- College of Civil Engineering, Central South University of Forestry and Technology, Changsha, China

Microbial Induced Calcite Precipitation method was used to improve the expansive soils of Nanning, Guangxi. The nonlinear shear creep behavior of microbially improved expansive soil was studied by triaxial consolidation drainage shear test. The results show that when the expansive soil was applied a small partial stress, the creep curve of soil exhibits transient deformation and decay creep. When the partial stress reaches a certain value, there is decay creep, steady-state creep and accelerated creep successively showed on the creep curve. The stress-strain isochronous curves reflect there are obvious nonlinear characteristics in the creep process of improved expansive soils. The degree of this nonlinearity is related to the creep time and stress level. The longer the creep time as well as the higher the stress level, the higher the degree of nonlinearity. Based on the fractional calculus theory and statistical damage theory, the probability density function of Weibull distribution was introduced, and the damage degradation of soft component viscosity coefficient was considered. As a result, a fractional-order damage creep model which can describe the shear creep evolution of microbially improved expansive soils is established. Compared with the Kelvin creep model of integer order and the Burgers creep model of fractional order, the fractional order damage creep model has not only better comparative evaluation results but also more higher computational accuracy. It indicates that the fractional-order damage creep model can better describe the whole process of shear creep in microbially improved expansive soils. The above findings provide a theoretical basis for the study of deformation analysis of microbially improved expansive soils under long-term loading.

Introduction

Expansive soils are widely distributed in the world and is a high liquid limit clay with expansion and contraction, fracture and super consolidation (Shi et al., 2014; Al-Mukhtar et al., 2012), which can easily cause cracking and instability of expansive soil slopes (Fu et al., 2017; Fu et al., 2020). Inorganic materials such as lime, cement and fly ash are usually used to improve expansive soils in engineering construction (Khadka et al., 2020). However, these improvement and improvement methods have disadvantages such as high cost, long construction period and unfriendly to the environment during the construction process (Ali 2018). In recent years, With the development of environmental geotechnical technology (Bai et al., 2021a; Bai et al., 2017), Microbial Induced Calcite Precipitation (MICP) method, has been widely used in construction projects for foundation strengthening (Liu et al., 2019), dust and sand consolidation (Naeimi and Chu 2017) and concrete fracture repair (Lors et al., 2017; Justo-Reinoso et al., 2021). MICP technology, as a new soil improvement method, can form carbonate precipitation with excellent consolidation performance. It is a modern biological technology with simple construction, low cost, rapid efficiency and environmental friendliness. Urease produced by microorganisms during their life activities hydrolyzes urea in an alkaline environment, producing ammonium ions and carbonate ions. The carbonate ions combine with calcium ions in the soil to form calcium carbonate precipitates adsorbed on the surface of the bacteria (Liu et al., 2017). Relevant literature have shown that the MICP method can effectively reduce the expansion and contraction of expansive soils (Tiwari et al., 2021; Li et al., 2021) and improve their strength (Jiang et al., 2021; Ouyang et al., 2022). However, most of the studies on the improvement of expansive soils using the MICP method have focused on the physical properties, strength properties, and deformation properties of the improved expansive soils under short-term loading. The creep properties of the improved expansive soils under long-term loading have not been reported in the literature. Therefore, the research on creep properties of microbially improved expansive soils is not only of great theoretical significance, but also has a broad prospect of engineering application.

The creep curve of soil reflects the stress-strain-time relationship of soil. It is the prerequisites to establish creep model for studying the creep properties of soil. In the early studies of creep properties of soils, scholars are used to adopt component models (Li et al., 2012; Yang and Li 2018) and empirical models (Fahimifar et al., 2015; Xue et al., 2020). In the element model, the nonlinear creep properties of the soil body cannot be described because the basic elements are linear (Xiao et al., 2011). Although the nonlinear creep of the soil can also be reflected by transforming the element parameters, the creep equation is complex and has more parameters. The empirical model lacks a rigorous theoretical basis and can only reflect the creep properties of geotechnical materials in a specific region and does not have universal applicability.

In recent decades, scholars have applied fractional order calculus theory and damage theory to the study of geotechnical rheological models in order to better describe the complex mechanical behavior of soils. Zhou et al. (2011) proposed a new creep instanton model with time-based fractional order derivatives by employing fractional order Abel viscous pots instead of Newtonian viscous pots in the classical Nishihara model. Gao and Yin (2021) developed a fractional order creep model describing the full stage creep behavior of rocks in order to characterize the creep properties of rocks more accurately. The model has a simple form, few parameters and clear physical concepts. Based on rheological mechanics and fractional order calculus theory (Ning et al., 2017), established the instanton and creep equations that can reflect the nonlinear rheological properties of expanded soils. Based on the fractional calculus theory (Zhang et al., 2018), established a three-component fractional model that can more accurately reflect the nonlinear stress relaxation characteristics of expansive soil. Xue et al. (2021) applied fractional order calculus and damage mechanics to the creep model of rock salt and established the Burgers model for fractional order creep damage considering temperature and volume stresses.

Many existing creep models of rock or geotechnical materials cannot completely describe the creep mechanical behavior for microbially improved expansive soils. Therefore, in this paper, triaxial drainage shear creep test is conducted on microbially improved expansive soil to study the deformation evolution law of the soil with time under the long-term loading. According to the creep test results, based on the fractional order calculus theory and statistical damage theory, the probability density function of Weibull distribution is introduced to consider the damage deterioration of the coefficient of viscosity of the soft element class. In this way, a fractional-order damage creep model describing the creep properties of microbially improved expanded soil was established.

Test Materials and Methods

Test Materials

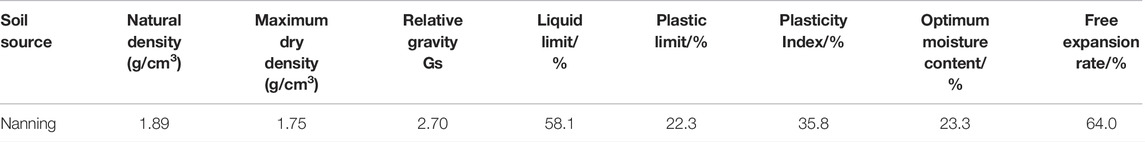

The expansive soil for the test was taken from a ring road section in Nanning, Guangxi. According to the Highway Soil Test Procedure (JTG 3430-2020), the basic physical property indexes of the soil sample were obtained, as shown in Table 1. According to the test results and the classification standard of expansive soil, the soil sample can be judged as high liquid limit medium expansive soil.

The microorganism used in the experimental study was Bacillus cereus (strain number ATCC11859) acquired by the Chinese General Microbial Strain Conservation and Management Center (CGMCC). This strain was isolated from natural soil, is non-pathogenic, and can produce large amounts of urease during its vital activity (Zhao 2014).

During the experiment, Bacillus cereus was first removed from the refrigerator and inoculated into the culture medium for rapid culture and propagation. The culture medium used in the experiment was composed of nutrients such as urea, casein peptone, soy peptone and sodium chloride. The inoculated culture medium was then placed in a shaker for 48 h and the bacterial concentration was measured by spectrophotometer. The concentration of the bacterial broth was considered to meet the requirements of the test when the absorbance density OD600 reached above 1.0 (Wu et al., 2020).

The natural expansive soils have a low content of calcium elements and thus the calcium carbonate yield during the MICP mineralization reaction is low. Therefore, in the experimental study, it was necessary to supplement the calcium source in the soil by adding cementation solution made from a mixture of calcium chloride and urea. In the dried and sieved expansive soil, the bacterial solution and the cementation solution were mixed. In this case, the molar ratio of calcium chloride and urea in the cementation solution was 1:1 and the molar concentration was 1.0 mol/L (Zhao et al., 2014; Wu et al., 2020).

Preparation of Specimens

According to the existing studies in our group, it was found that the best improvement of soil samples was achieved at a volume ratio of 1:2 between the bacterial solution and the cementation solution in the MICP process (Tian et al., 2022; Su et al., 2022). Therefore, the volume ratio of bacterial solution to cementation solution per unit mass of soil sample was controlled to 1:2. In this experiment, 50 ml of bacterial solution and 100 ml of cementation solution were mixed into each 500 g of soil sample. The specimens were prepared according to the Standard for Geotechnical Test Methods (GB/T 50123-2019). Firstly, the expansive soil was air-dried and passed through a 2 mm sieve, then the bacterial solution and the cementation solution were sprayed into the expansive soil separately. The mixed expanded soil was sealed with cling film, leaving part of the pore space to ensure the oxygen supply of bacteria.

Test Scheme

The instrument for the test is the TKA automatic triaxial apparatus produced by Nanjing TKA Technology Co., Ltd. Before the creep test, the triaxial consolidation and drainage shear (CD) test was conducted to determine the damage deflection stress of the specimen, which was used as the load classification basis for the triaxial consolidation and drainage shear creep test. the CD test results were obtained, when the surrounding pressure was 150 kPa, the damage deviatoric stress of the specimen was qf =270 kPa. Creep tests were performed using a graded loading method. The surrounding pressure was set to 150 kPa, and the partial stresses were 54 kPa, 108 kPa, 162 kPa, 216 kPa, and 270 kPa. The specimen would be damaged in a relatively slow process due to the drainage conditions (Zhang et al., 2011). To accelerate the shear damage of the specimen, another level of deflective stress can be applied at 324 kPa in the test, each level of loading is maintained for 48 h. When the deformation rate is not greater than 0.005 mm/d, creep can be considered stable and the next level of loading is performed.

Test Results and Analysis

Creep Curves

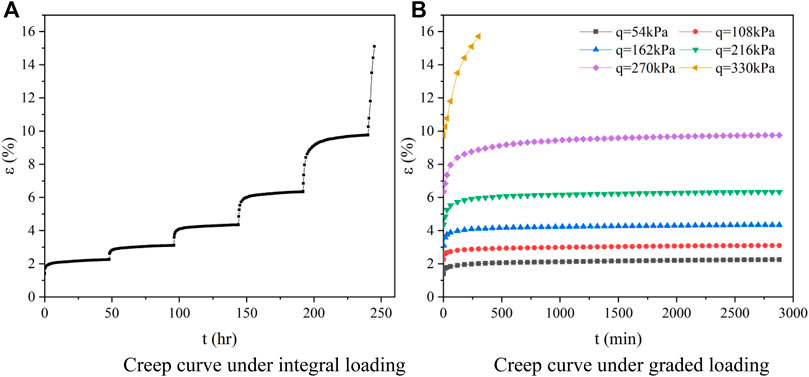

The creep curves of the specimen loaded as a whole were obtained by collating the triaxial creep test results, as shown in Figure 1. The creep curve of the specimen with graded loading was obtained by processing the creep data according to the Boltzmann linear superposition principle, as shown in Figure 2.

It can be found in Figure 1 that when the level of deviatoric stress is low, the strain of the specimen only includes two parts of transient strain and decay creep during the duration of the test. When the deviatoric stress was higher, the creep process of the specimen experienced three complete creep stages, such as decay creep, steady-state creep and accelerated creep, and the specimen finally underwent creep damage. In the transient elasto-plastic deformation phase, the load on the soil particle skeleton increases due to increasing deviatoric stress in a relatively short period of time, resulting in elastic deformation of the particles and plastic deformation caused by inter-particle position adjustment (Bai et al., 2021b; Zhou et al., 2022). Macroscopically, the soil axial strain increases in a short period of time. In the decay deformation phase, the stress chain within the soil skeleton stabilizes, the particle deformation and position adjustment gradually decreases (Bai et al., 2014), and the creep rate of the soil sample gradually decreases. In the steady-state deformation stage, the stress chain of the soil skeleton is basically stable, and the macroscopic deformation of the soil body is presented as stable creep. When the deviatoric stress continues to increase, the soil body enters the accelerated creep stage and eventually creep damage occurs. The deformation rate in the accelerated creep stage increases continuously and lasts for a very short time. At this time, the soil skeleton is basically destroyed, and the deformation of the specimen is no longer controllable.

Determination of Long-Term Intensity

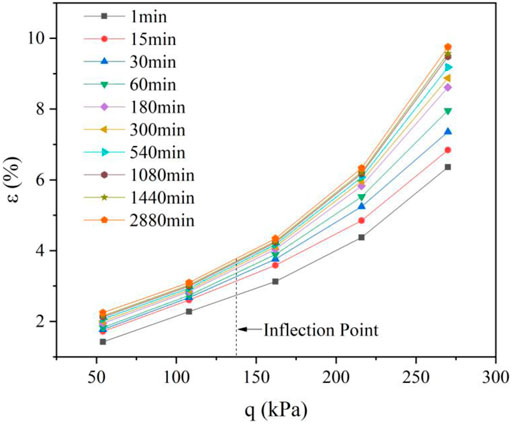

In order to observe the nonlinear creep pattern of soil specimen more visually, the stress-strain isochronous curve of soil specimen can be made. The stress-strain isochronous curve of the soil specimen, as shown in Figure 2. In Figure 2, ε is the axial strain and q is the deviatoric stress.

From Figure 2, it can be found that when the stress level is low, the stress-strain approximates a linear relationship. With the gradual increase of stress level, the stress-strain isochronous curve gradually shifts toward the strain axis. Meanwhile, as the creep time increases, the stress-strain isochronous curve gradually moves away from the stress axis and bends toward the strain axis. The longer the creep time, the more obvious the bending of the isochronous curve toward the strain axis. Therefore, microbially improved expansive soils, have nonlinear creep properties, and the degree of nonlinearity is related to the stress level and creep time. The range of linear creep decreases with the increase of stress level and creep time, and the degree of nonlinear creep increases accordingly.

According to the method proposed by (Shen et al., 2012) for determining long-term strength based on isochronous curves, the inflection point of the stress-strain isochronous curve cluster can be determined to be located at a stress of 138 kPa. After the inflection point, the curve cluster changes from dense to sparse. Therefore, 138 kPa can be taken as the long-term strength of the clay. When the stress is less than the long-term strength, the isochronous curve is almost linear, and the soil can be considered as a viscoelastic body. When the stress is greater than the long-term strength, the stress-strain relationship is no longer linear, and the soil can be considered as a viscoplastic body.

Intrinsic Structure Relations for Fractional-Order Damage Creep Model

Soft Components Based on Fractional Order Calculus

Fractional order calculus can accurately describe complex mechanical processes, portraying path dependence in space and memory in time. At present, fractional order calculus has several defined forms according to different application areas. In this paper, based on the Riemann–Liouville type fractional order calculus operator theory, the fractional order calculus for a continuous function f(x) is defined as (Lai et al., 2016)

where the t is the time, t0 is the initial time, β is the fractional order,

The Riemann–Liouville type definition is applied only to the region of Re(β)>0 to ensure that the integral converges at t=0. When 0≤β<1, the Laplace transform of the Riemann–Liouville type fractional order calculus operator is expressed as

where the s is the transformation covariate, F(s) is the Laplace transform of f(t).

Abel viscous pot element, a viscoelastic element between Hooke’s elastic solid and Newtonian viscous body, is also known as a soft-body element. The principal equation of the soft-body element using Riemann–Liouville type fractional order calculus theory can be expressed as

where the σ(t) is the stress, ε(t) is the strain, η is the class viscosity coefficient.

When β=0, let η=E, E be the elastic modulus, then Eq. 4 describes a Hooke elastic solid. When β=1, let η=ζ, ζ be the viscous hysteresis coefficient, then Eq. 4 describes an ideal Newtonian viscous body. When 0<β<1, the components are described by a visco-elastic soft body.

In Eq. 4, if σ(t) is a constant, when the stress is constant, the element describes the creep phenomenon of the soft body. According to the definition of Riemann–Liouville type fractional order calculus, Laplace transform and Laplace inverse transform of Eq. 4, the creep equation of the soft body element can be obtained as

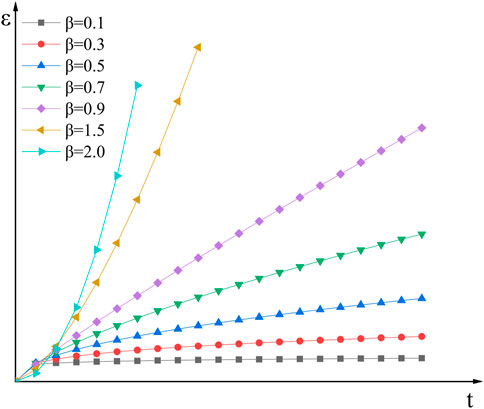

According to the creep equation of the soft element, the creep curve of the soft element can be depicted by taking the values of different orders under the condition of constant stress, as shown in Figure 3.

From Figure 3, it can be found that the strain increases slowly with increasing time when 0<β<1. As β increases, it exhibits enhanced creep properties, which describes exactly the nonlinear creep process of the material. When β>1, with the increase of time, the strain increases significantly, showing the accelerated creep properties of the material.

Viscoplastic Damage Body Based on Statistical Damage Variables

Since the traditional creep model can only describe the decay creep and stable creep stages of geotechnical body, it cannot describe its accelerated creep stage. Soil is a typical non-homogeneous material (Bai et al., 2020), and in the process of creep loading, it is in essence the process of internal fractures gradually expanding, linking through and forming macroscopic cracks destabilizing damage (Bai and Li 2013; Bai et al., 2019). Therefore, when studying the creep instantaneous equation of soil, it is necessary to consider the damage aging effect of soil in the creep process, and the creep damage aging effect, which will cause the viscosity coefficient of soil to change (Cai and Cao 2016). considered the failure damage of viscous coefficient and found that the viscous coefficient decays exponentially under the action of damage. Therefore, the non-constant Burgers model was established, which can better describe the accelerated creep phase of the soil (Ding et al., 2015). constructed the relationship between the number of acoustic emission events and loading time based on the Weibull distribution and obtained the evolutionary relationship of the damage variables. The Weibull probability distribution function, with characteristics such as easy integration, mean value greater than 0 and range of values greater than 0, satisfies the statistical characteristics of shear damage of geotechnical bodies. Therefore, in this paper, it is assumed that the damage of the soft element with class viscous coefficient, after the shear stress is higher than the long-term strength, follows the Weibull distribution about the creep time t. The probability density function of the Weibull distribution is that

where the k is the shape parameter reflecting the non-uniform degree of damage distribution in the micro-element body, λ is the scale parameter characterizing the internal damage of the soil body, t is the creep time.

Integration of Eq.6 yields the damage variable D as

Based on the damage variable D defined by the probability density function of the Weibull distribution, the damage degradation considering the viscous coefficient of the soft element class is obtained in the form that can be expressed as

where the η class viscosity coefficient, and the

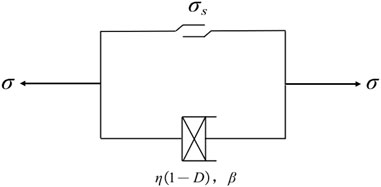

In this paper, a viscoplastic damage body based on the damage variable D is proposed, as shown in Figure 4.

According to Figure 4, it can be seen that the damage effect of the soil has a threshold value, and the damage effect will occur only when a certain threshold value is reached. When the creep loading stress is lower than the damage threshold, the soil does not occur damage, at this time the class viscosity coefficient is a constant number. When the damage threshold is exceeded, the soil internal constant class viscosity coefficient will damage deterioration, the soil will also appear viscoelastic accelerated creep phase. According to the above analysis, and combined with the Eqs 5–8, the creep equation of viscoplastic damage body can be obtained as

where the β is the fractional order,

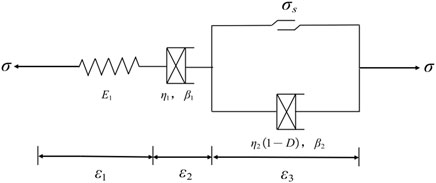

Establishment of Fractional-Order Damage Creep Model

As mentioned above, the creep deformation of microbially improved expansive soils contains a complex process in which multiple deformations such as elastic, viscoelastic and viscoplastic coexist. In order to accurately describe the whole process of nonlinear creep deformation of microbially improved expansive soil, the Hooke elastic solid, soft body element and viscoplastic damage body are combined into a fractional order creep damage model describing the whole process of creep deformation of microbially improved expansive soil by connecting them in series and parallel, as shown in Figure 5.

For the fractional order damage creep model shown in Figure 5, the long-term strength is taken to be the initiating stress of the friction piece. When

According to the series and parallel connection laws of the creep model, it is obtained that

where the

Substituting Eqs 5, 9 into Eq. 10, the creep equation of the fractional order damage creep model can be obtained as

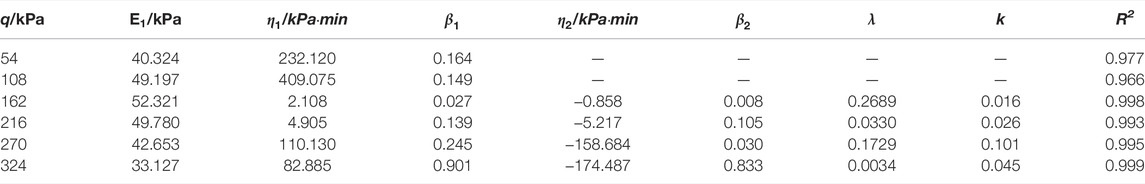

Inversion of Model Parameters and Their Validation

Based on the results of triaxial shear creep tests of microbially improved expansive soils, the parameters of the four-element fractional-order damage creep model were identified by inversion using the Levenberg-Marquardt optimization algorithm based on the least squares method. The obtained model parameters, as shown in Table 2.

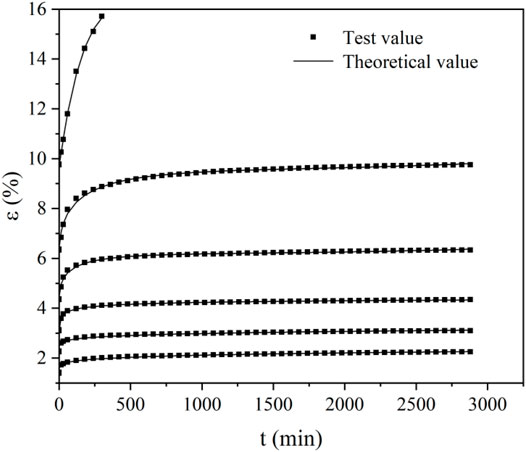

According to Eq. 10, the theoretical creep curve of microbially improved expansive soil can be obtained by substituting the relevant model parameters. The comparison of the theoretical creep curve obtained according to Eq. 11 with the experimental results is shown in Figure 6.

From Table 2, it can be found that although the microbially improved expansive soil specimens are somewhat discrete, leading to a less regularity in the variation of the parameters (e.g., class viscosity coefficient) obtained from the fit. However, the regularity of the variation of order β of the fractional order characterizing the nonlinear influence is more obvious. Also, the theoretical creep curves of the four-element fractional-order damage model and the experimental results are in good agreement as can be seen in Figure 6. Especially when

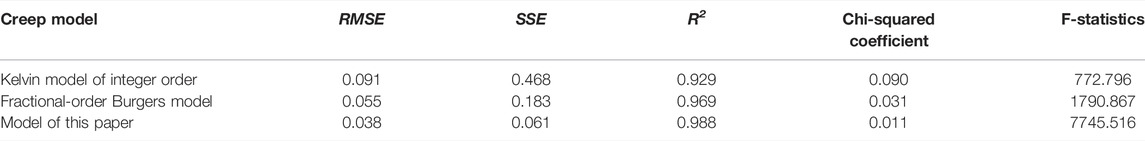

In the research of creep model, Kelvin model and Burgers model are widely used (Jiashun et al., 2020). To verify the superiority of the fractional-order damage creep model in this paper, the integer-order Kelvin model, the fractional-order Burgers model and this paper’s model were also selected for comparative analysis, and the fitting effects of the three models could be quantitatively evaluated. The root mean squared error (RMSE), sum of squares due to error (SSE), correlation coefficient (R2), chi-squared coefficient and F-statistics were selected as evaluation indexes to obtain the evaluation results of different models, as shown in Table 3.

From Table 3, it can be found that the RMSE, SSE and chi-square coefficients of the creep model evaluation results in this paper are smaller, and the values of R2 and F statistics are larger. It indicates that the fractional order damage creep model has better correlation with the test results. Therefore, the fractional-order damage creep model is verified to better reflect the whole process of shear creep of microbially improved expansive soils, and the model structure is simple and convenient for practical application.

Conclusion

1) The shear creep test of microbially improved expansive soil shows that when the deviatoric stress reaches a certain value, the creep curve shows three stages, such as decay creep, steady-state creep and accelerated creep.

2) The stress-strain isochronous curves show that the improved expansive soils have obvious nonlinear characteristics, and the degree of nonlinearity is related to creep time and stress level. The longer the creep time or the higher the stress level, the higher the degree of nonlinearity.

3) Based on fractional-order calculus and statistical damage theory, a fractional-order viscoplastic damage body is proposed by introducing the probability density function of Weibull distribution and considering the damage deterioration of soft body element class viscous coefficient. By combining Hooke’s spring, soft body element and viscoplastic damage body in series and parallel, a fractional-order damage creep model that can describe the shear creep evolution law of microbially improved expansive soil is established.

4) Compared with the Kelvin model of integer order and the Burgers model of fractional order, the model in this paper has better fitting accuracy, and the model structure is simple and easy to be applied in practice. It indicates that this model can better describe the shear creep properties of microbially improved expansive soils.

Data Availability Statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author Contributions

Conceptualization, XT and HX; methodology, XT and HX; software, XT and HX; validation, XT and HX; formal analysis, XT, HX, ZL, HS, QO, SL, and XY; investigation, XT, HX, ZL, HS, QO, SL, and XY; resources, XT and HX; data curation, XT, HX and ZL; writing-original draft preparation, XT and HX; writing-review and editing, XT, HX and ZL; visualization, XT, HX, ZL, HS, QO, SL, and XY; supervision, XT, HX, and ZL; project administration, XT and HX; funding acquisition, XT and HX. All authors have read and agreed to the published version of the manuscript.

Funding

The work described in this paper is supported by a grant from the National Natural Science Foundation of China (Project No. 50978097), Hunan Provincial Innovation Foundation For Postgraduate and the research Foundation of Education Bureau of Hunan Province of China (Project No. 19B581).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Acknowledgments

The assistance and guidance of the steering group members is gratefully acknowledged.

References

Al-Mukhtar, M., Khattab, S., and Alcover, J.-F. (2012). Microstructure and Geotechnical Properties of Lime-Treated Expansive Clayey Soil. Eng. Geol. 139-140, 17–27. doi:10.1016/j.enggeo.2012.04.004

Ali, B. (2018). Soil and Clay Stabilization with Calcium- and Non-calcium-based Additives: A State-Of-The-Art Review of Challenges, Approaches and Techniques. Transp. Geotech. 17, 14–32. doi:10.1016/j.trgeo.2018.08.002

Bai, B., Guo, L., and Han, S. (2014). Pore Pressure and Consolidation of Saturated Silty Clay Induced by Progressively Heating/cooling. Mech. Mater. 75, 84–94. doi:10.1016/j.mechmat.2014.04.005

Bai, B., and Li, T. (2013). Irreversible Consolidation Problem of a Saturated Porothermoelastic Spherical Body with a Spherical Cavity. Appl. Math. Model. 37 (4), 1973–1982. doi:10.1016/j.apm.2012.05.003

Bai, B., Long, F., Rao, D., and Xu, T. (2017). The Effect of Temperature on the Seepage Transport of Suspended Particles in a Porous Medium. Hydrol. Process. 31 (2), 382–393. doi:10.1002/hyp.11034

Bai, B., Yang, G.-c., Li, T., and Yang, G.-s. (2019). A Thermodynamic Constitutive Model with Temperature Effect Based on Particle Rearrangement for Geomaterials. Mech. Mater. 139, 103180. doi:10.1016/j.mechmat.2019.103180

Bai, B., Xu, T., Nie, Q., and Li, P. (2020). Temperature-driven Migration of Heavy Metal Pb2+ along with Moisture Movement in Unsaturated Soils. Int. J. Heat Mass Transf. 153, 119573. doi:10.1016/j.ijheatmasstransfer.2020.119573

Bai, B., Nie, Q., Zhang, Y., Wang, X., and Hu, W. (2021a). Cotransport of Heavy Metals and SiO2 Particles at Different Temperatures by Seepage. J. Hydrology 597, 125771. doi:10.1016/j.jhydrol.2020.125771

Bai, B., Zhou, R., Cai, G., Hu, W., and Yang, G. (2021b). Coupled Thermo-Hydro-Mechanical Mechanism in View of the Soil Particle Rearrangement of Granular Thermodynamics. Comput. Geotechnics 137, 104272. doi:10.1016/j.compgeo.2021.104272

Cai, Y., and Cao, P. (2016). A Non-stationary Model for Rock Creep Considering Damage Based on Burgers Model. Rock Soil Mech. 37 (S2), 369–374. doi:10.16285/j.rsm.2016.S2.047

Ding, J. Y., Zhou, H. W., Chen, Q., Liu, D., and Liu, J. (2015). Characters of Rheological Damage and Constitutive Model of Salt Rock. Rock Soil Mech. 36 (03), 769–776. doi:10.16285/j.rsm.2015.03.022

Fahimifar, A., Karami, M., and Fahimifar, A. (2015). Modifications to an Elasto-Visco-Plastic Constitutive Model for Prediction of Creep Deformation of Rock Samples. Soils Found. 55 (6), 1364–1371. doi:10.1016/j.sandf.2015.10.003

Fu, X., Sheng, Q., Zhang, Y., Chen, J., Zhang, S., and Zhang, Z. (2017). Computation of the Safety Factor for Slope Stability Using Discontinuous Deformation Analysis and the Vector Sum Method. Comput. Geotechnics 92, 68–76. doi:10.1016/j.compgeo.2017.07.026

Fu, X., Sheng, Q., Li, G., Zhang, Z., Zhou, Y., and Du, Y. (2020). Analysis of Landslide Stability under Seismic Action and Subsequent Rainfall: a Case Study on the Ganjiazhai Giant Landslide along the Zhaotong-Qiaojia Road during the 2014 Ludian Earthquake, Yunnan, China. Bull. Eng. Geol. Environ. 79, 5229–5248. doi:10.1007/s10064-020-01890-z

Gao, Y., and Yin, D. (2021). A Full-Stage Creep Model for Rocks Based on the Variable-Order Fractional Calculus. Appl. Math. Model. 95 (1), 435–446. doi:10.1016/j.apm.2021.02.020

Jiang, W. C., Zhang, C. S., Xiao, H., and Li, X. (2021). Preliminary Study on Microbially Modified Expansive Soils of Embankment. Geomechanics Eng. 26 (3), 301–310. doi:10.12989/gae.2021.26.3.301

Jiashun, L., Hongwen, J., Bo, M., Laigui, W., Jianjun, Y., Yanwei, Y., et al. (2020). Fractional-order Creep Model for Soft Clay under True Triaxial Stress Conditions. Arab. J. Geosci. 13, 834. doi:10.1007/s12517-020-05842-5

Justo-Reinoso, I., Heath, A., Gebhard, S., and Paine, K. (2021). Aerobic Non-ureolytic Bacteria-Based Self-Healing Cementitious Composites: A Comprehensive Review. J. Build. Eng. 42, 102834. doi:10.1016/j.jobe.2021.102834

Khadka, S. D., Jayawickrama, P. W., Senadheera, S., and Segvic, B. (2020). Stabilization of Highly Expansive Soils Containing Sulfate Using Metakaolin and Fly Ash Based Geopolymer Modified with Lime and Gypsum. Transp. Geotech. 23, 100327. doi:10.1016/j.trgeo.2020.100327

Lai, J., Mao, S., Qiu, J., Fan, H., Zhang, Q., Hu, Z., et al. (2016). Investigation Progresses and Applications of Fractional Derivative Model in Geotechnical Engineering. Math. Problems Eng. 2016, 1–15. doi:10.1155/2016/9183296

Li, Z. Y., Xiao, H. B., Jin, W-T., and Yi, W. (2012). Study of Nonlinear Rheological Model of Nanning Expansive Soils. Rock Soil Mech. 33 (08), 2297–2302. doi:10.16285/j.rsm.2012.08.035

Li, X., Zhang, C., Xiao, H., Jiang, W., Qian, J., and Li, Z. (2021). Reducing Compressibility of the Expansive Soil by Microbiological-Induced Calcium Carbonate Precipitation. Adv. Civ. Eng. 2021, 1–12. doi:10.1155/2021/8818771

Liu, L., Liu, H., Xiao, Y., Chu, J., Xiao, P., and Wang, Y. (2017). Biocementation of Calcareous Sand Using Soluble Calcium Derived from Calcareous Sand. Bull. Eng. Geol. Environ. 77 (4), 1–11. doi:10.1007/s10064-017-1106-4

Liu, L., Liu, H., Stuedlein, A. W., Evans, T. M., and Xiao, Y. (2019). Strength, Stiffness, and Microstructure Characteristics of Biocemented Calcareous Sand. Can. Geotech. J. 56 (10), 1502–1513. doi:10.1139/cgj-2018-0007

Lors, C., Ducasse-Lapeyrusse, J., Gagné, R., and Damidot, D. (2017). Microbiologically Induced Calcium Carbonate Precipitation to Repair Microcracks Remaining after Autogenous Healing of Mortars. Constr. Build. Mater. 141, 461–469. doi:10.1016/j.conbuildmat.2017.03.026

Naeimi, M., and Chu, J. (2017). Comparison of Conventional and Bio-Treated Methods as Dust Suppressants. Environ. Sci. Pollut. Res. 24 (29), 23341–23350. doi:10.1007/s11356-017-9889-1

Ning, X. L., Xiao, H. B., Zhang, C. X., He, B., Xie, J. Y., et al. (2017). Study on the Nonlinear Creep Model of Expansive Soil. J. Nat. Disasters 26 (01), 149–155. doi:10.13577/j.jnd.2017.0118

Ouyang, Q., Xiao, H., Li, Z., Jiang, W., Su, H., Tian, X., et al. (2022). Experimental Study on the Influence of Microbial Content on Engineering Characteristics of Improved Expansive Soil. Front. Earth Sci. 10, 863357. doi:10.3389/feart.2022.863357

Shen, M. R., Chen, H. J., and Zhang, Q. Z. (2012). Method for Determining Long-Term Strength of Discontinuity Using Shear Creep Test. Chin. J. Rock Mech. Eng. 31 (01), 1–7. doi:10.3969/j.issn.1000-6915.2012.01.001

Shi, B.-x., Zheng, C.-f., and Wu, J.-k. (2014). Research Progress on Expansive Soil Cracks under Changing Environment. Sci. World J. 2014, 1–6. doi:10.1155/2014/816759

Su, H., Xiao, H., Li, Z., Tian, X., Luo, S., Yu, X., et al. (2022). Experimental Study on Microstructure Evolution and Fractal Features of Expansive Soil Improved by MICP Method. Front. Mat. 9, 842887. doi:10.3389/fmats.2022.842887

Tian, X., Xiao, H., Li, Z., Li, Z., Su, H., and Ouyang, Q. (2022). Experimental Study on the Strength Characteristics of Expansive Soils Improved by the MICP Method. Geofluids 2022, 1–10. doi:10.1155/2022/3089820

Tiwari, N., Satyam, N., and Sharma, M. (2021). Micro-mechanical Performance Evaluation of Expansive Soil Biotreated with Indigenous Bacteria Using MICP Method. Sci. Rep. 11 (1), 1–12. doi:10.1038/s41598-021-89687-2

Wu, C. C., Zheng, J. J., Lai, H. J., Cui, M. J., and Song, Y. (2020). Experimental Study of the Strength Enhancing Mechanism of Bio-Cemented Sand and its Influential Factors. J. Civ. Environ. Eng. 42 (01), 31–38. doi:10.11835/j.issn.2096-6717.2019.140

Xiao, H. B., Jin, W. T., Ma, Q. L., Fu, H., Shi, M.-J., et al. (2011). Loading and Unloading Test and Creep Characteristics of Nanning Expansive Soils. J. Nat. Disasters 20 (02), 1–7. doi:10.13577/j.jnd.2011.0201

Xue, P., Zhou, X. Q., Cai, Y., Ma, L., Liao, R. G., Yu, J., et al. (2020). Triaxial Creep Characteristics and Empirical Model for Saturated Coral Sand. Chin. J. Geotechnical Eng. 42 (S2), 255–260. doi:10.11779/CJGE2020S2045

Xue, D. J., Lu, L. L., Yi, H. Y., Wu, Z. D., Zhang, Q. S., and Zhang, Z. P. (2021). A Fractional Burgers Model for Uniaxial and Triaxial Creep of Damaged Salt-Rock Considering Temperature and Volume-Stress. Chin. J. Rock Mech. Eng. 40 (02), 315–329. doi:10.13722/.cnkijrme.2020.0734

Yang, L., and Li, Z. D. (2018). Nonlinear Variation Parameters Creep Model of Rock and Parametric Inversion[J]. Geotechnical Geol. Eng. 36 (5), 1–9. doi:10.1007/s10706-018-0517-8

Zhang, X. W., Wang, C. M., and Li, J. X. (2011). Experimental Study of Coupling Behaviors of Consolidation-Creep of Soft Clay and its Mechanism. Rock Soil Mech. 32 (12), 3584–3590. doi:10.16285/j.rsm.2011.12.040

Zhang, C. X., Xiao, H. B., Bao, J-M., Yin, Y-H., and Yin, D-L. (2018). Stress Relaxation Model of Expansive Soils Based on Fractional Calculus [J]. Rock Soil Mech. 39 (05), 1747–1752+1760. doi:10.16285/j.rsm.2016.2371

Zhao, Q. (2014). Experimental Study on Soil Improvement Using Microbially Induced Calcite Precipitation (MICP). [dissertation]. Beijing: China University of Geosciences.

Zhou, H. W., Wang, C. P., Han, B. B., and Duan, Z. Q. (2011). A Creep Constitutive Model for Salt Rock Based on Fractional Derivatives. Int. J. Rock Mech. Min. Sci. 48 (1), 116–121. doi:10.1016/j.ijrmms.2010.11.004

Zhao, Q., Li, L., Li, C., Li, M., Amini, F., and Zhang, H. (2014). Factors Affecting Improvement of Engineering Properties of MICP-Treated Soil Catalyzed by Bacteria and Urease. J. Mat. Civ. Eng. 26 (12), 04014094. doi:10.1061/(ASCE)MT.1943-5533.0001013

Keywords: MICP, expansive soils improvement, microbial method, fractional calculus, statistical damage, creep model

Citation: Xuwen T, Hongbin X, Zhenyu L, Hunayu S, Qianwen O, Shenping L and Xinpei Y (2022) A Fractional Order Creep Damage Model for Microbially Improved Expansive Soils. Front. Earth Sci. 10:942844. doi: 10.3389/feart.2022.942844

Received: 13 May 2022; Accepted: 02 June 2022;

Published: 21 June 2022.

Edited by:

Xiaodong Fu, Institute of Rock and Soil Mechanics (CAS), ChinaReviewed by:

Jie Liu, Hunan University of Technology, ChinaSujatha Evangelin Ramani, SASTRA University, India

Tao Li, Beijing Jiaotong University, China

Copyright © 2022 Xuwen, Hongbin, Zhenyu, Hunayu, Qianwen, Shenping and Xinpei. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xiao Hongbin, dDIwMDkwMTY5QGNzdWZ0LmVkdS5jbg==

Tian Xuwen

Tian Xuwen Xiao Hongbin*

Xiao Hongbin* Su Hunayu

Su Hunayu Ouyang Qianwen

Ouyang Qianwen