Abstract

Polymer flooding is a popular enhanced oil recovery (EOR) technique; however, conventional polymers face challenges such as large dosages and limited shear resistance. To address these issues, we proposed a polymer/nanoparticle composite flooding method and investigated its feasibility through laboratory experiments. We first characterized the rheological properties and interfacial tension of various polymer/nano-SiO2 composite systems and examined their microscopic morphology using scanning electron microscopy (SEM). Subsequently, we conducted two-dimensional microscopic flooding experiments to evaluate sweep efficiency and analyze residual oil distribution patterns. Finally, we performed core flooding experiments to compare injection pressure and recovery efficiency among different flooding systems. Results indicate that the presence of nano-SiO2 effectively enhanced the viscosity of the polymer system. The viscosity-increasing mechanism is nanoparticles adsorbing onto polymer molecular chains to form network structures. The polymer/nano-SiO2 composite system significantly increased sweep efficiency and promoted the transformation of residual oil from reticulated patterns to cluster, membrane, and punctiform patterns. Compared to polymer flooding, the polymer/nano-SiO2 composite system required a smaller amount of usage, effectively avoids environmental pollution, and showed better injectivity, achieving a 6% higher recovery while reducing injection pressure by up to 14%.

1 Introduction

Polymer flooding is a widely adopted enhanced oil recovery (EOR) technique, which involves the injection of polymer solutions into hydrocarbon reservoirs to improve recovery. The displacement fluid systems viscosity increases by adding polymers, which will help inhibit the viscous fingering and enhance the sweep coefficient (Mohsenatabar Firozjaii and Saghafi, 2020; Rellegadla et al., 2017; Abidin et al., 2012), and then improve oil recovery significantly. In addition, recent viscoelastic theories have demonstrated that polymer viscoelasticity can enhance microscopic displacement efficiency by dragging the remaining oil out in the blind end of pores (Sandiford, 1964; Wever et al., 2011; Jacobsen, 2017; Song and Hatzignatiou, 2022; Mirzaie Yegane et al., 2022; Mahajan et al., 2021; Raffa and Druetta, 2019). Ensuring high viscosity of polymer solutions is a prerequisite and guarantee for improving oil recovery in polymer flooding (Sheng, 2013). However, polymer structures are susceptible to mechanical, chemical, thermal, and biological degradation, resulting in viscosity reduction (Song et al., 2018). Mechanical degradation occurs at all stages of the injection-reservoir production process and is mainly influenced by shear stress (Gumpenberger et al., 2012; Puls et al., 2016; Zechner et al., 2013; Ghoniem et al., 1981; Seright, 1983). Reservoir conditions (temperature and salinity) also affect polymer performance by altering molecular chain conformations (Aliabadian et al., 2019). Previous studies have demonstrated that the mechanical degradation of polymers is enhanced under high-salinity conditions. (Karami et al., 2018; Chen et al., 2012). The high temperature induces multiple effects on the system, including the reduction of solvent viscosity, which consequently shortens the molecular relaxation time of polymers, the weakening of physical interactions such as hydrogen bonding and chain entanglements, and the contraction of isolated polymer chains (Hu et al., 1995; Modig et al., 2003). Biodegradation results from microbial enzymatic activity that degrade the polymeric chains, reducing their efficiency (Wu et al., 2024). Undoubtedly, ensuring the injectivity of polymers is another key factor in polymer flooding. Polymers are high-molecular materials with a certain radius of gyration. When injected into reservoirs with small pore throats, high-concentration polymers will generate additional flow resistance, resulting in excessively high injection pressure (Kang et al., 2022). Due to limitations in oilfield injection equipment, excessive pressure will result in the inability to inject polymers.

As mentioned above, to improve polymer flooding performance, there are two directions for improvement, i.e., improving the shear resistance, temperature resistance, and salinity resistance of the polymer, and reducing the injection pressure of reservoir. A method is polymer/nanoparticle composite flooding, in which the polymer is a hydrophobically associative water-soluble polymer (HAWP) that has good temperature resistance and salinity resistance, and the nanoparticles can adsorb onto the rock surface and decrease the injection pressure. In the following, we will focus on the literature related to nanoparticles and look for whether there are some other interactions between polymers and nanoparticles in such a composite system.

Nanoparticles possess unique properties, including high specific surface area, unique chemical reactivity, and active surfaces. These characteristics enable them to adsorb onto reservoir surfaces, alter wettability, and reduce flow resistance of injection water, thereby enhancing waterflooding efficiency (Tafur et al., 2022). Currently, the most widely used nanoparticles in petroleum exploitation include metal oxide and inorganic nanoparticles, such as Al2O3, MgO, ZrO2, and Fe2O3 (Sun et al., 2023). Although they have excellent mechanical properties, temperature tolerance and salt resistance, their high cost and retention in the formation are still significant limiting factors. In contrast, SiO2 nanoparticles have attracted much attention due to their excellent performance and good chemical compatibility with sandstone formations (Alnarabiji and Husein, 2020).The nanoscale dimensions of these particles result in enhanced surface activity and specific surface area, leading to significant reductions in interfacial tension (IFT) (Eker et al., 2024; Cutroneo et al., 2021; Alvarez et al., 2013; Yekeen et al., 2020). Studies have confirmed that nanoparticles can alter or reverse rock surface wettability, increase oil contact angles, enhance oil displacement efficiency, and stabilize oil-water emulsions through interfacial adsorption (Bergfreund et al., 2019; Sharma et al., 2015). Further studies have revealed that under injection pressure, nanoparticles self-assemble into ordered microscopic layered structures within pore spaces, generating wedge-film structures at rock surface-oil droplet interfaces. The formation of this wedge-film structure increases the separation force, making it easier for the oil droplets to be detached (Trokhymchuk et al., 2001). Nanoparticles can effectively mitigate the challenges associated with high injection pressure and poor injectability in low-permeability reservoirs. (Zhao et al., 2024; Dai et al., 2015). Recent investigations have demonstrated synergistic effects between nanoparticles and chemical flooding in enhancing oil recovery. Adding nanoparticles into polymer flooding systems increased injection fluid viscosity, improved mobility ratio, and enhanced sweep efficiency (Cheraghian, 2015; Cheraghian and Hendraningrat, 2016; Rueda et al., 2020). Nanoparticle-polymer solutions demonstrate superior resistance to temperature and salinity effects compared to conventional polymer solutions (Elhaei et al., 2021; Corredor et al., 2019). Gbadamosi et al. (2019) found that the use of a combined system of HPAM and Al2O3 nanoparticles can further increase oil recovery by an additional 11.3% compared to using polyacrylamide (PAM). Overall, the nanoparticle-assisted polymer flooding technique exhibits superior performance compared to polymer flooding.

While extensive research has focused on nanoparticle modification, characterization, nanofluids stability, and macroscopic displacement efficiency, limited attention has been paid to microscopic residual oil mobilization in polymer/nanoparticle composite flooding systems. In this study, we optimized the formulation and characterized the performance of a hydrophobically associative water-soluble polymer (HAWP)/SiO2-nanoparticles composite system. Displacement experiments at the microscopic and core scales were carried out to study the microscopic oil displacement mechanisms of the composite system and improve the efficiency of oil recovery.

2 Material and methods

2.1 Materials

2.1.1 Simulated formation water and crude oil

We prepared simulated formation water based on the reservoir conditions of Shengli Oilfield. The mineralization degree reached 19,334 mg/L, with calcium and magnesium ions constituting 514 mg/L. Composition of chemical agents in simulated formation water: 17.786 g/L NaCl, 1.14 g/L CaCl2, 0.86 g/L MgCl2·6H2O. We obtained all analytical grade chemical reagents from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). To prepare the experimental crude oil, we diluted dehydrated crude oil with kerosene until its viscosity reached 42 mPa·s at ambient temperature (25°C).

2.1.2 Polymer and nano-SiO2

Shandong Noel Biotechnology Co., Ltd. (Shandong, China) provided the hydrophobically associating water-soluble polymer (HAWP) for this study. To achieve stable dispersion of SiO2-nanoparticles in the composite system, SiO2-nanoparticles modified by surface silanization were selected (later referred to as SiO2), with particle sizes ranging from 20 to 30 nm.

2.2 Experimental methods

2.2.1 Compounding of polymer/nano-SiO2 particle composite fluid

To obtain the polymer stock solution, we dissolved HAWP powder in the simulated formation water to achieve a mass concentration of 5,000 ppm and allowed the solution to age for 24 h. By diluting the stock solution, we prepared HAWP solutions at 1,000 ppm, 1,500 ppm, and 2,000 ppm. The addition of varying amounts of SiO2 to these solutions got composite systems containing 0.05 wt%, 0.1 wt%, 0.3 wt%, 0.5 wt%, and 1.0 wt% SiO2 at each HAWP concentration.

2.2.2 Surface microstructure morphology observation

To observe microscopic morphology more clearly, we prepared two additional composite systems by diluting 5,000 ppm HAWP solution to 3,000 ppm(0.3 wt%) with simulated formation water and adding SiO2 to achieve concentrations of 0.5 wt% and 1.0 wt%, that is, the ratios of HAWP to SiO2 were 3:10 (0.3 wt%:1 wt%) and 3:5 (0.3 wt%:0.5 wt%) respectively. Then we examined the surface microstructure of the HAWP solution, SiO2, and the composite systems using scanning electron microscopy.

2.2.3 Interfacial tension measurement

We selected four composite systems to test the interfacial tension: 2,000 ppm HAWP with SiO2 concentrations of 0.05 wt%, 0.1 wt%, 0.3 wt%, and 0.5 wt%. Before measurement, the composite systems underwent ultrasonic dispersion. Then we measured their interfacial tension with oil using an interfacial tensiometer at reservoir temperature (75°C) with a rotation speed of 6,000 r·min−1.

2.2.4 Rheological testing

We measured the viscosity, temperature-viscosity relationships, and rheological behavior of different systems using an Anton Paar M302 high-temperature and high-pressure rheometer. To accurately simulate reservoir conditions, the following tests were conducted: The influence of different formulations on composite system viscosity was tested at reservoir temperature (75°C) and wellbore shear rate (7.34 s−1); The effect of temperature on composite system viscosity was investigated from 25°C–90°C at wellbore shear rate (7.34 s−1); The impact of shear rate on composite system viscosity was examined at shear rates of 3.5–100 s-1 at reservoir temperature (75°C).

2.2.5 Investigation of microscopic oil displacement mechanism

The microscopic oil displacement experiments utilized a microfluidic device comprising a microinjection pump, microfluidic chip, microscope, and computer (Figure 1). The microfluidic chip (45 mm × 45 mm) with pore diameters ranging from 20–80 μm. We investigated four displacement systems: formation water, 0.1 wt% SiO2, 2,000 ppm HAWP, and 2,000 ppm HAWP +0.1 wt% SiO2, each stained with eosin.

FIGURE 1

Microfluidic experimental device.

The experimental oil was injected into the microfluidic chip at an injection rate of 0.5 mL/min until saturation was achieved. Subsequently, a displacement agent was injected at a rate of 0.5 mL/min to perform displacement until the water cut reached 98%, at which point injection was stopped. The process was repeated four times using different oil displacement systems to observe the displacement effects.

2.2.6 Core flooding experiments

Core flooding experiments employed the same displacement systems as the microscopic studies. The experimental setup (Figure 2) incorporated an ISCO pump (Teledyne ISCO, United States), three containers, a core holder, a six-way valve, a pressure transducer, and a hand pump.

FIGURE 2

Core flooding experimental apparatus.

This system is mainly targeted at medium-high permeability and high water-cut oil reservoirs. We conducted experiments using standard sandstone cores (permeability: 400 mD, diameter: 25 mm, length: 100 mm). After the core was saturated with crude oil, water flooding was carried out. Water flooding was carried out until the water content reached 98%, and the corresponding chemical flooding was carried out until the water content reached 98% for subsequent water flooding. Following the completion of each experimental run, the oil displacement systems were replaced, and the aforementioned procedures were repeated. Throughout the flooding process, injection pressure variations were continuously monitored, and effluent samples were collected every 3 min for oil recovery and water content analysis.

3 Results and discussion

3.1 Characterization of basic properties of the composite system

3.1.1 Microscopic morphology analysis

Figure 3 shows scanning electron microscopy (SEM) images of (a) HAWP, (b) SiO2, (c) 3,000 ppm HAWP +1.0 wt% SiO2 (3:10), and (d) 3,000 ppm HAWP +0.5 wt% SiO2 (3:5) systems.

FIGURE 3

SEM micrographs of (A) 3000 ppm HAWP, (B) SiO2, (C) 3000 ppm HAWP +1.0 wt% SiO2 composite system, and (D) 3000 ppm HAWP +0.5 wt% SiO2 composite system.

SEM image observations revealed the microstructural morphology of the polymer solutions and the SiO2 surface. The polymer molecules formed network structures. The SiO2 particles showed a spherical shape with diameters ranging from 20–30 nm and maintained a specific surface area of ≥120 m2/g.

Furthermore, SiO2 combined with HAWP to form stable composite systems, which increased the system viscosity through adsorption and bridging effects. As shown in Figure 3C, When the ratio of HAWP to SiO2 is 3:10, SiO2 aggregates were distributed throughout the polymer network structure, showing aggregate sizes between 2–3 μm, with a few aggregates reaching 4–5 μm. In comparison, when the ratio of HAWP to SiO2 is 3:5, SiO2 particles formed smaller aggregates of approximately 1–2 μm and displayed a more uniform distribution within the polymer network structure, indicating better compatibility between the nanoparticles and polymer.

3.1.2 Interfacial tension analysis

Figure 4 shows the dynamic interfacial tension curves of HAWP/SiO2 composite systems at different SiO2 concentrations. The addition of nano-SiO2 reduced the interfacial tension between the HAWP solution and crude oil. The polymer chains adsorbed onto the nano-SiO2 surface through hydrogen bonding. The nano-SiO2 particles became encapsulated within the free polymer chains. Both components adsorbed at the oil-water interface, leading to lower interfacial tension.

FIGURE 4

Dynamic interfacial tension profiles of 2000 ppm HAWP solutions with varying nano-SiO2 concentrations.

The oil-water interfacial tension continuously decreases as SiO2 mass concentration increases, exhibiting the most significant reduction at lower SiO2 concentrations. The interfacial tension drops to its minimum value at a SiO2 concentration of 0.3 wt%. The system maintains good stability when the SiO2 mass fraction remains below 0.3 wt%, and increasing the SiO2 mass fraction enhances its interfacial tension reduction capability. However, when the SiO2 mass fraction exceeds 0.3 wt%, the system stability declines, causing partial aggregation and failure of SiO2 particles, which weakens their ability to reduce interfacial tension. However, compared with surfactants, the magnitude of its interfacial tension reduction is relatively small, only decreasing by 2–3 mN m−1. While surfactants can reduce the interfacial tension to 10–2 – 10–3 mN m−1 (Negin et al., 2017). Therefore, reducing the interfacial tension is not the main mechanism for the composite system to improve the oil recovery rate. Considering factors such as cost comprehensively, a lower SiO2 concentration should be chosen.

3.1.3 Rheological analysis

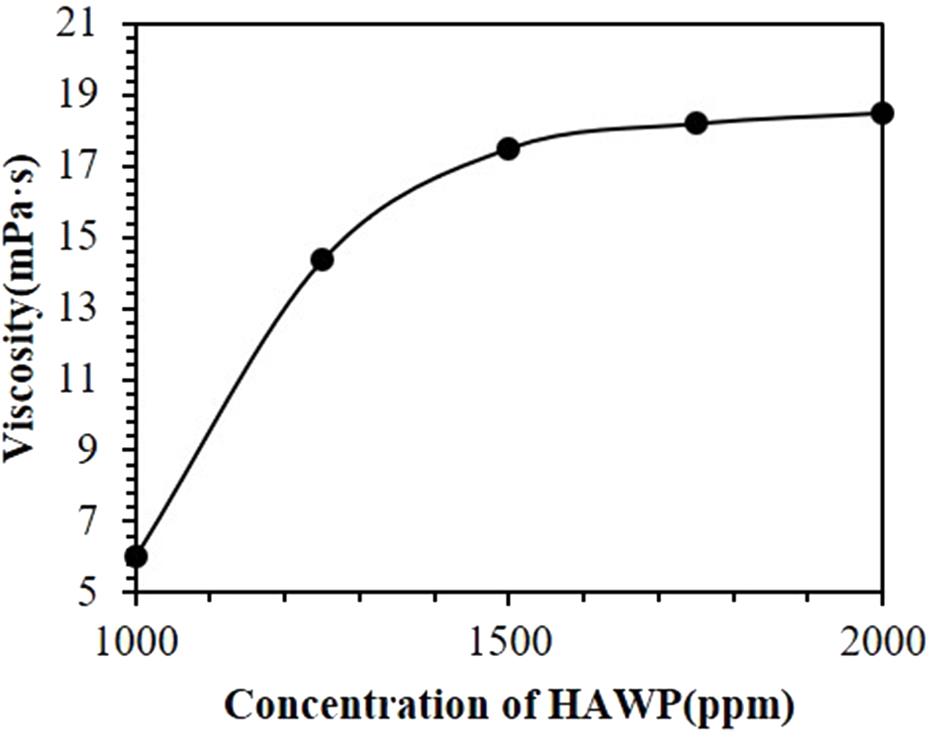

Figure 5 shows the viscosity of HAWP at 75°C under a shear rate of 7.43 s−1. The viscosity increased with higher polymer concentration. This increase occurred because polymer molecules formed network structures. At higher concentrations, polymer chains became more entangled, resulting in more stable network structures. Therefore, polymer viscosity increased with concentration at the same shear rate.

FIGURE 5

Viscosity of HAWP solutions as a function of concentration at 75°C.

When the HAWP concentration increased from 1,000 ppm to 1,500 ppm, the viscosity increased by 191.7%; however, as the concentration increased from 1,500 ppm to 2,000 ppm, the viscosity increment was only 5.7%. These results suggest that the polymer viscosity is more sensitive to concentration changes at lower concentrations, whereas the viscosity increment becomes less significant above a certain concentration threshold. This is mainly because the high-valence ions (such as Ca2+ and Mg2+) in high salinity water compress the electric double layer through the charge screening effect, causing the molecular chains to curl up prematurely. The hydrophobic groups preferentially undergo intramolecular association (rather than intermolecular association). At low concentrations, the molecular chains form a dynamic intramolecular association-dissociation cycle through instantaneous contact, and a slight change in concentration can significantly affect the viscosity. High salinity enhances the polarity of the solution and weakens the ability of the molecular chains to stretch, resulting in a significant increase in the critical association concentration. Even if the concentration increases, the intermolecular association network is difficult to form due to salt inhibition, and the viscosity cannot show the conventional exponential growth.

Figure 6 shows the viscosity variations of composite systems at 75°C, where we added different mass fractions of SiO2 into HAWP solutions at various concentrations. The results demonstrate that the viscosity of the composite systems increases with rising SiO2 content. This increasing trend is more pronounced at higher polymer concentrations. The figure shows that in the 2,000 ppm HAWP + SiO2 composite system, the maximum slope occurs at 0.1 wt% SiO2 concentration. This indicates that SiO2 nanoparticles at 0.1 wt% demonstrate the most significant tackifying effect on 2,000 ppm HAWP. In practical applications, considering that nanoparticles may still be adsorbed in the formation, a higher concentration can be selected.

FIGURE 6

Effect of SiO2 concentration on the viscosity of composite systems with different HAWP concentrations.

Figure 7 shows the viscosity variations of composite systems with different HAWP-to-SiO2 ratios as a function of temperature (25°C–90°C) at a constant wellbore shear rate of 7.34 s−1. The experimental results demonstrated that the viscosity of all composite systems exhibits a consistent declining trend with increasing temperature.

FIGURE 7

Temperature-viscosity curves of SiO2-HAWP composite systems at varying HAWP concentrations: (A) 1000 ppm HAWP, (B) 1500 ppm HAWP, and (C) 2000 ppm HAWP.

However, the viscosity of the HAWP/SiO2 composite system remained higher than that of HAWP. Furthermore, the viscosity increased with increasing SiO2 concentration. This phenomenon occurred because SiO2 could form a stable composite system with HAWP, enhancing the polymer chain network structure through adsorption and bridging effects, thereby increasing its viscosity. As shown in Figure 7C, when the HAWP concentration was 2,000 ppm, the temperature-viscosity curves of systems containing 0.8wt% and 1.0wt% SiO2 nearly overlapped. This indicated that beyond a certain threshold of SiO2 concentration, the viscosity-enhancing effect became insignificant, accompanied by decreased system stability, and SiO2 nanoparticles aggregated and lost their effectiveness.

Figure 8 shows the viscosity variations of composite systems with different ratios as a function of shear rate (3.5–100 s−1) at reservoir temperature (75°C). The experimental results demonstrated that all composite systems exhibited a decreasing trend in viscosity with increasing shear rate. Systems containing SiO2 show higher viscosity compared to HAWP solutions of the same concentration, and the viscosity increased with increasing SiO2 concentration.

FIGURE 8

Shear rate-viscosity profiles of SiO2-HAWP composite systems at varying HAWP concentrations: (A) 1000 ppm HAWP, (B) 1500 ppm HAWP, and (C) 2000 ppm HAWP.

However, the thickening effect of SiO2 varies across different HAWP concentrations. As shown in Figures 8A,B, the viscosity-shear rate curves of composite systems with 1,000 ppm and 1,500 ppm HAWP demonstrate uniform distribution with increasing SiO2 mass concentrations. Figure 8C reveals that in the 2,000 ppm HAWP composite system, the addition of 0.1 wt% SiO2 leads to a rapid increase in the viscosity-shear rate curve. Further increases in SiO2 concentration result in the rising speed of the viscosity slows down. This indicates that SiO2 at 0.1 wt% concentration exhibits the most pronounced tackifying effect on 2,000 ppm HAWP.

While the addition of SiO2 did not fully address the viscosity reduction of HAWP solutions at high temperatures and shear rates, it significantly enhanced the overall viscosity of the composite systems. The viscosity increased with rising SiO2 concentrations, with 0.1 wt% SiO2 showing the most significant thickening effect on 2,000 ppm HAWP. Considering cost-effectiveness and performance, the 0.1 wt% SiO2 + 2,000 ppm HAWP composite system was selected as the optimal flooding system.The viscosity of this system at 75°C under a shear rate of 7.43 s−1 is 1.73 times that of the polymer with the same concentration under the same conditions, which can effectively reduce the usage amount of the polymer.

3.2 Microscopic oil displacement mechanism analysis

We conducted oil displacement experiments using various displacing systems after saturating the microfluidic chip with oil. Digital processing of the microscopic images enabled the segmentation of oil and water phases, allowing us to analyze residual oil distribution patterns and flow characteristics.

Figure 9 shows the sweep areas of different displacing fluids, where the red color denotes the displacing phase and black indicates the oil phase. Water flooding, SiO2 flooding, HAWP flooding, and HAWP + SiO2 flooding achieved sweep coefficients of 12%, 41%, 63%, and 91%, respectively. The results showed that water flooding exhibited channeling and failed to effectively sweep residual oil, while SiO2 flooding showed some improvement over water flooding. HAWP flooding achieved a higher sweep coefficient than water flooding due to its higher viscosity, which improved the water-oil mobility ratio. When HAWP was combined with SiO2, the viscosity increased, and SiO2 enhanced the displacement efficiency of HAWP.

FIGURE 9

Microscopic images at breakthrough for different flooding systems: (A) water flooding, (B) SiO2 flooding, (C) HAWP flooding, and (D) HAWP + SiO2 flooding.

Figure 10 shows the relationship between residual oil saturation and injection volume for different oil displacement systems. During the early stage of displacement (before 0.3 PV), water flooding showed a slow change in residual oil saturation, while the other three displacement methods showed similar residual oil saturation levels. As injection volume increased, the residual oil saturation ranked from highest to lowest in the following order: water flooding, SiO2 flooding, HAWP flooding, and HAWP + SiO2 flooding. In the later stages of displacement, the residual oil saturation curves for water flooding and SiO2 flooding became relatively stable, while HAWP flooding and HAWP + SiO2 flooding showed a steady declining trend.

FIGURE 10

Relationship between residual oil saturation and injection volume for different flooding solutions.

The enhanced performance of HAWP and HAWP + SiO2 flooding resulted from two factors. First, their higher viscosity led to increased sweep coefficients. Second, nano-SiO2 altered the wettability, as shown in Figure 11. The wetting angle of the oil phase has changed from 62° to 28°, which has improved the utilization degree of the residual oil and the displacement efficiency. improving residual oil mobilization and displacement efficiency. Moreover, the dragging effect of nanoparticles on crude oil and the reduction of interfacial tension also play a significant role.

FIGURE 11

Oil-water contact angles of different systems: (A) formation water, (B) 2000 ppm HAWP +0.1wt% SiO2 composite system.

Understanding residual oil flow characteristics helps elucidate flow mechanisms, quantify the production contribution from different residual oil types, and enhance recovery efficiency.

Based on the shape factor (G, defined as the area of a single residual oil block divided by the square of its perimeter), residual oil was classified into punctiform-like(0.56 < G < 1), membrane-like(0.34 < G < 0.56), cluster-like(0.06 < G < 0.34), and reticulated-like patterns(0 < G < 0.06).

Figure 12 shows the variation trends in the proportions of different types of residual oil during the HAWP flooding process with increasing injection volume. The reticulated-like residual oil proportion demonstrates a consistent decline, whereas the cluster-like residual oil proportion shows a temporary increase followed by a decrease. Both membrane-like and punctiform-like residual oil proportions increase steadily. These trends reveal the transformation of residual oil during displacement: from reticulated-like to cluster-like patterns, and ultimately to membrane-like and punctiform-like configurations.

FIGURE 12

Proportions of different types of residual oil during the HAWP flooding process.

Figure 13 shows the evolution of different residual oil types under various displacement systems. During the initial displacement stage, where web-like residual oil transforms into cluster-like residual oil, the transformation rates followed by SiO2, water, and HAWP + SiO2 in descending. As the displacement progresses, the proportions of different residual oil types remain relatively stable in water flooding and SiO2 flooding systems, predominantly consisting of reticulated-like residual oil. However, in HAWP and HAWP + SiO2 flooding systems, the residual oil continues to transform into membrane-like and punctiform-like patterns.

FIGURE 13

Changes in different types of residual oil content: (A) reticulated-like residual oil, (B) cluster-like residual oil, (C) membrane-like residual oil, and (D) punctiform-like residual oil.

After injecting 3.0 PV of HAWP solution, reticulated-like residual oil accounts for 11.4%, while the proportions of cluster-like, membrane-like, and punctiform-like residual oil were approximately equal. The HAWP + SiO2 composite system achieves over 70% punctiform-like residual oil at the same injection volume. This indicated that the HAWP + SiO2 composite system shows a better transformation effect on residual oil, which is attributed to the nanoparticles' ability to adsorb onto the wall surface, improving the wall wettability and increasing the contact angle.

3.3 Analysis of oil displacement performance

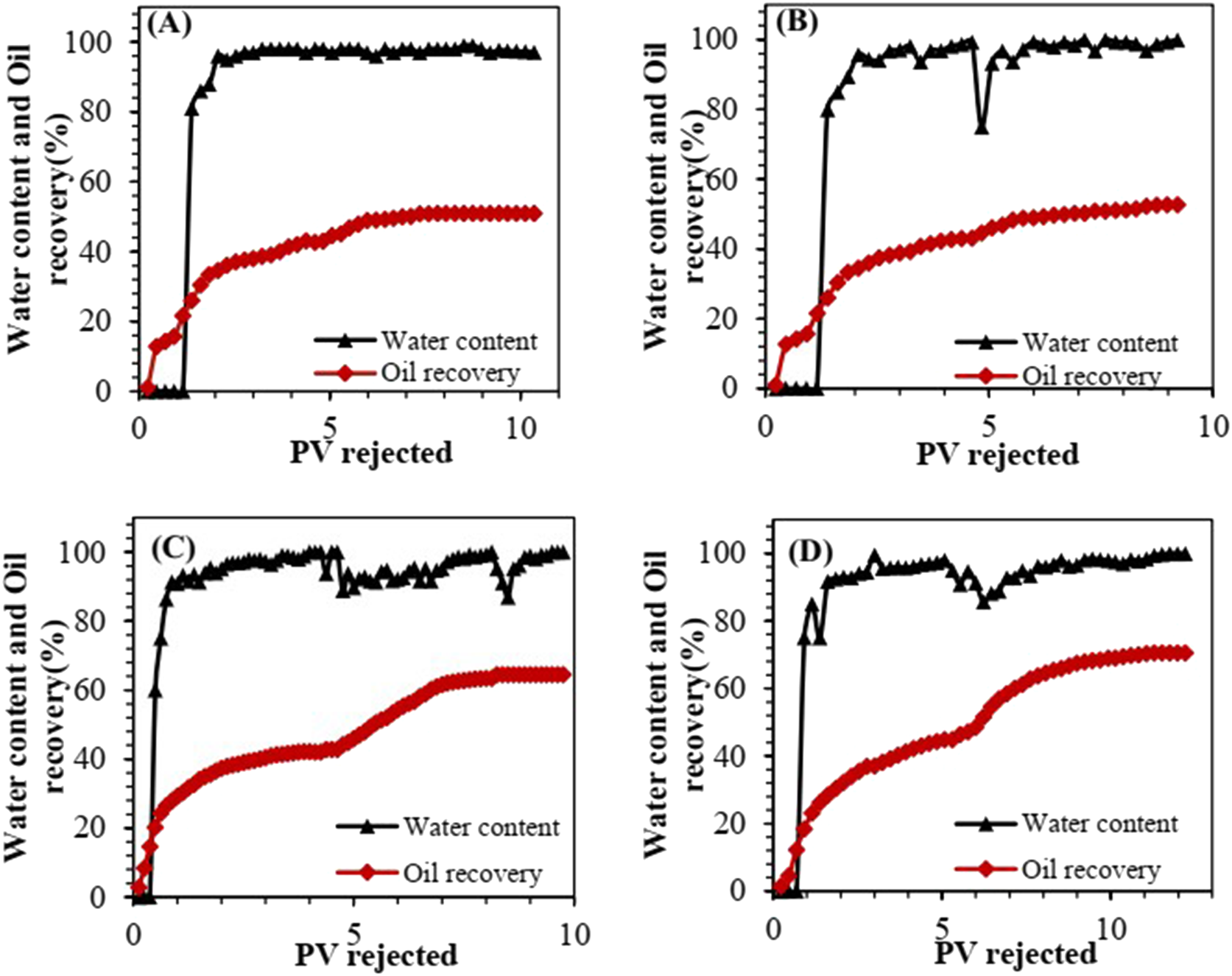

Figure 14 shows the variations in oil recovery and water content during the displacement process of different flooding systems.

FIGURE 14

Recovery efficiency and water content profiles for different flooding systems: (A) continuous water flooding, (B) 0.1% SiO2 flooding, (C) 2000 ppm HAWP flooding, and (D) 2000 ppm HAWP +0.1% SiO2 flooding.

For the continuous water flooding experiment, the water content remained near zero during the first 1.0 PV injection, while the oil recovery curve exhibited a significant increase. After 1.0 PV of formation water injection, water breakthrough occurred at the core outlet, resulting in the formation of high-permeability channels. Subsequently, the displacement efficiency decreased, leading to slow growth in oil recovery. As the formation water injection continued, the water content in the produced fluid increased rapidly, reaching 98% at 4.0 PV injection.

In the SiO2 flooding experiment, water flooding continued until the water content reached 98%. After switching to a 0.1 wt% SiO2 flooding system, the water content decreased initially but rose back to 98% after injecting 2.0 PV. The recovery curve showed a slight increase in slope after injecting 1.0 PV of this displacement system. This indicated that nanoparticle flooding showed moderate improvement over water flooding, though the effect was not significant. The improvement resulted from the nanoparticles' ability to reduce interfacial tension, alter wettability, and decrease crude oil viscosity.

In the HAWP flooding experiment, during the initial water flooding stage, the oil recovery increased rapidly while the water content remained relatively low, showing effective oil production performance. After injecting 4.0 PV of formation water, when the oil recovery was unchanged, the flooding system was switched to a 2,000 ppm HAWP solution. Similar to the initial water flooding stage, the early phase of HAWP flooding demonstrated a rapid increase in recovery efficiency accompanied by a significant decrease in water content. During the first 2.5 PV of HAWP injection, both the oil recovery and water content showed favorable performance. This enhancement can be attributed to the increased viscosity of the displacement fluid, which improved the mobility ratio and enhanced the sweep coefficient. We found that the water content would decrease after injecting 8 pore volumes (8 PV). This is mainly because the subsequent water flooding was adopted when injecting 8 pore volumes (8 PV). Before that, the displacement was carried out with 2,000 ppm HAWP. Due to its relatively high viscosity, its injection performance was not good. After switching to the subsequent water flooding, it was easier to inject, and there was still high-viscosity polymer remaining in the core. Subsequently, however, the water content began to increase again, leading to a gradual slowdown in recovery improvement.

In the combined HAWP + SiO2 flooding experiment, after 4.0 PV of water flooding, the water content of the produced fluid reached 98%. Upon switching to the 2,000 ppm HAWP +0.1wt% SiO2 displacement system, a rapid decrease in water content was observed, accompanied by an increased slope in the recovery efficiency curve, which was maintained for a considerable period. These results demonstrate that this composite system effectively displaced the residual oil in the core. The enhanced oil recovery performance can be attributed to two main mechanisms: firstly, the increased viscosity of the system improved the water-oil mobility ratio, thereby enhancing the macroscopic sweep coefficient; secondly, the system’s favorable surface activity and low interfacial tension facilitated the detachment of oil droplets from the rock surface, resulting in improved microscopic displacement efficiency.

The results indicate that a significant amount of crude oil was displaced during the initial water flooding stage. As water flooding continued, the increment in recovery efficiency gradually decreased. After switching to chemical flooding, both 2,000 ppm HAWP and 2,000 ppm HAWP +0.1wt% SiO2 systems demonstrated notable enhancement in oil recovery. The composite system achieved an additional 6% increase in recovery efficiency compared to the polymer flooding system. As shown in Figure 15, during the displacement experiments, we found that the 2000 ppm HAWP +0.1 wt% SiO2 systems could reduce the injection pressure by up to 14% compared with traditional polymers.

FIGURE 15

Injection pressure variation curves of different flooding systems.

4 Conclusion

(1) We compounded an optimal polymer/nanoparticle composite flooding system through rheological testing. The system consists of 2,000 ppm hydrophobically associating water-soluble polymer (HAWP) solution and hydrophilic SiO2-nanoparticles at a mass concentration of 0.1wt%.

(2) Basic performance tests demonstrate that the addition of SiO2 nanoparticles increases the polymer solution viscosity by over 76%. Interfacial tension measurements show that the nanoparticles effectively reduce interfacial tension. SEM image confirms that nanoparticles adsorb onto polymer molecular chains to form network structures, which explains the microscopic mechanism behind the improved viscosity of the composite system.

(3) Microscopic visualization displacement experiments reveal the oil displacement mechanism of the polymer/nano-SiO2 composite system. Compared to water flooding and polymer flooding, the polymer/nano-SiO2 composite flooding improves the sweep coefficient by 79% and 28%, respectively. It promotes the evolution of residual oil phase structure from reticular to cluster, film, and spotted patterns, enhancing displacement efficiency and achieving effective oil recovery.

(4) Core flooding experiments confirm the nanoparticle composite flooding system’s enhanced oil recovery and pressure reduction effects. Under the same injection volume, polymer/nano-SiO2 composite flooding achieves higher recovery efficiency than both water flooding and polymer flooding. As the displacement process continues, the recovery efficiency shows an increasing trend, achieving a 6% higher recovery than polymer flooding while reducing injection pressure by up to 14%.

Statements

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

BW: Methodology, Conceptualization, Resources, Writing – review and editing, Funding acquisition. NZ: Investigation, Validation, Writing – original draft, Visualization. YX: Methodology, Writing – original draft, Validation, Formal Analysis. JH: Conceptualization, Resources, Funding acquisition, Formal Analysis, Writing – review and editing. YL: Methodology, Writing – review and editing, Conceptualization. ZG: Methodology, Conceptualization, Writing – review and editing. XQ: Methodology, Writing – review and editing, Conceptualization. QD: Writing – review and editing, Conceptualization, Funding acquisition, Resources.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This project is supported by the Fund of State Key Laboratory of Deep Oil and Gas, China University of Petroleum (East China) (No. SKLDOG2024-ZYRC-04), the Natural Science Foundation of China (Grant No. 52004319, 52374061), the Joint Funds of the National Natural Science Foundation of China (Grant No. U21B2070), Science and Technology Support Plan for Youth Innovation of Colleges and Universities of Shandong Province (Grant No. 2024KJH122), and Taishan Scholars Program of Shandong Province.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1

Abidin A. Z. Puspasari T. Nugroho W. A. (2012). Polymers for enhanced oil recovery technology. Procedia Chem.4, 11–16. 10.1016/j.proche.2012.06.002

2

Aliabadian E. Ovaysi S. Rahimi M. Sundararaj U. (2019). Prevention of network destruction of partially hydrolyzed polyacrylamide (HPAM): effects of salt, temperature, and fumed silica nanoparticles. Phys. Fluids31 (1), 013104. 10.1063/1.5080100

3

Alnarabiji M. S. Husein M. M. (2020). Application of bare nanoparticle-based nanofluids in enhanced oil recovery. Fuel267, 117262. 10.1016/j.fuel.2020.117262

4

Alvarez N. J. Walker L. M. Anna S. L. (2013). A criterion for extensional stability of the interface between a fluid matrix and a dispersed fluid phase. J. Rheol.57 (6), 1596. 10.1122/1.4821555

5

Bergfreund J. Van Hooghten A. Moldenaers P. Dowding P. C. Vermant J. (2019). Adsorption of charged anisotropic nanoparticles at oil-water interfaces. Nanoscale Adv.1 (11), 4308–4312. 10.1039/c9na00506d

6

Cao J. Jiang H. Sun Y. Kuang Y. Zhang C. (2018). Application of amino-functionalized nanosilica in improving the thermal stability of acrylamide-based polymer for enhanced oil recovery. Energy and Fuels32 (1), 246–254. 10.1021/acs.energyfuels.7b02685

7

Cao R. B. Ding Z. H. Liu H. L. (2005). Experimental study on permeability limit and oil displacement effect of polymer flooding in low permeability reservoirs. Petroleum Geol. and Oilfield Dev. Daqing24 (5), 71–73.

8

Chen P. Cui Y. Lu H. Zhou J. Hu R. Jiang B. (2012). Experimental and theoretical study of dilute polyacrylamide solutions: effect of salt concentration. J. Mol. Model.18 (7), 3153–3160. 10.1007/s00894-011-1332-9

9

Cheraghian G. (2015). Thermal resistance and application of nanoclay on polymer flooding in heavy oil recovery. Pet. Sci. Technol.33 (17-18), 1580–1586. 10.1080/10916466.2015.1075036

10

Cheraghian G. Hendraningrat L. (2016). A review on applications of nanotechnology in the enhanced oil recovery part B: effects of nanoparticles on flooding. Int. Nano Lett.6 (1), 1–10. 10.1007/s40089-015-0170-7

11

Corredor L. M. Soto J. E. Parra A. F. Schechter R. S. Maini B. Sundararaj U. (2019). Heavy oil recovery by surface modified silica nanoparticle/HPAM nanofluids. Fuel252, 622–634. 10.1016/j.fuel.2019.04.145

12

Cutroneo M. Havranek V. Mackova A. Malinsky P. Silipigni L. Slepicka P. et al (2021). Synthesis of porous polydimethylsiloxane gold nanoparticles composites by a single step laser ablation process. Int. J. Mol. Sci.22 (22), 12155. 10.3390/ijms222212155

13

Dai C. Liu C. Wu A. Zou Y. Wang C. Sun Y. et al (2015). The first study of surface modified silica nanoparticles in pressure-decreasing application. RSC Adv.5 (76), 61838–61845. 10.1039/c5ra09883a

14

Eker F. Duman H. Akdaşçi E. Bolat E. Sarıtaş S. Karav S. et al (2024). A comprehensive review of nanoparticles: from classification to application and toxicity. Molecules29 (15), 3482. 10.3390/molecules29153482

15

Elhaei R. Kharrat R. Madani M. (2021). Stability, flocculation, and rheological behavior of silica suspension-augmented polyacrylamide and the possibility to improve polymer flooding functionality. J. Mol. Liq.322, 114572. 10.1016/j.molliq.2020.114572

16

Gbadamosi A. O. Junin R. Manan A. A. Agi M. Yusuff A. S. Usman J. (2019). Synergistic application of aluminium oxide nanoparticles and oilfield polyacrylamide for enhanced oil recovery. J. Pet. Sci. Eng.182, 106345. 10.1016/j.petrol.2019.106345

17

Ghoniem S. Sydberger A. Johnsson B. Wolff C. (1981). Mechanical degradation of semi‐dilute polymer solutions in laminar flows. Can. J. Chem. Eng.59 (4), 450–454. 10.1002/cjce.5450590406

18

Gumpenberger T. Mayr H. Hasse A. Saghafi H. R. Reichel S. Zechner M. (2012). “Experiments and simulation of the near-wellbore dynamics and displacement efficiencies of polymer injection, Matzen Field, Austria,” in Abu dhabi international petroleum exhibition and conference. 10.2118/162114-MS

19

Hu Y. Wang S. Q. Jamieson A. M. (1995). Rheological and rheooptical studies of shear-thickening polyacrylamide solutions. Macromolecules28 (6), 1847–1853. 10.1021/ma00110a019

20

Jacobsen J. G. (2017). Influence of residual oil on polymer injectivity. Bergen, Norway: The University of Bergen. MS thesis.

21

Kang W. L. Zhou B. B. Issakhov M. Gabdullin M. (2022). Advances in enhanced oil recovery technologies for low permeability reservoirs. Petroleum Sci.19 (4), 1622–1640. 10.1016/j.petsci.2022.06.010

22

Karami H. R. Rahimi M. Ovaysi S. (2018). Degradation of drag reducing polymers in aqueous solutions. Korean J. Chem. Eng.35 (1), 34–43. 10.1007/s11814-017-0264-1

23

Li D. D. Wang Y. F. Zhang P. (2014). Research progress on determination methods of relative molecular mass of polymers for oil displacement in low permeability reservoirs. Oilfield Chem.31 (3), 470–474.

24

Mahajan S. Sharma A. Patil P. A. Agrawal A. (2021). Polymers for enhanced oil recovery: fundamentals and selection criteria revisited. Appl. Microbiol. Biotechnol., 1–18. 10.1007/s00253-021-11378-2

25

Mirzaie Yegane M. Boukany P. E. Zitha P. (2022). Fundamentals and recent progress in the flow of water-soluble polymers in porous media for enhanced oil recovery. Energies15 (22), 8575. 10.3390/en15228575

26

Modig K. Pfrommer B. G. Halle B. (2003). Temperature-dependent hydrogen-bond geometry in liquid water. Phys. Rev. Lett.90 (7), 075502. 10.1103/PhysRevLett.90.075502

27

Mohsenatabar Firozjaii A. Saghafi H. R. (2020). Review on chemical enhanced oil recovery using polymer flooding: fundamentals, experimental and numerical simulation. Petroleum6 (2), 115–122. 10.1016/j.petlm.2019.09.003

28

Negin C. Ali S. Xie Q. (2017). Most common surfactants employed in chemical enhanced oil recovery. Petroleum3 (2), 197–211. 10.1016/j.petlm.2016.11.007

29

Puls C. Saghafi H. R. Gumpenberger T. Zechner M. (2016). “Mechanical degradation of polymers during injection, reservoir propagation and production-field test results 8 th reservoir, Austria,” in SPE europec featured at EAGE conference and exhibition, SPE. 10.2118/180132-MS

30

Raffa P. Druetta P. (2019). Chemical enhanced oil recovery: advances in polymer flooding and nanotechnology. Berlin, Germany: Walter de Gruyter GmbH and Co KG. 173. 10.1515/9783110608175

31

Rellegadla S. Prajapat G. Agrawal A. (2017). Polymers for enhanced oil recovery: fundamentals and selection criteria. Appl. Microbiol. Biotechnol.101 (11), 4387–4402. 10.1007/s00253-017-8307-4

32

Rueda E. Lira-Galeana C. Cortes-Corrberá L. Trujillo-Camacho L. Ochoa-Tapia R. (2020). Experimental investigation of the effect of adding nanoparticles to polymer flooding in water-wet micromodels. Nanomaterials10 (8), 1489. 10.3390/nano10081489

33

Sandiford B. B. (1964). Laboratory and field studies of water floods using polymer solutions to increase oil recoveries. J. Pet. Technol.16 (08), 917–922. 10.2118/844-pa

34

Seright R. S. (1983). The effects of mechanical degradation and viscoelastic behavior on injectivity of polyacrylamide solutions. SPE J.23 (03), 475–485. 10.2118/9297-PA

35

Sharma T. Kumar G. S. Cheema B. H. Chon J. S. (2015). Thermal stability of oil-in-water Pickering emulsion in the presence of nanoparticle, surfactant, and polymer. J. Ind. Eng. Chem.22, 324–334. 10.1016/j.jiec.2014.07.026

36

Sheng J. J. (2013). Enhanced oil recovery field case studies (Oxford, United Kingdom: Gulf Professional Publishing). 10.1016/B978-0-12-386545-8.00001-6

37

Smith J. D. Cappa C. D. Wilson K. R. Cohen R. C. Geissler P. L. Saykally R. J. (2005). Unified description of temperature-dependent hydrogen-bond rearrangements in liquid water. Proc. Natl. Acad. Sci.102 (40), 14171–14174. 10.1073/pnas.0506899102

38

Song B. Tang Y. Piao G. Yu Y. Zhang Z. Zydney A. L. et al (2018). Polyacrylamide degradation and its implications in environmental systems. NPJ Clean. Water1 (1), 17. 10.1038/s41545-018-0016-8

39

Song W. Hatzignatiou D. G. (2022). On the reduction of the residual oil saturation through the injection of polymer and nanoparticle solutions. J. Pet. Sci. Eng.208, 109430. 10.1016/j.petrol.2021.109430

40

Sun Y. Zhang W. Li J. Han R. Lu C. (2023). Mechanism and performance analysis of nanoparticle-polymer fluid for enhanced oil recovery: a review. Molecules28 (11), 4331. 10.3390/molecules28114331

41

Tafur N. Muñuzuri A. P. Soto A. (2022). Improvement of a surfactant blend for enhanced oil recovery in carbonate reservoirs by means of an ionic liquid. Int. J. Mol. Sci.24 (1), 726. 10.3390/ijms24010726

42

Trokhymchuk A. Nezbeda I. Jirsák J. Henderson D. (2001). A simple calculation of structural and depletion forces for fluids/suspensions confined in a film. Langmuir17 (16), 4940–4947. 10.1021/la010047d

43

Wever D. A. Z. Picchioni F. Broekhuis A. A. (2011). Polymers for enhanced oil recovery: a paradigm for structure-property relationship in aqueous solution. Prog. Polym. Sci.36 (11), 1558–1628. 10.1016/j.progpolymsci.2011.05.006

44

Wu J. Wang J. Zeng Y. Sun X. Yuan Q. Liu L. et al (2024). Biodegradation: the best solution to the world problem of discarded polymers. Bioresour. Bioprocess.11, 79. 10.1186/s40643-024-00793-1

45

Xie X. H. (2016). Research on performance evaluation of polymers in medium and low permeability reservoirs. Qingdao: China University of Petroleum East China. Ph.D. Dissertation.

46

Xu L. Zhang Y. Zhou X. Liu Q. Chen Y. (2015). Rheological properties and thickening mechanism of aqueous diutan gum solution: effects of temperature and salts. Carbohydr. Polym.132, 620–629. 10.1016/j.carbpol.2015.06.083

47

Yekeen N. Manan M. A. Taqaddas A. K. Nadeem M. J. Padmanabhan P. (2020). Synergistic influence of nanoparticles and surfactants on interfacial tension reduction, wettability alteration and stabilization of oil-in-water emulsion. J. Pet. Sci. Eng.186, 106779. 10.1016/j.petrol.2019.106779

48

Zechner M. Gumpenberger T. Saghafi H. R. Puls C. (2013). “Flow of polyacrylamide polymers in the near-wellbore-region, rheological behavior within induced fractures and near-wellbore area,” in SPE annual technical conference and exhibition, SPE. 10.2118/166281-MS

49

Zhao M. Xie Y. Li L. Dai C. Xu Z. Dong Y. et al (2024). Nanofluids with superhydrophobic nanoparticles for improved depressurization mechanism in low permeability reservoirs. Chem. Eng. J.495, 153467. 10.1016/j.cej.2024.153467

Summary

Keywords

polymer flooding, nano-SiO2, enhanced oil recovery, microscopic flooding experiments, core displacement experiment

Citation

Wei B, Zheng N, Xue Y, Hou J, Liu Y, Guo Z, Qin X and Du Q (2025) Study on multi-scale oil displacement mechanism polymer/nanoparticle composite flooding. Front. Chem. 13:1605416. doi: 10.3389/fchem.2025.1605416

Received

03 April 2025

Accepted

26 May 2025

Published

04 June 2025

Volume

13 - 2025

Edited by

Junwei Su, Xi’an Jiaotong University, China

Reviewed by

Tianyi Liu, Brewer Science, United States

Jianguang Wei, Northeast Petroleum University, China

Updates

Copyright

© 2025 Wei, Zheng, Xue, Hou, Liu, Guo, Qin and Du.

This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jian Hou, sllx_upc@126.com

Disclaimer

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.