- 1Food Technology Department, Faculty of Engineering, Bina Nusantara University, Jakarta, Indonesia

- 2Indonesian Coffee and Cocoa Research Institute (ICCRI), Jember, Indonesia

- 3Laboratory of Postharvest Science, Faculty of Agriculture, Kyushu University Motooka, Fukuoka, Japan

Coffee processing generates abundant by-products including husk, pulp, spent coffee grounds, and silver skin, which pose environmental challenges but potential as functional materials. This paper highlights recent advancements in the development of sustainable films enriched with coffee by-products for food packaging applications. Rich in lignocellulosic fibers, polyphenols, and antioxidants, by-products could be transformed into film-forming matrices, fillers, or bioactive additives to improve the bio/edible film performances. Tensile strength, elasticity, and thermal stability were improved through fiber and lignin content of coffee by-product inclusion. Their incorporation also improved barrier performance, reducing water vapor and gas permeability and enhancing ultraviolet (UV) resistance, thus extending food shelf life. Additionally, rich in biofunctional compounds such as caffeine and chlorogenic acid, these by-products significantly boost the films antioxidant and antimicrobial activities, offering protection against oxidative spoilage and microbial contamination. The challenges remained regarding material standardization, sensory impact, and large-scale application.

1 Introduction

Conventional plastics based on petroleum dominate packaging for food application because of their low cost, barrier properties, and durability, however, their environemntal shows significant ecological risks, with more than million ton accumulating in oceans and landfills every year (Plastics Europe, 2022). In response, research and industry efforts have increasingly focused on bio-based, biodegradable, and edible films obtained from eco-friendly resources, including polysaccharides, lipids, and proteins. Those type of materials not only provide reduced environmental footprints but can also be tailored with functional additives to enhance food preservation and safety.

Coffee (Coffea spp.) counts as among the most widely consumed on a global scale, with the market demonstrating expanded steadily due to rising consumption and a growing global population (McNutt and He, 2019). Cultivated in more than 80 countries, the coffee plant ranks among the top internationally traded commodities, following petroleum and mining industries (Campos-Vega et al., 2015). According to data from the Food and Agriculture Organization (FAO, 2021), Brazil led global green coffee production in 2021, with Vietnam and Indonesia ranking next. Despite the fruit’s widespread cultivation, only the beans are utilized, accounting for under 50% of the whole coffee fruit, are primarily used for consumption (Sengupta et al., 2020). After thermal processing, including drying and grinding, a considerable volume of waste is produced. Once the nutritional components are extracted from the beans, the total waste can reach up to 90–95% of the original fruit (Hernández-Varela and Medina, 2023).

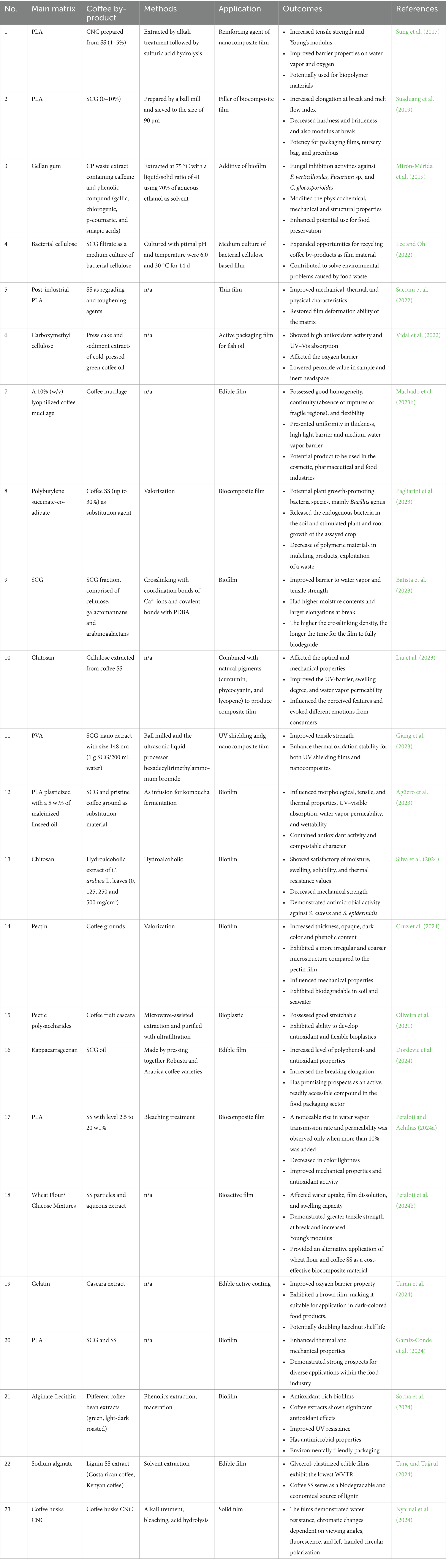

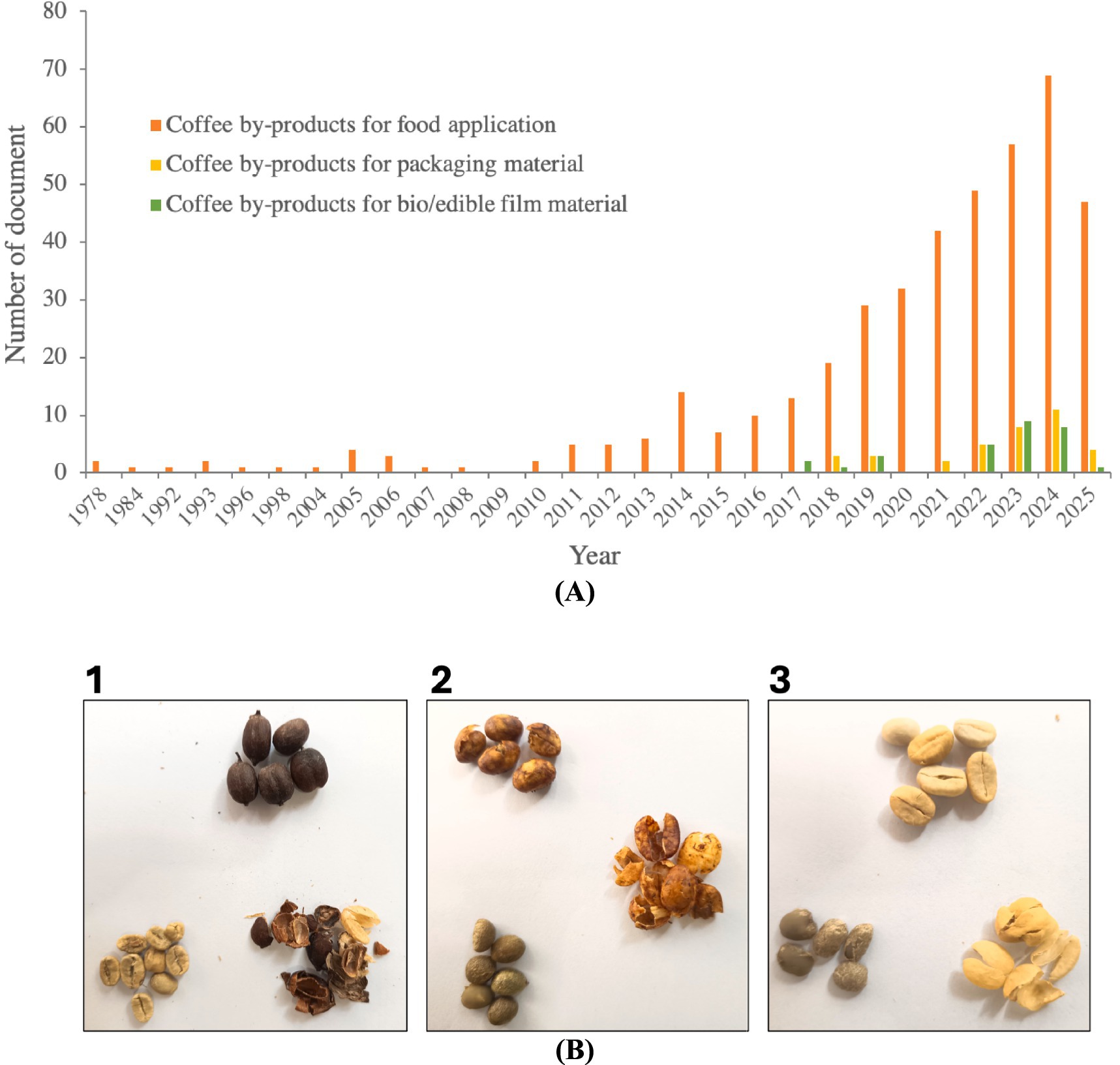

To address this waste issue, one promising approach is the conversion of coffee by-products into value-added products, bio-based or edible films as innovative sustainable packaging materials. This innovation aligns with the United Nations’ 2030 Sustainable Development Agenda, which emphasizes the need for immediate measures to address climate change (UN (United Nations), 2015). Utilization of coffee-derived residues for food purposes have gained notable interest, as demonstrated by 424 publications on the topic, with 36 and 29 studies specifically addressing packaging and edible film materials, respectively, as seen in Figure 1A. This paper aim to highlight recent advancements in the development of sustainable films enriched with coffee by-products, with a focus on their potential to improve material properties for food packaging applications.

Figure 1. (A) Number of Scopus-indexed annual reports, update-June 2025. (B) Coffee and its by-product from the final product. (1) Dry process (from top to clockwise direction): Whole dried bean, dried husk by-product containing dried skin, dried pulp, parchment and silverskin, and coffee green bean. (2) Honey/semi-wet process (from top to clockwise direction): Dried parchment coffee, by-product parchment covered in dried pulp, coffee green bean. (3) Wet process (from top to clockwise direction): Dried parchment coffee, parchment by-product, coffee green bean.

2 Methods

To collect relevant information, scientific publications from books and peer-reviewed journals were identified. Literature searches were conducted in databases including Scopus, and Google Scholar, using specific keywords such as “coffee by-product food,” “coffee by-product packaging,” and “coffee by-product bio edible film.” The titles, abstracts, and methods of the retrieved articles were screened to determine their relevance and alignment with the focus of this article.

3 Coffee by-products as matrix, added material and bioactive component of bio/edible film

Coffee processing generates substantial quantities of by-products with diverse chemical compositions, as seen in Figure 1B. Wet processing, involving multiple stages such as de-pulping, fermentation, washing, hulling, and polishing, produces various by-products: pulp, mucilage, wash water, coffee parchment (CP), and silver skin (SS) (Febrianto and Zhu, 2023). Conversely, using the dry process results solely in dried husk, a combination of mucilage, pulp, CP, and SS (dos Santos et al., 2021).

Wet processing offers more selective separation of by-products, enabling targeted utilization based on distinct chemical composition. As an agro-industrial by-product, coffee pulp is enriched with carbohydrates, pectin fractions, nitrogenous compounds, and bioactive phytochemicals. CP contains significant amounts of lignin, hemicellulose, and cellulose (Reis et al., 2020), while SS has a notable protein content (~20% dry weight) (Bessada et al., 2018). Additionally, Spent coffee grounds (SCG), a residue generated during instant coffee manufacturing, and green coffee sediments (GCS), derived from green coffee extract manufacturing, are both abundant in lignocellulosic materials and bioactives such as chlorogenic acid and caffeine (Ribeiro et al., 2018; Saratale et al., 2020; Dias et al., 2023).

These by-products has the potential to be upgraded into materials with added value, particularly for bio/edible film production. Dried materials such as husk, CP, and SS can be processed into fine powders or hydrolyzed into micro/nanocrystalline cellulose for use as functional additives (Sung et al., 2017; Suaduang et al., 2019; Sangta et al., 2024). Moist by-products like pulp and mucilage are suitable for bacterial cellulose production, while phenolic-rich SCG and GCS can be solvent-extracted to enhance film functionality. Lyophilized mucilage has also shown potential as a film-forming matrix (Lee and Oh, 2022; Machado and de Oliveira, 2023a), though its application faces technological barriers due to collection and drying challenges.

The integration of micro/nanocrystalline cellulose and bioactive extracts is increasingly attractive due to their versatility and compatibility with various film matrices. These components support improved transparency, reduced dependence on inorganic fillers, and enhanced antioxidant or antimicrobial properties (Janissen and Huynh, 2017; Boopasiri et al., 2023; Perera et al., 2023), as summarized in Table 1. However, excessive use of untreated husk can negatively affect film appearance (Borghesi et al., 2016). To optimize the potential of these by-products, alternative processes involving the bioactive extraction of materials followed by alkaline/acid hydrolysis can be employed to obtain both bioactive extract and crystalline cellulose (Ng et al., 2021). These materials have demonstrated compatibility with polylactic acid (PLA), polyvinyl alcohol (PVA), gelatin, carrageenan, pectin, and other biodegradable matrices, contributing both structural and biofunctional enhancements.

4 Mechanical and thermal characteristics

Mechanical and thermal properties serve as key elements in assessing the performance of bio/edible films. While some biopolymer matrices may have inherent limitations, the incorporation of fillers has been shown to enhance both properties significantly (Pires et al., 2024). Among various bio-based fillers, coffee by-products, particularly SCG and SS, have demonstrated promising effects in improving the physical properties of the films (Table 1), with CP emerging as a recent alternative.

Studies indicate that SCG and SS enhanced the thermal stability of biofilms, especially those based on PLA. Gamiz-Conde et al. (2024) reported that adding these by-products increased the PLA degradation temperature from 361.5 °C to 382 °C. This improvement was possibly due to the nucleation effect of bioactive compounds such as cellulose, hemicellulose, and lignin, which promote crystallinity and facilitate better thermal distribution (Shi et al., 2022). Furthermore, SCG’s antioxidant constituents, including caffeine and chlorogenic acid, contribute to improved thermal-oxidative stability in PVA-based nanocomposites (Giang et al., 2023). Mechanically, SCG and SS enhance the biofilm’s tensile strength and elasticity. Saccani et al. (2022) found that incorporating SS raised PLA’s elastic modulus by approximately 20%. Giang et al. (2023) observed a doubling of tensile strength from 24 MPa to 58 MPa without the addition of other fillers. These improvements were possibly due to the reinforcing effect of the high fiber content in SCG and SS (Hejna, 2020), as well as mechanisms involving particle dispersion strengthening and reinforcement by secondary phases (Petaloti and Achilias, 2024a). The presence of hydroxyl and other polar functional groups in SS and SCG could interact with polar biopolymers through hydrogen bonds or interfacial adhesion, enabling stress transfer from the biomatrix to the by-poduct filler, hence improving mechanical performance (Hejna, 2020). Additionally, SS and SCG contained bioactive compounds such as polyphenols (Hejna, 2020), presuming to stabilize polymers against oxidative degradation during processing or storage. However, excessive filler addition might negatively affect the film’s properties. High concentrations could lead to particle aggregation via Van der Waals forces, resulting in reduced elasticity and increased rigidity (Gamiz-Conde et al., 2024). Overloading could hinder polymer chain mobility, decreasing crystallization and thermal stability (Shi et al., 2022). Fillers above 5% have been associated with diminished mechanical and thermal performance (Gamiz-Conde et al., 2024). Nevertheless, the lack of standardized experimental protocols across studies complicates direct comparison of results. Differences in sample preparation, filler processing, and testing conditions may affect reproducibility and hinder consistent interpretation of findings. Additionally, the water activity of the by-products should be considered. Mirón-Mérida et al. (2019) reported that CP, due to its lower water activity, reduced tensile strength and elongation by limiting the plasticizing effect of glycerol.

5 Barrier properties

The exploration of bio-based edible films derived from coffee by-products has gained significant interest in response to the growing demand for sustainable packaging. Coffee SS and SCG, key by-products of coffee processing, are rich in bioactive compounds and contribute to enhanced film properties, particularly in terms of barrier performance against gases, water vapor, and UV light which influence product shelf life and quality, as summarized in Table 1. Lignin extracted from coffee SS demonstrated effective moisture barrier enhancement by lowering the water vapor transmission rate (WVTR), thereby extending food shelf life (Tunç and Tuğrul, 2024). Additionally, coffee-derived fillers reduced gas permeability, limiting oxygen and CO₂ diffusion, which were critical for preserving food freshness (Tunç and Tuğrul, 2024). This effect was attributed to the incorporation of lignin, which increased matrix hydrophobicity and compactness while reducing the polymer free volume for gas diffusion, thereby limiting water vapor transmission (Tunç and Tuğrul, 2024). Coffee extracts have also been reported to enhance UV barrier performance. Alginate-lecithin films enriched with medium-roasted coffee extracts significantly reduced UV transmission (200–400 nm), an advantage for protecting light-sensitive products (Socha et al., 2024). Cellulose-based films reinforced with natural pigments from coffee SS exhibited improved tensile strength and UV resistance, combining protective and aesthetic functions (Liu et al., 2023). This phenomenon was because polyphenols and melanoidins provided UV-absorbing chromophores and antioxidant activity that could prevent photodegradation and oxidative damage (Socha et al., 2024). However, while lipid plasticizers were used, they could enhance flexibility, they might also compromise barrier properties (Fadilla et al., 2023; Petaloti and Achilias, 2024a). Gas barrier properties could be highly influenced by the presence of chemical modifications or naturally derived additives in the films (Sisti et al., 2021). Natural additives like dyes enhanced both barrier efficiency and visual appeal without affecting the film’s sustainability (Sisti et al., 2021; Kruszelnicka et al., 2023). Despite these advances, the absence of standardized experimental protocols across studies leads to variability in reported results.

Optimizing formulations, such as varying the ratios of coffee by-products in polymer matrices, could tailor films for specific uses (Liu et al., 2023). Practical challenges remained, including film brittleness and excessive thickness, which hindered usability in commercial packaging (Fadilla et al., 2023). Lastly, the integration of safety regulations and consumer acceptance is essential to support the adoption of coffee by product-based edible films with desired barrier properties in the evolving market for biodegradable packaging (Oliveira et al., 2021).

6 Biofunctional features, sensory attributes, and scale-up

Coffee by-products, including pulp, husk, SS, and SCG, are rich in bioactive compounds such as chlorogenic acid, caffeic acid, and flavonoids. These compounds exhibit potent antioxidant, antifungal, and antibacterial properties, making coffee waste a promising sustainable ingredient in the development of bioactive edible coatings and films, as documented in Table 1.

Vidal et al. (2022) evaluated the antioxidant activity of cold-pressed green coffee oil (GCO), combined with press cake (CE) and sediment (SE) extracts, in carboxymethyl cellulose (CMC) films using the 2,2-diphenyl-1-picryl hydrazyl (DPPH) assay. Films containing CE and GCO (C-CE) or SE and GCO (C-SE) demonstrated significantly enhanced antioxidant properties, with C-CE and C-SE films recording 3.61 ± 0.01 and 2.03 ± 0.01 mmol Trolox equivalents/g dry weight, respectively. In contrast, plain CMC films showed no detectable antioxidant activity. The enhanced performance was attributed to the higher levels of chlorogenic acids and caffeine in CE and SE. Turan et al. (2024) incorporated cascara extract films made from gelatin and glycerol. All formulations exhibited DPPH radical scavenging activity exceeding 45% even after a tenfold dilution. Reducing the gelatin and glycerol content increased total phenolics, indicating that cascara extract was the main contributor to antioxidant activity. Dordevic et al. (2024) investigated the antioxidant potential of κ-carrageenan films containing SCG using ferric reducing antioxidant power (FRAP), 2,2-azino-bis (3-ethylbenzothiazoline-6-sulfonic acid) (ABTS), and cupric ion reducing antioxidant capacity (CUPRAC) assays. Films with more than 0.45% SCG showed enhanced activity in the FRAP assay, while the CUPRAC method indicated improved antioxidant potential across all SCG concentrations. ABTS results showed no significant improvement with SCG addition, emphasizing the influence of assay type on antioxidant assessment, as CUPRAC detected both hydrophilic and lipophilic compounds.

Mirón-Mérida et al. (2019) examined the antifungal properties of coffee parchment (CP) extract incorporated into gellan gum films. Films containing 8 mg of CP extract showed the highest antifungal activity against Fusarium verticillioides, Fusarium sp., and Colletotrichum gloeosporioides. In contrast, control films without CP showed no inhibition against Fusarium sp. and C. gloeosporioides, suggesting the activity stemmed from bioactives such as gallic acid, chlorogenic acid, p-coumaric acid, and caffeine. Variations in fungal sensitivity were attributed to film thickness, water sensitivity, and fungal cell wall differences. Silva et al. (2024) further demonstrated antibacterial activity of chitosan films incorporating coffee leaf extracts. These films inhibited Gram-positive bacteria (Staphylococcus aureus, Staphylococcus epidermidis) but not Gram-negative bacteria Pseudomonas aeruginosa, likely due to the latter’s outer membrane barrier. Chlorogenic acids contributed to the dual antioxidant and antimicrobial functionality, as also reported by Rebollo-Hernanz et al. (2023), reinforcing the potential of coffee by-products in multifunctional food packaging solutions. Yet, the absence of standardized protocols across assays and film preparations complicates result interpretation and limits cross-study comparability.

Due to the presence of phenolic compounds, aroma compounds, and textural components in coffee by-products, their incorporation may alter the sensory profile of bio/edible films by modifying the composition of volatile and non-volatile compounds, thereby affecting aroma, flavor, mouthfeel, and aftertaste. Shrestha et al. (2021) reported that higher incorporation of phenolic compounds intensified color, astringency, and mouthfeel, consequently altering the overall sensory profile of food products. Wan-Mohtar et al. (2025) explained that the taste and aroma of coffee influence consumer acceptance because of its distinct lipid, protein, and caffeine profiles compared to other beans. However, no studies have reported such phenomena in bio/edible films, opening opportunities to optimize the incorporation of coffee by-products in developing films that align with consumer preferences. Additionally, residual caffeine, tannins, and other phenolic compounds contained in the coffee by-products, at extreme concentrations, may exert cytotoxic effects, requiring careful toxicological assessment before their application in bio/edible film development (Mussatto et al., 2011).

Coffee by-product utilization faces challenges in consistent collection and drying due to seasonality, moisture content, and rapid spoilage. Coffee by-product streams are fragmented (household, commercial, industrial), are often wet and perishable so they need stabilization (e.g., drying), and show variable compositions that complicate consistent processing and quality control (Franca and Oliveira, 2022). Processing into standardized ingredients and integrating them into existing manufacturing lines remains difficult, with higher costs compared to conventional materials (Esquivel and Jiménez, 2011; Selvam et al., 2025). Furthermore, regulatory hurdles, particularly for food-contact applications, pose significant barriers to commercialization (Esquivel and Jiménez, 2011; Selvam et al., 2025).

7 Conclusions and future perspectives

Coffee by-products offer a promising, cost-effective, and environmentally sustainable alternative for improving the functional and ecological performance of bio/edible films. These agro-industrial residues exhibit a richness in biofunctional compounds such as polyphenols, caffeine, and dietary fibers, which contribute significant antioxidant, antimicrobial, and UV-barrier properties, making them ideal candidates for applications in active food packaging. Several studies indicate that adding coffee by-products into biopolymer matrices can enhance mechanical strength, water vapor barrier properties, as well as thermal stability, while extending the shelf life of highly perishable foods. Despite these encouraging findings, additional research is required to fully exploit the potential of coffee by-products in edible coating development. The future direction could involve the encapsulation and controlled release of coffee-derived bioactives within edible film matrices. Furthermore, the practical application of coffee by-product-based coatings on real food systems should be explored, along with thorough toxicological and sensory evaluations. These assessments are essential to ensure the safety, consumer acceptability, and to address potential concerns such as astringency when coffee-derived coatings are used in direct contact with food. Emerging technologies, such as nanotechnology for precise release mechanisms and 3D printing for customized edible film structures, may open new opportunities for designing next-generation coffee by-product-based packaging. Encapsulation strategies could help stabilize sensitive compounds while mitigating undesirable sensory impacts, thereby improving consumer perception. Integrating these advanced approaches will accelerate the translation of coffee by-product-based edible films from laboratory studies to commercial food applications.

Data availability statement

All relevant information is included in this article, and no additional datasets were produced or analyzed for the present study.

Author contributions

AW: Funding acquisition, Writing – review & editing, Writing – original draft, Validation, Data curation, Conceptualization. NF: Writing – review & editing, Writing – original draft. VM: Writing – review & editing, Writing – original draft. LW: Writing – review & editing, Writing – original draft. FN: Writing – review & editing, Writing – original draft. FuminT: Resources, Writing – review & editing, Writing – original draft. FumihT: Writing – review & editing, Resources, Writing – original draft.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by Research and Technology Transfer Office – Bina Nusantara University.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that Gen AI was used in the creation of this manuscript. The author(s) verify and take full responsibility for the use of generative AI in the preparation of this manuscript. Generative AI was used to make correction of grammatical error: chatGPT.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abbreviations

CNC, cellulose nanocrystals; CNF, cellulose nanofibers; CP, coffee parchment; PDBA, 1,4-phenylenediboronic acid; PLA, polylactic acid; PVA, polyvinyl alcohol; SCG, spent coffee grounds; SS, silver skin; WVTR, Water vapor transmission rate; UV, ultraviolet.

References

Agüero, A., Lascano, D., Ivorra-Martinez, J., Gómez-Caturla, J., Arrieta, M. P., and Balart, R. (2023). Use of bacterial cellulose obtained from kombucha fermentation in spent coffee grounds for active composites based on PLA and maleinized linseed oil. Ind. Crops. Prod. 202: 116971. doi: 10.1016/j.indcrop.2023.116971

Batista, M. J. P. A., Marques, M. B. F., Franca, A. S., and Oliveira, L. S. (2023). Development of films from spent coffee grounds’ polysaccharides crosslinked with calcium ions and 1,4-phenylenediboronic acid: a comparative analysis of film properties and biodegradability. Foods 12:2520. doi: 10.3390/foods12132520

Bessada, S., Alves, R., Costa, A., Nunes, M., and Oliveira, M. (2018). Coffea canephora silverskin from different geographical origins: a comparative study. Sci. Total Environ. 645, 1021–1028. doi: 10.1016/j.scitotenv.2018.07.201

Boopasiri, S., Sae-oui, P., Roamcharern, N., Jangpromma, N., Ngernyen, Y., and Siriwong, C. (2023). A bio-plastic composite film based on nanocrystalline cellulose-zinc oxide reinforced poly (lactic acid) with enhanced UV-shielding effect and antibacterial activity for food packaging applications. Food Packag. Shelf Life 38:101102. doi: 10.1016/j.fpsl.2023.101102

Borghesi, D. C., Molina, M. F., Guerra, M. A., and Campos, M. G. N. (2016). Biodegradation study of a novel poly-caprolactone-coffee husk composite film. Mater. Res. 19, 752–758. doi: 10.1590/1980-5373-MR-2015-0586

Campos-Vega, R., Loarca-Piña, G., Vergara-Castañeda, H. A., and Oomah, B. D. (2015). Spent coffee grounds: a review on current research and future prospects. Trends Food Sci. Technol. 45, 24–36. doi: 10.1016/j.tifs.2015.04.012

Cruz, R. M. S., Rainer, B., Wagner, I., Krauter, V., Janalíková, M., Vicente, A. A., et al. (2024). Valorization of cork stoppers, coffee-grounds and walnut shells in the development and characterization of pectin-based composite films: physical, barrier, antioxidant, genotoxic, and biodegradation properties. Polymers 16:1053. doi: 10.3390/polym16081053

Dias, L. D., Carbinatto, F. M., Almeida, I. S., Blanco, K. C., Marquele-Oliveira, F., Munari, C. C., et al. (2023). Eco-friendly extraction of green coffee oil for industrial applications: its antioxidant, cytotoxic, clonogenic, and wound healing properties. Fermentation 9:370. doi: 10.3390/fermentation9040370

Dordevic, D., Gablo, N., Zelenkova, L., Dordevic, S., and Tremlova, B. (2024). Utilization of spent coffee grounds as a food by-product to produce edible films based on κ-carrageenan with biodegradable and active properties. Foods 13:1833. doi: 10.3390/foods13121833

Esquivel, P., and Jiménez, V. M. (2011). Functional properties of coffee and coffee by-products. Food Res. Int. 46, 488–495. doi: 10.1016/j.foodres.2011.05.028

Fadilla, F. N., Rochima, E., Pratama, R. I., and Rostini, I. (2023). Physical characteristics of biocomposite edible film based on starch and nanochitosan with the addition of oil and acids: a review. Asian J. Fish. Aquat. Res. 22, 1–9. doi: 10.9734/ajfar/2023/v22i1560

Febrianto, N. A., and Zhu, F. (2023). Coffee bean processing: emerging methods and their effects on chemical, biological and sensory properties. Food Chem. 412:135489. doi: 10.1016/j.foodchem.2023.135489

Franca, A. S., and Oliveira, L. S. (2022). Potential uses of spent coffee grounds in the food industry. Foods 11:2064. doi: 10.3390/foods11142064

Gamiz-Conde, A. K., Burelo, M., Franco-Urquiza, E. A., Martínez-Franco, E., Luna-Barcenas, G., Bravo-Alfaro, D. A., et al. (2024). Development and properties of bio-based polymer composites using PLA and untreated agro-industrial residues. Polym. Test. 139:108576. doi: 10.1016/j.polymertesting.2024.108576

Giang, H. N., Tran, C. C., Huynh, T. N. A., and Doan, P. T. M. (2023). Spent coffee grounds utilization for green ultraviolet filter and nanocomposite fabrication. Express Polym Lett 17, 900–912. doi: 10.3144/expresspolymlett.2023.67

Hejna, A. (2020). Coffee Silverskin as a Potential Bio-Based Antioxidant for Polymer Materials: Brief Review. The First Int. Conf. Green Polym. Mater. 20:7220. doi: 10.3390/CGPM2020-07220

Hernández-Varela, J. D., and Medina, D. I. (2023). Revalorization of coffee residues: advances in the development of eco-friendly biobased potential food packaging. Polymers 15:2823. doi: 10.3390/polym15132823

Janissen, B., and Huynh, T. (2017). Chemical composition and value-adding applications of coffee industry by-products: a review. Resour. Conserv. Recycl. 128, 110–117. doi: 10.1016/j.resconrec.2017.10.001

Kruszelnicka, I., Michałkiewicz, M., Ginter-Kramarczyk, D., Muszyński, P., Materna, K., Wojcieszak, M., et al. (2023). Spent coffee as a composite filler for wastewater treatment. Materials 16:1181. doi: 10.3390/ma16031181

Lee, S. H., and Oh, H. W. (2022). A study on the production and quality characteristics of bacterial cellulose film using coffee by-products. Food Eng. Prog. 26, 195–202. doi: 10.13050/foodengprog.2022.26.3.195

Liu, X., Sun, H., and Leng, X. (2023). Coffee silverskin cellulose-based composite film with natural pigments for food packaging: physicochemical and sensory abilities. Foods 12:2839. doi: 10.3390/foods12152839

Machado, D. B., and de Oliveira, R. A. (2023a). Functional and technological properties of coffee mucilage (Coffea arabica) and its application in edible films. Quím. Nova 46, 778–784. doi: 10.21577/0100-4042.20230052

Machado, M., Espírito Santo, L., Machado, S., Lobo, J. C., Costa, A. S. G., Oliveira, M. B. P. P., et al. (2023b). Bioactive potential and chemical composition of coffee by-products: from pulp to silverskin. Foods 12:2354. doi: 10.3390/foods12122354

McNutt, J., and He, Q. (2019). Spent coffee grounds: a review on current utilization. J. Ind. Eng. Chem. 71, 78–88. doi: 10.1016/j.jiec.2018.11.054

Mirón-Mérida, V. A., Yáñez-Fernández, J., Montañez-Barragán, B., and Barragán Huerta, B. E. (2019). Valorization of coffee parchment waste (Coffea arabica) as a source of caffeine and phenolic compounds in antifungal gellan gum films. LWT 101, 167–174. doi: 10.1016/j.lwt.2018.11.013

Mussatto, S. I., Ballesteros, L. F., Martins, S., and Teixeira, J. A. (2011). Extraction of antioxidant phenolic compounds from spent coffee grounds. Sep. Purif. Technol. 83, 173–179. doi: 10.1016/j.seppur.2011.09.036

Ng, L. Y., Wong, T., Ng, C., and Chiang, A. (2021). A review on cellulose nanocrystals production and characterization methods from Elaeis guineensis empty fruit bunches. Arab. J. Chem. 14:103339. doi: 10.1016/j.arabjc.2021.103339

Nyaruai, C., Ollengo, M., and Muthakia, G. (2024). Iridescent patterns production from solid film cellulose nanocrystals prepared from coffee husks. Univ. J. Carbon Res. 22, 107–123. doi: 10.37256/ujcr.2120244851

Oliveira, G., Passos, C. P., Ferreira, P., Coimbra, M. A., and Gonçalves, I. (2021). Coffee by-products and their suitability for developing active food packaging materials. Foods 10:683. doi: 10.3390/foods10030683

Pagliarini, E., Totaro, G., Saccani, A., Gaggìa, F., Lancellotti, I., Di Gioia, D., et al. (2023). Valorization of coffee wastes as plant growth promoter in mulching film production: a contribution to a circular economy. Sci. Total Environ. 871:162093. doi: 10.1016/j.scitotenv.2023.162093

Perera, K. Y., Pradhan, D., Rafferty, A., Jaiswal, A. K., and Jaiswal, S. (2023). A comprehensive review on metal oxide-nanocellulose composites in sustainable active and intelligent food packaging. Food Chem. Adv. 3:100436. doi: 10.1016/j.focha.2023.100436

Petaloti, A.-I., and Achilias, D. S. (2024a). The development of sustainable biocomposite materials based on poly(lactic acid) and silverskin, a coffee industry by-product, for food packaging applications. Sustainability 16:5075. doi: 10.3390/su16125075

Petaloti, A.-I., Valtopoulou, A., Gkogkou, C., and Achilias, D. S. (2024b). An evaluation of the use of coffee silverskin particles and extracts as additives in wheat flour/glucose mixtures to produce bioactive films for food packaging. Appl. Sci. 14:7563. doi: 10.3390/app14177563

Pires, A. F., Díaz, O., Cobos, A., and Pereira, C. D. (2024). A review of recent developments in edible films and coatings—focus on whey-based materials. Foods 13:2638. doi: 10.3390/foods13162638

Plastics Europe (2022). Plastics – the Facts 2022. An analysis of the latest data related to plastics production, demand, conversion, and end-of-life management in Europe. Brussels: Plastics Europe.

Rebollo-Hernanz, M., Aguilera, Y., Gil-Ramírez, A., Benítez, V., Cañas, S., Braojos, C., et al. (2023). Biorefinery and stepwise strategies for valorizing coffee by-products as bioactive food ingredients and nutraceuticals. Appl. Sci. 13:14. doi: 10.3390/app13148326

Reis, R., Tienne, L., Souza, D., Marques, M., and Monteiro, S. (2020). Characterization of coffee parchment and innovative steam explosion treatment to obtain microfibrillated cellulose as potential composite reinforcement. J. Mater. Res. Technol. 9, 11747–11759. doi: 10.1016/j.jmrt.2020.05.099

Ribeiro, H. M., Allegro, M., Marto, J., Pedras, B., Oliveira, N. G., Paiva, A., et al. (2018). Converting spent coffee grounds into bioactive extracts with potential skin antiaging and lightening effects. ACS Sustain. Chem. Eng. 6, 6289–6295. doi: 10.1021/acssuschemeng.8b00108

Saccani, A., Fiorini, M., and Burzotta, G. (2022). Sustainable bio-composites obtained from recycling post-industrial PLA and fillers derived from coffee production. Recycling 7:89. doi: 10.3390/recycling7060089

Sangta, J., Ruksiriwanich, W., Chittasupho, C., Sringarm, K., Rachtanapun, P., Bakshani, C., et al. (2024). Utilization of the sugar fraction from Arabica coffee pulp as a carbon source for bacteria producing cellulose and cytotoxicity with human keratinocyte. Prep. Biochem. Biotechnol. 54, 587–596. doi: 10.1080/10826068.2023.2258195

Santos, E., Macedo, L., Tundisi, L. L., Ataide, J. A., Camargo, G., Alves, R., et al. (2021). Coffee by-products in topical formulations: a review. Trends Food Sci. Technol. 111, 378–388. doi: 10.1016/j.tifs.2021.02.064

Saratale, G., Bhosale, R., Shobana, S., Banu, R., Pugazhendhi, A., Mahmoud, E., et al. (2020). A review on valorization of spent coffee grounds (SCG) towards biopolymers and biocatalysts production. Bioresour. Technol. 314:123800. doi: 10.1016/j.biortech.2020.123800

Selvam, T., Rahman, N. M. A., Olivito, F., Ilham, Z., Ahmad, R., and Wan-Mohtar, W. A. Q. I. (2025). Agricultural waste-derived biopolymers for sustainable food packaging: challenges and future prospects. Polym. 17:1897. doi: 10.3390/polym17141897

Sengupta, B., Priyadarshinee, R., Roy, A., Banerjee, A., Malaviya, A., Singha, S., et al. (2020). Toward sustainable and eco-friendly production of coffee: abatement of wastewater and evaluation of its potential valorization. Clean Techn. Environ. Policy 22, 995–1014. doi: 10.1007/s10098-020-01841-y

Shi, K., Liu, G., Sun, H., Yang, B., and Weng, Y. (2022). Effect of biomass as nucleating agents on crystallization behavior of polylactic acid. Polymers 14:4305. doi: 10.3390/polym14204305

Shrestha, T. D., Kunathigan, V., Kitsawad, K., and Panprivech, S. (2021). Impact of fermentation conditions on the extraction of phenolics and sensory characteristics of mangosteen wine. Appl. Sci. Eng. Prog. 14, 406–416. doi: 10.14416/j.asep.2020.05.001

Silva, A. C., dos Santos Valle, A. B. C., de Oliveira Lemos, A. S., Campos, L. M., Fabri, R. L., Costa, F. F., et al. (2024). Development and characterization of chitosan film containing hydroethanolic extract of Coffea arabica leaves for wound dressing application. Mater Today Commun 38:108503. doi: 10.1016/j.mtcomm.2024.108503

Sisti, L., Celli, A., Totaro, G., Cinelli, P., Signori, F., Lazzeri, A., et al. (2021). Monomers, materials and energy from coffee by-products: a review. Sustainability 13:921. doi: 10.3390/su13126921

Socha, R., Such, A., Wisła-Świder, A., Juszczak, L., Nowak, E., Bulski, K., et al. (2024). Edible alginate–lecithin films enriched with different coffee bean extracts: formulation, non-cytotoxic, anti-inflammatory and antimicrobial properties. Int. J. Mol. Sci. 25:2093. doi: 10.3390/ijms252212093

Suaduang, N., Ross, S., Ross, G. M., Pratumshat, S., and Mahasaranon, S. (2019). Effect of spent coffee grounds filler on the physical and mechanical properties of poly(lactic acid) bio-composite films. Mater Today Proc 17, 2104–2110. doi: 10.1016/j.matpr.2019.06.260

Sung, S. H., Chang, Y., and Han, J. (2017). Development of polylactic acid nanocomposite films reinforced with cellulose nanocrystals derived from coffee silverskin. Carbohydr. Polym. 169, 495–503. doi: 10.1016/j.carbpol.2017.04.037

Tunç, M., and Tuğrul, N. (2024). Development and characterization of edible packaging film, with anise or cinnamon essential oil addition, plasticized with glycerol or sorbitol or polyethylene glycol, using lignin extracted from coffee silverskin. Bradleya 42, 1–5. doi: 10.61586/x0erl

Turan, D., Wang, Y., Grundmann, D., Paillart, M., Dieleman, R., and Rahn, A. (2024). Coffee by-product cascara as an edible active coating for enhancing hazelnut preservation and packaging. Food Packag. Shelf Life 45:101350. doi: 10.1016/j.fpsl.2024.101350

UN (United Nations). (2015). Global Sustainable Development Report. Available at: https://www.un.org/en/development/desa/publications/global-sustainable-development-report-2015-edition.html (Accessed on August 20, 2025).

Vidal, L. O., Santos, M. C. B., Batista, A. P., Andrigo, F. F., Baréa, B., Lecomte, J., et al. (2022). Active packaging films containing antioxidant extracts from green coffee oil by-products to prevent lipid oxidation. J. Food Eng., 312: 110744. doi: 10.1016/j.jfoodeng.2021.110744

Keywords: packaging, polysaccharide, quality, preservation, food

Citation: Wardana AA, Febrianto NA, Marcellino V, Wigati LP, Nkede FN, Tanaka F and Tanaka F (2025) Potency of coffee by-products as sustainable added material in bio/edible film development. Front. Sustain. Food Syst. 9:1667255. doi: 10.3389/fsufs.2025.1667255

Edited by:

Deepika Kohli, Vignan's Foundation for Science, Technology and Research, IndiaReviewed by:

Josue David Hernández-Varela, National Polytechnic Institute (IPN), MexicoMalinee Sriariyanun, King Mongkut's University of Technology North Bangkok, Thailand

Copyright © 2025 Wardana, Febrianto, Marcellino, Wigati, Nkede, Tanaka and Tanaka. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ata Aditya Wardana, YXRhLndhcmRhbmFAYmludXMuYWMuaWQ=

Ata Aditya Wardana

Ata Aditya Wardana Noor Ariefandie Febrianto

Noor Ariefandie Febrianto Vincensius Marcellino

Vincensius Marcellino Laras Putri Wigati3

Laras Putri Wigati3 Fumihiko Tanaka

Fumihiko Tanaka