Abstract

Climate change has become a worldwide concern with the rapid rise of the atmospheric Co2 concentration. To mitigate Co2 emissions, the research and development efforts in Co2 capture and separation both from the stationary sources with high Co2 concentrations (e.g., coal-fired power plant flue gas) and directly from the atmosphere have grown significantly. Much progress has been achieved, especially within the last twenty years. In this perspective, we first briefly review the current status of carbon capture technologies including absorption, adsorption, membrane, biological capture, and cryogenic separation, and compare their advantages and disadvantages. Then, we focus mainly on the recent advances in the absorption, adsorption, and membrane technologies. Even though numerous optimizations in materials and processes have been pursued, implementing a single separation process is still quite energy-intensive or costly. To address the challenges, we provide our perspectives on future directions of Co2 capture research and development, that is, the combination of flue gas recycling and hybrid capture system, and one-step integrated Co2 capture and conversion system, as they have the potential to overcome the technical bottlenecks of single capture technologies, offering significant improvement in energy efficiency and cost-effectiveness.

Introduction

Today’s primary energy supply is heavily relying on carbonaceous fuels, mainly the three typical fossil energies, that is, coal, petroleum, and conventional and unconventional natural gas. The control of pollutants emitted from combustion of these fuels in various stationaries including power plants, mobile energy systems, and industrial factories is a major challenge to the environment and human health and safety. It is initially related to the emissions of SOx, NOx, mercury, and particulate matters. Now, it also involves the emissions of carbon dioxide (Co2) and methane (Ch4), two major greenhouse gases which have been regarded as the main reason for the climate change worldwide. With increasing concerns on global climate change (Melillo et al., 1993; Houghton et al., 2001; IPCC, 2015), reducing greenhouse gases emissions, particularly Co2 emissions, has been significantly heightened in both academia and industry in recent years (Maroto-Valer et al., 2002; Brovkin et al., 2004; Song, 2006), in part because the increased Co2 emissions are believed to contributing to ocean acidification and sea level rise in addition to global warming and climate change.

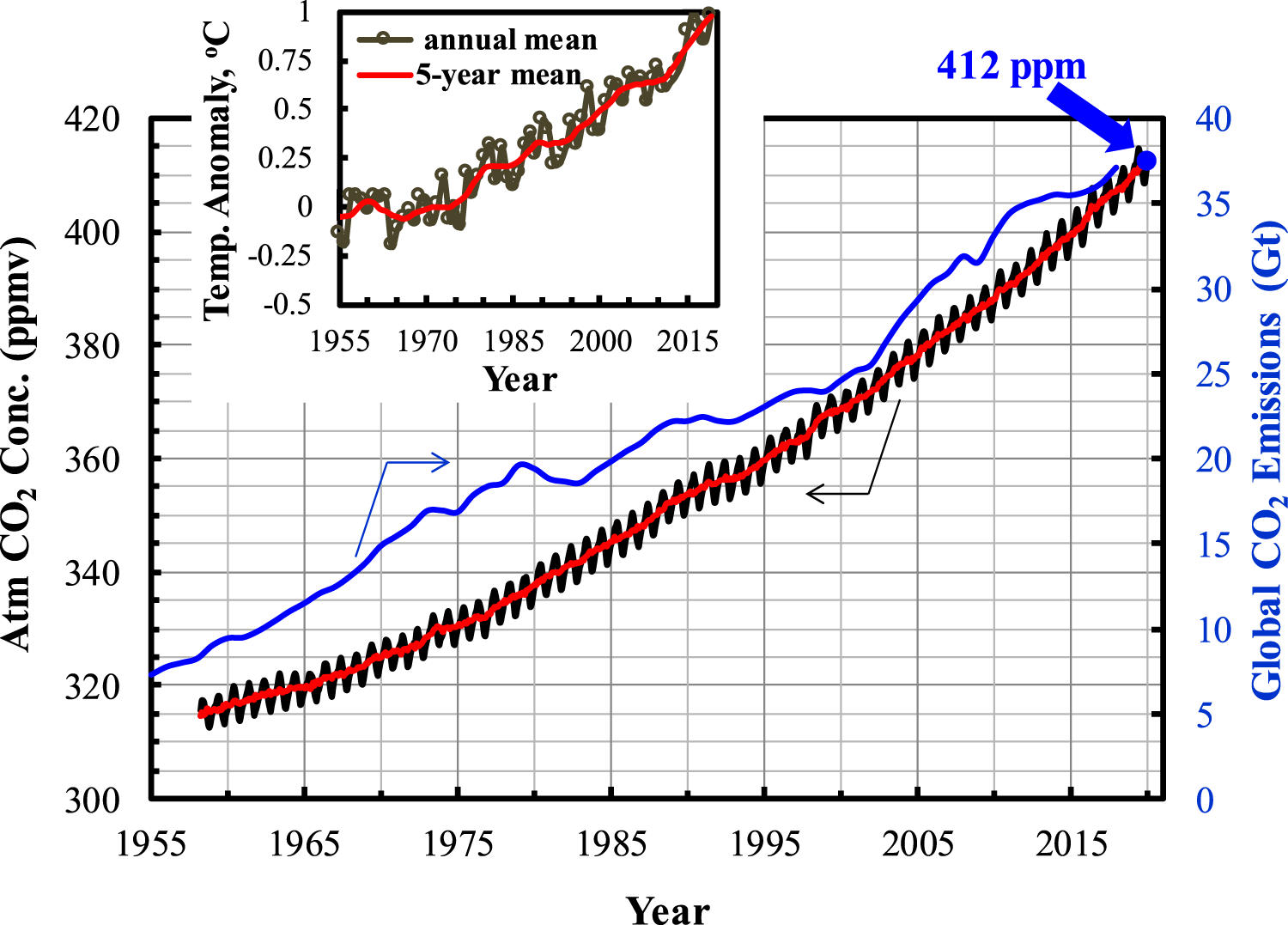

Since the industrial revolution, Co2 emissions have increased continuously due mainly to the anthropogenic activities. Figure 1 shows the Co2 concentration in the atmosphere within the last six decades from 1958 to 2019. As of December 2019, Co2 concentration in the atmosphere has reached 412 ppm, accounting for about 31% increase of that in 1958 (∼5.1‰ per year). In contrast, it took about a hundred years for the atmospheric Co2 concentration to reach 315 ppm by 1958 (IPCC, 2015; Seneviratne et al., 2016), an increase of ∼12.5% (∼1.25‰ per year). Such a change clearly shows that the atmospheric Co2 concentration has increased significantly, and the rising rate becomes faster and faster. The Co2 concentration in air would surpass 550 ppm by 2050 if no action were taken to curb Co2 emissions while keeping fossil fuels utilization as is (Smith and Myers, 2018), possibly reaching to 900–1,100 ppm by the end of this century (Kiehl, 2011). If so, it could cause catastrophic impact on global climate and human nutrition and societies.

FIGURE 1

Atmospheric Co2 concentration during 1950–2019 (data sources: http://climate.nasa.gov/vital-signs/carbon-dioxide/).

In 2015, a global agreement was reached at the United Nations Climate Change Conference, known as the Paris Agreement. It sets a target of keeping the global temperature rise at 2°C or less by the end of the 21st century (United Nations Climate Change, 2015), accentuating well on the urgency in reducing Co2 emissions (Seneviratne et al., 2016). However, with fast growth of global economies and world population which demands more and more energy supply globally, fossil fuels will continue playing a major role. Although the supply of alternative energies such as biomass, solar, and wind is increasing, they are still in the developing stage, yet far from ready to replace the fossil energy completely. Thus, developing strategies to significantly reduce Co2 emissions both from the stationary sources with high Co2 concentrations (e.g., coal-fired power plants, and manufacturing industries) and directly from air have attracted increasing attention worldwide (Lackner, 2003; Song, 2006; Keith, 2009; Lackner et al., 2012; IPCC, 2015; Sanz-Pérez et al., 2016; National Academies of Sciences, Engineering, and Medicine, 2019).

There are several pathways to mitigate Co2 emissions: reducing energy use, improving energy efficiency, shifting to low-carbon or even non-carbon energy, and implementing carbon capture and sequestration (CCS) (Pacala and Socolow, 2004). Reducing energy use is not realistic on a global scale, while improving energy efficiency is a highly challenging task to meet the climate change mitigation goals. The use of low-carbon energy such as natural gas can slow but not be able to solve the problem. Renewable energy such as biomass, wind, and solar is still at its early stage and not able to replace the current fossil fuel-based energy in near future, while the future of nuclear energy is under much debating with big uncertainty. In contrast, carbon capture, utilization, and sequestration (CCUS), which refers to a process that captures Co2 from sources like power plants or ambient air followed by recycling it for utilization or sequestrating it underground permanently, is now widely regarded as a viable option to quickly alleviate Co2 emissions within a midterm. Especially, when the captured Co2 is utilized as a valuable (and renewable) feedstock and cheap carbon source for industrial chemicals and fuels production, it offers a cost-competitive way to solve the contradict between the ever-increasing energy demand and Co2 emissions reduction (Markewitz et al., 2012).

Today, the global energy-related Co2 emissions are at the level of 35–37 gigatonnes per year (Gt/yr), with over 80% coming from fossil fuel combustion--> (National Academies of Sciences, Engineering, and Medicine, 2019; IEA, 2010; OECD, 2012). In the United States, the energy-related Co2 emissions are about 5.1–5.3 Gt/yr in recent years (U.S. Energy Information Administration, 2020). Among them, the Co2 emissions from power plants, industrial sector, and the transportation sector account for 30, 21, and 26% of total carbon emissions, respectively (United States Environmental Protection Agency, 2016). Capturing Co2 from these sources is thus critical to maintain or slow down the increase of the atmospheric Co2 level (Sanz-Pérez et al., 2016). About 1.3 Gt-Co2 is emitted annually from the transportation sector in the United States, which is expected to increase significantly by 2050 due to the increasing demand for vehicles and aviation (OECD, 2012). Unfortunately, till today, onboard Co2 capture from the mobile system is still not available. To address the challenge, negative emission strategies have recently been proposed. One method is directly removing Co2 from air, the so-called direct air carbon capture (DACC) (Keith, 2009; Lackner et al., 2012; Sanz-Pérez et al., 2016; National Academies of Sciences, Engineering, and Medicine, 2019). According to the Intergovernmental Panel on Climate Change (IPCC), the current global Co2 emissions are more than those envisaged with the most pessimistic model (Stocker et al., 2013). Thus, combining Co2 capture both from the high and low Co2 concentration sources could be essential to achieve the Paris Agreement goal of limiting anthropogenic global temperature increase below 2°C.

Aqueous amine scrubbing is the benchmark carbon capture technology currently commercially available in industry (Rochelle, 2009; Rochelle, 2016; Tontiwachwuthikul and Idem, 2013; Darunte et al., 2016). This process, however, is very energy intensive. It is predicted that the required parasitic loads or the so-called energy penalty for Co2 removal is around 0.2–0.5 MWh/ton-Co2, which is equivalent to 20–30% of power plant output (Rochelle, 2009). Particularly, the absorbent regeneration and Co2 recovery step consumes about 50% of the overall energy in the form of low-pressure steam for the stripper reboiler due largely to the high heating capacity of water. The high energy penalty induces both high capital cost and operating cost. The use of basic amine solution can cause corrosion to the equipment. Furthermore, the amine loss due to the degradation and evaporation in the process generates pollutants to the environment. It is estimated that the application of the technology could result in the increase in the cost of electricity by 25–40% (Rubin et al., 2015), thus limiting its widespread use (Haszeldine, 2009). Therefore, developing new technologies to minimize energy penalty and improve cost-effectiveness for carbon capture is highly desired yet quite challenging (Song, 2006; Chu, 2009; Keith, 2009). In this article, we first convey a short review on the R&D status of carbon capture technologies including absorption, adsorption, membrane, biological capture, and cryogenic separation; compare their advantages and disadvantages; and elaborate mainly on absorption, adsorption, and membrane technologies more in detail. Then, we provide our perspective on future directions in Co2 capture research and development.

Current Status of Carbon Capture Technologies

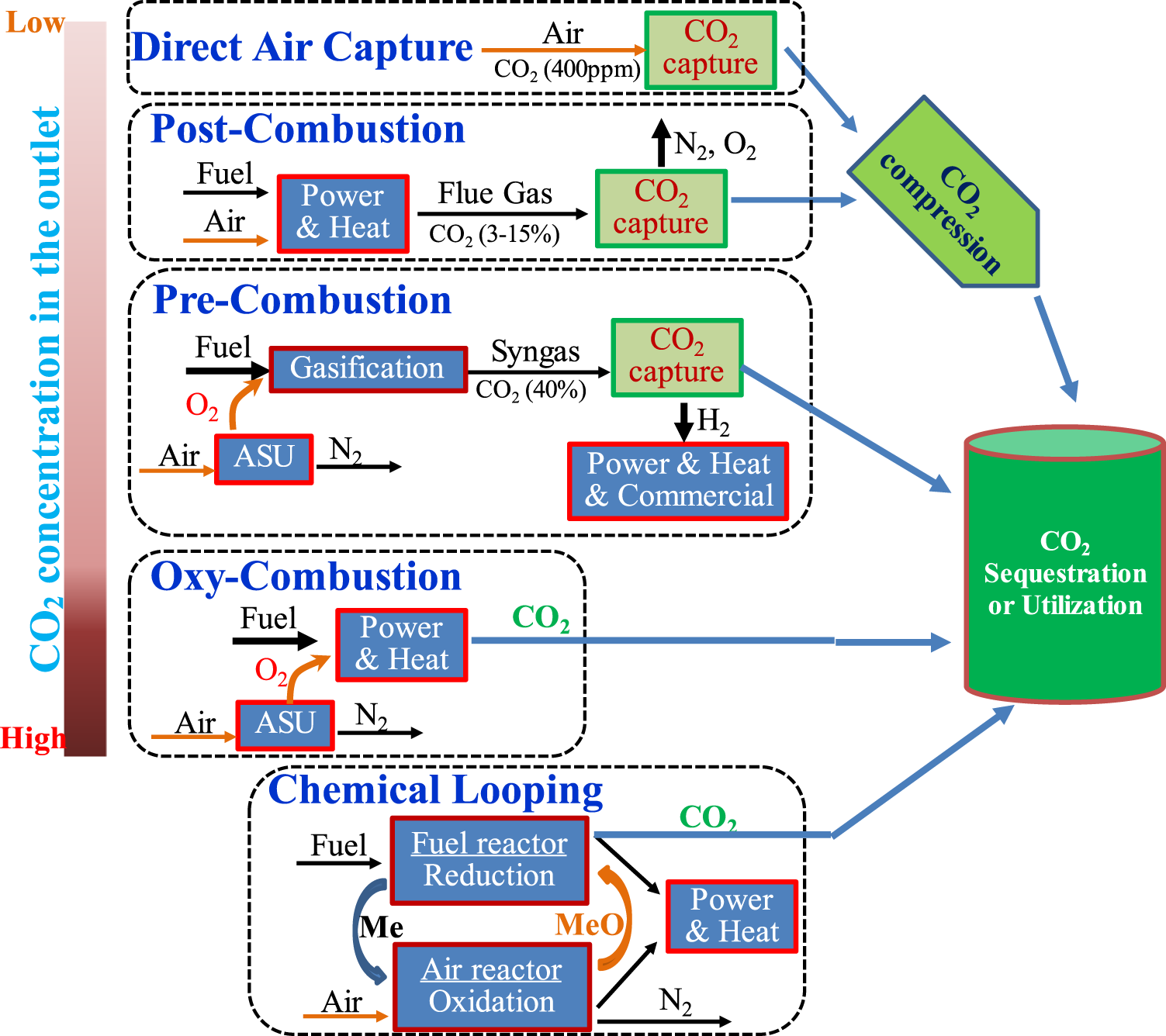

Currently, several technological pathways are pursued for Co2 separation and capture including carbon capture from post-combustion, pre-combustion, oxy-combustion, chemical looping combustion (CLC), and ambient air as well, which is illustrated in

Figure 2.

Table 1lists the advantages and disadvantages of those pathways (

Figueroa et al., 2008;

Rackley, 2017).

Post-combustion capture involves Co2 separation from flue gases after combustion, which has a low Co2 partial pressure (0.03–0.2 bar) and/or a low Co2 concentration (3–20%) (Figueroa et al., 2008; Feron and Hendriks, 2005). The carbon capture from some industrial sources such as cement manufacturing, stainless steel factory can also be categorized into post-combustion capture, although the Co2 concentration from those industrial processes is higher than that of a typical flue gas from post-combustion power plants. Table 2 lists the typical Co2 concentration of a flue gas stream from various sources (Metz et al., 2005; Husebye et al., 2012; Liguori and Wilcox, 2018). The commercially available post-combustion capture process is the chemical absorption-based aqueous amine solution, such as 30% monoethanolamine (MEA) solution. Post-combustion capture is considered as a more viable option for existing coal-fired power plants (Wang Y. et al., 2017).

In a pre-combustion process, which is based on the scaled industrial processes for the production of hydrogen and chemical commodities (Jansen et al., 2015), fuel feedstocks (i.e., coal and natural gas) are converted into syngas (H2 and CO) via gasification, steam reforming, auto thermal reforming, or partial oxidation (Steinberg and Cheng, 1989), and then CO is transferred into Co2 by water, with more hydrogen produced (the so-called water–gas shift reaction, WGS), followed by carbon capture system to remove Co2. After Co2 is captured, the hydrogen-rich fuel gas is utilized for power and heat generation such as boilers, gas turbines, and fuel cells (Metz et al., 2005). After WGS, the Co2 concentration in the flue gas is relatively high, which is in the range of 15–60% (dry basis) at a total pressure of 2–7 MPa (Gazzani et al., 2013a; Gazzani et al., 2013b), thus physical solvents such as Selexol and Rectisol rather than chemical solvents are commonly used for pre-combustion capture.

Oxy-combustion is a relatively new technology (Jurado et al., 2015) and involves the combustion of fuel feedstocks in a nearly pure oxygen (95–99%) or O2–Co2–rich environment (Miller, 2017), resulting in a flue gas with very high Co2 concentration, where the capture of Co2 is thus normally not needed and Co2 is basically ready for sequestration (Miller, 2017; Li et al., 2018; Wu et al., 2019). However, in order to obtain nearly pure oxygen (>95%) (Kather et al., 2008), usually a cryogenic air separation unit is required for oxygen separation from air, which makes the whole process costly.

CLC is an emerging combustion process similar to oxy-combustion producing the Co2-concentrated flue gas (Abanades et al., 2015; Miller, 2017), so that the separation of Co2 from fuel gas (e.g., pre-combustion) or flue gas (e.g., post-combustion) is not needed. In a typical chemical looping process, an oxygen carrier such as Fe, Mn, Cu, Ni, and Co metals is oxidized in air in one reactor (called the air-reactor), which is then reduced with a hydrocarbon fuel in another reactor (called the fuel-reactor) to regenerate the metal and release Co2 and water (Abanades et al., 2015). The metal is then sent back to start another cycle in the air- and fuel-reactors. The exothermic air-reactor provides higher temperature heat and power, while the fuel-reactor can also generate some heat and power as well. CLC was introduced first by Lewis et al. (Lewis et al., 1951) and later applied for Co2 mitigation by Ishida et al. (Ishida et al., 1987; Ishida and Jin, 1994). Since then over 900 materials have been tested (Lyngfelt and Mattisson, 2011) and a number of reviews have been published (Fan, 2010; Adanez et al., 2012; Lyngfelt, 2014; Abanades et al., 2015). Compared to oxy-combustion, CLC eliminates the costly air separation unit, thus is more cost-effective, but the process is relatively more complicated, requiring more studies. To be more cost competitive, a suitable metal/metal–oxide pair as the oxygen carrier plays a critical role in the chemical looping process. More recently, the machine learning algorithms and artificial neural networks have been utilized to estimate the performance of hetero- and multi-component materials as oxygen carriers for CLC (Yan et al., 2020).

DACC represents a process for Co2 extraction or removal directly from the atmosphere, which was first introduced for the mitigation of climate change by Lackner in 1999 (Lackner et al., 1999). DACC could play a crucial role for Co2 capture from decentralized and mobile emission sources such as vehicles, ships, or air planes (Sanz-Pérez et al., 2016; Bhown et al., 2020; Jones, 2011; Goeppert et al., 2012), thus gaining increasing attention. In 2012, Kulkarni and Sholl (Kulkarni and Sholl, 2012) developed a steam-based process using aminosilica sorbents, which can recover Co2 at 1–3 ton/unit/year. Currently, multiple companies including Carbon Engineering (Carbon Engineering, 2020), Climeworks (Climeworks, 2020), and Global Thermostat (Global Thermostat, 2020) are developing DACC systems at a commercial scale. However, it is quite challenging due to the exceptionally low Co2 concentration (∼400 ppm in air). It requires moving very large volume of air through the capture unit and high adsorption heat to execute the Co2 extraction, making this pathway more energy intensive and costly than removing Co2 from the concentrated sources. There is a debate on whether DACC is an enabling factor (Realmonte et al., 2019; Azarabadi and Lackner, 2020) or just a costly distraction for effective climate change mitigation (Chatterjee and Huang, 2020).

FIGURE 2

Schematic diagram of the existing Co2 capture pathways.

TABLE 1

| Capture pathway | Pros | Cons |

|---|---|---|

| Post-combustion | ✓Mature technology (e.g., aqueous monoethanolamine (MEA)), commercially deployed in some industries | •High parasitic power requirement |

| •Low capture efficiency due to low Co2 partial | ||

| ✓Good for most existing power plants | pressure | |

| •High capital and operating costs | ||

| ✓Possible for retrofit to existing plants | ||

| Pre-combustion | ✓High Co2 concentration | •Applicable mainly to new IGCC plants |

| •H2-rich gas-induced temperature and efficiency issues | ||

| ✓High partial pressure | ||

| ✓Mature physical absorption technology (e.g., Selexol and Recticol), commercially deployed in some industries, | ||

| Oxyfuel combustion | ✓Developed air separation technologies available | •Costly and energy intensive air separation step |

| ✓Very high Co2 concentration | •Retrofit unattractive due to Significant plant changes | |

| ✓Possible for retrofit and repowering to existing plants | ||

| Chemical looping combustion | ✓Very high Co2 concentration | •Immature, currently under development |

| ✓Low cost oxygen carrier materials | ||

| Air capture | ✓Truly and directly reduce the atmospheric Co2 concentration | •Immature, currently under development |

| •Costly and energy intensive due to extremely low Co2 concentration (∼400 ppm) in air | ||

| ✓Viable alternative for Co2 capture from mobile and decentralized sources |

Pros and cons of current Co2 capture technological approaches.

TABLE 2

| Flue gas source | Co2 conc. (%) | P (atm) | Co2 partial pressure (atm) |

|---|---|---|---|

| Gas turbine | 3–4 | 1 | 0.03–0.04 |

| Fired boiler of oil refinery and petrochemical plant | ∼8 | 1 | 0.08 |

| Natural gas fired boilers | 7–10 | 1 | 0.07–0.10 |

| Oil-fired boilers | 11–13 | 1 | 0.11–0.13 |

| Coal-fired boilers | 12–14 | 1 | 0.12–0.14 |

| IGCCa after combustion | 12–14 | 1 | 0.12–0.14 |

| Hydrogen production | 15–20 | 22–27 | 3–5 |

| Steel production (blast furnace) | 20–27 | 1–3 | 0.2–06 |

| Aluminum production | 1–2 | 1 | 0.01–0.02 |

| Cement process | 14–33 | 1 | 0.14–0.33 |

Typical Co2 concentration of a flue gas from various sources (Metz et al., 2005; Husebye et al., 2012; Liguori and Wilcox, 2018).

IGCC, integrated gasification combined cycle. Data extracted from the literature (Figueroa et al., 2008; Chu, 2009).

Other industrial processes such as hydrogen production, ammonia synthesis, and methanol manufacture release the tail gases with a high concentration of Co2, which could be captured and directly used or transported for storage after some purification. Similar to the oxy-combustion and CLC processes, an individual Co2 capture unit is normally not needed for those processes.

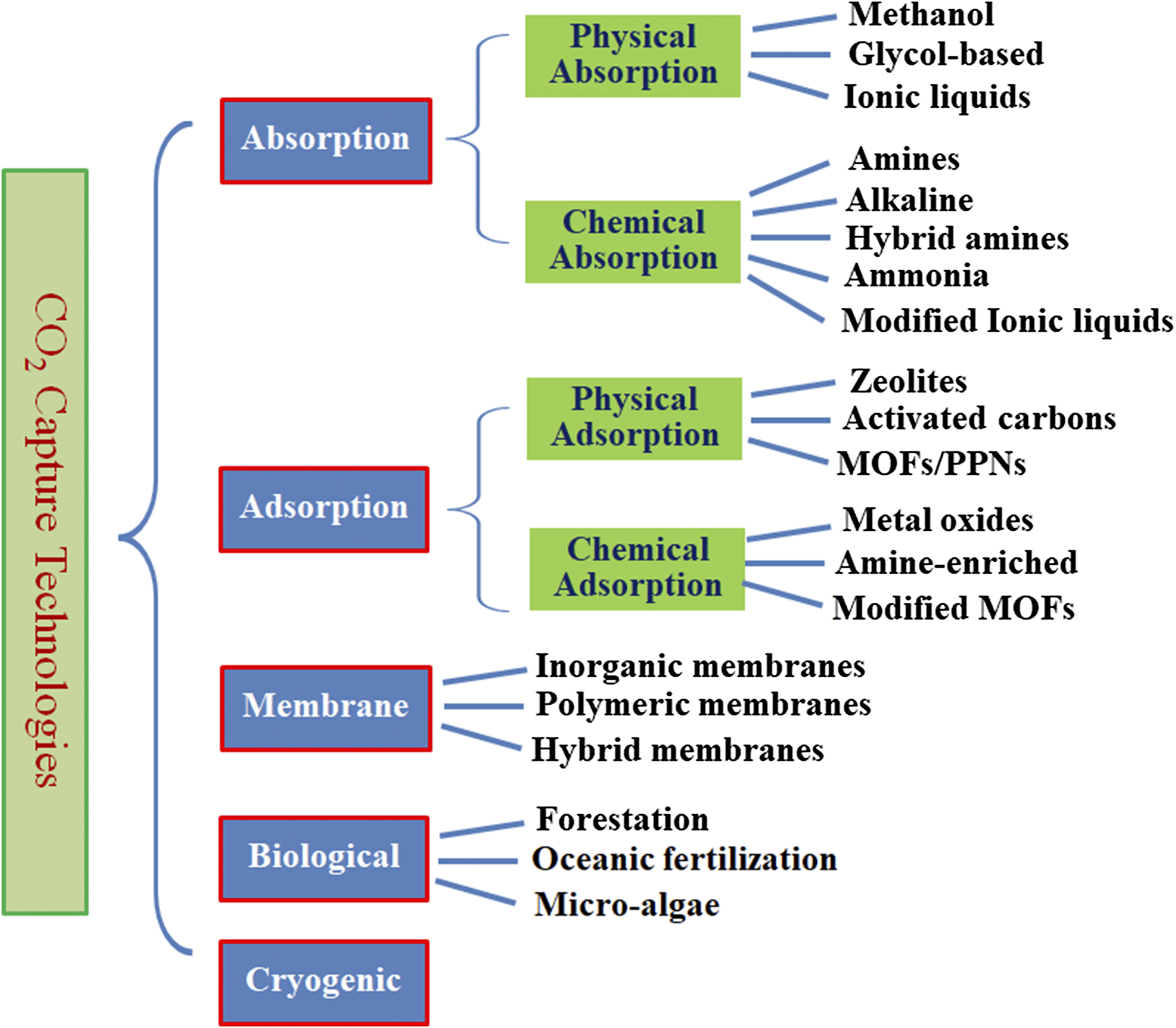

As shown in Figure 2, only post-combustion capture, pre-combustion capture and air capture require a Co2 capture system. So far, many technological approaches are available for a carbon capture system; however, the choice of a specific capture technology differs widely depending on the sources and Co2-generating processes, resulting in different energy penalties. Figure 3 illustrates various Co2 capture technologies including absorption, adsorption, membrane, biological capture, and cryogenic capture under investigation in both academia and industry for the past few decades, while Table 3 briefly compares the advantages and limitations of these carbon capture technologies (Singh and Dhar, 2019). Among them, absorption, adsorption, and membrane methods are more intensively studied, thus are further discussed in the following section.

FIGURE 3

Illustration of various Co2 capture technologies along with typical materials currently under investigation.

TABLE 3

| Technology | Mechanisms | Pros | Cons | |

|---|---|---|---|---|

| Absorption | Chemical absorption (e.g., MEA and NaOH) | chemical reaction between a solvent and Co2 | ✓High capacity at low Co2 pressure | •Energy-intensive regeneration |

| ✓Mature technology | •Low absorption–desorption rate | |||

| •Corrosion | ||||

| •Absorbent degradation | ||||

| •High operating cost | ||||

| Physical absorption (e.g.,methanol, Selexol, and Rectisol) | The solubility of Co2 in a solvent | ✓High capacity at low temperature and high pressure | •Low selectivity | |

| •High energy consumption | ||||

| ✓Cheaper solvent | ||||

| •Low capacity at high temperature and low pressure | ||||

| ✓Mature technology | ||||

| •Absorbent loss | ||||

| Adsorption | Physical adsorbents (e.g., AC, zeolites, and MOF) | Molecular sieve confinement effect of solid materials, normally with micropores | ✓High capacity at low temperature and high pressure | •Low Co2 selectivity |

| •Capacity decreases with temperature | ||||

| ✓Low waste generation | ||||

| •Normally require high pressure | ||||

| •Moisture degrades the adsorbent performance | ||||

| Chemical adsorbents (e.g., CaO and Na2sio3) | Through the formation of carbonates or bicarbonates | ✓Work at high temperature | •Require high temperature for Co2 sorption and adsorbent regeneration | |

| ✓High capacity | ||||

| — | — | •High energy consumption | ||

| ✓Low waste generation | ||||

| •Performance loss with cycles | ||||

| Solid amine sorbents (e.g., PEI/SiO2) | Chemical reaction between amine groups and Co2 | ✓High capacity at low Co2 pressure | •Thermal and oxidative degradation | |

| ✓High selectivity | •Degradation due to contaminants (e.g., SOx and NOx) | |||

| ✓Fast kinetics | ||||

| ✓Mild conditions | ||||

| ✓Positive effect of moisture | ||||

| ✓Lower energy consumption | ||||

| ✓Less corrosion | ||||

| ✓Low waste generation | ||||

| Membrane | Different gas permeability | ✓Relatively low operation cost | •High manufacturing cost | |

| •Relatively low separation selectivity | ||||

| ✓Easy handling and Operation | ||||

| •Permeability still low | ||||

| •Negative effect of moisture | ||||

| Biological absorption/utilization | Captured and utilized through photosynthesis in plants | ✓No hazards of chemicals | •Long time requirement | |

| •Large area requirement | ||||

| •May affect biological diversity | ||||

| •Sensitive to other flue gas contaminants (e.g., SOx and NOx) and culture conditions (pH, temperature, and salinity) | ||||

| ✓Coproduction of food, biofuels, and value-added products | ||||

| Cryogenic separation | Different condensation temperature | ✓High capture efficiency (up to 99.9%) | •High energy requirement | |

| •Low efficiency | ||||

| •Moisture pre-removal is required | ||||

| •Solidified Co2 may be accumulated on the surface of heat exchanger | ||||

Comparison of typical Co2 capture technologies.

Absorption

Among the abovementioned Co2 capture options, the technology based on liquid absorption is most mature and commercially available, especially in the petroleum and chemical industries. Based on the nature of the interaction between the absorbent and Co2, it separates as chemical absorption (mainly applied for Co2 capture from post-combustion flue gas) and physical absorption (mainly used for Co2 capture from pre-combustion flue gas). Aqueous amine solutions (e.g., 20–30 wt% MEA, and diethanolamine (DEA)) and liquid ammonia are typical solvents for chemical absorption. MEA solution has become the benchmark amine for Co2 capture from power plants because it has good Co2 transfer rates, relatively low cost, and biodegradable. However, it suffers from toxicity and solvent loss due to evaporation and degradation (Bui et al., 2018). In addition, at higher concentrations, MEA solution is highly corrosive to the equipment.

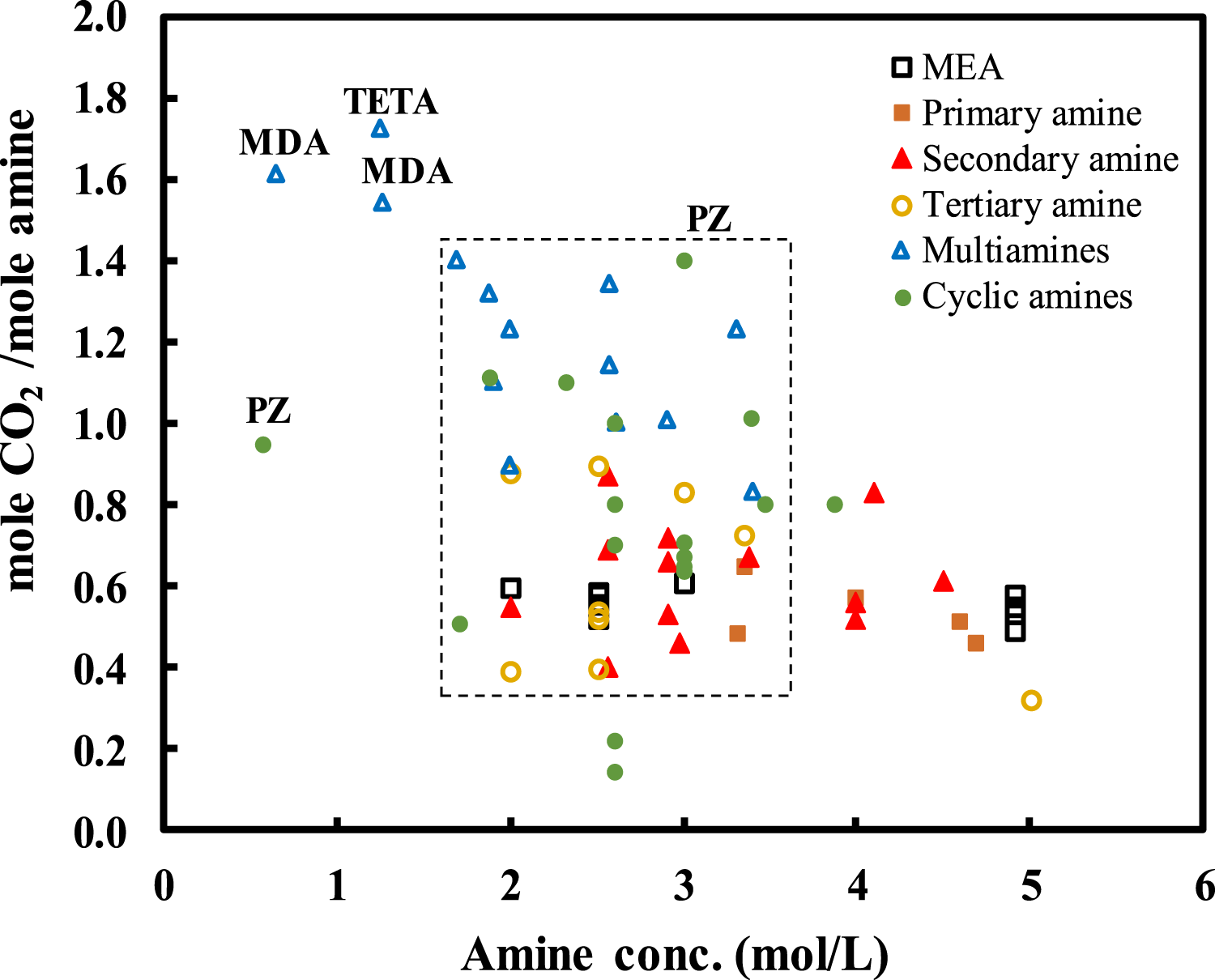

Developing new Co2 absorbents to replace MEA has thus aroused much interests and is still ongoing. Normally, thermal swing absorption–regeneration is used for chemical absorption; thus, selecting an absorbent with optimized thermal and physical properties is crucial to the development of energy-efficient and cost-effective carbon capture absorption technology. So far, a large number of solvents, including single amines, amine blends, and amino acids, have been evaluated individually for their performance in Co2 capture (Bui et al., 2018; Sreedhar et al., 2017). Figure 4 shows the Co2 absorption capacities in mol-Co2 per mol-amine obtained at 40°C and Co2 partial pressure of 15 kPa using different amines with different structures at different amine concentrations (Shen and Li, 1992; Jou et al., 1995; Park et al., 2002; Benamor and Aroua, 2005; Derks et al., 2005; Maneeintr et al., 2009; Puxty et al., 2009; Chen and Rochelle, 2011; Rebolledo-Morales et al., 2011; Schäffer et al., 2012; Tong et al., 2012; Chang et al., 2013; Monteiro et al., 2013; Yamada et al., 2013; Arshad et al., 2014; Bougie and Iliuta, 2014; Li et al., 2014; Li and Rochelle, 2014; Nouacer et al., 2014; Chen S. et al., 2015; Conway et al., 2015; Mondal et al., 2015; El Hadri et al., 2017). The majority were examined at the amine concentration between 2 and 3.5 mol/L. The Co2 absorption capacity is ranged from 0.4 to 1.4 mol-Co2/mol-amine. More specifically, for the primary, secondary, and tertiary mines in straight chains, multi-amines, and amines in cyclic chains, their capacities are in the range of 0.5–0.7, 0.4–0.8, 0.4–0.9, 0.8–1.4, and 0.5–1.1 mol-Co2/mol-amine, respectively. The Co2 absorption capacity decreases generally following the amine structure as cyclic amines ≈ multi-amines > tertiary-amines > secondary-amines > primary-amines. Among them, piperazine (PZ) absorbent has been suggested as a good alternative to conventional chemical solvents. Compared to MEA, it shows fast kinetics in reaction with Co2, better chemical stability, and requires lower energy input for regeneration (Rochelle, 2009; Dugas and Rochelle, 2011). It also exhibits better resistance to oxidative and thermal degradation (Freeman et al., 2010a). Other amine blends such as PZ/AMP (Seo and Hong, 2000; Khan et al., 2016) and K2Co3/PZ (Tim Cullinane et al., 2005; Cullinane and Rochelle, 2006) have also been studied, and it has been found that the blending can improve the absorption kinetics, thermodynamic efficiency, and resistance to degradation. The main drawback of PZ is that it could form precipitation and nitrosamine during Co2 capture process (Freeman et al., 2010b; Cousins et al., 2015).

FIGURE 4

Co2 uptakes obtained at 40°C and Co2 partial pressure of 15 kPa using different liquid amines with different structures at different amine concentrations. Data from the literature (Shen and Li, 1992; Jou et al., 1995; Park et al., 2002; Benamor and Aroua, 2005; Derks et al., 2005; Maneeintr et al., 2009; Puxty et al., 2009; Chen and Rochelle, 2011; Rebolledo-Morales et al., 2011; Schäffer et al., 2012; Tong et al., 2012; Chang et al., 2013; Monteiro et al., 2013; Yamada et al., 2013; Arshad et al., 2014; Bougie and Iliuta, 2014; Li et al., 2014; Li and Rochelle, 2014; Nouacer et al., 2014; Chen S. et al., 2015; Conway et al., 2015; Mondal et al., 2015; El Hadri et al., 2017).

There is another class of amine-based solvents which is called phase-change solvents including amine–alcohol system and amine–water system. Upon Co2 absorption or increasing the temperature after Co2 absorption, the solvent divides into two phases: Co2-rich and Co2-lean phases (Zhuang et al., 2016; Papadopoulos et al., 2019). In contrast to traditional solvents, only the Co2-rich phase is sent for regeneration; therefore, the energy demand and the size of the regenerator can be dramatically reduced in comparison to non–phase-change solvents. Gomez et al. compared the performance of phase-change solvent process to the conventional MEA process, showing the Co2 capture cost could be saved by 15.4% for the power plant, and as much as 51.7% for the cement plant (Gomez et al., 2014). Although the phase-change absorbent systems exhibit some potential merits and economic incentives for scaling up, they may be volatile and corrosive due to the use of amine solution in nature. The formation of precipitation and salts is another important issue for the implementation of the phase-change solvent-based absorption process.

Besides the chemisorption using amine solutions, another type of absorption technology is using physical solvents to absorb Co2, which is based on their Co2 solubility (Chakma, 1999). Physical absorption is generally preferred at higher pressures. Selexol, Rectisol, Purisol, and Fluor are the well-established commercial physical absorption technologies, and also energy-intensive processes due to their heat transfer requirements (Figueroa et al., 2008). Since the physical absorption is depended on physical interaction rather than chemical reaction, it normally requires higher partial pressure of Co2 and is preferred at low temperatures in order to achieve high Co2 capture capacity, which thus reduces its efficiency and increases its operation cost.

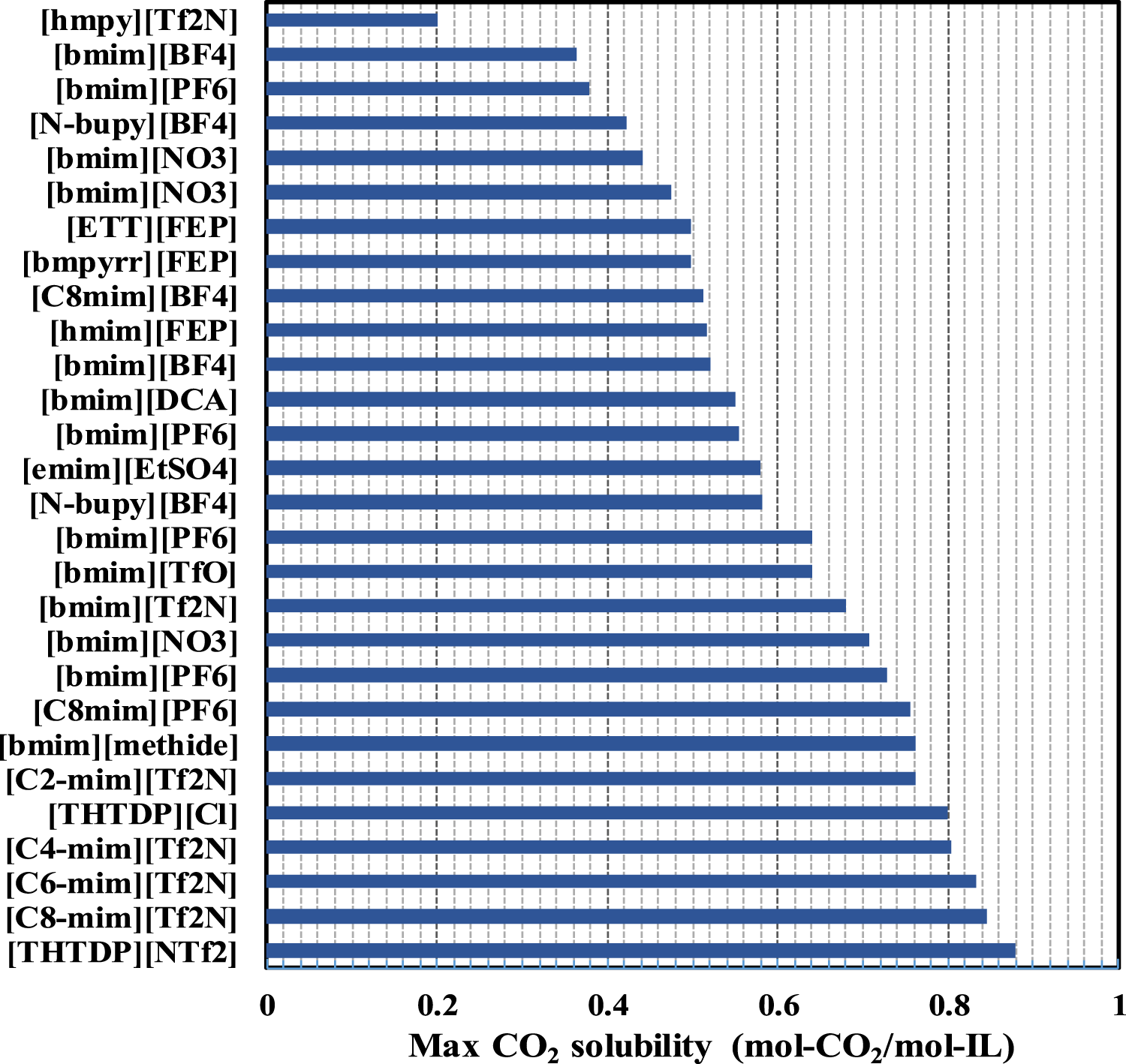

Recently, ionic liquids (ILs), which consist of ions and act as liquid at room temperature (Hallett and Welton, 2011), are considered as suitable alternatives to the traditional physical absorbents, because ILs have unique properties such as low volatility, low vapor pressure, and good thermal stability (Bates et al., 2002; Corvo et al., 2015; Zeng et al., 2017). In addition, after Co2 absorption, its energy requirement for regeneration is also relatively low. Figure 5 presents the Co2 absorption capacities of some typical ILs (Zhang et al., 2008; Pérez-Salado Kamps et al., 2003; Shiflett and Yokozeki, 2005; Shin et al., 2008; Carvalho et al., 2010; Kilaru and Scovazzo, 2008; Anderson et al., 2007; Aki et al., 2004; Blanchard et al., 2001). As seen, the Co2 absorption capacity varies with the type of ionic liquid. The highest value of 0.88 mol-Co2/mol-IL (moles of Co2 per mole of IL) was obtained with [THTDP][NTf2] ionic liquid, while the [hmpy][Tf2N] ionic liquid gave the lowest value of 0.20 mol-Co2/mol-IL (Anderson et al., 2007). The max Co2 solubility in ILs reported in the literature is largely within the range of 0.4–0.8 mol-Co2/mol-IL, which is comparable to those of most aqueous amine solutions as shown in Figure 4. However, their high viscosities and relatively low working capacity are the two main obstacles for their application in Co2 capture. To attain higher Co2 capacity, a series of the so-called task-specific ILs have been designed by incorporation of various functionalities, such as carboxylate anions, amine and amino acid groups, or azolates for chemisorption of Co2, thereby significantly boosting the absorption capacity up to about 0.5–2.0 mol-Co2/mol-IL under atmospheric pressure (Bates et al., 2002; Giernoth, 2010; Wappel et al., 2010; Petkovic et al., 2011; Shannon and Bara, 2012; Cui et al., 2016). Several groups have also studied the physical and chemical properties of Co2–IL systems using thermodynamic modeling (Zhang et al., 2008; de Riva et al., 2017), kinetics (Wang C. et al., 2011; Moya et al., 2014; de Riva et al., 2017) and Co2 sorption mechanisms (Carvalho et al., 2009; Shiflett et al., 2010). Although higher capacity can be obtained, the functionalized ILs show higher viscosities than unfunctionalized ILs. Therefore, how to greatly reduce the viscosity while maintaining its high capacity is the largest technical challenge for the successful use of ILs in CCS. High cost and difficulty in scale-up are other two significant barriers to the wide spread of ILs for CCS (Singh and Dhar, 2019).

FIGURE 5

The reported maximum Co2 absorption capacity of some typical ionic liquids for Co2 capture at 40°C with Co2 partial pressure of 15 kPa, data from the literature (Zhang et al., 2008; Pérez-Salado Kamps et al., 2003; Shiflett and Yokozeki, 2005; Shin et al., 2008; Carvalho et al., 2010; Kilaru and Scovazzo, 2008; Anderson et al., 2007; Aki et al., 2004; Blanchard et al., 2001).

Adsorption

Adsorption is widely deemed as a promising technology for Co2 capture as it can be retrofitted to any power plants, operated at various conditions with relatively high capacity, high Co2 selectivity, and low energy requirement for regeneration. It can be applied for both pre- and post-combustion pathways (Bui et al., 2018). If waste materials are utilized for preparation of adsorbents, the adsorption process could be potentially more sustainable. It should also be highlighted that adsorption method is well suited for Co2 capture directly from air.

Currently, most efforts in developing advanced adsorbents have been focused on improving Co2 adsorption capacity, Co2 selectivity, and impurity tolerance. So far, a large number of solid adsorbents have been investigated, including carbons and carbon nanotubes (Aaron and Tsouris, 2005; Huang et al., 2007; Plaza et al., 2007; Razavi et al., 2011), clays and oxides (Ding and Alpay, 2000; Yong et al., 2001; Gray et al., 2005; Hiyoshi et al., 2005), microporous zeolites and mesoporous molecular sieves (Takamura et al., 2001; Siriwardane et al., 2003; Son et al., 2008; Zelenak et al., 2008a), and microporous metal–organic framework materials (MOFs) (Torrisi et al., 2010; Zhang Z. et al., 2013; Gonzalez-Zamora and Ibrra, 2017).

Zeolites are widely used in refinery and gas separation industry, and have shown high Co2 uptake such as zeolite 13X and Ca-A, reaching about 3 and 3.72 mmol/g, respectively (Bae et al., 2013). Co2 adsorption over zeolites is derived from the interaction between the electric field of zeolite and the large quadrupole moment of Co2. Thus, both the structure and composition of zeolite framework, and the composition and location of cations govern its Co2 adsorption performance (Grajciar et al., 2012; Kim et al., 2012). Lin et al. screened over hundreds of thousands of zeolites and zeolitic imidazolate frameworks (ZIFs) via a computational approach and identified potential materials for Co2 capture (Lin et al., 2012). The main weakness of zeolites is their sensitivity to moisture, which results in a significant reduction of Co2 uptake (Bui et al., 2018).

MOFs are a relatively new class of crystalline porous materials constructed via self-assemblage of metal “nodes” and organic linkers (Long and Yaghi, 2009; Zhou et al., 2012; Lu et al., 2014). MOFs possess very high surface areas and pore volumes. Theoretically, by varying the metal and the linker, infinite different MOFs can be synthesized, and their physicochemical properties are consequently tuned in terms of Co2 capacity, selectivity, and heat of adsorption, which makes them highly attractive for Co2 capture (Singh et al., 2020). For example, MOF-74(Mg) showed a high Co2 adsorption capacity of 5.5 mmol/g at 0.15 bar Co2 and 40°C (Caskey et al., 2008; Bae et al., 2013), while UiO-66 and SIFSIX-6_Zn exhibited good resistance to other flue gas components such as water, SOx, and NOx (Nugent et al., 2013; Burtch et al., 2014; Wang C. et al., 2016). In a recent article, Ding et al. conducted a comprehensive review on MOFs for Co2 capture and conversion, where they summarized and compared the reported MOFs for Co2 capture in terms of their Co2 capacities (Ding et al., 2019).

Carbon materials including activated carbons, carbon nanotubes, and graphene have also been studied for Co2 capture due to their low cost and wide availability (Wang Q. et al., 2011; Montagnaro et al., 2015; Taheri Najafabadi, 2015; Mohamedali et al., 2016). The capability of carbon materials for Co2 adsorption mainly relies on its porosity; thus, the higher the pore volume, particularly the micropores, the higher the Co2 capacity (Estevez et al., 2018). Carbons work better at high pressure. While at low pressure, their Co2 capacities are typically lower than those of zeolites. Compared to zeolites, carbons possess much better stability in the presence of water (Xu et al., 2013).

Another type of solid adsorbents is oxides including CaO, MgO, and FeO (Feng et al., 2007; Florin and Harris, 2009; Mutch et al., 2018; Mora Mendoza et al., 2019); layered double hydroxides (LDHs) (Ram Reddy et al., 2006; Ram Reddy et al., 2008); and alkali metal–containing ceramics such as Li2ZrO3 (Nakagawa, 1998), Li4SiO4 (Gauer and Heschel, 2006), and Na2sio3 (Rodríguez and Pfeiffer, 2008). Those adsorbents are normally handled at high temperatures within the cyclic carbonation/calcination reactors. High temperature (>500°C) causes the sintering of oxides, which results in the dramatic reduction of their Co2 capture performance (Erans et al., 2016).

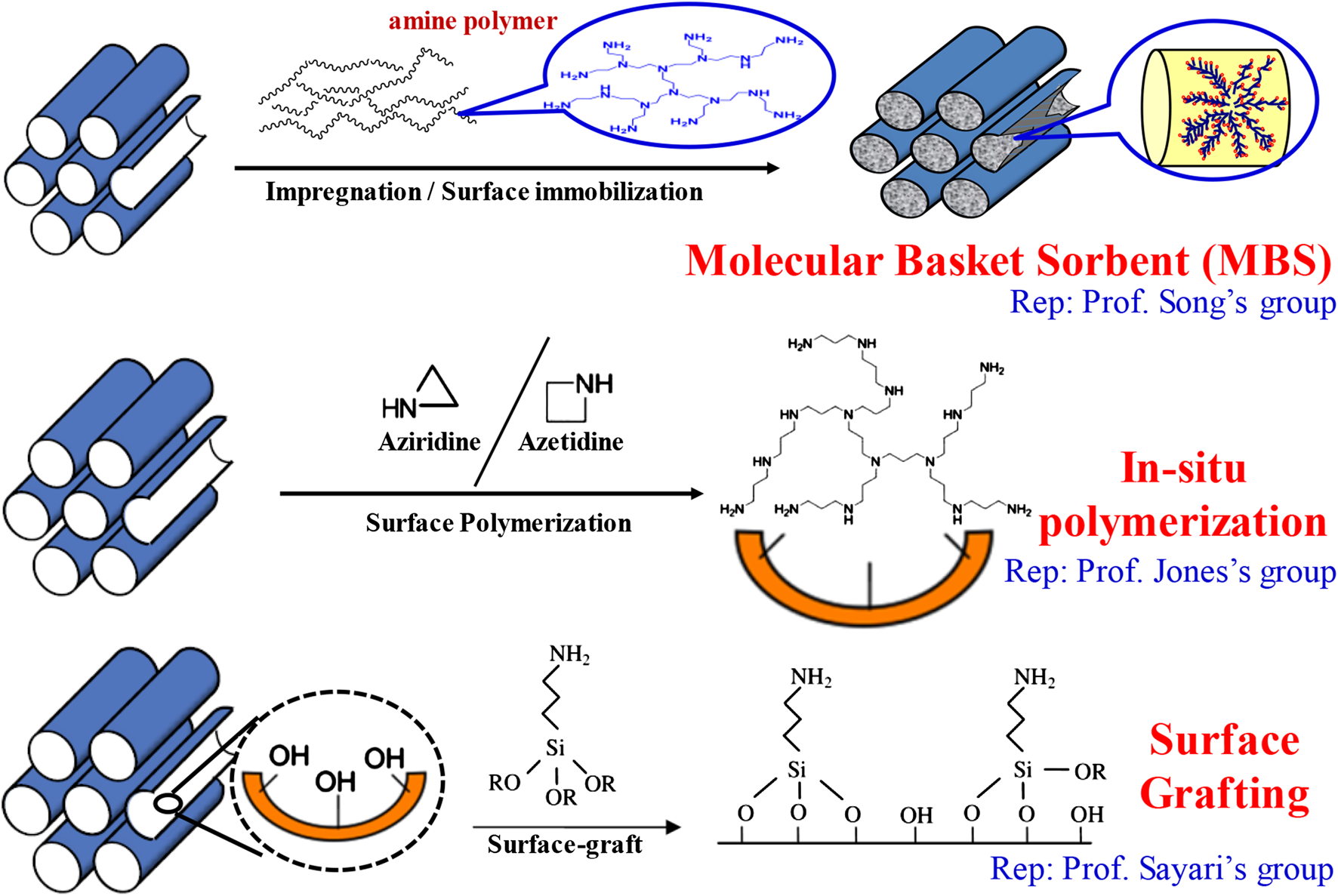

Compared to abovementioned adsorbents, amine-based solid sorbents are the center of investigation in adsorption. Since the first report on polyethylenimine (PEI)-based sorbents showing good performance for Co2 separation, the so-called molecular basket sorbents (Figure 6) (Xu et al., 2002), in the past twenty years, solid sorbents containing amines, have aroused significant interests for Co2 capture and later for Co2 removal directly from air (Yu et al., 2012). The use of amine-functionalized sorbents can greatly reduce the need in the parasitic energy input (mainly because solid has lower heat capacity than water), and offer high Co2 capacity and selectivity, fast kinetics, multicycle stability, and tolerance to water with no or less corrosion to the equipment (Ma et al., 2009; Choi et al., 2009; Wang et al., 2009; Bollini et al., 2011; Wang and Song, 2019). By far, three popular approaches are proceeding in preparation of those amine-based sorbents, which are outlined in Figure 6, including 1) immobilizing amine compounds (e.g., PEI, TEPA, DEA, and dendrimers (Wang et al., 2005; Yue et al., 2006; Liang et al., 2008; Qi et al., 2011)) onto a nanoporous support (Xu et al., 2002; Xu et al., 2003; Xu et al., 2005; Ma et al., 2009; Chen et al., 2010; Liu et al., 2010; Tanthana and Chuang, 2010; Wang D. et al., 2011; Zhang et al., 2012; Yang et al., 2013) and/or microporous zeolites (Kim et al., 2016) and MOFs (Demessence et al., 2009; Lee et al., 2014; McDonald et al., 2015) by a conventional wet impregnation method; 2) growing reactive amine monomers inside the porous material via in situ polymerization method or incorporating amine compounds with silica precursor during mesoporous material preparation via co-condensation method (Tsuda et al., 1992; Tsuda and Fujiwara, 1992; Rosenholm et al., 2006; Rosenholm and Linden, 2007; Hicks et al., 2008); and 3) covalently grafting amine compounds (e.g., (3-aminopropyl)trimethoxysilane and (3-aminopropyl)triethoxysilane) on a support surface via post-synthesis method (Huang et al., 2003; Hiyoshi et al., 2004; Hiyoshi et al., 2005; Zelenak et al., 2008b; Belmabkhout and Sayari, 2009; Kumar and Guliants, 2010).

FIGURE 6

Schematic illustration of the widely used three approaches in preparation of the amine-based sorbents.

Polymer PEI contains repeating -CH2CH2-NH-units. Because it has high nitrogen content in mass and relatively good thermal stability (Yue et al., 2008; Goeppert et al., 2011), PEI is often selected for amine-based sorbents, becoming a promising candidate suitable not only for Co2 capture from flue gases with relatively high Co2 concentration, but also good for direct air capture. Other amines such as tetraethylenepentamine (TEPA), pentaethylenehexamine (PEHA), MEA, DEA, and diisopropanolamine are more prone to leaching issue due to their relatively low molecular weight and boiling points, which could cause Co2 capacity loss and pollute the downstream equipment of the sorption system (Goeppert et al., 2014). Many reviews on solid-sorbent–based Co2 capture have been published (Song, 2006; Sanz-Pérez et al., 2016; Darunte et al., 2016; Choi et al., 2009; D'Alessandro et al., 2010; Lin et al., 2016; Didas et al., 2015; Dutcher et al., 2015; Chen C. et al., 2014; Gargiulo et al., 2014; Olajire, 2017). In a recent book chapter (Wang and Song, 2019), we summarized the recent advances of solid PEI-based sorbents for Co2 capture focusing on the development of sorbent materials, the mechanism and kinetics in Co2 sorption, the regeneration and deactivation, and the current and future Co2 capture approaches.

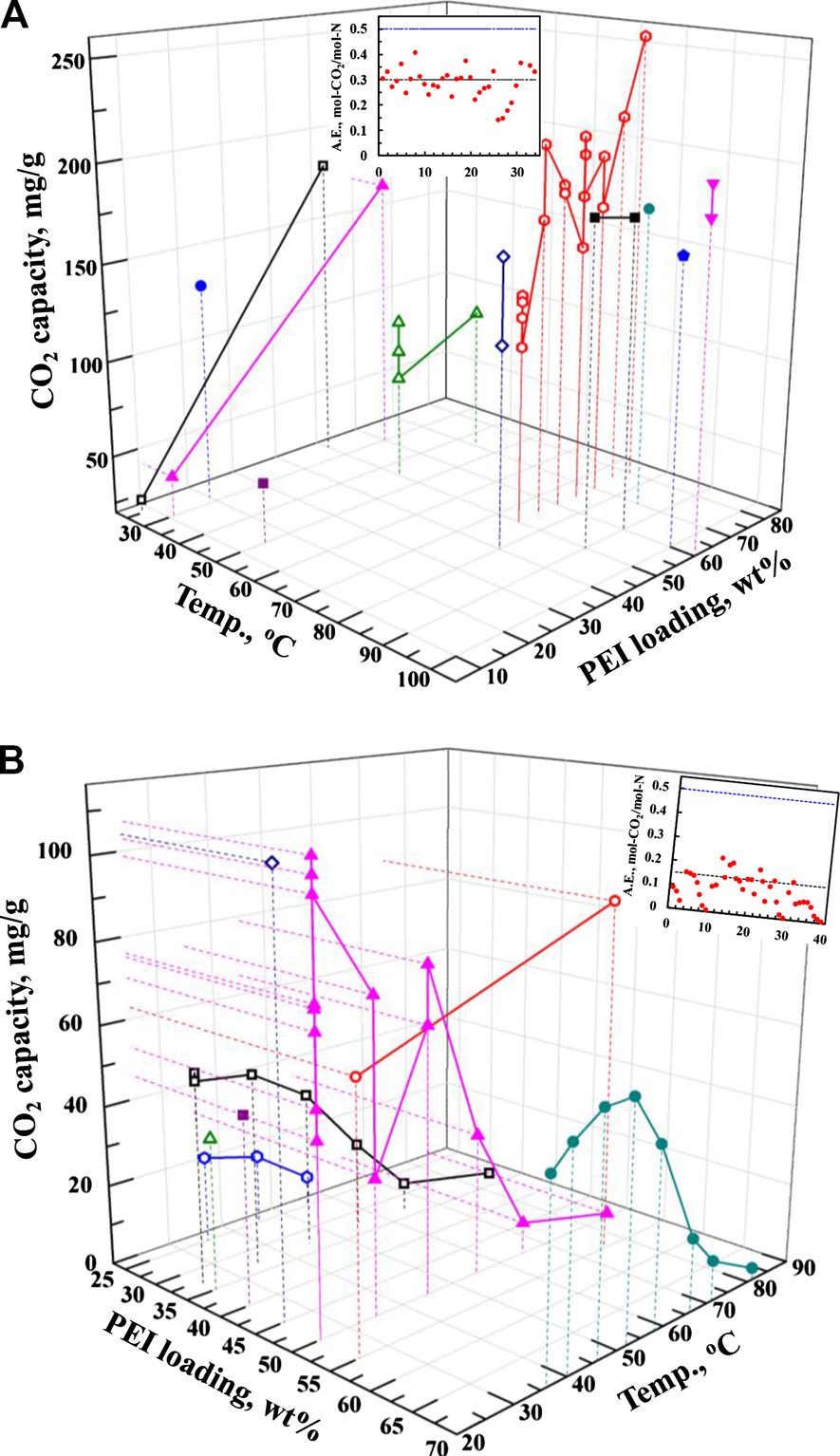

To have a better overall picture, the Co2 capacities reported in the literature with different support at different PEI loading and sorption temperature for Co2 capture from pure Co2 and the simulated air containing ∼400 ppm Co2 are plotted in Figure 7. For Co2 capture from pure Co2 (Figure 7A), the higher the PEI loading, the higher the Co2 uptake. Increasing temperature also benefits Co2 sorption. Generally, high Co2 capture capacity of around 150–200 mg/g is mostly reported, which is favored at 50–70 wt.% PEI loading at 70–90°C. The amine efficiency (termed as A.E.), which is defined as moles of Co2 captured per mole of N groups in the sorbent, is presented as an inset in Figure 7A. It shows the major value of about 0.30 (the black dot line in the inset of Figure 7A). It is widely accepted that under dry condition, two N sites are needed for one Co2 molecule through the formation of zwitterions. Although tertiary amine does not directly react with Co2, it could accept the proton from zwitterions generated by the reactions between Co2 and primary/secondary amines, contributing to Co2 sorption. Thus, it is projected that the theoretic value for the maximum amine efficiency would be 0.5 (the blue dot line in the inset of Figure 7A). Clearly, most PEI-based sorbents are still not able to achieve this theoretic value, although there are a few reports showing their amine efficiency close to 0.5. Only one article reported the amine efficiency over 0.5, which was attributed to the contribution of Co2 physisorption on the porous support (Gaikwad et al., 2019). As for the air capture (Figure 7B), most work was studied over the sorbents with PEI loading of 50 wt.% at room temperature. Unlike Co2 capture from pure Co2, increasing temperature results in the decrease of Co2 uptake, making it suitable for air capture operation. Compared to those amine efficiency for pure Co2, the amine efficiency for air capture is much lower, in between 0.05 and 0.15. It reflects that Co2 capture directly from the air is more challenging than that from the concentrated Co2 sources.

FIGURE 7

Co2 capacity reported in the literature with different support at different PEI loading and temperature for Co2 capture from (A) pure Co2 and (B) from simulated air with about 400 ppm Co2 along with the insets showing the amine efficiency (A.E., mol-Co2/mol-N). All data are from the reported values (Wang and Song, 2019).

Figure 7 displays an indication of the current development status of the PEI-based solid sorbents. Considering the low amine efficiency compared to the theoretic value, especially for the air capture, we believe there is still a possibility to further enhance Co2 capture from both the concentrated sources and the air. Thus, further investigations are required to determine at what level of PEI dispersion could be best for maximizing the amine efficiency with high capacity, or whether there is a limit in the amine efficiency in order to maintain the best Co2 sorption capacity and kinetics.

With the aid of modern and advanced characterization techniques, the Co2 sorption/deactivation mechanism over PEI-based sorbents has been fundamentally better understood. Zhang et al. studied Co2 sorption behavior with small angle neutron scattering (SANS) technique and identified that the swelling of PEI with Co2 sorption and temperature increase played an important role in Co2 sorption process (Zhang et al., 2019). Using solid-state nuclear magnetic resonance (SSNMR), Mafra et al. (Mafra et al., 2017) found three chemisorbed Co2 species involving hydrogen bonds with either surface silanols or amines. Chen et al. (2018) confirmed the formation of bicarbonate in the presence of water. During Co2 sorption, both carbamate and carbamic acid are formed (Foo et al., 2017; Shimon et al., 2018), but only carbamic acid desorbs while carbamate persists (Shimon et al., 2018). The formation of C=O and −CH = N- species is a main reason for the air degradation of amine sorbents (Ahmadalinezhad and Sayari, 2014). To improve the regeneration and long-term stability of PEI-based sorbents, a two-step synthesis strategy involving support modification followed by PEI loading has been proposed and studied (Choi et al., 2016; Jeon et al., 2018; Min et al., 2018a; Min et al., 2018b; Xu et al., 2018; Kim et al., 2019; Wang et al., 2020), which have been summarized and elaborated in our recent book chapter (Wang and Song, 2019).

Additionally, there has been important progress in the development of adsorption processes for Co2 capture. A large number of different cyclic regeneration processes using temperature, pressure, vacuum, steam or moisture, or combinations thereof have been studied. Recently, Inventys Inc. (now is Svante Inc.) reported the VeloxoTherm™ process using a rotary unit packed with structured honeycomb adsorbent for both Co2 adsorption and desorption, which can complete a full cycle in about 60 s (Greeson, 2016). The comprehensively review of the development of these processes can be found in the literature (Grande and Rodrigues, 2008; Webley, 2014).

It should be pointed out that with the advance of the technologies, some novel structured Co2 adsorbents have emerged, such as thin film nanocomposites (Shah and Imae, 2016; Yong, 2016; Niranjana et al., 2019) and adsorbent-coated monoliths made of zeolites, MOFs, or carbons (Öhrman et al., 2004; Ramos-Fernandez et al., 2011; Akhtar et al., 2014; Lee et al., 2015). Monolithic contactors have substantial advantages like uniform flow, high gas throughput, low pressure drop, and less attrition in comparison with conventional packed-bed reactors (Rezaei and Webley, 2009; Rezaei and Webley, 2010). Both the diameter of the parallel channels and the density per cross-sectional area of monoliths are controllable. Most recently, three-dimensional (3D) printing or additive manufacturing technique has gained worldwide attention and has been applied for fabrication of 3D-printed monoliths including zeolites (e.g., 5A and 13X) and MOFs (MOF-74-Ni and UTSA-16-Co (Thakkar et al., 2016; Thakkar et al., 2017a; Thakkar et al., 2017b; Thakkar et al., 2018; Nguyen et al., 2019; Regufe et al., 2019; Thompson et al., 2019). Compared to those prepared by conventional method, the 3D-printed adsorbent materials exhibited comparable Co2 capacity, fast adsorption rate, and relative stability and regenerability. Although 3D-printing shows flexibility in material design and requires less steps and resources, extensive study on fabricating the adsorbent materials at large scale for carbon capture is needed.

Membrane

Compared to other separation methods, membrane separation is generally more energy efficient and environmentally benign, thus has been much studied for Co2 removal from flue gases (Merkel et al., 2010; Japip et al., 2014). In membrane separation, the driving force is the pressure and/or concentration difference. The higher the pressure difference, the better the membrane separation. Therefore, it is more applicable to pre-combustion capture processes, while it is quite challenging for post-combustion capture due mainly to the low Co2 partial pressure and/or concentration in the post-combustion flue gases. Furthermore, unlike other methods, membrane separation involves multistage operation and streams recycling, which makes this method more complicated and complex.

Based on the properties of the fabrication materials, there are three types of membranes in general (Powell and Qiao, 2006; Low et al., 2013): inorganic (or ceramic), organic (or polymeric), and hybrid membranes. Those made up of zeolites, oxides (e.g., Al2o3, TiO2, and ZrO2), ceramics, carbons, and MOFs are typical inorganic membranes (Al-Mamoori et al., 2017). Inorganic membranes are capable of high temperature operation with good mechanical stability, but high fabrication cost limits their scale-up (Al-Mamoori et al., 2017). Compared to inorganic membranes, polymeric membranes have several advantages including ease of synthesis, low production cost, good mechanical stability, and excellent separation performance (Songolzadeh et al., 2014). Thus, more and more polymeric membranes are practically replacing inorganic membranes in large-scale industrial gas separation processes (Bernardo et al., 2009), and gradually dominating most commercial membranes (Siagian et al., 2019). However, their thermal stability is relatively low, which curbs their application in post-combustion Co2 capture. Flue gases normally have to be cooled down first for membrane process (Du et al., 2011; Favre, 2011). The separation performance of polymeric membrane materials can be further improved by incorporating or blending organic or inorganic compounds (Du et al., 2011; Dai et al., 2019).

Recently, new types of polymeric membranes have been developed, for example, thermally rearranged (TR) and intrinsic microporosity polymeric (PIM) membranes. TR membranes exhibit improved thermal stability through structural rearrangement and molecular transformation during the heat treatment, which can generate interconnected microcavities with narrow size distribution, decreasing the mechanical strength of TR membranes (Jo et al., 2015; Liu Q. et al., 2016; Scholes, 2016). PIM membranes are promising for Co2 capture as they exhibit high Co2 permeability and selectivity, surpassing the Robeson’s upper bond due largely to their pore structure, thus receiving much attention (Alaslai et al., 2016; Yong et al., 2016; Gemeda et al., 2017). Siagian et al. compared various polymeric membranes in terms of Co2/N2 selectivity vs. the permeability (Siagian et al., 2019). The conventional polymers are not able to reach the desired performance for Co2 separation. The performance of TR membranes is close to the Robeson’s upper bond, while some of PIM membranes show the performance above the Robeson’s upper value, suggesting PIM membranes are more promising than TR membranes for Co2 removal. However, more tests are needed for these new membranes to be practical for Co2 capture in industries.

Hybrid membrane, or mixed matrix membrane (MMM), which normally consists of an inorganic component such as zeolites, carbon nanotubes, silicates, alumina, or MOFs incorporated into the polymer matrix in the nanoparticles form (Vinoba et al., 2017; Ahmad et al., 2018; Sarfraz and Ba-Shammakh, 2018; Dilshad et al., 2019; Julian et al., 2019), is becoming a new trend to improve polymeric membranes’ properties, as it could possess both advantages of inorganic and organic materials. Incorporating inorganic particles improves both the mechanical and thermal properties, making the polymeric membranes more stable. Thus, it provides a solution to go beyond the restraint of polymeric membranes and the inherent drawbacks of inorganic membranes in cost and production (Ramasubramanian et al., 2012; Tanh Jeazet et al., 2012; Bae and Long, 2013). MMM membranes show the potential to exceed the Robeson’s upper value and are comparable to the PIM membranes. The main drawback for MMM membranes is that inorganic particles could be poorly dispersed, even aggregated within the polymer matrix, leading to membrane defects, deteriorating its overall performance (Zhang Y. et al., 2013; Siagian et al., 2019). In addition, they are under early development along with costly and complex fabrication processes (Ramasubramanian and Ho, 2011).

A new type of MMM membranes called facilitated transport hybrid membranes (FTHMs) or fixed carrier membranes (FCMs) has been proposed and studied (Wu et al., 2014). By incorporating the polymeric matrix with functional groups, it exhibits fairly high Co2 permeability, Co2 selectivity, and material stability (Wang S. et al., 2016), thus is promising as next-generation membrane for Co2 separation. For example, at 107°C and 15 bar, the Co2 permeability and the Co2/N2 selectivity of the FCM containing amino-functionalized multi-wall carbon nanotubes was 975 Barrer and 384, respectively (Ansaloni et al., 2015). The Co2 permeance of 5693 GPU and Co2/N2 selectivity of 268 were reported over the FCM incorporated with nanosized hydrotalcite in PEI–epichlorohydrin copolymer (PEIE) at around 25°C and 1.1 bar (Liao et al., 2014). Similar to other MMM membranes, one of the biggest challenges for industrial application of FCMs is to prepare the membranes without defects and the use of nanosized carriers without agglomeration.

Besides the membrane materials, the configuration of membrane modules is also crucial. There are four main types of modular configurations mostly adopted: tubular, plate-and-frame (Martín, 2016; Berk, 2018), spiral wound (Qi and Henson, 1998; Chen X. et al., 2015; Liu C. et al., 2016), and hollow fiber (Yoshimune and Haraya, 2013; Chen X. et al., 2015; Esposito et al., 2015; Liu C. et al., 2016). Compared to other types of modules, hollow-fiber membranes exhibit better popularity and more compact because of its optimum geometry and high surface-to-volume ratio (Koros, 2004; Al-Mamoori et al., 2017; Wang Y. et al., 2017). Furthermore, highly porous polymeric substructures supporting a thin selective layer of hollow fiber membranes show the potential in advancing the development of membranes (Chen H. et al., 2014).

Future Consideration of Carbon Capture Technologies

Combination of Flue Gas Recycling and Hybrid Capture

The current development of Co2 capture processes has largely centered on a single separation technology. Although numerous optimizations in materials and processes have been pursued, implementing a single separation process (e.g., aqueous amine-based chemical absorption) is either energy intensive or costly. Only few studies have looked at integrating two or more technologies (i.e., absorption, adsorption, membrane, and cryogenic) into a hybrid process for Co2 capture (Freeman et al., 2014). The integration of different separation technologies could avoid their individual disadvantages, thus may be superior to the standalone process (Scholz et al., 2013).

Recently, Song et al. reviewed the hybrid Co2 capture technologies and explored possible combinations (Song et al., 2018), including absorption-, adsorption-, membrane-, and cryogenic-based hybrid processes with different options. Nakhjiri and Heydarinasab compared the performance of the hybrid membrane absorption process using ethylenediamine (EDA), 2-(1-piperazinyl)-ethylamine (PZEA), and potassium sarcosinate (PS) absorbents (Nakhjiri and Heydarinasab, 2019). They found that the Co2 separation efficiency decreases as PZEA > PS > EDA. Atlaskin et al. (Atlaskin et al., 2020) studied a hybrid membrane-assisted gas absorption (MAGA) process for Co2 and H2S removal. The efficiency for Co2/H2S separation was significantly increased by mixing imidazolium ionic liquid (ca. 5 v%) into the methyldiethanolamine (MDEA) solution. Over the hybrid membrane absorption system using 2-methylpiperazine (2MPZ)-promoted potassium carbonate for Co2 separation, increasing 2MPZ concentration, absorbent flow rate, porosity to tortuosity ratio, and membrane fibers can enhance the Co2 removal percentage up to over 98% (Izaddoust and Keshavarz, 2017; Mesbah et al., 2019). Scholes et al. recently reported the pilot plant trials with hollow fiber membrane-MEA (MEA, 30 wt%) contactor for post-combustion Co2 capture, showing the energy duty less than 4.2 GJ/ton of Co2 captured (Scholes et al., 2020). Through the comparison to the standalone methods, they found that the hybrid processes are superior in terms of Co2 recovery, energy penalty, and installation investment, thus are promising as future carbon capture technology (Song et al., 2018).

As above-pointed out, the high energy penalty for Co2 capture process is mainly caused by the low concentration or partial pressure of Co2 in a flue gas, which results in high cost for CCS, as the capture step accounts for about 70–80% of the overall CCS cost (Figueroa et al., 2008). As shown in Table 2, the typical Co2 concentration in flue gases is about 3–14%. The current prevail economic analysis estimates a cost of $70–100/tonne-Co2 for carbon capture from flue gas (Vitillo et al., 2017). With only 400 ppm Co2 in air, a DACC process requires a cost between $300 and $1,500 per tonne of Co2 captured (National Academies of Sciences, Engineering, and Medicine, 2019). One viable strategy is to increase the partial pressure or concentration of Co2 in flue gas. For example, through exhaust gas recycling, in which flue gas from natural gas boiler (containing ∼4% Co2) is recycled and used in place of air for the fuel combustion, Co2 concentration in the flue gas can be enriched up to ∼8%, making Co2 capture less thermodynamically challenging (Vaccarelli et al., 2014). However, considering the significant capital investment in exhaust gas recycling with respect to the combustion unit, the balance between exhaust gas recycling and carbon capture energy penalty has to be carefully and thoroughly examined and optimized (Vaccarelli et al., 2014).

Membranes can also be utilized to concentrate Co2 from flue gas for recycling. Merkel et al. obtained up to 20% increase in Co2 concentration and up to 40% reduction in the minimum energy required for Co2 capture (Merkel et al., 2013). A set of membranes in series or parallel may be used for selective Co2 recycling, offering increased driving force for Co2 separation. It could be more efficient if coupled with other capture technologies (e.g., absorption, adsorption, and cryogenics), especially with those hybrid systems.

Although it could increase capital and maintenance costs, recycling flue gas or pre-concentrating Co2 with membranes can simplify the Co2 capture process. By combining the advantages of hybrid Co2 capture systems, we believe that the benefits in the subsequent Co2 capture step could be substantial, which may ultimately make this approach more energy efficient and cost effective. Although currently the experimental data are not enough, the primary results have convinced us that the proposed concept would be plausible as future CCS direction, especially to overcome the technical bottlenecks encountered when using single carbon capture technology.

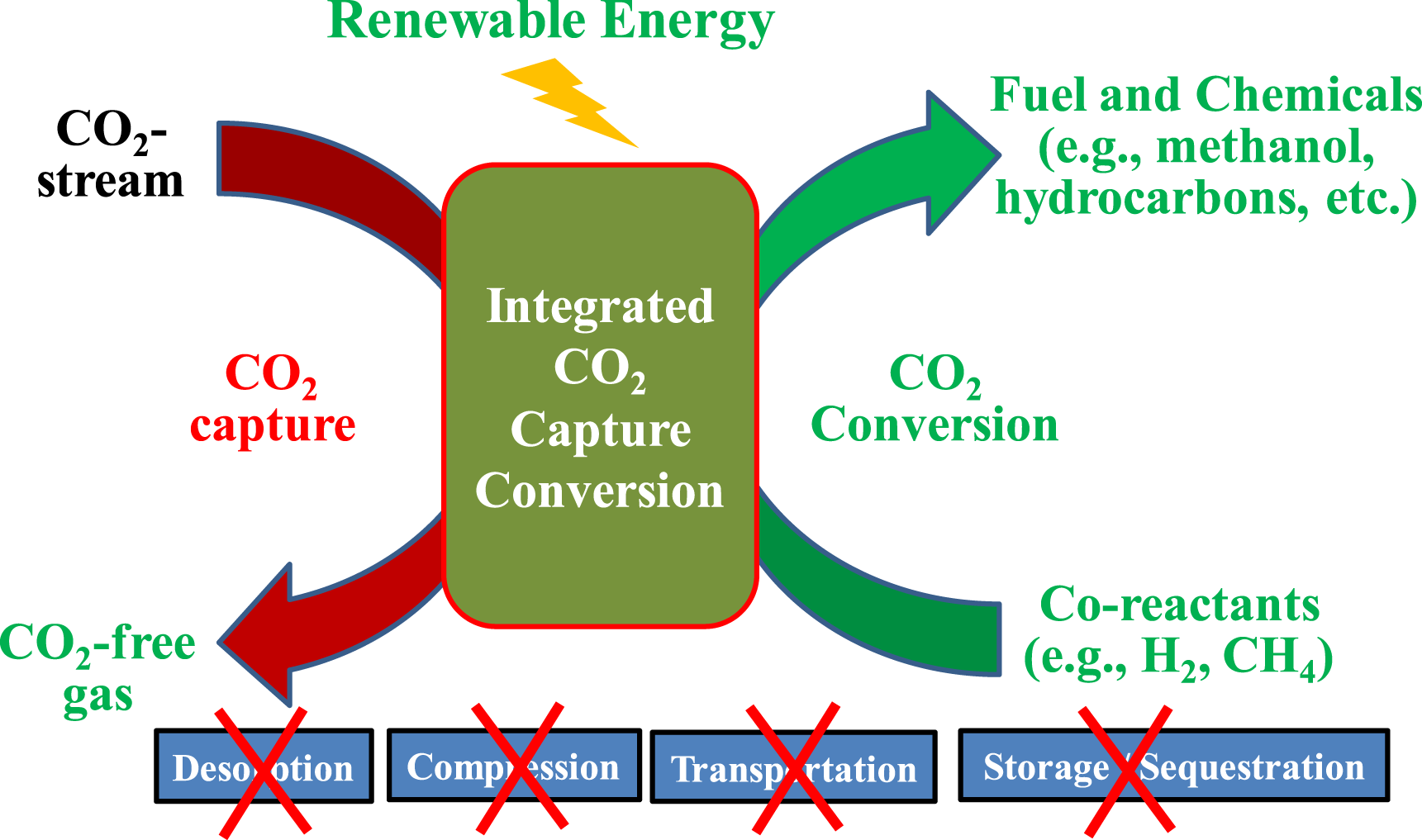

One-Step Integrated Co2 Capture and Conversion

Another encouraging strategy is integrating the Co2 capture and conversion in one stage. In nature, organisms or organelles indeed systematically utilize and store Co2 directly. However, compared to chemical-based approaches, they are much limited by the long time and large contact area requirements (Table 3). When Co2 capture is integrated directly with subsequent in situ Co2 utilization/conversion to value-added products in one step, the concept of which is depicted in Figure 8, the process could eliminate the needs of the steps for Co2 desorption, compression, transportation, and storage, eradicating the energy penalty associated with these steps. It is particularly useful to the chemical absorption-based Co2 capture technologies, where the significant energy penalty occurs at the desorption step. Furthermore, the production of value-added chemicals and fuels could generate revenues to compensate the cost for carbon capture, which helps reducing the economic barrier for the commercial deployment of the Co2 capture technologies. This is also a pathway to functionalizing metal–organic frameworks, electrocatalysts, photocatalysts, and more—for their potential applications in Co2 capture and conversion.

FIGURE 8

Concept of one step direct integration of Co2 capture and in situ Co2 conversion.

Recent years, more reports about the one-step integration of Co2 capture and conversion are coming out. Gassner and Leitner first reported the attempt to integrate catalytic Co2 conversion to capture via Co2 hydrogenation to formate in the presence of aqueous amine solutions (Gassner and Leitner, 1993). He et al. explored a combined system containing a superbase, a poly (ethylene glycol) (PEG), ionic liquid and amino acid for in situ Co2 capture-conversion to carbonates, urea, and formate salts (Yang et al., 2011a; Yang et al., 2011b; Liu et al., 2012). Kim et al. experimentally demonstrated a process directly integrating Co2 utilization into Co2 capture, allowing for the full conversion of the Co2 captured into syngas in a single reactor using limestone for Co2 capture and a non-precious metal catalyst for Co2 conversion with Ch4 (Kim et al., 2018). Liu et al. developed a novel hybrid MgAl(LDO)/TiO2 adsorbent/photocatalyst for the integrated Co2 capture plus photocatalytic conversion directly to C1 products at 100–200°C (Liu et al., 2015). The regeneration of the developed material can be easily achieved with low-grade waste heat and/or solar energy (Liu et al., 2015). Kar et al. systematically reviewed the current progress in the integrated capture-conversion process using aqueous amine and hydroxide solutions for Co2 capture followed by in situ hydrogenation using coexisted homogeneous metal complex catalysts to formate salts and methanol (Kar et al., 2019). The whole process is regenerable for multiple cycles. Consequently, they suggested that the amine-assisted Co2 capture and conversion to methanol process is very encouraging. Stuardi et al. also suggested the integration of Co2 capture and utilization as a priority research direction (Marocco Stuardi et al., 2019).

Besides the liquid amine processes, the solid adsorbent catalyst-based Co2 capture-conversion processes using dual function materials (DFMs) consisting of the methanation catalyst (e.g., Ru and Ni) and Co2 adsorbent (e.g., CaO, Na2O, and MgO) on a support have also been studied at mild conditions (200–350°C and 1 atm) (Duyar et al., 2015; Duyar et al., 2016; Miguel et al., 2017; Wang S. et al., 2017; Wang et al., 2018; Arellano-Treviño et al., 2019; Zhou et al., 2020).Those DFMs exhibit stable performance in Co2 capture and conversion to synthetic Ch4 for over 50 cycles. No loss in Co2 capture capacity and Ru dispersion was observed (Wang et al., 2018). Over the 2D-layered Ni–MgO–Al2o3 nanosheets, continuous and nearly 100% capture of Co2 during prolonged cycling tests was achieved at temperatures below 250°C (Zhou et al., 2020). Its hydrogen efficiency reached 60% for Co2 conversion to Ch4, making the process attractive for large Co2 emission sources.

Patterson et al. proposed an approach to recycle atmospheric Co2 into liquid fuels on a large-scale marine-based artificial island, using renewable energy (solar or wind) to power the production of hydrogen and Co2 extraction from seawater, followed by catalytic conversion to liquid methanol fuel (Patterson et al., 2019). The major advantage of the proposed approach is the utilization of sea as the Co2 absorber, in which it is always in equilibrium with the atmosphere, along with the usage of renewable energy, generating negative Co2 emission through the process.

These efforts in the integration of Co2 capture and conversion in one step have demonstrated their promise, although mainly C1 products are generated. Through the research entailing experimental results coupled with theory to improve fundamental understanding, and the design of innovative polyfunctional and multi-structured materials for the one-step integrated Co2 capture and conversion, the production of liquid hydrocarbon fuels, chemicals, polymers, carbon materials (e.g., nanotubes and nanofibers) directly from flue gas or atmospheric Co2 can be envisaged in future. It will also lead to developing carbon capture technologies with smaller size, greener process, and better energy efficiency. If implemented, it could significantly change the way in Co2 capture, compress, transport, conversion, and/or storage, thus increasing opportunities for Co2 valorization, and offer a feasible solution to the current global environmental problems associated with energy use.

Concluding Remarks

Through the past few decades of research and development, there have been significant progresses in Co2 capture technologies, but still far from economically attractive commercialization. It requires a comprehensive investigation on the characteristics and relationships of the materials and process performance, which is crucial to the development of next-generation carbon capture technologies with improved energy efficiency and cost-effectiveness. In this perspective, we believe the two plausible approaches, that is, the combination of flue gas recycling and hybrid capture system, and one-step integration of Co2 capture and conversion, are promising for future research, as they could offer significant improvement in energy efficiency and cost-effectiveness, by simplifying the capture process in the former and eliminating the desorption, compression, transportation, and storage steps in the latter, respectively. However, more research and development such as materials development, synergistic assessment, process design, process optimization, and scale-up are required. Their environmental impacts and the life-cycle analysis should also be considered. Nonetheless, the proposed and emerging approaches appear to be promising with better commercial potential in the future, and offer a viable solution to the technical bottlenecks of current carbon capture technologies, and to the global dilemma in meeting more energy demand while reducing environmental impact.

Statements

Author contributions

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

Acknowledgments

The financial support from the Pennsylvania State University and EMS Energy Institute Seed Grant is appreciatively acknowledged.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

1

Aaron D. Tsouris C. (2005). Separation of Co2 from flue gas: a review. Sep. Sci. Technol.40, 321–348. 10.1081/SS-200042244

2

Abanades J. C. Arias B. Lyngfelt A. Mattisson T. Wiley D. E. Li H. et al (2015). Emerging Co2 capture systems. Int. J. Greenh. Gas Control.40, 126–166. 10.1016/j.ijggc.2015.04.018

3

Adanez J. Abad A. Garcia-Labiano F. Gayan P. de Diego L. F. (2012). Progress in chemical-looping combustion and reforming technologies. Prog. Energy Combust. Sci.38, 215–282. 10.1016/j.pecs.2011.09.001

4

Ahmad M. Z Navarro M. Lhotka M. Zornoza B. Téllez C. de Vos W. M. et al (2018). Enhanced gas separation performance of 6FDA-DAM based mixed matrix membranes by incorporating MOF UiO-66 and its derivatives. J. Membr. Sci.558, 64–77. 10.1016/j.memsci.2018.04.040

5

Ahmadalinezhad A. Sayari A. (2014). Oxidative degradation of silica-supported polyethylenimine for Co2 adsorption: insights into the nature of deactivated species. Phys. Chem. Chem. Phys.16, 1529–1535. 10.1039/c3cp53928h

6

Akhtar F. Keshavarzi N. Shakarova D. Cheung O. Hedin N. Bergström L. (2014). Aluminophosphate monoliths with high Co2-over-N2 selectivity and Co2 capture capacity. RSC Adv.4, 55877–55883. 10.1039/C4RA05009F

7

Aki S. N. V. K. Mellein B. R. Saurer E. M. Brennecke J. F. (2004). High-pressure phase behavior of carbon dioxide with imidazolium-based ionic liquids. J. Phys. Chem. B108, 20355–20365. 10.1021/jp046895

8

Alaslai N. Ghanem B. Alghunaimi F. Pinnau I. (2016). High-performance intrinsically microporous dihydroxyl-functionalized triptycene-based polyimide for natural gas separation. Polymer91, 128–135. 10.1016/j.polymer.2016.03.063

9

Al-Mamoori A. Krishnamurthy A. Rownaghi A. A. Rezaei F. (2017). Carbon capture and utilization update. Energy Technol.5, 834–849. 10.1002/ente.201600747

10

Anderson J. L. Dixon J. K. Brennecke J. F. (2007). Solubility of Co2, Ch4, C2H6, C2H4, O2, and N2 in 1-hexyl-3-methylpyridinium bis(trifluoromethylsulfonyl)imide: comparison to other ionic liquids. Accounts Chem. Res.40, 1208–1216. 10.1021/ar7001649

11

Ansaloni L. Zhao Y. Jung B. T. Ramasubramanian K. Baschetti M. G. Ho W. S. W. (2015). Facilitated transport membranes containing amino-functionalized multi-walled carbon nanotubes for high-pressure Co2 separations. J. Membr. Sci.490, 18–28. 10.1016/j.memsci.2015.03.097

12

Arellano-Treviño M. A. He Z. Libby M. C. Farrauto R. J. (2019). Catalysts and adsorbents for Co2 capture and conversion with dual function materials: limitations of Ni-containing DFMs for flue gas applications. J. Co2 Util.31, 143–151. 10.1016/j.jcou.2019.03.009

13

Arshad M. W. Svendsen H. F. Fosbøl P. L. Von Solms N. Thomsen K. (2014). Equilibrium total pressure and Co2 solubility in binary and ternary aqueous solutions of 2-(Diethylamino)ethanol (DEEA) and 3-(Methylamino)propylamine (MAPA). J. Chem. Eng. Data59, 764–774. 10.1021/je400886w

14

Atlaskin A. A. Kryuchkov S. S. Yanbikov N. R. Smorodin K. A. Petukhov A. N. Trubyanov M. M. et al (2020). Comprehensive experimental study of acid gases removal process by membrane-assisted gas absorption using imidazolium ionic liquids solutions absorbent. Sep. Purif. Technol.239, 116578. 10.1016/j.seppur.2020.116578

15

Azarabadi H. Lackner K. S. (2020). Postcombustion capture or direct air capture in decarbonizing US natural gas power?Environ. Sci. Technol.54, 5102–5111. 10.1021/acs.est.0c00161

16

Bae T.-H. Long J. R. (2013). Co2/N2 separations with mixed-matrix membranes containing Mg2(dobdc) nanocrystals. Energy Environ. Sci.6, 3565–3569. 10.1039/c3ee42394h

17

Bae T.-H. Hudson M. R. Mason J. A. Queen W. L. Dutton J. J. Sumida K. et al (2013). Evaluation of cation-exchanged zeolite adsorbents for post-combustion carbon dioxide capture. Energy Environ. Sci.6, 128–138. 10.1039/C2EE23337A

18

Bates E. D. Mayton R. D. Ntai I. Davis J. H. (2002). Co2 capture by a task-specific ionic liquid. J. Am. Chem. Soc.124, 926–927. 10.1021/ja017593d

19

Belmabkhout Y. Sayari A. (2009). Effect of pore expansion and amine functionalization of mesoporous silica on Co2 adsorption over a wide range of conditions. Adsorpt.-J. Int. Adsorpt. Soc.15, 318–328. 10.1007/s10450-009-9185-6

20

Benamor A. Aroua M. K. (2005). Modeling of Co2 solubility and carbamate concentration in DEA, MDEA and their mixtures using the Deshmukh-Mather model. Fluid Phase Equil.231, 150–162. 10.1016/j.fluid.2005.02.005

21

Berk Z. (2018). “Membrane processes,” in Food process engineering and technology. 3rd Edn, Editors BerkZ. (Cambridge, MA: Academic Press), Chap. 10, 261–287

22

Bernardo P. Drioli E. Golemme G. (2009). Membrane gas separation: a review/state of the art. Ind. Eng. Chem. Res.48, 4638–4663. 10.1021/ie8019032

23

Bhown A. S. Bromhal G. Barki G. (2020). “Co2 capture and sequestration,” in Fossil energy. Editors MalhotraR. (New York, NY: Springer), 503–517

24

Blanchard L. A. Gu Z. Brennecke J. F. (2001). High-pressure phase behavior of ionic liquid/Co2 systems. J. Phys. Chem. B105, 2437–2444. 10.1021/jp003309d

25

Bollini P. Didas S. A. Jones C. W. (2011). Amine-oxide hybrid materials for acid gas separations. J. Mater. Chem.21, 15100–15120. 10.1039/C1JM12522B

26

Bougie F. Iliuta M. C. (2014). Solubility of Co2 in and density, viscosity, and surface tension of aqueous 2-amino-1,3-propanediol (serinol) solutions. J.Chem. Eng. Data59, 355–361. 10.1021/je4008298

27

Brovkin V. Sitch S. Von Bloh W. Claussen M. Bauer E. Cramer W. (2004). Role of land cover changes for atmospheric Co2 increase and climate change during the last 150 years. Global Change Biol.10, 1253–1266. 10.1111/j.1365-2486.2004.00812.x

28

Bui M. Adjiman C. S. Bardow A. Anthony E. J. Boston A. Brown S. et al (2018). Carbon capture and storage (CCS): the way forwardEnergy Environ. Sci.11, 1062–1176. 10.1039/c7ee02342a

29

Burtch N. C. Jasuja H. Walton K. S. (2014). Water stability and adsorption in metal–organic frameworks. Chem. Rev.114, 10575–10612. 10.1021/cr5002589

30

Carbon Engineering (2020). Carbon engineering website. Available at: https://carbonengineering.com/ (Accessed July 15, 2020).

31

Carvalho P. J. Álvarez V. H. Schröder B. Gil A. M. Marrucho I. M. Aznar M. et al (2009). Specific solvation interactions of Co2 on acetate and trifluoroacetate imidazolium based ionic liquids at high pressures. J. Phys. Chem. B113, 6803–6812. 10.1021/jp901275b

32

Carvalho P. J. Álvarez V. H. Marrucho I. M. Aznar M. Coutinho J. A. P. (2010). High carbon dioxide solubilities in trihexyltetradecylphosphonium-based ionic liquids. J. Supercrit. Fluids52, 258–265. 10.1016/j.supflu.2010.02.002Get

33

Caskey S. R. Wong-Foy A. G. Matzger A. J. (2008). Dramatic tuning of carbon dioxide uptake via metal substitution in a coordination polymer with cylindrical pores. J. Am. Chem. Soc.130, 10870–10871. 10.1021/ja8036096

34

Chakma A. (1999). Formulated solvents: new opportunities for energy efficient separation of acid gases. Energy Sources21, 51–62. 10.1080/00908319950014957

35

Chang Y. C. Leron R. B. Li M. H. (2013). Equilibrium solubility of carbon dioxide in aqueous solutions of (diethylenetriamine + piperazine). J. Chem. Thermodyn.64, 106–113. 10.1016/j.jct.2013.05.005

36

Chatterjee S. Huang K.-W. (2020). Unrealistic energy and materials requirement for direct air capture in deep mitigation pathways. Nat. Commun.11, 3287. 10.1038/s41467-020-17203-7

37

Chen X. Rochelle G. T. (2011). Aqueous piperazine derivatives for Co2 capture: accurate screening by a wetted wall column. Chem. Eng. Res. Des.89, 1693–1710. 10.1016/j.cherd.2011.04.002

38

Chen C. Son W. J. You K. S. Ahn J. W. Ahn W. S. (2010). Carbon dioxide capture using amine-impregnated HMS having textural mesoporosity. Chem. Eng. J.161, 46–52. 10.1016/j.cej.2010.04.019

39

Chen C. Kim J. Ahn W. S. (2014). Co2 capture by amine-functionalized nanoporous materials: a review. Korean J. Chem. Eng.31, 1919–1934. 10.1007/s11814-014-0257-2

40

Chen H. Z. Thong Z. Li P. Chung T.-S. (2014). High performance composite hollow fiber membranes for Co2/H2 and Co2/N2 separation. Int. J. Hydrog. Energy39, 5043–5053. 10.1016/j.ijhydene.2014.01.047

41

Chen S. Chen S. Fei X. Zhang Y. Qin L. (2015). Solubility and characterization of Co2 in 40 mass % N -ethylmonoethanolamine solutions: explorations for an efficient nonaqueous solution. Ind. Eng. Chem.54, 7212–7218. 10.1021/acs.iecr.5b01654

42

Chen X. Y. Vinh-Thang H. Ramirez A. A. Rodrigue D. Kaliaguine S. (2015). Membrane gas separation technologies for biogas upgrading. RSC Adv.5, 24399–24448. 10.1039/C5RA00666J

43

Chen C.-H. Shimon D. Lee J. J. Mentink-Vigier F. Hung I. Sievers C. et al (2018). The “missing” bicarbonate in Co2 chemisorption reactions on solid amine sorbents. J. Am. Chem. Soc.140, 8648–8651. 10.1021/jacs.8b04520

44

Choi S. Drese J. H. Jones C. W. (2009). Adsorbent materials for carbon dioxide capture from large anthropogenic point sources. ChemSusChem2, 796–854. 10.1002/cssc.200900036

45

Choi W. Min K. Kim C. Ko Y. S. Jeon J. W. Seo H. et al (2016). Epoxide-functionalization of polyethyleneimine for synthesis of stable carbon dioxide adsorbent in temperature swing adsorption. Nat. Commun.7, 12640. 10.1038/ncomms12640

46

Chu S. (2009). Carbon capture and sequestration. Science325, 1599. 10.1126/science.1181637

47

Climeworks (2020). Climeworks website. Available at: http://www.climeworks.com (Accessed July 15, 2020).

48

Conway W. Bruggink S. Beyad Y. Luo W. Melián-Cabrera I. Puxty G. et al (2015). Co2 absorption into aqueous amine blended solutions containing monoethanolamine (MEA), N,N-dimethylethanolamine (DMEA), N,N-diethylethanolamine (DEEA) and 2-amino-2-methyl-1-propanol (AMP) for post-combustion capture processes. Chem. Eng. Sci.126, 446–454. 10.1016/j.ces.2014.12.053

49

Corvo M. C. Sardinha J. Casimiro T. Marin G. Seferin M. Einloft S. et al (2015). A rational approach to Co2 capture by imidazolium ionic liquids: tuning Co2 solubility by cation alkyl branching, ChemSusChem, 81935–1946.10.1002/cssc.201500104

50

Cousins A. Nielsen P. T. Huang S. Rowland R. Edwards B. Cottrell A. et al (2015). Pilot-scale evaluation of concentrated piperazine for Co2 capture at an Australian coal-fired power station: nitrosamine measurements. Int. J. Greenh. Gas Control37, 256–263. 10.1016/j.ijggc.2015.03.007

51

Cui G. Wang J. Zhang S. (2016). Active chemisorption sites in functionalized ionic liquids for carbon capture. Chem. Soc. Rev.45, 4307–4339. 10.1039/c5cs00462d

52

Cullinane J. T. Rochelle G. T. (2006). Kinetics of carbon dioxide absorption into aqueous potassium carbonate and piperazine. Ind. Eng. Chem. Res.45, 2531–2545. 10.1021/ie050230s

53

Dai Z. Deng J. Aboukeila H. Yan J. Ansaloni L. Mineart K. P. et al (2019). Highly Co2-permeable membranes derived from a midblock-sulfonated multiblock polymer after submersion in water. NPG Asia Mater.11, 53. 10.1038/s41427-019-0155-5

54

D'Alessandro D. M. Smit B. Long J. R. (2010). Carbon dioxide capture: prospects for new materials. Angew. Chem. Int. Ed.49, 6058–6082. 10.1002/anie.201000431

55

Darunte L. A. Walton K. S. Sholl D. S. Jones C. W. , (2016). Co2 capture via adsorption in amine-functionalized sorbents. Curr. Opin. Chem. Eng.12, 82–90. 10.1016/j.coche.2016.03.002

56

de Riva J. Suarez-Reyes J. Moreno D. Díaz I. Ferro V. Palomar J. (2017). Ionic liquids for post-combustion Co2 capture by physical absorption: thermodynamic, kinetic and process analysis. Int. J. Greenh. Gas Control61, 61–70. 10.1016/j.ijggc.2017.03.019

57

Demessence A. D’Alessandro D. M. Foo M. L. Long J. R. (2009). Strong Co2 binding in a water-stable, triazolate-bridged Metal−Organic framework functionalized with ethylenediamine. J. Am. Chem. Soc.131, 8784–8786. 10.1021/ja903411w

58

Derks P. W. J. Dijkstra H. B. S. Hogendoorn J. A. Versteeg G. F. (2005). Solubility of carbon dioxide in aqueous piperazine solutions. AIChE J.51, 2311–2327. 10.1002/aic.10442

59

Didas S. A. Choi S. Chaikittisilp W. Jones C. W. (2015). Amine-oxide hybrid materials for Co2 capture from ambient air. Accounts Chem. Res.48, 2680–2687. 10.1021/acs.accounts.5b00284

60

Dilshad M. R. Islam A. Hamidullah U. Jamshaid F. Ahmad A. Butt M. T. Z. et al (2019). Effect of alumina on the performance and characterization of cross-linked PVA/PEG 600 blended membranes for Co2/N2 separation. Sep. Purif. Technol.210, 627–635. 10.1016/j.seppur.2018.08.026

61

Ding Y. Alpay E. (2000). Equilibria and kinetics of Co2 adsorption on hydrotalcite adsorbent. Chem. Eng. Sci.55, 3461–3474. 10.1016/S0009-2509(99)00596-5

62

Ding M. Flaig R. W. Jiang H.-L. Yaghi O. M. (2019). Carbon capture and conversion using metal–organic frameworks and MOF-based materials. Chem. Soc. Rev.48, 2783–2828. 10.1039/c8cs00829a

63