Abstract

With the rapid development of deep mining and geothermal exploitation, the influence of high-temperature environment on the mechanical properties of rocks has become a core challenge for engineering safety. This study focuses on gneiss (a common rock type in deep mining environments) to systematically investigate the thermal effects (25°C–800°C) on multiscale structural damage and permeability evolution. Through integrated experimental approaches including high-temperature treatment, uniaxial compressive strength tests, micro-CT scanning, scanning electron microscopy (SEM) analysis, and digital seepage simulations, we comprehensively characterize the temperature-dependent structural alterations and fluid transport properties. The results indicate that as the temperature increases, the mass loss rate and porosity of gneiss significantly increase, and the heterogeneity of pore distribution intensifies. Thermal cracks gradually coalesce and form macroscopic fracture surfaces above 600°C, leading to an increase in volumetric porosity from 1.87% to 6.78%. Seepage simulation reveals that the absolute permeability increases by approximately 135% at 800°C, showing a linear positive correlation with the total porosity. Microscopic analysis reveals that the evaporation of intercrystalline bound water and differential thermal expansion of minerals are the main causes of crack propagation, and the compressive strength of the rock decreases by 35.6% at high temperatures. This study innovatively combines X-CT scanning technology with digital core analysis to establish a three-dimensional quantitative evaluation system for gneiss fractures under high-temperature conditions, offering theoretical and technical support for deep mining engineering.

1 Introduction

Rock engineering is ubiquitously integral to national infrastructure and closely intertwined with societal development and the national economy. The construction and planning of deep mining operations are tightly linked to the mechanical properties of rocks (Yang et al., 2017; Brady and Brown, 2006; Li et al., 2015; Lei et al., 2025; Gao H. et al., 2024). Fractured rocks are considered the most common heterogeneous brittle materials in nature, characterized by the presence of numerous discontinuities such as joints, fractures, and weak interlayers, resulting from millions of years of geological activity (Nian et al., 2024). The complex compositional structure of fractured rock bodies and the development of joints render their mechanical properties susceptible to external influences such as thermal, hydraulic, and stress factors. In the context of the increasing prevalence of deep geological engineering projects, including the extraction of deep mineral resources (Ranjith et al., 2017), geothermal resources (Jolie et al., 2021), underground coal gasification (Bhutto et al., 2013), and the construction of storage facilities for high-level radioactive materials (Keerthi et al., 2025), the rock mechanics issues involved in the construction and protection of deep geological structures have become a focal point of research among scholars both domestically and internationally.

With increasing mining depths, high geothermal temperatures have emerged as a significant factor affecting the fundamental mechanical properties of rock (Zhang et al., 2014; Rossi et al., 2018; Zhang et al., 2017). The domain of high-temperature rock mechanics has witnessed extensive scholarly exploration, encompassing rock rheology and rock fracture mechanics, thereby establishing a robust theoretical and experimental framework for subsequent investigations (Luo and Wang, 2011). A multitude of engineering observations has underscored the profound structural degradation that elevated geothermal temperatures can inflict upon rock formations, necessitating heightened attention from the research community. In recent years, the mechanical behavior of fractured rock masses subjected to high-temperature conditions has garnered widespread academic interest (Yin et al., 2019; Zuo et al., 2017; Zhang et al., 2016; Ghassemi, 2012). XI et al. (Xi et al., 2020) performed high-temperature triaxial shear tests on granite from the Qinghai Gonghe region, observing that increases in temperature (ranging from 25°C to 300°C) led to increased rock strength indices and significantly reduced shear strength parameters. Wu et al. (Wu et al., 2022) further extended this line of inquiry by conducting uniaxial compression tests on fractured rocks following high-temperature treatment, and compared the mechanical responses under varying cooling conditions. Their results indicated that heating treatment coupled with water-cooling processes led to diminished strength and elastic modulus, along with an augmentation in failure strain. Additionally, Ma et al. (2020) used a real-time high-temperature true triaxial shear system to test the strength attenuation of granite at 400°C, discovering that horizontal stress and real-time high temperatures have a coupled effect on rock structure damage. Although significant progress has been made in understanding the macroscopic mechanical damage effects of fractured rock bodies in high-temperature environments, the understanding of the micromechanical evolution mechanisms of thermal fracturing under geothermal high temperatures remains inadequate (Chen et al., 2017; Kristinsdóttir et al., 2010; Masri et al., 2014; Tian et al., 2014). Thus, there is still a lack of in-depth knowledge regarding the degradation patterns of permeability under high-temperature conditions.

As experimental testing techniques continue to advance, an increasing array of high-precision testing technologies have been successfully applied to the study of rock fractures, such as acoustic emission, nuclear magnetic resonance, atomic force microscopy scanning, micro-CT scanning, and digital speckle techniques (Du et al., 2020; Golsanami et al., 2016; Gurgurewicz et al., 2019; Yang et al., 2021; Zhao et al., 2020). The adoption of these new technologies has facilitated the transition from macroscopic to microscopic analysis of rock defects (Rao et al., 2001). Micro-CT scanning, in particular, has become widely utilized in the analysis of rock structure damage, due to its capacity to visually display and reconstruct the three-dimensional fracture patterns within rocks, coupled with image analysis software that quantitatively characterizes fracture distributions, thereby revealing the micro-mechanisms behind macroscopic fracture phenomena (Yang et al., 2021). However, current research has yet to clearly define the thermal fracture patterns and microstructural damage mechanisms of fractured rocks under the complex and unique conditions of deep geological layers (Yu et al., 2015).

This study focuses on gneiss, a common rock type in deep mining, and initially conducts heating treatments under various high-temperature conditions. By integrating strength testing, micro-CT scanning, seepage simulation, and scanning electron microscopy results, it reveals the patterns of structural damage evolution across different scales and deeply analyzes the mechanisms by which high geothermal temperatures affect the physical and mechanical properties of rocks. The findings aim to provide technical guidance for deep mining operations, addressing the challenges posed by high geothermal temperatures in deep rock engineering construction.

2 Materials and methods

2.1 Rock materials

The gneiss used in this study appears grayish with densely packed crystal grains and contains numerous micro-fractures internally. The primary mineral components of the gneiss are quartz (66.6%), plagioclase (15.9%), sodium feldspar (11.8%), and biotite (5.7%). Through basic physical property tests of the rock, the average dry density of the gneiss is determined to be 2.78 g/cm3, with a longitudinal wave velocity ranging from 3890.2 to 4,437.3 m/s, and an average velocity of 4,014.8 m/s.

2.2 Experimental method

2.2.1 Specimen preparation

The experimental procedure, as illustrated in Figure 1, follows standardized rock sample preparation methods used in engineering rock body experiments. The process involves coring, cutting, and polishing bulk rock samples to produce cylindrical specimens with a diameter of 50 mm and a length of 100 mm. Specimens with anomalous wave velocities were discarded based on their wave speed measurements. This ensures that the research results are only related to the test conditions and not caused by the sample itself, ensuring the reliability and repeatability of the research structure.

FIGURE 1

The experimental flow of the study.

2.2.2 Heating experiment

The specimens were subjected to a heat treatment using a programmable temperature control chamber manufactured by Shanghai JIANHU Instrument Equipment Co., Ltd. The temperature was increased at a rate of 50°C/min to a predetermined temperature, which was then maintained for the duration of the experiment. After the completion of the experiment, the specimens were allowed to cool to room temperature under natural conditions. Based on a series of enclosed fire tests, the RABT temperature curve (Qiao et al., 2019) suggests that the internal temperature of a mine increases sharply to over 800°C within the first 5 min following a fire outbreak and remains constant for at least 60 min. Consequently, the heating temperature set for this study was set as 25°C–800°C, with durations of high-temperature exposure set at 180 min. After the heating processing, the mass loss rate of the gneiss sample was measured to quantitatively evaluate the rock integrity. Five groups of heating experiments at diverse temperatures were conducted in this study. Each group of experiments contained 3 rock samples. The mass loss rate was determined by calculating the average values of the three samples.

2.2.3 Micro-CT scanning

Scans were performed using a micrometer-scale X-ray CT scanner. The operational voltage and current of the device were 120 kV and 235 mA, respectively, with an image resolution of approximately 50 μm. Throughout the scanning process, 525 transverse grayscale slices were acquired from top to bottom for each specimen. Given the prevalence of scanning noise in the raw 2D CT images, which can interfere with image clarity and the differentiation of various components, it is customary to preprocess the CT images to eliminate noise. In this experiment, image processing software was utilized to perform smoothing and filtering on the raw CT images, followed by trimming and smoothing the rough edges to minimize statistical errors caused by redundant areas. Finally, a binarization segmentation algorithm was employed to extract fractures from the grayscale images, adjust image contrast to enhance the visibility of pores and fractures, and import the 2D images into software for three-dimensional reconstruction to obtain a stereoscopic distribution of the pores (Gao H. D. et al., 2024).

2.2.4 Uniaxial compression test

To systematically evaluate the mechanical degradation of gneiss under high-temperature conditions, uniaxial compression tests were performed on cylindrical specimens (50 mm diameter × 100 mm height). A servo-controlled digital compression testing machine was utilized, with a displacement-controlled loading rate of 0.5 mm/min to ensure quasi-static conditions. Prior to testing, specimens subjected to heating treatments at 25°C–800°C were cooled to ambient temperature (25°C) naturally to avoid thermal shock effects. During the loading process, axial force and displacement data were synchronously recorded at a sampling frequency of 10 Hz. To ensure reliability, three replicates were tested for each temperature condition, and the average values were reported. The failure modes of the specimens (e.g., axial splitting, shear failure) were visually documented, and post-failure fragments were collected for subsequent microstructural analysis.

2.2.5 Microstructural observation

The microstructural evolution of thermally treated gneiss was investigated using a TESCAN VEGA3 scanning electron microscope (SEM) equipped with a secondary electron detector. Prior to scanning, fracture specimens approximately 2 cm in thickness were prepared. To enhance electrical conductivity, a 10-nm gold layer was sputtered onto the fracture surfaces using a Quorum Q150R ES coater under vacuum conditions. Representative regions of interest (e.g., mineral boundaries, crack tips) were selected to analyze crack propagation paths, pore connectivity, and mineralogical alterations. Additionally, energy-dispersive X-ray spectroscopy (EDS) was employed to semi-quantitatively identify elemental compositions near thermally induced cracks.

3 Test results

3.1 Macroscopic properties of gneiss under high-temperature conditions

3.1.1 Mass loss rate

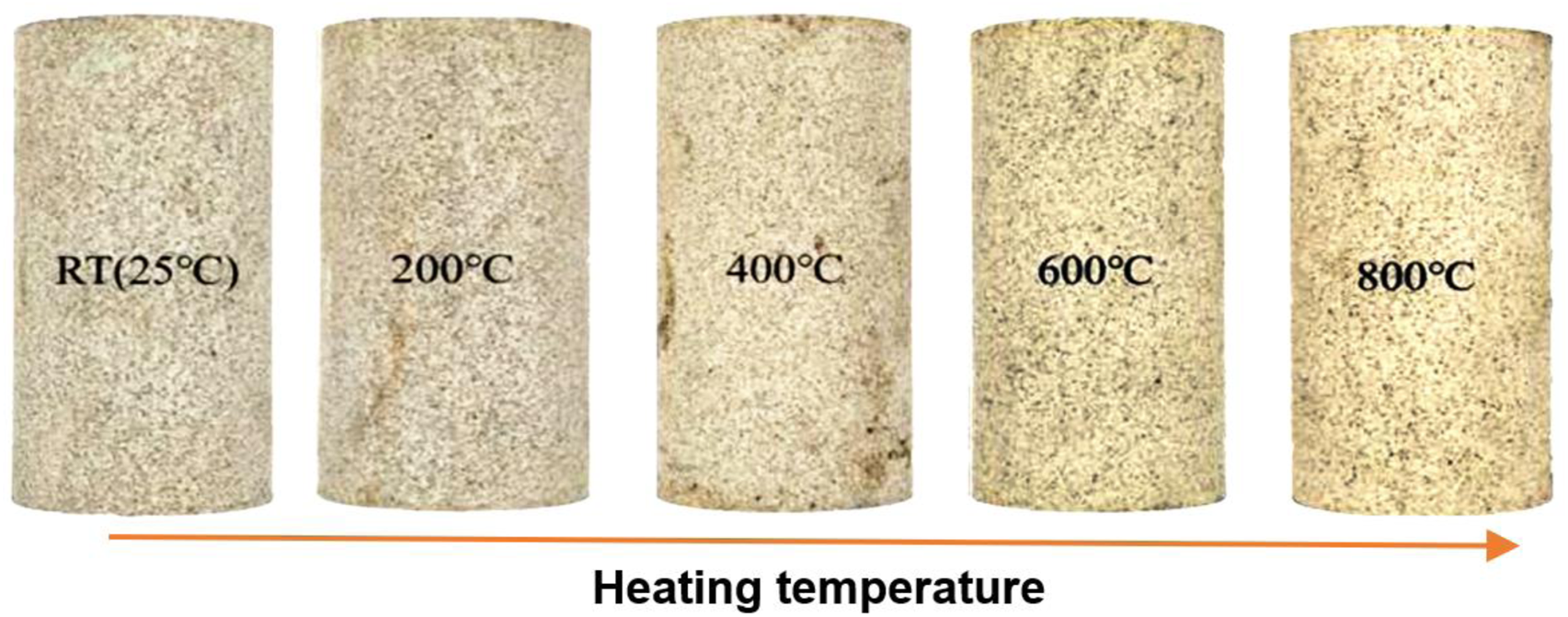

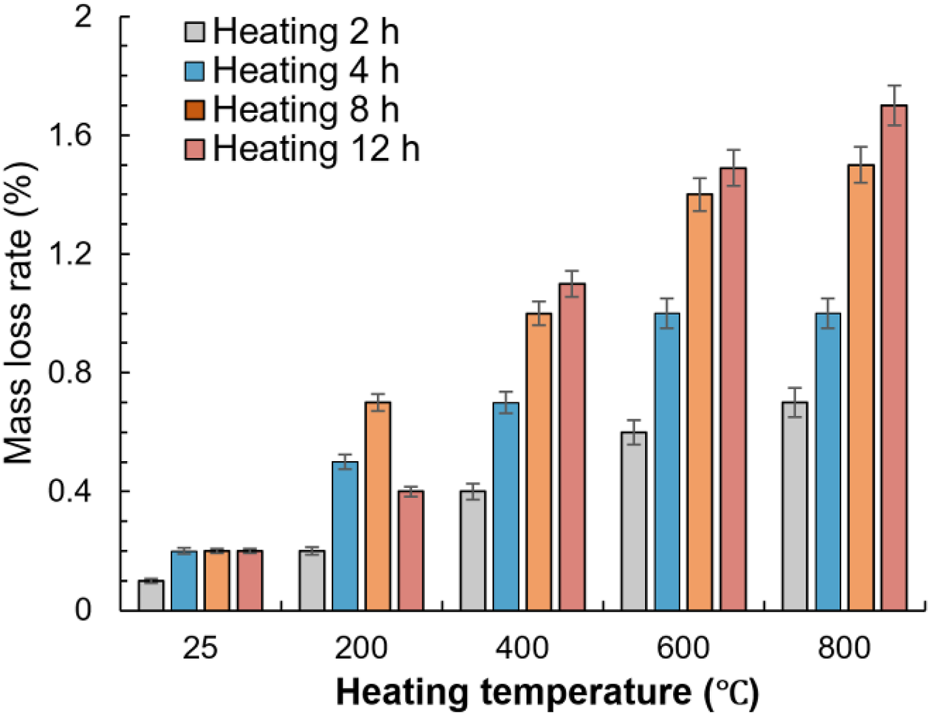

As illustrated in Figure 2, the appearance of the gneiss specimens under high-temperature conditions initially presents a smooth outer surface with no noticeable porosity. Upon heating treatment, the color of the gneiss surface progressively shifts from dark gray to light gray as the temperature increases, accompanied by minor particulate detachment; above 600°C, the surface of the gneiss exhibits pores and defects, with a marked lightening in color. This phenomenon indicates that high temperatures cause internal moisture evaporation and mineral crystallization to undergo carbonization, resulting in mass loss of the rock. During the heating process, the mass loss rate of the gneiss specimens was calculated using Equation 1, and the impact of high temperatures on the integrity of the rock was analyzed, with results depicted in Figure 3. After 12 h of heating, the final mass loss rates of the rock at temperatures of 25°C, 200°C, 400°C, 600°C, and 800°C were respectively 0.18%, 0.49%, 1.02%, 1.64%, and 1.76%. The curve of mass loss rate shows an initially rapid then slow trend; this can be attributed to the evaporation of free water and anisotropic expansion of crystals causing particle detachment during the initial 0–8 h of heating. After 8 h, the mineral composition within the rock stabilizes, and the evaporation of bound water diminishes, resulting in a gradual leveling off of the mass loss rate.

FIGURE 2

Appearance of samples under high-temperature conditions.

FIGURE 3

Mass loss rate under high-temperature conditions.

Wherein, φT represents the mass loss rate at temperature T, with m0 and mT denoting the mass of the specimen at room temperature and at temperature T, respectively.

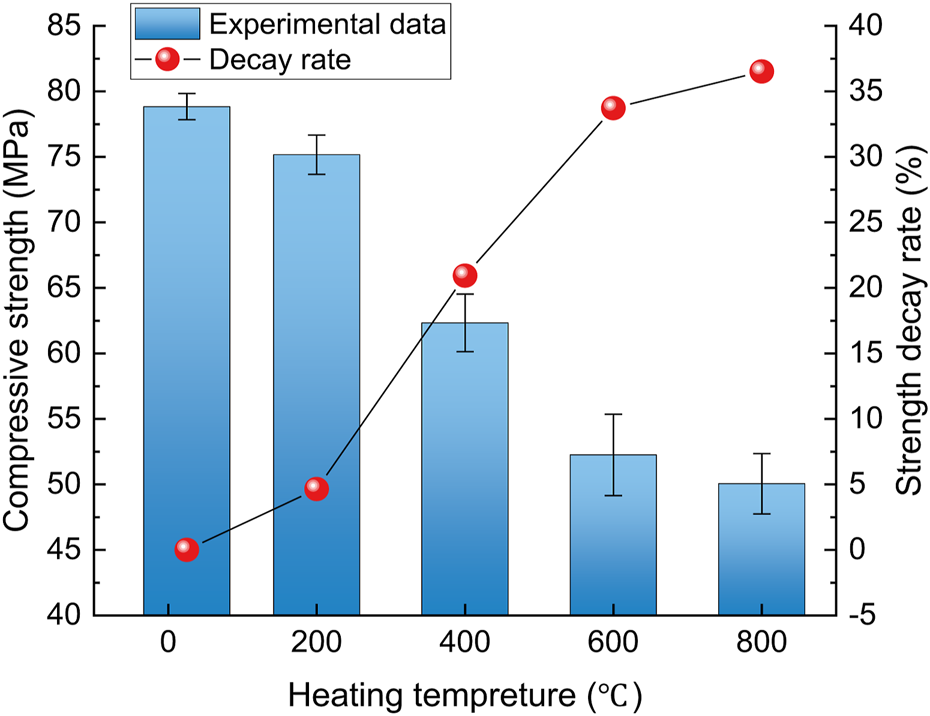

3.1.2 Mechanics characteristics

Figure 4 presents the results of uniaxial compressive strength tests of gneiss under various heating treatment conditions. The standardized uniaxial compressive strength of gneiss reached 78.77 MPa. Throughout the heating treatment process, the compressive strength of the rock gradually decreased. After exposure to a temperature of 800°C, the compressive strength of the gneiss ultimately diminished to 51.35 MPa, with a strength attenuation rate of 36.83%. The observed changes in mass and strength of gneiss under high geothermal temperatures indicate that structural damage to the rock mass significantly affects its macroscopic mechanical behavior. Notably, previous research has shown that at lower temperature ranges (generally below 100°C), an increase in temperature causes evaporation of fracture water and further hydration of the cementing materials, thereby enhancing rock strength. However, when the temperature reaches a certain level (typically above 200°C), the porosity structure of the rock changes significantly with temperature increase, and the formation of cracks along with the gradual decomposition of hydrates begins to negatively impact the ultimate strength of the fractured rock mass (Zhang et al., 2016; Kristinsdóttir et al., 2010). Therefore, in deep mining engineering, it is crucial to consider the effects of temperature on the load-bearing and deformation performance of the surrounding rock, optimize design, and implement timely measures to strengthen rock support to ensure the durability and safety of structures.

FIGURE 4

Uniaxial compressive strength of gneiss at different temperatures.

3.2 Examination of pore distribution

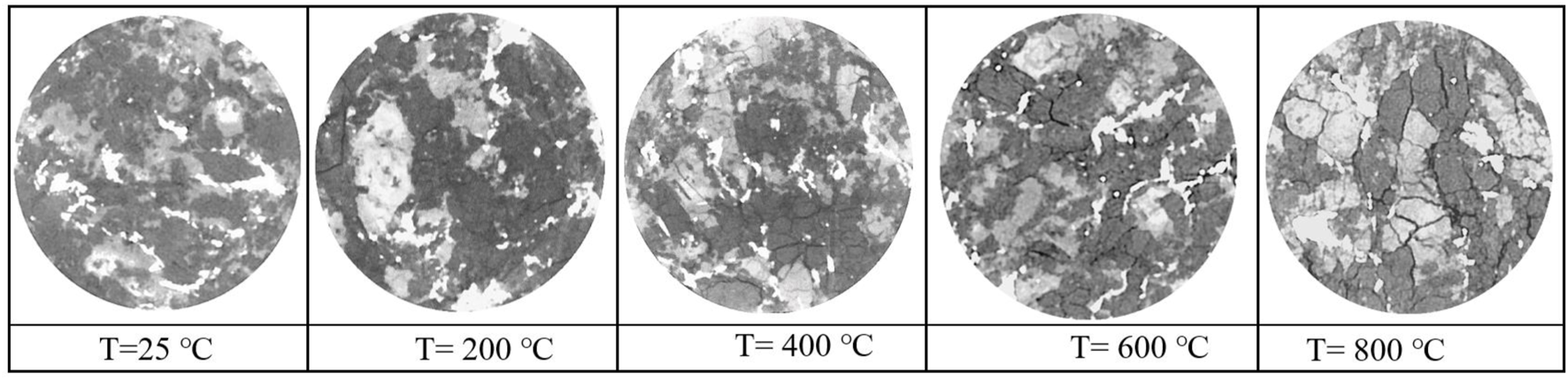

3.2.1 Distribution characteristics of two-dimensional pores

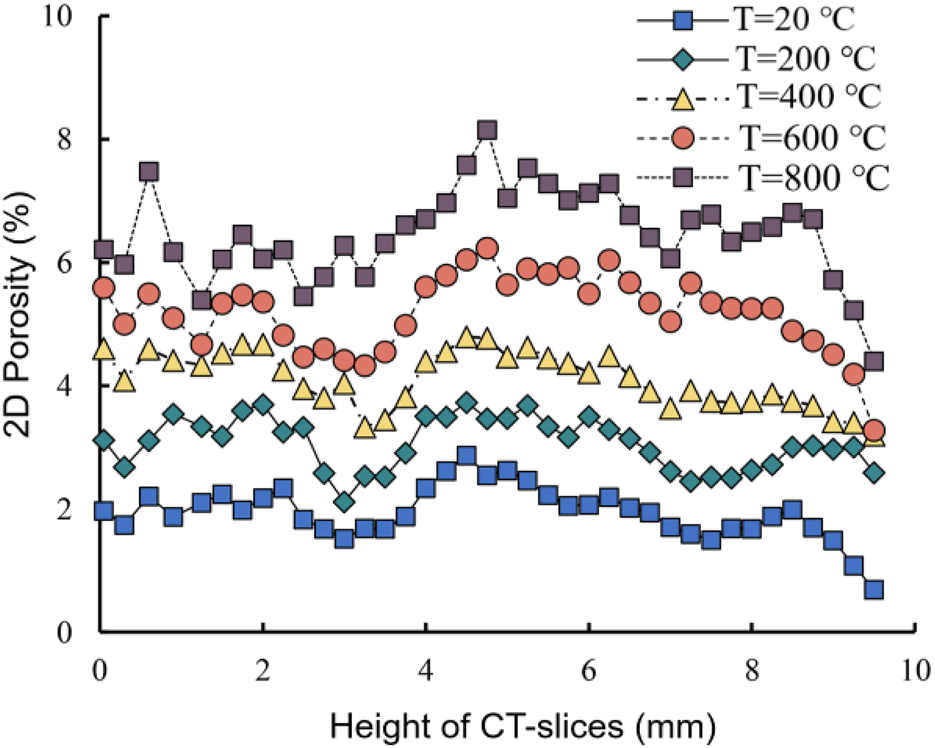

Based on the CT scanning experiments, grayscale scan slices of the gneiss specimens were obtained, revealing the evolution of two-dimensional (2D) pores within these specimens, as shown in Figure 5. Taking a typical scan slice from the central part of the specimen as an example, it is evident that the changes in porosity during the heating process exhibit significant heterogeneity. In specimens of gneiss that have not undergone thermal process, the internal arrangement of particles is relatively compact. After heating at 200°C for 12 h, micro-fractures begin to appear within the specimen. At a heatingtemperature of 400°C, both the number and length of internal fractures significantly increase. When the temperature reaches 600°C, under thermal damage, the number, length, and width of fractures markedly increase, with a concurrent rise in fracture connectivity. At 800°C, the fractures’ length and width continue to expand, and the complexity of pore distribution further increases. Quantitative analyses of the two-dimensional (2D) porosity distribution in gneiss were conducted. Using binarization techniques, the porosity of the rock surfaces at different sample heights was extracted, and the results are presented in Figure 6. The porosity curves of the gneiss surface exhibit significant fluctuations, with the ordinates of the curves gradually increasing as the heating temperature rises. The pore content data derived from CT data are presented in Table 1. With increasing temperatures, the fracture content in the gneiss increases, with the overall average surface porosity of the specimens rising from 1.74% to 6.28%. The statistical data including maximum, minimum, and variance of 2D porosity, as listed in Table 1. These results indicate that with increasing heating temperatures, the heterogeneity and anisotropy of internal pore distribution within the specimens significantly intensify.

FIGURE 5

Scanned images of two-dimensional microcosmic feature at various temperatures.

FIGURE 6

Quantitative analysis results of two-dimensional porosity.

TABLE 1

| Temperature (°C) | Mass loss rate (%) | 2D porosity (%) | Variance (%) | Maximum value (%) | Minimum value (%) | 3D porosity (%) |

|---|---|---|---|---|---|---|

| 25 | 0.18 | 1.74 | 9.01 | 2.87 | 0.91 | 1.87 |

| 200 | 0.49 | 2.90 | 17.13 | 3.95 | 2.13 | 2.81 |

| 400 | 1.02 | 4.54 | 25.68 | 4.85 | 3.63 | 3.75 |

| 600 | 1.64 | 5.83 | 31.23 | 6.14 | 3.91 | 5.52 |

| 800 | 1.76 | 6.28 | 40.92 | 8.23 | 5.85 | 6.78 |

CT testing statistical data of gneiss.

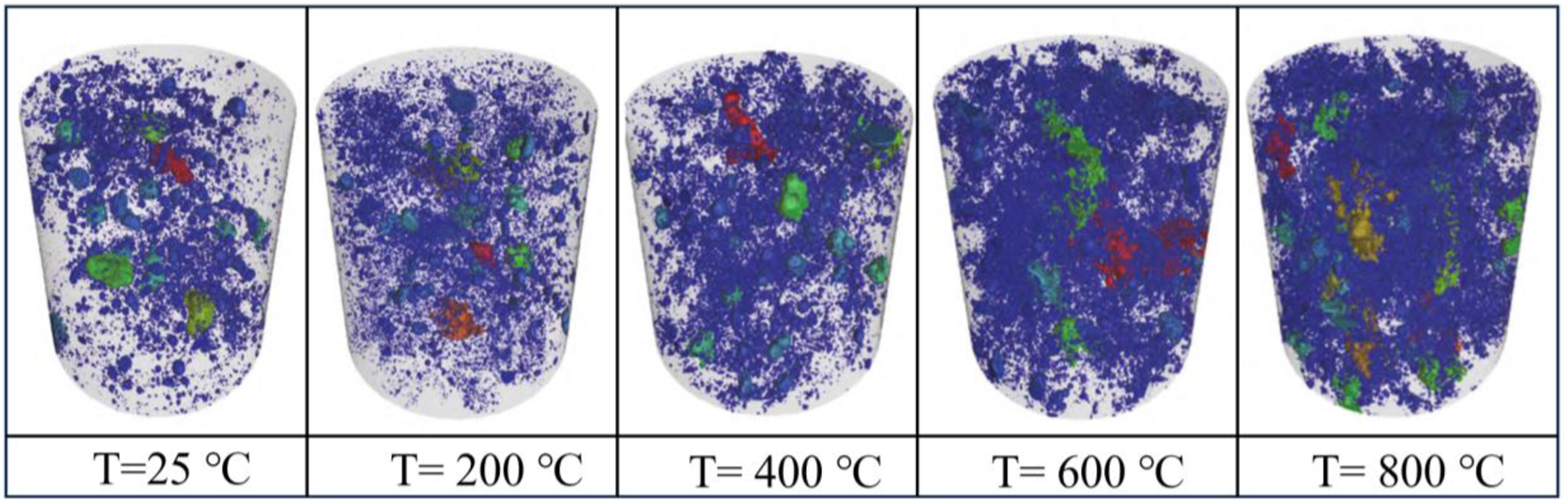

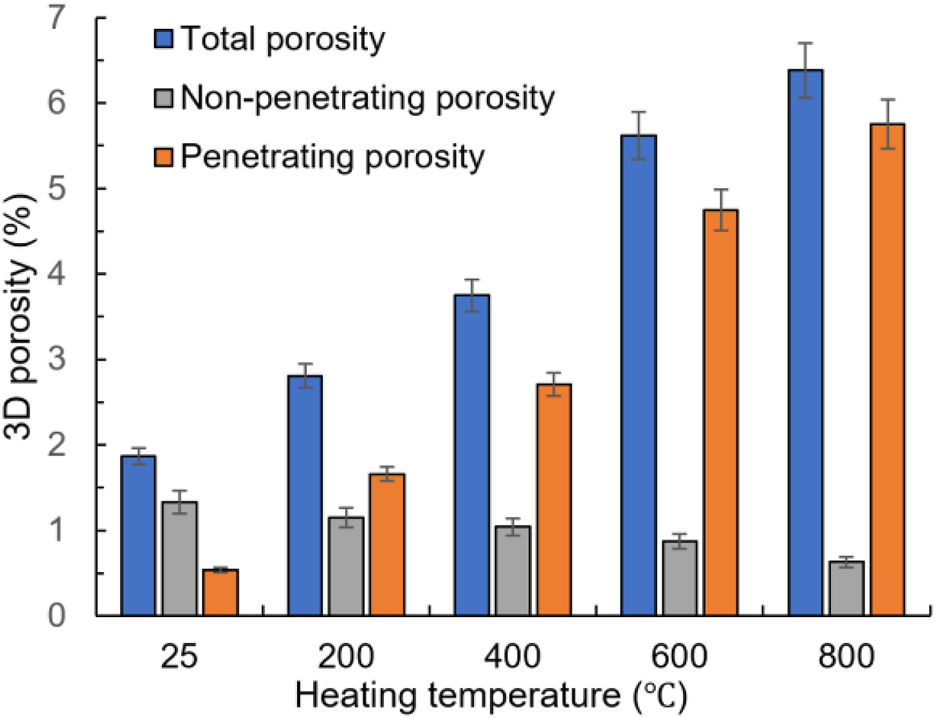

3.2.2 Evolution characteristics of three-dimensional pores

Through the stacking and reconstruction of CT images, a three-dimensional model of the pore structure in gneiss was obtained, as depicted in Figure 7. Pore categories within the rock were quantitatively classified based on fracture size parameters into connected and unconnected pores (Gao H. D. et al., 2024). Analysis revealed that during the process of increasing heating temperatures, the proportion of unconnected pores gradually decreased, while the proportion of connected fractures consistently increased. This indicates that high temperatures cause small-volume pores to gradually merge and connect into longer, interconnected fractures. At room temperature, most of the pores in the rock are unconnected, with unconnected pores comprising nearly 80% of the total pore volume. As the heating temperature increases, the thermal loss effect on the structure accumulates, and the volume content of connected fractures rapidly increases. At a heating temperature of 800°C, thermal fracture planes form and extend from the interior to the exterior, intensifying the thermal damage effect on the structure. Figure 8 presents the changes in volumetric porosity with increasing heating temperatures. It is evident that the overall porosity and connected porosity of the gneiss consistently exhibit an increasing trend, while the unconnected porosity shows a decreasing trend. This phenomenon indicates that under high temperatures, fractures expand and connect, leading to an increase in the overall volume of pores, while the number of unconnected pores decreases during the merging process. When the heating temperatures are 20°C, 200°C, 400°C, 600°C, and 800°C, the overall porosity reaches 1.87%, 2.81%, 3.75%, 5.52%, and 6.78%, respectively. The volume proportions of connected fractures at these temperatures are 39.1%, 53.3%, 63.7%, 75.1%, and 82.3%, respectively. The pattern of pore volume changes indicates that under the influence of high temperatures, the mesoscopic structure of the rock undergoes progressive damage, with the degree of damage continuously compounding. The formation, expansion, and connectivity of thermal fracture planes are the intrinsic causes of structural damage and destabilization in gneiss specimens (Kou et al., 2022). Therefore, by qualitatively and quantitatively characterizing the two-dimensional and three-dimensional pores in gneiss, the evolution mechanisms of internal thermal fracture planes and structural thermal damage are revealed.

FIGURE 7

Three-dimensional pore model of gneiss.

FIGURE 8

Pore volume distribution in gneiss under different temperature conditions.

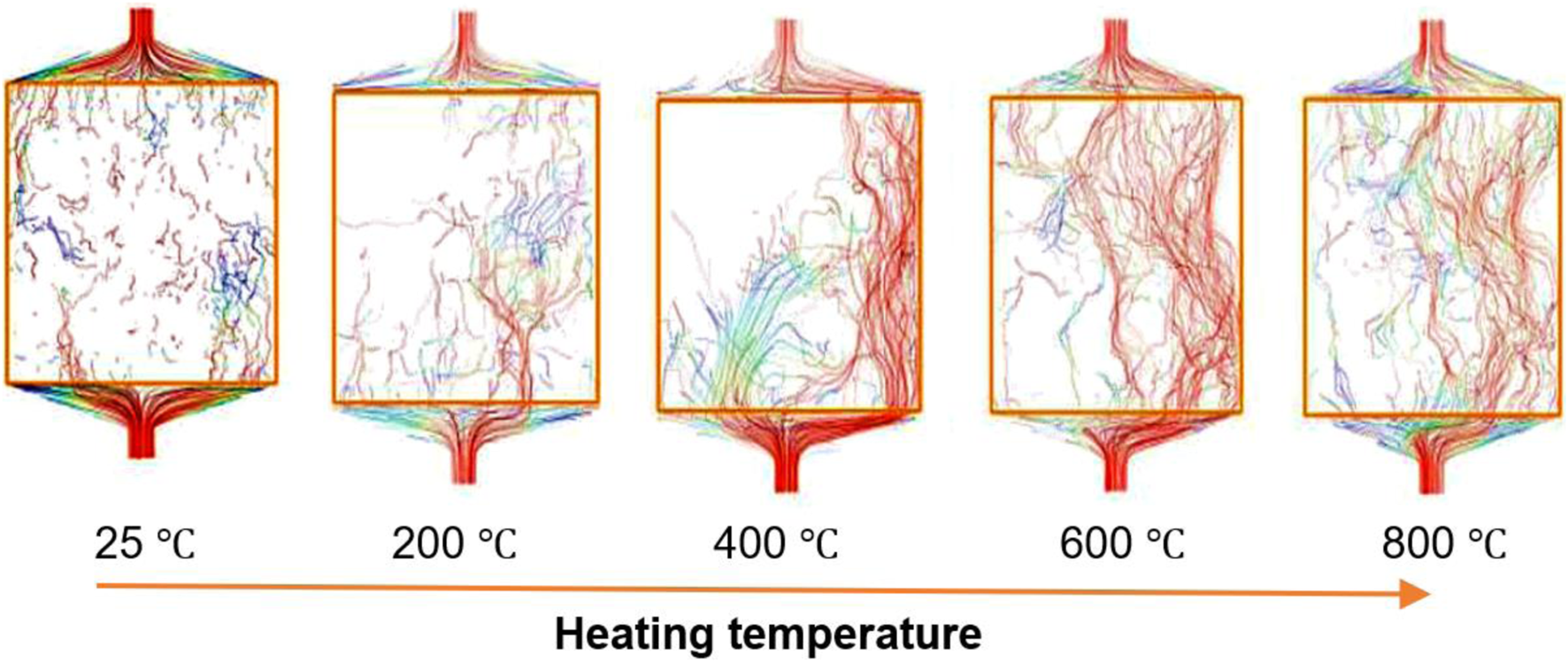

3.2.3 Microscopic seepage characteristics

Based on comprehensive information about the internal structure of the samples provided by CT scanning, including pore structure and fracture distribution, a three-dimensional fracture model of the gneiss specimens was extracted. The lattice Boltzmann method was employed to simulate multiphase seepage through the rock mass (Li et al., 2022). By simulating the distribution and movement of fluids within the specimen, the rock’s permeability coefficient was determined. The experiment used standard turbulence conditions at room temperature, and the controlling equations for the seepage simulation are shown in Equation 2.

Wherein, ρ represents the fluid density (kg/m3); t denotes time (s); u is the flow velocity (m/s); μ is the fluid viscosity coefficient (Pa·s), which is 1.0087 × 10−3 Pa·s at 20°C; σ is the stress tensor (Pa); e represents internal energy (J/kg); q is the heat flow density (W/m2); Δ is the Laplacian operator.

Based on Equation 3, the volumetric flow through the specimen was calculated by integrating the water flow velocity at the inlet and outlet boundaries of the seepage model. Then, using Darcy’s Law, the permeability coefficient K was derived:

Wherein, Q is the volumetric flow rate (m3/s); L is the length of the seepage sample (m); A is the cross-sectional area of the flow (m2); ΔP is the pressure difference between the inlet and outlet (kPa); γw is the specific weight of water (kg/m3).

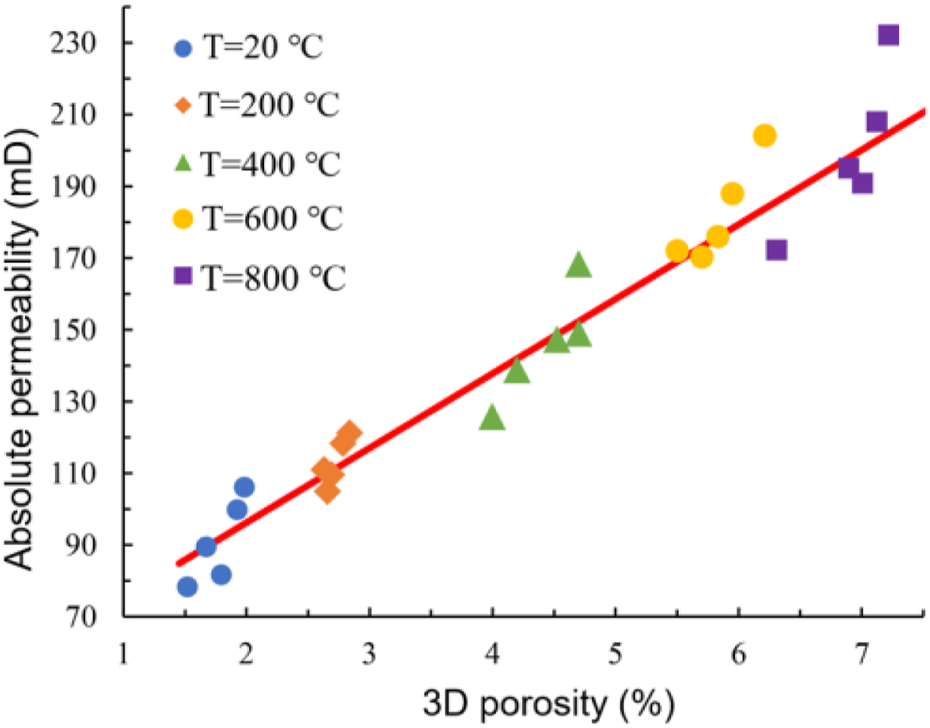

The three-dimensional pore model was used for seepage calculations, resulting in a streamline model of the gneiss, as shown in Figure 9. The density of the streamlines in the image is positively correlated with permeability, and the color of the streamlines relates to fluid pressure. As the number of connected fractures in the gneiss increased, no significant change in the colors of the streamlines was observed, but the density of streamline distribution significantly increased. At heating temperatures exceeding 600°C, through-going streamline trajectories formed in the gneiss, indicating a significant improvement in the rock’s permeability. The absolute permeability K of the rock was calculated from the seepage simulation. The results show that after the rock body underwent high-temperature treatment at 800°C, the increase in absolute permeability was approximately 135%. In this study, multiple cubic models were extracted from different locations within the three-dimensional fracture model for seepage simulation, and the permeability coefficients of the three-dimensional fracture model were calculated repeatedly. As shown in Figure 10, through data fitting and analysis, it was found that the total porosity and absolute permeability of the gneiss exhibited a clear linear correlation, indicating a strong relationship between permeability and the degree of rock fracturing.

FIGURE 9

Seepage model of gneiss at various temperatures.

FIGURE 10

Relationship between absolute permeability and 3D porosity.

3.3 Microstructural characteristics

As illustrated in Figure 11a, the mineral composition of this rock is mainly composed of quartz, feldspar and biotite. To investigate the damage characteristics of the microstructure of gneiss under various heating temperatures, SEM analysis was conducted on the fracture morphology of rock specimens. The results are displayed in Figures 11b–f. At the initial room temperature state (25°C), the distribution of microcracks within the gneiss was uneven, with poor connectivity between them. The heating treatment at 200°C led to the evaporation of free water within the rock, causing thermal expansion in mineral crystals and an increase in the number of microcracks and pores; the thermal cracks were in a closed state. At 400°C, the dehydration of biotite minerals caused thermal expansion, leading to the formation of connected fractures at the weak cementation faces of the rock specimens. Under the influence of 600°C, combined with the volatilization of bound water and expansion of crystals, mica and feldspar underwent thermal decomposition, resulting in connected cracks within the mineral crystals. Experimental results demonstrated that when the temperature exceeded 800°C, thermal cracks were clearly open, and the cracking scale of rocks increased with the heating temperature.

FIGURE 11

Microscopic morphology of rock at different heating temperatures: (a) cast specimen slice at T = 25°C, (b) SEM image at T = 25°C, (c) SEM image at T = 200°C, (d) SEM image at T = 400°C, (e) SEM image at T = 600°C, and (f) SEM image at T = 800°C.

4 Discussion

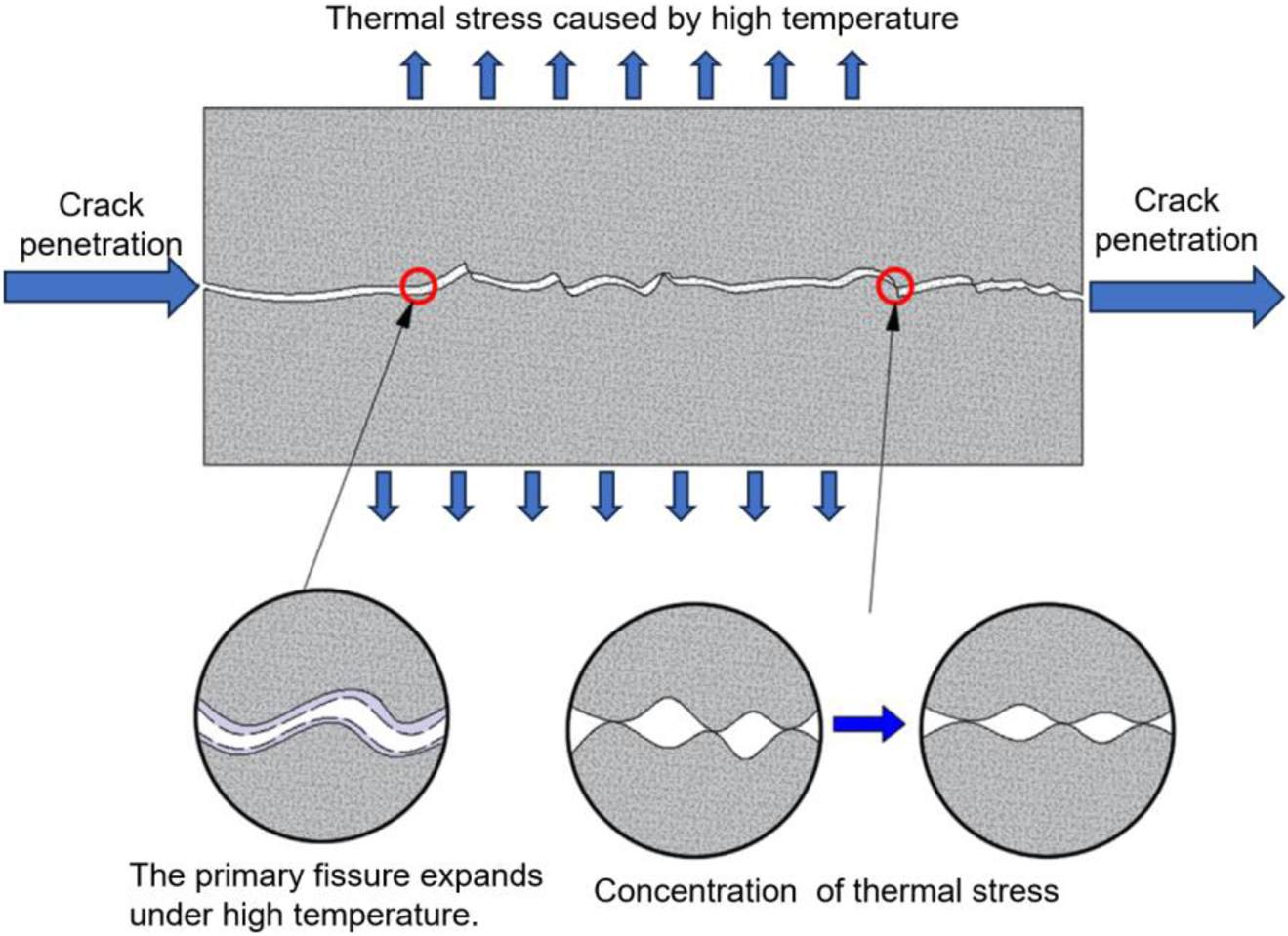

The fracture connectivity primarily involves changes in the physical and mechanical properties of gneiss under high-temperature conditions. When rock is subjected to high temperatures, a series of physical and chemical changes occur within it, significantly affecting its mechanical properties. Figure 12 shows a conceptual schematic diagram of the high-temperature-induced microstructural evolution and mechanical property degradation of gneiss. Rock inherently contains numerous micro-pores and micro-defects (Yin et al., 2019). As temperature increases, the micro-defects gradually develop and even connect into macroscopically visible fractures. When temperatures rise above 600°C, high temperatures cause minerals such as biotite and feldspar to decompose, undergo phase transformations, or even melt in gneiss. These changes in mineral composition disrupt the original microstructure and further promote the formation and extension of fractures (Costa et al., 2021). Under the sustained high-temperature heating, cracks within deep rocks gradually extend and connect, eventually forming a macroscopically visible network of cracks and achieving fractured permeability. With the expansion of rock cracks, the microstructure becomes increasingly loose and fragile, and it is more prone to fractured under the influence of external stress (Xu et al., 2020). Consequently, the mechanical properties of rock, such as compressive strength, elastic modulus, and cohesion, gradually decline with the rise in heating temperature.

FIGURE 12

conceptual schematic diagram of the high-temperature-induced microstructural evolution and mechanical property degradation of gneiss.

Based on macroscopic and microscopic experimental results, the multiscale effects of thermal fracturing of gneiss in high geothermal temperature environments and their severe impact on the stability of the rock mass were revealed. Specifically, high temperatures cause rapid expansion and connectivity of internal fractures, forming large-volume through-going fractures (Jayawickrama et al., 2021). These fractures become the primary regions for groundwater leakage, directly resulting in reduced impermeability and strength of the rock. Given the severe impact of mesoscopic fractures on the rock, timely and effective measures must be taken to seal these fractures. The specific operations are as follows: Firstly, enhance advanced geological forecasting and horizontal drilling ahead to preemptively assess the geothermal and water-rich conditions ahead of the tunnel face. Secondary grouting sealing technology is a feasible solution, where forming a grouting curtain fills the fractures, restoring the integrity of the fractured rock mass, thereby enhancing its engineering stability (Zheng et al., 2023). For areas that are severely damaged, chiseling out and recasting is an effective repair method, ensuring the integrity and safety of the structure. For superficial and shallow microcracks, although they have a minor impact on the overall stability of the fractured rock mass, they are also potential channels for groundwater leakage. It is recommended to use surface patching and surface bonding methods for localized repairs. These methods are simple to operate and low in cost but can significantly enhance the rock’s surface impermeability, reducing the likelihood of engineering accidents such as water and mud inrush, mine water inflow, and roof fall in deep mining processes involving surrounding rock in deep mining engineering.

5 Conclusion

The main conclusions are as follows:

(1) As the heating treatment temperatures increase, the mass loss rate and surface porosity of the gneiss specimens progressively rise. Additionally, the heterogeneity in pore distribution also intensifies. This suggests that high temperatures lead to increased heterogeneity in the distribution and arrangement of fractures.

(2) The dynamic evolution of mesoscopic fractures under high temperatures is vividly illustrated by three-dimensional pore models. As the heating treatment temperature rises, the non-connected pores within the rock continuously expand and become interconnected, forming distinct thermal fracture planes at temperatures above 600°C. The mesoscopic structure of gneiss progressively fractures as the temperature increases, with structural damage accumulating gradually.

(3) With increasing heating treatment temperatures, the streamlines in the seepage models of gneiss become denser, and the absolute permeability significantly improves. At a heating temperature of 800°C, the compressive strength loss rate of gneiss reaches as high as 35.6%, indicating that high geothermal temperatures severely impact the macroscopic performance of the fractured rock mass.

(4) The analysis of the microscopic morphology of gneiss reveals that the evaporation of inter-crystalline bound water, thermal deformation differences, and severe thermal damage effects lead to the formation of mesoscopic thermal cracks between mineral crystals, ultimately affecting the macroscopic physical and mechanical behavior of gneiss.

(5) The high geothermal temperature environment causes multiscale damage effects on gneiss. The fracture connectivity primarily involves changes in the physical and mechanical properties of gneiss under high-temperature conditions. In deep mining engineering, it is necessary to adopt measures such as secondary grouting sealing or surface bonding methods to seal fractures in deep formations.

Statements

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

JZ: Investigation, Methodology, Writing – original draft. ZH: Formal Analysis, Software, Writing – review and editing. DL: Conceptualization, Funding acquisition, Validation, Writing – review and editing. JQ: Software, Writing – review and editing. RA: Resources, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by the National Natural Science Foundation of China (51978210).

Acknowledgments

The authors thank the reviewers and editors for their comments on this manuscript.

Conflict of interest

Author JZ was employed by Ju’an Survey Co., Ltd. Author ZH was employed by Rongda Mining Co., Ltd. of New Barag Right Banner. Author JQ was employed by Zhejiang Guangchuan Engineering Consulting Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1

Bhutto A. W. Bazmi A. A. Zahedi Z. (2013). Underground coal gasification: from fundamentals to applications. Prog. Energy Combust. Sci.39, 189–214. 10.1016/j.pecs.2012.09.004

2

Brady B. H. G. Brown E. T. (2006). Rock mechanics for underground mining. 3rd ed. New York, NY, USA: Springer Science and Business Media.

3

Chen S. W. Yang C. H. Wang G. B. (2017). Evolution of thermal damage and permeability of Beishan granite. Appl. Therm. Eng.110, 1533–1542. 10.1016/j.applthermaleng.2016.09.075

4

Costa K. O. B. Xavier G. C. Marvila M. T. Alexandre J. Azevedo A. R. G. Monteiro S. N. (2021). Influence of high temperatures on physical properties and microstructure of gneiss. Bull. Eng. Geol. Environ.80, 7069–7081. 10.1007/s10064-021-02362-8

5

Du K. Li X. Tao M. Wang S. (2020). Experimental study on acoustic emission (AE) characteristics and crack classification during rock fracture in several basic lab tests. Int. J. Rock Mech. Min. Sci.133, 104411. 10.1016/j.ijrmms.2020.104411

6

Gao H. Xie H. P. Zhang Z. Lu J. Zhang D. Zhang R. et al (2024a). True triaxial energy evolution characteristics and failure mechanism of deep rock subjected to mining-induced stress. Int. J. Rock Mech. Min. Sci.176, 105724. 10.1016/j.ijrmms.2024.105724

7

Gao H. D. An R. Zhang X. W. Wang G. Liu X. Y. Xu Y. Q. (2024b). Dynamic evolution of desiccation cracks and their relationship with the hydraulic properties of expansive soil. Int. J. Geomech.24, 04023299. 10.1061/IJGNAI.GMENG-9299

8

Ghassemi A. A. (2012). A review of some rock mechanics issues in geothermal reservoir development. Geotech. Geol. Eng.30, 647–664. 10.1007/s10706-012-9508-3

9

Golsanami N. Sun J. Zhang Z. (2016). A review on the applications of the nuclear magnetic resonance (NMR) technology for investigating fractures. J. Appl. Geophy.133, 30–38. 10.1016/j.jappgeo.2016.07.026

10

Gurgurewicz J. Mège D. Skiścim M. Pers J. (2019). Nanotopographic characterization of microfractures in rocks by atomic force microscopy. J. Struct. Geol.124, 70–80. 10.1016/j.jsg.2019.04.010

11

Jayawickrama E. G. Muto J. Sasaki O. Nagahama H. (2021). Damage evolution of onnagawa shale by postmortem thresholding of X-Ray computed tomography. J. Geophys. Res. Solid Earth.126. 10.1029/2021JB022056

12

Jolie E. Scott S. Faulds J. Chambefort I. Axelsson G. Gutiérrez-Negrín L. C. et al (2021). Geological controls on geothermal resources for power generation. Nat. Rev. Earth Environ.2, 324–339. 10.1038/s43017-021-00154-y

13

Keerthi V. Madhumitha L. Gokul V. Vivek P. Ivo Romauld S. Rajakumari K. (2025). “Storage and disposal of radioactive materials,” in Radioactive pollutant. Editor KumarN. (Cham: Environmental science and engineering. springer). 10.1007/978-3-031-73796-1_9

14

Kou B. Zhang D. Meng T. Li Z. Wang Y. Liu G. et al (2022). Micro and macro evaluation of tensile characteristics of anisotropic rock mass after high temperatures treatment-a case study of Lingshi Gneiss. Geothermics102, 102409. 10.1016/j.geothermics.2022.102409

15

Kristinsdóttir L. H. Flóvenz Ó. G. Árnason K. Bruhn D. Milsch H. Spangenberg E. et al (2010). Electrical conductivity and P-wave velocity in rock samples from high-temperature Icelandic geothermal fields. Geothermics39 (1), 94–105. 10.1016/j.geothermics.2009.12.001

16

Lei W. Chai J. Zheng C. Zhao J. Wang S. Liu G. et al (2025). Research on the spatiotemporal evolution of deformation and unloading mechanical effects in underlying coal and rock during upper protective layer mining. Front. Earth Sci.13, 1516970. 10.3389/feart.2025.1516970

17

Li W. T. Li S. C. Xuan C. Wang Q. Wang X. Shao X. (2015). Mechanism and control of failure of rock roadway support in highly stressed soft rock. Chin. J. Rock Mech. Eng.34 (9), 1836–1848. 10.13722/j.cnki.jrme.2014.1594

18

Li Y. Chi Y. Zhao C. Miao Y. Han S. Chen L. (2022). Modelling fluid flow in carbon fibre porous media based on X-ray microtomography and lattice Boltzmann method. Compos. Struct.300, 116085. 10.1016/j.compstruct.2022.116085

19

Luo J. Wang L. (2011). High-temperature mechanical properties of mudstone in the process of underground coal gasification. Rock Mech. Rock Eng.44, 749–754. 10.1007/s00603-011-0168-z

20

Ma X. Wang G. Hu D. Liu Y. Zhou H. Liu F. (2020). Mechanical properties of granite under real-time high temperature and three-dimensional stress. Int. J. Rock Mech. Min. Sci.136, 104521. 10.1016/j.ijrmms.2020.104521

21

Masri M. Sibai M. Shao J. F. Mainguy M. (2014). Experimental investigation of the effect of temperature on the mechanical behavior of Tournemire shale. Int. J. Rock Mech. Min. Sci.70 (9), 185–191. 10.1016/j.ijrmms.2014.05.007

22

Nian G. Chen Z. Zhu T. Zhang L. Zhou Z. (2024). Experimental study on the failure of fractured rock slopes with anti-dip and strong weathering characteristics under rainfall conditions. Landslides21, 165–182. 10.1007/s10346-023-02142-3

23

Qiao R. Shao Z. Liu F. Wei W. (2019). Damage evolution and safety assessment of tunnel lining subjected to long-duration fire. Tunn. Undergr. Space Technol.83, 354–363. 10.1016/j.tust.2018.09.036

24

Ranjith P. G. Zhao J. Ju M. Silva R. Rathnaweera T. D. Bandara K. M. S. A. (2017). Opportunities and challenges in deep mining: a brief review. Engineering3, 546–551. 10.1016/J.ENG.2017.04.024

25

Rao Q. Sun Z. Wang G. Xu J. Zhang J. (2001). Microscopic characteristics of different fracture modes of brittle rock. J. Cent. South Univ. Technol.8, 175–179. 10.1007/s11771-001-0049-9

26

Rossi E. Kant M. A. Madonna C. Saar M. O. von Rohr P. R. (2018). The effects of high heating rate and high temperature on the rock strength: feasibility study of a thermally assisted drilling method. Rock Mech. Rock Eng.51, 2957–2964. 10.1007/s00603-018-1507-0

27

Tian H. Ziegler M. Kempka T. (2014). Physical and mechanical behavior of claystone exposed to temperatures up to 1000°C. Int. J. Rock. Mech. Min. Sci.70, 144–153. 10.1016/j.ijrmms.2014.04.014

28

Wu D. Yu L. Ju M. Li S. Liu R. Su H. et al (2022). Study on the mode I fracture properties of granites after heating and water-cooling treatments under different impact loadings. Rock Mech. Rock Eng.55, 4271–4290. 10.1007/s00603-022-02865-0

29

Xi B. He S. Wu Y. Chen Z. Cui J. (2020). “Rheological deformation and failure laws of boreholes in granite under thermo-mechanical coupling and its application in deep hole drilling of hot dry rock for geothermal energy exploitation,” in Proceedings of IOP conference series: earth and environmental science. Beijing, China, 23–26. 10.1088/1755-1315/570/3/032045

30

Xu G. He C. Wang X. (2020). Mechanical behavior of transversely isotropic rocks under uniaxial compression governed by micro-structure and micro-parameters. Bull. Eng. Geol. Environ.79, 1979–2004. 10.1007/s10064-019-01690-0

31

Yang B. Wang H. Wang B. Shen Z. Zheng Y. Jia Z. et al (2021). Digital quantification of fracture in full-scale rock using micro-CT images: a fracturing experiment with N2 and CO2. J. Petrol. Sci. Eng.196, 107682. 10.1016/j.petrol.2020.107682

32

Yang S. Q. Chen M. Jing H. W. Chen K. F. Meng B. (2017). A case study on large deformation failure mechanism of deep soft rock roadway in Xin'An coal mine, China. Eng. Geol.217, 89–101. 10.1016/j.enggeo.2016.12.012

33

Yin Q. Liu R. Jing H. Su H. Yu L. He L. (2019). Experimental study of nonlinear flow behaviors through fractured rock samples after high-temperature exposure. Rock Mech. Rock Eng.52, 2963–2983. 10.1007/s00603-019-1741-0

34

Yu Q. L. Ranjith P. G. Liu H. Y. Yang T. H. Tang S. B. Tang C. A. et al (2015). A Mesostructure-based damage model for thermal cracking analysis and application in granite at elevated temperatures. Rock Mech. Rock Eng.48, 2263–2282. 10.1007/s00603-014-0679-5

35

Zhang L. Mao X. Liu R. Guo X. Ma D. (2014). The Mechanical properties of mudstone at high temperatures: an experimental study. Rock Mech. Rock Eng.47, 1479–1484. 10.1007/s00603-013-0435-2

36

Zhang W. Sun Q. Hao S. Geng J. Lu C. (2016). Experimental study on the variation of physical and mechanical properties of rock after high temperature treatment. Appl. Therm. Eng.98, 1297–1304. 10.1016/j.applthermaleng.2016.01.010

37

Zhang Y. Sun Q. He H. Cao L. Zhang W. Wang B. (2017). Pore characteristics and mechanical properties of sandstone under the influence of temperature. Appl. Therm. Eng.113, 537–543. 10.1016/j.applthermaleng.2016.11.061

38

Zhao T. Zhang W. Gu S. Lu Y. Li Z. (2020). Study on fracture mechanics of granite based on digital speckle correlation method. Int. J. Solids Struct.193-194, 192–199. 10.1016/j.ijsolstr.2020.02.026

39

Zheng G. Sui W. Zhang G. Chen J. Zhang D. (2023). Propagation and sealing efficiency of chemical grouting in a two-dimensional fracture network with flowing water. Int. J. Min. Sci. Techno.33, 903–917. 10.1016/j.ijmst.2023.02.006

40

Zuo J. P. Wang J. T. Sun Y. J. Chen Y. Jiang G. H. Li Y. H. (2017). Effects of thermal treatment on fracture characteristics of granite from Beishan, a possible high-level radioactive waste disposal site in China. Eng. Fract. Mech.182, 425–437. 10.1016/j.engfracmech.2017.04.043

Summary

Keywords

deep mining, high-temperature, gneiss, mechanical properties, damage mechanism, seepage simulation

Citation

Zhang J, Hu Z, Liu D, Qiu J and An R (2025) Thermal-induced damage mechanisms and permeability evolution in gneiss for deep mining applications. Front. Earth Sci. 13:1603348. doi: 10.3389/feart.2025.1603348

Received

31 March 2025

Accepted

07 May 2025

Published

23 May 2025

Volume

13 - 2025

Edited by

Zhuangcai Tian, China University of Mining and Technology, China

Reviewed by

Yun Wu, China University of Mining and Technology, China

Essaieb Hamdi, University of Tunis, Tunisia

Updates

Copyright

© 2025 Zhang, Hu, Liu, Qiu and An.

This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Dakang Liu, liudk@zjtongji.edu.cn

Disclaimer

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.