- 1Department of Construction Management, Faculty of Technology Management and Business, Universiti Tun Hussein Onn Malaysia, Parit Raja, Malaysia

- 2College of Ecology and the Environment, Xiamen University, Xiamen, Fujian, China

- 3Advanced Membrane Technology Research Centre (AMTEC), School of Chemical and Energy Engineering, Universiti Teknologi Malaysia (UTM), Johor Baru, Malaysia

- 4Department of Chemical Technology, Urgench State University, Urgench, Uzbekistan

- 5Laboratory of Water, Biodiversity and Climate Changes, Faculty of Science Semlalia, Cadi Ayyad University, Marrakech, Morocco

- 6Laboratory of Process Engineering and Environment, Faculty of Science and Technology, Hassan II University, Mohammedia, Morocco

- 7Department of Chemistry, Jamia Millia Islamia, New Delhi, India

- 8Department of Mechanical Engineering, College of Engineering, Prince Mohammad Bin Fahd University, Al Khobar, Saudi Arabia

- 9Catalysis Science and Technology Research Centre, Faculty of Science, Universiti Putra Malaysia (UPM), Serdang, Selangor, Malaysia

- 10School of Renewable Energy, Inner Mongolia University of Technology, Hohhot, Inner Mongolia, China

- 11University of Kirkuk, Kirkuk, Iraq

- 12Faculty of AI and Engineering, Multimedia University, Cyberjaya, Selangor, Malaysia

- 13Department of Electrical, Electronic and Systems Engineering, Faculty of Engineering and Built Environment, Universiti Kebangsaan Malaysia, Bangi, Selangor, Malaysia

- 14Karshi State Technical University, Karshi, Uzbekistan

- 15Faculty of Data Science and Information Technology, INTI International University, Putra Nilai, Negeri Sembilan, Malaysia

Recently, landfill mining (LFM) has emerged as a promising strategy for addressing the challenges of waste management, resource recovery, and climate change mitigation. This work explores the potential of landfill mining to transform traditional landfills from environmental liabilities into assets. By recovering nutrients, energy, and materials from landfill leachate, landfill mining can reduce greenhouse gas (GHG) emissions, particularly methane (CH4), while contributing to the circular economy. This study evaluates the technologies applied in landfill mining, such as bioreactors, anaerobic digestion, and leachate recirculation, based on published literature from 2000 to 2025, focusing on their value in resource recovery. More specifically, this study aims at recovering renewable CH4 energy from leachate and extracting macro-nutrients such as nitrogen (N), phosphorus (P), and potassium (K) which can be turned into commercial fertilizers. This study further analyzes the advantages of landfill mining, which include reducing CH4 emissions by up to 30% and the potential energy value of 15 GWh from 1.5 million m3 of CH4. The study also explores the socio-economic consequences of landfill mining, focusing on employment opportunities, improved waste management systems, and enhanced local community welfare. Additionally, this work discusses the technological, financial, and regulatory challenges that hinder the widespread adoption of landfill mining for promoting circular economy. Finally, this work calls for further investment, research, and policy development to unlock the full potential of landfill mining as a sustainable waste management strategy and a key contributor to resource recovery in the circular economy paradigm.

1 Introduction

Landfills have long been the most cost-effective solution for managing solid waste globally, serving as the default method for disposing of the increasing waste generated by urban populations (Elleuch et al., 2020). The practice of landfilling, however, has deep historical roots, dating back to ancient civilizations, where simple pits were used to discard waste. Modern sanitary landfills emerged in the 20th century alongside urban expansion and industrial growth (Yaqoob et al., 2020). Earlier forms of landfills, such as open dumps, lacked hygienic controls and placed waste in designated areas without considering ecological impacts (Kumar et al., 2021). The development of formal landfills in the 1940s marked a significant advancement, aiming to confine waste to specific locations and reduce the spread of diseases and environmental damage (Singh, 2022). In the United States, solid waste management gained formal attention with the Solid Waste Disposal Act of 1965, which set standards for landfill systems, including the requirement for liners and leachate management (Azadi et al., 2021).

Environmental concerns regarding landfills gained prominence in the 1980s. Regulations introduced under the Resource Conservation and Recovery Act of 1976 included measures such as perimeter gas capture systems, leachate containment, and impermeable liners (Ali et al., 2018; Roudi et al., 2020). These advancements, however, brought new challenges. In the US alone, approximately 250 million metric tons of waste are disposed of annually, with each individual generating around 2.22 kg per day (Scandelai et al., 2019). With global waste production projected to increase by 70% by 2050, the pressure on landfill capacity is intensifying (Faggiano et al., 2023). Expanding existing landfills or establishing new sites is increasingly difficult due to zoning restrictions and public resistance in urban areas where land is scarce.

Landfills are also a significant source of greenhouse gas (GHG) emissions, primarily methane (CH4), produced under anaerobic conditions. Carbon dioxide (CO2) is generated during both aerobic and anaerobic decomposition. Landfill gas typically consists of 45%–60% CH4 and 40%–55% CO2, with trace amounts of other gases such as nitrogen, oxygen, hydrogen sulfide, and volatile organic compounds. Methane is particularly concerning because its global warming potential is 28–36 times higher than CO2 over a 100-year period. In the US, landfills contribute approximately 30%–40% of CH4 emissions, while globally they account for around 18% of human-induced CH4 emissions (Traid et al., 2022). Landfill mining provides an opportunity to mitigate these emissions by excavating and recovering biodegradable waste fractions, which reduces future gas production and enhances gas capture efficiency from remaining deposits. Accurate accounting of both CH4 and CO2 is therefore crucial for assessing the environmental impact of disposal sites and evaluating the benefits of landfill mining in GHG mitigation.

In addition to gaseous emissions, landfill leachate—a liquid formed when rainwater percolates through waste—poses serious environmental risks if not properly managed. Leachate contains a complex mixture of pollutants, including heavy metals and nutrients, which can contaminate groundwater and surface water. Poor landfill management contributes to 20%–25% of groundwater pollution in the European Union due to leachate contamination (Zakaria et al., 2023).

These environmental and spatial challenges highlight the urgent need for more advanced waste management systems. Innovative approaches, such as the circular economy, aim to “close the loop” by minimizing waste generation and promoting recycling and resource recovery. Among these approaches, landfill mining has emerged as an effective strategy, enabling the extraction of metals, biogas, organic matter, and other valuable materials from existing landfills, thereby mitigating the environmental impacts associated with traditional waste disposal methods (Moretti et al., 2023), (Alberto et al., 2022).

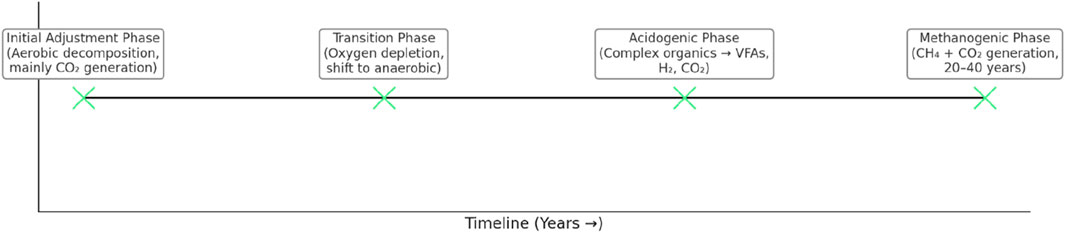

Biogas production in landfills occurs over several decades and follows a series of distinct phases. Initially, during the adjustment phase, aerobic decomposition dominates immediately after waste deposition, producing CO2. As oxygen is depleted, the transition phase establishes gradually, leading to anaerobic conditions. The acidogenic phase follows, marked by the breakdown of complex organic matter into volatile fatty acids (VFAs), hydrogen, and CO2. Finally, the methanogenic phase occurs, in which methanogenic archaea convert intermediate products into CH4 and CO2. Depending on factors such as waste composition, climate, and landfill management practices, the methanogenic phase can persist for 20–40 years (Azadi et al., 2021).

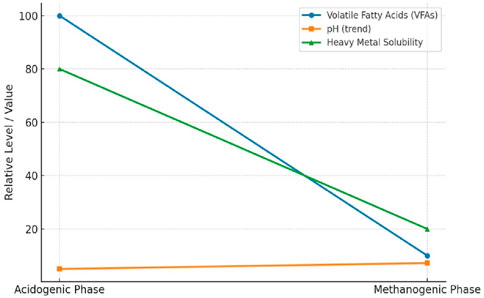

In the early stages of waste degradation, landfill leachate is typically acidic due to the accumulation of VFAs produced during acidogenesis (Figure 1). This acidity, generally ranging from pH 4.5 to 6.0, enhances the solubility and mobilization of heavy metals, creating significant environmental and groundwater contamination risks. As landfills mature and enter the methanogenic phase, methanogens metabolize VFAs, causing the pH to gradually rise toward neutral or slightly alkaline conditions. This chemical stabilization reduces the mobility of heavy metals and diminishes leachate toxicity over time. The dynamic nature of leachate chemistry underscores the importance of accounting for landfill age and microbial activity when designing effective leachate management and landfill mining strategies.

The extended timeline of landfill gas generation directly affects management costs, as operators must maintain long-term monitoring, leachate treatment, and gas capture infrastructure even after site closure (Figure 2). Without effective gas collection and utilization systems, fugitive emissions can accumulate, causing increased GHG emissions, odor problems, and potential safety risks. Understanding the temporal dynamics of biogas production therefore reinforces both the economic and environmental justification for landfill mining. By recovering secondary resources earlier and reducing residual gas formation, landfill mining can also minimize the need for prolonged post-closure management.

Landfill mining not only reduces waste but also promotes sustainable resource utilization. For example, methane captured from landfills can be recycled for energy production. A typical landfill can generate sufficient methane to produce approximately 15 gigawatt-hours of electricity, enough to power around 3,000 households for a year (Anukam et al., 2019). Additionally, landfill leachate contains nutrients such as nitrogen, phosphorus, and potassium, which, though potentially harmful in uncontrolled conditions, can be repurposed for fertilizer production, highlighting the potential for resource recovery.

Although landfills have long served as waste disposal solutions, their environmental impacts and finite capacity present significant challenges. Sustainable approaches like landfill mining address these issues by recovering valuable resources and reducing the environmental footprint of waste management (Abuabdou et al., 2020; Pirsaheb et al., 2017). By integrating circular economy principles and leveraging advanced recovery technologies, waste management can simultaneously mitigate climate change and support a sustainable future (Tałałaj et al., 2019; Gao et al., 2020).

The circular economy (CE) is an economic model designed to minimize waste and maximize resource efficiency through continuous use, reuse, repair, refurbishment, and recycling of products and materials (Derlon et al., 2016; Ren et al., 2017a). Unlike the traditional linear economy—where products are produced, used, and discarded—the CE extends product life cycles, reduces resource consumption, and mitigates environmental impacts (Ren et al., 2017b; Bueno et al., 2021). As global consumption rises, circular economy practices provide solutions to resource depletion, pollution, and the growing waste crisis, fostering a regenerative system that preserves natural resources and reduces ecosystem stress (Ren et al., 2017c).

While previous studies have examined landfill mining in isolation as a method for resource recovery, this review positions it as an integral part of the broader circular economy. Landfill mining enables the reclamation of metals, plastics, and organic matter that would otherwise be lost, thereby reducing the demand for virgin materials and closing material loops. By transforming waste streams into valuable resources, circular economy strategies reduce environmental degradation, decrease reliance on primary resources, and enhance energy recovery from materials such as food waste (Faggiano et al., 2023).

The global relevance of circular economy principles is evident in waste generation and recycling statistics. Over 2.01 billion tons of municipal solid waste (MSW) are generated annually, with projections reaching 3.4 billion tons by 2050 (Elmaadawy et al., 2022). Despite this, only 13%–15% of municipal waste is recycled worldwide. In contrast, countries like Germany, which have implemented robust circular economy policies, recycle more than 65% of their municipal waste (Elmaadawy et al., 2022). The Ellen MacArthur Foundation estimates that adopting circular economy practices could generate up to USD 4.5 trillion in economic benefits by 2030 through reduced resource consumption, innovative business models, and more efficient material use (Wang et al., 2022).

Circular economy practices also contribute to climate mitigation. The European Commission estimates that a full-scale circular economy could reduce CO2 emissions by up to 48% by 2030 (Sivic et al., 2017). Waste-to-energy and biogas recovery exemplify practical applications: landfills can produce CH4 through anaerobic decomposition, and a landfill processing 10,000 m3 of leachate annually could generate 1.5 million m3 of CH4, yielding 15 GWh of electricity—enough to power approximately 3,000 households (El Mrabet et al., 2022). Furthermore, circular strategies help address the global plastic pollution crisis, estimated at 8 million metric tons entering oceans each year (Remmas et al., 2018). Recycling, product redesign, and innovative plastic deconstruction methods are essential components of circular economy approaches. The EU aims to increase plastic packaging recycling rates to 50% by 2025, reflecting the importance of technology-driven solutions for sustainable plastic management (Remmas et al., 2018).

Transitioning from a linear “take-make-dispose” model to a circular economy, which emphasizes reuse, recycling, and resource recovery, enables more sustainable waste management. This framework reduces environmental impacts, protects natural resources, lowers emissions, and fosters economic opportunities (Jiang et al., 2021).

Within this context, landfill mining emerges as a promising strategy to recover resources, mitigate environmental impacts, and advance circular economy objectives. This review focuses on the potential of landfill mining to enhance sustainable resource recovery—including leachate treatment, biogas production, and nutrient recovery—while contributing to climate mitigation through carbon sequestration and emissions reduction. The specific objectives of this study are: i. to evaluate the potential of landfill mining for sustainable resource recovery and circular economy implementation; ii. to analyze technologies and strategies for leachate treatment, biogas, and nutrient recovery, including operational considerations; and iii. to assess the role of landfill mining in climate mitigation through carbon sequestration, energy recovery, and emissions reduction (Mahtab and Farooqi, 2022; Grosser et al., 2019).

Landfill mining involves the excavation and recovery of resources from existing waste, whereas enhanced landfill management focuses on in-situ strategies such as methane capture, leachate control, and waste stabilization without excavation. While enhanced management reduces environmental impacts and recovers energy at lower costs with minimal disturbance, landfill mining complements these approaches by enabling the recovery of secondary resources and reducing residual emissions.

The key stages of landfill mining include: i. excavation of buried waste, ii. sorting and separation of recyclables and organics, iii. leachate collection and treatment, iv. recovery of metals, biogas, and nutrients, and v. management of residual materials. This operational framework illustrates how landfill mining integrates sustainability principles into practical waste management strategies.

Recovering CH4 during landfill mining plays a key role in mitigating greenhouse gas emissions, preventing approximately 90% of the CH4 that would otherwise escape from landfills. For example, a landfill treating 10,000 m3 of leachate annually could generate around 15 GWh of electricity, sufficient to power approximately 3,000 homes for a year (Verma et al., 2023).

Beyond CH4 recovery, landfill mining enhances carbon sequestration potential. Controlling gas and leachate streams allows for the capture of CO2 and reduces the overall climate impact of landfill sites. Case studies indicate that combining CH4 recovery with landfill mining not only lowers emissions but also delivers multiple economic and ecological benefits (Zakaria et al., 2023; Tałałaj, 2022).

Nutrient recovery from landfill leachate is another important aspect that advances circular economy objectives. Leachate contains nitrogen (N), phosphorus (P), and potassium (K), which are valuable for soil fertility and agricultural production (Gao et al., 2022). Recovering these nutrients reduces dependence on synthetic fertilizers, a major contributor to water eutrophication. For instance, processing 10,000 m3 of leachate annually can simultaneously recover biogas, essential nutrients, and support soil health, thereby promoting environmentally sustainable farming practices (Kim et al., 2023).

Integrating leachate recovery with landfill mining further strengthens circular economy outcomes. This approach enables the reclamation of valuable materials, energy, and nutrients that would otherwise be lost. Recycling metals, plastics, and other recovered materials reduces the demand for virgin resources and lowers the environmental costs associated with extraction. CH4 recovery contributes to climate mitigation by substituting fossil fuels with biogas, while nutrient recovery supports sustainable food production (Seidmohammadi et al., 2022).

Abandoned landfill mining combined with leachate recovery is therefore expected to reduce emissions, conserve resources, and significantly advance circular economy objectives. These integrated strategies facilitate sustainable resource management, climate change mitigation, and the transition toward a more resilient and sustainable waste management system.

2 Landfill mining: concept and methodology

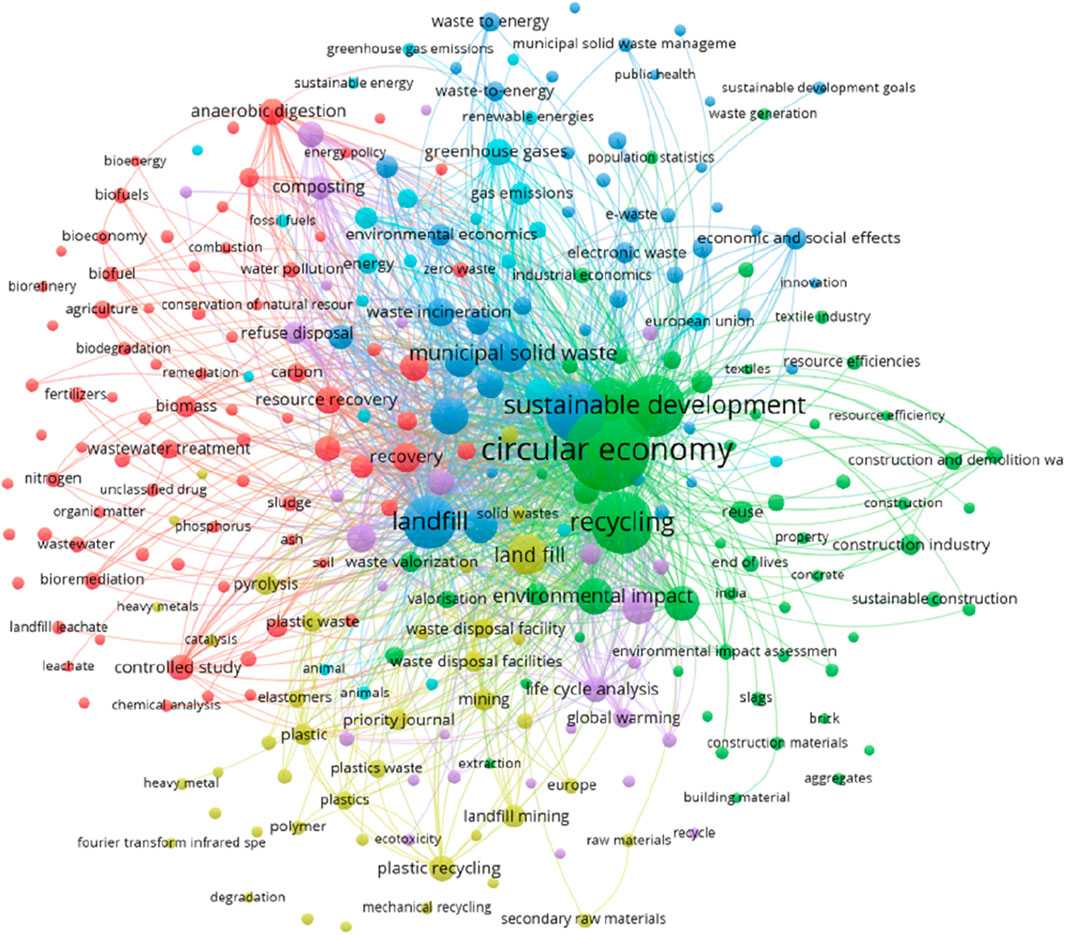

To illustrate the growing research interest in landfill mining, a bibliometric analysis was conducted using the Scopus database. Publications from the past decade were retrieved, and keyword co-occurrence and trends were analyzed using VOSviewer (Figure 3). The resulting visualization highlights the increasing number of studies published annually and identifies key research themes, reflecting the rising attention to landfill mining as a strategy for sustainable resource recovery, circular economy implementation, and climate mitigation.

2.1 Definition and scope of landfill mining

Landfill mining is an emerging waste management technique focused on excavating existing or closed landfills to recover valuable materials and resources (Tsompanoglou and Koutsou, 2023). Compared with conventional waste disposal, landfill mining is considered more environmentally advantageous (Fa et al., 2016). The process enables the recovery of energy, nutrients, and materials from sites that were previously seen as environmental liabilities. Excavation allows the extraction of metals, plastics, organic matter, and biogas, all of which can significantly reduce environmental impacts and support circular economy objectives (Derlon et al., 2016; Zha et al., 2018).

The landfill mining process typically begins with the collection of waste using modern machinery such as excavators and shovels. The waste is then transported to sorting stations, where materials are separated based on type through screening, air classification, and magnetic separation (Meier et al., 2021; Kurniawan et al., 2024b). Metals—including copper, aluminum, and iron, commonly found in electronics, appliances, and industrial waste—are recovered via shredding, magnetic, or electrostatic separation. Recycling these metals reduces the demand for virgin materials and minimizes environmental impacts associated with raw material extraction (Ren et al., 2017a; Hewawasam et al., 2018).

Organic waste recovery is a critical component of landfill mining. Organic matter can be transformed into biogas, primarily CH4, through anaerobic digestion or composting. This process reduces CH4 emissions, helping mitigate climate change while providing a renewable energy source. A landfill producing 10,000 m3 of leachate annually, for example, has the potential to generate approximately 15 GWh of electricity, enough to supply power to around 3,000 homes (Ren et al., 2017b; Burneo and Juárez, 2020).

Leachate management is another essential aspect of landfill mining. Leachate—a liquid formed as rainwater or other liquids percolate through waste—can contain heavy metals and organic pollutants that threaten surrounding ecosystems if untreated (Remmas et al., 2022). By extracting and treating leachate during mining, soil and groundwater contamination can be prevented. Furthermore, leachate contains valuable nutrients, including nitrogen (N), phosphorus (P), and potassium (K), which can be recovered and applied in agriculture to reduce dependence on synthetic fertilizers (Hoss et al., 2022).

Landfill mining also enhances environmental cleanup by encapsulating waste, mitigating methane production, and reducing pollution around the site. Inactive landfills are often managed using gas capture systems and soil treatment methods to minimize long-term ecological impacts, which can also increase the potential for site redevelopment (Song et al., 2020). By combining resource recovery, renewable energy generation, and environmental protection, landfill mining aligns closely with circular economy principles, transforming landfills from waste repositories into resource recovery hubs.

2.2 Recovery of nutrients from landfill leachate

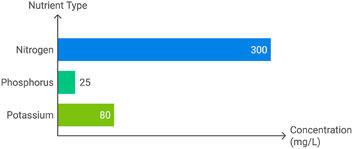

Landfill leachate, defined as the liquid percolating through refuse, is rich in dissolved nutrients such as nitrogen (N), phosphorus (P), and potassium (K) (Figure 4). While traditionally considered contaminants, these nutrients can serve as valuable fertilizers in agriculture, substituting artificial fertilizers. Nitrogen in leachate is primarily present as ammonium (NH4+) or nitrate (NO3−), with concentrations ranging from 100 to 1,000 mg/L depending on landfill age (Jurczyk et al., 2020). For instance, some municipal solid waste landfills contain around 300 mg/L of ammonium, representing a substantial source for fertilizer production. Phosphorus, typically present as orthophosphate (PO43-), ranges between 10 and 100 mg/L, though some landfills exhibit higher concentrations; a U.S. landfill study reported approximately 25 mg/L, demonstrating its potential for agricultural reuse. Potassium is generally lower, between 50 and 200 mg/L, yet still valuable; for example, German landfill leachate has been found to contain around 80 mg/L, supporting its recovery for fertilizer applications (Wang et al., 2022), (Thakur, 2019).

Figure 4. Nutrient concentrations in landfill leachate (Meier et al., 2021).

2.3 Nutrient recovery from landfill leachate

Advanced treatment methods enable the recovery of macro-nutrients from landfill leachate (Li et al., 2022). One widely used technique is struvite precipitation, which removes ammonium nitrogen by forming magnesium ammonium phosphate (MgNH4PO4·6H2O) (Equation 1):

This process can recover up to 90% of ammonium from leachate. Phosphorus can be recovered through chemical precipitation using calcium salts (80%–90%) or via electrocoagulation (up to 95%) (Kurniawan et al., 2024b). Potassium is typically recovered using ion exchange or reverse osmosis, achieving up to 80% recovery (Kurniawan et al., 2010).

In practice, leachate is first collected in a primary treatment tank where pH and magnesium levels are adjusted to favor struvite formation. Precipitation occurs in a controlled tank, and the resulting crystals are separated by settling, filtration, or centrifugation. This method enables efficient nutrient recovery while minimizing scaling and operational issues in downstream processes.

The potential for nutrient recovery is substantial (Figure 4). A landfill processing 10,000 m3 of leachate annually could yield approximately 3,000 kg of nitrogen, 250 kg of phosphorus, and 500 kg of potassium (Kurniawan et al., 2024b). These recovered nutrients can be converted into slow-release fertilizers, reducing reliance on synthetic inputs and mitigating nutrient runoff, thereby supporting sustainable agriculture, advancing circular economy practices, and decreasing dependence on non-renewable resources (Morseletto, 2020; Ghosh et al., 2023; Li et al., 2019).

2.4 Biogas production from landfill leachate

Landfill leachate, rich in organic matter, represents a valuable feedstock for biogas production, primarily methane (CH4), via anaerobic digestion (Figure 5). However, leachate often exhibits a low biodegradability ratio, which can limit digestion efficiency. Pre-treatment methods, including advanced oxidation processes (AOPs) such as ozone, Fenton, or UV-based treatments, are applied to enhance biodegradability (Grosser et al., 2019; Feij et al., 2023).

Anaerobic digestion proceeds through four stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Reactor types commonly used include continuously stirred tank reactors (CSTRs) and upflow anaerobic sludge blanket (UASB) reactors. Operational factors—such as temperature, pH, retention time, and organic loading—significantly influence performance (Ding et al., 2018). Biogas is subsequently purified through CO2 removal and H2S scrubbing to improve energy quality and usability.

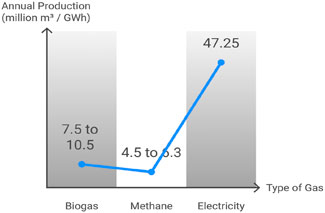

Organic pollutants in leachate, typically measured as chemical oxygen demand (COD), range from 1,000 to 10,000 mg/L, with about 2,000 mg/L representing biodegradable volatile solids essential for methane production (Li et al., 2018). For a landfill processing 10,000 m3 of leachate annually with 1,500 mg/L volatile solids, approximately 15,000 kg of volatile solids would be available for biogas generation (Li et al., 2020a). Using a conversion factor of 0.5 m3 of biogas per kg of volatile solids, this yields around 7.5 million m3 of biogas per year, of which 4.5–5 million m3 is CH4. Considering that 1 m3 of CH4 produces 10–12 kWh of energy, this corresponds to 45–60 GWh annually, enough to supply 4,500–6,000 households (Li et al., 2020a).

Capturing CH4 from leachate also mitigates GHG emissions. Methane is a potent greenhouse gas, and its recovery can reduce landfill CH4 emissions by up to 30% compared with conventional landfilling (Teng and Chen, 2023; Nguyen et al., 2020). The recovered biogas can be used for electricity, heating, or biomethane production, contributing to a renewable energy cycle and supporting circular economy principles (Wang et al., 2019; Anjum et al., 2023).

Using a standardized calculation approach, biogas yields from anaerobic digestion of landfill leachate can be estimated. For instance, a landfill processing 10,000 m3 of leachate annually with 1,500 mg/L of volatile solids would produce 7.5–10.5 million m3 of biogas, with 4.5–6.3 million m3 as CH4. This methane could generate roughly 47.25 GWh of electricity per year, sufficient to power approximately 4,700 households (Speth et al., 2016; Wang et al., 2020).

This energy recovery process not only provides a renewable energy source but also helps reduce the environmental impact of landfills by capturing CH4, a potent GHG. As CH4 is 28–36 times more potent than CO2 in terms of global warming potential, capturing and utilizing it for energy mitigates climate change. In this way, CH4 recovery from landfill leachate contributes both to sustainable energy production and to efforts in reducing landfill emissions, aligning with broader goals of climate change mitigation and the transition to a circular economy (Wang Y. et al., 2021).

3 Environmental and economic implications

3.1 Methane emission reduction

The energy recovery process not only generates renewable electricity but also mitigates one of the most critical environmental challenges associated with landfills—methane (CH4) emissions. Methane, a greenhouse gas (GHG) 28–36 times more potent than carbon dioxide (CO2) over a 100-year horizon, significantly accelerates global warming if released into the atmosphere (Tsui et al., 2018). By capturing and utilizing CH4 generated from landfill leachate, this process simultaneously contributes to sustainable energy production and reduces landfill-derived emissions, aligning directly with climate change mitigation strategies and circular economy objectives.

Landfill mining enhances CH4 recovery through advanced methods such as leachate recirculation and anaerobic digestion. Research shows that this approach can lower methane emissions by up to 30% compared to conventional landfill practices. For instance, a landfill processing 10,000 m3 of leachate annually can yield approximately 4.5 million m3 of CH4 (Tsui et al., 2020). By implementing landfill mining, up to 1.35 million m3 of CH4 emissions can be prevented from entering the atmosphere each year. This captured methane can be converted into around 14.2 GWh of electricity annually, which is sufficient to supply energy to 1,420 households (Zhou et al, 2021).

Beyond its immediate environmental benefits, methane recovery contributes to long-term economic resilience. The conversion of CH4 into electricity not only reduces reliance on fossil fuels but also provides a revenue stream for municipalities and private operators, transforming landfill liabilities into valuable energy assets (Zo et al., 2022). With methane responsible for 30% of global warming since the Industrial Revolution and projected emissions expected to rise by 13% by 2030 without intervention, landfill mining and CH4 recovery represent essential strategies for both sustainable development and climate adaptation (Mishra et al., 2018).

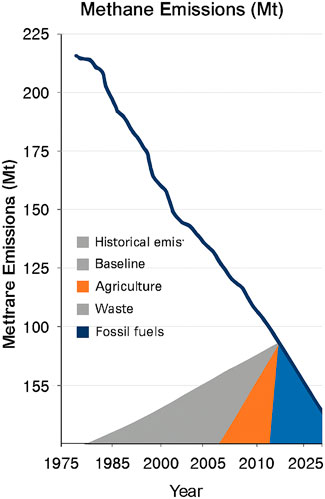

Methane (CH4) is not only a potent greenhouse gas but also a significant threat to human and ecological health. It acts as a precursor to ground-level ozone, a pollutant linked to nearly one million premature deaths worldwide each year, while also impairing crop productivity and ecosystem resilience. Elevated tropospheric ozone, largely driven by methane, is estimated to cause up to 15% of annual crop yield losses (Martínez-Jardines and de María Cuervo-López, 2024). Agriculture contributes about 40% of global methane emissions, followed by fossil fuels (35%) and waste (20%) (Chen et al., 2024). To remain on track with the Paris Agreement’s 1.5 °C target, the IPCC stresses that methane emissions must decline by 30%–60% by 2030, with the fossil fuel sector expected to deliver nearly half of these reductions.

Targeted methane mitigation has immediate climate and societal benefits. Beyond slowing atmospheric warming, it curtails climate feedbacks such as polar ice melt, while improving public health and food security. The Global Methane Assessment shows that available solutions—many of them cost-neutral or even cost-saving—could lower emissions by 45% by 2030 (Rajagopal et al., 2019). These outcomes also align with several Sustainable Development Goals (SDGs), including climate action, food security, and improved health. The Global Methane Pledge, launched at COP26, embodies this vision by seeking collective action to reduce methane emissions in line with a 1.5 °C pathway (Tsui et al., 2020). Achieving its targets would prevent hundreds of thousands of premature deaths, improve agricultural yields, and reduce economic losses from heat stress (Figure 6).

Figure 6. Projected emissions by sector by region in 2030 (Qadir et al., 2020).

From an economic standpoint, landfill mining demonstrates strong potential as both a mitigation strategy and a revenue source. Capturing methane from waste decomposition decrease emissions, while generating renewable energy that can be consumed locally or sold to the grid. In addition, the process facilitates recovery of valuable materials such as metals, plastics, and nutrients, which can be recycled or marketed. Depending on energy prices, the revenue from electricity generation alone could range from USD 1.4 to 2.1 million annually (Tsui et al., 2018). This dual role—climate mitigation and economic opportunity—positions landfill mining as a key component of a sustainable circular economy (Rajagopal et al., 2019).

Uncontrolled landfill emissions, however, remain a pressing concern. With a global warming potential 28–36 times higher than CO2 over a century, methane generated during anaerobic decomposition can reach 100–200 million m3 per year for every million tons of waste deposited. Over three decades, this may accumulate to 3–6 billion m3 of CH4, a substantial driver of climate change (Tsui et al., 2020). Advanced recovery strategies, such as landfill gas capture and mining, can intercept 60%–90% of these emissions before release. For instance, a landfill emitting 150 million m3 of methane annually could cut that figure to just 15 million m3 with a 90% recovery rate, while also supplying enough energy to power thousands of homes (Figure 7) (Zhou et al., 2021).

Figure 7. Methane mitigation to meet the GMP (Mishra et al., 2018).

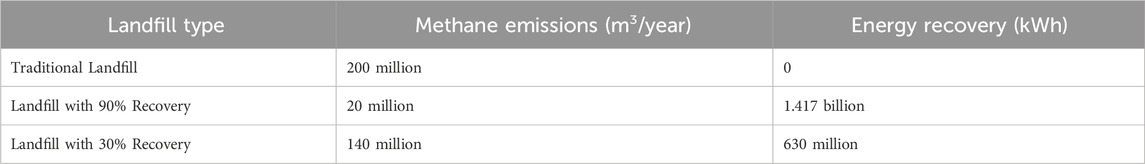

Even moderate recovery rates yield significant benefits. A 30% reduction from a site emitting 200 million m3 of CH4 annually would prevent 60 million m3 from entering the atmosphere (Li et al., 2020b). Since every cubic meter of methane can generate roughly 10.5 kWh of electricity, capturing 135 million m3 translates to 1.417 billion kWh—sufficient to supply around 141,700 households for 1 year (Table 1; Li et al., 2020b). Thus, methane recovery from landfill mining is not only an effective climate strategy but also a reliable contributor to renewable energy generation and economic resilience.

Overall, adopting recovery strategies in landfills can substantially cut CH4 emissions. Even modest reductions, such as 30%, generate meaningful environmental gains by limiting methane’s climate impact while enabling renewable energy generation. These measures also align with broader goals of sustainable waste management and the circular economy, where waste is reimagined as a source of resources and energy rather than an end product (Yukesh Kannah et al., 2022).

3.2 Carbon sequestration and climate change mitigation

Landfill mining not only curbs methane but also contributes to carbon sequestration, a vital approach for addressing climate change. Traditional landfills release large volumes of CH4 during anaerobic decomposition. Through mining, however, excavated waste can be stabilized in controlled environments such as aerated systems or bioreactors, which accelerate degradation while limiting methane release.

A significant addition to this process is biochar production. Using thermochemical conversion methods like pyrolysis, organic waste can be transformed into a carbon-rich material capable of long-term storage in soils. While pyrolysis can be cost-intensive and yield by-products such as syngas and tars, these outputs can themselves be harnessed: syngas as renewable heat or electricity, and tars through treatment or co-combustion for further energy recovery. Although operational costs may be higher, biochar offers substantial benefits, including carbon sequestration, soil improvement, and the immobilization of heavy metals—making it an effective tool within landfill mining for both climate mitigation and resource recovery (Kamaruddin et al., 2017).

As a stable form of carbon, biochar can persist in soils for centuries (Rasapoor et al., 2021). Research suggests that every ton of biochar has the potential to capture up to three tons of CO2, highlighting its strong role in offsetting the carbon footprint of landfills (Zamrisham et al., 2024; Kamaruddin et al., 2017; O'Toole, 2022). Beyond biochar, landfill mining contributes by capturing methane for energy. For instance, CH4 emissions from a landfill discharging 100 million m3 annually can be intercepted, preventing the equivalent of 1.3 million tons of CO2 from entering the atmosphere while producing energy for local or industrial use (Perera and Yatawara, 2021).

Additionally, once sites are mined and stabilized, they can be rehabilitated into parks, agricultural land, or other green spaces. Such conversions enhance natural carbon sequestration through vegetation and soil enrichment (Sarpong et al., 2021; Shahid et al., 2021). Thus, landfill mining simultaneously reduces methane, generates renewable energy, and enhances long-term carbon storage, reinforcing climate change mitigation while promoting sustainable resource recovery (Maneesuwannarat et al., 2013).

3.3 Economic benefits of landfill mining

Beyond environmental gains, landfill mining delivers considerable economic value. A central benefit lies in energy recovery, especially through biogas derived from captured methane (Wdowczyk and Szymańska-Pulikowska, 2022). Instead of being released into the atmosphere, CH4 can be processed into a renewable energy source that displaces fossil fuel use (Phusantisampan et al., 2016).

For example, if a landfill produces 10,000 m3 of leachate twice a year, it could yield approximately 2.5 million m3 of biogas. Filtering this gas may result in about 1.5 million m3 of purified methane, translating into roughly 15 GWh of electricity. This amount of energy could power an estimated 3,000 households annually, while also providing landfill operators with a significant revenue stream (Perera and Yatawara, 2021; Yalçuk and Ugurlu, 2020; Abbas et al., 2019). The profits from electricity sales can offset costs of excavation, processing, and resource recovery, strengthening the financial sustainability of landfill mining.

Additional economic advantages arise from reducing dependence on conventional energy, which lowers operating costs. By producing renewable energy, operators may also benefit from government subsidies, incentives, or tax reductions tied to clean energy targets (Barasarathi et al., 2022). At the same time, methane recovery for energy contributes to national climate commitments, potentially earning operators carbon credits under carbon pricing systems. These credits can be traded, creating an extra source of income while further incentivizing GHG reduction (Maine et al., 2022; Shi et al., 2021; Ezeudu et al., 2021).

The economic value of landfill mining extends beyond energy. It fosters job creation across excavation, processing, engineering, and environmental management. Skilled labor is required to operate equipment, design systems, and oversee environmental safeguards (Benoist et al., 2023). As resource recovery advances, specialized industries emerge around biogas technology, nutrient recycling, and water treatment, contributing to a green economy and promoting innovation in waste-to-resource solutions (Hernández-Castelán et al., 2024; Khandelwal and Lens, 2024).

Communities also gain indirect benefits. The need for transport, construction, and related services stimulates local economies, while training and upskilling initiatives prepare workers for roles in renewable energy and environmental management. Over time, these activities nurture a skilled labor pool capable of sustaining new industries (Wang et al., 2018).

Municipalities benefit as well, receiving tax revenues, land-use fees, and income from the sale of recovered resources (Wang Z. et al., 2021). Restored landfill sites can even be redeveloped into productive spaces, supporting urban renewal and strengthening the local economy. By converting waste into valuable assets, landfill mining creates a win–win scenario—delivering climate resilience, economic growth, and progress toward a circular economy (Chen et al., 2022).

4 Case studies and applications

4.1 Global examples of landfill mining projects

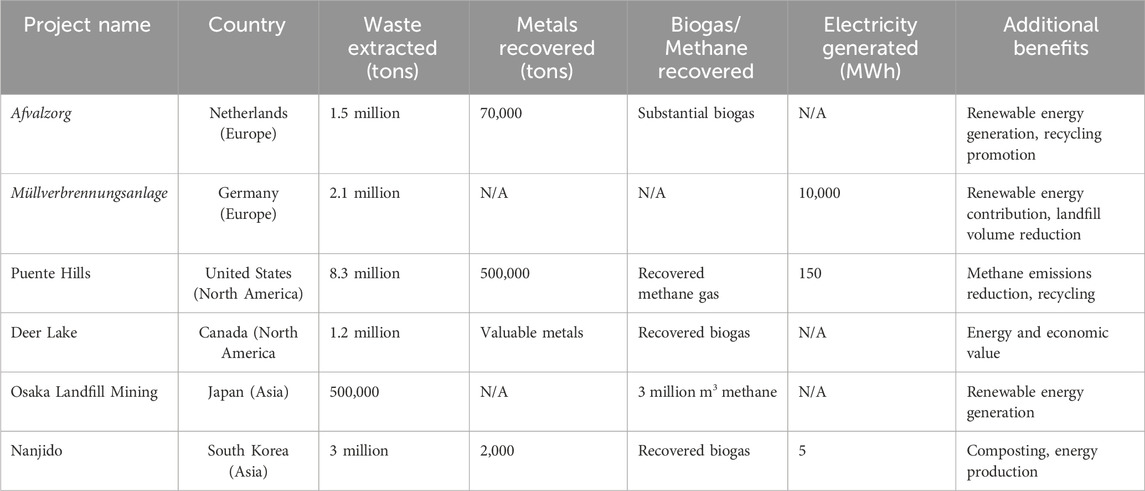

As shown in Table 2, landfill mining (LFM) is emerging as a forward-looking strategy that integrates waste management, resource recovery, and climate change mitigation. Several countries have already demonstrated its feasibility. In Europe, the Netherlands and Germany have pioneered large-scale projects with considerable success. For example, the Afvalzorg project at the Bovenkarspel landfill in the Netherlands excavated over 1.5 million tons of waste within 5 years. From this effort, more than 70,000 tons of metals were reclaimed, and substantial volumes of biogas were captured and subsequently converted into renewable energy (Rajagopal et al., 2019). In Germany, the Müllverbrennungsanlage initiative yielded similar benefits, recovering 2.1 million tons of waste and generating over 10,000 MWh of electricity annually (El Ouaer et al., 2020). These projects not only reduced landfill volumes but also transformed buried materials into viable energy and raw resources, highlighting the dual environmental and economic potential of LFM.

Table 2. Overview of waste management, resource recovery, and renewable energy generation based on countries.

North America has also embraced this approach. The Puente Hills Landfill in California, once the largest in the United States, processed around 8.3 million tons of waste through mining operations. This activity generated approximately 150 MW of electricity from recovered methane, while an additional 500,000 tons of recyclables were extracted for market use. The recovery of biogas in particular reduced methane emissions, demonstrating the critical role of LFM in both energy production and greenhouse gas mitigation. Canada’s Deer Lake project further illustrates this potential by excavating more than 1.2 million tons of waste, recovering metals and biogas, and selling them to recycling and energy markets, thereby converting buried waste into both economic value and renewable energy (Hu et al., 2021).

Asia has also advanced landfill mining (LFM), with Japan and South Korea leading notable projects. In Japan, the Osaka LFM initiative extracted approximately 500,000 tons of waste, recovering biogas equivalent to nearly 3 million m3 of methane annually, which was converted into renewable energy (Blair and Mataraarachchi, 2021; Rezania et al., 2023). Similarly, South Korea’s Nanjido landfill in Seoul processed more than 3 million tons of buried waste. This effort recovered 2,000 tons of metals and nearly 500,000 tons of organic matter, later utilized for composting and energy production. The captured biogas supported the generation of around 5 MW of electricity each year, demonstrating the dual benefits of material recovery and renewable energy supply (Zegzouti et al., 2020).

Taken together, these international case studies underscore how LFM contributes to renewable energy harvesting, landfill volume reduction, and material recovery. The recovered methane (CH4), often transformed into electricity, plays a vital role in reducing greenhouse gas emissions. For instance, projects such as Puente Hills in the United States produced about 150 MW of power solely from biogas recovery, while simultaneously extracting more than 500,000 tons of recyclable materials (Li et al., 2020b; Cherni et al., 2020). These outcomes highlight LFM as both an environmentally sustainable and economically viable pathway, aligning with circular economy objectives and supporting climate change mitigation.

4.2 Best practices in leachate treatment and resource recovery

Modern approaches to landfill sustainability increasingly emphasize leachate treatment and resource recovery. Leachate, typically rich in organics, heavy metals, and macronutrients such as nitrogen, phosphorus, and potassium (NPK), poses significant ecological risks if untreated (Chen et al., 2023). At the same time, it presents opportunities for nutrient recovery and clean water production, linking waste treatment with economic and environmental benefits (Jain et al., 2023).

One promising approach is struvite precipitation, which enables phosphorus recovery. In the Kampen Landfill project in the Netherlands, this method yielded nearly 50 tons of phosphorus annually while reducing phosphorus leachate levels by up to 90%. The recovered struvite was repurposed into high-value fertilizers, with costs 20%–30% lower than conventional alternatives (Amakdouf et al., 2023; Yi, 2019; Kyriakopoulos et al., 2019).

Reverse osmosis (RO) represents another effective practice, particularly in filtering dissolved solids and heavy metals. At Germany’s Mülheim Landfill, RO technology treats about 2,000 m3 of leachate daily, producing clean water suitable for irrigation and industrial use while capturing biogas for renewable energy. The integration of these systems reduces energy demands and enhances sustainability (Ghosh et al., 2023; Nordahl et al., 2020).

Anaerobic digestion also plays a crucial role in leachate treatment. At the Puente Hills Landfill in California, anaerobic bioreactors process approximately 10,000 m3 of leachate each year, generating 1.5 million m3 of CH4, later converted into about 15 GWh of electricity—enough to power more than 1,000 homes annually. In addition, nutrient-rich digestate is produced, serving as a natural fertilizer and closing the nutrient loop (Zakaria et al., 2022).

Similarly, membrane filtration technologies, such as ultrafiltration (UF) and microfiltration (MF), provide effective methods for leachate purification. In Turkey, the Samsun Landfill combines UF and MF to reclaim nearly 70% of leachate for irrigation and landscaping, while simultaneously recovering about 2 tons of phosphorus each year (Zainal et al., 2021).

In some cases, landfills employ integrated systems that combine multiple technologies. For example, the Vancouver Landfill in Canada integrates RO, anaerobic digestion, and struvite precipitation to treat 5,000 m3 of leachate daily. This system generates 500 m3 of biogas per day—equivalent to 5 MW of electricity—while reclaiming roughly 50 tons of phosphorus annually (de Brito et al., 2019).

Collectively, these case studies demonstrate how advanced leachate treatment can substantially reduce environmental risks, recover valuable nutrients, and provide renewable energy. By coupling nutrient recovery with energy generation, such practices strengthen landfill mining’s role in sustainable waste management and contribute meaningfully to the goals of the circular economy (Viegas et al., 2021).

4.3 Landfill mining operations and post-mining restoration

The objectives of landfill mining (LFM) extend beyond resource recovery to include the safe rehabilitation of mined sites. Once excavation activities conclude, the land requires systematic restoration to mitigate ecological risks and to prepare it for sustainable future use (Speth et al., 2016). Effective post-mining strategies typically include:

1. Reshaping and Capping–Excavated zones are regraded to enhance slope stability and water drainage. Impermeable caps are then applied to reduce infiltration and minimize leachate formation.

2. Soil Amendment–Replacing and enriching topsoil with organic matter enhances soil fertility, creating favorable conditions for vegetation.

3. Revegetation–Establishing adaptive and resilient plant species stabilizes the soil, reduces erosion, and contributes to biodiversity recovery.

4. Monitoring and Maintenance–Continuous assessment of groundwater, soil conditions, and vegetation ensures the effectiveness of restoration and helps prevent future environmental risks.

These restoration measures illustrate how LFM can serve not only the goals of resource recovery and circular economy but also long-term ecological rehabilitation and sustainable land management (Wang et al., 2020).

4.4 Impacts on local ecosystems and communities

Landfill mining provides wide-ranging ecological and socio-economic benefits, particularly for surrounding ecosystems and human settlements. One major ecological gain is the mitigation of eutrophication, which occurs when excess nutrients—primarily nitrogen and phosphorus—enter aquatic systems, leading to algal blooms and water quality degradation (Hogland et al., 2018). By extracting and reusing these nutrients from leachate, LFM prevents pollution and helps restore aquatic ecosystems. For instance, in India, a project utilizing struvite precipitation successfully recovered 40 tons of phosphorus annually, diverting it from watercourses and redirecting it into agriculture as fertilizer (Guo et al., 2022; Shabani et al., 2020; Patwardhan et al., 2021).

Another critical impact is methane capture, which directly addresses greenhouse gas mitigation. Methane, a potent contributor to global warming, is commonly emitted by unmanaged landfills. Through anaerobic digestion and gas recovery, LFM captures this resource for renewable energy generation. At the Puente Hills Landfill in California, methane derived from leachate is converted into approximately 15 GWh of clean electricity per year, supporting local energy demand while displacing fossil fuel reliance (Dawczak and Dudziak, 2020).

Nutrients recovered during LFM, such as nitrogen (N), phosphorus (P), and potassium (K), play a vital role in enhancing soil fertility. For example, Turkey’s Samsun Landfill extracts nearly 2 tons of phosphorus annually from leachate, which is reused in local agriculture to improve productivity and soil quality. In addition, organic fractions produced through leachate treatment enhance soil structure, nutrient retention, and biological activity, contributing to long-term agricultural resilience (Miao et al., 2019).

Beyond ecological benefits, LFM also generates economic and social opportunities. The development and operation of treatment systems create jobs across diverse skill levels, ranging from plant technicians and engineers to auxiliary workers. In Germany, one landfill mining initiative provided over 100 local jobs linked to fertilizer production, biogas recovery, and recyclable material processing (Negahban and Karbassi, 2023). Such projects also support broader community initiatives in renewable energy and sustainable farming, further strengthening local economies.

Overall, LFM demonstrates the capacity to improve environmental quality, reduce greenhouse gas emissions, enrich soils, and supply renewable energy while simultaneously advancing social welfare. The combined ecological and economic benefits underscore its role as a sustainable waste management strategy that contributes to climate change mitigation, circular economy principles, and regional resilience.

5 Challenges and barriers to implementation

5.1 Technological and operational challenges in landfill mining

While LFM holds promise for resource recovery and sustainability, it also faces substantial technological and operational challenges that limit its broader application. A key risk is the management of leachate, which is often acidic and rich in heavy metals and organic pollutants. Without adequate control, leachate can pose significant environmental hazards (Cingolani et al., 2015). Effective mitigation relies on integrated measures, including:

1. Containment Systems–Temporary liners and engineered barriers to prevent migration of leachate from excavation zones.

2. Leachate Collection Networks–Pumps, sumps, and drains that capture leachate for regulated treatment.

3. Treatment Processes–On-site neutralization, coagulation–flocculation, or advanced oxidation processes (AOP) to reduce toxicity.

4. Monitoring Programs–Continuous evaluation of contaminant concentrations, pH, and leachate volume for early warning.

5. Operational Controls–Regulating excavation rates, prioritizing dry-season operations, and rapid covering of exposed sections to limit leachate formation.

6. Emergency Preparedness–Spill containment kits, trained staff, and contingency plans to ensure compliance and minimize risks.

Applying these strategies helps safeguard the environment, protect workers, and maintain operational efficiency in LFM projects (Fu et al., 2022).

A further difficulty arises from the variable composition of leachate, which differs according to landfill age and waste type. This inconsistency affects the recovery rates of key nutrients. Some treatment systems report phosphorus recovery fluctuating between 30% and 80%, reflecting challenges in maintaining stable outputs (Beyazıt and Atmaca, 2021). Similarly, biogas production is unpredictable, especially in older landfills where much of the organic fraction has already degraded. For example, at California’s San Bernardino Landfill, leachate treatment facilities achieved only 60% of the expected methane yields, underscoring the challenge of optimizing energy recovery when feedstock composition is uncertain (Fu et al., 2022).

From an operational standpoint, LFM requires precise process control. Practices such as leachate recirculation for enhancing gas yields demand tight regulation of flow rates, temperature, and oxygen levels. At the Elmwood Landfill in the UK, minor deviations from optimal operating conditions reduced biogas output by nearly 40% (Barrera-Díaz et al., 2014). In addition, the initial capital investment for infrastructure—including bioreactors, gas capture systems, and treatment plants—is considerable. An Australian LFM project, for instance, required an investment of AUD 10 million, with returns on investment reaching only 20% after the first 5 years due to efficiency constraints (Beyazıt and Atmaca, 2021).

Excavation methods also bring environmental risks. Vertical mining of capped landfills may trigger uncontrolled methane venting or leachate migration, both of which demand extensive monitoring and mitigation (Beyazıt and Atmaca, 2021).

Beyond technical hurdles, economic and regulatory barriers also constrain LFM. Regulatory frameworks differ significantly between regions, complicating the approval and permitting process. Meanwhile, the profitability of projects is closely tied to volatile market prices for recovered nutrients and biogas. If prices fall, the financial viability of recovery systems declines sharply. Public resistance further complicates implementation, as nearby residents may object to potential health or environmental risks associated with disturbing dormant landfills. Such opposition can delay projects, drive up costs, and require extensive consultation processes (Barrera-Díaz et al., 2014).

In short, while LFM offers clear ecological advantages and contributes to climate and sustainability goals, its progress is hindered by technological uncertainties, operational complexities, and financial as well as regulatory barriers. Overcoming these challenges requires advances in treatment technologies, stronger management practices, and supportive policy frameworks that can enhance the efficiency, safety, and economic viability of LFM as a long-term solution.

5.2 Financial and regulatory barriers

The long-term viability of landfill mining (LFM) projects depends not only on their ecological benefits but also on their ability to overcome economic and regulatory constraints. These factors often determine whether projects can advance from pilot initiatives to fully operational systems.

One of the most significant barriers is the high upfront capital investment required to establish an LFM facility. Specialized infrastructure such as bioreactors, aeration systems, and leachate treatment plants demand substantial funding, often amounting to several million dollars. This cost can be prohibitive for smaller firms seeking to introduce innovative methods. For instance, a study in the Netherlands reported that setting up an LFM system integrating both biogas recovery and nutrient extraction required an initial outlay of approximately USD 5.5 million, alongside recurring annual costs of about USD 550,000 (Balogun et al., 2024).

In addition to steep startup costs, the financial return from LFM is generally slow to materialize. Many projects face extended payback periods, which discourage private investors. A case in point is the Orange County Landfill Mining Project in the United States, where profitability was not expected until 8–10 years after commencement due to the slow pace of revenue from energy recovery and material sales. While long-term prospects in biogas and nutrient markets remain promising, the delay in returns undermines investor confidence (Asaithambi et al., 2017).

The cost of excavation and waste handling adds another economic burden. Compacted waste, often decades old and partially decomposed, requires extensive machinery and processing, raising extraction expenses. A German study found that removal and treatment costs ranged from USD 50 to 70 per ton of refuse, rendering large-scale recovery projects financially challenging even before profitability thresholds were reached (Saleh and Zouari, 2020).

Regulatory frameworks further complicate project implementation. Policies governing landfill management—such as requirements for environmental assessments, leachate control, and gas monitoring—add operational complexity and cost. For example, methane control regulations under the California Air Resources Board have significantly increased compliance expenditures, with environmental monitoring and reporting alone accounting for 10%–20% of total project budgets (Badawi and Zaher, 2021).

The absence of clear legal frameworks also creates uncertainty. In some jurisdictions, landfills are legally classified as closed sites, making it difficult to reopen them for mining under existing construction and demolition regulations. Contradictory or poorly defined policies can discourage investment, as operators face unclear obligations and unpredictable costs. In Japan, inconsistent policy directives surrounding land reclamation forced one project to spend an additional USD 21 million over 3 years, exposing the risks posed by regulatory ambiguity (Ilmasari et al., 2022).

Finally, public opposition remains a persistent challenge. Communities often resist LFM due to fears of health impacts, noise, or disruption from excavation. In Toronto, Canada, local residents opposed a landfill mining project, citing concerns over air and water quality monitoring. Their resistance delayed the project by 18 months and required extra funding for community outreach and environmental safeguards (Abdelfattah et al., 2023).

Thus, while LFM presents clear environmental and resource recovery benefits, capital intensity, uncertain profitability, regulatory inconsistency, and community resistance create significant barriers. Overcoming these requires closer collaboration among local governments, private investors, and community stakeholders to establish clearer policies, supportive economic models, and socially inclusive approaches that can reduce financial risk and promote adoption.

5.3 Public perception and stakeholder engagement

The success of LFM projects is strongly influenced by community attitudes. Even when projects demonstrate tangible ecological and economic benefits—such as methane reduction or resource recovery—residents frequently oppose them due to concerns about odors, environmental risks, and disruption to local ecosystems. Social backlash can delay projects, raise costs, and reduce efficiency (Zakaria et al., 2022; Shahedi et al., 2020).

Odor emissions are one of the most visible issues during landfill excavation and leachate processing. To address this, operators employ measures such as biofiltration, aeration to biologically degrade odorous compounds, chemical neutralization with oxidizing agents, and negative-pressure enclosures to capture gases at the source (Zakaria et al., 2022). Optimizing moisture content and handling protocols also reduces anaerobic conditions that foster foul-smelling emissions. Applying these strategies ensures environmental sustainability while mitigating community discomfort (Shahedi et al., 2020).

Opposition is also fueled by misconceptions about risks and benefits. Many residents view landfills as purely harmful sites and are unsettled by the idea of reopening them for resource recovery. A 2019 North American survey found that 68% of respondents opposed LFM in their communities, citing fears of pollution and ecosystem disruption, even though projects sought to capture methane and recover nutrients (Wang LK. et al., 2021). Limited communication and lack of public awareness about the potential climate and agricultural benefits exacerbate this resistance.

To counter such concerns, public education and transparent engagement are essential. Demonstrating how LFM reduces methane emissions, supports renewable energy, and recovers fertilizers can help shift community attitudes (van Hullebusch et al., 2021). In South Korea, for example, strong initial opposition was reduced by one-third after public consultations and environmental impact assessments highlighted the benefits of methane capture, nutrient recycling, and green job creation.

Engaging stakeholders early in the decision-making process also builds legitimacy and trust. Inclusive consultations that involve local governments, NGOs, schools, and community-based organizations foster a sense of shared ownership. A German project that conducted extensive public forums gained community acceptance and proceeded without major delays, as residents felt their concerns had directly shaped project planning.

Transparency further strengthens trust. Providing real-time data on emissions, water quality, and noise levels—as seen in a Canadian LFM project—demonstrated environmental compliance and reassured residents about safety (Viegas et al., 2021; Dereli et al., 2021).

While public opposition can hinder LFM development, it can be mitigated through proactive communication, inclusive stakeholder engagement, and transparent reporting. By addressing misconceptions and involving communities in the planning process, projects are more likely to gain acceptance and move forward, aligning waste management innovation with broader goals of sustainability and climate mitigation (Clemente et al., 2024; Qadir et al., 2020).

6 Future directions and research needs

6.1 Technological advancements

Recent advancements in technologies for biogas production, nutrient recovery, and leachate treatment have opened new opportunities for landfill mining, making it more effective in addressing environmental concerns. These innovations are particularly important for reducing the ecological risks associated with landfills, such as groundwater contamination and methane emissions (Bove et al., 2015).

One of the most notable developments has been the shift towards bioreactor landfills, which have significantly improved the decomposition of organic matter and enhanced biogas yields. By creating optimized conditions for microbial processes, bioreactor systems are capable of producing nearly 50% more biogas compared to conventional landfills. On average, such systems can generate 100–150 m3 of biogas per ton of waste, translating to considerable methane recovery that can be utilized for energy production (Ayodele and Alao, 2020). For example, the treatment of 100,000 tons of waste annually can yield between 10 and 15 million m3 of biogas, which is sufficient to power approximately 5,000–7,000 households for an entire year, highlighting the strong energy recovery potential of landfill biogas (Jagaba et al., 2021).

Equally important is the progress in nutrient recovery from landfill leachate. Techniques such as struvite precipitation and membrane filtration enable the recovery of valuable nutrients, including nitrogen and phosphorus. Struvite precipitation has demonstrated recovery rates of up to 90% for phosphorus and 60%–70% for nitrogen. A Swiss case study reported that the treatment of 10,000 m3 of leachate annually produced 5–6 tons of struvite fertilizer, underscoring the feasibility of scaling such approaches.

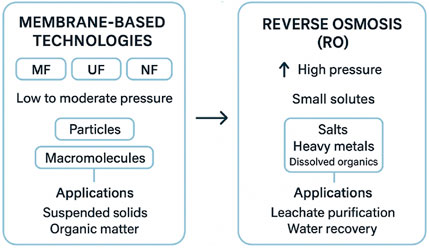

At the same time, membrane-based technologies, particularly reverse osmosis (RO), have shown promising results in contaminant removal. These systems can achieve up to 95% removal efficiency, enabling leachate to be reused for irrigation and, in some cases, potable water production (Shi et al., 2021). Membrane technologies cover a spectrum of separation processes, including microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and RO (Figure 8). While all of these rely on semi-permeable membranes, RO is distinct in operating under high pressure to eliminate dissolved salts and small solutes, offering the highest purification capacity. Thus, although RO is a subset of membrane-based processes, not all membrane technologies function at the level of RO (Shi et al., 2021).

Recent advancements in leachate treatment, particularly through anaerobic digestion and biofilm reactors, have markedly enhanced the breakdown of organic pollutants while simultaneously generating biogas (Cai et al., 2018; Igwegbe et al., 2024). These systems can remove 80%–90% of organic contaminants, offering both environmental benefits and additional energy recovery. For instance, a Canadian project reported a 20% increase in biogas production using anaerobic digestion compared to conventional aerobic approaches (Shi et al., 2021). Furthermore, advanced oxidation processes (AOPs), such as ozonation and UV-peroxide treatments, are emerging as highly effective solutions for residual pollutants, achieving up to 95% removal efficiency (Trifonova et al., 2015).

In parallel, data-driven strategies and artificial intelligence (AI) are playing an increasingly important role in optimizing landfill mining operations (Nordahl et al., 2020). Machine learning algorithms can predict ideal conditions for nutrient recovery and biogas production, enabling real-time adjustments to landfill management (Gopikumar et al., 2021). These technologies not only improve operational efficiency but also reduce costs, supporting more sustainable mining and leachate treatment practices (Fu et al., 2022; Clemente et al., 2024).

Technological progress in nutrient recovery, biogas capture, and leachate processing enhances the energy potential of landfill mining. With AI-assisted bio-information systems, energy recovery can be optimized, transforming public landfills into efficient green spaces while achieving cost-effective biosphere management.

6.2 Policy recommendations

Policy frameworks are essential to unlocking the full potential of landfill mining and resource recovery. Incentivizing private and public participation through financial mechanisms—such as tax breaks, subsidies, or depreciation benefits—can offset high initial capital costs associated with bioreactors, leachate treatment facilities, and methane recovery systems (Zorpas, 2020; de Marsily et al., 2016). In North America, such incentives have increased landfill mining investments by 15%–20% within the first 3 years. Additionally, policies that set CH4 and CO2 reduction targets and provide carbon credits can further support operations; a German project captured methane to reduce emissions by 30%, earning an estimated USD 1.5 million annually in carbon credits (Sharma et al., 2024).

Mandating the mining of older landfills contributes to greenhouse gas mitigation while recovering valuable materials. For example, Japan’s requirement to mine landfills older than 25 years led to a 20%–25% reduction in GHG emissions. Extended Producer Responsibility (EPR) programs also stimulate investment in mining technologies, as demonstrated in Canada, where EPR regulations increased recycling by 12% and reduced landfill waste by 14% (Premakumara et al., 2014).

Public-private partnerships (PPPs) provide additional support by combining government funding with private expertise. In France, PPPs facilitated the recovery of 30,000 tons of materials from legacy landfills, generating €4 million in cost savings. Similarly, Denmark’s policies improved nutrient recovery by 50% and methane capture by 20% (Ho and Goethals, 2019).

EU-funded programs have demonstrated that technology enhancements can reduce leachate treatment costs by 15% and increase methane extraction efficiency by 20%. Governments should also invest in research and development (R&D) for innovative mining solutions. Public education and awareness campaigns are equally critical: in Sweden, such initiatives increased public acceptance and contributed to a 20% growth in landfill mining projects over the past decade (Ghosh et al., 2023). Collectively, these policy measures create an enabling environment for landfill mining, delivering both environmental and economic benefits.

6.3 Knowledge gaps and opportunities

Landfill mining and leachate management remain evolving fields, with several knowledge gaps requiring attention to fully realize their potential for sustainable waste management and environmental protection. One critical area is optimizing leachate treatment technologies. Biological systems, such as constructed wetlands, have demonstrated nitrogen removal efficiencies of 60%–80%, yet performance varies with temperature and contaminant load (Ghosh et al., 2023). Reverse osmosis (RO) and membrane filtration are effective for heavy metal and contaminant removal but can be costly and inefficient for high-strength leachates. Research into hybrid treatment approaches that combine biological and physical processes could improve cost-effectiveness and treatment efficiency, potentially reducing operational expenses by up to 30% (Pujara et al., 2019).

A key limitation of RO is managing brines, which are concentrated in salts and potentially toxic contaminants. Improper disposal can pose significant environmental risks. Strategies such as Zero Liquid Discharge (ZLD), recovery of valuable salts or metals, and hybrid approaches combining RO with pre-treatment techniques (e.g., membrane distillation or forward osmosis) can mitigate environmental impacts while enhancing resource recovery, aligning with circular economy principles.

Predicting and optimizing biogas production from leachate also remains a knowledge gap. Organic content, such as volatile solids, can yield roughly 0.5 m3 of biogas per kg of solids, though methane production is sensitive to microbial activity, temperature, and pH (Ogunbiyi et al., 2021; Mishra et al., 2018). Accurate biogas yield models would improve the feasibility of recovery projects, which can substantially reduce methane emissions. For example, Canadian landfill projects have recovered up to 30 million m3 of CH4 annually (Badawi and Zaher, 2021; Kurniawan et al., 2022a).

Nutrient recovery from leachate is another promising research avenue. Essential nutrients like nitrogen, phosphorus, and potassium can be reclaimed, with struvite precipitation recovering up to 80% of phosphorus (Nordahl et al., 2020). Scaling these processes for large landfills remains a challenge, and understanding the agronomic impacts of recovered nutrients is essential. Given that fertilizers contribute approximately 3% of global GHG emissions, optimizing nutrient recovery could reduce reliance on synthetic fertilizers (Kurniawan et al., 2022b).

Technologies for recovering other valuable materials, including metals and plastics, are still developing. Automated sorting systems, particularly those integrating AI, could enhance recovery rates by up to 50%, yet further research is needed to refine these technologies for older landfills. Recovering rare earth elements, which are critical for electronics and renewable energy, represents a high-potential area for future investigation (Abdelfattah et al., 2023; Kurniawan et al., 2024a).

Long-term environmental and health impacts require more study. Although landfill mining can reduce methane emissions by 50%, short-term risks such as groundwater contamination during excavation remain concerns (Samberger, 2022; Robles et al., 2020). Comprehensive studies are needed to assess safety and prevent new environmental hazards (Zang et al., 2015).

The lack of standardized methodologies across landfill mining studies complicates the evaluation of outcomes. Techniques for excavation, sorting, and resource recovery vary, limiting comparability and scalability (Fa et al., 2016). Establishing unified protocols could create a reliable framework for broader implementation. Geographical variability also affects feasibility. Developed nations often employ formal, regulated mining with advanced technologies, whereas informal mining in developing countries may pose environmental and social risks. Factors such as waste composition, landfill age, policy frameworks, and socio-economic conditions influence performance, emphasizing the need for context-specific strategies (Fa et al., 2016).

A decision framework can help assess when landfill mining is environmentally justified, considering waste composition, landfill age, resource recovery potential, energy balance, economic feasibility, and regulatory context (Pesqueira et al., 2020). Successful implementation requires interdisciplinary integration across engineering, economics, policy, and social sciences. Engineering studies often focus on process optimization but may overlook economic viability, regulatory compliance, or social acceptance (Meier et al., 2021).

Environmental and health risks, including the release of methane, toxic chemicals, or pathogens, are under-researched (Kurniawan et al., 2022a; Kurniawan et al., 2022b). Disturbing landfills can release contaminants or GHG, undermining environmental benefits. Safety protocols for workers and surrounding communities are essential.

Economic feasibility remains uncertain due to high excavation, sorting, and recycling costs. Robust cost-benefit analyses are necessary to evaluate long-term viability compared to other waste management strategies (Trifonova et al., 2015; Ghosh et al., 2023). Financial incentives, such as carbon credits or government subsidies, may improve economic outcomes.

Landfill mining complements urban mining and waste prevention strategies. While urban mining targets concentrated metals in e-waste, landfill mining addresses broader objectives, including organic resource recovery, leachate treatment, and environmental remediation (Clemente et al., 2024; Premakumara et al., 2014). Waste prevention, such as source reduction and product redesign, remains the most effective approach, with landfill mining functioning as a complementary recovery method.

Currently, landfill mining relies heavily on manual labor, making operations slow, inefficient, and costly (Badawi and Zaher, 2021). Manual sorting reduces recovery rates and increases contamination, limiting economic value. Investment in automated robotic systems, sensor technologies, AI-driven sorting algorithms, and high-throughput processing could enhance efficiency, profitability, and resource recovery (Zuberi and Ali, 2015).

Life-cycle assessments (LCA) indicate that environmental benefits—such as GHG reduction, energy recovery, and resource reclamation—can be offset by energy-intensive excavation and processing (Sharma et al., 2024). Sustainability is highly context-dependent, necessitating site-specific assessments to guide environmentally and economically sound implementation. Without integration with waste prevention strategies, landfill mining risks becoming a short-term solution rather than a component of a circular economy (Trifonova et al., 2015; Blair and Mataraarachchi, 2021).

The quality and quantity of recoverable materials vary across landfill types, affecting market value and economic viability (Purmessur and Surroop, 2019). Contamination of recyclable materials further complicates resource recovery. Comprehensive assessments of landfill contents, coupled with robust financial models considering regional cost and revenue variations, are essential to improve feasibility. For instance, a U.S. landfill has generated USD 6 million annually from biogas production, yet broader economic viability requires careful cost-benefit evaluation (Fa et al., 2016).

In summary, landfill mining and leachate management offer significant opportunities for sustainable waste management, circular economy implementation, and climate mitigation. Advancing technologies in biogas production, nutrient and material recovery, and leachate treatment, coupled with supportive policies, can enhance operational efficiency and environmental outcomes. Nevertheless, interdisciplinary research, long-term environmental assessments, and economic evaluations remain critical to realizing the full potential of landfill mining as a sustainable practice.

7 Role of landfill mining in circular economy

The growing demand for critical raw materials such as lithium is intensifying pressure on global supply chains. Landfills often contain high-value metals, such as Cu and Al, which can be recovered and recycled, providing significant economic benefits. These materials are indispensable for electric vehicles. Estimates suggest that materials recovered through landfill mining could be worth USD 5–12 billion annually, depending on the quality and composition of the landfill (Fa et al., 2016). However, their extraction and processing are estimated to contribute nearly 20% of global GHG emissions, raising an important paradox: the low-carbon transition relies on materials which production is emission-intensive (Premakumara et al., 2014).

One viable solution is the shift towards circularity, where lower-carbon recycled materials are integrated into industrial production. Recycling not only reduces emissions but also helps unlock secondary supply markets, thereby diversifying resource availability and reducing reliance on virgin extraction. This approach is relevant to landfill mining, which offers access to vast reserves of secondary resources currently locked in landfilled waste. By systematically recovering metals, plastics, and other materials, landfill mining can contribute to closing resource loops and meeting projected demand in a more sustainable manner.