Abstract

The article concerns one of the most important issues related to occupational safety in Polish hard coal mines. In general, the issue of safety is related to the occurrence of two groups of factors in the extraction process: geological-mining and technical-organizational. Both of these groups cause a number of hazards. Hazards related to the exploitation of minerals from the underground have accompanied miners since the beginning of mining. In the Polish mining industry, over the last 22 years, it can be observed that the number of accidents has decreased by only 1/3. At the same time, the accident frequency index (Wz) increased from 17.31 in 2002 to 27.71 in 2023. Accident monitoring and indicator analysis are key to improving occupational safety conditions and preventing future accidents. The probability of an accident at work in mines is several times higher than the average value obtained for all positions in the economy, especially in Poland, where hard coal is extracted using the underground method. The article presents accident statistics in hard coal mining in Poland since 2002, calculates accident rates, and approximates the accident rate trend for subsequent years. The factors that determine accidents in Polish mines to the greatest extent were also analyzed. The division and mishaps of catastrophes, which unfortunately still occur in the Polish mining industry, were also discussed.

1 Introduction

Hazards associated with the extraction of mineral resources from beneath the Earth’s surface have accompanied mining operations since the inception of the industry. More than a century has passed since the Courrières mine disaster of 1906, which claimed the lives of 1,099 individuals. The tragedy was triggered by a coal dust explosion, and the magnitude of the incident mobilized public support for a nationwide miners’ strike aimed at demanding improvements in mine safety conditions (Szlązak and Szlązak, 2007). The most severe disasters in global hard coal mining have historically been linked to coal dust and methane explosions (Wang et al., 2024).

Despite the well-established body of knowledge and the implementation of preventive measures concerning the mechanisms and phenomena associated with coal dust and methane explosions, statistical analyses and operational experience suggest that it remains impossible to fully eliminate the occurrence of mining accidents (Cybulski et al., 2004).

The increasing depth of hard coal extraction presents new challenges for the mining industry, primarily due to the emergence of additional occupational hazards in the underground work environment (Zhenhua et al., 2025). A hazard, by definition, is a phenomenon that precedes an accident or disaster in time and arises in situations where the probability of injury or loss of life increases significantly. Such a situation occurs when there is a potential for an exchange of energy between a person and their surroundings at an intensity exceeding the level that the human body can absorb without adverse health consequences. Research and accident analyses investigating the causes of coal dust and methane explosions indicate that the root cause is most often the failure to adhere to basic safety regulations—ultimately resulting in human error as the decisive factor leading to disaster (Kapusta et al., 2019). The international scholarly literature contains research on mining disasters that establish hierarchical classifications of causes and hazards associated with accidents in hard coal mines (Dursun, 2023).

In the event of a mine disaster, it is crucial to ensure the rapid and effective provision of medical assistance, transportation, and evacuation of the injured. In underground mines, the first rescue operations are immediately undertaken by the operator’s own mine rescue units, which form organized rescue teams. Rescue and evacuation efforts are coordinated by the Rescue Operation Manager, who appoints an emergency response staff comprising the mine’s engineering and technical personnel as well as external experts.

2 Operational conditions of coal mining in Polish underground mines

Hard coal extraction in Polish deep underground mines is determined by factors that can be categorized into two main groups: mining and geological conditions, and technical and organizational conditions.

The mining and geological conditions include:

• Type of roof,

• Type of floor,

• Coal workability,

• Thickness and inclination of the coal seam,

• Presence of natural hazards.

Processes occurring within the rock mass are complex and difficult to define precisely due to the diverse geological and hydrogeological structure of the strata. Improper mining operations may lead to the formation of high-stress zones, sudden roof collapses, rock bursts, and other hazards. Even when conducted in accordance with best practices, mining operations inherently carry the risk of natural hazards (Krzemień, 1987).

Therefore, to maintain the highest level of safety, a thorough understanding of the mining and geological conditions within the exploited deposit is essential.

The type of roof is a key criterion in selecting the appropriate roof control method. This issue primarily depends on the classification of roof and floor rocks, as well as the thickness of the coal seam and the coal’s propensity for spontaneous combustion. To facilitate the selection of an appropriate mining system—particularly the method of roof control—various classifications of roof rocks have been developed.

In the overburden above a coal seam, two types of roof strata are distinguished: the immediate roof and the main roof.

The immediate roof consists of the rock layers located directly above the seam that collapse behind the mining front once the support is removed. These layers are capable of collapsing on their own and are typically composed of weak, fragmentable rocks.

The main roof refers to the hard, competent strata situated above the immediate roof. These layers do not collapse easily but rather deform towards the mined-out void and eventually break along planes of reduced strength (such as bedding planes or cleavage zones), while generally maintaining their geometric continuity.

In some cases, particularly in the Upper Silesian Coal Basin, mining conditions may lack an immediate roof altogether, with only a main roof present above the seam. Accordingly, the most general classification of roof rocks includes the following categories (

Piechota, 2008):

•Brittle roof rocks, typically associated with the immediate roof, characterized by low cohesion and strength, high deformability, and a tendency to disintegrate and fall into the mined-out area;

•Rigid roof rocks, which exhibit low deformability, high strength, and tend to collapse in large blocks behind the mining front;

•Plastic roof rocks, which possess the ability to undergo significant deformation and bending in response to the advancing excavation front.

For many years in Poland, the classification of roof rocks proposed by

Sałustowicz and Galanka (1960),

Chudek et al. (1979), and later refined by

Piechota (2008), was widely used. This system divided roof into four classes based on their geomechanical properties and structural characteristics:

•Class I: the immediate roof consists of brittle, easily collapsible rocks with a thickness exceeding five times that of the coal seam.

•Class II: the immediate roof consists of brittle, easily collapsible rocks with a thickness less than five times the thickness of the seam.

•Class III: the immediate roof is absent; the main roof is composed of a thick, rigid rock layer that is highly resistant to caving.

•Class IV: the roof strata are plastic, capable of bending and settling onto the floor without sudden collapse.

Over time, this classification was further developed, and alternative systems emerged, extending the number of roof classes to as many as six. For the conditions specific to the Upper Silesian Coal Basin, the first roof classification dedicated to the local geological context was introduced by Pawłowicz. This system was later modified by researchers at the Central Mining Institute. Detailed descriptions of these classifications can be found in the following studies: Pawłowicz (1962), Biliński and Konopko (1972), Kidybiński (1981), and Piechota (2008).

The floor (or floor) is defined as the bottom surface of the coal seam. Similar to roof strata, floor rocks are also classified based on their geomechanical behavior (

Chudek et al., 1979):

•Class I: the immediate floor consists of weak rock layers prone to creeping and deformation.

•Class II: the immediate floor consists of strong, competent rock layers.

•Class III: the floor is composed of plastic, swelling rocks that are easily extruded into the workings (e.g., claystones or mudrocks that swell upon water exposure).

Among the most disruptive geological conditions for face production are brittle roof rocks (such as shale layers that collapse immediately upon exposure) and weak floor rocks (such as swelling clays or soft mudstones), both of which can significantly interfere with stable mining operations. Coal workability is a property closely related to the cohesion of the coal. The higher the cohesion index, the more difficult the rock is to break. Workability refers to a rock’s susceptibility to separation from the solid mass using tools, cutting machines, or explosives. It is influenced not only by the rock’s hardness and cohesion, but also by in-situ stress conditions (geostatic pressure), the cross-sectional dimensions of the excavation, and the rate of its advance (Chudek et al., 1979).

Depending on the value of the workability index (denoted by the letter f), coal seams are categorized into three groups (

Poradnik Górnika, 1975):

•Group I – Easily workable seams: f = 0.4 to 1.2

•Group II – Difficult to work seams: f = 1.2 to 2.0

•Group III – Very difficult to work seams: f > 2.0

Natural hazards, particularly those related to rock and gas outbursts, are among the most dangerous phenomena encountered in underground coal mining. The risk of methane and rock outbursts increases with mining depth. As coal seams are exploited at greater depths, a noticeable rise in their methane content is observed. This, combined with a decrease in the coal’s gas permeability, significantly elevates the risk of such hazards. Key factors contributing to outburst risk include:

•The gas content of the deposit (methane-bearing capacity),

•Rock cohesion and structural integrity,

•Gas pressure and the rate of desorption,

•and mining operations conducted near geological disturbances.

There are two categories of methane and rock outburst hazards in underground hard coal mines:

•Seams prone to methane and rock outbursts – this category includes coal seams (or their parts) where:the methane content exceeds 8 m3/Mg (per metric ton of pure carbon substance), and the coal cohesion is less than 0.3, or the methane content exceeds 8 m3/Mg (per pure carbon substance), the coal cohesion is equal to or greater than 0.3, but the methane desorption rate exceeds 1.2 kPa.

•Seams threatened by methane and rock outbursts – this includes coal seams (or their parts) in which:

•A methane and rock outburst has occurred,

•A sudden outflow of methane has been recorded,

•or other symptoms have been identified indicating an increased risk of methane and rock outbursts.

The operational challenges and hazard-related conditions in Polish hard coal mines include the following (

Sikora, 2007):

•16% of coal reserves lie in seams classified as seismic hazard class II or III (rock burst-prone areas),

•25% of reserves are found in seams of methane hazard category III or IV,

•25% of reserves are located within various protective pillars,

•29% of reserves are found in seams where the rock mass temperature exceeds 28 °C.

In summary, the mining and geological conditions in Polish underground coal mines present a wide range of hazards and operational difficulties. Beyond the typical factors—such as seam inclination, roof rock cohesion, seam thickness, and coal workability—there are additional, particularly hazardous threats, including methane and rock outburst risks as well as rock burst hazards, which require specialized safety measures and mining techniques. A worker in underground mining is exposed to natural, technical, and personal hazards. Research and analyses are relatively well established for underground hard coal mines, where methane explosions have resulted not only from natural hazards but also from equipment failures (Dursun, 2020). The most difficult to control are natural hazards, which include methane and coal dust explosions, as well as rockbursts, fires, gas and rock outbursts, climatic hazards, and water-related threats (Szlązak et al., 2008). Technical hazards are primarily associated with energy stored in technical equipment or emitted during technological processes. These dangerous events typically involve contact between workers and moving machinery or transportation devices, exposure to electrical voltage, or contact with objects at excessively high temperatures. The last category comprises personal hazards, which most often arise from uncontrolled effects of muscular force and the body’s weight. This is the largest group of accidents and usually involves slips, trips, and falls, typically resulting in minor injuries (Wyższy Urząd Górniczy, 2025).

In underground mining, accident rates are determined by numerous industry-specific hazards, which can be categorized as follows:

•Natural hazards, subdivided into:

○ Catastrophic hazards: methane hazards, coal dust explosions, endogenous fires, collapses, rockbursts, methane and rock outbursts, and water hazards,

○ Non-catastrophic hazards: health-hazardous dusts, climatic and radiation hazards.

•Technical hazards associated with mechanization and electrification of mining operations, machinery and equipment design, use of explosives, and exogenous fires.

•Personal hazards caused by improper behavior of workers in the workplace (Rozporządzenia Ministra Energii z dnia, 2017).

Monitoring and alarm systems for major disasters in coal mines are based on the implementation of centralized platforms that process data using technology to ensure workplace safety in compliance with regulations and standards (Liu et al., 2014; de Freitas et al., 2022). The cornerstone of the safety system in Polish hard coal mines is the Work Environment Parameters Monitoring System SMP-NT/A. The key components of this system are sensors for continuous measurement of methane (CH4), oxygen (O2), carbon monoxide (CO) concentrations, temperature, humidity, and air flow velocity in mine workings. This system performs multiple complex functions, such as data transmission and visualization, emergency state signaling, and automatic activation of methane meter interlocks that prevent operation of machinery and technological devices under explosion hazard conditions (Krzystanek et al., 2004). Among natural hazards that carry the greatest risk and likelihood of causing a disaster in a mine, particular attention should be paid to methane and coal dust explosions (Yishan et al., 2024). Methane is a gas naturally occurring in coal seams and currently represents one of the greatest dangers associated with coal mining. In the rock mass, it exists both in a free state and in an adsorbed state, i.e., bound to the coal (Zhaoshun et al., 2025). It is a colorless, odorless gas, lighter than air, with explosive limits ranging from 5% to 15%. Especially coal seams in the central and southern parts of the Upper Silesian Coal Basin are classified as high-methane deposits, posing significant accident risks during mining operations. Methane preventive measures primarily focus on degassing the rock mass and continuously monitoring the gas concentration in mine workings, which must not exceed 2% (Turek, 2010). Coal dust in mines is considered both as an explosion hazard and in terms of its harmful effects on workers’ respiratory systems. Coal dust can explode when its concentration is within explosive limits, which for Polish geological and mining conditions range from 50 to 1,000 g/m3, and when a thermal source generates an ignition temperature of approximately 550 °C. In mining disasters, the possibility of coal dust explosion initiation and propagation triggered by a thermal factor is analyzed (Li et al., 2022). A coal dust explosion involves the rapid combustion of fine coal particles, accompanied by a sudden increase in temperature and pressure. Preventive and protective measures against explosions mainly aim to limit the formation, accumulation, and potential initiation of explosions.

3 Overview of accidents in Polish hard coal mines

3.1 Accident statistics in underground hard coal mines in the years 2002–2023

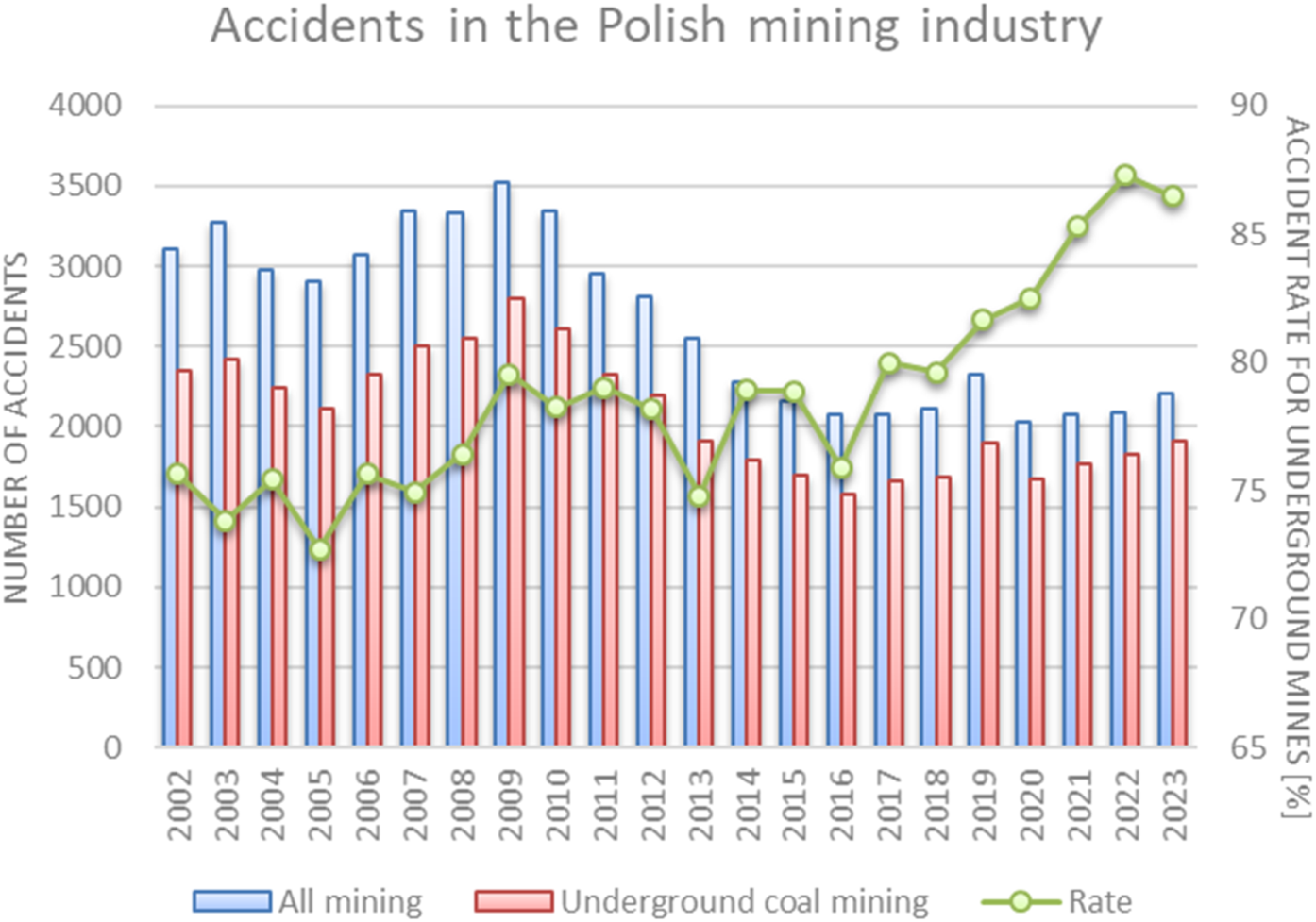

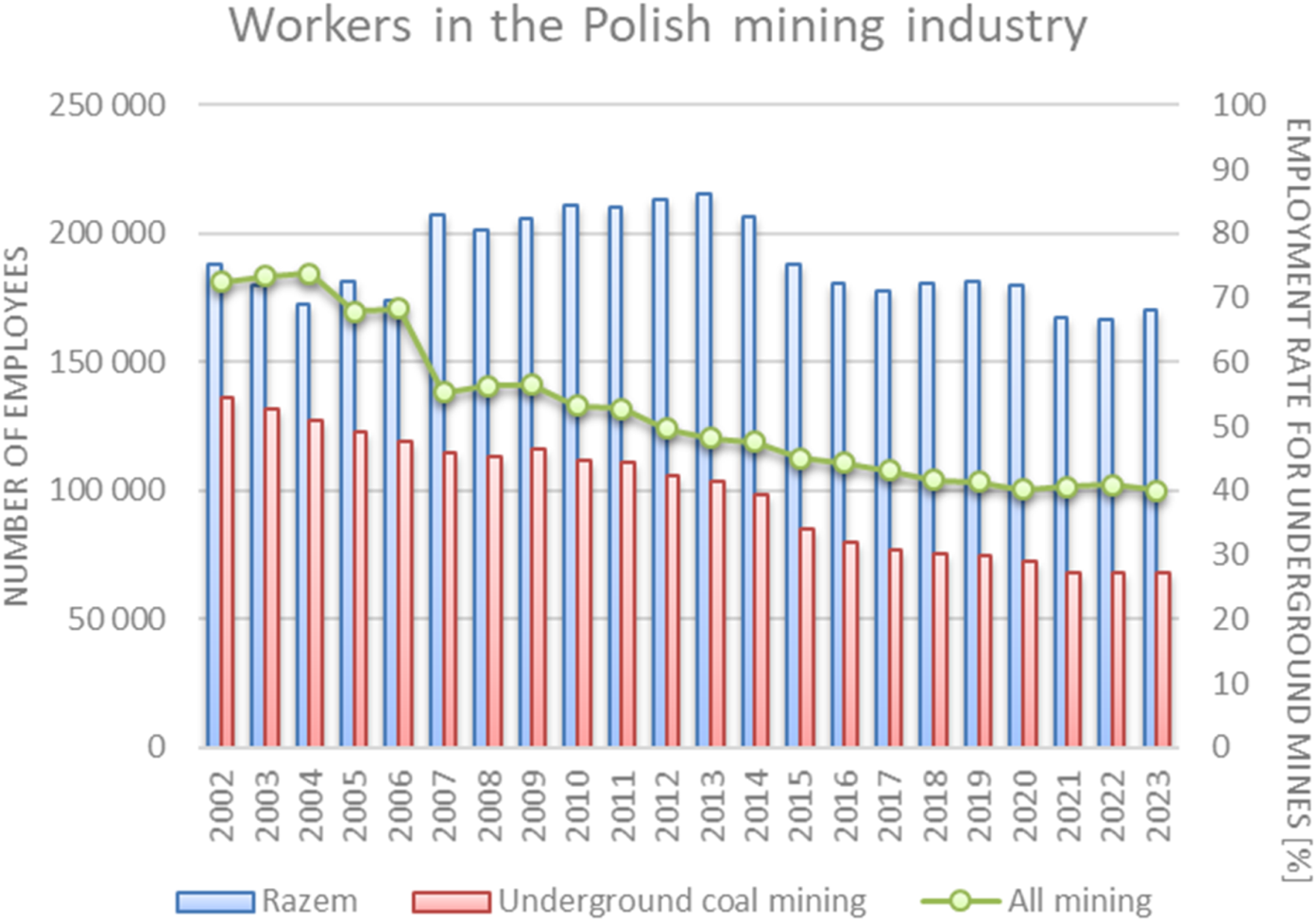

Work-related incidents are typically classified into injurious and non-injurious events. Among injurious incidents, occupational accidents are distinguished, whereas non-injurious events include near-miss incidents or potentially hazardous situations. Employers are obligated to systematically investigate the causes of workplace accidents and, based on the results of these analyses, implement appropriate preventive measures and safety interventions. In the context of hard coal mining, the predominant cause of accidents is the so-called “human factor,” which accounts for approximately 80% of incidents (Kapusta et al., 2024). Accident analysis serves not only as a tool for reporting the number and consequences of accidents, but more importantly, as a basis for implementing corrective and preventive actions aimed at reducing and eliminating accident causes. To benchmark safety performance across enterprises, accident frequency and severity rates are commonly used. However, the key element remains the development of appropriate worker attitudes and behaviors, often described in the literature as a “safety culture” (Kapusta et al., 2020). In 2023, there were a total of 2,205 occupational accidents in the Polish mining industry, of which 1,907 occurred in hard coal mines. Over the past 22 years, the total number of accidents has decreased by only one-third, despite the closure of more than half of the underground mines. Notably, in 2023, nearly 9 out of 10 accidents (86.3%) occurred in hard coal mines, compared to 3 out of 4 (75.7%) in 2002. Over the same period, hard coal production declined by more than 50%, from over 100 million tonnes in 2002 to 47.5 million tonnes in 2023. Total employment in the mining sector has remained relatively stable at approximately 170,000 employees over the last two decades. However, a clear downward trend can be observed in employment specifically within the hard coal mining segment (Kraszewska et al., 2022). In 2002, more than 70% of the mining workforce was employed in hard coal mines, whereas by 2023 this share had dropped to just 40%.

Accident data and employment trends in the mining industry over the past 22 years are presented in Table 1 and Figures 1, 2.

TABLE 1

|

Year |

Accidents | Employment | ||||

|---|---|---|---|---|---|---|

| Hard coal mines | Total mining | Share | Hard coal mines | Total mining | Share | |

| [Number of accidents] | [Number of accidents] | [%] | [Number of employees] | [Number of employee] | [%] | |

| 2002 | 2,352 | 3,108 | 75,68 | 135,850 | 187,688 | 72,38 |

| 2003 | 2,420 | 3,277 | 73,85 | 131,949 | 179,980 | 73,31 |

| 2004 | 2,242 | 2,972 | 75,44 | 127,288 | 172,585 | 73,75 |

| 2005 | 2,116 | 2,909 | 72,74 | 123,043 | 181,379 | 67,84 |

| 2006 | 2,321 | 3,068 | 75,65 | 119,019 | 174,172 | 68,33 |

| 2007 | 2,505 | 3,342 | 74,96 | 114,317 | 206,849 | 55,27 |

| 2008 | 2,551 | 3,337 | 76,45 | 113,319 | 201,080 | 56,36 |

| 2009 | 2,799 | 3,518 | 79,56 | 116,122 | 205,865 | 56,41 |

| 2010 | 2,615 | 3,342 | 78,25 | 111,911 | 210,591 | 53,14 |

| 2011 | 2,330 | 2,948 | 79,04 | 111,022 | 210,310 | 52,79 |

| 2012 | 2,196 | 2,809 | 78,18 | 106,097 | 213,486 | 49,70 |

| 2013 | 1,908 | 2,551 | 74,79 | 103,421 | 214,984 | 48,11 |

| 2014 | 1,795 | 2,274 | 78,94 | 98,066 | 206,370 | 47,52 |

| 2015 | 1,702 | 2,158 | 78,87 | 84,803 | 187,957 | 45,12 |

| 2016 | 1,575 | 2,074 | 75,94 | 79,762 | 180,213 | 44,26 |

| 2017 | 1,662 | 2,078 | 79,98 | 76,697 | 177,592 | 43,19 |

| 2018 | 1,686 | 2,117 | 79,64 | 75,225 | 180,422 | 41,69 |

| 2019 | 1,899 | 2,326 | 81,64 | 75,008 | 181,121 | 41,41 |

| 2020 | 1,674 | 2,029 | 82,50 | 72,234 | 179,730 | 40,19 |

| 2021 | 1,773 | 2,078 | 85,32 | 68,081 | 167,409 | 40,67 |

| 2022 | 1,826 | 2,092 | 87,28 | 68,165 | 166,821 | 40,86 |

| 2023 | 1,907 | 2,205 | 86,49 | 68,828 | 170,445 | 40,38 |

Occupational accidents and employment in Polish hard coal mines and in the entire mining sector in the years 2002–2023.

FIGURE 1

Number of accidents in the Polish mining industry in 2002÷2023.

FIGURE 2

Employment in the Polish mining industry in 2002÷2023.

3.2 Accident rate analysis in the years 2002–2023

Accident rate analysis is a tool used to convey information regarding the number and consequences of occupational accidents. The results of such analyses should be applied to implement corrective and preventive measures, with the aim of reducing and eliminating the root causes of accidents.

To monitor safety trends and compare safety levels across enterprises, various accident indicators are employed. The most commonly used metric is the accident frequency rate, which is published annually for all enterprises in Poland by the Central Statistical Office (GUS). This index reflects the number of reported accidents within a specific time period (usually 1 year) per 1,000 employees. In the case of hard coal mines, additional indicators are often calculated, taking into account production volume, working time, and the number of lost workdays resulting from accidents. These metrics provide a more comprehensive understanding of occupational risks and safety performance in the mining sector.

Accident Frequency Rate per 1,000 Employees

where:

• W – total number of persons injured in occupational accidents,

• Z – average number of employees.

This indicator reflects the number of accidents per 1,000 employees over a given time period (typically one calendar year). It is commonly used to compare the relative accident risk between enterprises or sectors.

Polish legislation also provides several other indicators used for the assessment of accident rates in the mining sector, although they are not as frequently applied. These include:

Accident Frequency Rate per 1 Million Megagrams of Production

Accident Frequency Rate per 100,000 Person-Days Worked

Accident Frequency Rate per 1 Million Hours Worked

Accident Severity Ratewhere:

W – total number of persons injured in occupational accidents,

T – amount of coal production in megagrams (Mg),

D – number of person-days worked,

G – number of hours worked,

DS – total number of lost workdays due to accidents,

WS – number of occupational accidents.

Monitoring of accidents and analysis of accident indicators are crucial for improving occupational safety conditions and preventing future incidents. Workstations in hard coal mines are characterized by numerous hazards and high occupational risks. The probability of occupational accidents in coal mines is several times higher than the average value observed across all job positions in the Polish economy. This is also due to the fact that in units employing a larger workforce (such as coal mines), the likelihood of an accident occurring is higher than in enterprises with fewer employees.

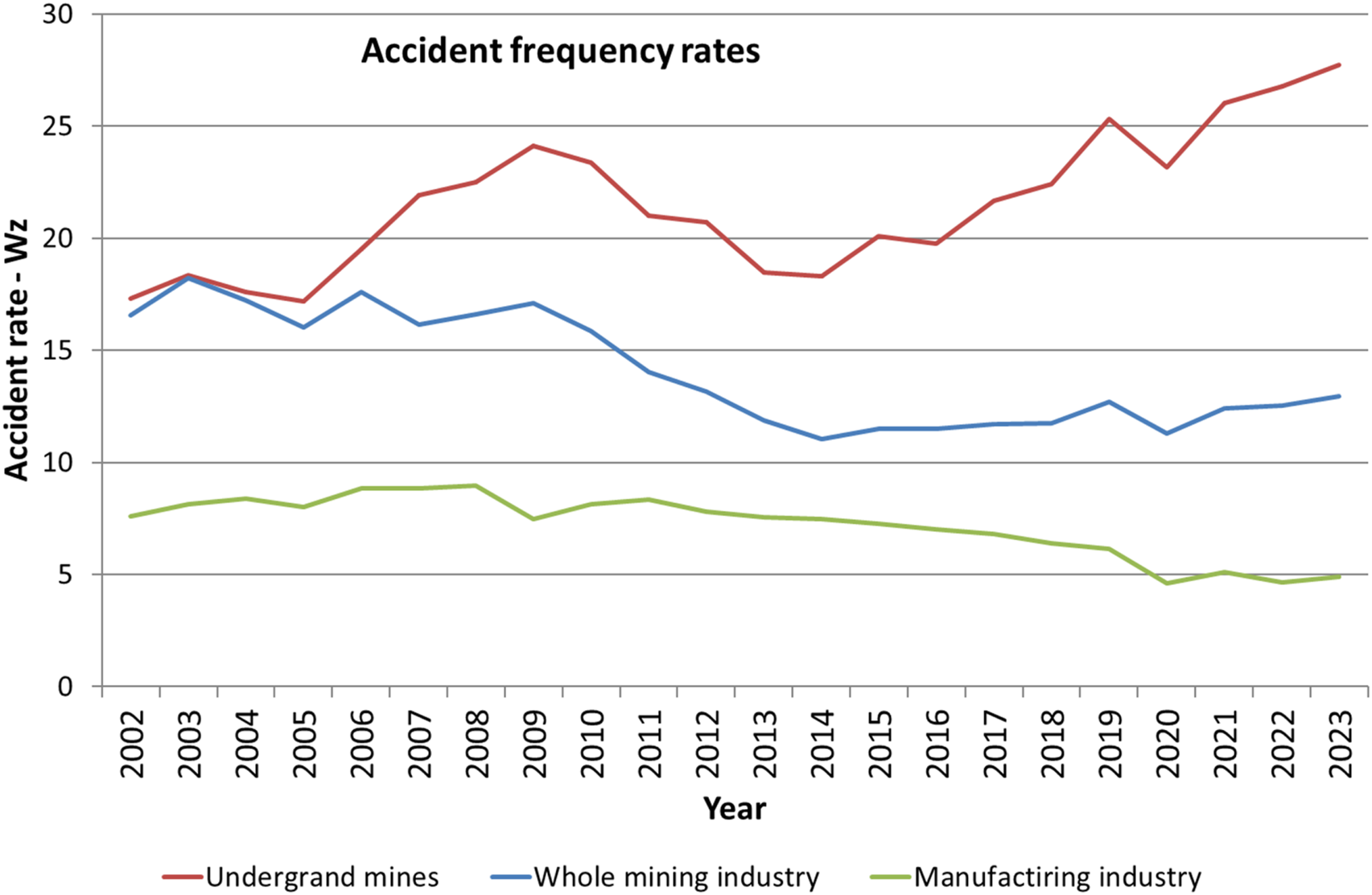

In 2002, the accident frequency rate Wz for the mining sector was approximately 17, while for the entire economy it was about 7.5. Over the following 22 years, an increasing trend in the accident frequency rate was observed in hard coal mines, reaching its highest value of 27.7 in 2023. The decline in employment did not result in a reduction in the number of accidents, which is attributed to increasingly challenging conditions of mineral extraction. In contrast, the overall mining sector (including surface mining and copper mining) as well as the entire economy exhibit a clear downward trend in accident frequency rates. In 2023, the accident frequency rate was 12.9 for the mining sector and 4.9 for the entire labor market in Poland. Changes in the accident frequency rate over the past 22 years are presented in Table 2 and illustrated in Figure 3.

TABLE 2

| Year | Accident frequency rate Wz | ||

|---|---|---|---|

| Hard coal mines | Total mining | Manufacturing industry | |

| 2002 | 17,31 | 16,56 | 7,60 |

| 2003 | 18,34 | 18,21 | 8,15 |

| 2004 | 17,61 | 17,22 | 8,38 |

| 2005 | 17,20 | 16,04 | 7,99 |

| 2006 | 19,50 | 17,61 | 8,83 |

| 2007 | 21,91 | 16,16 | 8,82 |

| 2008 | 22,51 | 16,60 | 8,96 |

| 2009 | 24,10 | 17,09 | 7,47 |

| 2010 | 23,37 | 15,87 | 8,12 |

| 2011 | 20,99 | 14,02 | 8,35 |

| 2012 | 20,70 | 13,16 | 7,78 |

| 2013 | 18,45 | 11,87 | 7,54 |

| 2014 | 18,30 | 11,02 | 7,45 |

| 2015 | 20,07 | 11,48 | 7,24 |

| 2016 | 19,75 | 11,51 | 7,00 |

| 2017 | 21,67 | 11,70 | 6,80 |

| 2018 | 22,41 | 11,73 | 6,40 |

| 2019 | 25,32 | 12,70 | 6,15 |

| 2020 | 23,17 | 11,29 | 4,62 |

| 2021 | 26,04 | 12,41 | 5,10 |

| 2022 | 26,79 | 12,54 | 4,66 |

| 2023 | 27,71 | 12,94 | 4,90 |

Accident frequency rates per 1,000 employees in the years 2002–2023.

FIGURE 3

Frequency rate of Wz accidents in the Polish mining industry in 2002÷2023.

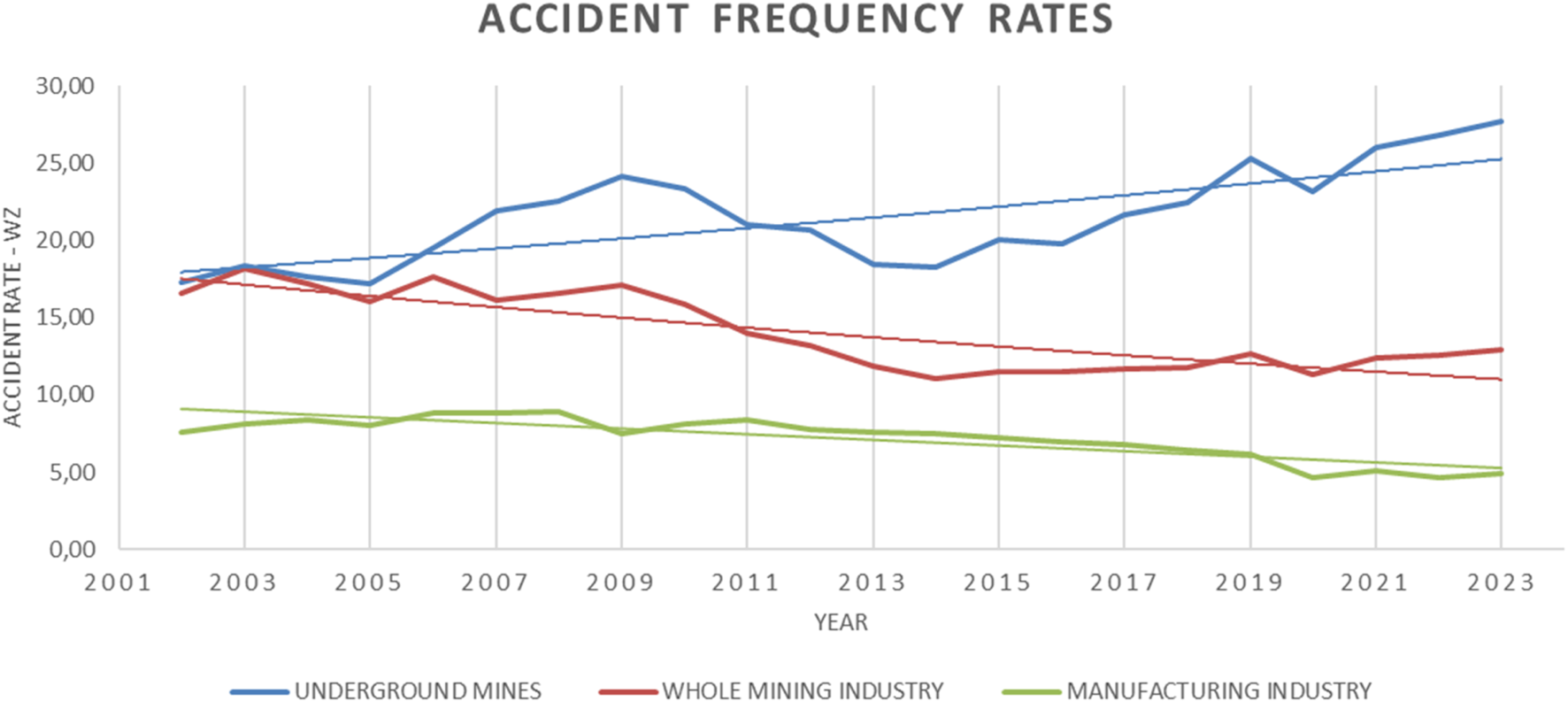

The accident frequency rate is one of the fundamental indicators of occupational safety in mining and industry. It shows how often accidents occur relative to a specific unit of production or employment. This metric enables the comparison of risk levels across different mines or time periods, regardless of their size. Accidents in mines are an undesirable phenomenon, and there is no doubt about that. Due to the complexity of causes and the stochastic nature of the production process, it is impossible to predict accidents in mines with certainty. Considering that preparations must be made both for bearing the consequences of accidents and for prevention, it is necessary to estimate future trends in accident rates.

Although this measure is not entirely objective and should be approached with a degree of tolerance, taking into account the most common types of trends, Table 3 and Figure 4 present various trend models for the accident frequency rate in hard coal mines, the mining sector in Poland overall, and the entire economy.

TABLE 3

|

Year |

Coefficient of determination R2 | ||

|---|---|---|---|

| Hard coal mines | Total mining | Manufacturing industry | |

| Exponential Model | 0,5490 | 0,7274 | 0,6873 |

| Linear Model | 0,5367 | 0,7028 | 0,7459 |

| Logarithmic Model | 0,5363 | 0,7035 | 0,7449 |

| Power Model | 0,5486 | 0,7279 | 0,6863 |

| Trend Line Equations | y = 1E-13e0,0163x | y = 3E+148x−44,61 | y = −0,1812x + 371,8 |

R2 coefficient for accident frequency index forecasting models.

FIGURE 4

Accident frequency rate trend analysis.

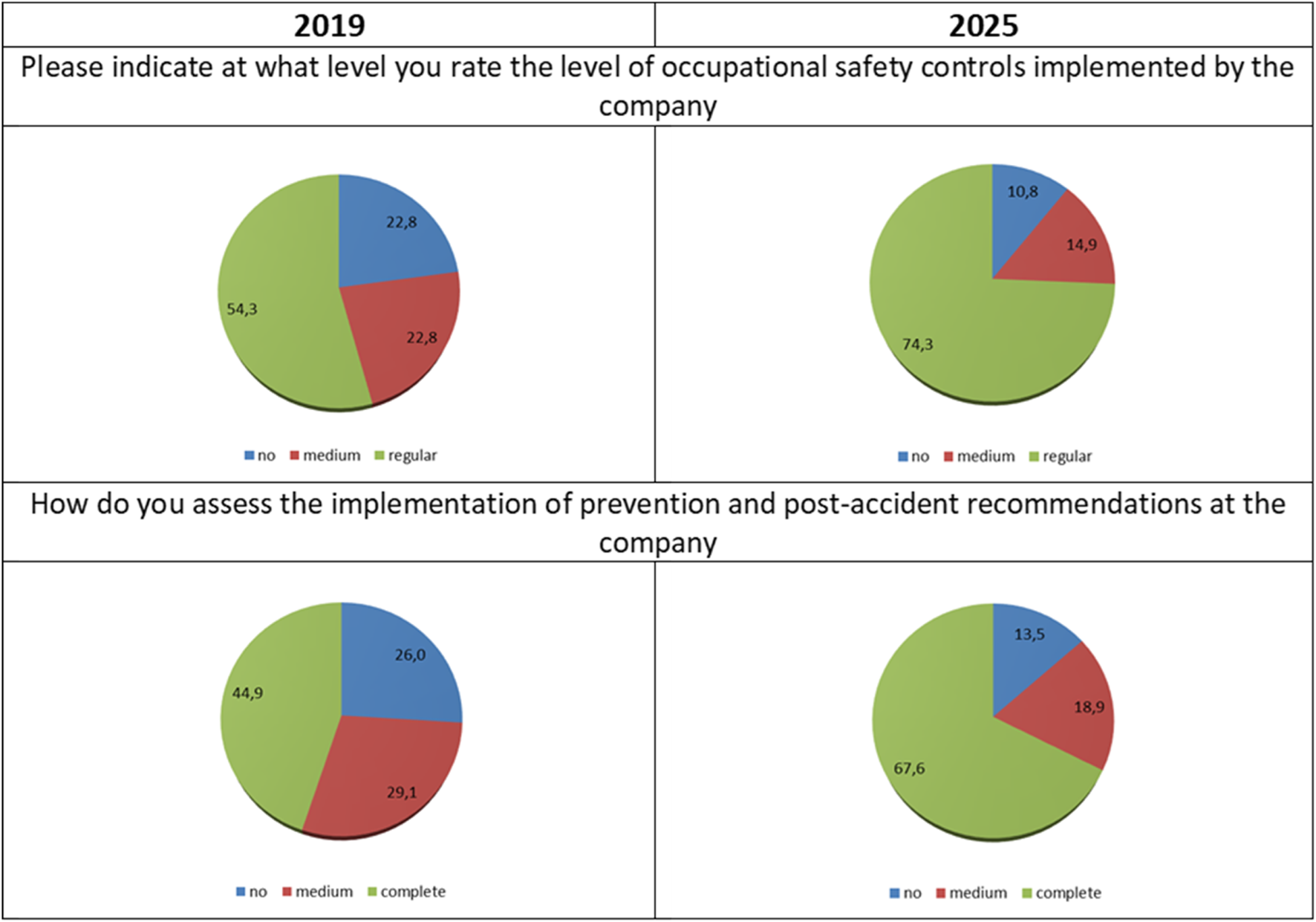

The authors of the article conducted extensive survey research to diagnose the implementation status and compliance with occupational health and safety (OHS) regulations in underground hard coal mines in Poland. The initial survey was conducted in 2019, and a follow-up survey was carried out in 2025. The results obtained are presented in Figure 5.

FIGURE 5

Comparison of safety culture survey results conducted in 2019 and 2025.

As can be seen, the occupational health and safety (OHS) situation improved over these 6 years. In response to the question regarding the level of OHS supervision in the mines, 54.3% of respondents answered “regularly” in 2019, whereas in 2025 this percentage increased to 74.3%. A significant change is also noticeable in the negative responses to this question: in 2019, as many as 22.8% of respondents stated that such supervision was lacking, while in 2025 only 10.8% reported the same. Unfortunately, this remains a relatively high proportion of negative responses, which should strongly motivate management to improve the situation. The question on how respondents assess the implementation of preventive measures and post-accident recommendations also shows a positive change. In 2019, 44.9% of respondents rated the implementation as complete, while in 2025 this increased to 67.6%. The share of negative responses dropped significantly—from 26% in 2019 to 13.5% in 2025.

3.3 Disasters in underground hard coal mines

According to the Polish Classification of Activities (Regulation of the Council of Ministers of 24 December 2007 on the Polish Classification of Activities (PKD)), the mining and quarrying section for employees engaged in hard coal extraction exhibits the highest accident frequency rates. This indicates that miners are the occupational group most exposed to accidents per 1,000 employees. However, mining accidents tend to attract public attention primarily when a disaster occurs. Table 4 presents the largest disasters in Polish hard coal mines over the past three decades, caused by methane or coal dust explosions.

TABLE 4

| No. | Mine | Number of victims | Year | Cause |

|---|---|---|---|---|

| 1 | Pniówek | 16 | 2022 | Methane explosion |

| 2 | Zofiówka | 10 | 2022 | Methane explosion |

| 3 | Mysłowice-Wesoła | 5 | 2014 | Methane explosion |

| 4 | Wujek | 20 | 2009 | Methane explosion |

| 5 | Borynia | 6 | 2008 | Methane explosion |

| 6 | Halemba | 23 | 2006 | Methane and coal dust explosion |

| 7 | Jas Mos | 10 | 2002 | Coal dust explosion |

| 8 | Halemba | 19 | 1990 | Methane explosion |

| 9 | Mysłowice | 17 | 1987 | Methane and coal dust explosion |

| 10 | Mysłowice | 19 | 1985 | Methane and coal dust explosion |

| 11 | Wałbrzych | 18 | 1985 | Methane explosion |

| 12 | Niwka-Modrzejów | 5 | 1985 | Methane and coal dust explosion |

| 13 | Dymitrow | 18 | 1982 | Coal dust explosion |

Disasters in Polish hard coal mines in the years 1982–2023.

The term mining disaster can be understood as a collective accident, which is defined as an accident resulting from the same event that affects at least two people (ISAP, 2002). However, in the context of mining, a disaster is most often referred to when extraordinary actions are required, necessitating the implementation of special management procedures and the use of forces and resources far exceeding the capabilities of the affected operational area. Such situations typically involve the engagement of rescue, technical, and security services, as well as specialized rescue teams from outside the given mine. In the initial phase of rescue operations, these tasks are carried out by on-duty rescuers from the Regional Mining Rescue Stations and teams of mining rescuers from neighboring mining facilities. When rescue operations require the application of specialized mining techniques, rescuers and specialists from the Central Mining Rescue Station in Bytom are involved.

When a methane or coal dust explosion occurs in underground mining workings, a confined space is created. Under these conditions, there is a sudden increase in pressure and temperature, accompanied by the formation of high concentrations of post-explosion gases. The extent of the spreading explosion zone is limited by the activation of water or dust explosion barriers.

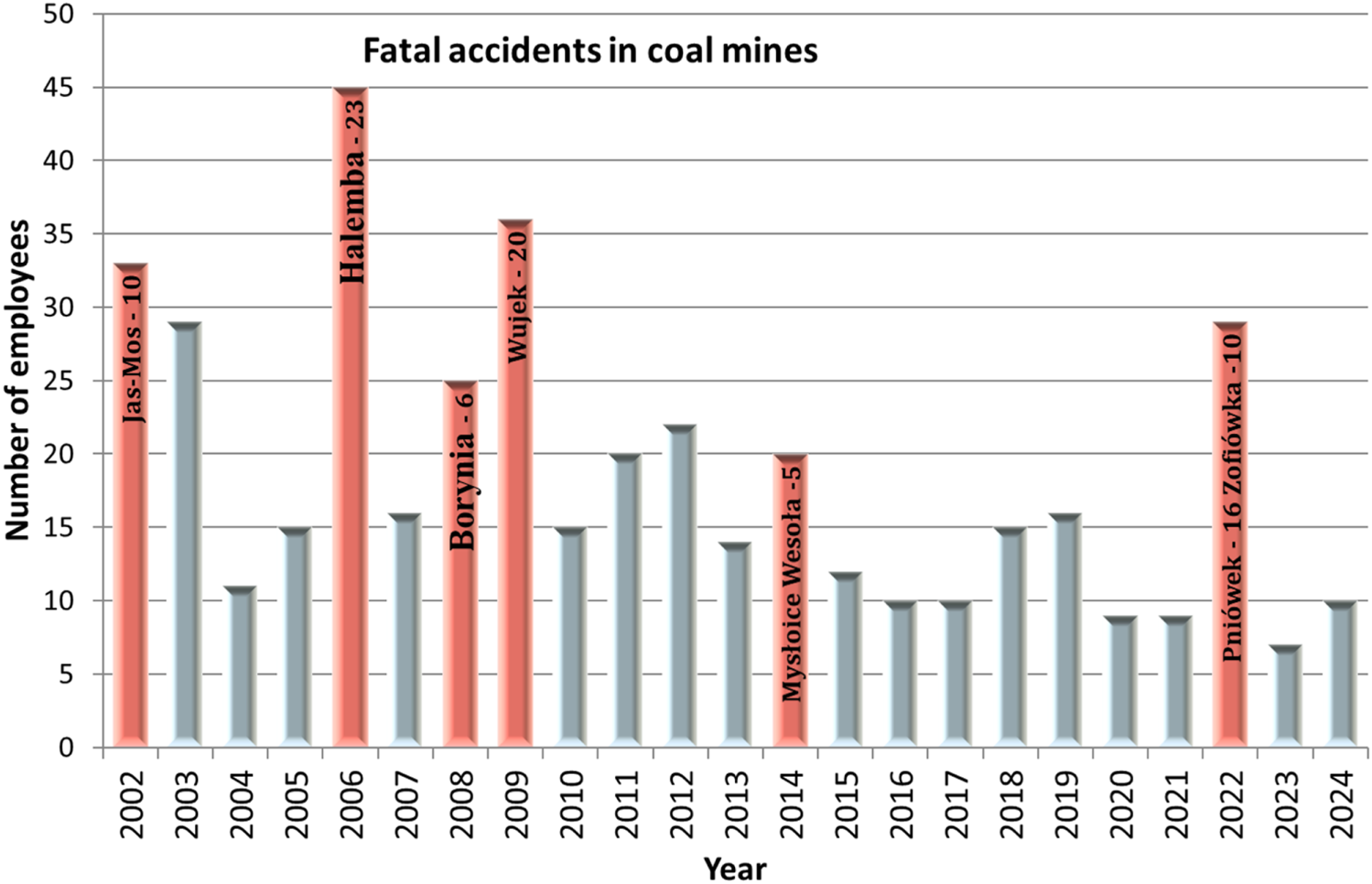

Figure 6 presents the number of persons injured in fatal accidents in coal mines from 2002 to 2024.

FIGURE 6

Number of fatal accidents in coal mines in 2002÷2024.

During the analyzed period, six incidents caused by methane and coal dust explosions were classified as mining disasters. The most tragic accidents occurred in 2006 at the Halemba mine (KWK “Halemba”), in 2009 at the Wujek mine (KWK “Wujek”), and in 2022 at the Pniówek mine (KWK “Pniówek”), resulting in a total of 59 miner fatalities. Particularly challenging rescue operations took place in April 2022 at two neighboring mines owned by Jastrzębska Spółka Węglowa (JSW S.A.). First, a methane ignition and explosion occurred on April 20 at the Pniówek mine, and after 75 h, on April 23, a methane explosion took place at the Borynia-Zofiówka mine (KWK “Borynia-Zofiówka”). Both disasters involved prolonged rescue operations lasting 13 and 4 days, respectively. In such cases, assistance is provided by the Central Mining Rescue Station (CSRG) in Bytom, along with rescuers from other mines. Specialized professional rescue teams conducted simultaneous operations in both mines, requiring precise coordination of activities and appropriate allocation of resources tailored to the evolving situations.

4 Procedures and standards of conduct in Poland

4.1 Medical care and first aid in mines

The legal framework defining the structure, organization, and tasks of mine rescue services in mining plants (mining enterprises) is provided by the Geological and Mining Law and its implementing acts, such as the Regulation of the Minister of Economy. In underground coal mines, medical assistance is provided by the employer’s mine rescue services as well as by entities professionally engaged in such activities. Furthermore, the employer is obliged to have a mine rescue plan and to ensure the constant availability of professional specialized rescue services engaged in mine rescue operations (Rozporządzenia Ministra Energii z dnia, 2017; Ustawa z dnia 9 czerwca, 2011). Medical care in mines includes periodic and preventive examinations that take into account the specific hazards and exposures faced by miners at their workplaces. In mining enterprises, these services are usually provided by entities located near the workplace, which is particularly important for the employees themselves. Doctors and nurses employed by the mines also provide first aid. However, in the case of severe, fatal accidents or disasters, this assistance is insufficient; therefore, mining companies (currently coal companies) have agreements with hospitals.

To ensure reliable and high-quality medical care for victims of workplace accidents, mines also conclude contracts or agreements with specialized hospitals, for example, in Sosnowiec, Siemianowice Śląskie, and Zabrze. An example is the Burn Treatment Center in Siemianowice Śląskie, which specializes in treating respiratory tract burns. These agreements guarantee the immediate admission of any employee injured in an individual accident or mining disaster.

Some mines also maintain a shaft-side first aid station, where doctors and nurses are on duty from 4:00 p.m. to 6:00 a.m. and during non-working days. Each mine develops its own individual solution for operating these stations, directly reflecting the specific needs in this area. The physicians are familiar with the particular conditions of the mining plant and descend underground (including female doctors), which contributes to the better quality of medical certificates issued, including those concerning fitness to work at specific positions. Moreover, the shaft-side first aid stations serve as clinics for mine employees, their family members, as well as retirees and pensioners, providing service around the clock. Attempts to centralize medical services in this area have shown that in practice there have been bad experiences, such as refusal of doctors to go underground in the mines, incompetence, disregard for duties, etc. caused, among other things, by random selection and high turnover of medical staff. Outsiders are also often characterized by a lack of knowledge of the specifics of a given mine, as well as the structure and hazards occurring at jobs in underground mining.

Each mine has its own solution regarding medical transport, which guarantees, for example, the presence of a specially equipped ambulance at a methane mine around the clock. The fact that the ambulance remains at the disposal of the mine also ensures support for other mines if such a need arises (e.g., multiple-casualty accident, mining disaster, etc.). This arrangement guarantees the provision of services at the required scope and quality.

4.2 Procedures for action during a mass accident or disaster

The main purpose of creating procedures in a mine is to establish the rules of conduct during rescue operations on the site. This especially concerns situations involving a mass accident or disaster, which create a threat to people and may lead to a crisis situation. The tasks related to conducting rescue work under stress are associated with media interest and determine the correct decision-making (

Zhu et al., 2018). This procedure also defines the operational scheme and information flow during rescue operations. In mines, the responsibility for developing and implementing procedures lies with the Director’s Safety Management Representative, while the Director is responsible for ensuring the resources necessary to carry out the tasks set out in the procedure. Employees and managers of organizational units are obliged to comply with the provisions of the procedure and are responsible for the activities assigned to them within its scope. Once a mass accident (disaster) occurs in a mine, an essential element is the order of alerting and simultaneous flow of information to the appropriate rescue services. According to the procedure for the mining facility, the order of alerting is as follows:

• Authorities, institutions, and services according to the mine’s rescue plan, which is developed and approved for each mining facility (Rozporządzenia Ministra Energii z dnia, 2017),

• Relevant crisis management center (provincial, county/city, or municipal),

• Relevant local medical dispatcher,

• Municipal or county command of the State Fire Service,

• Municipal or county Police command,

• Relevant prosecutor’s office,

• Other units (e.g., energy emergency services, gas services, water and sewage services, sanitary-epidemiological station).

The first step should be the decision to organize the Action Headquarters. Organizing the Action Headquarters involves making available the necessary rooms for conducting operations and obtaining access to documentation and information allowing for:

• Registration of the injured (creating lists of wounded, missing, and deceased persons),

• Providing conditions for medical and psychological assistance to the injured,

• Ensuring stationary and radio communication for the rescue operation,

• Ensuring transport and road passability,

• Ensuring free entry and exit of emergency vehicles to and from the rescue operation area,

• Providing a place to assist the injured and their relatives,

• Preparing copies of documentation indicated by the prosecutor, necessary for the proper further functioning of the facility, and securing other remaining documentation related to the facility’s operation to be handed over to the prosecutor.

4.3 Principles of medical rescue operations within the State Medical Rescue System

Tasks related to providing aid to persons in a state of sudden health threat are carried out under the Act on the State Medical Rescue System, effective since 1 January 2007. According to the regulations, the medical rescue system is composed of doctors, emergency nurses, and paramedics (

Ustawa z dnia 8 września, 2006). In the case of operations conducted at a mine, it is essential for the Rescue Operation Manager to ensure appropriate working conditions, which translates into the ability to provide fast and proper assistance to injured miners. In the event of a mining disaster, upon arrival of medical rescuers at the mine site, the injured should undergo triage — a rapid health assessment aimed at evaluating the threat to life. This allows classification according to the necessity of treatment and evacuation. At this stage, priorities are established to ensure the maximum number of injured persons can receive assistance using the available forces and means. Triage is initiated and then supervised by the person directing medical rescue activities, appointed by the medical dispatcher. The triage process includes:

• Removal of injured persons from the danger zone,

• Quick examination of the victims,

• Assessment of the need for decontamination, i.e., removal of harmful substances (life- or health-threatening) from the bodies of injured persons,

• Marking victims with color codes according to the triage card system based on the severity of injuries,

• Directing victims to the aid and waiting area, including the medical aid point,

• Reporting the number of injured persons.

In the medical aid point, zones are designated based on the degree of life threat:

• Red zone — highest priority, requiring immediate life-saving procedures and hospitalization within 1 h,

• Yellow zone — second priority, requiring hospital treatment, stable condition at the scene,

• Green zone — third priority, requiring examination and ambulatory care,

• Black color — deceased — those who died immediately at the scene remain there; those who die during treatment are gathered in a temporary morgue area.

In the red and yellow zones, continuous health assessment and basic life-saving medical procedures are performed. Evacuation of the injured is managed by the person in charge or a transport coordinator appointed by them.

For persons marked green who remain on site, the following should be provided:

• Shelter from weather conditions,

• Assistance in contacting relatives,

• Information about the fate of relatives (transported to hospital, evacuated),

• Possible psychological support provided by psychologists from Crisis Intervention Centers,

• Transport home.

When operating with the State Medical Rescue System units, it is important to organize a medical triage point or area, an aid and waiting area, and a transport area. The triage area is organized when medical rescuers can access the scene. In the case of methane or coal dust explosions, such sites are not accessible to medical services, and assistance is provided directly by mining rescue teams. Therefore, for the Medical Rescue Services, aid is provided in the aid and waiting areas. These are safe places with easy ambulance access and good communication for coordinating rescue activities. The designated transport area serves as a gathering point for ambulances and should also allow helicopter landing for air transport of the most severely injured persons requiring fast specialized care.

5 Result, discussion and conclusion

The work of a miner in an underground mine is associated with daily exposure to technical, natural, and personal hazards. Particularly tragic are the statistics of fatal accidents related to natural hazards. The greatest number of victims in Polish coal mines result from catastrophes caused by explosions of methane and coal dust. The specific danger related to methane or coal dust explosions lies in the fact that the accident occurs underground. The initial rescue operations immediately after the incident are conducted by rescue teams composed of miners working at their home mine. Membership in a rescue team is regarded by miners as an honor and distinction, with the motto “hope dies last” often repeated during rescue operations. A catastrophe in a mine caused by the sudden emergence of a natural hazard is always unexpected. In the initial phase of the accident, any supervisory person may act as the rescue operation leader, and their decisions can determine the success of the entire subsequent rescue effort. Therefore, knowledge of crisis procedures is crucial, as they can significantly reduce the scale of the catastrophe. The rescue operation leader acts based on procedures established for mass accident situations, and the principle of single-person command is extremely important due to the consequences of the decisions made. Coordination of underground and surface rescue services according to procedures helps avoid mistakes during situations of extreme stress and external pressure. The increasing depth of exploitation, the proximity of sedimentary and tectonic disturbances, as well as areas affected by mining remnants, are often the cause of high-energy shocks, often resulting in relaxations and rock bursts. The increase in seismic hazard and rock bursts may also occur with the co-occurrence of water hazard, especially when the drainage of water reservoirs, including lower-lying rock layers, may contribute to the disclosure or increase of seismic activity of the rock mass.

Recent survey data indicate a steady increase in occupational health and safety (OHS) awareness among workers in Polish hard coal mines. Over the 6-year period from 2019 to 2025, employee perceptions of safety supervision and preventive measures improved significantly, suggesting a gradual but meaningful transformation of safety culture within the industry. In 2019, 54.3% of respondents reported that OHS supervision in their workplace was conducted regularly. By 2025, this proportion rose to 74.3%, reflecting greater consistency in oversight practices. Similarly, only 44.9% of respondents in 2019 considered the implementation of preventive measures and post-accident recommendations to be complete, whereas by 2025 this share had grown to 67.6%. At the same time, the proportion of negative evaluations declined markedly, from 26% in 2019 to just 13.5% in 2025.

These findings point to a strengthening of safety awareness among miners and an increasingly proactive approach from management. Workers demonstrate greater recognition of the importance of adhering to safety procedures, while employers respond more effectively to identified risks. The observed changes are likely influenced by a combination of stricter oversight from regulatory authorities, the expansion of training programs, and targeted awareness campaigns within the mining sector. The steady rise in positive perceptions of OHS highlights the importance of maintaining momentum in this area. Building a culture of shared responsibility between employees and management is essential to achieving lasting improvements. Consistent implementation of preventive actions, supported by education and active supervision, offers the potential to reduce the number of workplace accidents and foster safer conditions in one of Poland’s most hazardous industries.

Statements

Author contributions

MK: Data curation, Investigation, Methodology, Project administration, Validation, Writing – review and editing. PB: Conceptualization, Formal Analysis, Methodology, Visualization, Writing – original draft. MS: Data curation, Formal Analysis, Investigation, Resources, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was prepared as part of AGH University of Krakow, scientific subsidy under number: 16.16.100.215.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1

Biliński A. Konopko W. (1972). Klasyfikacja stropów z punktu widzenia warunków stosowania obudów zmechanizowanych, prace GIG, Katowice.

2

Chudek M. Wilczyński St. Żyliński R. (1979). Podstawy górnictwa. Katowice: Wydawnictwo Śląsk.

3

Cybulski K. Lebecki K. Szulik A. (2004). Zasady eksploatacji złoża eliminujące wybuch pyłu węglowego.Szczyrk: Materiały Szkoły Eksploatacji Podziemnej 2004.

4

De Freitas C. M. da Silva M. A. de Menezes F. C. da Luz Z. M. P. (2022). Desastres em barragens de mineração como riscos sistêmicos. Rev. Bras. De. Epidemiol.25 (Suppl. 2), e220004. 10.1590/1980-549720220004.supl.2.1

5

Dursun A. E. (2020). Statistical analysis of methane explosions in Turkey’s underground coal mines and some recommendations for the prevention of these accidents: 2010–2017. Nat. Hazards104 (1), 329–351. 10.1007/s11069-020-04170-x

6

Dursun A. E. (2023). Fatal accident analysis and hazard identification in Turkish coal-extracting industry using analytic hierarchy process. Min. Metallurgy and Explor.41 (1), 149–172. 10.1007/s42461-023-00905-z

7

ISAP (2002). Ustawa z dnia 30 października 2002 r. o ubezpieczeniu społecznym z tytułu wypadków przy p10acy i chorób zawodowych. (Dz.U.Nr 199 poz. 1673 z późn.zm).

8

Kapusta M. Bąk P. Sukiennik M. (2019). A strategic analysis of selected factors that create the culture of occupational health and safety in mining companies in Poland, Pt. 1. J. Pol. Mineral Eng. Soc.21 Nr 2, 287–292. 10.29227/IM-2019-02-46

9

Kapusta M. Bąk P. Sukiennik M. (2020). Strategic analysis of selected factors shaping the occupational health and safety culture of mining companies in Poland, part 2. Pol. Mineral. Eng. Soc.1 (1), 243–247. 10.29227/IM-2020-01-81

10

Kapusta M. Bąk P. Sukiennik M. (2024). Model of the formation of work safety culture in Polish mining enterprises. Archives Min. Sci.69 (2), 253–270. 10.24425/ams.2024.150344

11

Kidybiński A. (1981). Bursting liability indices of coal. Int. J. Rock Mech. Min. Sci. Geomech. 18, 295–304. 10.1016/0148-9062(81)91194-3

12

Kraszewska M. Kashpruk N. Baranowski J. Kapusta M. (2022). “Forecasting models for Polish coal mining accidents,” in MMAR 2022: 26th International Conference on Methods and Models in Automation and Robotics, 399–402. 10.1109/MMAR55195.2022.9874303

13

Krzemień S. (1987). Zagrożenia litosferyczne w ujęciu teorii procesów losowych. Gliwice: Zeszyty Naukowe Politechniki Śląskiej.

14

Krzystanek Z. Dylong A. Wojtas P. (2004). Monitorowanie parametrów środowiska w kopalni - system SMP-NT. Mech. i Autom. Górnictwa, 91–100.

15

Li S. You M. J. Li D. W. Liu J. (2022). Coalbursts in China: theory, practice and management. J. Rock Mech. Geotechnical Eng.162, 1067–1081. 10.1016/j.psep.2022.04.054

16

Liu Y. L. Mao S. J. Li M. He X. Q. (2014). “Monitoring and alarm system of major disasters in coal mine,” in International Conference on Advanced Computer Science and Engineering (ACSE) (Guangzhou: Peoples R China), 365–369.

17

Pawłowicz K. (1962). Klasyfikacja stropów węgla w górnośląskiej niecce węglowej. Katowice: Praca doktorska, GIG.

18

Regulation of the Council of Ministers of 24 December 2007 on the Polish Classification of Activities (PKD), JL No 251, item 1885 (2007).

19

Piechota S. (2008). Technika podziemnej eksploatacji złóż i likwidacji kopalń. AGH Uczel. Wydaw. Naukowo-Dydaktyczne, Kraków.

20

Poradnik Górnika (1975). Poradnik Górnika, tom 2. Katowice: Wydawnictwo Śląsk.

21

Rozporządzenia Ministra Energii z dnia (2017). W sprawie ratownictwa górniczego (Dz.U.2022.1418).

22

Sałustowicz A. Galanka J. (1960). Mechanika górotworu. Kraków.

23

Sikora W. (2007). “Scenariusz rozwoju technologii wydobycia węgla w warunkach utrudnień górniczych,” in Konferencja Naukowo-Techniczna: Innowacyjne i bezpieczne maszyny i urządzenia dla górnictwa węgla kamiennego, Szczyrk.

24

Szlązak J. Szlązak N. (2007). Ratownictwo Górnicze. AGH uczelniane Wydawnictwo Naukowo-Dydaktyczne, Kraków.

25

Szlązak N. Obracaj D. Borowski M. (2008). Ocena stanu zagrożenia metanowego i temperaturowego w rejonie ścian eksploatacyjnych. Kraków: AGH Uczelniane Wydawnictwo Naukowo-Dydaktyczne.

26

Turek M. (2010). Podstawy podziemnej eksploatacji pokładów węgla kamiennego. Katowice: Wydawnictwo Główny Instytut Górnictwa.

27

Ustawa z dnia 8 września (2006). Państwowe ratownictwo medyczne (Dz.U.2025.637).

28

Ustawa z dnia 9 czerwca (2011). Prawo geologiczne i górnicze (Dz.U.2024.1290).

29

Wang Y. Fu G. Lyu Q. Wu J. R. Wu Y. L. Han M. et al (2024). Accident case-driven study on the causal modeling and prevention strategies of coal-mine gas-explosion accidents: a systematic analysis of coal-mine accidents in China. Resour. Policy88, 104425. 10.1016/j.resourpol.2023.104425

30

Wyższy Urząd Górniczy (2025). Ocena stanu bezpieczeństwa pracy, ratownictwa górniczego oraz bezpieczeństwa powszechnego w związku z działalnością górniczo-geologiczną w 2024 roku WUG, Katowice.

31

Yishan P. Pieśń Y. Hao L. Yonghui X. (2024). Coalbursts in China: theory, practice and management. J. Rock Mech. Geotechnical Eng.16 (Issue 1, 2024), 1–25. 10.1016/j.jrmge.2023.11.003

32

Zhaoshun G. Hui Z. Ruibin Y. Jian Y. Guangyong C. Yong M. et al (2025). Coal-bed methane migration analysis and numerical model construction of fractured coal body based on multi-field coupling conditions. Front. Earth Sci.13, 1596059. 10.3389/feart.2025.1596059

33

Zhenhua O. Qianhai Xu. Tianzi Z. Haiyang Y. Ningbo Z. Manman X. et al (2025). Coupling analysis of disaster-causing factors in coal mines and dual prevention mechanism based on the KeyBERT model and accident-causation theory model. Front. Earth Sci.13, 1586785. 10.3389/feart.2025.1586785

34

Zhu W. W. Yao N. Z. Yan J. (2018). Exploring the determinants of disaster coverage: evidence from coal mine disasters coverage in China. Int. J. Disaster Risk Reduct.31, 856–861. 10.1016/j.ijdrr.2018.08.002

Summary

Keywords

safety mining, risk management of mines, sustainable and safe production, mining disaster, mining rescue

Citation

Kapusta M, Bąk P and Sukiennik M (2025) Mine safety and personal health – in terms of mining accidents and disasters in the Polish coal mining industry. Front. Earth Sci. 13:1690436. doi: 10.3389/feart.2025.1690436

Received

21 August 2025

Accepted

07 October 2025

Published

30 October 2025

Volume

13 - 2025

Edited by

Chong Xu, Ministry of Emergency Management, China

Reviewed by

Nataliia Yevtushenko, Kharkiv Polytechnic Institute, Ukraine

Paola Zucchi, Federal University of São Paulo, Brazil

Updates

Copyright

© 2025 Kapusta, Bąk and Sukiennik.

This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Patrycja Bąk, pbak@agh.edu.pl

Disclaimer

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.