- 1Key Laboratory of Intelligent Rehabilitation and Barrier-free for the Disabled (Changchun University), Ministry of Education, Changchun, China

- 2College of Food Science and Engineering, Changchun University, Changchun, China

- 3College of Food Science and Engineering, Jilin Agricultural University, Changchun, China

Introduction: As consumers continue to demand healthy diets and plant-based foods, the acceptance of bean foods, especially non-soy legumes, is gradually increasing. Since the industrial processing of non-soy legumes has just started, it has borrowed many processing strategies from soybeans. However, since the basic ingredients, processing characteristics, and nutritional properties of non-soy legumes are different from those of soybeans, their processing strategies should also be different.

Methods: This paper systematically reviews and compares the similarities and differences between processing strategies for soybeans and non-soy legumes.

Results: Several suggestions are proposed in this paper, which provide a theoretical basis and strategic recommendations for the industrial processing of non-soy legumes.

Discussion: Several issues have been raised simultaneously, and their proper resolution will contribute to the high-quality development of non-soy legumes processing industry.

1 Introduction

As consumers pay more and more attention to healthy eating and plant-based foods, bean foods, also known as legume foods, are gradually increasing their market share (Hayat et al., 2014). Soybeans, in particular, have become an important source of plant protein and plant oil for modern humans (Qin et al., 2022; Zhao et al., 2022). At the same time, with the rapid changes in the international situation, soybeans have gradually become an important resource that various countries are competing for Kong et al. (2024) and De Maria et al. (2020). The soybean industry is directly affecting the food industry (Chen et al., 2012), the feed industry, and animal husbandry (Gaffield et al., 2024), and is profoundly affecting everyone’s life. As a result, some non-soy legumes have gradually come into the eyes of consumers and processors, replacing part of the use of soybeans. Meanwhile, non-soy legumes can be developed into healthy foods (Mansouri et al., 2024; Zahradka et al., 2013), such as mung bean (Vigna radiata), pea (Pisum sativum), adzuki bean (Vigna angularis), kidney bean (Phaseolus vulgaris), chickpea (Cicer arietinum), and more (Li et al., 2017; Wang et al., 2022; Kan et al., 2017). At the same time, with the rise of plant-based foods, the excellent processing characteristics and nutritional properties of bean foods make them an excellent raw material for most plant-based foods (Ashraf et al., 2024; McClements and Grossmann, 2021). Bean food processing has gradually become an important part of the modern food industry.

However, looking at the entire bean processing industry, there is a big gap between non-soy and soybean processing. Compared with the fully developed and modernized soybean processing industry, the non-soy legume industry mainly focuses on the application of raw grains, such as daily diet (Zahradka et al., 2013), whole seed processing (Ong et al., 2024) or simple separation of ingredients (Li et al., 2011), which lacks deep and high-value processing. Therefore, when producers consider non-soy legume processing, they will give priority to soybean processing strategies. After all, it is typical and worthy of reference, such as whether it can be used to process oils and fats, whether it can be used to separate proteins, whether the amino acid composition is reasonable, etc. Although this approach is not wrong, it lacks specificity. Chickpeas (Cicer arietinum), often used as a soybean substitute, are a typical example (de Camargo et al., 2019; Niño-Medina et al., 2017).

Non-soy legumes have their particularities in terms of raw material composition, processing characteristics, nutritional characteristics, etc. For example, adzuki beans (Vigna angularis) are ingredients of Medicine Food Homology (MFH) in traditional Chinese medicine (Sun et al., 2021), mung beans (Vigna radiata) have a high starch content (Li et al., 2011), faba beans (Vicia faba) have a high content of non-nutritional compounds (NNC) (Corzo-Ríos et al., 2022), and chickpea (Cicer arietinum) protein is less allergenic than soybean protein (Verma et al., 2013). Although they cannot be part of the daily diet like soybeans (due to insufficient protein and fat content, unbalanced amino acid composition, lack of key nutrients, etc.), the differences between the beans make them worthy of processing. Using a unified processing strategy will cause the disappearance of product characteristics and even the waste of functional ingredient resources, which is unreasonable. For example, in the process of soybean processing, organic solvents are often used to extract oils (Gasparetto et al., 2022), and acids and alkalis are used to prepare soy protein isolate (SPI) (Jiang et al., 2009). This process will be fatal to the retention of functional ingredients in non-soy legumes.

This review briefly describes the processing strategies of soybean foods, summarizes some guidelines applicable to the processing of non-soy legumes, and gives some differentiation suggestions on processing strategies applicable to different non-soy legumes by systematically summarizing the basic characteristics and processing variability of non-soy legumes, and briefly describes the pros and cons of each processing strategy. To provide some suggestions for processors, meanwhile, give some references and directions for researchers.

2 Search strategy

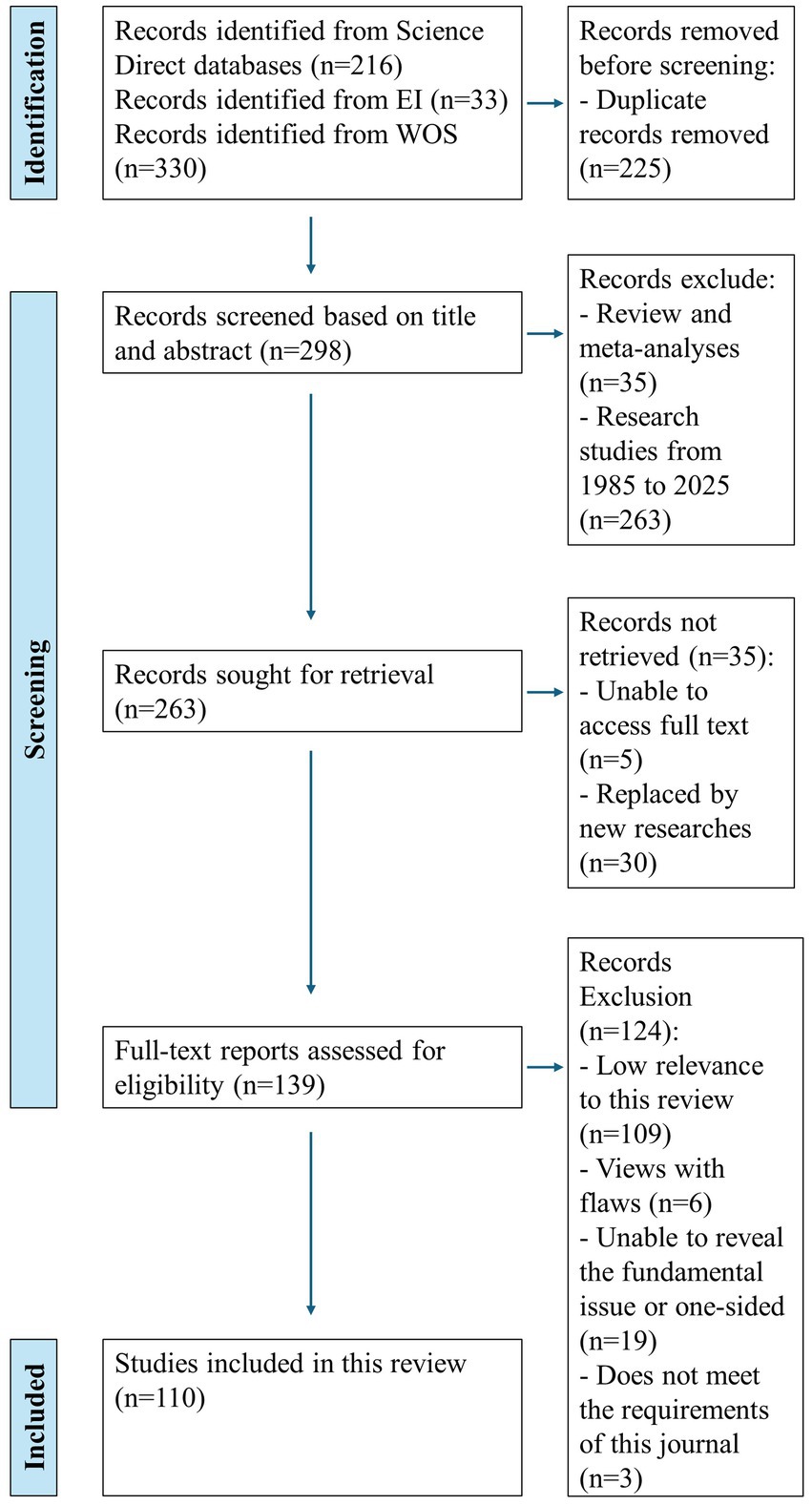

To identify eligible studies, we screened published articles related to non-soy and soybean processing. A preliminary search was conducted across 5 databases (Science Citation Index [SCI], Science Citation Index Expanded [SCIE], The Engineering Index [EI], Web of Science [WOS], and Science Direct databases) using keywords relevant to this article, such as Soybean; Non-soy Legume; Processing; Health; Nutrition; Ingredient, and so on. Based on the preliminary search, the researchers conducted the PRISMA selection flowchart (Figure 1). After removing duplicates and excluding studies with low relevance, this review included 110 literatures.

3 Overview of soybean processing strategies and the guidance

3.1 Soybean processing

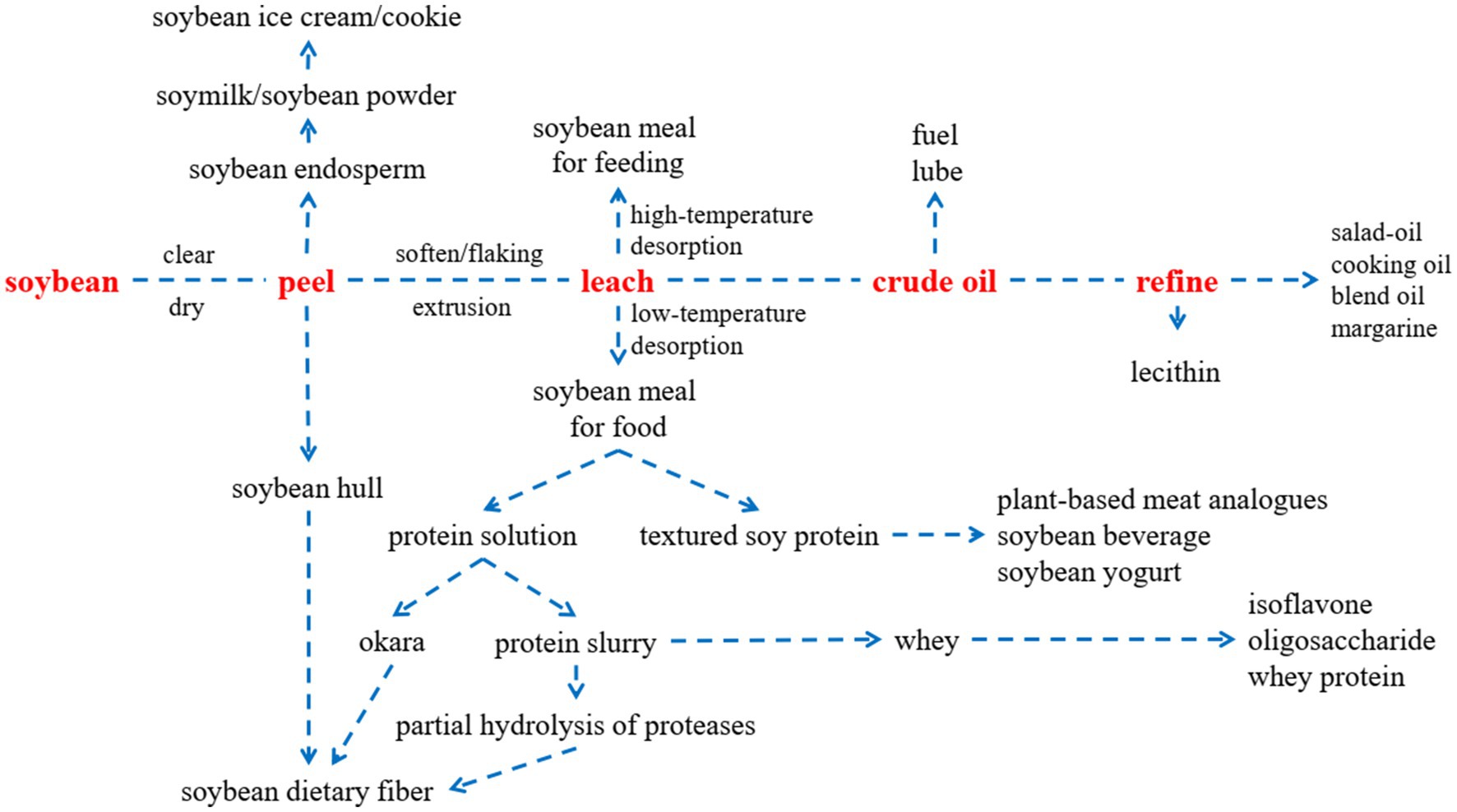

The soybean processing industry has become a representative full-chain industry. A simplified chain of soybean processing is shown in Figure 2 (Lyu et al., 2023). If we regard oil processing as the main chain, in addition to edible oil, many “by-products” will be produced, such as soybean hull, soy meal, whey, etc. (Lyu et al., 2023). But in fact, the value of these “by-products” may far exceed that of edible oil. Among them, soybean hull becomes the main raw material for preparing polysaccharides and dietary fiber (Liu et al., 2016), soybean meal is processed into soybean protein and feed (Wang et al., 2004; Mukherjee et al., 2016), soybean dregs are the raw material for producing insoluble dietary fiber (Lyu et al., 2021), and soybean whey can be used to separate functional substances such as isoflavones and whey protein (Chua and Liu, 2019; Hu et al., 2024). Therefore, in recent years, it has been customary to divide the soybean processing strategies chain into three parts, namely, oil processing, traditional soy product processing, and new product processing (including soy protein), to better describe and position the soybean processing strategy.

Figure 2. The chain of soybean processing (Lyu et al., 2023).

3.2 Soybean processing strategy

3.2.1 Stepwise processing

A notable feature of the soybean processing strategies is stepwise processing. Although there is no official definition of this concept, this feature or strategy is indeed being implemented throughout the entire industrial chain.

Taking food processing as an example (different from feed processing), soybeans need to be peeled before oil extraction, and soybean meal is produced after deoiling, and neither of them is discarded; soybean hull is generally used to produce soybean dietary fiber (Li L. et al., 2022), soybean polysaccharides (Han et al., 2021), and cellulose (Tummino et al., 2023), which almost uses up all the available resources in the hull; soybean meal directly enters the next level of the protein processing chain. After acid–base extraction or alcohol extraction, soybean meals can be used to obtain soy protein isolate (SPI) or soy protein concentrate (SPC), which become important raw materials for food processing (van den Berg et al., 2022). This process produces two main “by-products,” soybean whey and okara (also named soybean dregs). Soybean whey is mainly used to produce whey protein (Hu et al., 2024), extract trypsin heterojunctions and β-amylase (Zhang et al., 2022; Yao et al., 2024), while dregs are mainly used to separate small molecule peptides and dietary fiber (Fang et al., 2021; Wang et al., 2021). The above-mentioned end products can all be used as food raw materials or even developed into healthy food raw materials with potential physiological functions.

The processing and refining process of oils (the main chain of soybean processing) will also produce certain “by-products,” such as crude oil, oil sediment, oil deodorized distillates, etc., which are also used as industrial raw materials. For example, crude oil is processed into fuel oil and lubricating oil (Topare and Patil, 2021), oil sediment is used to separate phospholipids for use as food raw materials (Allegretti et al., 2021), and oil deodorized distillates are processed into biodiesel, vitamin E, phytosterols and fatty acids (Bezerra et al., 2022; Lv et al., 2021; Vernier et al., 2022). The above stepwise processing realizes the transformation and upgrading of soybeans from food raw materials to industrial raw materials.

3.2.2 High-value utilization

Another major feature of the soybean processing strategies is high-value processing. Due to its food properties, nearly half of soybeans are consumed directly as daily food, such as soy milk, which results in low economic benefits. However, due to the special value of soybeans in the international market, processors often hope to create higher economic value through high-value processing. The high-value processing of soybeans is reflected in the following three aspects:

The first is the specialization of soybean varieties. Many studies have shown that the composition of soybean raw materials has a huge impact on the processing characteristics, nutritional properties, and quality of the product. For example, the protein composition of the raw materials affects the gelation properties of SPI (Fu et al., 2023), and β-conglycinin has the potential to regulate lipid metabolism (Fu et al., 2022). A similar situation exists in the field of edible oils. For example, compared with triglycerides, the intake of diglycerides has less impact on the health of the body (Lai et al., 2022). In traditional processing, it is common to use different processing techniques to change the quality characteristics and nutritional properties of the product. However, this process has great uncertainty and may reduce the activity of the product due to the introduction of severe processing conditions, which has made people gradually realize the importance of precise use of raw materials to improve product quality. At present, soybeans with high β-conglycinin content and odor-free (lipoxygenase deficient) have been launched, and their value has been proven (Liu S. et al., 2022; Wang et al., 2020). The use of these special raw materials will improve the processing and nutritional properties of the products and create higher economic value.

The second is the comprehensive utilization of processing by-products. The by-product is a common key issue in the soybean processing industry and also in the food processing field. By-products represented by soybean dregs and soybean whey (also known as yellow pulp water in traditional soy products) cause serious environmental pollution and waste of resources. In traditional processing mode, soybean dregs are often directly used as animal feed and have almost no economic value. However, with the application of new food processing technologies, such as enzyme engineering (Lyu et al., 2021), bean dregs can be processed into food raw materials such as dietary fiber, which can be used as functional food material (Wang et al., 2023), and pet products such as cat litter (Vaughn et al., 2023), which greatly increases the added value. The problem of yellow pulp water is even more serious because, in the traditional processing industry, it not only fails to create value but also requires huge economic costs to be invested in treatment to meet emission standards. However, with the application of new technologies such as membrane separation, it is possible to separate whey protein, isoflavones, and oligosaccharides, creating an opportunity to create greater economic value (Chua and Liu, 2019). At the same time, with the preparation of harmless yellow pulp water (Chen et al., 2024), its processing cost will also be reduced. The high-value utilization of by-products has become inevitable.

The last is the development of new plant-based foods with soybeans as the main raw material. Plant-based food is not a new concept. People in China and East Asia have had a long tradition of plant-based diets. However, today, producers and consumers have given new value to plant-based foods (McClements and Grossmann, 2024), such as avoiding hormone risks, lowering cholesterol, and reducing dependence on livestock farming. Soy protein has become the core raw material for plant-based food processing due to its excellent processing and nutritional properties (Qin et al., 2022). The application scope and potential value of SPI and SPC have been greatly improved compared with soybean raw materials, and processing them into end products has made them truly high-value processing. Meanwhile, the use of technologies such as screw extrusion can upgrade by-products into new plant-based food raw materials while enhancing their nutritional properties (Shen et al., 2024), which is expected to truly turn waste into treasure.

3.2.3 Differentiated competition

The choice of processing materials best reflects the differentiated competition in the soybean industry. On the one hand, as mentioned earlier, the most suitable raw materials should be selected according to the product that makes the best use of different raw materials and achieves maximum utilization of resources. On the other hand, from a macro perspective, genetically modified (GMO) and non-genetically modified (non-GMO) soybeans are also engaging in differentiated competition. Although GMO soybeans offer certain advantages, such as indirect yield increases and reduced cultivation costs, they also present disadvantages due to biosafety concerns, particularly in food processing. At present, there are still many countries and regions that do not allow the cultivation of GMO soybeans or their use in food processing, such as China, Japan, and some EU countries. However, as international food trade continues to deepen, the above-mentioned countries and regions also need to import GMO soybeans. As a result, GMO soybeans are used to process feed and oils, while non-GMO soybeans are used to process food, which has become mainstream. This differentiated competition also enables the full utilization of global soybean resources.

Product segmentation is also an effective means to achieve differentiated competition. Taking traditional soy products as an example, there are many processed products using soy milk as raw material, such as tofu, dried tofu, bean curd sticks, fermented soy milk, various plant beverages, and so on (Golbitz, 1995). Fermented soy products are even more so. Various condiments have become an indispensable part of consumers’ daily diet, such as soy sauce, douchi, natto, and bean paste (do Prado et al., 2022). SPI is also processed into products with different processing characteristics, such as gel type, emulsification type, etc., to meet the processing needs of different products (Zheng et al., 2022; Liu G. et al., 2022).

The advantages of differentiated competition are reflected in three aspects. First, it greatly increases consumers’ selectivity in products, which helps to continuously increase the market share of soybean products. Second, it deeply binds daily diets with soybean products, cultivates consumers’ consumption habits, and improves the industry’s ability to resist risks. Third, it gives producers the power and autonomy to decide on products, effectively avoiding internal competition in the industry. This is also an important strategy worth learning in the non-soy legume processing industry.

3.2.4 Transformation from tradition to modernity

The soybean processing industry is both traditional and modern. On the one hand, soybean cultivation and processing have a long history and have become a characteristic industry in some countries and regions; on the other hand, with the increase in market demand, the soybean industry is also one of the first industries in the food processing field to integrate modern processing technology. Traditional processing methods include pressing, grinding, etc., which are used to produce soy milk and edible oil and are still in use today (Vishwanathan et al., 2011; Moses, 2014). Based on classic traditional processing technology, the application of modern processing technology has gradually been integrated into all links of the soybean processing industry chain. For example, sprouting soybeans before processing can enrich the nutrients in the product (Hu et al., 2022), synchronous preparation of oil and protein using enzyme-assisted aqueous method (Tong et al., 2020; Qian et al., 2010), preparation of dietary fiber from soybean dregs using a combined-enzyme method (Lyu et al., 2021), use membrane separation technology to separate functional components from soybean whey (Chua and Liu, 2019), use screw extrusion technology to prepare textured protein as a raw material for plant-based foods (Lyu et al., 2022), etc. Meanwhile, some new microorganisms (Peng et al., 2023), enzymes (Huang et al., 2022), and other raw materials (Tong et al., 2022) that contribute to product quality are also used in soy product processing to improve product quality. In short, the soybean processing industry has achieved a transformation from tradition to modernity in terms of raw materials, processing technology, and end products.

3.3 The strategies in guiding the processing of non-soy legumes

Since both soybeans and non-soy legumes are legumes, their processing strategies share many similarities, even though their composition can vary greatly. For example, most legumes are high-quality sources of plant protein and can be used in the production of protein-based foods, all contain many potential functional ingredients and can be used as potential raw materials for functional foods, and the by-products generally contain a large amount of dietary fiber, etc. Therefore, in the field of non-soy legume processing, many soybean processing strategies can be used as reference, such as high-value utilization and stepwise processing, which can significantly improve the traditional processing mode of non-soy legumes that are mainly used as raw grains.

However, due to the great differences in the composition of non-soy legumes and between non-soy legumes and soybeans, their processing strategies should be different. For example, most non-soy legumes cannot be used for oil processing, so new main chains should be found during the stepwise processing. Many non-soy legumes have a high starch content, which will put forward new requirements for the processing technology during the processing. Meanwhile, the functional ingredients of non-soy legumes are generally higher than soybeans, so some strong processing conditions are not suitable for non-soy legumes. Representative and food-processable non-soy legumes include: Mung Bean (Vigna radiata), Pea (Pisum sativum), Adzuki Bean (Vigna angularis), Kidney Bean (Phaseolus vulgaris), and Chickpea (Cicer arietinum). The five non-soy legumes mentioned above exhibit significant differences in processing strategies when compared to soybeans.

4 Differences in processing strategies for non-soy legumes compared to soybeans

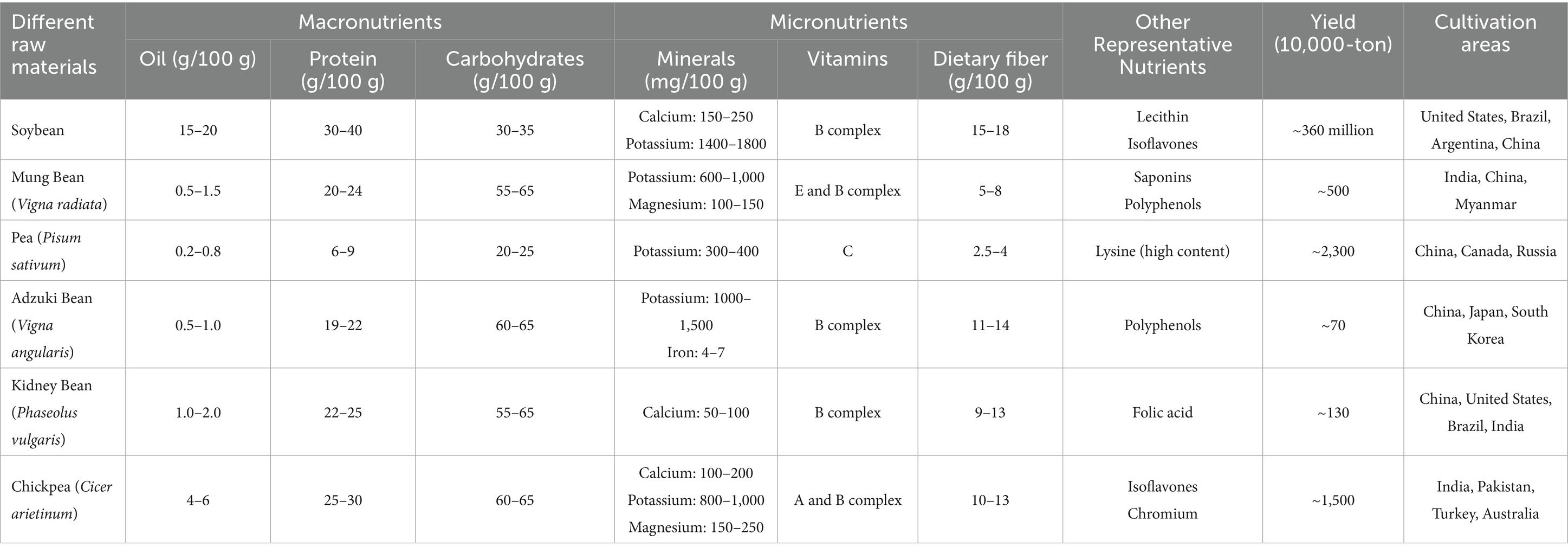

The reasons for the differences in processing strategies for soybeans and non-soy legumes are multifaceted, including but not limited to the following: primary ingredients, processing applications, functional components, extent of by-product creation, as well as various factors that could potentially influence the differences between the soybeans and non-soy legumes, such as yield and production regions. The nutritional composition, yield, and main cultivation areas of soybeans and representative non-soy legumes are shown in Table 1. How to transform the differences between the soybeans and non-soy legumes into precise high-value processing pathways is the core reason for formulating different processing strategies.

4.1 Differences in processing strategies for the main components of non-soy legumes

As mentioned, soybeans are the predominant source of plant-based protein and oil supply, but non-soy legumes vary considerably from this. While some non-soy legumes can still be used as a source of protein, such as peas, very few can be used as a source of fats and oils. In contrast, peas, mung beans, and kidney beans are all considered good sources of starch (Ratnayake et al., 2002; Abdel-Rahman et al., 2008; Punia et al., 2020), so starch processing should be recognized as the mainstay of non-soy legume processing, rather than protein and oil. The change in the main components then brings about a change in the processing strategy, a change that has had both beneficial and detrimental effects.

Advantageously, the processing of starch is much softer compared to the processing of oils, i.e., it does not involve the use of organic solvents, which brings with it a variety of advantages. First, food safety risks have improved significantly. Organic solvent residues in edible fats and oils have always been a food safety risk factor (Ghouila et al., 2019), and their removal has become an important part of the processing. In contrast, this process is virtually non-existent in the processing of non-soy legumes, and the resulting food safety risk factors do not exist. Second, mild processing conditions help retain the activity of functional ingredients. Functional components in non-soy legumes will be discussed later, but one thing is the same, functional performance scores are highly sensitive to processing. This makes non-soy legumes even more promising for high-value processing, i.e., processing into health foods and their ingredients, which may have a direct impact on the end use of the ingredient, as well as on consumer acceptance of the product. It’s also worth noting that non-soy legumes have almost no odor troubles. Soybeans generally have an off-flavor or soy-like odor that comes from the oxidation of lipids by lipoxygenase (Davies et al., 1987; Tian and Hua, 2021). Non-soy legumes, on the other hand, do not inherently possess this property.

Changes in processing due to changes in ingredient composition are not always an advantage, which is reflected in two potential aspects. On the one hand, there may be obstacles to the efficient separation and high-value utilization of by-products. The stepwise processing strategy of soybeans is a complex process, but it achieves a high utilization of raw materials, and the by-products can be used as feedstock for the next stage of processing at a lower cost. But this situation is costly for non-soy legume processing. Functional ingredients such as soy dietary fiber, whey protein, and isoflavones can usually be prepared using by-products of soybean processing (Lyu et al., 2021; Chua and Liu, 2019; Nile et al., 2021), but functional ingredients in miscellaneous grains, such as polyphenols in adzuki bean (Mukai and Sato, 2009), require a separately designed process to be used for their preparation. Even the seed coat of non-soy legumes is not viewed as a by-product, as consumers are accustomed to eating whole legumes. On the other hand, consumption and pollution caused by processing may be higher. While organic solvents and strong acids and bases used in soybean processing are potential sources of contamination, recycling strategies for various processing aids are sufficiently robust. For example, in soybean oil processing, the recovery of hexane is considered to be efficient and cost-effective (Gasparetto et al., 2022). The contaminant in non-soy legume processing is almost always contaminated water. Instead, wastewater management is one of the most important issues to be addressed in the food processing industry (Shrivastava et al., 2022). By the same token, the more pollution, the higher the consumption. The reason why the contamination issue is not given enough attention is maybe because the amount of processing of non-soy legumes is much smaller compared to soybeans. However, this does not mean that it is a problem to be ignored in industrial scale-up processing.

Therefore, as the non-soy legume processing industry is gradually taking shape, it makes sense to develop different refined processing strategies based on the differences in major components, which will contribute to the efficient green transformation of the industry.

4.2 Differences in whole-seed processing and staple food processing

The immediate impact of the compositional differences is the difference in processing patterns between soybeans and non-soy legumes. Although soybeans have also been subjected to some whole-seed processing, the purpose of processing for both has changed markedly compared to that of non-soy legumes.

The core objective of soybean processing is to separate the oils and proteins for use in the processing of other complex food systems, even if the primary processed products, such as soymilk and tofu, are not used as staple foods. So there is little concept of staple food processing for soybeans, and whole-seed processing is not intended to improve product quality or nutritional properties, but rather as a way to reduce by-product emissions (Lusas, 2004; Singh and Krishnaswamy, 2022; Karim et al., 2025).

The core objective of processing non-soy legumes is to address their difficulty in cooking and to make them a staple food as an alternative to refined rice and flour. Almost all non-soy legumes have the habit of being consumed directly as a staple food, maximizing the nutrients in them and enhancing the functionality of the staple food. As a carrier of high-quality carbohydrates, dietary fiber, and micronutrients, the consumption of non-soy legumes effectively optimizes the dietary structure of consumers (Bazzano et al., 2011). Non-soy legumes are also processed in whole-seed mode, for example, adzuki bean and mung beans can be directly processed into whole-bean paste and consumed (Han et al., 2020; Huang et al., 2024), peas are directly processed into frozen vegetables (Samoilov et al., 2021), kidney beans and chickpeas can be processed into canned goods (Dahl et al., 2014; Parmar et al., 2016), and so on. The implications of this model are also twofold. Advantageously, this mode of processing greatly reduces processing costs and processing losses and maximizes nutrient retention, which is one of the main reasons for the gradual increase in consumer acceptance of non-soy legumes. In contrast, however, this processing model may not be conducive to the long-term development and high-quality transformation of the industry. Simple processing strategies have prevented the non-soy legume industry from escaping the dilemma of primary processing, especially for the main production areas of non-soy legumes, which can bring limited economic benefits.

Some attempts have been made by the processing industry, such as using peas to prepare isolated protein (Lam et al., 2018), using adzuki beans to make beverages (Li H. et al., 2022), and using kidney beans to prepare α-amylase (Liu et al., 2024), etc. This provides a reference case for the high-value utilization of non-soy legumes. Whether the processing of non-soy legumes can find a balance between traditional food processing and new food processing, may be a new challenge.

4.3 Differences in the retention of functional ingredients during processing

The macronutrients in soybeans should be considered oils and proteins, which are the most critical components of soybeans as a major plant-based food ingredient. The typical micronutrients in soybeans include soy isoflavones, soy saponins, vitamins, and more. Differences in consumption habits and processing strategies lead to a completely different conception of macronutrients and micronutrients, with consumers consuming processed soy products without much regard for their health attributes, but more for the macronutrients’ basic function in the body’s metabolism. Even if some consumers are aware of the functionality of the micronutrients in soybeans, they are more inclined to consume higher-value products, such as health foods containing soy isoflavones, rather than simply consuming soybeans. Therefore, as mentioned earlier, the processing strategy for soybeans does not take into account the retention of functional constituents and also results in a large number of functional constituents becoming inactive with processing. Therefore, as mentioned, the processing strategy for soybeans does not take into account the retention of functional constituents and also results in a large number of functional constituents becoming inactive with processing. Non-soy legumes processing is just the opposite; people consume non-soy legumes more for nutritional retention and health needs.

For example, the polyphenols in peas have significant antioxidant, anti-inflammatory, and anticancer activities, and saponins have been reported to have cholesterol-lowering properties (Dahl et al., 2012; Singh et al., 2017). Combined with the highly digestible and hypoallergenic properties of its protein (Guillin et al., 2022; Shanthakumar et al., 2022), and the role of dietary fiber in promoting intestinal health (Hashemi et al., 2017), peas are most commonly processed by flash-freezing them to become a frozen vegetable, to maximize the retention of their functional components. In addition to the above ingredients, adzuki beans have additional flavonoids and alkaloids, which also have the same antioxidant, anti-inflammatory and other benefits, yielding potential applications in the medical field (Agarwal and Chauhan, 2019; Liu et al., 2017; Briguglio et al., 2018). This has led to adzuki beans being used in more healthcare applications, such as in traditional Chinese medicine, in addition to being processed into beverages or whole-seed processing. Mung beans also exhibit functions and applications similar to those described above (Hou et al., 2019). Kidney beans, which occupy a significant portion of international trade, also contain functional substances such as quercetin and more, which are important reasons why they are a favored source of plant-based food ingredients (Zhang et al., 2025; Kimothi and Dhaliwal, 2020). Complemented by its protein, starch, dietary fiber, excellent processing characteristics, and nutritional properties, kidney bean processing in the field of non-soy legumes reflects the obvious high value attributes. Meanwhile, there is also a trend towards staple foods and the daily consumption of kidney beans.

The presence of the above functional constituents places new demands on the processing strategies of non-soy legumes. The first is the necessity of non-thermal/low-temperature processing; most of the micronutrients mentioned above are thermosensitive, and functional macronutrients such as kidney bean proteins may also be thermally denatured. How to ensure the efficient retention of functional components puts higher requirements on all aspects of processing, storage, and logistics of non-soy legume products, compared to soybeans. The second is the necessity of non-vigorous processing. Soybeans and some staple grains are usually processed very vigorously, such as the consumption of sodium hydroxide, hydrochloric acid, organic solvents, etc., which is fatal to the retention of functional substances in the non-soy legumes. Novel processing technologies that are non-vigorous and allow for the preparation of macronutrients and retention of micronutrient activity are necessary. The third is that the use of biotechnology to achieve the separation of different components in the non-soy legumes is necessary. The soybean processing industry has begun such as enzyme-assisted aqueous extraction for simultaneous production of protein and oil and other prospective research (Tong et al., 2020), but limited by the amount of processing and enzyme costs, has not been put into production on a large scale. However, non-soy legumes are feasible to utilize biotechnology to achieve retention of functional components due to low processing requirements (compared to soybeans), strong health attributes, and high added value.

4.4 Different pathways for the use of non-soy legume by-products

Differences in processing strategies for by-products resulting from soybean processing and non-soy legumes processing similarly stem from differences in the composition of the by-products. The main by-products of soybean processing are whey and soybean dregs, whose core components should be regarded as protein and fiber (except for water). So the main pathway for the soybean by-products processing, i.e., feed. If used in food, it is used as a raw material for dietary fiber, functional peptides, and some other functional ingredients (Hu et al., 2024; Fang et al., 2021; Wang et al., 2021). That is, a pattern of closed loops within the processing chain is formed.

However, due to the non-soy legume processing strategy, it is difficult to define what the main chain of non-soy legume processing is, and it is not possible to precisely define what the by-products are. For example, soybean meal is a core by-product of soybean oil processing, and soybean dregs are a core by-product of protein. But in the field of non-soy legumes, there is no such concept. So non-soy legume processing by-products are mainly some seed coat and residue, with high fiber, high starch, and low protein as the main characteristics. There is a lack of systematic processing strategies for these by-products, for example, peas and other legumes with seed coats, which are often discarded directly or used as feed or fertilizer, with low added value. Adzuki beans, a category of legumes with color, are processed in wastewater that is barely used for processing, even though they contain some natural coloring. Only some product residues have the potential to be used in secondary processes.

Therefore, there is some uncertainty in the by-product processing strategy of non-soy legumes, which focuses more on the transformation of basic substances and lacks systematic high-value utilization. There is an urgent need to find effective strategies and ways to efficiently extract functional ingredients, upgrade to food raw materials, environmental protection, and green processing of non-soy legume by-products.

4.5 Allergenicity and anti-nutritional factors of non-soy legumes

Food safety issues cannot be ignored in the development of processing strategies. The allergenicity and anti-nutritional factors are the main endogenous food safety risk factors of soybeans and non-soy legumes.

Soybean is one of the top eight allergenic foods published by the Food and Agriculture Organization of the United Nations (FAO), and its allergenicity is triggered mainly by a variety of heat-stable proteins (L'Hocine and Boye, 2007). This may also be one of the reasons why some consumers whose diets are dominated by foods of animal origin have so far been unable to accept soybean. But in reality, processes greatly mitigate the allergenicity of soybean, such as thermal processing and fermentation (Pi et al., 2021; Franck et al., 2002). In contrast, a certain diversity of allergens exists for non-soy legumes. Examples include bran (esp. of cereals), α-amylase, trypsin inhibitors, and more (Satoh et al., 2019; Calcinai et al., 2022; Abu Risha et al., 2024). Meanwhile, although the allergenicity of non-soy legumes is relatively low, there is some cross-reactivity, for example, Vicilin and Convicilin in peas are structurally similar to peanut allergens (Sanchez-Monge et al., 2004), and chickpea allergy is associated with lentils, peas, and so on (Bar-El Dadon et al., 2014). Another thing to keep in mind is that while the allergenicity of a particular type of non-soy legume may be low, it is common to consume multiple types of non-soy legumes at the same time due to dietary habits. Whether there are interactions or cumulative effects between different allergens is also an important food safety issue. The allergic problems mentioned above should also be addressed with processing.

Anti-nutritional factors are also an important issue in plant-based foods. On the one hand, protein-based anti-nutritional factors are potential allergens, and there is a cumulative effect of them, and on the other hand, the presence of anti-nutritional factors restricts the body’s absorption of nutrients, which reduces the health benefits of consuming non-soy legume foods. Anti-nutritional factors in soybeans include protease inhibitors, plant lectins, and phytic acid (Di et al., 2024), in addition to tannins (e.g., in mung beans) and oxalic acid (e.g., in quinoa) in non-soy legumes (Dahiya et al., 2015; Filho et al., 2017). It can be said that the risk of anti-nutritional factors is higher in non-soy legumes than in soybeans.

It is feasible to address allergenicity and anti-nutritional factors using rational processing methods, such as removing or breaking down allergens and anti-nutritional factors using physical methods such as heat treatment, soaking, rinsing, shelling, etc., and transforming or metabolizing both of the above using biological methods such as fermentation and sprouting, and studies have emerged on the above methods (Verma et al., 2012; Poms and Anklam, 2004; Oyedeji et al., 2018; Ampofo and Abbey, 2023). In addition, with the continuous development of breeding techniques, the selection of raw materials with hypoallergenic and low anti-nutritional factors has become possible. This will also help reduce the stress and cost of food processing.

It is also important to note that, in addition to the production and processing of both soybeans and non-soy legumes, risk management for special populations during consumption is necessary, such as infants, young children, and allergy-prone individuals. End-products aimed at the above groups should be formulated with a processing strategy that strictly removes allergens and anti-nutritional factors, or at least identifies them on the packaging if there are difficulties.

In summary, the development of scientific processing strategies for different raw materials is of great significance to the development of the processing industry and the improvement of the health level.

5 Conclusion

This article provides a brief review of the similarities and differences in the processing strategies of soybean processing and non-soy legume processing, and incorporates some arguments. As high-quality plant-based food ingredients, both have made significant contributions to stabilizing the human diet and safeguarding human health. However, due to the differences in their processing strategies, the development of their industries is also different. It is hoped that the issues mentioned above will provide some inspiration and suggestions for producers and researchers, with a view to the high-quality development of the non-soy legume industry in a way that is different from the characteristics of soybeans.

Author contributions

TL: Writing – original draft, Writing – review & editing. MW: Data curation, Writing – original draft. YS: Supervision, Writing – original draft. BL: Funding acquisition, Supervision, Writing – original draft.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was funded by the Key Laboratory of Intelligent Rehabilitation and Barrier-free for the Disabled (Changchun University), Ministry of Education (2024KFJJ002) and Jianghuai Coarse Cereals Industry Engineering Technology R&D and Innovation Base Project of China (2025024).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdel-Rahman, E.-S. A., El-Fishawy, F. A., El-Geddawy, M. A., Kurz, T., and El-Rify, M. N. (2008). Isolation and physico-chemical characterization of mung bean starches. Int. J. Food Eng. 4, 1–12. doi: 10.2202/1556-3758.1184

Abu Risha, M., Rick, E.-M., Plum, M., and Jappe, U. (2024). Legume allergens pea, chickpea, lentil, lupine and beyond. Curr Allergy Asthma Rep 24, 527–548. doi: 10.1007/s11882-024-01165-7

Agarwal, S., and Chauhan, E. S. (2019). Adzuki beans-physical and nutritional characteristics of beans and its health benefits. Int. J. Health Sci. 9, 304–310.

Allegretti, C., Bono, A., D'Arrigo, P., Gatti, F. G., Marzorati, S., Rossato, L. A., et al. (2021). Exploitation of soybean oil acid degumming waste: biocatalytic synthesis of high value phospholipids. ChemistrySelect 6, 9157–9163. doi: 10.1002/slct.202102191

Ampofo, J., and Abbey, L. (2023). “Sprouted legumes: biochemical changes, nutritional impacts and food safety concerns” In: Majid, I., Kehinde, B.A., Dar, B., Nanda, V. (eds) Advances in Plant Sprouts. (Cham: Springer). doi: 10.1007/978-3-031-40916-5_7

Ashraf, Z., Gani, A., Shah, A., and Gani, A. (2024). Techno-functional characterization of pulse proteins (broad bean, mung bean, and lentil bean) as sustainable plant-based meat and dairy alternatives. ACS Food Sci. Technol. 4, 1341–1351. doi: 10.1021/acsfoodscitech.3c00657

Bar-El Dadon, S., Pascual, C. Y., and Reifen, R. (2014). Food allergy and cross-reactivity-chickpea as a test case. Food Chem. 165, 483–488. doi: 10.1016/j.foodchem.2014.05.138

Bazzano, L. A., Thompson, A. M., Tees, M. T., Nguyen, C. H., and Winham, D. M. (2011). Non-soy legume consumption lowers cholesterol levels: A meta-analysis of randomized controlled trials. Nutr. Metab. Cardiovasc. Dis. 21, 94–103. doi: 10.1016/j.numecd.2009.08.012

Bezerra, I. D., Belisário, C. M., Favareto, R., Taham, T., and Castejon, L. V. (2022). Industrially concentrated tocopherols from soybean oil deodorizer distillate. Braz. J. Food Technol. 25:e2021156. doi: 10.1590/1981-6723.15621

Briguglio, M., Dell’Osso, B., Panzica, G., Malgaroli, A., Banfi, G., Zanaboni Dina, C., et al. (2018). Dietary neurotransmitters: a narrative review on current knowledge. Nutrients 10:591. doi: 10.3390/nu10050591

Calcinai, L., Bonomini, M. G., Leni, G., Faccini, A., Puxeddu, I., Giannini, D., et al. (2022). Effectiveness of enzymatic hydrolysis for reducing the allergenic potential of legume by-products. Sci. Rep. 12:16902. doi: 10.1038/s41598-022-21296-z

Chen, J., Cai, L., Huang, X., Fu, H., Sun, L., Yuan, C., et al. (2024). Mathematical modeling of optimal coagulant dosage for tofu preparation using MgCl2. Food Chem. X 21:101137. doi: 10.1016/j.fochx.2024.101137

Chen, K.-I., Erh, M.-H., Su, N.-W., Liu, W.-H., Chou, C.-C., Cheng, K.-C., et al. (2012). Soyfoods and soybean products: from traditional use to modern applications. Appl. Microbiol. Biotechnol. 96, 9–22. doi: 10.1007/s00253-012-4330-7

Chua, J.-Y., and Liu, S.-Q. (2019). Soy whey: more than just wastewater from tofu and soy protein isolate industry. Trends Food Sci. Technol. 91, 24–32. doi: 10.1016/j.tifs.2019.06.016

Corzo-Ríos, L., Jiménez-Martínez, C., Cid-Gallegos, M., Cardador-Martínez, A., Martínez-Herrera, J., Sánchez-Chino, X. M., et al. (2022). Chemical and non-nutritional modification of faba bean (Vicia faba) due to the effect of roasting and boiling. Int. J. Gastron. Food Sci. 30:100622. doi: 10.1016/j.ijgfs.2022.100622

Dahiya, P., Linnemann, A., Van Boekel, M., Khetarpaul, N., Grewal, R., and Nout, M. J. R. (2015). Mung bean: technological and nutritional potential. Crit. Rev. Food Sci. Nutr. 55, 670–688. doi: 10.1080/10408398.2012.671202

Dahl, W. J., Foster, L. M., and Tyler, R. T. (2012). Review of the health benefits of peas (Pisum sativum L.). Br. J. Nutr. 108, S3–S10. doi: 10.1017/S0007114512000852

Dahl, W. J., Hanifi, A., Zello, G. A., and Tyler, R. T. (2014). Gastrointestinal tolerance to daily canned chickpea intake. Can. J. Diet. Pract. Res. 75, 218–221. doi: 10.3148/cjdpr-2014-018

Davies, C., Nielsen, S., and Nielsen, N. C. (1987). Flavor improvement of soybean preparations by genetic removal of lipoxygenase-2. J. Am. Oil Chem. Soc. 64, 1428–1433. doi: 10.1007/BF02636994

de Camargo, A. C., Favero, B. T., Morzelle, M. C., Franchin, M., Alvarez-Parrilla, E., de la Rosa, L. A., et al. (2019). Is chickpea a potential substitute for soybean? Phenolic bioactives and potential health benefits. Int. J. Mol. Sci. 20:2644. doi: 10.3390/ijms20112644

De Maria, M., Robinson, E. J., Kangile, J. R., Kadigi, R., Dreoni, I., Couto, M., et al. (2020). Global soybean trade-the geopolitics of a bean. Global soybean trade - the geopolitics of a bean. Report. UK Research and Innovation Global Challenges Research Fund (UKRI GCRF) Trade, Development and the Environment Hub.

Di, D., He, S., Zhang, R., Gao, K., Qiu, M., Li, X., et al. (2024). Exploring the dual role of anti-nutritional factors in soybeans: a comprehensive analysis of health risks and benefits. Crit. Rev. Food Sci. Nutr. 19, 1–18. doi: 10.1080/10408398.2024.2430757

do Prado, F. G., Pagnoncelli, M. G. B., de Melo Pereira, G. V., Karp, S. G., and Soccol, C. R. (2022). Fermented soy products and their potential health benefits: A review. Microorganisms 10:1606. doi: 10.3390/microorganisms10081606

Fang, J., Lu, J., Zhang, Y., Wang, J., Wang, S., Fan, H., et al. (2021). Structural properties, antioxidant and immune activities of low molecular weight peptides from soybean dregs (Okara). Food Chem. X 12:100175. doi: 10.1016/j.fochx.2021.100175

Filho, A. M. M., Pirozi, M. R., Borges, J. T. D. S., Pinheiro Sant'Ana, H. M., Chaves, J. B. P., and Coimbra, J. S. D. R. (2017). Quinoa: nutritional, functional, and antinutritional aspects. Crit. Rev. Food Sci. Nutr. 57, 1618–1630. doi: 10.1080/10408398.2014.1001811

Franck, P., Moneret Vautrin, D., Dousset, B., Kanny, G., Nabet, P., Guénard-Bilbaut, L., et al. (2002). The allergenicity of soybean-based products is modified by food technologies. Int. Arch. Allergy Immunol. 128, 212–219. doi: 10.1159/000064254

Fu, H., Li, J., Yang, X., Swallah, M. S., Gong, H., Ji, L., et al. (2023). The heated-induced gelation of soy protein isolate at subunit level: exploring the impacts of α and α′ subunits on SPI gelation based on natural hybrid breeding varieties. Food Hydrocoll. 134:108008. doi: 10.1016/j.foodhyd.2022.108008

Fu, H., Shan, D., Li, J., Swallah, M. S., Yang, X., Ji, L., et al. (2022). Potential functionality of β-conglycinin with subunit deficiencies: soy protein may regulate glucose and lipid metabolism. Food Funct. 13, 12291–12302. doi: 10.1039/D2FO02869G

Gaffield, K. N., Goodband, R. D., DeRouchey, J. M., Tokach, M. D., Woodworth, J. C., Denny, G., et al. (2024). A review of soybean processing by-products and their use in swine and poultry diets. Transl. Anim. Sci. 8:txae063. doi: 10.1093/tas/txae063

Gasparetto, H., de Castilhos, F., and Salau, N. P. G. (2022). Recent advances in green soybean oil extraction: a review. J. Mol. Liq. 361:119684. doi: 10.1016/j.molliq.2022.119684

Ghouila, Z., Sehailia, M., and Chemat, S. (2019). Vegetable oils and fats: Extraction, composition and applications. In: Plant Based “Green Chemistry 2.0”. Green Chemistry and Sustainable Technology, eds. Li, Y., and Chemat, F. Singapore: Springer. 339–375.

Golbitz, P. (1995). Traditional soyfoods: processing and products. J. Nutr. 125, 570S–572S. doi: 10.1093/jn/125.suppl_3.570S

Guillin, F. M., Gaudichon, C., Guérin-Deremaux, L., Lefranc-Millot, C., Airinei, G., Khodorova, N., et al. (2022). Real ileal amino acid digestibility of pea protein compared to casein in healthy humans: a randomized trial. Am. J. Clin. Nutr. 115, 353–363. doi: 10.1093/ajcn/nqab354

Han, K.-H., Ohashi, S., Sasaki, K., Nagata, R., Pelpolage, S., Fukuma, N., et al. (2020). Dietary adzuki bean paste dose-dependently reduces visceral fat accumulation in rats fed a normal diet. Food Res. Int. 130:108890. doi: 10.1016/j.foodres.2019.108890

Han, L., Song, H., Fu, L., Li, J., Yang, L., Liu, H. J. F. S., et al. (2021). Effect of extraction method on the chemical profiles and bioactivities of soybean hull polysaccharides. Food Sci. Nutr. 9, 5928–5938. doi: 10.1002/fsn3.2483

Hashemi, Z., Fouhse, J., Im, H. S., Chan, C. B., and Willing, B. P. (2017). Dietary pea fiber supplementation improves glycemia and induces changes in the composition of gut microbiota, serum short chain fatty acid profile and expression of mucins in glucose intolerant rats. Nutrients 9:1236. doi: 10.3390/nu9111236

Hayat, I., Ahmad, A., Masud, T., Ahmed, A., and Bashir, S. (2014). Nutritional and health perspectives of beans (Phaseolus vulgaris L.): an overview. Crit. Rev. Food Sci. Nutr. 54, 580–592. doi: 10.1080/10408398.2011.596639

Hou, D., Yousaf, L., Xue, Y., Hu, J., Wu, J., Hu, X., et al. (2019). Mung bean (Vigna radiata L.): bioactive polyphenols, polysaccharides, peptides, and health benefits. Nutrients 11:1238. doi: 10.3390/nu11061238

Hu, M., Du, X., Liu, G., Zhang, S., Wu, H., Li, Y., et al. (2022). Germination improves the functional properties of soybean and enhances soymilk quality. Int. J. Food Sci. Technol. 57, 3892–3902. doi: 10.1111/ijfs.15461

Hu, M., Gao, Y., Wen, W., Zhang, P., Zhang, F., Fan, B., et al. (2024). The aggregation behavior between soybean whey protein and polysaccharides of diverse structures and their implications in soybean isoflavone delivery. Food Chem. 439:138061. doi: 10.1016/j.foodchem.2023.138061

Huang, P.-H., Cheng, Y.-T., Chan, Y.-J., Lu, W.-C., and Li, P.-H. (2024). Effect of cooking treatment on the formation mechanism and physicochemical properties of mung bean (Vigna radiata L.) paste. J. Agric. Food Res. 16:101054. doi: 10.1016/j.jafr.2024.101054

Huang, Z., Sun, J., Zhao, L., He, W., Liu, T., and Liu, B. (2022). Analysis of the gel properties, microstructural characteristics, and intermolecular forces of soybean protein isolate gel induced by transglutaminase. Food Sci. Nutr. 10, 772–783. doi: 10.1002/fsn3.2706

Jiang, J., Chen, J., and Xiong, Y. L. (2009). Structural and emulsifying properties of soy protein isolate subjected to acid and alkaline pH-shifting processes. J. Agric. Food Chem. 57, 7576–7583. doi: 10.1021/jf901585n

Kan, L., Nie, S., Hu, J., Wang, S., Cui, S. W., Li, Y., et al. (2017). Nutrients, phytochemicals and antioxidant activities of 26 kidney bean cultivars. Food Chem. Toxicol. 108, 467–477. doi: 10.1016/j.fct.2016.09.007

Karim, A., Osse, E. F., and Khalloufi, S. (2025). Innovative strategies for valorization of byproducts from soybean industry: a review on status, challenges, and sustainable approaches towards zero-waste processing systems. Heliyon 11:e42118. doi: 10.1016/j.heliyon.2025.e42118

Kimothi, S., and Dhaliwal, Y. S. (2020). Nutritional and health promoting attribute of kidney beans (Phaseolus vulgaris L.): a review. Int. J. Curr. Microbiol. App. Sci. 9, 1201–1209. doi: 10.20546/ijcmas.2020.905.134

Kong, W., Wei, M., Khan, N., Liang, J., Han, D., and Zhang, H. J. (2024). Assessing sustainable future of import-independent domestic soybean production in China: policy implications and projections for 2030. Front. Sustain. Food Syst. 8:1387609. doi: 10.3389/fsufs.2024.1387609

Lai, O.-M., Lee, Y.-Y., Phuah, E.-T., Tang, T.-K., Wang, Y., Cheong, L.-Z., et al. (2022). “Diacylglycerol oil: health benefits, synthesis and applications” In: Recent Advances in Edible Fats and Oils Technology eds. Lee, Y., Tang, TK., Phuah, ET., Lai, OM. (Singapore: Springer), 249–264. doi: 10.1007/978-981-16-5113-7_8

Lam, A. C. Y., Can Karaca, A., Tyler, R. T., and Nickerson, M. T. (2018). Pea protein isolates: structure, extraction, and functionality. Food Rev. Int. 34, 126–147. doi: 10.1080/87559129.2016.1242135

L'Hocine, L., and Boye, J. I. (2007). Allergenicity of soybean: new developments in identification of allergenic proteins, cross-reactivities and hypoallergenization technologies. Crit. Rev. Food Sci. Nutr. 47, 127–143. doi: 10.1080/10408390600626487

Li, W., Shu, C., Zhang, P., and Shen, Q. (2011). Properties of starch separated from ten mung bean varieties and seeds processing characteristics. Food and Bioprocess Technol. 4, 814–821. doi: 10.1007/s11947-010-0421-6

Li, L., Yang, T., Liu, R., Redden, B., Maalouf, F., and Zong, X. (2017). Food legume production in China. Crop J. 5, 115–126. doi: 10.1016/j.cj.2016.06.001

Li, L., Zhao, Y., Li, J., Ban, L., Yang, L., Wang, S., et al. (2022). The adhesion of the gut microbiota to insoluble dietary fiber from soy hulls promoted the proliferation of probiotics in vitro. LWT 153:112560. doi: 10.1016/j.lwt.2021.112560

Li, H., Zou, L., Li, X. Y., Wu, D. T., Liu, H. Y., Li, H. B., et al. (2022). Adzuki bean (Vigna angularis): chemical compositions, physicochemical properties, health benefits, and food applications. Compr. Rev. Food Sci. Food Saf. 21, 2335–2362. doi: 10.1111/1541-4337.12945

Liu, T., Gu, Y., Waleed, A. A., Wang, L., Li, Y., Qian, H., et al. (2024). Challenges and opportunities in developing low glycemic index foods with white kidney bean α-amylase inhibitor. Trends Food Sci. Technol. 147:104397. doi: 10.1016/j.tifs.2024.104397

Liu, G., Hu, M., Du, X., Liao, Y., Yan, S., Zhang, S., et al. (2022). Correlating structure and emulsification of soybean protein isolate: Synergism between low-pH-shifting treatment and ultrasonication improves emulsifying properties. Colloids Surf. A 646:128963. doi: 10.1016/j.colsurfa.2022.128963

Liu, C., Lin, X.-L., Wan, Z., Zou, Y., Cheng, F.-F., and Yang, X.-Q. (2016). The physicochemical properties, in vitro binding capacities and in vivo hypocholesterolemic activity of soluble dietary fiber extracted from soy hulls. Food Funct. 7, 4830–4840. doi: 10.1039/c6fo01340f

Liu, S., Luo, T., Song, Y., Ren, H., Qiu, Z., Ma, C., et al. (2022). Hypocholesterolemic effects of soy protein isolates from soybeans differing in 7S and 11S globulin subunits vary in rats fed a high cholesterol diet. J. Funct. Foods 99:105347. doi: 10.1016/j.jff.2022.105347

Liu, R., Zheng, Y., Cai, Z., and Xu, B. (2017). Saponins and flavonoids from adzuki bean (Vigna angularis L.) ameliorate high-fat diet-induced obesity in ICR mice. Front. Pharmacol. 8:687. doi: 10.3389/fphar.2017.00687

Lv, W., Wu, C., Lin, S., Wang, X., and Wang, Y. (2021). Integrated utilization strategy for soybean oil deodorizer distillate: synergically synthesizing biodiesel and recovering bioactive compounds by a combined enzymatic process and molecular distillation. ACS Omega 6, 9141–9152. doi: 10.1021/acsomega.1c00333

Lyu, B., Li, J., Meng, X., Fu, H., Wang, W., Ji, L., et al. (2022). The protein composition changed the quality characteristics of plant-based meat analogues produced by a single-screw extruder: four main soybean varieties in China as representatives. Foods 11:1112. doi: 10.3390/foods11081112

Lyu, B., Wang, F., Li, Y., Quek, S. Y., and Yu, H. (2023). Innovative high value-added processing of soybean and its by-products. Front. Nutr. 10:1240249. doi: 10.3389/fnut.2023.1240249

Lyu, B., Wang, H., Swallah, M. S., Fu, H., Shen, Y., Guo, Z., et al. (2021). Structure, properties and potential bioactivities of high-purity insoluble fibre from soybean dregs (Okara). Food Chem. 364:130402. doi: 10.1016/j.foodchem.2021.130402

Mansouri, F., de Simone, G., Bordoni, L., and Gabbianelli, R. (2024). The effects of non-soy legumes consumption on serum levels of inflammatory biomarkers and adiponectin in overweight/obese adults: a systematic review and meta-analysis of randomized controlled trials. J. Nutr. Biochem. 133:109718. doi: 10.1016/j.jnutbio.2024.109718

McClements, D. J., and Grossmann, L. (2021). The science of plant-based foods: constructing next-generation meat, fish, milk, and egg analogs. Compr. Rev. Food Sci. Food Saf. 20, 4049–4100. doi: 10.1111/1541-4337.12771

McClements, D. J., and Grossmann, L. (2024). Next-generation plant-based foods: challenges and opportunities. Annu. Rev. Food Sci. Technol. 15, 79–101. doi: 10.1146/annurev-food-072023-034414

Moses, D. R. (2014). Performance evaluation of continuous screw press for extraction soybean oil. Am. J. Sci. Technol. 1, 238–242.

Mukai, Y., and Sato, S. (2009). Polyphenol-containing azuki bean (Vigna angularis) extract attenuates blood pressure elevation and modulates nitric oxide synthase and caveolin-1 expressions in rats with hypertension. Nutr. Metab. Cardiovasc. Dis. 19, 491–497. doi: 10.1016/j.numecd.2008.09.007

Mukherjee, R., Chakraborty, R., and Dutta, A. (2016). Role of fermentation in improving nutritional quality of soybean meal—a review. Asian Australas. J. Anim. Sci. 29, 1523–1529. doi: 10.5713/ajas.15.0627

Nile, S. H., Venkidasamy, B., Samynathan, R., Nile, A., Shao, K., Chen, T., et al. (2021). Soybean processing wastes: novel insights on their production, extraction of isoflavones, and their therapeutic properties. J. Agric. Food Chem. 70, 6849–6863. doi: 10.1021/acs.jafc.1c04927

Niño-Medina, G., Muy-Rangel, D., and Urías-Orona, V. (2017). Chickpea (Cicer arietinum) and soybean (Glycine max) hulls: Byproducts with potential use as a source of high value-added food products. Waste Biomass Valorization 8, 1199–1203. doi: 10.1007/s12649-016-9700-4

Ong, D. S. M., Lee, H. W., Yeo, M. T. Y., and Chiang, J. H. (2024). Nutritional, anti-nutrient, stability and organoleptic characterisation of plant-based milk alternatives derived from adzuki bean (Vigna angularis) and mung bean (Vigna radiata). Future Foods 10:100402. doi: 10.1016/j.fufo.2024.100402

Oyedeji, A. B., Mellem, J. J., and Ijabadeniyi, O. A. (2018). Potential for enhanced soy storage protein breakdown and allergen reduction in soy-based foods produced with optimized sprouted soybeans. LWT 98, 540–545. doi: 10.1016/j.lwt.2018.09.019

Parmar, N., Singh, N., Kaur, A., Virdi, A. S., and Thakur, S. (2016). Effect of canning on color, protein and phenolic profile of grains from kidney bean, field pea and chickpea. Food Res. Int. 89, 526–532. doi: 10.1016/j.foodres.2016.07.022

Peng, X., Yang, S., Liu, Y., Ren, K., Tian, T., Tong, X., et al. (2023). Application of kombucha combined with fructo-oligosaccharides in soy milk: colony composition, antioxidant capacity, and flavor relationship. Food Biosci. 53:102527. doi: 10.1016/j.fbio.2023.102527

Pi, X., Sun, Y., Fu, G., Wu, Z., and Cheng, J. (2021). Effect of processing on soybean allergens and their allergenicity. Trends Food Sci. Technol. 118, 316–327. doi: 10.1016/j.tifs.2021.10.006

Poms, R. E., and Anklam, E. (2004). Effects of chemical, physical, and technological processes on the nature of food allergens. J. AOAC Int. 87, 1466–1474. doi: 10.1093/jaoac/87.6.1466

Punia, S., Dhull, S. B., Sandhu, K. S., Kaur, M., and Purewal, S. S. (2020). Kidney bean (Phaseolus vulgaris) starch: a review. Legum. Sci. 2:e52. doi: 10.1002/leg3.52

Qian, J.-Q., Qin, D.-H., Xie, X.-M., and Zhou, W.-W. (2010). Study on enzyme-assisted aqueous extraction of oil from soybean. J. Sci. Ind. Res. 69, 860–865.

Qin, P., Wang, T., and Luo, Y. (2022). A review on plant-based proteins from soybean: health benefits and soy product development. J. Agric. Food Res. 7:100265. doi: 10.1016/j.jafr.2021.100265

Ratnayake, W. S., Hoover, R., and Warkentin, T. (2002). Pea starch: Composition, structure and properties—A review. Starch 54, 217–234. doi: 10.1002/1521-379X(200206)54:6<>3.0.CO;2-R

Samoilov, A., Suraeva, N., and Zaytseva, M. (2021). Assessment of microstructural changes in processed products from green peas. Food Syst. 4, 213–219. doi: 10.21323/2618-9771-2021-4-3-213-219

Sanchez-Monge, R., Lopez-Torrejón, G., Pascual, C., Varela, J., Martin-Esteban, M., and Salcedo, G. (2004). Vicilin and convicilin are potential major allergens from pea. Clin. Exp. Allergy 34, 1747–1753. doi: 10.1111/j.1365-2222.2004.02085.x

Satoh, R., Tsuge, I., Tokuda, R., and Teshima, R. (2019). Analysis of the distribution of rice allergens in brown rice grains and of the allergenicity of products containing rice bran. Food Chem. 276, 761–767. doi: 10.1016/j.foodchem.2018.10.080

Shanthakumar, P., Klepacka, J., Bains, A., Chawla, P., Dhull, S. B., and Najda, A. (2022). The current situation of pea protein and its application in the food industry. Molecules 27:5354. doi: 10.3390/molecules27165354

Shen, Y., Huang, X., Nan, Y., Yu, H., and Lyu, B. J. F. S. F. S. (2024). Possibility of immediate treatment to soybean processing by-products using screw extrusion: a mini review. Front. Sustain. Food Syst. 8:1372148. doi: 10.3389/fsufs.2024.1372148

Shrivastava, V., Ali, I., Marjub, M. M., Rene, E. R., and Soto, A. M. F. (2022). Wastewater in the food industry: treatment technologies and reuse potential. Chemosphere 293:133553. doi: 10.1016/j.chemosphere.2022.133553

Singh, P., and Krishnaswamy, K. (2022). Sustainable zero-waste processing system for soybeans and soy by-product valorization. Trends Food Sci. Technol. 128, 331–344. doi: 10.1016/j.foodchem.2017.04.161

Singh, B., Singh, J. P., Singh, N., and Kaur, A. (2017). Saponins in pulses and their health promoting activities: a review. Food Chem. 233, 540–549.

Sun, C., Ge, J., He, J., Gan, R., and Fang, Y. (2021). Processing, quality, safety, and acceptance of meat analogue products. Engineering 7, 674–678. doi: 10.1016/j.eng.2020.10.011

Tian, Q., and Hua, Y. (2021). Oxidation reactions in model systems simulating the processing of soybeans into soymilk: role of lipase and lipoxygenase in volatile flavors formation. Int. J. Food Prop. 24, 192–202. doi: 10.1080/10942912.2021.1873363

Tong, X., Cao, J., Tian, T., Lyu, B., Miao, L., Lian, Z., et al. (2022). Changes in structure, rheological property and antioxidant activity of soy protein isolate fibrils by ultrasound pretreatment and EGCG. Food Hydrocoll. 122:107084. doi: 10.1016/j.foodhyd.2021.107084

Tong, X., Lian, Z., Miao, L., Qi, B., Zhang, S., Li, Y., et al. (2020). An innovative two-step enzyme-assisted aqueous extraction for the production of reduced bitterness soybean protein hydrolysates with high nutritional value. LWT 134:110151. doi: 10.1016/j.lwt.2020.110151

Topare, N. S., and Patil, K. D. (2021). Biodiesel from waste cooking soybean oil under ultrasonication as an alternative fuel for diesel engine. Mater Today Proc 43, 510–513. doi: 10.1016/j.matpr.2020.12.025

Tummino, M. L., Laurenti, E., Bracco, P., Cecone, C., Parola, V. L., Vineis, C., et al. (2023). Antibacterial properties of functionalized cellulose extracted from deproteinized soybean hulls. Cellulose 30, 7805–7824. doi: 10.1007/s10570-023-05339-w

van den Berg, L. A., Mes, J. J., Mensink, M., and Wanders, A. J. (2022). Protein quality of soy and the effect of processing: a quantitative review. Front. Nutr. 9:1004754. doi: 10.3389/fnut.2022.1004754

Vaughn, S. F., Liu, S. X., Berhow, M. A., Winkler-Moser, J. K., Peterson, S. C., Selling, G. W., et al. (2023). Production of an odor-reducing, low-dust, clumping cat litter from soybean hulls and soybean hull biochar. Bioresour. Technol. Rep. 21:101317. doi: 10.1016/j.biteb.2022.101317

Verma, A. K., Kumar, S., Das, M., and Dwivedi, P. D. (2012). Impact of thermal processing on legume allergens. Plant Foods Hum. Nutr. 67, 430–441. doi: 10.1007/s11130-012-0328-7

Verma, A. K., Kumar, S., Das, M., and Dwivedi, P. D. (2013). A comprehensive review of legume allergy. Clin. Rev. Allergy Immunol. 45, 30–46. doi: 10.1007/s12016-012-8310-6

Vernier, L. J., Nunes, A. L. B., Albarello, M., and de Castilhos, F. (2022). Continuous production of fatty acid methyl esters from soybean oil deodorized distillate and methyl acetate at supercritical conditions. J. Supercrit. Fluids 186:105603. doi: 10.1016/j.supflu.2022.105603

Vishwanathan, K., Singh, V., and Subramanian, R. J. (2011). Wet grinding characteristics of soybean for soymilk extraction. J. Food Eng. 106, 28–34. doi: 10.1016/j.jfoodeng.2011.04.002

Wang, H., Johnson, L., and Wang, T. J. (2004). Preparation of soy protein concentrate and isolate from extruded-expelled soybean meals. J. Am. Oil Chem. Soc. 81, 713–717. doi: 10.1007/s11746-004-966-8

Wang, J., Kuang, H., Zhang, Z., Yang, Y., Yan, L., Zhang, M., et al. (2020). Generation of seed lipoxygenase-free soybean using CRISPR-Cas9. Crop J. 8, 432–439. doi: 10.1016/j.cj.2019.08.008

Wang, S., Sun, W., Swallah, M. S., Amin, K., Lyu, B., Fan, H., et al. (2021). Preparation and characterization of soybean insoluble dietary fiber and its prebiotic effect on dyslipidemia and hepatic steatosis in high fat-fed C57BL/6J mice. Food Funct. 12, 8760–8773. doi: 10.1039/d1fo01050f

Wang, S., Wang, J., Zhang, J., Liu, W., Jing, W., Lyu, B., et al. (2023). Insoluble dietary fiber from okara combined with intermittent fasting treatment synergistically confers antiobesity effects by regulating gut microbiota and its metabolites. J. Agric. Food Chem. 71, 13346–13362. doi: 10.1021/acs.jafc.3c03948

Wang, Y., Yao, X., Shen, H., Zhao, R., Li, Z., Shen, X., et al. (2022). Nutritional composition, efficacy, and processing of Vigna angularis (adzuki bean) for the human diet: an overview. Molecules 27:6079. doi: 10.3390/molecules27186079

Yao, B., Jin, C., Guan, Y., Chang, Z., Liu, Q., and Gao, H. (2024). Purification and characteristics of β-amylase from soybean whey wastewater. Catalysts 14:909. doi: 10.3390/catal14120909

Zahradka, P., Wright, B., Weighell, W., Blewett, H., Baldwin, A., Karmin, O., et al. (2013). Daily non-soy legume consumption reverses vascular impairment due to peripheral artery disease. Atherosclerosis 230, 310–314. doi: 10.1016/j.atherosclerosis.2013.07.048

Zhang, M., Wu, L., Zhao, Q., Zhang, S., and Li, Y. (2025). Complexes of black kidney bean protein, pectin, and quercetin as potential antioxidant food ingredients: fabrication and characterization. Food Chem. 492:145441. doi: 10.1016/j.foodchem.2025.145441

Zhang, Y., Zhang, Y., Ying, Z., Li, W., Li, H., and Liu, X. (2022). Trypsin inhibitor from soybean whey wastewater: Isolation, purification and stability. Appl. Sci. 12:10084. doi: 10.3390/app121910084

Zhao, Q., Xu, Y., and Liu, Y. (2022). Soybean oil bodies: a review on composition, properties, food applications, and future research aspects. Food Hydrocoll. 124:107296. doi: 10.1016/j.foodhyd.2021.107296

Keywords: non-soy legumes, processing strategy, processing suitability, grain deep processing, high-value utilization

Citation: Liu T, Wang M, Shen Y and Lyu B (2025) Differences in processing strategies between non-soy legumes and soybean: a review. Front. Sustain. Food Syst. 9:1674400. doi: 10.3389/fsufs.2025.1674400

Edited by:

Maria Allegra, Council for Agricultural Research and Agricultural Economy Analysis | CREA, ItalyReviewed by:

Yunus Temitayo Imam, University of Abuja, NigeriaHelena Schmidt, Hospital de Clínicas de Porto Alegre, Brazil

Natoavina Faliarizao, Michigan State University, United States

Copyright © 2025 Liu, Wang, Shen and Lyu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yue Shen, c2hlbnl1ZTUwMjJAMTYzLmNvbQ==; Bo Lyu, bWljaGFlbF9sdmJvQDE2My5jb20=

†These authors have contributed equally to this work

Tong Liu

Tong Liu Mingyu Wang1,2

Mingyu Wang1,2 Bo Lyu

Bo Lyu