact purposes. Table 2 provides a synopsis of the primary categories of naturally occurring food waste, along with their annual production volumes, content, and the types of bioplastics to which they are applied. Bioplastics represent an alternative to synthetic plastics for their biodegradability, with the aim of reducing environmental impact (García-Depraect et al., 2021). This review by Chamas et al. (2020) reported all the data available in the literature on the degradation rates of the most common thermoplastic plastics on the market (Chamas et al., 2020). For synthetic plastics, degradation times ranging from 10 to 1.000 years have been estimated, with some media outlets even describing them as non-degradable. However, this always depends on the type of plastic in question. Degradation methods are classified as abiotic and biotic; biotic methods include microbial methods, while abiotic methods are divided into chemical, physical, mechanical and thermal methods (Kaur and Chauhan, 2024). For example, a study conducted by Feijoo et al. (2023) evaluated how the addition of cellulose and wood flour to existing PHBV increased the rate of thermal and microbial degradation. PLA, the most widely produced biopolymer, undergoes various degradation processes, including: photodegradation, hydrolytic degradation, thermal degradation and enzymatic degradation (Feijoo et al., 2023). A study conducted by Hedthong et al. (2023) evaluated the addition of natural additives such as hemp fiber to PLA, showing a material degradation rate of 30 days. Bioplastics derived from polysaccharides (cellulose, starch) are subject to various degradation methods, such as photodegradation, thermal degradation and enzymatic degradation (Hedthong et al., 2023). A study conducted by Tan et al. (2022) evaluated the difference in degradation between a pure starch-based film and one with chitosan added as an additive. The latter showed less degradation of the material, equal to 47%, unlike the pure starch film, which showed 53% degradation of the material. Furthermore, this recent review reported by Rosenboom et al. (2022) includes a table comparing the production costs of synthetic plastics and the major bio-based plastics currently on the market. By classifying plastics into two categories: fossil-based and biological, which are in turn divided into durable and degradable, it is clear that fossil-based and degradable plastics have higher costs, such as PBS, which can reach as much as US$4.5 per kg (Künkel, 2016). As regards degradable bioplastics, PLA costs US$2–3 per kg (Senila et al., 2024), while PHB has been shown to have a higher price than PLA. Durable bioplastics have also shown lower prices. Suffice it to say that bioPe costs between US$1.8 and US$2.4 per kg. Table 2 summarizes the various types of bioplastics, the origin of the raw materials, the properties of bioplastics and their current application.

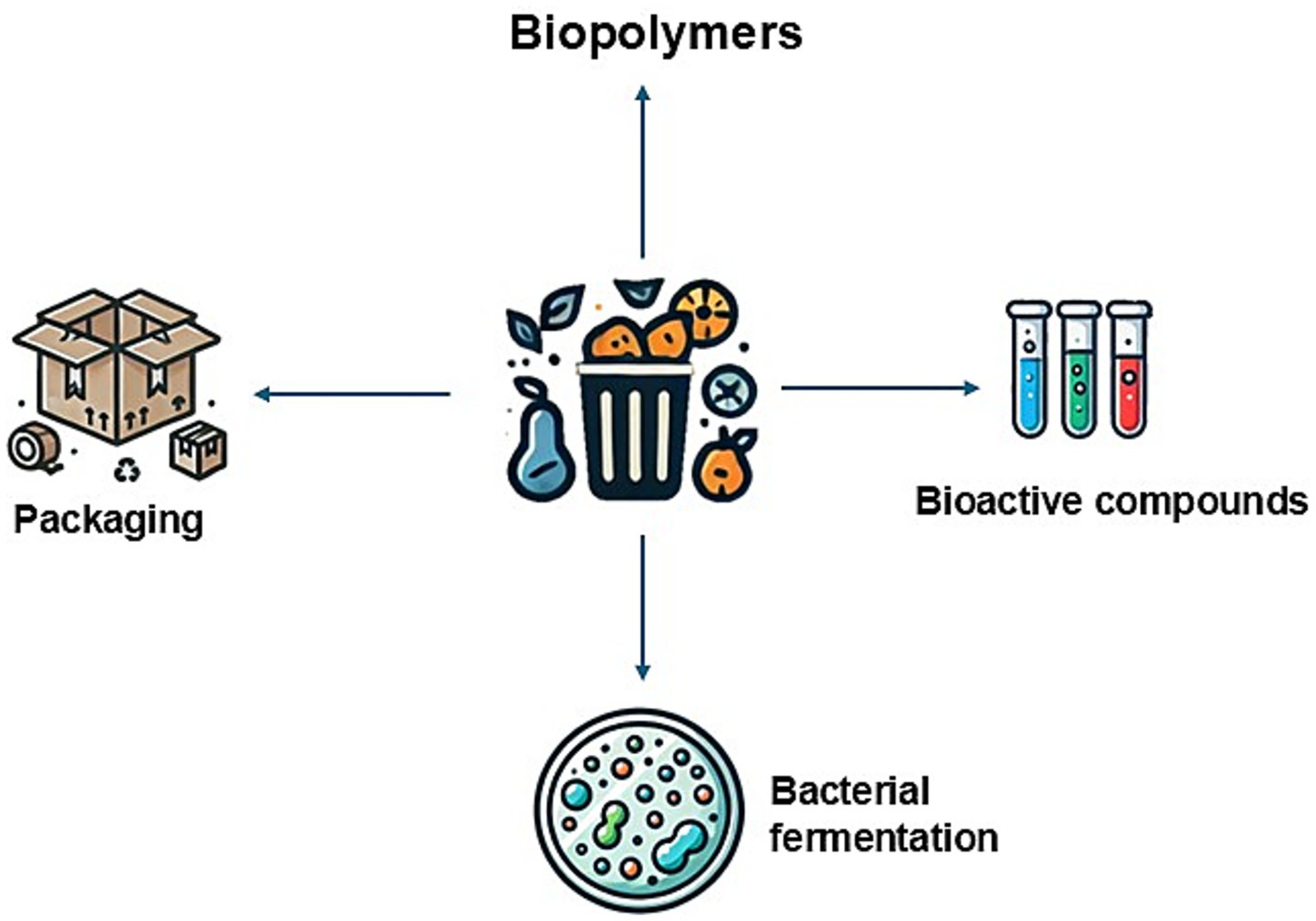

Figure 3. Food waste, which is abundant in cellulose, can be used to obtain value-added products. These include the extraction of bioactive compounds, the provision of a substrate for microbial fermentation, and the production of packaging materials.

4 Development of the bioplastics concept and its characteristics

In the context of a CE, agricultural waste, like vegetable waste, raw materials and food waste could be used to create new products, such as bioplastics, thanks to their intrinsic qualities (Castro-Criado et al., 2023). Among the various definitions of bioplastics, the European Bioplastics Definition defines “bioplastics” as all plastic materials that are biodegradable and derived from biological raw materials (European Bioplastics, 2020). Bioplastics can be classified in three ways according to the polymer: bio-based and biodegradable, bio-based only, or biodegradable only (Madhavan Nampoothiri et al., 2010). Bio-based plastics are made from renewable biological materials. In addition, bioplastics can be classified as biodegradable and compostable. Di Bartolo et al. (2021) define biodegradable when microorganisms metabolize the raw material as a substrate, breaking it down into simple molecules like H2O, CO2, and biomass to be categorized as biodegradable plastics. Should meet specific biodegradability standards, where the degree of degradability is scientifically proved under specific conditions and over a defined period (Di Bartolo et al., 2021) while biodegradable bioplastics can also be compostable under industrial conditions. Today compostable bioplastics are gaining importance due to their ability to degrade during an industrial composting process, their biogenic nature, and their capacity to degrade by 90% within a few months (Siracusa et al., 2008). These materials follow the same life cycle as biomass, eventually producing carbon dioxide, water, and fossil resources (Polman et al., 2021). In summary, biological resources are crucial in the creation of biomaterials, helping to lower the environmental impacts of fossil-based materials and promoting the future of the CE (Brodin et al., 2017). As reported by Acquaviva et al. (2021) although plastic products are made from degradable materials, they are not entirely degradable because the assessment of degradability is linked to official standards that must be fulfilled. The biodegradation process is affected by environmental factors such as temperature, humidity, and microbial concentrations (Romano et al., 2024). In addition, the production of bioplastics involves higher costs and lower yields compared to conventional plastics. Some bioplastics have lower strength than conventional plastics and they show a higher brittleness due to weak mechanical and physical properties and high hydrophilicity (water vapor permeability) (Acquaviva et al., 2021). Lignocellulosic biomass, the most abundant form of plant-based biomass, has seen a surge in interest as a source for biopolymers, offering potential replacements for traditional plastics (Mujtaba et al., 2023; Machado et al., 2020) and can enhance the properties of bioplastics (Kawaguchi et al., 2021). Bioplastics are composed of biopolymers which, depending on their nature, can be polysaccharide-based, protein-based or microbial derivatives. These polymers have proven to be versatile in the production of film coatings, gels and fibers (Dutta and Sit, 2024; Donkor et al., 2023). As regards polysaccharides, in recent years there has been significant development in the use of pectin as a substitute for conventional polymers especially in the development of food packaging (Mellinas et al., 2020). In a review conducted by Mellinas et al. (2020) various sources of food waste and pectin extraction technologies were reported. Pectin is found mainly in the skin of fruit and vegetables such as bananas, aubergines, tomatoes and tropical fruit, as well as in pulp and other waste. Furthermore, in a recent review proposed by Dirpan et al. (2024) the use of pectin as a bioplastic for the development of active and intelligent food packaging was evaluated for its improvement of mechanical and barrier properties. However, when combined with other bioactive compounds, pectin could improve not only the mechanical and barrier properties of pectin-based films, but also their functionality. Examples of this can be found in Zhang et al. (2024) where a film based on citrus pectin with lignin nanocrystals demonstrated improved mechanical properties and water resistance, as well as UV protection. A bioplastic film made from persimmon pectin and a mixture of sodium alginate, guar gum and baobab seed oil has shown significant improvements. These include increased mechanical strength and water resistance, as well as effective biological activity. This film has proven effective in extending the shelf life of mushrooms (Yang et al., 2024; Song et al., 2023). Cellulose is another polysaccharide of interest as it constitutes 30–50% of the components present in food waste. This can be found in waste products such as rice husks, sugar cane bagasse, wheat straw, banana skins and spent mushroom substrate (Sharif et al., 2020). Appropriate processing allows cellulose to be isolated from other non-cellulosic components. This process generates a pure, biodegradable polymer, which is a valid alternative to traditional plastics (Selvam et al., 2025). Cellulose is defined as one of the most interesting biopolymers for bioplastics due to its excellent mechanical properties, thermal stability, transparency and film production (Carolin et al., 2023). In the latter case, cellulose-based films are considered sustainable and promising alternatives for food packaging. These materials are ideal due to their characteristics such as transparency, biodegradability, resistance and low oxygen permeability (Selvam et al., 2025). Furthermore, cellulose-based films stand out as an environmentally friendly alternative to traditional plastics, offering the advantage of degrading naturally without producing microplastics. Unlike synthetic plastic films, which, despite being more water-resistant and economical, contribute to waste accumulation and environmental pollution, cellulose films are produced from renewable sources and are compostable (Carolin et al., 2023; Oza et al., 2025). Using cellulose-based biopolymers is a promising approach to sustainable packaging (Dhalsamant et al., 2025). Being biodegradable and compostable, these materials help reduce plastic pollution and align with global sustainability goals. In this way, they promote material recovery and more efficient end-of-life management practices (Rosenboom et al., 2022). Starch is another biopolymer that has been used in recent years as an alternative to synthetic plastics especially in the food packaging sector (Tagliapietra et al., 2021). The highest starch content in food waste is found in rice husks, corn husks, potato skins and banana skins (Maqsood et al., 2025), Starch is used as a substitute for synthetic plastic in packaging and medicinal products (Arruda et al., 2025; Singh et al., 2024). Starch is used in film production due to certain properties such as transparency, flexibility, biodegradability and gas barrier, which are important characteristics for the development of packaging (Gonçalves et al., 2024). Although starch appears to be a very interesting biopolymer for use in the development of food packaging, it nevertheless has limitations that restrict its application, such as low mechanical properties, thermal stability, water resistance and limited industrial producibility. Recently, protein biopolymers have emerged as another bio-based alternative to synthetic plastics, offering excellent gas barrier properties, biodegradability and film-forming properties. Contrary to what one might think, there are many food waste products from which protein can be extracted. In fact, we can find it in oily waste, wheat and rice bran, and animal waste such as fish and poultry (Abedini et al., 2022). Protein-based films offer numerous advantages, including oxygen barrier properties that make them ideal for food packaging. They are also biodegradable and edible, with a smooth, transparent texture (Purewal et al., 2023; Khin et al., 2024). As with starch-based films, protein-based films also have limitations in their development, such as low mechanical and thermal resistance (Coltelli et al., 2015; Zhao et al., 2025). The study conducted by Eranda et al. (2024a) was interesting in terms of the development of new bioplastics that have been emerging in recent years, such as chitosan-based edible coatings and films assessing the challenges and future prospects for the synthesis of these new types of bioplastics. They found that the main limitations associated with the production of bioplastics are related to costs and product quality, due to extraction costs and ensuring the quality of the final product, which can affect the mechanical and organoleptic properties of the material, thereby influencing the quality of the material and its permeability to water vapor. Due to these limitations, future challenges are focusing on various aspects: combining multiple polymers to improve material properties, developing smart packaging that uses sensors, such as pH sensors, to help improve food shelf life, and designing coatings that do not come into direct contact with food in order to limit organoleptic alteration and unpleasant flavors.

4.1 Food waste to bioplastics: a sustainable solution for environmental impact

Finding methods to recycle plastics and food waste can help solve environmental pollution problems such as water and soil contamination, while also identifying cost effective solutions. In 2019, the FAO calculated the carbon emissions throughout the food chain: agriculture accounted for 13%, pre and post production stages for 11%, and land use for 6.5%, highlighting that carbon is a major contributor to environmental pollution (Food and Agricultural Organisation, 2019). As Ranganathan et al. (2020) and Kakadellis and Harris (2020) report, the growing global population has resulted in an increased demand for food:

• Resulting in more waste biomass and increased disposal costs.

• Inadequate management of agro-industrial waste.

• Economic impact.

• Environmental impact (FW is a potent emitter of greenhouse).

On this basis, seeking processes to reduce FW, in small quantities, is a step forward for environmental sustainability to reduce the environmental impacts it causes (Tsegaye et al., 2019). To address this issue, initiatives have been defined to reduce environmental impacts and implement sustainable production systems, not surprisingly, scientific research is working on finding technological applications to reuse these FW and transform them into other valuable products (Mak et al., 2020). One solution, documented by Acquaviva et al. (2021) the valorization of fruit and vegetable products is particularly significant as they can replace Fossil-based resources used for plastic production and can be defined as an excellent strategy toward sustainability. To date, bioplastics obtained from lignocellulosic biomass derived from food waste have been analyzed, and the environmental benefits of their use have already been widely discussed. When discussing lignocellulosic biomass, it is necessary to make a distinction based on the raw material used. These can be divided into: “virgin” lignocellulosic biomass, which includes, for example, energy crops (a type of biomass used for energy production), grasses/herbaceous crops, conifers and broadleaf trees (Vigneswari et al., 2021). The use of these raw materials, which are also sources of food, requires vast tracts of land, large quantities of water, chemicals and energy for all stages, from cultivation to processing. Their use in the polymer industry reduces their availability for food, leading to higher food prices and limiting their commercial distribution (Possidónio et al., 2025).

4.1.1 Environmental sustainability and bioplastics

The importance of bioplastic production in reducing environmental impact is supported by scientific data. Replacing conventional plastics with bioplastics obtained from food waste can lead to energy savings and reduced greenhouse gas emissions. The main advantage of bioplastics is that they derive from renewable resources (Álvarez-Chávez et al., 2021). According to literature, the manufacture of bioplastics can lead to a decrease of 80% in CO2 emission compared to traditional plastics. Furthermore, the synthesis of bioplastics consumes significantly less energy, with a reduction of about 65% in energy utilization (Mehta et al., 2021). The manufacturing and application of bioplastics can lessen the negative effects of improper waste disposal on the environment, including chemical spills and pollution of the land and sea (Mangal et al., 2023). Additionally, a recent review by Islam et al. (2024) pointed out that bioplastics may negatively affect the environment throughout their lifecycle, from production to disposal. The authors stressed that the most significant environmental impacts occur during the production stage, including intensive land use, soil acidification, and eutrophication. Moreover, improper degradation can lead to the release of micro and nanoplastics. Due to regulations aimed at preventing climate change and reducing the use of plastic bags, the processing of bioplastics is increasing and gaining market importance. The European Union (EU) has the highest consumption of biopolymers, driven by European Parliament regulations that promote the production of disposable items from sustainable sources (Gautam et al., 2022; Acquaviva et al., 2021). Especially in the food sector, bioplastics are becoming increasingly important for packaging, where they have been shown to have a positive impact not only on food safety and preservation but also on reducing environmental impact (Versino et al., 2023).

4.1.2 Environmental sustainability of compostable and biodegradable bioplastics

The importance of using biodegradable and compostable bioplastics has already been emphasized, but in this recent study reported by Dolci et al. (2023) however, compostable bioplastics present critical issues related to their disposal management, as there is no adequate and uniform methodology for their handling, leading to environmental and economic problems. To date, the disposal of bioplastics poses a significant challenge because of some common characteristics shared with conventional plastics. A potential solution is to use materials that are more compatible with biological treatment processes or to replace plastic with paper, which offers some advantages in terms of pre-treatments for digestion (Dolci et al., 2023). It is crucial to bear in mind that, even though biodegradable plastic seems to be a viable solution, it requires specific disposal methods. Biodegradable polymers need a controlled environment for degradation, yet ensuring complete degradation is difficult (Acquaviva et al., 2021). The increased use of plastics and the very long degradation times are favoring the reduction of their use and their replacement by degradable plastics. The environment may be further contaminated by fragmentation into microplastics as a result of inappropriate disposal or an incomplete degradation process (Shruti and Kutralam-Muniasamy, 2019). Because of their expanding use, rules related to the production, application, and disposal of bioplastics are necessary. For example, Bhagwat et al. (2020) and Qin et al. (2021) shown that the decomposition of bioplastics could potentially increase greenhouse gas emissions. PLA decomposes in landfills and emits methane, which accumulates and is released into the environment. The European Directive 2018/851 states that EU member states may accept biodegradable and compostable plastics if they comply with European or national packaging laws. Biodegradation or composting is encouraged as a more sustainable method and should be managed together with organic waste (Dolci et al., 2023).

4.1.3 Standards used in assessing the biodegradability of bioplastics

The standards used in assessing the degradability of bioplastics depend mainly on the degradation environment, whether soil, aquatic environment or compost (ASTM International, 2018a). With regard to soil, we find two types of standard regulations adopted: ASTM D5988-18, which compares biodegradable material and a reference material in terms of CO2 emissions produced by microorganisms in the soil over a given period of time (Šerá et al., 2020; ASTM International, 2015) and ISO 17556:2019, which is based on the assessment of the biodegradability of biomaterial in soil under standardized and controlled conditions and monitors the production of O2 and CO2 produced(ISO, 2012). These two regulations set out standard conditions to be maintained when assessing the degradation of biomaterial, namely that samples must be placed in containers with soil and mesophilic microorganisms (at room temperature), with humidity and oxygen levels being monitored (ASTM International, 2018a). However, these standards have limitations, including:

• No realistic condition: since the tests are carried out on a laboratory scale, where conditions are controlled, which is not the case in real terrain.

• Limits on time and degree of degradation: i.e. no precise times are defined in which a biomaterial is considered to be completely degraded

• difficulties in comparison with other studies: Since there is no standard methodology, each scientist decides to adopt different methodologies, making it difficult to compare data found in the literature.

• Failure to assess many factors that influence degradability, such as the type of bioplastic and environmental factors

• No ecotoxicological assessment

• Complementary approaches: Standardized laboratory tests must be combined with field studies to gain a better understanding of the biodegradation of bioplastics (ASTM International, 2018a)

Regarding to standard regulations concerning the degradation of bioplastics in composting environments, there are several: ISO 14855-1:2012 evaluates the conversion of carbon in the raw material into CO2 to assess biodegradability (ASTM International, 2018a). ASTM D5338-15 evaluates the aerobic biodegradation of plastic materials by increasing the temperature for thermophilic microorganisms in a controlled environment (ISO, 2018a). ISO 14855-2:2018. is an implementation of other regulations that assesses the mineralization of biopolymers (ISO, 2021), ASTM D6400-21includes phytotoxicity and elemental analyses (ASTM International, 2018a), ISO 17088:2021 is similar to the previous one, but also evaluates the final compost and the negativity of the process (ASTM International, 2018a), ISO 16929:2021 is used to determine the degradation and composting of plastic materials on a large scale (ISO, 2016a).

As in the previous case, limitations were also found here in the standard regulations used for bioplastic degradation:

• These standard do not assess domestic composting, only industrial composting.

• Limited tests to assess the degradability of the material, such as ecotoxicological assessment and chemical and morphological characterization of the degraded material.

• No single methodology for assessing the degradability of the material

• The costs of administering the tests are high

• Also add tests in the assessment of ecotoxicity and environmental safety (ASTM International, 2018a)

Finally, as regards the standard regulations established for aquatic environments, unlike previous ones, they have been established both on a laboratory scale and in the field. For laboratory testing standards, ISO 18830:2016 and ISO 19679:2020 focus on measuring biodegradation in environments that simulate the interface between seawater and sandy sediments. Depending on the standard, the assessment is based on the oxygen demand of microorganisms or the amount of carbon dioxide produced (ISO, 2016b; ISO, 2020a). ISO 23977-1:2020 e ISO 23977-2:2020 recreate the conditions of a column of seawater in the laboratory. Biodegradation is assessed by measuring the carbon dioxide emitted or oxygen consumption, respectively (ISO, 2020b; ASTM International, 2017). ASTM D6691-17 is a standard that determines biodegradation in a controlled marine microbial consortium by measuring the amount of CO₂ generated (ASTM International, 2018b). Finally, ASTM D570-98, ASTM D5229, and ISO 62 are complementary standards that measure the water absorption of plastics, providing useful data for evaluating the hydrolytic degradation of materials (ASTM International, 2020; ISO, 2008; ASTM International, 2021). As regards the standards used in the field: ASTM D7473/D7473M-21: Evaluate biodegradation by weight loss in a continuous aquarium system (ISO, 2018b), ISO 15314:2018 and ISO 22766:2020: Establishes methods for marine exposure on the water surface and evaluates the disintegration of plastic materials in marine habitats under real conditions (ISO, 2020c; Eranda et al., 2024a).

As regards the limitations associated with the application of these regulations in an aquatic environment, there are several:

• Lack of standard regulations for degradation in freshwater environments

• Standard methodologies have shortcomings in the preparation of the inoculum and fail to accurately reproduce the conditions of real aquatic environments.

• There are no specific guidelines for the use of different test materials, which may affect the validity of the results (ASTM International, 2018a).

• Other limitations listed in other environments where bioplastics degrade

Since there are no official guidelines on the biodegradability of bio-based polymers, it is difficult to ensure that products made from these materials are accurately labeled. For this reason, both researchers and certification companies rely on existing standards, originally designed for conventional plastics. Many studies also combine results obtained from standards such as ISO and ASTM with data collected through other laboratory methodologies to obtain a more complete picture (ASTM International, 2018a).

4.1.4 Switching from traditional plastics to bioplastics for less environmental impact

For waste management and environmental preservation, new viewpoints on the value-adding of organic waste and the decrease of traditional plastics are essential (Bartolucci et al., 2023). The environment is severely harmed by the manufacture of traditional plastics, which are dependent on fossil fuels. Due to their sustainability and biodegradability, bioplastics have become a viable strategy for cutting greenhouse gas emissions (Fredi and Dorigato, 2021). Standard plastics’ widespread usage has led to massive trash production, and the issue of “plastic pollution” has been exacerbated by their poor degradability (Reshmy et al., 2022). Moving from “fossil-based” to “bio-based” plastics becomes increasingly important as the demand for bioplastics keeps growing (Fredi and Dorigato, 2021). The literature discusses various processing procedures and compares different biomass sources, especially lignocellulosic residues, used to make bioplastics and biopolymers. This information can help reduce either the production costs or the environmental impact of bioplastics (Versino et al., 2023).

4.2 Recycling as a solution to environmental impact

According to European Directive (2018) recycling is a preferable method for disposing of bio-based plastics, helping to reduce environmental pollution and conserve non-renewable resources. Recent research has emphasized the importance of recycling as an alternative approach to:

• Plastic recycling could foster the development of a green economy and sustainability by valorizing waste to obtain polymeric materials (Morici et al., 2022).

• Effective recycling methodology plays a key role in waste management to address environmental pollution issues (Bigdeloo et al., 2021).

Despite its many advantages, recycling can be less suitable due to the presence of additives or other materials that complicate the process and increase costs, or due to the incorrect identification of materials (Yates and Barlow, 2013). Furthermore, recycling could not be the best method for biodegradable plastics, as these materials require specific conditions for proper disposal (Fredi and Dorigato, 2021). Plastic pollution is indeed exacerbated by the high recycling and reuse of existing plastic products, particularly disposable materials, and by a lack of sustainable alternatives (Di Bartolo et al., 2021). Therefore, it is essential to reduce environmental waste also through the consideration of recycling, reduction, reuse, and energy recovery by applying the so called 4R rule (Morici et al., 2022) the European Union is working to address environmental and sustainability issues through the European Green Deal, aiming to zero net emissions by 2050. The EC is attempting to address several plastic related issues, such as lowering the application of non-reusable plastic products, enhancing labeling, decreasing the production of microplastics, and minimizing greenhouse gas emissions during production or insufficient recycling (Di Bartolo et al., 2021; European Commission, 2020).

4.3 The importance of LCA in environmental sustainability

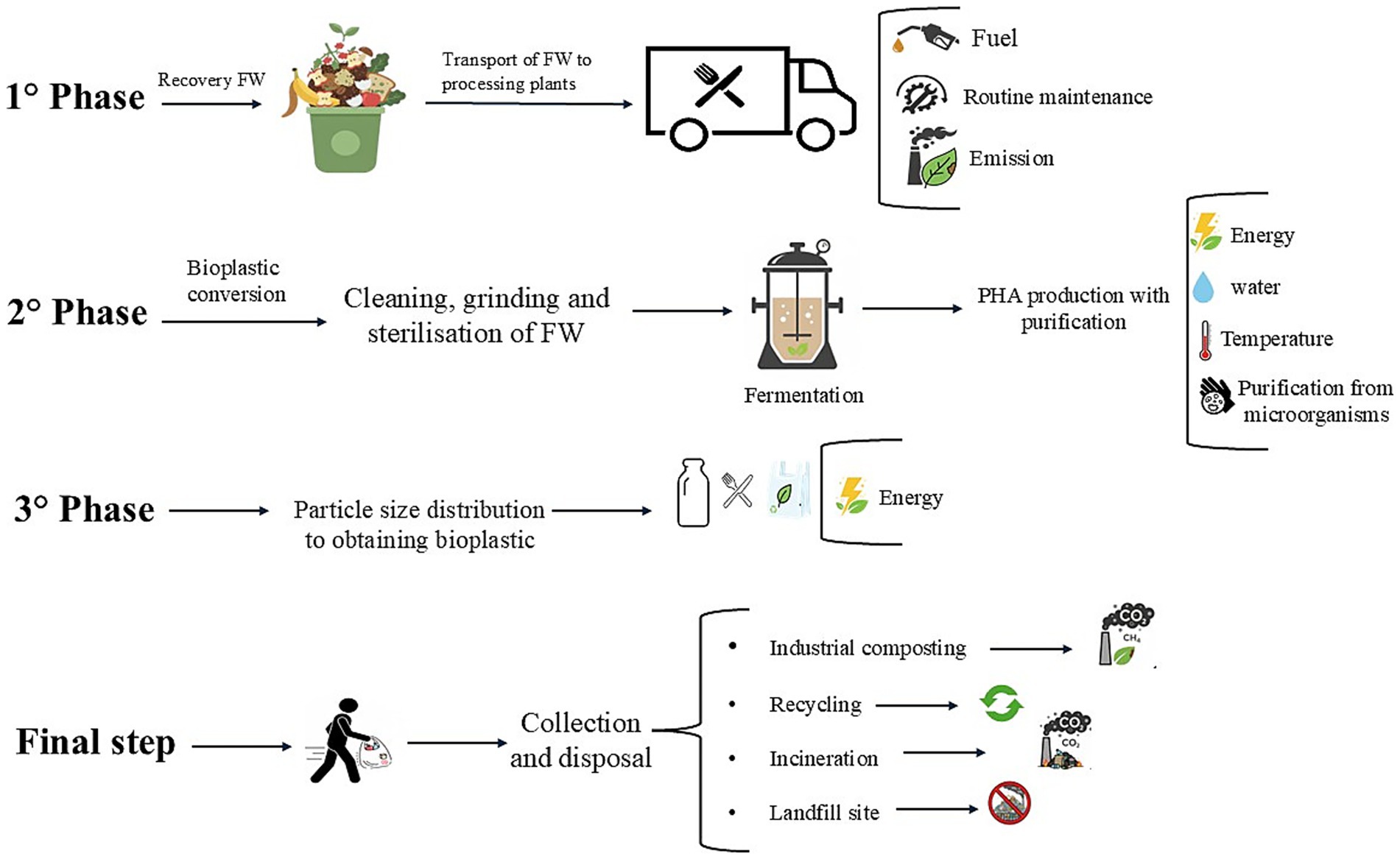

Through the analysis of numerous studies, the crucial role played by LCA in environmental sustainability was established. LCA is extensively employed to evaluate ecological consequences, particularly within food production systems (Di Bartolo et al., 2021) and is defined as a method for quantitative and qualitative analyses of the production chain. The LCA model has also been very useful in the definition of the best balance between a food product and its packaging in terms of sustainability (Versino et al., 2023). Several articles on different types of polymers of fossil and biological origin have been produced and compared, but the study has not highlighted any significant differences in the environmental impact of the two different categories of polymers (Walker and Rothman, 2020). An example of an LCA study conducted on bioplastics was performed by Groot and Borén (2010) on the industrial production of polylactic acid (PLA), showing how bioplastics may mitigate environmental impact compared to synthetic polymers. LCA studies reveal that manufacturing bio-based plastics can reduce greenhouse gas emissions by nearly 200% and curtail fossil fuel usage by 95% (Banu et al., 2021). Conversely, referring to an LCA of synthetic plastic (derived from non-renewable chemicals), it was observed that the emission of hazardous substances and gases into the environment significantly increases its overall environmental footprint. The final phase of the LCA cycle, i.e., the disposal of plastic waste, is considered the most critical because improper disposal leads to a high environmental impact (Acquaviva et al., 2021) Based on the information gathered from the literature, the environmental impact of fossil-based plastics compared to bioplastics has been established. However, it is equally important to assess the environmental effects of bioplastics, especially if appropriate disposal methods are not implemented. Currently, recycling is considered the most effective way to minimize environmental harm, though there is limited data in the literature supporting it as the optimal solution. Additionally, conducting an LCA can help measure the environmental impact across the entire life cycle of bioplastics. Overall, the authors found no significant numerical data on the environmental impact associated with bioplastic production. A recent case study conducted by Senila et al. (2024) applied the LCA model to bioplastics such as PLA and PHB starting from lignocellulosic waste. The standard methodology ISO 14040 and ISO 14044 was taken as a reference, divided into four parts: defining the objective, inputs and outputs and all processes involved, quantitative assessment of materials, and defining process categories and units of measurement. The “cradle-to-gate” system was considered. As an initial unit of measurement, we started with 100 g of biomass treated to obtain 6.8 g of PLA and 7.3 g of PHB. In addition, a specific impact analysis was carried out using the Impact 2002 + model, considering more than 15 environmental impacts. GWP emissions were 512.3 kg/ton. With regard to human toxicity, the non-carcinogenic human toxicity value was 0.5 kg of C₂H₃Cl equivalents per kg of PLA. This shows that the greatest environmental impact of PLA production occurs during the biomass pre-treatment phase. With regard to human carcinogenic toxicity, a greater impact is evident during the pre-treatment phase, with a value of 2.85 kg C₂H₃Cl eq, if followed by biomass processing, polymerization and lactic acid purification. As far as PHB is concerned, microbial fermentation has the greatest environmental impact in PHB production. As regards PHB, microbial fermentation has the greatest environmental impact in PHB production. Fermentation is the stage that has the greatest impact on non-renewable energy production, amounting to 12,883.54 MJ. Furthermore, to produce 1 kg of PHB, the amount of CO₂ produced is equal to 45 kg of CO₂ equivalents, which is less than the production of PLA. Therefore, from an example of life cycle analysis applied to the production of bioplastics such as PLA and PHB, it can be seen that both are materials with different properties but excellent in terms of sustainability and the circular economy, even though the production of PHB has shown a lower impact than PLA. Figure 4 illustrates a flow chart of a full life cycle LCA, beginning with food waste and concluding with the production of a bioplastic such as PHA, through to the end of its life cycle. Each stage highlights the main impacts affecting PHA production, and the final stage outlines the various methods that can be adopted for the disposal of the biomaterial obtained. Dolci et al. (2025) examined data from recent literature (2019–2023), comparing different types of plastics, from synthetic to bioplastics, and the use of life cycle analysis. A comparison of these studies shows that LCA analysis currently has many limitations due to the scarcity of methodologies. Among the various limitations, incomplete analyses, lack of primary data and omission of uncertainty analysis have been found. Furthermore, when comparing different materials currently used in the packaging sector, it would appear that paper and glass have the same environmental impact in terms of transport and production complexity. Bioplastics, on the other hand, have only shown an advantage from a climate perspective. This has given rise to a debate linked to the public perception of synthetic plastics, which contrasts with an LCA that does not condemn the use of synthetic plastics. The problem is linked to the fact that applying an LCA analysis fails to identify the environmental damage caused by the dispersion of plastics in the environment. For this reason, it is necessary to expand new impact methodologies. The areas for improvement therefore lie both in the type of material to be used, i.e., the use of recycled polymers, which an LCA identifies as ideal for reducing impact, and in finding solutions for the end of life of bioplastics, i.e., not only biodegradation but also the alternative of recycling and, finally, introducing reuse systems. In addition, the scientific community must adopt methodologies that complement LCA through a holistic approach, thus also implementing economic and social aspects to better analyze the environmental impact caused by materials.

Figure 4. LCA flow diagram of PHA production following the cradle-to-grave model. In the first phase, dedicated to the recovery of lignocellulosic biomass and its transport to the processing plant, an LCA considers the use of fuel for transport, gas emissions and routine maintenance to be applied. The second phase is based on processing the raw material to obtain the biomaterial. In this case, for the production of PHA, the pre-treatment of the raw material and the use of a bioreactor for fermentation must be taken into account. In an LCA analysis, the energy and water used, the maintenance of the temperature to perform the fermentation correctly, and the purification of the material from microorganisms used must be taken into account. The third phase involves processing the material, both to remove the coarse parts and to produce bottles, bags and cutlery. In an LCA analysis, the energy wasted in using tools to obtain the desired shapes must also be taken into account. In the final stage, the use of the material must be considered and the various methods of disposing of the biomaterial must be evaluated. In an LCA analysis, it is important to establish the type of disposal of the biomaterial as it affects the environmental impact. For example, landfill disposal is one of the least appropriate methods as it involves high emissions of greenhouse gases and methane into the environment, as is also the case with incineration. Among these, the most suitable alternative is recycling the material, evaluating the energy savings and comparing it with a synthetic material. Another alternative, but less suitable, is composting, which produces compost, water and releases carbon dioxide into the environment. In this case, the emission of greenhouse gases into the environment and the quality of the compost obtained are assessed.

4.4 The importance of technical economic assessment for bioplastic

Another type of analysis needed to assess the economic and environmental impact of producing bioplastics from food waste is TEA. By definition, TEA is used to assess the effect of an industrial production process in terms of whether the product obtained is economically advantageous (Thoppil and Zein, 2021). This methodology is widely used by companies because it allows them to understand the most economically advantageous procedure and also to define the final price of the product. It is based on the use of a program that analyses the costs incurred by the company, production costs and revenues based on incoming technical and economic data (Meng et al., 2020; Zimmermann et al., 2020). TEA is based on two types of technical criteria, which, depending on the choice, determine the efficiency of the technology used to obtain the product: technical criteria based on energy and mass efficiency, and technical criteria based on costs, returns, technology and investment (Gutiérrez Ortiz, 2020; Cristóbal et al., 2018). The TEA method can be summarized in four stages:

• Design the methodology: Refers to the inflows and outflows (solid, liquid and gaseous) of the designed system (Cristóbal et al., 2018).

• Project presentation: The project model under consideration is examined in detail. The result is presented in the form of a table showing the material balances based on the project flows (Murthy, 2021; Chris Burk, 2018).

• Assessment of the equipment used: energy consumption, tool efficiency, costs, and dimensions (Meng et al., 2020; Sangtani et al., 2023).

• Operating and financing costs.

In recent years, bioplastics have become increasingly important as substitutes for synthetic plastics. However, there are still many limitations to the production of bioplastics, particularly in terms of production costs, which prevent their large-scale commercialization (Ratshoshi et al., 2021). According to studies in the literature, it is clear that the technical-economic analysis for the production of bioplastics must consider both upstream factors (biomass accumulation and production capacity) and downstream factors (processing and market) to ensure economic sustainability (Ratshoshi et al., 2021). In the TEA analysis conducted for the production of two types of bioplastics, PLA and PBS, both obtained from sugar cane molasses and bagasse, the selling prices were US$2.9/kg of product and US$3.1/kg of product, respectively (Ioannidou et al., 2022). Meanwhile, obtaining PLA and PBS from sugar beet pulp resulted in lower costs, equal to US$1.14/kg and US$1.37/kg (Levett et al., 2016). Regarding to PHB production, the literature contains numerous TEA analyses on the production of this bioplastic, modifying both the starting raw material and the microbiological aspects (microorganisms responsible for fermentation). In a study conducted by Levett et al., the polysaccharide substrate was replaced with methane, applying methanotrophic fermentation and solvent extraction, which resulted in a production cost of 4.1–6.8 US$/kg (Levett et al., 2016). In another case study conducted by Pavan et al. (2019), they focused on the production costs of PHB influenced by the necessary equipment and the use of extraction methods and raw materials. They used Cupriavidus necator as a microorganism, with waste molasses as the starting raw material and different extraction techniques. This had a significant impact on the production costs of the bioplastic in question, which fell from US$5.50/kg for a production capacity of 2,000 tons/year to US$2.71/kg for 10,000 tons/year. Other types of TEA analysis applied to PHB production involved evaluating production costs through photosynthetic processes, associated with extraction methods and the use of cyanobacteria, which showed a reduction in PHB production costs of 7.7 US4/kg (Wiesmeth, 2021).

5 From food waste to future: a circular economy approach with bioplastics

In recent years, many scientific articles analyzed have shown a high level of interest in the application of the CE concept to food and plastic waste management. According to Pugazhendhi et al. (2019), to reduce FW, BCE seems to be a viable and practical solution at every stage of the food supply chain where waste occurs. Riera and Maldonado (2021) support the idea that innovation in bio-based materials within a bioeconomy framework is crucial for fostering sustainable growth in industry. The concepts of CE and circular bioeconomy both aim to reduce gas emissions throughout the food production process, but they differ in their starting materials. According to Kumar et al. (2021), the concept of bioeconomy can be summarized in four cornerstones:

• Zero FW generation.

• Suitable FW management.

• Reduced waste management costs.

• More sustainable production of value-added products.

5.1 Applied circular bioeconomy to manage FW

Reducing food waste requires the application of the circular bioeconomy concept. The BCE focuses on exploiting renewable biological resources to convert them into bioactive molecules, biobased polymers, or energy in order to reduce costs and address environmental challenges (Mak et al., 2020; Rathan et al., 2019). Understanding the origins of garbage is essential for implementing optimal disposal techniques and efficiently managing waste (Mishra et al., 2020). It is essential to manage FW in conjunction with other organic waste for landfill disposal or energy recovery (Mak et al., 2020). Boccalon and Gorrasi (2022) have made a good distinction between the two concepts: the CE emphasizes switching from a linear to a circular model, optimizing resource efficiency by reusing and recycling products, and creating a waste free system, the circular bioeconomy concentrates on turning renewable biological resources into value-added products.

5.2 Circular economy for bioplastics management

The circular economy for bioplastics management is essential to address the environmental impact of conventional plastic production, which follows a linear economy model (Tsegaye et al., 2019). An ineffective waste management of plastic due to inadequate collection, sorting, and recycling capacity, hinders the transition to a CE (European Commission, 2019). From the perspective of BCE, bioplastics are designed to be completely biodegradable within months or years, demonstrating the vigorous economic processes of bioplastic production (Karan et al., 2019). It is important to define the type of bioplastics and develop indicators for the CE (Spierling et al., 2019). Sustainability, or the balancing of economic, social, and environmental factors, is linked to the development of bioplastics (Koller et al., 2017). So promoting a circular economy is essential for sustainable production and minimizing wastes and turning them into value-added products can positively impact bioplastics production costs (Tsang et al., 2019).

5.3 The concept of the BCE applied in Europe

Another aspect is to assess how the circular bioeconomy model is being applied in Europe for the analysis of FW and bioplastics. This section contains articles on European laws on the application of the circular bioeconomy model. The EU is addressing FW management and following the circular economy model by implementing projects that encourage easier recyclability, focusing on the market for recycled plastics (European Commission, 2018). The EU is also executing a plan involving the BCE model to ensure sustainability and circularity in the production process (European Union, 2018). The Federal Ministry of Education and Research (2010) created the National Research Strategy for the Bioeconomy 2030, which focuses on five main points: safety, sustainability, healthy food, using renewable resources, and sustainable energy from biomass: this strategy aims to support the circular bioeconomy (Schütte, 2018). The EC is also promoting a CE through legislation designed to make products, services, and the market more sustainable. Politically, this involves supporting bioplastic production as a method of reducing CO2 through funding and regulations (Di Bartolo et al., 2021). European legislation is constantly evolving in the area of proper plastic management, always with a view to the circular economy and sustainability (Kiessling et al., 2023). Starting in 2018, the EU introduced legislation based not only on the concept of recycling, but also on innovation in the design of new plastics with the aim of making them recyclable (Beghetto et al., 2023). In 2019, the EU introduced a law prohibiting the use of single-use plastics, adding guidelines for manufacturers to follow on the correct management of separate waste collection (Beghetto et al., 2023; Yang et al., 2013). Regarding to food packaging regulations, the EU has implemented regulations for the recycling of plastic materials and the reuse of packaging (Costa et al., 2023; Beghetto et al., 2023). In general, the EU is taking action to reduce plastic consumption, promote reuse and find more environmentally friendly solutions for plastic (Kiessling et al., 2023). To indicate the use of compostable plastics in accordance with EN 13432, European Bioplastics has created a logo called “seeding” (Garrido et al., 2021). Looking at some European countries, Germany, since the early 2000s, has been concerned with promoting the bioeconomy and biotechnology model. In 2009, the Council for Research and Technology in Bioeconomy was established. It is managed by experts whose role is to advise the government on policies to be adopted in promoting the bioeconomy model. In 2011, the national bioeconomy research strategy 20,230 was introduced, promoting the use of bioplastics (Müller, 2012; Federal Ministry of Education and Research, 2011; Lainez et al., 2018). Spain is also one of the European countries that, since 2000, has been mobilizing to promote initiatives and regulations for bioplastics and the bioeconomy. It all began in 2007, with the design of the BIOPLAT platform with the aim of promoting the use of biomass and sustainability. In 2015, however, the National Programme for Innovation and Research in Agri-Food and Forestry was launched to promote the bioeconomy model (Agency, 2011). In Italy, legislation has been implemented regarding the use of biodegradable and reusable bags for long periods of time (DL152/2006, the 2007 Finance Act and the New Act 28 of 24/3/2012). This is defined as the only political regulation in terms of bioplastics in Italy. There are many projects funded by the European Union and the Italian Ministry of Education and Research for sustainability, the development of new biomaterials and green chemistry (USDA, 2020).

5.4 The concept of bioeconomy around the world

From the perspective of a sustainable future, it is essential to assess the circular bioeconomy’s development on a global scale. The circular bioeconomy is becoming more popular in Latin America and the Caribbean as a means of achieving sustainability (Trigo et al., 2014). These nations’ substantial raw material availability combined with the large amount of waste produced by biomass and organic materials can serve as the foundation for the development of a circular bioeconomy (Rodríguez et al., 2019). Implementing suitable regulatory plans, overcoming limitations for companies, guaranteeing funds, and proper waste management are essential obstacles to consider in following the circular bioeconomy model. In Eastern countries, India defines the bioeconomy as using biotechnological techniques from renewable food sources for a sustainable economy (Venkata Mohan et al., 2018). Given the high amount of waste produced in India, it can be used as a substitute for fossil sources. India follows the BCE model using agricultural waste (AW) for producing biofuels and chemicals (Gottumukkala et al., 2013). This model is also applied in the pharmaceutical sector. In India, strategies for promoting biomass to advance the circular bioeconomy model and the production of bioplastics, began in 2016, following the introduction of the strategy for the development of biotechnology between 2015 and 2020 (Biote Canada, 2009). As regards China, over the last 20 years, the country has been evolving in the implementation of environmental policies. In fact, China is one of those countries that, over time, has sought to promote the importance of technology, the circular economy and environmental sustainability. The path toward achieving these objectives began in 2002 with the law promoting cleaner production, followed by the law on raising awareness of the importance of environmental sustainability in 2008, and finally the law on the circular economy in 2009 (USDA, 2020). Furthermore the government implemented a 5 year plan (2020–2025) for the development of the BCE mode (Schmid and Xiong, 2023) Specifically, China is applying this model in many sectors, including agriculture, food, and biomaterials for packaging. By 2035, it is anticipated that biotechnology industries in China will favor environmentally sustainable processes and the circular bioeconomy, through the use of FW sources (Schmid and Xiong, 2023). The choice to evaluate the application of the circular economy model in these three countries, China, India, and Latin America, was made based on information in the literature. And their application of the BCE model for FW. The transition from a linear to a CE model has been gradually progressing in recent years. Research on applying the CE approach to address the issues of FW and bioplastics is still at an early stage, with limited data available on the topic. However, significant efforts are being made to adopt the circular economy framework, both in Europe and globally, driven by new legislative regulations being introduced. In the USA, the Society of the Plastics Industry developed an identifier for all biodegradable plastics and bioplastics in 1988, with the acronym ASTM, which is now managed by ASTM International (Garrido et al., 2021). In 2002, BioPreferred program was established by the United States Department of Agriculture (USDA). It was subsequently reused by the 2008 Farm Bill, which provides for the use of organic products and renewable resources and promotes the economy of these products (Hüttl, 2010). As regards Canada, national strategies for the development of the BCE model were introduced as early as 2008. In 2008, a document was drawn up aimed at developing biotechnology, and in 2011, a document was drawn up on the strategies to be applied for the implementation of BCE (Binder, 2017; Taniguchi, 2018). For Japan, however, following the Kyoto Protocol of 2002, Japan launched two major initiatives to promote the bioeconomy: firstly, Biotechnology Strategic Scheme (2002): The goal was to replace 20% of traditional plastics with those from renewable sources by 2020. Subsequently, Biomass Nippon Strategy (2002, revised in 2006): This strategy aimed to promote the use of biomass. It ensured that multinationals such as Toyota and NEC promoted the use of bioplastics. The Japan BioPlastics Association (JBPA) created the “BiomassPla” certification program, under which products must contain at least 25% bio-based plastic (Chanprateep, 2010; National Innovation Agency, 2012). Lastly, Thailand is one of the countries with such high biomass production that it has decided to invest in the production of bioplastics. The Thailand government has defined the bioplastics industry as excellent in terms of environmental sustainability. In fact, 2 years later, the National Roadmap for the Development of the Bioplastics Industry was introduced (Eranda et al., 2024b).

6 Latest developments in the production of bioplastics from food waste

In this section, the authors summarize the progress made over the last year, analyzing several articles in the literature on the use of bioplastics obtained from FW and the challenges to be overcome in the future. Selvam et al. (2025) sought to analyze studies in the literature on the use of different types of agricultural waste to obtain bioplastics for use as food packaging, comparing them with synthetic plastics in terms of their environmental impact and analyzing the properties of biomaterials. However, the authors also analyze the limitations associated with the production of bioplastics. One of the most pressing issues concerns the scalability of biomaterial production on an industrial scale, as it represents a limitation linked to processing costs, energy requirements, equipment and extraction techniques, which not only impact the operational phase but also the economic one (Carvalho et al., 2025). Another issue is the efficiency of biopolymers due to their low water resistance and mechanical properties, which limit their use as food packaging (Klai et al., 2021). Despite its limitations, the future of biopolymers obtained from agricultural residues, such as wheat straw or rice husks, appears very promising, particularly for the food packaging sector. These raw materials, once considered waste, are now being exploited in a process involving several stages: pre-treatment, extraction and purification of biopolymers such as cellulose, starch and proteins. If necessary, these compounds undergo chemical modifications to improve their performance (Klai et al., 2021). The biopolymers obtained in this way are transformed into films or composite materials using techniques such as extrusion or melting to create packaging that is sustainable and biodegradable (ISO, 2020b). The challenges and future directions in the field of active food packaging are complex and require a multidisciplinary approach. Despite significant advances in research on biopolymer-based packaging enriched with plant extracts, large-scale adoption remains limited. The main obstacles include the need to optimize the mechanical and barrier properties of materials, which are often compromised by the addition of active substances. Furthermore, future research should focus on exploring plant resources that have not yet been thoroughly studied in order to discover new bioactive sources and make production processes more sustainable. Only through constant innovation and collaboration between chemists, engineers, and food technologists can we ensure that these new-generation packaging materials can compete effectively with synthetic alternatives, contributing to a circular economy and a reduction in environmental impact (Segers et al., 2024). This line of research is perfectly aligned with the principles of the circular economy, contributing to waste reduction and resource efficiency. This approach is consistent with global Sustainable Development Goals (SDGs), as it transforms agricultural waste into value-added products, promoting responsible production and consumption patterns (ISO, 2020b).

7 Conclusion

According to several data found in the literature, the amount of FW produced annually is high, with economic, environmental, and social impacts. One solution could be to use FW, which is rich in substances that are not only beneficial to human health, such as polyphenols but are also rich in macronutrients and lignocellulosic material, to produce products with added value. Among the various methods of using FW, this review analyzed how it could be used to solve another problem, according to the literature, the use of conventional plastics significantly affects the environment, highlighting the importance of replacing them with bioplastics. So far, life cycle assessment has been applied to measure the environmental effects of improper FW and bioplastic disposal. The review reports on studies using the LCA model for conventional plastics and bioplastics confirming how the use of bioplastics can have a positive environmental impact by reducing gas emissions. Additionally, the sustainability of plastics through LCA is only achievable if disposal options include recycling. In addition, an assessment was made of the implementation of the CE model in UE through the implementation of waste and plastics management legislation. From what was found in the literature, the European Union has been mobilizing a lot in recent years with the implementation of laws for the management of plastics by favoring their replacement with bioplastics and in the application of the CE model to increasingly reduce environmental impact. In addition, the research was also extended to other non-European countries to make a comparison. From what was found in the literature, little information was reported on the application of the CE model, especially about plastics management. With some data reported, the authors aimed to address the issue of environmental sustainability and the circular economy of which, as also shown by the data reported and the regulations in force, to date the European Union seems to be addressing this issue more than other countries, especially waste management and the promotion of bioplastics.

Author contributions

CV: Conceptualization, Methodology, Writing – original draft. TC: Writing – review & editing, Resources, Supervision. FE: Writing – review & editing, Supervision, Validation.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abbade, E. B. (2020). Estimating the nutritional loss and the feeding potential derived from food losses worldwide. World Dev. 134:105038. doi: 10.1016/j.worlddev.2020.105038

Abdul Khalil, H. P. S., Adnan, A. S., Yahya, E. B., Olaiya, N. G., Safrida, S., and Hossain, M. S. (2019). A review on plant cellulose nanofibre-based aerogels for biomedical applications. Polymers 12:1759. doi: 10.3390/polym12081759

Abedi, E., and Hashemi, S. M. (2020). Lactic acid production. Producing microorganisms and substrates sources-state of art. Heliyon 6:e04974. doi: 10.1016/j.heliyon.2020.e04974

Abedini, A., Alizadeh, A. M., Mahdavi, A., Golzan, S. A., Salimi, M., Tajdar-Oranj, B., et al. (2022). Oilseed cakes in the food industry; a review on applications, challenges, and future perspectives. Curr. Nutr. Food Sci. 18, 345–362. doi: 10.2174/1573401317666211209150147

Abo, B. O., Gao, M., Wang, Y., Wu, C., Ma, H., and Wang, Q. (2019). Lignocellulosic biomass for bioethanol: an overview on pretreatment, hydrolysis and fermentation processes. Rev. Environ. Health 34, 57–56. doi: 10.1515/reveh-2018-0054

Acquaviva, M. A., Pascale, R., Martelli, G., Bondoni, M., and Bianco, G. (2021). Natural polymeric materials: a solution to plastic pollution in the Agri-food sector. Polym. 13:158. doi: 10.3390/polim13010158

Agency, E. E. Annex 10—Spain country case study, European Environment Agency, Copenhagen. Available online at: https://www.eea.europa.eu/publications/blossom/annex-10-2014-spain-country (2011) (Accessed September 22, 2025).

Ahmad, T., Aadil, R. M., Ahmed, H., Rahman, U. U., Soares, B. C. V., Souza, S. L. Q., et al. (2019). Treatment and utilization of dairy industrial waste: a review. Trends Food Sci. Technol. 88, 361–372. doi: 10.1016/j.tifs.2019.04.003

Álvarez-Chávez, C. R., Edwards, S., Eraso, R. M., and Geise, K. (2021). Sustainability of bio-based plastics: general comparative analysis and recommendations for improvement. J. Clean. Prod. 23, 47–56. doi: 10.1016/j.jclepro.2011.10.003

Arruda, T. R., Machado Gde Marques, C. S., Souza, A. L., Pelissari, F. M., Oliveira, T. V., and Silva, R. R. (2025). An overview of starch-based materials for sustainable food packaging: recent advances, limitations, and perspectives. Macromol 5:19. doi: 10.3390/macromol5020019