Abstract

Polyurethane (PU) pyrolysis characteristics were investigated using reactive force field molecular dynamics simulations to reveal the product distribution and thermal decomposition mechanisms. A PU molecular model was constructed and simulated its pyrolysis process at 1,500–3,000 K, analyzing potential energy changes, product species, carbon-containing component distribution, main gas products, main intermediate products and initial cleavage pathways. At 1,500 K, PU mainly decomposes into NHCOO and CH2 fragments, with concurrent gas release. At 1,800–2,100 K, aromatic amines, olefins, and gases (including CO2, CO, and NH3) are formed through radical recombination. At higher temperatures (2,400–3,000 K), carbon rearrangement is promoted, yielding dense C40+ species alongside persistent gases. The results show that PU pyrolysis initiates with the C-O-C bond cleavage of the NHCOOCH2 group, generating NHCOO and CH2 fragments, and this cleavage occurs via a homolytic pathway. The dynamic competition between main chain scission and radical recombination drives the complex pyrolysis network, with temperature governing product diversity. This work provides microscopic insights into PU thermal degradation, supporting applications in fire safety assessment and material recycling.

1 Introduction

Polyurethane (PU) materials have been widely applied in traditional industries, new energy fields, and high-end fields where specific applications include furniture manufacturing, construction, transportation, and electronic devices, owing to their exceptional thermal insulation properties, lightweight characteristics, high mechanical strength, and outstanding adhesion capabilities (Hu et al., 2022; Nishiyama et al., 2020; Qin et al., 2020; Zhang et al., 2024). With the continuous increase of PU materials, the amount of waste generated has also risen significantly, posing substantial environmental threats (Yao et al., 2018). Effective management of discarded PU materials can reduce dependence on petroleum-based raw materials and mitigate the risks of environmental pollution, thus being of vital significance for the sustainable development of the chemical industry and the protection of the ecological environment (Fang et al., 2024; Oenema et al., 2022).

Within the domain of PU recycling, pyrolysis technology plays a crucial role in the resource recovery, feedstock recycling, and energy conversion of waste (Chuang, 2007). Under high temperatures, PU is decomposed into smaller molecular weight compounds, which can then be further converted into valuable chemicals or fuels (Sharuddin et al., 2016). Ha et al. studied the pyrolysis behavior of PU in a nitrogen atmosphere and noted that the pyrolysis of PU proceeds through two distinct weight loss steps (Ha and Jeon, 2024). Tang et al. investigated the dynamic pyrolysis behavior of PU and revealed that its pyrolysis yielded a diverse array of products, including alkenes, alkanes, aromatics, esters, and alcohols, while the pyrolytic gas products comprised CO2, CH4, and C2H2 (Tang et al., 2021). However, the majority of existing research in this field has centered on traditional experimental approaches, which primarily employ thermogravimetry and mass spectrometry for product analysis (Chen et al., 2023; Yao et al., 2020). The high temperature not only significantly elevates reaction complexity but also makes it challenging for traditional methods to accurately capture critical short-lived radicals and intermediate products during pyrolysis.

In contrast, the reactive force field molecular dynamics (ReaxFF MD) demonstrates its unique application advantages (van Duin et al., 2001), which can accurately simulate the bonding and debonding processes of chemical bonds at the atomic scale. ReaxFF MD has been conducted to investigate the pyrolysis and combustion processes of polymer materials (Liu et al., 2023; Wan et al., 2021; Xu et al., 2023; Yan et al., 2024; Zhang et al., 2025). Yan et al. investigated the mechanism of CO2 generation in HT long-flame coal molecule combustion via ReaxFF MD simulation at 2,000–3,500 K, and these simulations also demonstrate that ReaxFF MD can describe HT coal combustion behaviors (Yan et al., 2024). Zhang et al. studied the pyrolysis and combustion mechanisms in PP dust explosions through the integration of ignition experiments and ReaxFF MD simulations, which revealed the molecular-level intrinsic mechanisms of flame propagation both inside and outside the tube for PP dust (Zhang et al., 2025). Afroz et al. used ReaxFF to investigate the physicochemical, mechanical properties, stimulus response behavior of the PU rigid segment, with the stress relaxation trend consistent with experimental results (Afroz et al., 2023).

As a result, this paper will employ ReaxFF MD to study the pyrolysis process of PU at varying temperatures. The pyrolysis mechanism of PU is systematically elucidated by analyzing the potential energy of PU, the product species, the weight percentage distribution of carbon-containing species, and the composition of main gaseous products, as well as the initial cracking pathways of PU molecular chains. All of these offer microscopic insights into the pyrolysis product generation mechanisms and PU thermal degradation behaviors, which are essential for developing applications in environmental protection, material recycling, and fire safety evaluation.

2 Simulation details

2.1 Model construction

The exploration of PU pyrolysis requires a suitable PU model. PU is synthesized by reacting isocyanates and polyols, and the most representative synthesis involves diphenylmethane diisocyanate (MDI) and polyols (Afroz et al., 2023; Shin et al., 2022). Based on the published article, the repeating unit of PU was first built using Materials Studio 8.0 modeling software based on the molecular structure, as depicted in Figure 1a. To generate PU polymer segments, each end of the polymer chain was terminated with a methyl (CH3) group (Afroz et al., 2023). To simulate the decomposition mechanism of PU, a molecular model was constructed. The value of n in Figure 1a is 8, and therefore the molecular formula of a single PU chain is C154H166O32N16. This chain contains 368 atoms and has a molecular weight of 2,753 g/mol (Figure 1b). The amorphous cell of PU was constructed by Rotational Isomeric State (RIS) model (Flory, 1969) to pack chains in a three-dimensional box subject to periodic boundary conditions at realistic density without close contacts. An amorphous cell containing 10 polymer chains was constructed as the initial configuration (Figure 1c), with a cubic box length of 35.70 Å and with a PU density of 1.0 g/cm3 (Galadari, 2023; Wei et al., 2024).

FIGURE 1

Molecular models of PU. (a) PU repeat unit (b) PU chain (c) PU amorphous cell with 10 chains.

2.2 Molecular dynamics simulations

The PU systems were annealed from 300 to 600 K at intervals of 50 K to eliminate the local irrational structure. The condensed-phase optimized molecular potentials for atomistic simulation studies (COMPASS) forcefield (Sun, 1998) was applied to the MD simulation. The MD simulation of NPT (constant pressure and temperature) and NVT (canonical ensemble) was carried out for 500 ps with a time step of 0.1 fs, respectively. The temperature and pressure were both controlled by Berendsen method.

2.3 ReaxFF MD simulation

The appropriate force field is the key to molecular simulation, and the ReaxFF is the latest generation of molecular force field, which not only has the basic properties of traditional forcefields, but also can simulate the process of chemical reaction by judging the formation or breaking of chemical bonds in molecules, and iterates circularly (Li et al., 2021). After classical MD simulation, a 30 ps low-temperature equilibration simulation was performed at 300 K with the NVT ensemble by ReaxFF. The high temperature accelerated reaction kinetics was commonly adopted, in which simulations were conducted at elevated temperatures to accelerate reactions within workable computational time (Salmon et al., 2009; Sorensen and Voter, 2000). Thus six temperatures (1,500, 1,800, 2,100, 2,400, 2,700, and 3,000 K) were chosen for the products collection and analysis in the pyrolysis process of PU.

Berendsen thermostat (Arvelos et al., 2019) was used to control the temperature, and the temperature damping coefficient was set to 10 fs. The time step was 0.1 fs, and data were outputted every 50 fs. After the simulation was completed, the product distribution and main reaction mechanisms were analyzed, and the molecular structure was visually analyzed by OVITO software (Stukowski, 2009). The output file was implemented in Chemical Trajectory Analyzer (ChemTraYzer), and bond type assignment is currently implemented using the bond order perception function in Open Babel Library (Dontgen et al., 2015; O'Boyle et al., 2011).

3 Results and discussion

3.1 Potential energy and species number of the PU

The activation energy of PU decomposition was calculated. The calculated data and procedures are provided in the Supplementary Material. From Supplementary Figure S1, the Ea of PU was 136.35 kJ/mol, which is in good agreement with the experimental data (Sun et al., 2023; Wang et al., 2014). Additionally, the linear correlation coefficient was 0.99. These results proved that the ReaxFF MD method was practicable to the study of the decomposition process of PU.

The total energy of the system is composed of kinetic and potential energy, where the dynamic variations in potential energy reveal the endothermic and exothermic characteristics of the system throughout the pyrolysis process (Hong and Guo, 2017). Figure 2 displays the evolution of potential energy and species number of the PU as a function of time at different temperatures.

FIGURE 2

Potential energy (a) and species number (b) of the PU as a function of time at different temperatures.

As shown in Figure 2a, the potential energy reflecting the endothermic energy required for bond dissociation during pyrolysis exhibits a distinct increase with temperature. When the temperature increases, the potential energy rises, and the energy absorption is enhanced. As shown in Figure 2b, at 1,500–2,400 K, the number of product species continuously increases before stabilizing. In contrast, at 2,700–3,000 K, the product species first rise sharply and then decline gradually over time. The results indicated that insufficient energy leads to incomplete reactions and fewer product species at 1,500 K. At 1,800–2,400 K, the number of product species increases with rising temperature, as higher temperatures promote collisions between intermediate products, generating a wider variety of fragment species. At temperatures of 2,700 K and 3,000 K, the number of product species exhibits a gradual decline following a peak, indicating at least two distinct chemical reaction stages during pyrolysis. PU undergoes rapid decomposition into small molecular species, with some products serving as reactants in subsequent reaction stages.

These findings are consistent with the multi-stage decomposition mechanism of PU proposed by Chen et al. (2023). In the initial two stages, C - O bond cleavage occurs via relatively weak intermolecular interactions or bond ruptures requiring moderate energy input. Conversely, the decomposition of the isocyanate segment and char formation in the final two stages involve the rupture of stronger chemical bonds within rigid isocyanate moieties, concomitantly with the formation of stable condensed-phase char structures. The latter two processes involve the absorption of more heat, thereby leading to a significant elevation in potential energy at high temperatures. These results indicate the critical role of temperature in governing pyrolysis reaction pathways and thermochemical behaviors.

3.2 Product distribution

To further study the product distribution, the components with different number of carbon atoms were classified in Figure 3. Gaseous species are subdivided into C0 and C1–C4 according to the number of carbon atoms. The lumps of C5–C40 represent tar. C40+ can be considered as solid char product (Yin et al., 2018).

FIGURE 3

Pyrolysis composition of PU at different temperatures. (a) C0, (b) C1–C4, (c) C5–C40, and (d) C40+.

Figure 3 illustrates the variations in the weight percentage of C0, C1–C4, C5–C40, and C40+ at different temperature. At 1,500 K, the weight percentage of C0 and C5-C40 are negligible, C1–C4 gases are scarcely generated, and the pyrolysis products of PU are dominated by intact C40+ macromolecules. As temperature increases to 1,800–2,100 K, C1–C4 gases accumulate gradually, while C5–C40 intermediates emerge and stabilize, reflecting initial cleavage of PU chains into smaller fragments. At 2,400–3,000 K, C1–C4 gases peak rapidly within 25 ps, C5–C40 species surge initially but decline over time due to secondary reactions, and C40+ weight percentage plummets sharply in the first 10 ps. Notably, beyond 50 ps, C40+ content rises slowly with temperature, indicating recombination of C5–C40 fragments into larger organic substances. A temperature-dominated two-stage pyrolysis mechanism was revealed in this pyrolysis process.

In the moderate-temperature stage of 1,800–2,100 K, PU molecules underwent moderate decomposition to generate C1–C4 gases and C5–C40 intermediates, without complete chain scission, which was confirmed by the stabilization of C40+ content after an initial decline. When the temperature rose to 2,400–3,000 K, radical chain scission reactions dominated, producing abundant short and medium-chain fragments. Subsequently, the recombination of C5–C40 species into C40+ reflected the dynamic balance between fragmentation and recombination. This process is closely associated with the endothermic nature of PU decomposition.

3.3 Analysis of main products

3.3.1 Main gas products

In the analysis of pyrolysis gas products of PU, the number of CO2 was found to be dominant, followed by CO and NH3, which is consistent with the conclusion by Jiao et al. (2013) pointed out that CO2 is the primary product at high temperatures. The number distribution of CO2, CO, and NH3 is closely linked to their formation mechanisms. As the main gas products of PU pyrolysis, the number of CO2, CO, and NH3 at different temperatures, and the production and consumption percentages of reaction paths for the CO2, CO, and NH3 at 2,700 K were statistically classified, respectively. The production and consumption percentages refer to the proportion of occurrences of this specific reaction relative to the total occurrences of the listed major reactions.

Figure 4 presents the number of CO2 at different temperatures and the reaction pathways of CO2 at 2,700 K. According to Figure 4a, the number of CO2 increases sharply with rising temperature during the initial pyrolysis stage. When the pyrolysis temperature ranges from 1,500–1,800 K, CO2 molecules accumulate gradually over simulation time. At 2,100 K, CO2 molecules first surge abruptly and then stabilize. In the high-temperature range of 2,400–3,000 K, CO2 molecules rapidly increase to a peak value and subsequently decline, with the descent rate accelerating at higher temperatures. To investigate the balance between the CO2 production and consumption percentages, the reaction pathways of CO2 at 2,700 K are selected and depicted in Figure 4b.

FIGURE 4

The number of CO2 at different temperatures (a) and the reaction pathways of CO2 at 2,700 K (b).

The primary formation pathway for CO2 is CHO2 → CO2 + H. CO2 generation originates from the decomposition of -NH-COO- groups in the PU chain. This process is extremely rapid, causing CO2 to reach peak values quickly as pyrolysis temperature increases. Differences in CO2 production and consumption are observed across temperatures. At lower pyrolysis temperatures (e.g., 1,500–2,100 K), limited consumption pathways lead to a steady increase in CO2 molecules over time. Conversely, at higher temperatures (e.g., 2,400–3,000 K), the consumption rate exceeds the formation rate, causing CO2 molecules to decrease with faster declines at higher temperatures. This is likely attributed to enhanced participation of CO2 in subsequent chemical reactions at high temperatures, where increased radicals and reactive species promote CO2 conversion and consumption to form other gas products, such as CO and hydrocarbons.

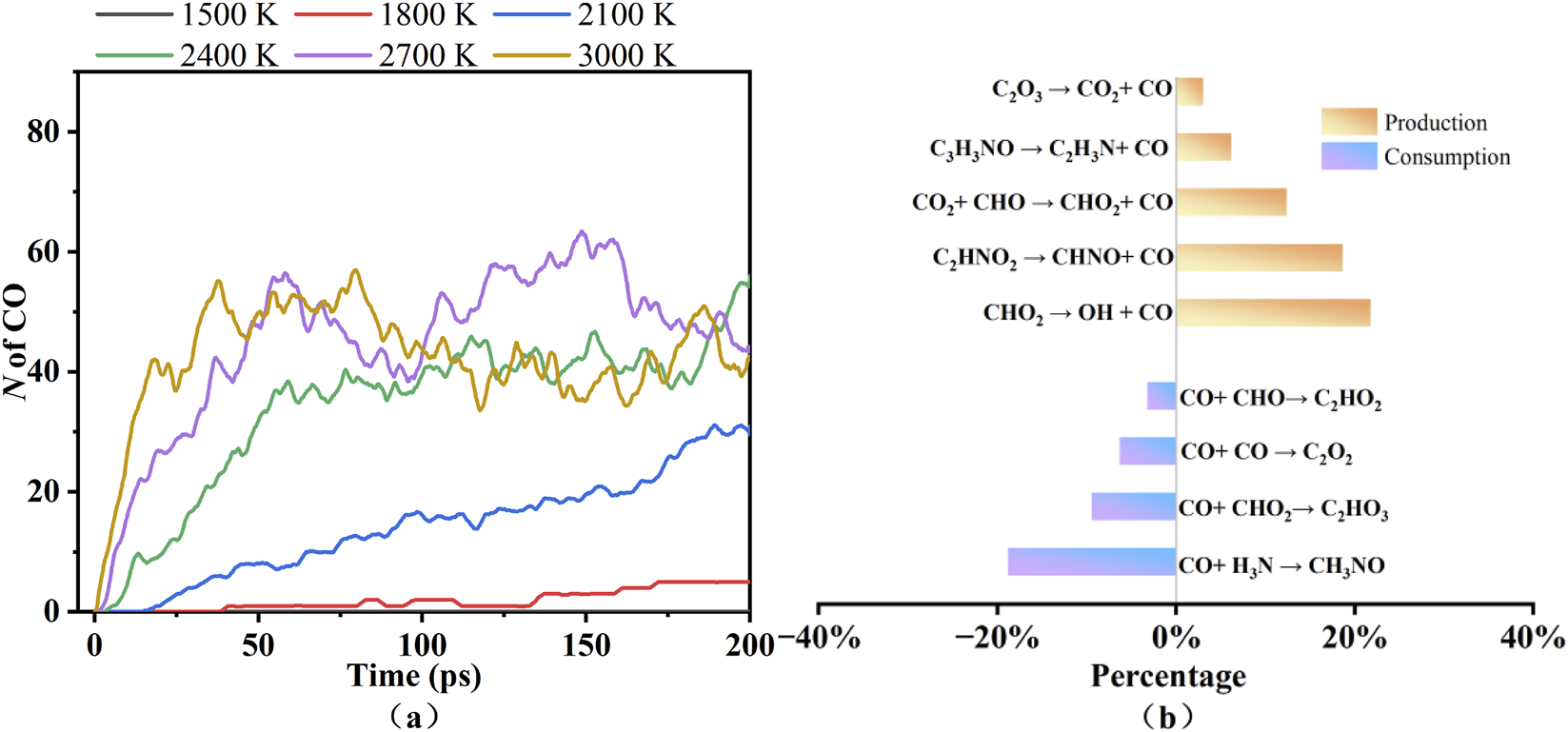

Figure 5 displays the dynamic profiles of CO number at different temperatures and the reaction pathways at 2,700 K. As shown in Figure 5a, the number of CO gradually increases with rising pyrolysis temperature. The number of CO remains zero throughout the simulation at 1,500 K. At lower temperatures (e.g., 1,800 K, 2,100 K), the growth of the CO molecular number is much slower. By contrast, in the higher temperature range (e.g., 2,700 K, 3,000 K), the CO formation rate significantly accelerates, leading to a marked increase in molecular number. However, due to the relatively high reaction energy barriers, its total amount is significantly lower than that of CO2. Figure 5b reveals that the percentage of production exceeding that of consumption, resulting in a gradual increase in CO molecular number. The primary formation pathway for CO is CHO2 → OH + CO, while CO + H3N → CH3NO represents a key consumption pathway.

FIGURE 5

The number of CO at different temperatures (a) and the reaction pathways of CO at 2,700 K (b).

Compared with CO2 and CO, the number of NH3 is relatively low, and it exhibits remarkable periodic fluctuations throughout the simulation time. The number of NH3 is constrained by the localized nitrogen enrichment in PU, as its formation requires C-N bond cleavage and radical recombination processes. Figure 6 illustrates the number of NH3 at different temperatures and the reaction pathways of NH3 at 2,700 K. The high temperature further aggravates such fluctuations, indicating that both the production and consumption of NH3 are characterized by high reaction rates. As shown in Figure 6a, the number of NH3 remain at extremely low levels, effectively approaching zero at 1,500 K and 1,800 K. Within the 2,100–3,000 K temperature, the number of NH3 exhibits pronounced temperature dependent oscillatory behavior over simulation time. The initial appearance time of NH3 progressively advances with increasing pyrolysis temperature. In Figure 6b, at 2,700 K, the production percentage of NH3 is slightly lower than that of consumption. Combined with the oscillatory characteristics exhibited by the time-dependent variations in NH3 number, this imbalance is likely attributed to the complex chemical reaction network in high-temperature environments, where competitive mechanisms exist between NH3 production and consumption pathways. This phenomenon indicates that high-temperature significantly enhance the kinetic rates of relevant chemical reactions, activating the NH3 production-consumption reaction network and leading to high-frequency, large-amplitude oscillations in its concentration.

FIGURE 6

The number of NH3 at different temperatures (a) and the reaction pathways of NH3 at 2,700 K (b).

3.3.2 Main intermediate products

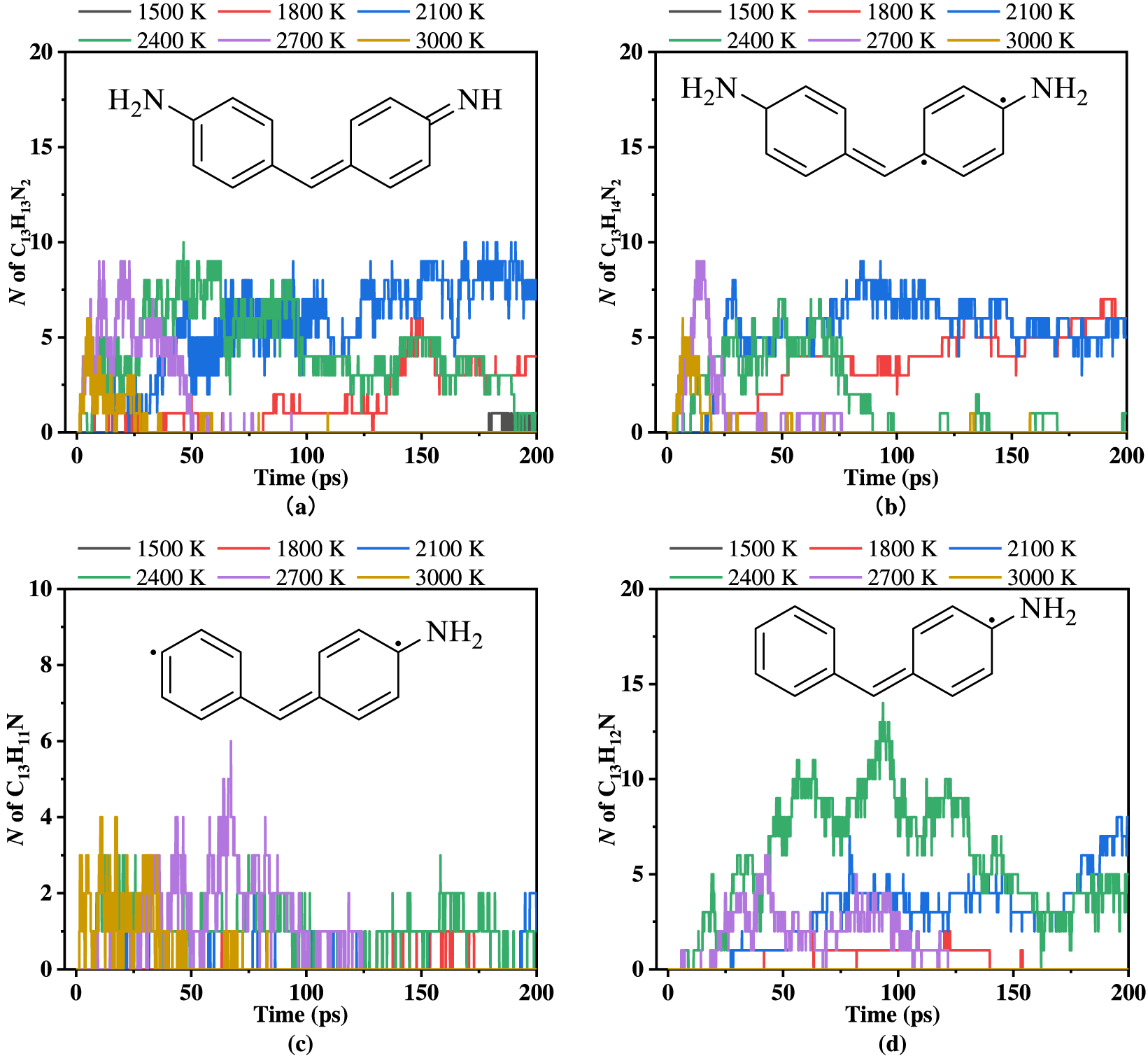

Based on the analysis of the structure of PU in Figure 1 and the pyrolysis products of PU, C13 is a typical intermediate product. Figure 7 illustrates the molecular number of C13H13N2, C13H14N2, C13H11N, and C13H12N at different pyrolysis temperatures. As the pyrolysis temperature gradually increases from 1,500 K to 3,000 K, the emergence time of these nitrogen-containing products advances significantly, and their number initially rises. However, within the temperature range of 2,400–3,000 K, their numbers decrease, with the decline accelerating at higher temperatures. This phenomenon indicates that although intense pyrolysis reactions occur at high temperatures, excessively high temperatures lead to further cleavage or recombination of intermediate products. As shown in Figure 3, the mass fractions of C1–C4 and C5–C40 decrease with the increase in pyrolysis temperature, while the mass fraction of C40+ increases, suggesting that excessive temperature promotes the recombination of intermediate products into C40+.

FIGURE 7

The number of C13H13N2(a), C13H14N2(b), C13H11N (c), and C13H12N (d) at different temperatures.

To investigate the distribution characteristics of carbon atom numbers in C40+ components, the detailed analyses of pyrolysis products at each simulation step are performed. Therein, the product with the highest carbon atom count is defined as the maximum carbon fragment. To explore the molecular structure of C40+, analysis combined with Figure 3 indicated that at pyrolysis temperatures of 2,700 K and 3,000 K, the mass fraction of C40+ exhibited a gradual upward trend during late-stage pyrolysis. OVITO software was employed to conduct visual analyses of the final products at these two temperatures. Hydrogen atoms were excluded from the analysis to enhance observation clarity. The carbon atom and the total numbers of the maximum carbon fragments and the visual structures of the final products are presented in Figure 8.

FIGURE 8

The number of carbon and total atoms in the maximum carbon fragments at different temperatures (a,b), the molecular structure of PU at 200 ps (2,700 K (c), 3,000 K(d)).

As demonstrated in Figure 8a, the maximum carbon fragment at 1,500 K contained 154 carbon atoms, which precisely matched the carbon atom number in the C154H166O32N16 fragment of PU. This finding further confirms that 1,500 K is insufficient to induce PU decomposition. With increasing temperature, the carbon number of the maximum fragment decreased abruptly. Above 1,500 K, the number remained below 154 within the range of 1,800–2,400 K. Notably, between 2,700 K and 3,000 K, the carbon number first declined rapidly and then increased, reaching approximately 1,200 atoms at 3,000 K. As shown in Figure 8b, the total number of the maximum carbon fragments and that of carbon atoms exhibit a consistent trend, with the total number reaching approximately 1,950 atoms at 3,000 K.

At 200 ps, the molecular structures of PU at 2,700 K and 3,000 K are presented in Figures 8c,d, respectively. These figures illustrate typical C40+ fragments marked with yellow circles, which exhibit benzene ring recombination structures. These observations indicate that high temperatures promote carbon recombination, leading to the formation of larger carbon fragments. At 2,700 K, the molecular structure of C40+ appeared relatively loose, characterized by sparse carbon-carbon linkages, whereas at 3,000 K, the C40+ structure became more compact with denser connections, forming a thermodynamically stable fragment. This phenomenon strongly supports the proposed dynamic competition mechanism involving main chain scission and radical recombination, highlighting that PU pyrolysis does not represent a unidirectional degradation process but rather a complex network process encompassing primary bond cleavage and secondary chain formation. These findings provide critical microscopic evidence for elucidating the distribution patterns of PU pyrolysis products and the formation mechanisms of solid residues.

3.4 Thermal decomposition mechanism for PU pyrolysis

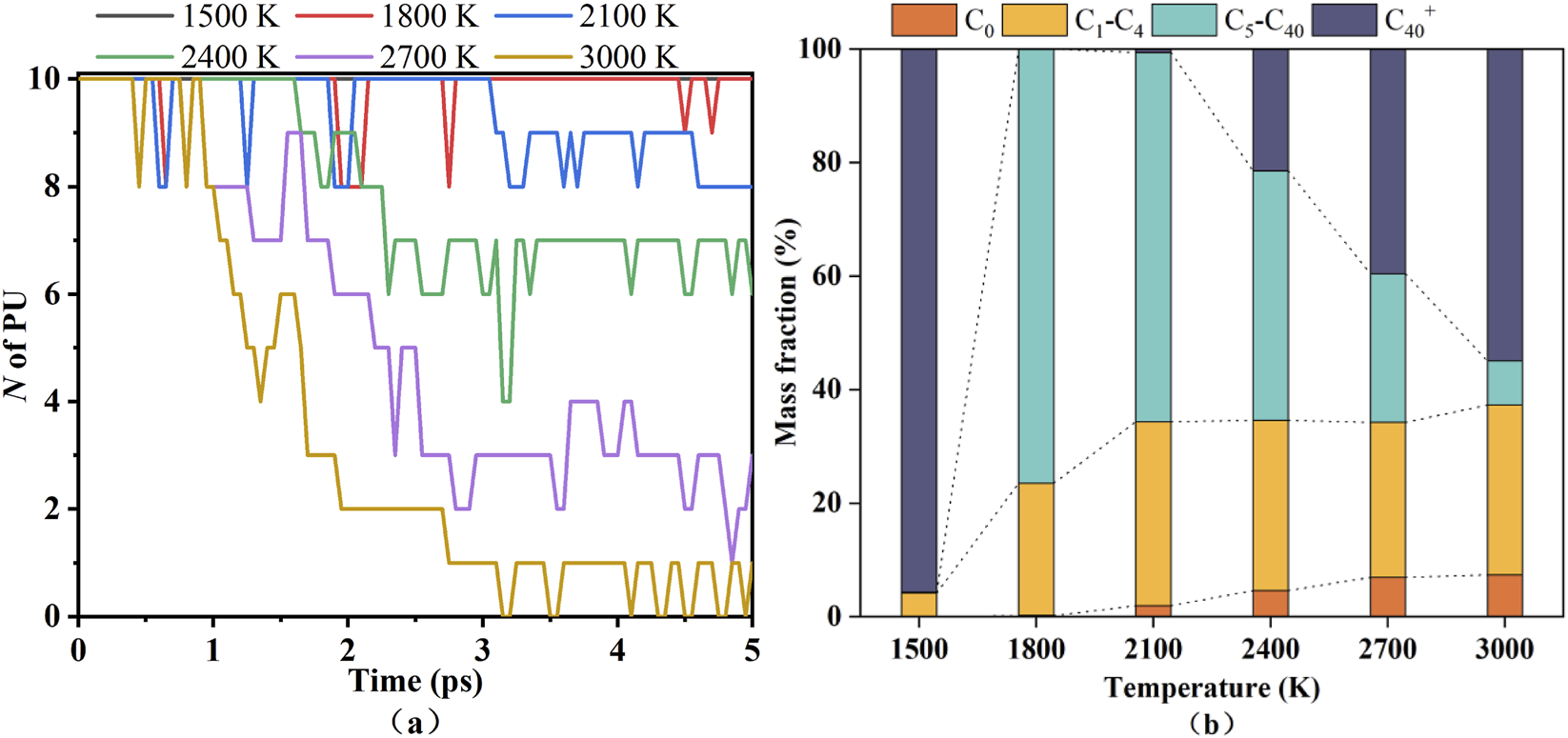

To deeply explore the pyrolysis mechanism of PU, simulation study on the pyrolysis process of PU within the time frame of the first 5 ps was conducted. Figure 9a depicts the number of PU across the temperature range of 1,500–3,000 K. A clear positive correlation exists between temperature and the decomposition rate of PU, with higher temperature facilitating more rapid depletion of PU molecules. Notably, within the first 3 ps, PU remains incompletely dissociated into small molecule fragments, thereby rendering this temporal regime a unique window for probing the initial pyrolysis pathways of PU.

FIGURE 9

The number of PU at different temperatures (a) and weight percentages of C0, C1–C4, C5–C40, and C40+ at 200 ps (b).

Based on the analysis of the initially generated products, regardless of high temperature or low temperature, it can be inferred that PU pyrolysis initiates with the C-O-C bond cleavage of the NHCOOCH2 group, generating NHCOO and CH2 fragments, and this cleavage occurs via a homolytic pathway. This is consistent with the results of the stress - strain behavior of PU (Afroz et al., 2023). They pointed out that each of the chains was observed to break at the same spot on the polymer backbone where the MDI and BDO segment of the molecule were connected, more specifically, the C-O-C cleavage. None of the molecules was broken at the C-C-C or C-N-C cleavages (Afroz et al., 2023). Extracting the mass percentages of C0, C1–C4, C5–C40, and C40+ at 200 ps for each temperature from Figure 3 and plotting them (Figure 9b) reveals distinct evolution trends of pyrolysis fragments. At 1,500 K, where pyrolysis proceeds minimally, the C40+ macromolecular fraction dominates. With increasing temperature, the mass fraction of C5–C40 declines sharply, that of C40+ increases steadily, while C0 and C1–C4 exhibit negligible variations. Such trends validate the two - stage pyrolysis mechanism of PU, whereby low - temperature pyrolysis first produces gases (C1–C4) and intermediate C5–C40 fragments, which then recombine into C40+ macromolecules at higher temperatures.

The proposed CO2 release mechanism is presented in Figure 10. The generation of CO2 is detected as early as 0.28 ps, and its generation process is shown in Figure 10. The release of CO2 mainly results from the thermal instability of -NH-COO- in the PU chain. Under thermal conditions, these bonds preferentially cleave through hydrogen radical transfer reactions, thus releasing CO2. According to the types of pyrolysis products, the pyrolysis mechanism of PU was obtained, as shown in Figure 11.

FIGURE 10

Formation of CO2 observed in the pyrolysis of PU.

FIGURE 11

Thermal decomposition mechanism for PU pyrolysis.

Figure 11 depicts the pyrolysis mechanism of PU, initiated by C-O-C bond cleavage within the NHCOOCH2 moiety, yielding NHCOO and CH2 fragments, and this cleavage occurs via a homolytic pathway. At 1,500 K, PU remains thermally stable with intact C40+ macromolecules, characteristic of low-temperature ester scission. In the 1,800–2,100 K range, deeper decomposition generates aromatic amines, olefins, and gases (CO, NH3), indicative of radical recombination. At 2,400–3,000 K, high temperature induces carbon rearrangement (e.g., benzene ring recombination), forming dense C40+ networks coexisting with persistent gases.

It can be seen from Figure 11 that the temperature determines product diversity, where lower temperatures yield NHCOO and CH2 fragment, moderate temperatures produce aromatic amines and olefins, and high temperatures form C40+ solids, reflecting scission-recombination dynamics. The visual progression from intact PU to fragmented NHCOO and CH2 fragment and finally to C40+ networks maps the temperature-driven structural evolution. Gas products such as CO2, CO, and NH3 persist through all stages, while C40+ emerges at extreme temperatures (2,400–3,000 K), indicating a shift towards stable char structures.

This integration of bond cleavage, product formation, and structural evolution offers a visual roadmap for PU thermal degradation, from molecular fragmentation to solid residue formation, consistent with the mechanistic analysis presented in the study. The complexity of this pyrolysis behavior holds significant practical implications: the release of flammable C1–C4 gases requires key prevention and control in fire safety design, while the presence of tar-like C5–C40 intermediates poses challenges for PU recycling technologies. The findings further highlight the unique advantages of ReaxFF MD in capturing the complex thermochemical behaviors of PU pyrolysis, as they can reveal radical reaction pathways and dynamic equilibrium mechanisms that are difficult to observe experimentally.

4 Conclusion

This study employs ReaxFF MD to unravel the pyrolysis mechanisms and product distribution of PU, revealing a temperature-dependent decomposition process. At 1,500 K, PU remains thermally stable with intact C40+ macromolecules, while moderate temperatures (1,800–2,100 K) induce ester bond cleavage, yielding NHCOOCH2 group, generating NHCOO and CH2 fragments and CO2 alongside C1–C4 gases and C5–C40 intermediates. At 2,400–3,000 K, radical-driven scission dominates, followed by recombination of C5–C40 fragments into dense C40+ networks, demonstrating a dynamic balance between fragmentation and carbon rearrangement.

The major pyrolysis products include CO2, CO, NH3, and olefins. C5–C40 tar-like intermediates peak at moderate temperatures but decline at high temperatures due to secondary reactions, while C40+ content rebounds at 2,700–3,000 K through aromatic recombination, forming thermodynamically stable char structures. Nitrogen-containing species (e.g., C13H13N2) exhibit similar temperature-dependent trends, reflecting their role as transient intermediates.

Mechanistically, PU pyrolysis initiates with C-O-C bond cleavage in NHCOOCH2 groups, driving a complex network of chain scission and radical recombination. Temperature dictates product diversity: low temperatures favor NHCOO and CH2 fragment/gas release, moderate temperatures promote aromatic amine/olefin formation, and high temperatures enable solid residue generation. These findings validate ReaxFF MD as a robust tool for polymer pyrolysis studies, offering critical insights for fire safety assessment, waste recycling, and thermal material design.

Statements

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding authors.

Author contributions

TD: Software, Formal Analysis, Project administration, Writing – review and editing, Validation, Supervision, Methodology, Writing – original draft, Investigation, Data curation. TZ: Software, Formal Analysis, Data curation, Writing – original draft. XH: Investigation, Resources, Formal Analysis, Validation, Methodology, Writing – review and editing, Data curation. YL: Validation, Project administration, Data curation, Writing – review and editing, Methodology, Formal Analysis, Investigation.

Funding

The authors declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Correction note

This article has been corrected with minor changes. These changes do not impact the scientific content of the article.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fchem.2025.1691308/full#supplementary-material

References

1

Afroz M. M. Shin Y. K. van Duin A. C. T. Li-Oakey K. D. (2023). ReaxFF reactive force field model enables accurate prediction of physiochemical and mechanical properties of crystalline and amorphous shape‐memory polyurethane. J. Appl. Polym. Sci.140, 54466. 10.1002/app.54466

2

Arvelos S. Abrahao O. Hori C. E. (2019). ReaxFF molecular dynamics study on the pyrolysis process of cyclohexanone. J. Anal. Appl. Pyrol.141, 104620. 10.1016/j.jaap.2019.05.009

3

Chen X. Cai D. Yang Y. Sun Y. Wang B. Yao Z. et al (2023). Pyrolysis kinetics of bio-based polyurethane: evaluating the kinetic parameters, thermodynamic parameters, and complementary product gas analysis using TG/FTIR and TG/GC-MS. Renew. Energ.205, 490–498. 10.1016/j.renene.2023.01.078

4

Chuang F. S. (2007). Analysis of thermal degradation of diacetylene-containing polyurethane copolymers. Polym. Degrad. Stabil.92, 1393–1407. 10.1016/j.polymdegradstab.2007.02.020

5

Dontgen M. Przybylski-Freund M.-D. Kroeger L. C. Kopp W. A. Ismail A. E. Leonhard K. (2015). Automated discovery of reaction pathways, rate constants, and transition states using reactive molecular dynamics simulations. J. Chem. Theory Comput.11, 2517–2524. 10.1021/acs.jctc.5b00201

6

Fang D.-X. Chen M.-J. Zeng F.-R. Guo S.-Q. He L. Liu B.-W. et al (2024). Self-evolutionary recycling of flame-retardant polyurethane foam enabled by controllable catalytic cleavage. Mater. Horiz.11, 3585–3594. 10.1039/D4MH00039K

7

Flory P. (1969). Statistical mechanics of chain molecules. New York: Interscience.

8

Galadari M. (2023). Robust polyurethane-zeolite composites with diverse applications. Ph.D. Thesis (Los Angeles, CA, USA: University of California).

9

Ha Y. Jeon J. (2024). Thermogravimetric analysis and pyrolysis characterization of expanded–polystyrene and polyurethane–foam insulation materials. Case Stud. Therm. Eng.54, 104002. 10.1016/j.csite.2024.104002

10

Hong D. Guo X. (2017). Molecular dynamics simulations of zhundong coal pyrolysis using reactive force field. Fuel210, 58–66. 10.1016/j.fuel.2017.08.061

11

Hu S. He S. Wang Y. Wu Y. Shou T. Yin D. et al (2022). Self-repairable, recyclable and heat-resistant polyurethane for high-performance automobile tires. Nano Energy95, 107012. 10.1016/j.nanoen.2022.107012

12

Jiao L. Xiao H. Wang Q. Sun J. (2013). Thermal degradation characteristics of rigid polyurethane foam and the volatile products analysis with TG-FTIR-MS. Polym. Degrad. Stabil.98, 2687–2696. 10.1016/j.polymdegradstab.2013.09.032

13

Li W. Yu S. Zhang L. Chen J. Cao W. Lan Y. (2021). ReaxFF molecular dynamics simulations of n-eicosane reaction mechanisms during pyrolysis and combustion. Int. J. Hydrogen Energ.46, 38854–38870. 10.1016/j.ijhydene.2021.08.234

14

Liu S. Wei L. Zhou Q. Yang T. Li S. Zhou Q. (2023). Simulation strategies for ReaxFF molecular dynamics in coal pyrolysis applications: a review. J. Anal. Appl. Pyrol.170, 105882. 10.1016/j.jaap.2023.105882

15

Nishiyama Y. Kumagai S. Motokucho S. Kameda T. Saito Y. Watanabe A. et al (2020). Temperature-dependent pyrolysis behavior of polyurethane elastomers with different hard- and soft-segment compositions. J. Anal. Appl. Pyrol.145, 104754. 10.1016/j.jaap.2019.104754

16

O'Boyle N. M. Banck M. James C. A. Morley C. Vandermeersch T. Hutchison G. R. (2011). Open babel: an open chemical toolbox. J. Cheminform.3, 33. 10.1186/1758-2946-3-33

17

Oenema J. Liu H. Coensel N. Eschenbacher A. Vijver R. Weng J. et al (2022). Review on the pyrolysis products and thermal decomposition mechanisms of polyurethanes. J. Anal. Appl. Pyrol.168, 105723. 10.1016/j.jaap.2022.105723

18

Qin X. Wang J. Zhang Y. Wang Z. Li S. Zhao S. et al (2020). Self-assembly strategy for double network elastomer nanocomposites with ultralow energy consumption and ultrahigh wear resistance. Adv. Funct. Mater.30, 2003429. 10.1002/adfm.202003429

19

Salmon E. van Duin A. C. T. Lorant F. Marquaire P.-M. Goddard W. A. (2009). Thermal decomposition process in algaenan of Botryococcus braunii race L. part 2: molecular dynamics simulations using the ReaxFF reactive force field. Org. Geochemo40, 416–427. 10.1016/j.orggeochem.2008.08.012

20

Sharuddin S. D. A. Abnisa F. Daud W. M. A. W. Aroua M. K. (2016). A review on pyrolysis of plastic wastes. Energ. Convers. Manage.115, 308–326. 10.1016/j.enconman.2016.02.037

21

Shin E. J. Jung Y. S. Choi H. Y. Lee S. (2022). Synthesis and fabrication of biobased thermoplastic polyurethane filament for FDM 3D printing. J. Appl. Polym. Sci.139, 52959. 10.1002/app.52959

22

Sorensen M. R. Voter A. F. J. (2000). Temperature-accelerated dynamics for simulation of infrequent events. J. Chem. Phys.112, 9599–9606. 10.1063/1.481576

23

Stukowski A. (2009). Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Model. Simul. Mater. Sc.18, 015012. 10.1088/0965-0393/18/1/015012

24

Sun H. (1998). COMPASS: an ab initio force-field optimized for condensed-phase applications overview with details on alkane and benzene compounds. J. Phys. Chem. B102, 7338–7364. 10.1021/jp980939v

25

Sun Y. Cai D. Yang Y. Chen X. Wang B. Yao Z. et al (2023). Investigation of the thermal conversion behavior and reaction kinetics of the pyrolysis of bio-based polyurethane: a reference study. Biom. Bio.169, 106681. 10.1016/j.biombioe.2022.106681

26

Tang X. Chen Z. Liu J. Chen Z. Xie W. Evrendilek F. et al (2021). Dynamic pyrolysis behaviors, products, and mechanisms of waste rubber and polyurethane bicycle tires. J. Hazard. Mater.402, 123516. 10.1016/j.jhazmat.2020.123516

27

van Duin A. C. T. Dasgupta S. Lorant F. Goddard W. A. (2001). ReaxFF: a reactive force field for hydrocarbons. J. Phys. Chem. A105, 9396–9409. 10.1021/jp004368u

28

Wan Y. Yu S. Jiang S. Pei Q. Xu S. Cao W. et al (2021). Microscopic pyrolysis mechanism on the octyphenylsiloxane flame retarded polycarbonate by reactive molecular dynamics. J. Anal. Appl. Pyrol.158, 105274. 10.1016/j.jaap.2021.105274

29

Wang S. Chen H. Zhang L. (2014). Thermal decomposition kinetics of rigid polyurethane foam and ignition risk by a hot particle. J. Appl. Polym. Sci.131, 39359. 10.1002/APP.39359

30

Wei W. Bi Y. Bi G. (2024). Study on the cross-scale effects of microscopic interactions and mechanical properties of rigid polyurethane foam driven by negative-temperature environments. Polymers16, 1517. 10.3390/polym16111517

31

Xu B. Wang Y. Liu G. (2023). Reactive molecular dynamics study on catalytic pyrolysis and steam reforming of hydrocarbon fuel. J. Anal. Appl. Pyrol.169, 105875. 10.1016/j.jaap.2023.105875

32

Yan Z. Zeng J. Xiao Y. Wang Z. Li Q. Lu X. (2024). Exploring carbon dioxide generation in combustion of long-flame coal in huating mining area by using ReaxFF MD. Case Stud. Therm. Eng.55, 104171. 10.1016/j.csite.2024.104171

33

Yao Z. Ling T.-C. Sarker P. K. Su W. Liu J. Wu W. et al (2018). Recycling difficult-to-treat e-waste cathode-ray-tube glass as construction and building materials: a critical review. Renew. Sust. Energ. Rev.81, 595–604. 10.1016/j.rser.2017.08.027

34

Yao Z. Yu S. Su W. Liu J. Wu W. Tang J. et al (2020). Probing the combustion and pyrolysis behaviors of polyurethane foam from waste refrigerators. J. Therm. Anal. Calorim.141, 1137–1148. 10.1007/s10973-019-09086-8

35

Yin F. Tang C. Wang Q. Liu X. Tang Y. (2018). Molecular dynamics simulations on the thermal decomposition of meta-aramid fibers. Polymers10, 691. 10.3390/polym10070691

36

Zhang X. Wang Z. Fu Y. Wang Z. Xie H. (2024). Thermal, mechanical property and flame retardant analysis of biobased rigid polyurethane foam modified with expandable graphite. Case Stud. Therm. Eng.61, 105112. 10.1016/j.csite.2024.105112

37

Zhang T. Meng W. Sang Z. Geng S. Guo Z. Yuan M. et al (2025). Exploring pyrolysis characteristics and combustion mechanism of polypropylene dust via experiments and molecular dynamic simulation. J. Anal. Appl. Pyrol.186, 106909. 10.1016/j.jaap.2024.106909

Summary

Keywords

polyurethane, reactive force field, product distribution, main products, pyrolysis mechanism

Citation

Dong T, Zhang T, Han X and Lan Y (2025) Investigation of polyurethane pyrolysis characteristics using reactive force field molecular dynamics. Front. Chem. 13:1691308. doi: 10.3389/fchem.2025.1691308

Received

28 August 2025

Revised

19 November 2025

Accepted

24 November 2025

Published

10 December 2025

Corrected

15 December 2025

Volume

13 - 2025

Edited by

Giuseppe Mensitieri, University of Naples Federico II, Italy

Reviewed by

Ajay Devidas Padsalgikar, Biolinq Inc., United States

Giacomo Damonte, University of Genoa, Italy

Joseph Zeaiter, American University of Beirut, Lebanon

Updates

Copyright

© 2025 Dong, Zhang, Han and Lan.

This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xinghua Han, hxh@nuc.edu.cn; Yanhua Lan, yhlan@nuc.edu.cn

Disclaimer

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.