- 1Research Institute of Exploration and Development, Xinjiang Oilfield Company, PetroChina, Karamay, China

- 2College of Earth and Planetary Sciences, University of Chinese Academy of Sciences, Beijing, China

Introduction: The Mahu Sag tight conglomerate reservoirs in the Junggar Basin exhibit rapid pressure depletion and severe degassing in horizontal wells due to low reservoir-saturation pressure differences (<5 MPa), resulting in poor recovery efficiency under primary depletion. This study investigates the feasibility of early-stage CO₂ injection at the reservoir top to enhance oil recovery through gravity-assisted displacement.

Methods: Long-core gravity drainage experiments and numerical simulations were conducted to evaluate the effects of formation dip angle (0°∼90°) and permeability (0.85∼1.7 mD) on displacement efficiency. Comparative analyses of CO₂, N₂, and hydrocarbon gas performance were performed.

Results: Top CO₂ injection significantly improves recovery when the formation dip exceeds 10° and permeability is >0.85 mD. CO₂ exhibits superior pressure maintenance and forms a stable near-miscible oil-gas interface, delaying gas breakthrough (13.5 years for CO₂ vs. 6.5 years for N₂) and achieving 38.7% recovery in the gas chamber – double that of other gases. The small phase contrast between CO₂ and crude oil enables uniform vertical advancement, mitigating gas channeling risks. Furthermore, a hybrid well pattern (vertical injectors + horizontal producers) optimizes sweep efficiency, with vertical wells enhancing multilayer coverage and stability.

Discussion: This work demonstrates that leveraging CO₂ miscibility to stabilize displacement fronts provides an effective strategy for tight reservoir development, particularly in dipping formations.

1 Introduction

Driven by integrated geomechanical engineering approaches, horizontal well volume fracturing pattern has been scaled up in Mahu Sag, enabling economic development of tight conglomerate reservoirs (Cao et al., 2024). However, the Baikouquan reservoir’s low reservoir-saturation pressure difference causes production wells to exhibit high initial rates but rapid pressure depletion below bubble point, triggering GOR surges and severe production decline. Lab studies highlight CO2’s multifaceted roles in pressure maintenance, viscosity reduction, and miscibility, facilitating displacement of oil trapped in micron-sized pores. As a result, gas injection for EOR has been established as a central research priority (Hashemi and Pouranfard, 2014; Song et al., 2024; Shi et al., 2021). Especially for dipping reservoirs, Gas-Assisted-Gravity-Drainage (GAGD) offers a promising solution for energy replenishment and enhanced recovery.

The research on Gas-Assisted-Gravity-Drainage in the United States and the Middle East dates back decades, with extensive laboratory experiments and field trials conducted across diverse reservoir types. The Hawkins Field in the U.S., a fault-block reservoir with active edge and bottom water, initially relied on waterflooding. In the 1970s, cyclic gas injection into the upper zones of certain units enabled gas-assisted gravity drainage, displacing water-invaded oil columns and reducing residual oil saturation by up to 20% compared to primary waterflooding (King and Lee, 1976; Carlson, 1988). Al-Mudhafar WJ et al. quantified the effects of reservoir heterogeneity and anisotropy on gravity drainage in heterogeneous multi-layer sandstone reservoirs using geological modeling and numerical simulation in 2018. They believed that gravity drainage is a process of vertical fluid migration, and therefore the impact of permeability anisotropy on gravity flooding is stronger than heterogeneity (Al-Mudhafar et al., 2018). Saikia B D et al. piloted a single-well gas-assisted-gravity-drive experiment in the deepwater of the Gulf of Mexico in 2021, achieving 65%–80% recovery efficiency under immiscible conditions by integrating gas injection and oil production within a single wellbore. This innovative approach reduced development costs while enhancing overall recovery (Bikash and Dandina, 2021). Zobeidi K et al. simulated the flow process of crude oil in matrix and fractures under the condition of gravity oil displacement in 2022 for fractured reservoirs in Zagros sedimentary basin, southwest Iran, demonstrating that gravity drainage amplifies vertical segregation in fractures, contributing over 50% of incremental recovery compared to matrix-dominated displacement mechanisms (Zobeidi et al., 2022). Al Obaidi D.A. et al. conducted extensive research on strong bottom-water drive reservoirs from 2020 to 2024, demonstrating that Gas-Assisted-Gravity-Drainage achieves higher oil recovery than continuous gas injection (CGI) and gas water alternating gas (WAG). Their findings highlight that the synergistic effect between bottom-water drive and immiscible CO2 gravity flooding significantly enhances crude oil recovery. As aquifer strength increases, gas breakthrough is delayed, while both the recovery at breakthrough and the ultimate recovery improve. The study recommends optimizing gas injection and oil production rates during field implementation to leverage the stability of gravity flooding fully while mitigating early breakthrough risks (Al-Obaidi and Al-Jawad, 2020a; Al-Obaidi and Al-Jawad, 2020b; Al-Obaidi et al., 2022; Al-Obaidi et al., 2024).

The research on Gas-Assisted-Gravity-Drainage in China was relatively late. In 1986, the Huabei Oilfield conducted a top injection N2 immiscible gravity flooding experiment, forming a secondary gas cap at the top of the buried hill and using gravity differentiation to displace the attic oil at the top and move it downwards (Bai et al., 1998). Yang et al. believe that when implementing gravity assisted gas flooding in oil reservoirs, it is required that the dip angle of the reservoir formation be greater than 15° to facilitate oil and gas differentiation (Yang et al., 2006). Zhou et al. used a bottom water sandstone reservoir with top gas injection gravity flooding as an example and believed that the stability of the gas-liquid interface is the key to the success of gravity flooding technology (Zhou et al., 2017). Li conducted a visualization flat-plate model experiment on nitrogen-assisted gravity flooding in typical high-porosity, high-permeability reservoirs with strong edge water. The study revealed that gravity segregation and immiscible displacement are the dominant mechanisms for enhancing oil recovery. Additionally, it was found that larger formation dip angles, earlier gas injection timing, higher formation pressure, lower water cut in production wells, more stable artificial gas caps and higher oil displacement efficiency are interrelated positive correlations (Li, 2022). When Liu et al. studied hydrocarbon gas assisted gravity flooding, they found that in reservoirs with low reservoir pressure, it is difficult for hydrocarbon gas to mix with crude oil, and the gas flooding effect is significantly lower than that of water flooding (Liu et al., 2023). Yang et al. conducted a study on the micro mechanism of CO2 gravity assisted oil displacement, and the results showed that the heterogeneity of sand and gravel can exacerbate the fingering phenomenon. Controlling the injection rate is beneficial for improving the affected area, and oil wet rocks help the remaining oil in micro pores to overcome capillary pressure and be discharged smoothly (Yang et al., 2025). Chen conducted horizontal gas injection, top gas injection, and bottom gas injection oil displacement experiments through long rock cores, and believed that for CO2 immiscible flooding, top gas injection had the best effect, while for miscible flooding, reservoir thickness and gas injection direction had little effect on CO2 oil displacement (Chen, 2023).

Current researches on Gas-Assisted-Gravity-Drainage primarily focus on immiscible displacement during the middle-to-late development stages of moderate-to-high permeability reservoirs. It is widely acknowledged that a stable oil-gas interface is critical for enhancing recovery efficiency. Previous studies have emphasized the role of oil-gas density contrast, asserting that larger density differences help maintain a more stable interface. Injecting gases with significant density disparities from crude oil (e.g., Nitrogen, Hydrocarbon gases) into reservoirs enhances gravity segregation, thereby improving oil displacement efficiency (Yang et al., 2006; Zhou et al., 2017; Li, 2022; Li, 2020; Han et al., 2016; Lei et al., 2022; Guoxin et al., 2020; Rao et al., 2004; Xiao et al., 2024; Kong et al., 2023; Mahmoud and Rao, 2007; Liang et al., 2014; Bautista et al., 2014). However, the role of miscibility between injected gas and crude oil in Gas-Assisted-Gravity-Drainage has received limited attention, and research on whether CO2-miscible drainage can form a stable oil-gas interface remains scarce.

This study therefore focuses on early-stage top CO2 injection for energy replenishment in tight conglomerate reservoirs, taking the Baikouquan Formation as a case study. By integrating long-core-oil-displacement experiments and reservoir numerical simulations, we evaluate the impacts of formation dip angle and reservoir permeability on top gas injection performance. We compare and analyze the pressure-maintaining capacity, oil-gas interface migration characteristics, and sustained production capability of different injection media, clarify the feasibility of top CO2 injection under miscible conditions, and optimize gas injection well patterns. The findings aim to provide guidance for improving development performance and recovery efficiency in tight conglomerate reservoirs of the Mahu Depression.

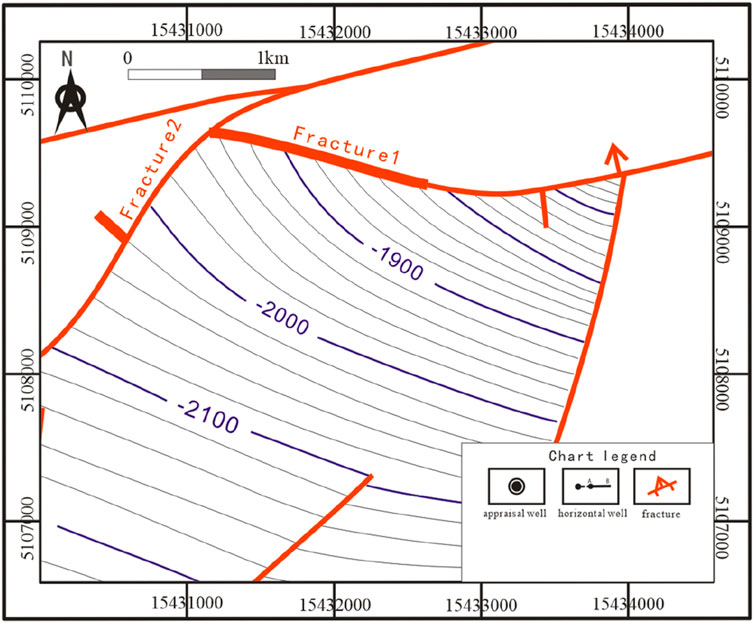

2 Geological overview of oil reservoir

The X7 Block is located in the Mabei slope area of the Mahu Depression, with the main production layer being the Triassic Baikouquan Formation, which is a southeast dipping monocline (Figure 1). The reservoir lithology is mainly gray sandstone, gravel bearing coarse sandstone, and sandy conglomerate. The average porosity of the Baikouquan Formation reservoir in the target layer is 10.0%, with an average permeability of 0.99 mD. The temperature in the middle of the reservoir is 64.11°C, the pressure is 22.72 MPa, the pressure coefficient is 0.917, the saturation pressure is 18.03 MPa, and the reservoir-saturation pressure difference is 4.69 MPa. It is a typical reservoir characterized by low reservoir-saturation pressure difference.

Based on early evaluation and well group testing, in 2021, a three-dimensional development plan was implemented for the X7 Block, with 18 horizontal wells deployed in the Baikouquan Formation. The production wells had high gas-oil ratios and exhibited rapid declines, with an average daily oil production of nearly 5 t/d per well, which is below the economic limit. Due to the low reservoir-saturation difference, dissolved gas in crude oil started to separate prematurely, leading to a rapid increase in gas-oil ratio and significant production decline in these wells. Efficient pressure maintenance is the basis and key to delaying degassing, improving single-well EUR and overall benefits in this reservoir.

3 Feasibility study on top gas injection

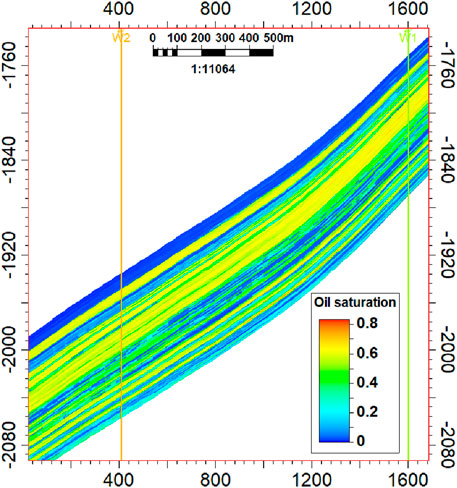

3.1 Favorable conditions for top gas injection

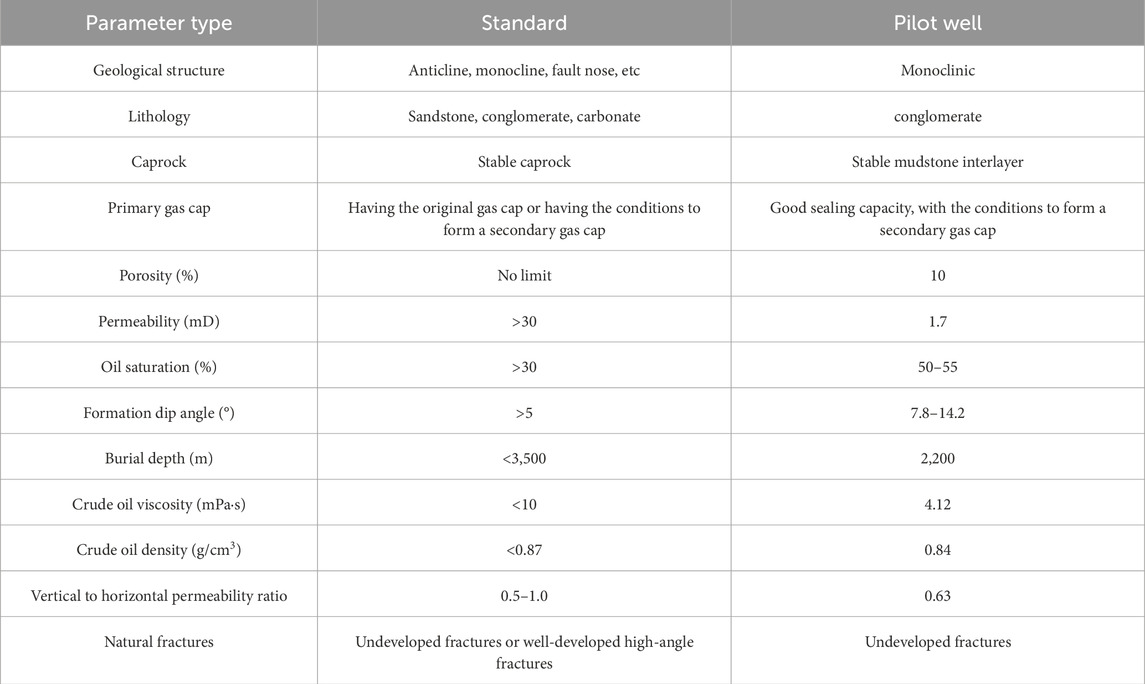

The reservoir of the Baikouquan Formation in the Mahu Depression is dense, and there is a difficulty in injecting water into the micro pores and throats of the formation. Laboratory experiments and field practices have shown that gas injection is an effective method to enhance reservoir pressure and single-well production (Hashemi and Pouranfard, 2014; Song et al., 2024; Shi et al., 2021; Xiao et al., 2024; Kong et al., 2023; Mahmoud and Rao, 2007; Liang et al., 2014; Bautista et al., 2014; Gai et al., 2022; Pu et al., 2021). Compared with the reservoir screening criteria of successful GAGD field practices (Yang et al., 2006; Zhou et al., 2017; Xiao et al., 2024; Kong et al., 2023; Mahmoud and Rao, 2007; Liang et al., 2014; Bautista et al., 2014; Gai et al., 2022; Pu et al., 2021; Tiwari and Kumar, 2001; Kulkarni and Rao, 2006; ROSTAMI et al., 2018; Chang et al., 2016; HAGOORT, 1980; Bangla et al., 1993) (Table 1), the X7 Block has good geological conditions for top gas injection. The reservoir in the Baikouquan Formation has confirmed configurations and sufficient reservoirs. The overall structure is a southwest dipping monocline, with local formation dip angles exceeding 10°. The formation dip angle and vertical permeability (Kv/Kh = 0.63) are suitable for gas-assisted-gravity-drainage. The top of the reservoir is controlled by the controlling boundary faults and has good sealing properties. The stable mudstone interlayer developed at the top of the Baikouquan Formation can ensure effective gas displacement and prevent gas leakage during injection.

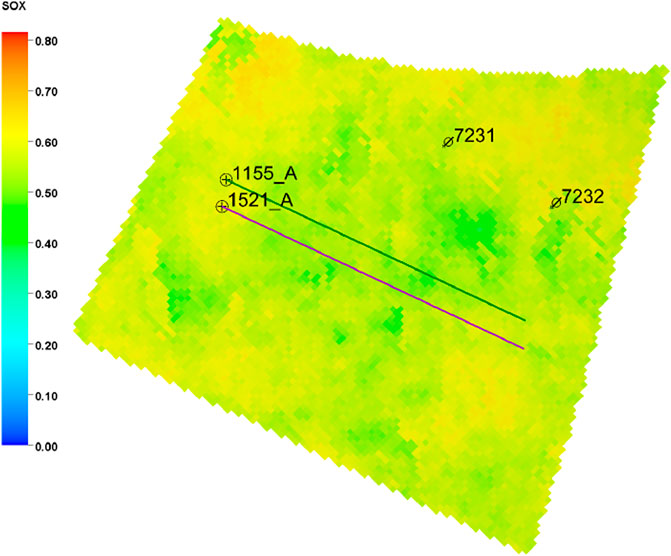

From the above analysis, it can be concluded that the reservoir has favorable geological conditions for top gas injection. Therefore, a typical area was selected in the X7 Block for top gas injection (pilot test). From the reservoir profile of the pilot area (Figure 2), it can be seen that the pilot area is located at the top of the reservoir, with an elevation difference of 320 m and dip angles range from 7.8° to 14.2°,with an average of 11.2°. Vertically, the two main reservoir series are T1b31 and T1b32, with an average porosity of 10.0%, an average permeability of 1.7 mD, an average oil saturation of 56.5%, and a reservoir thickness of 10∼18 m. A mudstone interlayer with a thickness range from 5.6 to 7.9 m is well-developed at the top of T1b31.

3.2 The influence of formation dip angle on gas injection effect

3.2.1 Experimental method

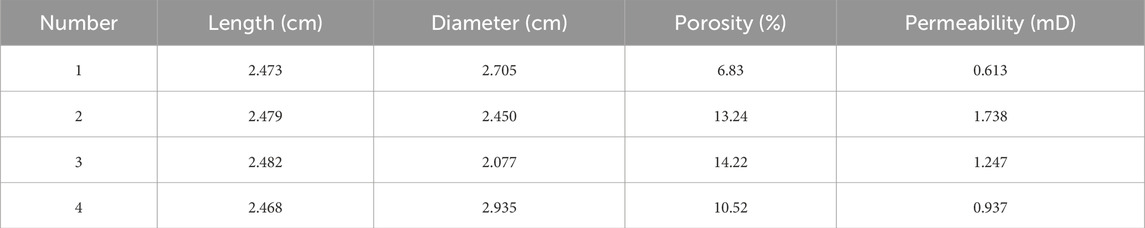

The experimental method employs cores from the Baikouquan Formation reservoir of the X7 Block in the Mahu Depression. The long core has a length of 12.17 cm, an average porosity of 11.2%, and a permeability of 1.13 mD. Based on the gas-oil ratio, live oil is prepared using crude oil and natural gas from the wellhead in the study area. The live oil has a density of 0.82 g/cm3 and a solution gas-oil ratio of 70 m3/m3. The basic physical properties of the experimental core are shown in Table 2.

Core pretreatment and experimental steps are as follows:

(1) The core is cleaned of oil and then dried.

(2) The permeability and porosity of the dried core are measured.

(3) The dried core is placed in a vacuum device and vacuumed for 24 h, then saturated with formation water under vacuum for another 24 h. Four core samples are connected in series, fixed with heat-shrinkable tubing, and placed in a long core holder. Prepared oil is injected into the core at a constant flow rate until the outlet is water-free and the flow rate is stable, at which point the pump is stopped.

(4) The temperature of the incubator is adjusted to 65°, and the confining pressure of the core is gradually increased to 24 MPa (slightly higher than the reservoir pressure to ensure core integrity).

(5) The injection pressure and back pressure are set to 23 and 22.8 MPa, respectively, with a differential pressure of 0.2 MPa, which is close to the miscibility pressure of CO2 and crude oil. CO2 gas is used for the gas flooding experiment, and the oil and gas production are recorded.

(6) A secondary displacement is performed using petroleum ether, and the outlet fluid is recorded until no more oil is produced. After the petroleum ether evaporates, the volume of crude oil is recorded.

(7) The core is cleaned of oil for a second time, and steps (3) to (6) are repeated. During the experiment, the angle of the core holder is adjusted to simulate different formation dips.

3.2.2 Analysis of experimental results

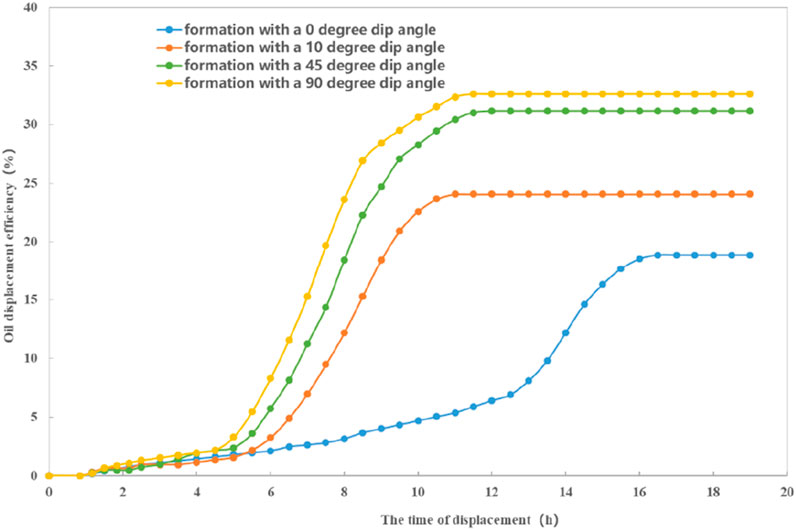

As shown in Figure 3, the oil displacement efficiency varies with different formation dip angles. When the formation dip angle is 0°, the oil displacement efficiency is 18.88%. As the formation dip angle increases to 10°, the oil displacement efficiency rises to 24.06%, representing an increase of 5.18% compared to the 0° formation. At a formation dip angle of 45°, the oil displacement efficiency is 31.14%, which is 7.08% higher than that at 10°. When the formation dip angle reaches 90°, the oil displacement efficiency is 32.59%, an increase of 1.45% compared to the 45°. By comparing the incremental oil displacement efficiencies of formations with different dips to that of a horizontal formation, it can be observed that as the formation dip angle increases, the gravity displacement effect becomes more pronounced when CO2 is injected from the top, and the oil displacement efficiency shows a clear upward trend. When the formation dip angle exceeds 45°, the oil displacement efficiency hardly increases anymore, indicating that the gravity displacement effect diminishes beyond this angle. At a formation dip angle of 10°, The gravity displacement effect is more pronounced compared to a horizontal formation. Additionally, under near-miscible conditions, the oil displacement efficiency can be improved, thus top gas injection demonstrates better oil enhancement effects. The average formation dip angle in the pilot area of the X7 Block is 11.2°, making top gas injection a feasible option for enhancing oil recovery. References (Hashemi and Pouranfard, 2014; Song et al., 2024; Shi et al., 2021) suggest that CO2 miscible flooding can improve oil recovery efficiency, while reference (Lei et al., 2022) indicates that CO2-assisted gravity drainage (CAGD) becomes increasingly effective when formation dip angles exceed 5°, which is consistent with the conclusion of this study.

3.3 The influence of permeability on gas injection effect

3.3.1 Basic information of the model

Based on detailed reservoir characterization, a 3D fine geological model of the X7 Block has been established. The model for the gas injection pilot area has a grid spacing of 20 m × 20 m×2 m, comprising 2.7878 million grids, and is vertically divided into two oil-bearing formations: T1b31 and T1b32. The fluid model adopts a component model fitted to the phase behavior, with formation crude oil density of 0.7432 g/cm3, formation crude oil viscosity of 4.12 mPa·s, initial solution gas-oil ratio of 69 m3/m3, and bubble point pressure of 18.0 MPa. The model utilizes Schlumberger’s Intersect simulator and the easyfrac plugin for simulation calculations. To investigate the feasibility of gravity drive in low-permeability reservoirs, based on the geological model of the pilot area, while keeping other parameters unchanged, the influence of reservoir permeability on the oil displacement effect of top CO2 injection is studied by varying the reservoir permeability. Referring to the volume fracturing and gas injection parameters in other blocks of the Mahu Depression, two gas injection wells are deployed at the structural top, and two horizontal wells are stereoscopically staggered 500 m away from the gas injection wells, targeting the two oil-bearing formations. The horizontal wells are nearly parallel to the structural trend and the maximum principal stress direction, with a horizontal section length of 1,400 m and a planar spacing of 200 m (Figure 4). The horizontal wells are designed for volume fracturing simulation upon completion. According to the actual fracturing monitoring data of Mahu, the effective fracture half length is 80–120 m, the effective support fracture height is 15–35 m, and the injection-production ratio is set to 1.2.

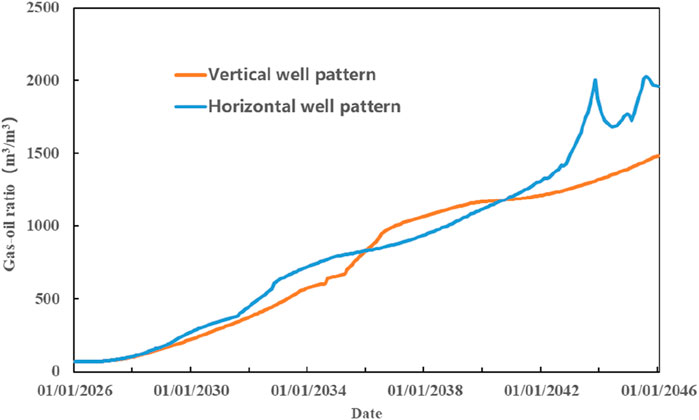

3.3.2 Analysis of model results

For the convenience of result comparison, the model’s gas breakthrough criterion is set as a rapid decline in production coupled with a CO2 component concentration in the produced gas exceeding 0.8. Figure 5 illustrates the normalized oil production and the recovery degree of produced reserves at the moment of gas breakthrough under different reservoir permeabilities (or at the end of year 20 if the gas breakthrough criterion has not been met by then). As permeability increases, pressure propagation and displacement front migration accelerate, leading to more obvious production well response. When the permeability is less than 0.85 mD, the displacement front migration is restricted, making it difficult to achieve gas breakthrough by the end of year 20, with a recovery degree of less than 15%. This indicates the production wells may face the risk of neither gas breakthrough nor effective response. When the permeability exceeds 0.85 mD, the production wells respond significantly, with higher reserve mobilization at the moment of gas breakthrough and a recovery degree greater than 35%. Numerical simulation methods determine that the permeability threshold for top CO2 injection in the X7 Block is 0.85 mD. When the reservoir permeability is below 0.85 mD, production wells are less likely to respond, and the recovery degree is low. When the permeability is above 0.85 mD, production wells respond markedly, and the recovery degree is high. The average permeability in the X7 Block is 1.7 mD, making top gas injection feasible.

Figure 5. Normalized cumulative oil production and recovery degree under different reservoir permeabilities.

4 Optimal selection of gas injection medium feasibility study on top gas injection

Under formation conditions, the density of CO2 is close to that of crude oil (CO2 density: 0.6854 g/cm3), while the densities of N2 and hydrocarbon gas differ significantly from that of crude oil (N2 density: 0.2052 g/cm3, hydrocarbon gas density: 0.1520 g/cm3). This paper, based on the actual geological conditions of the X7 Block, compares the gas injection performance of different media mainly in terms of pressurization capacity, stability of the oil-gas interface, and capacity of suppressing gas channeling, to elucidate the advantages of top CO2 injection for enhanced oil recovery in tight reservoirs.

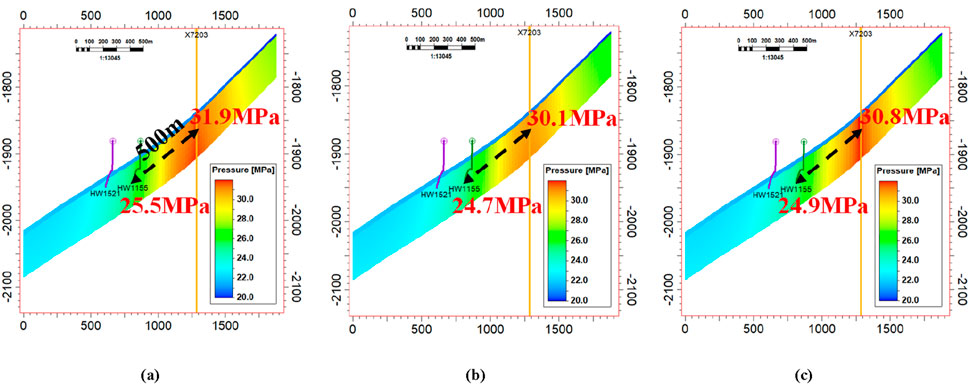

4.1 Advanced gas injection pressurization capacity

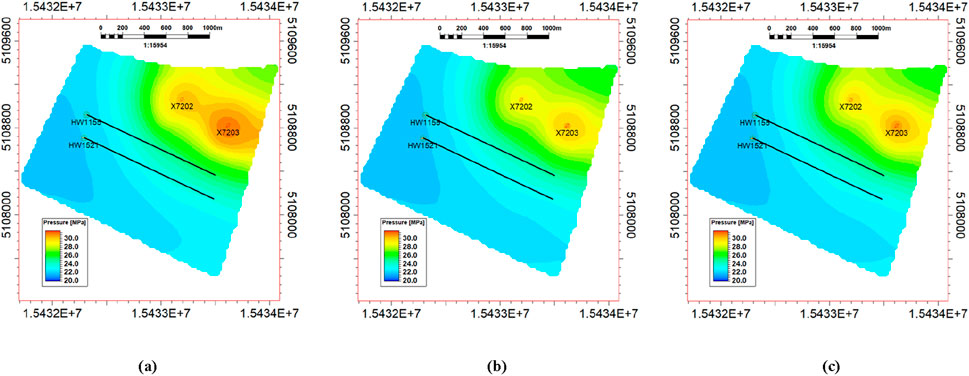

Numerical simulation study on advanced gas injection for pressure maintenance was carried out for X7 Block. The pressure distribution of different gas injection media under the same HCPV ratio is shown in Figures 6, 7. When injecting 0.028 HCPV, the reservoir pressure around the injection well rises to 31.9 MPa, the reservoir pressure around the production well at a distance of 500 m is 25.5 MPa, and the pressure difference between injection and production wells is 6.7 MPa. Under the same conditions, the pressure difference between injection and production wells is 5.9 MPa when N2 is injected in advance, while it is 5.4 MPa when hydrocarbon gas is injected in advance. Among the three injection media, CO2 has the strongest pressurization capacity.

Figure 6. Advanced gas injection pressure profile of X7 Block (0.028 HCPV). (a) CO2. (b) Hydrocarbon gas. (c) N2.

Figure 7. Advanced gas injection pressure plan view of X7 Block (0.028 HCPV). (a) CO2. (b) Hydrocarbon gas. (c) N2.

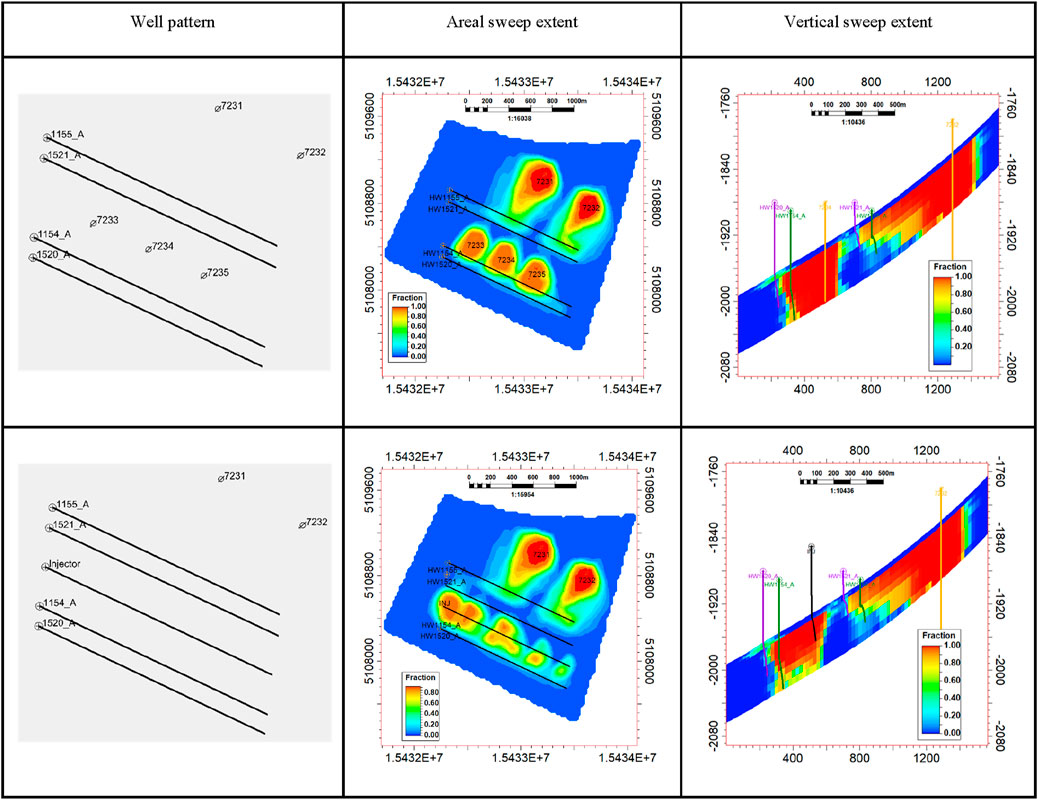

4.2 Gas chamber range

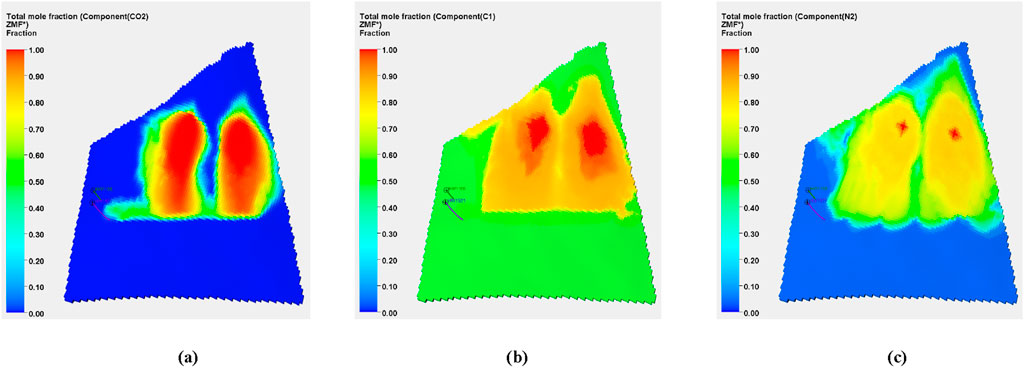

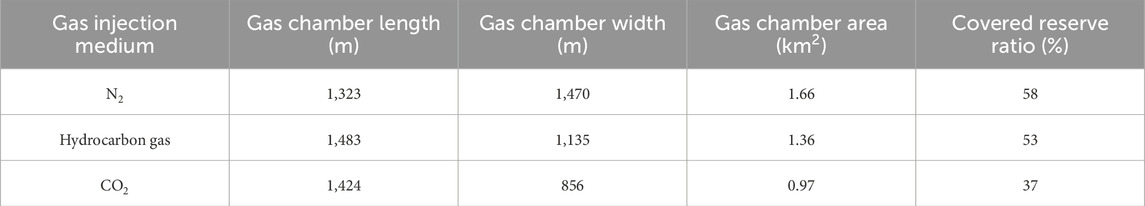

During top gas injection, the range of gas chambers formed by different gas media under the same HCPV number is compared (injection-production ratio of 1.2) and the same production time (20 years) (Figure 8; Table 3). The research results indicate that injecting hydrocarbon gas or N2 at the top has a large impact range, forming an approximately rectangular gas chamber and covering over 50% of the reserves; The range of CO2 injection is not as wide as that of hydrocarbon gas or N2, and the gas chamber is approximately elliptical, covering a reserve ratio of 37%, which is smaller than that of hydrocarbon gas or N2.

Figure 8. Gas chamber range diagram formed by different injection media after 20 years. (a) CO2. (b) Hydrocarbon gas. (c) N2.

Table 3. Sweep range and covered reserve of gas chamber after 20 years for different injection media.

4.3 Oil-gas interface migration velocity

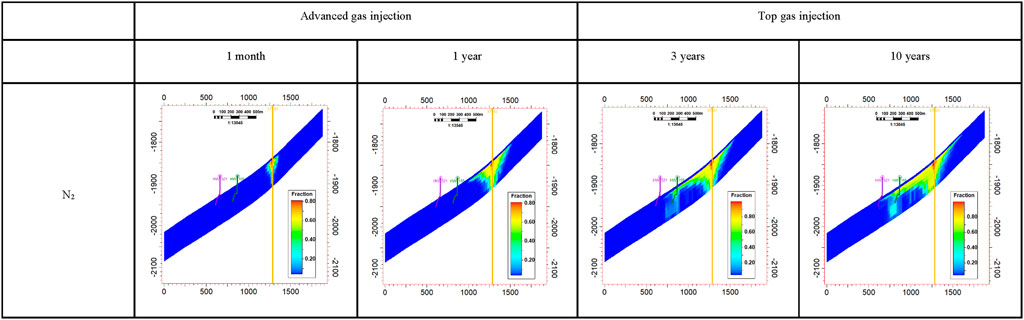

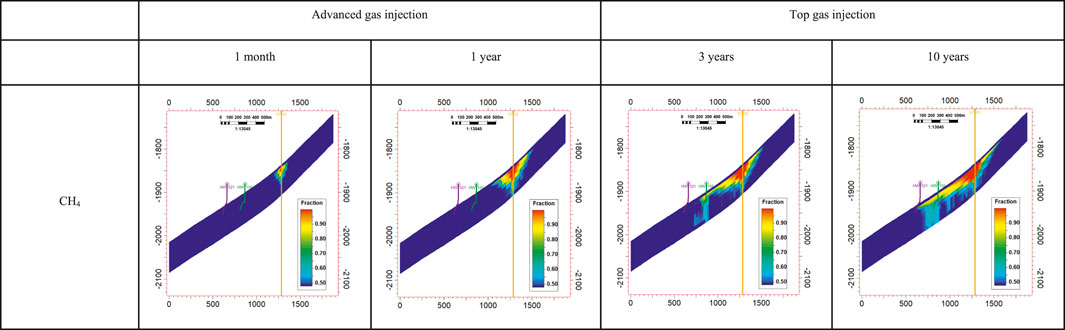

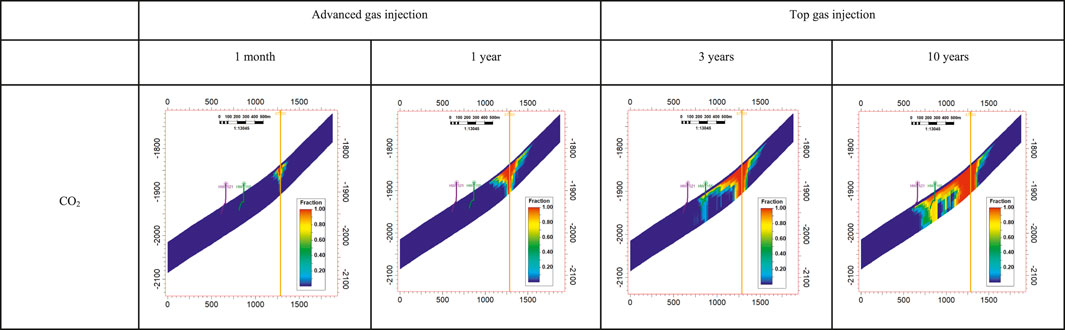

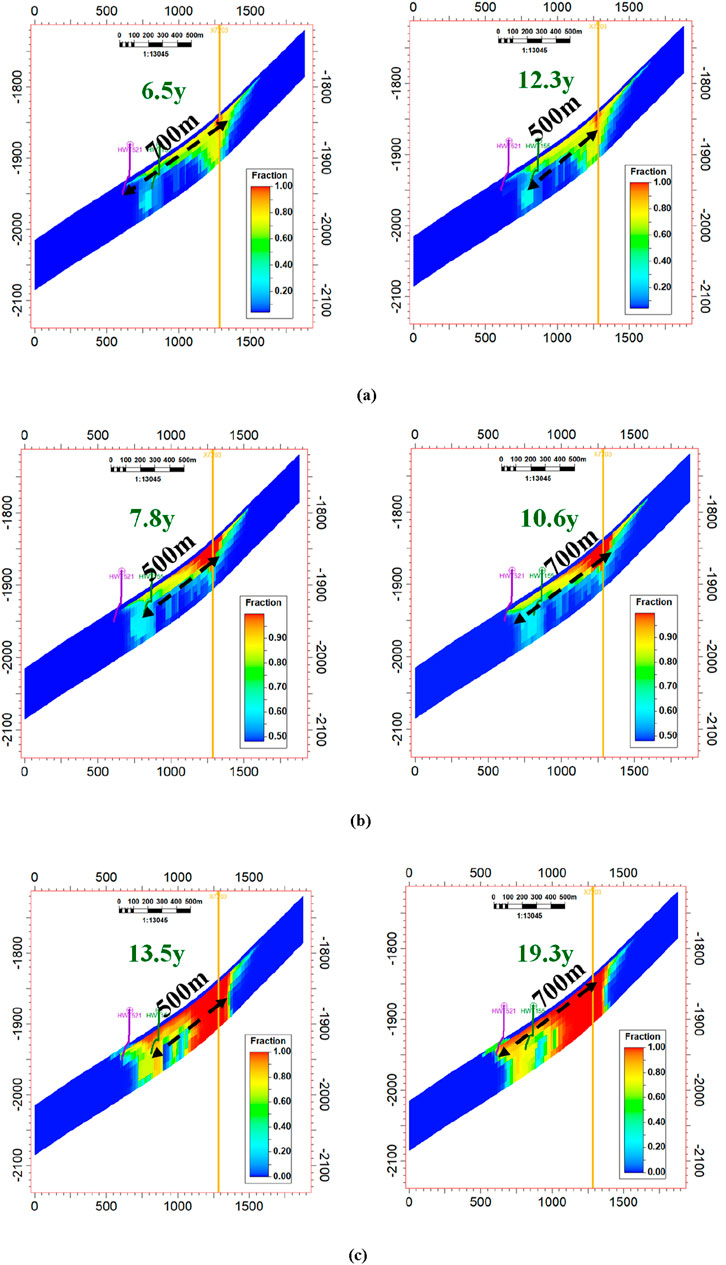

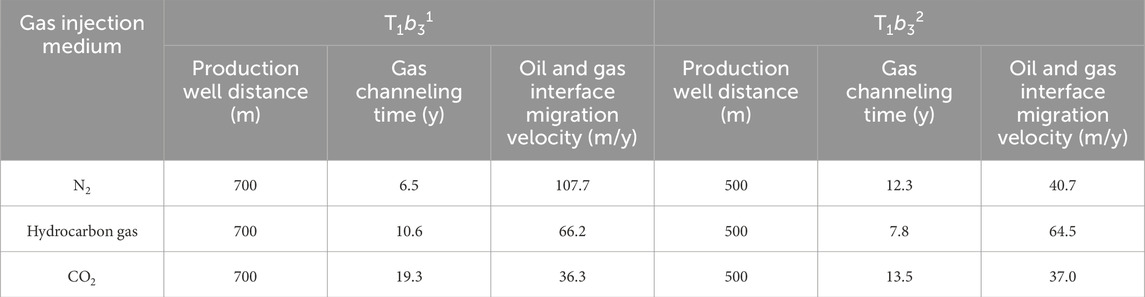

From the component concentration profiles of different gas media at the same time (Figures 9–11), it can be seen that the migration of the oil-gas interface is greatly affected by the difference in oil and gas density. The density difference between hydrocarbon gas or N2 and crude oil is large, and the sweep range is large in the plane, with significant vertical differentiation. The density difference between CO2 and crude oil is small, and the migration in the plane is slow, while the vertical influence is uniform.

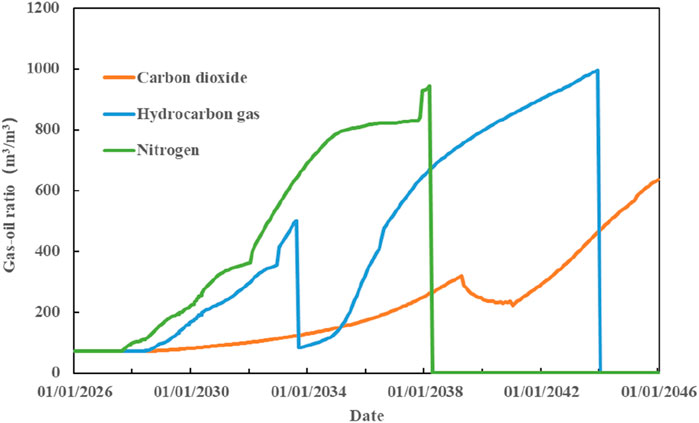

Based on the oil-gas interface migration characteristics, the gas breakthrough time and oil-gas interface migration velocity of different media in different layers were finely characterized according to numerical simulation results. Among them, the identification criteria for single-well gas breakthrough in numerical simulation research are that component concentration exceeds 0.8, production starts to decline rapidly, the gas-oil ratio rises rapidly and exceeds 500 m3/m3. From the perspective of interface migration speed, N2 migration speed is the fastest, at 107.7 m/y, forming gas channeling in 6.5 years; The migration rate of hydrocarbon gas is second, at 66.2 m/y, and gas channeling occurs in 7.8 years; The CO2 migration rate is the slowest, at 36.3 m/y, forming gas channeling in 13.5 years. From the perspective of interface migration uniformity, there is a significant difference in the migration velocity of N2 in different layers, which poses a high risk of premature gas breakthrough; There is little difference in the migration velocity of hydrocarbon gas and CO2 in different layers, and the oil-gas interface is relatively uniform (Figure 12; Table 4).

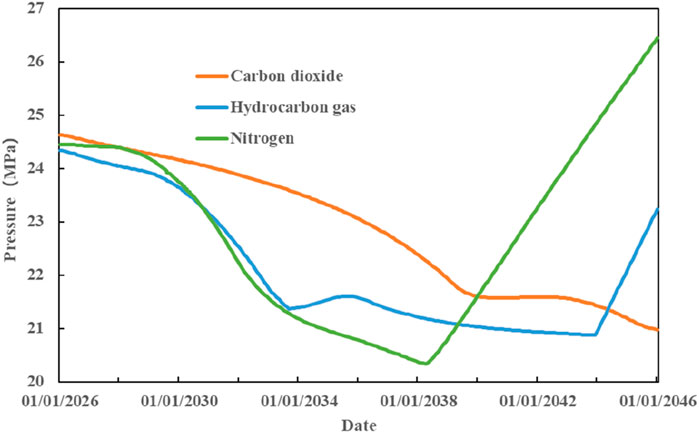

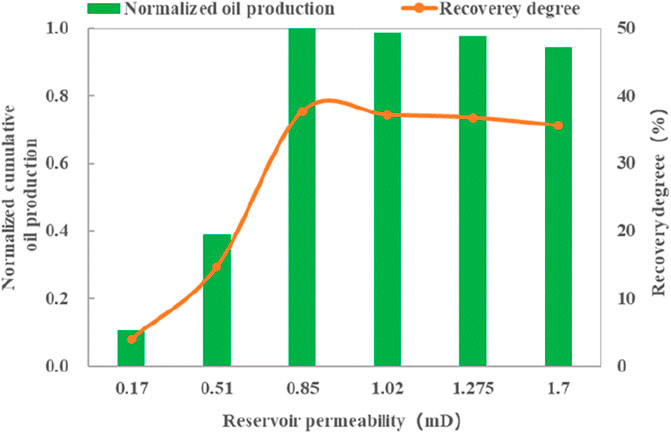

4.4 Capacity to suppress gas channeling

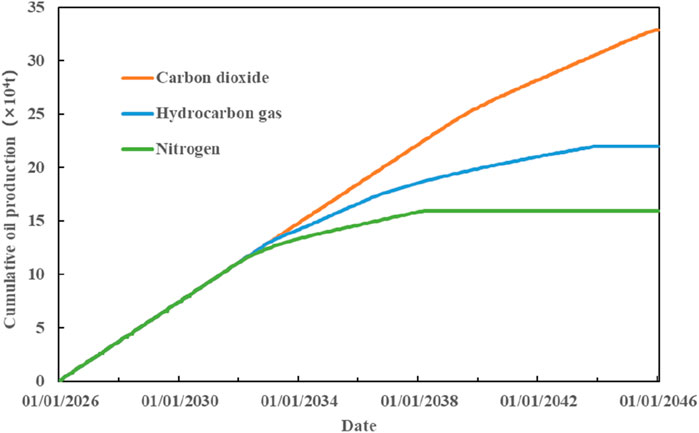

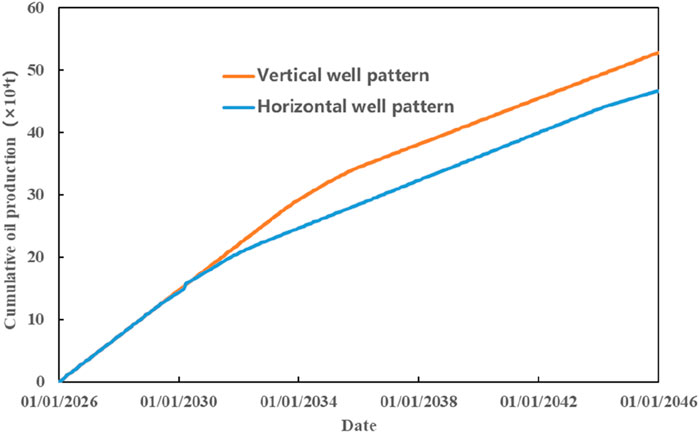

The set well shut-in condition is that the concentration of the medium component in the produced gas is 0.9. From the production performance and oil displacement efficiency of different gas injection media, it can be seen that after 20 years, CO2 displacement has the highest cumulative oil production, reaching 32.48 × 104 t, while N2 and hydrocarbon gas displacement have cumulative oil production of less than 25 × 104 t. The CO2 displacement has the highest recovery degree of recovered reserves, reaching 38.67%, while the recovery degree of N2 and hydrocarbon gas displacement are both less than 20%; In addition, The gas-oil ratio of CO2 displacement is relatively low and the degree of reservoir pressure maintenance is high (Figures 13–15; Table 5).

Considering the results of interfacial tension measurement by laboratory experimental, at reservoir temperature, the MMP (minimum miscibility pressure) between CO2 and crude oil is 22.3 MPa, the MMP between hydrocarbon gas and crude oil is 42 MPa, and N2 is still difficult to achieve miscible at a pressure of 45 MPa. Under reservoir conditions (reservoir pressure of 22.7 MPa), CO2 and crude oil can achieve miscibility or near-miscibility by advanced gas injection, while hydrocarbon gas and N2 are difficult to miscible with crude oil.

From the perspective of production performance, production wells by CO2 displacement exhibit relatively uniform gas breakthrough, with a gradual increase in the gas-oil ratio (GOR) and slow pressure decline. In contrast, Multi-stage fractured horizontal wells displaced by N2 or hydrocarbon gas show uneven gas breakthrough, characterized by rapid GOR increase with multiple abrupt changes. Among them, horizontal wells with early gas channeling experience rapid production decline and sharp pressure drop around the wellbore, making it difficult to maintain normal production and leading to well shut-in. This results in a temporary rebound in reservoir pressure. As GOR increases in horizontal wells with delayed gas channeling, the reservoir pressure decreases accordingly. The analysis of gas chamber stability and inter-phase migration reveals that CO2 achieves miscibility or near-miscibility with oil, minimizing phase behavior contrast and facilitating piston-like displacement front movement. Consequently, following gas breakthrough in producing wells, oil production declines slowly; the gas-oil ratio rises steadily; and pressure depletion occurs gradually, characterized by low gas channeling risk, robust stable production capacity, and high reservoir sweep efficiency. In contrast, hydrocarbon gas and N2 have weaker mutual solubility and miscibility with crude oil, resulting in significant differences in flow capacity between oil and gas phases. Therefore, after gas breakthrough, oil production declines rapidly; the GOR rises sharply; injected gas circulates inefficiently along dominant channels; and pressure drops rapidly, collectively exhibiting high gas channeling risk, poor stable production capacity, and low reservoir mobilization efficiency. Reference (Liu et al., 2023) points out that when hydrocarbon gas cannot be mixed with crude oil, the effect of assisted gravity gas flooding is not as good as that of water flooding. It emphasizes the importance of mixing relative to assisted gravity gas flooding, which is consistent with the conclusion of this study. References (Al-Obaidi and Al-Jawad, 2020a; Al-Obaidi and Al-Jawad, 2020b; Al-Obaidi et al., 2022; Al-Obaidi et al., 2024) highlight that bottom water presence delays gas channeling in CO2 immiscible gravity flooding, with more pronounced delays observed in reservoirs with larger aquifer volumes. However, tight conglomerate reservoirs exhibit underdeveloped aquifers, increasing the risk of gas channeling during immiscible gravity. Key focus areas for enhancing recovery in unconventional reservoirs include optimizing gas injection timing and injection-production parameters, improving gas-oil miscibility, and maintaining displacement front stability.

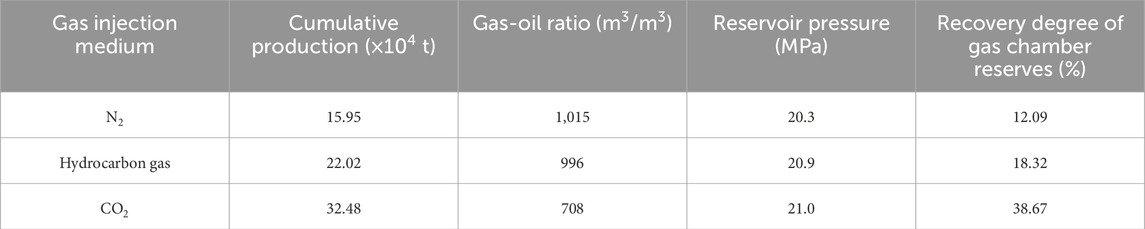

5 Optimization of gas injection well pattern

The formation dip angle of the pilot area ranges from 7.8° to 14.2°. Numerical simulation results indicate that CO2- Assisted-Gravity-Drainage demonstrates significant effects in pressure maintenance, oil displacement, and gas channeling control. However, the migration velocity of the oil-gas interface is relatively slow, at only 37.0 m3/y. To enhance oil production rate and shorten the investment payback period, a gas injection strategy is proposed: deploying gas injectors in structurally lower areas while maintaining top gas injection, forming a gravity-assisted and areal-coordinated multi-directional displacement pattern. This approach provides a pilot basis for establishing a full-reservoir gas injection well pattern.

Considering the gas injection characteristics of vertical and horizontal wells, a comparative design of gas injection via vertical vs. horizontal wells was conducted in the lower structural sections. The well pattern is illustrated in Figure 16. Production performance analyses (Figures 17, 18) show that, at the same HCPV ratio, replacing one horizontal well with three vertical wells results in higher cumulative oil production and lower gas-oil ratio. In terms of sweep characteristics:

• Horizontal well exhibit strong injectivity and extensive areal sweep, but suffer from uneven vertical progression, high gas breakthrough risk, and poor suitability for dynamic control and three-dimensional development.

•Vertical wells enable multi-layer gas injection, featuring smaller areal sweep but uniform vertical progression, higher overall sweep efficiency, and lower gas breakthrough risk.

For the pilot area, a recommended well pattern is proposed: vertical wells for gas injection, horizontal wells for oil production, combined with gravity-assistance and areal-coordinated displacement.

6 Discussions

This study systematically evaluates the feasibility of early-stage top CO2 injection in tight conglomerate reservoirs through integrated experimental and numerical simulations. The key findings validate the applicability of CO2-Assisted -Gravity-Drainage in low-permeability reservoirs while providing novel technical insights for developing analogous reservoirs. The discussion examines mechanistic interpretations, compares findings with existing literature, and explores field applications.

6.1 Critical geological parameters and miscibility effects

Experimental results reveal formation dip angle and permeability as fundamental controls on CO2 top injection efficacy. The identified threshold values reflect hydrodynamic and thermodynamic interactions unique to tight conglomerates. Formation dips below 10° provide insufficient gravitational potential to overcome viscous forces, resulting in CO2 accumulation rather than effective oil displacement. This explains the improved recovery observed at the X7 Block’s average dip angle of 11.2°. Similarly, permeabilities below 0.85 mD restrict CO2 diffusion, preventing adequate pressure continuity - a finding that challenges conventional GAGD screening criteria which typically require higher permeability. The synergy between these geological parameters and CO2’s near-miscibility (MMP = 22.3 MPa at reservoir conditions) enables stable displacement fronts, demonstrating how tight reservoirs require coupled gravitational and miscibility effects for effective recovery.

6.2 Comparative advantages of CO2 injection

CO2 demonstrates superior performance relative to alternative gases through interconnected mechanisms. Its density (0.6854 g/cm3), closer to crude oil than N2 or hydrocarbon gas, promotes stable frontal advancement and delays breakthrough. The near-miscible conditions minimize interfacial tension, facilitating oil mobilization from microporous networks that characterize conglomerate reservoirs. This combination yields a gas chamber recovery of 38.7%, substantially exceeding immiscible gas injection results. Furthermore, CO2 maintains stronger pressure support, with inter-well differentials measuring 6.7 MPa compared to 5.9 MPa for N2, thereby mitigating rapid pressure depletion observed with other injection media.

6.3 Theoretical context and advancements

The findings both corroborate and extend established knowledge in gravity drainage processes. While confirming the importance of dip angles for segregation efficiency, the results demonstrate how near-miscibility can compensate for marginally sub optimal structural configurations. The study also contrasts with conventional wisdom regarding permeability requirements, showing that appropriate gas selection and injection strategies can overcome traditional limitations. Notably, the work addresses a knowledge gap regarding miscibility’s role in gravity drainage stability, particularly in absence of aquifer support that features prominently in many successful conventional applications.

6.4 Implementation considerations and forward outlook

Field application benefits from the proposed hybrid well architecture combining vertical injectors with horizontal producers. This configuration addresses common challenges in tight reservoir development by improving vertical conformance and enabling dynamic flood management. The slower CO2 advance rate facilitates monitoring and adjustment, reducing premature breakthrough risks. However, several factors require further investigation, including potential long-term injectivity reduction from mineral trapping and the influence of fracture networks on displacement efficiency. These aspects highlight the need for integrated modeling approaches incorporating geochemical and geomechanical considerations.

The comprehensive analysis presented establishes CO2-Assisted -Gravity-Drainage as a technically viable strategy for tight conglomerates that concurrently addresses production enhancement and carbon management objectives. Future efforts should focus on validating the mechanisms through targeted experimentation and controlled field trials.

7 Conclusion

To address the challenges of gas segregation and rapid production decline in horizontal wells of tight conglomerate reservoirs, this study evaluates the feasibility of early-stage top CO2 injection through long-core-oil-displacement experiments and reservoir numerical simulation. The key conclusions are as follows:

(1) Under the conditions of a formaiton dip angle greater than 10° and reservoir permeability exceeding 0.85 mD, injecting CO2 into the top of the Baikouquan Formation reservoir in the Mahu Depression demonstrates significant oil production enhancement, confirming the feasibility of CO2 injection at the top of tight conglomerate reservoirs.

(2) N2 and hydrocarbon gas struggle to achieve miscibility with crude oil, making gas breakthrough and premature channeling prone to occur during gravity flooding. In contrast, CO2 establishes a stable oil-gas interface with crude oil under miscible or near miscible conditions, mitigating phase behavior and mobility disparities between the two phases. This enables more uniform displacement, delays gas breakthrough effectively, and enhances the sustained productivity of oil wells. Such mechanisms are pivotal for implementing efficient CO2-Assisted-Gravity-Drainage in tight conglomerate reservoirs.

(3) Horizontal wells face high risks of planar gas channeling during gas injection, whereas vertical wells enable uniform longitudinal gas advance with high sweep efficiency and low channeling risks. A gravity-assisted displacement mode integrated with areal well pattern, featuring gas injection via vertical wells and oil production through horizontal wells, can improve oil recovery and enhance displacement efficiency.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

WZ: Conceptualization, Data curation, Formal Analysis, Methodology, Writing – original draft. CC: Investigation, Methodology, Writing – original draft. XH: Data curation, Methodology, Writing – original draft. SL: Methodology, Software, Writing – original draft. YF: Data curation, Investigation, Writing – original draft. LT: Methodology, Software, Supervision, Writing – original draft. JZ: Methodology, Software, Supervision, Writing – original draft. RJ: Writing – review and editing. FT: Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was supported by the China Petroleum Corporation’s Key Research and Application Technology Special Project “Research on key technologies for increasing reserves, production and recovery efficiency in conglomerate oil reservoirs” (2023ZZ24YJ03).

Acknowledgments

China Petroleum Corporation provided support in terms of experimental materials, instruments, and simulation software for the smooth conduct of this study.

Conflict of interest

Authors WZ, CC, XH, SL, YF, LT, and JZ were employed by Xinjiang Oilfield Company, PetroChina.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The authors declare that this study received funding from China Petroleum Corporation. The funder had the following involvement in the study: study design, collection, analysis, interpretation of data, the writing of this article, and the decision to submit it for publication.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abbreviations

GAGD, Gas-Assisted-Gravity-Drainage; CGI, Continuous Gas Injection; WAG, Water-Alternating-Gas; MMP, Minimum Miscibility Pressure; EUR, Estimated Ultimate Recoverey; HCPV, Hydrocarbon Pore Volume; m/y, meter per year; t/d, ton per day.

References

Al-Mudhafar, W. J., Rao, D. N., and Srinivasan, S. (2018). Reservoir sensitivity analysis for heterogeneity and anisotropy effects quantification through the cyclic CO2-Assisted Gravity Drainage EOR process – a case study from South Rumaila oil field. Fuel 221, 455–468. doi:10.1016/j.fuel.2018.02.121

Al-Obaidi, D. A., and Al-Jawad, M. S. (2020a). Immiscible CO2-assisted gravity drainage process for enhancing oil recovery in bottom water drive reservoir. Assoc. Arab Univ. J. Eng. Sci. 27 (2), 60–66. doi:10.33261/jaaru.2020.27.2.007

Al-Obaidi, D. A., and Al-Jawad, M. S. (2020b). Numerical simulation of immiscible CO2-assisted gravity drainage process to enhance oil recovery. Iraqi J. Sci. 61 (8), 2004–2016. doi:10.24996/ijs.2020.61.8.17

Al-Obaidi, D. A., Al-Mudhafar, W. J., and Al-Jawad, M. S. (2022). Experimental evaluation of Carbon Dioxide-Assisted Gravity Drainage process (CO2-AGD) to improve oil recovery in reservoirs with strong water drive. Fuel 324, 124409. doi:10.1016/j.fuel.2022.124409

Al-Obaidi, D. A., Al-Mudhafar, W. J., Hussein, H. H., and Rao, D. N. (2024). Experimental influence assessments of water drive and gas breakthrough through the CO2-assisted gravity drainage process in reservoirs with strong aquifers. Fuel 370, 131873. doi:10.1016/j.fuel.2024.131873

Bai, F., Shen, Y., Meng, Q., Song, F., and Weng, Y. (1998). Reservoir engineering research of the nitrogen injection pilot in Yanling oil field. Acta Pet. Sin. 19 (4), 61–68. doi:10.7623/syxb199804011

Bangla, V. K., Yau, F. F., and Hendricks, Q. R. (1993). Reservoir performance of a gravity stable vertical CO2 miscible flood: Wolfcamp Reservoir, Wellman Unit. SPE Reserv. Eng. 4 (8), 261–269. doi:10.2118/22898-PA

Bautista, E., Barillas, J. L., Dutra, J., and da Mata, W. (2014). Capillary, viscous and gravity forces in gas⁃assisted gravity drainage. J. Petroleum Sci. Eng. 122, 754–760. doi:10.1016/j.petrol.2014.09.018

Bikash, D. S., and Dandina, N. R. (2021). A single-well gas-assisted gravity drainage enhanced oil recovery process for U.S. Deepwater Gulf of Mexico operations. Energies 14 (6), 1743. doi:10.3390/en14061743

Cao, W., Xian, C., Wu, B., Wen, H., Yu, H. Y., Shen, Y., et al. (2024). Integrated well spacing optimization for geological engineering of conglomerate tight oil-A case of Ma131 tight spacing stereoscopic development demonstration area. Petroleum Sci. Bull. 9 (1), 103–116. doi:10.3969/j.issn.2096-1693.2024.01.008

Carlson, L. O. (1988). Performance of Hawkins Field unit under gas drive-pressure maintenance operations and development of an enhanced oil recovery project. SPE. doi:10.2118/17324-MS

Chang, Y., Jiang, H., Li, J., Ma, K., Gao, Y., Hu, J., et al. (2016). The study on crestal injection for fault Block reservoir with high dip and low permeability. Sci. Technol. Eng. 16 (33), 179–183. doi:10.3969/j.issn.1671-1815.2016.33.032

Chen, X. (2023). Influence of miscibility and gravity on CO2 flooding for oil recovery enhancement and storage potential. Petroleum Geol. Oilfield Dev. Daqing. doi:10.19597/J.ISSN.1000-3754.202308024

Gai, C., Wang, M., Zhang, X., Qiao, S., and Bi, Y. (2022). Research and application of gas-cap gravity flooding technology in high inclination reservoirs. Complex Hydrocarb. Reserv. 15 (4), 71–75. doi:10.16181/j.cnki.fzyqc.2022.04.013

Guoxin, L., Jianhua, Q., Chenggang, X., Xibin, F., Jing, Z., and Yi, D. (2020). Theoretical understandings, key technologies and practices of tight conglomerate oilfield efficient development: a case study of the Mahu oilfield, Junggar Basin, NW China. Petroleum Explor. Dev. 47 (6), 1185–1197. doi:10.11698/PED.2020.06.11

Hagoort, J. (1980). Oil recovery by gravity drainage. Soc. Petroleum Eng. J. 20 (3), 139–150. doi:10.2118/7424-pa

Han, J. J., Lee, M., Lee, W., Lee, Y., and Sung, W. (2016). Effect of gravity segregation on CO2 sequestration and oil production during CO2 flooding. Appl. Energy 161 (1), 85–91. doi:10.1016/j.apenergy.2015.10.021

Hashemi, F. A., and Pouranfard, A.-R. (2014). Evaluation of miscible and immiscible CO2 injection in one of the Iranian oil fields. Egypt. J. Petroleum 23 (3), 255–270. doi:10.1016/j.ejpe.2014.08.002

King, R. L., and Lee, W. J. (1976). An engineering study of the Hawkins (Woodbine) field. J. Petroleum Technol. 28 (2), 123–128. doi:10.2118/5528-pa

Kong, F., Li, Y., Guo, T., Liu, J., and Nan, J. (2023). Applicability of CO2 gravity drainage technology for high⁃dip fault block reservoirs in Hailar Oilfield. Petroleum Geol. Oilfield Dev. Daqing 42 (6), 75–81. doi:10.19597/J.ISSN.1000-3754.202302026

Kulkarni, M. M., and Rao, D. N. (2006). Characterization of operative mechanisms in gravity drainage field projects through dimensional analysis. SPE. doi:10.2523/103230-MS

Lei, M., Qu, Y., Wan, C., Yang, B., He, D., Ma, G., et al. (2022). Analysis of influencing factors on the development effect of CO2 assisted gravity flooding. Special Oil Gas Reservoirs 29 (6), 133–140. doi:10.3969/j.issn.1006-6535.2022.06.017

Li, Y. (2020). Technical advancement and prospect for CO2 flooding enhanced oil recovery in low permeability reservoirs. Petroleum Geol. Recovery Effic. 27 (1), 1–10. doi:10.13673/j.cnki.cn37-1359/te.2020.01.001

Li, Y. (2022). Research on mechanism and numerical simulation of artificial gas cap displacement in high porosity, high permeability reservoir with strong edge water. Chengdu: Chengdu University of Technology. doi:10.26986/d.cnki.gcdlc.2022.000662

Liang, S., Zhou, W., and Zhang, J. (2014). Investigation on effect application of the technology of crestal gas injection for stable gravity flooding. J. Southwest Petroleum Univ. Technol. Ed. 36 (4), 86–92. doi:10.11885/j.issn.1674-5086.2013.09.02.01

Liu, Y., Wang, S., Zhao, W., Yan, H., Guo, P., Zhang, J., et al. (2023). Multi-dimensional experimental study of hydrocarbon gas-assisted gravity drainage. Arabian J. Sci. Eng. 48 (48), 17031–17048. doi:10.1007/s13369-023-08333-3

Mahmoud, T. N., and Rao, D. N. (2007). Mechanisms and performance demonstration of the gas⁃assisted gravity⁃drainage process using visual models. SPE. doi:10.2118/68169-MS

Pu, W., Wang, Y., Li, L., Gao, H., Shan, D., and Wang, W. (2021). Feasibility of supercritical CO2 huff⁃puff development of tight conglomerate reservoirs. Xinjiang Pet. Geol. 42 (4), 456–461. doi:10.7657/XJPG20210409

Rao, D. N., Ayirala, C., and Kulkarni, M. M. (2004). Development of the gas assisted gravity drainage (GAGD) process for improved light oil recovery. SPE. doi:10.2523/89357-MS

Rostami, B., Pourafshar, P., Fathollahi, A., Yassin, M. R., Hassani, K., Khosravi, M., et al. (2018). A new approach to characterize the performance of heavy oil recovery due to various gas injection. Int. J. Multiph. Flow 99, 273–283. doi:10.1016/j.ijmultiphaseflow.2017.10.014

Shi, L., Zhang, Y., Ye, Z., Zhang, J., Wang, Y., Wang, R., et al. (2021). Field test effect analysis of CO2 huff and puff for EOR of horizontal wells in tight glutenite reservoir of Mahu oilfield. Petroleum Reserv. Evalu-ation Dev. 11 (6), 871–877. doi:10.13809/j.cnki.cn32-1825/te.2021.06.011

Song, P., Cui, C., Zhang, J., Liu, K., Deng, Z., Tan, L., et al. (2024). Simultaneous CO2 huff⁃n⁃puff test in highly sensitive reservoirs in upper Wuerhe formation, Mahu sag. Xinjiang Pet. Geol. 45 (3), 355–361. doi:10.7657/XJPG20240313

Tiwari, S., and Kumar, S. (2001). Nitrogen injection for simultaneous exploitation of gas cap. SPE. doi:10.2118/68169-MS

Xiao, Z., Qi, H., Zhang, Y., Li, Y., Yao, S., and Liu, T. (2024). Characteristics and influencing factors of natural gas gravity drainage in sanjianfang formation reservoir of pubei Oilfield. Xinjiang Pet. Geol. 45 (3), 355–361. doi:10.7657/XJPG20230310

Yang, L., Cai, J., Kong, C., Liu, Y., Jiang, X., and Gong, F. (2025). Microscopic mechanism of gravity assisted gas flooding in glutenite based on phase field method. J. South China Normal Univ. Sci. Ed. 57 (1), 30–42. doi:10.6054/j.jscnun.2025004

Yang, L., Chen, X., and Xu, H. (2006). Analysis of the influence of formation parameters on the gas injection development effect of oil reservoirs. West-China Explor. Eng. (4), 95–97. doi:10.3969/j.issn.1004-5716.2006.04.049

Zhou, W., Zhang, J., Tang, Y., Chai, Y., and Zhou, Y. (2017). Application of top gas injection-assisted gravity drainage in bottom water reservoirs. J. Southwest Petroleum Univ. Sci. Technol. Ed. 39 (6), 92–100. doi:10.11885/j.issn.1674-5086.2016.05.10.03

Keywords: tight conglomerate reservoir, low reservoir-saturation differences, CO2 injection at the top, miscibility, oil-gas interface, displacement fronts

Citation: Zhai W, Cui C, Hu X, Li S, Feng Y, Tan L, Zhang J, Jiang R and Tan F (2025) Feasibility study of CO2 injection at the top of tight conglomerate reservoir in Mahu Sag, Junggar Basin, China. Front. Earth Sci. 13:1586641. doi: 10.3389/feart.2025.1586641

Received: 24 March 2025; Accepted: 20 June 2025;

Published: 18 July 2025.

Edited by:

Muhammad Hammad Rasool, Universiti Teknologi PETRONAS, MalaysiaReviewed by:

Duraid Albayati, University of Kirkuk, IraqEugene N. Ngouangna, University of Technology Petronas, Malaysia

Copyright © 2025 Zhai, Cui, Hu, Li, Feng, Tan, Zhang, Jiang and Tan. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Fengqi Tan, dGFuZmVuZ3FpQHVjYXMuYWMuY24=

Wenya Zhai

Wenya Zhai Chenguang Cui1

Chenguang Cui1 Ruihai Jiang

Ruihai Jiang Fengqi Tan

Fengqi Tan