- School of Geology and Mining Engineering, Xinjiang University, Urumqi, China

The structural integrity of slopes in the Ili Valley is critically influenced by the inherent characteristics of loess, particularly when it is subjected to the seasonal climatic changes. In the present research, a series of triaxial shear tests were carried out to examine the mechanical behavior of the Ili loess under different dry–wet and frost–thaw cycles. In parallel, some testing methods, including scanning electron microscopy (SEM) and nuclear magnetic resonance (NMR), were applied to investigate the progressive damage characteristics and the alterations in terms of the microstructures. Test results demonstrated a strong correlation between the macroscopic mechanical resistance and microstructural changes of the Ili loess subjected to the dry–wet and freeze–thaw cycles. The impact of the freeze–thaw cycles was more pronounced than other parameters, when the reduction in shear strength of the Ili loess under dry–wet cycles was accounted for. The results also showed that either the cohesion or the internal friction angle is very different from each other. Furthermore, changes in terms of the microstructure, such as the particle size, porosity, morphology, soil structure, and particle contact mode, exhibited distinct characteristics under varying climates. The research outcomes obtained from this research offer valuable data reference and theoretical guidelines to prevent or postpone the occurrence of the landslide in the Ili Valley under critical environmental conditions.

1 Introduction

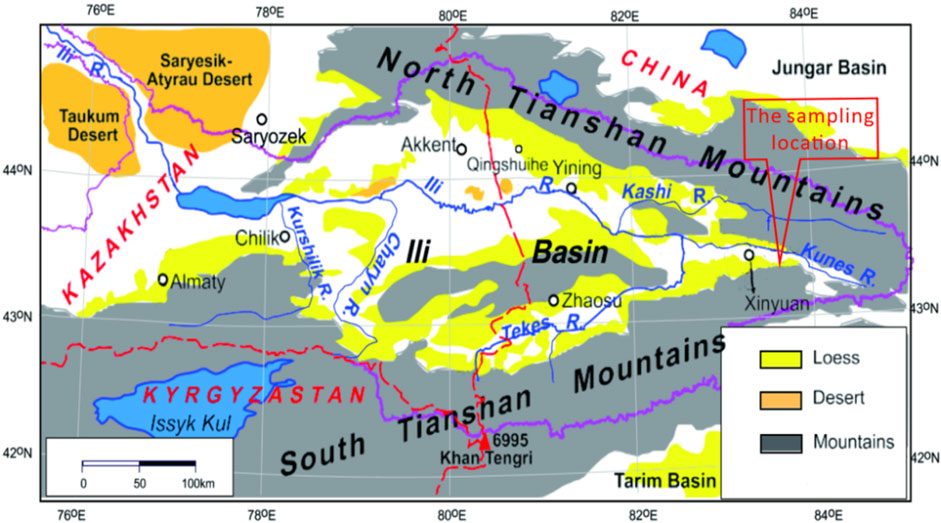

Either the loess or the loess-like deposits, being the most widely distributed sediment on the earth, are of significant importance for engineering safety. As illustrated in Figure 1, the Ili Valley located in the eastern part of Central Asia is not only the northern hub of the ancient Silk Road but also the primary region for widespread distribution of the loess in China (Song et al., 2014; Song and Shi, 2010). The slope stability is critically affected by the mechanical characteristics of the Ili loess, and any potential degradation of it will significantly threaten the safety of local inhabitants and public properties.

Climate change has been observed to significantly affect the seepage, strength, deformation, and other physico-mechanical characteristics of the Ili loess (Lv et al., 2021). Notably, low temperatures, which cause the ground to freeze, coupled with the elastic thermal expansion and plastic thermal softening, pose some critical engineering challenges. Previous studies have shown a strong connection between the mechanical properties of Ili loess and the region’s abundant rainfall, intense sunshine, and high evaporation rates (Mo et al., 2018). In addition to these critical factors, changes in water content can alter the physico-mechanical properties of the surface soil, with subsequent degradation potentially resulting in landslides in mountainous regions.

To evaluate the impact of climate changes on the mechanical properties of the loess, laboratory tests considering the dry–wet and freeze–thaw cycles are widely adopted (Cai et al., 2019; Chou et al., 2019; Tian et al., 2020; Zhou et al., 2018). Numerous laboratory tests have concentrated on the macro-mechanical behavior to understand how large-scale mechanical properties respond to environmental changes (Chou et al., 2019; Hu et al., 2020; Kong et al., 2021; Li et al., 2019a; Liu et al., 2020; Qin et al., 2021; Shi, 2022; Xu et al., 2020; Yuan et al., 2022; Nie, 2021; Zhang et al., 2022; Chou and Wang, 2021). Only limited research, however, was carried out to explore the impacts of the changed microstructure (Cai et al., 2019; Tian et al., 2020; Li et al., 2019b; Xu et al., 2020; Yuan et al., 2022; Nie et al., 2021; Zhang et al., 2022). Various experimental methods have been applied to investigate the mechanical behavior of the loess. Key approaches include the direct shear test (Chou, 2019; Zhou, 2018) and the triaxial shear test (Mo et al., 2018; Hu et al., 2020; Li et al., 2019a; Qin et al., 2021; Wang et al., 2019; Yuan et al., 2017), as well as advanced imaging techniques such as scanning electron microscopy (SEM) (Mo et al., 2018; Tian et al., 2020; Hu et al., 2020; Shi, 2022; Nie, 2021; Chou and Wang, 2021; Zhuang et al., 2021), nuclear magnetic resonance (NMR), and computed tomography (CT) (Yuan et al., 2022). For instance, Pan et al. (2019) conducted the dry–wet cycle tests on the loess obtained from Yan’an city. Their research verified that the increased number of cycles and water content weakened the cementation of soil particle, leading to reduced shear strength, cohesion, and internal friction angle. Cai et al. (2019) revealed the degradation process and failure mechanisms of expansive soils in cold regions under combined dry–wet and freeze–thaw cycles with the application of CT. Tian et al. (2020) examined the microstructure of the loess via the SEM and determined that the pore structure of the loess would reach the dynamic equilibrium stage after repeated cycles. Other studies have examined how mineral content (Li et al., 2019b; Shi, 2022), water content (Shi, 2022), and changes in the soil–water characteristic curve (Nie, 2021; Chou and Wang, 2021) impact the loess properties.

The current research in terms of the effects of freeze–thaw cycles on the loess mainly focused on its mechanical strength (Li et al., 2019b; Li et al., 2020; Liu et al., 2022a; Zheng et al., 2021), water content, permeability (Lv et al., 2021; Lu, 2019; Xu et al., 2021; Zhang, 2020; Zhao et al., 2020), and microstructural changes (Liu et al., 2022b; Xu et al., 2021; Fu et al., 2021; Liu et al., 2021; She, 2019). Li et al. (2020) examined the impacts of freeze–thaw cycles on the shear strength of undisturbed loess in the Xining city. Notably, temperature gradients significantly affected the strength attenuation, with the most detrimental range from −15°C to 15°C. Similarly, Liu et al. (2022b) investigated the stability of loess roadbeds subjected to freeze–thaw cycles, revealing an initial increase in strength, followed by a subsequent decline. Zheng et al. (2021) examined the strength characteristics of loess under complex stress paths, discovering that freeze–thaw cycles had a relatively minor effect on the stress–strain curve. Additional research studies were also carried out to investigate the morphological changes in water (Liu et al., 2020) and wave velocity (Shi et al., 2022). These experimental methods generally included compression tests (Liu et al., 2022c; Liu et al., 2021; She, 2019), triaxial shear tests (Li et al., 2019a; Li et al., 2020; Zheng et al., 2021), permeability experiments (Li et al., 2019b; Xu et al., 2021; Zhao et al., 2020), SEM analysis (Mo et al., 2018; Li et al., 2019a; Liu et al., 2022a; Liu et al., 2021; She, 2019), NMR (Shi et al., 2022), and CT scanning (Xu et al., 2021).

Currently, a huge number of research studies on loess have predominantly focused on the Loess Plateau region; however, studies on loess in the Ili Valley are still in their nascent stages. Due to its unique formation environment, both the material composition and physico-mechanical properties of loess in the Ili Valley are very different from those of loess distributed in other regions, the characteristics of which are generally influenced by the terrain and geological conditions (Song et al., 2014; Li, 2018; Song et al., 2018). Limited research has investigated the change in Ili loess properties under dry–wet and freeze–thaw conditions (Lv et al., 2021; Mo et al., 2018; Shi, 2022; Huang et al., 2021). Although existing research mainly concentrated on the impacts of individual factors, the loess is simultaneously subjected to both dry–wet and freeze–thaw cycles, which involve multiple interacting variables. Without comparative analyses of combined or differential effects, the current research does not fully capture the evolution of loess strength characteristics under multiple cycles. Consequently, it is necessary to investigate the degradation mechanisms of Ili loess strength under different cycling conditions.

In the present research, the effects of dry–wet and freeze–thaw cycles on the mechanical properties of the Ili loess were investigated via the triaxial shear tests. Meanwhile, some critical parameters related to the microstructure (e.g., the particle size, porosity, pore water distribution, and particle contact modes) were evaluated with the application of the SEM and NMR instruments.

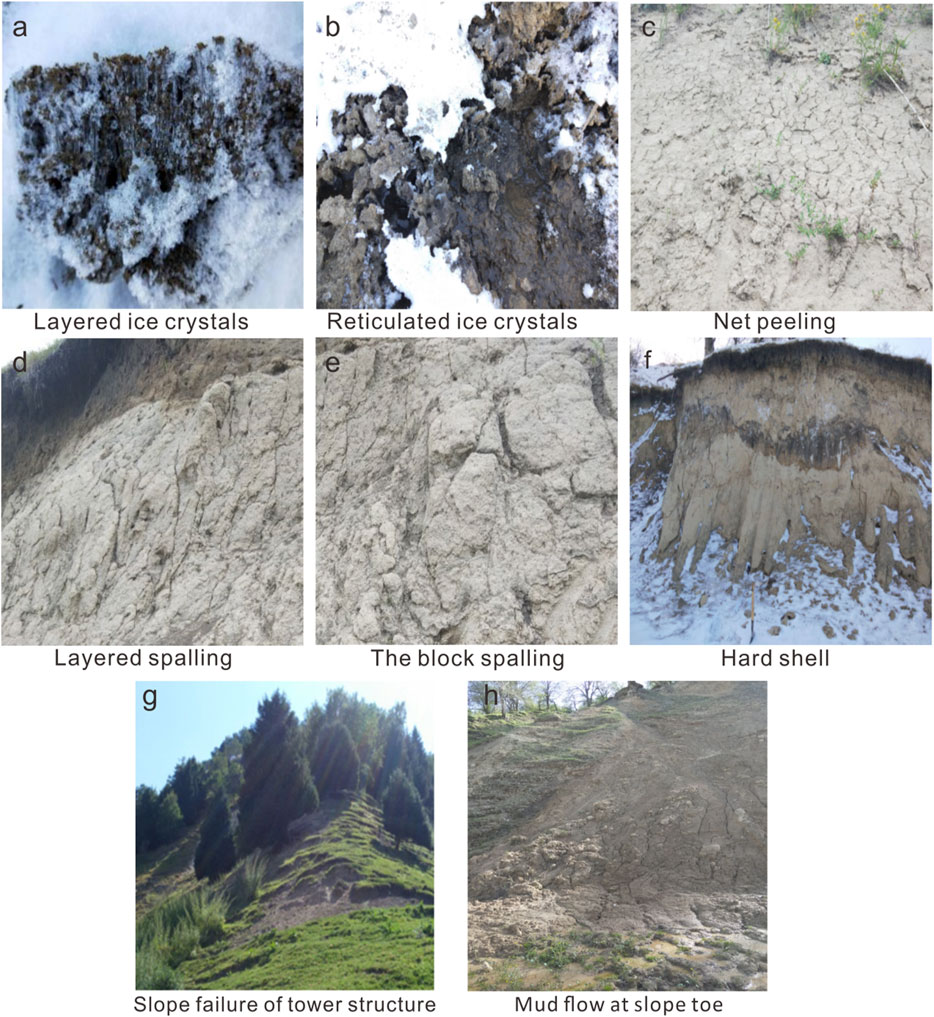

2 Failure characteristics of the Ili loess slope

The sharply increasing temperature from April to May accelerates the melting of ice and snow, resulting in the daily repeated dry–wet and freeze–thaw cycles. During this period, both the physical and mechanical properties of the loess slope undergo the damage associated with the dynamic and static water-level changes. The deformation characteristics of mountain slopes are primarily manifested as the spalling of the surface layer, which is often accompanied by creeping slips, collapses, and mudflows. As per the convective heat transfer principle between the air and soil, warmer water migrates from deeper layers to the surface, leading to the formation of layered ice lenses on the surface (see Figures 2a, b). Affected by the dry–wet and freeze–thaw cycles, the deformation patterns of the slope in the Ili Valley are dominated by reticulated spalling (Figure 2c), layered spalling (Figure 2d), and block spalling (Figure 2e). Additionally, some slopes are featured with convex-shaped, layered hard shells (Figure 2f) in the cold winter. As these hard shells melt and collapse, progressive deformation originates from the slope toe, eventually leading to complete instability (Figures 2g, h).

Figure 2. Failure modes of Ili loess slope under dry-wet and freeze-thaw cycles. (a,b) are layered ice lenses; (c) is reticulated spalling; (d) is layered spalling; (e) is block spalling; (f) is hard shells; (g,h) are hard shells melt and collapse.

3 Laboratory tests

3.1 Raw materials and specimen preparation

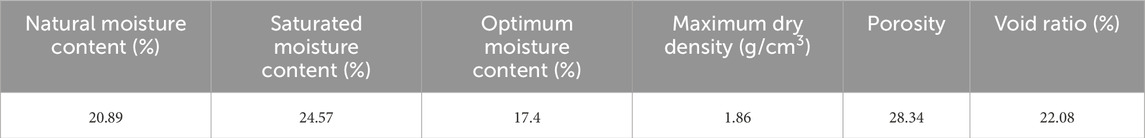

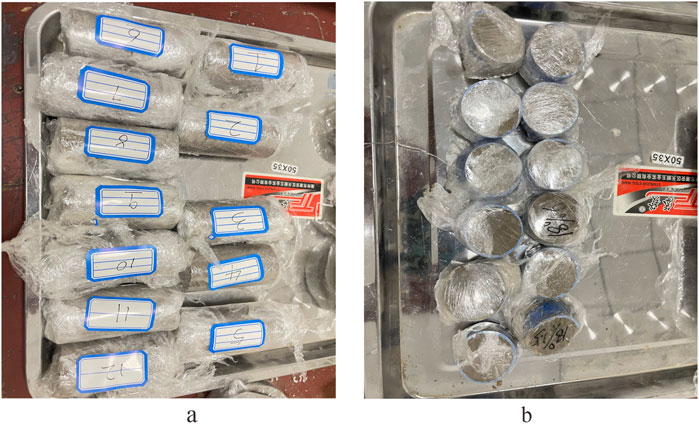

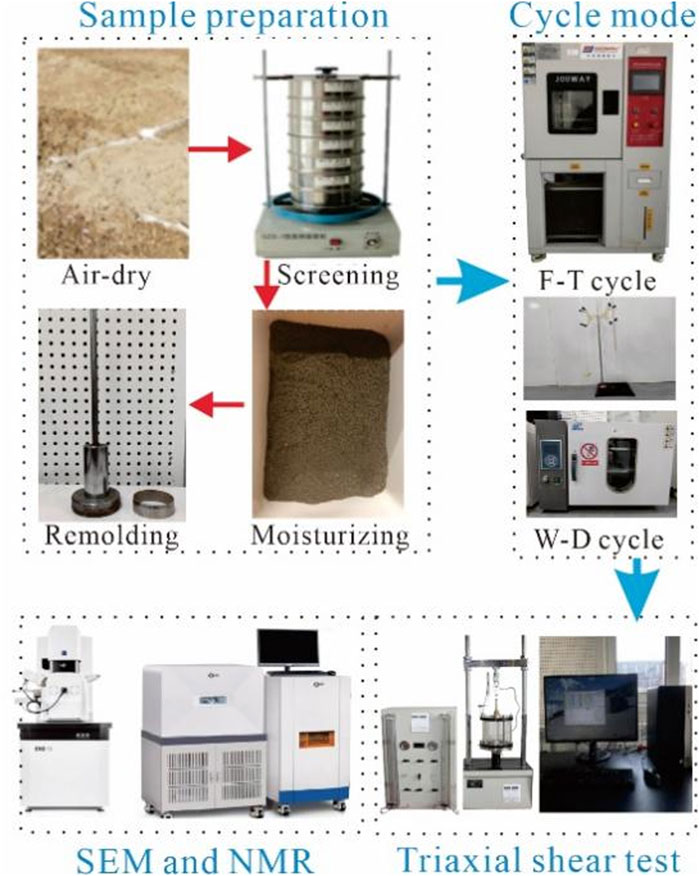

The Ili loess used in the present research was collected from Xinyuan County, Xinjiang, and its basic physico-mechanical parameters are listed in Table 1 for reference. The preparation procedures of samples for both the freeze–thaw and dry–wet cycling tests were identical. In practice, the soil samples were air-dried, pulverized, and then sieved through a 2-mm mesh to generate test specimens (Figure 3). The averaged water content of the prepared specimens is 17.4% (equal to the optimal water content), and their maximum dry density was measured at 1.86 g/cm3.

3.2 Experimental design

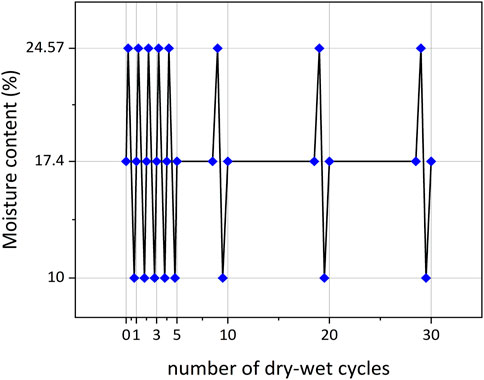

The number of dry–wet cycles was set to 0, 1, 3, 5, 10, 20, and 30. During these processes, the initial water content of the loess began at 17.4%, with a minimum and a maximum (saturated) content of 10% and of 24.57%, respectively. As depicted in Figure 4, the preset water content was consistently achieved at the end of each full dry–wet cycle.

Upon completion of the designated dry–wet cycles, triaxial shear tests and microstructural analyses were conducted using a stress-controlled instrument (TFB-1). As illustrated in Figure 5, the prepared specimens were placed into the instrument, and confining pressures of 100 kPa, 200 kPa, and 300 kPa were then applied. The selected specimens were analyzed with SEM to examine surface morphology, whereas seven groups were evaluated using NMR (MesoMR23-60H-I).

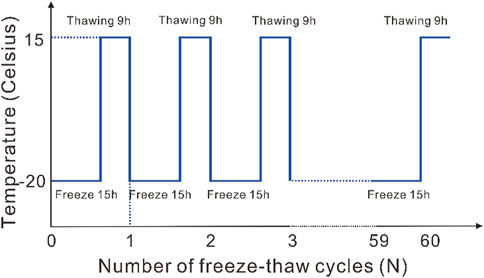

The freeze–thaw cycle tests were carried out by the JW-2000 test chamber. The freezing temperature was set at −20°C, with each cycle lasting 15 h, whereas the melting temperature was set at 15°C for a constant period of 9 h. A previous research has demonstrated that the original cementation of soil samples is completely disrupted after 50 freeze–thaw cycles (Qi et al., 2014). Considering the high frequency and prolonged nature of freeze–thaw processes in the Ili Valley, the maximum number of cycles was set to 60 times. Samples subjected to 0, 5, 10, 20, 30, 45, and 60 cycles were selected for triaxial compression tests to examine the damage characteristics of Ili loess under freeze–thaw conditions. The freeze–thaw cycling path is depicted in Figure 6 for reference.

4 Experimental results

4.1 Behavior of the loess subjected to dry–wet cycles

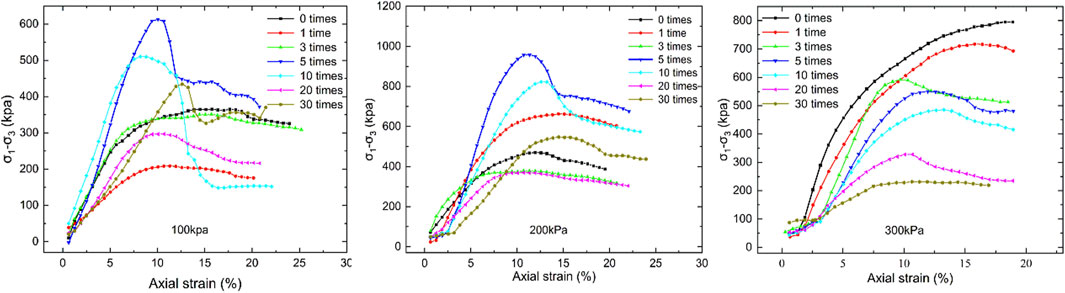

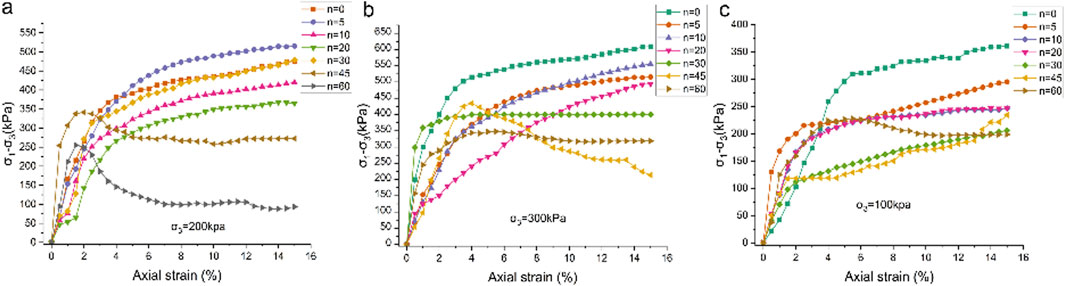

The stress–strain curves of the tested specimens with variable principal stress are depicted in Figure 7, in which different confinement conditions were also accounted for. It is evident from Figure 7 that the peak values of the principal stress for different samples are much variable. Notably, samples exposed to various numbers of dry–wet cycles exhibit a significant reduction in the difference between principal stresses compared to those that did not undergo any cycles. This indicates a weakening of the soil’s structural integrity as a result of repeated dry–wet cycling. Taking the stress–strain curves of the specimen with a confining pressure of 300 kPa, for example, the stress–strain curve of the untreated sample exhibits the highest peak, indicating that the dry–wet cycles lead to mechanical degradation of the loess, accompanied by a reduction in strength.

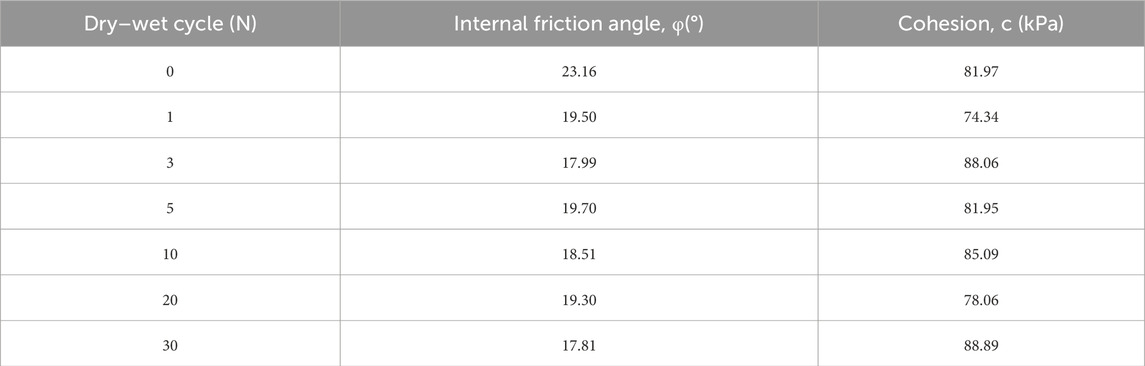

The maximum and minimum principal stresses were fitted using the σ1–σ3 method to determine the shear strength parameters of Ili loess under varying frequencies of dry–wet cycles. The results are summarized in Table 2, which indicates the potential degradation in mechanical properties with increased number of cycles.

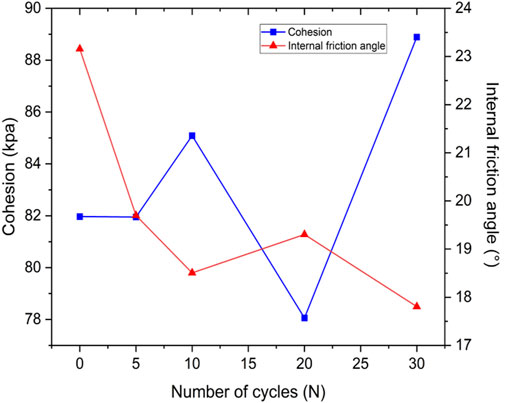

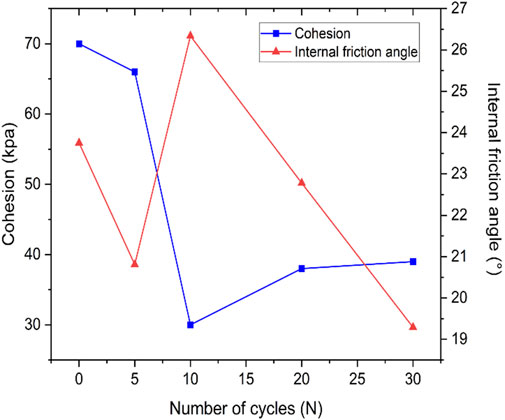

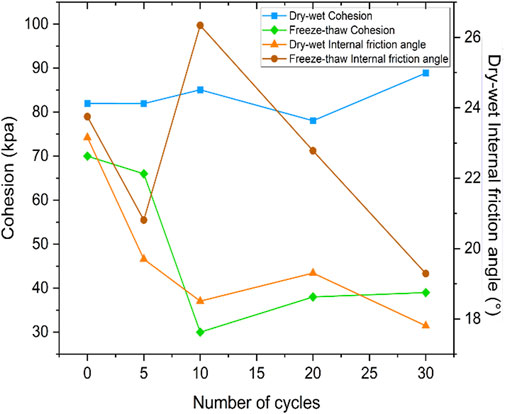

Figure 8 illustrates the relationship between the friction and the cohesion values at the given number of dry–wet cycles. Compared to the untreated sample, those subjected to dry–wet cycles exhibit a reduction in the internal friction angle. This reduction varies initially but stabilizes as the number of cycles increases. It is evident in Figure 8 that the impact of dry–wet cycles is most pronounced at the initial stages, which significantly affects the cohesion of the specimens.

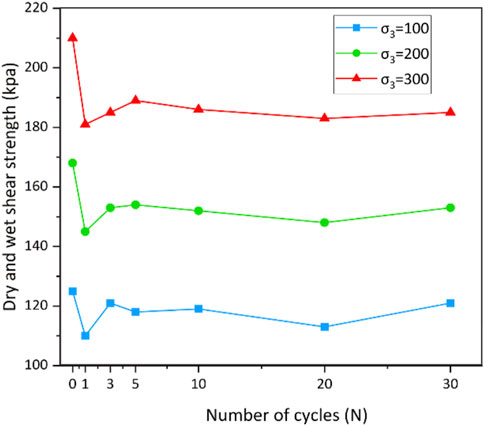

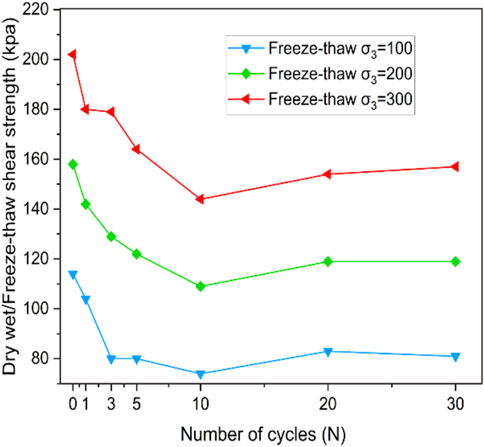

Figure 9 illustrates the shear strength of the tested specimens at different numbers of dry–wet cycles, in which the shear strength was calculated by the Mohr–Coulomb law. Compared to samples that were not subjected to any dry–wet cycles, there is a noticeable reduction in shear strength immediately following the initial dry–wet cycle. With the increased number of wet and dry cycles, the shear strength exhibited an initial fluctuation but then experienced a slight increase before eventually stabilizing.

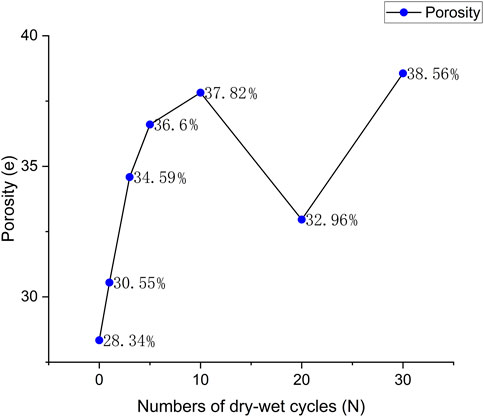

Figure 10 presents the results of porosity at various dry–wet cycles, as determined by NMR testing. The data revealed a significant increase in porosity with the increased number of dry–wet cycles. Notably, significant changes in porosity occur at cycle counts of N = 1 and N = 3. As the number of dry–wet cycles continues to rise, the range of porosity variation gradually decreases. This trend is likely due to the redistribution of moisture within the specimen during the cycling process. That is, the induced motion of microparticles in the soil and the connected pores in the loess form a water conveyance channel when the specimens are suffering from the dry–wet cycles. This phenomenon is especially evident at the initial stage, where significant changes in porosity occur. As the number of dry–wet cycles increases, more water conveyance channels are formed, which likely reduces the effect of moisture on soil particle migration over time. Consequently, the internal particle structure tends to stabilize, associated with a gradual decrease in the range of porosity variation, which eventually reached a constant state.

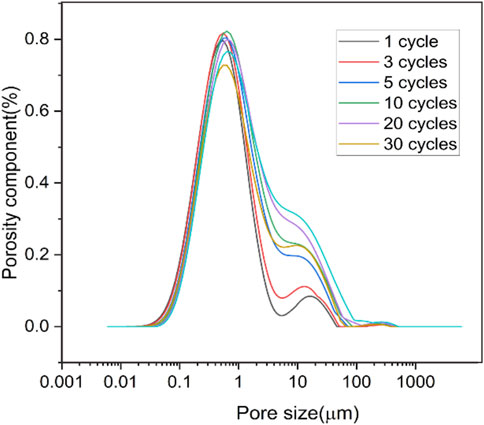

Figure 11 illustrates the pore size distribution of the loess subjected to various dry–wet cycles, with pore diameters predominantly within the 0.01–100 μm range. These untreated Ili loess samples exhibited a bimodal pore size distribution, peaking at 1 μm and 20 μm. With the increased number of wet and dry cycles, the pore size distribution gradually transitioned to the unimodal type, and the peak value was 1 μm. As can be seen from Figure 11, the pore size distribution curve progressively shifts to the right, indicating an increase in pores, with approximately 10 μm in diameter. This observation showed that micropores gradually connected to form pores in the soil and became enlarged in the process of dry–wet cycling. Consequently, the number of micropores gradually decreases, whereas the amount of large and medium-sized pores steadily increases. The formation of enhanced water conveyance channels and larger pores will weaken the loess structure, and the created potential failure surfaces will quickly lead to sliding surfaces. This phenomenon is generally associated with reduced shear capacity and strength degradation.

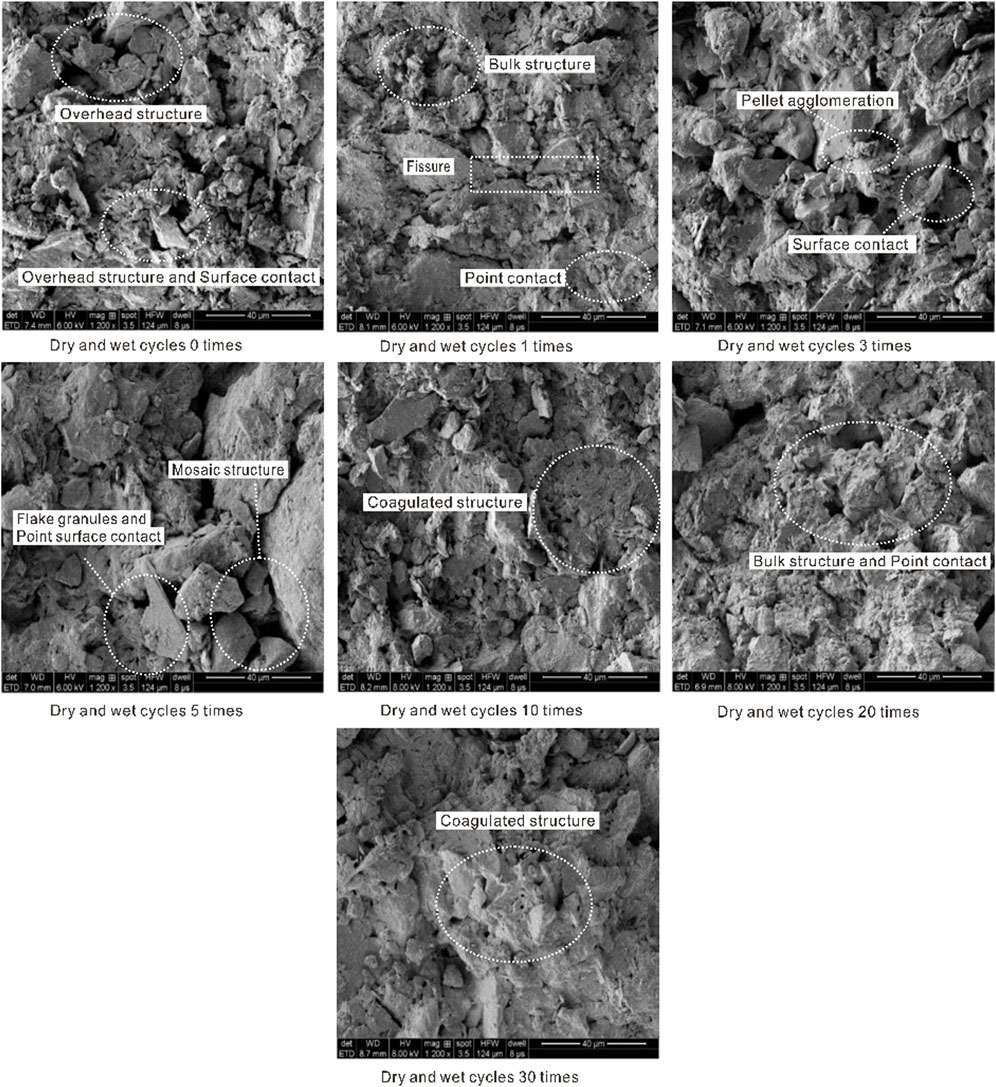

Specimens subjected to various numbers of dry–wet cycles were analyzed using SEM, and the results of them are presented in Figure 12. According to the characterization by SEM, the particles became smaller, and both the abundance of particle units and pores inside the soil increased. However, the anisotropy rate decreased, and the inner structure of the soil became simple.

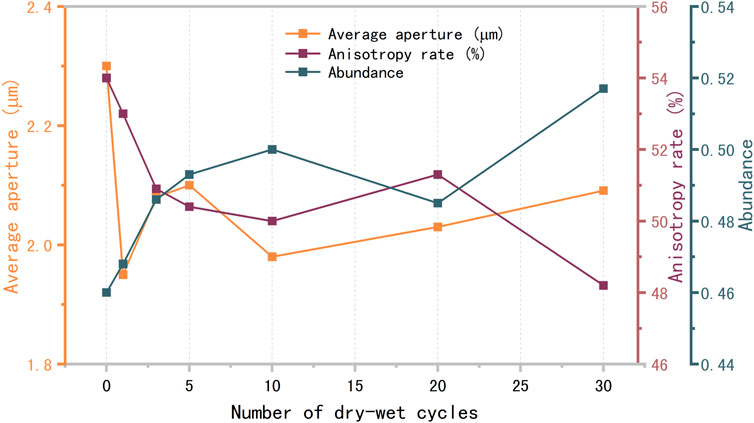

Figure 13 demonstrates the changes in microstructural parameters of the loess sample, suggesting significant fluctuations in the average pore size. This observation suggests that the particle units and pores become more circular in shape with improved uniformity. As the dry–wet cycle progress continues, particles and pores become more uniform and smoother, whereas the anisotropy rate of the loess decreases. This development trend implied that the internal structure of the soil gradually simplified under the influence of dry–wet cycling.

4.2 Behavior of the loess subjected to freeze–thaw cycles

4.2.1 Variation in the shear strength of loess under freeze–thaw cycles

The stress–strain curves of the loess after different numbers of freeze–thaw cycles are illustrated in Figure 14. The corresponding internal friction angle and cohesion values, calculated upon the Mohr–Coulomb law, are shown in Figure 15. With the increased number of freeze–thaw cycles, the cohesive force of the loess initially declined, followed by a rise, and ultimately stabilized by the end of the tests. The internal friction angle follows a similar pattern (i.e., initially decreasing, then increasing, and then experiencing another decline before reaching a stable state).

Figure 14. Stress-strain curves of loess under different numbers of freeze-thaw cycles. (a):200kpa; (b):300kpa; (c):100kpa.

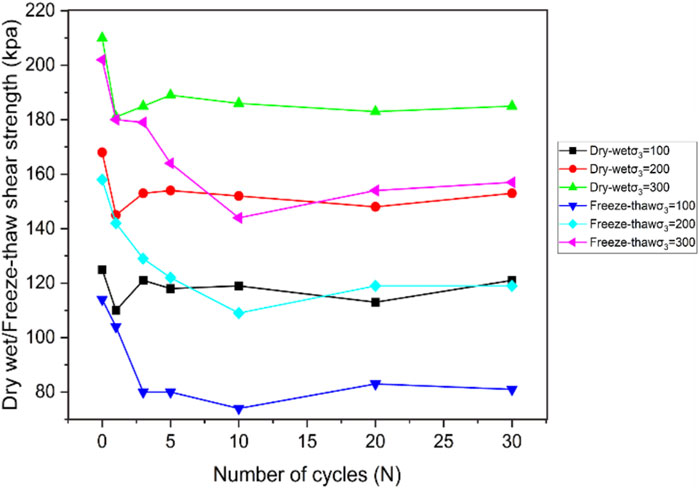

The calculated shear strength parameters, such as the cohesion (c) and internal friction angle (φ), were employed to determine the shear strength of the specimens. As illustrated in Figure 16, the shear strength exhibits varying trends across different numbers of wet–dry cycles and confining pressures. Unlike specimens without freeze–thaw cycles, those specimens subjected to freeze–thaw cycles exhibited a reduction in shear strength, which was particularly notable during the initial stages. With the increased number of freeze–thaw cycles, shear strength experienced a slight increase and eventually stabilized after prolonged fluctuations.

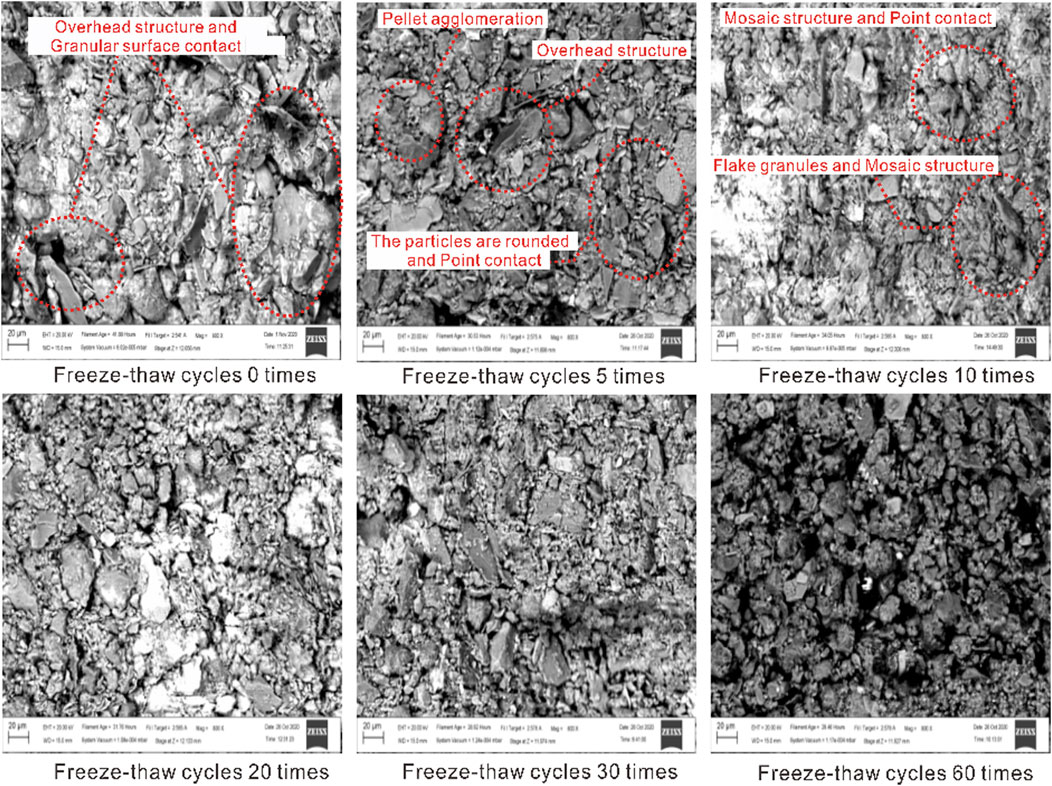

Figure 17 depicts the microscopy images of loess samples after varying numbers of freeze–thaw cycles. It is clear that the particles, pores, and overall structure of the specimens undergo significant changes following the freeze–thaw cycles. Unlike the samples without freeze–thaw cycles, the details of skeleton particles of these specimens were more precise, featured with noticeable holes. The structure predominantly displays an overhead configuration, where uneven particles mainly achieve surface contact. Additionally, there is a notable size disparity between large and small particles, and irregular fractures appear on the surfaces of the skeletal particles, marked by sharp edges and corners.

Following five freeze–thaw cycles, the morphology of the particles experienced an initial change and some fine particles were agglomerated, during which a small number of large flake particles were partially cracked. Affected by the freeze–thaw cycles, both the edges and corners of the particle surface fracture were no longer clear, which appeared more rounded. Although the soil maintained an overhead structure, numerous point-to-surface contacts began to form between different particles. After ten freeze–thaw cycles, the splitting of larger particles led to the formation of numerous flake particles, and the overall loess structure transitioned to a new arrangement, which was characterized by increased point contacts between particles.

As freeze–thaw cycles increased, particles continued to aggregate or crack. The edges and corners of the loess particles were progressively worn down due to freeze–thaw-induced extrusion and friction, leading to increased structural stability over time. After 60 freeze–thaw cycles, the fragmentation of larger particles generated numerous fine granular particles, culminating in a more homogeneous granular structure, which can be seen from Figure 17.

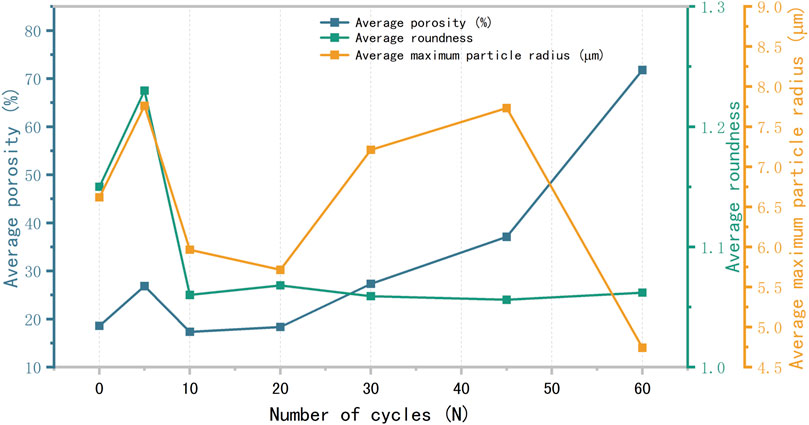

Upon the application of the MATLAB software, the processed SEM images (Figure 18) were binarized for further quantitative analysis. As the number of freeze–thaw cycles increased, the average roundness of loess particles decreased, except notably at the fifth cycle. This observation suggests that the number of round particles close to the equiaxial region of the loess in Ili Valley decreased under the freeze–thaw cycles. The loess particles continuously underwent splitting or aggregation, as evidenced by the average maximum pore size, which exhibited a twofold increase before beginning to decrease. At the same time, freeze–thaw cycles induced continuous particle splitting and aggregation. During the splitting phase, particles filled in the pores, leading to a reduction in the maximum pore size. Conversely, both the maximum pore size and the average pore area ratio generally increased with successive freeze–thaw cycles during the particle aggregation process.

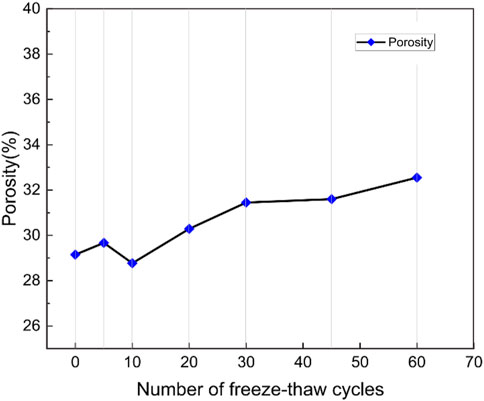

The porosity of the tested specimens, as investigated through NMR, are shown in Figure 19, which suggests that the porosity generally increased, except at the tenth freeze–thaw cycle, which agrees well with the trends observed in the SEM images.

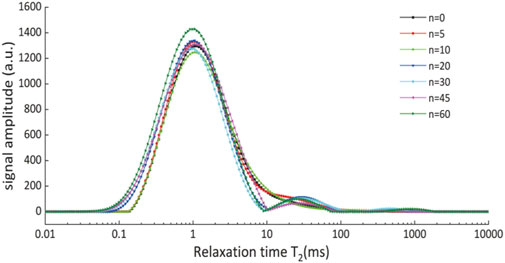

The T2 curve distribution for the saturated specimen is shown in Figure 20, revealing two peaks in the T2 spectrum as various frequencies of freeze–thaw cycles were evaluated. The slack time of the first peak ranged from 0.1 to 10 m. As the number of freeze–thaw cycles increased, the amplitude of the NMR signal rose, and the T2 spectrum distribution shifted to the right. This rightward shift effectively indicates that the number of internal pores in the specimen increased with the number of freeze–thaw cycles.

Loess pores are classified into four categories: micropores with a radius of less than 1 μm, micropores with a radius of 1–4 μm, medium pores with a radius of 4–16 μm, and large pores with a radius exceeding 16 µm. As presented in Figure 21, micropores in the topsoil specimen gradually decreased with an increasing number of freeze–thaw cycles. Meanwhile, small, medium, and large pores increased slightly, suggesting a loosening of the overall structure due to freeze–thaw cycling.

5 Discussion

5.1 Macro- and micro-characteristics of loess under dry–wet cycles

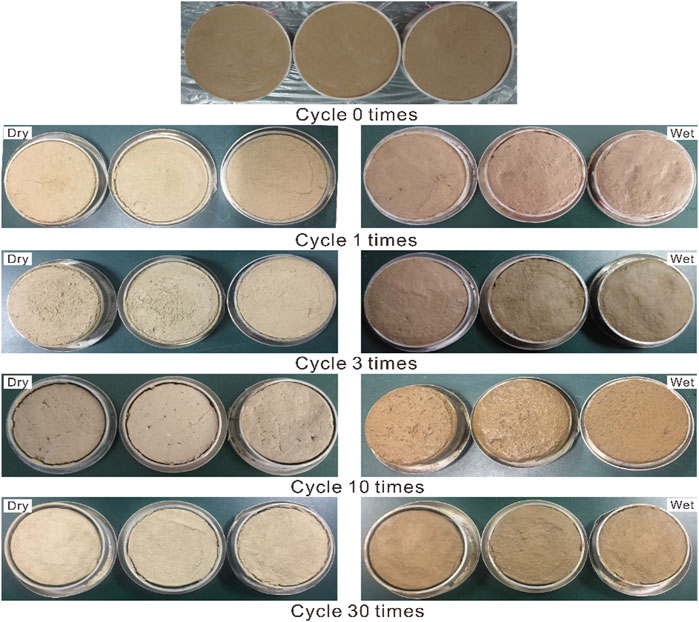

It has been well noticed that the shear strength of loess decreases gradually when it is under the dry and wet cycles (Qin et al., 2021). Initially, the effect of these cycles is pronounced, but shear strength continues to diminish as the number of cycle increases. This behavior is primarily attributed to the progressive breakdown of soil particles into smaller sizes throughout the dry–wet process. Moreover, the repeated cycles of shrinkage and expansion in loess lead to an increase in the internal pore volume and the gradual propagation of pores, which is associated with the convergence and penetration of small cracks (Wang et al., 2020; Ye et al., 2020). Note that this degradation is an accumulative process, which transited from the microscopic quantitative aspect to the macroscopic qualitative changes (see Figure 22).

Figure 22. Sample morphological diagram of dry–wet cycles (left is the dried sample and right is the wet sample).

The difference between the results of this experiment and the previous research results is obvious (Chou et al., 2019; Li and Xie, 2019; Liu, 2022; Qin et al., 2021; Xu et al., 2020; Yuan et al., 2017; Ma et al., 2022). As observed from this research, the internal friction angle generally decreased, except for five dry–wet cycles, whereas the cohesion fluctuated with the increasing number of cycles. The internal friction angle reflects the soil’s resistance to deformation, encompassing both sliding friction and interlocking friction between soil particles. Initially, the internal friction angle is high due to the irregular morphology of the soil grains. However, as dry–wet cycles progress, larger particles break down into smaller fragments, causing a shift in the predominant friction mode from interlocking friction to sliding friction.

Considering that the sliding friction is smaller than the occluding friction, the angle of internal friction of the soil decreases to some extent under dry–wet cycles. Meanwhile, the structure of the loess changes from an overhead structure (Liu et al., 2022b) to a mosaic structure, and then develops to a granular structure and flocculent structure. Notably, at the fifth dry–wet cycle, the soil’s shape factor reached its minimum, with particles adopting a flake-like appearance marked by rounded edges. This led to the formation of interlocking particles due to increased occluding friction, which in turn caused a moderate increase in the internal friction angle. Cohesion fluctuations were primarily linked to the contact pattern between particles and the state of fine particles (Wang et al., 2020; Liu et al., 2022c). When the contact between particles occurs in a surface-to-surface manner, the fine particles aggregate into a condensed form, resulting in increased cohesion. Conversely, the cohesion is lower and the fine particles are in a loose state when the particles’ connection mode is either the point-to-point or point-to-surface contact.

5.2 Macro- and micro-characteristics of loess under freeze–thaw cycles

As the number of freeze–thaw cycles increased, a decrease in shear strength correlated with changes in the pore structure was observed. The Ili loess, with its distinct composition and structure, exhibited different patterns in cohesion and internal friction angle under freeze–thaw effects compared to prior studies (Liu et al., 2019; Li et al., 2020; Liu et al., 2022a; Zheng et al., 2021; Liu et al., 2021; She et al., 2019). It is apparent that the cohesion of the soil samples decreased significantly, whereas the internal friction angle increased within 10 freeze–thaw cycles. This behavior is attributed to the freeze–thaw cycles disrupting the strong cementation between grains, as the freezing and migration of water progressively weaken the inner particle bonds. As point-to-point contacts between particles become more prevalent, the reduction in cohesion becomes pronounced. Associated with the rearrangement of the soil particles, the mosaic structure developed with the increased internal friction angle. With further freeze–thaw cycling, the effects of freeze–thaw cycles on the loess gradually diminished due to the formation of new structural bonds among loess particles.

5.3 Characteristics of loess after different numbers of dry–wet and freeze–thaw cycles

Comparative studies have previously indicated that the degradation of loess characteristics subjected to dry–wet and freeze–thaw cycles differs significantly, which is primarily attributed to differences in the material’s composition, structure, and particle characteristics, as well as differences in experimental methodologies adopted by different research workers. Chou et al. (2019), Zhang (2018), and Zhao (2019) found that the effect of dry–wet cycles is much more significant than that of the freeze–thaw cycles, whereas Li et al. (2017) reported the opposite trend. Figures 23, 24 show that the shear strength degradation for specimens subjected to freeze–thaw cycles is more significant than that of the specimens under the dry–wet cycles, when the same number of cycles is accounted for. This pronounced impact of freeze–thaw cycles is corroborated by the observation that most landslides occur in April and May during the ice and snow melting period (Cao et al., 2020).

Figure 23. Structural degradation of shear strength under wet and dry cycles and freeze–thaw cycles.

Figure 24. Degradation of cohesion and angle of internal friction under dry–wet and freeze–thaw cycles.

The fundamental reason for this difference lies in the distinct deterioration mechanisms induced by dry–wet and freeze–thaw cycles on loess. The degree of strength deterioration of loess under dry–wet cycles was primarily affected by the salt content of the soil (Xiao et al., 2018). During the cycles, the water content varies from the natural state to saturation, leading to the detachment of hydrophilic minerals within the loess, which disrupts the internal cementation and alters its internal structure, promoting an increase in the content of medium-sized pores. This process is irreversible, as evidenced by the results of the NMR tests. In contrast, the water content remains unchanged during freeze–thaw cycles. When the soil freezes, the water within it generates frost heaving and migration forces, continuously reducing the interparticle bite force and the original cementation within the soil. During the thawing process, the internal ice transforms into water, prompting the migration of soil particles and altering the internal soil structure. That is, the deterioration capability of dry–wet cycles on the loess strength is jointly constrained by the water content and the salt content. Future research is thus necessary to explore the correlation between different cycling patterns.

Under natural conditions, loess is simultaneously affected by both dry–wet and freeze–thaw cycles, and the two are not independent of each other. In the present research, a series of advanced techniques such as SEM and NMR were applied to conduct a macro- and micro-comparative analysis of the deterioration characteristics of loess under different cycles. It is indicated that the deteriorating effect of freeze–thaw cycles is more pronounced than that of dry–wet cycles in the Ili Valley. This discovery not only further enriches the triggering factors of loess landslides in the Ili area but also provides meaningful theoretical support and practical guidance for the management of loess landslide disasters and local engineering construction.

In the present study, the effects of freeze–thaw and dry–wet cycles on Ili loess characteristics are independently examined. In the actual situation, however, these two actions often occur simultaneously. Given that the behavior of loess under the combined dry–wet and freeze–thaw cycles differs significantly from that under the isolated condition (Zhou et al., 2018; Li, 2017), future investigations should focus on the assessment of the characteristics of Ili loess under the combined cyclic conditions.

6 Conclusion

To explore the impacts of dry–wet and freeze–thaw cycles on the mechanical degradation of the Ili loess, a series of triaxial shear tests were carried out in the present research. In parallel, some advanced techniques, such as SEM and NMR, were employed to conduct a comprehensive macro-level and microlevel comparative analysis of loess deterioration under different cyclic conditions. The conclusions drawn from this research are as follows:

(1) Under dry–wet cycling conditions, both the shear strength and the internal friction angle of the Ili loess exhibited significant reduction, whereas the cohesion experienced some degree of fluctuation.

(2) The increased number of medium and large voids caused by the increased porosity is identified as the primary cause of strength degradation of the Ili loess.

(3) Both the dry–wet and freeze–thaw cycles resulted in the fragmentation of large particles and aggregation of small particles, during which the overall particle size progressively developed to the uniform distribution state.

(4) The contact between particles of the Ili loess gradually shifts from the initial surface contact to point-to-point contact when it is exposed to the climatic fluctuations.

(5) The impact of the freeze–thaw cycles is more pronounced than that of the dry–wet cycles when the mechanical properties of the Ili loess is comprehensively evaluated.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material; further inquiries can be directed to the corresponding author.

Author contributions

ZZ: conceptualization, writing – original draft, and writing – review and editing. YH: writing – original draft. QL: writing – review and editing. RH: writing – review and editing. GT: writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by the National Natural Science Foundation of China (41967036), Xinjiang Uygur Autonomous Region Special Program for Key R&D Tasks (2021B03004), the State Key Laboratory for GeoMechanics and Deep Underground Engineering, the China University of Mining and Technology (SKLGDUEK 2028), Graduate Student Scientific Research Innovation Projects in Xinjiang Uygur Autonomous Region (XJ2021G076), and Xinjiang University National College Student Innovation Training Program Project (202110755006).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Cai, Z., Zhu, X., Huang, Y., and Zhang, C. (2019). Evolution rules of fissures in expansive soils under cyclic action of coupling wetting-drying and freeze-thaw. Chin. J. Geot Eng. 41, 1381–1389.

Cao, X., Meng, H., Shang, Y., Zhang, J., Aibibaier, M., and Xu, J. (2020). The development and distribution of loess landslides in Yili Valley and its causes. Xinjiang Geol. 38, 405–411.

Chou, Y., and Wang, L. (2021). Soil-water characteristic curve and permeability coefficient prediction model for unsaturated loess considering freeze-thaw and dry-wet. Soils Rocks 41.

Chou, Y., Zhang, Q., and Jia, S. (2019). Experiment on strength of unsaturated remodeled loess based on freeze-thaw and dry-wet effects. J. Lanzhou Univ. Technol. 45, 118–125.

Chouksey, A., Dev, N., Kantarao, V., and Verma, M. (2024). Application of paper mill lime sludge waste in building construction material: state of the art report. J. Polym. and Compos. 12 (7), 172–187.

Chouksey, A., Puri, K., Ahlawat, A., and Verma, M. (2025). Impact of polymer chemistry on population and land use pattern to identify black spot. J. Polym. and Compos. 13 (1), 540–558.

Fu, X., Zhang, Z., Yang, C., Yun, Q., and Ming, J. (2021). Study on geometric type changes of Fuping loess microstructure under freeze-thaw cycles. J. Glaciol. Geocryol. 43, 484–496.

Hu, C. M., Yuan, Y. L., Mei, Y., Wang, X. y., and Liu, Z. (2020). Comprehensive strength deterioration model of compacted loess exposed to drying-wetting cycles. Bull. Eng. Geol. Environ. 79, 383–398. doi:10.1007/s10064-019-01561-8

Huang, W., Tao, Y., Liu, Q., and Xiang, W. (2021). Experimental study on tensile strength of remolded loess in Xinjiang Ili valley. J. Huazhong Univ. Sci. Technol. Sci. Ed. 49, 92–97.

Kong, J., Zhuang, J., Zhan, J., Bai, Z. w., Leng, Y. q., Ma, P. h., et al. (2021). A landslide in heifangtai, northwest of the Chinese Loess Plateau: triggered factors, movement characteristics, and failure mechanism. Landslides 18, 3407–3419. doi:10.1007/s10346-021-01752-z

Kumar, R., Verma, M., and Dev, N. (2022). Investigation on the effect of seawater condition, sulphate attack, acid attack, freeze–thaw condition, and wetting–drying on the geopolymer concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 46, 2823–2853. doi:10.1007/s40996-021-00767-9

Kumari, S., Jaglan, S., Chouksey, A., Walia, R., Ahlawat, A., Atul, G., et al. (2024). Carbon footprint analysis of cement production in India. Evergreen 11 (2), 2881–2889. doi:10.5109/7326930

Li, B. (2017). Effect of freeze-thaw cycle and dry-wet alternation on mechanical properties of loess and its application in slope engineering. Dissertation: Lanzhou University of Technology.

Li, P., Xie, W., Pak, R. Y., and Vanapalli, S. K. (2019a). Microstructural evolution of loess soils from the Loess Plateau of China. Catena 173, 276–288. doi:10.1016/j.catena.2018.10.006

Li, S., Li, Y., Gao, X., and Shi, D. (2019b). Experimental study on the triaxial stress-strain curve of undisturbed loess in xining by freeze-thaw cycles. Earth Environ. Sci. 304, 052065. 052065-052065. doi:10.1088/1755-1315/304/5/052065

Li, S., Li, Y., Gao, X., and Shi, D. (2020). Effect of freezing and thawing on shear strength of intact loess. J. Civ. Environ. Eng. 42, 48–55.

Li, Y., Song, Y., Fitzsimmons, K. E., Chen, X., Wang, Q., Sun, H., et al. (2018). New evidence for the provenance and formation of loess deposits in the ili river basin, arid central asia. Aeolian Res. 35, 1–8. doi:10.1016/j.aeolia.2018.08.002

Liu, K., Gu, T., Wang, X., and Wang, J. (2022a). Time-dependence of the mechanical behavior of loess after dry-wet cycles. Appl. Sci. 12, 1212. doi:10.3390/app12031212

Liu, L., Zhang, W., Zhang, B., Gu, Y., and Xie, B. (2021). Effect of freezing-thawing cycles on mechanical properties and microscopic mechanisms of loess. Hydrogeology Eng. Geol. 48, 109–115.

Liu, Q., Zhao, K., Laishuan, Z., and Wang, L. (2022b). Methods and exploration for mechanical testing and microscopic testing of loess under freeze-thaw cycles. MATEC Web Conf. 358, 01030. doi:10.1051/matecconf/202235801030

Liu, X., Qin, H., and Lan, H. (2020). On the relationship between soil strength and wave velocities of sandy loess subjected to freeze-thaw cycling. Soil Dyn. Earthq. Eng. 136, 106216. doi:10.1016/j.soildyn.2020.106216

Liu, Y., Wang, G., Lai, H., Xie, M., and An, C. (2022c). Study on macro-micro parameter relationship of undisturbed loess under dry-wet cycle. J. Hydraulic Eng. 53, 421–432.

Lu, J., Wang, T. H., Cheng, W. C., Yang, T., and Luo, Y. (2019). Permeability anisotropy of loess under influence of dry density and freeze–thaw cycles. Int. J. Geomechanics 19, 04019103. doi:10.1061/(asce)gm.1943-5622.0001485

Lv, Q., Zhang, Z., Zhang, T., Hao, R., Guo, Z., Huang, X., et al. (2021). The trend of permeability of loess in yili, China, under freeze-thaw cycles and its microscopic mechanism. Water 13, 3257. doi:10.3390/w13223257

Ma, X., Zhang, Y., Zhang, P., and Wang, X. (2022). Experimental research on the effect of repeated drying - wetting cycles other mechanical properties of remolded unsaturated loess. J. Railw. Eng. Soc. 39, 1–6+12.

Mo, T., Guo, M., Lou, Z., and Gao, Y. (2018). Laboratory text on effect of moisture content on deformation and shearing characteristics of ili loess. China Rural Water Hydropower, 87–90+94.

Nie, Y., Ni, W., Li, X., Wang, H., Yuan, K., Guo, Y., et al. (2021). The influence of drying-wetting cycles on the suction stress of compacted loess and the associated microscopic mechanism. Water 13, 1809. doi:10.3390/w13131809

Pan, Z., Yang, G., Ye, W., Tian, J., and Liang, B. (2020). Study on mechanical properties and microscopic damage of undisturbed loess under dry and wet cycles[J]. J. Eng. Geol., 28(6): 1186–1192.

Qi, J., and Ma, W. (2014). Influence of freezing-thawing cycles on micro-structure and shear strength of loess. J. Glaciol. Geocryol. 36 (04), 922–927.

Qin, Y., Li, G., Chen, X., and Fan, K. (2021). Study on shear strength and structure of malan loess under wetting–drying cycles. Arabian J. Geosciences 14, 2854. doi:10.1007/s12517-021-09259-6

She, H., Hu, Z., Qu, Z., Li, H., Guo, H., and Ma, X. (2019). Structural strength deterioration characteristics and a model of undisturbed loess under the action of wetting and freeze-thaw cycles. Math. Problems Eng. 2019, 1–23. doi:10.1155/2019/4790250

Shi, G., Li, X., Guo, Z., Zhang, Z., and Zhang, Y. (2022). Effect of mica content on shear strength of the yili loess under the dry-wet cycling condition. Sustainability 14, 9569. doi:10.3390/su14159569

Shi, Y., Zhang, L., Ma, W., Yang, C., Han, D., and Shang, F. (2022). Investigating unfrozen water and its components during freeze–thaw action in loess using a novel nmr technique. Eur. J. Soil Sci. 73. doi:10.1111/ejss.13262

Song, Y., Chen, X., Qian, L., Li, C., Li, Y., Li, X., et al. (2014). Distribution and composition of loess sediments in the ili basin, central asia. Quat. Int. 334-335, 61–73. doi:10.1016/j.quaint.2013.12.053

Song, Y., and Shi, Z. (2010). Distribution and compositions of loess sediments in yili basin, central asia. Sci. Geol. Sin. 30, 267–272.

Song, Y., Zeng, M., Chen, X., Li, Y., Chang, H., An, Z., et al. (2018). Abrupt climatic events recorded by the ili loess during the last glaciation in central asia: evidence from grain-size and minerals. J. Asian Earth Sci. 155, 58–67. doi:10.1016/j.jseaes.2017.10.040

Tian, H., Li, L., Zhang, K., and Wang, P. (2020). Effects of dry-wet and freeze-thaw cycles on microstructure of soil based on SEM. J. Lanzhou Univ. Technol. 46, 122–127.

Wang, J., Zhang, D., Wang, N., and Gu, T. (2019). Mechanisms of wetting-induced loess slope failures. Landslides 16, 937–953. doi:10.1007/s10346-019-01144-4

Wang, T., Hao, Y., Wang, Z., Cheng, L., and Li, J. (2020). Experimental study on dynamic strength properties of compacted loess under wetting-drying cycles. Chin. J. Rock Mech. Eng. 39, 1242–1251.

Xiao, Z., and Lai, Y. (2018). Study on water and salt transfer mechanism in saline soil under freezing-thawing and dry-wet conditions. Chin. J. Rock Mech. Eng. 37 (S1), 3738–3746.

Xu, J., Li, Y., Ren, C., and Lan, W. (2020). Damage of saline intact loess after dry-wet and its interpretation based on sem and nmr. Soils Found. 60, 911–928. doi:10.1016/j.sandf.2020.06.006

Xu, J., Li, Y., Ren, C., Wang, S., Vanapalli, S. K., and Chen, G. (2021). Influence of freeze-thaw cycles on microstructure and hydraulic conductivity of saline intact loess. Cold Regions Sci. Technol. 181, 103183. doi:10.1016/j.coldregions.2020.103183

Ye, W., Qiang, Y., Zhang, W., Wu, Y., and Chen, Y. (2020). Macroscopic and microscopic experimental study on remolded loess under humidification-dehumidification conditions. Sci. Technol. Eng. 20, 12058–12064.

Yuan, K., Ni, W., and Xiangfei, L. (2022). Influence of wetting–drying cycles on the compression behavior of a compacted loess from microstructure analysis. Bull. Eng. Geol. Environ. 81, 1–13.

Yuan, Z. H., Ni, W. K., and Tang, C. (2017). Experimental study of structure strength and strength attenuation of loess under wetting-drying cycle. Rock Soil Mech. 38, 1894–1902.

Zhang, H., Zhi, B., Liu, E., and Wang, T. (2020). Study on varying characteristics of temperature field and moisture field of shallow loess in the freeze-thaw period. Adv. Mater. Sci. Eng. 2020. doi:10.1155/2020/1690406

Zhang, W. (2018). Experimental study on compressive deformation and microscopic properties of remolded loess under coupling effect of dry-wet and freezing-thawing. Dissertation: Chang’an University.

Zhang, W., Li, Y., Wang, R., and Beroya-Eitner, M. A. (2022). A model for the formation and evolution of structure of initial loess deposits. Catena 214, 106273. doi:10.1016/j.catena.2022.106273

Zhao, Q. (2019). Investigation on the influence of freezing-thawing cycle anddrying-wetting alternation on the permeability anisotropy and spatial variability of loess. Dissertation. Xi'an: Xi’an University of Architecture and Technology.

Zhao, Q., Su, L., Liu, H., and Yang, J. (2020). Investigation on the influence of freezing-thawing cycle on the permeability coefficient anisotropy of loess. J. Glaciol. Geocryol. 42, 843–853.

Zheng, F., Shao, S., and Wang, S. (2021). Influences of freeze-thaw on strength of loess under complex stress path. Chin. J. Geot Eng. 43, 224–228.

Zhou, Y., Wu, X., Li, F., Liu, H., and Meng, J. (2018). Experimental study on inf luence of freeze-thaw cycles and dry-wet alternation on mechanical properties of loess. Railw. Eng. 39, 1242–1251.

Keywords: Ili loess, dry–wet cycles, freeze–thaw cycles, shear strength, microstructure

Citation: Zhang Z, Hu Y, Lv Q, Hao R and Tang G (2025) Comparative analysis on the damage properties of the Ili loess under dry–wet and freeze–thaw cycles. Front. Earth Sci. 13:1465320. doi: 10.3389/feart.2025.1465320

Received: 16 July 2024; Accepted: 26 March 2025;

Published: 15 May 2025.

Edited by:

Yunhui Zhang, Southwest Jiaotong University, ChinaReviewed by:

Gordon Woo, Risk Management Solutions, United KingdomYongqiang Zhou, Chinese Academy of Sciences (CAS), China

Manvendra Verma, GLA University, India

Copyright © 2025 Zhang, Hu, Lv, Hao and Tang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zizhao Zhang, emhhbmd6aXpoYW9AeGp1LmVkdS5jbg==, enl5QHhqdS5lZHUuY24=

Zizhao Zhang

Zizhao Zhang Yang Hu

Yang Hu Qianli Lv

Qianli Lv