- 1Department of Industrial Engineering, University of Salerno, Fisciano, Italy

- 2ProdAl Scarl, c/o University of Salerno, Fisciano, Italy

- 3Laboratory of Natural Substances (LSN), National Institute of Research and PhysicoChemical Analysis (INRAP), Sidi Thabet, Tunisia

- 4Faculty of Pharmacy, University of Coimbra, Polo III, Azinhaga de Stª Comba, Coimbra, Portugal

- 5Center for Study in Animal Science (CECA), ICETA, University of Porto, Apartado, Porto, Portugal

- 6Associate Laboratory for Animal and Veterinary Sciences (Al4AnimalS), Lisbon, Portugal

Introduction: The valorization of agrifood residues into phenolic-rich extracts represents a promising approach to reduce residues and recover resources within a circular economy framework.

Methods: In this study, a comparative Life Cycle Assessment (LCA) of three extraction processes from agrifood by-products was conducted, namely date pits powder, citrus by-products, and cherry press-cake, producing phenolic-rich extracts to be applied in packaging, food, and cosmetic products. Using the ReCiPe 2016 method and a functional unit of 1 kg of total phenolic compounds (TPC), environmental impacts across 18 categories were assessed from a gate-to-gate perspective.

Results and discussion: The extracts from date pits powder, citrus by-products, and cherry press-cake showed TPC of 243 ± 5.6 mg GAE/g extract, 33.57 ± 0.07 mg GAE/g extract, and 445 ± 5 mg GAE/g extract, respectively. Results identified electrical energy consumption as the dominant contributor to environmental burdens in all scenarios, due to the energy-intensive steps of freeze-drying and chemical treatments. The citrus by-products scenario exhibited the lowest environmental impacts due to simplified processing and effective ethanol recovery, despite the total biomass valorization not being considered. In contrast, the cherry press-cake upcycling pathway showed the highest environmental footprint, primarily due to the cascade extraction method implemented. Date pits powder valorization presented an intermediate trend, where the high resource usage was balanced with the total valorization of the biomass to obtain cellulose nanocrystals (CNC). The findings highlight a critical trade-off between environmental performance and resource efficient use, emphasizing the need for the individuation of alternative unit operations, focusing particularly on the reduction of energy usage, to enhance the sustainability of biomass valorization processes in view of their industrial application.

1 Introduction

In the context of the increasing global concerns about environmental sustainability and food security, the valorization of agrifood by-products has emerged as a critical strategy to reduce waste, recover valuable resources, and support circular economy strategies (Mirabella et al., 2014; Carpentieri et al., 2021). Traditionally regarded as low-value residues, agrifood by-products are increasingly recognized for their rich content of functional compounds which can be repurposed for applications in food, cosmetic, and pharmaceutical products (Del Rio Osorio et al., 2021; Rațu et al., 2023). This paradigm shift is driven not only by the need of improving resource efficiency but also by growing consumer demand for natural ingredients and sustainable production practices (Aschemann-Witzel et al., 2020). Among the various industrial agro-industrial residues, conventionally used either as animal feed or soil fertilizer, date pits, citrus by-products, and cherry press-cake stand out due to their significant compositional value. Date pits, a by-product generated from the date processing industry, account for 10–15% of date fruits. Over 990,000 tons of date pits are produced annually, considering that the global production of this fruit was more than 9.9 million tons in 2023 (Keskin et al., 2025). Date pits contain 60–80% fiber, 4–14% oil, up to 12.5% protein, and a wide range of phytochemicals such as alkaloids, flavonoids, terpenoids, and tannins in addition to essential minerals (Najjar et al., 2020; Al-Khalili et al., 2025). Their high phenolic content and lignocellulosic content make them ideal candidates for producing cellulose nanocrystals (CNC), which, when incorporated in packaging materials, can enhance their mechanical strength as well as antioxidant, enzyme inhibitory, and antimicrobial properties (Djaoudene et al., 2023). These properties are critical for extending the shelf life of perishable foods and reducing food spoilage (Al-Khalili et al., 2025). For instance, Khwaldia et al. (2023) produced active food packaging films from alginate and date palm pit extract (10–20%) with strengthened physical, mechanical, antioxidant, and light barrier properties.

Citrus processing generates about 15 million tons of residues, namely peels, which are the major citrus by-product, seeds, and pulp, worldwide every year (Navarra and Tellone, 2024). These by-products contain a wide spectrum of phytochemical compounds, such as phenolic compounds (mainly flavonoids), terpenoids, carotenoids, vitamins, fatty acids, and aromatic compounds, with well-documented antioxidant activities (Andrade et al., 2023). Extracts from citrus by-products can potentially be utilized as natural flavoring agents and preservatives in bakery products, contributing both to product functionality and consumer satisfaction (De Castro et al., 2020; Andrade et al., 2023).

Similarly, industrial cherry press-cake, or cherry pomace, consisting of skin and pulp, is generated after juice extraction and constitutes approximately 15–28% of the total fruit weight (Rrucaj et al., 2024). Cherry pomace is a valuable source of anthocyanins, particularly cyanidin-3-O-rutinoside and cyanidin-3-O-glucoside, phenolic acids, and flavonoids (Khoo et al., 2017; Rrucaj et al., 2024). Despite its high phenolic content and associated bioactivity, cherry press-cake remains underexploited. Valorizing this by-product through phenolic extraction not only mitigates environmental burdens but also allows obtaining valuable compounds with significant nutraceutical potential. For example, Loukri et al. (2022) investigated the use of Cornelian cherry pomace extract as a natural colorant to produce a novel acidic non-carbonated red beverage.

While the recovery of bioactive compounds with functional properties from agro-industrial residues offers clear benefits, the environmental loads of the extraction processes utilized must be carefully considered. Extraction processes, ranging from conventional solvent extraction to processes assisted by innovative green technologies, such as ultrasound, microwave, pulsed electric field, supercritical fluid, and high-voltage electric discharge, show a very wide range of variability in terms of energy consumption, solvent use, yield, and overall environmental footprint (Carpentieri et al., 2021). Therefore, a holistic evaluation of these processing methods is crucial to ensure that the valorization processes of agro-industrial by-products are environmentally sustainable. To this purpose, Life Cycle Assessment (LCA) is a robust and widely accepted methodology for quantifying the environmental impacts associated with all stages of a product’s life cycle, from raw material acquisition through processing, use, and end-of-life (ISO, 2006a). Applying LCA to the valorization of agro-industrial by-products allows for the identification of environmental hotspots, the comparison of different processing pathways, and the individuation of more sustainable technologies. Despite the growing interest in the valorization of agrifood by-products, LCA has been used to study a variety of food waste-to-animal feed scenarios, especially focusing on insect farming as a promising solution (Dominguez Aldama et al., 2023). Few recent studies have investigated the environmental impacts of biorefinery approaches for obtaining high-value compounds, such as polyphenols, pectin, and biofuels, from agro-industrial residues, including anaerobic digestion pathways (Valenti, 2020; Pampuri et al., 2021; Azarakhsh et al., 2024; Midolo et al., 2024; Sabia et al., 2025). To the best of our knowledge, no studies have systematically compared the environmental impacts of extracting phenolic-rich compounds from different agro-industrial by-products using different extraction processes, have identified environmental hotspots, and provided guidance for future optimization of processing methods. This study aims to conduct a comprehensive LCA study of three different valorization scenarios involving the laboratory-scale production of high-value-added extracts from date pit powder, citrus by-products, and industrial cherry press-cake. The specific objectives of this work are to quantify and compare the environmental impacts associated with each extraction process, to identify the critical steps that contribute most significantly to environmental loads, and to provide a scientific basis to define operational guidelines for future decision-making processes aimed at implementing the valorization of agro-industrial by-products on an industrial scale.

2 Methods

2.1 Description of the extraction processes

2.1.1 Date pits powder

The extraction process from date pits powder was conducted in the laboratories of the National Institute of Research and Physicochemical Analysis (INRAP) in Tunisia and focused on their valorization. The aim was to produce a phenolic-rich extract on the laboratory scale. The residual biomass was used to produce nanoscale cellulose fibers (CNC) to be used in the packaging industry to improve the shelf life of products by providing antimicrobial effects and to remove contaminants and heavy metals from wastewater (Jolliet et al., 2015).

Date pits were transported to the laboratory with a utility car over from the sourcing company (distance traveled 36 km). The extraction process started by grinding the date pits. 50 g of the resulting powder was dispersed into a 50% (v/v) ethanol-water solution, with a solid to liquid ratio of 1:20 (w/v) per batch. The suspension was sonicated for 20 min using an ultrasonic probe (Sonics & Materials Inc., Kolkata, India) at 20 kHz with a power of 500 W. During sonication, the sample was held in a thermostatic bath at 20 °C. The resulting suspension was centrifuged for 15 min at 2000 rpm. The supernatant was filtered using a 0.45 μm syringe filter and concentrated by vacuum evaporation (Schwabach, Germany). The residual ethanol was recovered after vacuum evaporation and used in further applications. The extract obtained was freeze-dried (Christ-Alpha, Osterode, Germany) and stored in amber glass bottles at −20 °C. The extract obtained from date pits powder, showed TPC of 243 ± 5.6 mg GAE/g extract. After the extraction step, the residual biomass was dried in a convection oven for 2 h at 70 °C. The dry sample was then treated with a NaOH solution prepared in water at 5% (v/v) and washed, followed by NaClO2 solution prepared in water at 1.4% (v/v) and washed for the cellulose synthesis. No detectable residual biomass remained after this last step, and all liquid waste was collected and disposed of according to institutional protocols.

2.1.2 Citrus by-products

The extraction process from citrus by-products was conducted in the laboratories of the National Institute of Agrarian and Veterinary Research (INIAV) in Portugal and focused on the valorization of citrus by-products from orange, lemon, and lime resulting from industrial juice extraction. The aim was to produce a concentrated phenolics-rich extract on a laboratory scale. This extract shows potential use as a flavoring agent in bakery products. Citrus by-products were transported to the laboratory by means of a small truck over (distance traveled 240 km) from the citrus fruit juice production plant. The extraction process consisted of a solid–liquid extraction step using absolute ethanol as solvent, at a solid to liquid ratio of 1:10 w/v with 100 g of by-products. The sample was homogenized for 1 min and then subjected to an ultrasound treatment in an ultrasound bath for 15 min and agitated on a horizontal shaker for 30 min. The sample was then centrifuged at 4000 rpm, for 10 min, at 4 °C. The resulting supernatant was filtered with Whatman® filter papers and then concentrated in a vacuum evaporator where ethanol was recovered. The final residue was removed and subsequently incinerated with other laboratory waste, while the ethanol was reused internally for cleaning purposes. The extract from citrus by-products showed TPC of 33.57 ± 0.07 mg GAE/g extract.

2.1.3 Cherry press-cake

The extraction process from cherry press-cake was conducted in the laboratories of the interuniversity research center ProdAl Scarl in Italy and focused on the valorization of cherry press-cake. The aim was to produce a phenolic-rich extract on the laboratory scale. The potential applications of this extract include its use as a natural colorant.

Cherry press-cake was transported to the laboratory by a small truck (distance traveled 46 km) from the fruit juice production plant. The extraction process consisted of a solid–liquid extraction step using water (pH = 2.5) as the extracting solvent, at a solid to liquid ratio of 1:5 w/v, extraction time of 120 min, and extraction temperature of 50 °C. The extract obtained was concentrated in a vacuum evaporator (BÜCHI Labortechnik AG), freeze-dried in a 25 L VirTis Genesis freeze-drier (SP Scientific, United States), packaged in multilayer pouches, and stored under refrigerated conditions. The residual biomass was subjected to a second extraction step (cascade extraction) under the same extraction conditions to maximize the recovery of bioactive compounds, resulting in an additional extract and a new fraction of residual biomass. The extract obtained in the second extraction step was concentrated and freeze-dried following the same downstream processing as described for the first extraction. The final residue was removed and subsequently incinerated with other laboratory waste. The extract from cherry press-cake showed an average TPC of 445 ± 5 mg GAE/g extract.

2.2 Life cycle assessment methodology

LCA is a method consisting of a standardized framework defined by ISO 14040-14044 used to assess the environmental impact of a product along its entire life cycle. It includes four steps: definition of the goal and scope of the study, preparation of the inventory data, life cycle impact assessment, and interpretation of the results. This approach provides a clear understanding of the environmental impacts of the product studied. SimaPro software (version 9.0.048) was used to model the systems studied and to obtain the results of the environmental impact assessment (ISO, 2006a; ISO, 2006b).

2.2.1 Definition of the goal and scope of the study

The goal of this study was to conduct an LCA to quantify and compare the environmental impacts associated with the production processes of phenolic compounds from three agro-industrial residues, identify environmental hotspots, and provide a scientific basis for future decision-making processes.

2.2.2 Functional unit

In LCA studies, the functional unit (FU) is often attributed to the mass of the final product. It serves as a basis for inventory data, allowing for the comparison between different products. In this study, the FU is 1 kg of total phenolic compounds expressed in gallic acid equivalent (GAE) recovered from the different biomasses utilized.

2.2.3 System boundaries and key assumptions

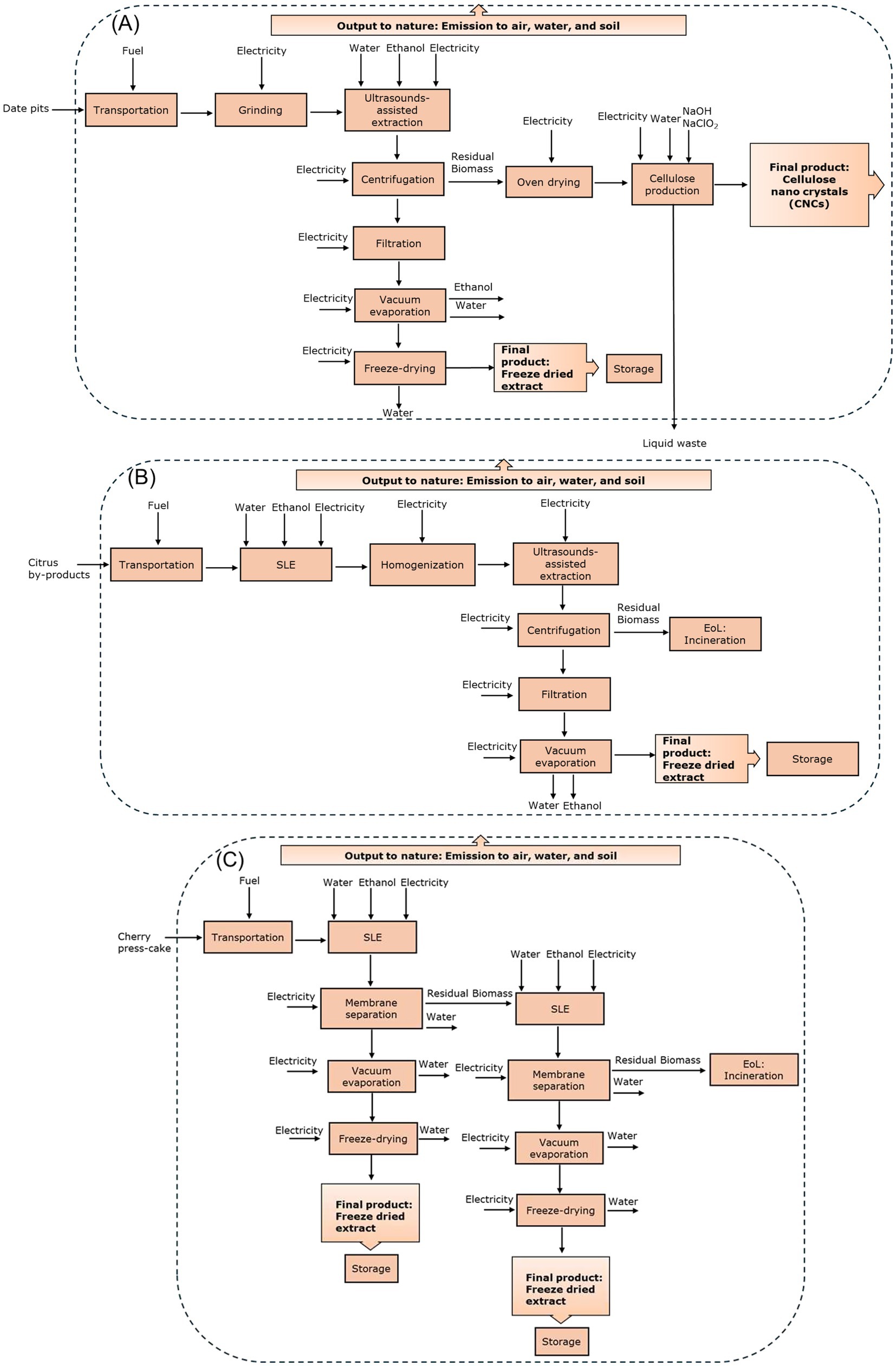

A “gate-to-gate” approach has been used to assess the environmental impact of the different extraction processes investigated. Figure 1 shows the system boundaries of the three case studies considered. The study includes the energy used (electrical energy and fuels for transportation), and resource consumption (water, solvents, chemicals, laboratory material).

Figure 1. System boundaries for the three scenarios analyzed (A) date pits powder, (B) citrus by-products (C) cherry press-cake.

The production of the starting material (date pits, citrus by-products, and cherry press-cake) was not included within the system boundaries, as this study focused on the evaluation of the environmental impact of the extraction methods to recover phenolic compounds and the downstream processes to obtain stable extracts. However, transportation required for raw material collection and delivery to the processing facilities was considered in this study.

Extraction steps generate several wastes and/or by-products, including solvents, laboratory material, and in some cases residual biomass. Wastewater treatment was not considered as it lies outside the defined system boundaries. In cases where ethanol was used as extraction solvent, the amount recovered from vacuum evaporation was always repurposed for other uses and not discarded. As a result, the amount of solvent considered was adjusted accordingly. Regarding the solid residual biomass generated during the extraction processes, its end-of-life (EoL) was included and modeled as incineration with energy recovery.

Allocation was applied to account for the presence of co-products generated from the extraction processes. In the case of date pits powder extraction process, two co-products were identified: cellulose nanocrystals and the freeze-dried extract. Environmental burdens were allocated between these co-products on a mass basis. Ethanol recovery was included within the system boundary and reused internally in subsequent extraction cycles. Therefore, ethanol was not treated as an independent co-product, and its recovery benefits were accounted for within the system.

For the cherry press-cake extraction process, two output streams, with comparable composition and TPC content, were obtained and considered as a single product stream. Therefore, no further allocation was applied.

2.2.4 Data collection and life cycle inventory

The life cycle inventory (LCI) has been prepared also considering the inputs and outputs to the system considered along the life cycle of the products. These include raw materials, energy consumption, and emissions to air, water, and soil. Accurate data collection leads to more reliable and credible results, which highlights the crucial importance of a precise inventory analysis and of data of high quality. The quantification of the flows entering and exiting the system are important for the interpretation of the results and help to identify improvement opportunities (ISO, 2006a).

The data collection phase was conducted by integrating primary data, obtained from ad hoc survey tools administered to the three research groups to collect the experimental data, with secondary data collected from internationally recognized databases, namely Ecoinvent, and from scientific literature. A general information section has been prepared as well as the description of the techniques utilized, the specifications of the different equipment used and their processing parameters, all the material flows and energy consumptions involved in each processing step, the potential application of the extracts, and EoL scenarios for the biomass residues and wastes. The LCI of the three scenarios is reported in Supplementary Table S1.

Background data on the supply of electrical energy and water were obtained from the Ecoinvent database (Version 3.5) specifically for each country. In cases where such data were unavailable, broader European data were used (Supplementary Table S2).

2.2.5 Impact assessment

In this study, the ReCiPe 2016 Midpoint (H) method, Version 1.03, was used to assess the environmental impacts of the extraction processes investigated. This method, developed by the National Institute for Public Health and the Environment in the Netherlands, allows the evaluation of environmental impacts for 18 impact categories (Huijbregts et al., 2017). A sensitivity analysis was conducted by varying the main input, such as electricity consumption, by ±20% across all processes investigated.

3 Results and discussion

3.1 Extraction process from date pits powder

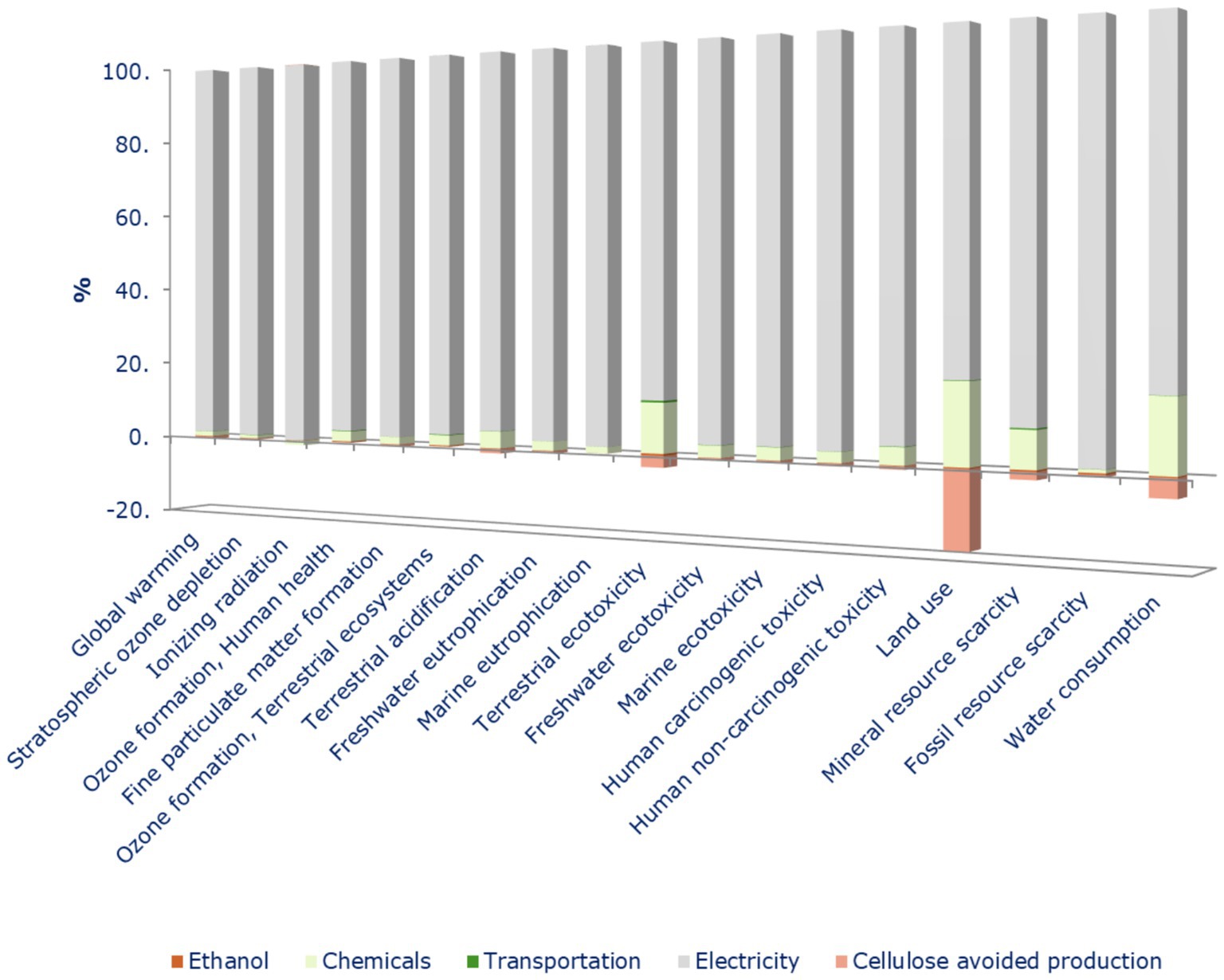

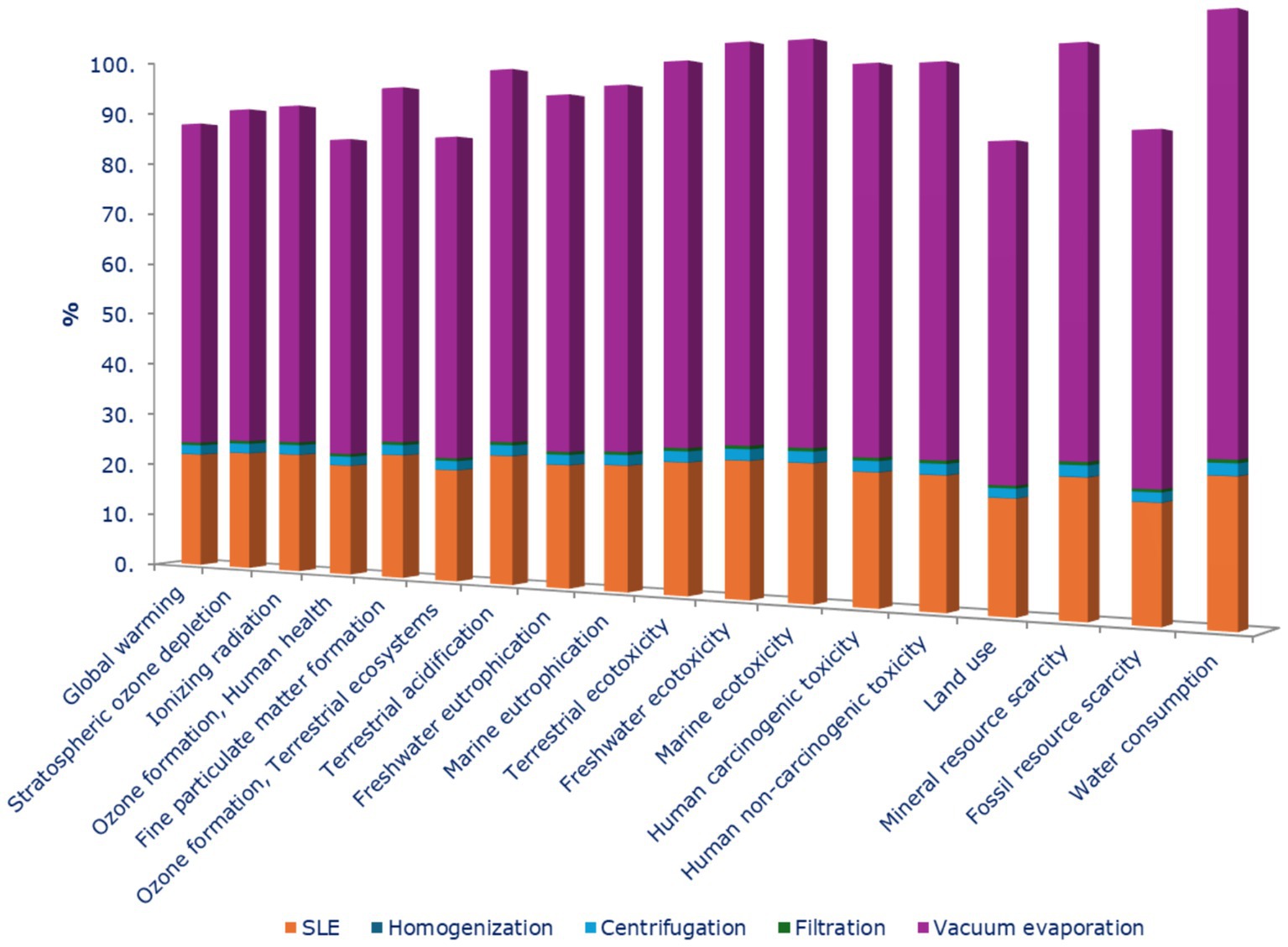

Figure 2 illustrates the relative environmental contributions (%) of the processing stages and input flows per functional unit across the impact categories considered in the environmental assessment of date pits powder processing. Supplementary Table S3 shows the absolute values and midpoint indicators. Electrical energy consumption made the highest contribution in all of the impact categories, followed by chemical and solvent use (sodium hydroxide and ethanol).

Figure 2. Relative contributions (%) of the date pits powder extraction process to each environmental impact category analyzed.

Electrical energy usage contributed at 99% to global warming, stratospheric ozone depletion, fossil resource scarcity, and ionizing radiation categories (highest contribution), and at 78% to water consumption (lowest contribution). Vacuum evaporation and freeze-drying phases were the main contributors to the overall environmental impact due to the high electrical energy consumption (accounting for 35 and 45% of the total electrical energy consumed, respectively), as reported in Figure 3. These results are consistent with findings from LCA studies on biomass valorization, where energy-intensive unit operations, particularly freeze-drying and evaporation, have been shown to drive most environmental impacts due to their high electrical energy consumption (Smetana et al., 2017; Valenti, 2020; Valdez-Valdes et al., 2024).

Figure 3. Relative contributions (%) of the energy-consuming phases of the date pits powder extraction process to each environmental impact category analyzed.

Following the extract production, the residual biomass was further processed to produce CNC, aiming at achieving a zero-waste valorization approach. This additional treatment involved the use of sodium hydroxide, which emerged as the second most significant contributor to the environmental impacts of the overall process. Specifically, sodium hydroxide accounted for 12% of terrestrial ecotoxicity, 17% of water consumption, and 19% of land use. These results are consistent with findings on the environmental impact of CNC production where the use of chemicals has been identified as one of the major contributors to the overall environmental load (Zhang et al., 2022). However, the integration of CNC production in the extraction process not only avoided biomass waste generation but also positively influenced several impact categories by replacing disposal or low-value uses of the biomass (Batool et al., 2024). Notably, the recovery of ethanol, used as a solvent during extraction, played a significant role in mitigating the environmental burdens related to solvent usage and disposal. Its recovery contributed to lowering emissions, reducing waste generation, and minimizing resource losses, as also reported in other LCA-based biorefinery studies that emphasized that the reuse of solvents is a key strategy for circular economy implementation (Dominguez Aldama et al., 2023; Sabia et al., 2025). This supports the growing consensus that well-optimized integrated biorefinery designs can substantially improve the environmental performance of biomass valorization processes. Extraction processes characterized by energy-intensive and complex operations, along with the use of chemical reagents, can contribute significantly to the environmental impact of the overall process, which can be significantly reduced in this way. This is of utmost importance when the scale-up of the process is considered (Pampuri et al., 2021).

3.2 Extraction process from citrus by-products

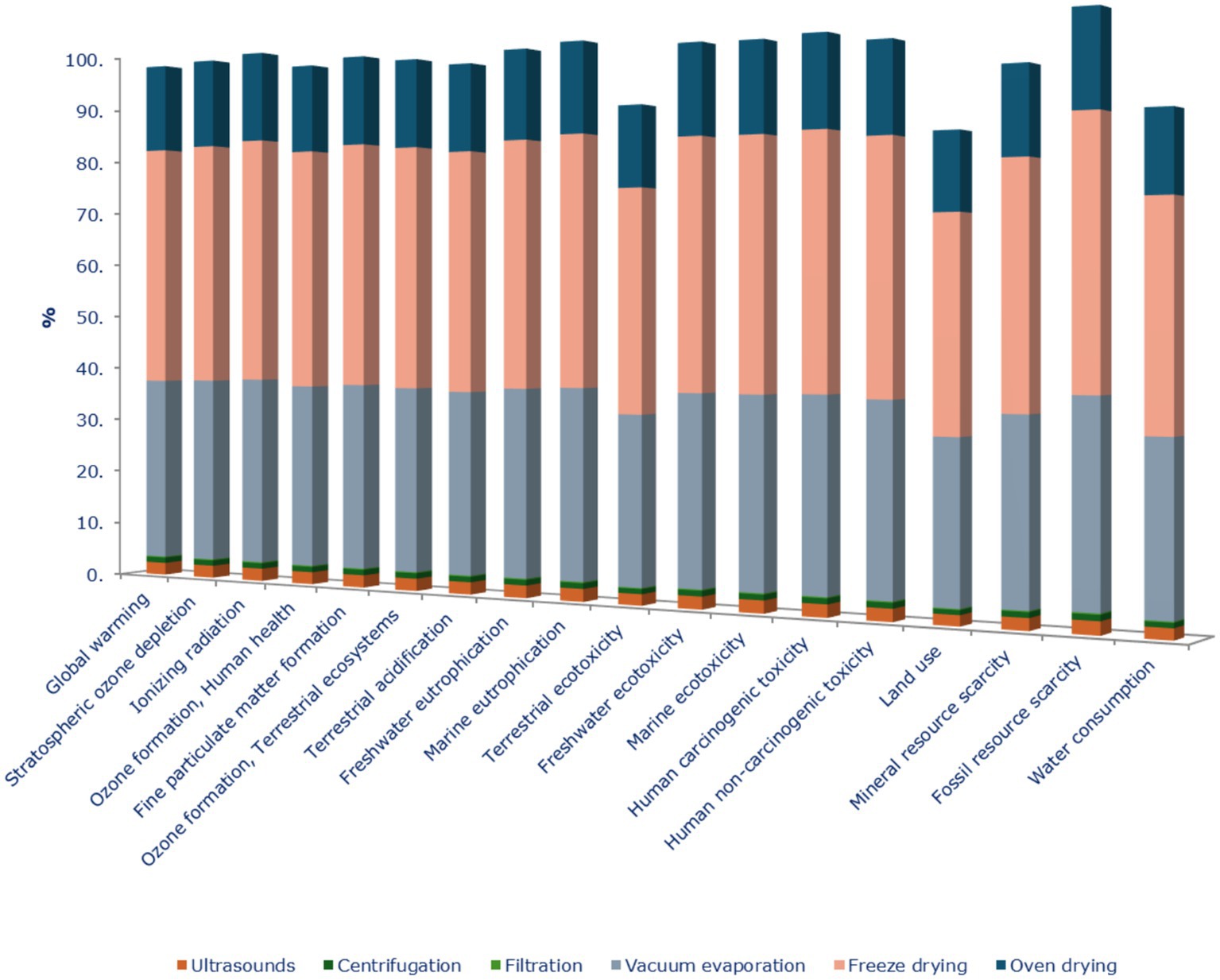

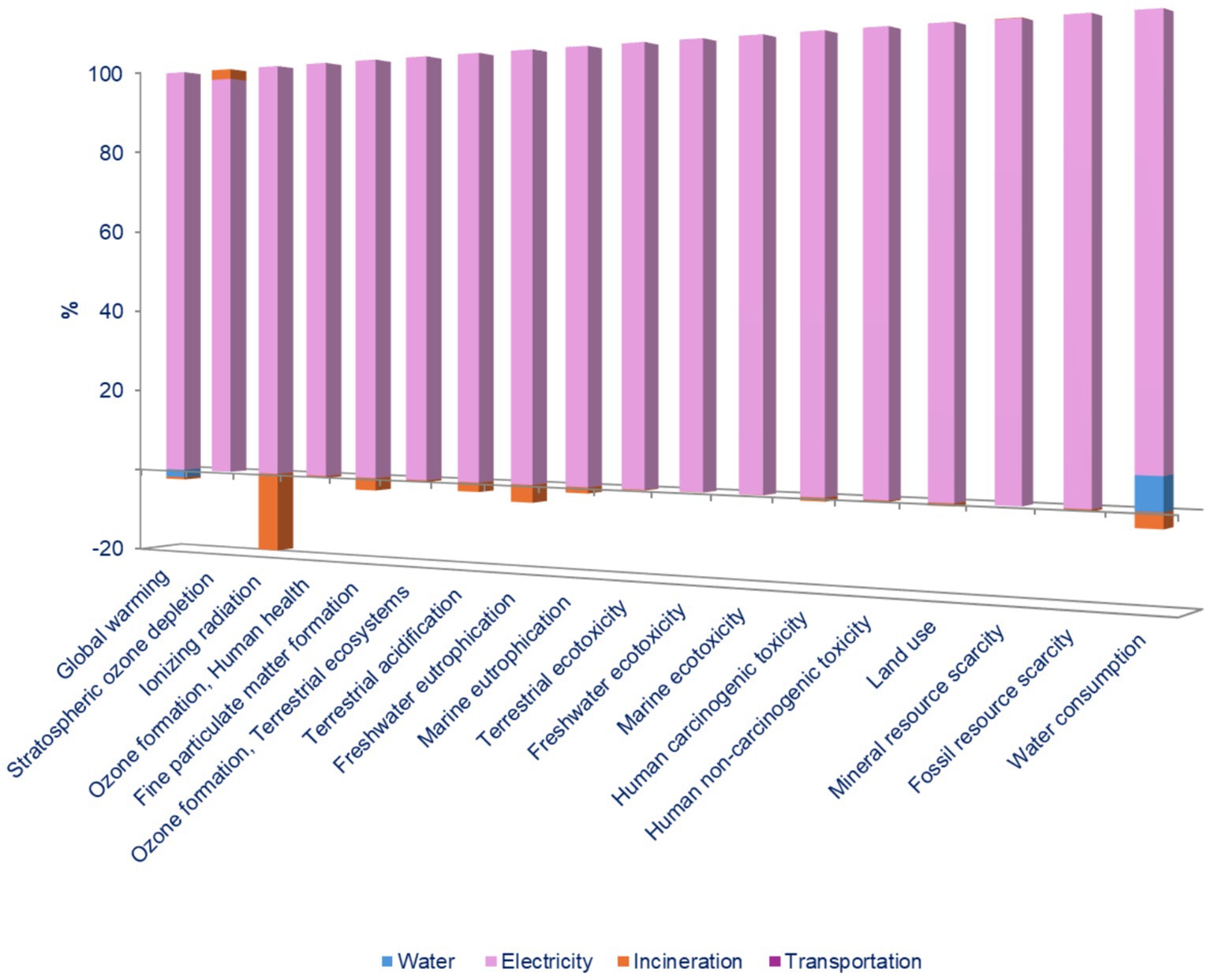

Figure 4 are reported the relative environmental contributions (%) of the processing stages and input flows per functional unit across the impact categories considered in the environmental assessment of citrus by-products processing. Supplementary Table S4 shows the absolute values and midpoint indicators. Similarly, to the date pits scenario, electrical energy had the highest contributions to the environmental profile of the extraction process with values ranging between 79 and 99%. This significant environmental burden was primarily associated with the vacuum evaporation stage, which accounted for approximately 70% of the total electrical energy consumed in the extraction process, as emerged from Figure 5.

Figure 4. Relative contributions (%) of the citrus by-products’ extraction process to each environmental impact category analyzed.

Figure 5. Relative contributions (%) of the energy-consuming phases of the citrus by-products’ extraction process to each environmental impact category analyzed.

Transportation contributed more importantly to the environmental load in this case reaching contributions of 7% for GWP, 12% for ozone formation, and 9% for fossil fuel scarcity. These results align with findings of LCA studies where transport logistics significantly affected the overall environmental footprint of biowaste valorization processes, especially when feedstock is sourced from decentralized suppliers (Batool et al., 2024; Sabia et al., 2025).

Ethanol, used as solvent during extraction, showed a low contribution to the overall environmental impact, ranging between 1 and 3% in most of the impact categories. This is due to ethanol recovery after the extraction process, internally reused in the laboratory, which helps to mitigate the overall environmental load of the extraction process. However, when ethanol is not recovered or reused, its environmental impact can become significant. For instance, results reported by Midolo et al. (2024) revealed that pectin extraction had a substantially higher environmental footprint than limonene extraction from citrus by-products, primarily due to the intensive use of ethanol, followed by electrical energy consumption. Their study also demonstrated that replacing ethanol with more sustainable alternative solvents could reduce the environmental footprint of pectin extraction by up to 73.4%. Moreover, the incineration of residual biomass, considered as EoL scenario, was shown to offer partial mitigation of environmental impacts by offsetting emissions through energy recovery.

Substituting low-efficiency equipment and exploring alternative drying methods have emerged as viable strategies to improve process efficiency and reduce environmental impacts.

3.3 Extraction process from cherry-press cake

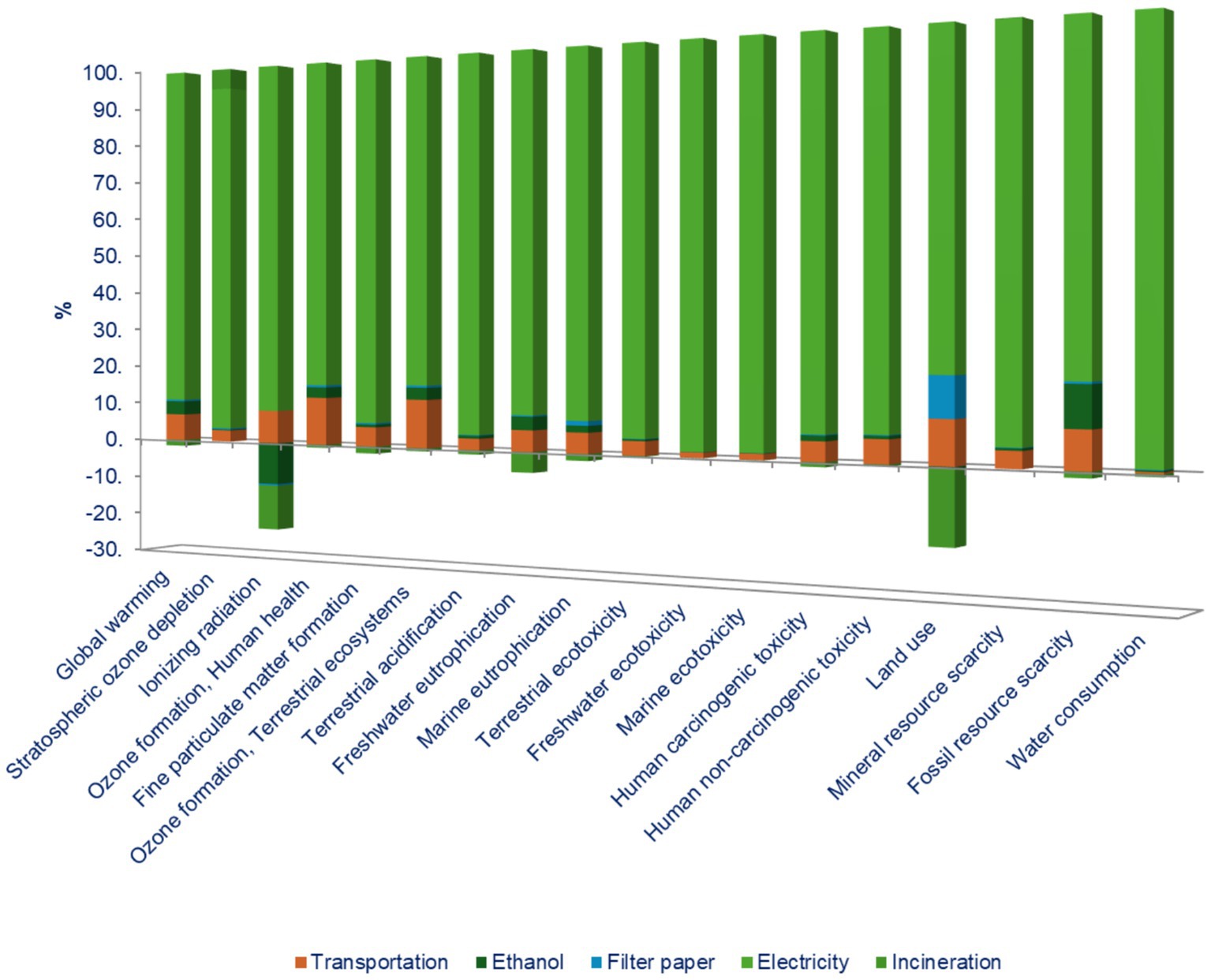

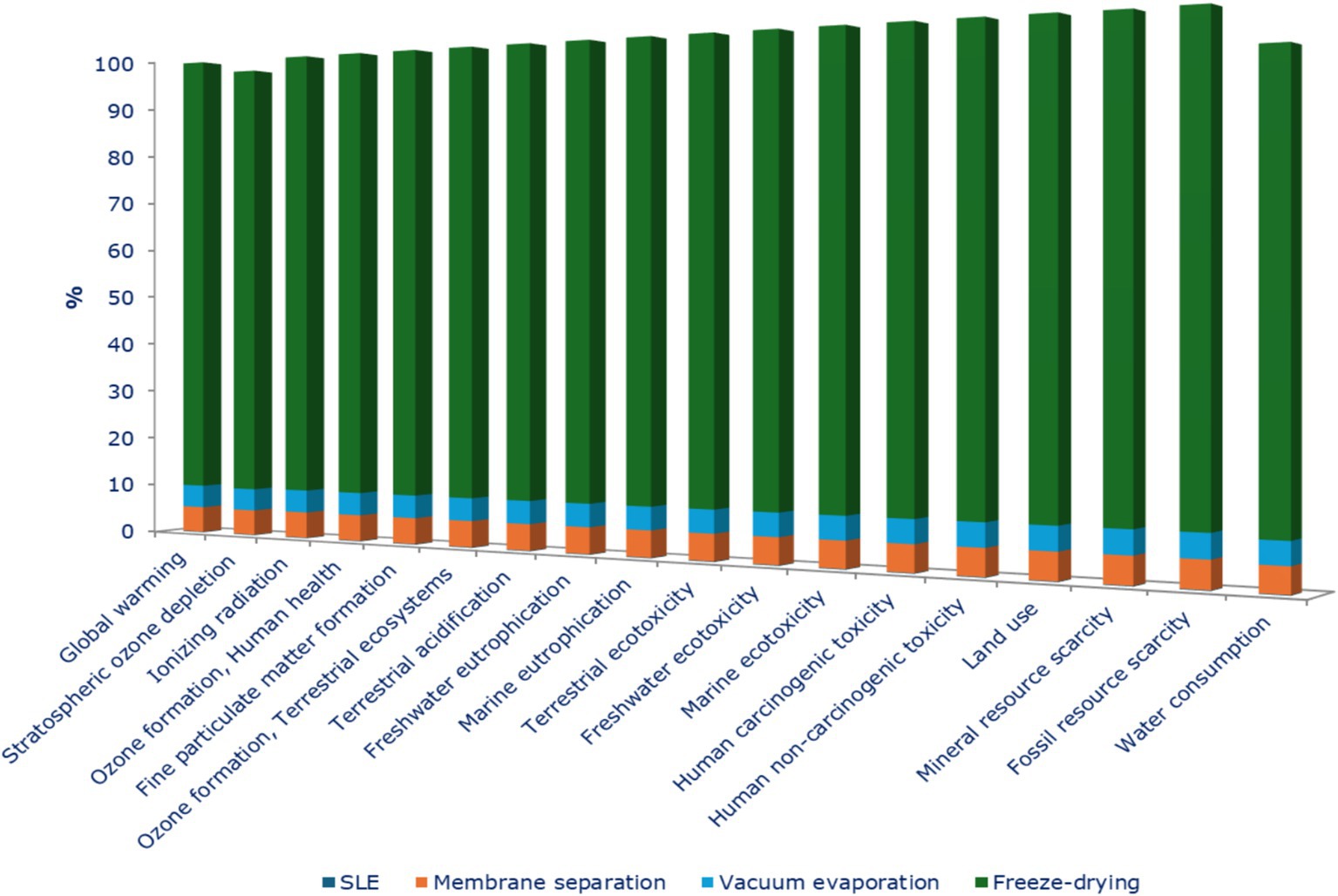

In Figure 6, the relative contributions (expressed as percentages) of water use, electrical energy consumption, and biowaste treatment to the overall environmental impact of the extraction process from cherry press-cake are reported. Supplementary Table S5 shows the absolute values and midpoint indicators. In this scenario, the extraction was carried out using a cascade approach, aiming to maximize the recovery of bioactive compounds through sequential steps. As a result, the residual biomass was incinerated with no further valorization.

Figure 6. Relative contributions (%) of the cherry press-cake extraction process to each environmental impact category analyzed.

Electrical energy consumption emerged as the dominant contributor to the environmental profile. It accounted for nearly the entire impact across all categories, with the lowest relative contribution still reaching 93% in the water consumption category. Specifically, the vacuum evaporation and freeze-drying steps were identified as the most impactful unit operations, together representing approximately 80% of the total electrical energy consumption, as illustrated in Figure 7, highlighting the high potential for implementing energy-saving measures.

Figure 7. Relative contributions (%) of the energy-consuming phases of the cherry press-cake extraction process to each environmental impact category analyzed.

Indeed, the cascade approach increases the yield of the extraction process although it requires additional energy-intensive steps. These findings are consistent with existing literature data in which similar unit operations used in biowaste valorization processes were identified as hotspots for energy demand and environmental impact (Valdez-Valdes et al., 2024; Midolo et al., 2024; Pampuri et al., 2021).

The use of large volumes of water, albeit being a green solvent, was a further critical issue, showing a 7% contribution to the water consumption category. However, although the residual biomass was incinerated, opportunities for the valorization of residual biomass have emerged, such as composting or anaerobic digestion. Studies by Valenti (2020) demonstrated that anaerobic digestion of agro-industrial residues can significantly reduce environmental impacts when compared to conventional disposal methods, offering renewable energy recovery and nutrient recycling.

3.4 Comparison of the environmental impacts of the three scenarios

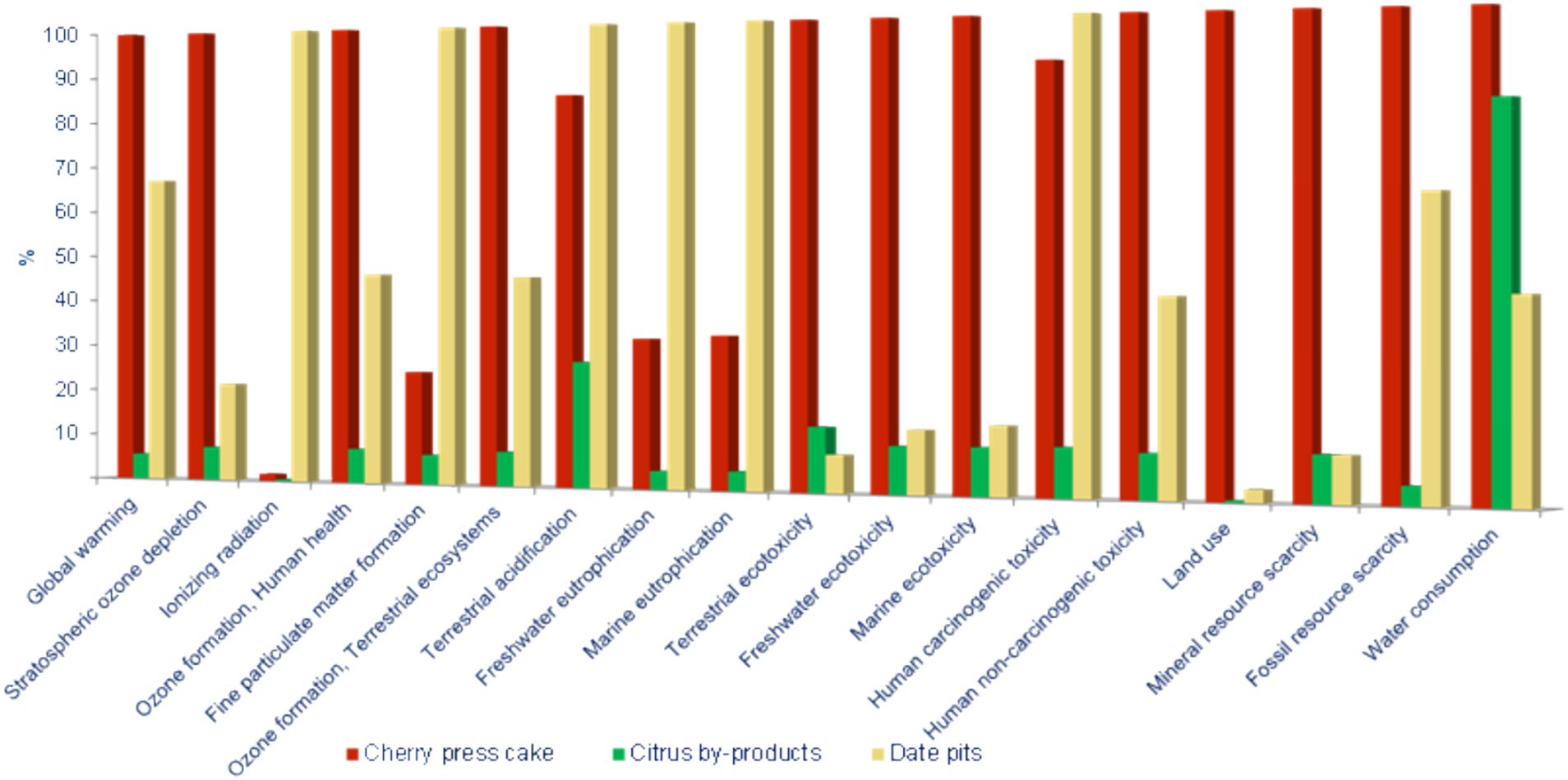

Figure 8 presents a relative comparison of the environmental impacts of the three scenarios investigated across all 18 impact categories, enabling the identification of the highest and lowest contributors within each category.

Figure 8. Comparison of the environmental impact categories of the three scenarios analyzed: date pits powder, citrus by-products and cherry press-cake.

The cherry press-cake scenario consistently exhibited the highest environmental impacts across most categories, including global warming, stratospheric ozone depletion, fine particulate matter formation, freshwater and marine ecotoxicity, and human non-carcinogenic toxicity, often accounting for over 90% in relative contributions. These elevated impacts are largely driven by the cascade extraction strategy and energy-intensive unit-operations, particularly freeze-drying.

In contrast, the citrus by-products scenario showed low environmental impacts across almost all categories, with most contributions falling below 10% and, in some cases approaching zero, such as in stratospheric ozone depletion, ionizing radiation, and terrestrial acidification. Exceptions are observed in marine eutrophication, freshwater ecotoxicity, and land use, where moderate environmental impacts occurred. The overall low environmental footprint of this process is attributed to efficient ethanol recovery, simplified processing steps, and the incineration of residual biomass, an approach that not only avoids further processing but also provides environmental credits through energy recovery.

The date pits scenario presented an intermediate environmental profile. It showed the highest contributions among the three scenarios for ionizing radiation, fossil resource scarcity, human carcinogenic toxicity, mineral resource scarcity, and land use. These impacts stem primarily from the downstream valorization of residual biomass into CNC, a process that supports circular economy principles but involves high energy demand and the use of chemicals such as sodium hydroxide and sodium chlorite.

The cherry press-cake and date pits scenarios focused on maximizing the use of biomass, aiming at obtaining as much value as possible in line with circular economy principles. However, this extensive utilization requires complex and energy-intensive processing, leading to significantly higher electrical energy consumption and chemical use, and as a result, greater environmental impacts. In contrast, in the citrus by-products valorization the residual biomass was no further processed but, instead, incinerated, which provided environmental credits through energy recovery.

Moreover, each scenario also showed a distinct environmental profile across different impact categories. The date pits process contributed most strongly to land use and human carcinogenic toxicity due to the downstream conversion of biomass into cellulose nanocrystals using chemicals. The cherry press-cake pathway showed the highest impacts in global warming and marine ecotoxicity, primarily due to high energy and water demands. The citrus by-products process, aside from showing moderate impacts in marine eutrophication, exhibited the lowest impacts across nearly all the other environmental categories.

A sensitivity analysis was performed to assess the influence of electricity consumption on the environmental impact results, focusing on a ± 20% variation of the baseline energy use. Given that electricity is the dominant contributor to most impact categories, the midpoint results showed a nearly linear response to changes in electricity consumption. For example, global warming potential and stratospheric ozone depletion impacts varied by approximately ±19%, while impacts such as mineral resource scarcity and water consumption changed by ±12–15%. This highlights the significant role of energy use in the environmental profile of the extraction process and underscores the importance of optimizing electricity consumption in future scale-up or process optimization.

The sensitivity analysis performed on the electricity consumption across the three extraction scenarios (date pits powder, citrus by-products, and cherry press-cake) shows a sensitivity factor of 0.80 for all systems.

4 Conclusion

This study applied an LCA approach to evaluate and compare the environmental impacts of producing phenolic-rich extracts from three agrifood by-products, namely date pits powder, citrus by-products, and cherry press-cake. The results obtained showed that in all three cases analyzed, operations with high electrical energy consumption, such as vacuum evaporation and freeze-drying, contribute significantly to impact categories such as climate change, freshwater and marine ecotoxicity and human toxicity, representing the main environmental hotspots.

Among the evaluated cases, citrus by-products showed the lowest overall environmental impact due to simpler processing steps and efficient ethanol recovery, despite the lack of complete biomass valorization. In contrast, the date pits scenario, while more resource-intensive, achieved full valorization by converting residual biomass into cellulose nanocrystals, aligning with circular economy goals. The cherry press-cake process exhibited the highest environmental impacts due to energy-intensive operations and considerable water consumption. However, mitigation strategies such as solvent recovery, the use of less energy-intensive drying technologies, improvement of energy efficiency and the adoption of renewable energy sources can significantly reduce the overall environmental impact of these processes.

Furthermore, the upcycling of the residual biomasses could open further possible scenarios for by-product valorization, making the overall process circular and more sustainable.

These measures are crucial to promote a truly sustainable supply chain for the valorization of agro-industrial biomasses in line with circular economy objectives. These findings provide a comprehensive understanding of the advantages and limitations of the proposed approaches for the valorization of agro-industrial by-products, paving the way for the development of greener extraction methods. This will support agro-industrial sector stakeholders in aligning toward more sustainable practices by leveraging the opportunities offered by the exploitation of natural and low-cost resources. Although it is widely recognized that environmental impact tends to decrease significantly when processes are scaled industrially, a detailed assessment of the environmental impact associated with industrial-scale processes, as well as scenario, uncertainty, and sensitivity analyses, are considered crucial steps for future research.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

SC: Data curation, Writing – original draft, Investigation, Conceptualization, Visualization, Methodology, Formal analysis. AG: Investigation, Conceptualization, Writing – original draft, Visualization. KK: Funding acquisition, Writing – review & editing, Investigation. AS: Funding acquisition, Investigation, Writing – review & editing. GF: Investigation, Writing – review & editing, Supervision, Conceptualization, Project administration, Funding acquisition.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was carried out in the frame of the research project ValICET (PRIMA Call: Section 1 Agro-Food Value Chain 2020), funded by the Italian Ministry of University and Research (MUR) (B45F20003170005) and received support from University of Salerno through the project 300395FRB21FERRARI.

Acknowledgments

The authors wish to thank Ervehe Rrucaj and Gianpiero Pataro for having provided the data on cherry press-cake valorization and Ana Rita Mateus for having provided the data on citrus byproducts valorization.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Generative AI statement

The author(s) declare that no Gen AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2025.1693181/full#supplementary-material

References

Al-Khalili, M., Rahman, S., and Al-Habsi, N. (2025). Date seed–added biodegradable films and coatings for active food packaging applications: a review. Packag. Technol. Sci. 38, 445–472. doi: 10.1002/pts.2893

Andrade, M. A., Barbosa, C. H., Shah, M. A., Ahmad, N., Vilarinho, F., Khwaldia, K., et al. (2023). Citrus by-products: valuable source of bioactive compounds for food applications. Antioxidants 12, 1–20. doi: 10.3390/antiox12010038

Aschemann-Witzel, J., Gantriis, R. F., Fraga, P., and Perez-Cueto, F. J. A. (2020). Plant-based food and protein trend from a business perspective: markets, consumers, and the challenges and opportunities in the future. Crit. Rev. Food Sci. Nutr. 61, 3119–3128. doi: 10.1080/10408398.2020.1793730

Azarakhsh, F. A. S., Ziloue, H., Ebrahimian, F., Khoshnevisan, B., Denayer, J. F. M., and Karimi, K. (2024). Life cycle analysis of apple pomace biorefining for biofuel and pectin production. Sci. Total Environ. 951:175780. doi: 10.1016/J.SCITOTENV.2024.175780

Batool, F., Kurniawan, T. A., Mohyuddin, A., Othman, M. H. D., Aziz, F., Al-Hazmi, H. E., et al. (2024). Environmental impacts of food waste management technologies: a critical review of life cycle assessment (LCA) studies. Trends Food Sci. Technol. 143:104287. doi: 10.1016/J.TIFS.2023.104287

Carpentieri, S., Soltanipour, F., Ferrari, G., Pataro, G., and Dons, F. (2021). Emerging green techniques for the extraction of antioxidants from Agri-food by-products as promising ingredients for the food industry. Antioxidants 10, 1417–1459. doi: 10.3390/antiox10091417

De Castro, L. A., Lizi, J. M., das Chagas, E. G. L., de Carvalho, R. A., and Vanin, F. M. (2020). From orange juice by-product in the food industry to a functional ingredient: application in the circular economy. Foods 9, 1–17. doi: 10.3390/foods9050593

Del Rio Osorio, L. L., Flórez-López, E., and Grande-Tovar, C. D. (2021). The potential of selected Agri-food loss and waste to contribute to a circular economy: applications in the food, cosmetic and pharmaceutical industries. Molecules 26, 1–42. doi: 10.3390/molecules26020515

Djaoudene, O., Bachir-Bey, M., Cásedas, G., Les, F., and López, V. (2023). Phenolic compounds recovery from date seed and assessment of their antioxidant and enzyme inhibitory properties. The Annals University Dunarea de Jos of Galati. Fascicle VI 47, 190–206. doi: 10.35219/foodtechnology.2023.2.12

Dominguez Aldama, D., Grassauer, F., Zhu, Y., Ardestani-Jaafari, A., and Pelletier, N. (2023). Allocation methods in life cycle assessments (LCAs) of Agri-food co-products and food waste valorization systems: systematic review and recommendations. J. Clean. Prod. 421, 1–18. doi: 10.1016/j.jclepro.2023.138488

Huijbregts, M. A. J., Steinmann, Z. J. N., Elshout, P. M. F., Stam, G., Verones, F., Vieira, M., et al. (2017). ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 22, 138–147. doi: 10.1007/s11367-016-1246-y

ISO (2006a). International Organization for Standardization (ISO). 2006. ISO 14040:2006 – Environmental management – Life cycle assessment – Principles and framework. Geneva: ISO.

ISO (2006b). International Organization for Standardization (ISO). 2006. ISO 14044:2006 – Environmental management – Life cycle assessment – Requirements and guidelines. Geneva: ISO.

Jolliet, O., Saadé-Sbeih, M., Shaked, S., Jolliet, A., and Crettaz, P. (2015). Environmental life cycle. Boca Raton, Florida, USA.

Keskin, B., Uzundumlu, A. S., and Karabacak, T. (2025). Production estimates of leading countries in date production for the period 2023–2028. Applied Fruit Science 67, 1–12. doi: 10.1007/s10341-025-01307-9

Khoo, H. E., Azlan, A., Tang, S. T., and Lim, S. M. (2017). Anthocyanidins and anthocyanins: colored pigments as food, pharmaceutical ingredients, and the potential health benefits. Food Nutr. Res. 61:1361779. doi: 10.1080/16546628.2017.1361779

Khwaldia, K., M’Rabet, Y., and Boulila, A. (2023). Active food packaging films from alginate and date palm pit extract: physicochemical properties, antioxidant capacity, and stability. Food Sci. Nutr. 11, 555–568. doi: 10.1002/fsn3.3093

Loukri, A., Christaki, S., Kalogiouri, N. P., Menkissoglu-Spiroudi, U., and Mourtzinos, I. (2022). Anthocyanin-rich extracts from cornelian cherry pomace as a natural food colorant: a spectroscopic and LC-QTOF-MS study. Eur. Food Res. Technol. 248, 2901–2912. doi: 10.1007/s00217-022-04099-4

Midolo, G., Cutuli, G., Porto, S. M. C., Ottolina, G., Paini, J., and Valenti, F. (2024). LCA analysis for assessing environmenstal sustainability of new biobased chemicals by valorising citrus waste. Sci. Rep. 14:21418. doi: 10.1038/s41598-024-72468-y

Mirabella, N., Castellani, V., and Sala, S. (2014). Current options for the valorization of food manufacturing waste: a review. J. Clean. Prod. 65, 28–41. doi: 10.1016/j.jclepro.2013.10.051

Najjar, Z., Stathopoulos, C., and Chockchaisawasdee, S. (2020). Utilization of date by-products in the food industry. Emir. J. Food Agric. 32:808. doi: 10.9755/ejfa.2020.v32.i11.2192

Navarra, M., and Tellone, E. (2024). Recovery of nutraceutical compounds from citrus fruit processing waste: a circular economy strategy to lessen environmental impact. Future Postharvest and Food 1, 278–282. doi: 10.1002/fpf2.12033

Pampuri, A., Casson, A., Alamprese, C., Di Mattia, C. D., Piscopo, A., Difonzo, G., et al. (2021). Environmental impact of food preparations enriched with phenolic extracts from olive oil mill waste. Foods 10, 1–23. doi: 10.3390/foods10050980

Rațu, R. N., Veleșcu, I. D., Stoica, F., Usturoi, A., Arsenoaia, V. N., Crivei, I. C., et al. (2023). Application of Agri-food by-products in the food industry. Agriculture 13, 1–25. doi: 10.3390/agriculture13081559

Rrucaj, E., Carpentieri, S., Scognamiglio, M., Siano, F., Ferrari, G., and Pataro, G. (2024). Sustainable valorization of industrial cherry pomace: a novel Cascade approach using pulsed electric fields and ultrasound assisted-extraction. Foods 13, 1–24. doi: 10.3390/foods13071043

Sabia, E., Braghieri, A., Vignozzi, L., Paolino, R., Cosentino, C., Di Trana, A., et al. (2025). Carbon footprint of by-product concentrate feed: a case study. Environments - MDPI 12, 1–10. doi: 10.3390/environments12020042

Smetana, S., Sandmann, M., Rohn, S., Pleissner, D., and Heinz, V. (2017). Autotrophic and heterotrophic microalgae and cyanobacteria cultivation for food and feed: life cycle assessment. Bioresour. Technol. 245, 162–170. doi: 10.1016/J.BIORTECH.2017.08.113

Valdez-Valdes, S. A., Tejeda-Benitez, L. P., and González-Delgado, Á. D. (2024). Assessing the environmental impacts of the valorization of creole-Antillean avocado via an extractive-based biorefinery in the Montes de María region. Sustainability 16, 1–20. doi: 10.3390/su162411057

Valenti, F. W. L. P. S. M. C. (2020). Life cycle assessment of agro-industrial by-product reuse: a comparison between anaerobic digestion and conventional disposal treatments. Green Chem. 22, 7119–7139. doi: 10.1039/d0gc01918f

Keywords: agro-industrial by-products, valorization, extraction process, phenolic compounds, LCA, environmental impact

Citation: Carpentieri S, Ghanem A, Khwaldia K, Silva AS and Ferrari G (2025) Life cycle assessment of agro-industrial residues valorization processes to obtain phenolic-rich extracts. Front. Sustain. Food Syst. 9:1693181. doi: 10.3389/fsufs.2025.1693181

Edited by:

Narashans Alok Sagar, Chandigarh University, IndiaReviewed by:

Carolina Ramírez-López, National Polytechnic Institute (IPN), MexicoVishal Khanpit, TUMCREATE, Singapore

Copyright © 2025 Carpentieri, Ghanem, Khwaldia, Silva and Ferrari. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Giovanna Ferrari, Z2ZlcnJhcmlAdW5pc2EuaXQ=

Serena Carpentieri

Serena Carpentieri Antoine Ghanem

Antoine Ghanem Khaoula Khwaldia

Khaoula Khwaldia Ana Sanches Silva

Ana Sanches Silva Giovanna Ferrari

Giovanna Ferrari