- Ningbo Municipal Center for Disease Control and Prevention, Ningbo, China

Introduction: To investigate the major existing occupational hazards and to assess the occupational health risks for ferrous metal foundries (FMFs) in Ningbo, China.

Methods: Unified questionnaires were formulated to investigate the information on the basic situations, occupational hazards, and occupational health management for 193 FMFs in Ningbo. Furthermore, we used the semi-quantitative risk assessment model, which was developed by the International Council on Mining and Metals (ICMM), to assess occupational health risks for 59 of 193 the FMFs.

Results: The casting process of FMFs in Ningbo was mainly divided into sand casting and investment casting, and silica-dust and noise were the major occupational hazards in both sand casting and investment casting foundries. Silica-dust mainly occurred in industries with such work as sand handling, modeling, falling sand, and sand cleaning, with the median of the permissible concentration-time weighted average (PC-TWA) was 0.80, 1.15, 3.52, 0.83 mg/m3, respectively. The noise mainly existed in industries with such work as sand handling, core making, falling sand, sand cleaning, cutting and grinding, and smelting with median of PC-TWA was 81.72 dB(A), 82.93 dB(A), 90.75 dB(A), 80.18 dB(A), 90.05 dB(A), 82.70 dB(A), respectively. In addition, the results of the ICMM assessment model indicated that 100 and 98.7% of the jobs exposed to silica-dust and noise in 59 FMFs have an “intolerable risk” level of risks of causing pneumoconiosis and noise deaf, respectively.

Discussion: The hazard risk of silica-dust and noise is serious for FMFs in Ningbo. It is necessary to supervise enterprises to improve operating environmental conditions, accelerate the reduction of silica-dust and noise exposure risks, and promote the healthy and sustainable development of the foundry industry.

Introduction

As the largest developing country, China is experiencing one of the worst occupational health problems in the world and faced with more severe threats and challenges induced by occupational hazardous factors than most other countries. Over 200 million workers from at least 20 million enterprises are at risk of occupational diseases in China (1). It is estimated that at least one million subjects suffered from occupational diseases (OD) with nearly 30,000 newly diagnosed cases per year over the past decade, leading to a considerable burden on the society (2). The increase in OD incidence in China, in large part, is ascribed to serious occupational hazards in workplace, such as silica-dust and noise, and inadequate personal protective equipment (3).

Ningbo is an economic center of Zhejiang Province, which is also a coastal city with a population over than 9 million, with a high level of economic development comparing to the general situation of China (GDP per capita in 2021 $2,3846 vs.$1,2462) (4). With the rapid growth of social economy, the foundry industry has developed rapidly and has become a pillar industry in Ningbo (5). However, FMFs are one of the industries with serious dust hazards, and the newly diagnosed cases of pneumoconiosis in Ningbo in recent years were concentrated in this industry (6). Currently, 20% of newly diagnosed occupational hearing loss was observed in this industry, according to the investigation by Zhejiang Provincial Center for Disease Control and Prevention (7). Due to regulatory and legal measures, more and more companies and organizations give attention to employee health and safety, try to control occupational hazards, and seek to improve the level of worker safety (8, 9).

Occupational Health and Safety (OHS), defined as the science of the anticipation, recognition, evaluation and control of hazards arising in or from the workplace that could impair the health and wellbeing of workers, is an important issue for both employees and employers (10–12). As one critical process in OHS practice, occupational health risk assessment (OHRA) is an effective tool to assess the risk of occupational hazards in workplace and take required control measures for providing safety (13, 14). Developed countries and international organizations have developed several OHRA methods, including the models from the United States Environmental Protection Agency (EPA) (15), the United Kingdom's Control of Substances Hazardous to Health Essentials (COSHH Essentials) (16), Australia (17), Romania (18), the International Council on Mining and Metals (ICMM) (19), and Singapore (20). The ICMM model was used to evaluate the occupational health risk in this study mainly attributing to several reasons: first, the model has a broad scope of evaluated substances; second, the model could be applied to various industries, including ferrous metal casting industry; third, the model was based on qualitative or subjective descriptions, and less detailed information was required for use (13).

According to Ningbo Municipal Statistics Bureau, there were ~267 FMFs with over workers until June 2020 (5). It is necessary to understand the characteristics of occupational hazards in the main positions of the FMFs and evaluate the corresponding occupational hazard risks to provide a scientific basis for formulating policies of occupational disease prevention and control.

The primary purpose of this study was to investigate the exposure characteristics and occupational health risks of silica-dust and noise, and provide a basis for developing reasonable control measures to reduce the health risks for workers. Accordingly, the following two step were conducted successively: (1) occupational hygiene survey and field investigation for normally operating ferrous metal foundries (FMFs); (2) assess occupational health risk by using the model developed by ICMM.

Methods

Description of Ferrous metal casting industry

Ferrous metal casting industry, one of the most important foundry industries in Ningbo, is the process of smelting iron and steel metal into a liquid that meets certain requirements and pouring it into a mold, in order to obtain castings of predetermined shape, size, and properties, after cooling, solidification, and cleaning (21). Currently, commonly used process flow of casting including sand casting, investment casting, pressure casting and centrifugal casting, etc., (21). The process flow of sanding casting and investment casting were selected for this study. The inherent risk (IR) of ferrous metal casting industry was directly obtained from a normative document, Catalog of Classification and Management of Occupational Disease Hazard Risks in Construction Projects, formulated by the National Health Commission of China (22). Based on the document, the occupational hazards are assigned a level of risk according to the advice and consultation of China's top occupational health experts. Accordingly, the IR level of ferrous metal casting industry was classified as “severe” in this study. In addition, the enterprises classification standard was formulated by the National Bureau of Statistics of China (23).

Occupational hygiene survey

Questionnaires were used to investigate the basic information of FMFs, including enterprise size, production process, job setting, and etc. For occupational health management information, engineering protection facilities, personal protective equipment and occupational hygiene management system formulation and implementation, and etc. were investigated. In order to maintain the quality of the survey, we formulated unified questionnaire, compiled survey operation technical manuals, and conducted technical training for investigators. In this study, the field measurements and interviews were performed by experts who had title of associate chief physician or senior engineer.

Identification of occupational hazardous factors

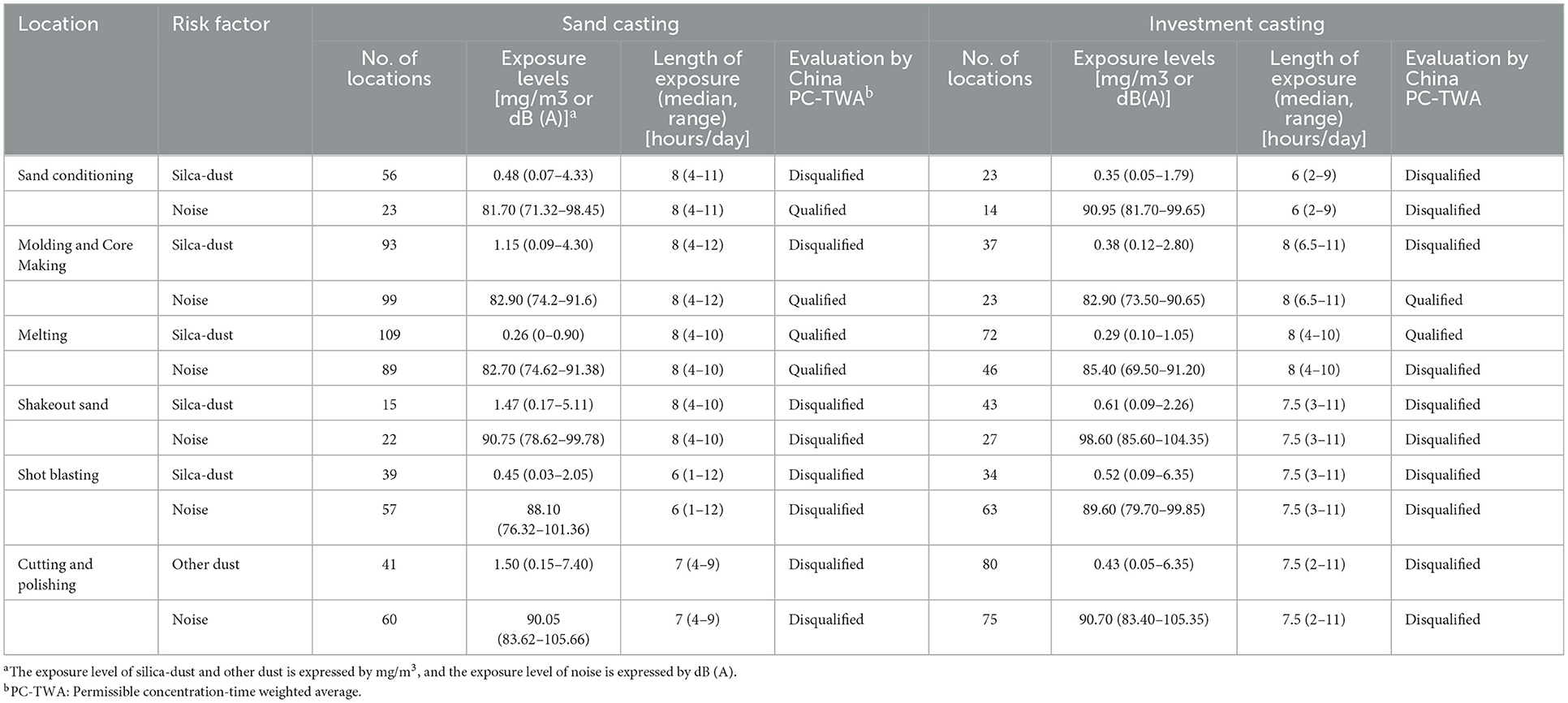

Occupational hazardous factors were determined through field investigation, air sampling, and laboratory tests based on two occupational health standards in China, that is, the “Specifications of air sampling for hazardous substances monitoring in the workplace (GBZ 159)” and “Determination of toxic substances in workplace air (GBZ/T 160 and 300).” The levels of occupational hazards in FMFs were qualified by using the Chinese Occupational Exposure limits for Hazardous Agents in Workplace (GBZ 2.1-2019). Onsite measurement of noise was conducted according to the standard “The physical factor measurement in the workplace (GBZ/T189.8-2007).” The exposure levels of silica-dust and noise at various locations in the sand conditioning, molding and core making, melting, shakeout sand, shot blasting, and cutting and polishing had different degrees of exceed the permissible concentration time weighted average (PC-TWA) permitted by China. The evaluation of silica-dust and noise was based on the PC-TWA. “Qualified” or “Disqualified” was equal to the exposure level of risk factor not exceed the standard of PC-TWA or exceed the standard of PC-TWA, respectively. For silica-dust, the PC-TWA by China was 0.3 mg/m3 for free SiO2 content higher than 50% and lower than 80%, according to GBZ 2.1-2019. The permissible level of noise was 85 dB(A), according to GBZ 189.8-2007.

Methodology for the ICMM model

The ICMM model was based on two factors: the inherent harmful consequences and their probability of occurrence, which were evaluated by four procedures step by step: hazard identification, hazard characterization, exposure assessment, and risk characterization. The detailed principles of the ICMM model were reported in previous publication (19). The ICMM model applies a matrix method to evaluate risk levels, including matrix combinations of health hazards and the probability of exposure occurring in a similar exposure group or process, as well as matrix combinations of health hazards and exposure levels with existing control measures.

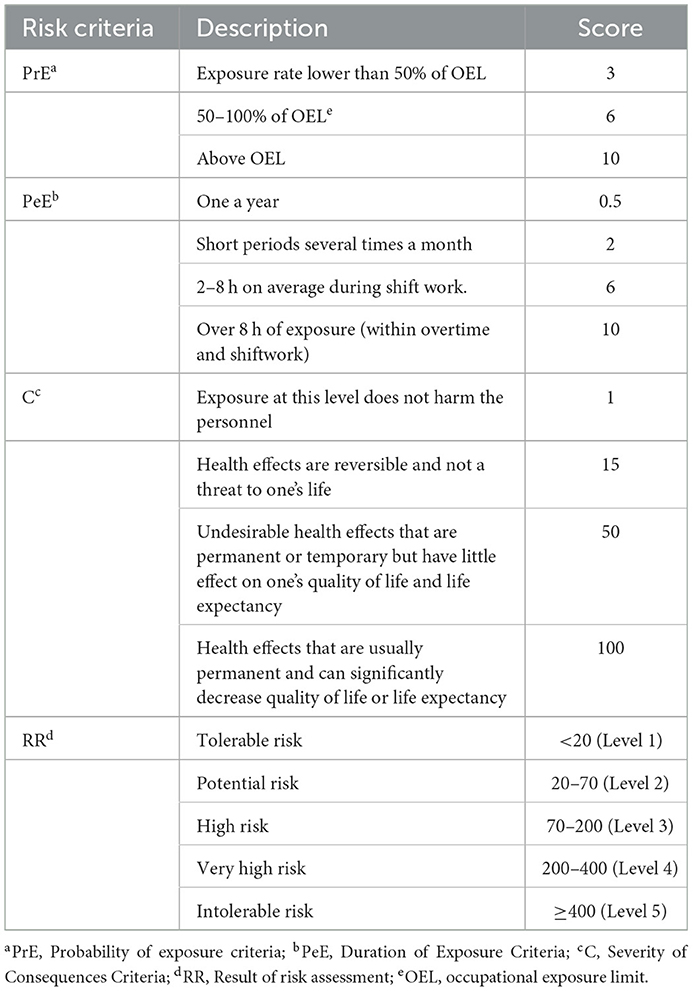

In this equation, RR is the risk ratio; C is level of occupational hazard health consequences; PrE is the probability of exposure, based on the ratio of the exposure level (E) and occupational exposure limit (OEL); PeE is the length of exposure; U is uncertainty factor. The result of ICMM model (RR) was also converted into a classification of five risk levels, which could vary from 1 to 5: Level 1, RR < 20 represents a tolerable risk; Level 2, RR ranges from 20 to 70, which represents a potential risk; Level 3, RR ranges from 70 to 200, which represents a high risk; Level 4, RR ranges from 200 to 400, which represents a very high risk; Level 5, RR greater or equal to 400 represents an intolerable risk. Risk scoring for risk criteria is showed in Table 1. In this study, quantitative risk assessment was performed by statisticians who had background of medical or public health, and examined by experts subsequently.

Briefly, the process of performing the ICMM model had two phases in the current study. The first phase was identification of risk criteria. According to previous investigations and publications, three risk criteria were considered for this method, which included the probability of exposure to hazardous factors (PrE), the duration of exposure criteria (PeE), and the severity of consequence (C).

The second phase was determining the risk scoring system and risk level. To rate this criterion for PrE, control measures for any potential hazard are required to be assessed directly or indirectly. In direct assessments, the exposure level needs to be measured and compared with the standards. In indirect assessments, documents of recent measurements can be used. If the exposure rate was lower than 50% of occupational exposure limit (OEL), the corresponding score was three points. If the exposure rate was between 50 and 100% of OEL, the corresponding score was 6 points. While if the exposure rate was over the OEL, the corresponding score was 10 points. For the duration of exposure criteria, the exposure duration criterion was set at 4 levels: one a year, short periods several times a month, 2–8 h on average during shift work, and over 8 h of exposure (within overtime and shiftwork), which were equal to scores of 0.5, 2, 6, 10 points, respectively. For severity of consequence, the score of 4 levels was 1, 15, 50, 100 points, which represents exposure at this level does not harm the personnel, health effects are reversible and not a threat to one's life, undesirable health effects that are permanent or temporary but have little effect on one's quality of life and life expectancy, and health effects that are usually permanent and can significantly decrease quality of life or life expectancy, respectively. Finally, the equation “RR = C × PrE × PeE × U” was used to calculate the RR.

Statistical analysis

Results are presented as median and interquartile range (IQR) for continuous data under biased distribution and categorical data. We performed a logarithmic conversion for the concentration of silica-dust before statistical analysis in this study. Exposure time and exposure concentration are also showed as median (range). The permissible concentration time weighted average (PC-TWA) was used to assess if the exposure level of silica-dust and noise exceed the standard in the current study. The ANOVA and LSD-test were used to analyze the differences between different tasks for silica-dust and noise. EpiData 3.1 was used to compile the database and input the data of occupational hygiene survey. All statistical analyses were calculated by SAS version 9.4 (SAS Institute, Cary, NC, USA).

Results

Basic information of FMFs in Ningbo

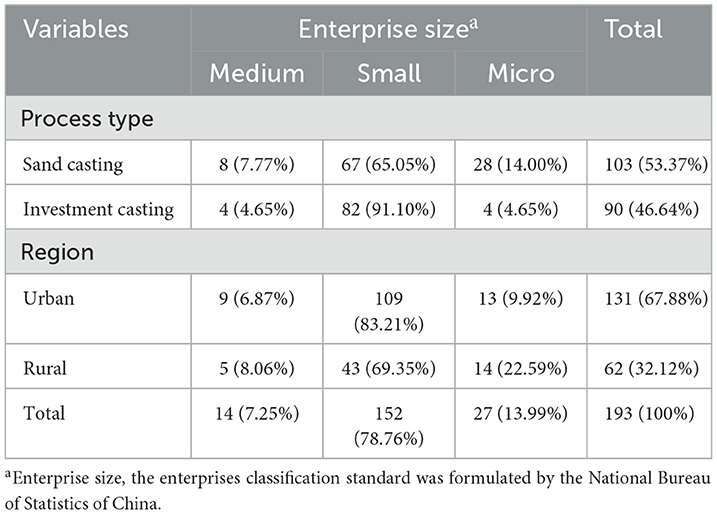

Finally, a total of 193 FMF were included in this study (Table 2). They comprised 14 (7.25%) medium enterprises, 152 (78.75%) small enterprises, and 27 (14.00%) micro enterprises. For process type, there were 103 (53.37%) sand casting foundries and 90 (46.64%) investment casting foundries in the present study. Besides, most of FMFs in Ningbo (131, 67.88%) were located in urban area.

We observed that silica-dust and noise were the main occupational hazards for the 193 FMFs of Ningbo in the occupational hygiene survey. Sand conditioning, molding and core making, melting, shakeout sand, shot blasting, and cutting and polishing were key locations, which were exposed to the silica-dust and noise.

Characteristic of occupational hazards

Table 3 shows the key locations and exposure level of silica-dust by different process type. The levels of silica-dust from the majority of location were disqualified both for sand casting foundries and investment casting foundries. For noise, we observed that the levels of noise were qualified from sand conditioning, molding and core making, and melting in sand casting foundries and melting in investment casting foundries. For different locations, the exposure level of silica-dust in shakeout sand was higher than other location (P < 0.05) in both sand casting foundries and investment casting foundries. Besides, the exposure level of noise in shakeout sand was also higher than other location (P < 0.05).

Results of occupational risk assessment

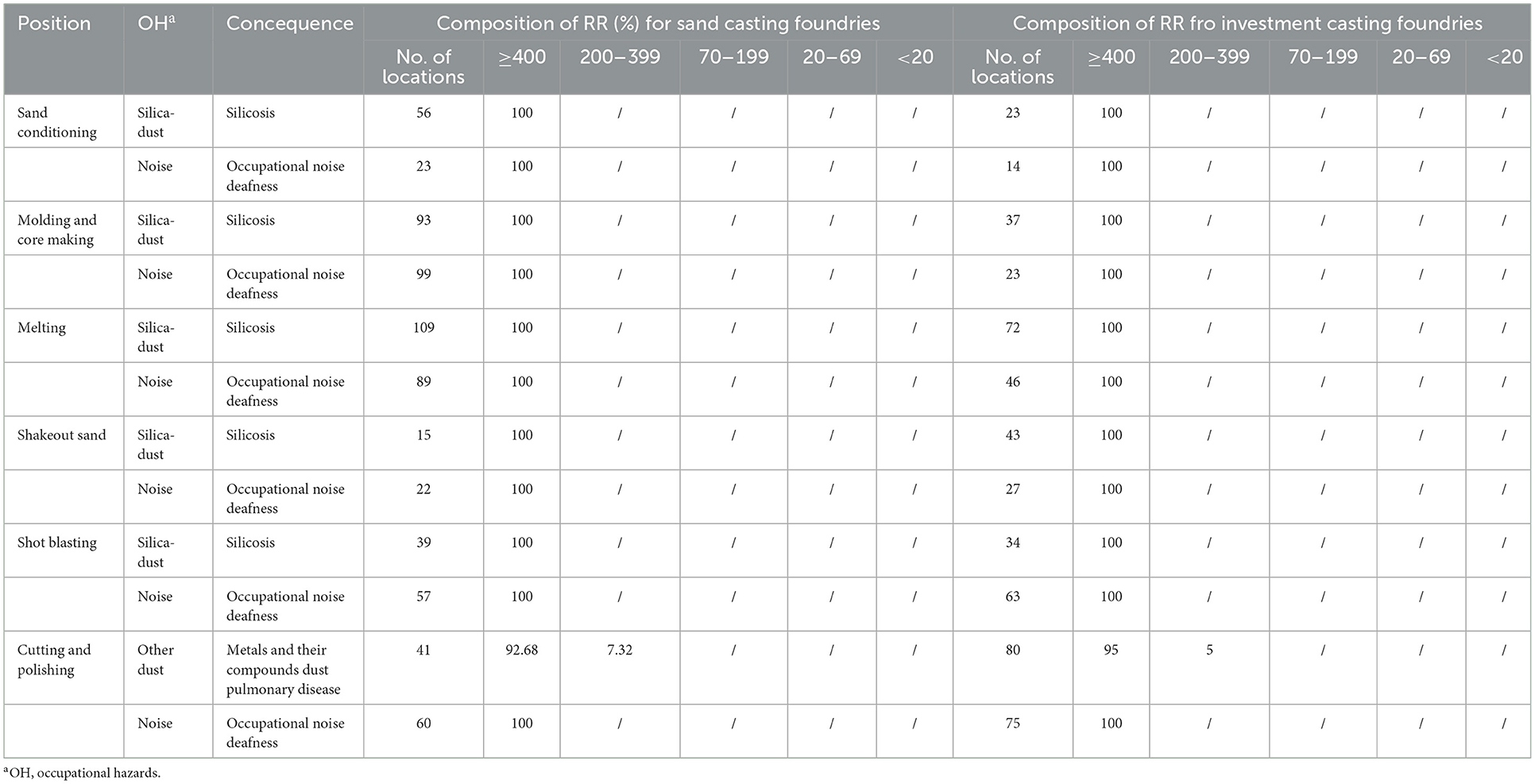

In Table 4, we observed that the RRs for silica-dust in the positions of sand conditioning, molding and core making, melting, shakeout sand, and shot blasting were all greater or equal to 400, which represented that workers were exposed to intolerable health risk of silica-dust in the workplace. The RR for 7.32% of No. cutting and polishing was between 200 and 400, which represented very high risk of silica-dust exposure in the workplace. For noise, the RRs in all positions were also greater or equal to 400, which represented that workers were exposed to an intolerable health risk of noise in the workplace.

Table 4. Composition of risk ratios (RRs) of different positions for sand casting foundries and investment casting foundries.

Discussion

In this study, most of the ferrous metal foundries in Ningbo were small and micro enterprises, which was in accordance with the distribution of previous studies in other cities. This might be related to the overall distribution of enterprises in China. At present, most of FMFs in China are small enterprises, because small enterprises are the main force of development. Besides, it might also be related to the small investment, low cost and flexible operation required by small foundry enterprises.

Silica-dust is the most common occupational hazard in the foundry industry. Silica-dust is one of the most harmful to human health, and the occupational exposure limit (OEL) is the lowest among all dusts. Silicosis caused by silica dust accounts for the largest proportion of pneumoconiosis and is the most harmful. In this study, the dust excess rate of all FMFs, sand casting foundries, and investment casting foundries in Ningbo was 40.61, 37.97%, and 44.11, respectively. However, we found no statistical significant difference between casting process and dust excess rate, which was similar to the previous study (24). The silica dust concentration rate of the main positions was lower than 40%, which was significantly lower than the Shanghai (25) and Jiangsu Province (26). This might be related to the transformation and upgrading of the foundry industry in Ningbo in 2014 (27). Besides, the concentration of silica-dust in sand casting foundries is higher than that in investment casting foundries, which is partly due to the relatively large castings of sand casting technology enterprises, the large amount of sand used, and the poor effectiveness of dust protection facilities (5). The concentration of silica-dust in the shakeout sand of sand casting is higher than that of the sand conditioning and shot blasting. This may be due to the completeness of protective facilities in the shakeout sand is lower than that in the sand conditioning and shot blasting (28). In addition, artificial hammers are usually used to shake the sand and vibrating sand machines are used to shake the sand in the process of shakeout sand, which lead to a serious dust escape, and finally, it is difficult to be effectively captured by local ventilation and dust removal facilities (29).

Silica in foundry dust not only causes silicosis, Gabriella et al. found in a study of two cases of accelerated silicosis that respirable silica could enter the liver and cause granulomas and liver involvement (30). Vihlborg et al. (31) in Sweden In the Iron Foundry Occupational Silica Exposure Risk Study, moderate to high exposure to respirable silica was associated with an increased risk of sarcoidosis and seropositive rheumatoid arthritis. Andjelkovich et al. (32) found that gastric cancer in foundry workers may be associated with respirable silica exposure. In addition to high silica content, foundry dust also contains a certain amount of carcinogenic cadmium, chromium, nickel, etc. and their compounds, as well as other chemically harmful components such as binders and curing agents (33). Studies have shown that these harmful components Causes respiratory and lung inflammation more closely than respirable silica.

In this study, the overall noise exceeding rate of FMFs in Ningbo was 54.47%, among which the noise exceeding rate of sand casting foundries and investment casting foundries were 45.69 and 64.86%, respectively, with the average noise intensity 85.07 and 83.92 dB(A), respectively. The overall noise exceeding rate of sand casting foundries in Ningbo is lower than that in Zhangjiagang City (34), and higher than that of foundry enterprises in Shanghai (25) and Jingjiang City (35). In this study, statistically significant difference was observed between the noise exceeding rate of the sand casting foundries and investment casting foundries, which indicated that FMFs should strengthen noise management, reduce noise pollution, and avoid hearing fatigue or even occupational noise deafness, especially for those adopting the investment casting process. Noise-induced hearing loss is sensory deafness caused by prolonged exposure of the auditory system to a noisy environment (36). Auditory fatigue is an early symptom of noise-induced hearing loss, and hearing can gradually recover after people leave the noisy environment. Prior studies observed that occupational noise exposure is associated with permanent hearing loss (37). The NIH reported that nearly 20 million workers are regularly exposed to noise, of which 50% (10 million) suffer hearing damage of varying severity (38). The WHO estimated that ~16% of disabling hearing impairment results from occupational noise exposure (39). In addition to the damage to the auditory system, noise can also cause damage to the non-auditory system, such as stress, damage to the cardiovascular system, and decline in cognitive and behavioral abilities, so attention should be paid to the impact of noise (40).

The result of occupational health risk evaluation showed that the health risk of silica-dust was the highest level, that is, an intolerable risk (RR ≥400), which was in accordance with the evaluation results of previous studies by using other OHRA models. In addition, we observed that the health risk of noise was also the highest level, which was inconsistent with the result of Gu et al. (40). This may be mainly due to taking different occupational health consequences. However, some occupational health examination results were not available, such as lung and inner ear examination, which limited our further analysis.

In conclusion, there were intolerable risks for silica-dust and noise for FMFs in Ningbo. Exposure to silica-dust and noise in the workplace remains a major concern in the field of occupational health in developing and developed countries, therefore, mature experience in silica-dust and noise control should be performed as soon as possible. Besides, as an important foundry production base in China, it is necessary to supervise enterprises to improve operating environmental conditions, accelerate the reduction of silica-dust and noise exposure risks, and promote the healthy and sustainable development of the foundry industry.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding authors.

Author contributions

DD and AW conceived and coordinated its overall structure. DD, PL, and AW acquired data and performed statistical analyses. DD and PL contributed to the writing and editing of draft. DD worked closely with other authors to align the structure and develop the conclusions. DZ contributed to the overall concept of the draft. DD, PL, XL, GM, DZ, and AW contributed to the editing and revising the draft. All authors interpreted data, revised the manuscript for intellectual content, and approved the final manuscript.

Funding

The study was supported by grants from Project of Ningbo Leading Medical & Health Discipline (Preoject Number: 2022-B18), Ningbo Medical and Health Brand Discipline (No. PPXK2018-10), and Zhejiang Province Medical and Health Science and Technology Program (No. 2020KY901).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1. Brown A, Gibson R, Tavener M, Guest M, D'Este C, Byles J, et al. Sexual function in F-111 maintenance workers: the study of health outcomes in aircraft maintenance personnel. J Sex Med. (2009) 6:1569–78. doi: 10.1111/j.1743-6109.2009.01237.x

2. General Office of the State Council of China. Notice of the General Office of the State Council on the Issuance of the National Occupational Disease Prevention Plan (2016–2020). Beijing: General Office of the State Council of China (2016).

3. Xu Q, Yu F, Li F, Zhou H, Zheng K, Zhang M. Quantitative differences between common occupational health risk assessment models. J Occup Health. (2020) 62:e12164. doi: 10.1002/1348-9585.12164

4. China NBOSO. China Statistical Yearbook 2021. S.S. Bureau, Editor. Beijing: China Statistics Press (2021).

5. Leng PB, Duan DH, Li XH, Mao GC, Qu LY, Zhang DD, et al. Analysis of dust hazard characteristics in 59 ferrous metal foundry enterprises in Ningbo City. Chinese J Indust Hyg Occupat Dis. (2022) 40:8. doi: 10.3760/cma.j.cn121094-20210401-00186

6. Wang A, Leng P, Li X, Wang Q, Gu S, Zhang M. Application of two risk assessment methods to occupational health risk assessment in a ferrous metal foundry. J Environ Occupat Med. (2017) 34:10. doi: 10.13213/j.cnki.jeom.2017.17209

7. Zou H, Fang X, Zhou L, Zhang M. Characteristics of occupational hearing loss in Zhejiang Province from 2006 to 2020. J Environ Occupat Med. (2022). 39:57–61. doi: 10.11836/JEOM21332

8. Stefanović V, Urošević S, Mladenović-Ranisavljević I, Stojilković P. Multi-criteria ranking of workplaces from the aspect of risk assessment in the production processes in which women are employed. Saftety Science. (2019) 116:116–26. doi: 10.1016/j.ssci.2019.03.006

9. Liu R, Mou X, Liu HC. Occupational health and safety risk assessment based on combination weighting and uncertain linguistic information: method development and application to a construction project IISE. Trans Occup Ergon Hum Factors. (2020) 8:175–86. doi: 10.1080/24725838.2021.1875519

10. Gridelet L, Delbecq P, Hervé L, Boissolle P, Fleury D, Kowal S, et al. Proposal of a new risk assessment method for the handling of powders and nanomaterials. Ind Health. (2015) 53:56–68. doi: 10.2486/indhealth.2014-0046

11. Shur PZ, Zaitseva NV, Alekseev VB, Shliapnikov DM. Occupational health risk assessment and management in workers in improvement of national policy in occupational hygiene and safety. Gig Sanit. (2015) 94:72–5.

12. Schall MC, Fethke NB, Roemig V. Digital human modeling in the occupational safety and health process: an application in manufacturing IISE. Trans Occup Ergon Hum Factors. (2018) 6:64–75. doi: 10.1080/24725838.2018.1491430

13. Tian F, Zhang M, Zhou L, Zou H, Wang A, Hao M. Qualitative and quantitative differences between common occupational health risk assessment models in typical industries. J Occupat Health. (2018) 60:337–47. doi: 10.1539/joh.2018-0039-OA

14. Valley M, Stallones L. A Thematic analysis of health care workers' adoption of mindfulness practices workplace. Health Saf. (2018) 66:538–44. doi: 10.1177/2165079918771991

15. Agency UEP. Risk Assessment Guidance for Superfund Volume I: Human Health Valuation Manual. Washington DC: Office of Superfund Remediation and Technology Innovation Environmental Protection Agency (2009).

16. Danny G. COSHH essentials: Easy steps to control chemicals. Ann Occup Hygiene. (2000) 44:160–1. doi: 10.1093/annhyg/44.2.160

17. Queensland Uo. Occupational Health and Safety Risk Assessment and Management Guideline. Brisbane: Occupational Health and Safety Unit. (2011).

18. Pece ES, Dascalescu EA. Risk Assessment Method for Occupational Accidents and Diseases. Romania: European Agency for Safety and Health at Work (1998).

19. International Council on Mining and Metals. Good Practice Guidance on Occupational Health Risk Assessment, 2nd Edn. London: International Council on Mining and Metals (2009)

20. MoMS. A Semi-Quantitative Method to Assess Occupational Exposure to Harmful Chemicals. Singapore: Occupational Safety and Health Division (2017).

21. Wang S. Reviews of occupational disease protection facilities in ferrous metal foundry enterprises. Foundry Technol. (2019) 40:316–8. doi: 10.16410/j.issn1000-8365.2019.03.020

22. China NHCo. Catalogue of Classification and Management of Occupational Disease Hazard Risks in Construction Projects (2021 edition). Beijing: GOOTNH Commission (2021).

23. Statistics NB. Notice of the National Bureau of Statistics on the Issuance of Measures on the Classification of Large, Medium, Small and Micro Enterprises. Beijing National Bureau of Statistics (2020).

24. Wang J, Ma J, Ding Y, Ding L. Investigation on current situation of occupational health in foundry industry in Chongming County of Shanghai in 2014. Occupat Health. (2016) 32:153–9. doi: 10.13329/j.cnki.zyyjk.2016.0003

25. Dai Y, Zhu S, Chen Z, Yang S. Status of occupational hazards and management strategies in 95 foundry enterprises in Shanghai. J Environ Occupat Med. (2009) 26:290–2.

26. Wang F, Zhang Q. Current situation of occupational hazards in 30 small-scale stainless steel casting companies of town in Jiangsu Province. J Environ Occupat Med. (2018) 34:3321–8. doi: 10.13329/j.cnki.zyyjk.2018.0932

27. Government NM. Implementation Opinions of the General Office of Ningbo Municipal People's Government on Promoting the Transformation and Upgrading of the City's Foundry Industry. Ningbo: GOONM Government (2014).

28. Yu X. Current situation of occupational hazards of dust in a foundry enterprise of Ma'anshan City in 2018. Occupat Health. (2019) 35:2740–3. doi: 10.13329/j.cnki.zyyjk.2019.0777

29. Bai PQ, Yang MJ, Shen HP, Chen XL. Investigation on occupational dust hazards in casting industry of subruban area in Shanghai. Chin Occupat Med. (2010) 37:518–9. doi: 10.1000-6486(2010)06-0518-02

30. Guarnieri G, Bizzotto R, Gottardo O, Velo E, Cassaro M, Vio S, et al. Multiorgan accelerated silicosis misdiagnosed as sarcoidosis in two workers exposed to quartz conglomerate dust. Occup Environ Med. (2019) 76:178–80. doi: 10.1136/oemed-2018-105462

31. Vihlborg P, Bryngelsson I-L, Andersson L, Graff P. Risk of sarcoidosis and seropositive rheumatoid arthritis from occupational silica exposure in Swedish iron foundries: a retrospective cohort study. BMJ Open. (2017) 7:e016839. doi: 10.1136/bmjopen-2017-016839

32. Andjelkovich DA, Mathew RM, Yu RC, Richardson RB, Levine RJ. Mortality of iron foundry workers II Analysis by work area. J Occup Med. (1992) 34:391–401.

33. Jing Z. Analysis and Research on Distribution Characteristics of Air Particulate Matter in Typical Sand Casting Workshop. Beijing: Chinese Center for Disease Control and Prevention. 2017. p. 98.

34. Li N, Yang Y, Sun Z, Jiang X, Ji D. Investigation and analysis on the status quo of occupational disease hazards in foundry enterprises in Zhangjiagang City. Indust Health Occupat Dis. (2022) 48:140–3. doi: 10.13692/j.cnki.gywsyzyb.2022.02.014

35. Sun Z, Zhu J, Chen J, Jin Y. The present situation and prevention strategy of occupational hazards in foundry industry in Xinqiao Town, Jingjiang City. Chin Occupat Med. (2016) 43:755–61. doi: 10.11763/j.issn.2095-2619.2016.06.028

36. Ding TA, Yan, Liu K. What is noise-induced hearing loss? Br J Hosp Med. (2019) 80:525–9. doi: 10.12968/hmed.2019.80.9.525

37. Pelegrin AC, Canuet L, Rodríguez ÁA, Morales MPA. Predictive factors of occupational noise-induced hearing loss in Spanish workers: a prospective study. Noise Health. (2015) 17:343–9. doi: 10.4103/1463-1741.165064

39. Nelson DI, Nelson RY, Concha-Barrientos M, Fingerhut M. The global burden of occupational noise-induced hearing loss. Am J Ind Med. (2005) 48:446–58. doi: 10.1002/ajim.20223

Keywords: risk assessment, occupational and environmental exposure, ferrous metal, silica-dust exposure, noise exposure

Citation: Duan D, Leng P, Li X, Mao G, Wang A and Zhang D (2023) Characteristics and occupational risk assessment of occupational silica-dust and noise exposure in ferrous metal foundries in Ningbo, China. Front. Public Health 11:1049111. doi: 10.3389/fpubh.2023.1049111

Received: 20 September 2022; Accepted: 20 January 2023;

Published: 09 February 2023.

Edited by:

Meibian Zhang, Chinese Center for Disease Control and Prevention, ChinaReviewed by:

Renata Sisto, National Institute for Insurance Against Accidents at Work (INAIL), ItalyLin Zhang, Shandong University, China

Copyright © 2023 Duan, Leng, Li, Mao, Wang and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Dandan Zhang,  MzE3NTY5NzI1QHFxLmNvbQ==; Aihong Wang,

MzE3NTY5NzI1QHFxLmNvbQ==; Aihong Wang,  Nzc4MjgwNzlAcXEuY29t

Nzc4MjgwNzlAcXEuY29t

Donghui Duan

Donghui Duan Pengbo Leng

Pengbo Leng Aihong Wang

Aihong Wang