- 1School of Business Administration, The Hong Kong Polytechnic University, Hong Kong, China

- 2Division of Biostatistics, Medical College of Wisconsin, Milwaukee, WI, United States

The global food packaging industry is undergoing a transformative shift toward sustainable alternatives to conventional petroleum-based materials, driven by escalating environmental concerns, regulatory pressures, and consumer demand for greener products. Biodegradable polymers such as chitosan, starch, cellulose, PLA, and PBS have gained prominence due to their renewability and reduced ecological footprint. However, their inherent limitations, including poor mechanical strength, moisture sensitivity, and limited bioactivity, have restricted widespread adoption. Lignin nanoparticles (LNPs), derived from the abundant and underutilized biopolymer lignin, have emerged as multifunctional nanofillers capable of significantly enhancing the structural and functional properties of biodegradable films. Owing to their antioxidant, UV-blocking, antimicrobial, and barrier-enhancing characteristics, LNPs improve film performance while aligning with circular economy principles. This review critically examines the sources, structural characteristics, extraction methods, and synthesis techniques of lignin, emphasizing their impact on nanoparticle formation and functionality. It further explores recent advances in LNP-reinforced packaging systems across diverse biopolymer matrices, including polysaccharides, proteins, and biodegradable polyesters. Special attention is given to interfacial interactions, dispersion behavior, and structure–property correlations. Finally, emerging trends such as LNP surface engineering, smart coating systems, and hybrid fabrication strategies are discussed in the context of future scalability, recyclability, and regulatory compliance.

1 Introduction

The global food industry is increasingly challenged by the urgent need to transition toward more sustainable packaging solutions, driven by escalating concerns over environmental degradation, resource depletion, and human health risks associated with conventional materials (1). Petroleum-derived plastics, aluminum, and perfluorinated compounds have been the mainstay of food packaging due to their excellent barrier properties, mechanical strength, and low cost (2). However, these materials present significant environmental and sustainability drawbacks. Petroleum-based plastics, including polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET), are non-biodegradable and widely used for their flexibility and barrier capabilities (3–5), yet their persistence in ecosystems leads to accumulation in landfills and marine environments, contributing to global microplastic pollution (6). The global production of plastics surpassed 400 million tons in 2022, with food packaging accounting for approximately 40% of total consumption (7). Alarmingly, less than 20% of plastics are effectively recycled, exacerbating long-term waste management challenges (8). Although aluminum is technically recyclable and commonly used in food packaging as metalized films or containers, its production from bauxite ore involves highly energy-intensive processes that result in considerable greenhouse gas emissions and ecological disruption through land degradation and mining waste (9). Moreover, the use of metallic films in food packaging raises concerns about material circularity and environmental compatibility, particularly in applications where recovery and recycling are impractical or uneconomical. In contrast, biodegradable packaging materials can be composted or decomposed in natural environments, avoiding such resource-intensive end-of-life scenarios. Perfluorinated organic compounds (PFCs), often used to impart grease and water resistance to packaging, have also been linked to endocrine disruption, bioaccumulation, and long-term ecological toxicity. The detection of PFC residues in food products and human serum samples has further intensified public health concerns (10, 11), reinforcing the urgent need to develop safer, functional, and environmentally benign alternatives such as biodegradable films containing lignin nanocomposites.

These challenges have accelerated research into biodegradable packaging materials derived from renewable resources. Among biopolymers, polysaccharides (e.g., starch, cellulose), proteins (e.g., gelatin, soy protein), and polyesters (e.g., polylactic acid, polyhydroxyalkanoates) are prominent candidates. Starch-based films offer biodegradability and film-forming abilities but suffer from poor water vapor resistance, brittleness, and mechanical weakness (12, 13). Cellulose, abundant and renewable, provides good mechanical strength and oxygen barrier properties but remains hydrophilic, limiting its performance under high humidity conditions (14). Furthermore, the native crystallinity of cellulose often necessitates chemical modifications or blending with other biopolymers to tailor its functional properties (15, 16). Chitosan films are inherently antimicrobial and biodegradable but present processing challenges, high water sensitivity, and brittleness under dry conditions (17). Proteins such as gelatin and soy protein have been widely investigated for packaging films but face issues of poor mechanical stability and moisture sensitivity (18). Thus, reinforcing these biodegradable polymers with functional additives, nanoparticles, or cross-linkers has emerged as a promising strategy to overcome their intrinsic limitations.

Lignin, the second most abundant biopolymer after cellulose, has received growing attention in this context. Accounting for up to 30% of lignocellulosic biomass, lignin is a complex, three-dimensional aromatic macromolecule characterized by high phenolic content, crosslinked structures, and inherent antioxidative and antimicrobial properties (19, 20). The unique chemical structure of lignin, composed of p-hydroxyphenyl (H), guaiacyl (G), and syringyl (S) units, imparts hydrophobicity and stability, making it a suitable candidate for enhancing barrier and functional properties of biodegradable polymer films (21, 22). Despite its abundance—estimated at over 70 million tons annually as an industrial byproduct—lignin remains underutilized, primarily being incinerated for low-value energy recovery in pulp and paper mills. Its underexploitation is attributed to the heterogeneity in lignin’s structure depending on the botanical source and extraction method, which complicates its direct utilization in high-value applications.

The valorization of lignin into value-added products, such as functional fillers or antioxidants, aligns well with circular economy strategies, aiming to reduce waste and maximize resource efficiency (23). Its functional groups, such as hydroxyl, methoxyl, and carboxyl groups, offer opportunities for chemical modification, improving its compatibility with various biopolymer matrices (24).

Recent advancements in nanotechnology have enabled the production of lignin nanoparticles (LNPs), which dramatically enhance the applicability of lignin in food packaging. LNPs, typically ranging between 50 and 300 nm, exhibit high surface area-to-volume ratios, improved dispersibility, and enhanced functional reactivity compared to native lignin (25). LNPs are emerging as a versatile and sustainable material with promising applications across various industries. The global lignin market has seen significant growth, with kraft lignin production increasing by 150% from 2014 to 2018 (26). These nanoparticles offer advantages such as non-toxicity, low cost, and potential biodegradability, making them attractive for use in antioxidants, UV-protectants, drug carriers, and tissue engineering (27). The world market for nanoparticles is expected to increase markedly in the coming years, suggesting a growing demand for lignin nanoparticles. However, challenges remain in scaling up technologies and optimizing lignin applications to achieve technical and economic feasibility (26). A critical review by Österberg et al. (28) highlights the sustainability, performance, stability, and degradation aspects of spherical lignin particles, further emphasizing their potential in various applications (28).

Preparation methods for LNPs include solvent–antisolvent precipitation, ultrasonication, aerosol flow reactors, and dialysis, each influencing the particle morphology, size distribution, and surface chemistry (29). Antisolvent precipitation is one of the most commonly employed approaches, yielding spherical and uniform LNPs through rapid aggregation of lignin in poor solvents such as water or acidified ethanol. This method is simple, scalable, and free from harsh reagents, although it may require process optimization to avoid particle aggregation (30). Alternatively, solvent exchange (dialysis) offers a greener route for producing highly stable and pure nanoparticles by gradually replacing organic solvents with water, allowing controlled self-assembly of lignin into nanoscale structures. Although time-consuming and relatively costly due to membrane use, this approach ensures high colloidal stability and avoids post-synthesis aggregation (31). Ultrasonication provides a rapid and chemical-free method by utilizing acoustic cavitation to break down bulk lignin into nanoparticles. While easy to implement, it may lead to broader size distributions and potential oxidative modification of lignin unless conditions are carefully controlled (32). For continuous and scalable production, aerosol flow reactor synthesis has emerged as a promising method where lignin droplets are atomized and thermally dried to yield dry, uniform LNPs powders suitable for large-scale packaging applications (33).

Controlling the particle size and surface charge is crucial, as these parameters affect the stability of the nanoparticles and their interaction with the biodegradable polymer matrix. Incorporating LNPs into biodegradable films has demonstrated substantial improvements in mechanical properties, barrier functions, and active packaging functionalities. Studies have shown that LNPs enhance tensile strength, Young’s modulus, and elasticity while reducing water vapor permeability and oxygen transmission rates (34). Furthermore, LNPs act as UV-blocking agents, protecting packaged foods from photooxidation and extending shelf life (35). The antioxidant activity of LNPs helps to retard lipid oxidation in packaged foods, while their antimicrobial properties inhibit bacterial and fungal growth, reducing spoilage and enhancing food safety without relying on synthetic additives (19, 36). Such multifunctional benefits position LNPs as attractive candidates for developing active and intelligent packaging systems.

Despite these promising findings, challenges persist regarding the scalability of LNPs production, reproducibility of particle characteristics, potential migration of lignin-derived compounds into food, and regulatory hurdles. Variations in lignin source (kraft, organosolv, soda), extraction methods, and particle preparation techniques influence the physicochemical properties and performance of LNPs-reinforced biodegradable films (37, 38). Additionally, aggregation of LNPs at high loading concentrations can compromise film uniformity and mechanical performance, necessitating strategies such as surface functionalization or compatibilizer addition (39). Regulatory approval remains a major hurdle, as detailed toxicological assessments and migration studies are required to meet food contact material safety standards set by authorities such as the U. S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) (40). From a sustainability perspective, integrating lignin valorization into biodegradable packaging systems not only offers material performance benefits but also contributes to the broader goals of reducing industrial waste streams and creating high-value, biodegradable materials (41). Life cycle assessment (LCA) studies are beginning to show that lignin-enhanced biodegradable films have lower overall environmental impacts compared to traditional petrochemical-based packaging (42).

It is important to emphasize that the scope of this review centers on biodegradable food packaging materials incorporating LNPs, irrespective of whether the matrix polymer is bio-based or synthetic in origin. While many of the matrices discussed, such as starch, chitosan, and cellulose, are derived from renewable resources, others like polyvinyl alcohol (PVA) originate from petrochemical sources but are still biodegradable under industrial conditions. Such materials serve as transitional or benchmark systems in sustainable packaging development and offer valuable insight into structure–function relationships of LNP-based composites. As such, this review considers both natural and synthetic biodegradable matrices to provide a comprehensive understanding of LNP integration strategies and performance outcomes. This review critically explores the incorporation of lignin nanoparticles into biodegradable films for food packaging applications. It discusses the current state of knowledge regarding LNPs synthesis, characterization, and integration into different biodegradable polymer matrices. The impact of LNPs on the physicochemical, mechanical, and functional properties of composite films is analyzed, alongside the existing challenges and perspectives for future research and commercialization. By elucidating these aspects, the review aims to foster the development of next-generation sustainable food packaging materials aligned with circular economy principles and emerging consumer expectations for greener packaging solutions.

2 Source and structure of lignin

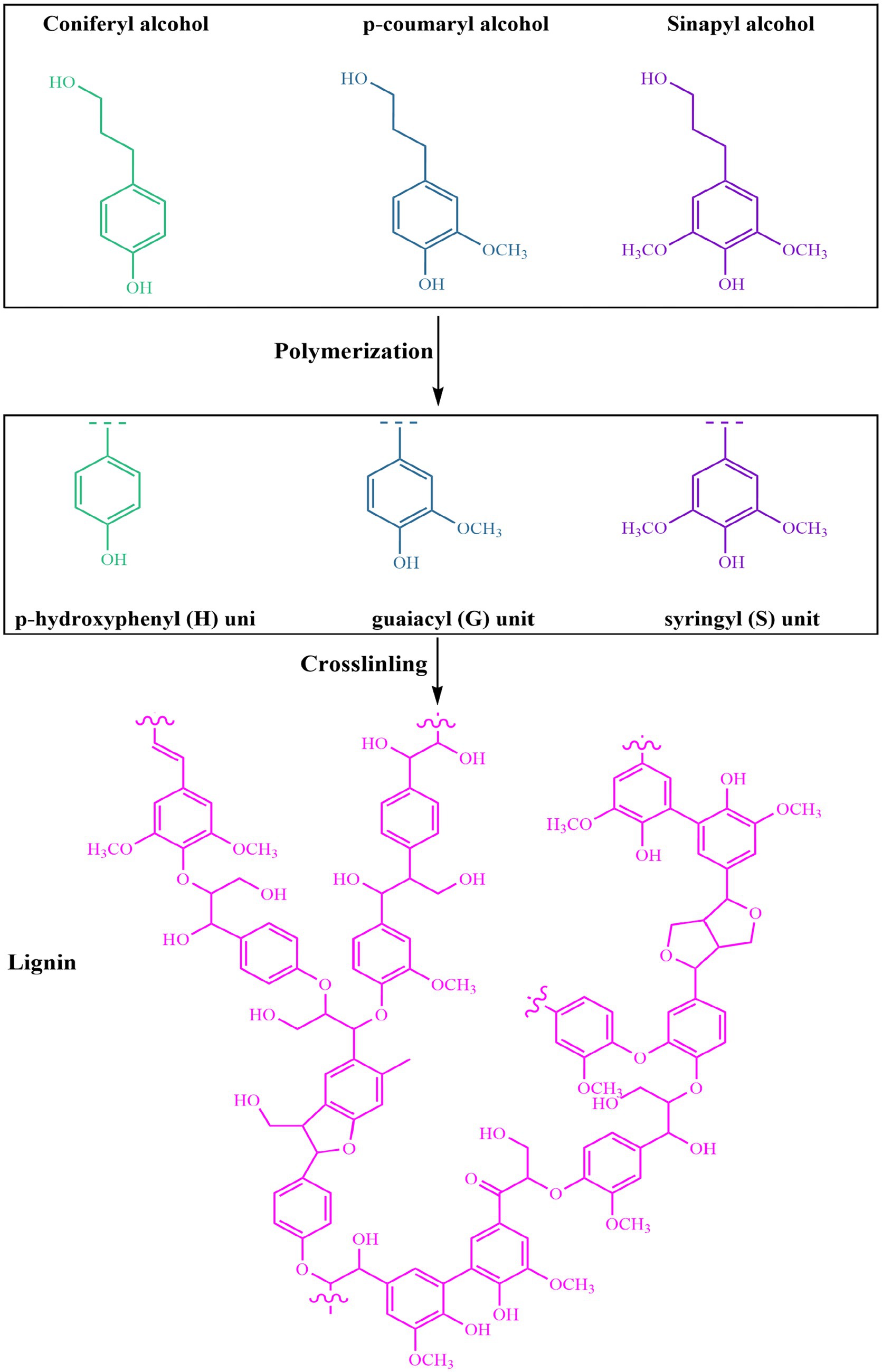

Lignin is an irregular, three-dimensional aromatic polymer found abundantly in lignocellulosic biomass. Its content typically ranges from 15 to 30% of the plant’s dry mass, depending on the species and the specific tissue type (20, 43). In addition to cellulose and hemicellulose, lignin is essential for providing plants with structural support, water resistance, and protection against microbial attacks (44). Its complex architecture and wide range of natural sources largely determine its physical and chemical properties, making lignin an increasingly valuable material for developing sustainable products such as biodegradable food packaging (45). Lignin is formed through an oxidative radical coupling process involving three key monolignol precursors: p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol (46). These compounds, which differ mainly in the number of methoxy groups attached to their aromatic structures, polymerize to produce p-hydroxyphenyl (H), guaiacyl (G), and syringyl (S) units, respectively (Figure 1). The combination and arrangement of these structural units give lignin its highly complex and irregular macromolecular framework (47). The relative abundance of H, G, and S units depends strongly on the plant source. In softwoods, lignin is mainly built from guaiacyl (G) units, making up about 90–95% of its structure. In contrast, hardwood lignins contain a blend of guaiacyl and syringyl units, with syringyl groups generally being more abundant, representing between 50 and 75%. Meanwhile, lignins isolated from grasses and herbaceous species are notable for their higher levels of hydroxyphenyl (H) units, typically ranging from 10 to 25%, while also containing significant amounts of G and S units (43, 48, 49).

Figure 1. Schematic representation of lignin biosynthesis from monolignol precursors. The three main monolignols, p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol, polymerize via radical coupling to form the structural units of lignin: p-hydroxyphenyl (H), guaiacyl (G), and syringyl (S) units, respectively. These units are then crosslinked into a complex and highly branched lignin macromolecule.

The high structural complexity of lignin results not only from its diverse monomer composition but also from the variety of chemical bonds formed during its polymerization. Among these, β-O-4 (β-aryl ether) linkages are the most prevalent, accounting for approximately 43–65% of all interunit connections, especially in lignin found in native plant cell walls (49). Besides β-O-4 bonds, lignin contains other important linkages such as β-5 (phenylcoumaran), 5–5 (biphenyl), β-β (resinol), and 4-O-5 (diaryl ether), each contributing differently to its three-dimensional structure and overall stability (50). The β-O-4 bonds, due to their chemical nature, are relatively easy to break under appropriate conditions, making them a primary target in depolymerization and valorization processes (51). In contrast, carbon–carbon linkages like β-5 and 5–5 are much stronger and more resistant to cleavage, which explains the notable thermal stability and chemical durability of lignin polymers (52). The macromolecular architecture of lignin is highly irregular and extensively branched, lacking the uniformity and repeating structures typically seen in polysaccharides like cellulose. Because of its random polymerization during biosynthesis, many researchers suggest that lignin should be described as a random polyphenolic copolymer rather than a traditional biopolymer (53). In its native form, lignin is not present as a completely isolated molecule; instead, it is closely bonded to hemicelluloses through covalent linkages, resulting in the formation of lignin–carbohydrate complexes (LCCs). These associations significantly impact the extraction, structural characteristics, and functional behavior of lignin (54).

The molecular weight of lignin shows considerable variation, largely depending on the plant source and several biological factors. In general, native lignin has a weight-average molecular weight (Mw) that falls between 3,000 and 50,000 g/mol, although in some cases, these values can differ significantly based on species type and the conditions under which the lignin is isolated (55). Lignins derived from softwood species usually possess higher Mw values and broader polydispersity indexes when compared to those extracted from hardwoods and grasses, indicating a greater degree of branching and molecular complexity (56, 57). Differences in molecular size directly influence key properties of lignin, such as its solubility, thermal stability, and chemical reactivity, all of which are critical for its modification and use in the development of advanced composite materials (58). The chemical properties of lignin are largely determined by the wide variety of functional groups present within its structure. Among these, phenolic hydroxyl groups, mostly found on non-condensed aromatic rings, play a vital role in providing antioxidant capabilities, radical scavenging efficiency, and the potential for crosslinking reactions (59). Methoxy groups, located at the aromatic rings, significantly affect the electron distribution and redox behavior of lignin, which in turn influences its ability to absorb ultraviolet light and stabilize radicals (60). Aliphatic hydroxyl groups, attached to the lignin side chains, enhance its polarity and offer sites for chemical transformations such as esterification (61). Additionally, carboxyl and carbonyl groups, often introduced through oxidation reactions, provide more reactive centers and increase the hydrophilic character of lignin molecules (62).

The botanical source plays a crucial role in determining the detailed structure of lignin. In softwood species, lignin is mainly composed of guaiacyl (G) units, resulting in a polymer that is densely crosslinked due to a high frequency of β-5 and 5–5 carbon–carbon bonds, which contributes to its notable thermal stability and condensed nature (63). In contrast, hardwood lignins contain a greater proportion of syringyl (S) units, which promote a more linear molecular structure dominated by β-O-4 linkages, making them generally more reactive and easier to modify chemically (64). Lignins from grasses present an even more complex architecture, as they incorporate significant amounts of hydroxyphenyl (H) units and unique cross-linkages involving p-coumarates and ferulates, which are less commonly found in lignins from woody plants (65). Thus, the behavior and properties of lignin are largely determined by its unique combination of monolignol composition, the variety of interunit linkages, molecular weight characteristics, and abundance of functional groups. Gaining a detailed understanding of these structural features is essential for optimizing lignin’s role in the development of innovative materials. This knowledge is particularly important in the growing area of biodegradable-based food packaging, where lignin’s antioxidant, antimicrobial, and ultraviolet (UV) protective abilities are increasingly being recognized and utilized.

3 Lignin extraction methods: classification and perspectives

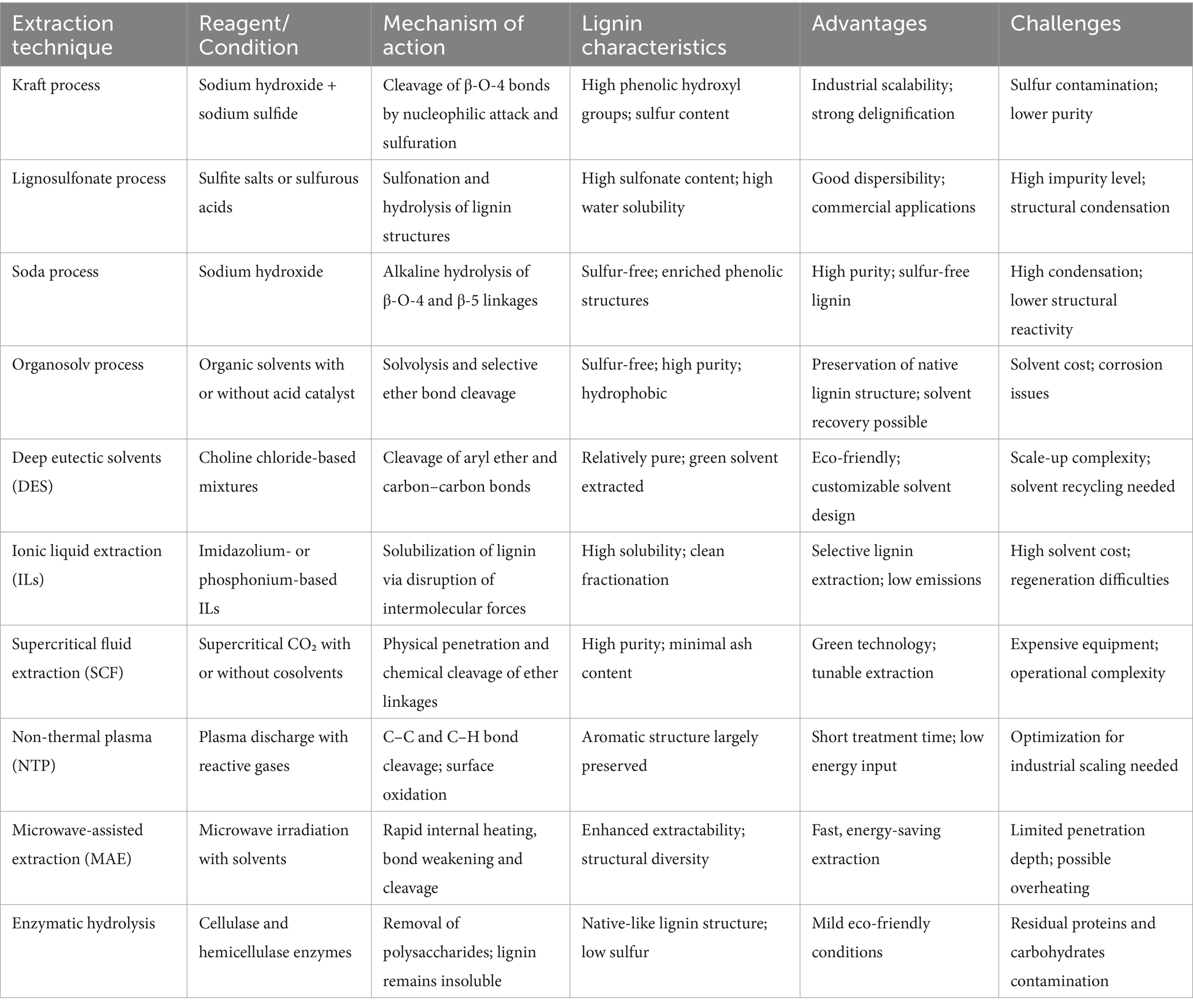

The extraction of lignin from lignocellulosic biomass is a critical step in biomass valorization, offering pathways for the development of bio-based chemicals, materials, and fuels. Over the past decades, a wide range of lignin extraction techniques have been developed, encompassing traditional chemical methods, organic solvent-based approaches, physical and green pretreatments, biological methods, and specialized extraction strategies. Each technique differs in its mechanism of action, the structural characteristics of the recovered lignin, and its associated advantages and limitations. Table 1 provides a comparative overview of these major lignin extraction technologies, summarizing their underlying mechanisms, lignin characteristics, process advantages, and challenges. This section systematically discusses the principles, operational features, and perspectives of key lignin extraction methods, highlighting both conventional and emerging strategies.

3.1 Traditional chemical methods

3.1.1 Kraft lignin extraction

Kraft lignin (KL) is a by-product generated during the kraft pulping process, which remains the most widely used industrial method for removing lignin from lignocellulosic biomass, particularly wood sources (66). In this process, biomass is treated with a solution called white liquor, composed of sodium hydroxide and sodium sulfide, at elevated temperatures ranging from 165 to 175 °C under strongly alkaline conditions (pH 13–14) (67). The highly basic environment promotes the ionization of phenolic hydroxyl groups, resulting in the formation of quinone methide intermediates. These reactive species are then targeted by bisulfide ions through nucleophilic attack (67, 68), leading to the cleavage of β-O-4-aryl ether bonds — essential linkages that account for approximately 50–70% of the internal structure of lignin (69). Additionally, the process breaks α-aryl and α-alkyl ether bonds and introduces small amounts (about 1–3%) of thiol groups into the lignin structure (70).

After delignification, lignin is separated from the black liquor through acidification, often using sulfuric acid, to lower the pH to around 5–7.5 (71). The resulting kraft lignin typically shows a broad molecular weight range, from 500 to 20,000 Da, depending on the type of biomass processed (71). Compared to lignosulfonates, kraft lignin is considered purer, as it contains fewer inorganic components and carbohydrate impurities (72). However, due to its low sulfur content, it has limited water solubility and usually requires chemical modification before practical application (73). Today, kraft lignin is primarily utilized in the production of polymer composites, industrial dispersants, and as a feedstock for the synthesis of biofuels and various value-added chemicals after undergoing further chemical processing or depolymerization (66).

3.1.2 Soda lignin extraction

Soda lignin is obtained by processing biomass—especially herbaceous plants such as wheat straw and bagasse—using sodium hydroxide (NaOH) solutions, without incorporating any sulfur-based chemicals (66). In this method, biomass is typically treated with 13–16 wt% NaOH at elevated temperatures ranging from 140 to 170 °C for about 90 min (66). The strong alkaline environment causes the breakdown of β-O-4 and β-5 bonds within the lignin structure, leading to the formation of new vinyl ether and phenolic hydroxyl groups (74). After the cooking stage, the lignin is separated from the black liquor by acidifying the solution to approximately pH 5.5, prompting lignin precipitation (75). One of the major distinctions between soda lignin and kraft lignin is that soda lignin is entirely free from sulfur, thereby eliminating concerns related to sulfur contamination. It generally shows a higher concentration of phenolic hydroxyl functionalities and a lower molecular weight (76). Additionally, the alkaline treatment often introduces more carboxylic acid groups due to oxidative modifications. However, despite these advantages, soda lignin tends to suffer from significant condensation reactions, which may reduce its reactivity and limit its range of applications. Nonetheless, the sulfur-free nature and relatively high purity of soda lignin make it a valuable candidate for producing bioplastics, adhesives, resins, and various composite materials (77).

3.1.3 Lignosulfonate extraction

Lignosulfonates are produced through the sulfite pulping process, which is performed either under acidic conditions (pH 1–5) or near-neutral conditions (pH 5–7). In acidic environments, lignin first experiences cleavage of α-ether bonds, generating quinone methide intermediates. These intermediates subsequently react with bisulfite ions, resulting in the formation of benzyl sulfonic acid groups that greatly enhance lignin’s solubility in water (77, 78). In contrast, under neutral conditions, sulfonation mainly targets the β-aryl ether bonds, leading to a different structural modification pathway (79). The lignosulfonate produced through these reactions possesses a combination of hydrophilic groups, including sulfonate, carboxyl, and phenolic hydroxyl groups, alongside hydrophobic aliphatic and aromatic regions, making it highly suitable for use as an anionic surfactant (80).

Following the pulping stage, lignosulfonates are separated from the spent liquor primarily through filtration, often coupled with ultrafiltration techniques to further concentrate and purify the product (81). The molecular weights of lignosulfonates show significant variation depending on the biomass source, with values around 12,000 Da for hardwood-derived lignosulfonates and reaching up to 60,000 Da for those obtained from softwoods (80). Although lignosulfonates are inexpensive and available in large quantities, their broader use is limited by issues such as high sulfur content (ranging from 3 to 8%), structural condensation, and the presence of residual carbohydrates and minerals (82). Despite these drawbacks, their excellent water solubility and favorable surface-active properties have enabled their application as dispersants across multiple industries.

3.1.4 Alkaline and acid pretreatment

Chemical pretreatment using alkaline or acidic solutions remains one of the most commonly applied strategies for extracting lignin from lignocellulosic biomass. Alkaline pretreatment involves the use of bases such as sodium hydroxide (NaOH), potassium hydroxide (KOH), or ammonium hydroxide (NH₄OH) to break lignin–carbohydrate linkages and solubilize lignin components (83). Conducted under moderate conditions of temperature and pressure, this treatment causes biomass swelling, enhances the accessibility of cellulose fibers, and facilitates the cleavage of ester bonds connecting lignin and hemicellulose structures (83). Among alkaline reagents, NaOH is widely preferred due to its strong alkalinity, broad availability, and relatively low cost (84). One key benefit of alkaline-based extraction is the production of sulfur-free lignin, which is especially suitable for creating bio-based polymers, fuel additives, and other high-value products (85). However, this method is not without drawbacks: alongside lignin removal, there can be unwanted degradation of hemicellulose and cellulose, and significant amounts of alkaline wastewater must be neutralized and managed properly (Figure 2). In contrast, acid pretreatment uses inorganic acids like sulfuric or nitric acid, or organic acids such as acetic or formic acid, to primarily hydrolyze hemicellulose and dissolve acid-soluble fractions of lignin (83). Dilute acid treatments are particularly effective for targeting hemicellulose removal while minimizing cellulose degradation. However, acid pretreatment can lead to the formation of acidifying and toxic compounds, which must be carefully controlled during processing (86).

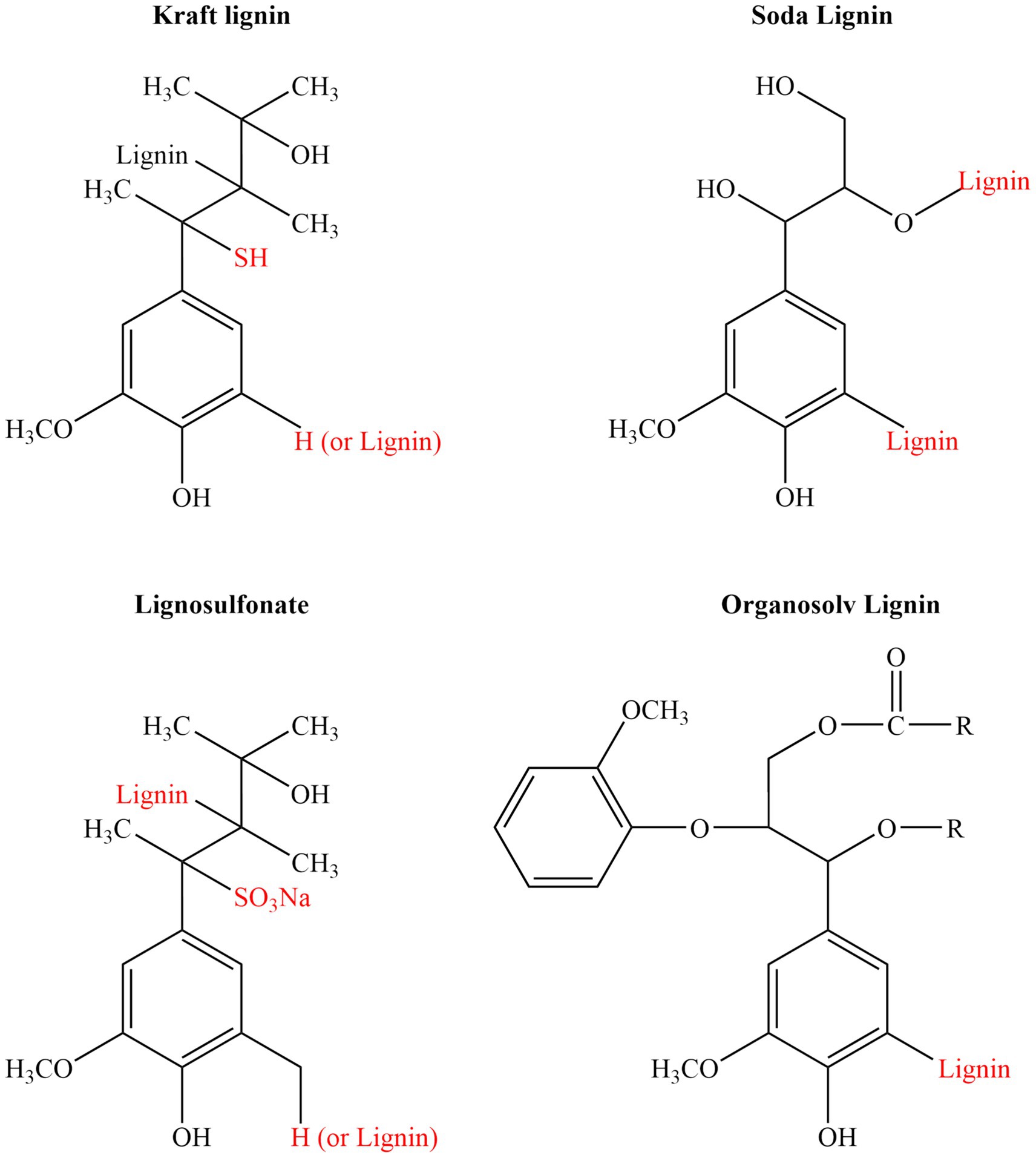

Figure 2. Representative chemical structures of technical lignins derived from major industrial extraction methods: Kraft lignin, Soda lignin, Lignosulfonate, and Organosolv lignin. Each type exhibits characteristic functional groups introduced during the pulping process, such as thiol groups (–SH) in kraft lignin, sulfonate groups (–SO₃Na) in lignosulfonates, or additional hydroxyl groups (–OH) in soda and organosolv lignins, which significantly affect their solubility, reactivity, and applications.

3.2 Organic solvent-based methods

3.2.1 Organosolv lignin extraction

Organosolv lignin is isolated through a relatively eco-friendly method where lignocellulosic materials are delignified using organic solvents such as ethanol, methanol, acetone, ethylene glycol, or various organic acids, typically blended with water (87). In many cases, mineral acids or Lewis acids are introduced as catalysts to enhance the dissolution of lignin and hemicellulose components (88). The extraction process usually operates at temperatures between 160 and 210 °C, with the reaction medium containing more than 60% organic solvent (89). The delignification mechanism primarily involves the cleavage of β-O-4 and α-ether bonds within the lignin structure, facilitating its release from the biomass matrix (90).

After the pulping step, organosolv lignin is separated by either lowering the pH or cooling the solution, resulting in lignin with relatively low molecular weights, typically around 4,000–10,000 Da, and narrow polydispersity (91). Unlike kraft lignin, organosolv lignin is completely free of sulfur and exhibits high purity, maintaining much of the original structure of native lignin. These features enhance its chemical reactivity and make it suitable for a wide range of applications (71). However, the broader adoption of organosolv processes on an industrial scale faces challenges due to the high cost of solvents, corrosion-related equipment damage, and significant energy demands for solvent recovery. Despite these obstacles, organosolv lignin is highly valued for the development of specialty chemicals, adhesives, and advanced polymer composites (92).

3.2.2 Deep eutectic solvent extraction

Deep eutectic solvents (DESs), formed by combining hydrogen bond donors and acceptors, have emerged as promising green solvents for lignin extraction, offering advantages such as low toxicity, biodegradability, and adjustable properties. In the DES extraction process, the breakdown of lignin’s structure mainly occurs through the cleavage of aryl ether (C–O) and carbon–carbon (C–C) bonds, facilitated by hydrogen bonding interactions and acid-catalyzed solvolysis mechanisms (93). Typically, DESs are prepared through a straightforward method of mixing compounds like choline chloride with organic acids at specific molar ratios, without producing by-products (94). Lignin isolated through DES treatment usually exhibits high purity levels, ranging between 75 and 98%, although minor impurities such as polysaccharide residues and traces of the DES components may remain. The efficiency of lignin extraction and the extent of its depolymerization are highly influenced by factors such as the choice of DES formulation, operational temperature, and the presence of acidic catalysts that assist in protonating β-O-4 bonds (95). Importantly, lignin obtained by this method often preserves functional groups crucial for further chemical transformations, making it a valuable raw material for producing antioxidants, sustainable resins, and bio-based composite materials (96).

3.2.3 Ionic liquids extraction

Ionic liquids (ILs) have emerged as promising alternatives for lignin extraction, offering advantages like low volatility, high thermal stability, non-flammability, and strong dissolving power for lignocellulosic components. Their tunable structure—comprising bulky organic cations and variable anions—allows customization for specific biomass treatments (97). Two main approaches are used: direct cellulose dissolution and selective lignin extraction through ionosolv pretreatment. In the ionosolv method, ILs disrupt lignin–carbohydrate bonds, enabling lignin removal while largely preserving cellulose integrity (98). Recent advances in designing functionalized ILs have further improved lignin solubility and selectivity. Protic ILs, in particular, enhance β-O-4 bond cleavage, crucial for generating valuable lignin-based products (99). Despite their potential, IL technologies face hurdles such as high production costs, toxicity concerns, and complex solvent recovery. However, ongoing efforts to develop biodegradable and affordable ILs are bringing this technology closer to large-scale lignin valorization (100).

3.3 Physicochemical and assisted extraction techniques

The development of sustainable lignin isolation strategies has gained increasing interest as industries seek environmentally friendly methods for biomass valorization. While several techniques are often described as green, it is important to clarify that physical-assisted methods such as microwave-assisted extraction (MAE) and plasma-assisted treatment are not inherently green unless paired with appropriate chemical systems. These technologies serve primarily as process intensification tools that can improve extraction efficiency when used in conjunction with alkaline, acidic, or deep eutectic solvents. The actual environmental footprint of these methods depends heavily on the nature of solvents and reagents employed.

3.3.1 Supercritical fluid extraction

Supercritical fluid extraction (SFE) has emerged as a promising physicochemical approach for lignin isolation, offering reduced use of organic solvents, high selectivity, and potential for solvent recovery. In this method, fluids above their critical temperature and pressure exhibit enhanced diffusivity and tunable solvation capabilities, allowing deep penetration into lignocellulosic matrices and facilitating lignin dissolution (101). Supercritical carbon dioxide (SC-CO₂) is the most commonly used fluid due to its mild critical parameters (31.1 °C, 73.8 bar), low toxicity, and ease of recycling (84). However, SC-CO₂ alone exhibits limited solubility for lignin, and is often combined with co-solvents such as ethanol or methanol to enhance lignin extraction efficiency and disrupt hydrogen bonding networks. Studies report lignin yields exceeding 70% in SC-CO₂–ethanol systems, particularly when process parameters are optimized (102, 103). Additionally, supercritical water has been explored as an alternative medium for lignin depolymerization. Although SFE is associated with high initial equipment costs and energy demands to maintain supercritical conditions, its ability to produce sulfur-free lignin of high purity makes it an attractive candidate for scalable biorefinery applications (104).

3.3.2 Microwave-assisted extraction

Microwave-assisted extraction (MAE) is widely investigated for accelerating lignin release by applying high-frequency electromagnetic radiation to biomass. Microwave energy penetrates biomass particles and induces rapid dielectric heating via dipolar rotation and ionic conduction, which causes localized rupture of the cell wall and enhances mass transfer (105). However, MAE alone is not sufficient for effective lignin extraction and must be used in combination with chemical agents, typically alkaline (e.g., NaOH) or acidic solutions, that actively cleave ester and ether bonds within the lignocellulosic structure (106). The role of microwave energy in these hybrid systems is to enhance molecular motion, accelerate reaction kinetics, and improve solvent diffusion. More recently, green solvents such as deep eutectic solvents (DESs) have been explored in MAE systems to reduce environmental burden while maintaining high efficiency (107, 108). Despite limitations such as non-uniform heating and specialized reactor requirements, MAE remains a valuable process intensification strategy when integrated with sustainable chemical formulations. Its advantages include shorter processing times, reduced solvent consumption, and potential retention of lignin’s functional moieties (109).

3.3.3 Plasma-assisted extraction

Plasma-assisted pretreatment is a novel approach that utilizes ionized gases to alter biomass structure through chemical and physical interactions. Plasma, comprising electrons, ions, UV photons, and reactive oxygen or nitrogen species, can induce bond scission and surface modification of lignocellulosic substrates (110). Non-thermal plasma (NTP), in particular, has gained attention due to its operation at near-ambient temperatures, minimizing thermal degradation. However, like MAE, plasma treatment alone does not suffice for efficient lignin solubilization, and is generally combined with alkaline or oxidizing agents to facilitate effective delignification. For example, applying NTP to alkali-impregnated biomass significantly improves lignin removal by enhancing hydroxyl radical formation and disrupting recalcitrant bonds (111, 112). In such integrated systems, plasma accelerates depolymerization reactions, reduces inhibitor formation, and improves enzyme accessibility in downstream processes. While current research has demonstrated high delignification rates and improved accessibility for saccharification, key challenges remain in energy efficiency, reactor design, and scale-up feasibility (113–115). However, challenges like optimizing energy efficiency, reactor design, and scaling up remain. Although still under development, plasma-assisted delignification holds strong potential as a green and efficient alternative for future lignin extraction technologies (110). As such, plasma-assisted lignin pretreatment is better considered a complementary technique rather than a standalone green extraction method.

3.4 Biological/enzymatic extraction

3.4.1 Enzymatic hydrolysis lignin

Enzymatic hydrolysis lignin, often referred to as cellulolytic enzyme lignin (CEL), is obtained as a solid residue following the enzymatic breakdown of lignocellulosic biomass. In this process, cellulase, and hemicellulase enzymes are employed to selectively hydrolyze polysaccharides (cellulose and hemicellulose) under mild, aqueous, and environmentally benign conditions, leaving lignin as an unreacted component. These conditions largely preserve lignin’s native structure and avoid the introduction of sulfur or other chemical contaminants typically associated with pulping or harsh chemical pretreatments (116, 117). However, the crude residue resulting from enzymatic hydrolysis still contains entrapped carbohydrates, proteins, and ash, which can interfere with downstream applications or structural characterization. Therefore, to obtain purified CEL, the lignin-rich fraction is typically subjected to solvent extraction using dioxane–water mixtures (commonly 96:4 v/v). This step efficiently dissolves lignin while leaving behind polysaccharides and other insoluble impurities. The resulting CEL exhibits relatively high lignin content (typically 65–80%) and retains important native features such as phenolic hydroxyls, β–O–4 linkages, and aromatic ring structures, making it valuable for detailed structural analysis and functionalization (73, 118, 119). Although CEL is poorly soluble in water and many conventional organic solvents, its chemical integrity and absence of harsh modifications make it a promising candidate for diverse applications. These include its use as a dispersant, binder, adsorbent, antioxidant additive, or renewable precursor in polymer and composite synthesis. Further chemical modification or nanoparticle formulation may be required to overcome solubility challenges in specific applications.

3.5 Specialized lignin type extraction

3.5.1 Catechyl lignin

Catechyl lignin (C-lignin) is a recently identified type of lignin, predominantly located in the seed coats of certain plants such as castor, vanilla orchid, and cactus (120). Unlike conventional lignins, which are composed of a mixture of guaiacyl, syringyl, and p-hydroxyphenyl units, C-lignin is exclusively formed from caffeyl alcohol monomers connected through benzodioxane bonds. This distinct linear structure results in a highly uniform and less branched polymer compared to the complex, heterogeneous architecture of typical lignins (121). The presence of stable benzodioxane linkages grants C-lignin exceptional resistance to chemical degradation, especially under acidic environments. This structural stability allows C-lignin to undergo clean and efficient depolymerization into catechol-based products using relatively straightforward catalytic processes. Extraction of C-lignin has been effectively achieved using deep eutectic solvents, particularly from biomass sources like castor seed coats, producing lignin fractions with low molecular weights (ranging from 1,800 to 3,500 Da) and narrow polydispersity. Due to its simple depolymerization pathway and the potential to yield valuable catecholic compounds, C-lignin is regarded as an attractive option for future sustainable lignin valorization efforts (122, 123).

Therefore, the extraction of lignin from lignocellulosic biomass encompasses a broad range of traditional and emerging technologies, each offering distinct advantages and challenges. Conventional methods such as kraft, sulfite, soda, and organosolv processes have been widely implemented, yielding large volumes of technical lignins with varying structural properties. Innovations including deep eutectic solvents, ionic liquids, microwave-assisted extraction, and plasma-assisted techniques have been developed to enhance lignin purity, reduce environmental impact, and preserve native lignin structures. Despite the progress achieved, challenges such as scalability, cost-effectiveness, solvent recovery, and process optimization remain critical barriers to the widespread industrial application of newer methods. Nevertheless, advances in green solvent technologies, supercritical fluids, and plasma-based systems offer promising avenues for sustainable lignin extraction, enabling the production of high-value lignin suitable for a wide range of industrial and biotechnological applications.

3.6 Recyclability and long-term performance of LNPs

While much of the current research has focused on the functional performance of LNPs in biopolymer films, there is a notable lack of experimental data on how these materials behave during or after recycling processes. In particular, it is unclear how thermal, mechanical, or chemical recycling methods affect the structural integrity, antioxidant activity, or barrier properties of LNPs once incorporated into food packaging matrices. As LNPs are biodegradable and often sensitive to heat and oxidation, their performance may degrade with repeated processing. However, no comprehensive studies have quantified these changes under real-world recycling conditions. This represents a critical knowledge gap in validating the role of LNP-based packaging within circular economy frameworks. Future investigations should assess the retention of nanoparticle functionality after recycling, evaluate nanoparticle migration behavior in reprocessed films, and explore strategies to enhance LNPs recyclability in bio-based composites.

3.7 Influence of extraction methods on LNPs properties

The extraction method applied to isolate lignin from biomass significantly influences the physicochemical characteristics of the resulting lignin, which in turn governs its behavior during nanoparticle formation and the properties of the produced LNPs. Variations in extraction severity, chemical environment, and process conditions lead to lignin fractions with different molecular weights, functional group profiles, condensation degrees, and residual carbohydrate contents. These compositional and structural differences have critical implications for nanoparticle morphology, stability, and potential end-use functionality (124). For example, lignins obtained through relatively harsh treatments such as kraft pulping tend to have higher molecular weights, a greater degree of condensation, and more aliphatic and phenolic hydroxyl groups exposed due to ether bond cleavage (125). Despite its structural heterogeneity and lower solubility, kraft lignin has demonstrated exceptional potential for producing small-sized, monodisperse LNPs with high colloidal stability (126). The presence of abundant carboxylic acid groups and possible co-extracted hydrophobic compounds, such as resinous by-products from pulping, appear to facilitate the formation of nanoparticles with low diameters and strong negative zeta potentials, without the need for added surfactants or stabilizing agents (127).

On the other hand, lignins extracted via milder organosolv or acid-catalyzed methods typically retain a larger proportion of native ether linkages, especially β-O-4 bonds, and show lower levels of structural degradation. These lignins usually possess a narrower molecular weight distribution and higher chemical purity, which make them well-suited for applications where biocompatibility and reactivity are prioritized (128, 129). However, the resulting nanoparticles from these lignins often exhibit slightly larger sizes (ranging from approximately 60 to 100 nm), broader size distributions, and somewhat reduced colloidal stability compared to those derived from kraft lignin (130–132). Adjusting the pH during nanoprecipitation has been shown to be a simple yet highly effective strategy for tuning LNPs characteristics. Increasing the pH of the lignin solution prior to solvent shifting leads to deprotonation of carboxylic and phenolic groups, enhancing electrostatic repulsion and promoting the formation of smaller and more stable nanoparticles (133). The use of neutral to slightly basic conditions during nanoparticle precipitation has consistently resulted in reduced particle size and improved dispersion stability across multiple lignin types (127, 132).

Overall, while all major classes of technical lignin can be converted into nanoscale dispersions using appropriate techniques, the properties of the resulting LNPs are intricately tied to the origin and extraction pathway of the precursor lignin. Lignins derived from kraft processes may be more suitable for applications that require small, thermally stable nanoparticles with narrow size distributions, whereas lignins isolated through organosolv or acidolysis routes may offer advantages in terms of functional group availability, purity, and biocompatibility. The interplay between extraction conditions, molecular structure, and nanoparticle formation underscores the importance of tailoring lignin selection and processing strategies to match the performance requirements of specific material applications.

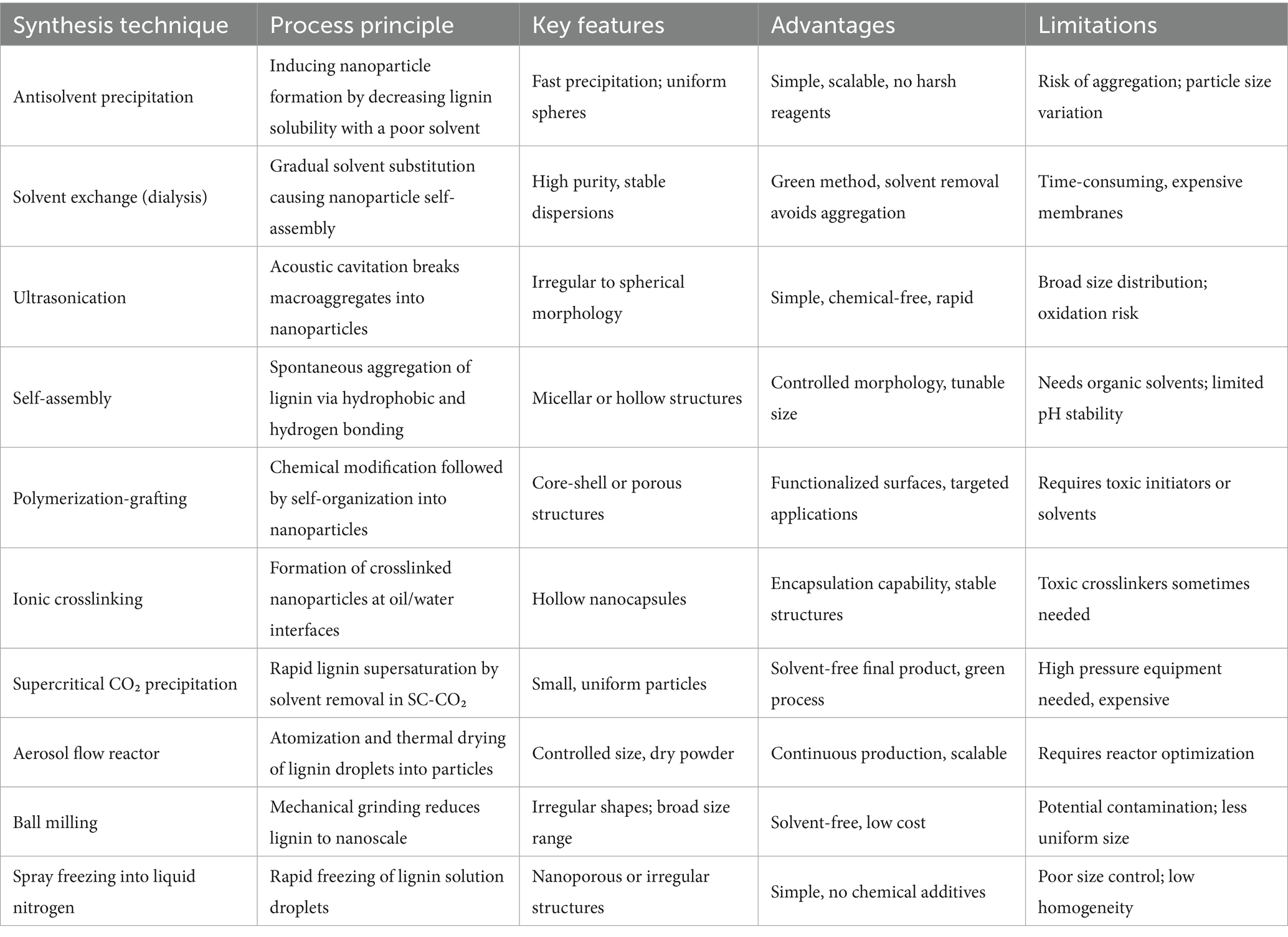

4 Lignin nanoparticles synthesis techniques for food packaging applications

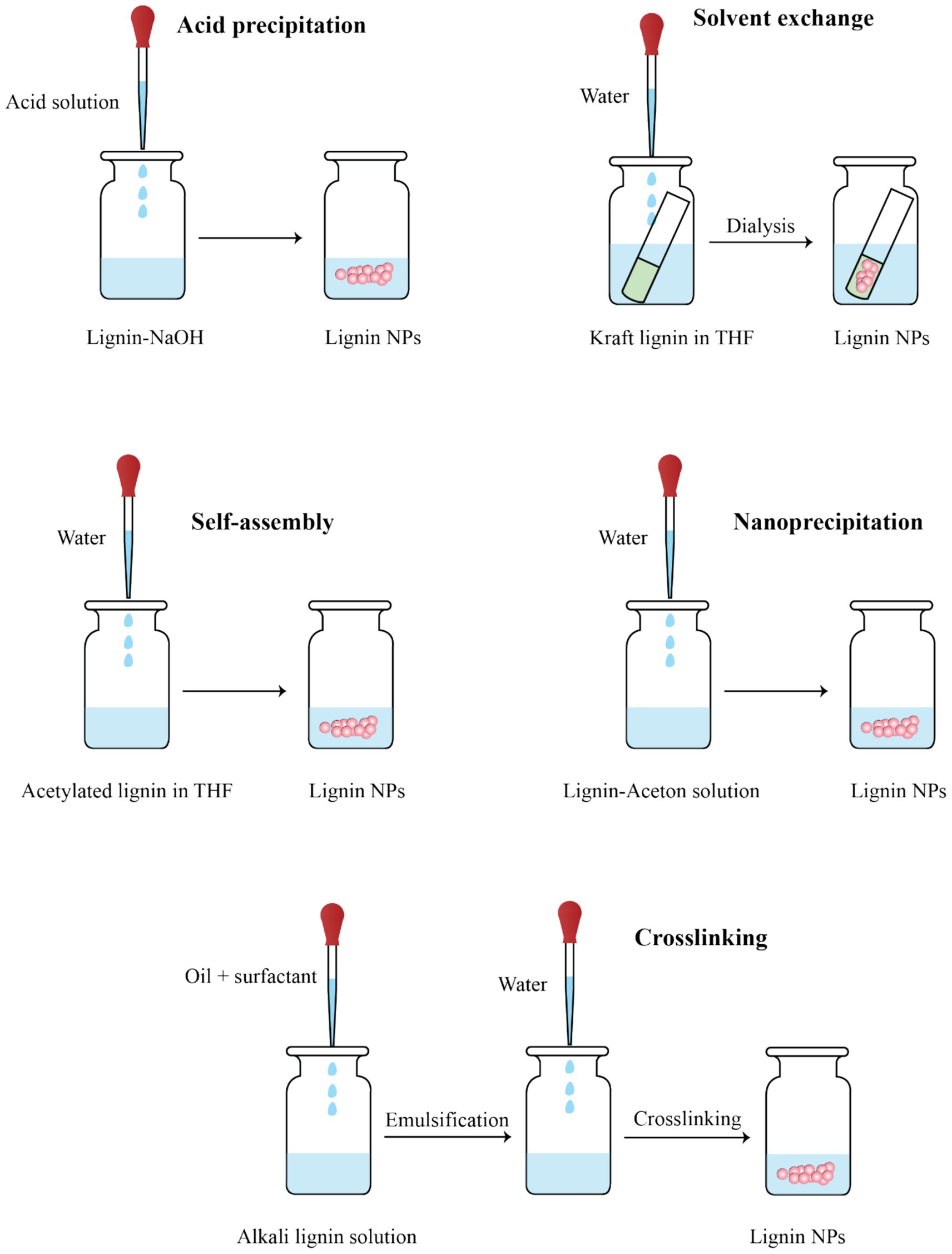

The synthesis of LNPs has gained increasing attention due to its critical influence on particle morphology, size, surface chemistry, and colloidal stability, all of which directly affect their performance in food packaging applications (Figure 3). A wide range of fabrication techniques has been developed, including mechanical, physicochemical, chemical, and biological approaches. Among these, methods such as antisolvent precipitation, homogenization, and electrospray have already been successfully applied to produce LNPs that, when incorporated into food packaging films, have demonstrably improved their mechanical strength, barrier properties, UV shielding, antioxidant activity, and antimicrobial function, as confirmed in numerous studies detailed below and in section 5. In contrast, several other strategies such as enzymatic modification, polymer grafting, or aerosol flow reactors are still in early development for lignin systems and have not yet been applied in packaging contexts. Table 2 summarizes the underlying principles, advantages, and limitations of these synthesis methods. To bridge synthesis conditions with material functionality, this section also highlights selected examples where specific LNPs fabrication methods have resulted in measurable improvements in packaging performance. These interconnections are further elaborated in Table 3, which compiles published studies on the application of LNPs in packaging systems.

Figure 3. Schematic representation of six major methods for synthesizing lignin nanoparticles (LNPs), including acid precipitation, solvent exchange, self-assembly, nanoprecipitation, and interfacial crosslinking.

4.1 Top-down mechanical methods

4.1.1 Homogenization

Homogenization is a mechanical method for synthesizing LNPs by applying intense shear forces to disrupt lignin aggregates without chemical modification (134). In this process, lignin is dispersed in solvents like water or ethanol and subjected to high-speed shearing, where cavitation effects fragment the particles. Solvent choice critically influences cavitation intensity and thus nanoparticle size and morphology. Ethanol–water systems, particularly with pre-treatment or acidic catalysts (as in HOS-SE), enhance size reduction and particle reshaping (135). Compared to ultrasonication, homogenization yields smaller, more uniformly sized nanoparticles while preserving lignin’s chemical structure (136). Prolonged treatment improves colloidal stability by minimizing agglomeration (135). The resulting LNPs also exhibit high thermal stability, and the method’s simplicity, chemical-free nature, and scalability make it highly suitable for industrial applications, provided that operational conditions are carefully optimized. A representative application of LNPs prepared via homogenization is their incorporation into cellulose-based paper coatings, where they enhanced water and oil repellency, improved tensile strength by 48%, and reduced water vapor permeability by over sixfold, demonstrating their effectiveness as multifunctional barrier layers (137).

4.1.2 Ultrasonication

Ultrasonication is an efficient, green method for producing LNPs by using acoustic cavitation to induce particle size reduction, bond cleavage, and oxidation without major chemical alteration. Its effectiveness depends on sonication time, power, solvent type, pressure, and temperature (138). Higher ultrasonic intensities and optimized conditions yield smaller, more uniform LNPs, whereas insufficient intensity leads to broader size distributions and irregular morphologies (139). Ultrasonication also promotes functional group exposure, enabling complex formation with other molecules, such as gelatin and chitosan (140, 141). Excessive sonication can cause lignin degradation or, alternatively, radical-induced crosslinking, depending on conditions (142). Advanced techniques like ultrasonic-assisted solvent shifting enhance particle uniformity (143). Despite challenges like non-uniform particle sizes under suboptimal conditions, ultrasonication remains a versatile, scalable, and environmentally friendly approach for nanostructured lignin production (144, 145).

4.1.3 Ball milling

Ball milling is a simple, solvent-free mechanical technique used to reduce lignin particle size by applying impact and shear forces through rotating balls within a cylindrical shell (146). Different types of mills, including tumbler, vibratory, and planetary mills, enable the efficient breakdown of lignin depending on milling parameters such as ball size, rotational speed, and temperature (147).

Modified ball milling methods, like low-temperature milling, have produced LNPs smaller than 10 nm (148). Despite its advantages of low cost, simplicity, and scalability, this method can result in size variation, broad particle distributions, and contamination risks (149). Nonetheless, ball milling remains a practical approach for large-scale lignin nanoparticle production.

4.2 Solvent-based precipitation methods

4.2.1 Antisolvent precipitation method

Antisolvent precipitation is a simple and effective approach for synthesizing LNPs by reducing lignin solubility through the addition of water or acid into lignin solutions prepared in organic solvents like THF, ethanol, acetone, or DMSO. This induces rapid aggregation, yielding spherical nanoparticles with smooth surfaces and uniform sizes (150, 151). Lignin properties, including molar mass, hydroxyl content, and solubility, significantly affect nanoparticle formation. Process parameters such as lignin concentration, solvent/antisolvent ratio, and pH control the particle size and stability (152). For example, adjusting pH in sodium p-toluenesulfonate solutions can reduce particle size by promoting dissociation of lignin functional groups (148). Acid precipitation using HCl or HNO₃ also forms stable LNPs by protonating lignin, improving stability and imparting antibacterial properties (153, 154). While environmentally friendly and cost-effective, this method may cause aggregation during solvent removal if not carefully controlled (155). Overall, antisolvent precipitation produces functional, biodegradable LNPs suitable for food packaging, cosmetics, and drug delivery. Antisolvent precipitation has been widely used to fabricate well-dispersed LNPs for bioactive films. For instance, chitosan and PVA films incorporating LNPs synthesized via this method exhibited marked improvements in mechanical strength (up to 55%), UV-blocking, and antibacterial activity (e.g., >99% inhibition against E. coli and S. aureus) (156, 157). When applied to refrigerated fish preservation, these films prolonged shelf life by up to 4 days compared to controls (158).

4.2.2 Solvent exchange method

The solvent exchange method is a simple and chemical-free approach for LNPs synthesis, where lignin is first dissolved in an organic solvent like THF or DMSO, then gradually dialyzed against water to induce nanoparticle formation (127, 159). Lievonen et al. produced stable LNPs by dissolving kraft lignin in THF followed by water dialysis, with particle size tunable by adjusting lignin concentration [8]. Lintinen et al. (159) prepared metal–organic nanoparticles by introducing iron-isopropoxide into lignin/THF solutions before dialysis [6]. Figueiredo et al. (71) extended this approach by forming Fe₃O₄–lignin hybrid nanoparticles. Similarly, Zikeli et al. (160) generated LNPs from wood waste lignin dissolved in DMSO and dialyzed against water. While the method offers high nanoparticle stability and simplicity, the need for dialysis membranes and solvent handling can increase production costs.

4.3 Spray and aerosol techniques

4.3.1 Electrospinning method

Electrospinning uses a high-voltage electric field to create a fine jet of lignin solution, forming continuous nanofibers as the solvent evaporates. Typically, the lignin solution is loaded in a syringe connected to the positive electrode, while the collector is attached to the negative electrode. Upon applying voltage, the solution forms a thin stream that solidifies into fibers (161). Ruiz-Rosas et al. (162) produced lignin submicron fibers by electrospinning Alcell lignin/ethanol mixtures, achieving good oxidation resistance and microporous carbon fibers after stabilization and carbonization. Dallmeyer et al. (163) evaluated various lignins (kraft, organosolv, sulfonated, pyrolytic) for electrospinning and found that fiber formation was improved by adding poly(ethylene oxide) (PEO), enabling uniform fibers. Overall, electrospinning allows the fabrication of defect-free, thermally stable lignin fibers, though fiber morphology is influenced by lignin type, solution properties, and solvent choice. Electrospray-based LNPs fabrication enables uniform nanoparticle deposition and has shown strong application potential in PLA films. These films displayed excellent UV-blocking ability (transmittance below 1.1% at 280 nm), antioxidant enhancement (10-fold increase in DPPH scavenging), and improved mechanical integrity, validating the role of this synthesis method in producing optically active and oxidation-resistant packaging layers (164).

4.3.2 Spray freezing

Spray freezing involves dissolving lignin in a solvent such as DMSO and rapidly spraying the solution onto a surface cooled by liquid nitrogen. Upon contact, the lignin droplets instantly freeze, forming solid particles without extensive solvent-lignin interaction. This method offers simple, continuous nanoparticle production and avoids chemical modifications, but typically results in particles with heterogeneous size and morphology (165).

4.3.3 Aerosol flow reactor synthesis

The aerosol flow reactor technique offers a continuous, one-step method for LNPs production with uniform size distribution. In this process, lignin is dissolved in a solvent like water or DMF, atomized into fine droplets, and carried by a nitrogen gas stream through a heated laminar flow reactor, where solvent evaporation yields solid nanoparticles. Ago et al. (166) demonstrated that lignin concentration influences particle size and dispersion, with higher concentrations producing larger but more narrowly distributed LNPs. The resulting particles showed excellent mechanical integrity and stable redispersibility in oil/water systems, efficiently stabilizing Pickering emulsions. This method is valued for its simplicity, scalability, high product yield, and minimal liquid waste generation (166).

4.4 Polymerization and crosslinking strategies

4.4.1 Polymerization method

Polymerization techniques for LNPs often involve grafting polymer chains onto lignin to improve functionality. Barakat et al. (167) synthesized nanoparticles from arabinoxylan–dehydrogenation polymers through polymerization of coniferyl and sinapyl alcohols in the presence of heteroxylans. Qian et al. (168) grafted 2-(diethylamino)ethyl methacrylate onto alkali lignin via ATRP, enabling switchable Pickering emulsions. Other approaches, such as miniemulsion polymerization, produced lignin nanocarriers with various morphologies, where porous nanoparticles exhibited faster release profiles. Further, solvent-free radical polymerization has been used to create lignin–PMMA composites, improving mechanical, thermal, and UV-resistant properties. Grafting PMMA onto lignin by ATRP or radical polymerization enhanced miscibility with other polymers and promoted biomedical applications (169). Although polymerization improves lignin compatibility and functionality, it often involves costly and hazardous reagents. Polymer-grafted LNPs obtained via organocatalyzed ring-opening polymerization of lactide displayed enhanced compatibility in PLA matrices. These hybrid materials demonstrated superior nanoparticle dispersion, increased UV-shielding (up to 85% reduction in UV-A transmission), and sustained antioxidant release profiles over time, enabling their use in intelligent or active packaging systems (170).

4.4.2 Emulsion and crosslinking methods

Emulsion and crosslinking techniques have been widely applied to synthesize lignin-based nanocapsules and microspheres. Typically, lignin is first emulsified in an oil/water system and stabilized using surfactants, followed by crosslinking at the droplet interfaces to form stable nanostructures. Yiamsawas et al. (171) developed hollow lignin nanocapsules by crosslinking sodium lignosulfonate and alkali lignin using toluene diisocyanate (TDI) at the miniemulsion interface, resulting in stable capsules suitable for aqueous or organic dispersions. Similarly, application of ultrasound-assisted crosslinking in oil/water emulsions formed kraft lignin microcapsules with biocompatibility properties (171). Chemical crosslinkers like epichlorohydrin have been used to form porous lignosulfonate spheres with enhanced porosity and mechanical properties. Lignin supracolloids also synthesized through microemulsion formation followed by crosslinking. Similarly, pH-responsive lignin nanocapsules fabricated via interfacial miniemulsion polymerization (172–174). Overall, these methods enable the formation of structurally stable, functional lignin nanoparticles with potential applications in controlled release systems, packaging, and biomedicine.

4.5 Biological and enzymatic methods

4.5.1 Biological method

The biological method for LNPs synthesis utilizes enzymes or microorganisms to break down lignocellulosic structures and release lignin, offering a green and low-cost approach. Accordingly, cuboidal LNPs has been produced by enzymatically hydrolyzing Indian ridge gourd lignocellulose. Similarly, combination of enzymatic hydrolysis with a solvent exchange process led to prepare stable LNPs from various biomasses. Although the biological route avoids hazardous chemicals and is environmentally sustainable, it typically results in low nanoparticle yield, irregular shapes, and larger particle sizes. Nevertheless, this method remains attractive for sustainable nanomaterial production where eco-friendliness is prioritized (174, 175).

Thus, various physical, chemical, and biological strategies have been employed for LNPs synthesis, each offering specific advantages and limitations. Mechanical approaches such as ultrasonication, homogenization, and ball milling provide simplicity but may lead to broad particle size distributions. Techniques based on self-assembly, antisolvent precipitation, solvent exchange, and aerosol flow reactors enable better control over particle morphology and dispersibility, although process optimization remains crucial. Crosslinking and polymerization methods enhance the structural integrity and functional versatility of LNPs, whereas biological and dialysis routes offer greener alternatives with minimal chemical input. Ice segregation-induced self-assembly and spray freezing present emerging methods that capitalize on environmentally friendly conditions for nanoparticle fabrication. Overall, the selection of the appropriate synthesis method depends on the desired particle size, stability, functionalization potential, and application field, particularly in sustainable food packaging.

In summary, this section illustrates that the choice of LNP synthesis technique has a direct impact on packaging film performance. Methods like antisolvent precipitation, electrospray, and polymer grafting yield nanoparticles with defined morphologies, surface functionalities, and dispersion characteristics that significantly enhance film strength, antioxidant capacity, UV resistance, and antimicrobial behavior. These correlations between synthesis and functionality are critical for designing high-performance food packaging systems, as further demonstrated in section 5.

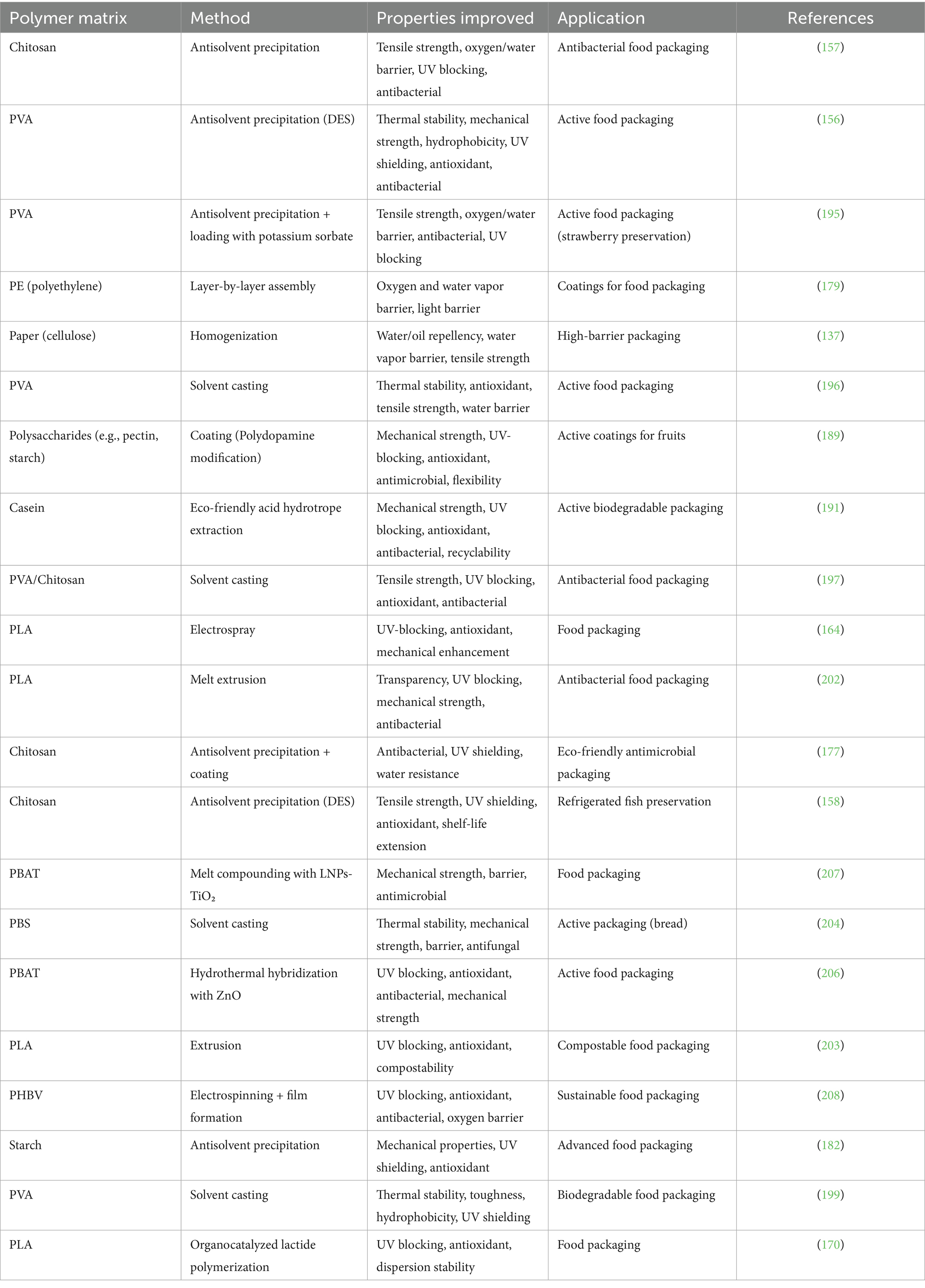

5 Applications of lignin nanoparticles in food packaging

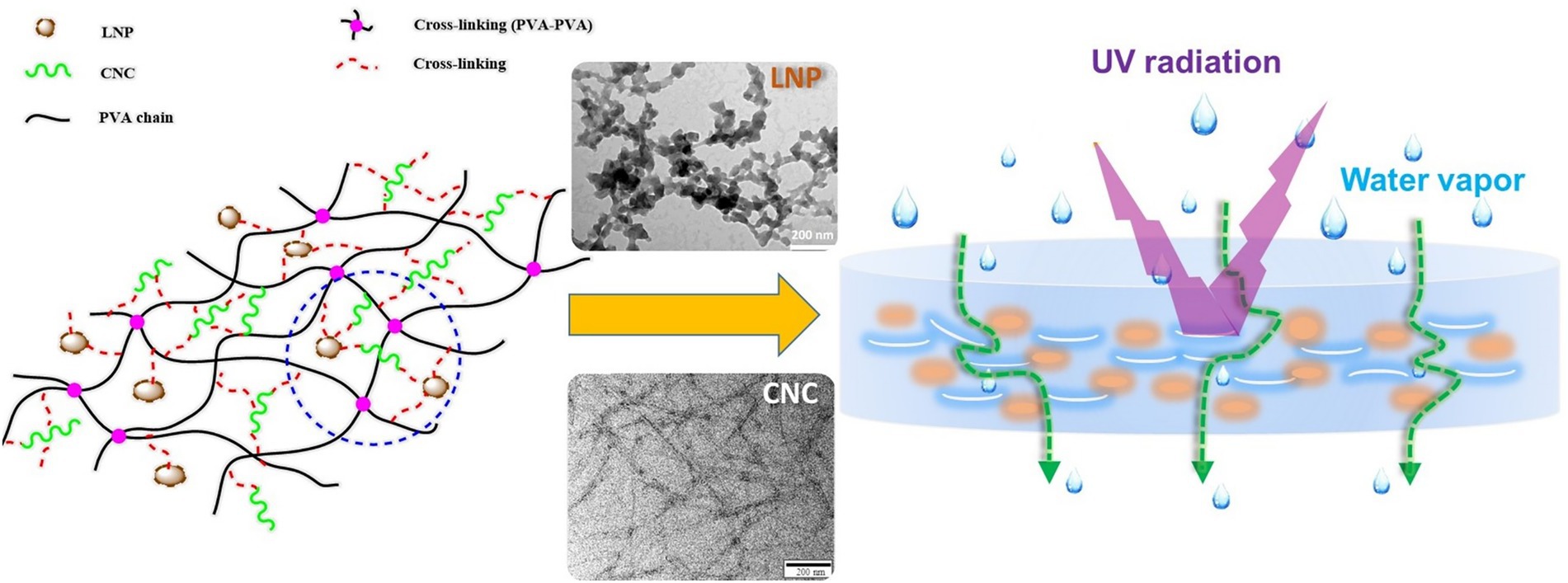

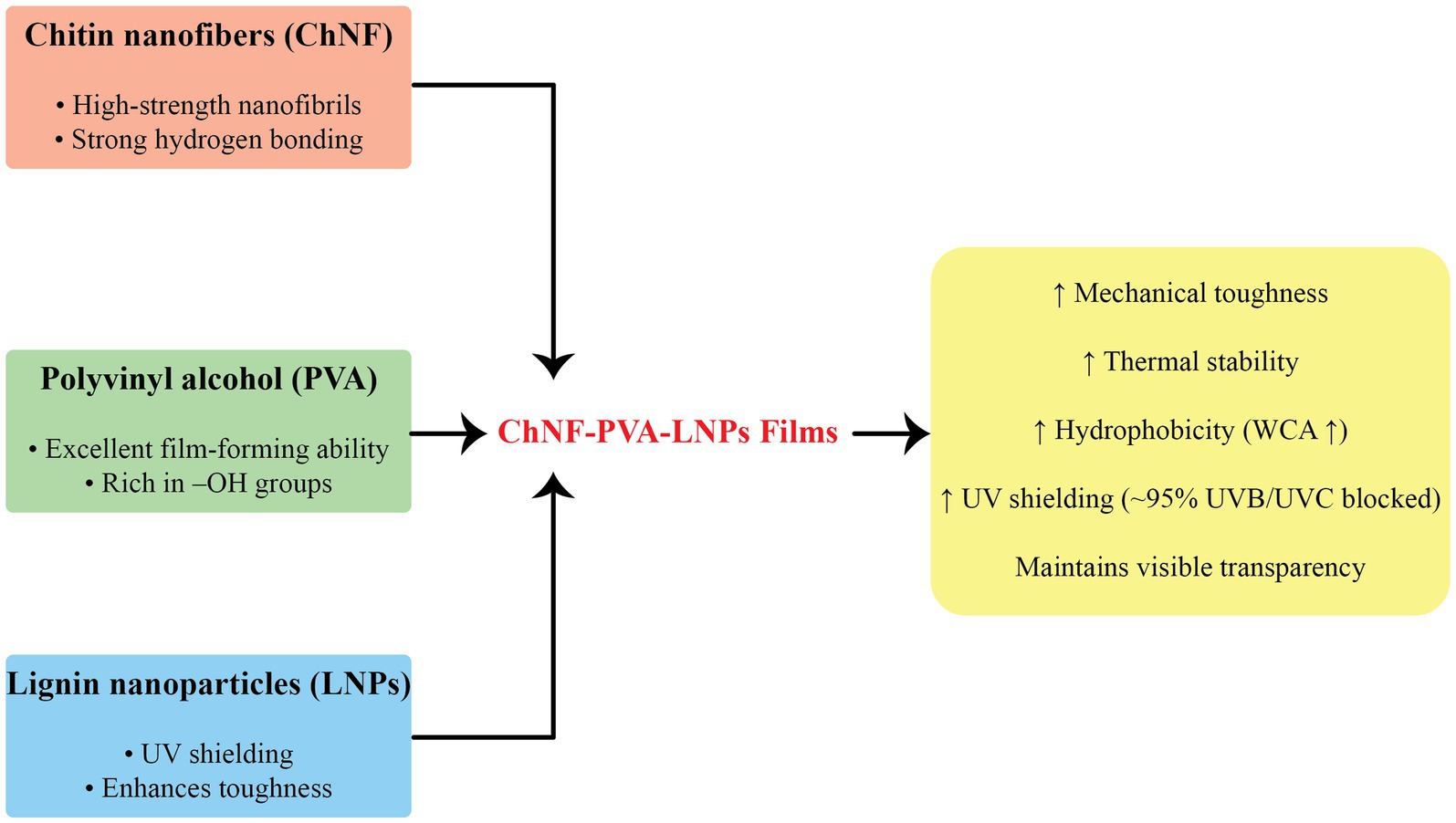

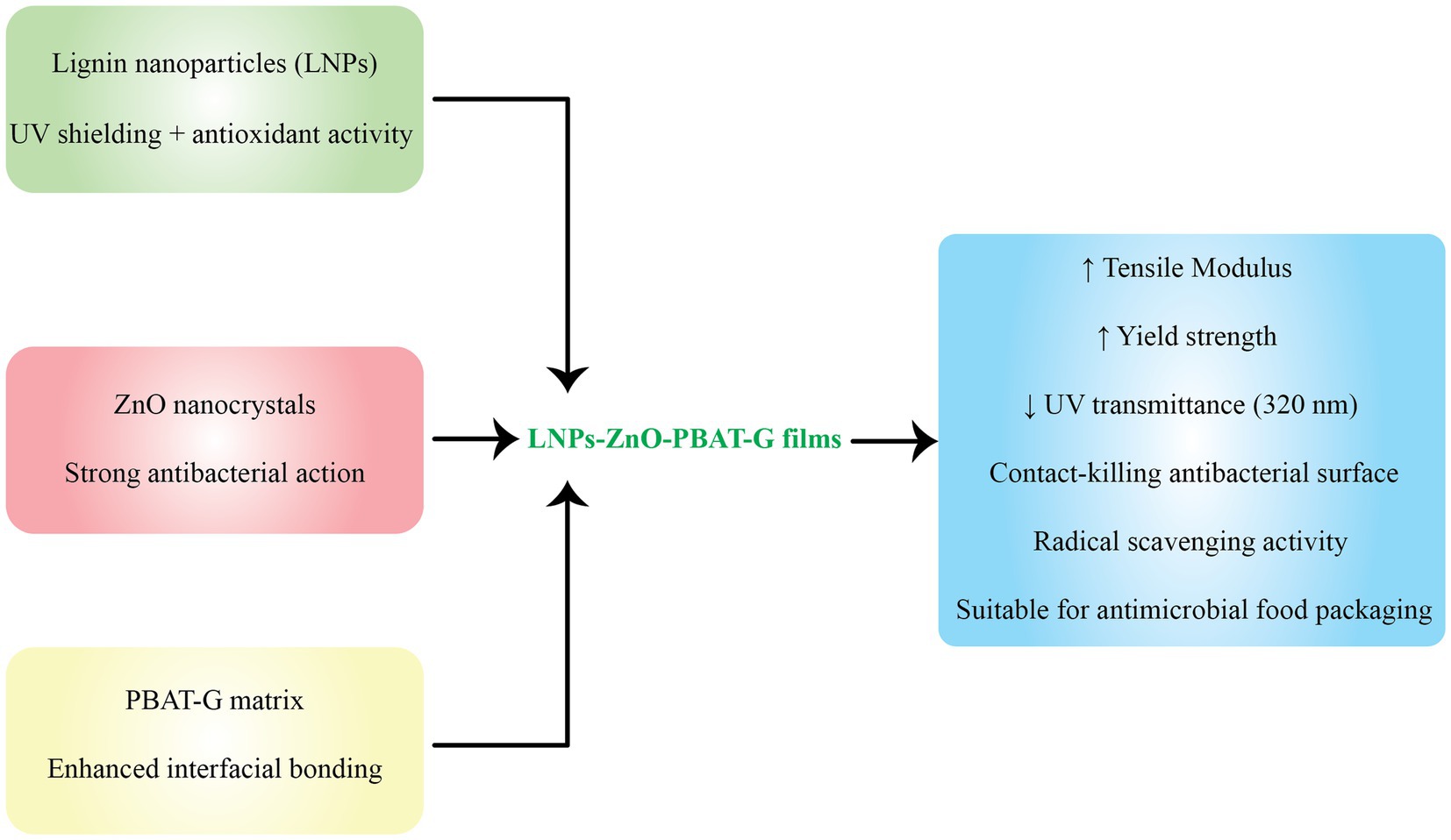

The integration of LNPs into biodegradable polymer matrices has emerged as a promising strategy for enhancing the functional performance of food packaging materials. Owing to their intrinsic antioxidant, UV-blocking, and antimicrobial properties, as well as their ability to form strong interfacial interactions, LNPs significantly improve the mechanical strength, barrier properties, and functional bioactivity of biodegradable films. Various biodegradable polymers, including polysaccharides, proteins, and polyesters, have been reinforced with LNPs to develop active and intelligent food packaging systems that meet both sustainability objectives and regulatory standards. Among these matrices, chitosan, polyvinyl alcohol (PVA), polylactic acid (PLA), and polybutylene succinate (PBS) have received particular attention due to their film-forming ability and environmental compatibility (Table 3). This section categorizes and discusses recent advances in LNPs-enhanced biodegradable packaging materials, organized by polymer type, beginning with chitosan-based systems.

6 Applications of lignin nanoparticles in sustainable food packaging

6.1 Chitosan-based systems (CH matrix)

Chitosan (CH), a naturally derived polysaccharide obtained from chitin deacetylation, is one of the most promising candidates for replacing petroleum-derived plastics in sustainable food packaging. Its film-forming ability, biodegradability, biocompatibility, and intrinsic antimicrobial activity make it highly attractive. Nonetheless, native chitosan films suffer from low mechanical strength, limited oxygen and UV barrier properties, and high water vapor permeability, which restrict broader industrial adoption.

To overcome these limitations, numerous studies have explored the incorporation of LNPs into chitosan matrices. LNPs offer multiple functionalities, including UV shielding, antioxidative activity, moisture resistance, and mechanical reinforcement. This combination creates synergistic nanocomposites with markedly enhanced packaging performance.

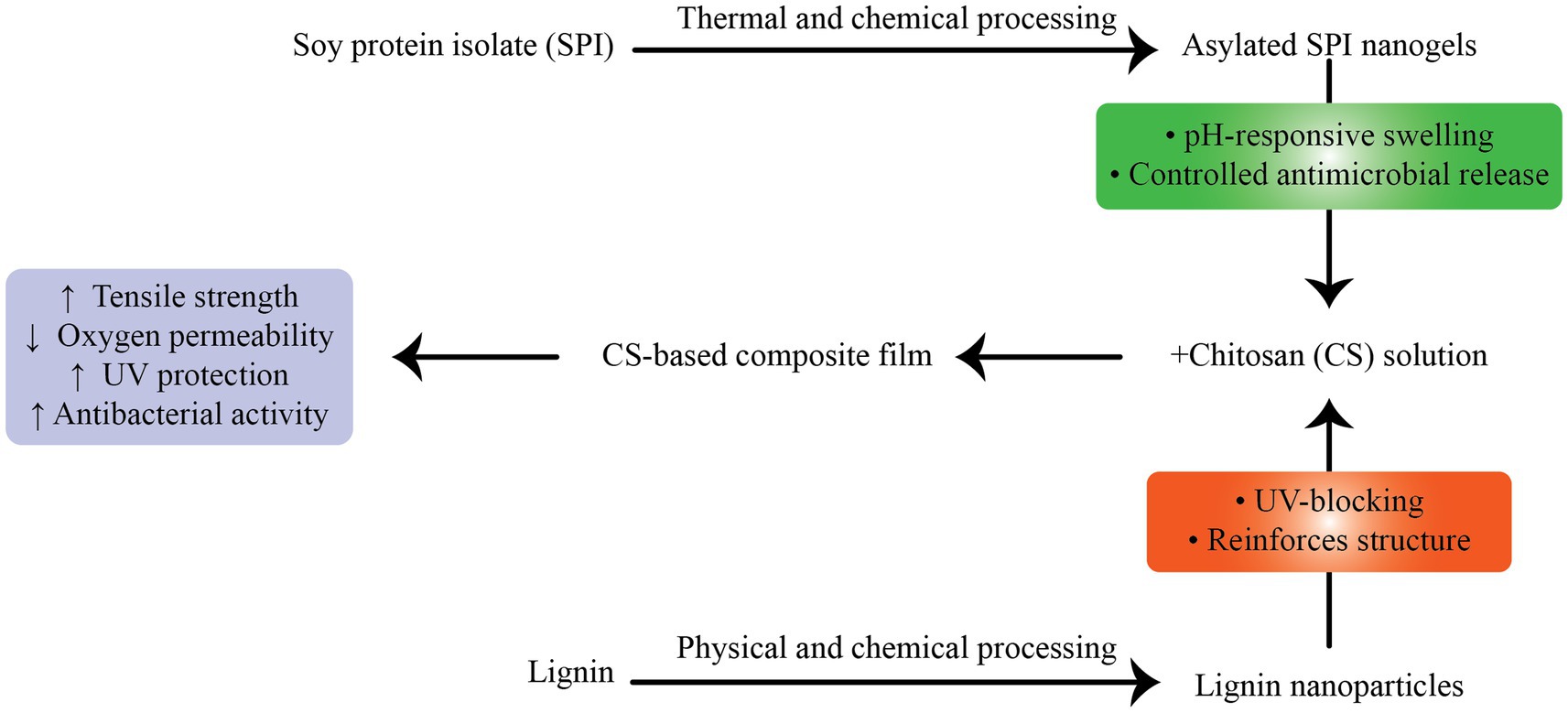

Zou et al. (157) developed CH films containing LNPs and acylated soy protein isolate nanogels (ASPNG), which significantly improved film tensile strength (from 37.29 to 54.29 MPa), reduced oxygen permeability, and imparted strong antibacterial properties (Figure 4). The co-incorporation strategy demonstrated a synergistic effect, with ASPNG providing controlled release and LNPs reinforcing the film structure while also improving UV protection (157). In a separate study, Zhang et al. (176) prepared chitosan nanoparticle-based films (NCH) reinforced with alkali LNPs. The resulting NCH–LNPs composites showed increased crystallinity and thermal stability, along with a 1.5–3.4-fold increase in antioxidant capacity relative to controls. Applied to grape and cheese preservation, these films reduced lipid peroxidation and extended shelf life, underscoring their translational utility (176).

Figure 4. Preparation and characterization of chitosan (CS) composite films incorporating lignin nanoparticles (LNPs) and acylated soy protein isolate nanogels (ASPNG). The co-incorporation improved mechanical strength, barrier properties, UV-blocking, and antibacterial activity. FT-IR spectra and UV-transmittance curves confirmed functional enhancements, while SEM imaging showed uniform dispersion of LNPs and ASPNG within the CS matrix.

A similar enhancement was observed by Winotapun et al. (177), who applied CH–LNPs coatings onto bagasse paper using fractionated kraft lignin. The coatings showed nearly complete bacterial inhibition (>2 log CFU/cm2 reduction against S. aureus and E. coli), as well as enhanced hydrophobicity. These eco-friendly multilayered systems demonstrate how CH–LNPs nanocomposites can be scaled for biodegradable paper packaging, replacing synthetic wax or polyethylene layers. Zhang et al. (158) used a deep eutectic solvent (DES)-assisted antisolvent method to prepare LNPs for CH film matrices. Their composite films exhibited ~40% higher tensile strength, significantly better UV-blocking, and enhanced radical scavenging capacity. Importantly, real-food applications demonstrated 10-day extended shelf life of refrigerated grass fish, confirming functional applicability for cold-chain packaging (158).

Another compelling approach was introduced by Vijayakumar et al. (178), who employed acid precipitation to generate LNPs of ~55 nm and incorporated them into CH films. With 15% LNPs loading, tensile strength and modulus increased by 86 and 93%, respectively, while water vapor transmission dropped by 32%. The films also achieved significant UV shielding and antioxidant improvements, critical for perishables sensitive to light and oxidation (178). Recent work by Abbadessa et al. (179) further explored layer-by-layer (LbL) assembly of lignin-based polymers with chitosan onto polyethylene substrates. While not fully biobased, this method demonstrated stepwise deposition of CH/LNPs bilayers, improving oxygen and water vapor barrier properties. This highlights CH’s versatility as both a standalone film matrix and a barrier-enhancing coating layer in hybrid designs (179).

Together, these studies demonstrate a consistent structure–property relationship: LNPs contribute to tighter polymer networks via hydrogen bonding, π–π interactions, and electrostatic attraction. These interactions reduce free volume, resulting in decreased gas/moisture diffusion and improved film integrity. Furthermore, the nanoscale dispersion of LNPs enables effective light scattering, enhancing UV blocking while contributing to opacity, a desirable trait in light-sensitive packaging. Despite these advances, key challenges remain. Achieving homogeneous LNPs dispersion, avoiding aggregation, and controlling interfacial compatibility require further optimization. Moreover, while antioxidant and antimicrobial activities are promising, their long-term migration behavior and safety profiles need evaluation for regulatory compliance. Thus, chitosan–LNPs nanocomposites are among the most promising fully biobased packaging candidates. They offer multifunctional enhancements, process compatibility, and effective food preservation, making them suitable for fresh produce, seafood, dairy, and bakery applications. With ongoing innovation in LNPs synthesis and film engineering, CH-based materials are poised to play a central role in next-generation sustainable packaging.

6.2 Starch-based systems (ST matrix)

Starch (ST), a low-cost, abundant, and renewable polysaccharide, has been widely studied as a sustainable alternative to petroleum-based films. Its natural biodegradability and film-forming ability make it attractive for food packaging. However, starch films inherently suffer from poor moisture resistance, low mechanical strength, and weak barrier properties, especially under humid conditions. To address these issues, incorporation of LNPs has been explored as a biocompatible, multifunctional strategy to reinforce starch matrices.

Firouzjaei et al. (180) developed starch-based nanocomposite films incorporating LNPs (1, 3, and 5% w/w) and cinnamaldehyde (CI), a natural antimicrobial agent. Their binary (ST–LNPs) and ternary (ST–LNPs–CI) films showed marked enhancement in physical and barrier properties. Water vapor permeability (WVP) decreased from 3.97 to 3.06 × 10−1⁰ g·s−1·m−1·Pa−1, and water solubility dropped from 53.00 to 19.76%—indicative of a denser, more hydrophobic polymer network. Tensile strength improved from 3.66 to 5.15 MPa with up to 3% LNPs. However, at 5% LNPs loading, a slight decline in tensile strength was observed, suggesting nanoparticle aggregation and phase separation. This underscores the importance of maintaining uniform LNPs dispersion to avoid forming defects that compromise membrane integrity—an issue echoed across multiple biopolymer matrices (180). Santhosh et al. (181) provided further evidence of LNPs–matrix synergy using a blend of litchi seed starch (LSS) and tamarind kernel xyloglucan (XG), reinforced with LNPs. Their LSS–XG–LNPs films exhibited a tensile strength of 14.83 MPa and an elastic modulus of 0.41 GPa, a significant improvement over neat LSS films. The water vapor permeability reduced to 5.63 × 10−7 g·m−1·s−1·Pa−1, and surface hydrophobicity increased (contact angle ~80°). The enhancement was attributed to strong hydrogen bonding between starch, XG, and LNPs, as well as the phenolic content of LNPs that conferred UV shielding and antioxidant protection. Application-wise, these films effectively extended the shelf life of bananas by minimizing weight loss and discoloration, validating real-world functionality (181).

Sun et al. (182) developed starch-based composite films using LNPs derived from bamboo via green fractionation. The 2% LNPs films showed optimal performance, with tensile strength increasing from 12.1 MPa (neat film) to 48.9 MPa, and modulus rising nearly 4-fold. FTIR confirmed hydrogen bonding, while SEM and AFM showed uniform dispersion at low LNPs content but agglomeration at 5%. Thermal stability improved by ~5–8 °C, and DPPH radical scavenging rose from 13.3 to 44.8% (2%) and 70.8% (5%). UV shielding was nearly complete at 2%, and oxygen permeability halved. The 2% LNPs film effectively delayed soybean oil oxidation, demonstrating strong barrier, UV-blocking, and antioxidant properties, making it a promising bio-based packaging solution (182).

Gai et al. (137) adopted a different approach, using LNPs with cationic starch as a coating material on paper substrates. The coating improved water resistance (Cobb value: 37.5 g·m−2), oil resistance (Kit rating: 9), and tensile strength (48.93 MPa), while lowering water vapor transmission more than sixfold. The use of LNPs provided superior interfacial adhesion and barrier formation. Though this system utilized paper as a structural base, the functional layer itself was built from starch and lignin, confirming their feasibility as green barrier alternatives to fluorinated or petroleum-based coatings (137).

Across these studies, a clear structure–property–function relationship emerges. LNPs act as nanoscale reinforcers that reduce polymer mobility, tighten chain packing, and introduce antioxidant and UV-resistant properties. Their interaction with starch matrices is governed by hydrogen bonding and phenolic π-interactions, leading to improved gas barrier, optical, and mechanical properties. However, above optimal LNPs loadings (typically >3–5%), performance degradation can occur due to aggregation, emphasizing the need for dispersion control and interfacial optimization. Therefore, starch–LNPs nanocomposites represent a scalable and eco-friendly solution for biodegradable packaging films, particularly in cold-chain, moisture-sensitive, and oxidation-prone applications. As part of the broader polysaccharide matrix class alongside chitosan, cellulose derivatives, and pectin, starch’s compatibility with LNPs makes it a key contributor to the ongoing replacement of fossil-based packaging with fully biobased systems. Future directions should focus on nanoparticle surface functionalization, co-polymer blends, and migration safety to enable industrial-scale translation.

6.3 Cellulose-based systems (CL matrix)

Cellulose, the most abundant natural polymer, offers significant potential as a sustainable and biodegradable substitute for petroleum-derived packaging materials. However, pure cellulose or regenerated cellulose (RC) films often suffer from poor moisture resistance, insufficient strength, and low durability. The integration of LNPs into cellulose-based systems presents an eco-friendly strategy to overcome these limitations by leveraging LNPs’ inherent rigidity, antioxidant potential, and UV-barrier properties. Recent studies have demonstrated a clear structure–property–function relationship between LNPs and cellulose matrices, positioning these nanocomposites as highly competitive alternatives to synthetic plastics.

Amini et al. (183) synthesized all-cellulose nanocomposite (ACNC) films using a green ionic liquid-assisted and ultrasound-modified approach, incorporating 3–7 wt% LNPs. Their films exhibited enhanced UV-blocking capacity (97% at 280 nm for 7% LNPs), and increased antioxidant activity (up to 68% over the control). Mechanical strength also improved with 3 and 5% LNPs additions, but began to decline at 7%, suggesting overloading-induced aggregation. The authors noted that excessive LNPs content could reduce film uniformity and diminish antibacterial activity (e.g., 63.88% reduction in E. coli inhibition at 7% LNPs). These findings emphasize the need to optimize nanoparticle concentration for balanced multifunctionality (183). Tian et al. (184) explored the incorporation of LNPs into bacterial cellulose (BC) during fermentation. While LNPs had negligible impact on BC productivity, they significantly retarded enzymatic biodegradability, enhancing the material’s stability in humid conditions. The extent of degradation delay was influenced by the source of technical lignin. For instance, BC films containing soda LNPs degraded only ~58 wt% under high enzyme load (5 mg·g−1 BCE), compared to ~97% for deep eutectic solvent (DES)-derived LNPs. This suggests that lignin–cellulose interactions can be tuned to modulate biodegradation kinetics, expanding the application scope to packaging scenarios requiring extended shelf life (184).

Tian et al. (185) synthesized high-strength regenerated cellulose (RC) films enriched with esterified lignin nanoparticles (ELNPs). With only 5% ELNPs, tensile strength soared to 110.4 MPa, and hydrophobicity improved dramatically (water contact angle: 103.6°; WVP: 1.127 × 10−12 g·cm·cm−2·s−1·Pa−1). Water absorption dropped to 36.6% at 120 min. These enhancements were attributed to the interfacial bonding between esterified LNPs and cellulose chains, which created a dense, cohesive film network. Moreover, the films exhibited complete biodegradation under soil conditions (12–30% moisture), satisfying environmental criteria for compostable packaging. The combination of mechanical robustness and environmental degradability underscores the potential of ELNPs–RC films as next-generation bioplastics (185). García-Fuentevilla et al. (186) introduced enzymatically polymerized LNPs into cellulose nanofiber (CNF) films via a laccase pretreatment. This method reduced particle size (6.8 ± 2.4 nm), increased molecular weight, and enhanced film performance. Films with 5% polymerized LNPs showed better thermal stability, UV shielding, and antioxidant and antibacterial activity than those with unmodified lignin. The enhanced properties are attributed to both the nanoparticle size reduction and the presence of conjugated phenolic structures, which reinforced the CNF matrix at both structural and functional levels. Importantly, elongation at break and film transparency also improved, indicating minimal trade-offs in flexibility and appearance (186).

Zhao et al. (187) conducted an in-depth mechanistic study on LNPs–cellulose reinforcement. They showed that LNPs melted during hot pressing and filled voids within the CNF matrix, leading to a dense, cross-linked structure. The resulting biocomposite achieved an exceptional tensile strength of 202 MPa, Young’s modulus of 9.55 GPa, and maximum degradation temperature of 375.1 °C. Surface analysis confirmed hydrogen bonding and self-assembly between CNFs and LNPs. Contact angle measurements (~70°) and 100% UV-blocking demonstrated the film’s dual hydrophobic and photoprotective functions. These results validate that LNPs can serve as both structural enhancers and functional additives, significantly advancing cellulose-based packaging technologies (187).