- 1Environmental Sciences Division, Oak Ridge National Laboratory, Oak Ridge, TN, United States

- 2Department of Ecology and Evolutionary Biology, University of Tennessee, Knoxville, Knoxville, TN, United States

- 3Three3, Inc., Knoxville, TN, United States

The Coronavirus Disease 2019 (COVID-19) instigated a pandemic that impacted economies, employment, and shipping worldwide. This paper reviews how one international supply chain performed and identifies lessons that may be helpful to improve future resilience. Economic and employment data through November 2020 are used to review the effects of COVID-19 on operations of the bioenergy supply chain in the southeastern United States (SE United States) that utilizes wood fiber to fabricate pellets. Conditions associated with the production of pellets in the SE United States changed with the outbreak of COVID-19. Federal and state government programs and classification of workers in this sector as “essential” during the pandemic helped maintain the woody pellet supply chain and other industries during a period of general shut down in 2020. The availability of personal protective equipment, long-term supply contracts, and established safety cultures are among the factors that enhance supply chain resilience while limited availability of skilled workers, inadequate stakeholder engagement, and dependence on external policies are among factors that reduce resilience. The analysis concludes with recommendations for the SE pellet supply chain, and other biomass supply chains, to improve their resilience to future disturbances. When best practices are implemented, SE United States biomass offers opportunities to contribute to post-pandemic economic recovery while incentivizing better forest resource management.

Introduction

Coronavirus Disease 2019 (COVID-19) was first identified in Wuhan, China, in December 2019 and by the middle of January 2020 was detected in the United States. COVID-19 is caused by a novel severe acute respiratory syndrome coronavirus (SARS-CoV-2), which can readily spread from person to person. Hence a proven preventative measure to reduce contagion is social distancing, as documented by research on prior pandemics (Barry, 2018). Whereas most COVID-19 illnesses are mild, and most patients recover with some supportive care, as of June 2021, more than 600,000 people had died in the United States, and the global death toll exceeded 3.8 million [World Health Organization (WHO), 2021].

The pandemic caused by the spread of the COVID-19 has affected countries and supply chains in many ways. Researchers have documented significant impacts on employment, trade, energy and other sectors, oil price and other variables, as well as acute, localized, supply/demand disequilibrium, resulting in economic losses and price volatility, e.g., (Goodell, 2020; Iyke, 2020; Maliszewska et al., 2020; Padhan and Prabheesh, 2021). The purpose of this paper is to document the effects of COVID-19 on the production, transport, and use of woody pellets (i.e., pellets made of or containing wood or wood fiber) sourced in the Southeast United States (herein referred to as the SE pellet supply chain). The analysis also identifies opportunities to enhance the resiliency of this and similar supply chains to future disturbances.

Resiliency refers to the ability of a system to recover quickly following a disturbance (Angeler et al., 2018; Falk et al., 2019). A system able to resist damage from a disturbance is termed resilient. Important characteristics to build resilience include learning from past situations and the capacity to analyze events to better prepare for the future (e.g., Plieninger and Bieling, 2012; Biggs et al., 2015; Simonsen et al., 2016). The term robustness (the persistence of system characteristics) is sometimes used interchangeably with resilience to describe the ability to continue required functions throughout a disturbance. However, even highly robust systems have weaknesses and breaking points that may be unknown until unexpected events occur. Therefore, resiliency is recognized as a desired trait for more sustainable systems in the face of an uncertain future of stressors associated with climate change and altered disturbance regimes (Norgaard et al., 2021).

The rationale for assessing the resilience of the SE pellet supply chain is threefold. First, the review aims to identify conditions and interventions that influenced the effects on the SE pellet supply chain during the pandemic and potential areas for improvement. Second, this case study facilitates comparative analyses with similar supply chains around the world that responded uniquely, offering opportunities to identify useful lessons for biomass supply chains globally. Third, understanding risks and opportunities to improve the resilience for this and other biomass supply chains is valuable because the implementation of state, national, and global strategies for achieving climate and development goals over coming decades rely on biomass resources (Hellweg et al., 2020). For example, the EU established the European Circular Bioeconomy Fund “to de-risk innovative projects and stimulate private investments” (Fritsche et al., 2021).

Understanding of the factors affecting resilience of biomass supply chains to the COVID-19 pandemic can be improved by coordinating this and other supply chain assessments (i.e., linking the first two aims; see section “Methods”). The third aim is to inform decision makers about the limitations, opportunities, and resilience of biomass supply chains when developing and implementing green investments and economic recovery plans. Governments are developing post-COVID-19 strategies that encourage investments to address goals for employment and economic growth [International Energy Agency (IEA), 2020; IICA, 2020]. IEA Bioenergy is coordinating reviews of supply chains in Europe, Canada, the United States, and other nations. These studies review challenges encountered, responses, and lessons that could enhance future resilience.

The risks, resilience, and opportunities offered by biomass supply chains are important to understand because biomass, including woody pellets, is expected to play a pivotal role in climate change and energy transition plans around the globe (Birol, 2020; IEA, 2021). Over 100 nations, including the United States, are working toward net-zero emission targets (van Soest et al., 2021), and most plans and emission-reduction pathways rely heavily on bioenergy (Gielen et al., 2019). For example, the International Energy Agency (IEA, 2021) finds that bioenergy must play a major role to achieve net zero emissions by 2050, contributing 100 Exajoules. As of December 2020, at least 30 states in the United States had adopted renewable portfolio standards or set specific renewable energy goals in which biomass is expected to play a role [National Conference on State Legislatures (NCSL), 2020b]. Recent Presidential Orders in the United States call for all renewable energy options to be employed including biomass (Executive Order 14008, 2021) and for the risks to be carefully assessed, disclosed, and mitigated (Executive Order 14030, 2021). Thus, as investments are made in renewable energy over the coming years, information that identifies opportunities to improve the resilience of woody biomass supply chains can be useful to inform decisions and reduce risks in the face of future, unexpected disturbances.

Methods

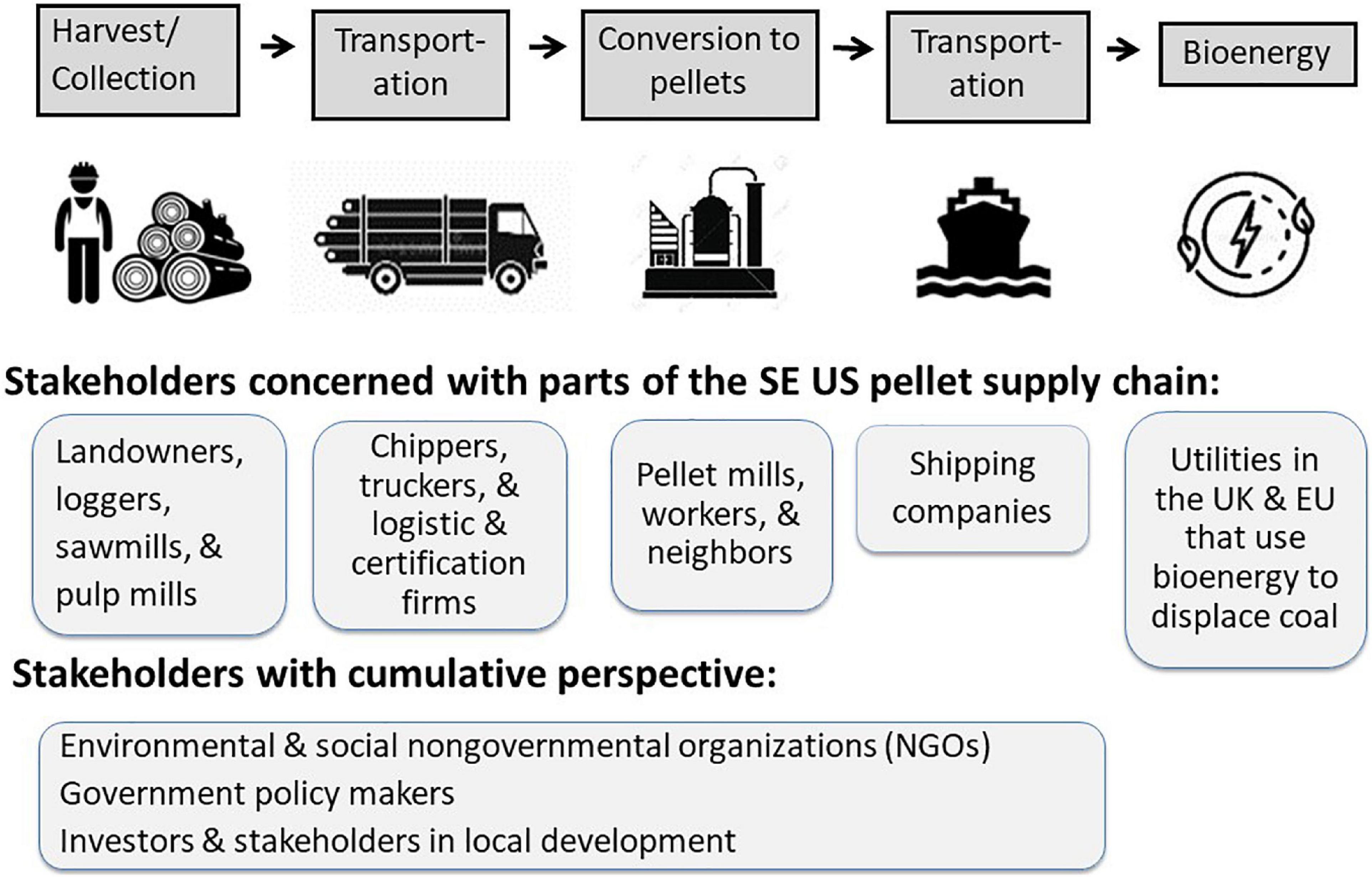

This paper summarizes findings of a review of the influence of the COVID-19 pandemic on the SE pellet supply chain which, as illustrated in Figure 1, produces densified biomass feedstock (utility grade pellets) used primarily for electric power generation in Europe. The selection of the SE pellet supply chain and the methods applied for this case study were coordinated with IEA Bioenergy Task 43 to complement case studies in other countries and other biomass supply chains (IEA Bioenergy T43, 2020). The research includes analysis of how the pandemic impacted the supply chain, factors influencing resilience of the supply chain, and recommendations to address the question, “What can be learned from the experiences (lock-down policies, work and transport restrictions, increased trade barriers) to enhance supply chain resiliency and reduce economic, social, and environmental costs under future crises?” (IEA Bioenergy T43, 2020). This study also identifies supply chain conditions that facilitate synergistic renewables growth where bioenergy supplements investment and utilization of other renewables and that complement other initiatives coordinated by the IEA Bioenergy TCP (IEA Bioenergy, 2021b). Below, the methods to collect information are described, and then background is presented on production of woody pellets in the SE United States before COVID-19.

Figure 1. The SE United States woody pellet supply chain and selected stakeholders associated with each step. The risks, resilience, and ultimate effects of COVID-19 on the supply chain and stakeholders can vary by place, sector, or socio-economic group, and over time.

Data Collection and Analysis

Data were collected based on information published up to December 30, 2020 (some sources were subsequently updated with manuscript revisions). Official data sources were used whenever possible, including the United States Bureau of Statistics, the United States Energy Information Administration (United States EIA), and United States Department of Agriculture Forest Service data and reports. It should be noted that detailed data on the industry have been collected by the United States EIA since 2016, when a survey was implemented to monitor the woody pellet industry in the United States. The United States EIA publishes Monthly Densified Biomass Fuel Reports [US Energy Information Administration (EIA), 2021] that are accessible to the public. These reports collect data from biomass fuel producers of more than 10,000 dry tons of pellets per year, with smaller producers surveyed annually. Most of the United States EIA data are disaggregated into the three geographic regions where densified biomass is produced in the United States: the South (equivalent to the SE United States in this study), North, and West. Data for densified biomass in the United States is collected for two basic pellet types: “premium/standard” used primarily for residential consumption and marketed as bagged pellets, and “utility pellets” produced primarily for export and use in large thermal electric plants (Brandeis et al., 2021).

To estimate effects of the pandemic on the SE pellet supply chain, we first review trends and operations prior to March 2020. We then compare those data with available information on performance of the SE pellet supply chain following the COVID-19 outbreak, officially declared in the United States on March 13, 2020. Literature searches were conducted using the advanced search function in Google Scholar focusing on 2019–2020 publications addressing resilience to the pandemic. Searches on the title of publication were performed using the following search terms: pandemic OR resilience plus wood OR pellets OR biomass. Additional title searches were performed using the following combinations:

• Resilience AND south AND United States plus pandemic OR wood OR pellets OR biomass.

• Pellets AND southeast plus pandemic OR biomass OR resilience.

• Resilience AND pellets plus southeast OR pandemic.

• Pandemic AND pellets plus southeast OR resilience.

A search was also performed seeking the following words anywhere in 2019–2020 publications: pellets, Southeast, United States, pandemic, biomass, or resilience. We broadened our search for available literature and government statistics on economic, social, and environmental conditions related to the production, transport, and use of woody pellets.

The analysis of available data led to the following approach: (A) Pandemic effects on the United States economy as reflected in economic and employment data through November 2020 are documented; (B) Effects identified are compared to the effects of COVID-19 on operations of the SE pellet supply chain; and (C) Available trend data of the SE pellet supply chain before and after the start of the pandemic are considered and compared with data available for other sectors and industries, including the United States lumber industry in the SE United States. Given that limited information was available due to the recent occurrence of the pandemic, targeted interviews were conducted, and trade journal and industry reports were also reviewed. Internal peer reviews led to several improvements to the manuscript.

Background: Production of Woody Pellets in the SE United States Before COVID-19

Woody pellets are produced in the SE United States and shipped to Europe for the generation of heat and power. Exports of pellets from the SE United States have increased from near zero in 2007 to over 600,000 tons exported per month in 2019 (USDA, 2020). The supply chain has grown in response to incentives promoting renewable energy in the United Kingdom and the European Renewable Energy Directive (EU-RED) (European Commission, 2021). However, the volume of biomass used for pellets in the SE represented less than 3% of total industrial wood harvest removals in the SE United States in 2018 (Brandeis and Abt, 2019; USDA, 2020).

The SE pellet supply chain is characterized by large, industrial pellet plants designed to serve foreign markets. Although the resilience of the supply chain to the COVID-19 pandemic has not been assessed previously, aspects of the SE pellet supply chain that influence resilience have been examined such as: impacts on forest area and economics (Costanza et al., 2017; Henderson et al., 2017), sustainability of feedstock sourcing (Parish et al., 2017; Kittler et al., 2020), relationships to the United Nations Sustainable Development Goals (Kline et al., 2021), and other environmental and economic indicators (Cornwall, 2017; Aguilar et al., 2020; Favero et al., 2020). The EU-RED market established clear specifications for biomass procurement, processing, and pellet qualities, including certification of compliance with sustainability requirements (Olesen et al., 2016). The supply chain supports the implementation of best forest management practices (e.g., National Association of State Foresters, 2015) that are required for producing pellets for export (Kittler et al., 2020; IEA Bioenergy, 2021a). SE United States pellet mills are typically located in areas with access to large volumes of standing timber with relatively low value (i.e., low stumpage price) or areas where other forest industries generate large volumes of sawdust and other woody residues that can serve as feedstock to the pellet mills (Dale et al., 2017; Kline et al., 2021). The closure of dozens of paper mills in the region over the past 25 years combined with timber inventory volumes growing faster than demand, has contributed to low stumpage price and economically stranded timber stands (Hodges et al., 2012; Brandeis and Guo, 2016; USDA, 2020), which support the SE pellet supply chain.

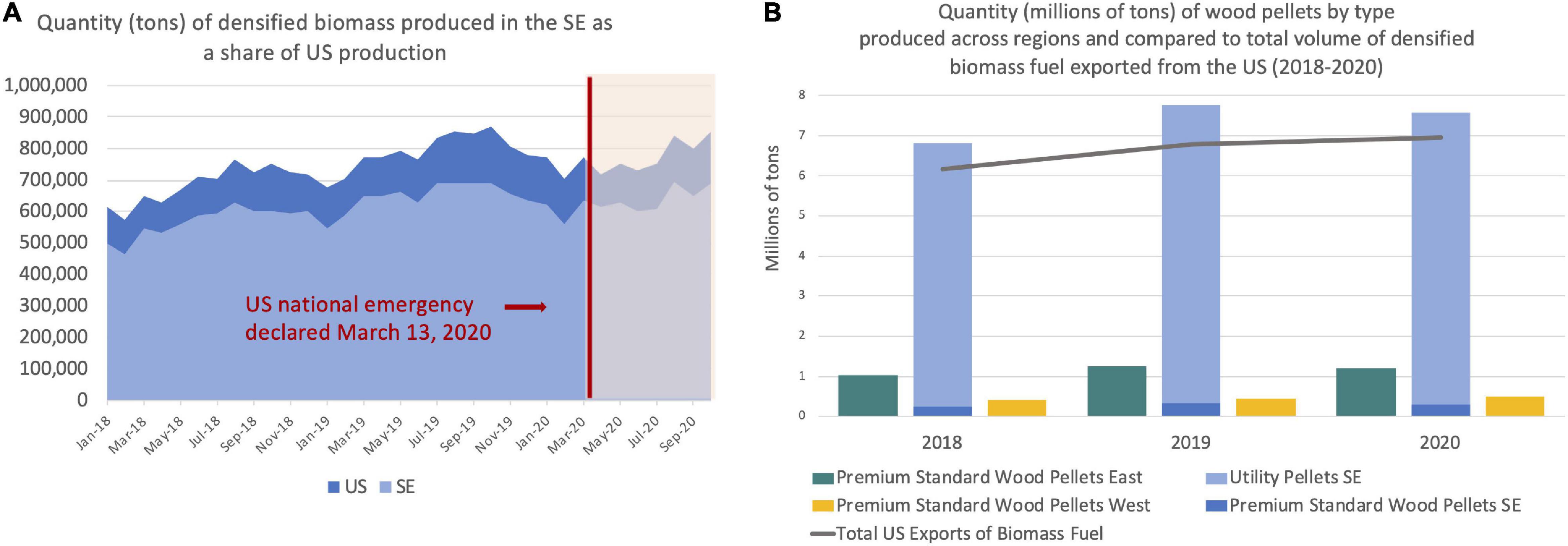

Figure 2 illustrates that the SE United States supply chain represents over 80% of total United States pellet production over the past 3 years. And over 90% of total SE pellet production is exported each year, with the remainder serving domestic markets. While the use of wood for domestic energy production in the United States has been relatively stable for two decades, the SE pellet supply chain represents rapid growth based on utility pellets for export (Brandeis et al., 2021). Within the United States, utility pellets for export have been produced only in the SE while premium standard pellets have been produced in much smaller quantities across all three regions [Brandeis et al., 2021; US Energy Information Administration (EIA), 2021].

Figure 2. (A) Quantity (tons) of pellets produced monthly in the SE United States as share of total United States production, January 2018–October 2020 and (B) Quantity of pellets produced annually in the United States by region and type of pellet, relative to annual United States export volumes. United States exports are comprised almost exclusively of utility pellets.

There is interest in determining the effects of COVID-19 on the many stakeholders in the SE woody pellet supply chain (Figure 1). Stakeholders include residents of communities where the feedstock is sourced, family and corporate private landowners, foresters, truck drivers, pellet mill owners and workers, owners and workers at wood processing facilities that produce residues that go to pellet mills, the shipping industry, utilities in the United Kingdom and European Union, forest certification groups, local governments and businesses, environmental non-governmental organizations, industries that compete for biomass feedstocks, and other members of society who benefit from forest ecosystem services such as clean water, esthetic values, and carbon sequestration.

Stakeholders who are most directly affected by changes in the SE pellet supply chain are contractors and other workers involved in the harvest, collection, chipping, loading, and transport of biomass for delivery to mills, and workers involved in construction, operation, and maintenance of the mills. Contractors that provide supporting services in local communities are also affected. Sawmills and wood-product processing industries, including those generating residues used by pellet mills, and other entities competing for residues and feedstocks, have economic interests intertwined with the pellet supply chain. In areas where traditional forestry activities have declined and mills have closed, jobs and investments associated with the pellet supply chain are important to the local economy, governments, and businesses, as well as for investments to improve or maintain ports and other transportation infrastructure (Hodges et al., 2012; Brandeis and Guo, 2016).

Logging practices depend on local context and geography. One reason that the SE United States is globally competitive in forest products is that harvests typically involve efficient, mechanized operations to fell, haul, and load wood with limited labor compared to other regions in the United States (Baker and Mendell, 2020). SE United States pellet mills, and power plants receiving imported pellets as fuel, tend to be located near rail and waterborne transport facilities and ports, and utilize advanced, mechanized material handling systems, thereby reducing logistic and shipping costs, as well as net GHG emissions associated with less efficient forms of transport for biomass along the supply chain (Kline et al., 2021).

Results

A review of available literature identified no peer-reviewed papers specifically addressing the resilience of the SE pellet supply chain during the COVID-19 pandemic. A private consultancy report was identified that focused on actual and potential effects of the pandemic on cash flows in the SE forestry sector (Forisk, 2020). The various combinations of key word searches in titles generated zero results for papers published 2019–2020. Broader parameters for key words anywhere in a paper generated 173 publications, but none of them addressed the resilience of the SE pellet supply chain to the pandemic. Therefore, the 80 + sources cited in this study reflect government reports and publications that discuss aspects of the SE pellet supply chain that influence resilience more generally. It is useful to frame issues in terms of the effects of COVID-19 on the United States economy overall before we present results on the effects of other parts of that economy, such as the SE pellet supply chain and the lumber sector.

Effects of COVID-19 on the United States Economy

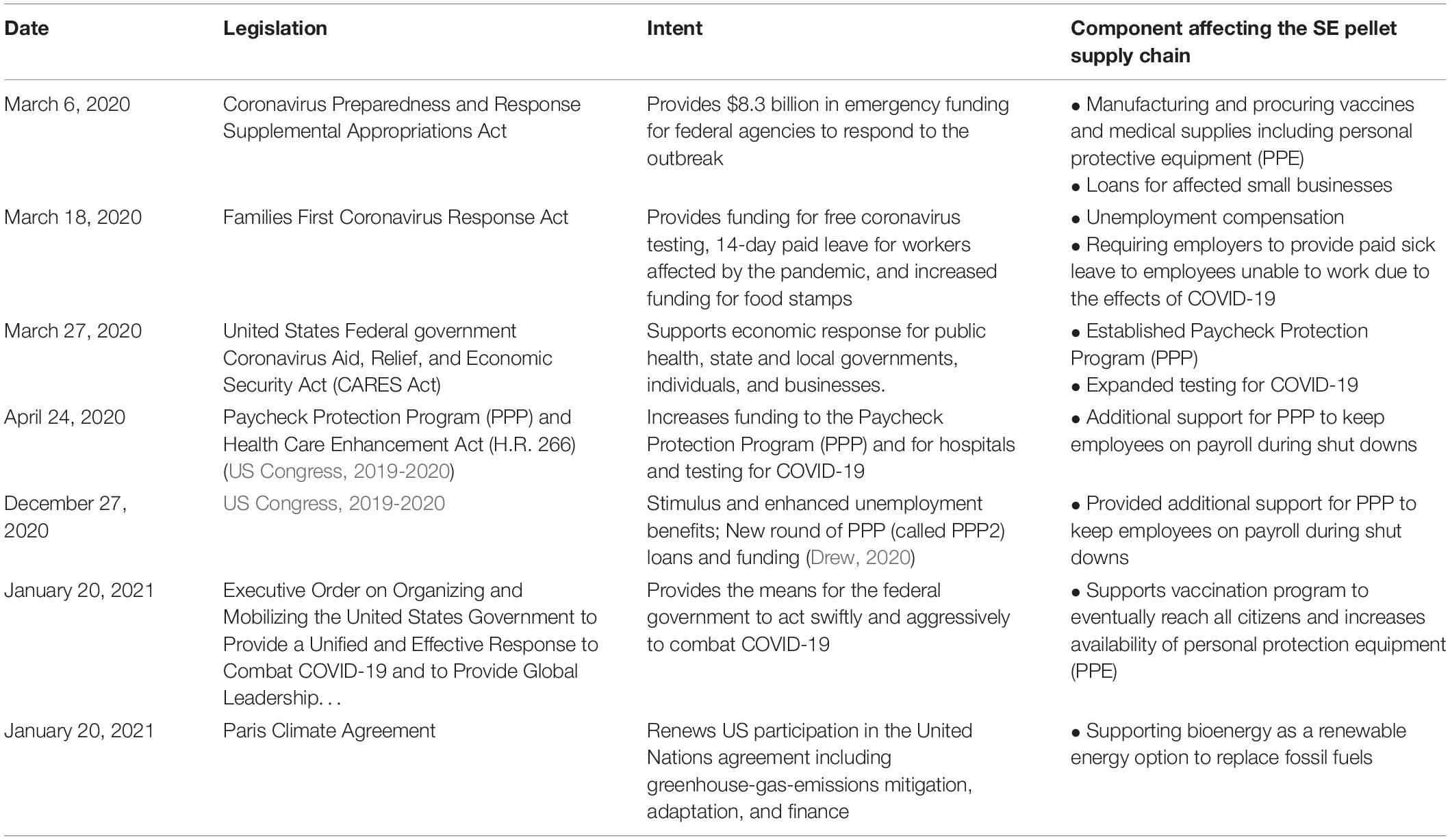

The first United States fatality attributed to COVID-19 was on February 6, 2020. Over the following month, many more fatalities occurred, and the United States Congress approved three laws to mitigate the impacts to individuals and businesses (Table 1). The Coronavirus Preparedness and Response Supplemental Appropriations Act was enacted on March 6, 2020, providing $8.3 billion in emergency funding for federal agencies to respond to the pandemic. A national emergency was declared on March 13, 2020. State and local responses to the outbreak were variable. Many states and localities canceled public events, prohibited large-scale gatherings, ordered temporary business shut-downs, modified or suspended in-person classroom teaching, and implemented a range of other orders encouraging people to stay-at-home to reduce the spread of the virus. In early 2021, additional measures were taken via Executive Orders, and an additional relief package was being debated in Congress.

Table 1. Examples of legislation and executive orders related to the pandemic in the United States and their relationship to the SE pellet supply chain.

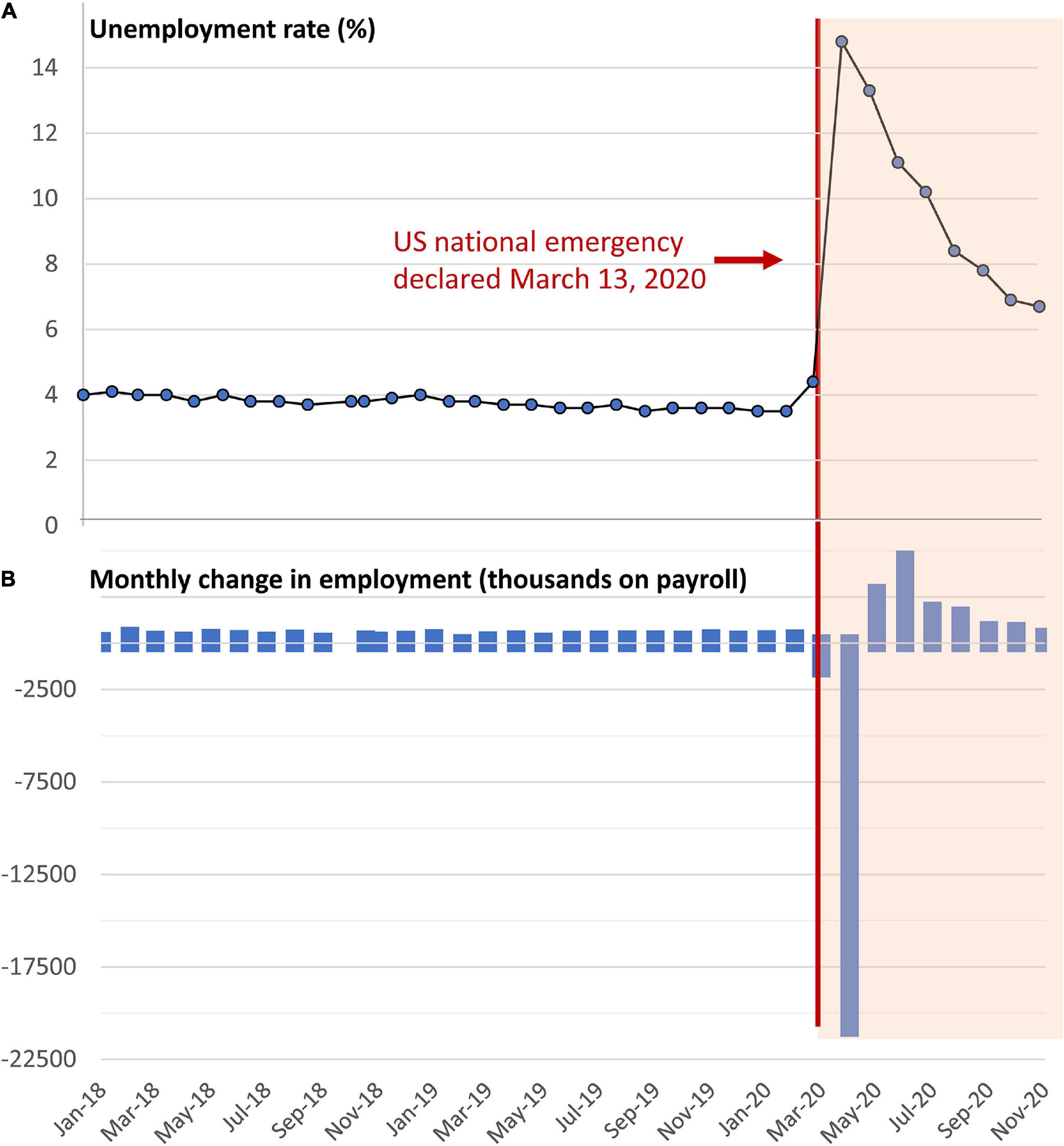

Effects of the COVID-19 pandemic on the United States economy were extensive—disrupting travel, shipping, and other industries. A World Bank study estimated that total United States exports could drop 2.4–4.6% below benchmark expectations although the impacts on agriculture and natural resource exports were modest relative to services and manufacturing (Maliszewska et al., 2020). Financial markets and employment had a sharp dip in the spring of 2020 (Alderman and Buehlmann, 2020). Payroll jobs fell by 1.4 million in March 2020, and another 20.8 million jobs were lost in April as the United States unemployment rate increased from 3.5% in February to a high of 14.7% in April (US BLS, 2021b; Figure 3).

Figure 3. (A) United States national monthly unemployment rate (%) and (B) monthly change in total non-farm employment (thousands of full-time equivalent employees on payroll) for 2018–2020 based on Bureau of Labor Statistics (US BLS, 2021a). Note that the unemployment rate does not include those people who are no longer eligible for unemployment benefits. The shaded areas indicate the period during which the COVID-19 pandemic occurred.

United States job losses were particularly high in industries that rely on in-person interactions. Smaller and newer businesses were more impacted than larger, well-established enterprises. The US Census Bureau (2021) reported that during week 21 (December 9–21, 2020) 31% of adults expected someone in their household to have a loss of employment income in the next 4 weeks. During this same time period, 37.5% of survey respondents were teleworking, 13.7% reported food scarcity in the last seven days, 35.5% reported likelihood of eviction or foreclosure in the next 2 months, 37.5% reported difficulty in paying for usual household expenses, and 9.5% reported housing insecurity as a result of being behind on rent or mortgage payments. Fortunately, the US Congress (2019-2020) addressed some of the difficulties.

By the winter of 2020–2021, the southeast region was leading employment recovery in the United States with persistent growth in jobs and wages, driven largely by the construction industry (Fiorille and Nichols, 2020). Nationally, however, millions remained unemployed. Despite some signs of recovery in professional services and education, there were still 10 million fewer non-farm workers on payrolls in January 2021 than 1 year earlier (US BLS, 2021b). Given ongoing job losses in leisure, hospitality, and similar service industries, combined with a growing potential workforce, a large employment gap remained unfilled as the year began (US BLS, 2021a).

Effects of COVID-19 on the SE Pellet Supply Chain and Other Timber Products

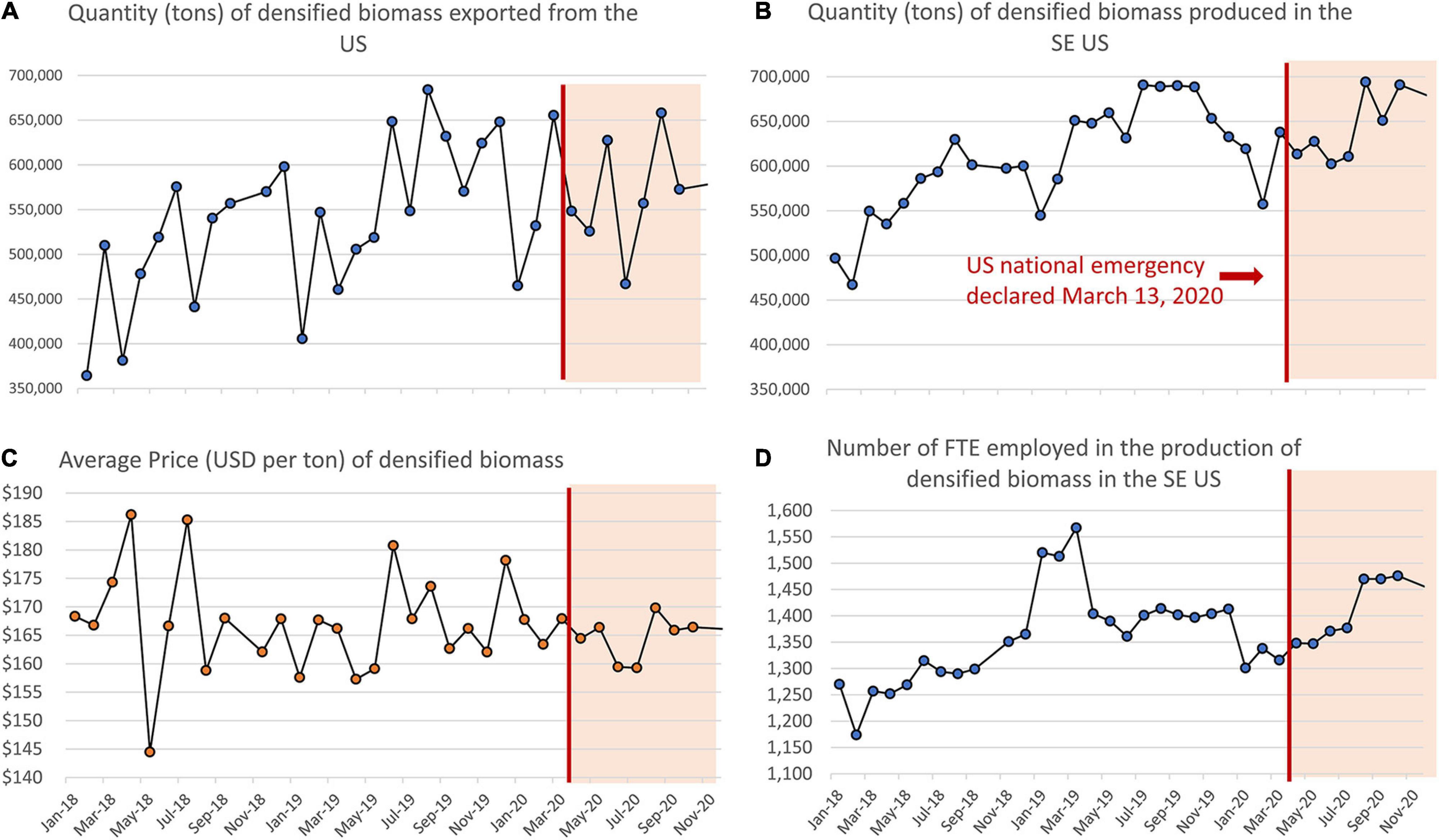

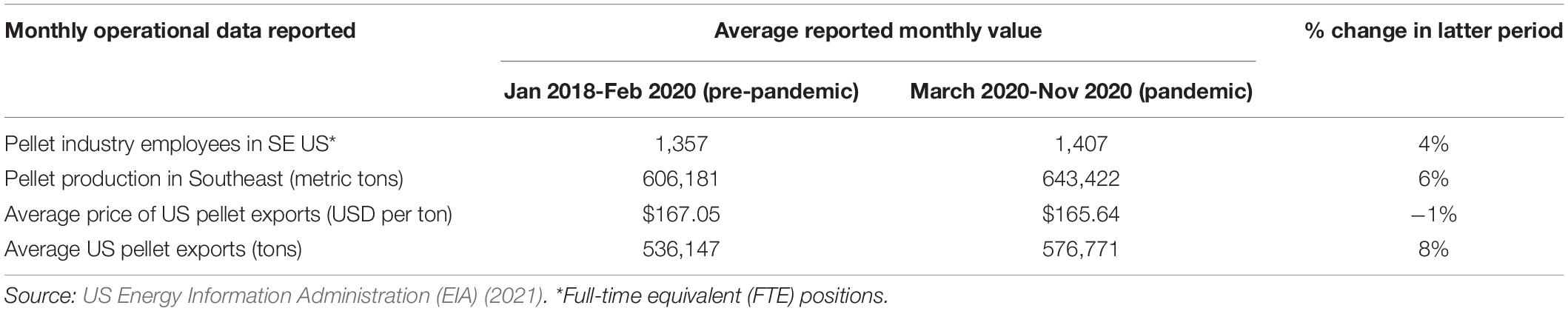

Contrary to the United States economy overall (Figure 3), the employment in the SE pellet supply chain did not diminish during the pandemic (Figure 4). Production, exports, prices, and employment had few changes pre- and post-pandemic. Indeed, the share of total United States pellet production represented by the SE United States continued at the same 82% rate for both the pre-pandemic period January 2018–February 2020, and the post pandemic period March-December 2020 [US Energy Information Administration (EIA), 2021].

Figure 4. Changes over time in the quantity (tons) of densified biomass (A) exported from the United States and (B) produced in the SE United States; and (C) average price per ton of densified biomass, and (D) number of full-time equivalent employees (FTEs) employed in the production of densified biomass in the SE United States. Data from United States Energy Information Administration. A national emergency was declared in the United States on March 13, 2020 (as indicated by the red line and shaded area).

The SE United States pellet supply chain displayed resilience to the COVID-19 pandemic, as illustrated by Figure 4 and data summarized in Table 2. The trends pre-pandemic did not change notably, either maintaining or growing modestly.

Table 2. Pellet supply chain monthly operational data averaged for periods pre- and post- onset of the COVID-19 pandemic.

However, some conditions associated with the production of woody pellets in the SE United States changed with the outbreak of COVID-19. Industry leaders needed to weigh uncertainties inherent in a global pandemic and exercise professional judgment relying upon knowledge from available resources in order to make decisions in the best interest of their companies and the economy while being in compliance with public health guidance and rules (Aven and Bouder, 2020). These were difficult decisions given uncertainties and expert opinions that the “risks in relation to the negative effects of shutdown [were] as least as large as the risks related to the Coronavirus” (Aven and Bouder, 2020, p.852).

Temporary shortages of truckers for moving wood arose in some locations not only due to drivers contracting COVID-19, but also due to the difficulty in obtaining tests for COVID-19 and the increasing costs of insurance (Forisk, 2020). Despite widely available biomass and low stumpage prices that have persisted in the SE United States since 2008–2009 (TimberMart-South, 2021), transporting wood continues to be a costly link in most forest-products’ supply chains, including the SE pellet industry (Visser et al., 2020).

Both the supply of woody feedstocks and the demand for pellets were affected to some degree by the pandemic. The consumption of wood by sawmills collapsed in the second quarter of 2020 as shutdowns and fear of COVID-19 led to great uncertainty in markets. Employment, production and exports of solid lumber products all fell far below normal between April and July, 2020. However, major disruptions to the forestry sector were being resolved by the third quarter of the year (Baker and Mendell, 2020). In fact, there was a subsequent surge in residues because of the increase in demand for solid timber products such as lumber, oriented strand board (OSB), toilet paper, and packaging for shipping goods. This surge occurred partially because many people who no longer had to report to work began home-improvement projects. The upsurge in demand for solid wood products surprised the timber industry and sparked a rapid recovery in the last quarter of 2020. Thus, despite the sharp drop in production of wood products in the second quarter, production curtailments on average for 2020 caused annual volume in SE sawmill timber to fall only about 3% below normal, and 10% below normal for pulpwood (Forisk, 2020). In comparison, wood pellet production in the SE United States continued apace and increased 6% in 2020. And rather than suffering from curtailment, the SE United States pellet exports continued to grow by 8% over the prior year (Table 2).

Comparison of Effects of COVID-19 on the SE Pellet Supply Chain to Other Sectors

While there are notable exceptions of sectors that rapidly grew in response to the crisis, many businesses suffered declines starting in the second quarter of 2020, when stay-at-home orders went into effect, as reflected by national employment statistics (Figure 3). Like other global crises in the past, the COVID-19 pandemic triggered a series of events that impacted and tested the resilience of upstream supply chain components, logistics and purchasing networks, and diverse business operations within multi-domain networks and specific policy frameworks (Golan et al., 2020). The United States government enacted legislation and executive orders related to the pandemic (Table 1) that benefited some parts of the economy.

The shutdowns that began in March 2020 curtailed economic activity, employment, and provision of goods and services around the world (Hilmola et al., 2020; IRENA, 2020). Volatility was observed in many markets due to mismatches in supply and demand. Bottlenecks in supply occurred when availability of urgently required goods were limited in one place, leading to price spikes in items such as masks and hand sanitizer. Simultaneously, surpluses and deeply depressed prices were observed for goods that could not reach markets or be processed on time. Global agricultural markets were impacted by the significant decline in economic growth causing international price fluctuations in industries ranging from liquid biofuels to meat and dairy (Elleby et al., 2020).

It is estimated that approximately 436 million enterprises risked serious disruption globally (IRENA, 2020). Global demand in the energy sector fell 6% in 2020 compared to 2019 (IEA, 2020) and 25% in countries with strict lockdown measures (IRENA, 2020). However, electricity systems with high shares of renewable technologies were relatively resilient in their capability to continue to operate when compared to fossil fuels. The fossil sector displayed higher volatility in prices and larger curtailments in production and jobs (IRENA, 2020). In 2020, and for the first time ever, the United States likely produced more electricity from renewables than from coal; as it made economic sense to dispatch renewable power before coal (Watts and Ambrose, 2020). The shift away from coal for power generation is likely to continue during post-pandemic recovery (Watts and Ambrose, 2020), particularly with the renewed United States commitment to the Paris Accords (Table 1). On the other hand, the economic downturn during the pandemic curtailed decarbonization of heating and cooling solutions (IRENA, 2020), as well as the demand for alternative and more efficient transportation as a result of lockdown policies (Elleby et al., 2020).

Network analyses of supply chain resilience illustrate the interdependent relationships within and between sectors and the cascade effect if a critical component in a supply chain fails (Golan et al., 2020). For example, lockdowns in Ecuador reportedly led to a shortage of balsa wood supply, a raw material used in the fabrication of wind turbine blade cores, and curtailed project operations worldwide (Dempsey, 2020). Across the globe, wind turbine projects have been delayed or canceled due to this and other supply-chain disruptions constraining production of parts ranging from turbine blades to gearbox bearings and threatening billions of dollars in scheduled production (Dempsey, 2020).

Notable differences between the pellet supply chain and the overall economy can be observed by comparing Figure 3 with Figure 4. For example, while non-farm employment fell drastically at the national level and has yet to recover, employment in the southeast pellet industry has continued with little change, growing on average about 4% since March 2020. Similarly, pellet production and export volumes grew, and prices remained steady despite the pandemic. While the market price for pellet exports declined by about 1%, this is minimal relative to large drops in price for other solid fuels (IRENA, 2020), and compared to volatility in prices observed in other sectors.

Discussion

Effects of COVID-19 on the United States Economy

The economic effects of COVID-19 on the United States economy are large but extremely heterogeneous and variable over time (Kaplan et al., 2020; Padhan and Prabheesh, 2021). Therefore, specific case studies are helpful to help illuminate the distribution of impacts. The United States federal government classified certain occupations as being frontline in view of the pandemic. Frontline workers are defined as employees within essential industries who must physically be present to perform their jobs. The list of Essential Critical Infrastructure Workers [United States Department of Homeland Security, Cybersecurity and Infrastructure Security Agency (CISA), 2020] specifically includes the following two categories relevant to the SE supply chain:

• Workers who support sawmills and the manufacture and distribution of fiber and forestry products, including, but not limited to timber, paper, and other wood and fiber products, as well as manufacture and distribution of products using agricultural commodities.

• Workers supporting the energy sector through renewable energy infrastructure (including, but not limited to, wind, solar, biomass, hydrogen, ocean, geothermal, and hydroelectric) and microgrids, including those supporting construction, manufacturing, transportation, permitting, operation and maintenance, monitoring, and logistics.

Explicit guidance was issued for health, workplace, and worker safety issues related to the pandemic for essential workers [United States Department of Homeland Security, Cybersecurity and Infrastructure Security Agency (CISA), 2020]. However, some states developed and applied their own guidance while others had no guidance, resulting in a patchwork of diverse rules and recommended practices [National Conference on State Legislatures (NCSL), 2020a]. Studies suggest that the number of COVID-19 infections in the United States could have been reduced if federal guidelines had been clearly and effectively communicated from the outset of the pandemic and consistently enforced (Woolhandler et al., 2021).

A limited pool of skilled labor and contractors capable of providing logistics, shipping, and other specialized skills created bottlenecks when regular employees could not work. For example, designing and implementing forest roads, fire breaks, prescribed burns, pest control, and other forest management fieldwork require specialized skills. Getting experienced and well-trained trucker, loggers, and other specialty-skill workers is often a challenge and became nearly impossible in some regions during the pandemic (Forisk, 2020).

Effects of COVID-19 on the SE Pellet Supply Chain

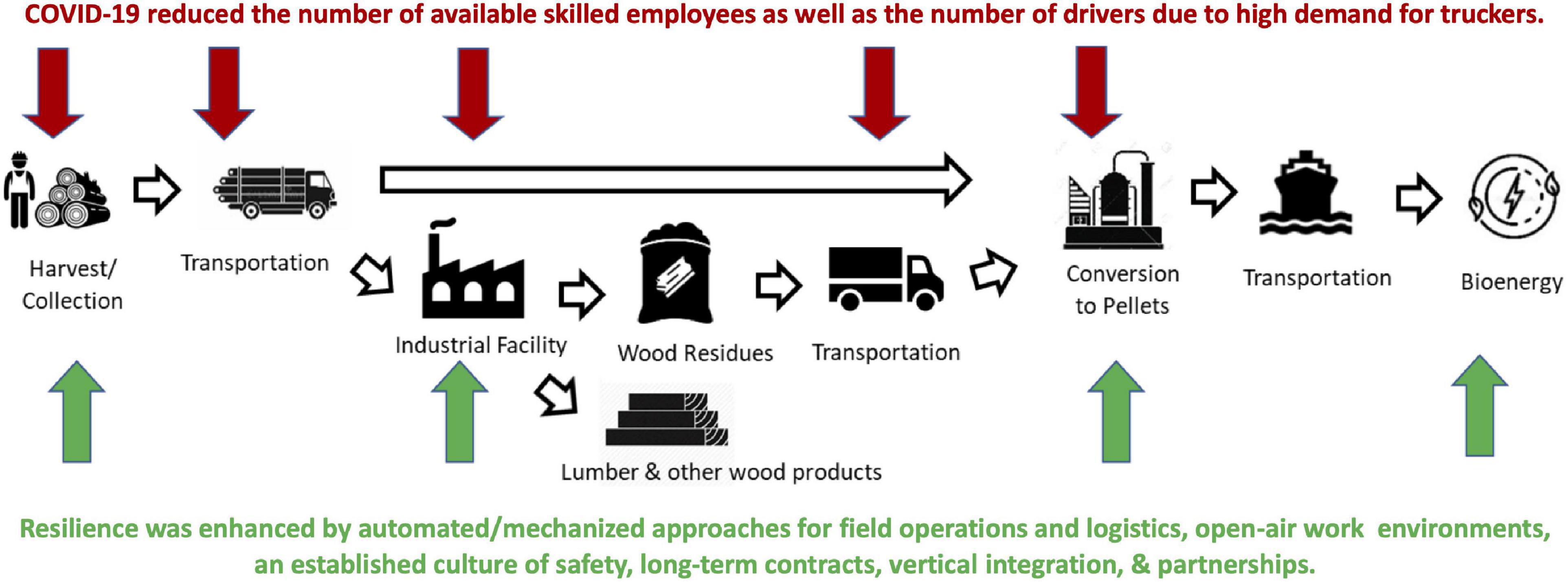

Effects of the pandemic on the SE pellet supply chain are illustrated in Figure 5. Federal and state government programs benefited the SE pellet supply chain along with most other small and medium industries. The Paycheck Protection Program (PPP), the availability of personal protective equipment (PPE), and definition of certain occupations as being frontline in view of the pandemic were critical factors mitigating negative impacts and accelerating recovery. The federal PPP, a $669-billion business loan program established under the CARES Act (Table 1), allowed businesses with less than 500 employees to continue paying their workers. The subsequent PPP and Health Care Enhancement Act provided an additional $484 billion. In the first round of PPP, businesses in the farming, forestry, and hunting sectors received $8.18 billion, which is substantial since the aggregate annual payroll for this sector is $100 billion (Fatka, 2020). PPP covered 2 months of payrolls at the critical time in early summer when some states issued “stay at home” orders. Payroll is the largest cost for most logging businesses, and PPP helped retain workers (Baker and Mendell, 2020; Drew, 2020). If not for PPP, the shutdowns and their consequences on businesses and workers would have been more severe, and recovery would have been slower and more difficult for many segments of the United States economy (Kaplan et al., 2020) including timber industries in the southeast (Forisk, 2020). Thanks largely to PPP, and despite shutdowns across the SE United States economy, total forest sector employment fell by merely 1% in the second quarter of 2020 (Forisk, 2020).

Figure 5. Supply chain for wood-based pellets from the SE United States shipped overseas for bioenergy illustrating steps where COVID-19 had impacts (solid red arrows) and examples of mitigating conditions that supported resilience (green arrows) [modified from Kline et al. (2021)].

The forestry sector’s resilience was supported by well-ventilated work environments and existing protocols for protecting worker health and safety. The availability of PPE to increase safety and reduce the transmission of COVID-19, benefited forest workers, pellet mills, and the paper and lumber mills that provide residues for pellets. Availability of PPE varied by state. Many workers in the Southeast contracted COVID-19, and it was difficult for some lumber mills to secure skilled replacements. COVID-19 caused some forestry operations and mills to shut-down for 2–6 weeks due to positive cases and lack of backup crews. Initially, availability of PPE equipment was a bottleneck and convincing everyone to follow social isolation rules was operationally difficult. Use of manual paper-ticket tracking systems could induce risk of exposure. For example, if a scale operator tested positive, there was potential to infect every trucker that used the scale (L. Jones, IndusTREE, personal communication, February 19, 2021). Hence, one result of the pandemic was an acceleration of industry transitioning toward digital tracking and payment systems.

Demand is important to support woody pellet production and investment. If demand falls sharply, surplus supplies drive prices downward and force industries to reduce output or close. The fact that demand for pellets persisted or increased throughout 2020 contributed to the supply chain’s resilience. Although many United States exports were impacted by new tariffs associated with renegotiating trade agreements (Amiti et al., 2020; York, 2020), the existence of long-term “take-or-pay” contracts to ship pellets from the SE United States to Europe and other nations provided some stability in demand (Enviva, 2020a).

Comparison of Effects of COVID-19 on the SE Pellet Supply Chain to Other Sectors

The SE pellet supply chain fared better in terms of employment than many other industries and the United States economy overall (Figures 3, 4). The United States forestry sector was relatively well-prepared to respond to the pandemic due to previously implemented systems designed to promote safe operations. Logging is recognized as one of America’s most dangerous jobs based on fatalities documented annually by the United States BLS (Suneson, 2021). Forestry workers use dangerous machinery (chainsaws, cables, large vehicles on rough terrain) in changing environments, are exposed to extreme weather and “widow-makers” (falling limbs and trees), and typically work in remote areas, relatively far from emergency care. The number of injuries and fatalities in the sector has declined in recent years (Suneson, 2021), which is important to enable the industry to recruit and retain skilled workers. The industry has spent decades establishing a strong culture of safety, investing in training, communications, and protocols to keep workers safe (D. LaMontagne, Seven Islands Land Company, personal communication, February 21, 2021).

The resilience of the SE pellet supply chain appears to offer both similarities and differences when compared to other biomass supply chains being investigated under the IEA Bioenergy TCP. For example, the effects of the pandemic on bioenergy supply chains in Eastern Europe included an interruption of exports due to initial lockdowns but markets were able to readjust to new circumstances as economies reopened (B. Kulisic, personal communication). In Canada, the effects of the pandemic appear to vary over time and space. In general, the first wave of the pandemic (March 2020) with widespread industry closures had larger economic effects on biomass supply chains than two subsequent waves of infection even though the second and third waves impacted more personnel and more mills than the first (B. Gagnon, personal communication). An assessment of the impacts of COVID-19 in the EU found severe impacts on the food sector and effects that varied on bioenergy, noting that “in some areas, there has been significant disruption in forest management and forestry sector activities” (Fritsche et al., 2021).

The SE pellet supply chain’s resilience to the COVID-19 pandemic is distinct from other forest-product supply chains such as lumber, where COVID-19 caused imbalances in supply and demand, disrupted some wood supply chains, with impacts that varied widely among regions and over time (Riddle, 2020). Unlike pellet operations, many United States lumber mills closed or curtailed operations and by April 2020, United States lumber production capacity was 40% below normal and did not fully recover to pre-pandemic levels until December 2020 (Dezember, 2021). The closures and curtailments exacerbated a domestic supply shortage driven by a sharp rise in United States demand (Forisk, 2020). The imbalance of supply and demand caused “an extraordinary spike in lumber prices” in August-September 2020 (Riddle, 2020). Further price spikes were observed in lumber retail and futures markets in December 2020 and April 2021 (Morgan and Hayes, 2021). United States lumber futures prices reached a record level, exceeding four times the 2015–2019 average, on May 3, 2021 (Dezember, 2021). And in 2020, with high domestic demand, United States lumber exports fell to their lowest levels in a decade (Forth, 2021). The variability in lumber prices, production levels, and trade during the pandemic portray a sharp contrast with the steadiness observed in the SE pellet supply chain.

Factors Affecting Resilience

Among the factors supporting resilience during the pandemic were the national relief policies, inclusion of this industry among those designated for “essential workers,” and the security provided by vertical integration and long-term supply contracts (Figure 5). Reliability of the supply chain is of particular concern for energy sources, upon which the economy depends (IEA, 2020). The COVID-19 pandemic exposed vulnerabilities in supply chains impacting national economies as well as potential opportunities for woody pellets. Electricity provision is an essential service that generally performed well during the pandemic with some support from renewable resources including biomass (IEA, 2020). Furthermore, demand for wood pellets from the SE United States is projected to increase in the future, as markets in Korea, Japan and other nations appear to be growing and the Drax Group (the major purchaser of woody pellets from the SE United States) announced plans to expand United States operations over coming years for its United Kingdom power stations (Drax, 2020). The observed declines in demand and consumption of biofuels and petroleum transport fuels again provide a contrast with the SE pellet supply chain (Elleby et al., 2020).

Other aspects may improve resilience under the current case but prove to be liabilities under other circumstances. For example, technology, mechanization, and other innovations may improve resilience by reducing the costs and risks associated with manual labor. However, the same modernizations may be more susceptible to other (non-health related) disruptions, such as cyber-attacks, prolonged power failures, or electro-magnetic disturbances. Continual learning and adaptation are therefore among the basic principles for building resilience in social-ecological systems (Biggs et al., 2015). Additional principles include, encouragement of inclusive stakeholder participation, maintenance of diversity and redundancy, and management of connectivity, slow-changing variables, and feedbacks.

Most small business operations are accustomed to short-term disruptions, such as those caused by extreme weather, and have alternatives or contingencies in place for small or short-term curtailments. But the effects of COVID-19 were distinct and the impacts would have been far greater in the absence of the government programs (Table 1) that kept employees on payrolls despite the disruptions (Kaplan et al., 2020; Padhan and Prabheesh, 2021). The subsequent increase in timber demand was a welcome surprise for pellet mills seeking to maximize the use of residues from sawmills. The trend data for the SE pellet supply chain during the pandemic, and the recovery of other forest products industries later in the year, are consistent with Baker and Mendell’s (2020) conclusion that logging capacity is resilient in the short term, but that extended periods without market demand such as the housing market crisis and recession of 2008–2009, could result in longer-term mill closures that are devastating for local communities.

The SE pellet industry is linked with markets for solid heating fuels, electricity, and especially, other forestry products. When analyzing its resilience, the SE pellet supply chain—and other supply chains—must therefore be considered within broader, complex, and interactive supply networks with multiple supply and value chains (Golan et al., 2020). Resilient supply chains strengthen connected industries, as they can collectively plan, absorb, recover, and adapt to systemic disruptions.

The energy sector is well positioned to advance climate mitigation and further align itself with the United Nations Sustainable Development Goals during post-pandemic recovery efforts that aim to build resilient economies. Sustainable recovery establishes economic and energy infrastructure for the future, advancing long-term climate goals (IEA, 2020, 2021). In its Sustainable Recovery Plan, the IEA focuses on six key sectors to meet economic development, employment opportunity and sustainable development goals: electricity, transportation, industry, buildings, fuels, and emerging low-carbon technologies (IEA, 2020). The energy sector can and will play a critical role in economic recovery efforts post-pandemic through innovative technologies and the creation of jobs (IRENA, 2020). Stimulus investments and policies that focus on green energy transitions help strengthen economic recovery and supply chains, provide new opportunities for skilled and unskilled workers, and help advance sustainable development and decarbonization efforts (IRENA, 2020).

Dr. Fatih Birol (IEA, 2020), Executive Director of the IEA, noted that:

“Bioenergy is the overlooked giant of the renewable energy sector and will be paramount to a successful global energy transition. But its growth is currently not on track to meet sustainable development goals. It is critical that governments incorporate bioenergy in their COVID economic recovery plans, promoting jobs in the sector and ensuring its considerable potential does not remain untapped.”

There are limitations to this analysis of resilience. First and most important, the focus of this study is on the specific supply chain in the SE United States and its performance during the initial months of the COVID-19 pandemic. The data available for several statistics run through November 2020, comprising 9–10 months of activities since the outbreak. Therefore, the first caveat is that things may change as more time transpires. The second caveat is that the findings and recommendations that emerge from the SE United States case may not be applicable to other disruptions, other supply chains, or this supply chain under different circumstances. However, an improved understanding of the factors impacting resilience of the SE pellet supply chain contributes to a broader knowledge, enriches other analyses, and can help identify useful practices and lessons.

Lessons Learned

This review of the resilience of the SE pellet supply chain offers lessons about opportunities for biomass to play a positive role in economic and social recovery post COVID-19 (Birol, 2020). First, it was worthwhile to invest in training for skilled trades to prepare for labor scarcities. Second, rapid and aggressive government actions forestalled economic and social debacles across many industries as evidenced by the benefits of the PPP and PPE provisions in the CARES Act as well as the classifications of essential workers. Some additional factors that improved resilience of SE pellet supply chain during the pandemic include:

• Vertical integration of the industry.

• Long-term contracts that limit disruptions in demand.

• Labor and processing activities that take place outdoors.

• Mill locations near transportation lanes and ports.

• Mechanized forestry field operations to fell, haul, and load wood with limited labor.

• Automation of handling and transport of biomass between the forest and final users.

• An established culture of safety.

Investments to modernize the SE pellet supply chain while applying basic principles for learning and adaptive management (Biggs et al., 2015) can further enhance resilience. These investments include continued innovation and improvement in safety, efficiency, technology, and equipment to harvest, handle, and transport woody biomass. Investing in practical systems for electronic tagging and automation can facilitate tracking, compliance with chain-of-custody requirements from buyers, sustainability assessments, and communications to diverse stakeholders. The importance of innovation to resilience was highlighted by the theme of the USDA’s 97th annual Agricultural Outlook Forum on February 18–19, 2021: “Building on Innovation: A Pathway to Resilience.” Key topics for discussion included Supply Chain Resilience; United States Trade and the Global Market Place; Managing Risk and Ensuring Sustainability; and Innovation, Technology, and Productivity. Improving the resilience of managed landscapes is also an explicit objective for the United States Forest Service under the Climate-21 Strategy (USDA, 2021).

Building trust through effective participation represents one of the biggest challenges for the SE pellet supply chain today (Kline et al., 2021). The possibility that increasing wood pellet production in the SE United States might lead to increased timber harvest (Abt et al., 2014) and alterations to forest structure (Duden et al., 2017) has raised concerns about potential long-term impacts on forests. Impacts of high concern include effects on areas of high conservation value and biodiversity (Evans et al., 2013; Pelkmans et al., 2014; Olesen et al., 2016; Cornwall, 2017; Costanza et al., 2017; Dale et al., 2017), and effects on air quality that raise environmental justice concerns (Ketcham, 2021). Furthermore, political support, which can be essential in the event of a disturbance, can be influenced by public opinion. Hence there is a need to increase public engagement when working out sustainable paths to address renewable energy needs using woody biomass for energy (IEA, 2017). Empirical evidence shows pellet demand can be met in a way that supports healthy forest ecosystems (Dale et al., 2017). Designing sustainable landscapes to support production of woody pellets depends on stakeholder participation, effective communication, transparency and trust, timely monitoring, and continuous improvement (Dale et al., 2019).

The experience of the COVID-19 pandemic demonstrates that the SE pellet supply chain can be maintained despite a major global economic disruption. Further, there is some evidence to suggest that supply chain actors were able to weather the pandemic without compromising environmental integrity, as documented by the continuation of training activities and inspections to protect water quality and improve forest management, as well as financial and logistical support for increasing conservation of priority wetland and forest ecosystems (Enviva, 2020b). The pellet industry creates a market for low-value stems, residues, and roundwood (where demand is otherwise weak), which can facilitate better forest management, such as reducing the practice of slash burning to dispose of unmerchantable biomass. Markets for products made from low-value wood provide extra income (Malmsheimer and Fernholz, 2015) that can be used for improved management. Pre-commercial forest thinning activities decrease the risks of insect outbreaks, disease, and destructive wildfire (Coppoletta et al., 2016) and are supported by local biomass-for-energy markets. The management of forest resources for this supply chain is aligned with the United States Department of Agriculture’s climate strategy, which includes specific goals to partner with forest landowners to reduce net GHG emissions, promote sustainable bioenergy, and enable climate-smart economic development in rural communities (USDA, 2021). The management and market-related attributes of the pellet industry can bolster forest and woody biomass supply resilience.

Recommendations

Stakeholders who play a key role in the supply chain are the primary audience for recommendations that identify lessons and opportunities for sustainable bioenergy to play an appropriate role, not only in recovery plans, but also under future crisis conditions (IEA Bioenergy T43, 2020). In the SE United States, key stakeholders include investors, forest managers, and supply chain actors depicted in Figure 1.

Based on this review of the experiences with COVID-19 to date, future resilience of the SE United States pellet supply chain can likely be increased by the following activities:

• Establishing trade schools for the specialized skills required in the SE forest sector, not just in mill operation and maintenance, but also in planning, construction, and maintenance of forest roads, fire breaks, and prescribed burns;

• Increasing localized capacities to provide services specializing in logistics and trucking;

• Investing in innovation and systematic, continual, improvements in procedures, technologies, and equipment that protect workers, public health, and the environment;

• Ensuring continued support of the policies that provide a safety net when required, such as the financial stimulus programs that helped the sector successfully endure the impacts of the pandemic;

• Encouragement of long-term contracts that maintain consistency in demand for woody pellets;

• Ongoing communications to help stakeholders understand the variables that impact forest conditions and services of interest to them, including factors affecting risks and resilience of economic operations.

• Plans, investment activities, and other interventions sponsored by actors in the supply chain, especially those that affect forest resources, local jobs, worker health, and community resources; shared in a timely manner with stakeholders.

The SE pellet supply chain can play a role in global economic recovery from the COVID-19 pandemic. Lessons learned from the resilience of the supply chain offer insights for other systems that were more seriously affected by the pandemic. Climate change, weather extremes, changes in disturbance regimes, and other unforeseen events are likely to become more frequent over coming decades.

Author Contributions

KK: conceptualization. KK, VD, and ER: analysis and investigation. VD: writing—preparation and organization with contributions from KK and ER. ER and KK: project administration and funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

KK’s contribution was supported by the United States Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE), Bioenergy Technologies Office (BETO), under award number EE0007088 to ORNL. ORNL is managed by the UT-Battelle, LLC, for DOE under contract DE-AC05-00OR22725. Contributions of VD and ER were partially supported by International Energy Agency (IEA) Bioenergy Technology Collaboration Program, Task 43: Sustainable Biomass Supply Integration for Bioenergy within the Broader Bioeconomy. The University of the Sunshine Coast (ABN 28 441 859 157), Sippy Downs, Queensland, Australia, manages and administers funding on behalf of IEA Bioenergy Task 43.

Conflict of Interest

ER and VD received partial support from ThreeCubed, a registered non-profit research group based in Knoxville, TN, United States. ThreeCubed was contracted by IEA Bioenergy to support this study.

The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

We would like to thank Henrietta Jager, Kyla Cheynet, and Thomas Schuler for helpful comments on prior versions of this manuscript. We would also like to thank collaborators in IEA Bioenergy—particularly Jim Spaeth, Bruno Gagnon, Jean Blair, and Mark Brown—for support and guidance.

Footnotes

- ^ †Copyright Notice: This manuscript has been authored in part by UT-Battelle, LLC, under contract DE-AC05-00OR22725 with the United States Department of Energy (DOE). The United States government retains and the publisher, by accepting the article for publication, acknowledges that the United States government retains a non-exclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States government purposes. DOE will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan).

References

Abt, K. L., Abt, R. C., Galik, C. S., and Skog, K. E. (2014). Effect of policies on pellet production and forests in the US South. Asheville, NC, USA: USDA Forest Service Southern Research Station.

Aguilar, F. X., Mirzaee, A., McGarvey, R. G., Shifley, S. R., and Burtraw, D. (2020). Expansion of US wood pellet industry points to positive trends but the need for continued monitoring. Sci. Rep. 10:18607. doi: 10.1038/s41598-020-75403-z

Alderman, D., and Buehlmann, U. (2020). The Virginia Tech–USDA Forest Service Housing Commentary. Blacksburg, Virginia: Virginia Tech.

Amiti, M., Redding, S. J., and Weinstein, D. E. (2020). Who’s paying for the US tariffs? A longer-term perspective. AEA Pap. Proc. 110, 541–546. doi: 10.1257/pandp.20201018

Angeler, D. G., Allen, C. R., Garmestani, A., Pope, K. L., Twidwell, D., and Bundschuh, M. (2018). Resilience in environmental risk and impact assessment: concepts and measurement. Bull. Environ. Contam. Toxicol. 101, 543–548. doi: 10.1007/s00128-018-2467-5

Aven, T., and Bouder, F. (2020). The COVID-19 pandemic: how can risk science help? J. Risk Res. 23, 849–854. doi: 10.1080/13669877.2020.1756383

Baker, S., and Mendell, B. (2020). Wood supply chain impacts from the Coronovirus pandemic: regional analysis and a case study. Forisk Res. Q. 4, 8–11.

Barry, J. (2018). The Great Influenza: The Story of the Deadliest Pandemic in History. New York: Penguin Books.

Biggs, R., Schlüter, M., and Schoon, M. L. (2015). Principles for Building Resilience: Sustaining Ecosystem Services in Social-Ecological Systems. Cambridge, UK: Cambridge University Press.

Birol, F. (2020). Biofuture Platform Launches Five Principles For Post-Covid Bioeconomy Recovery And Acceleration. Brazil: Biofuture platform.

Brandeis, C., and Abt, K. L. (2019). Roundwood use by southern wood pellet mills: findings from timber product output mill surveys. J. For. 117, 427–434. doi: 10.1093/jofore/fvz042

Brandeis, C., and Guo, Z. (2016). Decline in the pulp and paper industry: effects on backward-linked forest industries and local economies. For. Prod. J. 66, 113–118. doi: 10.13073/FPJ-D-14-00106

Brandeis, C., Taylor, M., Abt, K. L., Alderman, D., and Buehlmann, U. (2021). Status and trends for the U.S. forest products sector: a technical document supporting the Forest Service 2020 RPA Assessment. USDA Forest Service Southern Research Station Technical Report SRS–258. Asheville, NC: U.S. Department of Agriculture Forest Service, Southern Research Station, doi: 10.2737/SRS-GTR-258

Coppoletta, M., Merriam, K. E., and Collins, B. M. (2016). Post-fire vegetation and fuel development influences fire severity patterns in reburns. Ecol. Appl. 26, 686–699. doi: 10.1890/15-0225

Cornwall, W. (2017). Is wood a green source of energy? Scientists are divided. Science 355, 18–21. doi: 10.1126/science.aal0574

Costanza, J. K., Abt, R. C., McKerrow, A. J., and Collazo, J. A. (2017). Bioenergy production and forest landscape change in the southeastern United States. GCB Bioenergy 9, 924–939. doi: 10.1111/gcbb.12386

Dale, V. H., Kline, K. L., Parish, E. S., Cowie, A. L., Emory, R., Malmsheimer, R. W., et al. (2017). Status and prospects for renewable energy using wood pellets from the southeastern United States. Glob. Change Biol. Bioenergy 9, 1296–1305. doi: 10.1111/gcbb.12445

Dale, V. H., Kline, K. L., Parish, E. S., and Eichler, S. E. (2019). Engaging stakeholders to assess landscape sustainability: experiences and insights. Landsc. Ecol. 34, 1199–1218. doi: 10.1007/s10980-019-00848-1

Dempsey, H. (2020). Wind Power Boom Under Threat As Coronavirus Hits Supply Chains. Bracken House: Financial Times.

Dezember, R. (2021). Lumber Prices Break New Records, Adding Heat To Home Prices. New York City: Wall Street Journal.

Drax. (2020). Pellet production. Available Online at: https://www.drax.com/ (accessed January 26, 2021).

Drew, J. (2020). Covid-19 Relief Bill Addresses Key Ppp Issues. Available Online at: https://www.journalofaccountancy.com/news/2020/dec/COVID-19-relief-bill-addresses-key-ppp-issues.html (accessed February 26, 2021).

Duden, A. S., Verweij, P. A., Junginger, H. M., Abt, R. C., Henderson, J. D., Dale, V. H., et al. (2017). Modeling the impacts of wood pellet demand on forest dynamics in southeastern United States. Biofuels Bioprod. Biorefin. 11, 1007–1029. doi: 10.1002/bbb.1803

Elleby, C., Dominguez, I. P., Adenauer, M., and Genovese, G. (2020). Impacts of the COVID-19 pandemic on the global agricultural markets. Environ. Resour. Econ. 76, 1067–1079. doi: 10.1007/s10640-020-00473-6

Enviva. (2020a). Enviva Reported Limited Covid-19 Impact In Uncertain Environment Reaffirms Full-Year Distribution Guidance And Confirms Strong Liquidity Position. San Francisco: Business Wire.

Enviva. (2020b). 2020 Impact report. Available Online at: https://test-envivabiomass.pantheonsite.io/wp-content/uploads/2020-Impact-Report.pdf (accessed February 9, 2021).

European Commission. (2021). Renewable energy directive (RED). Available Online at: https://ec.europa.eu/energy/topics/renewable-energy/renewable-energy-directive/overview_en (accessed February 26, 2021).

Evans, J. M., Fletcher, R. J., Alavalapati, J., Calabria, J., Geller, D., Smith, A. L., et al. (2013). Forestry Bioenergy In The Southeast United States: implications For Wildlife Habitat And Biodiversity. Charlottesville, VA: Southern Environmental Law Center.

Executive Order 14008. (2021). Tackling the Climate Crisis at Home and AbroadUnited States Executive Office of the President, 86. Washington DC: Federal Registry, 7619–7633.

Executive Order 14030. (2021). Climate-Related Financial Risk United States Executive Office of the President, 86. Washington DC: Federal Registry, 27967–27971.

Falk, D. A., Watts, A. C., and Thode, A. E. (2019). Scaling ecological resilience. Front. Ecol. Evol. 7:275. doi: 10.3389/fevo.2019.00275

Fatka, J. (2020). Ppp Changes In Covid Relief Bill Offer More Aid For Farmers. St. Charles, Illinois: FarmProgress.

Favero, A., Daigneault, A., and Sohngen, B. (2020). Forests: carbon sequestration, biomass energy, or both? Sci. Adv. 6:eaay6792. doi: 10.1126/sciadv.aay6792

Forisk. (2020). Wood flows and cash flows. Forisk Continuing Education Program. Available Online at: https://woodflowscashflows.com (accessed February 26, 2021).

Forth, K. D. (2021). U.s. Softwood lumber prices jump as exports decline in third quarter. Washington DC: Woodworking Industry News.

Fritsche, U., Brunori, G., Chiaramonti, D., Galanakis, C. M., Matthews, R., and Panoutsou, C. (2021). Bioeconomy opportunities for a green recovery and enhanced system resilience. Industr. Biotech. 17, 134–150. doi: 10.1089/ind.2021.29248.ufr

Gielen, D., Boshell, F., Saygin, D., Bazilian, M. D., Wagner, N., and Gorini, R. (2019). The role of renewable energy in the global energy transformation. Energy Strategy Rev. 24, 38–50. doi: 10.1016/j.esr.2019.01.006

Golan, M. S., Jernegan, L. H., and Linkov, I. (2020). Trends and applications of resilience analytics in supply chain modeling: systematic literature review in the context of the COVID-19 pandemic. Environ. Syst. Decis. 40, 222–243. doi: 10.1007/s10669-020-09777-w

Goodell, J. W. (2020). COVID-19 and finance: agendas for future research. Finance Res. Lett. 35, 101512. doi: 10.1016/j.frl.2020.101512

Hellweg, S., Brunori, G., Galanakis, C., Panoutsou, C., Chiaramonit, D., Fritsche, U., et al. (2020). Future transitions for the bioeconomy towards sustainable development and a climate-neutral economy. European Commission Joint Research Center, Knowledge Synthesis Final Report. City of Brussels: European Union. doi: 10.2760/667966

Henderson, J. E., Joshi, O., Parajuli, R., and Hubbard, W. G. (2017). A regional assessment of wood resource sustainability and potential economic impact of the wood pellet market in the U.S. south. Biomass Bioenergy 105, 421–427. doi: 10.1016/j.biombioe.2017.08.003

Hilmola, O. P., Lahdeaho, O., Henttu, V., and Hilletofth, P. (2020). COVID-19 pandemic: early implications for north European manufacturing and logistics. Sustainability 12:8315. doi: 10.3390/su12208315

Hodges, D. G., Hartsell, A. J., Brandeis, C., Brandeis, T. J., and Bentley, J. W. (2012). Recession effects on the forests and forest products industries of the south. For. Prod. J. 61, 614–624. doi: 10.13073/0015-7473-61.8.614

IEA. (2017). Technology Roadmap - Delivering Sustainable Bioenergy. Paris, France: International Energy Agency.

IEA. (2020). Sustainable recovery. International Energy Agency World Energy Outlook Special Report. Paris, France: IEA.

IEA Bioenergy. (2021b). Technology Collaboration Platform. Available Online at: https://www.ieabioenergy.com/ (accessed June 10, 2021).

IEA Bioenergy. (2021a). Is Energy From Woody Biomass Positive For The Climate? Available Online at: https://www.ieabioenergy.com/iea-publications/faq/woodybiomass/ (accessed February 22, 2021).

IEA Bioenergy T43. (2020). Lessons learned from case studies of response of biomass supply chains to Covid-19 crisis – Activity Proposal Approved by Task 43 on 19 May 2020. [In the author’s possession]. Paris, France: IEA.

IICA. (2020). After a “perfect storm”, bioenergy is offering solutions for post-pandemic recovery. san isidro: Inter-American Institute for Cooperation on Agriculture Press Release.

IRENA. (2020). The post-COVID recovery; An agenda for resilience development and equality. Abu Dhabi: International Renewable Energy Agency.

Iyke, B. N. (2020). COVID-19: the reaction of US oil and gas producers to the pandemic. Energy Res. Lett. 1:13912. doi: 10.46557/001c.13912

Kaplan, G., Moll, B., and Violante, G. L. (2020). The Great Lockdown and the Big Stimulus: tracing the Pandemic Possibility Frontier for the U.S. National Bureau of Economic Research Working Paper Series (27794). Cambridge, Massachusetts: National Bureau of Economic Research. doi: 10.3386/w27794

Ketcham, C. (2021). Forests to burn: the biomass-energy industry is a climate and environmental justice disaster. Available Online at: https://www.sierraclub.org/sierra/2021-1-january-february/protect/forests-burn (accessed February 26, 2021).

Kittler, B., Stupak, I., and Smith, C. T. (2020). Assessing the wood sourcing practices of the U.S. industrial wood pellet industry supplying European energy demand. Energ. Sustain. Soc. 10:23. doi: 10.1186/s13705-020-00255-4

Kline, K. L., Dale, V. H., Rose, E., and Tonn, B. (2021). Effects of production of woody pellets in the southeastern United States on the Sustainable Development Goals. Sustainability 13:821. doi: 10.3390/su13020821

Maliszewska, M., Mattoo, A., and van der Mensbrugghe, D. (2020). The potential impact of COVID-19 on GDP and trade: a preliminary assessment. In: world Bank Research Working Paper 9211. Washington, DC: World Bank.

Malmsheimer, R. W., and Fernholz, K. (2015). How laws, practices, and markets ensure sustainable forest biomass feedstocks from the southeast US. World Biomass 2015–2016. York, UK: DCM Productions, 8–12.

Morgan, T. A., and Hayes, S. W. (2021). Lumber prices skyrocket during pandemic: costs Soar Amid Construction and Remodeling Boom. Montana Business Q. 59, 22–26.

National Association of State Foresters. (2015). Best management practices. Available Online at: https://www.stateforesters.org/bmps/ (accessed February 26, 2021).

National Conference on State Legislatures (NCSL). (2020b). State Renewable Portfolio Standards and Goals. Available Online at: https://www.ncsl.org/research/energy/renewable-portfolio-standards.aspx (accessed January 02, 2021).

National Conference on State Legislatures (NCSL). (2020a). COVID-19: essential workers in the states. Available Online at: https://www.ncsl.org/research/labor-and-employment/COVID-19-essential-workers-in-the-states.aspx (accessed January 26, 2021).

Norgaard, R. B., Wiens, J. A., Brandt, S. B., Canuel, E. A., Collier, T. K., Dale, V. H., et al. (2021). Preparing for a fast-forward future in the Sacramento-San Joaquin Delta. San Francisco Estuary Watershed Sci. 19:2. doi: 10.15447/sfews.2021v19iss2art2

Olesen, A. S., Kittler, B., Price, W., and Aguilar, F. X. (2016). Environmental Implications of Increased Reliance of the EU on Biomass from the South East US. European Commission Report ENV.B.1/ETU/2014/0043. Brussels, Belgium: Publications Office of the European Union, doi: 10.2779/30897

Padhan, R., and Prabheesh, K. P. (2021). The economics of COVID-19 pandemic: a survey. Econ. Anal. Policy 70, 220–237. doi: 10.1016/j.eap.2021.02.012

Parish, E. S., Dale, V. H., Kline, K. L., and Abt, R. C. (2017). Reference scenarios for evaluating wood pellet production in the southeastern United States. WIREs Energy Environ. 6:e259. doi: 10.1002/wene.259

Pelkmans, L., Goh, C. S., Junginger, H. M., Parhar, R., Bianco, E., Pellini, A., et al. (2014). Impact of Promotion Mechanisms for Advanced and Low-iLUC Biofuels on Biomass markets: Summary Report. IEA Bioenergy Task 40. Paris, France: IEA, doi: 10.13140/RG.2.1.4624.5925

Plieninger, T., and Bieling, C. (2012). Resilience and the Cultural Landscape: Understanding and Managing Change in Human-Shaped Environments. UK: Cambridge University Press.

Riddle, A. (2020). COVID-19 and the U.S. Timber Industry. Congressional Research Service Report 46636. Available Online at: https://www.everycrsreport.com/reports/R46636.html (accessed June 15, 2021).

Simonsen, S. H., Biggs, R., Schlüter, M., Schoon, M., Bohensky, Cundill, G., et al. (2016). Applying Resilience Thinking: Seven Principles for Building Resilience in Social-ecological systems. Stockholm, Sweden: Stockholm Resilience Centre.

Suneson, G. (2021). 25 Most Dangerous Jobs in America. Available Online at: https://247wallst.com/special-report/2021/01/08/25-most-dangerous-jobs-in-america-4/ (accessed February 22, 2021).

TimberMart-South (2021). Southwide average prices (2000-2020). Available Online at: http://www.timbermart-south.com/prices.html (accessed February 22, 2021).

US BLS (2021a). Employment, Hours, and Earnings From the Current Employment Statistics Survey (National). Washington DC: US Unemployment Rate source.

US BLS (2021b). Bureau of Labor Statistics, Economic News Release, 05 Feb 2021. The Employment Situation. Washington, DC: U.S. BUREAU OF LABOR STATISTICS.

US Census Bureau (2021). Household Pulse Survey Data Tables. Available Online at: https://www.census.gov/programs-surveys/household-pulse-survey/data.html (accessed February 10, 2021).

US Congress (2019–2020). H.R.133 – Consolidated Appropriations Act. 116th Congress. Available Online at: https://www.congress.gov/bill/116thcongress/house-bill/133 (accessed February 26, 2021).

United States Department of Homeland Security, Cybersecurity and Infrastructure Security Agency (CISA) (2020). Guidance on the Essential Critical Infrastructure Workforce: ensuring Community and National Resilience in COVID-19 Response. Available Online at: https://www.cisa.gov/sites/default/files/publications/ECIW_4.0_Guidance_on_Essential_Critical_Infrastructure_Workers_Final3_508_0.pdf (accessed February 26, 2021).

US Energy Information Administration (EIA) (2021). Monthly Densified Biomass Fuel Report, Data Archive Form EIA-63C. Available Online at: https://www.eia.gov/biofuels/biomass/ (accessed June 18, 2021).

USDA (2020). Foreign Agricultural Service Searchable Database. Available Online at: https://apps.fas.usda.gov/Gats/default.aspx (accessed February 26, 2021).

USDA. (2021). US Department of Agriculture Climate 21 Project. Available Online at: https://climate21.org/usda/ (accessed February 24, 2021).

van Soest, H. L., den Elzen, M. G. J., and van Vuuren, D. P. (2021). Net-zero emission targets for major emitting countries consistent with the Paris Agreement. Nat. Commun. 12:2140. doi: 10.1038/s41467-021-22294-x

Visser, L., Hoefnagels, R., and Junginger, M. (2020). Wood pellet supply chain costs: a review and cost optimization analysis. Renew. Sustain. Energy Rev. 118:109506. doi: 10.1016/j.rser.2019.109506

Watts, J., and Ambrose, J. (2020). Coal Industry Will Never Recover After Coronavirus Pandemic, Say Experts. London, United Kingdom: The Guardian

Woolhandler, S., Himmelstein, D. U., Ahmed, S., Bailey, Z., Bassett, M. T., and Bird, M. (2021). Public policy and health in the Trump era. Lancet 397:705–753. doi: 10.1016/S0140-6736(20)32545-9

World Health Organization (WHO) (2021). WHO Coronavirus (COVID-19) Dashboard. Available Online at: https://covid19.who.int/ (accessed June 14, 2021).

Keywords: bioenergy, COVID-19, pandemic, resilience, forestry, supply chain, densified biomass fuel, woody pellets

Citation: Kline KL, Dale VH and Rose E (2021) Resilience Lessons From the Southeast United States Woody Pellet Supply Chain Response to the COVID-19 Pandemic. Front. For. Glob. Change 4:674138. doi: 10.3389/ffgc.2021.674138

Received: 28 February 2021; Accepted: 21 July 2021;

Published: 11 August 2021.

Edited by:

Steven George Mcnulty, USDA Southeast Climate Hubs, United StatesReviewed by:

Svetlana Proskurina, Lappeenranta University of Technology, FinlandMark Andrew Adams, Swinburne University of Technology, Australia

Copyright © 2021 Kline, Dale and Rose. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Keith L. Kline, a2xpbmVrbEBvcm5sLmdvdg==

Keith L. Kline

Keith L. Kline Virginia H. Dale

Virginia H. Dale Erin Rose3

Erin Rose3