- 1Business School, Beijing information Science and Technology University, Beijing, China

- 2Development Research Center of China Geological Survey, Beijing, China

As China transitions towards a circular, green, and efficient economy, the mining industry, as a crucial pillar of national economic growth, faces dual challenges of resource efficiency and environmental governance. Against this backdrop, this study emphasizes the evaluation of green total factor productivity (GTFP) in China’s mining industry, aiming to provide scientific insights to environmental pollution. To overcome the limitations of traditional radial and non-radial Data Envelopment Analysis (DEA) models, this study adopts the SBM model and incorporates the Malmquist-Luenberger (ML) index to analyze GTFP from both static and dynamic perspectives across 31 provinces in China from 2005 to 2021, and provides specific suggestions.

1 Introduction

As the global understanding of sustainable development deepens, the green transition of resource-based industries has become a critical strategic direction for national economic and social development. China, as the world’s largest producer and consumer of mineral resources, plays an irreplaceable role in driving economic growth and ensuring resource supply through its mining industry. The mining industry not only provides vast amounts of raw materials for industries, energy production, and infrastructure development but also significantly contributes to employment and fiscal revenue. However, this traditional growth model is based on high resource consumption and significant environmental costs (Mohsin et al., 2021).

It is crucial to explore how China can reconcile resource conservation and environmental protection with sustained economic growth in its mining sector (Cai et al., 2022; Yu et al., 2019). Particularly in the context of increasing global resource constraints and environmental pressures, promoting a green, low-carbon, and sustainable transformation of the mining industry is not only essential for enhancing the sector’s competitiveness but also for ensuring high-quality national economic development.

In the mining industry, given the inevitable environmental degradation caused during the extraction and development processes, Green Total Factor Productivity (GTFP) has gradually emerged as an important research focus. It aims to assess the sector’s capacity to balance resource utilization and environmental impact. Studies on TFP primarily focus on the application of parametric and non-parametric methods. Parametric methods usually estimate TFP by employing production functions, relying on specific functional form assumptions. Therefore, scholars have attempted to combine parametric and non-parametric methods to better measure and analyze TFP. Non-parametric methods, represented by data envelopment analysis (DEA), avoid assumptions about production functions and provide a method of measuring efficiency based on actual data.

In China’s mining industry, the DEA method is widely used due to its non-parametric nature and its capacity to handle multiple input and output indicators efficiently. There are various perspectives for measuring the efficiency of China’s mining industry. For example, Zhu et al. (2018) employed DEA model from a global perspective to measure the GTFP of China’s mining industry. They found that although overall productivity has improved, there is still considerable room for enhancement in environmental efficiency, particularly in provinces with high resource extraction intensity. Chen et al. (2022) analyzed changes in mining efficiency from a spatiotemporal perspective, revealing that mining efficiency in the eastern region is significantly higher than in the western region. Their research suggests that regional characteristics should be considered by policymakers to formulate more targeted policies for promoting coordinated regional development. Zuo et al. (2022) employed a two-stage DEA model to analyze technological innovation efficiency and ecological efficiency in China’s mining industry, finding that improvements in technological innovation efficiency can significantly enhance ecological efficiency, indicating that technological advancement is a key driver of green transformation in mining.

Similarly, various calculation methods have been used in TFP studies. For instance, Wu et al. (2019) introduced a heterogeneous input-output DEA model in their study of energy and environmental efficiency in China’s industrial sector, accounting for differences in resource consumption and pollution emissions across industries to make efficiency evaluations more realistic. Xiao et al. (2018) evaluated energy-environment efficiency across sectors in China using the S-U-SBM model, analyzing the key factors affecting efficiency. To further quantify the impact of undesirable outputs (e.g., pollutants) on environmental efficiency, Zhou et al. (2013) proposed a weighted SBM model, which focused on analyzing environmental efficiency in China’s industrial sector, revealing that the environmental efficiency of the mining industry is among the lowest across all industrial sectors, with high pollutant emissions being the main cause of low efficiency. Liu and Meng (2018) used a DEA model incorporating environmental pollutants such as wastewater and exhaust emissions to evaluate energy efficiency in 20 mining cities in eastern and central China, uncovering the critical role of technological progress and energy structure optimization in improving energy efficiency in mining cities.

Substantial scholarly attention has likewise been directed toward assessing total factor productivity (TFP) in resource-dependent economies where the mining sector constitutes a cornerstone industrial pillar. Hosseinzadeh et al. (2016) conducted a firm-level analysis of efficiency dynamics in the Australian mining sector between 2008 and 2014 by applying a bootstrap data envelopment analysis (DEA) approach. The mining sector in Chile, prominently represented by its copper industry, has been a focal point of economic analysis. De Solminihac et al. (2018) employed the traditional Solow methodology to measure total factor productivity (TFP) through a copper-centric framework, revealing a paradoxical trend: while capital investment substantially contributed to sectoral growth throughout the study period, TFP exhibited a statistically significant decline. This phenomenon is attributed to the structural limitations of capital-driven expansion at Chile’s current developmental stage, indicating that mere capital accumulation cannot sustainably enhance productivity or maintain growth trajectories in the mining sector. In contrast, Ilboudo (2014) demonstrated through empirical investigation that foreign direct investment (FDI) had a positive and statistically significant correlation with TFP in Chilean mining.

Fang et al. (2009) employed data envelopment analysis (DEA) to compare the relative technical efficiency performance of listed coal mining corporations in China and the United States. The findings revealed that the superior institutional environment and other systemic advantages in the U.S. context contributed to significantly higher relative efficiency levels among American coal enterprises compared to their Chinese counterparts. Mahapatra et al. (2020) conducted an input-oriented Data Envelopment Analysis (DEA) assessment to evaluate and rank the relative operational efficiency of 28 selected open-pit mines operated by a major state-owned coal corporation in India during the 2018–2019 fiscal year. Henriksson et al. (2014), Flávia De Castro Camioto et al. (2014), Phuong (2018), SeribolatAzhibay, 2023; Majola and Langerman, 2023, conducted empirical analyses of mining sectors in Sweden, Brazil, Vietnam, Kazakhstan and South Africa, respectively, formulating tailored policy recommendations addressing context-specific operational challenges.

Scholars have integrated total factor productivity (TFP) in the mining sector with complementary indicators. Yousefian et al. (2024) examined the impact of corporate social responsibility (CSR) on mining sector TFP across Europe, incorporating both microeconomic and macroeconomic moderators in the CSR-TFP relationship. Their findings demonstrated statistically significant positive effects of firm-level CSR implementation on TFP performance among European mining corporations.

As mentioned above, many studies have explored the environmental efficiency of China’s mining industry using traditional radial or non-radial DEA models. However, radial and non-radial DEA models have their respective limitations. In DEA analysis, radial models assume proportional changes in all input or output variables. Yet, in many practical production and operational environments, resource usage and output changes are often non-proportional. Radial models are particularly inadequate in capturing these non-proportional changes when dealing with undesirable outputs such as pollutants. Additionally, radial models are not suitable for addressing resource overuse or output shortfalls, which may lead to overestimation of efficiency for certain Decision-Making Units (DMUs). Nonetheless, radial models have been extended by introducing environmental constraints to better handle undesirable outputs, thereby enhancing the accuracy and credibility of results.

To overcome the limitations of radial models, non-radial models were introduced, allowing for non-proportional adjustments of inputs and outputs and using slack variables to capture resource overuse and output shortfalls. While non-radial models address the asymmetry of resource utilization and output adjustment, they introduce greater computational complexity and demand higher data quality. If the number of DMUs is small or the data precision is insufficient, non-radial models may result in unstable estimations of the efficiency frontier.

To address the shortcomings of both radial and non-radial DEA models, Tone, (2010) proposed the epsilon-based measure model, which has been widely applied in environmental efficiency evaluations in recent years.

This study proposes a novel environmental efficiency evaluation model that incorporates the cumulative impact of mining activities on land occupation and degradation. The model aims to quantify the environmental efficiency of the mining sector, shedding light on its environmental shortcomings and potential for improvement. Initially, the study applies the Epsilon-Based Measure (EBM) model to estimate the total factor static environmental efficiency (TFSEE) of the mining industry across China’s provinces. While the EBM model serves as a robust tool for assessing static efficiency, it has limitations in capturing the dynamic changes in efficiency over time and fails to identify the driving factors behind such changes.

To address this gap, we further employ the Malmquist-Luenberger (ML) productivity index, which not only reflects changes in total factor productivity (TFP) but also provides insights into the dynamic nature of environmental efficiency. By applying the ML index, we estimate the total factor dynamic environmental efficiency (TFP) of the mining sector across China’s provinces. Additionally, we decompose the productivity index to identify the key drivers of improvements in environmental efficiency. These drivers may include technological progress, resource utilization efficiency, policy support, and industrial structure adjustments.

Moreover, this research explores regional and sectoral variations in the enhancement of environmental efficiency, offers more targeted recommendations for policymakers. Thus, the aim of this study is to investigate the characteristics of GTFP using global data envelopment analysis (DEA). The main contributions are as follows. First, the EBM model incorporating both radial and non-radial advantages is structured under the total factor frame work, which provides a new method for evaluating the TFP of China’s provincial mining industry. Such work has not been found in the existing research. Additionally, this study analyzes the changes in green total factor productivity (GTFP) by applying the global Malmquist (GM) index. This approach allows for the identification of the primary factors driving the variations in GTFP within the mining sector. Furthermore, the study examines the returns to scale, input excess, output deficiency, and the issue of over-emissions across different sub-sectors within the mining industry. The findings provide valuable insights into the strategies needed to enhance GTFP in China’s mining industry.

The remainder of this study is organized as follows. Section 2 presents the research methods used in this study in detail. Section 3 introduces the variable selection and data sources. Section 4 provides the results and discussion. Conclusions will be drawn and corresponding policy implications proposed in Section 5.

2 Research methods

The traditional DEA model uses radial and oriented measurements but overlooks the slack variables. Avkiran and Rowlands (2008) considered that although the non-radial and non-oriented SBM model can avoid the shortcomings, the traditional radial and oriented DEA model may overestimate the regional environmental efficiency. In the traditional DEA model, radial and oriented measurements are employed, but the model slack variables, which can limit its accuracy in evaluating efficiency. However, the relationship between resources, energy consumption (input variables), and pollutant emissions is inherently “inseparable.” This relationship is radial and varies according to the ratio of

In this study, the EBM model is applied to calculate the total factor productivity (TFP) of China’s provincial mining industry. By utilizing the EBM model, we aim to obtain efficiency scores that are closer to the actual values, thereby improving the accuracy and reliability of the results. This enhances the credibility of the research and provides a more robust foundation for further analysis.

An input-oriented EBM model under constant returns to scale (EBM-I-C) is established, as shown in Formula 1:

In this model,

Considering the presence of undesirable outputs in this study, we extend the EBM-I-C model from Formula 1 to a non-oriented EBM model designed to account for such outputs. This modification is illustrated in Formula 2 below.

In Formula 2,

The EBM model described above focuses on analyzing production technology at a specific point in time. However, the production process is typically long-term and continuous, with the level of production technology evolving over time. When panel data is available for DMUs, it becomes possible to examine changes in productivity and analyze the impact of efficiency and technical changes on these productivity shifts by Malmquist Total Factor Productivity (TFP) index (1953). Färe et al. (1992) employed the DEA model to calculate the Malmquist index for the first time, and decomposed the Malmquist index into efficiency change and production technological change to reflect the change of production frontier. Chung et al. (1997) applied the directional distance function incorporating undesirable output to the Malmquist index, and the obtained productivity index was named the Malmquist–Luenberger productivity index. The Malmquist-Luenberger productivity index is based on the directional distance function. ML needs to define directional distance functions of two adjacent different periods:

Each Chinese province in certain year can be regarded as a DMU, then following the ML index method, the GTFP in the mining industry of province p0 between

Then, GTFP is further decomposed into the product of EC index and TC index to dig out the causes of productivity change. The functional expression is as follows:

Where

3 Variable selection and data sources

In this study, we define the input variables for China’s mining industry based on its specific characteristics. The primary inputs include labor, capital, and land use. Labor input is represented by the average annual number of employees in the mining sector, while capital input is represented by capital stock, which is estimated using the perpetual inventory method. Land use is measured by the registered area approved by mining licenses, which reflects the spatial extent of mining activities.

The desirable output in this context is the industrial total output value of the mining sector, which represents the economic production of the industry. On the other hand, the undesirable output is the cumulative area of land degraded or occupied due to mining activities, which reflects the environmental costs of resource exploitation. It is worth noting that the data are lagged, and our research data cover up to 2021.

Data for labor input, capital input, and industrial total output value are sourced from the China Industrial Statistical Yearbook. The data for the approved registered area and the cumulative area affected by mining come from the China Land and Resources Statistical Yearbook. The fixed asset investment price index and the producer price index for industrial products are provided by the National Bureau of Statistics, which are used to adjust for inflation and ensure consistency across time periods.

4 Results and discussion

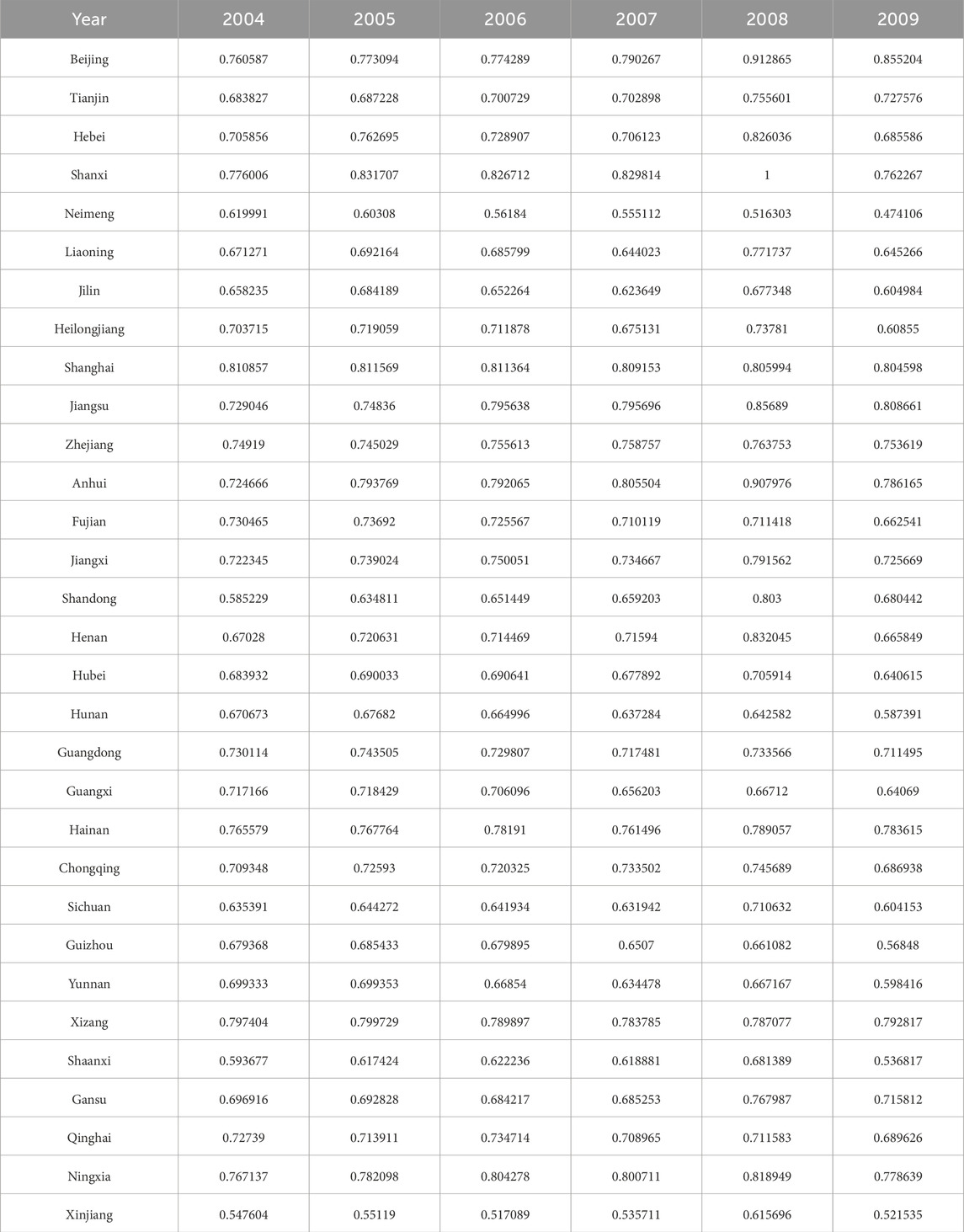

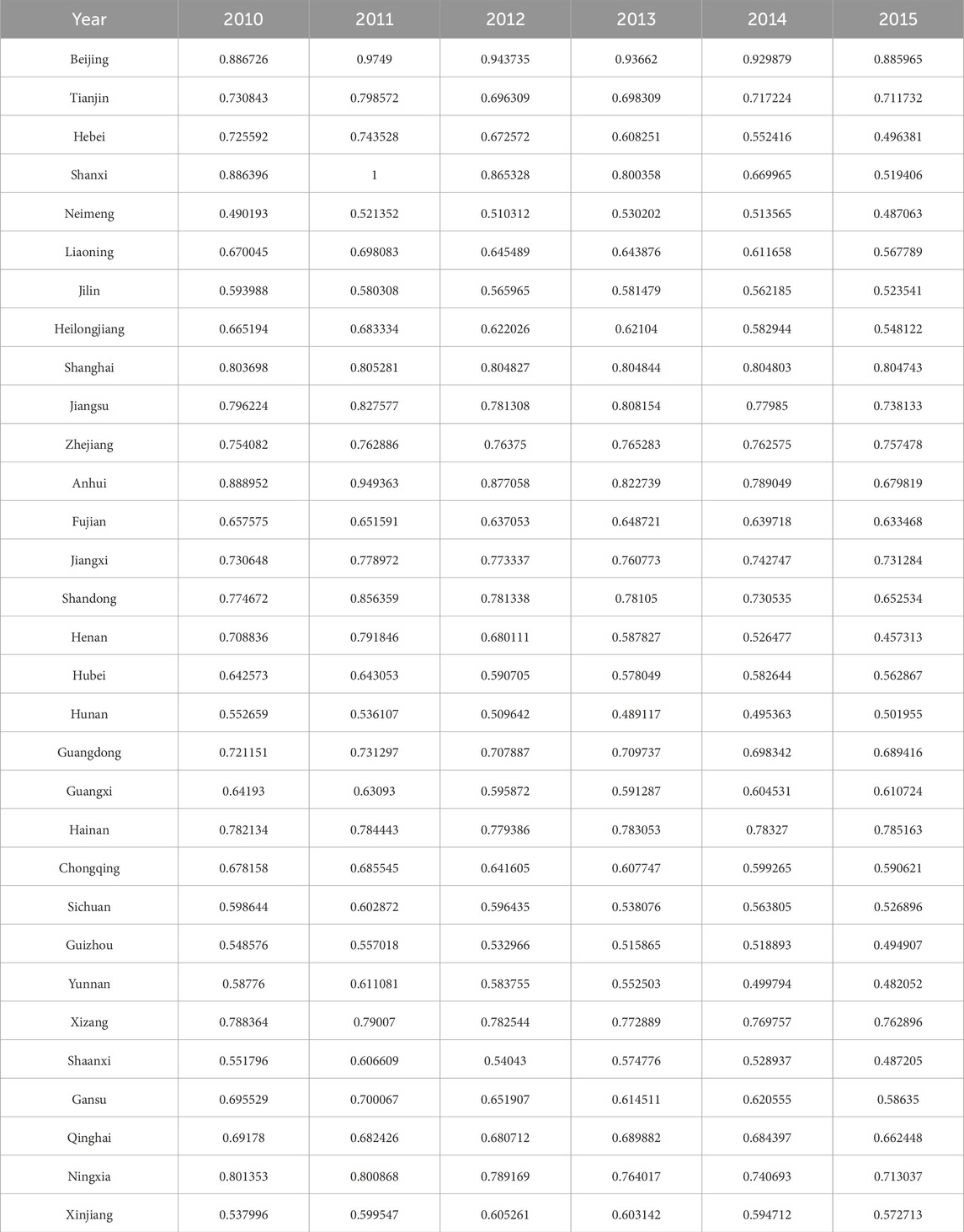

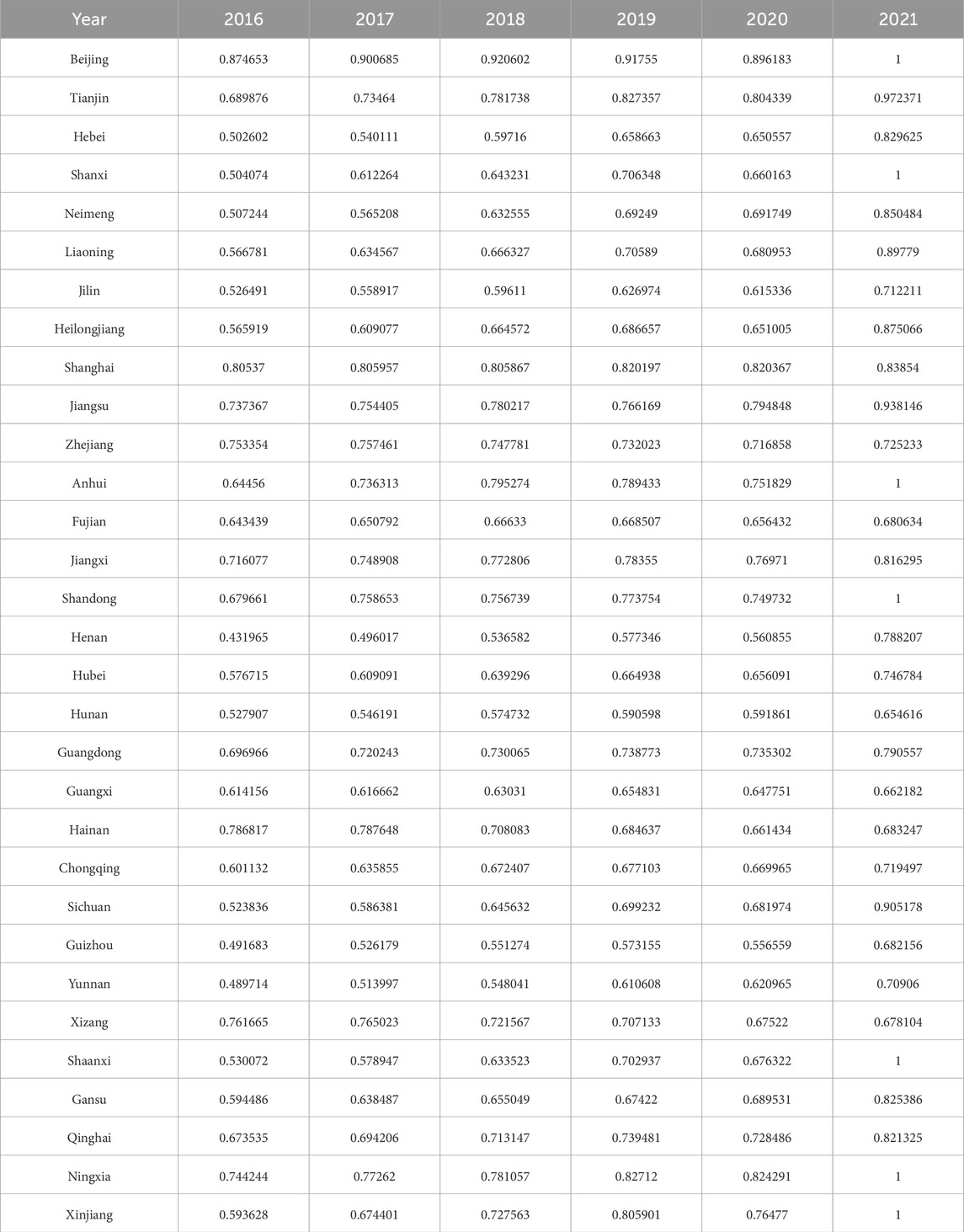

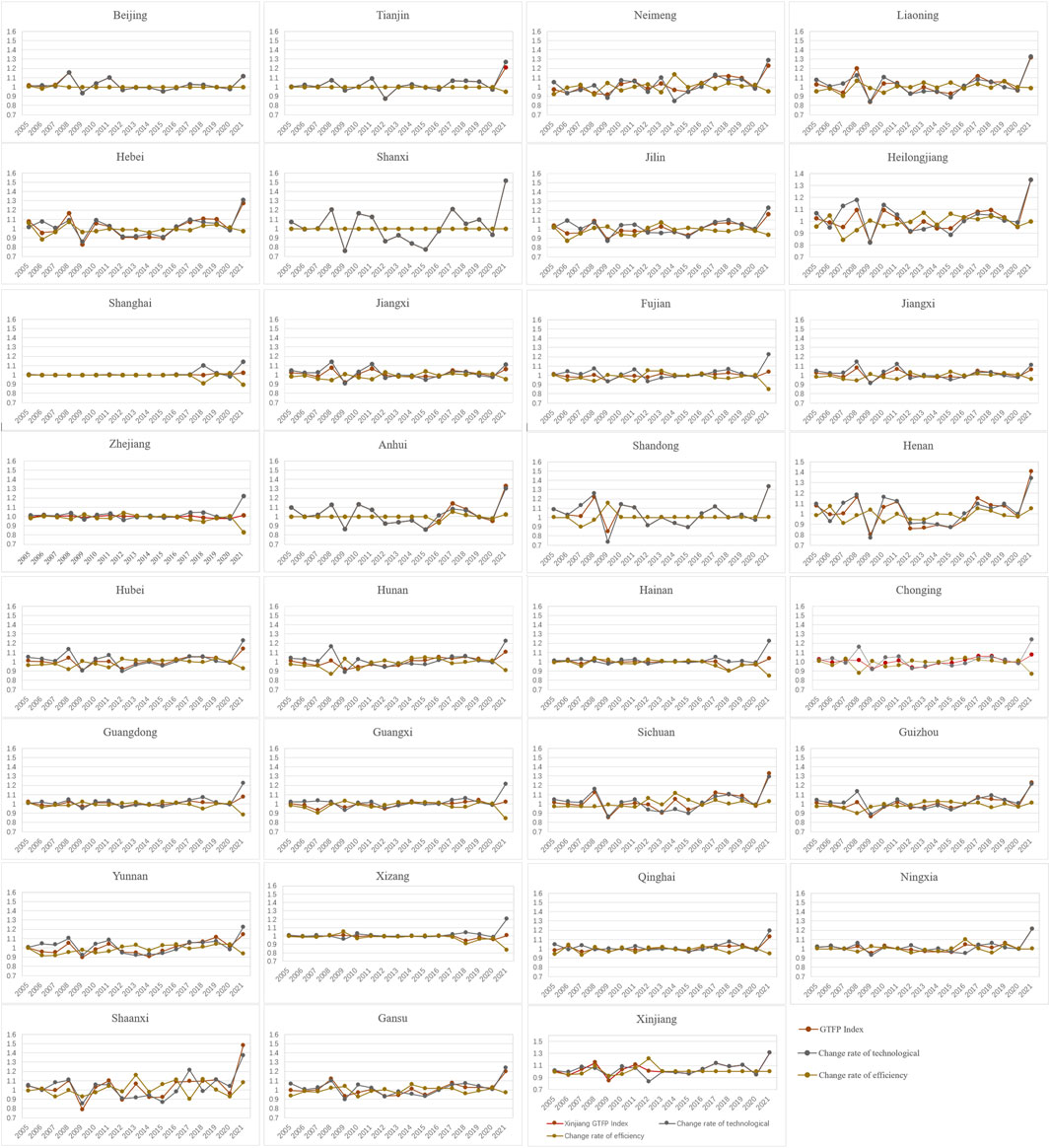

The technical efficiency values of 31 provinces from 2004 to 2021 are listed in Tables 1–3. GTFP index and its decomposition indices in various regions from 2005 to 2021 are shown in Figure 1.

The provinces with higher GTFP are Shandong, Shanxi, Shaanxi, and Xinjiang. These provinces have abundant mineral resources, including coal, iron ore, rare metals, and new energy minerals. These provinces have implemented strict environmental regulation policies aimed at controlling pollution and protecting the ecological environment. More advanced technologies and equipment have been adopted in the process of mineral development and processing, which not only improves production efficiency but also reduces environmental pollution and resource waste. By optimizing the development and utilization of mineral resources, the rational allocation of resources has been achieved, and the overall production efficiency has been improved. Obtained funding and technological support from the government or international investors, which helps promote technological innovation and sustainable development in the mineral industry. Actively participating in international cooperation and exchanges, learning advanced mineral development and environmental protection technologies from other countries, these experiences and technological exchanges can help improve their green total factor productivity.

The changes of GTFP in Beijing, Tianjin, Shanghai, Zhejiang, Fujian, Hainan, Qinghai, Ningxia and Xizang are relatively stable. These regions are distributed in different areas of China. Beijing, Tianjin, Shanghai, Zhejiang and Fujian are in the east, Hainan is in the southern coastal area, and Qinghai, Ningxia and Xizang are in the west. These regions have diverse types of mineral resources. The eastern regions, such as Beijing, Tianjin, Shanghai, Zhejiang, and Fujian, have abundant resources such as aquatic products, oil, iron ore, salt, etc., Due to their geographical advantages. Hainan, as an island province, also has its unique resource advantages. The western regions of Qinghai, Ningxia and Xizang are rich in mineral resources and have great development potential, although their natural conditions are relatively poor. The mineral resources in the eastern region play an important role in the overall economic development. Due to its long history of development, advantageous geographical location, high cultural quality of workers, strong technical strength, and strong industrial and agricultural foundation, this region has a strong industrial and agricultural foundation. Although there is a gap in economic development and technological management level between the western region and the eastern and central regions, due to their relatively late development history, these regions have enormous potential for mineral resource development.

The changes in GTFP in Hebei, Jiangsu, Guangdong, Hubei, Hunan, Henan, Jiangxi, Anhui, Chongqing, Sichuan, Guizhou, Yunnan, Gansu, Guangxi, Inner Mongolia, Liaoning, Heilongjiang, and Jilin are relatively significant. The fluctuation of green total factor productivity in various regions is influenced by various factors, including technological progress, technological efficiency, geographical proximity, economic structural differences, environmental pollution and resource consumption, as well as policy and market factors. These factors have varying degrees and directions of influence in different regions, leading to fluctuations in GTFP.

Compared with change rate of technology, the fluctuation of change rate of efficiency in various regions is relatively stable. China’s mining industry has made significant progress in adopting advanced technologies such as big data, artificial intelligence, and the Internet of Things. The integration and application of these technologies have greatly improved the efficiency and accuracy of mining in management, and resource assessment. Change rate of technology has a greater impact on the GTFP Index.

5 Conclusion

As a special industry, the research on GTFP of mineral resources is very important. The GTFP of China’s mining industry has shown an overall downward trend for a period, but has rebounded in recent years. The innovation of green technology and the upgrading of industrial structure have had a significant positive impact on the GTFP of China’s mining industry. China’s mining industry made significant progress in technology, especially in the application of big data, artificial intelligence, and the Internet of Things. The development and application of these technologies have made mining more efficient and accurate in mining, management, resource assessment, and other aspects. Compared to 2020, the change rate of technology in various provinces and cities in China has been improved in 2021.

The mineral resources involves multiple aspects such as industrial structure, market structure, technological progress, and government support. Through analysis, we found that: (1) Technological innovation promotes the improvement of green mining technology; (2) Appropriate policy support can reduce regional disparities and promote regional coordination; (3) Improving resource utilization and environmental management can promote the sustainable development of the mining industry.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding authors.

Author contributions

Y-YL: Data curation, Investigation, Methodology, Software, Writing – original draft. X-LM: Formal Analysis, Funding acquisition, Project administration, Resources, Writing – original draft. BC: Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work is funded by R&D Program of Beijing Municipal Education Commission (KM202311232007), the Young Backbone Teacher Support Plan of Beijing Information Science and Technology University (YBT202432).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Avkiran, N. K., and Rowlands, T. (2008). How to better identify the true managerial performance: state of the art using DEA. OMEGA-International J. Manag. Sci. 36 (2), 317–324. doi:10.1016/j.omega.2006.01.002

Cai, L., Guo, Z., and Zhang, J. (2022). An empirical study on green total factor productivity of mining industry of Shanxi, Shaanxi and inner Mongolia. Ecol. Econ. 38 (9), 95–102.

Chen, J., Wen, S., and Liu, Y. (2022). Research on the efficiency of the mining industry in China from the perspective of time and space. Resour. Policy 75, 102475. doi:10.1016/j.resourpol.2021.102475

Chung, Y. H., Färe, R., and Grosskopf, S. (1997). Productivity and undesirable outputs: a directional distance function approach. J. Environ. Manag. 51 (3), 229–240. doi:10.1006/jema.1997.0146

De Solminihac, H., Gonzales, L. E., and Cerda, R. (2018). Copper mining prod uctivity: lessons from Chile. J. Policy Model. 40 (1), 182–193. doi:10.1016/j.jpolmod.2017.09.001

Fang, H., Wu, J., and Zeng, C. (2009). Comparative study on efficiency performance of listed coal mining companies in China and the US. Energy Policy 37 (12), 5140–5148. doi:10.1016/j.enpol.2009.07.027

Färe, R., Grosskopf, S., Lindgren, B., and Roos, P. (1992). Productivity changes in Swedish pharamacies 1980-1989: a non-parametric Malmquist approach. J. Prod. Analysis 3 (1), 85–101. doi:10.1007/BF00158770

Flávia De Castro, C., Mariano, E. B., and Rebelatto, D. A. D. N. (2014). Efficiency in Brazil's industrial sectors in terms of energy and sustainable development. Environ. Sci. and Policy 37, 50–60. doi:10.1016/j.envsci.2013.08.007

Henriksson, E., Söderholm, P., and Wårell, L. (2014). Industrial electricity demand and energy efficiency policy: the case of the Swedish mining industry. Energy Effic. 7, 477–491. doi:10.1007/s12053-013-9233-7

Hosseinzadeh, A., Smyth, R., Valadkhani, A., and Le, V. (2016). Analyzing the efficiency performance of major Australian mining companies using bootstrap data envelopment analysis. Econ. Model. 57, 26–35. doi:10.1016/j.econmod.2016.04.008

Ilboudo, P. S. (2014). Foreign direct investment and total factor productivity in the mining sector: the case of Chile. Econ. Honors Pap., 18. Available online at: http://digitalcommons.conncoll.edu/econhp/18.

Liu, X., and Meng, X. (2018). Evaluation and empirical research on the energy efficiency of 20 mining cities in Eastern and Central China. Int. J. Min. Sci. Technol. 28 (3), 525–531. doi:10.1016/j.ijmst.2018.01.002

Mahapatra, B., Bhar, C., and Mondal, S. (2020). Performance assessment based on the relative efficiency of Indian opencast coal mines using data envelopment analysis and malmquist productivity index. Energies 13 (18), 4902. doi:10.3390/en13184902

Majola, C. M. D., and Langerman, K. E. (2023). Energy efficiency in the South African mining sector: a case study at a coal mine in Mpumalanga. J. South. Afr. Inst. Min. Metallurgy 123 (9), 451–462. doi:10.17159/2411-9717/1788/2023

Malmquist, S. (1953). Index numbers and indifference surfaces. Trab. De. Estad. 4 (2), 209–242. doi:10.1007/BF03006863

Mohsin, M., Zhu, Q., Naseem, S., Sarfraz, M., and Ivascu, L. (2021). Mining industry impact on environmental sustainability, economic growth, social interaction, and public health: an application of semi-quantitative mathematical approach. Processes 9 (6), 972. doi:10.3390/pr9060972

Phuong, V. H. (2018). Total factor productivity growth, technical progress and efficiency change in Vietnam coal industry—nonparametric approach[C]/E3S web of conferences. EDP Sciences 35, 01009.

SeribolatAzhibay, Z. A., and Azhibay, S. (2023). Assessing economic sustainability of mining in Kazakhstan. Mineral. Econ. 36 (4), 719–731. doi:10.1007/s13563-023-00387-x

Tone, K., and Tsutsui, M. (2010). An epsilon-based measure of efficiency in DEA – a third pole of technical efficiency. Eur. J. Operational Res. 207 (3), 1554–1563. doi:10.1016/j.ejor.2010.07.014

Wu, J., Li, M., Zhu, Q., Zhou, Z., and Liang, L. (2019). Energy and environmental efficiency measurement of China's industrial sectors: a DEA model with non-homogeneous inputs and outputs. Energy Econ. 78, 468–480. doi:10.1016/j.eneco.2018.11.036

Xiao, C., Wang, Z., Shi, W., Deng, L., Wei, L., Wang, Y., et al. (2018). Sectoral energy-environmental efficiency and its influencing factors in China: based on S-U-SBM model and panel regression model. J. Clean. Prod. 182, 545–552. doi:10.1016/j.jclepro.2018.02.033

Yousefian, M., Bascompta, M., Sanmiquel, L., Vintró, C., and Sidki-Rius, N. (2024). Corporate social responsibility and total factor productivity: the case of European mining industry. Mineral. Econ. 37 (1), 149–161. doi:10.1007/s13563-024-00423-4

Yu, L. H., Wang, Y., and Chen, J. Y. (2019). Green total factor productivity of Chinese mining industries considering negative intergenerational and environmental externalities. Resour. Sci. 41 (12), 2155–2171. doi:10.18402/resci.2019.12.01

Zhou, Y., Liang, D., and Xing, X. (2013). Environmental efficiency of industrial sectors in China: an improved weighted SBM model. Math. Comput. Model. 58 (5-6), 990–999. doi:10.1016/j.mcm.2012.09.021

Zhu, X., Chen, Y., and Feng, C. (2018). Green total factor productivity of China's mining and quarrying industry: a global data envelopment analysis. Resour. Policy 57, 1–9. doi:10.1016/j.resourpol.2017.12.009

Keywords: mining industry, green total factor productivity, EBM model, malmquist-luenberger index, mineral resource efficiency

Citation: Li Y-Y, Meng X-L and Chen B (2025) Research on green total factor productivity of China’s mining industry. Front. Earth Sci. 13:1569365. doi: 10.3389/feart.2025.1569365

Received: 31 January 2025; Accepted: 27 May 2025;

Published: 10 June 2025.

Edited by:

Guochang Wang, Saint Francis University, United StatesReviewed by:

Guwang Liu, Chinese Academy of Geological Sciences, ChinaJunBo Wang, Tsinghua University, China

Amjad Hussain, China University of Geosciences Wuhan, China

Copyright © 2025 Li, Meng and Chen. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xiao-Li Meng, bXhsaGV1dEAxNjMuY29t; Bo Chen, Y2hlbmJvMDFAbWFpbC5jZ3MuZ292LmNu

Yu-Yang Li

Yu-Yang Li Xiao-Li Meng

Xiao-Li Meng Bo Chen

Bo Chen