- 1Guangdong Company, China Huadian Corporation, Ltd., Guangzhou, China

- 2Sichuan Energy Internet Research Institute, Tsinghua University, Chengdu, China

- 3Guangdong Huadian Qingyuan Energy Corporation, Ltd., Qingyuan, China

The advancing integration of Cyber-Physical-Social Systems (CPSS) within the modern power industry has highlighted the need for enhanced data integrity and multi-entity coordination. In this context, the pursuit of secure and trustworthy lifecycle management for power materials, regarded as a foundational component in ensuring system stability and operational efficiency, has attracted increasing attention. However, existing systems often face limitations such as information opacity, insufficient data accuracy, and the absence of a secure trust mechanism, hindering intelligent development and long-term sustainability. Blockchain technology, distinguished by its distributed ledger, transparency, immutability, and smart contract capabilities, offers a promising solution by enhancing data security and ensuring information reliability. This study introduces a blockchain-based framework for the secure and trustworthy lifecycle management of power materials within CPSS environments, which ensures lifecycle traceability, real-time monitoring, and trustworthy information exchange. By integrating key application scenarios, such as refined equipment management and paperless execution of contracts, the proposed approach addresses crucial operational needs. A multidimensional analysis with conventional systems reveals its advantages in improving management efficiency, optimizing resource allocation, enhancing data security, and reducing operational costs. The proposed framework thus provides both theoretical foundations and practical pathways for leveraging blockchain in power material lifecycle management, enabling digital transformation, managerial innovation, and collaborative industry development.

1 Introduction

As a key pillar of the national economy, the electricity industry is heavily dependent on the reliable and efficient management of diverse power materials. Given the intricate nature of power systems, the power industry demands diverse materials with complex structures, including power transmission and transformation equipment, generator sets, energy storage systems, smart grid components, and various auxiliary materials [1]. The efficient allocation and management of these materials directly impact the operational efficiency of power systems, levels of energy utilization, and the stability of the supply chain [2]. Moreover, with the accelerated global energy transition and deepening of the sustainable development goals (SDGs), the power industry’s requirements have evolved beyond the mere optimization of supply chain efficiency and cost to enhance the comprehensive performance throughout the entire lifecycle of materials [3, 4]. Meanwhile, the growing integration of Cyber-Physical-Social Systems (CPSS) in power systems introduces heightened demands on secure and collaborative material management. CPSS extend traditional cyber-physical systems by explicitly incorporating social aspects, such as human operators, organizational policies, and user interactions, into system design and operation. By unifying cyber, physical, and social components into an interactive environment where devices, systems, and human participants engage, CPSS necessitates robust measures for data security, trust establishment, and coordinated stakeholder management.

Lifecycle management of power materials is a holistic, end-to-end management framework encompassing procurement, storage, utilization, maintenance, reuse, and final disposal of materials [5, 6]. Its primary objective is to optimize material utilization efficiency, enhance resource allocation, and minimize both costs and environmental impacts through refined, data-driven management strategies. In contrast to traditional material management models, lifecycle management emphasizes systematic tracking, documentation, and analysis of material status, movement trajectories, and historical data throughout the lifecycle [6]. However, existing systems often lack trusted and secure mechanisms, which are essential in CPSS environments involving multi-agent interaction and distributed data. Establishing a structured lifecycle management framework enables enterprises to effectively address operational risks arising from information asymmetry, material redundancy, or supply chain disruptions. Additionally, enhancing material reusability, reducing waste, and optimizing resource utilization efficiency contribute to a more integrated circular economy within the power sector. Blockchain technology, with its decentralization, immutability, and smart contracts, offers a promising foundation for improving trust, transparency, and automation in CPSS-based material management. Ultimately, lifecycle management serves as a crucial enabler in enhancing the operational efficiency of power systems, ensuring a stable electricity supply while advancing the industry’s sustainable goals [4].

Recently, scholars worldwide have conducted extensive research on lifecycle management of power materials, aiming to enhance the operational efficiency and sustainable development of power assets through systematic and refined management approaches [7, 8]. The objectives, strategies, and framework construction measures for implementing lifecycle management based on practical considerations are proposed in [7], with the goal of optimizing material management costs, safety assurance, and management effectiveness, thereby improving asset management capabilities. Danyi C. developed an integrated and visualized lifecycle management platform for substation materials with the big data technology in [9]. This platform integrates three models to achieve intelligent material management, optimize procurement processes, and enhance material management, providing a reliable foundation for substation material lifecycle management. With technological advancements, blockchain technology, characterized by its decentralization, immutability, and transparency, has gradually become a research hotspot in the lifecycle management of power materials. The design and implementation of a power material lifecycle management system in the context of blockchain are explored from multiple perspectives in [8, 10]. The unique characteristics of blockchain technology are aimed to be leveraged in their research to address existing shortcomings in material management and to explore new development directions for the lifecycle management of power materials. Similar ideas are also explored in [11, 12], with the concept of building relevant business systems using blockchain technology further proposed. In [11], a lifecycle management system for power materials based on the Internet of Things (IoT) and consortium blockchain was proposed. Traceable management throughout the entire lifecycle of materials is enabled by the integration of IoT and consortium blockchain technologies.

Lifecycle management of power materials serves as a critical support element in the modern energy system, and its management efficiency directly influences the reliability and sustainability of the power grid [13]. Traditional lifecycle management models often face systemic challenges, such as fragmented traceability, information silos, and high trust costs. Blockchain technology, with its distributed ledger architecture, cryptographic validation mechanisms, and smart contract execution systems, provides a new solution for the digital transformation of power material management [14, 15]. Blockchain effectively ensures the secure storage and transmission of data across multiple nodes by establishing a trust-based collaborative network involving multiple parties. Further, the key features of blockchain, including immutability, transparency, auditability, and decentralized autonomy, align closely with the stringent requirements of power material management, particularly in terms of data integrity, process standardization, and multi-party cooperation [16]. The integration of blockchain with the energy sector drives innovation in power material management and creates strategic opportunities with significant potential for related fields [17].

Although blockchain-based solutions for the management of power material have attracted global attention, existing frameworks are largely confined to cyber–physical integration and lack a comprehensive mechanism for unified trust across all dimensions. This omission constrains their ability to establish trust and coordination among stakeholders, which is essential in CPSS. When embedded in CPSS, however, blockchain can serve as a trusted digital infrastructure, enabling secure, verifiable, and coordinated lifecycle operations. Building on these, a blockchain-based framework for secure lifecycle management of power materials is proposed in this study. This framework adopts a multi-layered architecture and leverages blockchain’s core features, including trusted data storage, decentralized consensus mechanisms, and smart contract programmability, to build a secure and trustworthy power material management system. Within the CPSS paradigm, it enhances dynamic data collaboration, supports intelligent decision-making, and facilitates coordinated supervision among stakeholders. By integrating the social dimension, the framework introduces human-centric trust mechanisms, in which managers, operators, suppliers, and regulators participate as blockchain nodes to verify and contribute data, thereby linking organizational processes with cyber–physical infrastructure. Leveraging blockchain’s transparency and accountability, it cultivates shared trust, facilitates cross-organizational collaboration, extends trust to human and organizational domains, and strengthens security and reliability in power material management. Furthermore, the framework improves supply chain collaboration, optimizes resource allocation, and advances the digital and intelligent transformation of the power industry. The main contributions of this work are as follows.

1. We propose a novel multi-layer blockchain-based framework specifically tailored for power material lifecycle management within a CPSS context, integrating the cyber, physical, and social dimensions to ensure security, transparency, and trust among stakeholders.

2. The framework incorporates smart contract programmability, decentralized trust mechanisms, and dedicated layers for data management, security assurance, and regulatory compliance, providing an end-to-end solution beyond existing conceptual models.

3. This study combines intelligent warehousing with smart contract-enabled paperless contract management, extending prior research that often focused only on isolated aspects of the lifecycle management of power materials by providing comprehensive operational details and validations.

4. We conduct a comparative analysis between the proposed system and traditional material management approaches, showing that our framework significantly enhances information transparency, data security, process automation, and sustainability outcomes.

The remainder of this paper is structured as follows. Section 1 introduces the research background, significance, and objectives. Section 2 examines the current state of sustainable lifecycle management of power materials, identifies the limitations of traditional models, and explores future development trends. Section 3 outlines blockchain technology, focusing on its core characteristics and applications in power material management. Section 4 presents the proposed blockchain-based system for sustainable lifecycle management. Finally, Section 5 concludes by summarizing the findings and offering directions for future research.

2 Lifecycle management of power materials: current status and challenges

Lifecycle management of power materials is critical for ensuring sustained operational stability in power systems. Despite recent advancements in material management, challenges remain, particularly concerning information transparency, data accuracy, management efficiency, cost control, security, and trust mechanisms [18–20]. These issues not only undermine the efficiency of material management but also constrain the decision-making capability of power enterprises. With the growing adoption of CPSS in the power industry, such challenges are intensified by the requirements for secure, real-time, and multi-agent collaboration. Accordingly, this section provides an in-depth analysis of the primary challenges currently faced in the lifecycle management of power materials, focusing on four key aspects: information transparency, data integrity, management efficiency, and trust security.

2.1 Information opacity and data silos: deficiency in system collaboration

The lifecycle management of power materials involves multiple stages, from procurement and inventory management to maintenance and recycling [6]. However, limited data sharing between departments has created severe information silos, restricting the integration and collaboration across these sections. This lack of transparency hinders real-time synchronization and data sharing, thereby affecting the accuracy and coordination of management decisions [13]. For example, the inventory department’s inability to access procurement data in time leads to material shortages or over-purchasing, while the maintenance department lacks complete material status information would delay the maintenance plans. This reduces the resource allocation efficiency of power companies and may contribute to energy waste. Moreover, the fragmented data management prevents the formation of a systematic and comprehensive global view, impairing the precise control of business processes and operational efficiency [21]. In CPSS environments, such silos hinder coordinated actions among physical sensing systems, cyber control platforms, and human operators, reducing the flexibility and reliability of lifecycle management.

2.2 Data inaccuracy and incompleteness: bottleneck of trustworthy traceability

Traditional power material management heavily relies on manual operations and record-keeping, which compromise data accuracy and completeness. Due to errors in manual data entry, redundancy, synchronization delays, and omissions often cause inconsistencies, undermining the reliability of lifecycle management process [22]. For example, key stages such as procurement, warehousing, maintenance, and decommissioning are particularly vulnerable to inaccuracies or incompleteness arising from human errors or delayed system updates. This not only affects daily inventory scheduling and material allocation but also weakens the organization’s ability to make data-driven decisions, thereby decreasing operational efficiency [23]. Within the CPSS context, incomplete or inaccurate data further impedes traceability of critical information, such as maintenance histories and usage status, heightening risks of equipment failure and repair delays, compromising assets sustainability and longevity [24].

2.3 Inefficient management and excessive costs: dual loss in resource metabolism

The traditional power material management relies on paper documents, manual approvals, and data entry, resulting in complex processes, low management efficiency, and high operational costs [25, 26]. Across procurement, warehousing, allocation, inventory checking, and dispatching, extensive manual operations consume significant time and labor, making them prone to errors, duplication, redundancy, and even management loopholes. As the complexity of the power grid business increases and CPSS integration introduces higher demands for autonomous coordination, this model is increasingly inadequate for the modern power industry needs [27]. Furthermore, reliance on manual management generates resource waste, including costs for document storage, transportation, and maintenance, reducing flexibility and adding operational burdens. Such inefficiency also conflicts with the principles of green and sustainable development [28].

2.4 Inadequate security and trust: structural defects in sustainable systems

Power material management involves large volumes of sensitive data, including procurement contracts, inventory records, and maintenance logs, whose security and reliability are crucial to the operational stability of enterprises. However, the dependence on centralized databases in traditional management models exposes data to risks of tampering, loss, and leakage [29]. Furthermore, the absence of unified trust mechanism across departments hampers information sharing, often resulting in inconsistencies and inefficiencies. More seriously, internal data falsification or opaque operations compromise the authenticity and traceability of materials [30]. For example, falsified supplier data in procurement increases operational risks and undermines both internal collaboration and external supply chain transparency [31]. These issues are magnified in CPSS-based systems, as insufficient trust mechanisms compromise data reliability and create coordination conflicts across departments and organizational levels. Addressing these deficiencies highlights the urgency of developing a secure and trustworthy framework for lifecycle management of power materials. Therefore, emerging technologies like blockchain should be explored to establish such a secure and trustworthy framework within CPSS, as discussed in the next section.

3 Blockchain technology

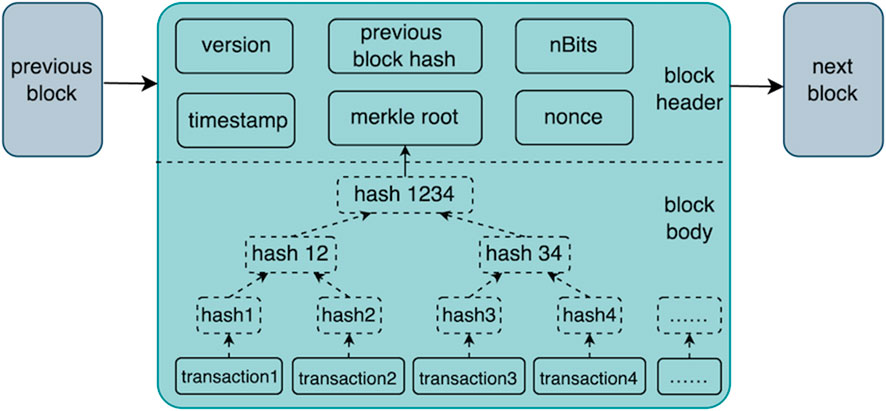

Blockchain technology is an advanced distributed ledger technology with broad applicability across domains such as data management, information security, and financial systems [32]. In the context of the global digital economy, blockchain has emerged as a pivotal technology for ensuring data integrity, enhancing system transparency, and strengthening trust mechanisms, thereby providing significant technological support for sustainable development [33]. Specifically, blockchain arranges data blocks sequentially, with each block comprising a block header and a block body [34]. The typical blockchain architecture is illustrated in Figure 1. The header contains metadata, such as the timestamp, previous block hash and merkle root, which together link blocks and ensure tamper-proof records. The body stores the transaction data. Transactions are summarized in a merkle tree, whose root is stored in the block header to enable efficient integrity verification without needing to embed the entire tree [34, 35].

Blockchain technology enables a secure and trustworthy resource management system which has enhanced resource utilization efficiency, reduced management costs, and optimized the sustainability strategies of enterprises [34, 36]. Its core characteristics include decentralization, distribution, immutability, programmability, transparency and anonymity.

Decentralization and Distribution: Blockchain operates on a peer-to-peer (P2P) network in which multiple nodes jointly manage data, eliminating reliance on a centralized authority. This architecture enables distributed storage and processing, improving robustness, fault tolerance, and reducing risks of single-point failure and data misuse inherent in centralized models [37]. In power material management, stakeholders such as suppliers, logistics providers, warehouse managers, and regulators share responsibility for data validation and updating, thereby lowering security risks [36]. Decentralization further strengthens trust among participants, enhances collaborative efficiency, and fosters transparent information sharing, supporting more reliable and scientific decision-making.

Immutability: Blockchain employs a chain structure in which each block contains the hash of the previous one. Once recorded, data is extremely difficult to alter, as any modification changes subsequent hashes and exposes tampering. This mechanism enables trusted digital ledgers and secures the authenticity, integrity, and traceability of records [34]. In power material management, it prevents malicious modification or forgery of critical data such as procurement contracts, inventory records, and maintenance logs [38]. Immutability thus ensures compliance, transparency, and accuracy in lifecycle management while supporting reliable, evidence-based decision-making.

Transparency and Anonymity: Blockchain systems are inherently transparent, allowing participants to query transaction information across the network, thereby enhancing data sharing and information flow [39]. In power material management, this ensures real-time visibility of material movement for all supply chain parties, reducing information asymmetry and improving collaboration [40]. Meanwhile, transactions are identified through encrypted addresses rather than true identities, safeguarding privacy while maintaining transparency [40, 41]. This dual capability enables efficiency gains through openness while protecting sensitive information, thus balancing transparency, compliance, and confidentiality in power material management systems.

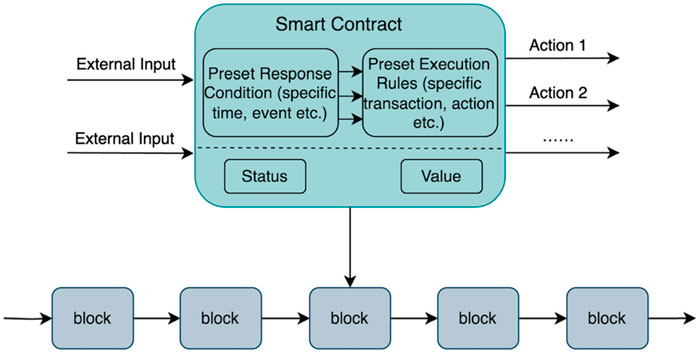

Smart Contracts and Programmability: Smart contracts are programmable protocols encoded with predefined rules and conditions. Although their execution must be initiated by transactions from externally owned accounts (EOA), once invoked they operate deterministically and automatically within the blockchain environment, enabling reliable, rule-based automation without further human intervention [42]. In power material management, they facilitate the automation of procurement approval, inventory updates, logistics scheduling, equipment maintenance, and recycling [43]. Such automation typically relies on off-chain scripts or applications that monitor specific events and issue the required transactions, while the on-chain contracts ensure rule-based enforcement. This combination not only reduces transaction costs but also minimizes human errors and enhances operational efficiency. Moreover, the programmability of smart contracts enables compliance checks, workflow optimization, and adaptive resource allocation, providing a reliable and scalable foundation for digitalization and supply chain governance.

In particular, these features provide a robust foundation for secure and trustworthy lifecycle management of materials in CPSS-based power systems [36, 44]. Decentralization, supported by a distributed ledger, mitigates information opacity and data silos, overcoming deficiencies in system collaboration. Immutability and cryptographic security ensure data accuracy and completeness, removing bottlenecks in trustworthy traceability. Transparency fosters security and trust among stakeholders, resolving structural defects in sustainable systems. Meanwhile, smart contracts’ programmability enables deterministic on-chain execution, supporting the automation of business processes, reducing inefficiencies and costs in resource management and improving coordination.

4 Blockchain-enabled secure and trustworthy lifecycle management of power materials

4.1 System architecture design

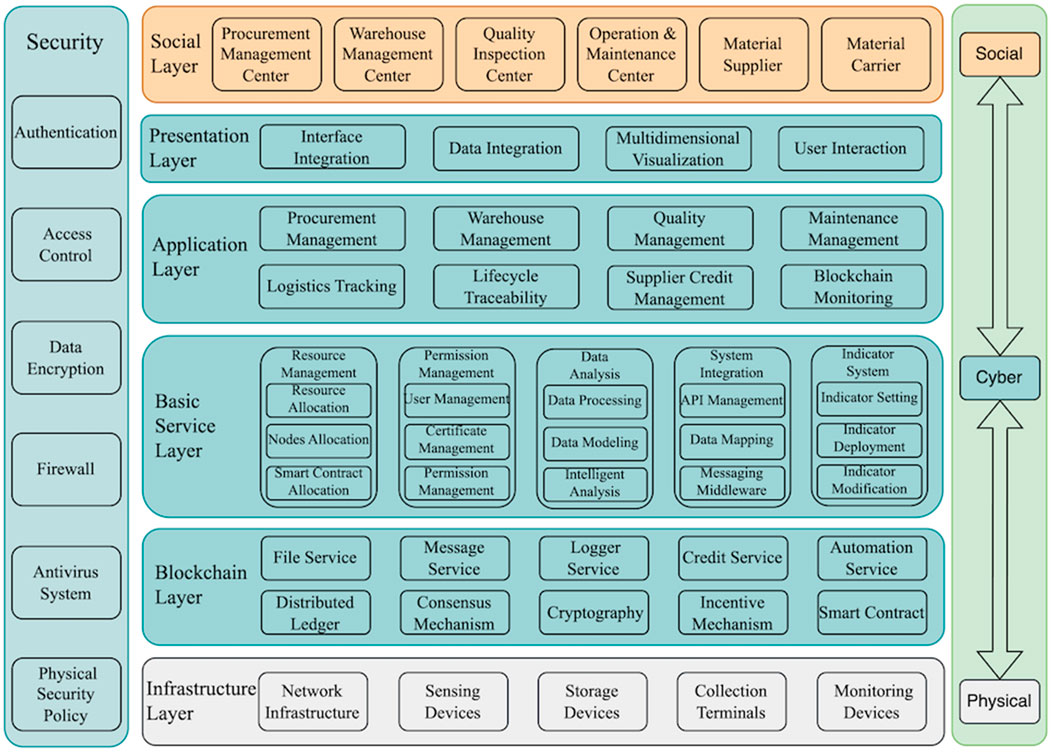

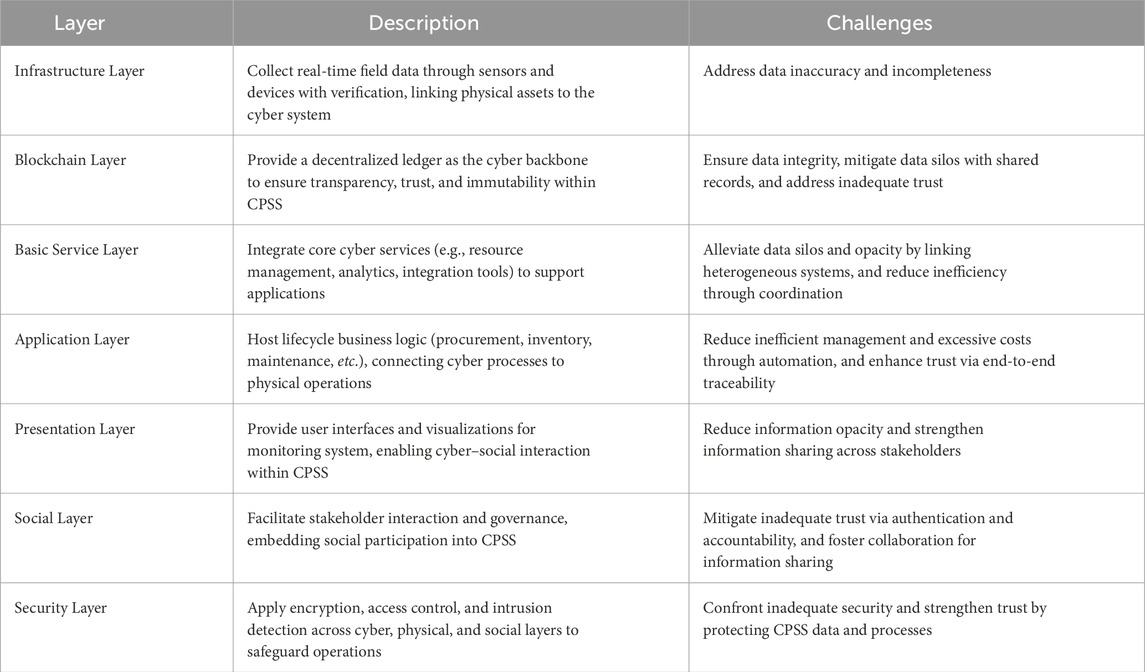

The efficient lifecycle management of power materials is of great significance for resource optimization, energy consumption control, and sustainable development. To ensure the transparency, security, and traceability of the management process, relevant material management systems, operational standards, maintenance and repair regulations, as well as various information security measures such as identity authentication, access control, and data encryption, must be considered to persist data security, privacy, and compliance. Building upon these, a framework for lifecycle management of power materials is established, which consists of six primary layers including the physical infrastructure layer, the blockchain layer, the basic service layer, the application layer, the presentation layer, and the social layer. These layers are supported by a dedicated security layer and are structured in alignment with the CPSS paradigm, integrating physical, cyber, and social domains to ensure secure, transparent, and intelligent lifecycle management of power materials. The multi-tiered architecture is presented in Figure 2.

The proposed system enables comprehensive digitalization of power material lifecycle management by integrating physical sensing devices and standardized communication protocols within the infrastructure layer, representing the physical dimension of CPSS. It supports data reuse through information-sharing technologies and ensures logical consistency via digital validation mechanisms. The blockchain layer forms the core trust foundation, offering transparency, immutability, and traceability, while establishing a multi-party trust framework in CPSS environments. The basic service layer provides functional modules, such as resource management, data analytics, and system integration, to support operations and applications. The presentation layer merges interface logic with data visualization, facilitating clear, real-time information delivery and enabling effective social interaction among stakeholders within the CPSS framework. A dedicated security layer underpins all tiers, enforcing encryption, identity and access management, and real-time intrusion detection to protect operational data and control commands, thereby protecting the integrity of the entire CPSS framework. By leveraging data digitalization, blockchain trust mechanisms, and intelligent decision-making tools, the architecture enhances management efficiency, reduces manual errors, and ensures secure, collaborative, and sustainable operations, aligning with the automation and green development goals of the power industry.

Infrastructure Layer. As the foundational component of the system, the infrastructure layer performs essential functions including data collection, environmental sensing, and communication. It connects the physical space of the CPSS with the digital environment, enabling real-time monitoring and accurate recording of the full material lifecycle. This supports intelligent decision-making, resource optimization, and inter-organizational collaboration. The layer integrates key technologies such as Radio Frequency Identification (RFID), smart tags, IoT devices, intelligent terminals, 5G and fiber-optic communication, and database systems to ensure accurate acquisition and efficient transmission of material data [45]. To ensure data reliability, the framework incorporates robust validation mechanisms. All collecting devices are registered with verified digital identities and must digitally sign their outputs. Smart contracts are employed to validate incoming data formats and values, flagging anomalies for manual review. For critical operations such as material transfers, the system enforces multi-party verification, requiring cryptographic signatures from both sending and receiving entities. These measures collectively enhance the credibility of on-chain data and reinforce the integrity of the blockchain ledger.

Blockchain Layer. As the core technological foundation of the framework, the blockchain layer enables secure, transparent, and traceable data management in CPSS-based power material lifecycle systems. It integrates distributed ledger technology, consortium governance, consensus mechanisms, and smart contracts to support data encryption, storage, transmission, transaction verification, and rule-based process enforcement. Operated by authorized stakeholders such as power companies, suppliers, and regulators, the consortium blockchain ensures efficient block validation without excessive energy consumption. Functional modules, including file and messaging services, log management, and supplier credit records, provide robust support for upper-level operations. Large documents are stored off-chain in secure distributed systems, with cryptographic hash references maintained on-chain for integrity verification. Whenever off-chain data is updated, a new transaction records its updated hash on-chain to synchronize the state. By replacing centralized storage with decentralized architecture, the blockchain layer mitigates security risks, strengthens supply chain transparency and trust. Moreover, it streamlines material management through the smart contracts’ execution, thereby enhancing efficiency, reducing manual intervention, and optimizing resource utilization.

Basic Service Layer. As the system’s central hub for data processing and management, the basic service layer integrates core modules such as resource management, data analytics, access control, and performance indicator settings to ensure operational stability, data security, and scalability. Built on a modular architecture, it provides efficient data handling, computational logic, and service orchestration, with dynamic configuration to meet varied business demands. Through seamless interoperability with Enterprise Resource Planning (ERP), Warehouse Management System (WMS), IoT platforms, and regulatory portals, combined with real-time analytics, administrators can configure parameters, assign permissions, and optimize resource allocation. For example, procurement orders generated in ERP can be hashed and recorded on-chain, while blockchain-validated delivery records are synchronized back for financial reconciliation. Middleware adapters translate ERP transactions into blockchain-compatible formats via standardized APIs, while high-frequency updates are batched off-chain with periodic commitments on-chain to reduce latency. This design preserves consistency and auditability between blockchain and ERP, clarifies practical integration with legacy systems, and provides robust functional support to the application layer, thereby enabling precise strategy formulation and effective decision-making.

Application Layer. The application layer constitutes the business logic core of the blockchain-based power material management system. It integrates procurement, warehouse management, quality control, maintenance, logistics tracking, lifecycle traceability, supplier credit evaluation, and blockchain status monitoring, covering the full lifecycle of power materials. Designed with modularity and scalability, it supports role-based secure access and flexible deployment of new business components. By aligning lifecycle processes with decision-making agents from various departments and organizations, it enhances operational coordination, ensures intelligent and secure lifecycle management, and supports sustainable practices. As the cyber-social logic center within the CPSS framework, this layer bridges technological infrastructure with human decision-making, enabling adaptive, collaborative, and resilient management across diverse operational scenarios.

Presentation Layer. The presentation layer functions as the system’s visual and interactive interface, consolidating data from multiple sources for real-time display and analysis. It delivers dynamic dashboards and visual reports on procurement, inventory, logistics, and blockchain status, supporting role-based, cross-platform access. Through multidimensional visualization, users can efficiently interpret operational insights, monitor key processes, and make informed decisions, thereby enhancing transparency, usability, and decision support across the power material lifecycle.

Social Layer. The social layer represents the user-centric interface of the proposed framework, embodying the social dimension of CPSS by facilitating interactions among diverse stakeholders, including procurement officers, warehouse managers, quality inspectors, maintenance teams, suppliers, and transporters. It supports multi-terminal and multi-channel access through graphical user interfaces, mobile applications, and web portals, enabling users to manage operations and access lifecycle data anytime and anywhere. Each user and device are assigned a unique cryptographic identity, and all data entries are digitally signed at the source to ensure traceability and authenticity. This design enhances operational responsiveness and material flow efficiency while safeguarding data integrity against unauthorized or falsified input, thereby reinforcing trust throughout the lifecycle management. The layer also embeds governance by granting role-based access to authorities and encoding organizational policies in smart contract rules. Transparent audit logs and provenance records reinforce accountability, while trust mechanisms, including reputation scores and audit trails, complement contract enforcement with human oversight. In this way, the social layer institutionalizes interaction and governance, reflecting the essential social component of CPSS.

To address the challenges of information opacity and data silos, data inaccuracy, inefficient management, and inadequate security identified in Section 2, this study proposes a blockchain-based framework for secure and trustworthy lifecycle management of power materials within CPSS. The framework employs a consortium blockchain to connect key stakeholders such as utilities, suppliers, and regulators, enabling decentralized governance with fine-grained access control and high transaction throughput. Leveraging distributed ledgers, encryption algorithms, and consensus mechanisms such as practical byzantine fault tolerance, it ensures data authenticity, integrity, and immutability while avoiding the high energy consumption of proof-of-work systems. Smart contracts enforce predefined rules to automate procurement, contract approvals, inventory updates, and maintenance tracking, thereby reducing manual intervention, improving efficiency, and lowering costs. To maintain scalability, large documents are stored off-chain in systems, such as the InterPlanetary File System (IPFS) or consortium-managed distributed databases, with cryptographic hash references recorded on-chain to verify data integrity. IPFS provides content-addressed storage, enabling efficient file distribution and versioning, while distributed databases allow scalable enterprise data management anchored to the blockchain. Platforms such as Hyperledger Fabric can offer robust capabilities for privacy protection, identify management, and regulatory compliance, ensuring practical feasibility in enterprise contexts. By integrating automation, secure data sharing, and multi-party collaboration, the framework overcomes the limitations of traditional systems. Table 1 provides an overview of the architecture, outlining each layer and the challenges addressed. The framework further enhances cross-departmental coordination, optimizes resource utilization, and strengthens information security, offering a scalable and sustainable pathway for digital transformation and intelligent material management in the power sector.

4.2 System applications

4.2.1 Fine-grained management of power materials

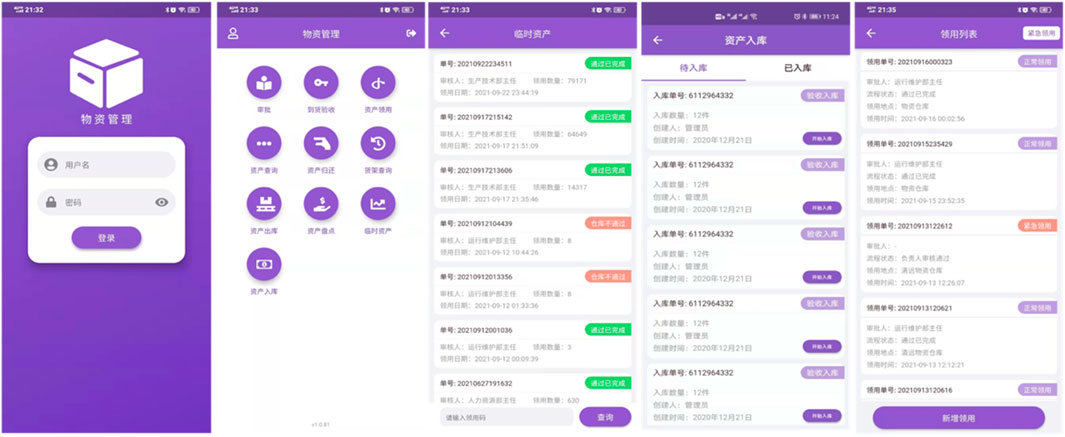

Fine-grained management of power equipment is critical to lifecycle management and the stability and reliability of power supply [46]. To support the oversight of regional materials and equipment, an intelligent warehousing management system is designed, as shown in Figure 3. This system adheres to key principles of high availability, intelligence, flexibility and scalability, observability, and security. It integrates IoT, RFID, augmented reality (AR), barcoding, electronic tagging, big data analytics, web-based application and mobile platforms. Each material item is assigned a unique identifier (e.g., a RFID tag or barcode), and its movements such as intake, relocation, and dispatch, are captured by IoT sensors, with real-time updates to ensure accurate inventory data. These records are simultaneously logged in the management platform and synchronized via blockchain middleware to ensure accuracy, timeliness, and tamper resistance across distributed nodes. This integrated capability supports warehouse management, wireless scanning, intelligent sorting, smart inventory, and dynamic material allocation, thereby improving operational efficiency, promoting information sharing, data visualization, and big data–driven decision-making, and early warning [47]. Ultimately, the system accelerates the digital transformation of material management and strengthens seamless interaction within the CPSS framework.

Through the intelligent storage system, we have established a regional integrated intelligent material management platform. At the regional level, the platform enables joint material storage and reserve, material information sharing, big data analytics, data visualization, remote surveillance, and early warning. At the grassroots level, it supports digital tagging, visual sorting and inbound management, real-time reconciliation of inventory, intelligent digital stocktaking, barcode-based outbound management, remote material inspection and inquiry, and visual reporting. However, the requirements for material management systems are constantly increasing. To meet evolving requirements, blockchain modules can be seamlessly integrated via middleware, forming a more secure and trustworthy CPSS-based management framework. Material movements or status changes are captured by IoT sensors, which trigger blockchain transactions that update the distributed ledger in real time with timestamps and responsible party identifiers, creating a tamper-proof, auditable lifecycle record [20]. This automated data capture and update mechanism ensures stakeholders have consistent, up-to-date information without manual input, minimizes discrepancies, safeguards data authenticity and integrity, and reduces operational costs. Meanwhile, smart contracts promote the automated execution of business logic, such as restocking or settlements, improving the responsiveness and efficiency in lifecycle management while further reducing both process and operational complexity. Specifically, the advantages are as follows.

Scalability and flexibility enhancement of the system: The decentralized nature of blockchain technology make the intelligent storage system more flexible and scalable. Blockchain technology allows the system to easily add new functional modules or expand nodes without altering the core architecture. It also enables access to material supply chain data, covering production, manufacturing, processing, and assembly, as well as storage, inventory, outbound, and disposal. This ensures the fine-grained management of the entire lifecycle of materials and equipment to meet the increasingly complex and diverse material management needs. The flexibility and scalability not only enhance the system’s adaptability but also provide strong technical support for the continuous innovation and optimization of material lifecycle management in the power industry.

Supply chain collaboration optimization: Blockchain technology also demonstrates significant potential in optimizing supply chain collaboration. It enables information sharing and collaborative work between upstream and downstream enterprises in the supply chain, thereby significantly improving the transparency and efficiency of the supply chain. Specifically, after integrating blockchain technology into the intelligent storage system, this collaborative effect is further enhanced, helping to reduce operational costs and improve the overall competitiveness of the supply chain and material lifecycle management.

Data authenticity and reliability assurance: Blockchain’s immutability provides a solid guarantee for the authenticity and reliability of data in warehouse management. Once recorded in lifecycle management, data cannot be easily altered or falsified. This feature not only enhances the transparency of information but also effectively prevents the risk of malicious data manipulation or forgery. As a result, it ensures the integrity and accuracy of data throughout the power material supply management and provides robust security support for lifecycle material management.

Traceability and anti-counterfeiting enablement: Blockchain technology enables the traceability and anti-counterfeiting of materials. By recording the production process of materials and equipment, including the production of raw materials, manufacturing, and assembly, it ensures the quality and safety of materials and equipment. Establishing blockchain records for the entire process, from storage to shipment and disposal, allows for precise tracking of the material’s source, circulation path, and destination. This traceability mechanism not only helps verify the authenticity and legality of materials but also effectively prevents the entry of counterfeit and substandard products by assigning a unique digital identity to the materials, thereby protecting the legitimate rights and interests of power enterprises.

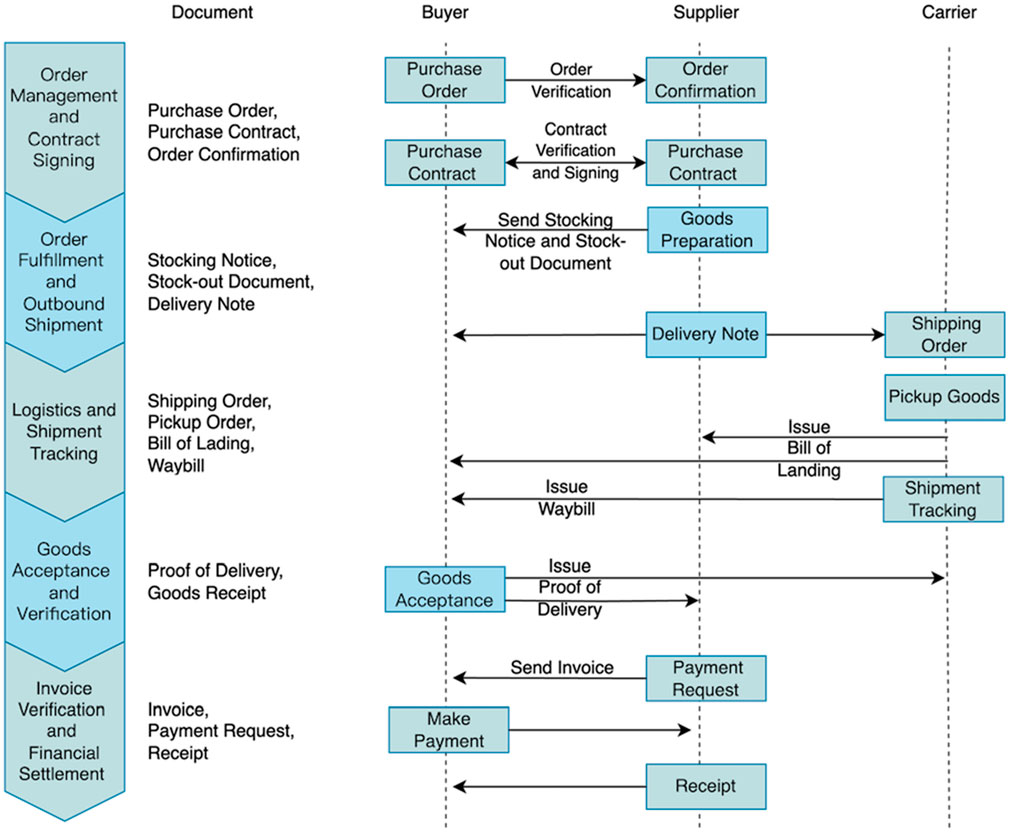

4.2.2 Paperless contract execution and document flow

The lifecycle management of power materials emphasizes the integration and optimization of various stages, including planning, procurement, inventory, usage, and disposal, with the aim of achieving efficient resource allocation and refined management. Efficient management of procurement is a key guarantee for the stable and reliable supply of power materials. The key working processes are displayed in Figure 4. In traditional power material lifecycle management processes, procurement contract signing and the circulation of related documents often rely on paper-based files. This not only consumes a significant amount of time and resources but also poses risks such as forged signatures, document loss, or damage [48]. Moreover, in CPSS, contract execution involves multiple departments, systems, and personnel, while paper-based workflows hinder responsiveness, coordination, and auditability.

The proposed blockchain-based lifecycle management framework provides a secure and streamlined alternative for contract and document handling. In the paperless contract approach, smart contracts are used not only to manage agreements but also to enforce them, where signed documents remain off-chain with only cryptographic hashes recorded on-chain to guarantee authenticity and integrity. The agreement’s key terms and conditions are encoded into a smart contract, which is instantiated once the parties digitally sign using secure signatures. Subsequent lifecycle events, such as delivery confirmations or invoice approvals, trigger off-chain applications or authorized accounts to issue transactions, which in turn invoke the smart contract. Once triggered, the contract executes deterministically on-chain, releasing payments or updating ledger status in real time. This design enforces contractual clauses in a trustless environment, enabling secure signing, automated circulation, improved efficiency, enhanced traceability, and strengthened auditability.

Firstly, the security, authenticity, and reliability of contract signing and document circulation are ensured through the blockchain’s decentralized, transparent, and tamper-resistant ledger. In the management of power material supply, transactions between suppliers, material companies, and power enterprises involve many contract signings and document circulations. Traditionally, these processes rely on paper documents, which are prone to loss, forgery, and are difficult to trace. However, blockchain technology, through digital signatures and consensus algorithms, enables the full recording and verification of contract signing and document circulation, ensuring the integrity and authenticity of the data and effectively preventing the risks of forgery and tampering.

Secondly, the efficiency of contract signing and document circulation is firmly enhanced. Traditional paper-based procedures are cumbersome, requiring printing, mailing, and storage. In contrast, paperless contract signing and document circulation based on blockchain technology enable online editing, signing, storage, and querying, significantly improving work efficiency and reducing costs. Smart contracts embedded in the blockchain further automate key terms: once preset conditions, such as delivery confirmation or invoice validation, are captured by external applications, resulting transactions invoke the contract, which then executes deterministically on-chain to trigger payment or status updates. As shown in Figure 5, this hybrid mechanism supports reliable, rule-based execution across decentralized CPSS components, enhancing both operational speed and compliance [49].

Furthermore, the transparent management of contracts and documents is easily achieved. Through the public ledger of blockchain, all participants can view the circulation of contracts and documents at any time and understand the entire lifecycle management process of materials, thereby enhancing transparency and traceability in management. In CPSS scenarios, this ensures visibility and accountability across organizational boundaries, reducing the likelihood of errors, fraud, or unauthorized operations. The enhanced auditability provided by blockchain further contribute to strengthen internal supervision and prevent corruption and violations.

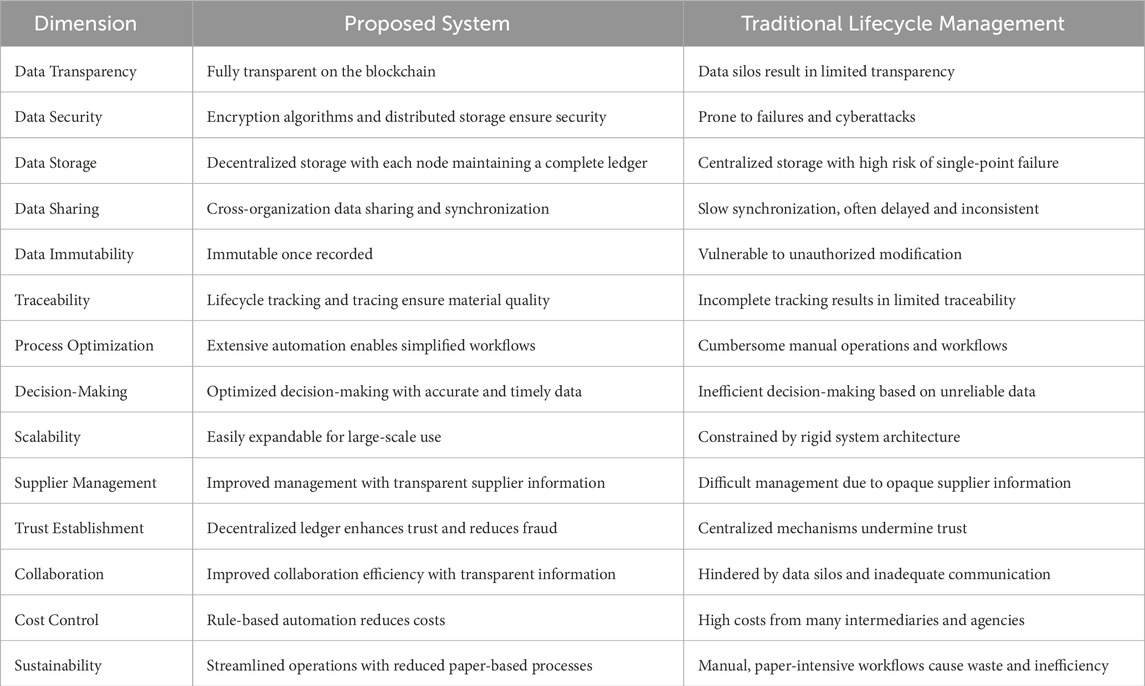

4.3 Comparative analysis of the proposed framework

Within the lifecycle management of power materials, the proposed blockchain-based lifecycle management framework demonstrates significant advantages, particularly in the refined management of materials and equipment, as well as the efficient execution of paperless contract and document circulation. It streamlines business processes and supports the transition toward intelligent, digitized, and sustainable operations within CPSS context. As shown in Table 2, the framework outperforms traditional systems across multiple dimensions. The blockchain ledger provides all stakeholders with a real-time, single source of truth, eliminating data silos and information opacity inherent in conventional systems. Cryptographic algorithms and distributed storage ensure data integrity and resilience against tampering or loss, addressing the vulnerabilities of traditional centralized databases. Smart contracts invoked by external information enforce business rules deterministically on-chain, streamlining domain-specific processes such as procurement, inventory control, and logistics updates with faster workflows than traditional systems. Furthermore, the decentralized trust mechanism further enhances inter-party trust, reduces reliance on intermediaries, and lowers fraud risk, representing a substantial improvement over the weaker trust enforcement of legacy processes.

Table 2. Comparative analysis of the proposed system and conventional material management systems across multiple dimensions.

By leveraging distributed ledger technology, data immutability, and rule-based automation, the framework enhances supply chain collaboration, operational transparency, and traceability, while enabling real-time monitoring of material flows. These capabilities support optimized inventory management, reduced backlog and capital occupation, and alignment with sustainable development goals. Moreover, since the consortium blockchain achieves transaction finality within seconds and offers higher throughput than public blockchains with massive nodes, it is sufficient for typical power material workflows. As a result, procurement approvals that previously took several days in a sequential, paper-based process can now be completed within hours through parallel digital approvals, where each party signs electronically and generates the transactions that invoke the smart contract. Triggered contract executes deterministically on-chain to verify predefined conditions and authorize payments or status updates. This mechanism, in contrast to traditional sequential and manual approval processes, significantly improves operational efficiency and demonstrates clear advantages in terms of time and cost reduction. Likewise, material traceability that previously required manual collation of records across departments can be achieved conveniently in seconds via distributed ledger queries. These scenarios demonstrate the framework’s potential to deliver substantial efficiency gains, accuracy improvements, and enhanced trust, with future validation to be supported by comprehensively empirical performance data.

While the proposed framework delivers substantial benefits, it must address compliance, governance, and technical constraints. From a regulatory perspective, data privacy is paramount. The adoption of a consortium blockchain ensures that only authorized entities can access the ledger, while sensitive or personal data are stored off-chain with secure hashed references on-chain to meet privacy regulations such as the GDPR. Smart contracts, once invoked, further verify the required security inspections to enforce compliance with industry standards, while the immutable ledger also facilitates regulator audits by producing verifiable provenance trails. By incorporating regional off-chain storage, immutable on-chain hash pointers, and rule-based smart contracts for compliance with diverse privacy regulations, this framework balances blockchain immutability with privacy mandates, thereby ensuring both data integrity and adherence across jurisdictions. Despite these safeguards, several limitations remain. Blockchain use inherently introduces performance overhead and scalability constraints as transaction volumes or participating nodes increase, requiring optimization in large-scale deployments. Off-chain storage for bulk sensor data, along with Layer-2 solutions such as state channels or rollups, which consolidate frequent updates and periodically anchor summaries on-chain, can mitigate scalability constraints. In addition, sharding by region or material type can further enhance parallel processing for consortium-based operations. Achieving broad stakeholder adoption also presents challenges, as effective incentive mechanisms and governance adjustments are essential to secure participation across enterprises. At the same time, because smart contract operations depend on off-chain events and data feeds, the framework introduces a trust dependency on these external oracles. Through the introduction of consortium governance protocols, oracle-provided data can be validated, and corrective measures (such as pausing a contract or overriding a transaction) can be enabled if an external trigger is found erroneous or malicious. Furthermore, blockchain immutability complicates correction of erroneous or sensitive entries, while redaction-enabled protocols and off-chain data references provide remedies that balance preservation of data integrity with compliance requirements.

5 Conclusion

This study examines the current development status, inherent challenges, and feasibility of applying blockchain technology to the secure and trustworthy lifecycle management of power materials. Through systematic analysis of existing issues and blockchain’s core capabilities, we highlight the potential of distributed ledger technology, data immutability, and smart contracts to establish secure, transparent, and trustworthy coordination within CPSS. The proposed blockchain-based framework embeds advanced security assurance mechanisms, privacy protection, and regulatory compliance alongside business logic support to achieve comprehensive, intelligent, and efficient material management. Comparative analysis with conventional systems highlights the framework’s notable security advantages, including resistance to tampering, improved access control, and verifiable audit trails, while also enhancing transparency, automation, and operational efficiency. The proposed approach advances the digitalization, automation, and sustainability of material management. Large-scale deployment, however, requires careful consideration of performance scalability, secure integration with legacy systems, governance, and risks such as collusion and privacy leakage. Future research should enhance system resilience and applicability by advancing consensus optimization and incentive mechanisms to foster multi-stakeholder adoption. Integrating artificial intelligence for predictive analytics and decision support would further optimize resource management, while robust cybersecurity strategies remain essential to mitigate risks such as inference attacks or collusion in transparent ledgers. Collectively, the proposed framework establishes a secure and trustworthy foundation for enterprise decision-making, supply chain optimization, and competitiveness in the power sector. It can be further generalized to other industrial domains requiring lifecycle management, enhancing security, transparency, and trust in multi-entity operations.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

NG: Conceptualization, Writing – original draft. CZ: Writing – original draft, Supervision, Conceptualization. JF: Writing – original draft, Methodology. XZ: Writing – original draft, Formal Analysis. HX: Writing – review and editing, Methodology. WZ: Writing – review and editing, Formal Analysis. XC: Writing – review and editing, Visualization.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This research was funded by the Science and Technology Project of China Huadian Corporation Ltd. (No. CHDKJ23-02-101). The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article, or the decision to submit it for publication.

Conflict of interest

Authors NG, JF, and XZ were employed by China Huadian Corporation, Ltd. Authors HX, WZ, and XC were employed by Guangdong Huadian Qingyuan Energy Corporation, Ltd.

The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1. Deetman SP, de Boer HS, van Engelenburg M, van der Voet E, van Vuuren DP. Projected material requirements for the global electricity infrastructure – generation, transmission and storage. Resour Conservation Recycling (2021) 164:105200. doi:10.1016/j.resconrec.2020.105200

2. Rao H, Li J, Sun X. Demand forecasting and allocation optimization of green power grid supply chain based on machine learning algorithm: a study based on the whole-process data of power grid materials. Sustainability (2025) 17:1247. doi:10.3390/su17031247

3. Al-Nory MT. Optimal decision guidance for the electricity supply chain integration with renewable energy: aligning smart cities research with sustainable development goals. IEEE Access (2019) 7:74996–5006. doi:10.1109/ACCESS.2019.2919408

4. Al-Kuwari A, Kucukvar M, Onat N. Uncovering the role of sustainable value chain and life cycle management toward sustainable operations in electricity production technologies. Operations Manag Res (2024) 17:1360–79. doi:10.1007/s12063-024-00510-3

5. Sonnemann G, Gemechu ED, Remmen A, Frydendal J, Jensen AA. Life cycle management: implementing sustainability in business practice. In: G Sonnemann, and M Margni, editors. Life cycle management. Dordrecht: Springer Netherlands (2015). p. 7–21. doi:10.1007/978-94-017-7221-1_2

6. Wang K, Li Y, Wang X, Zhao Z, Yang N, Yu S, et al. Full life cycle management of power system integrated with renewable energy: concepts, developments and perspectives. Front Energ Res (2021) 9:680355. doi:10.3389/fenrg.2021.680355

7. Tao W. Research on problems and countermeasures of asset life-cycle management in power grid companies (2019).

8. Wang T, Guo J, Yang X. Application of block chain technology in life cycle asset management. Electr Meas and Instrumentation (2021) 58:21–5. doi:10.19753/j.issn1001-1390.2021.06.003

9. Cao D-Y. Research on the improvement in life-cycle management of transformer substation material of C power-supply company based on big data (2023).

10. Liu D, Zhou W, Wu F, Chen Q. Design of a blockchain-based elaborated management system for power materials. Electric Eng (2024) 166–8. doi:10.19768/j.cnki.dgjs.2024.14.047

11. Jiang Q, Liu H, Liu K. Total life cycle management system for power supplies based on IoT and consortium chain. Supply Chain Manag (2023) 4:48–53. doi:10.19868/j.cnki.gylgl.2023.05.005

12. Fan J, Gao Z, Yuan K, Shen H. Electric power materials total life cycle management system research based on alliance chain. Rural Electrification (2020) 57–60. doi:10.13882/j.cnki.ncdqh.2020.04.018

13. Zhang A, Zhong RY, Farooque M, Kang K, Venkatesh VG. Blockchain-based life cycle assessment: an implementation framework and system architecture. Resour Conservation Recycling (2020) 152:104512. doi:10.1016/j.resconrec.2019.104512

14. Wang H, Yu X, Peng J, Zhang L, Xu T. Design of power material management system basing on internet of things identification and blockchain. In: 2020 IEEE conference on telecommunications, optics and computer science (TOCS) (2020). p. 160–3. doi:10.1109/TOCS50858.2020.9339714

15. Queiroz MM, Telles R, Bonilla SH. Blockchain and supply chain management integration: a systematic review of the literature. SCM (2019) 25:241–54. doi:10.1108/SCM-03-2018-0143

16. Song J, Yang Y, Mei J, Zhou G, Qiu W, Wang Y, et al. Proxy re-encryption-based traceability and sharing mechanism of the power material data in blockchain environment. Energies (2022) 15:2570. doi:10.3390/en15072570

17. Zha D-S, Feng T-T, Gong X-L, Liu S-Y. When energy meets blockchain: a systematic exposition of policies, research hotspots, applications, and prospects. Int J Energ Res (2022) 46:2330–60. doi:10.1002/er.7398

18. Reynolds S. Unpacking the challenges of supply chain transparency and traceability: perspectives from industry practitioners (2024). doi:10.20944/preprints202406.0644.v1

19. Azis AM, Irjayanti M. Strengthening the accuracy and visibility of supply chain management data in the coffee industry. Cogent Business and Manag (2024) 11:2380811. doi:10.1080/23311975.2024.2380811

20. Xia J, Li H, He Z. The effect of blockchain technology on supply chain collaboration: a case study of lenovo. Systems (2023) 11:299. doi:10.3390/systems11060299

21. Zhao X, Xie J, Zhang WJ. The impact of information sharing and ordering co-ordination on supply chain performance. Supply Chain Manag Int J (2002) 7:24–40. doi:10.1108/13598540210414364

22. Dionne L, Kempf KG. Data in production and supply chain planning. In: KG Kempf, P Keskinocak, and R Uzsoy, editors. Planning production and inventories in the extended enterprise: a state of the art handbook, volume 1. New York, NY: Springer US (2010). p. 167–84. doi:10.1007/978-1-4419-6485-4_8

23. Sargiotis D. Data quality management: ensuring accuracy and reliability. In: D Sargiotis, editor. Data governance: a guide. Cham: Springer Nature Switzerland (2024). p. 197–216. doi:10.1007/978-3-031-67268-2_5

24. Azevedo P, Gomes J, Romão M. Supply chain traceability using blockchain. Oper Manag Res (2023) 16:1359–81. doi:10.1007/s12063-023-00359-y

25. Katsikouli P, Wilde AS, Dragoni N, Høgh-Jensen H. On the benefits and challenges of blockchains for managing food supply chains. J Sci Food Agric (2021) 101:2175–81. doi:10.1002/jsfa.10883

26. Yang R, Wang J, Zhang X, Fu J, Jia X. Research on power system material management digitalization technology based on process reengineering. J Phys Conf Ser (2022) 2186:012020. doi:10.1088/1742-6596/2186/1/012020

27. Xie L, Zheng X, Sun Y, Huang T, Bruton T. Massively digitized power grid: opportunities and challenges of use-inspired AI. Proc IEEE (2023) 111:762–87. doi:10.1109/JPROC.2022.3175070

28. Wang Y, Song S, Gao M, Wang J, Zhu J, Tan Z. Accounting for the life cycle cost of power grid projects by employing a system dynamics technique: a power reform perspective. Sustainability (2020) 12:3297. doi:10.3390/su12083297

29. Li H, Zhu L, Shen M, Gao F, Tao X, Liu S. Blockchain-based data preservation system for medical data. J Med Syst (2018) 42:141. doi:10.1007/s10916-018-0997-3

30. Duan J, Zhang C, Gong Y, Brown S, Li Z. A content-analysis based literature review in blockchain adoption within food supply chain. IJERPH (2020) 17:1784. doi:10.3390/ijerph17051784

31. Wang B, Lin Z, Wang M, Wang F, Xiangli P, Li Z. Applying blockchain technology to ensure compliance with sustainability standards in the PPE multi-tier supply chain. Int J Prod Res (2023) 61:4934–50. doi:10.1080/00207543.2022.2025944

32. Habib G, Sharma S, Ibrahim S, Ahmad I, Qureshi S, Ishfaq M. Blockchain technology: benefits, challenges, applications, and integration of blockchain technology with cloud computing. Future Internet (2022) 14:341. doi:10.3390/fi14110341

33. Centobelli P, Cerchione R, Vecchio PD, Oropallo E, Secundo G. Blockchain technology for bridging trust, traceability and transparency in circular supply chain. Inf and Manag (2022) 59:103508. doi:10.1016/j.im.2021.103508

34. Hossain Md R, Nirob FA, Islam A, Rakin TM, Md A-A. A comprehensive analysis of blockchain technology and consensus protocols across multilayered framework. IEEE Access (2024) 12:63087–129. doi:10.1109/ACCESS.2024.3395536

35. Tabatabaei MH, Vitenberg R, Veeraragavan NR. Understanding blockchain: definitions, architecture, design, and system comparison. Comput Sci Rev (2023) 50:100575. doi:10.1016/j.cosrev.2023.100575

36. Mohammadi F, Saif M. Blockchain technology in modern power systems: a systematic review. IEEE Systems, Man Cybernetics Mag (2023) 9:37–47. doi:10.1109/MSMC.2022.3201365

37. Jiang T, Fang H, Wang H. Blockchain-based internet of vehicles: distributed network architecture and performance analysis. IEEE Internet Things J (2019) 6:4640–9. doi:10.1109/JIOT.2018.2874398

38. Zhou M, Huang Y, Li K, Li Z, Wei J. Design of intelligent power material storage information management system based on blockchain technology. In: 2020 13th international conference on intelligent computation technology and automation (ICICTA) (2020). p. 479–85. doi:10.1109/ICICTA51737.2020.00108

39. Venkatesh VG, Kang K, Wang B, Zhong RY, Zhang A. System architecture for blockchain based transparency of supply chain social sustainability. Robotics and Computer-Integrated Manufacturing (2020) 63:101896. doi:10.1016/j.rcim.2019.101896

40. Qatbi MRSA, Rathinam G. Enhancing supply chain management: a blockchain-based approach for data privacy and transparency in the IoT era. In: 2023 10th international conference on electrical engineering, computer science and informatics (EECSI) (2023). p. 667–71. doi:10.1109/EECSI59885.2023.10295696

41. Zhang B, Pan H, Li K, Xing Y, Wang J, Fan D, et al. A blockchain and zero knowledge proof based data security transaction method in distributed computing. Electronics (2024) 13:4260. doi:10.3390/electronics13214260

42. Khan SN, Loukil F, Ghedira-Guegan C, Benkhelifa E, Bani-Hani A. Blockchain smart contracts: applications, challenges, and future trends. Peer-to-peer Netw Appl (2021) 14:2901–25. doi:10.1007/s12083-021-01127-0

43. Wu J, Lin J, Lai Y. Research on power material supply method based on smart contract system. In: M Atiquzzaman, NY Yen, and Z Xu, editors. Proceedings of the 4th international conference on big data analytics for cyber-physical system in smart city - volume 2. Singapore: Springer Nature (2022). p. 201–8. doi:10.1007/978-981-99-1157-8_25

44. Li Y, Hao Y, Luo W, Yu X, Zhu J. Research on the application of blockchain in the quality traceability of power resources and materials. In: D Qiu, Y Jiao, and W Yeoh, editors. Proceedings of the 2022 international conference on bigdata blockchain and economy management (ICBBEM 2022) atlantis highlights in intelligent systems. Dordrecht: Atlantis Press International BV (2022). p. 518–25. doi:10.2991/978-94-6463-030-5_52

45. Abdelmalak M, Bhusal N, Gautam M, Benidris M. Cyber-physical power system layers: classification, characterization, and interactions. In: 2023 IEEE Texas power and energy conference (TPEC). College Station, TX, USA: IEEE (2023). p. 1–6. doi:10.1109/TPEC56611.2023.10078602

46. Khalyasmaa AI, Stepanova AI, Eroshenko SA, Matrenin PV. Review of the digital twin technology applications for electrical equipment lifecycle management. Mathematics (2023) 11:1315. doi:10.3390/math11061315

47. Xiong G, Nyberg TR, Dong X, Shang X. Intelligent technologies and systems of material management. In: C Kahraman, and S Çevik Onar, editors. Intelligent techniques in engineering management: theory and applications. Cham: Springer International Publishing (2015). p. 295–330. doi:10.1007/978-3-319-17906-3_13

48. Guo L, Liu Q, Shi K, Gao Y, Luo J, Chen J. A blockchain-driven electronic contract management system for commodity procurement in electronic power industry. IEEE Access (2021) 9:9473–80. doi:10.1109/ACCESS.2021.3049562

49. Vaish K, Uniyal V, Kathuria S, Dumka A, Gehlot A, Joshi A. The role of integrating blockchain, digital signature, and cloud computing for robust smart contract structuring. In: 2023 2nd edition of IEEE Delhi section flagship conference (DELCON) (2023). p. 1–5. doi:10.1109/DELCON57910.2023.10127528

Keywords: power materials management, lifecycle management, blockchain technology, smart contracts, CPSS

Citation: Geng N, Zhou C, Feng J, Zhang X, Xu H, Zu W and Chen X (2025) Towards a blockchain-based framework for secure and trustworthy lifecycle management of power materials in CPSS. Front. Phys. 13:1634964. doi: 10.3389/fphy.2025.1634964

Received: 25 May 2025; Accepted: 26 September 2025;

Published: 14 November 2025.

Edited by:

Yuanyuan Huang, Chengdu University of Information Technology, ChinaReviewed by:

Lulu Gao, Chengdu University of Information Technology, ChinaYiping Tang, Shandong University of TCM, China

Copyright © 2025 Geng, Zhou, Feng, Zhang, Xu, Zu and Chen. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Can Zhou, emhvdWNhbkB0c2luZ2h1YS1laXJpLm9yZw==

Nan Geng1

Nan Geng1 Can Zhou

Can Zhou