- 1Key Lab of Solid State Laser, Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, Beijing, China

- 2Key Lab of Function Crystal and Laser Technology, Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, Beijing, China

- 3University of Chinese Academy of Sciences, Beijing, China

A several-kilowatt level laser at 946 nm is demonstrated in a cryogenically cooled diode-pumped Nd:YAG slab system. The oscillator realizes the record of the output power of 2.85 kW in a compact cavity with the homemade cryogenically cooled Nd:YAG crystal slab. The pulse repetition rate and pulse width of the laser are 400 Hz and 200 µs, respectively, and the center wavelength under full power is 946.2 nm with a bandwidth of about 0.5 nm. The absorption linewidth at 808 nm is a little narrowed and blue shifts at the cryogenic temperature, while the cooling temperature decreases from 300 to 77 K. The measured thermal conductivity increases from 10 to 70 W/mˑK, and the thermal expansion coefficient decreases from 7.5*10−6 to 1.5*10−6/K. These results could guide us in simulating the temperature gradient and thermal-induced stress distributions in the crystal slab.

1 Introduction

High-power lasers with special wavelengths offer a wide range of applications in the fields of medical aesthetics, laser processing, and nonlinear optics [1–5]. As the most widely used solid-state gain medium, neodymium-doped yttrium aluminum garnet (Nd:YAG) crystals with different shapes have received widespread attention in the fields of high-power laser oscillators and short-pulse laser amplifiers [6–8]. The common radiation wavelengths of Nd:YAG include 946 nm, 1064 nm, and 1319 nm [9, 10]. The 4F3/2→4I9/2 transition of Nd:YAG is attractive for achieving a high-power radiant source with a wavelength of 946 nm. Such laser sources are suitable for differential absorption LiDAR systems or for generating into the blue at 473 nm radiation for various applications, such as medical imaging, data storage, manufacturing and processing, and remote sensing [11–14]. However, the 946-nm laser radiation from Nd:YAG with the quasi-three-level transition suffers from some limitations, including significant reabsorption losses, a small stimulated emission cross section compared to the 1064-nm transition, and an intense thermal loading of the gain medium [15]. However, the laser performance could be enhanced for the quasi-three-level 946-nm Nd:YAG laser by cryogenic cooling, which breaks the physical limitation of thermodynamics at room temperature and is inspired from the demonstration of cryogenic Yb:YAG lasers [16–18]. In recent years, extensive research has since been performed toward power scaling of 946-nm Nd:YAG lasers. For example, a 3.8-W continuous wave 946-nm Nd:YAG laser was demonstrated under cryogenic cooling with the temperature range of 90 K–290 K [19]. A 30.2-W 946-nm laser was obtained by using an 8-mm Nd:YAG crystal at 130 K [20]. A 60-W cryogenically cooled Nd:YAG laser at 946 nm was reported with a high-brightness pumping diode laser array of 869 nm [21]. In addition, G Shayeganrad broke through the 100-W level Nd:YAG laser at 946 nm with a closed-cycle cryogenically cooled laser [22]. In our previous reports, a 1.06-kW quasi-continuous wave surface-pumped cryogenically cooled 946-nm Nd:YAG slab laser was developed [23]. These demonstrations suggest that cryogenic cooling is an excellent solution for achieving high-power 946-nm laser radiation.

In this paper, a cryogenically cooled Nd:YAG crystal slab laser with quasi-continuous wave operation having an output power of 2.85 kW at 946 nm is demonstrated. We first thoroughly measure the absorption spectra of the 0.6-at.% Nd:YAG crystal at the temperatures of 300 K and 77 K. Then, the temperature-dependent thermal expansion coefficient and thermal conductivity of the 0.6-at.% Nd:YAG crystal were studied simultaneously. The results indicate that the peak of absorption is shift to 808.9 nm when the sample is cooled to 77 K and the bandwidth of the absorption spectrum is narrowed. The conversion efficiency can be improved according to the optimization of the wavelength of the pumped diode laser. To date, this is the highest power laser at 946 nm, acquired in a single Nd:YAG slab, to the best of our knowledge. These results can be used in simulating the temperature gradient and thermal-induced stress distributions in the crystal slab, which guides in optimizing the cooling system of the module.

2 Experimental setup

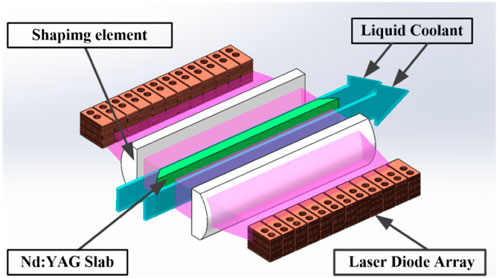

The key for the performance enhancement of Nd:YAG slab lasers is to increase the overlap region of the Nd:YAG absorption spectrum and the pump laser emission spectrum. The stimulated absorption spectra of the Nd:YAG crystal are measured at the temperatures of 77 K and 300 K. Figure 1A gives the absorption spectra of 0.6 at % Nd:YAG samples from 4F3/2 to 4I9/2 transition, which is carried out using a fluorescence spectrometer (Edinburgh FLSP980) with a 0.02-nm resolution. It can be observed that the absorption intensity around 809 nm is increased as the temperature decreases, where the bandwidth of the absorption spectrum is narrowed from ∼1 nm to 0.6 nm, with the temperature decreasing from 300 K to 77 K. Meanwhile, the peak wavelength was decreased by 0.1 nm over this range. Traditionally, diode lasers are used as pump sources for high-power solid-state lasers due to their merits, including a high conversion efficiency, wavelength tunability, and compactness. Taking the measured absorption spectrum of Nd:YAG in a cryogenic environment, we optimized the pump absorption efficiency at different coolant temperatures of diode laser arrays. As shown in Figure 1B, the emission spectra of the pump sources were measured using an Aurora 4000 spectrum analyzer. The wavelength of a laser diode array (LDA) was temperature-tuned to reach the maximum absorption when it passes through the slab that is cryogenically cooled. This can be realized when the coolant temperature is 303.5 K and the corresponding center wavelength is 809.0 nm with a bandwidth of 1.3 nm.

FIGURE 1. (A) Absorption spectrum of Nd:YAG at 77 K and 300 K and (B) output spectrums of the diode laser array at the coolant temperatures of 299 K, 300 K, 301 K, 302 K, 303 K, and 304 K.

In order to enhance the output performance of the 946-nm laser, the cryogenic temperature for the cooling slab needs to be reduced to below 140 K to practically eliminate the reabsorption loss [24]. Moreover, we need to minimize the temperature excursion and thermal stress across the slab to ensure the reliability of the laser operation due to the large size of the slab. Therefore, the temperature-dependent thermal expansion coefficient and thermal conductivity of the gain medium should be studied.

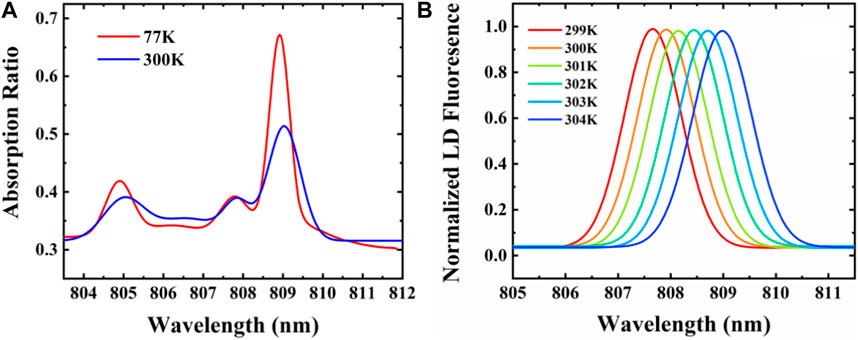

It was demonstrated that the cooling of the gain medium to cryogenic temperatures resulted in a significant increase in thermal and mechanical properties compared to that at the room temperature [25, 26]. The measurements presented in this paper were carried out with the φ3 × 9-mm Nd:YAG sample. Thermal conductivity was measured using PPMS-9 by the steady-state longitudinal heat-flow method, and thermal expansion was measured in the temperature range of 77–300 K using a Linseis L75 thermal dilatometer whose accuracy deviation is estimated to be within 1%. The measured thermal conductivity and thermal expansion of Nd:YAG versus the temperature is shown in Figure 2. It can be seen that the thermal expansion coefficient tends to get substantially lower when the cryogenic temperature decreases below 300 K, and the thermal conductivity increases up to almost an order of magnitude as the temperature decreases to 77 K.

FIGURE 2. Thermal expansion coefficient and thermal conductivity of Nd:YAG as a function of temperature.

The heat transfer coefficient could be affected by the physical characteristics of the gain medium, geometry of the slab, and parameters of the coolant. Slab lasers are well-suited for high-efficiency cooling systems, thus exhibiting favorable results, further realizing the high output power with a high beam quality [27], compared to rod active media. Considering the growth size of the crystals and the absorption efficiency for a pumping laser, the 0.6 at.% doping concentration of the Nd:YAG slab is cut into 173.6 mm × 66 mm × 10 mm. The two end faces of the crystal slab with the angle of 40° are polished and anti-reflection-coated at 1061 nm and 946 nm to reduce the surface reflection. To suppress the parasitic oscillation, we adopt the non-parallel structure with small angle deviations between the two opposite side faces along the length of the slab. At the same time, the two large side faces need to be rough in order to suppress effectively the ASE along the width direction of the slab [28].

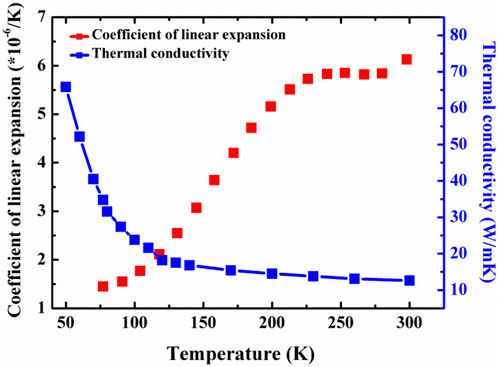

Figure 3 shows the experimental setup of the LDA-pumped double face-cooled Nd:YAG slab laser. It is quite important for obtaining a good performance of the slab laser by controlling the intensity distribution and irradiation size of the pump beam [29]. Here, the spot of the LDA-adopted micro-lens array and cylindrical lens is shaped into a well for the overlapping and uniformity pumping intensity. The cooling liquid flows along the two large side faces, entraining the heat when the 946-nm beam passes through the slab in a zigzag path. For improving the cooling efficiency, liquid nitrogen usually flows in a turbulent manner along the large side faces of the slab within the 1.2-mm gap between the shaping element and the slab. A large flow rate is beneficial for improving the heat transfer coefficient; however, a large flow rate also can break down the sealing structure. In addition, a strong turbulent flow may generate vortices that will affect the pump laser transmission, suggesting that the heat transfer coefficient is about 15 kW/K-m2 between the crystal and the liquid nitrogen coolant at a flow rate of 60 kg/min.

According to the measured result of the absorption spectrum (α = 0.9 cm-1), with a low doping concentration, the absorption ratio for the pumping laser is around 60%. In the simulation, we adopt the curves of thermal conductivity and thermal expansion of the Nd:YAG crystal versus temperature. When the pumping power reaches up to 20 kW, the simulated temperature gradient in the slab is about 39 K and the highest value of thermal stress is about 45 MPa, which is quite smaller than the limit of the fracture [30]. The simulated results indicate that the cooling structure we designed can effectively remove the extra heat in the slab under the high power pumped. Thus, the meticulous design of thermal management for the gain medium can play a role in developing the high-power quasi-three-level lasers.

3 Experimental results

In order to evaluate the laser performance of the cryogenic Nd:YAG slab module operating at 946 nm, we adopted the short cavity structure. A plano-concave mirror with a radius of 750 mm was chosen for its high reflectivity at 946 nm and high transmission at 1061 nm to suppress parasitic lasing. Moreover, we use different plane–plane output coupler transmissions of Toc = 7%, 10%, and 15% to examine the laser performance, considering it as the low-stimulated emission cross section.

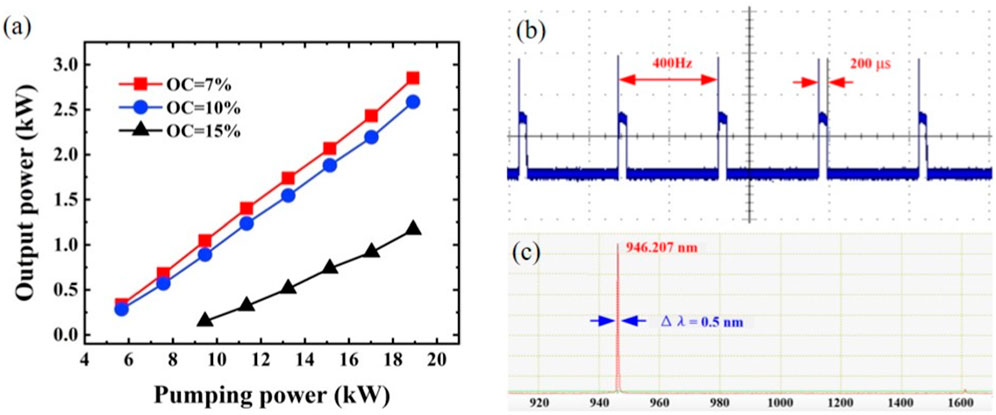

The output power of the Nd:YAG slab laser at 946 nm is measured using the Ophir Nova II power meter. Figure 4A shows the results of output power by comparing it with three OCs as a function of the pump power. The maximum optical efficiency was obtained with the output coupling of 7%. We can see that the average output power at 946 nm approximately increases linearly in accordance with the incident pump power. At the pumping power of 18.9 kW, the maximum output power is 2.85 kW, with a corresponding optical-to-optical efficiency of 15.1%. In order to achieve high output power, the profile of the laser beam is in multiple transverse modes, owing to the short cavity setup [31]. The pulse profile of 946-nm laser is measured using a Thorlabs DET200 photodetector whose increase in time is less than 25 ns. The oscillator trace of laser pulses is shown in Figure 4B. The output-pulse temporal characteristics of the 946-nm laser are measured under the maximum output power, and it indicated that the pulse repetition rate of the laser is 400 Hz; the pulse width is about 200 µs. Emission wavelengths of the Nd:YAG slab laser are measured using an Ocean Optics NIRQuest256-2.5 optical spectrum analyzer, as shown in Figure 4C. It can be seen that the center peak of the laser spectrum is 946.2 nm with a bandwidth of 0.5 nm under the full output laser and no evident peak at 1 μm.

FIGURE 4. (A) Output power of the 946-nm Nd:YAG cryogenic slab laser as a function of diode pump power with 7%, 10%, and 15% optical couplers. (B) Oscillator trace of output pulses. (C) Emission spectrum for Nd:YAG under full power.

4 Discussion and conclusion

We have undertaken a thorough examination of the variations of adsorption, thermal expansion coefficients, and thermal conductivity of the Nd:YAG crystal with temperature. Employing this measured data source, a model temperature gradient and thermal stress distribution in laser slabs can be simulated and calculated to optimize the cooling system design during the development of a high-power laser module. Based on the design parameters, such as the characteristics of the coolant flow, wavelength of the pumping laser, and gain medium geometry, the cryogenic cooling of the multi-kilowatt QCW double face-pumped 946-nm Nd:YAG slab is realized. The laser oscillator delivers a record high average power of 2.85 kW at 946.2 nm, with the conversion efficiency of 15%. The oscillator operates at a repetition frequency of 400 Hz with a pulse width of 200 µs.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

Conceptualization, Q-JP and YB; methodology, Q-JP; software, J-QC; validation, J-QC; writing—original draft preparation, J-QC; writing—review and editing, QB and YS; project administration and funding acquisition, Q-JP and YS. All authors contributed to the article and approved the submitted version.

Funding

This research was funded by the National Key Research and Development Program of China (Key Special Projects, Young Scientist, No. 2022YFB3607900); the Key Laboratory Foundation of the Chinese Academy of Sciences, Key Lab of Solid-State Laser (No. CXJJ-22S020); and the National Special Support Program for High-Level Talents in Science and Technology (Innovation Leading Talent Program of the Defense Technology Innovation Foundation, no. SQ2022RA24910010).

Acknowledgments

The authors acknowledge some crystal support from Chengdu Dien Photoelectric Technology Co., Ltd. (DIEN TECH).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1. Liang L, Yuan J, Lin G Effect of the scanning speed on the microgroove formation regime in nanosecond-pulsed laser scanning ablation of cermet. Int J Adv Manufacturing Technol (2020) 107:97–107. doi:10.1007/s00170-020-05017-2

2. Kerse C, Kalaycıoğlu H, Elahi P, Çetin B, Kesim DK, Akçaalan Ö, et al. Ablation-cooled material removal with ultrafast bursts of pulses. Nature (2016) 537:84–8. doi:10.1038/nature18619

3. Jin D, Bai Z, Lu Z, Fan R, Zhao Z, Yang X, et al. 22.5-W narrow-linewidth diamond Brillouin laser at 1064 nm. Opt Lett (2022) 47:5360–3. doi:10.1364/ol.471447

4. Jin D, Bai Z, Li M, Yang X, Wang Y, Mildren RP, et al. Modeling and characterization of high-power single frequency free-space Brillouin lasers. Opt Express (2023) 31:2942–55. doi:10.1364/oe.476759

5. Chen H, Bai Z, Cai Y, Yang X, Ding J, Qi Y, et al. Order controllable enhanced stimulated Brillouin scattering utilizing cascaded diamond Raman conversion. Appl Phys Lett (2023) 122:092202. doi:10.1063/5.0137542

6. Zhou B, Kane TJ, Dixon GJ, Byer RL. Efficient, frequency-stable laser-diode-pumped Nd: YAG laser. Opt Lett (1985) 10(2):62–4. doi:10.1364/ol.10.000062

7. Bai Z, Zhao C, Gao J, Chen Y, Li S, Li Y, et al. Optical parametric oscillator with adjustable pulse width based on KTiOAsO4. Opt Mater, 2023 136, 113506 doi:10.1016/j.optmat.2023.113506

8. Li K, Wang Y, Yu Y, Yue J, Song C, Cao C, et al. Amplification of high repetition-rate, picosecond laser pulses using a zig-zag slab configuration. Opt Laser Technol (2023) 157:108717. doi:10.1016/j.optlastec.2022.108717

9. Lü Y, Zhao L, Zhai P, Xia J, Fu X, Li S. Simultaneous three-wavelength continuous wave laser at 946 nm, 1319 nm and 1064 nm in Nd: Yag. Opt Commun (2013) 286:257–60. doi:10.1016/j.optcom.2012.08.073

10. Li X, Javed F, Zhang H, Liu X, Chen T, Yang S, et al. High power diode end-pumped 1.3 μm Nd: YAG InnoSlab laser. Results Phys (2022) 37:105468. doi:10.1016/j.rinp.2022.105468

11. Mackenzie JI. An efficient high-power 946 nm Nd:YAG planar waveguide laser. Appl Phys B (2009) 97(2):297–306. doi:10.1007/s00340-009-3693-7

12. Fan TY, Bye RL. Continuous-wave operation of a room-temperature, diode-laser-pumped, 946-nm Nd:YAG laser. Opt Lett (1987) 12(10):809–11. doi:10.1364/ol.12.000809

13. Zhou R, Li E, Li H, Wang P, Yao J. Continuous-wave, 15.2 W diode-end-pumped Nd:YAG laser operating at 946 nm. Opt Lett (2006) 31(12):1869–71. doi:10.1364/ol.31.001869

14. Freitag I, Henking R, Tünnermann A, Welling H. Quasi-three-level room-temperature Nd: YAG ring laser with high single-frequency output power at 946 nm. Opt Lett (1995) 20(24):2499–501. doi:10.1364/ol.20.002499

15. Bjurshagen S, Koch R. Modeling of energy-transfer upconversion and thermal effects in end-pumped quasi-three-level lasers. Appl Opt (2004) 43(24):4753–67. doi:10.1364/ao.43.004753

16. AggarwalRipinOchoa RLDJJR, Fan TY. Measurement of thermo-optic properties of Y3Al5O12, Lu3Al5O12, YAIO3, LiYF4, LiLuF4, BaY2F8, KGd(WO4)2, and KY(WO4)2 laser crystals in the 80–300K temperature range. J Appl Phys (2005) 98(10):103514. doi:10.1063/1.2128696

17. Yasuhara R, Furuse H, Iwamoto A, Kawanaka J, Yanagitani T. Evaluation of thermo-optic characteristics of cryogenically cooled Yb:YAG ceramics. Opt Express (2012) 20(28):29531–9. doi:10.1364/oe.20.029531

18. Zhou R, Zhang T, Li E, Ding X, Cai Z, Zhang B, et al. 8.3 W diode-end-pumped continuous-wave Nd: YAG laser operating at 946-nm. Opt express (2005) 13(25):10115–9. doi:10.1364/opex.13.010115

19. Cho CY, Lee CY, Chang CC, Tuan PH, Huang KF, Chen YF. 24-W cryogenically cooled Nd:YAG monolithic 946-nm laser with a slope efficiency >70%. Opt Express (2015) 23(8):10126–31. doi:10.1364/oe.23.010126

20. Cho CY, Huang TL, Cheng HP, Huang KF, Chen YF. Exploring the power scaling of the cryogenic 946 nm monolithic laser. Laser Phys Lett (2018) 15(8):085801. doi:10.1088/1612-202x/aac357

21. Cante S, Valle S, Yoon SJ, Mackenzie JI. 60-W 946-nm cryogenically-cooled Nd: YAG laser. Appl Phys B (2019) 125(7):135–6. doi:10.1007/s00340-019-7244-6

22. Shayeganrad G, Cante S, Mosquera JP, Bailey WOS, Mackenzie JI. Highly efficient 110-W closed-cycle cryogenically cooled Nd: YAG laser operating at 946 nm. Opt Lett (2020) 45(19):5368–71. doi:10.1364/ol.401011

23. Song ZX, Wang BS, Shen Y, Bo Y, Chang JQ, Chen ZZ, et al. QCW surface-pumped cryogenically cooled single-slab laser with 1 kW level at 946 nm. Appl Opt (2022) 61(10):2898–902. doi:10.1364/ao.451288

24. Yoon SJ, Mackenzie JI. Cryogenically cooled 946 nm Nd:YAG laser. Opt Express (2014) 22(7):8069–75. doi:10.1364/oe.22.008069

25. Schulz PA, Henion Scott R. Liquid-nitrogen-cooled Ti:Al/sub 2/O/sub 3/laser. IEEE J Quan Electron (1991) 27(4):1039–47. doi:10.1109/3.83339

26. Brown DC. Ultrahigh-average-power diode-pumped Nd:YAG and Yb:YAG lasers. IEEE J Quan Electron (1997) 33(5):861–73. doi:10.1109/3.572162

27. Xie W, Tam SC, Yang H, Gu J, Zhao G, Lam YL, et al. Heat transfer for diode side-pumped YAG slabs. Opt Laser Technol (1999) 31(7):521–8. doi:10.1016/s0030-3992(99)00111-5

29. Meng S, Chen ZZ, Bo Y, Yuan L, Li Y, Guo YD, et al. 6.2 kW quasi-continuous-wave diode-pumped Yb:YAG ceramic slab laser. Laser Phys (2020) 30(1):015802. doi:10.1088/1555-6611/ab570c

Keywords: high power, cryogenically cooled, diode-pumped, Nd:YAG, slab laser, 946 nm

Citation: Chang J-Q, Bian Q, Bo Y, Shen Y and Peng Q-J (2023) 2.85-kW cryogenic Nd:YAG slab laser operating at 946 nm. Front. Phys. 11:1190569. doi: 10.3389/fphy.2023.1190569

Received: 21 March 2023; Accepted: 09 May 2023;

Published: 01 June 2023.

Edited by:

Shuo Liu, Hebei University of Technology, ChinaReviewed by:

She Shengfei, Chinese Academy of Sciences (CAS), ChinaQuan Sheng, Tianjin University, China

Wang Pengyuan, Chinese Academy of Sciences (CAS), China

Copyright © 2023 Chang, Bian, Bo, Shen and Peng. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yu Shen, c2hlbnl1QG1haWwuaXBjLmFjLmNu; Qin-Jun Peng, cGVuZ3Fpbmp1bkBtYWlsLmlwYy5hYy5jbg==

Jin-Quan Chang

Jin-Quan Chang Qi Bian1,2

Qi Bian1,2