Abstract

Cacao beans are essential components of chocolate production, and their quality is due to the formation of aromas and flavors during fermentation and drying processes. This study aimed to characterize the drying process and analyze the physicochemical properties of fermented and dried cacao beans using hot-air and infrared-assisted solar drying. Fermentation was performed in a portable fermenter and drying was performed using four methods: solar (S), hot-air-assisted solar (HA-S), infrared-assisted solar (IR-S), and hot-air- and infrared-assisted solar (HA-IR-S). The drying rate, effective moisture diffusivity, energy consumption, bean dimensions, acidity, pH, and cut test results were evaluated. The results showed the influence of the HA-IR-S method on the drying rate compared to the S method, as the assisted drying system increased the temperature of the cacao bean by 3.8°C, resulting in an increase in the effective diffusivity of 3.4% (1.22 × 10−9 m2/s). The HA-IR-S method achieved a drying effect similar to that of the HA-S method but with lower energy consumption. Significant differences were found in the physicochemical properties between the solar and assisted solar methods, with the HA-IR-S method showing the lowest acidity and pH, thus improving the degree of bean fermentation. In conclusion, the drying of cacao beans using solar energy with hot air and infrared radiation has been shown to improve their drying characteristics and physicochemical properties. This development constitutes a viable alternative for improving the drying efficiency and quality of beans.

1 Introduction

Cacao (Theobroma cacao L.) is an agricultural crop of economic interest in the tropical countries. Appropriate agronomic management allows for the increased production and quality of cacao beans. Cacao, an essential component of chocolate, is the most cultivated species of the genus Theobroma (Lima et al., 2011; De Souza et al., 2018). The diversification and domestication of T. cacao occurred in northeastern South America which was relevant for cultural interactions between Amazonia and the Pacific coast 5,300 years ago (Zarrillo et al., 2018; Thomas et al., 2023).

Harvesting and processing cacao is essential for obtaining beans with desirable commercial characteristics, which ensures better market acceptance and a higher price for the product. Cacao processing involves breaking, fermentation, and drying. During fermentation, enzymes and microorganisms transform the cacao components (polyphenols, proteins, and carbohydrates), developing precursors that determine the chocolate flavor (De Souza et al., 2018; Kongor et al., 2025).

Fermentation continues through the first hours of drying, which ultimately reduces moisture to 5–8%, prevents mold formation, and improves flavor, which are essential for chocolate production (Banboye et al., 2020a; CAOBISCO/ECA/FCC, 2015; Lima et al., 2011). Cacao beans can be dried either in the sun or hot air. Small producers prefer natural drying, which takes 6–10 days, to produce beans with a milder flavor, and should begin immediately after fermentation. In the case of artificial dryers, it is crucial to control the drying speed to avoid acidic and brittle bean or mold development. Such dryers have been used to process large quantities of cacao (Banboye et al., 2020a; CAOBISCO/ECA/FCC, 2015; Lima et al., 2011; Hii et al., 2019).

Several drying methods have been developed for cacao beans, such as oven drying, freeze drying, heat pump drying, and microwave drying, which improve product quality but are not feasible on a large scale because of their high cost (Banboye et al., 2020a; Hii et al., 2019; Sinuhaji et al., 2024). Hot air, infrared, and infrared-assisted hot air are used to dry fruits and vegetables. Hot air is economical and easy to use on a large scale; however, it is disadvantageous in terms of efficiency and product quality. Infrared improves drying time and quality with lower energy consumption (Li et al., 2024; Baldeón et al., 2024a). A rotary dryer combining convection and infrared for cacao beans has been shown to preserve polyphenol and methylxanthine levels similar to those of fresh and sun-dried cacao (Castellanos et al., 2018).

In small-and medium-scale agriculture, drying still relies on non-standardized conventional methods that are characterized by low energy efficiency and inconsistent final product quality. These include sun drying and greenhouse dryers, which are environmentally friendly but require long processing times; gas or diesel dryers, which require precise control to avoid quality issues; and hot-air drying, which is preferred but can negatively affect quality at high temperatures. Drying consumes a large amount of energy, from 12 to 25% of the industrial total, increasing greenhouse gas production. Furthermore, slower conventional methods can cause loss of volatile organic compounds and protein degradation (Pita-Garcia et al., 2025; Kaplan et al., 2025; Kaveh et al., 2023).

Hybrid drying is a technology that optimizes the cost-effectiveness and energy efficiency of conventional drying methods while also being sustainable and clean. It combines heat transfer mechanisms using solar energy and secondary sources such as electric heaters, biomass ovens, and LPG when the sun is dark. It can also use hot air with infrared radiation or microwaves. The advantages of hybrid drying include greater energy efficiency with savings of 50–70%; lower energy consumption compared to individual methods, reduced processing times, improved moisture diffusivity, and improved product quality by maintaining a constant temperature, avoiding problems such as cracking or mold (Pita-Garcia et al., 2025; Kaveh et al., 2023). From this perspective, research has focused on the implementation of solar dryers assisted by hot air and infrared. This assistance was activated when the intensity of solar radiation decreased, allowing the drying temperature to be maintained, thereby improving the quality of the product. The objective of this study was to characterize drying using drying curves, modeling drying kinetics, and effective diffusivity. In addition, the dimensions, physicochemical properties, and cut tests of the fermented and dried cacao beans were analyzed.

2 Materials and methods

2.1 Raw materials

Cacao samples of ecotype CYP-99 (Yopla Pucalpillo Collection) were collected in the Ledoy or Huallaga district, Bellavista province, San Martin region, Peru, at a south latitude of 7°7′52′′ S (−7.13112230000), a west longitude of 76°38′54.9′′ W (−76.64857092000), and an altitude of 263 m a.s.l. The CYP 99 cultivar is starting to be cultivated in Peru because of its earliness, high productivity and sensory quality (Thomas et al., 2023). Samples were collected from trees of productive age in good agronomic conditions.

2.2 Meteorological conditions

Between July 29 and August 4, during the drying process, SENAMHI (2024) reported the meteorological conditions at Bellavista station. Minimum temperatures of 22.0 ± 0.9°C and a maximum temperatures of 37.0 ± 1.3°C were observed. Similarly, the relative humidity was 70.0 ± 2.8%, and no rain was recorded in the Ledoy district. More details can be found in the Supplementary material on the weather conditions at Bellavista Station.

2.3 Reagents

The following salts, including H2SO4 (CAS No. 7664-93-9), were used to determine water desorption isotherms: KNO3 (CAS No. 7757-79-1), NaCl (CAS No. 7647-14-5), MgCl2 (CAS No. 7791-18-6), and LiCl (CAS No. 7447-41-8).

2.4 Experimental solar dryers

2.4.1 Materials

The materials used for the dryers were cheap and easy to find in rural areas, such as a 12 m black weed-control mesh blanket for agriculture (polypropylene raffia fabric), 12 m transparent polyethylene plastic, 16 wooden slats, thumbtacks, and nails. In addition, electrical devices such as two upright fan heaters of 2,000 W and two infrared lamps of 275 W with flexible arms and extension cables resistant to high temperatures were used. Polypropylene mesh blankets, in conjunction with plastic materials, are frequently employed for the purpose of drying fermented grain. The grains were spread over black blankets, which absorbed electromagnetic waves to aid evaporation.

2.4.2 Design of the dryers

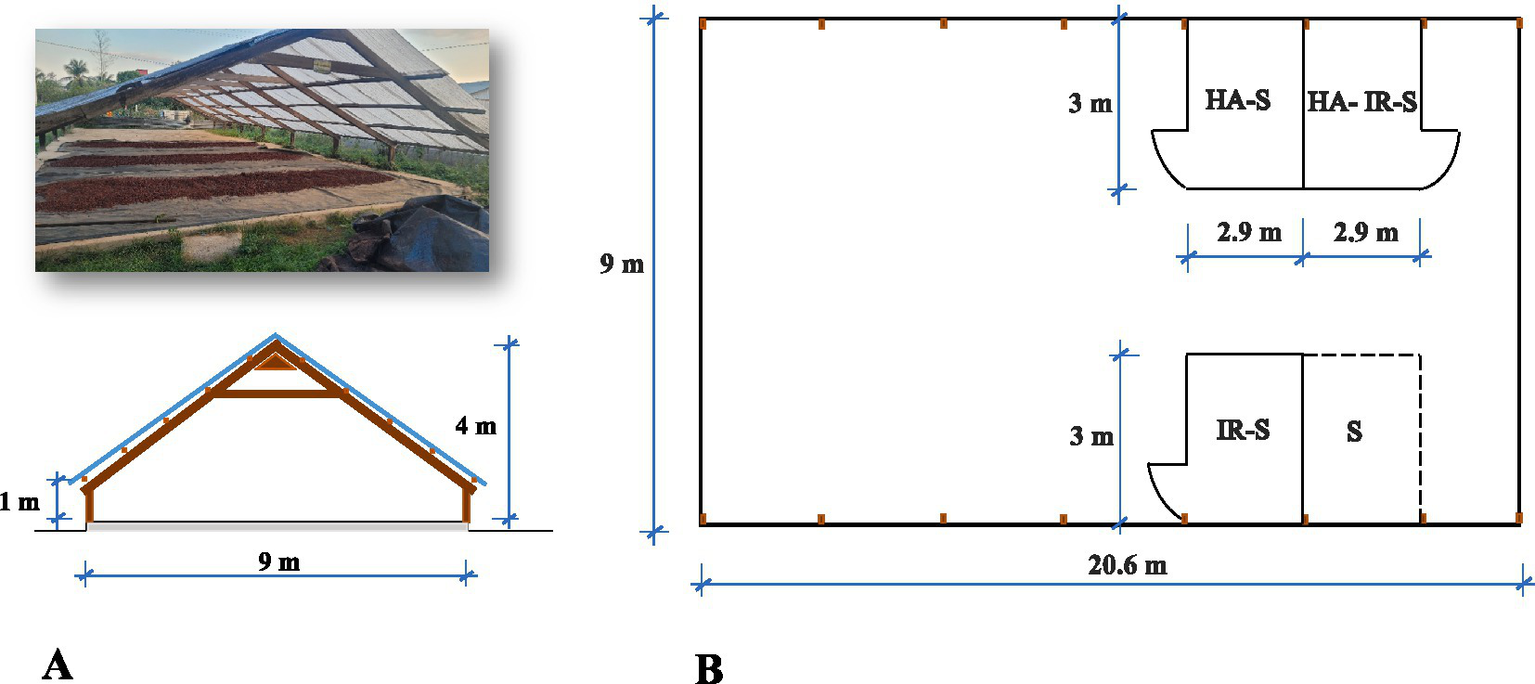

The design of the solar dryers assisted by artificial heaters was based on an existing solar dryer, to which electric heaters and infrared lamps were added. During the 10.5 h of operation, the first 6 h were used as a solar dryer, taking advantage of the high solar radiation. When the temperature decreased, the assisted system was activated to maintain the initial temperature. The solar dryer was 9 m wide and 20.6 m long with, a central height of 4 m and a lower height at the ends of the roof of 1 m.

The roof was made of transparent polypropylene corrugated sheets with a wooden structure supported by hanging beams and cross-slats. The structure was supported by 16 wooden columns 1 m in length. The floor was made of concrete and was raised 20 cm above the ground. The construction was distributed in four areas, each with a 2.9 m long, 3 m of width and 2.3 m high. Figure 1 shows the views and dimensions of the solar dryer and areas allocated for its construction.

Figure 1

Solar dryer: (A) dimensions and view of the dryer and (B) distribution of the solar dryer and assisted solar dryers. HA-S, hot-air-assisted solar; HA-IR-S, hot-air and infrared-assisted solar; S, solar; IR-S, infrared-assisted solar.

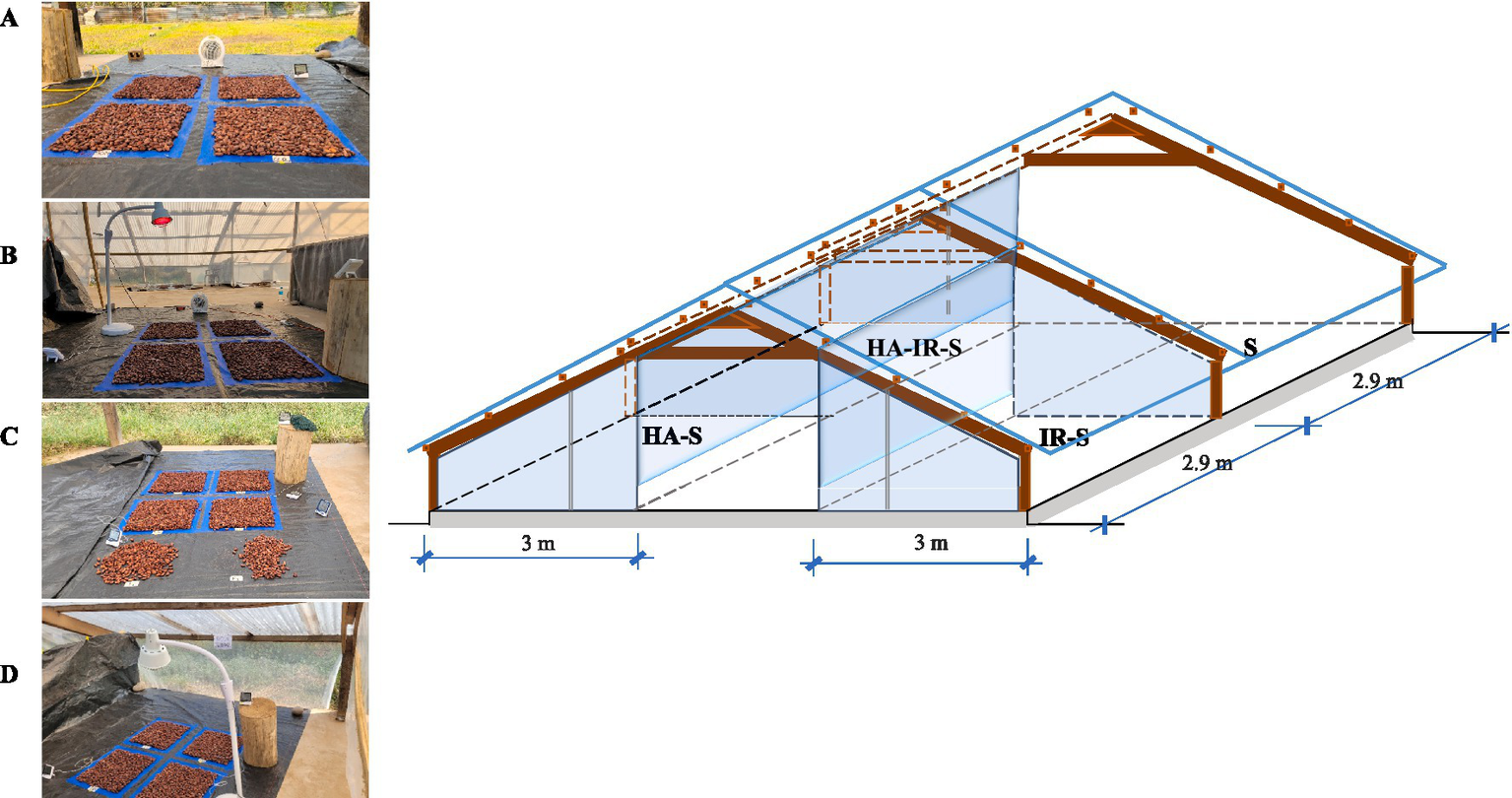

Figure 2 shows the four types of dryers, from solar dryers to solar dryers assisted by heaters and/or infrared lamps. The specifications of the dryers are as follows.

Figure 2

Solar dryers assisted by heaters and infrared lamps. HA-S, hot-air-assisted solar (A); HA-IR-S, hot-air and infrared-assisted solar (B); S, solar (C); IR-S, infrared-assisted solar (D).

Hot-air-assisted solar dryer (HA-S): The characteristics of this drier were similar to those of the previous model. A 2,000 W heater was placed on the floor, maintaining a distance of 40 cm between the device and the mass of the cacao beans. Every hour of operation, the heater was moved to the opposite side to improve heat transmission (Figure 2A).

The hot-air and infrared-assisted solar dryer (HA-IR-S) had characteristics similar to those of previous models. During the operation, half the power of the 1,000 W heater was used with a 275 W infrared lamp with a pedestal. Both devices were moved to the opposite side every hour to optimize the heat distribution (Figure 2B).

Solar dryer (S): The solar drier was the control dryer without a transparent plastic wall (Figure 2C).

Infrared-assisted solar dryer (IR-S): This was characterized by a transparent plastic wall supported by a wooden structure, with side windows 80 cm and 30 cm high. A 275 W infrared lamp with a pedestal was used, adjusted to be 1.2 m above the floor. During use, the lamp was moved hourly to cover a large drying area (Figure 2D).

2.5 Drying processing of cacao beans

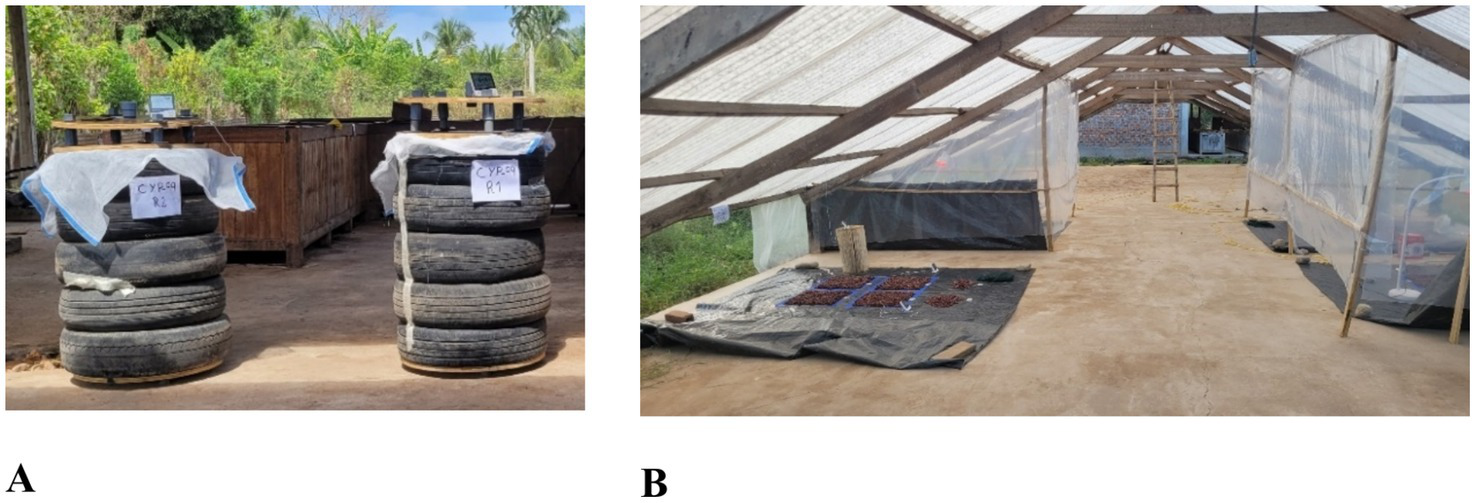

Figure 3 shows the fermentation and drying of the cacao beans. Cacao pods were harvested by separating the fruit from the tree by pruning the shears and separating the ripe from the overripe. The pods were broken with a machete without damaging the beans and were then placed in sacks and buckets. Fermentation occurred spontaneously in portable fermenters made of tires (Figure 3A) with a capacity of 50 kg (Ureña and Sandoval, 2021). The fermenter serves as an inexpensive support structure that retains daytime heat, enabling fermentation to continue overnight, owing to its partially adiabatic properties. It also made it easier to move the fermenter around the field and turn the grains during aerobic fermentation, moving them from one side of the soil to the other; mucilage was removed every 48 h. In this study, temperature, cotyledon acidity, and pH were monitored (data not show). Fermentation was terminated when the fermentation index was at least 60%. This index is based on color change, fissuring, and the appearance of wine color liquid inside the grain.

Figure 3

Fermentation and drying of cacao beans. (A) Portable fermenters and (B) solar and assisted solar-drying areas.

The fermented beans were transferred to solar dryers (Figure 2), where 16 kg of beans was divided into four parts. They were placed on black polypropylene blankets to form a “mountain” and covered with blankets of the same material. Pre-drying lasted for 2 days: the first day the beans remained covered, and the second day, the blankets were removed. The beans were distributed in quadrants of 50 × 50 cm using a 3 cm thick wooden frame and a paddle. Each dryer contained four quadrants, resulting in a loading density of 16 kg/m2 (Figure 2). Drying was performed for 10.5 h per day (8 a.m.–6:30 p.m.) using four different methods: S, IR-S, HA-S, and HA-IR-S (Figure 3B). At the end of the experiment, the sample was covered with black polypropylene blankets, and drying continued until it reached 8% humidity in 5.5 days.

Fermented cacao samples were stored at −18°C. To measure the moisture content, part of the mass was thawed, and the cotyledon was manually separated from the mucilaginous shell. The dried beans were weighed, cleaned, and sorted. Cleaning was performed using a nylon sieve to remove residual dust. The selection consisted of separating, classifying, and weighing the defective beans according to “Cacao de Excelencia (2023).” The selected beans were subjected to physicochemical analyses and cut tests.

2.5.1 Temperature and weight control

A hygrometer (Boeco SH-110, Germany) was used to measure the temperature (inlet) and relative humidity of the drying system. To record the temperature in the beans (outlet), a probe was inserted into the cacao mass, approximately 1 cm from the surface. The cacao beans were weighed manually (Sartorius Balance, ELT-1001, Germany). Measurements of temperature (inlet), relative humidity, temperature (outlet), and weight were performed at five different times (8 a.m., 11 a.m., 2 p.m., 5 p.m., and 6:30 p.m.) and in four quadrants of each dryer (four replicates).

2.6 Desorption isotherm

2.6.1 Preparation of the desiccator and sample

The desorption isotherm of the fermented beans was determined by the static method using a plastic desiccator consisting of a 1.5 L airtight container with a screw-on lid. A polyvinyl chloride (PVC) tube was placed inside each container to hold the perforated disk.

The solutions used in this experiment were H2O, KNO3, NaCl, MgCl2, LiCl, and H2SO4. The fermented beans were hulled to obtain cotyledons and then ground using a knife mill (RETSCH, model GM200, Germany) at 3,000 rpm for 30 s. A total of 2.5 g of the ground sample was weighed in triplicate and placed in six desiccators. The samples were then placed in an oven (JSR; JSON-050, China) at 35 ± 1°C. The water activity of the samples was determined upon the completion of desorption, and equilibrium was reached.

2.6.2 Desorption isotherm modeling

Mathematical models used for desorption isotherm modeling include those developed by Stephen Brunauer, Paul Emmet, and Edward Teller (BET) and those of Guggenheim, Anderson, and De Boer (GAB). Equation 1 expresses the BET model.

where Xe is the equilibrium moisture content (kg water/kg dry solid), Xm is the monolayer moisture content (kg water/kg dry solid), CB is the constant associated with the BET model, and aw is the water activity.

Equation 2 describes the GAB model as follows:

where Xe is the equilibrium moisture content (kg water/kg dry solid), Xm is the monolayer moisture content (kg water/kg dry solid), CG and K are the GAB model constants and aw is the water activity.

2.7 Drying characterization

Characterization was performed for the different drying methods analyzing the drying curves, modeling the kinetics, and calculating the effective moisture diffusivity.

2.7.1 Drying curves

The drying curves for cacao beans showed a relationship between free moisture and effective time, as well as between the drying rate and free moisture.

Equation 3 was used to calculate the free moisture as follows:

where X, X′, and Xe are the free moisture content, total moisture content at any time, and equilibrium moisture content, respectively, expressed in kg total water/kg dry solid. Xe′ was determined using the desorption isotherm with air relative humidities between 17 and 23%.

The drying rate is expressed as Equation 4:

where R is the drying rate (kg H2O/day. m2), Wds is the kg of dry solid used, A is the surface area of the moisture transfer surface in m2, ∆X is the variation in the free moisture content at any time, and ∆t is the variation in the effective time at a given moment expressed in days.

2.7.2 Drying kinetics

The drying kinetics of cacao beans were described by the moisture content versus the effective time. This relationship is calculated using the following Equation 5:

where MR is the moisture ratio and X′, Xe, Xo′, X, and Xc represent the total moisture content at a given time, equilibrium moisture content, initial moisture content corresponding to the decreasing period, free moisture content at any time, and critical free moisture content, respectively. These values are expressed in kg H2O/kg of dry solids.

2.7.3 Mathematical modeling of drying kinetics

The drying kinetics of the cacao beans were modeled using theoretical and semi-empirical mathematical models. Table 1 presents the four selected models that describe the drying behavior.

Table 1

| Model | Equation mathematical | References |

|---|---|---|

| Fick | Baldeón et al. (2024b) | |

| Newton/Lewis | Banboye et al. (2020b) | |

| Page | Banboye et al. (2020b) | |

| Henderson-Pabis | Banboye et al. (2020b) |

Mathematical models for the drying kinetics of cacao beans.

where MR is the moisture ratio (dimensionless), k is the drying constant, a and n are model constants, and t is the effective drying time (days).

2.7.4 Calculation of effective diffusivity

Fick’s second law of unsteady-state diffusion was used to explain mass transfer during cacao bean drying. This model assumes a homogeneous moisture distribution, symmetrical mass transfer, negligible shrinkage, and constant diffusion coefficient. The analytical solution to Fick’s equation is expressed in terms of an infinite series, according to Equation 6 (Zeng et al., 2024; Baldeón et al., 2024b).

where MR is the moisture ratio, Deff is the effective moisture diffusivity (m2/s), L is the half-thickness (m), t is the effective time of cacao drying (days), and n denotes the number of terms in a series.

If the drying time is long, Equation 6 can be simplified to the first term without loss of accuracy (Zeng et al., 2024; Baldeón et al., 2024b), as expressed in Equation 7.

Equation 7 was simplified by applying the logarithm of both sides of the terms of the equation (Zeng et al., 2024; Baldeón et al., 2024b), as expressed in Equation 8.

The slope was calculated by plotting the ln (MR) regression graph against drying time. Equation 9 can be used to estimate effective moisture diffusion (Deff).

2.8 Specific energy consumption

The energy consumptions of the heater and infrared lamps were calculated using Equation 10 (Zeng et al., 2024):

where EC is the energy consumed (kWh), P is the power of the assistive device (kW), and ∆t is the drying assistance time (h). For solar drying assisted by hot air and infrared, the assistance time was calculated as 4.5 h per day multiplied by 4 days, resulting in a total of 18 h of drying assistance.

The specific energy consumption was calculated using Equation 11:

where EC is the specific energy consumption (kWh/kg) and mw is the mass of water removed (kg).

2.9 Moisture determination

Moisture content was determined according to the NTP method 208.017, as cited in NTP (2021). The cacao beans were ground, weighed, and dried for 16 h in an oven at 103 ± 2°C.

2.10 Bean dimensions

The dimensions of the dried cacao beans were evaluated using an electronic Vernier caliper (Stainless Hardened®), measuring the length, width, and thickness, according to the methodology of Chire et al. (2014). Thirty-two representative clean beans were selected. The geometric diameter (Equation 12) and sphericity of each bean (Equation 12) were calculated (Dursun et al., 2007).

where L is the length, which is the longest part of the bean; W is the width, the widest part, and T is the thickness, which is the most prominent and thick part.

The grain index (IG) was the average bean weight in grams (g) obtained from a sample of 100 dry cacao beans (g/grain) (Bacca-Villota et al., 2023).

2.11 Physicochemical analysis

2.11.1 pH

pH was measured following the NTP 208.026:2015 method described by INACAL (2021). Cotyledons of dry cacao beans were ground at 6,000 rpm for 10 s. Five grams of ground beans were placed in a 50 mL beaker, to which 10 mL of distilled water was added. The mixture was homogenized using a magnetic stirrer and a calibrated electrode was used to measure the pH of the supernatant liquid, waiting for a stable reading for 30 s. Measurements were performed in triplicates.

2.11.2 Titratable acidity

Potentiometric titration was performed to determine titratable acidity following the NTP 208.026:2015 method, as mentioned by INACAL (2021). 10 g of ground beans were weighed into a 250 mL beaker, 90 mL of hot distilled water was added, and the mixture was stirred for 20 min. It was then cooled and titrated with NaOH (0.1 N) to a pH of 8.2, using a magnetic stirrer to homogenize the mixture. Measurements were performed in triplicate, recording the volume consumed to calculate the titratable acidity and expressing it as acetic acid per 100 g cacao.

2.11.3 Water activity

Water activity (aw) was determined in fermented and dried cacao beans using an AQUA LAB 4 TEV DUO meter at 25 ± 1°C following the method of García-Alamilla et al. (2007). The cacao beans were de-stemmed, ground, and sieved through a standard 20-mesh sieve (850 μm). Measurements were performed in triplicate.

2.12 Cut test

A cut test was performed according to the methodology established by “Cacao de Excelencia (2023).” Three hundred representative beans were randomly selected for each sample. Fifty beans were cut longitudinally through the center using a guillotine (MAGRA 14; Teserba, Switzerland) to expose the maximum cut surface of the cotyledons. Half of each bean was examined under daylight conditions, and the beans were counted and classified into three groups. This test was repeated six times.

Group 1: Defective beans: moldy beans, insect-damaged/infested beans, germinated beans, and slaty beans.

Group 2: Classification by color light brown/yellowish, fully light brown, fully brown, partly purple/violet, partly brown, fully purple/violet, ivory/white/blond, fully dark brown and fully black. The percentage of each color was then calculated.

Group 3: Degree of fissuring, classifying the alveoli into grades 1, 2, 3, or 4. Percentages were calculated based on this classification.

The percentage of fermentation was calculated by summing the percentage of light brown/yellowish, fully light brown and fully brown and the percentage of partly purple/violet and partly brown color categories from Group 2.

2.13 Statistical analysis

The results of the study are expressed as the mean ± standard deviation (SD), based on three replicates for assessing physicochemical properties, 32 replicates for measuring cocoa bean dimensions, and six replicates for conducting the cut test. These results were evaluated using analysis of variance (ANOVA) and Tukey’s test for differences between groups (p < 0.05). The experiments were performed using a completely randomized design (CRD). Data analysis was performed using the Statgraphics Centurion 19 software (Statgraphics Technologies, Inc., United States). In addition, the drying kinetic data were fitted by nonlinear regression using the Excel (Microsoft United States) Solver tool to fit the models and obtain the equation coefficients and constants (a, k, and n). The suitability of the models was determined using statistical tests, specifically the coefficient of determination (R2) and the root mean square error (RMSE).

3 Results and discussion

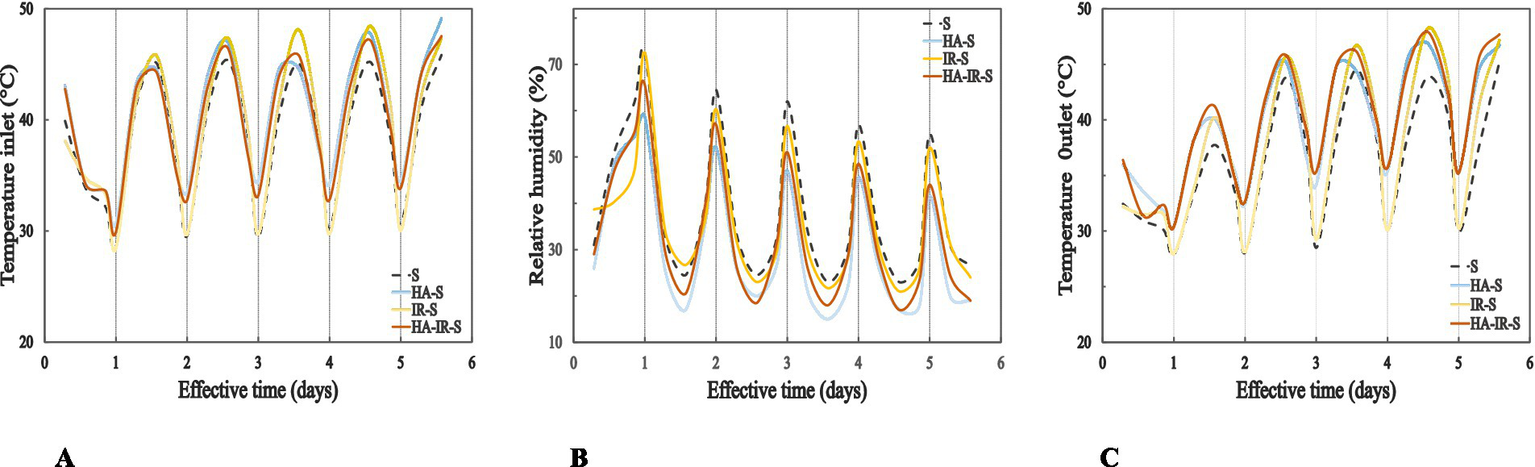

3.1 Temperature and relative humidity profiles

Figure 4 shows the temperature of the drying system (inlet), the relative humidity of the drying system, and the temperature in the cacao beans (outlet) using different methods: solar (S), hot air-assisted solar (HA-S), infrared-assisted solar (IR-S), and hot air and infrared-assisted solar (HA-IR-S). The minimum temperatures (inlet) recorded at the beginning of the second day of drying were 28.6°C, 30.7°C, 28.4°C, and 29.9°C for the S, HA-S, IR-S, and HA-IR-S methods, respectively; however, at the beginning of the fourth day of drying, differences of 4.5°C were observed for the HA-S and HA-IR-S methods compared to the S method (Figure 4A). This is because the solar-assisted dryers accumulate more energy during the rest period (6:30 p.m. to 8 a.m.).

Figure 4

Temperature and relative humidity profiles during cacao bean drying. (A) Temperature of drying system (inlet), (B) relative humidity of drying system, and (C) temperature in the beans (outlet). S, solar; HA-S, hot-air-assisted solar; IR-S, infrared-assisted solar; HA-IR-S, hot-air and infrared-assisted solar.

The maximum temperature (inlet) remained almost constant, except in the last few days when a 2°C difference was observed between the assisted solar methods and the S method (Figure 4A). The maximum temperature was reached at 2:00 p.m., being 45.8°C, 49.1°C, 48.4°C, and 47.5°C for the S, HA-S, IR-S, and HA-IR-S methods, respectively. In the open sun and solar drying of cacao beans, the maximum temperature ranges have been reported to occur between 12:00 and 2:00 p.m., because during this period, the intensity of sunlight reaches its peak (Sinuhaji et al., 2025; Obinze et al., 2022).

The minimum relative humidity of the drying system was recorded over an effective period of 4.5 days, with values of 23, 17, 21, and 17% for methods S, HA-S, IR-S, and HA-IR-S, respectively (Figure 4B). Methods HA-S and HA-IR-S showed a 6% reduction compared to method S. This is because the ambient air initially removed more water from the cacao beans, and then the relative humidity of the air decreased as the beans released less water.

The maximum relative humidity of the drying system was reached at the beginning of the second day of drying, with values of 72.5, 58.7, 72.5, and 65.5% for S, HA-S, IR-S, and HA-IR-S, respectively (Figure 4B). There were no differences between the IR-S and S methods, but there were differences between the HA-S and HA-IR-S methods with respect to method S, with decreases of 14 and 7%, respectively. In the solar drying of cacao beans, the temperature and relative humidity of the system were recorded at 32.29°C and 52.21%, respectively (Banboye et al., 2020b).

The minimum temperatures (outlet) were recorded at the beginning of the second drying day at 27.9°C, 30.5°C, 28°C and 30.4°C for the S, HA-S, IR-S, and HA-IR-S methods, respectively (Figure 4C). No differences were observed between the S and IR-S methods, but there was a difference of 2.5°C when comparing the S with the HA-S and HA-IR-S methods. It was noted that this difference doubled from the fourth day of drying because during the resting period, the bean and its environment retained heat that counteracted the nighttime cooling, something that did not occur with the S method, where the surrounding air cooled the bean (Raju et al., 2022).

The maximum temperatures (outlet) were recorded on the fourth and a half day and were 43.9°C, 46.9°C, 48.3°C, and 47.9°C for the S, HA-S, IR-S, and HA-IR-S methods, respectively (Figure 4C). Compared to the S method, the assisted solar methods showed an average increase in temperature (outlet) of 3.8°C. It was observed that the bean temperature gradually increased by 5°C until the third day, and then stabilized for all drying methods. This behavior was related to a decrease in the relative humidity of the system as the temperature in the beans increased.

This study confirmed that higher temperatures lead to lower relative humidity, which in turn leads to a higher evaporation rate of water from the sample. Establishing a good relationship between these parameters is essential as it affects the drying and quality of beans (Sinuhaji et al., 2025; Obinze et al., 2022; Banboye et al., 2020b). A 4°C variation in temperature (outlet) was observed when using the HA-IR-S method compared to the S method. This phenomenon can be attributed to the heating of the hot-air and infrared-assisted drying systems during periods of low solar radiation.

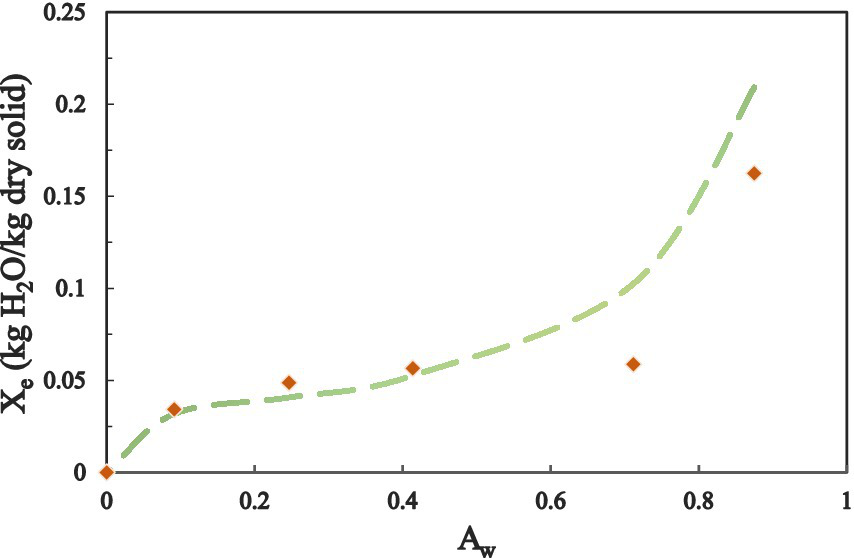

3.2 Desorption isotherm

Table 2 shows the mathematical models used to model the desorption isotherms at 35°C for the fermented cacao beans. Both the GAB and BET models provide a good fit to the experimental data. The GAB model was particularly effective for aw < 0.95, making it suitable for application to cacao samples with a high aw (Figure 5). A similar result was found in a study on the adsorption isotherm of dried cacao beans, in which the GAB model was highlighted as the most accurate (Navarro-Pinedo et al., 2024; Koua et al., 2016; Bidias et al., 2022).

Table 2

| Model | Parameters | R 2 | RMSE |

|---|---|---|---|

| GAB |

Xm = 0.032 CG = 99.999 K = 0.968 |

0.938 | 0.058 |

| BET |

Xm = 0.035 CB = 120.639 |

0.982 | 0.088 |

Mathematical models for desorption isotherms of fermented cacao beans.

Figure 5

Desorption isotherm of fermented cacao beans at 35°C. Experimental data (♦) and GAB model (─ ─ ─).

The BET and GAB models are used to calculate the moisture content of the monolayer (Xm) (Table 2). Similar studies have indicated that different cacao cultivars have Xm values of 0.030–0.035 kg H2O/kg dry solids in fermented and dried beans, respectively (Herman et al., 2018; Navarro-Pinedo et al., 2024), whereas another study reported a value of 0.061 kg H2O/kg dry solids in fermented beans (Akmel et al., 2015). Figure 5 shows the desorption isotherm of the fermented cacao beans with a sigmoidal curve typical of food sorption isotherms. According to the Brunauer classification, it is type II because of the presence of multilayers on the internal surface of the material (Blahovec and Yanniotis, 2009), as reported by other authors (Navarro-Pinedo et al., 2024; Koua et al., 2016; Akmel et al., 2015).

The equilibrium moisture content (Xe) is the moisture level at which the cacao beans remain stable and neither gain nor lose moisture because they are in equilibrium with the ambient relative humidity. It is crucial to calculate the free moisture content and outline the drying curve. In hot-air and infrared-assisted solar drying of cacao beans, the final relative humidities were 23, 17, 21, and 17% for the S, HA-S, IR-S, and HA-IR-S methods, respectively. These values were applied in Equation 2, yielding Xe values of 0.040, 0.036, 0.040, and 0.036 kg H2O/kg dry solids, respectively. During the hybrid drying of cacao, value fitting was determined to be 0.036 kg H2O/kg dry solid (Pita-Garcia et al., 2025), similar to those in this study; other Xe values have been reported to be 0.0464 to 0.067 kg H2O/kg dry solid (Mujaffar et al., 2017).

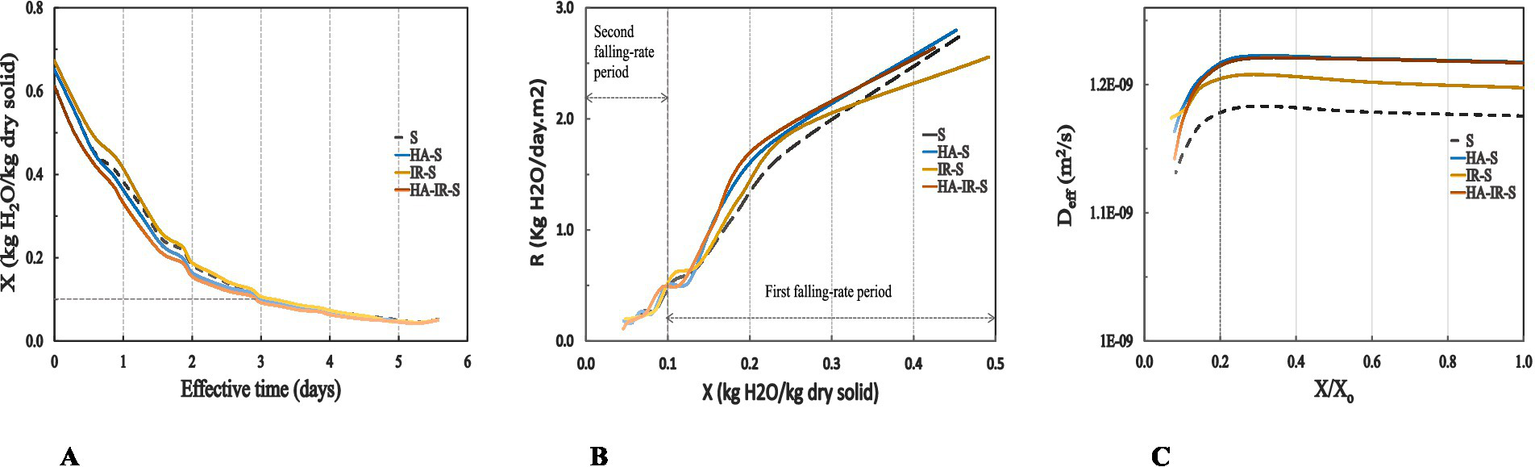

3.3 Drying characterization

Figure 6 shows the drying curves of the cacao beans using different drying methods. The free moisture versus effective time curve (Figure 6A) shows that free moisture decreases rapidly to 0.10 kg H2O/kg dry solid in an effective time of 3 days. It then decreases more slowly until reaching moisture levels close to equilibrium in a total effective time of five and a half days (Figure 6A). In indirect drying, the moisture content decreases rapidly during the first day of drying (Koua et al., 2019). During the first 3 days of drying, the method used exerted a significant influence, with HA-IR-S being the most prominent, followed by the HA-S method, while the IR-S and S methods exhibited similar behaviors.

Figure 6

Drying curves of cacao beans. (A) Free moisture vs. effective time curve, (B) velocity vs. free moisture curve, and (C) effective moisture diffusivity vs. moisture ratio curve. S, solar; HA-S, hot-air-assisted solar; IR-S, infrared-assisted solar; HA-IR-S, hot-air and infrared-assisted solar.

The falling-rate period of drying was observed in the drying rate curve versus free moisture content. The first falling-rate period extends from the initial free moisture content to 0.10 kg H2O/kg dry solid (Figure 6B). During this period, approximately 84% of the water in cacao beans evaporated. This behavior resulted from the faster diffusion of free water from the interior of the bean to the surface.

However, the remaining water in the bean is eliminated during the second falling-rate period, which runs from the end of the first falling-rate period until a moisture content close to equilibrium is reached. This period requires an effective time of two and a half days. This phenomenon is due to the fact that most of the water is not free, but bound, and is eliminated by sorption (Koua et al., 2019). In the convective drying of cacao beans, the drying process is divided into two falling rate periods, with diffusivity being the controlling factor (Herman et al., 2018). This finding was similar to that of the present study.

Drying rate curve analysis showed that the HA-S and HA-IR-S methods had similar drying characteristics. The same was true for the S and IR-S methods. Furthermore, when comparing drying rates up to X = 0.3 kg H2O/kg dry solid, the drying rate of the HA-IR-S method was found to be 10% higher than that of the S method. However, at X = 0.2 kg H2O/kg dry solid, this difference increased to 30.8%. Subsequently, a decrease in the drying-rate ratio was observed between the two methods (Figure 6B). This indicates that the support of the HA-S and HA-IR-S methods has a greater influence on the drying rate during the first falling-rate period, whereas their influence is less in the second falling-rate period.

The effective moisture diffusivity (Deff) values for the cacao beans were 1.18 × 10−9 m2/s and 1.20×10−9 m2/s for the S and IR-S methods, respectively. For the HA-S and HA-IR-S methods, the average value was the same at 1.22×10−9 m2/s, with a 3.4% increase in Deff for the HA-IR-S method compared to the S method. Based on the temperature profile results, a 4°C increase in temperature was determined for the HA-IR-S method compared to the S method. This suggests that Deff of assisted solar drying is higher than that of solar drying because Deff increases at higher temperatures, which favors the transfer of moisture from the interior of the material to its surface (Sinuhaji et al., 2025; Koua et al., 2019).

During indirect solar drying of cacao beans, Deff values ranging from 5.49 × 10−10 m2/s to 4.26 × 10−10 m2/s were identified (Koua et al., 2019). Similarly, during convective drying of cacao beans, Deff was 0.68×10−10 m2/s at 30°C, and this value doubled to reach 1.83 × 10−10 m2/s at 60°C (Herman et al., 2018). These values were lower than those obtained in the present study. This difference could be related to bean size, since the CYP-99 ecotype was large and the drying technique used. In addition, increasing the layer thickness and temperature can significantly improve drying efficiency (Zeng et al., 2024).

The graph of Deff vs. moisture content shows that Deff remains constant up to a moisture content ratio of 0.2; beyond this point, Deff decreases (Figure 6C). This is because the water evaporation mechanism is no longer controlled by diffusion (Figure 6B), and water removal becomes more limited after the second falling-rate period. In contrast to the indirect solar drying of cacao beans, a linear decrease in Deff with respect to the moisture content was observed (Koua et al., 2019).

3.4 Drying kinetics modeling

Table 3 presents the calculated parameters for the cacao drying models with coefficients of determination and RMSE values. All models had RMSEs between 0.068 and 0.020, and R2 values greater than 0.98. The Newton model was the most appropriate for the S method, with an RMSE of 0.020 and an R2 of 0.995. The Page model is suitable for assisted solar methods such as HA-IR-S, with an RMSE of 0.020 and R2 of 0.994. The.

Table 3

| Drying method | Model | Parameters | R 2 | RMSE |

|---|---|---|---|---|

| Solar (S) | Fick | k = 0.467, a = 0.811 | 0.984 | 0.062 |

| Newton/Lewis | k = 0.571 | 0.995 | 0.020 | |

| Page | k = 0.557, n = 1.037 | 0.994 | 0.022 | |

| Henderson-Pabis | k = 0.582, a = 1.018 | 0.995 | 0.021 | |

| Hot-air-assisted solar (HA-S) | Fick | k = 0.495, a = 0.811 | 0.981 | 0.060 |

| Newton/Lewis | k = 0.613 | 0.994 | 0.022 | |

| Page | k = 0.630, n = 0.957 | 0.994 | 0.021 | |

| Henderson-Pabis | k = 0.611, a = 0.997 | 0.994 | 0.022 | |

| Infrared-assisted solar (IR-S) | Fick | k = 0.463, a = 0.811 | 0.984 | 0.068 |

| Newton/Lewis | k = 0.571 | 0.993 | 0.022 | |

| Page | k = 0.557, n = 1.037 | 0.994 | 0.022 | |

| Henderson-Pabis | k = 0.582, a = 1.018 | 0.993 | 0.022 | |

| Hot-air and infrared-assisted solar (HA-IR-S) | Fick | k = 0.501, a = 0.811 | 0.981 | 0.057 |

| Newton/Lewis | k = 0.621 | 0.994 | 0.023 | |

| Page | k = 0.649, n = 0.931 | 0.994 | 0.020 | |

| Henderson-Pabis | k = 0.611, a = 0.985 | 0.994 | 0.022 |

Coefficients and constants of the mathematical models for the drying kinetics of cacao beans.

Page model is most favorable for greenhouse solar and convective drying (Banboye et al., 2020b). For intermittent drying, the Newton model provided the best fit (Sahadeo et al., 2024). For hybrid solar drying, the Henderson-Pabis model was the most suitable (Pita-Garcia et al., 2025), which is comparable to the results of this study. The drying kinetics curve obtained using the HA-IR-S method demonstrated a more pronounced decrease in humidity than that curve obtained using the S method alone. This behavior can be described using the Page model, which incorporates constants k and n into its mathematical equation. Conversely, the Newton model is more aptly suited to the description of the S-method. Page model constants have been shown to be associated with mass transfer rate (Pita-Garcia et al., 2025).

The influence of the drying method on the drying constant (k) was determined (Table 3). The HA-S and HA-IR-S methods presented the highest k values, with a 12% increase in the case of the HA-IR-S method compared to the S method. This pattern was also reflected in the Deff, which was higher for the HA-S and HA-IR-S methods, resulting in higher drying rates. This can have a significant impact on crucial aspects of final cacao quality, allowing for fast and efficient drying (Pita-Garcia et al., 2025). Another factor affecting the variation in K values is the drying conditions, including temperature, relative humidity, and solar radiation. All these factors influence the drying process (Pita-Garcia et al., 2025; Sinuhaji et al., 2025). During solar drying, solar radiation and relative humidity fluctuate throughout the day. During the maximum drying temperature of the HA-IR-S method, low relative humidity was observed, resulting in increased K values. Consequently, the drying rate of the cocoa beans increased.

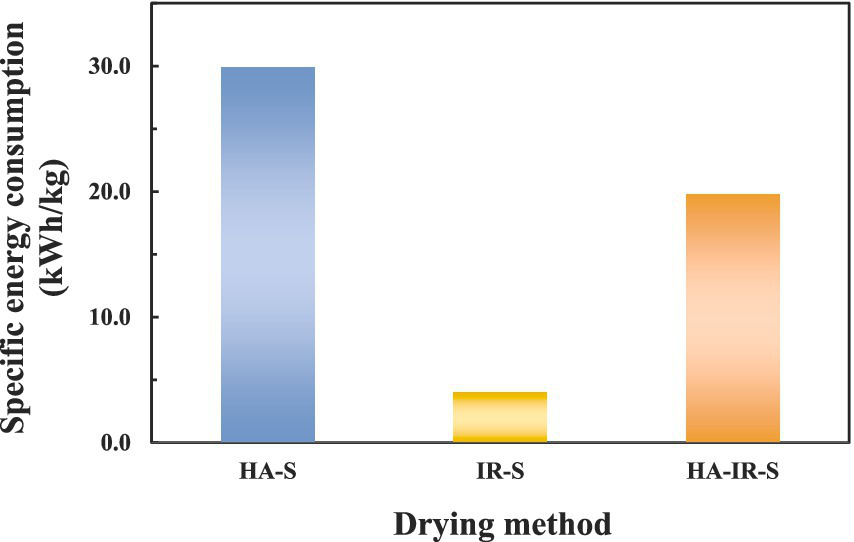

3.5 Specific energy consumption

Energy use is an essential factor in the agroindustry, particularly in the drying process, because of the high consumption of electricity and liquefied petroleum gas, which increases the operating costs (Pita-Garcia et al., 2025). Therefore, the implementation of technologies, such as hot air and infrared, is an alternative to improve the efficiency of solar drying during periods of low radiation. Figure 7 shows the specific energy consumption (SEC) of the air and infrared solar dryers for cacao beans. The lowest SEC was observed in the IR-S method (3.99 kWh/kg), while the HA-S method (29.87 kWh/kg) recorded a higher SEC, followed by the HA-IR-S method (19.77 kWh/kg), the latter representing a 33.8% decrease compared with the HA-IR-S method.

Figure 7

Specific energy consumption of different drying methods for cacao beans. HA-S, hot-air-assisted solar; IR-S, infrared-assisted solar; HA-IR-S, hot-air and infrared-assisted solar.

A study on alfalfa drying using various techniques revealed that the hybrid microwave-convection drying method resulted in the highest SEC of 1.67 kWh/kg, while the convective drying method had the lowest SEC of 0.26 kWh/kg (Kaplan et al., 2025). Similarly, in vacuum microwave drying of Chilean abalone, SEC values ranging from 7.15 to 35.67 kWh/kg were reported (Pérez-Won et al., 2024). In contrast, research focusing on the drying of pear slices using different techniques showed that combined drying methods, such as microwave convection or infrared convection, are more energy-efficient than individual methods, such as microwave, infrared, or convection drying (Kaveh et al., 2023).

The results of the present study align with previous findings, showing that solar drying, when aided by hot air and infrared radiation, can lead to a reduction in energy consumption. Although the IR-S method consumes less energy, its effectiveness as a complementary method to solar drying is limited owing to its low drying rate. Compared with the HA-S and HA-IR-S methods, the latter is a viable option owing to its lower energy consumption. Combining technologies with solar drying improves the sustainability of the cocoa drying processes (Sinuhaji et al., 2025). The increased effectiveness of hot air and infrared-assisted solar drying is due to the synergy between the two. Infrared radiation penetrates and heats the core of cocoa beans, promoting moisture circulation. Hot air removes surface moisture and facilitates the heating process. This combination accelerates mass transfer and consumes less energy than each method separately (Jeevarathinam et al., 2021).

3.6 Dimensions of fermented and dried beans

Table 4 presents the dimensions of the fermented (F) and dried beans according to the drying method. The highest values for L (27.86 mm), W (15.01 mm), and T (13.87 mm) were observed in F, while the lowest values were found in the HA-S method, with measurements of 25.89 mm, 13.87 mm, and 8.52 mm, respectively. There were significant differences (p < 0.05) between the F and HA-S methods. For the L dimension, no differences were observed between F, S, and HA-IR-S, and the same was true for HA-S and IR-S. For the W dimension, there were no significant differences (p < 0.05) between F, S, IR-S, and HA-IR-S. However, differences were found between F and all methods for the T-dimension.

Table 4

| Drying method | L, mm | W, mm | T, mm | Dg | φ | GI |

|---|---|---|---|---|---|---|

| F | 27.86 ± 3.15a | 15.01 ± 1.59a | 11.28 ± 1.72a | 16.70 ± 1.41a | 0.60 ± 0.04a | 3.15 ± 0.49a |

| S | 26.43 ± 1.93ab | 14.94 ± 0.94a | 8.71 ± 1.43b | 15.03 ± 0.80b | 0.57 ± 0.05ab | 1.94 ± 0.25b |

| HA-S | 25.89 ± 2.73b | 13.87 ± 1.12b | 8.52 ± 1.12b | 14.46 ± 0.88b | 0.56 ± 0.05b | 1.80 ± 0.28b |

| IR-S | 25.93 ± 2.55b | 14.61 ± 1.08ab | 9.07 ± 1.36b | 15.03 ± 0.99b | 0.58 ± 0.05ab | 1.95 ± 0.31b |

| HA-IR-S | 26.23 ± 2.54ab | 14.51 ± 1.09ab | 8.47 ± 1.29b | 14.71 ± 0.99b | 0.56 ± 0.05b | 1.89 ± 0.28b |

Dimensions of cacao beans.

F, Fermented beans before drying; S, solar; HA-S, hot-air-assisted solar; IR-S, infrared-assisted solar; HA-IR-S, hot-air and infrared-assisted solar; L, Length; W, Width; T, Thickness; Dg, Geometric diameter; φ, Sphericity; GI: Grain index. Means and standard deviations followed by different letters within a column indicate significant differences (p < 0.05).

During sun-drying of cacao beans of the ICS 6 ecotype, measurements of L (23.39 mm), W (12.82 mm), and T (9.32 mm) were recorded (Andrade-Almeida et al., 2019). Likewise, in the convective drying of Forastero variety cacao beans at 40°C and 0.6 m/s, measurements of L (24.3 mm), W (13 mm), and T (10 mm) were reported (Herman et al., 2018). The L and W values were lower than those obtained in the present study, whereas the T values were slightly higher. This variation in dimensions can be attributed to the fact that cocoa is cultivated in different areas and uses different agronomic methods.

Before drying, fermented beans had the largest dimensions. After drying, these dimensions were affected by the drying method used, with the HA-S method reducing the L and W by 6.9 and 7.6%, respectively. This reduction was even greater for T (24.5%) than for fermented beans. This indicates a greater deformation in thickness, suggesting a lower resistance to mass transfer compared with L and W. In a hybrid drying study combined with solar drying, greater shrinkage was observed in the radial direction of beans (Sinuhaji et al., 2025). The elliptical shape of the cocoa bean and the arrangement of its internal components indicate that it exhibits distinct mechanical properties along three main axes: length, width, and thickness (Adrover and Brasiello, 2020). The internal organization of the bean, combined with the moisture removal process and the mechanical properties of its cellular components, results in uneven shrinkage. The thickness of the cocoa bean is the most affected dimension because of its lower structural rigidity compared to the other two dimensions.

Regarding the geometric diameter (Dg), the highest value corresponded to the F (16.7), whereas the lowest was for the HA-S method (14.46). No significant differences (p < 0.05) were observed in the Dg of the S and assisted solar methods, but there were differences between S and F. Regarding sphericity (φ), the highest value was found in F (0.60) and the lowest in HA-S (0.56), with slight differences between the drying methods (Table 4).

Previous studies on the drying of cocoa beans from Ghana and Mexico, involving genotypes different from CYP-99, reported Dg values of 12.26 and 12.55, and φ values of 0.57 and 0.58, according to Bart-Plange et al. (2012) and Tobias-Baeza et al. (2024). Clearly, these figures are both lower and closer to the results obtained in the current study. The differences between cacao beans are mainly due to genetics, soil and climate conditions, postharvest treatment, and water content (Tobias-Baeza et al., 2024). Measuring the physical properties of cacao beans provides insights into the drying process and enables the optimization of machine designs such as sorters, peelers, dryers and roasters, which are tailored to the needs of each variety.

The highest GI was observed in F (3.15 g/grain) and the lowest in the HA-S method (1.80 g/grain), with no significant differences (p < 0.05) between the methods (Table 4). In solar drying of cacao beans from Colombia, a GI range of 1.59–2.43 was determined (Horta-Téllez et al., 2019) and in Ecuador and Peru between 1.24 and 1.50 g/grain (Andrade-Almeida et al., 2019). In this study, beans of the CYP-99 ecotype, with a GI greater than 1.7 g/grain, were classified as having a high bean index, similar to those from Colombia (Bacca-Villota et al., 2023). Knowing the GI is essential for cacao roasting because larger beans require higher temperatures and times (Andrade-Almeida et al., 2019).

3.7 Moisture and physicochemical properties

Table 5 shows the moisture content and physicochemical properties of the fermented and dried beans. The highest moisture content was recorded in the F (42.04%), and the lowest in the HA-IR-S method (8.16%). No significant differences (p < 0.05) were observed between the solar-assisted methods, although the S method presented 4.6% more moisture than the HA-IR-S method. This increase could be related to a 3.8°C increase in the maximum cacao bean temperature of the assisted solar method, which would increase the rate of water evaporation. Previous studies agree with these results and show that the moisture content of fermented beans varies between 41 and 49.86%, and that of dried beans between 5.95 and 9.78% (Pita-Garcia et al., 2025; Guda et al., 2017; Banboye et al., 2020b). The values obtained were close to commercial humidity (6–8%) (Hii et al., 2006; Mujaffar et al., 2017). The desired humidity should be maintained during storage to ensure chemical, biochemical, and microbiological stability.

Table 5

| Drying method | Humidity (%) | aw | Acidity (g acetic acid/100 g cacao) | pH |

|---|---|---|---|---|

| F | 42.04 ± 0.04a | 0.97 ± 0.01a | 1.83 ± 0.16a | 4.31 ± 0.11a |

| S | 8.55 ± 0.07b | 0.65 ± 0.00b | 2.69 ± 0.05b | 3.51 ± 0.01b |

| HA-S | 8.22 ± 0.04c | 0.66 ± 0.00b | 2.68 ± 0.04b | 3.37 ± 0.01c |

| IR-S | 8.32 ± 0.10c | 0.69 ± 0.00c | 2.81 ± 0.03c | 3.44 ± 0.01d |

| HA-IR-S | 8.16 ± 0.02c | 0.64 ± 0.11b | 2.51 ± 0.04d | 3.46 ± 0.01d |

Physicochemical properties of the cacao beans.

F, Fermented beans before drying; S, solar; HA-S, hot-air-assisted solar; IR-S, infrared-assisted solar; HA-IR-S, hot-air and infrared-assisted solar. Means and standard deviations followed by different letters within a column indicate significant differences (p < 0.05).

Fermented beans had a high aw value (0.97), indicating high water availability before drying, classifying them as fresh or perishable agricultural products (Table 5). For dried beans, the IR-S method had the highest aw value (0.69), and the HA-IR-S method had the lowest (0.64) with no significant differences (p < 0.05) between the S, HA-S, and HA-S-R methods (Table 5). In solar and artificial drying, aw values of 0.95–0.98 were determined for fermented beans and 0.41–0.79 for dried beans (Mujaffar et al., 2017; Salazar et al., 2020). These values are similar to those obtained in the present study. In general, this value represents moderate activity that provides stability and low aw levels for the development of pathogenic microorganisms.

Fermented beans had the lowest acidity (1.83 g acetic acid/100 g cacao) and highest pH (4.31). In dried beans, no significant differences (p < 0.05) in acidity were observed between the S (2.69 g acetic acid/100 g cacao) and HA-S methods, but there were differences between the IR-S and HA-IR-S methods. The IR-S method had the highest acidity, whereas the HA-IR-S method had the lowest acidity (2.51 g acetic acid/100 g cacao) (Table 5). The pH of cacao beans decreased with the drying method, and there were significant differences between them (p < 0.05), with the highest pH for the S method (3.51) and the lowest pH for the HA-S method (3.37), with no significant differences between the IR-S and HA-IR-S methods (Table 5).

Drying using the tested methods began with fermented beans containing 1.83 g of acetic acid per 100 g of cocoa and a pH of 4.31. At the end of the drying process, there were no significant differences (p < 0.05) in acidity between the S (2.69 g of acetic acid/100 g of cocoa) and HA-S methods, contrary to the results obtained using the IR-S and HA-IR-S methods (2.51 g of acetic acid/100 g of cocoa) (Table 5). The pH of the fermented cocoa beans decreased significant with the drying method (p < 0.05). The highest pH value corresponded to the S method (3.51) and the lowest to the HA-S method (3.37), with no significant difference between the IR-S and HA-IR-S methods (Table 5).

In cacao cultivars in Ecuador and Peru, acidity varies between 0.82 and 2.49% and pH between 4.93 and 5.36, with acidity in Peru being three times higher than that in Ecuador, possibly because of its origin and postharvest handling (Andrade-Almeida et al., 2019). The CYP-99 ecotype in this study had similar acidity, but differed in pH. In cacao bean drying, tray and sun drying resulted in lower acidity (1.68 and 1.51 g acetic acid/100 g) and pH (5.18 and 5.0, respectively) (Guda et al., 2017). Similarly, it showed changes in acidity (1.04 and 0.92 g acetic acid/100 g) and pH (5.52 and 5.57, respectively) were observed in hybrid drying and combined with solar drying. In this study, after drying, the acidity increased and the pH decreased, and this effect was lower for the HA-IR-S method. In general, solar drying decreases total acidity and increases the pH (Hii et al., 2006).

The relationship between acidity and pH is fundamental to cacao quality and determines the flavor of fermented and dried beans. It is critical for the beans to reach a pH between 5.0 and 5.5 during fermentation to produce fermented and dried cacao beans with desirable flavors (Pita-Garcia et al., 2025; Oliveira et al., 2021). Conversely, a pH between 4.0 and 4.5 could indicate lower-quality beans with less desirable flavors (Pita-Garcia et al., 2025; Oliveira et al., 2021). In other studies, the pH of the fermented beans varied from 4.64 to 5.0 (Hii et al., 2006; Mujaffar et al., 2017). For the fermentation of CYP-99 ecotype beans, ventilation, fermentation time, and type of fermentation may have affected pH, acidity, and cacao quality (Oliveira et al., 2021).

The S method, which was used as a control, showed beans with higher acidity and pH values, whereas the HA-IR-S method showed lower values. During the first few days of drying, most of the water, acetic acid, and other volatiles were eliminated. Subsequently, the bean shell became impermeable, leading to acid concentration. Slow drying favors the elimination of acetic acid, whereas rapid drying hardens the surface and prevents acid diffusion (Pita-Garcia et al., 2025). Beans dried using HA-IR-S showed good drying and physicochemical properties. Although beans are partially fermented (Oliveira et al., 2021), they are suitable for chocolate production because acidity can be adjusted during conching, thus developing chocolate flavors (Andrade-Almeida et al., 2019).

3.8 Cut test

According to the cut test results for the four drying methods (Table 6), there were no defective beans, and no significant differences (p < 0.05) were found between the light brown/yellowish, fully light brown and fully brown groups and the partial fermentation group (partly purple/violet and partly brown). However, there were differences among the treatments in the percentage of fully purple/violet and ivory/white/blond beans, with a lower percentage in the HA-IR-S method, indicating that this treatment resulted in greater fermentation. According to Guda et al. (2017), a cut test reveals the presence of defects and indicates the degree of fermentation as a quality indicator, which is of great importance to buyers (Hii et al., 2006).

Table 6

| Category (%) | Drying method | |||

|---|---|---|---|---|

| S | HA-S | IR-S | HA-IR-S | |

| Color evaluation | ||||

| Light brown/yellowish, fully light brown and fully brown | 27.3 ± 4.8a | 25.3 ± 7.7a | 25.7 ± 5.3a | 25.0 ± 4.9a |

| Partly purple/violet and partly brown | 35.7 ± 5.4a | 36.0 ± 10a | 36.7 ± 7.9ª | 46.7 ± 7.4a |

| Fully purple/violet and ivory/white/blond | 37.0 ± 6.8ab | 38.7 ± 3.5b | 37.7 ± 6.5b | 28.3 ± 4.9a |

| Fully dark brown and fully black | 0 ± 0.0 | 0 ± 0.0 | 0 ± 0.0 | 0 ± 0.0 |

| Total | 100 | 100 | 100 | 100 |

| Degree of fermentation | ||||

| Fermentation percentage | 63.0 ± 6.8ab | 61.3 ± 3.5b | 62.3 ± 6.5b | 71.7 ± 4.9a |

| Degree of fissuring | ||||

| Grade 1 | 22.0 ± 5.1a | 34.0 ± 6.8b | 36.7 ± 3.7b | 31.0 ± 5.3b |

| Grade 2 | 35.3 ± 8.1a | 21.7 ± 4.1b | 25.0 ± 2.1b | 23.0 ± 4.1b |

| Grade 3 | 25.3 ± 6.5a | 18.0 ± 7.2ab | 15.7 ± 1.5b | 24.7 ± 6.8ab |

| Grade 4 | 17.3 ± 6.2a | 26.3 ± 4.1b | 22.7 ± 3.3ab | 21.3 ± 3.3ab |

| Total | 100 | 100 | 100 | 100 |

Cut test results.

F, Fermented beans before drying; S, solar; HA-S, hot-air-assisted solar; IR-S, infrared-assisted solar; HA-IR-S, hot-air and infrared-assisted solar. Means and standard deviations followed by different letters within a row indicate significant differences (p < 0.05).

For the degree of fissuring (Table 6), it was observed that the S method showed differences in all grades compared to the other methods, whereas in the HA-IR-S method, a greater number of grains were observed in grades 3 and 4, corresponding to grains with greater separation in the alveoli. This was consistent with the percentage of fermentation, where significant differences (p < 0.05) were observed, with the HA-IR-S method showing the highest average degree of fermentation at 71.7% (Table 6). In the initial stages of drying, when grain fermentation is still ongoing, air renewal creates a humidity gradient between the air and grain, facilitating greater mass transfer. Regarding heat transfer, solar and infrared radiation help to maintain the final fermentation rate. These results are similar to those found by Pita-Garcia et al. (2025), where the combined processes of solar drying and electric drying presented the best results and could be an efficient alternative that contributes to the innovation and sustainability of production.

4 Conclusion

The hot-air infrared-assisted solar dryer (HA-IR-S) has shown a greater impact on drying characteristics and consumes less energy than the hot air-assisted solar (HA-S) method. The former raised bean temperature by 3.8°C compared to the latter, resulting in a 3.4% increase in effective diffusivity and a 30.8% increase in drying rate, for a free moisture content of 0.2 kg/kg of dry solids. The HA-S method resulted in a significant reduction in bean dimensions compared to the HA-IR-S method, which was attributable to the intensity of the applied heat. However, the latter method produced higher fermentation values, improving the color and aroma of the cocoa beans, accompanied by reduced acidity and a balanced pH level.

The HA-IR-S drying method has proven to be the most efficient and sustainable method for producing high-quality cocoa beans. This technology is viable for producers as it strengthens their economic stability by offering a faster and more reliable drying method. Although solar drying assisted by hot air and infrared radiation improves the drying characteristics of cocoa beans and complements the fermentation process, challenges remain regarding its implementation and application. Additional studies are needed to examine aspects such as changes in physical and chemical properties, economic feasibility, and optimization of the assisted drying methods. The latter requires calculating the number of infrared lamps required, the appropriate distance between the radiation source and the sample surface, the dimensions of the electric heaters, and the drying area.

Statements

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

EB: Data curation, Writing – original draft, Methodology, Validation, Investigation, Supervision, Software, Conceptualization, Writing – review & editing, Formal analysis. LM-O: Formal analysis, Writing – original draft, Methodology, Data curation, Investigation. BS-S: Writing – original draft, Investigation, Formal analysis, Data curation, Methodology. GC-F: Software, Writing – original draft, Resources, Methodology, Investigation, Data curation. NM-G: Data curation, Methodology, Investigation, Writing – original draft. MU-P: Data curation, Project administration, Writing – review & editing, Funding acquisition, Formal analysis, Methodology.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was supported by Peru-Hub, a collaborative project aimed at promoting sustainable agricultural, economic, and social development in the San Martín region of Peruvian Amazon.

Acknowledgments

We appreciate the valuable support of the technical and administrative staff of the “Cooperativa Agraria Cacaotera (ACOPAGRO), “located in the Central Huallaga Valley, in the San Martín region of Peru. They provided access to facilities for drying cocoa beans.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2025.1596519/full#supplementary-material

References

1

Adrover A. Brasiello A. (2020). 3-D modeling of dehydration kinetics and shrinkage of ellipsoidal fermented Amazonian cocoa beans. PRO8:150. doi: 10.3390/pr8020150

2

Akmel D. C. Kakou K. E. Koné K. Y. Assidjo N. E. Kouamé P. (2015). Desorption isotherms and isosteric heats of fermented cocoa beans (Theobroma cocoa). J. Food Res.4, 138–147. doi: 10.5539/jfr.v4n3p138

3

Andrade-Almeida J. Rivera-García J. Chire-Fajardo G. C. Ureña-Peralta M. O. (2019). Physical and chemical properties of cacao cultivars Theobroma cacao L. from Ecuador and Peru. Enfoque UTE10, 1–12.

4

Bacca-Villota P. Acuña-García L. Sierra-Guevara L. Cano H. Hidalgo W. (2023). Untargeted metabolomics analysis for studying differences in high-quality Colombian cocoa beans. Molecules28:4467. doi: 10.3390/molecules28114467

5

Baldeón E. O. Bracamonte-Herrera Á. Soto-Torres A. Salas-Valerio W. F. Vidaurre-Ruiz J. M. (2024a). Effect of convective drying and far-infrared radiation on the physical properties and microstructure of yacón chips (Smallanthus sonchifolius). Ing. Investig.44:e104346. doi: 10.15446/ing.investig.104346

6

Baldeón E. O. Salas-Valerio W. F. Vidaurre-Ruiz J. M. Comettant-Rabanal R. (2024b). Convective drying kinetics of yacon (Smallanthus Sonchifolius Poepp. & Endl.) slabs and evaluation of the dryer PID temperature control system. Chilean J. Agricult. Anim. Sci.40, 44–55. doi: 10.29393/chjaas40-5cder40005

7

Banboye F. D. Ngwabie M. N. Eneighe S. A. Nde D. B. (2020b). Assessment of greenhouse technologies on the drying behavior of cocoa beans. Food Sci. Nutr.8, 2748–2757. doi: 10.1002/fsn3.1565

8

Banboye F. D. Ngwabie M. N. Nde D. B. (2020a). A review of cocoa drying technologies and the effect on bean quality parameters. Int. J. Food Sci.2020:11. doi: 10.1155/2020/8830127

9

Bart-Plange A. Addo A. Abano E. E. Akowuah J. O. (2012). Compressive properties of cocoa beans considering the effect of moisture content variations. Int. J. Eng. Technol.2, 849–858.

10

Bidias J. B. Mouthe Anombogo G. A. Ndjeumi C. C. Djomdi D. Tchaya G. B. Nsouandele J. L. (2022). Study of water desorption isotherms from cocoa beans (Theobroma cacao L.) of Cameroon. Eur. Sci. J.18:1. doi: 10.19044/esj.2022.v18n11p1

11

Blahovec J. Yanniotis S. (2009). Modified classification of sorption isotherms. J. Food Eng.91, 72–77. doi: 10.1016/j.jfoodeng.2008.08.007

12

Cacao de Excelencia (2023). “Guía para la Evaluación de la Calidad y el Sabor del Cacao” in Compilado por el programa Cacao de Excelencia de la Alianza de Bioversity International y CIAT, en colaboración con los miembros del Grupo de Trabajo de International Standards for the Assessment of Cacao Quality and Flavour - ISCQF (Bioversity International), 216.

13

CAOBISCO/ECA/FCC (2015) in Cocoa beans: Chocolate and cocoa industry quality requirements. eds. EndM. J.DandR..

14

Castellanos J. M. Quintero C. S. Carreno R. (2018). Changes on chemical composition of cocoa beans due to combined convection and infrared radiation on a rotary dryer. IOP Conf. Ser. Mater. Sci. Eng.437:012011. doi: 10.1088/1757-899X/437/1/012011

15

Chire G. Orosco P. Valdivia R. Ureña M. (2014). Determinación de las propiedades Físicas, Químicas y termo físicas de diferentes granos de cacao del Perú. CIBIA3, 545–551.

16

De Souza P. A. Moreira L. F. Sarmento D. H. A. da Costa F. B. (2018). “Cacao- Theobroma cacao” in Exotic fruits. eds. RodriguesS.de Oliveira SilvaE.de BritoE. S. (Academic Press), 69–76. doi: 10.1016/C2014-0-02888-2

17

Dursun İ. Tuğrul K. M. Dursun E. (2007). Some physical properties of sugar beet seed. J. Stored Prod. Res.43, 149–155. doi: 10.1016/j.jspr.2006.03.001

18

García-Alamilla P. Salgado-Cervantes M. A. Barel M. Berthomieu G. Rodríguez-Jimenes G. C. García-Alvarado M. A. (2007). Moisture, acidity and temperature evolution during cacao drying. J. Food Eng.79, 1159–1165. doi: 10.1016/j.jfoodeng.2006.04.005

19

Guda P. Gadhe S. Jakkula S. (2017). Drying of cocoa beans by using different techniques. Inte. J. Agricult. Innovat. Res.5, 2319–1473.

20

Herman C. Spreutels L. Turomzsa N. Mayumi E. Haut B. (2018). Convective drying of fermented Amazonian cocoa beans (Theobroma cacao var. Forasteiro). Experiments and mathematical modeling. Food Bioprod. Process.108, 81–94. doi: 10.1016/j.fbp.2018.01.002

21

Hii C. L. Menon A. S. Chiang C. L. (2019). “Drying principles and practices of cocoa beans” in Drying and roasting of cocoa and coffee. eds. HiiC. L.BorémF. M. (Boca Raton, FL: CRC Press), 21–45.

22

Hii C. L. Rahman R. A. Jinap S. Man Y. B. C. (2006). Quality of cocoa beans dried using a direct solar dryer at different loadings. J. Sci. Food Agric.86, 1237–1243. doi: 10.1002/jsfa.2475

23

Horta-Téllez H. B. Sandoval-Aldana A. P. Garcia-Muñoz M. C. Cerón-Salazar I. X. (2019). Evaluation of the fermentation process and final quality of five cacao clones from the department of Huila, Colombia. DYNA86, 233–239. doi: 10.15446/dyna.v86n210.75814

24

INACAL (2021). Guía de Implementación de la Norma Técnica Peruana NTP 208.026: 2015 Cacao y chocolates, manteca de cacao. Primera edición Edn. Lima.

25

Jeevarathinam G. Pandiselvam R. Pandiarajan T. Preetha P. Balakrishnan M. Thirupathi V. et al . (2021). Infrared assisted hot air dryer for turmeric slices: effect on drying rate and quality parameters. LWT144:111258. doi: 10.1016/j.lwt.2021.111258

26

Kaplan M. Çetin N. Çiftci B. Karpuzcu S. (2025). Comparison of drying methods for biochemical composition, energy aspects, and color properties of alfalfa hay. Biomass Conv. Bioref.15, 10331–10346. doi: 10.1007/s13399-024-05920-8

27

Kaveh M. Çetin N. Gilandeh Y. A. Sharifian F. (2023). Comparative evaluation of greenhouse gas emissions and specific energy consumption of different drying techniques in pear slices. Eur. Food Res. Technol.249, 3027–3041. doi: 10.1007/s00217-023-04346-2

28

Kongor J. E. Aji Muhammad D. R. (2025). “Processing of cocoa and development of chocolate beverages” in Natural products in beverages. eds. MérillonJ. M.RivièreC.LefèvreG., Reference Series in Phytochemistry (Cham: Springer), 157–192.

29

Koua B. K. Koffi P. M. E. Gbaha P. (2016). Moisture desorption isotherms characteristics of cocoa beans. Pak. J. Food Sci.26, 143–152.

30

Koua B. K. Koffi P. M. E. Gbaha P. (2019). Evolution of shrinkage, real density, porosity, heat and mass transfer coefficients during indirect solar drying of cocoa beans. J. Saudi Soc. Agric. Sci.18, 72–82. doi: 10.1016/j.jssas.2017.01.002

31

Li M. Li M. Zhang X. Zhang Q. Yang X. (2024). Effect of infrared-combined hot air intermittent drying of jujube (Zizyphus jujuba miller) slices: drying characteristics, quality, and energy consumption dimensions. Agriculture14:214. doi: 10.3390/agriculture14020214

32

Lima L. J. R. Almeida M. H. Nout M. J. R. Zwietering M. H. (2011). Theobroma cacao L., “the food of the gods”: quality determinants of commercial cocoa beans, with particular reference to the impact of fermentation. Crit. Rev. Food Sci. Nutr.51, 731–761. doi: 10.1080/10408391003799913

33

Mujaffar S. Sukha D. Ramroop A. (2017). Comparison of the drying behavior of fermented cocoa (Theobroma cacao L.) beans dried in a cocoa house, greenhouse and mechanical oven. International Symposium on Cocoa Research (ISCR), Lima.

34

Navarro-Pinedo E. Garay-Montes R. Medina-Vivanco M. L. Mendieta-Taboada O. W. (2024). Adsorption isotherms and isosteric heat of dry fermented cocoa beans (Theobroma cacao L.). Chem. Eng. Trans.109, 589–594. doi: 10.3303/CET24109099

35

NTP (2021). NTP 208.017:2021. CACAO Y CHOCOLATE. 4th Edn. Lima: Determinación de humedad. Método gravimétrico.

36

Obinze S. Ojimelukwe P. C. Eke B. A. (2022). Box fermentation and solar drying improve the nutrient composition and organoleptic quality of chocolate from cocoa beans. Front. Sustain. Food Syst.6:1023123. doi: 10.3389/fsufs.2022.1023123

37

Oliveira M. M. Cerqueira B. V. Barbon S. Barbin D. F. (2021). Classification of fermented cocoa beans (cut test) using computer vision. J. Food Compos. Anal.97:103771. doi: 10.1016/j.jfca.2020.103771

38

Pérez-Won M. González-Cavieres L. Palma-Acevedo A. Jara-Quijada E. Tabilo-Munizaga G. Lemus-Mondaca R. (2024). Vacuum microwave drying of PEF-pretreated Chilean abalone (Concholepas Concholepas) slices: drying features, sustainability parameters, and protein quality properties. Food Prod. Process. Nutr.6:21. doi: 10.1186/s43014-023-00202-8

39

Pita-Garcia J. Reinoso-Tigre J. Palacios-Ponce S. Delgado-Plaza E. Coello-Montoya D. Salazar R. et al . (2025). Impact of combined sun and hybrid drying technologies on cocoa drying process and quality. Heliyon11:e42884. doi: 10.1016/j.heliyon.2025.e42884

40

Raju R. N. Heyes J. A. Archer R. H. Chen Q. (2022). Predicting the dried moisture content in Fijian Theobroma cacao beans using a mechanistic model. N. Z. J. Crop. Hortic. Sci.53. doi: 10.1080/01140671.2022.2150234

41

Sahadeo P. J. Sukha D. Chadee X. T. Umaharan P. Clarke R. M. (2024). Assessing mathematical models for the intermittent drying of cocoa (Theobroma cacao L.) beans. Discov. Appl. Sci.6:435. doi: 10.1007/s42452-024-06134-3

42

Salazar E. Valenzuela R. Aguilar M. Aranda N. Sotelo A. Chire G. et al . (2020). Physicochemical properties and microbial group behavior of postharvest Peruvian cocoa bean (Theobroma cacao L.). Enfoque UTE11, 48–56. doi: 10.29019/enfoqueute.v11n4.602

43

SENAMHI . (2024). Pronóstico del Tiempo a nivel nacional. Lima. Available online at: https://www.senamhi.gob.pe/?p=pronostico-meteorologico (Accessed August 15, 2024).

44

Sinuhaji T. R. F. Suherman S. Hadiyanto H. (2024). A systematic literature review of the drying of cocoa in 2003-2023. Food Hum.3:100347. doi: 10.1016/j.foohum.2024.100347

45

Sinuhaji T. R. F. Suherman S. Hadiyanto H. Ardan A. Rahmawati S. (2025). Evaluation and comparison of drying models in open sun drying and photovoltaic and LPG burner assisted hybrid solar drying system. Case Stud. Chem. Environ. Eng.11:101104. doi: 10.1016/j.cscee.2025.101104

46

Thomas E. Iman S. Atkinson R. Zavaleta D. Rodriguez C. Lastra S. et al . (2023). “Diversidad genética de cacao en el Perú” in en Catalogo de cacaos de Perú. eds. ThomasE.LastraS.ZavaletaD. (Lima: Bioversity International y MOCCA), 9–56.

47

Tobias-Baeza A. Avendaño-Arrazate C. H. García-Alamilla R. Carrera-Lanestosa A. García-Alamilla P. (2024). Determination of geometric properties of cocoa beans (Theobroma cacao L.). Agro Productividad., 11–22. doi: 10.32854/agrop.v17i5.2582

48

Ureña M. Sandoval A. (2021). Innovación tecnológica en cacao andino. Producto 6: Prototipo de fermentador portátil ecológico, optimización del proceso de fermentación FONTAGRO (Fondo de Tecnología Agropecuaria). Available online at: https://www.fontagro.org/new/uploads/productos/16109_-_Producto_6.pdf.

49

Zarrillo S. Gaikwad N. Lanaud C. Powis T. Viot C. Lesur I. et al . (2018). The use and domestication of Theobroma cacao during the mid-Holocene in the upper Amazon. Nat. Ecol. Evol.2, 1879–1888. doi: 10.1038/s41559-018-0697-x

50

Zeng Z. Han C. Wang Q. Yuan H. Zhang X. Li B. (2024). Analysis of drying characteristic, effective moisture diffusivity and energy, exergy and environment performance indicators during thin layer drying of tea in a convective-hot air dryer. Front. Sustain. Food Syst.8:1371696. doi: 10.3389/fsufs.2024.1371696

Summary

Keywords

renewable drying, efficient drying, energy harvesting, hybrid drying, cacao CYP-99, cacao quality, cut test

Citation

Baldeón EO, Mamani-Olgado LR, Silva-Santisteban BOY, Chire-Fajardo GC, Martínez-Guerrero NC and Ureña-Peralta MO (2025) Impact of hot-air and infrared-assisted solar drying on the drying characteristics and physicochemical properties of cacao beans (Theobroma cacao L.). Front. Sustain. Food Syst. 9:1596519. doi: 10.3389/fsufs.2025.1596519

Received

19 March 2025

Accepted

15 June 2025

Published

04 July 2025

Volume

9 - 2025

Edited by

Giovanna Ferrari, University of Salerno, Italy

Reviewed by

Francesco Marra, University of Salerno, Italy

Lia Ratnawati, National Research and Innovation Agency (BRIN), Indonesia

Updates

Copyright

© 2025 Baldeón, Mamani-Olgado, Silva-Santisteban, Chire-Fajardo, Martínez-Guerrero and Ureña-Peralta.

This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Edwin O. Baldeón, eobch@lamolina.edu.pe

Disclaimer

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.