- 1Research Institute of Standards and Norms Ministry of Housing and Urban-Rural Development, Beijing, China

- 2Inner Mongolia University of Finance and Economics, Hohhot, China

With the world facing increasingly severe environmental and energy challenges, the role of the construction industry in achieving the dual-carbon goals has become increasingly prominent. However, China’s existing text-based engineering construction standards system is insufficient in effectively supporting the realization of these goals. Therefore, based on the Model-Based Systems Engineering (MBSE) approach and utilizing the Systems Modeling Language (SysML), this paper proposes a new engineering construction standards system tailored to Chinese characteristics, addressing aspects including requirements, behavior, and structure. This system not only supports the construction standard requirements in the energy transition process but also aims to improve energy efficiency, emission reduction, and resource recycling in the building industry from both energy and environmental economics perspectives. The system is validated through carbon dioxide capture standards, and the results demonstrate that the MBSE-based engineering construction standards system holds significant application prospects in promoting energy economic sustainability and environmental protection. It can provide strong support for achieving green and dual-carbon goals.

1 Introduction

As a major carbon emitter, China’s carbon emissions from the construction sector were 5.08 billion tons in 2020, accounting for 50.9% of total emissions. Carbon emissions from building material production were 28.2%, building operations 21.7%, and construction activities 1.0% (Wang et al., 2015; Yang et al., 2024). China has suggested carbon peak and carbon neutrality targets to ensure global sustainable development, with the building industry playing a critical role in emissions reduction (Li et al., 2021; Qi and Xia, 2022). Carbon reduction in the building industry is dependent on the development of standards. First, current research focuses on carbon emission monitoring standards in the building industry. Most research solely evaluates direct carbon emissions; however, a few studies analyze indirect carbon emissions generated by carbon emission transfer (Arıoğlu Akan et al., 2017; Gao et al., 2021). The second is the evaluation standards. Over the past few decades, various organizations have developed green building evaluation tools. The United Kingdom introduced the first green building certification system in 1990, establishing the earliest assessment standard (Sartori et al., 2021). Subsequently, many countries launched their own green certification systems. Among these, the Leadership in Energy and Environmental Design (LEED) system, introduced by the United States in 1995, has gained the most widespread influence (Clay et al., 2023).

While these standards primarily target residential and commercial buildings, limited research has been conducted on engineering construction standards, which are critical for achieving energy efficiency and carbon reduction throughout the building lifecycle. These standards regulate emissions from material production, enhance energy efficiency in building operations, and ensure sustainability across all phases of construction (Chen et al., 2018). Therefore, establishing a comprehensive system of engineering construction standards is crucial for the construction industry to achieve its dual carbon goals.

It is clear that energy standards, especially those for non-residential buildings, will become increasingly crucial in shaping both national and potentially international energy efficiency policies in the future (Janda and Busch, 1994). While some developing countries have established green building rating programs, many others have yet to adopt building energy standards. Future research should focus on exploring effective strategies for implementing these standards to reduce energy consumption in buildings (Lu and Lai, 2019). A growing number of organizations are adopting certified Environmental Management Systems (EMS) and Energy Management Systems (EnMS), with ISO 14001 and the Eco-Management and Audit Scheme (EMAS) serving as the leading standards for EMS certification, while ISO 50001 is widely recognized for EnMS certification (Shi et al., 2013; Laskurain et al., 2015). The sustainable transformation of the built environment heavily relies on standards for products, processes, and management systems. By advancing international facilities management (FM) standards, the sustainability of buildings can be significantly enhanced. The CIB (International Council for Research and Innovation in Building and Construction) and other standardization organizations play a vital role in accelerating societal shifts and addressing the growing demands for resilience and sustainability (Klungseth et al., 2022). Policy promotion is crucial for advancing zero-carbon buildings in society. The experiences of the United States in zero-carbon building policies, regulations, and standards can provide valuable references for other countries in developing their zero-carbon roadmaps. Coordination among the construction industry, energy systems, materials production, and government financial incentives are essential for achieving zero-carbon buildings (Gong et al., 2021). Collaborative efforts among different levels of government and professional associations are also important (Yu et al., 2022).

Research indicates that the standards governing engineering construction related to carbon reduction are highly fragmented, making it exceedingly difficult to integrate them into a coherent framework. This fragmentation is largely attributed to several challenges inherent in the existing standardized management in the construction industry. Firstly, standardization remains in its early digital phase, with many documents unstructured, resulting in high management costs. With the growing number of carbon reduction-related standards, this further exacerbates the complexity of the management process. Secondly, the characteristics of standardization are interdependence, dynamism, and intricacy. In particular, in the energy and environmental sectors, which involve virtually all industries, various standards and committees are interconnected, with emerging technologies and needs requiring continuous optimization of existing standards. This often leads to overlapping, missing, or delays in standard updates, as they require interdisciplinary expertise. Lastly, the creation and updating of standards rely heavily on the specialized knowledge and experience of standardization experts. Thus, generalists find it challenging to accurately identify requirements and effectively participate in the standardization process.

The text-based engineering construction standard system faces significant challenges. Researchers are actively addressing these issues through methods such as Work Breakdown Structure (WBS) and systems engineering (Elsye et al., 2018). For instance, Su et al. (2022) developed a prefabricated building cost management model based on Hall’s three-dimensional structure and conducted a benefit analysis for a specific building. Existing studies have explored ways to digitize standard knowledge and integrate it into work environments. Manoharan and Thivakar proposed a concept that utilizes RESTful services as a central knowledge repository, offering knowledge through microservices. To meet required quality standards and ensure effective implementation, standard content must be prepared in a machine-readable and cross-system compatible format. This involves converting the full text of standards into XML format and providing access to the standard content (Manoharan et al., 2019).

Model-Based Systems Engineering marks a transition from the traditional Document-Based Systems Engineering (DBSE) approach (Gregory et al., 2020). MBSE has become increasingly popular in organizations engaged in the development of complex systems, where collaboration across multidisciplinary domains is essential (Biggs et al., 2018; Wilking et al., 2024). For example, Adams et al. (2024) introduced the 15288-SysML grid framework to align the guidance provided in the 15288 standard with SysML. The key design elements captured in the SysML model are: (1) behavior, (2) requirements, (3) structure, and (4) parametric relationships (Hoffmann et al., 2024). These four key design elements are integrated to form a unified model that comprehensively represents the system’s various aspects and their interdependencies.

Although existing research has made preliminary progress in the methodology and digitization of engineering construction standards, several issues remain. First, engineering construction standards involve numerous fields, and while there are commonalities among the engineering construction standards of each industry, there are also differences. This results in carbon reduction-related standards being scattered among tens of thousands of standards, making it nearly impossible to analyze the emission reduction effects of engineering construction standards in any given industry. Second, there is a disconnect between these advancements and the current state of standardization in China’s engineering sector (Ping, 2011). China’s standardization research started relatively late, the theoretical foundation needs to be strengthened, and the understanding of the standardization system needs to be further improved, which makes it difficult to directly adopt international frameworks. Finally, progress in the digitization of standards has been relatively slow, with significant challenges related to machine interpretability and cross-system interoperability, which impede the development of effective solutions.

This paper makes the following contributions: (1) It applies a MBSE approach to develop a structured framework for engineering construction standards, into which all emission reduction-related engineering construction standards can be incorporated, providing support for subsequent research; (2) It provides a comprehensive review of the current status, management system, and key features of China’s engineering construction standards, constructing a framework for engineering construction standards with Chinese characteristics; (3) It uses carbon dioxide capture standards as a case study to validate the proposed approach and explore its potential in reducing carbon emissions within the engineering construction sector.

The rest of this article is organized as follows: Section 2 presents an overview of the development of engineering construction standardization in China, the current management system, and the measures taken to achieve carbon neutrality goals. Section 3 outlines a framework for the engineering construction standard system based on the MBSE approach. Section 4 provides a case study that validates the framework using standards for carbon dioxide capture. Section 5 describes the conclusions and future work.

2 Background

2.1 Development of engineering construction standardization in China

Standardization has evolved from firm-level standardization during the early industrial revolution, to private standardization organizations and voluntary standards in market economies, and then to national and international standardization organizations and their related standards driven by industrialization and international trade. China’s standardization agencies and relevant departments pay great attention to this issue, especially after joining the World Trade Organization (WTO). Participation in WTO/TBT has made China aware of the importance of standardization in international trade, thus deciding to implement a standardization strategy. At the same time, China’s standardization system originates from a planned economy and is relatively government-led, resulting in significant disparities in standardization capabilities between various industries and their overseas counterparts (Ping, 2011).

Since the 1950s, China has benefited from the Soviet Union’s expertise developing and implementing technical standards in the field of standardization. Following the reform and opening up, China increasingly absorbed industrialized nations’ standardization concepts and methods, resulting in a standard system with Chinese features (Ping, 2011; Breznitz and Murphree, 2013). The Chinese government issued “The Standardization Law of the People’s Republic of China” (1988) and “The Implementing Regulations of the Standardization Law of the People’s Republic of China” (1990), laying the groundwork for the establishment of a standardization system for engineering construction in China.

In 2015, the State Council issued the “Plan for Deepening the Reform of Standardization Work,” outlining the overall goal of the reform: to establish a new standardization system that promotes coordinated development and synergy between government-led and market-driven standards. This initiative aims to enhance a unified, coordinated, and efficient standardization management system that integrates both government oversight and market dynamics. It seeks to create a standardization framework characterized by government guidance, market-driven innovation, social participation, and collaborative advancement, thereby effectively supporting the development of a unified market system (Liu, 2018; Yang et al., 2023).

In 2016, the Ministry of Housing and Urban-Rural Development of the People’s Republic of China (MOHURD) issued the “Opinions on Deepening the Reform of Engineering Construction Standardization,” setting the goal of establishing a new engineering construction standard system by 2025. This system will be centered on mandatory standards, supplemented by recommended and group standards. The initiative aims to further enhance the international influence and contributions of China’s engineering construction standards. Additionally, the implementation of the revised “The Standardization Law of the People’s Republic of China” in 2018 has significantly accelerated the pace of standardization reform in the engineering construction sector.

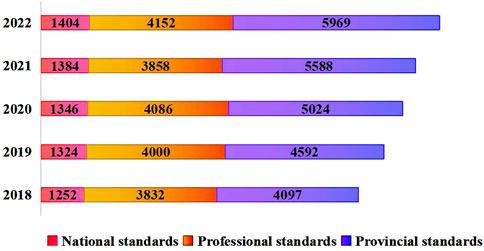

In recent years, the standardization process for engineering construction in China has been accelerating, with the number of national, professional, and provincial standards steadily increasing (Tong et al., 2021). By the end of 2022, China had established a total of 11,525 standards for engineering construction, covering national, professional, and provincial categories. Figure 1 presents an overview of the status and development trends of these standards from 2018 to 2022.

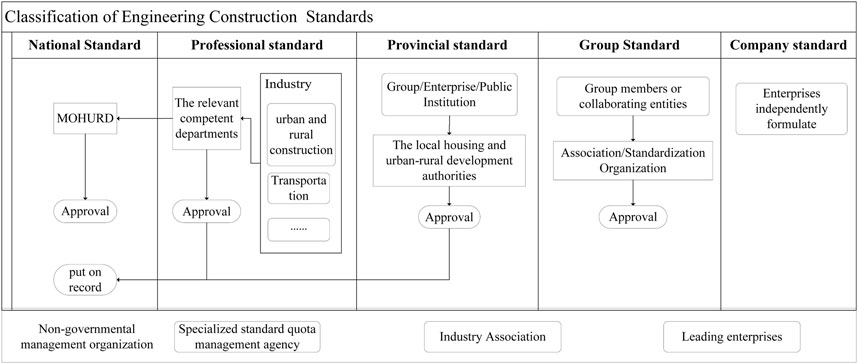

The standardization management system for engineering construction in China adopts a management system of “unified management and divided responsibilities”, characterized by a clear delineation of responsibilities among various departments and stakeholders. The Ministry of Housing and Urban-Rural Development undertakes the comprehensive management of national engineering construction standardization (Shi et al., 2013). Additionally, the relevant competent departments of the State Council are responsible for the management of engineering construction standardization within their respective sectors. Currently, there are various configurations for standardization management bodies across different industries. These configurations primarily include those managed by regulatory departments, industry associations, and relevant enterprise departments. This structured approach ensures that engineering construction standards are effectively implemented, promoting quality, safety, and efficiency in construction projects throughout the country.

The local housing and urban-rural development authorities are responsible for the management of engineering construction standardization within their respective administrative regions. Group standards are developed by legally established social organizations to meet market and innovation needs, formulated through collaborative efforts among relevant market participants. Company standards are designed to coordinate and unify technical, management, and operational requirements within an enterprise, serving as the basis for organizing production and business activities. The entire lifecycle of national engineering construction standards in China generally includes the following stages: initiation, preparation, solicitation of comments, submission for review, submission for approval, approval, issuance, implementation, review, revision, and withdrawal (see Figure 2).

2.2 Measures to achieve dual carbon goals through standardization in engineering construction

As China continues to experience robust economic growth and technological advancements, the scale and sophistication of engineering construction have significantly increased. This progress brings with it substantial challenges in energy conservation and emission reduction, highlighting the urgent need for sustainable development practices.

In recent years, the Ministry of Housing and Urban-Rural Development has implemented several energy efficiency policies for buildings, promoting the adoption of energy-saving and renewable energy technologies to reduce overall energy consumption in construction projects (Akram et al., 2022; Zhou and Zhou, 2023). However, a gap remains between the actual energy performance of buildings and the targets set by design standards. Despite improvements in energy efficiency standards for building design, energy consumption in the urban civil construction sector has continued to rise (Berardi, 2017). This trend can be attributed to the ongoing lack of localized design in energy-saving standards and insufficient scientific management in building operations. As a result, there is an inadequate energy consumption management system during the operational phase of buildings.

Therefore, efforts should be actively encouraged and guided in regions with favorable conditions to promote ultra-low energy buildings, nearly zero-energy buildings, zero-energy buildings, and zero-carbon buildings. In terms of engineering construction standardization, it is imperative to uphold mandatory standards as the core focus, supported by voluntary standards and leading with advanced group standards. This will gradually improve the level of energy efficiency and carbon reduction in building construction. Specifically, mandatory standards, such as the “General code for energy efficiency and renewable energy application in buildings (GB 55015–2021),” should be strictly implemented. Additionally, national standards, such as the “Technical Standard for Nearly Zero-Energy Buildings (GB/T 51,350–2019)” and the “Standard for design of carbon dioxide capture and purification engineering for flue gas (GB/T 51,316–2018)” should also be complied with. Furthermore, the formulation of new engineering construction standards, such as the “Technical Standard for Zero-Carbon Buildings” should be accelerated.

Moreover, we should facilitate the development of group standards for green and low-carbon development in the construction sector and establish a green and low-carbon engineering construction standard system comprising three levels: mandatory standards, voluntary standards, and group standards. Additionally, we must improve the construction, operation, and maintenance standards for the application of renewable energy in buildings. Meanwhile, we need to leverage information technology to enable the monitoring and tracking of carbon emissions and further refine the standards for calculating and verifying carbon emissions. It is necessary to improve and finalize the standards for carbon emission accounting, carbon emission intensity control, and the application of low-carbon and carbon reduction technologies in the construction sector, ensuring alignment with international standards.

While some low-carbon and zero-carbon standards have been formulated in the field of construction and engineering projects, they are scattered across national, professional, provincial, group, and company standards. Within this framework, there is no systematic approach to emission reduction in the construction sector, which makes it difficult to effectively coordinate the standards. Therefore, this paper adopts Model-Based Systems Engineering to construct a system of construction standards, which will facilitate the digitalization of China’s construction standards, enable better analysis of carbon reduction standards in the building sector, and contribute to the formation of a harmonious, multi-level, and multi-industry carbon reduction standard system.

3 Approach

3.1 Modeling of engineering construction standard system based on MBSE

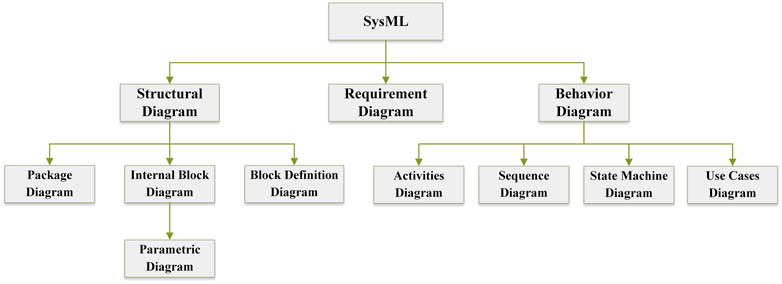

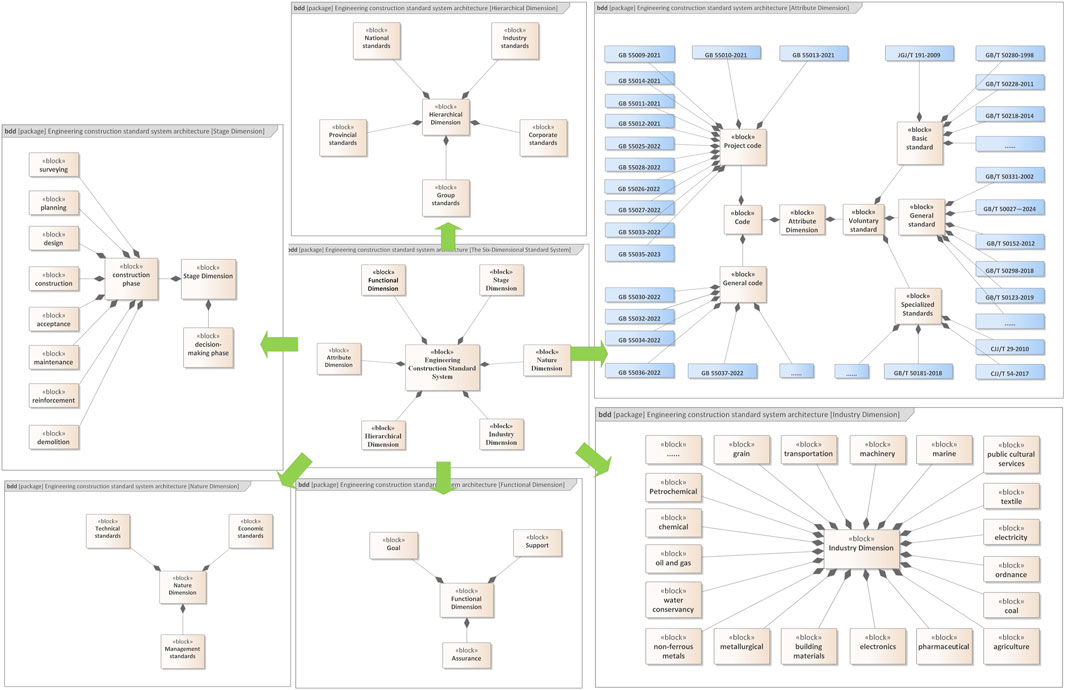

Model-Based Systems Engineering (MBSE) is widely recognized as an essential approach for understanding various domains and is extensively applied in complex systems, such as aerospace engineering. Research on MBSE primarily focuses on systems engineering, languages, and aspects of digitalization (Li et al., 2024). The core of MBSE lies in the construction of system models, for which several modeling languages exist, including the Systems Modeling Language (SysML) and the Unified Modeling Language (UML) (Bock, 2006). The SysML modeling language was developed by the Object Management Group (OMG) and the International Council on Systems Engineering (INCOSE) as a reuse and extension of UML 2.0 (Hampson, 2015). In the field of systems engineering, SysML effectively supports the analysis, design, and verification of complex integrated systems. SysML includes three main types of view models: behavioral models, requirements models, and structural models (Hossain et al., 2022). The structural diagrams are used to describe the system’s structure, including Package Diagram, Block Definition Diagram, Internal Block Diagram, and Parametric Diagram. Behavioral diagrams are used to represent the activities supported by the system and the sequences of activities that occur over time, including Activity Diagram, Sequence Diagram, State Machine Diagram, and Use Case Diagram. The requirements model includes requirement diagrams and elements from other view models, which describe the structural relationships between requirements as well as the relationships between requirements, system behavior, and system structure during the system design process (Friedenthal and Wolfrom, 2010). Figure 3 illustrates the classification of SysML models. MBSE modeling tools include IBM Rational, Rhapsody, Enterprise Architect, MagicDraw, Ansys SCADE, Capella, and others (Zhe et al., 2018). This paper will use Enterprise Architect (EA) to establish an appropriate standard system model.

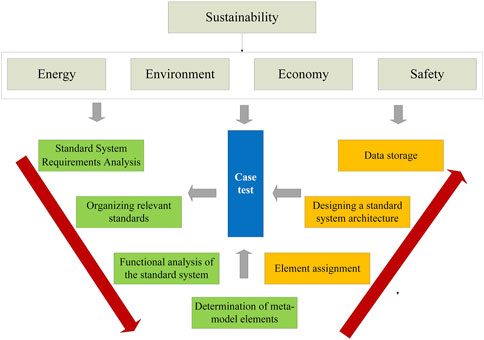

The V-model of systems engineering begins with requirements analysis. After the requirements are implemented, continuous integration testing and comprehensive verification are performed until final confirmation is achieved. On the left side of the V-model, requirements gathering and analysis are first conducted to determine the needs that the system must fulfill. This is followed by system design to ensure that the system architecture can meet the requirements. At the bottom of the V-model, the system is implemented and integrated. The stages on the right side include system validation and confirmation, which ensure that the system operates according to the expected functions and performance (Khan et al., 2014). Since the construction of engineering standards systems differs from software and product development, this paper adopts the Object-Oriented Systems Engineering Method (OOSEM). This method fully accounts for the meta-modeling mechanism and general construction methods for engineering standards systems.

The meta-modeling process for constructing the engineering standards system is illustrated in Figure 4. The left side of the V-model represents the requirements analysis phase, where the needs for constructing the standards system are defined. This phase includes understanding the existing standardization foundation, the technological development level, and stakeholder requirements. Based on the scope and boundaries of the standards system, various standards within the system are identified. By refining and decomposing the requirements of the standards system, meta-model data entities and relationship entities for the functional analysis phase are generated. At the bottom, meta-model elements are defined. These elements serve to explain the data and rules of the standards system model, primarily including meta-classes, meta-relations, and meta-commentaries. Meta-classes define the attributes of the core data entities in the meta-model, such as name, identifier, and so on. Meta-relations describe the relationships between the core data entities and between meta-classes, such as <generalization>, <association>, <aggregation> and so forth. Meta-commentaries are used to annotate the meta-model, enhancing its readability. By defining the meta-model elements, guidance is provided for data collection and organization. The right side of the model includes element assignment, the design of the standards system architecture, and data storage, followed by verification through a case study.

In this article, we have added a sustainable goal based on the V-model, positioned above the V-model, which encompasses four aspects: energy, environment, economy, and safety. When formulating the standards for engineering construction, it is essential to fully consider the sustainable development goals of energy efficiency, environmental friendliness, economic benefits, and the safety of life and property. The aforementioned goals should also be fully integrated during the demand analysis, behavior, and structural modeling of the engineering construction standard system.

3.2 Meta-model of engineering construction standard system

3.2.1 Meta-model for requirements analysis

Requirements are expressions of the necessary or desired characteristics and behaviors of a system. Requirements analysis typically encompasses functional, non-functional, user, and performance requirements, among others. Specific requirements may vary depending on the particular needs of a given project. During the requirements analysis process, the key task is to accurately collect and clearly define the various types of requirements.

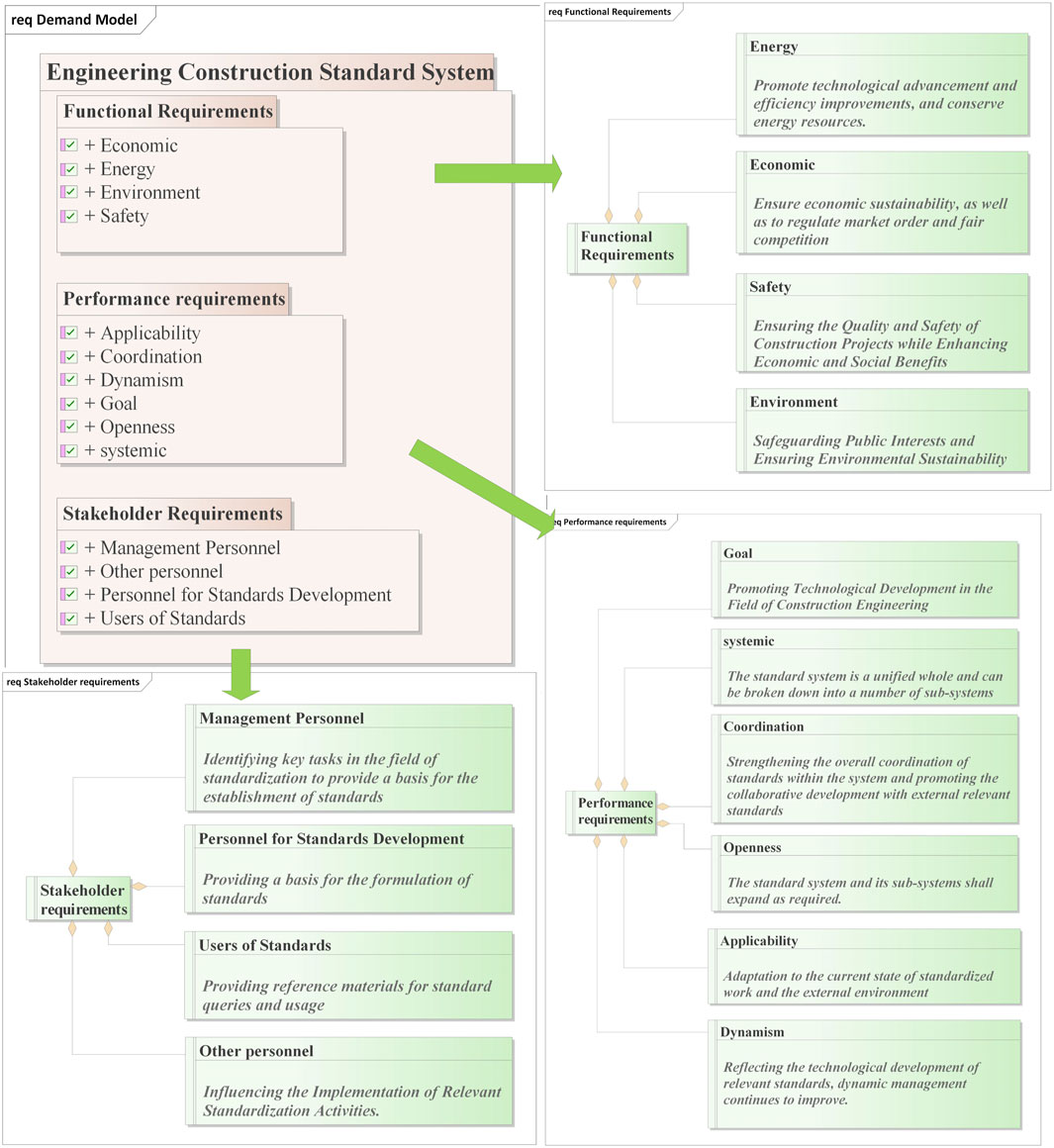

The requirements for constructing an engineering standards system include functional, performance, and stakeholder requirements. Functional requirements are key to achieving sustainability in the construction field. In terms of energy and environment, it is necessary to promote technological advancement and efficiency improvements, protect the environment, and conserve and rationally utilize energy resources. Economically, it is essential to ensure economic sustainability, as well as to regulate market order and fair competition. In terms of safety, it is important to ensure the quality and safety of construction projects. Performance requirements include indicators such as goal orientation, systematization, coordination, openness, applicability, and dynamism. Stakeholder requirements include those of engineering construction standardization managers, standard developers, standard users, and the management personnel of relevant standardization organizations. Specific requirements are detailed in Figure 5.

3.2.2 Meta-model of functional analysis

Based on Gao (2020), the functional analysis of the engineering construction standards system model mainly includes the following components:

3.2.2.1 Identify and integrate the key semantic information of the standards

Each standard is represented as a meta-class, with its data attributes including the standard number, standard name, standard label, Status of the Standard, object of standardization, issuance and implementation dates, scope of applicability, main content of the standard, editorial department, drafting department, and standard issuing authority. Among them, standard labels can be set as needed. For example, we can add carbon reduction-related labels based on whether the standard is related to carbon emission reduction. For specific parameter requirements, see Supplementary Tables S1.

3.2.2.2 Identify the relationship between different standards

Each standard within the standards system is related to other standards in some way. The relationship attributes of a standard include <dependency>, <generalization>, and <association>. The dependency relationship refers to situations in which two or more standards are used together; the generalization relationship typically indicates one standard replacing another; and the association relationship refers to cases in which one standard is cited by another. For specific parameter requirements, see Supplementary Tables S1.

3.2.2.3 Identify standardization organizations relevant to this field

The field of engineering construction standards encompasses 43 industries, each supported by its own standardization organizations, which include governing bodies, organizing units, and responsible entities. Governing bodies typically refer to industry regulatory authorities, such as the Ministry of Industry and Information Technology, the Ministry of Housing and Urban-Rural Development, and the National Energy Administration. Organizing units vary in form, including technical committees, as well as enterprises and institutions. Examples of these organizing units include the China Electricity Council, National Technical Committee for Standardization of Building Energy Efficiency, and the Department Engineering Construction of Sinopec. Drafting entities are primarily composed of enterprises and institutions.

The relationships between standardization organizations are characterized by <composition>, <dependency>, and <association>. The composition relationship refers to a hierarchical or subordinate relationship between entities, as seen between the China Communications Industry Association and its sub-organization, the Communications Engineering Construction Branch. The dependency relationship highlights situations in which the standards developed by one technical committee may impose certain constraints on the standards of other technical committees. The association relationship denotes the interrelated nature of different technical committees’ areas of expertise, particularly when standards from one committee are referenced or cited by another.

3.2.3 Meta-model for system architecture design

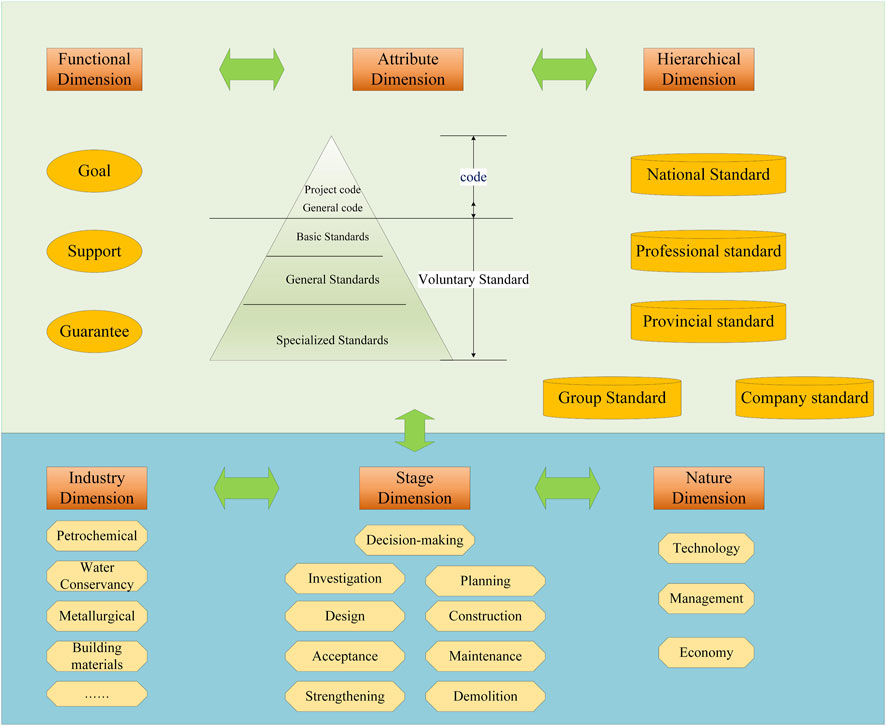

According to the national guidelines on the reform of engineering construction standardization, the key design points for the new framework of the engineering construction standards system are as follows: First, it emphasizes a new standards system centered around mandatory standards for the entire engineering construction process, supported by complementary voluntary standards, and leading with advanced group standards. Second, based on the actual needs of industry development and following the approach of “relatively fixed, dynamically adjustable,” a dimensional hierarchical structure for the new engineering construction standards system has been further planned and designed. This structure forms the framework of the new engineering construction standards system, which consists of six dimensions.

3.2.3.1 Functional dimension

The functional classification method categorizes standards based on the functions they serve within the standards system. The hierarchical structure of the new engineering construction standards system follows the principle of “mandatory standards at the core, supported by technical measure standards, and supplemented by functional standards.” It is divided into three levels: Goal, Support, and Assurance. The goal level primarily refers to the collection of mandatory standards formulated based on clear requirements from national leaders’ directives, a series of policy decisions made by the central government regarding industry development and supporting policy documents from relevant departments. In this article, this goal mainly refers to the dual carbon goals and the relevant legal and policy requirements that promote the realization of this goal. The full set of mandatory engineering construction standards constitutes the baseline requirements and is legally binding, carrying mandatory enforceability.

Supporting layer refers to a collection of engineering construction technical standards aimed at meeting mandatory standards. The assurance layer, on the other hand, primarily refers to a collection of standards that fulfill technical specifications and requirements, effectively supporting the practical application of engineering. This ensures that construction projects meet safety, energy efficiency, environmental protection, and durability goals while safeguarding the essential conditions for maintaining construction quality. For example, these standards include engineering construction product standards that support all stages of the full lifecycle construction of engineering projects, ensuring quality control throughout its execution.

3.2.3.2 Attribute dimension

The attribute classification method is a relatively recent approach used to categorize engineering construction standards based on the extent to which they must be enforced in practical construction activities, distinguishing them by their legal attributes. This classification is generally not applicable to group standards or company standards. The term “legal attribute” refers to whether a standard possesses mandatory legal force. Using this classification, national engineering construction standards are divided into mandatory (code) and voluntary standards. This classification only applies to standards formulated by the government. Mandatory standards must be implemented. These regulations primarily encompass technical specifications for various types of construction projects and stages, serving as baseline control requirements with mandatory enforceability. They include both mandatory project-specific standards (referred to as “project codes”) and mandatory general technical standards (referred to as “general codes”).

Within the system of mandatory engineering construction standards, project codes form the core, while general codes address common, universal technical measures applicable to various projects. Project codes focus on the overall construction project, encompassing five key elements: scale, layout, functionality, performance, and critical technical measures. General codes, in contrast, target technical requirements common to all engineering construction projects, such as investigation, design, construction, maintenance, and repair, addressing generic technical needs throughout all phases of a project.

Voluntary technical standards that complement mandatory engineering construction regulations are encouraged for adoption by the government. Voluntary standards represent mature technical measures that have been validated through practical application, ensuring compliance with the requirements of mandatory regulations. These standards can be categorized into basic, general, and specialized standards. Basic standards refer to those that serve as the basis for other standards within the scope of engineering construction and are widely used. These standards typically include terms, symbols, graphical representations, measurement units, and other universally applicable guidelines. General standards are broad, overarching standards that address common technical aspects of engineering standardization objects. These standards have a wide scope and can serve as the foundation for formulating specialized standards. Specialized standards are developed for specific engineering construction standardization objects or act as supplementary or extended standards to general standards.

3.2.3.3 Hierarchical dimension

The hierarchical classification method categorizes engineering construction standards based on their scope of application, i.e., the extent of their coverage. According to this classification, engineering construction standards can be divided into international standards, regional international standards, national standards, professional standards, provincial standards, group standards, and company standards, among others. International standards are those developed or recognized by international standardization organizations, such as the International Organization for Standardization (ISO) or the International Electrotechnical Commission (IEC), and are intended for use across member countries. Regional international standards are those intended for use within a specific geographical region. National standards are those applied nationwide within a particular country. Professional standards apply to specific industry sectors at the national level. Provincial standards are those applied within a specific local administrative region. Corporate standards are those established for use within a specific enterprise. This hierarchical classification ensures that standards are appropriately structured and tailored to their specific application contexts, facilitating their implementation at various levels of governance and industry.

Due to varying conditions and circumstances across countries, the classification of engineering construction standards is not entirely uniform. According to the newly revised “Standardization Law of the People’s Republic of China,” standards are classified into national, professional, provincial, group, and company standards. National standards are further divided into mandatory and voluntary standards, while professional and provincial standards are regarded as recommended.

3.2.3.4 Industry dimension

The industry classification method categorizes engineering construction standards based on the industry sector to which a project belongs. Given the broad scope of these standards, they can be divided into various categories according to the specific characteristics and needs of different industries. These categories include, but are not limited to, petrochemical, chemical, oil and gas, water conservancy, non-ferrous metals, metallurgical, building materials, electronics, pharmaceutical, agriculture, coal, ordnance, electricity, textile, public cultural services, marine, machinery, transportation, grain, forestry and grassland, civil aviation, civil affairs, light industry, telecommunication, health, postal services, civil air defense, railway, security, nuclear industry, shipbuilding, aviation, commerce, ecological environment, civil explosive, emergency services, meteorology.

3.2.3.5 Nature dimension

The nature classification method categorizes engineering construction standards based on their content, dividing them into different types according to their nature. These standards can be classified into three categories based on their nature: technical standards, management standards, and economic standards. Technical standards refer to those developed to coordinate and unify the technical requirements needed in engineering construction. Economic standards are designed to address the economic aspects of engineering construction, aiming to specify or measure the economic performance and costs of a project. Management standards are established by management organizations to exercise their management functions and contain specific management regulations. This classification method ensures that the various aspects of engineering construction, including technical, economic, and managerial aspects, are appropriately standardized and harmonized.

3.2.3.6 Stage dimension

The stage classification method divides standards into different stages based on each phase of a construction project’s lifecycle. This includes the preliminary decision-making phase, as well as the subsequent stages of investigation, planning, design, construction, acceptance, maintenance, strengthening, demolition, and more. Among these, the standard for the preliminary decision-making phase is determined through economic, technical, and efficiency analysis and comparison, ultimately verifying the feasibility of the construction project. Standards for the various phases of a construction project primarily focus on how to execute the project, ensuring its safety and quality, while also striving for technological advancement, economic rationality, and functional suitability.

As shown in Figure 6, the relationships between the six dimensions are illustrated. National standards include both mandatory and voluntary standards. Mandatory standards correspond to the goal layer, whereas voluntary standards correspond to the supporting and assurance layers. The classification of the six dimensions is not unique and may overlap; for example, national standards can also be subdivided according to industry, stage, and nature.

Figure 7 illustrates the engineering construction standard system framework constructed by EA. Taking the attribute dimension as an example, it can be further divided into mandatory and recommended standards. Mandatory standards are further divided into project standards and general standards, while recommended standards are classified into basic standards, general standards, and specialized standards. The blue block represent specific standard numbers: At present, “GB” represents national standards that contain mandatory provisions; GB/T refers to national standards that do not contain mandatory provisions.

4 Case study

In the above text, we constructed the demand model, behavioral model, and structural model for the engineering construction standard system, and all engineering construction standards are included within this framework. Specifically, how each standard is embedded into the standard system and how to verify the applicability of the model are discussed. This article is based on the dual carbon targets, focusing on energy and environmental fields. As global climate change intensifies, controlling and reducing carbon dioxide emissions has become crucial for achieving carbon neutrality goals. Flue gas carbon dioxide capture technology (CCUS) is considered an important means to address climate change, while engineering design standards ensure its effectiveness, safety, and economic viability. Optimizing the design standards for the capture process helps enhance energy efficiency, reduce energy loss, and promote the development of low-carbon technologies. At the same time, standardized designs ensure stable system operations, prevent carbon dioxide leaks, reduce industrial emissions, and protect the ecological environment. Comprehensive design standards also drive technological innovation, support the research and development of new carbon capture materials, and promote industrial growth.

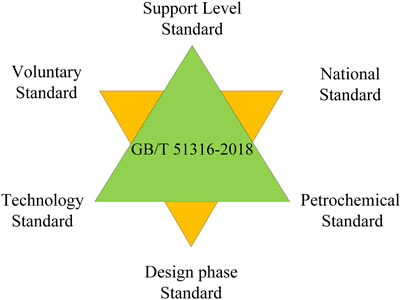

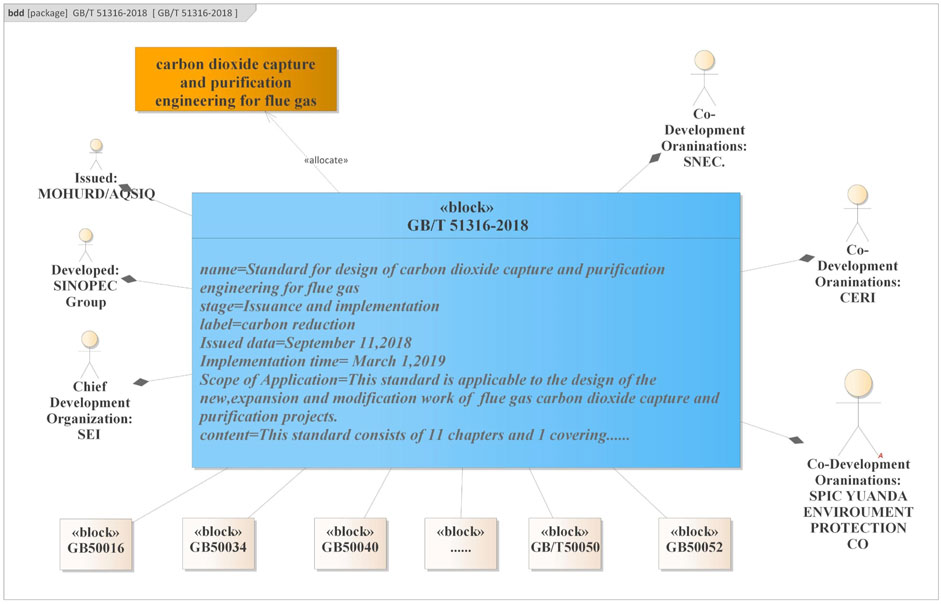

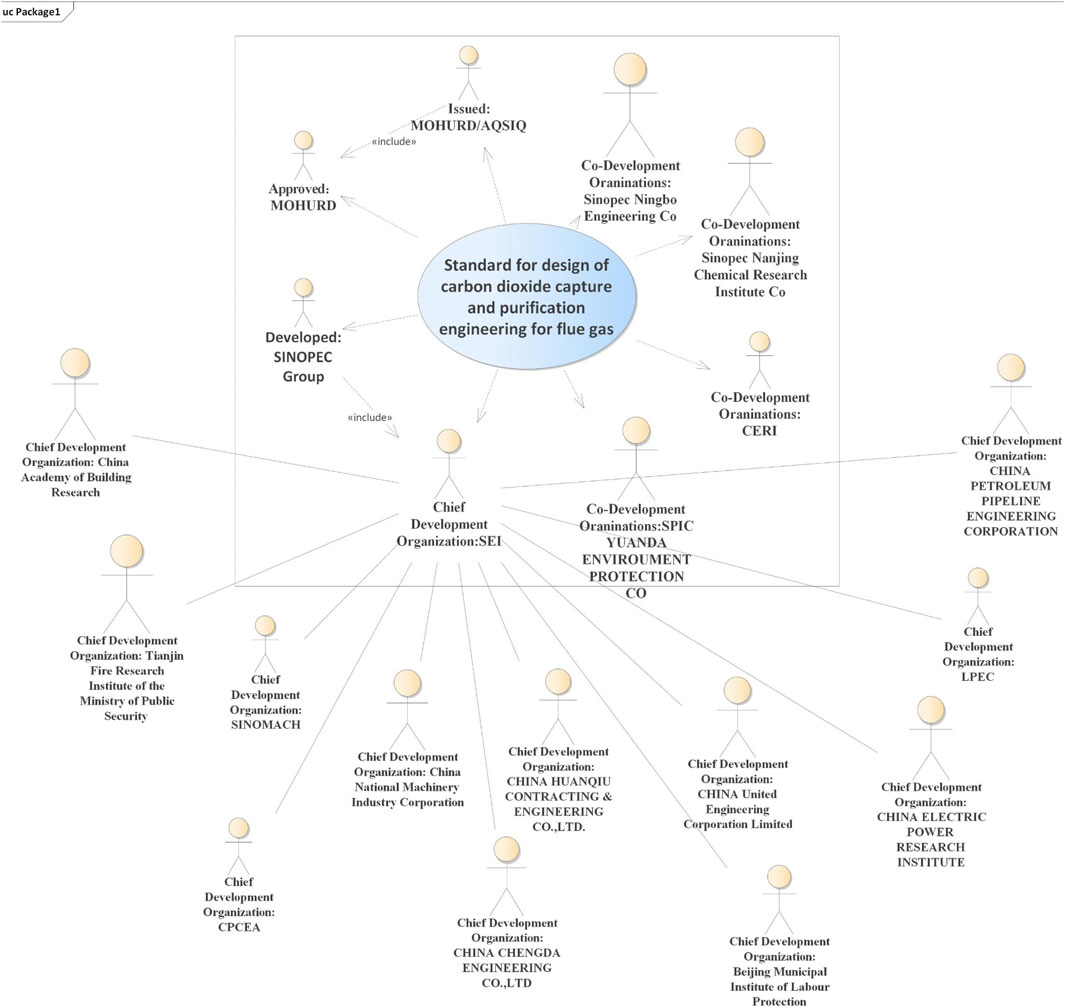

Thus, this paper selects the Standard for Design of Carbon Dioxide Capture and Purification Engineering for Flue Gas (GB/T 51316–2018) as a specific case for verification. The standard was published in September 2018 and is applicable to the design of new, expanded or modified flue gas carbon dioxide capture and purification projects. The standard comprises 11 chapters with the main contents as follows: General provisions, Terms, Basic requirements, Processes systems, Equipment and materials, General layout, Equipment layout and piping design, Instrumentation and control systems, Utility, Energy saving and environment protection, Safety and occupational health.

As shown in Figure 8, GB/T 51316–2018 can be uniquely categorized into support layer standards, national standards, voluntary standards, technical standards, petrochemical industry standards, and design phase standards. Within the engineering construction standards system, each standard can be uniquely identified using the six-dimensional system, which helps users quickly understand the nature of the standards.

As shown in Figures 9, 10, the functional model of the GB/T 51316–2018 standard is presented. This model uses a module definition diagram to describe the key information of the standard and its relationship with other standards. A use case diagram is employed to depict the main entities involved in the formulation of the standard and the related standardization organizations. In Figure 9, the name of the standard is displayed in the upper left corner, while the middle blue box represents the object unit, which refers to the standard and its specific attributes. The orange framework symbolizes the standardized object, and the relationship between it and the object unit is indicated by the term “allocate”. The user legends on the left and right represent the primary contributors to the standard, including the publishing body, organizer, chief editor, and participating units, with their relationship to the object unit represented by “aggregation”. The yellow box denotes standards related to this standard, with a solid triangular arrow indicating “generalization”, which represents replacement situations, pointing to the standard being replaced. The straight connecting lines represent “association”, indicating the citation relationships of the standards. In this case, GB/T 51316–2018 does not replace any other standards. In Figure 10, the entities involved in the formulation of this standard are shown within the framework, including the publisher, approval body, organizer, chief editorial unit, and participating units. Since SEI is a subordinate organization of SINOPEC, their relationship is indicated as “include”. The entities outside the boxes are organizations or institutions that have a related relationship with this standard.

After establishing the standard system model, it is necessary to verify the integrity of the model data and the rationality of the model architecture. The released and in-development standards should be compared to check whether the model includes each standard. At the same time, it is important to verify whether effective information exchange can occur between different views. Upon verification, it was confirmed that the model contains key information from the standards and has achieved dynamic tracing of related information.

5 Conclusions and future work

In conclusion, this study has comprehensively analyzed the modern engineering and construction standards system and identified its primary challenges, particularly the inefficiencies arising from the text-based management system and the dispersion of dual-carbon-related standards across various domains. The proposed MBSE-based system offers a structured approach to address these issues by integrating standards into a cohesive framework that enhances their interoperability and applicability.

The findings demonstrate that the MBSE-based engineering construction standards system can effectively consolidate existing standards and align them with the broader goals of China’s social development. This approach not only facilitates the integration of dual-carbon objectives but also enhances the overall efficiency and adaptability of the standards system.

Based on the study, several key conclusions can be drawn.

(1) System Integration: The MBSE-based system significantly improves the integration of diverse standards, reducing the complexity and fragmentation inherent in traditional text-based systems. This integration is crucial for achieving the dual-carbon goals by ensuring that relevant standards work in harmony.

(2) Scalability and Adaptability: The MBSE framework allows for the scalable and adaptable management of standards, enabling the system to evolve in response to technological advancements and policy changes. This flexibility is essential for maintaining relevance and effectiveness in a rapidly changing environment.

(3) Enhanced Decision-Making: By modeling the demand, behavior, and structure of standards, the MBSE system provides a clearer and more comprehensive view of the standards ecosystem. This enhanced visibility supports more informed decision-making and the development of targeted interventions to address specific challenges.

(4) Synergy and Collaboration: The proposed system fosters greater synergy and collaboration among different stakeholders, including policymakers, industry practitioners, and researchers. This collaborative environment is vital for driving innovation and ensuring that standards are both practical and forward-looking.

Future work may focus on two key aspects: First, the application of this framework to a specific industry, creating a database to facilitate the digitization of engineering construction standards. By utilizing standard labels, all standards related to carbon emission reduction can be identified for in-depth analysis, which will assist standard setters and implementers in evaluating the emission reduction effects within the engineering construction sector. Second, the framework can be further expanded in collaboration with the construction industry by integrating it with systems such as BIM (Building Information Modeling). This integration would enable the automatic execution of engineering construction standards, thereby bridging the gap between established energy-saving standards and their practical implementation, ultimately improving energy efficiency.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author contributions

SH: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Writing–original draft. XW: Methodology, Software, Supervision, Writing–review and editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This work was supported by the Research Foundation of the Research Institute of Standards and Norms, Ministry of Housing and Urban-Rural Development, the Natural Science Foundation of Inner Mongolia Autonomous Region of China [grant number 2021BS07001& 2022MS07003], the National Natural Science Foundation of China [grant number 72463023], Construction and Empirical Analysis of Carbon Emission Reduction Monitoring and Evaluation Model System of Power Industry Under Dual carbon goals, and Basic Scientific Research Business Fee Project of Inner Mongolia Provincial Universities [grant number NCYWR22012].

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fenvs.2025.1564133/full#supplementary-material

References

Adams, K. M. G., Ibrahim, I., and Krahn, S. (2024). Engineering systems with standards and digital models: development of a 15288-SysML grid. Systems 12, 276. doi:10.3390/systems12080276

Akram, Md. W., Mohd Zublie, M. F., Hasanuzzaman, Md., and Rahim, N. A. (2022). Global prospects, advance technologies and policies of energy-saving and sustainable building systems: a review. Sustainability 14, 1316. doi:10.3390/su14031316

Arıoğlu Akan, M. Ö., Dhavale, D. G., and Sarkis, J. (2017). Greenhouse gas emissions in the construction industry: an analysis and evaluation of a concrete supply chain. J. Clean. Prod. 167, 1195–1207. doi:10.1016/j.jclepro.2017.07.225

Berardi, U. (2017). A cross-country comparison of the building energy consumptions and their trends. Resour. Conservation Recycl. 123, 230–241. doi:10.1016/j.resconrec.2016.03.014

Biggs, G., Juknevicius, T., Armonas, A., and Post, K. (2018). Integrating Safety and Reliability Analysis into MBSE: overview of the new proposed OMG standard. INCOSE Int. Symp. 28, 1322–1336. doi:10.1002/j.2334-5837.2018.00551.x

Bock, C. (2006). SysML and UML 2 support for activity modeling. Syst. Eng. 9, 160–186. doi:10.1002/sys.20046

Breznitz, D., and Murphree, M. (2013). The rise of China in technology standards: new norms in old institutions.

Chen, Y., Ng, S. T., and Hossain, Md. U. (2018). Approach to establish carbon emission benchmarking for construction materials. Carbon Manag. 9, 587–604. doi:10.1080/17583004.2018.1522094

Clay, K., Severnini, E., and Sun, X. (2023). Does LEED certification save energy? Evidence from retrofitted federal buildings. J. Environ. Econ. Manag. 121, 102866. doi:10.1016/j.jeem.2023.102866

Elsye, V., Latief, Y., and Sagita, L. (2018). Development of work Breakdown structure (WBS) standard for producing the risk based structural work safety plan of building. MATEC Web Conf. 147, 06003. doi:10.1051/matecconf/201814706003

Friedenthal, S., and Wolfrom, J. A. (2010). Modeling with SysML. INCOSE Int. Symp. 20, 1847–1995. doi:10.1002/j.2334-5837.2010.tb01160.x

Gao, J. (2020). Research on ISO/TC10/SC6 standard system and typical standards based on MBSE. doi:10.27161/d.cnki.gshcs.2020.000041

Gao, P., Yue, S., and Chen, H. (2021). Carbon emission efficiency of China’s industry sectors: from the perspective of embodied carbon emissions. J. Clean. Prod. 283, 124655. doi:10.1016/j.jclepro.2020.124655

Gong, T., Zhang, W., Liang, J., Lin, C., and Mao, K. (2021). Forecast and analysis of the total amount of civil buildings in China in the future based on population driven. Sustainability 13, 14051. doi:10.3390/su132414051

Gregory, J., Berthoud, L., Tryfonas, T., Rossignol, A., and Faure, L. (2020). The long and winding road: MBSE adoption for functional avionics of spacecraft. J. Syst. Softw. 160, 110453. doi:10.1016/j.jss.2019.110453

Hampson, K. (2015). Technical evaluation of the systems Modeling Language (SysML). Procedia Comput. Sci. 44, 403–412. doi:10.1016/j.procs.2015.03.054

Hoffmann, M., Inkermann, D., Knieke, C., Zeng, F., Kopp, T., Terörde, M., et al. (2024). Early design stage evaluation of all electric aircraft power systems focusing on long-term behavior. Energies 17, 4653. doi:10.3390/en17184653

Hossain, N. U. I., Lutfi, M., Ahmed, I., Akundi, A., and Cobb, D. (2022). Modeling and analysis of unmanned aerial vehicle system leveraging systems Modeling Language (SysML). Systems 10, 264. doi:10.3390/systems10060264

Janda, K. B., and Busch, J. F. (1994). Worldwide status of energy standards for buildings. Energy 19, 27–44. doi:10.1016/0360-5442(94)90102-3

Khan, A. H., Khan, Z. H., and Weiguo, Z. (2014). “Model-based verification and validation of safety-critical embedded real-time systems: formation and tools,” in Embedded and real time system development: a software engineering perspective: concepts, methods and principles. Editors M. A. Khan, S. Saeed, A. Darwish, and A. Abraham (Berlin, Heidelberg: Springer Berlin Heidelberg), 153–183. doi:10.1007/978-3-642-40888-5_6

Klungseth, N. J., Nielsen, S. B., Alves Da Graça, M. E., and Lavy, S. (2022). Research and Evidence-based standards: research and standards in combined efforts for a sustainable transformation of the built environment. IOP Conf. Ser. Earth Environ. Sci. 1101, 062039. doi:10.1088/1755-1315/1101/6/062039

Laskurain, I., Heras-Saizarbitoria, I., and Casadesús, M. (2015). Fostering renewable energy sources by standards for environmental and energy management. Renew. Sustain. Energy Rev. 50, 1148–1156. doi:10.1016/j.rser.2015.05.050

Li, H., Qiu, P., and Wu, T. (2021). The regional disparity of per-capita CO2 emissions in China’s building sector: an analysis of macroeconomic drivers and policy implications. Energy Build. 244, 111011. doi:10.1016/j.enbuild.2021.111011

Li, Z., Wang, G., Lu, J., Broo, D. G., Kiritsis, D., and Yan, Y. (2024). Bibliometric analysis of model-based systems engineering: past, current, and future. IEEE Trans. Eng. Manage. 71, 2475–2492. doi:10.1109/TEM.2022.3186637

Liu, H. (2018). “Analysis on change of formulation of standards in the new standardization Law,” in Proceedings of the 2018 2nd international conference on education, economics and management research (ICEEMR 2018) (Singapore: Atlantis Press). doi:10.2991/iceemr-18.2018.171

Lu, M., and Lai, J. H. K. (2019). Building energy: a review on consumptions, policies, rating schemes and standards. Energy Procedia 158, 3633–3638. doi:10.1016/j.egypro.2019.01.899

Manoharan, T., Loibl, A., Nagarajah, A., and Köhler, P. (2019). Approach for a machine-interpretable provision of standard contents using welded constructions as an example. Proc. Int. Conf. Eng. Des. 1, 2477–2486. doi:10.1017/dsi.2019.254

Ping, W. (2011). A brief history of standards and standardization organizations: a Chinese perspective.

Qi, Y., and Xia, Y. (2022). Research on accounting and transfer pathways of embodied carbon emissions from construction industry in China. Sustainability 14, 15165. doi:10.3390/su142215165

Sartori, T., Drogemuller, R., Omrani, S., and Lamari, F. (2021). A schematic framework for life cycle assessment (LCA) and green building rating system (GBRS). J. Build. Eng. 38, 102180. doi:10.1016/j.jobe.2021.102180

Shi, Y., Li, S., and Wang, Y. (2013). “Review of agricultural engineering construction standardization management in China,” in 2013 Kansas city, Missouri, july 21 - july 24, 2013 (American Society of Agricultural and Biological Engineers). doi:10.13031/aim.20131749291

Su, D., Fan, M., and Sharma, A. (2022). Construction of lean control system of prefabricated mechanical building cost based on Hall multi-dimensional structure model. IJCAI 46. doi:10.31449/inf.v46i3.3914

Tong, R., Fan, B., Li, Z., Wang, H., and Zhang, J. (2021). Progress of work safety standardization in China: a case study of hundred local standards in Beijing. Process Saf. Prog. 40, e12187. doi:10.1002/prs.12187

Wang, W., Zhang, S., and Sun, Z. (2015). “Research on the establishment of a rural construction standard system based on petri net,” in Iccrem 2015 (Luleå, Sweden: American Society of Civil Engineers), 538–546. doi:10.1061/9780784479377.062

Wilking, F., Horber, D., Goetz, S., and Wartzack, S. (2024). Utilization of system models in model-based systems engineering: definition, classes and research directions based on a systematic literature review. Des. Sci. 10, e6. doi:10.1017/dsj.2024.3

Yang, Y., Gao, P., and Zhou, H. (2023). Understanding the evolution of China’s standardization policy system. Telecommun. Policy 47, 102478. doi:10.1016/j.telpol.2022.102478

Yang, Y., Xu, M., Miao, Z., and Ren, P. (2024). Optimizing insulation material selection in conceptual building design: a simulation-based study on lifecycle cost and carbon emissions. E3S Web Conf. 580, 02016. doi:10.1051/e3sconf/202458002016

Yu, F., Feng, W., Leng, J., Wang, Y., and Bai, Y. (2022). Review of the U.S. Policies, codes, and standards of zero-carbon buildings. Buildings 12, 2060. doi:10.3390/buildings12122060

Zhe, W., Hugues, J., Chaudemar, J.-C., and LeSergent, T. (2018). “An integrated approach to model based engineering with SysML, AADL and FACE,” in Aerospace Systems and Technology Conference, London, UK, November 06, 2018-November 08, 2018. doi:10.4271/2018-01-1942

Keywords: energy and environment sustainability, engineering construction standard, MBSE, building industry, carbon dioxide capture

Citation: Han S and Wang X (2025) Designing an engineering construction standards system for energy and environment sustainability: based on model-based systems engineering. Front. Environ. Sci. 13:1564133. doi: 10.3389/fenvs.2025.1564133

Received: 21 January 2025; Accepted: 10 February 2025;

Published: 10 April 2025.

Edited by:

Yi Jin, Jiangsu University, ChinaReviewed by:

Yingchao Chen, Shandong Technology and Business University, ChinaKaipeng Ren, China University of Petroleum, China

Copyright © 2025 Han and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xiaoyu Wang, d2FuZ3hpYW95dTg1MTFAMTYzLmNvbQ==

Song Han

Song Han Xiaoyu Wang

Xiaoyu Wang