- Institute for the Advanced Study of Sustainability, United Nations University, Shibuya-ku, Tokyo, Japan

As global industrial waste demands rise alongside increasing water scarcity, it becomes imperative to adopt circular economy principles within industrial water management. Traditional linear models of resource use have become unsustainable, demanding systemic transitions toward circular, closed-loop approaches. This paper explores the intersection of circular economy education and industrial water uses by examining how circular economy education and practices can transform industrial water use and improve sustainability outcome. Through case studies and best practices, this research illustrates successful implementations of circular water economy principles, demonstrates the implementation of closed-loop water systems, cascading reuse and zero liquid discharge technologies can reduce freshwater intake in industrial applications and emphasises the role of public-private partnerships in promoting water reuse projects. The paper also addresses the challenges and barriers to implementation, focusing on regulatory issues, resource limitations, and gaps in awareness. It concludes by proposing future directions for integrating circular economy principles into industrial water management and offers policy recommendations to foster circular water economy education. Hence, it contributes qualitative analysis to the growing body of knowledge on sustainable water management practices and provides valuable insights for policymakers and industry professionals seeking to advance circular economy approaches in industrial water use.

1 Introduction

Water scarcity has become an increasingly critical global challenge, particularly as industrial water demand continues to rise due to expanding production activities. The rapid growth of industrial operations, combined with the impacts of climate change and population growth, is placing unprecedented pressure on already limited water resources (UN-Water, 2024). Most industries continue to rely on a conventional linear water management model, where water is extracted, used, and then discharged, without sufficient treatment or reuse (Manav, 2024). This linear model not only leads to water wastage but also has negative effects on environmental degradation. In many cases, insufficient treatment of industrial effluents under linear model results in the release of hazardous substances, such as heavy metals (e.g., lead, mercury), toxic chemicals, and pathogens, into municipal water systems and natural water bodies (Singh et al., 2023; Trity Environ Solution, 2025). In response to these challenges, the concept of a circular economy has emerged as a sustainable alternative that promotes water reuse, recycling, and overall resource efficiency throughout industrial operations.

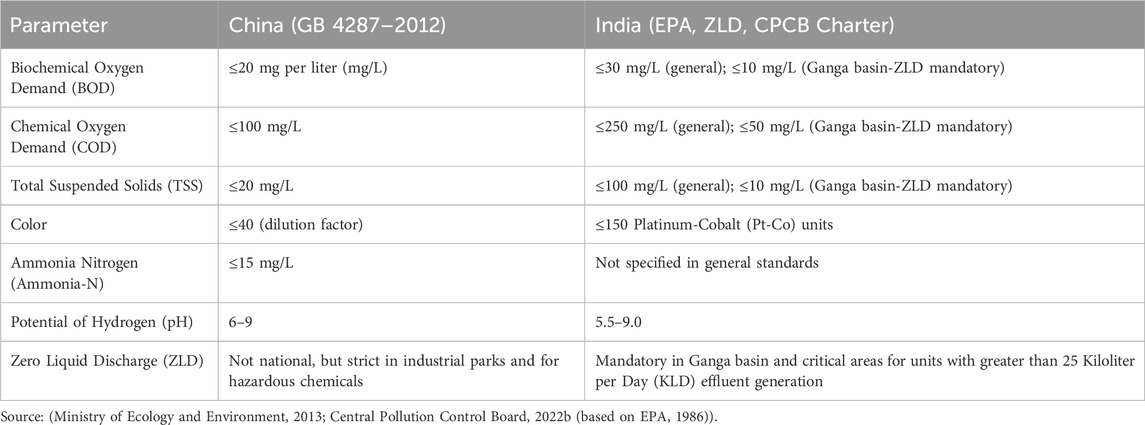

Recognizing these unsustainable practices, the circular economy has gained traction as an innovative and sustainable alternative for industrial water management. The circular economy model, when applied to water management, focuses on minimizing water intake, reducing waste, and maximizing the potential for water recovery within industrial processes. It represents a paradigm shift from the traditional linear “take-make-dispose” model to a more sustainable “reduce-reuse-recycle” framework. Figure 1 illustrates this transition, highlighting strategies such as closed-loop water system that treat and recirculate water within the industry, cascading water use that assigns varying water qualities to different processes, and zero liquid discharge techniques that recover water and valuable byproducts, thereby eliminating wastewater release (Khajuria et al., 2022; Caucci and Ozkul, 2024). The use and implementing advanced treatment technologies, closed-loop systems, cascading water use, and resource recovery strategies offers industries substantial potential to minimize environmental footprints while simultaneously conserving water and reducing costs. Beyond direct operational benefits, circular water strategies also foster greater urban resilience by mitigating the downstream impacts of untreated effluent, contributing to climate adaptation and public health (Khajuria and Verma, 2025; Amoatey et al., 2021).

Figure 1. Linear economy versus circular economy. Adapted with permission from Ref. Khajuria and Verma (2025). Copyright 2025, Khajuria and Verma.

A clear understanding of circular water strategies includes closed-loop water systems, cascading water use, and advanced wastewater recovery and reuse techniques, which also enable the recovery of valuable resources like materials and energy from wastewater streams. The adoption of circular economy principles in industrial water management presents a promising solution to the growing challenges of water scarcity and environmental degradation. By embracing these strategies, industries can significantly reduce their water footprint, minimize environmental impacts, and potentially reduce operational costs associated with water use and treatment. Furthermore, integrating circular economy education and practices, the industrial sector can play a pivotal role in ensuring water security, mitigating environmental degradation, and building resilience against future water-related risks (Owen, 2024). This paradigm shift is not only an environmental imperative but also a strategic necessity for sustainable industrial growth in the long term. Water security, as defined by the United Nations (UN) Water, encompasses access to sufficient and safe water, supports livelihoods and sustains socio-economic development within the context of environmental stability (UN-Water, 2013; Megdal, 2013). Notably, circular economy approaches directly contribute to water security by closing water loops, reducing waste, and maximizing resource efficiency and mitigating pollution at its source.

Circular economy education is pivotal in equipping current and future generations with the knowledge and skills needed to design, implement, and sustain water-secure systems. By embedding circular economy principles into curricula and professional training, learners gain an understanding of how to transition from traditional linear water management-where water is extracted, used, and disposed-to circular models that prioritize resource recovery, water reuse, and ecosystem regeneration. Such educational initiatives emphasize the interconnectedness of water cycles, highlight innovative technologies for treating and recycling water, and foster systems thinking for integrated water management at micro, meso, and macro levels. Moreover, circular economy education encourages collaboration across sectors and disciplines, empowering stakeholders to co-create solutions that minimize waste, reduce pollution, and maximize the value derived from water resources. By democratizing access to information and promoting transparency, education accelerates the adoption of circular practices in the water sector, supporting resilient, equitable, and sustainable water security for communities worldwide.

Circular economy principles, such as water reuse, resource recovery, and nature-based solutions-help ensure reliable access to water of acceptable quality, even under conditions of scarcity (Khajuria et al., 2025). The scale of the water scarcity challenge is further highlighted by data indicating that approximately two-thirds of the global population face water scarcity for at least 1 month each year, with a significant 50% of this population residing in the rapidly developing nations of China and India (UNESCO, 2017). Hence, these two most populous nations are facing immense challenges to meet their water demands. Both are urbanizing and industrializing at unprecedented rates, consequently, exceeding their water demands and generating excessive wastewater. In both nations, industrial sector plays a crucial role in economic growth, for instance, industrial sector contributes around 14% and 27% to total gross domestic production in India and China respectively. The industrial sector currently accounts for 8% and 16.6% of total freshwater withdrawal in India and China, respectively (Li et al., 2024; Central Water Commission, 2014). Given their trajectories of industrial development, industrial water demands in both nations will increase many folds in future. Nevertheless, water pollution and scarcity pose severe challenges to their socio-economic and ecological sustainability in both nations. By promoting the recycling and reuse of water, optimizing operations, and integrating innovative technologies, circular approaches can reduce dependence on finite freshwater sources, lower pollution, and enhance resilience to climate and supply disruptions. This systemic shift not only addresses scarcity but also supports the broader goals of water security (World Bank, 2021). A thorough understanding of the industrial water use cycle within these and other industrializing nations is crucial for advancing the United Nations Agenda for 2030 Sustainable Development Goals (UN SDGs), particularly SDG 6 on Clean Water and Sanitation (United Nations, 2015) and formulating effective policies and reforming practices (Li et al., 2024).

This study distinguishes itself by explicitly integrating circular economy education within the context of industrial water management, an area underexplored in the existing literature. The objectives of this paper are fourfold: (1) to systematically analyze the role and integration of circular economy education in advancing sustainable industrial water management; (2) to quantify and compare patterns of industrial water use, gaps in wastewater treatment, and policy mechanisms in India and China; (3) to present detailed, sector-specific case studies, especially in the textile industry, to illustrate both advances and challenges in circular water approaches; and (4) to formulate future-oriented educational and policy recommendations for scaling water sustainability in the industrial sector.

This comparative approach between India and China, two countries critical for global water and industry dynamics, offers new insights into policy design and practical governance mechanisms targeting industrial water challenges. By adopting a textile sector focus, the study highlights both the significant environmental burden and the pioneering circular interventions already underway. Through this lens, the research not only advances conceptual understanding but serves as a practical guide for policymakers, educators, and industry leaders. The novelty of this work lies in its dual emphasis on bridging educational frameworks and operational best practices for circular economy adoption in industrial water management and providing actionable comparative analysis to accelerate transitions toward water security and sustainability.

2 Literature review: empowering industrial water use by utilizing circular economy strategies

Industrial water consumption is significant across sectors, including manufacturing, textiles, energy production, and chemical processing. Nations with a strong industrial base and well-developed institutional capacities, such as Japan, Canada, and those in Western Europe, are expected to see only a moderate increase in industrial water use. In contrast, Global South nations are projected to rise significantly in their industrial water consumption due to rapid industrialization and urbanization (Wada et al., 2016; Ritchie and Roser, 2018; Caucci and Ozkul, 2024). Projections indicate a highly concerning surge in industrial water demand over the coming decades, with some emerging African economies expecting increases of up to 800% and certain parts of Asia facing a 250% rise (Boretti and Rosa, 2019). This industrial water use in the Global South is accompanied by climate vulnerabilities, precarious institutional and political stability and freshwater water demands for increasing population and agriculture. For long-term sustainability and water security, pathways for circular practices are required to operationalize for industrial water use.

A circular economy approach in industrial water use emphasizes three core strategies: reduction, reuse, and recycling. Circular economy principles redefine water as a continuously reusable resource, emphasizing reduction, reuse, recycling, and recovery across industrial processes. Industries are increasingly adopting closed-loop water systems that recirculate and treat water for repeated use, significantly reducing reliance on external freshwater sources and minimizing wastewater discharge. Key measures for improving water efficiency include implementing closed-loop water systems and utilizing advanced treatment technologies such as membrane filtration and reverse osmosis. Together, these strategies, along with the concept of industrial symbiosis, play crucial roles in minimizing water consumption and reducing wastewater discharge in industrial settings.

Water reduction in industrial processes involves optimizing water usage and minimizing waste. This can be achieved through various methods, including evaluating current water usage patterns, implementing leak detection systems, and upgrading to more efficient equipment. By conducting thorough water audits and installing water meters and submeters, industries can identify areas of high-water consumption and implement targeted reduction strategies. Regular maintenance of equipment and systems is also crucial in preventing water waste through wear and tears or improper use. Another effective approach to water reduction is the implementation of closed-loop water systems. These systems recirculate water within industrial processes, treating and purifying used water for reuse in the same or different processes (Manav, 2024). This approach significantly reduces reliance on external water sources and minimizes freshwater intake.

Water reuse is a key strategy in circular economy approaches to industrial water management. On-site water treatment and recycling systems allow industries to reuse wastewater, reducing their dependence on external water sources. This approach not only conserves water but also provides a consistent supply of treated water for industrial processes. Water recycling in industrial settings involves treating wastewater to a quality suitable for reuse in various applications. Advanced treatment technologies such as Membrane Bioreactors and other membrane-based treatment systems are commonly used for water recycling in industrial plants (Shehata et al., 2023). These systems can effectively treat heavily saturated wastewater, making it suitable for reuse in industrial processes.

Industrial symbiosis is an innovative approach that involves collaboration between different industries to optimize resource use, including water (Palagonia et al., 2025). In the context of water management, industrial symbiosis can take various forms, such as utility sharing for alternative water supply or wastewater treatment, water recovery, energy recovery from water, and material recovery from water. This approach extends beyond individual companies and creates networks of industries that can benefit from each other’s water-related resources and by-products (Ramin et al., 2024). For example, one industry’s wastewater might be suitable for use in another industry’s processes after minimal treatment. Industrial symbiosis not only reduces overall water consumption but also promotes resource efficiency and reduces environmental impacts (Ramin et al., 2024).

Public-private partnerships (PPPs) can play a significant role in creating alternative water reuse schemes and optimizing urban water management. Additionally, the development of fit-for-purpose water regulations and financial incentives can encourage the adoption of water reuse practices in industries (Caucci and Ozkul, 2024). By embracing these circular economy principles, industries can significantly reduce their water footprint, minimize environmental impacts, and potentially reduce operational costs associated with water use and treatment. Education is the linchpin that enables these circular strategies to take root and flourish. Comprehensive training and capacity-building programs equip industry professionals with the technical, managerial, and collaborative skills needed to design, operate, and continuously improve circular water systems. By promoting a culture of innovation and systems thinking, circular economy education ensures that best practices are disseminated, public acceptance of water reuse is strengthened, and a new generation of leaders is prepared to drive the transition toward water-secure, resilient industrial economies.

3 Conceptual framework

This study explores circular economy education approaches to industrial water use, recognizing the need for a structured conceptual framework to effectively capture the complex interplay between environmental pressures, societal responses, and industrial water management outcomes. To achieve this, the DPSIR (Drivers-Pressures-State-Impact-Response) framework (European Environment Agency, 1999) is employed as an evaluative lens well-suited for systematically analyzing the role of circular economy education in facilitating sustainable transformations within industrial water systems.

Within this framework, Drivers denote the underlying social, economic, and environmental forces that escalate industrial water demand and consumption (Khajuria, 2020). In the context of India and China, these include rapid industrialization, urban population growth, and escalating water scarcity issues (UN-Water, 2024; Li et al., 2024). Pressures correspond to the direct consequences of these drivers, manifested primarily through traditional linear water use models characterized by excessive withdrawal, inefficient industrial processes, and insufficient wastewater treatment, which amplify water depletion and pollution risks (Manav, 2024; Singh et al., 2023).

The State element reflects current conditions of industrial water resources, including availability, quality, and infrastructure adequacy. Empirical evidence from India and China reveals considerable variation in water treatment capacity, pollution levels, and technological adoption, underscoring differing stages of circular economy implementation (Central Water Commission, 2014; Zhang et al., 2023). The Impacts denote the ecological and societal consequences triggered by the state of water resources, chiefly environmental degradation, public health challenges, and economic inefficiencies incurred through unsustainable practices (Khajuria and Verma, 2025).

Crucially, the Response component involves the spectrum of societal actions designed to mitigate adverse impacts and pressures, ranging from policy and regulatory reforms to technological innovations. At the core of this research is the role of circular economy education as a strategic response, aimed at empowering stakeholders with the knowledge, skills, and collaborative capacities required to redesign and operationalize sustainable water use patterns within industrial systems (Owen, 2024; Caucci and Ozkul, 2024). Circular economy education facilitates systemic shifts toward resource efficiency, water reuse, and pollution prevention by fostering both individual competencies and institutional changes.

Integrating the DPSIR framework into this study enhances analytical clarity by providing a holistic structure to evaluate how circular economy education interacts with and influences each component, particularly emphasizing education’s potential to shape effective responses that reduce pressures, improve the state of water resources, and alleviate environmental and socioeconomic impacts. This approach enables the identification of critical intervention points such as curriculum development, professional training programs, and cross-sectoral collaborations, which are necessary to accelerate the adoption of circular water management practices in industrial sectors.

This linkage between environmental systems thinking and educational strategies remains underrepresented in current literature. By explicitly embedding the DPSIR model, this research contributes novel conceptual rigor and practical relevance, advancing scholarly understanding and policy discourse on how circular economy education can systematically address industrial water challenges within complex social-ecological systems (Waas et al., 2014; Ellen MacArthur Foundation, 2017).

4 Methodology

This research employs a qualitative methodology to explore the critical intersection of circular economy education and industrial water use, particularly in the context of escalating global water scarcity and the environmental imperatives for sustainable industrial practices. Recognizing the limitations of traditional linear water management models, this study delves into the transformative potential of circular economy principles, specifically water reuse, recycling, and resource efficiency within the industrial sector.

To achieve a nuanced understanding of this complex relationship, the research undertakes a comprehensive analysis of secondary data sourced from a diverse range of scholarly publications, including academic journals, in-depth policy reports issued by governmental and international organizations, and detailed industry case studies showcasing both successful implementations and persistent challenges in adopting circular water economy strategies.

A key feature of the methodological approach is a comparative case study analysis focusing on India and China. Both countries offer a compelling comparative perspective, given their rapid industrialization, significant water scarcity challenges, and divergent policy and educational frameworks influencing water reuse and recycling. By analyzing these differences, the study seeks to identify enabling factors and barriers to the integration of circular economy principles into industrial water management. This comparison provides insights into the effectiveness of policy mechanisms, the influence of distinct industrial development trajectories on water consumption, and the pivotal role of education and awareness in advancing circular approaches. The examination of sectoral case studies, in particular, from high-impact sectors like textiles, serves to highlight best practices that may be adapted and scaled in other contexts.

While this qualitative secondary data driven methodology carries certain limitations. The reliance on published secondary sources may introduce bias, as data availability and reporting quality vary by country and sector. There might be gaps or inconsistencies in the data, especially relating to recent or proprietary industry practices. Furthermore, the absence of primary empirical data through interviews, surveys, or field observations, which may limit the depth of stakeholder perspectives and real-time policy implementation insights. The comparative analysis is also limited by the contextual differences between India and China, which may affect the transferability of findings. Additionally, while case studies can illustrate best practices, their successful implementation depends on local regulatory, economic, and educational contexts that may not be fully captured in qualitative analysis. Acknowledging these limitations is crucial for careful interpreting the findings of the study and for guiding future research directions toward more comprehensive or mixed methods approaches.

5 Case studies

5.1 Case study of India

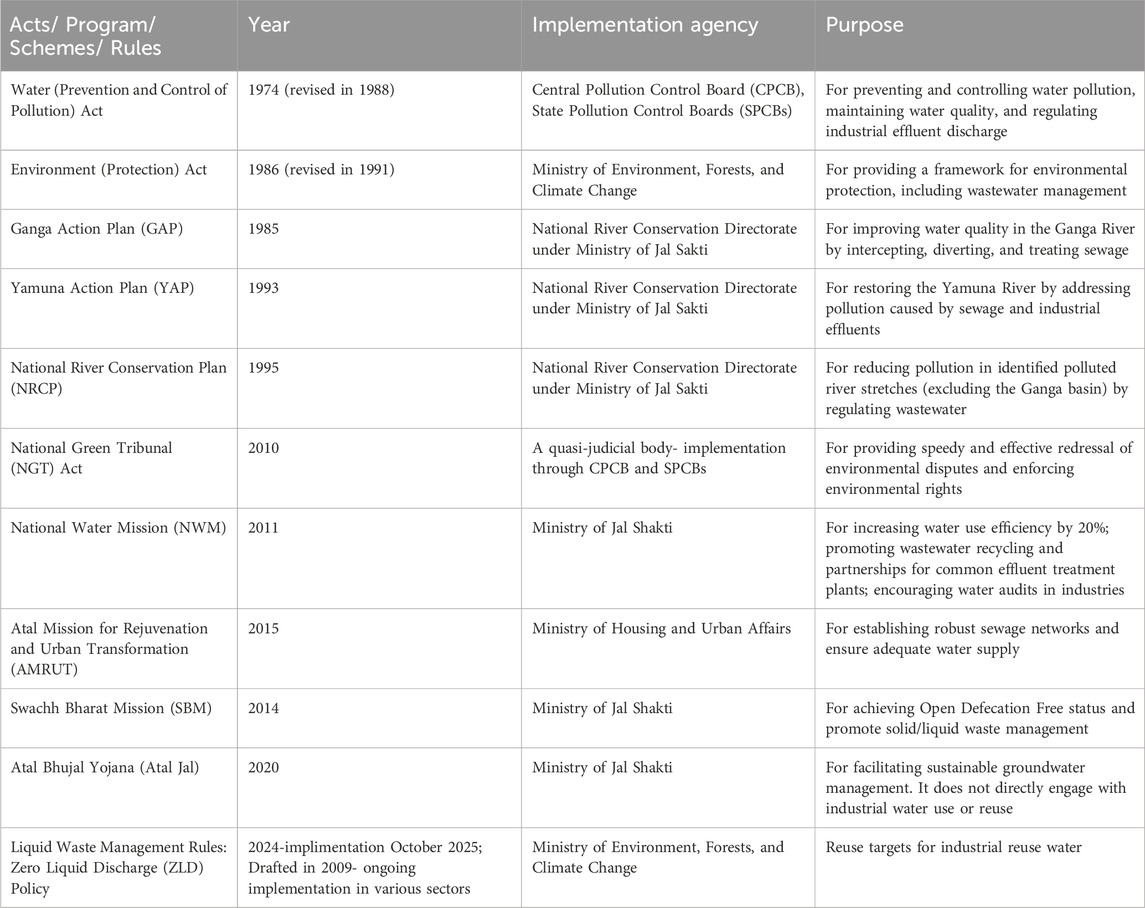

India faces significant challenges in developing its wastewater management infrastructure, particularly in urban and industrial areas. The gap between wastewater generation and treatment capacity is stark. Indian cities produced approximately 72,368 million liters per day (MLD) of wastewater in 2021–2022, but the installed treatment capacity was only 31,841 MLD—just 44% of the total generated (Central Pollution Control Board, 2022a). Furthermore, only about 28% of this wastewater is treated as many facilities operate below optimal standards (NITI Aayog, 2022). Furthermore, of the 28 states, only 11 have formulated wastewater reuse policies; however, the majority of these policies lack well-defined implementation plans, sustainable financing mechanisms, and comprehensive monitoring frameworks (Singhal and Ahmad, 2025). This shortfall contributes to environmental pollution and intensifies water scarcity, especially as industrial and urban demands continue to rise. India has established legal frameworks, policy and programs for wastewater management and reuse for both residential areas and industries as shown in Table 1. The Water (Prevention and Control of Pollution) Act, 1974, and the Environment (Protection) Act (EPA), 1986, serve as the foundational legislation underpinning all policies, programs, and schemes related to water and wastewater management in India. Despite the significant contribution of industries to water pollution, industrial wastewater reuse has yet to receive adequate policy attention in India. Most of these programs and schemes are oriented towards residential wastewater management, for example, Atal Mission for Rejuvenation and Urban Transformation, Swachh Bharat Mission and Atal Bhujal Yojana.

Recently, a notable development was the introduction of the Liquid Waste Management Rules 2024 articulate a clear and targeted vision for effective wastewater management addressing industries that consume more than 5,000 L of water per day or generate a pollution load exceeding 10 kg per day in terms of Biochemical Oxygen Demand (BOD). Specific reuse targets for industrial reuse water respect to freshwater consumption are 60% by 2027–2028, 70%–80% by 2028–2029, 80%–90% by 2029–2030 and 90% by 2030–2031, respectively, for four most water intensive industries, namely, thermal power plants, pulp and paper, textile industry and iron and steel industry. They also stipulate the use of recovered wastewater for various utilities such as cooling towers, boilers, or for gardening, sanitation, and irrigation. These rules further strengthen the Zero Liquid Discharge (ZLD) policy, which was drafted in 2009 and implemented in a piecemeal manner in some of states such as Tamil Nadu and Gujarat. ZLD refers to an approach underlain by the “reduce–reuse–recycle” principle (Grönwall and Jonsson, 2017). It is a wastewater treatment process involving biological treatment, reverse osmosis, and crystallizers which aim to purify and recycle all wastewater.

The circular economy model is gaining traction in Indian industrial water management, particularly through the adoption of advanced treatment technologies and innovative business models. In cities like Chennai, public utilities have partnered with industries to supply high-quality, treated wastewater for industrial use. The Chennai Metropolitan Water Supply and Sewerage Board (CMWSSB) operates tertiary treatment and reverse osmosis plants that supply over 120 MLD of treated wastewater to local industries, freeing up freshwater for domestic needs (World Bank, 2021). This approach not only conserves water but also ensures a reliable supply for industrial operations, demonstrating the practical benefits of circular water management.

5.1.1 Case study: Tirupur textile industry, Tamil Nadu

India is the sixth-largest exporter of textiles and apparel in the world, contributing 8.21% to the country’s total exports in 2023–2024. The textile industry contributes 14% of total industrial production and provides direct employment to over 45 million people while indirectly supports the livelihoods of more than 100 million, including a significant number of women and members of the rural population (Christian et al., 2023). The textile industry uses 170.34 MLD of water and releasing wastewater containing dynes, pigments, heavy metals and other complex pollutants directly into environment (Christian et al., 2023). This underscores the challenges, resistance, and successful implementation of ZLD in the Tirupur textile industry. This transformative journey has evolved from higher freshwater consumption and the discharge of untreated toxic wastewater to an advanced approach of sustainable industrial wastewater management (Grönwall and Jonsson, 2017; Gupta, 2022).

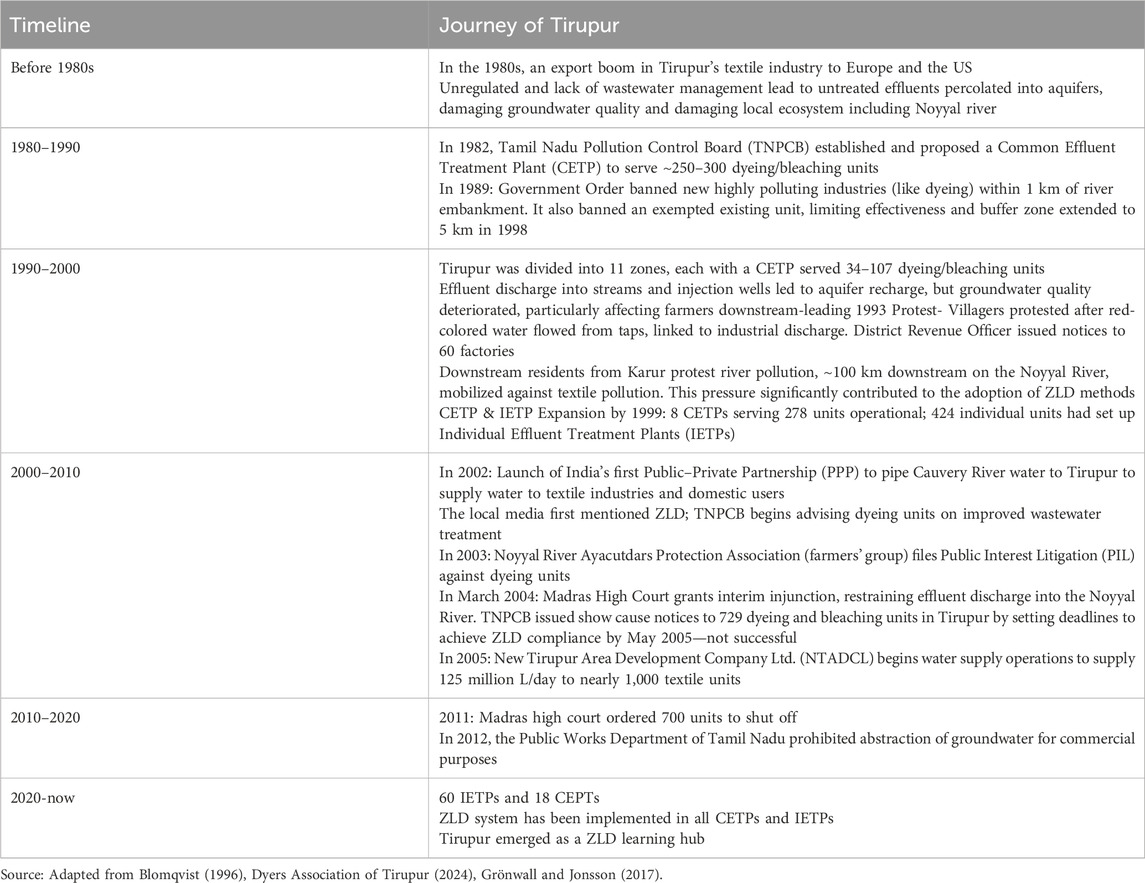

Tirupur is a textile hub located in Tamil Nadu, popular as India’s knitwear capital. It plays a central stage in the global important textile hub, with an export of approximately USD 4 billion in the 2022–2023 financial year as per the Tiruppur Exporters Association (2024). This city is home to around 800 garment factories, 369 dyeing units, 1,200 merchant exported, more than 3,000 finishing units, and about 2,000 micro small and medium sized enterprises (Grönwall and Jonsson, 2017). It provides direct employment for 600,000 workers directly and indirectly up to 1 million people. In the 1970s and 1980s, as Tirupur was becoming a global knitwear site, the environmental externalities were not prioritized. The availability of freshwater worked was advantageous for this wet process-based industry. The detailed landscape of Tirupur textile industry hub is mentioned in Table 2. However, within two decades, the local environment and water sources became severely polluted. The groundwater emerged as a contested resource between industries and agriculture. This situation further worsened in many areas, as untreated effluents from factories were discharged into streams and injected into wells, causing a rise in the groundwater table (Grönwall and Jonsson, 2017).

Protests by farmers, particularly from the Noyyal River Ayacutdars Protection Association, along with downstream residents of the Noyyal River, have led to legal actions. These actions, combined with growing water scarcity and the adverse impact of pollution on trade, have prompted the region to adopt cleaner technologies such as the Common Effluent Treatment Plant (CEPT) and the Individual Effluent Treatment Plants (IETPs). Around USD 98.72 million has already been invested in ZLD infrastructure, which treats effluent generated daily with 94% of the water being reused for processing. The remaining 6% is recovered as salt solution or salt to reuse (Dyers Association of Tirupur, 2024). To operate ZLDs and wastewater treatment plants, electricity is sourced from renewable energy, primarily solar and wind. This generates 160 kilo Volt-Ampere (kVA) against a demand of 250 kVA (Gupta, 2022). The surplus electricity is supplied to the Tamil Nadu Power Grid. Hence, collective actions and increased awareness about ZLDs technologies have advanced the Tirupur Textile hub, positioning it as a global leader in ZLD experimenting and learning hub for the world.

5.2 Case study of China

China is one of the largest generators and processors of municipal wastewater globally, with a treatment capacity of approximately 220 million cubic meters per day (Qu et al., 2019; Zhou et al., 2024). The country successfully treats 95% of its urban wastewater and has improved rural wastewater treatment from 6% to 19% between 2010 and 2018 (Rong et al., 2023). However, due to rapid industrialization, the generation of industrial wastewater gradually increased from 19.4 × 109 cubic meter (m3) in 2000 to 24.7 × 109 m3 in 2007 and decreased to 20.0 × 109 m3 in 2015 (Xu et al., 2020). Nevertheless, China has been facing major challenges, including water storage, severe water pollution, insufficient capacity for water-related disaster mitigation (Asian Development Bank, 2018).

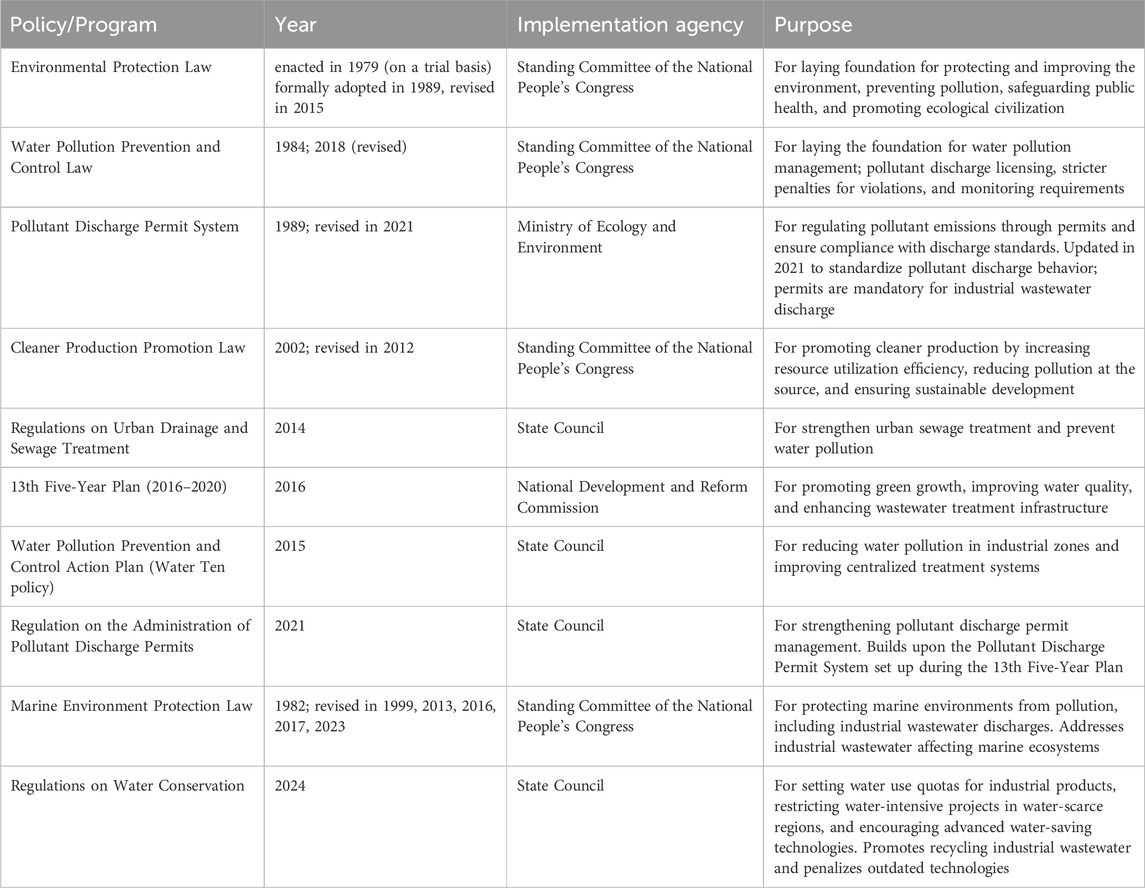

China has made significant investments in wastewater treatment and has enforced policies and programs to promote wastewater reuse and improve water efficiency. The foundation for wastewater management was established with the Environment Protection Law of 1979 and the Water Pollution Prevention and Control Law of 1984. The National Environmental Protection Bureau (now the Ministry of Ecology and Environment) was established in the 1980s under the Environment Protection Law as a central agency responsible for formulating policies and enforcing environment related legislation (Zhang et al., 2023). The detailed legal framework and policies for wastewater and reuse of China is shown in Table 3. With the increased scale and intensity of industrialization, more targeted effluent discharge standards were issued and implemented (Zhang et al., 2023). Recently, Regulations on Water Conservation were introduced to ensure sustainable water use, especially in water-scarce regions and high-consumption industries. These regulations set quotas, promote efficiency, and enforce penalties for wasteful practices (State Council, 2024).

5.2.1 Case study: Zhejiang textile industry

China is the largest exporter of textile accounting for around 32% of the global market and amounting to US$301.1 billion in 2024 (China Textile Leader, 2024). The textile sector directly employs over 20 million people and provides indirect employment to an additional 80 million underscoring its significant role in China’s economy and employment (International Labor Organization, 2023; Kanungo, 2012). However, the textile industrial growth is accompanied by challenges such as water pollution and water shortages. Textile wastewater constitutes over 10% of total industrial wastewater (Zhang et al., 2023). The Zhejiang textile hub is the largest contributor to textile and apparel exporters in China, accounting for approximately 28.64% of China’s total textiles and apparel exports in 2019 (Feng et al., 2022). In 2023, the Zhejiang region, mostly from textile hub, consumed approximately 53.6 million cubic meters of water, according to data from the National Bureau of Statistics of China (2024). During the same period, the region generated 54,299.17 tons of chemical oxygen demand (COD), 41,594.20 tons of ammonia nitrogen, 117,004.40 tons of total nitrogen, 12,706.10 tons of total phosphorus, 107 tons of petroleum, and 1,145 kg of volatile phenol. The high intensity of water-use, and generation of these pollutants put grave stress over water resources in the region. The detailed landscape of Zhejiang is shown in Table 4.

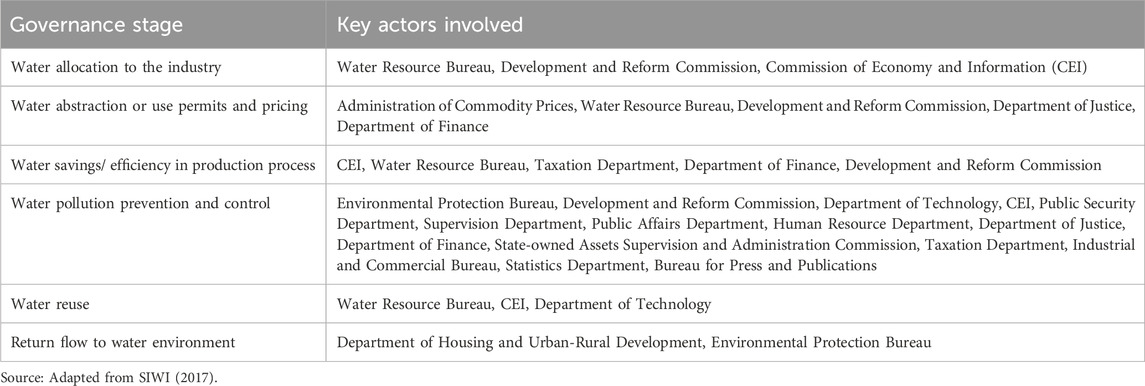

To tackle these challenges, local administrations in Zhejiang have implemented the Zhejiang industrial water strategy, which is based on governance innovation. This strategy has become a role model for the national level Water Pollution Prevention and Control Action Plan (Stockholm International Water Institute (SIWI, 2017). The primary objective is to tackle both water shortage and pollution at all administrative levels with a priority. This approach moves beyond the standard traditional silos governance model to include all actors for water conservation and sustainable wastewater management. The governance landscape exhibits a high degree of coordination among economically oriented agencies, including the Commission of Economy and Information, the Department of Finance, the Development and Reform Commission, and the Department of Technology with water related agencies. In this framework, the Water Resource Bureau plays a leading role in managing water resources while the Environmental Protection Bureau leads efforts related to water pollution control and the protection of aquatic environments. The strategy employs a combination of both command-and-control mechanisms as well as market-based approaches such as technical innovation, closed-loop of water use, sectoral re-structuring, reformation of water institutions and supervision of law enforcement by involving all actors (SIWI, 2017). This has created synergies and harmonies between water, management, industrial development and economic policy. Furthermore, an assessment of the Zhejiang textile industry water footprint, which measures water volume per unit of product, conducted by Feng et al. (2022) showed that it decreased more than 20% from 2008 to 2018.

6 Results and discussion

This analysis highlights significant differences in industrial water management between India and China, specifically in the textile industry. Both countries are adopting aspects of the circular economy, such as closed-loop water systems and advanced treatment technologies. However, successful implementation relies on clear regulations, effective enforcement, active stakeholder engagement, strong coordination among institutions, and building capacity in circular economy practices.

While both countries are focusing on water reuse, China has achieved more consistent outcomes due to its specific and centrally enforced standards, compared to India’s broader guidelines with inconsistent enforcement. Nonetheless, India’s experience with community involvement and judicial advocacy in policy development presents an alternative approach for grassroots change.

Educational initiatives in both nations are still in the early phases but show potential for growth. China has made greater progress by mandating the inclusion of circular economy and sustainability topics in education, whereas India is starting to offer elective courses and integrating sustainability into technical programs. Despite these advancements, both countries face considerable challenges, including fragmented policies, financial and technical obstacles, a need for ongoing professional development, and the integration of circular economy concepts into organizational culture at all levels.

The findings of this study substantiate the assertion that the integration of circular economy strategies within industrial water management can lead to significant improvements in water use efficiency, pollution mitigation, and overall environmental resilience. The case studies illustrate that regulatory innovation alone does not suffice; successful transitions necessitate synchronized governance frameworks, multi-stakeholder engagement, and continuous educational initiatives that promote a collective understanding of circular economy principles. This conclusion aligns with a growing body of scientific literature, which emphasizes that the success of circular water management hinges not only on technological innovations but also on institutional capacity, robust policy frameworks, and a well-equipped workforce (Ellen MacArthur Foundation, 2017; SIWI, 2017; Khajuria et al., 2025).

A prominent finding of this study is the substantial influence of the policy context on water management practices. For instance, China’s command-and-control regulatory framework, characterized by stringent sector-specific limits and centralized database monitoring, stands in stark contrast to India’s more fragmented and reactive system, which, despite its limitations, leverages bottom-up pressures through legal activism to partially address institutional shortcomings. This divergence is reflected in the global literature, where successful reforms in industrial water usage often merge regulatory leadership with adaptability and localized solutions (World Bank, 2021; Zhang et al., 2023).

Furthermore, the study underscores the critical role of education, not merely in formal and vocational contexts, but as a vital tool for public and stakeholder engagement. Education in circular economy principles empowers industries to adopt complex water reuse technologies, enhances the skills of existing professionals, and fosters new avenues for cross-sectoral collaboration and innovation. Nonetheless, current educational initiatives tend to be disjointed and lacking in cohesion, mirroring trends identified in existing literature (UNESCO-UNEVOC, 2024; Oyejobi et al., 2024). There is an urgent need for comprehensive curricula that seamlessly integrate technical training, business model innovation, regulatory knowledge, and lifelong learning pathways to ensure continuous skills development in tandem with evolving technological and regulatory landscapes.

Despite advancements in both contexts, several limitations are present in this research. Firstly, the reliance on secondary data and published sources introduces variability in the quality and completeness of reported outcomes, resulting in a lack of granular empirical data regarding the lived experiences of industry professionals. Secondly, the structural differences within each country’s textile sector and regulatory environment hinder the universal applicability of the lessons identified. Moreover, the intricate nature of implementing circular economy strategies in emerging economies, characterized by constrained financial resources and path-dependent infrastructure, may result in conflicts or delays that are not adequately represented in the more optimistic narratives often found in policy documents or best-practice reports.

Discrepancies between these findings and existing literature emerge, particularly regarding the enforcement of policies, the scalability of advanced treatment technologies, and sector-specific implementation challenges. For example, while certain studies document the rapid and large-scale adoption of water recycling practices in China, reports from the field indicate that smaller enterprises frequently encounter compliance difficulties due to financial constraints and technical limitations (Zhang et al., 2023; Chen, 2023). Similarly, in India, the high capital expenditure associated with ZLD technologies, coupled with obstacles in inter-agency coordination, may lead to uneven adoption rates, mirroring previous studies that highlight institutional and funding challenges (Grönwall and Jonsson, 2017).

The impacts of dams and climate change is a critical consideration when discussing circular economy education and industrial water use management, especially in the contexts of India and China. Dams, particularly large hydropower projects in regions such as the Tibetan Plateau where many of Asia’s major rivers originate, significantly influence water availability downstream. China, as an upstream country, has constructed thousands of dams on transboundary rivers shared with India (including the Brahmaputra/Yarlung Tsang Po), which affect flow timing, volume, and sediment transport. These dams offer China strategic control over water resources, with potential implications for downstream industrial water supply in India and Bangladesh due to altered water flows and sediment retention that can reduce agricultural fertility and impact industrial water availability (Vidya, 2022; Manhas, 2023). Regarding climate change, it intensifies water scarcity by altering precipitation patterns, increasing drought frequency, and impacting glacier melt that feeds many of these rivers, further complicating water availability for industry. Climate change effects amplify pressures on water systems already stressed by industrial demands, population growth, and infrastructure challenges (Rosińska et al., 2024; Khajuria and Verma, 2025).

6.1 Challenges and barriers to implementation

Both India and China have established comprehensive legal and policy frameworks for managing wastewater including industrial wastewater. The international initiatives, particularly the Human Environment (popularly known as the Stockholm Conference 1972) have played a significant role in shaping the environmental legislation and policies of both nations. During the 1970s and 1980s, various water and environmental acts laid the groundwork for institutionalizing pollution control measures. Recently, both nations have shown a noticeable shift in policy and program focus, moving from primarily addressing pollution control to emphasizing water use efficiency and promoting wastewater reuse as integral components of a circular economy.

However, despite these shared policy objectives, the approaches to implementation and the challenges encountered differ significantly between the two nations. In India, the strategy for managing wastewater is largely reactive, relying on manual inspections by CPCB and SPCBs. The country also lacks centralized databases for tracking pollution or water use and proactive monitoring mechanisms. There has led to a significant implementation gap, with most policies and guidelines being executed in a fragmented and piecemeal manner. However, there has been considerable environmental mobilization among communities, characterized by active participation and judicial activism in India. For example, the National Green Tribunal is a quasi-judicial body that addresses environmental disputes and ensuring rights. The Tirupur case study shows how the citizens raised concerns about water pollution caused by the textile industry and promoting judiciary intervention to enforce ZLD regulations. This highlights the potential for bottom-up pressure to drive more sustainable practices, even within a challenging regulatory landscape.

In contrast, China has implemented proactive and state-led policies that utilize centralized databases. There is a strong emphasis on advancing monitoring systems to ensure effective implementation, which allows for better tracking of compliance. Additionally, China has established a comprehensive legal framework and guidelines for industrial water reuse and pollution control based on the principles such as “polluter pays”. The key components of this framework include the Pollutant Discharge Permit System, the Cleaner Production Promotion Law, the Action Plan for Prevention and Control of Water Pollution, and the Regulation on the Administration of Pollutant Discharge Permits. As demonstrated by the case of the Zhejiang textile hub, China has strengthened its governance mechanism and implemented integrated governance framework to effectively manage industrial wastewater.

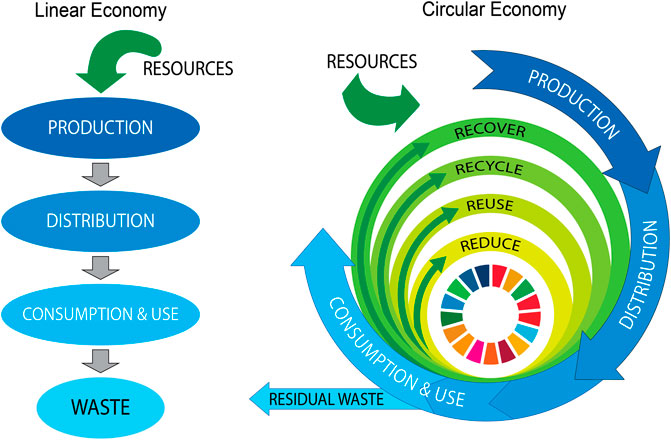

Furthermore, a closer examination of the textile sector in both countries reveals marked differences in wastewater standards, particularly in terms of regulatory stringency and thematic priorities. China enforces strict, sector-specific standards (GB 4287–2012) that set low limits on pollutants like Biochemical Oxygen Demand, Chemical Oxygen Demand, total suspended solids, and colour, emphasizing pollution control at the source (Ministry of Ecology and Environment, 2013). In contrast, India lacks any sector specific standard for textile industries and relies on general standards. It emphasizes a ZLD approach mandating its implementation for large textile units situated in environmentally sensitive regions, particularly in Ganga basin Table 5. This sectoral analysis highlights China relies on stringent, sector-focused pollutant limits while India’s regulatory strategy emphasizes ZLD mandates for high-impact regions and using general standards elsewhere. India has established legal frameworks and bidding processes for industrial wastewater management and reuse; however, effective implementation is hindered by fragmented and unclear institutional responsibilities, leading to a lack of accountability and weak coordination among agencies. Moreover, policy gaps, persistent financial constraints, and technical limitations further complicate the implementation landscape, hindering the transition towards more sustainable industrial water management. While, in China, challenges such as inconsistent enforcement, financial barriers for smaller enterprises, and regional disparities in implementation have limited the overall effectiveness of their wastewater management efforts.

Recognizing the ongoing need for progress, both India and China have recently introduced significant regulatory updates aimed at accelerating the transition towards greater water sustainability Recently, India introduced the Liquid Waste Management Rules (2024), and China enacted the Regulations on Water Conservation (2024). Both regulations mark significant progress toward water sustainability, particularly with their emphasis on defined targets for industrial water reuse and improvements in water use efficiency. These recent developments signal a renewed commitment in both nations to overcome existing barriers and foster a more circular approach to industrial water management, although the ultimate success will depend on effective and consistent implementation across all levels.

6.2 Importance of circular economy education in promoting sustainable industrial water use

A key reason for unsustainable industrial wastewater practices is the lack of awareness at the manufacturing level about the direct, indirect, and long-term negative impacts of these actions (SIWI, 2017). By integrating principles of sustainability and environmental responsibility into educational programs, we can significantly enhance awareness among industry professionals and future leaders, ultimately promoting more sustainable industrial water use.

Both India and China have taken steps to integrate principles of sustainable development and environmental awareness into their educational systems. In India, this effort is reflected in the National Education Policy (NEP-2020) which emphasizes curriculum development that fosters environmental responsibility and sustainability. Recently, the All-India Council for Technical Education (AICTE), a national-level apex advisory body, introduced a credit-based elective course titled “Circular Economy”, aimed at integrating sustainability principles into technical education across India (All India Council for Technical Education, 2022). However, India’s circular economy initiatives are fragmented and yet to be integrated in education system (Khajuria, 2025; Sharma and Hartley, 2025). While the Ministry of Education in China has made Environmental Education compulsory in primary and secondary schools emphasizing key sustainable development themes such as water conservation and pollution prevention (Choi et al., 2009). Law for the Promotion of the Circular Economy (2008) requires the integration of circular economy principles into education, research, and public awareness to ensure that new industrial policies and educational initiatives support circular economy objectives. Nevertheless, China has been facing challenges to operationalize circular economy principles because of high investment, lack of circular economy talent and public awareness (Chen, 2023).

Circular economy education plays a pivotal role in fostering sustainable industrial growth by instigating fundamental shifts in traditional production and consumption paradigms. In terms of DSIPR framework, circular economy education will help to address “drivers” by raising awareness about the resource limitations and encouraging industries for promoting regenerative water use. It will help to reduce “pressures” by encouraging industries to minimize water withdrawal, reduce pollutants, and invest in water-efficient technologies, for example, ZLDs. Hence, it can identify and encourage industrial processes that are based on reduce, reuse and recycle principles. Furthermore, circular economy education can enhance “state” by incentivizing use of fit-for-purpose water and adaptation of water management technologies suited to local contexts (Caucci, 2024). By building a circular economy ecosystem, the overall “impacts” of industrial wastewater can be mitigated. Also, the adoption of nature-based and technological solutions, such as constructed wetlands, harvesting rainwater, and water reuse for industrial and community wellbeing will reduce overall negative impacts. Most importantly, circular economy education can help to catalyse “responses” by preparing stakeholders for framing policies for managing industrial wastewater, hence, providing long-term benefits. By equipping both current and future professionals with the essential knowledge and practical skills, effective circular economy education paves the way for a transition from linear “take-make-dispose” models to more regenerative and resource-efficient circular models (Oyejobi et al., 2024).

Effective circular economy education aims to build a workforce that is not only aware of the environmental and economic benefits of circularity but also equipped with the practical skills to implement it Khajuria (2024). Educational programs should integrate theoretical knowledge with hands-on training, case studies, and real-world projects, enabling learners to apply circular economy principles in diverse industrial settings (Ellen MacArthur Foundation, 2017; Manav, 2024). In addition to formal education, continuous professional development programs are vital for existing industry professionals. By embedding circular economy concepts within engineering, business, and environmental science curricula, educational institutions can produce graduates who are not only technically competent but also environmentally conscious and capable of driving sustainable industrial transformations (Waas et al., 2014). These innovations enable industries to recycle treated water efficiently, conserve freshwater resources, and reduce environmental impacts (Yager, 2024).

Furthermore, continuous professional development and training programs are essential for existing industry professionals to stay abreast of the latest circular economy practices and technologies. This proactive educational approach fosters a mindset of resource efficiency and waste minimization, encouraging the design of industrial processes and technologies that inherently prioritize water reuse, recycling, and the minimization of freshwater consumption. Moreover, continuous professional development programs play an indispensable role in keeping pace with the rapidly evolving landscape of circular economy practices and technological advancements in industrial water management. These programs facilitate knowledge transfer, promote best practices, and encourage collaboration across sectors, thereby accelerating the adoption of circular economy principles in industrial water management (Yager, 2024). By empowering individuals with the knowledge and tools to make informed choices, education can drive demand for sustainable products and services, creating a market pull for circular economy solutions (UNESCO-UNEVOC, 2024).

Beyond formal and professional education, public awareness campaigns and vocational training initiatives are crucial for creating a broader societal understanding of the importance of water conservation and the principles of the circular economy. The flow of water in a circular industrial system, emphasizing the critical role of education and knowledge development at each stage, from sustainable sourcing and efficient use to advanced treatment and effective reuse, driving a shift away from traditional linear water management. Figure 2 depicts a circular industrial water flow diagram that integrates educational touchpoints at each stage. Starting from sustainable water sourcing, it moves through efficient usage, on-site treatment, advanced recovery, and reuse within or across industrial units. Industrial water pollution stems from both point sources—such as direct discharges from manufacturing plants, and non-point sources, including runoff from industrial sites—which collectively contribute a range of contaminants. The key pollution sources typically include organic loads, heavy metals, nutrients such as nitrogen and phosphorus and emerging contaminants like microplastics. At each sector, specific educational interventions are mapped, ranging from vocational training and environmental awareness programmes to technical upskilling and executive leadership education. This integrated approach combines advanced technological solutions with continuous education, aiming to mitigate industrial water pollution and optimize resource use. The systematic monitoring of water quality indicators through scientifically calibrated water quality models, which rely on robust water quality data collection and analysis. Such calibration is vital to accurately predict pollutant loads and inform targeted remediation efforts. Ultimately, a multi-faceted educational approach, encompassing formal academic programs, continuous professional development, and broad public engagement, is essential for cultivating the systemic changes in mindset and practice required to achieve widespread adoption of circular economy principles in industrial water use, paving the way for a more water-secure and environmentally sustainable industrial future.

7 Future perspective and conclusion

This study underscores that the adoption of circular economy principles and strategies, particularly water reuse, recycling, and reduction, offers a transformative pathway for transitioning the industrial sectors of India and China toward water security and sustainability. Both countries illustrate the potential for circular water management to reduce environmental impacts, conserve freshwater resources, enhance regulatory effectiveness, and unlock operational efficiencies, especially in resource-intensive sectors like textiles. However, the analysis also reveals significant challenges that must be addressed: regulatory fragmentation, uneven enforcement, capacity gaps, and financial and technical constraints. These obstacles underline that while progress is notable, the journey toward robust, circular, and water-resilient industrial systems is ongoing and complex.

The evolution of policy and legal frameworks for industrial wastewater management, as examined through case studies from both countries’ textile sectors, illustrates a critical shift. There is a move away from narrowly focusing on pollution control toward adopting more holistic strategies that prioritize water-use efficiency and systemic wastewater reuse in line with circular economy objectives. Both India and China are responding to the mounting pressures of water scarcity and rising awareness of the economic and environmental benefits inherent in resource efficiency. These factors collectively position the circular economy as a pivotal and future-oriented framework for industrial water management on scale.

Looking ahead, future research should prioritize empirically grounded, mixed-methods studies to provide a deeper understanding of on-the-ground challenges facing industries and communities in adopting circular solutions. Cross-national comparative research, especially involving additional Global South nations, will help identify best practices and context-sensitive solutions suited to resource-constrained settings. In addition, there is a need for targeted action research focusing on the human and organizational factors underpinning successful circular economy education, especially involving the upskilling and re-skilling of existing industrial workforces.

The future educational initiatives will need to expand beyond technical training to cultivate a holistic understanding of circular economy principles, encompassing economic, environmental, and social dimensions. This includes fostering a culture of innovation and problem-solving, empowering future engineers, business leaders, and policymakers to champion and implement circular solutions in industrial water management. Moreover, raising public awareness about the importance of water conservation and the role of the circular economy in achieving water security will be crucial for building societal support and driving demand for sustainably produced goods.

In terms of education, future initiatives must transcend conventional technical training and work toward cultivating a holistic and integrated understanding of circular economy principles, encompassing economic, environmental, and social dimensions. There is a critical need to foster cultures of innovation and collaborative problem-solving that empower engineers, sector leaders, and policymakers to champion circular approaches in industrial water management. Raising public awareness about the importance of water conservation and the role of the circular economy in achieving water security will also be essential in building broad societal support and stimulating demand for sustainably produced goods, thereby creating market incentives for deeper adoption of circular models.

Finally, the role of policy innovation cannot be overemphasized. Governments should persist in strengthening legal and institutional frameworks, building transparent systems for monitoring and evaluation, and developing adaptive financial tools to support industries that are spearheading the circular transition. Policies must be tailored to fit local contexts and industrial sector profiles and should actively foster broad-based engagement among all relevant stakeholders. Only through this inclusive, context-sensitive approach will the widespread, effective, and resilient adoption of circular water management strategies be achieved across diverse industrial landscapes.

In conclusion, by embedding circular economy principles across vocational training, engineering education, and executive leadership programs, both nations can transform their textile industries into models of water resilience while addressing the urgent need to decouple production growth from freshwater extraction. The adoption of circular economy principles offers a transformative pathway for addressing industrial water challenges; nevertheless, implementation must account for path dependency in existing infrastructure and regional water stress differences. By shifting from linear to circular models of water management, industries can significantly reduce their reliance on freshwater resources, minimize wastewater discharge, and balance environmental gains with economic feasibility.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

AK: Data curation, Methodology, Supervision, Conceptualization, Formal analysis, Visualization, Writing – original draft, Writing – review and editing. RR: Methodology, Data curation, Formal analysis, Writing – original draft, Writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Acknowledgments

We express our gratitude to Dr. Jain Pu from Toyo University for supervision this work and providing useful ideas to enhance the quality of this work.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

All India Council for Technical Education (2022). Circular economy: a credit point course. Available online at: https://www.aicte-india.org/sites/default/files/Model_Curriculum/Open%20elective%20Circular%20Economy.pdf (Accessed July 29, 2025).

Amoatey, P., Izady, A., Al-Maktoumi, A., Chen, M., Al Harthy, I., Al-Jabri, K., et al. (2021). A critical review of environmental and public health impacts from the activities of evaporation ponds. Sci. Total Environ. 796, 149065. doi:10.1016/j.scitotenv.2021.149065

Asian Development Bank (2018). Managing water resources for sustainable socioeconomic development: a country water assessment for the Republic of China. Manila, Philippines: Asian Development Bank. Available online at: https://www.adb.org/sites/default/files/institutional-document/473576/country-water-assessment-prc.pdf (Accessed August 22, 2025).

Blomqvist, A. (1996). Food and fashion: water management and collective action among irrigation farmers and textile industrialists in South India. Linköping: Linköping University. Available online at: https://liu.diva-portal.org/smash/get/diva2:305279/FULLTEXT01.pdf (Accessed August 22, 2025).

Boretti, A., and Rosa, L. (2019). Reassessing the projections of the world water development report. Npj Clean Water 2 (1), 15. doi:10.1038/s41545-019-0039-9

Caucci, S. (2024). Revitalising resource efficiency for industrial water reuse in the circular economy. Dresden: United Nations University. Available online at: https://unu.edu/publication/revitalising-resource-efficiency-industrial-water-reuse-circular-economy (Accessed July 29, 2025).

Caucci, S., and Ozkul, Z. (2024). Revitalising resource efficiency for industrial water reuse in the circular economy. Available online at: https://unu.edu/sites/default/files/2024-09/UNU-FLORES%20Water%20Policy%20Brief.pdf (Accessed August 22, 2025).

Central Pollution Control Board (2022a). General standards for discharge of environmental pollutants part: effluents. Available online at: https://cpcb.nic.in/effluent-emission/ (Accessed August 22, 2025).

Central Pollution Control Board (2022b). Water quality data of drains, sewage treatment plants (STPs), and water treatment plants (WTPs) under NWMP-2022. New Delhi: Government of India. Available online at: https://cpcb.nic.in/wqm/2022/Water_Quality_Drains_STPs__WTPs_2022.pdf (Accessed August 22, 2025).

Central Water Commission (2014). Guidelines for improving water use efficiency in irrigation, domestic and industrial sectors. Ministry of Water Resources, Central Water Commission. Available online at: https://nwm.gov.in/sites/default/files/Final%20Guideline%20Wateruse.pdf (Accessed: April 13, 2025).

Chen, R. (2023). China’s circular economy transition: challenges and solutions ahead. Copenhagen, Denmark: Circular Innovation Lab. Available online at: https://circulareconomy.europa.eu/platform/sites/default/files/2023-08/China%27s%20Circular%20Economy%20Transition_%20Challenges%20and%20Solutions%20Ahead.pdf (Accessed: April 13, 2025).

China Textile Leader (2024). China textile leader. Available online at: https://www.texleader.com.cn/en/news-34741.html (Accessed April 22, 2025).

Choi, M. Y., Jiang, D., Guo, R., Li, F., and Cao, X. (2009). Education for sustainable development practice in China. Institute for Global Environmental Strategies. Available online at: https://www.iges.or.jp/en/pub/education-sustainabledevelopment-practice/en (Accessed May 1, 2025).

Christian, D., Gaekwad, A., Dani, H., M.A., S., and Kandya, A. (2023). Recent techniques of textile industrial wastewater treatment: a review. Mater. Today Proc. 77, 277–285. doi:10.1016/j.matpr.2022.11.301

Dyers Association of Tirupur (2024). Dyers association of Tirupur colourful dressing universe. Available online at: https://datindia.org/ (Accessed April 13, 2025).

Ellen MacArthur Foundation (2017). A new textiles economy: redesigning fashion’s future. Available online at: https://www.ellenmacarthurfoundation.org/a-new-textiles-economy (Accessed July 28, 2025).

EPA (1986). The environment (protection) Act, 1986. Ministry of environment, Forest and climate change. Government of India. Available online at: https://cpcb.nic.in/envprotection-act/ (Accessed May 1, 2025).

European Environment Agency (1999). Environmental indicators:typology and overview. Technical report 25. Copenhagen: European Environment Agency. Available online at: https://www.eea.europa.eu/en/analysis/publications/tec25 (Accessed July 28, 2025).

Feng, X., Sun, L., Wang, X., and Wang, L. (2022). A single-indicator approach to assessingthe water footprint of zhejiang’stextile industry. Pol. J. Environ. Stud. 31 (6), 5683–5691. doi:10.15244/pjoes/150641

Grönwall, J., and Jonsson, A. C. (2017). The impact of ‘Zero’ coming into fashion: Zero Liquid Discharge uptake and socio-technical transitions in Tirupur. Water Alternatives 10 (2), 602–624. Available online at: https://www.water-alternatives.org/index.php/alldoc/articles/vol10/v10issue2/372 a10-2-22/file (Assessed on October 18, 2025).

Gupta, A. (2022). Tirupur: a shining global example of sustainability. ANI News. Available online at: https://www.aninews.in/news/national/general-news/tirupur-a-shining-global-example-of-sustainability20221119134340/ (Accessed April 13, 2025).

International Labour Organization (2023). Responsible business conduct in China textile industry. Tirupur: International Labour Organization. Available online at: https://www.ilo.org/resource/project-document/responsible-business-conduct-china-textile-industry (Accessed April 22, 2025).

Kanungo, A. K. (2012). China’s textiles sector: performance and challenges. Transnatl. Corp. Rev. 4 (2), 61–89. doi:10.1080/19186444.2012.11658327

Khajuria, A. (2020). Integrated approach between DPSIR, planetary boundaries and sustainable development goals ∼ towards 3Rs and resource efficiency. World Environ. 10 (2), 52–56. doi:10.5923/j.env.20201002.03

Khajuria, A. (2024). How circular economy initiatives are changing the world. The Japan Times. Available online at: https://www.japantimes.co.jp/commentary/2024/07/22/japan/circular-economy-improving-world/ (Accessed October 18, 2025).

Khajuria, A. (2025). Integrating circular economy education into education for sustainable development: a conceptual advancement and typology of integration strategies. J. Environ. Educ., 1–15. doi:10.1080/00958964.2025.2565488

Khajuria, A., and Verma, P. (2025). Circular economy for “blue skies” in building resilient cities—towards the UN 2030 agenda for sustainable development goals. Front. Sustain. 6, 1479452. doi:10.3389/frsus.2025.1479452

Khajuria, A., Atienza, V. A., Chavanich, S., Henning, W., Islam, I., Kral, U., et al. (2022). Accelerating circular economy solutions to achieve the 2030 agenda for sustainable development goals. Circ. Econ. 1 (1), 100001. doi:10.1016/j.cec.2022.100001

Khajuria, A., Verma, P., Vella, A., Zanini-Freitag, D., Xin, H., Murthy, I. K., et al. (2025). The SDG accelerator: circular economy solutions through efficient sustainable consumption. Circ. Econ. 4 (2), 100140. doi:10.1016/j.cec.2025.100140

Li, M., Tong, Y., Zhu, J., and Xu, S. (2024). A high-resolution multi-scale industrial water use dataset in China. Sci. Data 11 (1), 1327. doi:10.1038/s41597-024-04204-0

Manav (2024). Circular economy principles in industrial water management. Future Bridge NetZero. Available online at: https://netzero-events.com/circular-economy-principles-in-industrial-water-management/ (Accessed April 25, 2025).

Manhas, N. S. (2023). A fragile lifeline: india and China must collaborate on water. Lowy Institute. Available online at: https://www.lowyinstitute.org/the-interpreter/fragile-lifeline-india-china-must-collaborate-water (Accessed July 28, 2025).

Megdal, S. B. (2013). On defining and achieving water security | water resources research center. Arizona: The University of Arizona. Available online at: https://wrrc.arizona.edu/publication/defining-and-achieving-water-security (Accessed May 12, 2025).

Ministry of Ecology and Environment (2013). Discharge standards of water pollutants for dyeing and finishing of textile industry, the Republic’s of China. Available online at: https://english.mee.gov.cn/Resources/standards/water_environment/Discharge_standard/201301/t20130107_244749.shtml (Accessed May 10, 2025).

National Bureau of Statistics of China (2024). Statistical communique of the People's Republic of China on the 2023 national economic and social development. Available online at: https://www.stats.gov.cn/english/PressRelease/202402/t20240228_1947918.htmlpdf (Accessed May 12, 2025).

NITI Aayog (2022). Wastewater: india's untapped resource. New Delhi: NITI Aayog. Available online at: https://www.niti.gov.in/sites/default/files/2022-09/WasteWater-A4_20092022.pdf (Accessed May 12, 2025).

Owen, E. (2024). Sustaining the flow: water’s role in a circular economy, SLR consulting. Available online at: https://www.slrconsulting.com/apac/insights/waters-role-in-a-circular-economy/ (Accessed April 25, 2025).

Oyejobi, D. O., Firoozi, A., Fernández, D. B., and Avudaiappan, S. (2024). Integrating circular economy principles into concrete technology: enhancing sustainability through industrial waste utilization. Results Eng. 24, 102846. doi:10.1016/j.rineng.2024.102846

Palagonia, C., Michelini, L., and Mattelin-Pierrard, C. (2025). Spanning the industrial symbiosis within the circular economy: critical issues and future research agenda. J. Industrial Ecol. 29, 746–765. doi:10.1111/jiec.70005

Qu, J., Wang, H., Wang, K., Yu, G., Ke, B., Yu, H. Q., et al. (2019). Municipal wastewater treatment in China: development history and future perspectives. Front. Environ. Sci. Eng. 13 (6), 88. doi:10.1007/s11783-019-1172-x

Ramin, E., Faria, L., Gargalo, C. L., Ramin, P., Flores-Alsina, X., Andersen, M. M., et al. (2024). Water innovation in industrial symbiosis - a global review. J. Environ. Manag. 349, 119578. doi:10.1016/j.jenvman.2023.119578

Ritchie, H., and Roser, M. (2018). Water use and stress, our world in data. Available online at: https://ourworldindata.org/water-use-stress (Accessed July 29, 2025).

Rong, Y., Tang, H., Zhang, Y., Sun, Y., and Liu, Z. (2023). Study on sewage characteristics in rural China and pollutants removal performance of biologically enhanced internal circulation treatment system. Sci. Rep. 13 (1), 18058. doi:10.1038/s41598-023-45085-4

Rosińska, W., Jurasz, J., Przestrzelska, K., Wartalska, K., and Kaźmierczak, B. (2024). Climate change’s ripple effect on water supply systems and the water-energy nexus – a review. Water Resour. Industry 32, 100266. doi:10.1016/j.wri.2024.100266

Sharma, S., and Hartley, K. (2025). India’s circular economy: lofty ambitions, limited progress. Available online at: https://www.orfonline.org/expert-speak/india-s-circular-economy-lofty-ambitions-limited-progress (Accessed May 1, 2025).

Shehata, N., Egirani, D., Olabi, A., Inayat, A., Abdelkareem, M. A., Chae, K. J., et al. (2023). Membrane-based water and wastewater treatment technologies: issues, current trends, challenges, and role in achieving sustainable development goals, and circular economy. Chemosphere 320, 137993. doi:10.1016/j.chemosphere.2023.137993

Singh, B. J., Chakraborty, A., and Sehgal, R. (2023). A systematic review of industrial wastewater management: evaluating challenges and enablers. J. Environ. Manag. 348, 119230. doi:10.1016/j.jenvman.2023.119230

Singhal, S., and Ahmad, F. (2025). Policy and governance roadblocks are the biggest challenges to treated water reuse, Down to Earth. Available online at: https://www.downtoearth.org.in/water/policy-and-governance-roadblocks-are-the-biggest-challenges-to-treated-water-reuse (Accessed April 14, 2025).

SIWI (2017). Water governance mapping report: textile industry water use in China – case study of Zhejiang Province. Stockholm International Water Institute. Available online at: https://siwi.org/wpcontent/uploads/2017/06/Water-governance-mapping-reportChina.pdf (Accessed May 1, 2025).

State Council (2024). China unveils regulations on water conservation. Available online at: https://english.www.gov.cn/policies/latestreleases/202403/20/content_WS65fab2acc6d0868f4e8e547c.html (Accessed April 22, 2025).

Tiruppur Expoters Association (2024). Tiruppur’s knitwear exports surge despite global challenges. Tirupur: Tiruppur Expoters Association. Available online at: https://tea-india.org/news-board/16762-tiruppur-s-knitwear-exports-surge-despite-global-challenges-exceed-rs-30-000-cr-in-fy24-21st-january-2026 (Accessed April 13, 2025).

Trity Environ Solution (2025). Industrial effluents and Urban water safety: understanding the impact. Available online at: https://trityenviro.com/bd/the-link-between-industrial-effluents-and-urban-water-safety (Accessed May 1, 2025).

UN-Water (2013). Water security and the global water agenda. Geneva, Switzerland: UN-Water. Available online at: https://www.unwater.org/publications/water-security-and-global-water-agenda (Accessed March 31, 2025).

UN-Water (2024). UN world water development report 2024. Geneva, Switzerland: UN-Water. Available online at: https://www.unwater.org/publications/un-world-water-development-report-2024 (Accessed April 25, 2025).

UNESCO (2017). UN world water development report 2017 - wastewater, the untapped resource. Paris: UNESCO. Available online at: https://www.unesco.org/en/wwap/wwdr/2017 (Accessed: April 25, 2025).

UNESCO-UNEVOC (2024). Closing the institutional gap perspectives on the circular economy from selected African TVET institutions. Available online at: https://unevoc.unesco.org/home/UNEVOC+Publications/lang=sp/akt=detail/qs=6755 (Accessed April 25, 2025).

United Nations (2015). Transforming our world: the 2030 agenda for sustainable development. New York: Department of Economic and Social Affairs. Available online at: https://sdgs.un.org/2030agenda (Accessed April 25, 2025).

Vidya, J. (2022). China’s water weaponisation: implications for India’s security. Pune, India: Indian Review of Global Affairs. Available online at: https://irga.in/world_desc.php?id=1231 (Accessed July 28, 2025).

Waas, T., Hugé, J., Block, T., Wright, T., Benitez-Capistros, F., and Verbruggen, A. (2014). Sustainability assessment and indicators: tools in a decision-making strategy for sustainable development. Sustainability 6 (9), 5512–5534. doi:10.3390/su6095512

Wada, Y., Flörke, M., Hanasaki, N., Eisner, S., Fischer, G., Tramberend, S., et al. (2016). Modeling global water use for the 21st century: the water futures and solutions (WFaS) initiative and its approaches. Geosci. Model Dev. 9 (1), 175–222. doi:10.5194/gmd-9-175-2016

World Bank (2021). Water in circular economy and resilience (WICER): the case of Chennai, India. Available online at: https://documents.shihang.org/zh/publication/documents-reports/documentdetail (Accessed April 25, 2025).

Xu, A., Wu, Y. H., Chen, Z., Wu, G., Wu, Q., Ling, F., et al. (2020). Towards the new era of wastewater treatment of China: development history, current status, and future directions. Water Cycle 1, 80–87. doi:10.1016/j.watcyc.2020.06.004

Yager, B. (2024). A circular path: innovating water management for a sustainable future. Schneider Electric Blog. Available online at: https://blog.se.com/digital-transformation/2024/10/04/how-a-circular-approach-can-transform-global-water-management/ (Accessed April 25, 2025).

Zhang, C., Quan, B., Tang, J., Cheng, K., Tang, Y., Shen, W., et al. (2023). China’s wastewater treatment: status quo and sustainability perspectives. J. Water Process Eng. 53, 103708. doi:10.1016/j.jwpe.2023.103708

Keywords: circular economy, education, water use, industrial sector, industrial water management