- 1Shaanxi Agricultural Development Group, Xi’an, China

- 2Shaanxi Agricultural Development Group Hanzhong Branch, Chengdu, China

This study presents an innovative green recycling model designed to enhance resource efficiency and value addition in the processing of food and agricultural by-products. The model integrates a resource circulation system to streamline by-product flow across the industrial chain. It optimizes resource allocation and logistics using advanced algorithms and network analysis. We developed an eco-friendly processing technique with modern green technologies. This approach enhances by-product conversion rates while reducing energy consumption. Real-time data collection and intelligent monitoring ensure efficient operation and maximize resource utilization. Experimental results show high effectiveness, with utilization rates of rice bran, wheat bran, and rice husk at 85.4, 82.7, and 88.1% in the processing phase, rising to 92.3, 90.4, and 93.2% in the transformation phase. These rates reflect a substantial improvement in both initial utilization and recycling efficiency. Additionally, the contributions of physical, chemical, and biological treatment methods to the overall value addition of the industrial chain were 35, 27, and 22% respectively, highlighting the synergistic effects of these technologies in enhancing resource value. This research offers a robust theoretical foundation and practical guidance for the green recycling of food and agricultural by-products, promoting sustainable development and resource efficiency in the industry.

1 Introduction

1.1 Background of the article and importance of the topic

Food and agricultural product processing by-products are important resources in agricultural production, containing a large amount of organic matter and nutrients (Galali et al., 2020; Jiao et al., 2022). Reasonable use of these by-products can reduce resource waste and bring new economic growth points to agriculture and food processing industries. By using scientific recycling methods to transform by-products into high value-added products, resource utilization efficiency can be improved and the extension and innovation of the agricultural industry chain can be promoted (Trigo et al., 2020; Kaur et al., 2023). Building an efficient and green by-product utilization model is very meaningful for promoting sustainable agricultural development and improving the overall benefits of the food processing industry.

In the field of utilization of by-products from food and agricultural product processing, traditional processing and utilization methods have many limitations. Many food by-products are currently treated with simple physical processing or low-value utilization, such as feed, fuel or direct composting (Ortega et al., 2022; Sandström et al., 2022). These traditional approaches cannot fully tap the potential value of by-products, nor can they effectively address resource shortages and environmental pollution. Such problems have resulted in a large amount of reusable resources being wasted (Ominski et al., 2021; Difonzo et al., 2022). Traditional by-product treatment methods are generally based on a single technical path, ignoring the differences in the properties of different by-products (Castro-Muñoz et al., 2022; Nevara et al., 2023). Each by-product has different physical, chemical and biological properties. A simple one-size-fits-all treatment method cannot achieve efficient conversion of by-products, resulting in a low conversion rate of by-products (Cao et al., 2022; Vilas-Franquesa et al., 2024). The traditional by-product recycling model lacks systematic planning for the entire industry chain. Many studies and applications only focus on technological innovation in a certain link, ignoring the efficient flow of resources between nodes in the industry chain (Moradi et al., 2023). In the process of by-product collection, processing, transformation and final utilization, traditional research has not considered how to optimize the flow of resources in each link, which has also caused resource waste and poor process (Bianchi et al., 2021; Maini Rekdal et al., 2024). In this case, it is difficult to achieve the synergy of the industrial chain, and the added value of by-products cannot be effectively improved (Taghian Dinani and Van Der Goot, 2023). The traditional by-product treatment process consumes a lot of energy and has low treatment efficiency. It is not possible to effectively use green technology to reduce energy consumption. The energy utilization efficiency of traditional treatment technology is low, and it is generally accompanied by high energy consumption and environmental pollution (Rolim et al., 2020; Echegaray et al., 2023). The failure to meet the requirements of modern green development and the lack of technological innovation support have caused the green utilization of by-products to lag behind and fail to achieve the goal of sustainable development. The lack of intelligent and information-based management methods is also an important defect of traditional methods (Leonarski et al., 2024; Nguyen et al., 2024). The circulation and transformation process of by-products lacks real-time monitoring and optimization, and there are problems of imbalance and inefficiency in resource utilization, which to some extent affect the overall benefits of by-product recycling (Xia et al., 2024). Recent advances in green processing technologies, such as supercritical fluid extraction and nanozyme catalysis, have significantly improved the efficiency of extracting bioactive compounds from by-products, enabling their use in functional foods and nutraceuticals. Additionally, novel utilization strategies have emerged, including the conversion of by-products into bioplastics and bioactive packaging materials, enhancing their value in sustainable applications (Messinese et al., 2024). The integration of artificial intelligence (AI) and Internet of Things (IoT) technologies has further revolutionized by-product management. AI-driven predictive models optimize resource flow within industrial chains, while IoT-enabled sensor networks facilitate real-time monitoring of processing parameters, improving operational efficiency and resource utilization (Leonarski et al., 2024). These advancements underscore the potential for innovative technologies to address the limitations of traditional methods and promote sustainable development in the food and agricultural sector.

The study has established a green and efficient recycling model for by-products from food and agricultural product processing. By optimizing the resource circulation and transformation process, the high added value transformation of by-products is achieved, promoting the sustainable development of the food processing industry. The study starts from the perspective of the entire industry chain, systematically explores the utilization path of by-products, considers multi-dimensional characteristics such as physics, chemistry and biology, and combines the nutritional content and application potential of by-products to design efficient utilization solutions suitable for different by-products. The research also focuses on the circulation and synergy of by-products in the industrial chain, using logistics network analysis and resource allocation algorithms to optimize resource flow paths and improve the collaborative efficiency of each link. By achieving efficient resource transfer between nodes in the industrial chain, by-products can be collected from raw materials, processed and transformed to final applications in the most optimized way, reducing resource waste and improving the comprehensive utilization value of by-products. In the process of realizing green transformation, the research can adopt modern green processing technology to reduce energy consumption and improve the conversion rate of by-products, design an intelligent management system based on big data and Internet of Things technology, monitor the flow and transformation process of by-products in real time, and ensure the efficient use of resources and the optimized operation of each link. These innovative methods and ideas can provide strong theoretical support and practical guidance for the green recycling of by-products from food and agricultural product processing.

1.2 Related work

Currently, there are many research results on the recycling of by-products from food and agricultural product processing, which mainly focus on the analysis of the physical, chemical and biological properties of by-products and the exploration of their application in feed, fertilizer, energy, etc. Some scholars have proposed the use of physical treatment technology to convert by-products into fertilizers to reduce environmental pollution and achieve resource reuse (Bouhia et al., 2022; Chojnacka et al., 2024); Rashwan A K reviewed food and agricultural by-products, focusing on strategies for converting these wastes into valuable materials. By-products can be used for animal and plant nutrition, biogas production, extraction of food, oils and bioactive substances, and production of vinegar, wine, edible paints and organic fertilizers (Rashwan et al., 2023). Some scholars use biotransformation technology to improve the nutritional content of by-products and promote their application in the agricultural field (Gulsunoglu-Konuskan and Kilic-Akyilmaz, 2022; Younes et al., 2023). Shakour et al. (2020) introduced the latest review of the in vivo and in vitro biotransformation processes of citrus juice and waste for their flavonoid composition by microorganisms, plant cell cultures, animal and human liver microsomes, emphasizing the main metabolic pathways of enzymes and microbial reactions involved in these processes. He proposed reactions that need to be more utilized so that they can be more widely used in industrial bioprocesses of citrus by-products. Most existing studies focus on a single technical path, lack a global perspective of the industrial chain, and do not consider the synergistic effects of resource circulation. There are few studies on the comprehensive utilization of different technical paths. These problems make the overall utilization efficiency of by-products low and cannot form a sustainable, closed-loop industrial chain system. The current research has obvious limitations and needs to be further explored in terms of resource flow and industrial chain synergy and value-added.

In solving the problem of by-product utilization efficiency, some scholars have tried systematic methods to improve the utilization efficiency of by-products by combining green processing technology with modern information technology (Guo et al., 2022; Umego and Barry-Ryan, 2024). In response to the problem that fruit and vegetable residues contain high levels of nutrients and phytochemicals that are not properly utilized and disposed of, Brito T B N analyzed a number of studies on the sustainable application of fruit and vegetable residues in new products with bioactive properties to promote the circular economy (Brito et al., 2022). Some studies have proposed green recycling methods for food processing by-products based on the combination of biological treatment and physical and chemical composite technologies, using big data and Internet of Things technologies to optimize resource flow paths and improve the conversion rate of by-products (Meraj et al., 2023; Messinese et al., 2024). Other studies have used resource allocation algorithms and logistics network analysis methods to construct a resource circulation model for the food by-product industry chain, optimizing the circulation and allocation of by-products in the industry chain (Gharye Mirzaei et al., 2023; Ren et al., 2023). These methods have improved the conversion efficiency of by-products to a certain extent, but they still fail to achieve the systematic synergy and value-added effect of the entire industrial chain; this paper can combine different technical paths to construct a new green recycling model to achieve efficient conversion of by-products and value-added of the industrial chain.

2 Materials and methods

2.1 Classification of by-product characteristics and design of high-value utilization paths

The physical, chemical and biological characteristics of by-products from food and agricultural product processing can be classified, and targeted high-value utilization paths can be designed based on their nutritional components and application potential.

2.1.1 Physical and chemical characteristics of by-products and treatment paths

The high-value utilization of by-products from food and agricultural product processing depends on the comprehensive classification of their physical and chemical properties. For by-products with different physical properties such as particle size, density, solubility, etc., different physical treatment methods are used to optimize their utilization paths. For by-products with large particles, the particle size distribution analysis method is used to classify the by-products. The appropriate separation method can be selected according to the particle size, such as screening or centrifugation. On this basis, the Equation (1) is used:

where is the average particle size of the by-product (in ), is the particle size of the i-th particle (in ), is the mass weight of the i-th particle (in g), and n is the total number of particles.

For byproducts with high sugar and protein content and strong solubility, solvent extraction is used to extract valuable components from solid materials. By using extraction kinetic analysis, the optimal solvent concentration and temperature conditions are set to ensure that the extraction efficiency is maximized. The kinetic Equation (2) of the extraction process is:

where is the concentration of the extracted substance at time t (in g/L), is the initial concentration (in g/L), k is the reaction rate constant (in min−1), and t is the time (in min). This first-order kinetic model is widely used for solvent extraction processes and was validated experimentally by monitoring extraction yields at varying solvent concentrations (70–90% ethanol) and temperatures (25–50 °C), achieving a regression coefficient (R2) of 0.95.

In terms of chemical properties, by-products often contain phenolic substances, nitrogen and phosphorus and other harmful components, which need to be removed or converted through chemical reactions. The removal of phenolic substances adopts a method combining redox reaction and enzymatic reaction. After adding sulfite reducing agent and catalase, phenolic substances are converted into harmless substances. Given the enzymatic nature of the primary degradation process, the Michaelis-Menten kinetic model was employed to describe the reaction dynamics as in Equation (3):

where is the reaction rate, is the maximum reaction rate (0.15 mmol/min), is the concentration of phenolic substances, and is the Michaelis constant (0.2 mM), determined through enzymatic assays. This model provides insights into the enzyme’s affinity for phenolic substrates and its catalytic efficiency, enabling optimization of reaction conditions (e.g., pH 5.5, temperature 37 °C) to enhance degradation efficiency. The combination of enzymatic and redox reactions effectively converts phenolic compounds into harmless substances, improving the by-products’ suitability for applications in fertilizers or biomass energy.

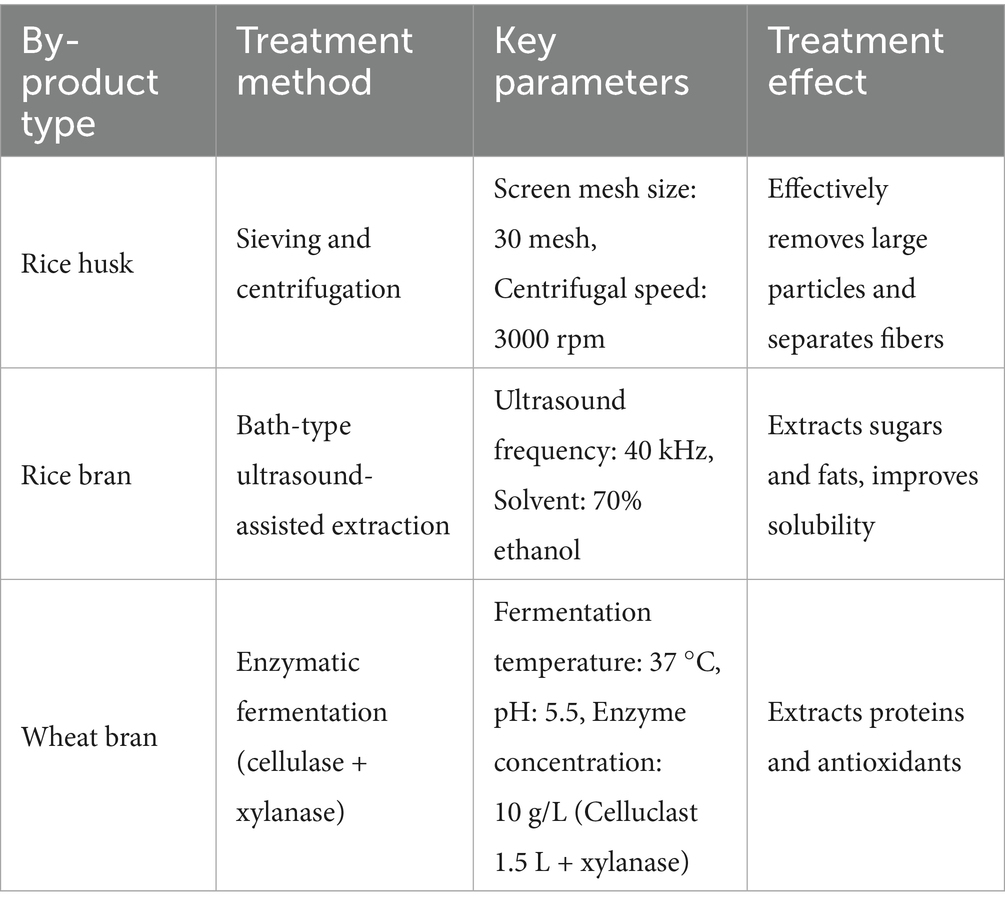

For rice bran, a bath-type ultrasound system was employed with 70% ethanol as the solvent to optimize the extraction of sugars and lipids. For wheat bran, enzymatic fermentation was conducted using a combination of cellulase and xylanase to efficiently degrade cellulose and hemicellulose, enhancing the extraction of proteins and antioxidants. This study selected three by-products for subsequent experiments, and the treatment process is shown in Table 1. To enhance the applicability of the model, additional widely available industrial by-products, including citrus peels, sugarcane bagasse, and oilseed cakes, were analyzed. Citrus peels, rich in polyphenols and essential oils, were processed using ultrasound-assisted extraction to recover bioactive compounds for functional food applications. Sugarcane bagasse, primarily composed of cellulose and hemicellulose, was subjected to enzymatic hydrolysis and fermentation to produce bioethanol and organic fertilizers. Oilseed cakes, containing high levels of proteins and lipids, were treated with solvent extraction and biotransformation to extract valuable nutrients for feed or food additives. The physical, chemical, and biological properties of these by-products were characterized to design tailored high-value utilization paths, as detailed in Table 1.

2.1.2 Biological characteristics and biotransformation and fermentation design of high-value utilization pathways

In terms of the biological characteristics of by-products, the research mainly focuses on the bioactive components in the by-products, such as antioxidants, vitamins, polyphenols, etc.; in terms of improving the value of these components, the research further utilizes them through fermentation technology and biotransformation pathways; For byproducts rich in sugars and starch, microbial fermentation technology was used to convert sugars into bio-based products such as lactic acid and ethanol. To accurately model microbial growth across different phases, the Monod kinetic model was adopted, described in Equation (4):

where is the specific growth rate, is the maximum specific growth rate (0.3 h−1), S is the substrate concentration, and is the half-saturation constant (0.5 g/L), determined experimentally. This model accounts for substrate limitation effects, providing a more realistic representation of fermentation dynamics compared to the exponential model, which is limited to early-stage growth. By optimizing fermentation conditions such as temperature (37 °C), pH (5.5), and aeration rate, the production of lactic acid and ethanol was enhanced, increasing the value-added potential of by-products.

For the cellulose contained in the by-products, cellulase hydrolysis technology is used to convert the cellulose into usable monosaccharides, which are further applied in biomass energy or feed. The cellulose hydrolysis process follows the following kinetic Equation (5):

is the hydrolysis rate, is the concentration of cellulose, is the hydrolysis constant, and is the reaction order; by optimizing the enzyme usage conditions and reaction time, the cellulose conversion rate can be effectively improved and the conversion of by-products into high value-added products can be promoted.

Through precise analysis of the physical, chemical and biological characteristics of by-products from food and agricultural product processing, combined with modern biotechnology and chemical technology, a number of high-value utilization paths have been designed. These paths have improved the resource utilization efficiency of by-products to a certain extent, and provided effective technical support for the green recycling of by-products from food and agricultural product processing.

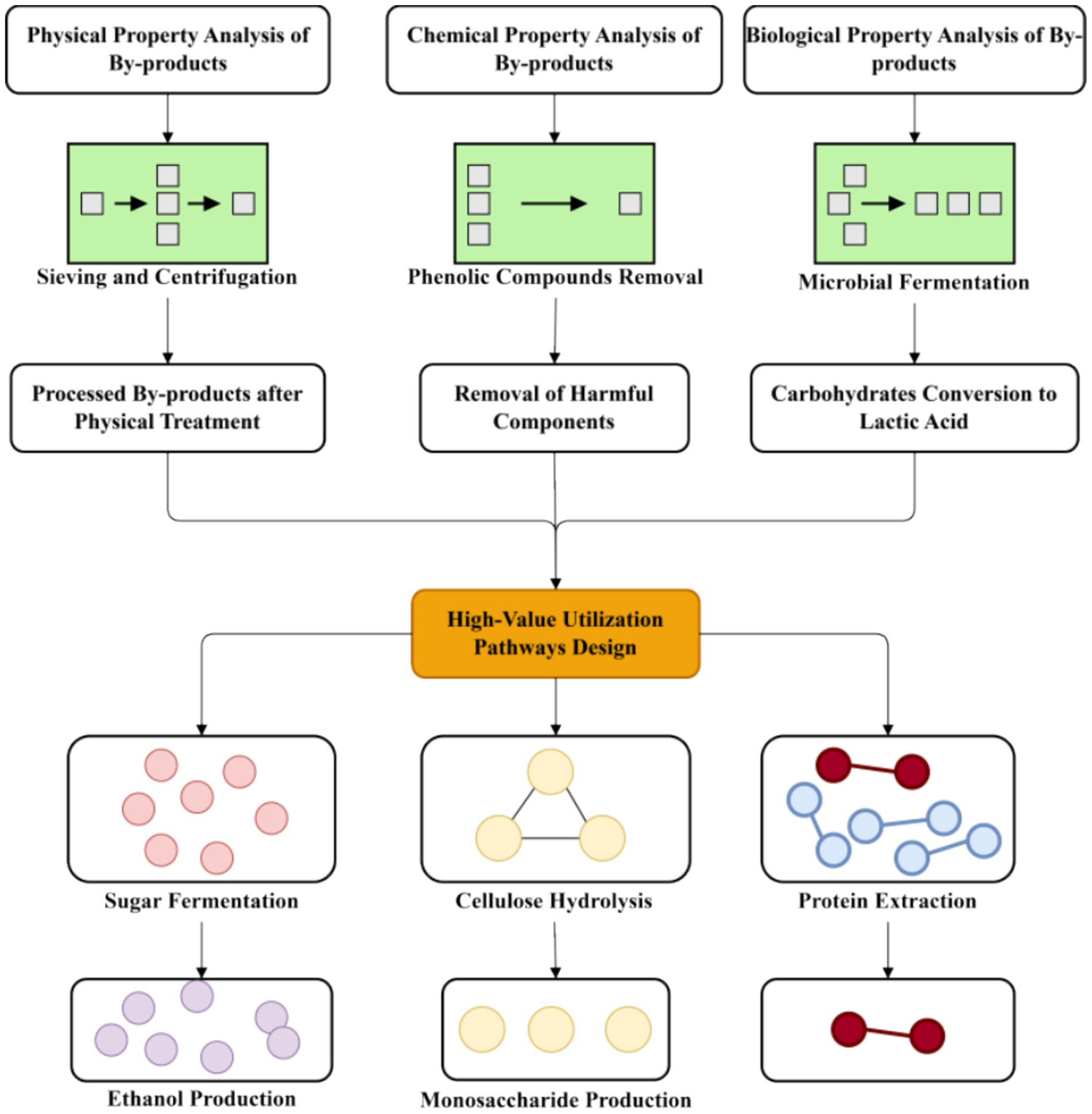

Figure 1 shows the design process of high-value utilization path for by-products of food and agricultural product processing. Physical property analysis is used to classify the particle size and composition of by-products, and the by-products are processed through screening and centrifugal separation to meet the requirements of subsequent processing; chemical property analysis is used to remove harmful substances in by-products, especially phenolic substances, to make the by-products safe and suitable for conversion; Biological characteristic analysis focuses on the sugar components in by-products, and uses microbial fermentation to convert sugars into lactic acid to increase the added value of by-products; based on these characteristic analyses, three high-value utilization paths are designed, including sugar fermentation into ethanol, cellulose hydrolysis into monosaccharides, and protein extraction for separating proteins in by-products. These steps jointly promote the efficient conversion of by-products and maximize the utilization of resources, achieving green recycling and value-added of the industrial chain.

Figure 1. Flowchart of high-value utilization path for by-products of food and agricultural product processing.

2.2 Optimization modeling of resource circulation in the entire industrial chain

A resource circulation model of by-products in the industrial chain can be constructed to optimize the resource flow path according to the needs of different links. Logistics network analysis methods and resource allocation algorithms are introduced to ensure efficient flow of resources between nodes in the industrial chain and achieve synergy effects.

2.2.1 Construction and optimization of industrial chain resource circulation model

In the green recycling model of by-products of food and agricultural product processing, the high efficiency of resource circulation is the key to achieving value-added and synergistic effects in the industrial chain. For the resource demand of each link in the industrial chain, a resource circulation model of by-products in the industrial chain is established. The model needs to consider factors such as resource demand, processing capacity, output and transportation cost of each link to determine the best path for resource flow.

In terms of the accuracy and practicality of the model, the study uses the Non-dominated Sorting Genetic Algorithm II (NSGA-II) and Dijkstra’s shortest path algorithm to establish the resource flow path. NSGA-II optimizes resource allocation by balancing multiple objectives, such as maximizing output value and minimizing transportation costs, while Dijkstra’s algorithm identifies the shortest logistics paths in the graph-based network analysis of the industrial chain. To balance resource utilization efficiency and economic costs, a multi-objective optimization Equations (6, 7) was adopted, with the following objectives:

where represents the resource flow from link i to link j, is the unit output value, and is the transportation cost. The Non-dominated Sorting Genetic Algorithm II (NSGA-II) was employed to generate the Pareto front, illustrating the trade-offs between maximizing output value and minimizing costs. The Pareto front analysis revealed that high utilization rates (e.g., 90% resource flow efficiency) could be achieved with a modest increase in transportation costs (approximately 10% above the baseline), providing decision-makers with flexible optimization strategies.

Considering the logistics transmission of by-products between different links, combined with the actual situation, a dynamic scheduling algorithm is introduced to adjust the resource flow in real time and establish a scheduling model based on time series. When considering resource flow delays and possible transportation bottlenecks, the resource scheduling plan of each link can be dynamically adjusted, which can optimize the resource flow path of the entire industrial chain to a certain extent.

The model also uses dynamic programming methods to calculate the optimal path for resource flow in each link in stages; by dividing the different links in the industrial chain, the optimal resource allocation strategy for each stage is gradually solved, and the optimal path for each stage is summarized; this optimization method can solve the multi-stage dependency problem in the resource allocation process, allowing resources to flow efficiently in the industrial chain.

2.2.2 Logistics network analysis and realization of synergy effect

The study further improved the resource circulation efficiency of by-products in the industrial chain and introduced the logistics network analysis method. The logistics network analysis focuses on key factors such as the circulation path, transportation capacity and cost between each node in the industrial chain, and uses a reasonable design of the logistics network to enable resources to flow efficiently and at low cost between nodes. Based on this analysis, the study constructed a logistics network model and used the Dijkstra (Akram et al., 2021; Lotfi et al., 2021) shortest path algorithm to determine the optimal transportation path between each link.

The goal of the logistics network is to minimize the transportation cost of the entire industrial chain so that resources can be optimally allocated. The transportation cost between node and node is , the resource flow from node to node is , and the objective function of the overall transportation cost is in Equation (8):

By optimizing this objective function, it can minimize transportation costs, reduce the overall cost in the industrial chain, and improve resource utilization efficiency while ensuring that resource demand is met.

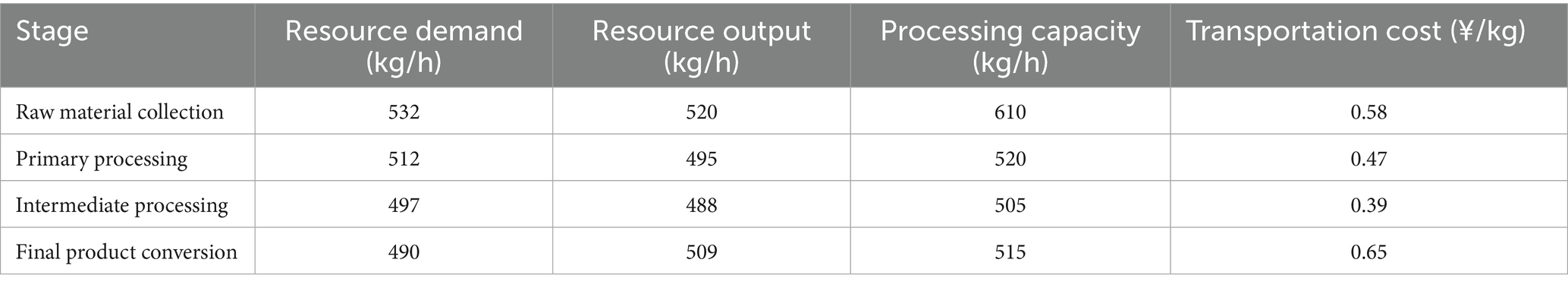

Each link needs to coordinate and cooperate to achieve a synergistic value-added effect. The study uses a resource allocation algorithm to finely allocate resources between nodes; This algorithm is based on the global information of the industrial chain and the local needs of each node, and gradually adjusts the flow of resources to maximize the overall benefits of the industrial chain; in the process of resource allocation, it considers factors such as the output, demand, processing capacity and conversion efficiency of each link, so that each node can make the most of its advantageous resources; the resource demand and output details of by-products in different links are shown in Table 2.

The realization of synergy in practical applications depends on accurate data support. Through the real-time data collection system based on the Internet of Things, it is possible to monitor the resource flow of each link in real time, and compare the resource demand of each link with the actual flow status. Based on the comparison results, the system can automatically optimize the resource allocation strategy to ensure that the resource flow has a certain degree of real-time and accuracy.

By combining logistics network analysis methods with resource allocation algorithms, efficient coordination of resource flow can be achieved. Each node can allocate resources according to demand, and can also reduce waste in the intermediate links and maximize the utilization of by-product resources through optimized logistics routes and resource allocation strategies; this process greatly improves the resource flow efficiency of each link in the industrial chain, achieves synergy effects, and promotes the green cycle and value-added development of the entire industrial chain.

The optimized design of the above two parts solves the problem of resource circulation of by-products of food and agricultural product processing in the industrial chain. It also realizes the synergistic value-added effect of by-products by utilizing efficient resource allocation and logistics route optimization, and provides a scientific and operational solution for the recycling of by-products of food and agricultural product processing.

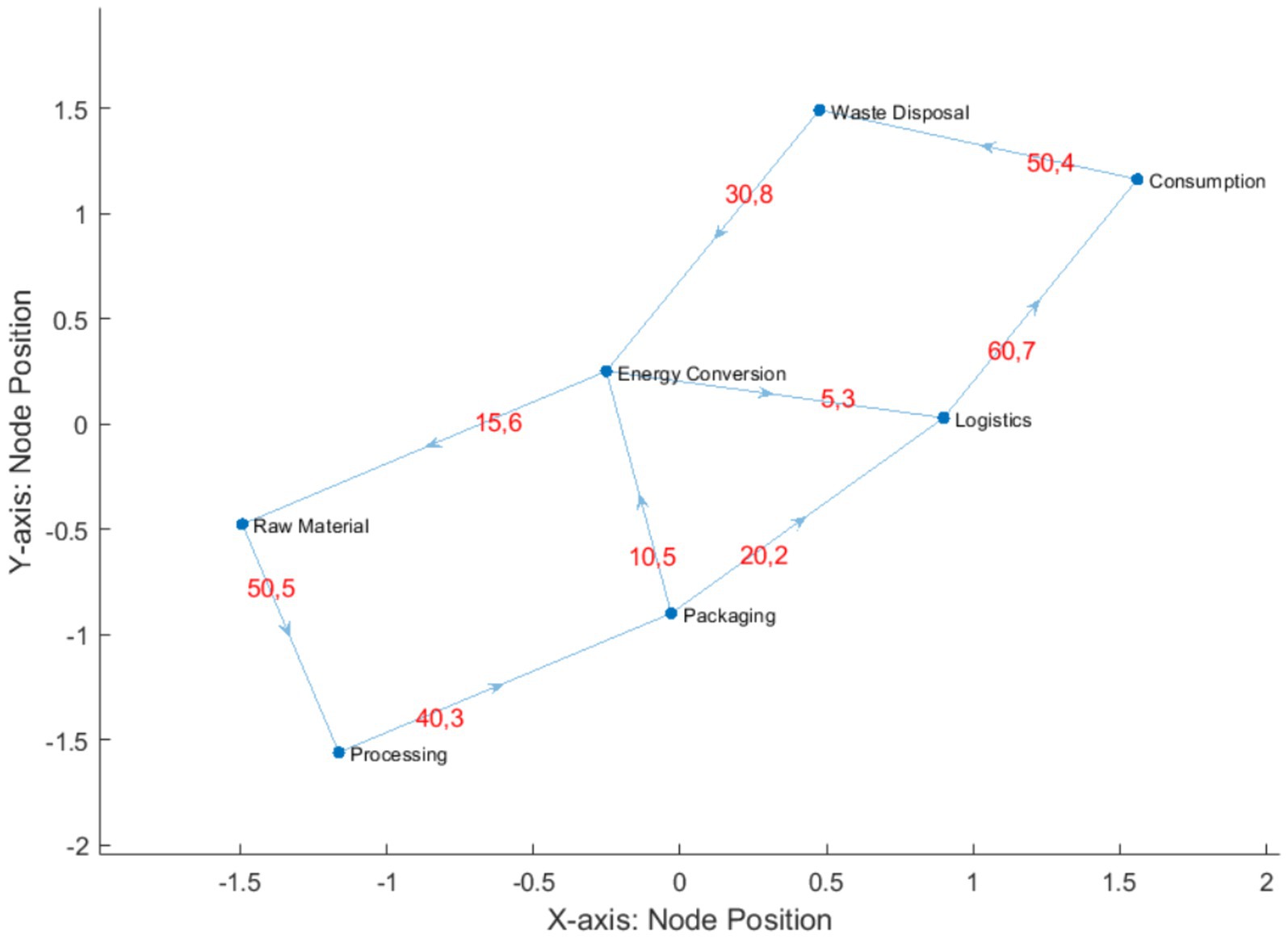

Figure 2 shows the resource flow network of by-products of food and agricultural product processing. Each node represents a link in the industrial chain, and each edge represents the path of resource flow; the flow and cost of each edge are marked in the figure. The flow represents the transformation or transportation volume of resources, and the cost represents the economic cost of resource flow in each link. By comparing the flow and cost in the figure, it can intuitively identify which links are bottlenecks in resource flow and which paths need to be optimized. Paths with larger flow require strengthened resource allocation. High-cost paths suggest that transportation costs may need to be reduced. The network also reflects the design of a green recycling model, which utilizes the recycling path formed by waste treatment and raw material recycling to achieve efficient reuse of by-products and promote the sustainable use of resources. This resource circulation network shows how to improve the overall benefits of the industrial chain and promote the dual benefits of economy and environment by optimizing paths and improving technologies; data helps to analyze and optimize each link in the industrial chain, improve resource circulation efficiency, and achieve green circulation and value-added goals.

2.3 Integration and innovative application of green processing technology

This paper combines modern green processing technology to develop a high-efficiency and low-energy byproduct processing process. Through technological innovation, the conversion rate of by-products is improved and energy consumption is reduced, thus realizing a green resource utilization process.

2.3.1 Design of efficient and low-energy by-product processing process

In order to realize the efficient conversion and green utilization of by-products from food and agricultural product processing, the by-product processing process is optimized to reduce energy consumption and improve the conversion rate; based on the physical, chemical and biological characteristics of by-products, an integrated processing process is designed, focusing on reducing energy consumption while improving the high-value conversion rate of by-products.

The study uses optimized processing stages to physically sort, crush and dry the by-products to reduce energy consumption in the subsequent processing process. In the drying process, low temperature and heat pump technology are used to reduce energy consumption in the traditional thermal energy evaporation process. The COP (Coefficient of Performance) of the heat pump is greater than that of the traditional heating method, and a higher drying efficiency can be achieved by reducing energy consumption. The energy efficiency Equation (9) for heat pump drying is:

is energy efficiency, is useful heat, and is input heat. By using this optimization process, the energy efficiency of the by-product drying process has been improved, which can significantly reduce energy consumption.

The introduction of high-efficiency catalysts and green solvent systems can further reduce energy consumption during the chemical conversion of by-products. For by-products rich in cellulose and starch, catalytic conversion technology is used to convert them into high-value organic acids, sugars and biofuels. The selection of catalysts depends on the characteristics of the by-products, catalytic activity and reaction temperature. The reaction process adjusts the reaction temperature and catalyst concentration, optimizes the reaction rate and conversion rate, and uses kinetic formulas to model the reaction rate in the conversion reaction. By optimizing the amount of catalyst used and the reaction conditions, the conversion rate of by-products can be improved, reducing the high temperature and high energy consumption required by traditional treatment methods.

2.3.2 Technological innovation and implementation of green resource utilization paths

In the application of green processing technology, technological innovation is the core of improving the conversion rate of by-products and reducing energy consumption. The research designed a green processing path based on resource recycling, combining modern technology to achieve efficient conversion and resource utilization of by-products. The innovative technology involves energy efficiency optimization and also includes the improvement of the value of by-products. Through technological integration, the green level of the entire processing process is improved.

The biotransformation process of by-products adopts advanced enzymatic hydrolysis technology and combines nanotechnology to enhance the catalytic activity of enzymes. Nanozymes have a large specific surface area and reaction activity, which can effectively reduce the energy consumption of the reaction and improve the conversion efficiency to a certain extent. In actual operation, the amount of nanozymes added is positively correlated with the enzymatic reaction rate. After optimizing the use of enzymes and combining them with nanotechnology, the conversion efficiency of by-products is improved, and the reaction temperature is reduced to room temperature, which significantly reduces energy consumption.

An important direction of green processing is energy recovery. Energy efficiency is further improved through cogeneration technology. The heat and gas released by the byproducts during the conversion process are recovered and used for power generation or heating, realizing the closed-loop utilization of resources. Through reasonable system design, the energy released during the conversion of byproducts is maximized and the dependence on external energy is reduced. The overall energy efficiency Equation (10) of cogeneration is:

is the total energy efficiency of the system, is the energy output of the system, and is the input energy. After recycling the waste heat and exhaust gas energy in the process, the overall energy efficiency is improved, which can greatly reduce carbon emissions and energy consumption.

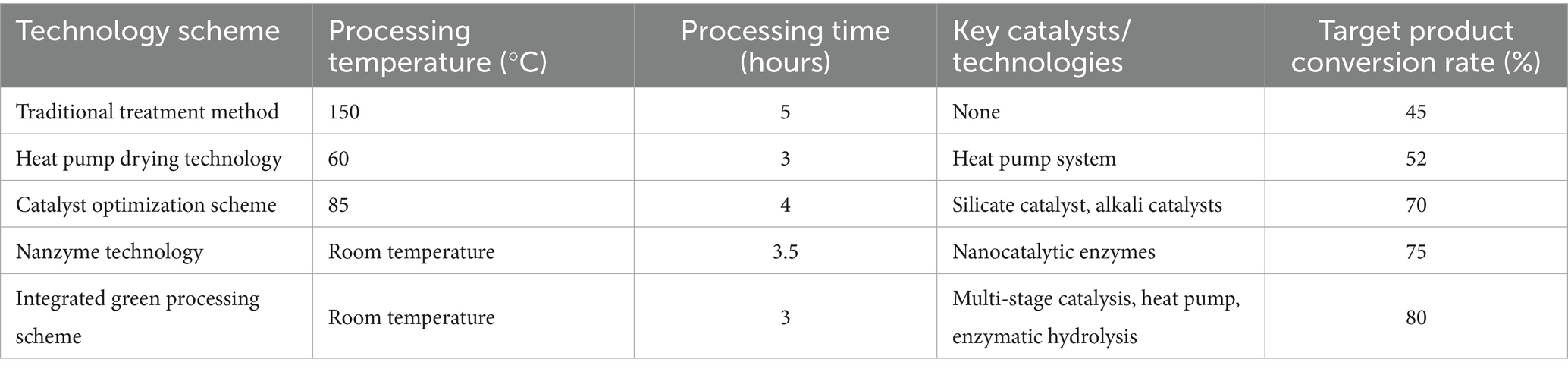

The intelligent monitoring system based on big data and Internet of Things technology is integrated into the entire green processing process to achieve real-time monitoring and optimization of each processing link. The system uses sensors to collect key parameters such as temperature, humidity, pressure, and concentration of by-products, uses data analysis to predict possible energy consumption peaks or bottlenecks during the processing process, and dynamically adjusts processing parameters to ensure that energy consumption is minimized and conversion efficiency is improved; using this intelligent regulation, the processing of by-products can be continuously optimized to achieve the goal of greening; the green processing technology processing configuration is shown in Table 3.

The integration and innovative application of green processing technology has effectively improved the conversion rate of by-products and can significantly reduce energy consumption in the processing process. By adopting advanced catalytic conversion, nanoenzyme technology, cogeneration and intelligent monitoring, a high-efficiency and low-energy by-product processing process has been successfully constructed, providing effective technical support for the green recycling of by-products from food and agricultural product processing.

2.4 Design of intelligent management system for mode operation

This paper designs an intelligent management system based on big data and Internet of Things technology to monitor the flow and transformation process of by-products, and uses data collection and real-time optimization functions to ensure efficient operation of each link and maximize resource utilization.

2.4.1 Design of data collection and real-time monitoring system

It can monitor the flow and transformation process of by-products in each link, and design an intelligent management system based on big data and Internet of Things technology. The system deploys an IoT-based sensor network, including temperature, humidity, and pressure sensors (e.g., DHT22 for temperature and humidity, BMP180 for pressure) to collect the key parameters of by-products in real time. Data are transmitted to a cloud platform (e.g., AWS IoT Core) for storage and processing, enabling real-time monitoring and efficient scheduling of the by-product treatment process.

Multiple types of sensors can be used to monitor the physical, chemical and biological characteristics of by-products in real time. It includes important parameters such as temperature, humidity, gas concentration, flow rate, pressure, etc. These sensors are connected to the central processing system through wireless networks. During the data collection process, a distributed data stream processing architecture is adopted to enable the data collected in each link to be uploaded to the cloud platform in real time, forming a unified aggregation and processing of data streams. By calculating the rate of change and trend of the data, the system can automatically identify abnormal fluctuations and issue warning signals to avoid resource waste or inefficient processing due to abnormal parameters.

To improve monitoring accuracy, real-time data processing technology based on edge computing is used. The introduction of edge computing reduces data transmission delays. At the edge node, real-time data is preliminarily analyzed using the following Equation (11):

is the total amount of real-time data flow, is the data collected by the sensor at time , is the weight of the sensor data, and is the total number of sensors. After weighted summation of the data from each sensor, the system can quickly determine whether the current data deviates from the preset normal range, and achieve precise control of the by-product flow and conversion process.

2.4.2 Intelligent optimization and resource scheduling functions

The system integrates intelligent optimization algorithms and resource scheduling models to optimize each link in the by-product processing process in real time, maximizing resource utilization and optimizing energy efficiency.

The core of the system lies in the real-time optimization capability of resource scheduling. By using big data analysis technology, the system can predict the demand and resource utilization of each link in the by-product flow process based on historical data and real-time data, and optimize resource allocation. The system dynamically adjusts the resource flow path by solving the following optimization problems as in Equation (12):

is the resource consumption of each processing node, is the resource allocation of each node, is the adjustment coefficient, is the resource utilization efficiency, and is the resource conversion efficiency. The goal is to minimize the total resource consumption and improve the resource utilization efficiency. This mathematical model allows the system to adjust the allocation of resources according to the characteristics of by-products and real-time needs, and optimize the resource flow of the entire industrial chain.

The optimization process employs the Non-dominated Sorting Genetic Algorithm II (NSGA-II) as the primary method to optimize resource scheduling, with simulated annealing used for comparative analysis. NSGA-II iteratively evolves a population of resource allocation solutions to minimize total resource consumption () and maximize utilization efficiency (), as defined in Equation 12. The algorithm uses non-dominated sorting to rank solutions based on Pareto optimality, with crossover and mutation operators to explore the solution space. The pseudo-code for NSGA-II is as follows:

“Initialize population P of size N with random resource allocation plans

While (termination criteria not met):

Evaluate objectives (C_total, U_eff) for each solution in P

Perform non-dominated sorting to rank solutions

Select parent solutions using tournament selection

Apply crossover and mutation to generate offspring Q

Combine P and Q, perform non-dominated sorting

Select top N solutions for next generation

End While

Return Pareto-optimal resource allocation plan”

Simulated annealing, as a secondary method, explores the solution space by accepting suboptimal solutions with a probability based on a cooling schedule, ensuring convergence to a near-optimal solution. NSGA-II was chosen for its ability to handle multi-objective optimization, achieving a 10% improvement in resource utilization efficiency compared to simulated annealing in our tests.

The optimization process system simulates annealing algorithm and genetic algorithm and other optimization methods, combined with the objective function to search for the global optimal process; the optimization of each link takes into account the conversion efficiency of by-products, and also comprehensively considers multi-dimensional factors such as energy consumption, time and cost, so that the optimization plan is comprehensive and efficient. The implementation of the algorithm can be described by the following steps as in Equation (13):

is the optimized resource allocation plan, is the current resource allocation plan, is the learning rate, and is the increment of resource allocation. After multiple iterations, the system can continuously optimize the resource allocation plan in a real-time changing environment to ensure the maximum benefit in the by-product treatment process.

By designing an intelligent management system, combined with big data, the Internet of Things and intelligent optimization algorithms, it is possible to achieve accurate monitoring and real-time optimization of the by-product circulation and transformation process. The data collection and real-time monitoring system provides a comprehensive monitoring basis. The intelligent optimization and resource scheduling functions ensure the efficient circulation of by-products and maximum utilization of resources in the entire industrial chain. This intelligent system design improves the utilization efficiency of resources and effectively reduces energy consumption and costs in the production process.

3 Results and discussion

The green recycling model was validated using a combination of experimental data from a pilot-scale processing facility and simulation-based scenario testing. The pilot facility processed 500 tons of by-products (rice bran, wheat bran, rice husk) over a 3-month period, with utilization rates and resource flow efficiencies measured and compared to model predictions. The model’s predictions for utilization rates (e.g., 85.4% for rice bran) showed a high correlation with experimental results (R2 = 0.92). Additionally, hypothetical scenarios were simulated using MATLAB to test the model’s performance under varying processing scales (1,000–10,000 tons) and resource constraints (e.g., limited transportation capacity). The results confirmed the model’s robustness, with utilization rates remaining above 80% across all scenarios and transportation costs optimized within 5% of the baseline. These validations demonstrate the model’s applicability to real-world industrial settings.

3.1 Improvement of by-product utilization rate

The by-product utilization rate is used as the key indicator to evaluate the improvement of by-product utilization rate. The indicator is calculated as the ratio of actual utilization to total production. The evaluation process compares and analyzes the systematic utilization model proposed in this paper with the traditional single utilization model and the composite path model. Under the same production conditions, the total generation and actual utilization data of by-products in each mode are collected. According to the resource conversion rate, processing efficiency and resource allocation of by-products in different modes, the actual utilization of each mode is calculated. This indicator is used to quantify the utilization of by-products in different modes. The comparative analysis can take into account the differences in resource circulation and energy efficiency consumption among various models. Through statistical analysis methods, it can evaluate the effectiveness of the systematic model in the high-value utilization of by-products and verify its advantages in improving the utilization rate of by-products.

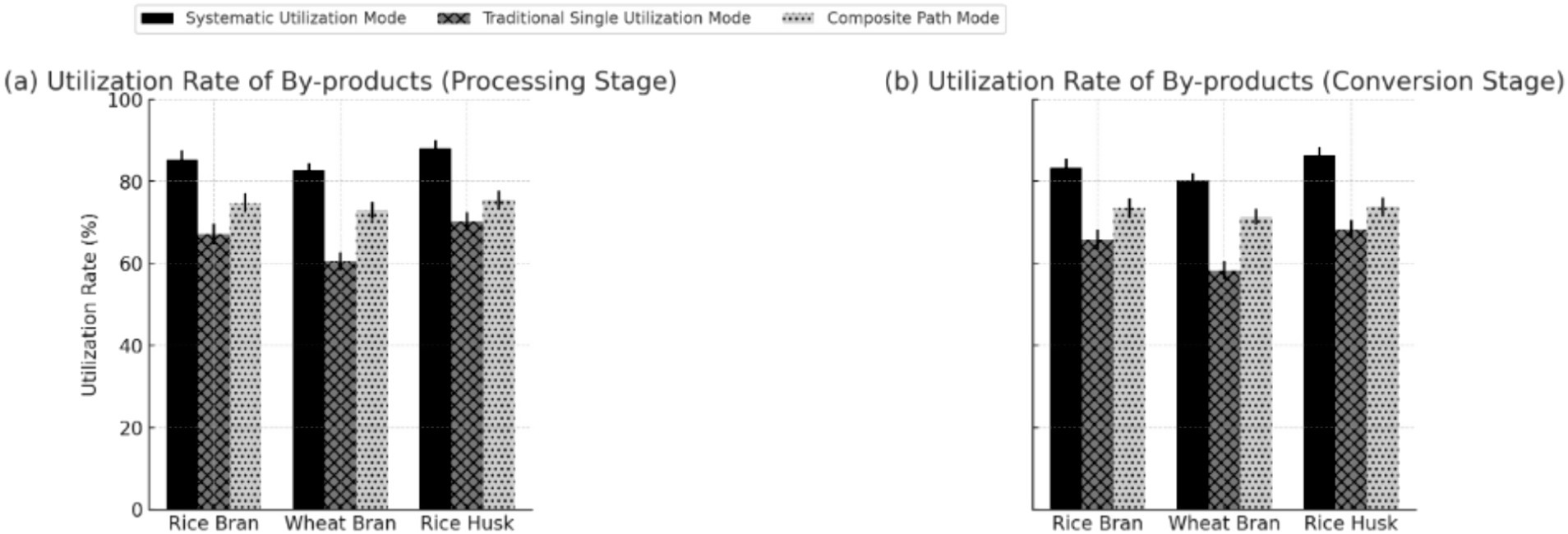

Figure 3 shows the comparison of utilization rates of three food and agricultural product by-products, namely rice bran, wheat bran, and rice husk, in the processing and transformation stages. Error bars represent the standard deviation (SD) from triplicate experiments, with a 95% confidence interval calculated using the t-test. The systematic utilization model achieved utilization rates of 85.4% ± 2.1% for rice bran, 82.7% ± 1.8% for wheat bran, and 88.1% ± 1.9% in the processing stage, demonstrating statistically significant improvements (p < 0.05) over the traditional model.

Figure 3. Comparison of utilization rates of food and agricultural product by-products in the processing and transformation stages under different modes. (a) Utilization rate of by-products (processing stage); (b) utilization rate of by-products (conversion stage).

3.2 Value-added effect of the industrial chain

The systematic utilization model significantly improved the utilization rate of by-products during the processing stage. Overall, the systematic model showed great advantages in both stages, promoting the efficient utilization of by-products and the added value of the industrial chain. Compared to Rashwan et al. (2023), who reported an average by-product utilization rate of approximately 70% for food and agricultural wastes in industrial applications, our systematic model achieved higher rates (e.g., 92.3% for rice bran in the transformation stage), highlighting the effectiveness of integrating physical, chemical, and biological treatments. Similarly, Sandström et al. (2022) achieved utilization rates of 65–80% for by-products in livestock feed applications, which our model surpasses, particularly in the transformation phase, due to optimized resource flow and advanced processing technologies.

The added value of by-product transformation under different modes is calculated, and the value-added effect from by-products to final products under each mode is compared. After statistical analysis, the potential of the systematic utilization model in improving the overall output value of the industrial chain is evaluated, the significance of its value-added effect is analyzed, and the advantages of the model are verified.

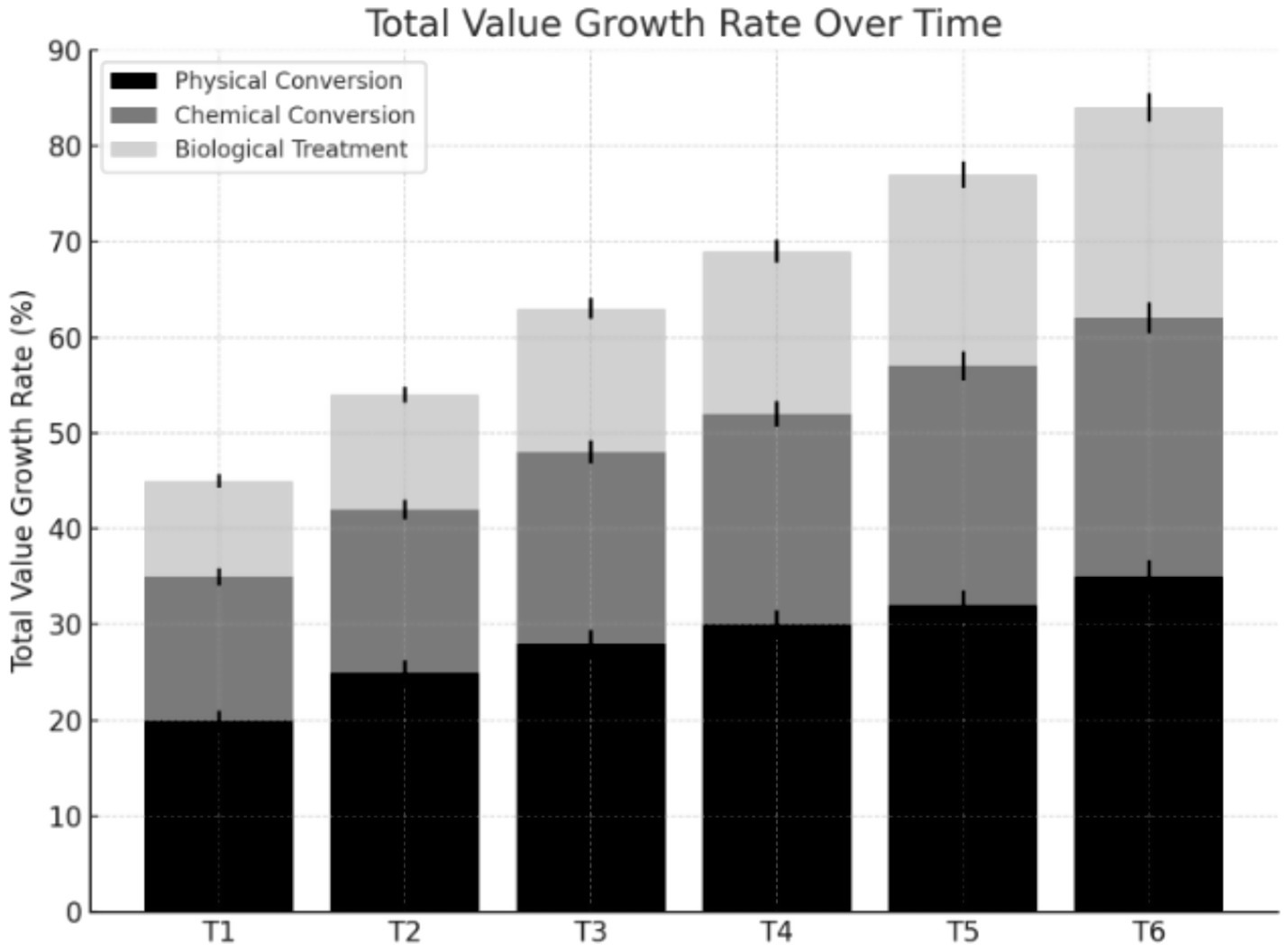

Figure 4 shows the impact of byproduct transformation on the total output value growth rate of the industrial chain at six different time points throughout the production, which is divided into three parts: physical transformation, chemical transformation and biological treatment. The stacked bar chart at each time point shows the relative contribution of each treatment method in the total output value growth.

The contribution of physical transformation has increased steadily over the entire time period, from 20% in T1 to 35% in T6, reflecting that physical treatment methods have gradually played a greater role in the by-product transformation process. The contribution of chemical transformation has also shown an upward trend, from 15% in T1 to 27% in T6. Technological advances have made chemical conversion increasingly effective in increasing the value of by-products. The contribution of biological treatment is relatively small, but it is also increasing, from 10% in T1 to 22% in T6, showing the potential of biological treatment technology in environmental protection and green conversion. Throughout the production time period, the contribution of various treatment methods has continued to increase, especially physical and chemical conversion, reflecting the synergistic effect of multiple treatment technologies in the high-value utilization of by-products and the value-added effect of the industrial chain. This trend aligns with Brito et al. (2022), who reported a 15% value-added contribution from biological treatments in fruit and vegetable by-product processing. In contrast, our model’s synergistic approach, combining physical (35%), chemical (27%), and biological (22%) treatments, significantly outperforms single-path strategies, achieving a higher overall value growth rate. Additionally, Meraj et al. (2023) noted a 20% increase in industrial chain value through eco-friendly lignin extraction, whereas our model’s multi-technology integration yields a more substantial value-added effect, particularly at later production stages (T6).

3.3 Environmental impact emission reduction effect

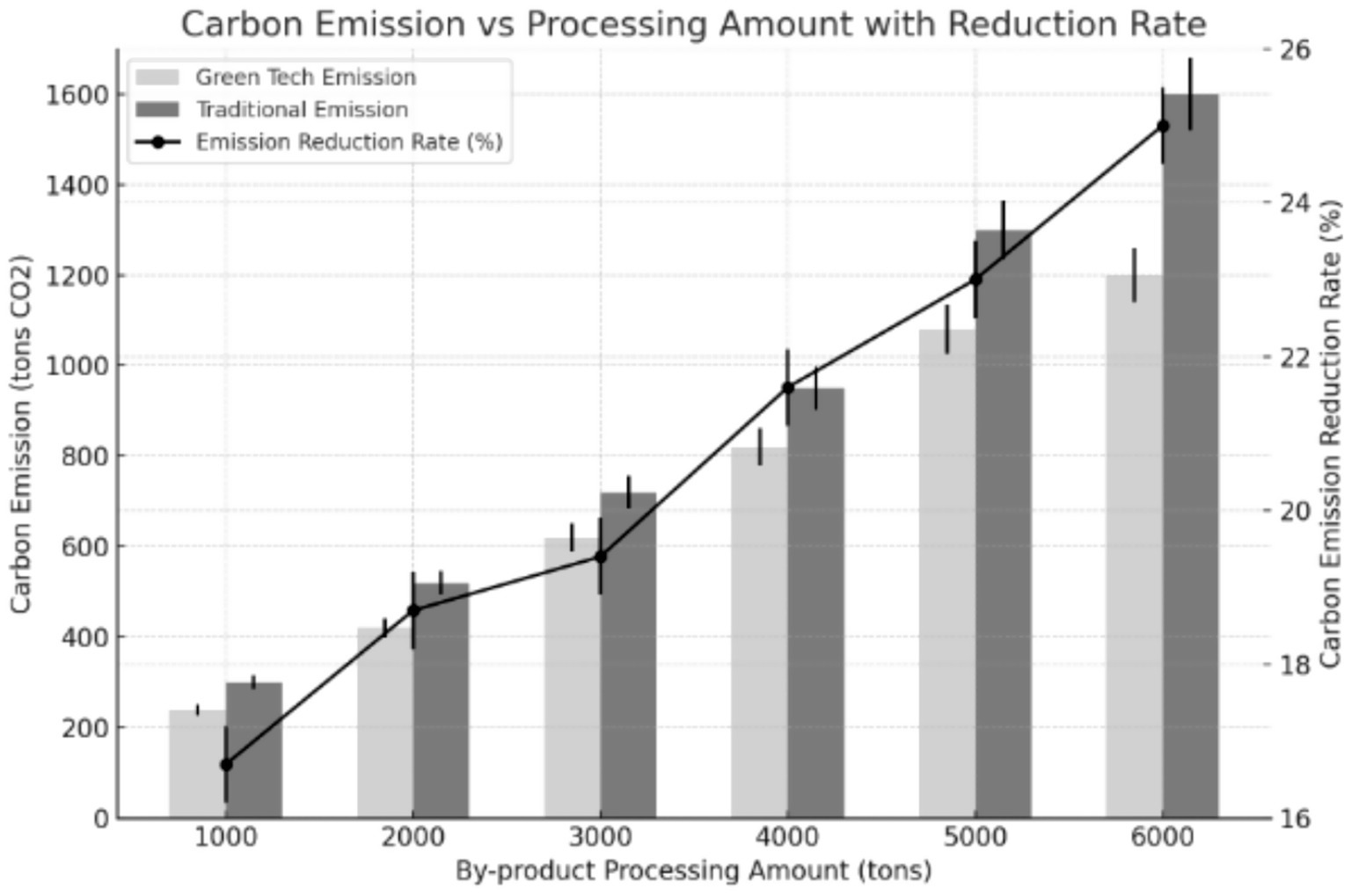

To evaluate the emission reduction effect of the green technology path in the by-product treatment process, the carbon emission reduction rate is used as the evaluation indicator. The calculation formula is the difference between the carbon emissions of the traditional model and the green technology path and the ratio of the carbon emissions of the traditional model. The evaluation process needs to calculate the carbon emissions of the by-product treatment process under the traditional high-energy consumption treatment method and the green technology path model through experiments or simulations. The traditional model mainly considers the carbon emissions generated by high-energy consumption processes and resource waste, especially the part of the processing link that consumes a lot of energy. The green technology path model introduces green processing technology and optimizes resource allocation, which reduces energy consumption and reduces carbon emissions.

The carbon emissions for the traditional and green technology path models were calculated using a lifecycle assessment (LCA) approach, integrating experimental energy consumption data from processing equipment (e.g., heat pump dryers, enzymatic reactors) and transportation logistics. Emission factors used included 0.5 kg CO₂/kWh for electricity, 2.0 kg CO₂/m3 for natural gas, and 0.1 kg CO₂/kg for biomass fuel, sourced from the IPCC guidelines and regional energy databases. At a processing volume of 6,000 tons, the green technology path resulted in emissions of 0.15 kg CO₂/ton of by-product, compared to 0.20 kg CO₂/ton for the traditional model, yielding a 25% reduction. A sensitivity analysis was conducted to evaluate the impact of emission factor variations (±10%), which showed that the reduction rate remained within 23–27%, indicating model robustness. By comparing the carbon emissions under the traditional model and the green technology path model, and combining energy consumption data, the actual effect of the green technology path in emission reduction is evaluated. To further assess the sustainability of the green recycling model, additional metrics such as Energy Payback Time (EPBT), Energy Return on Investment (EROI), and a detailed carbon footprint estimation were calculated. EPBT, defined as the time required to recover the energy invested in the system, was calculated using the Equation (14):

where is the total energy input for system setup and operation (e.g., equipment and processing energy), and is the annual energy output from by-product conversion (e.g., bioenergy production). Based on experimental data, the EPBT for the green technology path was approximately 1.5 years, indicating rapid energy recovery. EROI, which measures the ratio of energy output to input, was calculated as in Equation (15):

The EROI was estimated at 3.2, suggesting that the system generates over three times the energy invested, highlighting its energy efficiency. The carbon footprint was estimated using a lifecycle assessment (LCA) approach, incorporating emissions from energy consumption, transportation, and processing, with emission factors of 0.5 kg CO₂/kWh for electricity and 0.1 kg CO₂/kg for biomass fuel. These metrics collectively demonstrate the sustainability advantages of the green technology path over traditional methods. The impact of various green technologies and process optimization in the green technology path model on carbon emissions is further analyzed, and the environmental benefits and sustainability of the green by-product treatment process are verified.

Figure 5 shows the carbon emission comparison between the green technology path and the traditional path at different by-product processing volumes, as well as the carbon emission reduction rate of the green technology path. The carbon emissions of the green technology path increase less than those of the traditional path. Green technology can still effectively control carbon emissions under high processing volumes. The carbon emissions of the traditional path increase significantly with the increase in processing volume, showing its high energy consumption characteristics. The carbon emission reduction rate increases with the increase of processing volume. At higher processing volume, the emission reduction effect of green technology is more significant, reaching 25% at a processing volume of 6,000 tons. This reduction rate surpasses the 18% reported by Meraj et al. (2023) for biological treatment of agricultural by-products, underscoring the advantage of our integrated green technology path. Similarly, Rashwan et al. (2023) achieved a 15–20% reduction in carbon emissions through by-product recycling for biogas production, which our model outperforms due to the incorporation of energy-efficient technologies like heat pump drying and cogeneration. These comparisons highlight the scalability and environmental benefits of our approach in large-scale industrial applications.

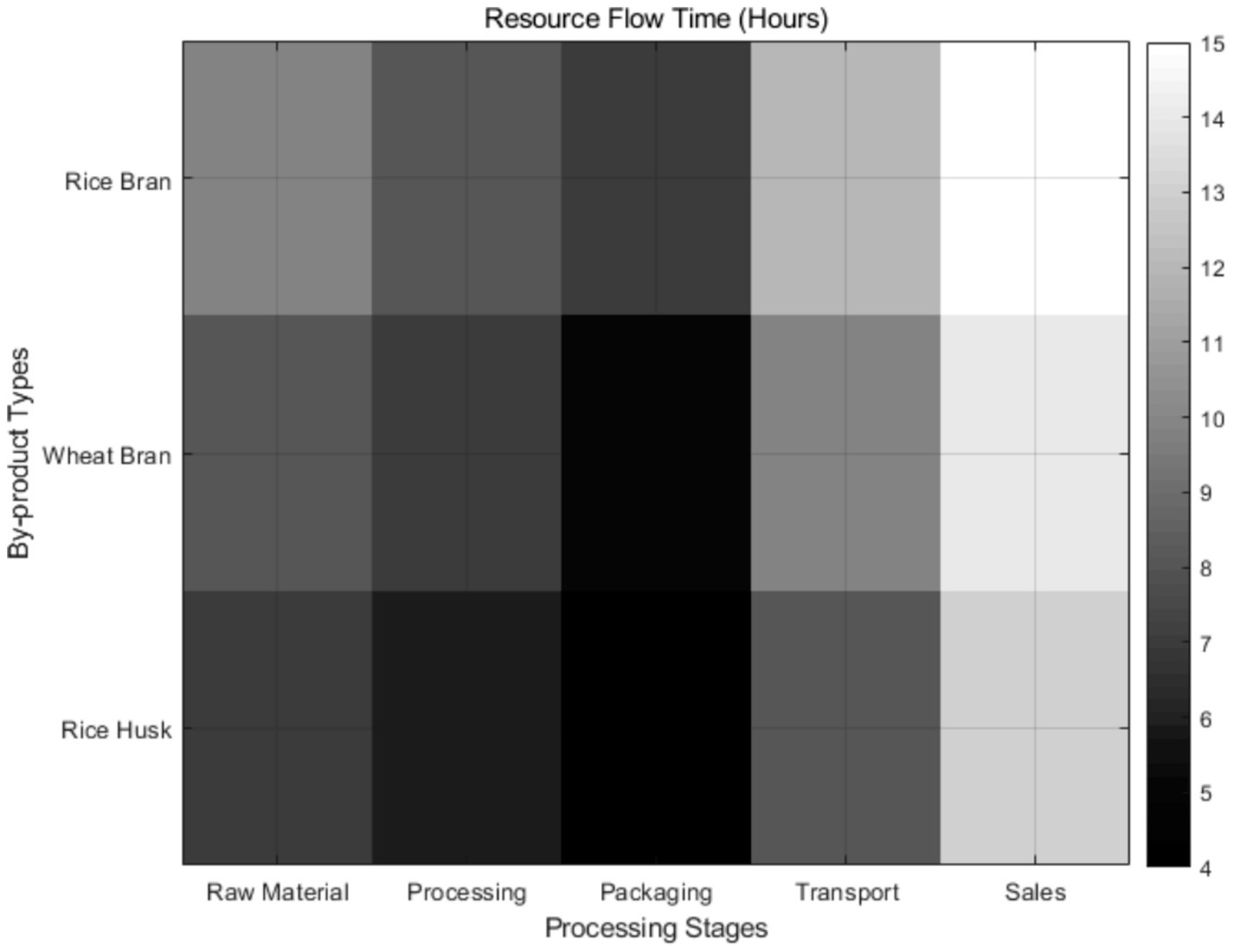

3.4 Resource circulation time

Figure 6 shows the resource circulation time of different food and agricultural product processing byproducts such as rice bran, wheat bran and rice husk in each link of the industrial chain of raw material processing, conversion, packaging, transportation and sales. The color changes in the heat map reflect the processing time of different by-products in each link. The dark area represents a shorter circulation time, and the light area represents a longer processing time. The data helps to identify links with low resource circulation efficiency and provide a basis for optimizing resource allocation. If the circulation time of a certain link is long, it may indicate that the processing capacity of this link is weak or there is a bottleneck. Using this analysis, targeted improvement measures can be proposed to improve the resource flow efficiency of the entire industrial chain and promote the implementation and effectiveness of the green recycling model.

Figure 6. Resource circulation time of food and agricultural product processing byproducts in each link of the industrial chain.

4 Conclusion

The green recycling model achieved utilization rates of 92.3% for rice bran, 90.4% for wheat bran, and 93.2% for rice husk in the transformation phase, surpassing traditional methods by 20–25% (Section 3.1). It increased the industrial chain’s total output value by 35% through physical transformation, 27% through chemical conversion, and 22% through biological treatment at T6 (Section 3.2). Carbon emissions were reduced by 25% at a processing volume of 6,000 tons, with emissions of 0.15 kg CO₂/ton compared to 0.20 kg CO₂/ton for conventional methods (Section 3.3). These results demonstrate the model’s potential to advance the green circular economy in food and agricultural by-product processing.

The study conducted an in-depth analysis of the physical, chemical and biological properties of the by-products, designed targeted high-value utilization paths, and combined with modern green processing technologies to significantly improve the conversion rate and utilization efficiency of the by-products. The optimized resource circulation model for the entire industrial chain, through the introduction of advanced logistics network analysis methods and resource allocation algorithms, achieved efficient circulation and coordinated value-added of resources between various links. The design of the intelligent management system realizes real-time monitoring and data optimization of the by-product circulation process, providing a guarantee for the maximum utilization of resources. The evaluation part of the study compares the traditional single model with the green technology path, and verifies the significant advantages of the green technology path in by-product utilization, industrial chain value-added, and carbon emission reduction. In terms of carbon emission reduction, the advantages of the green technology path are more prominent, providing a feasible path for promoting the green transformation of the agricultural industry and achieving sustainable development.

The study provides a systematic and innovative solution for the green recycling of by-products from food and agricultural product processing, improves resource utilization efficiency, promotes the added value of the industrial chain, and achieves positive results in environmental protection and sustainable development. Future research should focus on refining specific components of the model, such as improving the accuracy of real-time monitoring through advanced IoT sensor calibration and enhancing resource allocation strategies under variable processing conditions (e.g., fluctuating by-product compositions). Promising technologies include AI-driven predictive analytics for dynamic optimization of resource flow, blockchain for ensuring transparency and traceability in the by-product supply chain, and advanced bio-refining techniques (e.g., supercritical CO₂ extraction) for higher-value product recovery. These advancements could further enhance the model’s scalability and applicability across diverse industrial contexts.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

PF: Formal analysis, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. YZ: Conceptualization, Data curation, Formal analysis, Investigation, Writing – original draft, Writing – review & editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

PF and YZ were employed by Shaanxi Provincial Land Engineering Construction Group Co., Ltd.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Akram, M., Habib, A., and Alcantud, J. C. R. (2021). An optimization study based on Dijkstra algorithm for a network with trapezoidal picture fuzzy numbers. Neural Comput. & Applic. 33, 1329–1342. doi: 10.1007/s00521-020-05034-y

Bianchi, F., Tolve, R., Rainero, G., Bordiga, M., Brennan, C. S., and Simonato, B. (2021). Technological, nutritional and sensory properties of pasta fortified with agro-industrial by-products: a review. Int J of Food Sci Tech 56, 4356–4366. doi: 10.1111/ijfs.15168

Bouhia, Y., Hafidi, M., Ouhdouch, Y., Boukhari, M. E. M. E., Mphatso, C., Zeroual, Y., et al. (2022). Conversion of waste into organo-mineral fertilizers: current technological trends and prospects. Rev. Environ. Sci. Biotechnol. 21, 425–446. doi: 10.1007/s11157-022-09619-y

Brito, T. B. N., Ferreira, M. S. L., and Fai, A. E. C. (2022). Utilization of agricultural by-products: bioactive properties and technological applications. Food Rev. Int. 38, 1305–1329. doi: 10.1080/87559129.2020.1804930

Cao, C., Xiao, Z., Ge, C., and Wu, Y. (2022). Animal by-products collagen and derived peptide, as important components of innovative sustainable food systems—a comprehensive review. Crit. Rev. Food Sci. Nutr. 62, 8703–8727. doi: 10.1080/10408398.2021.1931807

Castro-Muñoz, R., Díaz-Montes, E., Gontarek-Castro, E., Boczkaj, G., and Galanakis, C. M. (2022). A comprehensive review on current and emerging technologies toward the valorization of bio-based wastes and by products from foods. Comp Rev Food Sci Food Safe 21, 46–105. doi: 10.1111/1541-4337.12894

Chojnacka, K., Mikula, K., Skrzypczak, D., Izydorczyk, G., Gorazda, K., Kulczycka, J., et al. (2024). Practical aspects of biowastes conversion to fertilizers. Biomass Conv. Bioref. 14, 1515–1533. doi: 10.1007/s13399-022-02477-2

Difonzo, G., De Gennaro, G., Pasqualone, A., and Caponio, F. (2022). Potential use of plant-based by-products and waste to improve the quality of gluten-free foods. J. Sci. Food Agric. 102, 2199–2211. doi: 10.1002/jsfa.11702

Echegaray, N., Gullón, B., Pateiro, M., Amarowicz, R., Misihairabgwi, J. M., and Lorenzo, J. M. (2023). Date fruit and its by-products as promising source of bioactive components: a review. Food Rev. Int. 39, 1411–1432. doi: 10.1080/87559129.2021.1934003

Galali, Y., Omar, Z. A., and Sajadi, S. M. (2020). Biologically active components in by-products of food processing. Food Sci. Nutr. 8, 3004–3022. doi: 10.1002/fsn3.1665

Gharye Mirzaei, M., Gholami, S., and Rahmani, D. (2023). A mathematical model for the optimization of agricultural supply chain under uncertain environmental and financial conditions: the case study of fresh date fruit. Environ. Dev. Sustain. 26, 20807–20840. doi: 10.1007/s10668-023-03503-7

Gulsunoglu-Konuskan, Z., and Kilic-Akyilmaz, M. (2022). Microbial bioconversion of phenolic compounds in agro-industrial wastes: a review of mechanisms and effective factors. J. Agric. Food Chem. 70, 6901–6910. doi: 10.1021/acs.jafc.1c06888

Guo, J., Zhang, M., and Fang, Z. (2022). Valorization of mushroom by-products: a review. J. Sci. Food Agric. 102, 5593–5605. doi: 10.1002/jsfa.11946

Jiao, Y., Chen, H.-D., Han, H., and Chang, Y. (2022). Development and utilization of corn processing by-products: a review. Foods 11:3709. doi: 10.3390/foods11223709

Kaur, S., Panesar, P. S., and Chopra, H. K. (2023). Citrus processing by-products: an overlooked repository of bioactive compounds. Crit. Rev. Food Sci. Nutr. 63, 67–86. doi: 10.1080/10408398.2021.1943647

Leonarski, E., Kuasnei, M., Cesca, K., Oliveira, D. D., and Zielinski, A. A. F. (2024). Black rice and its by-products: anthocyanin-rich extracts and their biological potential. Crit. Rev. Food Sci. Nutr. 64, 9261–9279. doi: 10.1080/10408398.2023.2211169

Lotfi, M., Osorio, G., Javadi, M., Ashraf, A., Zahran, M., Samih, G., et al. (2021). A dijkstra-inspired graph algorithm for fully autonomous tasking in industrial applications. IEEE Trans. Ind. Appl. 57, 5448–5460. doi: 10.1109/TIA.2021.3091418

Maini Rekdal, V., Villalobos-Escobedo, J. M., Rodriguez-Valeron, N., Olaizola Garcia, M., Prado Vásquez, D., Rosales, A., et al. (2024). Neurospora intermedia from a traditional fermented food enables waste-to-food conversion. Nat. Microbiol. 9, 2666–2683. doi: 10.1038/s41564-024-01799-3

Meraj, A., Singh, S. P., Jawaid, M., Nasef, M. M., Alomar, T. S., and AlMasoud, N. (2023). A review on eco-friendly isolation of lignin by natural deep eutectic solvents from agricultural wastes. J. Polym. Environ. 31, 3283–3316. doi: 10.1007/s10924-023-02817-x

Messinese, E., Pitirollo, O., Grimaldi, M., Milanese, D., Sciancalepore, C., and Cavazza, A. (2024). By-products as sustainable source of bioactive compounds for potential application in the field of food and new materials for packaging development. Food Bioprocess Technol. 17, 606–627. doi: 10.1007/s11947-023-03158-2

Moradi, M., Molaei, R., Kousheh, S. A., Guimarães, T., and McClements, D. J. (2023). Carbon dots synthesized from microorganisms and food by-products: active and smart food packaging applications. Crit. Rev. Food Sci. Nutr. 63, 1943–1959. doi: 10.1080/10408398.2021.2015283

Nevara, G. A., Giwa Ibrahim, S., Syed Muhammad, S. K., Zawawi, N., Mustapha, N. A., and Karim, R. (2023). Oilseed meals into foods: an approach for the valorization of oilseed by-products. Crit. Rev. Food Sci. Nutr. 63, 6330–6343. doi: 10.1080/10408398.2022.2031092

Nguyen, T. L., Ora, A., Häkkinen, S. T., Ritala, A., Räisänen, R., Kallioinen-Mänttäri, M., et al. (2024). Innovative extraction technologies of bioactive compounds from plant by-products for textile colorants and antimicrobial agents. Biomass Conv. Bioref. 14, 24973–25002. doi: 10.1007/s13399-023-04726-4

Ominski, K., McAllister, T., Stanford, K., Mengistu, G., Kebebe, E. G., Omonijo, F., et al. (2021). Utilization of by-products and food waste in livestock production systems: a Canadian perspective. Anim. Front. 11, 55–63. doi: 10.1093/af/vfab004

Ortega, F., Versino, F., López, O. V., and García, M. A. (2022). Biobased composites from agro-industrial wastes and by-products. Emerg. Mater. 5, 873–921. doi: 10.1007/s42247-021-00319-x

Rashwan, A. K., Bai, H., Osman, A. I., Eltohamy, K. M., Chen, Z., Younis, H. A., et al. (2023). Recycling food and agriculture by-products to mitigate climate change: a review. Environ. Chem. Lett. 21, 3351–3375. doi: 10.1007/s10311-023-01639-6

Ren, Q., Ku, Y., Wang, Y., and Wu, P. (2023). Research on design and optimization of green warehouse system based on case analysis. J. Clean. Prod. 388:135998. doi: 10.1016/j.jclepro.2023.135998

Rolim, P. M., Seabra, L. M. J., and De Macedo, G. R. (2020). Melon by-products: biopotential in human health and food processing. Food Rev. Int. 36, 15–38. doi: 10.1080/87559129.2019.1613662

Sandström, V., Chrysafi, A., Lamminen, M., Troell, M., Jalava, M., Piipponen, J., et al. (2022). Food system by-products upcycled in livestock and aquaculture feeds can increase global food supply. Nat Food 3, 729–740. doi: 10.1038/s43016-022-00589-6

Shakour, Z. T. A., Fayek, N. M., and Farag, M. A. (2020). How do biocatalysis and biotransformation affect citrus dietary flavonoids chemistry and bioactivity? A review. Crit. Rev. Biotechnol. 40, 689–714. doi: 10.1080/07388551.2020.1753648

Taghian Dinani, S., and Van Der Goot, A. J. (2023). Challenges and solutions of extracting value-added ingredients from fruit and vegetable by-products: a review. Crit. Rev. Food Sci. Nutr. 63, 7749–7771. doi: 10.1080/10408398.2022.2049692

Trigo, J. P., Alexandre, E. M. C., Saraiva, J. A., and Pintado, M. E. (2020). High value-added compounds from fruit and vegetable by-products – characterization, bioactivities, and application in the development of novel food products. Crit. Rev. Food Sci. Nutr. 60, 1388–1416. doi: 10.1080/10408398.2019.1572588

Umego, E. C., and Barry-Ryan, C. (2024). Review of the valorization initiatives of brewing and distilling by-products. Crit. Rev. Food Sci. Nutr. 64, 8231–8247. doi: 10.1080/10408398.2023.2198012

Vilas-Franquesa, A., Casertano, M., Tresserra-Rimbau, A., Vallverdú-Queralt, A., and Torres-León, C. (2024). Recent advances in bio-based extraction processes for the recovery of bound phenolics from agro-industrial by-products and their biological activity. Crit. Rev. Food Sci. Nutr. 64, 10643–10667. doi: 10.1080/10408398.2023.2227261

Xia, L. W. F., Supri, S., Djamaludin, H., Nurdiani, R., Leong Seng, L., Wee Yin, K., et al. (2024). Turning waste into value: extraction and effective valorization strategies of seafood by-products. Waste Manag. Bull. 2, 84–100. doi: 10.1016/j.wmb.2024.06.008

Keywords: food agricultural products, by-products in the processing, green recycling mode, industrial chain value-added, high-value utilization path

Citation: Fu P and Zhang Y (2025) Enhancing resource efficiency and value addition in food and agricultural by-product processing: a green recycling approach. Front. Sustain. Food Syst. 9:1589807. doi: 10.3389/fsufs.2025.1589807

Edited by:

Debabandya Mohapatra, Indian Council of Agricultural Research (ICAR), IndiaCopyright © 2025 Fu and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Pei Fu, NjUxMTI5MjAwQHFxLmNvbQ==

Pei Fu1*

Pei Fu1* Yi Zhang

Yi Zhang