- 1China Petroleum Exploration and Development Research Institute, Beijing, China

- 2National Key Laboratory of Green Exploitation of Continental Shale Oil, Daqing, Heilongjiang, China

- 3College of Petroleum Engineering, China University of Petroleum (Beijing), Beijing, China

- 4School of Civil Engineering and Geomatics, Southwest Petroleum University, Chengdu, Sichuan, China

The fracture toughness is an essential mechanical parameter to measure the difficulty of hydraulic fracture expansion. As the reservoir depth increases, the temperature and stress become higher. In particular, the high-temperature and high-pressure characteristics of the 10,000-m-deep reservoir are particularly pronounced. Furthermore, investigating the fracture toughness evolution under such coupled thermomechanical conditions serves as a critical focus of ultra-deep reservoir studies, providing essential insights for optimizing hydraulic fracturing designs. This study investigates the coupled effects of temperature and confining pressure on the fracture toughness of carbonate rocks through systematic experimental and theoretical analyses. Utilizing outcrop samples from the Cambrian Sholbrak Formation (analogous to the 10,000-m-deep target layer of the Ke exploration well), fracture toughness tests were conducted under thermomechanical coupling conditions (25°C–200°C, 0–200 MPa) via the double-wing symmetric crack thick-wall cylinder method implemented on a GCTS high-temperature/high-pressure rock mechanics system. Key findings reveal a temperature-dependent degradation of fracture toughness (40% reduction from 25°C to 200°C at zero confining pressure) and a confining pressure-driven enhancement (76% increase from 0 to 100 MPa at ambient temperature). A damage mechanics-based constitutive model was developed to quantify these dual effects, demonstrating strong agreement with experimental data (mean absolute error <5%). This model addresses the critical gap in fracture toughness characterization under deep reservoir conditions, enabling enhanced accuracy in hydraulic fracture propagation simulations for ultra-deep carbonate reservoir stimulation.

1 Introduction

Fracture toughness, a key parameter measuring a rock’s resistance to crack propagation, is critically important in hydraulic fracturing operations for hydrocarbon reservoirs (An et al., 2025; Huang et al., 2025; Tan et al., 2024a; Tan et al., 2024b; Wang et al., 2024). With the surging global energy demand, the development of deep to ultra-deep resources (burial depth >3,500 m) has become a prevalent practice (Fu et al., 2022; Zhang et al., 2021; Zhang et al., 2021). As a core reservoir stimulation technology, hydraulic fracturing’s crack propagation efficiency is directly influenced by the thermomechanical coupling effects on rock fracture toughness (Dai et al., 2024; Zhang et al., 2024). A representative example is the Cambrian carbonate reservoirs in the Tarim Basin, China, characterized by burial depths ranging from 6,000 to 11,000 m, formation temperatures of 170°C–220°C, and in-situ stresses exceeding 100 MPa (Chen et al., 2025; Xiaotong et al., 2024; Zeng et al., 2025). Traditional fracture toughness models developed for shallow formations (burial depth <3,500 m) fail to accurately predict crack propagation under high-temperature and high-pressure (HTHP) coupled conditions (Ji et al., 2019; Pandey and Rasouli, 2021; Peng et al., 2023). Experimental studies demonstrate that at temperatures above 150°C, mineral phase transformations and thermally activated microcracking intensify, leading to nonlinear reductions in fracture toughness (Al-Shayea et al., 2000; Gao et al., 2023; Longinos et al., 2024). Under high confining pressures, restricted crack deflection further complicates fracture paths (Lin et al., 2025; Xu et al., 2015; Zhou et al., 2024). These coupled thermomechanical interactions introduce substantial uncertainties in reservoir fracturability assessments, necessitating a systematic investigation of fracture toughness evolution under temperature-confining pressure coupling to advance fracture network control in deep reservoirs (Cao et al., 2025; Gao et al., 2024; Zhang et al., 2024).

Recent advances in rock fracture mechanics have elucidated temperature and confining pressure dependencies. Wen et al. (2024) prepared three - point bending semi - circular disk samples of Longmaxi Formation shale with different crack inclination angles, calibrated dimensionless fracture parameters using the finite element method, and conducted quasi - static loading experiments to determine the fracture toughness of Longmaxi shale at different crack angles. Ignacio et al. (2023) used DTS and BTS tests to study the tensile failure mechanisms of granitic rock samples at different scales, finding that differences may arise from varying rock properties and testing methods. Zhou et al. (2022) proposed a phase-transition-informed predictive model for granite, linking high-temperature toughness reduction to feldspar melting-induced crack tip blunting. Huang et al. used a 2D particle discrete element approach, considering factors like the fracture toughness between rock particles, to realize the propagation of hydraulic fractures between rock particles (Huang et al., 2019; Huang et al., 2023). Luo et al. (2022) conducted a sensitivity analysis of rock mechanical parameters and fracturing parameters at different scales using a dimensionless analysis method and found that low-toughness samples can reproduce the initiation and propagation of field fractures in experiments.Additionally, statistical damage constitutive models incorporating temperature, confining pressure, and porosity effects have been developed (Chen et al., 2021; Lu et al., 2024; Ren et al., 2022; Ye et al., 2022). These research findings have provided innovative insights into hydraulic fracturing reservoir stimulation technology, where scholars have made significant breakthroughs in key areas such as optimization of perforation initiation mechanisms, three-dimensional fracture propagation control, and precision height control of fractures, laying a solid theoretical foundation for the efficient and economical development of oil and gas resources (Detournay et al., 2022; Dontsov, 2022; Huang et al., 2020; Huang et al., 2022; Huang et al., 2023; Huang et al., 2024; Huang et al., 2025). However, existing studies predominantly focus on isolated thermal or mechanical fields (Kataoka et al., 2017; Li et al., 2024; Zhang et al., 2024), leaving the coupled thermomechanical behavior of carbonate reservoirs—exhibiting pronounced thermal sensitivity—largely unexplored. The absence of a universally applicable multiphysics-coupled prediction model remains a critical knowledge gap (Dai et al., 2021; Huang et al., 2024; Zhang et al., 2024).

To address these limitations, this study conducts simultaneous temperature-confining pressure fracture toughness experiments on deep carbonate reservoir rocks. By integrating advanced experimental protocols with constitutive modeling, we establish a preliminary predictive framework for fracture toughness evolution under thermomechanical coupling. The results provide a theoretical foundation for optimizing fracturing parameters in deep carbonate reservoirs, bridging the cognitive gap in high-temperature/high-stress fracture toughness evolution, and enabling precise fracture network design in ultra-deep wells.

2 Test method and experimental scheme

2.1 Experimental system and method

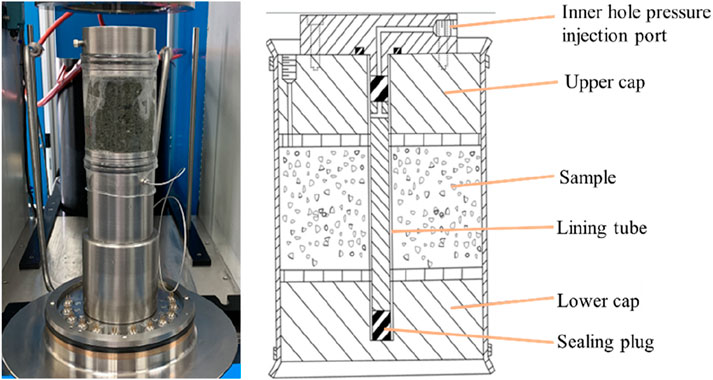

The experimental tests were carried out on a high temperature and high pressure rock mechanics triaxial experimental system produced by GCTS, which has a maximum confining pressure and internal hole pressure of 200 MPa and a maximum temperature of 200°C. The confining pressure is loaded with hydraulic oil, and the inner hole pressure is loaded with clear water. The pressure resolution for both is 0.01 MPa. The temperature is measured and controlled by loading with two thermocouples, and the sensor and signal regulation module are included. The temperature accuracy is 1°C, and the temperature loading rate is adjustable, ranging from 0.5°C to 1°C per minute. During the experiment, the sample mounted on the base is lifted into the pressurized chamber, and the axial stress is applied through the axial piston, and the confining pressure and the internal hole pressure are applied respectively through the confining pressure and the internal hole pressure injection pump, and the temperature is provided by the high temperature heating belt outside the installed pressurized chamber. The loading path and rate can be set by software to test the fracture toughness under temperature-confining pressure coupling.This experiment adopts the method of precracked thick-wall cylinder to test fracture toughness, and the reliability of this method has been verified by Clifton (Clifton et al., 1976) experiment. The test sample is a prefabricated crack thick-wall cylinder rock sample. An inner hole with a diameter of 10 mm is drilled along the middle of the rock sample, and the prefabricated crack of the inner hole wall is made parallel to the central axis of the inner hole along the radial direction. The inner diameter is 6 mm, and the outer diameter of 9 mm hose is the lining tube in the inner hole, the liquid pressure through the hose to the inner hole wall, with the sealing plug, and the plug with the seal of the hose, the periphery of the rock sample and the cover with heat shrink pipe, for the applied pressure to isolate hydraulic oil (Figure 1).

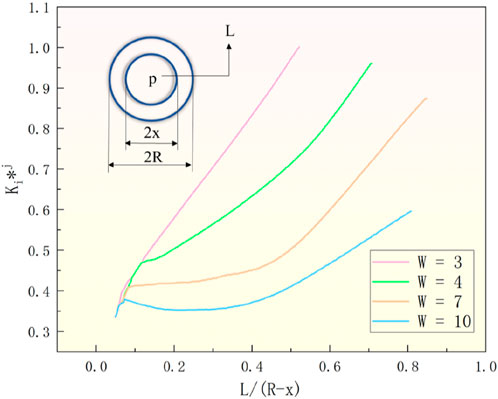

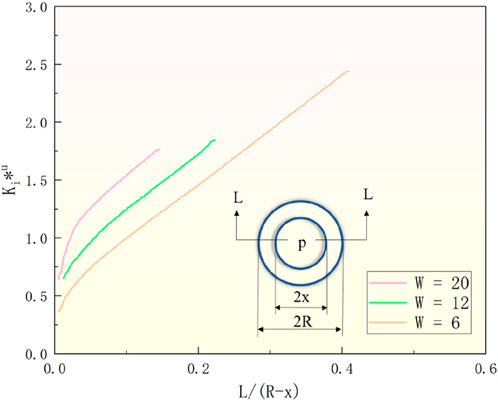

During the experiment, the rock sample bears the external surrounding pressure, the inner bore wall bears the compressive stress, and the surrounding pressure is applied to the set value by the inner bore hose bushing at a certain speed until the rock sample reaches the fracture. The fracture toughness size of the sample was calculated according to the following equation:

Where

Where

2.2 Experimental scheme

To investigate the influence of temperature and confining pressure on rock fracture toughness, 15 core samples were prepared according to the sample size in Figure 4. Samples were divided into three groups. The first group did not apply peripheral pressure, only to investigate the effect of temperature on fracture toughness, and the temperatures were 25°C, 50°C, 100°C, 150°C, and 200°C, respectively. The second group of room temperature conditions applied different ambient pressures, namely, 20 MPa, 40 MPa, 60 MPa, 80 MPa, and 100 MPa, respectively. The third group simultaneously applied temperature and confining pressure; temperature and confining pressure (In the following text, the confining pressure in the tables or figures is denoted by pc) were (40°C, 20 MPa), (80°C, 40 MPa), (120°C, 60 MPa), (160°C, 80 MPa), (200°C, 100 MPa). During the experiment, the test sample and pressure cover were sealed with a pressure-resistant heat shrink tube and then placed into the high-temperature pressure autoclave. Then, the test sample was fixed with 1 MPa axial pressure through the axial piston. The autoclave was filled with hydraulic oil. After applying the set temperature and surrounding pressure, the inner hole pressure was applied evenly at 0.05 MPa/s through the hole pressure supercharger until the rock sample was destroyed.

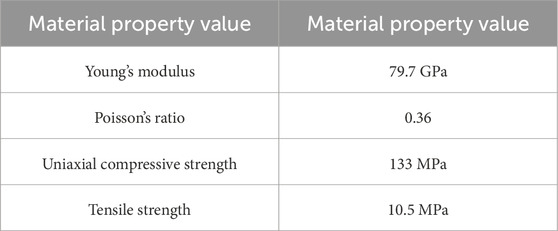

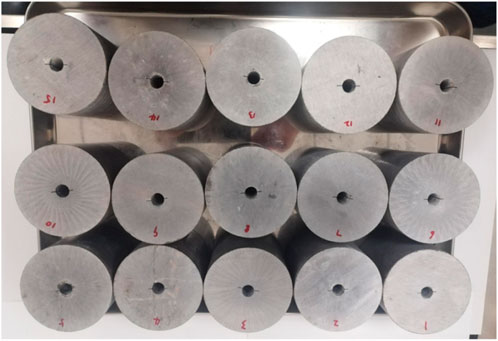

2.3 Specimen

The samples used in this paper are carbonate rocks, taken from the outcrop of the Cambrian Shawerbulak Formation in the Tarim Basin, Xinjiang. The carbonate content is 60%–90%, including 46.8%–76.4% calcite and 14.5%–41.77% dolomite. The core is dense with an average porosity of 1%. The average density is 2.82 g/cm3, and other material characteristics are listed in Table 1. The shape and size of the sample are shown in Figure 4. During the preparation of the sample, core is first drilled from the rock block and then cut into a cylinder, the parallelism of the two end faces is no more than 0.02 mm. The coring bit was used to drill holes along the axial direction in the center of the cylinder, and the holes ran through the entire cylinder. The prefabricated cracks were symmetrically cut on both sides of the holes by using fine diamond wire. The processed samples were shown in Figure 5.

3 Test results analysis

3.1 Results

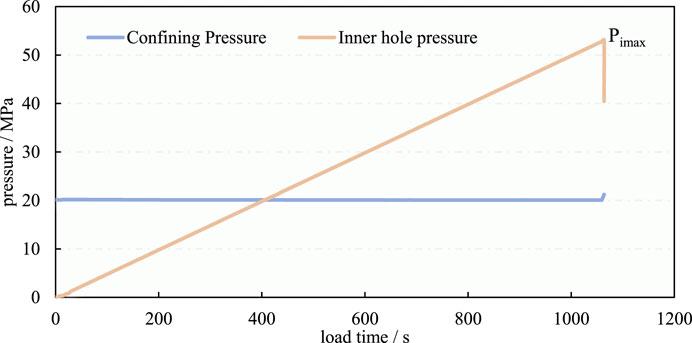

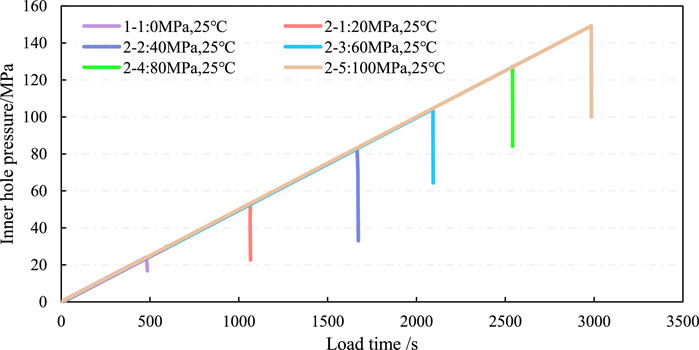

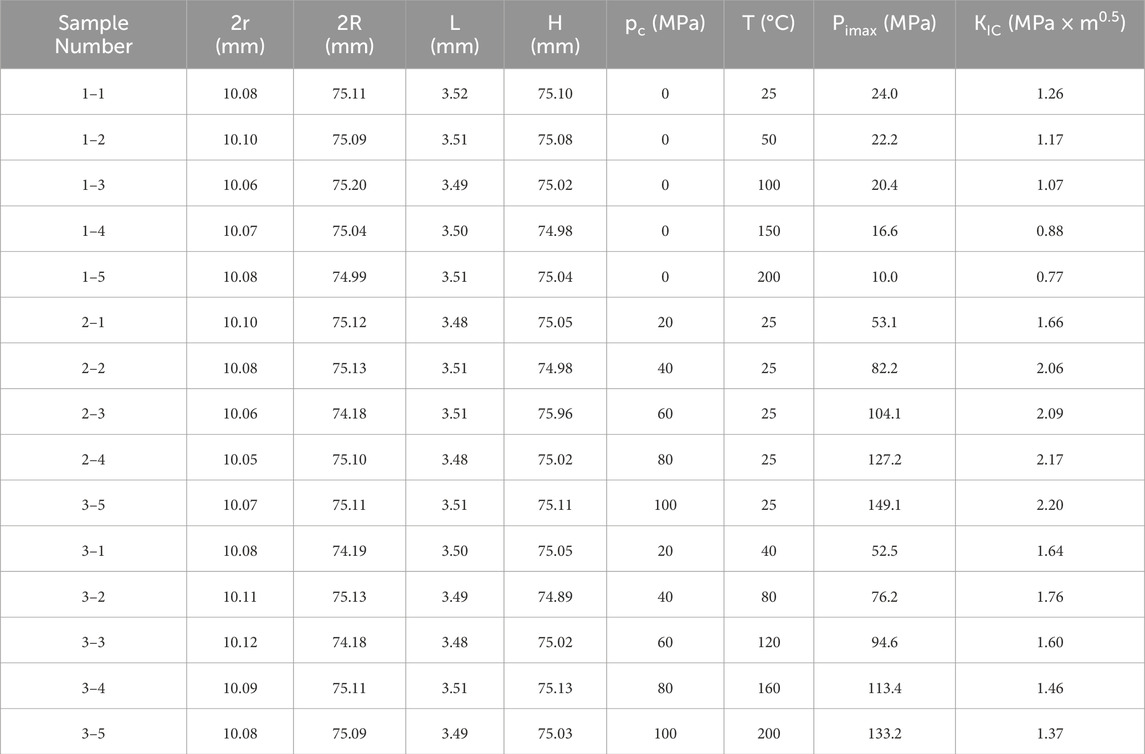

According to the above experimental scheme, fracture toughness tests were carried out on the three groups of samples under temperature and confining pressure conditions, and the experimental results were summarized in Table 2. The typical pressure-time curve is shown in Figure 6. The inner hole pressure is loaded according to the set loading rate, and it changes as a straight line with time. After the inner hole pressure reaches the maximum value, the sample breaks along the prefabricated crack, and the inner hole pressure pimax is obtained when the sample breaks, and then the fracture toughness is calculated using formula 1. The fracture section characteristics of the sample are shown in Figure 7.

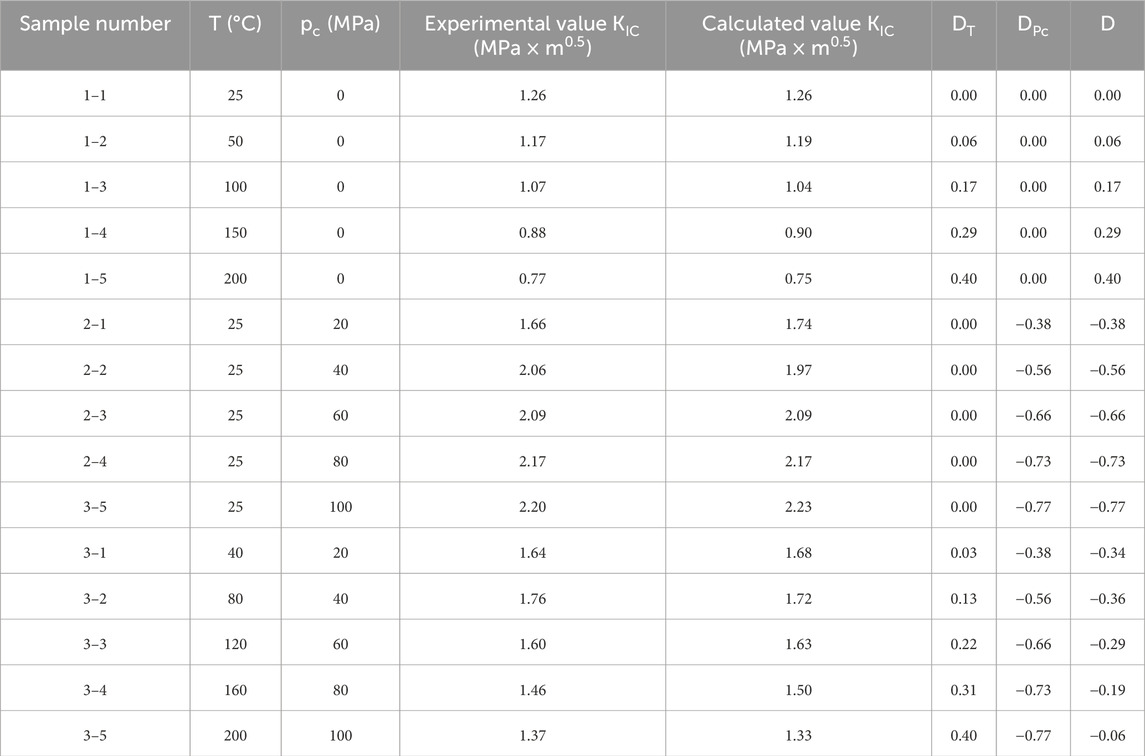

Table 2. Results of fracture toughness of rock samples under different temperature and ambient pressure conditions.

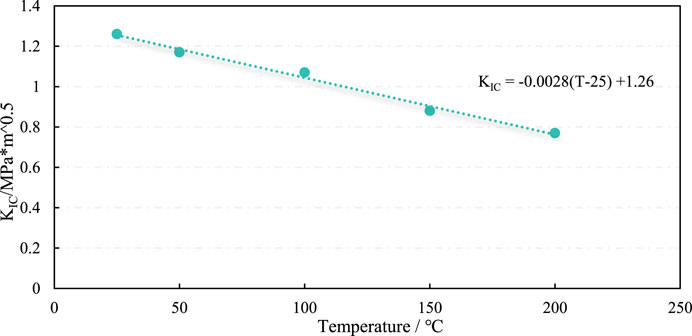

3.2 Relation between fracture toughness and temperature

The confining pressure of the first group of samples was 0, and the fracture toughness of the samples showed a linear decreasing trend with the increase of temperature. When the temperature increased from 25°C to 200°C, the fracture toughness decreased by 40%. According to the experimental results, formula 2 was used to fit the test results of fracture toughness at different temperatures without confining pressure, and a better fitting result was obtained. The relationship between fracture toughness and temperature of the sample was shown in Figure 8. The loading curve of internal pore pressure-time at different temperatures is shown in Figure 9. As the loading rate is the same, the internal pore pressure increases linearly with time before failure. When the internal pore pressure reaches the highest point, the sample breaks, the internal pore pressure suddenly drops, and the highest point of internal pore pressure decreases with the increase of temperature, which is because micro-cracks occur in the rock as the temperature increases. It is more likely to fracture along prefabricated cracks under inner hole pressure.

Where

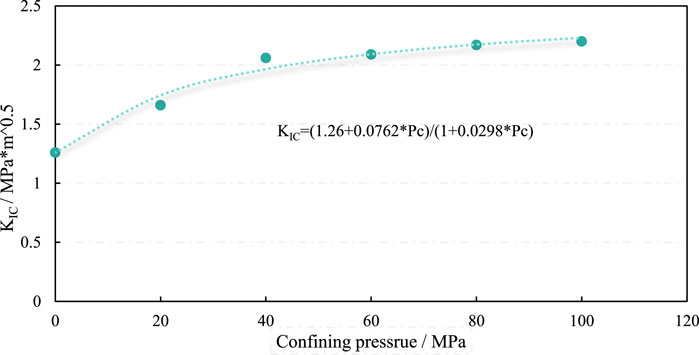

3.3 Relation between fracture toughness and confining pressure

The results of samples No. 1–1, 2–1∼2-5 were used to analyze the influence of confining pressure on fracture toughness at 25°C. It can be seen from Table 2 that the fracture toughness of the sample increases with the increase of confining pressure, from 0 MPa to 100 MPa, and the fracture toughness increases by 76%. The variation of sample fracture toughness with confining pressure is shown in Figure 10. The fracture toughness does not increase linearly with the increase of confining pressure, but increases rapidly when the confining pressure is lower than 40 MPa, while the fracture toughness increases slowly when the confining pressure is higher than 40 MPa. This phenomenon likely occurs because under low confining pressure (<40 MPa), the gradual closure of pre-existing microcracks and pores within the rock significantly increases the material’s compactness, thereby rapidly enhancing fracture toughness. Under high confining pressure (>40 MPa), as most microcracks are already closed, the confining pressure primarily improves toughness by suppressing macroscopic crack propagation or promoting plastic deformation, causing the strengthening effect to become more gradual. After analysis, the fitting of the relationship between fracture toughness and confining pressure by Equation 3 can obtain better fitting results. The pressure time loading curve of the inner hole under different confining pressures is shown in Figure 11. The higher the confining pressure, the higher the pressure of the inner hole will be when the sample breaks.

Where,

4 Prediction model of fracture toughness under the combination of temperature and confining pressure

It can be seen from the experimental curve that the fracture toughness of rock samples decreases with the increase of ambient pressure. Based on the principle of damage mechanics (Hou et al., 2021; 2022; 2024), the damage factor of fracture toughness with ambient temperature and ambient pressure is introduced:

Under the combination of temperature and surround pressure, damage D of rock consists of two parts: damage

The fracture toughness of rock samples under the action of temperature and surrounding pressure can be obtained from the principle of damage mechanics:

By Equation 4, Equation 5 and Equation 6 into Equation 7, the prediction model of the fracture toughness evolution of rock sample with temperature and confining pressure is obtained:

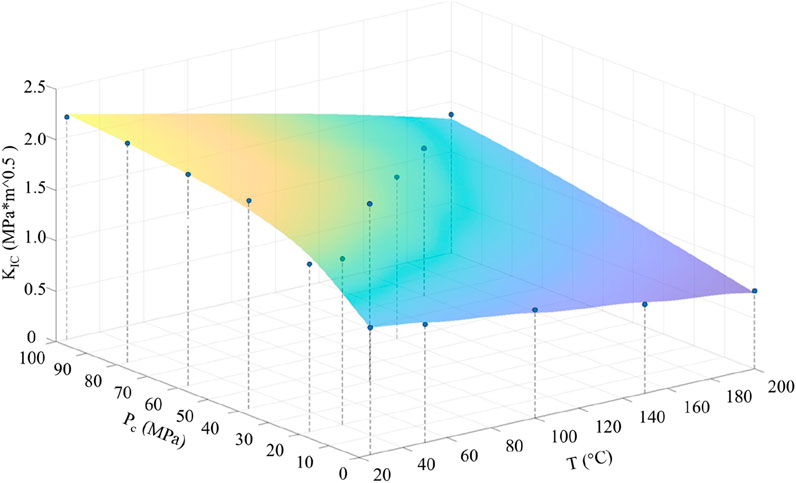

According to Equation 8, the experimental temperature and the fracture toughness are calculated and predicted, and the calculation results and experimental results are shown in Table 3:

Table 3. Experimental and calculated fracture toughness at different temperatures and ambient compression conditions.

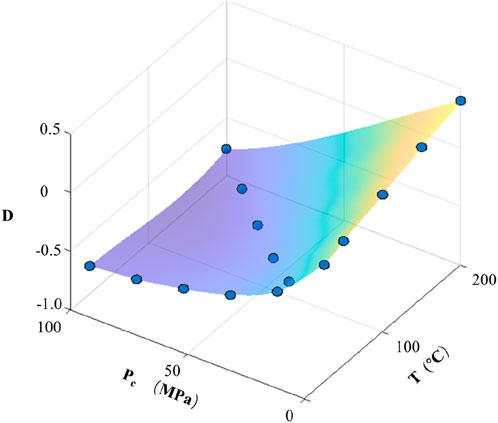

As can be seen from Table 3, When the temperature is higher than room temperature (25°C), the temperature damage DT is positive and increases with the increase of temperature, indicating that the temperature damage of fracture toughness of rock samples increases and the fracture toughness decreases with the increase of temperature. When the confining pressure is greater than 0 MPa, the confining pressure damage DPc is negative, indicating that the confining pressure makes the microcracks close, the fracture extension is difficult, and the fracture toughness increases. Damage value (D) changes with temperature and confining pressure as shown in Figure 12. The calculated results of the fracture toughness prediction model considering temperature-confining pressure are in agreement with the experimental results (Figure 13). The proposed model effectively characterizes the nonlinear evolution of rock fracture toughness under temperature-confining pressure coupling conditions. By incorporating the temperature damage DT and confining pressure damage DPc derived from damage mechanics theory, the model ensures explicit physical interpretability of its parameters. It achieves decoupled calculation of multi-field coupling effects through the linear superposition principle, significantly reducing parameter inversion complexity while maintaining theoretical rigor. Experimental validation demonstrates exceptional prediction accuracy within the ranges of 0°C–200°C and 0–200 MPa confining pressure, providing a reliable theoretical framework for hydraulic fracturing design in deep carbonate reservoirs.

5 Conclusion

This study systematically investigates the thermo-mechanical coupling effects on Mode I fracture toughness of carbonate rocks through double-wing symmetric crack thick-wall cylinder tests under temperature (25°C–200°C) and confining pressure (0–200 MPa) conditions. The key contributions and findings are summarized as follows:

(1) Temperature Dominance: Under zero confining pressure, the fracture toughness damage value exhibits a positive correlation with temperature (25°C–200°C), revealing a 40% reduction in Mode I fracture toughness. This highlights the thermally-induced microcracking mechanism that dominates fracture propagation in high-temperature environments.

(2) Confining Pressure Reinforcement: At ambient temperature (25°C), increasing confining pressure (0–100 MPa) induces negative damage values, demonstrating a 76% enhancement in Mode I fracture toughness. This quantifies the pressure-driven crack closure effect critical for fracture containment in deep reservoirs.

(3) Predictive Framework: A damage mechanics-based model integrating temperature-dependent degradation and confining pressure enhancement factors is established. Validated against experimental data (mean absolute error <5%), this model provides a robust tool for evaluating fracture toughness under extreme conditions (200°C/200 MPa), directly addressing the challenges of hydraulic fracturing design in ultra-deep carbonate reservoirs.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

BC: Writing – original draft, Writing – review and editing. NX: Writing – review and editing. DL: Writing – review and editing. HF: Conceptualization, Writing – review and editing. XD: Writing – review and editing. DD: Writing – review and editing. HZ: Writing – review and editing. XH: Writing – review and editing. SY: Writing – review and editing. LD: Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. Fundings:This work was supported by CNPC Science and Technology Special Project “Common basic research of unconventional reservoir volumetric fracturing” (2023ZZ28YJ01), state fund project “Propagation and control mechanism of joint force-chemical action of hydraulic fracture network under super-deep strong stress” (U23B2084), forward-looking basic technology research projects of CNPC “Reservoir characterization technology based on core image recognition” (2023DJ84) and supported by the “Sichuan Youth Sci-Tech Innovation Team Project” (2022JDTD0007). The authors declare that this study received funding from CNPC. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Al-Shayea, N. A., Khan, K., and Abduljauwad, S. N. (2000). Effects of confining pressure and temperature on mixed-mode (I-II) fracture toughness of a limestone rock. Int. J. Rock Mech. Min. Sci. 37 (4), 629–643. doi:10.1016/S1365-1609(00)00003-4

An, M., Huang, R., Elsworth, D., Zhang, F., Yin, Z. Y., Huang, L., et al. (2025). Reactivation of critically-stressed basement faults and related induced seismicity in the southeastern Sichuan basin. Tectonophysics 898, 230628. doi:10.1016/J.TECTO.2025.230628

Cao, Z. Z., Zhang, S. Y., Du, F., Ma, D., Li, Z. H., Huang, C. H., et al. (2025). Water inrush mechanism and variable mass seepage of karst collapse columns based on a nonlinear coupling mechanical model. MINE WATER Environ. doi:10.1007/s10230-025-01041-4

Chen, P., Chen, X., Yang, S., Li, Z., Shen, C., Qiu, H., et al. (2025). Complex in-situ stress distributions in ultra-deep marine carbonate reservoirs: 3D numerical simulation in the Yuemanxi Block, Tarim Basin. Mar. Petroleum Geol. 173, 107297. doi:10.1016/J.MARPETGEO.2025.107297

Chen, Y., Xiao, P., Du, X., Wang, S., Wang, Z., and Azzam, R. (2021). Study on damage statistical constitutive model of triaxial compression of acid-etched rock under coupling effect of temperature and confining pressure. Materials 14 (23), 7414. doi:10.3390/MA14237414

Clifton, R. J., Simonson, E. R., Jones, A. H., and Green, S. J. (1976). Determination of the critical-stress-intensity factor KIc from internally pressurized thick-walled vessels - the critical-stress-intensity factor of thick-walled rock specimens is determined from the pressure at failure. Exp. Mech. 16 (6), 233–238. doi:10.1007/BF02329274

Dai, Y., Hou, B., Lee, S., and Wick, T. (2024). A thermal–hydraulic–mechanical–chemical coupling model for acid fracture propagation based on a phase-field method. Rock Mech. Rock Eng. 57 (7), 4583–4605. doi:10.1007/S00603-024-03769-X

Dai, Y., Hou, B., Zhou, C., Zhang, K., and Liu, F. (2021). Interaction law between natural fractures-vugs and acid-etched fracture during steering acid fracturing in carbonate reservoirs. Geofluids 2021, 1–16. doi:10.1155/2021/6649874

Detournay, C., Damjanac, B., Torres, M., Cundall, P., Ligocki, L., and Gil, I. (2022). Heat advection and forced convection in a lattice code – implementation and geothermal applications. Rock Mech. Bull. 1 (1), 100004. doi:10.1016/J.ROCKMB.2022.100004

Dontsov, E. V. (2022). Analysis of a constant height hydraulic fracture driven by a power-law fluid. Rock Mech. Bull. 1 (1), 100003. doi:10.1016/J.ROCKMB.2022.100003

Fu, H., Cai, B., Geng, M., Jia, A., Weng, D., Liang, T., et al. (2022). Three dimensional simulation of hydraulic fracture propagation based on vertical reservoir heterogeneity. Nat. Gas. Ind. 42 (5), 56–68. doi:10.3787/J.ISSN.1000-0976.2022.05.006

Gao, M., Yang, M., Lu, Y., Levin, V. A., He, P., and Zhu, H. (2024). Mechanical characterization of uniaxial compression associated with lamination angles in shale. Adv. Geo-Energy Res. 13 (1), 56–68. doi:10.46690/AGER.2024.07.07

Gao, W., Zhao, J., and Wang, H. (2023). Rock physics experiment and rock physical modeling of hot dry rock under high temperature. J. Min. Sci. Technol. 8 (6), 758–767. doi:10.19606/J.CNKI.JMST.2023.06.003

Hou, B., Dai, Y., Zhou, C., Zhang, K., and Liu, F. (2021). Mechanism study on steering acid fracture initiation and propagation under different engineering geological conditions. Geomechanics Geophys. Geo-Energy Geo-Resources 7 (3), 73. doi:10.1007/S40948-021-00271-4

Hou, B., Zhang, Q., Liu, X., Pang, H., and Zeng, Y. (2022). Integration analysis of 3D fractures network reconstruction and frac hits response in shale wells. Energy 260, 124906. doi:10.1016/J.ENERGY.2022.124906

Hou, B., Zhang, Q., and Lv, J. (2024). Distributed fiber optic monitoring of asymmetric fracture swarm propagation in laminated continental shale oil reservoirs. Rock Mech. Rock Eng. 57 (7), 5067–5087. doi:10.1007/S00603-024-03791-Z

Huang, L., He, R., Yang, Z., Tan, P., Chen, W., Li, X., et al. (2023). Exploring hydraulic fracture behavior in glutenite formation with strong heterogeneity and variable lithology based on DEM simulation. Eng. Fract. Mech. 278, 109020. doi:10.1016/J.ENGFRACMECH.2022.109020

Huang, L., Liao, X., Fu, H., Wang, X., Weng, D., Feng, G., et al. (2025). Interaction behaviors between finite-scale natural and hydraulic fractures in hot dry rock geothermal systems. Phys. Fluids 37 (2). doi:10.1063/5.0252814

Huang, L., Liu, J., Zhang, F., Dontsov, E., and Damjanac, B. (2019). Exploring the influence of rock inherent heterogeneity and grain size on hydraulic fracturing using discrete element modeling. Int. J. Solids Struct. 176–177, 207–220. doi:10.1016/J.IJSOLSTR.2019.06.018

Huang, L., Liu, R., He, R., Ma, J., Tan, P., and Wang, C. (2024). Numerical simulation of mesoscopic deformation and failure for glutenite in triassic baikouquan formation, junggar basin. Petroleum Geol. Exp. 46 (4), 833–844. doi:10.11781/SYSYDZ202404833

Huang, L. K., Dontsov, E., Fu, H. F., Lei, Y., Weng, D. W., and Zhang, F. S. (2022). Hydraulic fracture height growth in layered rocks: perspective from DEM simulation of different propagation regimes. Int. J. SOLIDS Struct. 238, 111395. doi:10.1016/j.ijsolstr.2021.111395

Huang, L. K., Liao, X. C., Fu, H. F., Zhang, L. H., Zhao, Y. L., Wang, X. H., et al. (2024). Interplay mechanisms between hydraulic fractures and natural fractures in various propagation regimes. Phys. FLUIDS 36 (10). doi:10.1063/5.0234922

Huang, L. K., Liao, X. C., Zhang, Y. M., Zhao, Q. Y., Liu, Q., Li, J. T., et al. (2025). Multi-hole synchronous linkage control fracturing in low permeability coal seams based on three-dimensional lattice method. Phys. FLUIDS 37 (4). doi:10.1063/5.0264244

Huang, L. K., Liu, J. J., Zhang, F. S., Fu, H. F., Zhu, H. Y., and Damjanac, B. (2020). 3D lattice modeling of hydraulic fracture initiation and near-wellbore propagation for different perforation models. J. PETROLEUM Sci. Eng. 191, 107169. doi:10.1016/j.petrol.2020.107169

Huang, L. K., Tan, J., Fu, H. F., Liu, J. J., Chen, X. Y., Liao, X. C., et al. (2023). The non-plane initiation and propagation mechanism of multiple hydraulic fractures in tight reservoirs considering stress shadow effects. Eng. Fract. Mech. 292, 109570. doi:10.1016/j.engfracmech.2023.109570

Ignacio, P.-R., Muñoz-Ibáñez, A., González-Fernández, M. A., Muñiz-Menéndez, M., Penabad, M. H., Estévez-Ventosa, X., et al. (2023). Size effects on the tensile strength and fracture toughness of granitic rock in different tests. J. Rock Mech. Geotechnical Eng. 15, 2179–2192. doi:10.1016/j.jrmge.2022.11.005

Ji, G. F., Li, K. D., Zhang, G. S., Li, S. M., Zhang, L., and Liu, W. (2019). Fractal calculation method of model I fracture toughness of shale rock and its application. Yantu Lixue/Rock Soil Mech. 40 (5), 1925–1931. doi:10.16285/J.RSM.2018.0390

Kataoka, M., Mahdavi, E., Funatsu, T., Takehara, T., Obara, Y., Fukui, K., et al. (2017). Estimation of mode i fracture toughness of rock by semi-circular bend test under confining pressure condition. Procedia Eng. 191, 886–893. doi:10.1016/J.PROENG.2017.05.258

Li, C., Feng, G., Zhang, X., Zhang, C., Hu, Y., and Meng, T. (2024). Study on the failure mechanism of high-temperature granite under two cooling modes. Sci. Rep. 14 (1), 15630. doi:10.1038/S41598-024-66073-2

Lin, H., Liu, W., Zhang, D., Chen, B., and Zhang, X. (2025). Study on the degradation mechanism of mechanical properties of red sandstone under static and dynamic loading after different high temperatures. Sci. Rep. 15 (1), 11611. doi:10.1038/S41598-025-93969-4

Longinos, S. N., Skrzypacz, P., and Hazlett, R. (2024). Cryofracturing effectiveness using liquid nitrogen on granite: fracture toughness and Brazilian tests following freezing-thawing cycle. Results Eng. 21, 101895. doi:10.1016/J.RINENG.2024.101895

Lu, T., Wu, H., Yin, S., and Xu, X. (2024). Study of rock damage constitutive model considering temperature effect based on weibull distribution. Appl. Sci. Switz. 14 (9), 3766. doi:10.3390/APP14093766

Luo, H., Xie, J., Huang, L., Wu, J., Shi, X., Bai, Y., et al. (2022). Multiscale sensitivity analysis of hydraulic fracturing parameters based on dimensionless analysis method. Lithosphere 2022 (SpecialIssue12). doi:10.2113/2022/9708300

Pandey, V. J., and Rasouli, V. (2021). Fracture height growth prediction using fluid velocity based apparent fracture toughness model. Rock Mech. Rock Eng. 54 (8), 4059–4078. doi:10.1007/S00603-021-02489-W

Peng, Y., Xie, J., Zhu, Z., Liu, J., and Xue, K. (2023). An error-correction analysis of scaled model for mode-I fracture toughness of sandstone under impact load. Theor. Appl. Fract. Mech. 125, 103837. doi:10.1016/J.TAFMEC.2023.103837

Ren, C., Yu, J., Liu, S., Yao, W., Zhu, Y., and Liu, X. (2022). A plastic strain-induced damage model of porous rock suitable for different stress paths. Rock Mech. Rock Eng. 55 (4), 1887–1906. doi:10.1007/S00603-022-02775-1

Tan, P., Chen, Z. W., Huang, L. K., Zhao, Q., and Shao, S. R. (2024b). Evaluation of the combined influence of geological layer property and in-situ stresses on fracture height growth for layered formations. Petroleum Sci. 21 (5), 3222–3236. doi:10.1016/J.PETSCI.2024.07.014

Tan, P., Fu, S., Huang, L., Chen, Z., and Cao, J. (2024a). Effects of orthogonal cleat structures on hydraulic fracture evolution behavior. Geoenergy Sci. Eng. 241, 213119. doi:10.1016/J.GEOEN.2024.213119

Wang, X., Feng, G., Hu, Y., Huang, L., Xie, H., Zhao, Y., et al. (2024). Recent advancements in petroleum and gas engineering. Energies 17 (18), 4664. doi:10.3390/EN17184664

Wen, J., Yin, Y., and Zhang, M. (2024). Experimental study on fracture toughness of shale based on three-point bending semi-circular disk samples. Processes 12 (7), 1368. doi:10.3390/PR12071368

Xiaotong, X. U., Zeng, L., Dong, S., Diwu, P., Haiming, L. I., Liu, J., et al. (2024). Fracture effectiveness and its influence on gas productivity in ultra-deep tight sandstone reservoirs of the keshen gas field, Tarim Basin. Acta Geol. Sin. Engl. Ed. 98 (6), 1557–1573. doi:10.1111/1755-6724.15259

Xu, J. G., Dong, S. M., and Hua, W. (2015). Effect of confining pressure on stress intensity factors determined by cracked Brazilian disk. Yantu Lixue/Rock Soil Mech. 36 (7), 1959–1965. doi:10.16285/J.RSM.2015.07.017

Ye, Q., He, X., Suo, Y., Zhao, S., Ai, C., Qiao, L., et al. (2022). The statistical damage constitutive model of Longmaxi shale under high temperature and high pressure. Lithosphere 2022 (SpecialIssue12), 2022. doi:10.2113/2022/2503948

Yu, S., Deng, H., and Zhang, Y. (2018). The constitutive relationship of rock damage considering the effect of temperature and confining pressure. J. Railway Sci. Eng. 15 (4), 893–901.

Zeng, L., Song, Y., Han, J., Han, J., Yao, Y., Huang, C., et al. (2025). Control of structure and fluid on ultra-deep fault-controlled carbonate fracture-vug reservoirs in the Tarim Basin, NW China. Petroleum Explor. Dev. 52 (1), 143–156. doi:10.1016/S1876-3804(25)60010-3

Zhang, F., Lu, M., Yang, F., Cao, G., and Zhang, L. (2024). Recent advancements and practices of fracturing technology in continental shale reservoirs. Adv. Geo-Energy Res. 13 (3), 237–240. doi:10.46690/AGER.2024.09.08

Zhang, F., Wu, J., Huang, H., Wang, X., Luo, H., Yue, W., et al. (2021). Technological parameter optimization for improving the complexity of hydraulic fractures in deep shale reservoirs. Nat. Gas. Ind. 41 (1), 125–135. doi:10.3787/J.ISSN.1000-0976.2021.01.011

Zhang, L., Yang, D., Zhao, K., Zhao, Y., Jin, J., Wang, X., et al. (2024). Investigation of high-temperature effects on the strengthening and degradation of mechanical property in sandstone. Appl. Energy 357, 122532. doi:10.1016/J.APENERGY.2023.122532

Zhang Q., Q., Hou, B., Lin, B., Liu, X., and Gao, Y. (2021). Integration of discrete fracture reconstruction and dual porosity/dual permeability models for gas production analysis in a deformable fractured shale reservoir. J. Nat. Gas Sci. Eng. 93, 104028. doi:10.1016/J.JNGSE.2021.104028

Zhang, X., Gong, H., Luo, Y., Peng, J., Li, Q., and Yang, C. (2024). Characterization and constitutive modeling of the high strain rate behavior of granite at low temperatures. Mech. Time-Dependent Mater. 28, 2681–2704. doi:10.1007/S11043-024-09667-7

Zhou, L., Dong, Y., Zhu, Z., Gao, W., Yang, Z., and Wang, X. (2022). Influence of high temperature on micro and macro mechanical fracture characteristics of granite. Zhongnan Daxue Xuebao (Ziran Kexue Ban)/Journal Central South Univ. Sci. Technol. 53 (4), 1381–1391. doi:10.11817/J.ISSN.1672-7207.2022.04.023

Keywords: fracture toughness, temperature, confining pressure, rock mechanics, carbonate rock

Citation: Cai B, Xiu N, Li D, Fu H, Dai X, Deng D, Zhao H, Han X, Yuan S and Deng L (2025) Experimental study on rock fracture toughness under temperature and confining pressure coupling condition. Front. Earth Sci. 13:1603219. doi: 10.3389/feart.2025.1603219

Received: 31 March 2025; Accepted: 22 May 2025;

Published: 30 May 2025.

Edited by:

Kouqi Liu, Peking University, ChinaReviewed by:

Hongjian Zhu, Yanshan University, ChinaZhengzheng Cao, Henan Polytechnic University, China

Copyright © 2025 Cai, Xiu, Li, Fu, Dai, Deng, Zhao, Han, Yuan and Deng. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Liangang Deng, MTAzOTM3MTM5NEBxcS5jb20=

Bo Cai1

Bo Cai1 Liangang Deng

Liangang Deng