- 1Textile and Clothing School, Yancheng Polytechnic College, Yancheng, China

- 2Department of Mathematical Sciences, Saveetha School of Engineering, SIMATS, Chennai, Tamil Nadu, India

- 3School of Jia Yang, Zhejiang Shuren University, Hangzhou, Zhejiang, China

- 4School of Mathematics and Big Data, Hohhot Minzu College, Hohhot, Inner Mongolia, China

- 5School of Information Engineering, Yango University, Fuzhou, China

- 6School of Sciences and Humanities, Mathematics Department, Laboratory for Electro-Mechanics and Mathematics with Applications (LEMMA), Nazarbayev University, Astana, Kazakhstan

- 7Faculty of Electronics, Photonics and Microsystems, Wrocław University of Science and Technology, Wrocław, Poland

Magnetically actuated micro-electro-mechanical systems (magMEMSs) are pivotal for wearable sensor applications that need high sensitivity, fast response, and compact integration, such as biomedical monitoring and motion-tracking devices. In this paper, we investigate the dynamic pull-in instability and periodic trajectory analysis of magMEMS models with current-carrying filaments, addressing critical challenges in a miniaturized sensor design. A simplified Galerkin approach is used to analyze a Lorentz-force-driven MEMS oscillator, deriving approximate expressions for the dynamic pull-in threshold—a key criterion for stable periodic operation—and the corresponding oscillation frequency and periodic solutions. Extensive numerical simulations support and validate the analytical results. These findings offer valuable insights to assist in the design and optimization of MEMS devices in wearable sensors.

1 Introduction

Micro-electro-mechanical systems (MEMSs) have revolutionized numerous fields by enabling the development of miniaturized devices with exceptional performance and diverse functionalities, particularly in wearable sensor technologies where compactness, low power consumption, and high sensitivity are paramount. These systems combine mechanical, electrical, and optical components in a single device of micrometric dimensions, forming compact, multifunctional chips when integrated with electronic signal-processing units [1, 2]. In wearable applications—such as biomedical monitoring (e.g., real-time health tracking via magnetoencephalography probes), environmental sensing, and motion-tracking systems—MEMSs offer unparalleled advantages, including their ability to detect minute physical changes (e.g., magnetic field fluctuations and mechanical vibrations) with fast response times [3, 4]. Characterized by their compact size and energy efficiency, MEMSs are ideal for power-constrained wearable devices operating in the Internet of Things (IoT) ecosystem [5, 6]. Among MEMS subclasses, magnetically actuated MEMSs (magMEMSs) have emerged as a promising solution for wearable sensors due to their linear response, directional actuation, and dimensional stability at the nanoscale [7, 8], making them suitable for applications requiring precise, repeatable displacement control in dynamic environments (e.g., wearable accelerometers or flexible biosensors).

However, a major challenge in the performance and reliability of magMEMSs is pull-in instability—a nonlinear phenomenon that can significantly impair device operation. This instability occurs when the magnetic attraction between a movable microstructure (such as a beam, plate, or membrane) and a magnetic actuator (typically a coil or permanent magnet) exceeds the mechanical restoring force. Beyond a critical threshold—referred to as the pull-in point—the structure collapses onto the actuator, often irreversibly, leading to permanent device failure [9–13].

This behavior is particularly problematic in magMEMS actuators and sensors, where precise and repeatable displacement control is crucial. The issue becomes even more critical in nanoelectromechanical systems (NEMSs), which utilize components typically smaller than 100 nm. At such scales, proximity forces—including Van der Waals forces, covalent bonding, and electrostatic interactions—can dominate over the magnetic driving force, adding further complexity to the dynamics [14, 15]. The strong nonlinear interaction between magnetic forces and structural elasticity is typically modeled through coupled magneto-mechanical equations [16], posing substantial challenges for both theoretical analysis and practical design. A rigorous investigation of pull-in dynamics under magnetostatic loading is thus essential for ensuring robust and safe operation of magMEMS devices.

To address this challenge, a variety of analytical, numerical, and semi-analytical methods have been developed. The variational iteration method (VIM) is widely appreciated for its flexibility in handling nonlinear dynamics [17, 18]; however, its practical application is often hindered by the difficulty in constructing appropriate Lagrange multipliers. Alternatives include reduced-order modeling, phase-plane analysis, and perturbation methods, which aim to approximate the pull-in threshold and capture critical behavior near instability points [9, 19, 20]. Energy-based methods and bifurcation analysis offer qualitative insights into collapse dynamics [11], whereas numerical continuation and shooting methods allow for high-accuracy tracking of periodic orbits and stability boundaries [10]. Semi-analytical frameworks such as the homotopy perturbation method (HPM) are also popular [21] although they are sensitive to initial guesses and homotopy construction. To enhance convergence and reliability, hybrid methods combining homotopy with Laplace transforms have been proposed [22].

Di Barba et al. [23] developed a geometric formulation of the electrostatic field in membrane MEMS devices, in which the electric field magnitude is assumed to be proportional to the membrane curvature. Although focused on electrostatic actuation, this work shares strong methodological parallels with the present study. This parallel is particularly evident in the treatment of singular nonlinearities and instability conditions, for which rigorous existence results were established using Schauder–Tychonoff’s fixed-point theorem. In fact, the analytical insights from the electrostatic framework by Di Barba et al. [23], especially those concerning solution existence and uniqueness, also provide a mathematical foundation for the magnetodynamic model developed here. Additionally, frequency-based approximations have been explored by reformulating the problem into a standard form amenable to harmonic solutions [24–26]. Recently, there has been a resurgence of interest in classical analytical techniques, which often yield surprisingly accurate results with minimal computational effort [27, 28]. Frequency-based methods, while conceptually simple and non-iterative, may sacrifice some accuracy in capturing complex dynamics [29]. Algebraic techniques leveraging Sturm’s theorem have also shown promise as fast and reliable tools for approximating pull-in thresholds [30, 31].

In this context, the present work makes a novel contribution to the analysis of magMEMS by studying a Lorentz-force-driven model involving current-carrying filaments using a simple and effective Galerkin approximation. Unlike transformation-based techniques required for harmonic approximations under zero initial conditions [24], our method yields closed-form expressions for the dynamic pull-in threshold, oscillation frequency, and periodic trajectories. In particular, we derive an explicit pull-in condition that serves as a practical criterion for the existence of periodic orbits. The analytical results are systematically validated through numerical simulations, confirming their accuracy across a broad range of parameters. This approach enhances the understanding of nonlinear dynamics in magMEMS and offers a practical tool for device design and optimization.

The paper is organized as follows. In Section 2, we derive the nonlinear differential equation that governs the dynamics of the magMEMS model under Lorentz actuation. Section 3 presents the Galerkin method and outlines the derivation of approximate periodic solutions and the dynamic pull-in threshold. Section 4 provides numerical results that validate the analytical predictions. Finally, concluding remarks and potential directions for future research are offered in Section 5.

2 Mathematical model for magMEMS with current-carrying filaments

The fundamental principles governing magnetic actuation in MEMS are briefly outlined in this section. In particular, in magnetostatics, the attractive or repulsive force between two current-carrying wires is typically described by Ampère’s force law, which assumes the existence of infinitely long, parallel conductors. However, on the microscale—where wire lengths are finite—Neumann’s formulation, based on the concept of mutual inductance [32], provides a more appropriate model. In this framework, the magnetic force between the wires can be expressed as minus the negative gradient of the magnetic energy coupled between the wires,

where

which confirms the validity of the magnetic force formula.

Furthermore, under certain assumptions (He et al. [9]), the dynamics of the wires in the MEMS sensor can be approximated by modeling each as a point mass, leading to a lumped-parameter differential equation. In this formulation, the motion of the filament is governed by Newton’s second law, which leads to Equation 2:

where

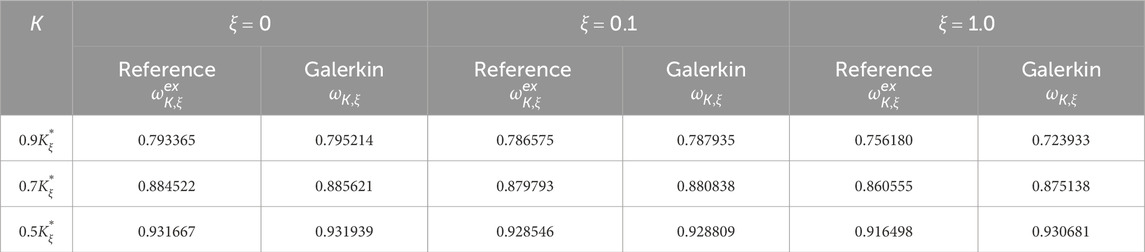

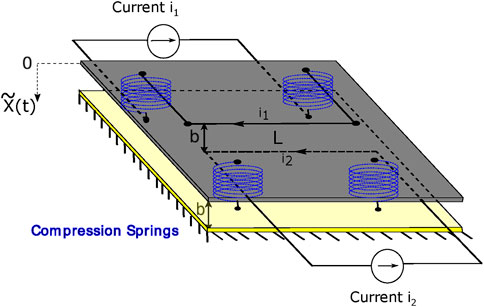

Ultimately, the motion of the platform, shown in Figure 1, satisfies differential Equation 3:

Figure 1. magMEMS with current-carrying filaments. The instantaneous distance between filaments is

Note that the governing differential Equation 3 does not include a damping term as the air resistance is assumed to be negligible. This assumption is typically valid for sufficiently small MEMS devices, for example, Rhoads [33], Gorelick et al. [34], and references therein. However, in practical applications where damping effects cannot be neglected or to extend the model’s applicability, a damping term can be incorporated as discussed in Section 3.

Furthermore, it is a common practice to rescale the single-degree-of-freedom Equation 3 to facilitate interpretation. To this end, we introduce the following dimensionless distance and time variables

respectively, in Equation 4. The transformation yields the following dimensionless form of the governing Equation 5:

and the excitation parameter

and the dimensionless geometric parameter is given by

Finally, we complement Equation 5 with zero initial conditions

and additionally, we assume that the currents in both wires are unidirectional, that is,

It should be noted that Equation 5 reduces to

in the case where the filament’s motion is driven by the magnetic field of an infinite current-carrying conductor, that is,

and

respectively. In addition, the dynamic pull-in threshold

Next, multiplying both sides of Equation 5 by

from which it follows Equation 10:

As noted previously by He et al. [9] and Skrzypacz et al. [10], the solution

has a root in the interval

has a root in the interval

On the other hand, in the critical case

This condition is satisfied when

which leads to the following transcendental Equation 13 for

The value of

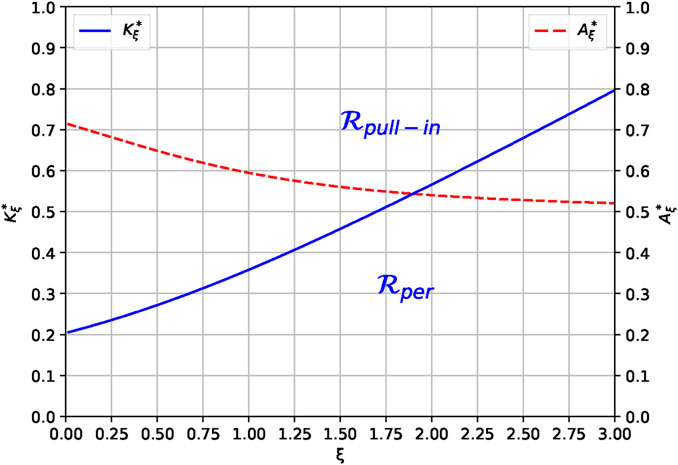

which follows from the condition

Figure 2. Dynamic pull-in threshold

In the regime of small values of the geometric parameter

with its derivative given by

To facilitate further analysis, we introduce the simplified function in Equation 15:

which captures the leading-order behavior of

This leads to approximate model Equation 16 for the magnetic MEMS:

subject to the initial conditions Equation 17:

In the presence of damping effects, this equation can be generalized to Equation 18:

where

3 Dynamical model analysis via the Galerkin approach

In this section, we apply the Galerkin approach to approximate periodic solutions of the magMEMS model, first in the undamped case and subsequently in the presence of damping.

3.1 Undamped case

Let us rewrite Equation 16 as follows:

To obtain the weak formulation, we need to find periodic

holds for all

Note that the periodic Galerkin ansatz by Equation 20 satisfies the initial conditions

Substituting the corresponding Galerkin ansatz into the weak formulation in Equation 19 and testing over one period

From the second equation in Equation 21, we obtain Equation 22:

As

the maximal deflection is

Here,

where Equation 25

and Equation 26

In our case, we obtain Equation 27:

where (Equation 28)

The condition

constitutes the approximate separatrix.

If

Note that the discriminant condition

where the

Note that the ansatz in Equation 20 can be systematically extended by incorporating additional terms from the Fourier expansion. For instance, a single-term ansatz with adaptive coefficients may reduce computational effort without compromising accuracy, which is consistent with minimalist modeling principles in MEMS analysis. However, increasing the number of trigonometric terms in the ansatz inevitably results in higher-order nonlinear algebraic systems, which must be solved using numerical methods. Accurate models are essential for capturing the nonlinear dynamics of oscillators. Among the notable analytical–semi-analytical techniques are the VIM [37] and the HPM [38, 39]. VIM is particularly effective in treating strongly nonlinear systems and has been successfully used to predict pull-in conditions in electrostatic MEMS. HPM, a semi-analytical method that combines homotopy theory with perturbation techniques, offers robust solutions to problems with not well-defined initial guesses. It is especially suitable for complex nonlinear scenarios as it can transform intricate governing equations into tractable forms more efficiently than many traditional approaches [37–39]. Recently, He’s frequency formula and Ma’s modification have been applied to the analysis of fractal vibration systems [40]. Both VIM and HPM demonstrated the capability to yield approximate pull-in thresholds with relatively high accuracy [18, 41]. For example, J.-H. He, in [18], used VIM to determine the approximate pull-in threshold for the magMEMS oscillator in the case of an infinitely long wire

3.2 Damped case

Let us rewrite Equation 18 as follows:

To obtain the weak formulation for the damped case, we need to find a periodic

holds for all

We seek a Galerkin approximation that includes both transient damping effects and the correct steady-state behavior. Let

which follows from Equation 18 assuming

The Galerkin ansatz takes the form, as shown in Equation 34:

where

For the damped case, we use

This leads to the damped pull-in threshold, as shown in Equation 36:

This formulation recovers the undamped solution as

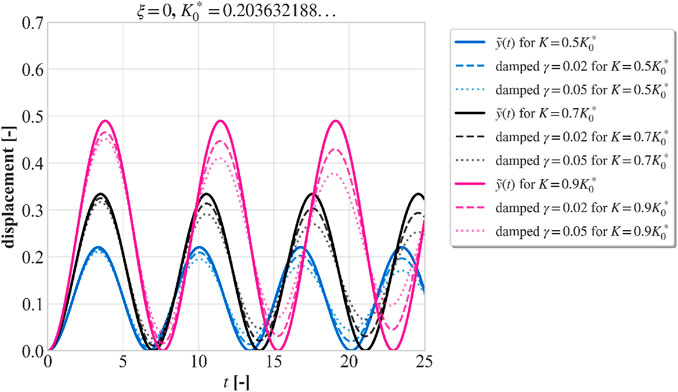

Figure 3 shows a comparison between undamped and damped solutions. The plots demonstrate how damping affects transient behavior while maintaining correct steady-state convergence. Galerkin approximations (solid lines) match numerical ODE solutions (dashed lines).

Figure 3. Comparison between undamped and damped magMEMS solutions for different excitation parameters. It shows how damping affects transient behavior while maintaining correct steady-state convergence. Galerkin approximations (solid lines) match numerical ODE solutions (dashed lines).

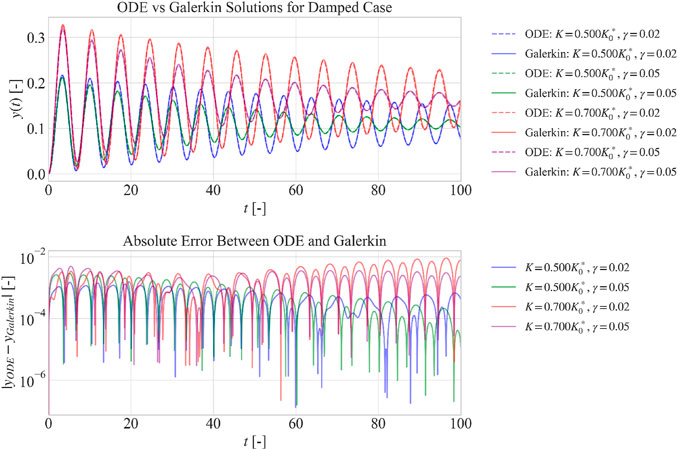

The accuracy of the Galerkin formulation is demonstrated in Figure 4, which compares numerical ODE solutions with analytical Galerkin approximations. The upper subplot shows the time evolution of both solutions, whereas the lower subplot displays the absolute error between them.

Figure 4. Comparison between numerical ODE solutions and analytical Galerkin approximations. The upper subplot shows the time evolution of both solutions. The lower subplot displays the absolute error, demonstrating the accuracy of analytical approximation.

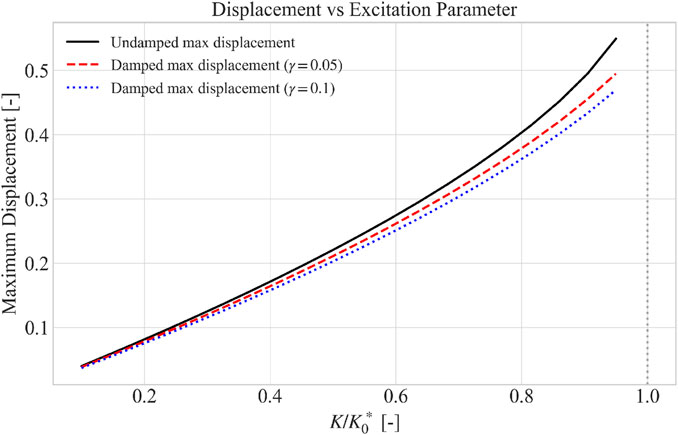

Figure 5 shows the effect of damping on the maximum amplitude as a function of excitation parameter

Figure 5. Effect of damping on maximum displacement as a function of the excitation parameter

4 Discussion and simulation results

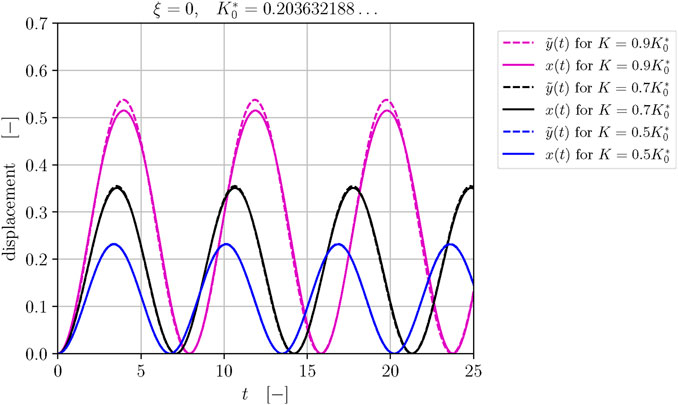

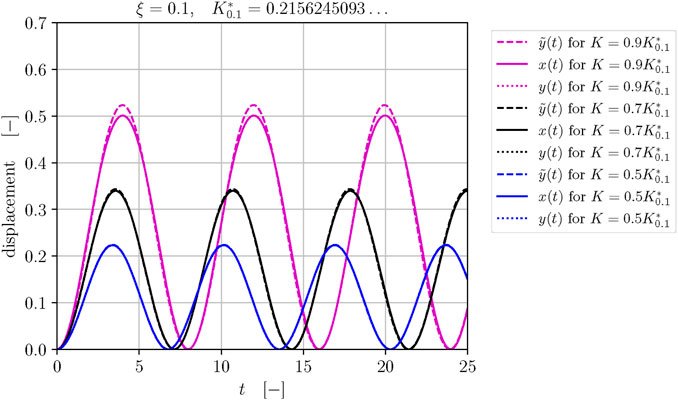

In this section, we present numerical simulations of the normalized deflection of the platform,

Figure 6. Profiles of Galerkin solutions

Figure 7. Profiles of Galerkin solutions

Figure 8. Profiles of Galerkin solutions

Note that the range of dimensionless parameters

Furthermore, as the value of

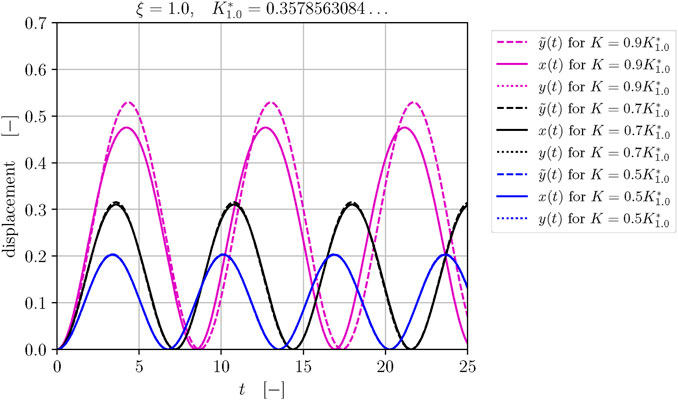

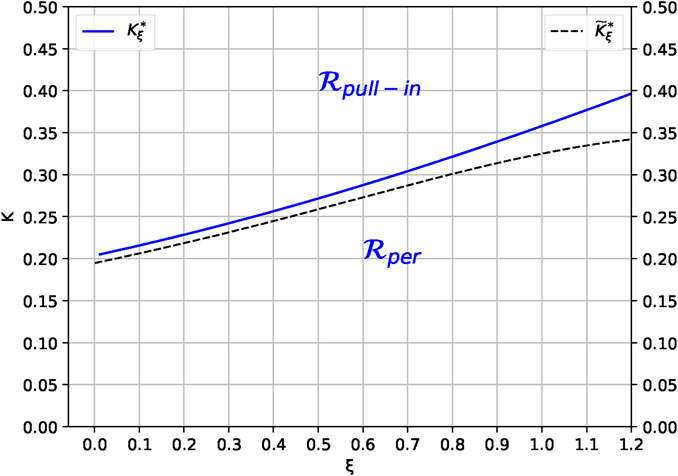

Figure 9. Exact and approximate separatrix. Pairs

The exact (harmonic) frequency of oscillations is defined as shown in Equation 37:

where

where

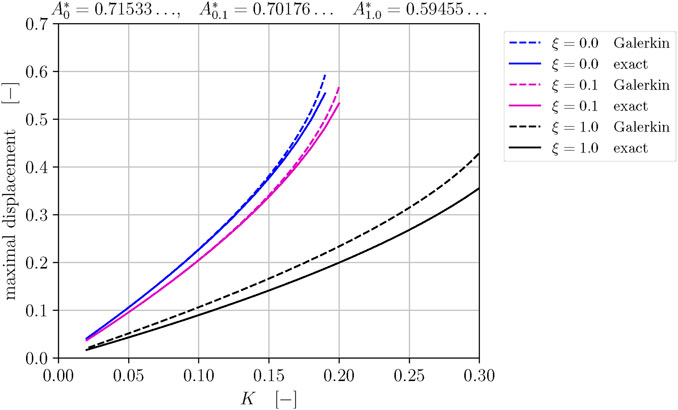

In Figure 10, the maximal displacement and its Galerkin approximation is presented versus varying excitation parameter K for ξ = 0; 0.1; 1.0. The Galerkin approximation of the maximum displacement is close to its exact value for small values of the geometric parameter ξ.

5 Conclusions and outlooks

In this paper, the Galerkin approach is used to derive approximate expressions for the pull-in threshold, oscillation frequency, and periodic solutions of the magMEMS. It has been demonstrated that these approximations maintain a high degree of accuracy for excitation parameters below the critical pull-in value, denoted by

Furthermore, we have extended the analysis to include damping effects for the small damping coefficient

Data availability statement

The source code and supplementary materials for this research are available at https://github.com/armanbolatov/magmems_damping.

Author contributions

LZ: Methodology, Investigation, Funding acquisition, Writing – review and editing. J-HH: Methodology, Writing – review and editing, Writing – original draft, Conceptualization, Funding acquisition, Validation. PS: Visualization, Formal Analysis, Project administration, Resources, Validation, Data curation, Methodology, Software, Supervision, Investigation, Conceptualization, Writing – review and editing, Writing – original draft, Funding acquisition. AB: Methodology, Investigation, Validation, Data curation, Software, Writing – original draft. DK: Writing – review and editing, Investigation, Methodology, Validation. GE: Methodology, Validation, Investigation, Writing – review and editing. BP: Validation, Methodology, Investigation, Writing – original draft, Writing – review and editing. PP: Writing – review and editing, Methodology, Formal Analysis, Writing – original draft, Investigation, Validation, Conceptualization.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. PS, AB, DK, and GE were supported by the Ministry of Education and Science of the Republic of Kazakhstan within the framework of Project AP19676969. The work is funded by the National Foreign Experts Program of the Ministry of Education (G2023014001L), the Technology Innovation Team of Yancheng Polytechnic College (YGKJ202502), and the doctoral research initiation fund project of Yancheng Polytechnic College (2023). The key technology innovation platform for flame retardant fiber and functional textiles in Jiangsu Province (2022JMRH-003) also supports this research. PS and GE have been supported by the Ministry of Education and Science of the Republic of Kazakhstan within the framework of Project AP19676969 Modeling, Analysis, and Optimization of MEMS and magMEMS. PPu and BP have received funding from a project co-financed by the Polish Ministry of Science and Higher Education under the European Union’s Horizon Europe programme under Marie Skłodowska-Curie Actions–Staff Exchanges (SE) grant agreement No. 101086226-ENSIGN.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Footnotes

1This quantity is also called the co-energy of the magnetic field.

References

1. Younis MI MEMS linear and nonlinear statics and dynamics, 20. Springer Science & Business Media (2011).

2. Li W, Zhao X, Cai B, Zhou G, Zhang M. Magnetically actuated mems variable optical attenuator. Micromachining Microfabrication Process Technology Devices (SPIE) (2001) 4601:89–96. doi:10.1117/12.444689

3. Gao W, Emaminejad S, Nyein HYY, Challa S, Chen K, Peck A, et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature (2016) 529:509–14. doi:10.1038/nature16521

4. Amjadi M, Kyung K-U, Park I, Sitti M. Stretchable, skin-mountable, and wearable strain sensors and their potential applications: a review. Adv Funct Mater (2016) 26:1678–98. doi:10.1002/adfm.201504755

5. Masoud M, Jaradat Y, Manasrah A, Jannoud I. Sensors of smart devices in the internet of everything (ioe) era: big opportunities and massive doubts. J Sensors (2019) 2019:1–26. doi:10.1155/2019/6514520

6. Iannacci J. Microsystem based energy harvesting (eh-mems): powering pervasivity of the internet of things (iot)–a review with focus on mechanical vibrations. J King Saud University-Science (2019) 31:66–74. doi:10.1016/j.jksus.2017.05.019

7. Babij M, Majstrzyk W, Sierakowski A, Janus P, Grabiec P, Ramotowski Z, et al. Mems displacement generator for atomic force microscopy metrology. Meas Sci Technology (2021) 32:065903. doi:10.1088/1361-6501/abc28a

8. Pruchnik B, Orłowska K, Świadkowski B, Gacka E, Sierakowski A, Janus P, et al. Microcantilever-based current balance for precise measurement of the photon force. Scientific Rep 2023 (2023) 13(13):466–9. doi:10.1038/s41598-022-27369-3

9. He J-H, Nurakhmetov D, Skrzypacz P, Wei D. Dynamic pull-in for micro–electromechanical device with a current-carrying conductor. J Low Frequency Noise, Vibration Active Control (2021) 40:1059–66. doi:10.1177/1461348419847298

10. Skrzypacz P, Ellis G, He J-H, He C-H. Dynamic pull-in and oscillations of current-carrying filaments in magnetic micro-electro-mechanical system. Commun Nonlinear Sci Numer Simulation (2022) 109:106350. doi:10.1016/j.cnsns.2022.106350

11. Yang Q. A mathematical control for the pseudo-pull-in stability arising in a micro-electromechanical system. J Low Frequency Noise, Vibration Active Control (2023) 42:927–34. doi:10.1177/14613484221133603

12. He J-H, Yang Q, He C-H, Alsolami AA. Pull-down instability of the quadratic nonlinear oscillators. Facta Universitatis, Ser Mech Eng (2023) 21:191–200. doi:10.22190/fume230114007h

13. He J-H, Bai Q, Luo Y-C, Kuangaliyeva D, Ellis G, Yessetov Y, et al. Modeling and numerical analysis for mems graphene resonator. Front Phys (2025) 13:1551969. doi:10.3389/fphy.2025.1551969

15. Ghourichaei M, Kerimzade U, Demirkazik L, Pruchnik B, Kwoka K, Badura D, et al. Multiscale fabrication and characterization of a nems force sensor. Adv Mater Tech (2024) 10:2400022. doi:10.1002/admt.202400022

16. Yeatman E. Design and performance analysis of thermally actuated mems circuit breakers. J Micromechanics Microengineering (2005) 15:S109–15. doi:10.1088/0960-1317/15/7/016

17. Rezazadeh G, Madinei H, Shabani R. Study of parametric oscillation of an electrostatically actuated microbeam using variational iteration method. Appl Math Model (2012) 36:430–43. doi:10.1016/j.apm.2011.07.026

18. Anjum N, He J-H, He C-H, Gepreel KA. Variational iteration method for prediction of the pull-in instability condition of micro/nanoelectromechanical systems. Phys Mesomechanics (2023) 26:241–50. doi:10.1134/s1029959923030013

19. Skrzypacz P, Ellis G, Pruchnik B, Putek P. Generalized analysis of dynamic pull-in for singular magmems and mems oscillators. Scientific Rep (2025) 15:23691. doi:10.1038/s41598-025-09515-9

20. Skrzypacz PS, Putek PA, Pruchnik BC, Turganov A, Ellis GA, Gotszalk TP. Analysis of dynamic pull-in for lumped mems model of atomic force microscope with constant magnetic excitation. J Sound Vibration (2025) 617:119215. doi:10.1016/j.jsv.2025.119215

21. He J-H. Periodic solution of a micro-electromechanical system. Facta Universitatis, Ser Mech Eng (2024) 187–98. doi:10.22190/fume240603034h

22. Nadeem M, Ain Q-T, Almakayeel N, Shao Y, Wang S, Shutaywi M. Analysis of nanobeam-based microstructure in n/mems system using van der waals forces. Facta Universitatis, Ser Mech Eng (2024) 673–88. doi:10.22190/fume240904048n

23. Di Barba P, Fattorusso L, Versaci M Electrostatic field in terms of geometric curvature in membrane mems devices. Commun Appl Ind Math (2017) 8:165–84. doi:10.1515/caim-2017-0009

24. Skrzypacz P, He J-H, Ellis G, Kuanyshbay M. A simple approximation of periodic solutions to microelectromechanical system model of oscillating parallel plate capacitor. Math Methods Appl Sci (2020) mma.6898–8. doi:10.1002/mma.6898

25. He J-H, Skrzypacz PS, Zhang Y, Pang J. Approximate periodic solutions to microelectromechanical system oscillator subject to magnetostatic excitation. Math Methods Appl Sci (2020):mma.7018. doi:10.1002/mma.7018

26. He C-H, He J-H, Ma J, Alsolami AA, Yang X-J. A modified frequency formulation for nonlinear mechanical vibrations. Facta Universitatis, Ser Mech Eng (2025) 23:197. doi:10.22190/fume250526022h

27. Liu Y-P, He J-H. A fast and accurate estimation of amperometric current response in reaction kinetics. J Electroanalytical Chem (2025) 978:118884. doi:10.1016/j.jelechem.2024.118884

28. He J-H, Ma J, Alsolami AA, He C-H, Yang XJ. Variational approach to micro-electro-mechanical systems. Facta Universitatis, Ser Mech Eng (2025) 23:197.

29. Mohammadian M. Application of he’s new frequency-amplitude formulation for the nonlinear oscillators by introducing a new trend for determining the location points. Chin J Phys (2024) 89:1024–40. doi:10.1016/j.cjph.2024.03.047

30. Omarov D, Nurakhmetov D, Wei D, Skrzypacz P. On the application of sturm’s theorem to analysis of dynamic pull-in for a graphene-based mems model. Appl Comput Mech (2018) 12. doi:10.24132/acm.2018.413

31. Anjum N, He J-H. Geometric potential in nano/microelectromechanical systems: Part i mathematical model. Int J Geometric Methods Mod Phys (2024):2440027. doi:10.1142/s0219887824400279

33. Rhoads JF. Me 597: mechanics of mems and nems (2013). Available online at: https://engineering.purdue.edu/jfrhoads/ME597/Mechanics%20of%20MEMS%20and%20NEMS.pdf (Accessed May 26, 2025).

34. Gorelick S, Dekker JR, Leivo M, Kantojärvi U. Air damping of oscillating mems structures: modeling and comparison with experiment. In: Proc. Comsol Conf. 1–5 (2013).

35. Boyd JP. Solving transcendental equations: the Chebyshev polynomial proxy and other numerical rootfinders, perturbation series, and oracles. Society for Industrial and Applied Mathematics. (2014).

36. Zucker IJ. 92.34 the cubic equation - a new look at the irreducible case. The Math Gaz (2008) 92(No. 524):264–8. doi:10.1017/s0025557200183135

37. He J-H. Variational iteration method–a kind of non-linear analytical technique: some examples. Int J non-linear Mech (1999) 34:699–708. doi:10.1016/s0020-7462(98)00048-1

38. He J-H. Homotopy perturbation technique. Computer Methods Appl Mech Eng (1999) 178:257–62. doi:10.1016/s0045-7825(99)00018-3

39. He J-H. Homotopy perturbation method: a new nonlinear analytical technique. Appl Mathematics Comput (2003) 135:73–9. doi:10.1016/s0096-3003(01)00312-5

40. Feng G. A circular sector vibration system in a porous medium. Facta Universitatis, Ser Mech Eng (2023) 23:377. doi:10.22190/fume230428025f

41. He CH, Mohammadian M. A fast insight into high-accuracy nonlinear frequency estimation of stringer-stiffened shells. Facta. Univ.-Ser. Mech. (2025). doi:10.22190/FUME250525028H

Keywords: magMEMS, Galerkin approach, dynamic pull-in, periodic solutions, singular MEMS oscillators, wearable sensors

Citation: Zhao L, He J-H, Skrzypacz P, Bolatov A, Kuangaliyeva D, Ellis G, Pruchnik B and Putek P (2025) Optimizing dynamic pull-in threshold and periodic trajectories for magnetically actuated MEMS (magMEMS) in wearable sensors. Front. Phys. 13:1638299. doi: 10.3389/fphy.2025.1638299

Received: 30 May 2025; Accepted: 25 August 2025;

Published: 23 September 2025.

Edited by:

Yee Jiun Yap, University of Nottingham Malaysia Campus, MalaysiaReviewed by:

Mario Versaci, Mediterranea University of Reggio Calabria, ItalyGuangqing Feng, Henan Polytechnic University, China

Copyright © 2025 Zhao, He, Skrzypacz , Bolatov, Kuangaliyeva, Ellis, Pruchnik and Putek. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ji-Huan He, aGVqaWh1YW5AeWd1LmVkdS5jbg==; Piotr Skrzypacz, cGlvdHIuc2tyenlwYWN6QG51LmVkdS5reg==

Lei Zhao

Lei Zhao Ji-Huan He

Ji-Huan He Piotr Skrzypacz

Piotr Skrzypacz  Arman Bolatov6

Arman Bolatov6