- Centre for Advanced Engineering Materials, School of Engineering, Robert Gordon University, Aberdeen, United Kingdom

The two-dimensional macro molecule graphene and its derivatives have widely been investigated for their application as nanofiller in carbon fiber-reinforced composites (CFRC). Research has progressed from techniques that disperse graphene as a mixing constituent within the composite material to more complex examples where graphene is covalently bonded to fiber, matrix or both via multiple reaction steps. This field of research is multi-disciplinary whereby branches of materials, engineering, polymer science, physics and chemistry often overlap. From the materials engineering perspective, the desire is to discover the novel materials targeting industrial applications and obtain a full understanding of the graphene oxide chemistry and interaction of graphene oxide with a polymer matrix. To date, most of the research is targeted at (i) improving the fiber/matrix interface properties and/or (ii) improving the dispersion of nanofiller within the matrix; both factors ultimately improve composite performance. Organizing that information critically can lead to emergence of a generalization of material design. Therefore, the objective of this work is to critically review current state of art in the field of graphene oxide/epoxy CFRCs and propose the design rules based on current scientific trend and common themes for future works.

Introduction

The British physicist, chemist and inventor Sir Joseph Wilson Swan was responsible for giving birth to the carbon fiber industry in the 1860s when he utilized a form of carbonized paper as a filament in the early development of incandescent light bulbs (The Editors of Encyclopaedia Britannica, 2018). Research concerning carbon fiber materials accelerated through the 1950s and 1960s producing the discovery of polyacrylonitrile (PAN) based carbon fiber by Akino Shindo while working at the Government Industrial Research Institute, Osaka, Japan (GIRIO) (Nakamura et al., 2009). PAN based carbon fibers are generally preferred over pitch or rayon-based alternatives due to their relatively cost-effective manufacture and superior mechanical properties (McConnell, 2008; Naito et al., 2009).

PAN fibers are the foundation of the modern carbon fiber industry and now carbon fibers are routinely combined with a thermoset or thermoplastic polymer matrix to make a rigid, strong and lightweight composites (Masuelli, 2013). The most common thermoset resins in use today are epoxy based due to their mechanical, thermal and corrosion resistant properties (Miracle and Donaldson, 2001; Vautard et al., 2013). This composite appealed the Rolls Royce RB211 turbofan jet-engine that was put in to service in 1971 complete with a single carbon fiber-reinforced composites (CFRC) fan stage (Lazonick and Prencipe, 2005). The trend continues to the present day with the development of General Electric GE9X CFRC turbofan for use on the next generation of Boeing 777 aircraft (Trimble, 2013). CFRP is now widely used as aircraft structural components (Soutis, 2005; Njuguna, 2016) however; its technological benefits are not limited to the aerospace industry and has transmitted to many other industries such as in Formula 1 (Savage, 2008) and the automotive industry. For example, use of CFRC material in 903 bhp McLaren P1 supercar has helped achieving the astonishing power to weight ratio of 647 bhp/ton (McLaren Technology Group, 2019). With the reduction in the cost, the benefits of these technologies are reaching to general consumers as wider automotive industry is using CFRC in a variety of applications such as bonnets, structural members and vehicle interior finishing (Feraboli and Masini, 2004; Rezaei et al., 2008; Pimenta and Pinho, 2011). CFRCs are also utilized in the building industry to reinforce concrete (Masuelli, 2013; Wang et al., 2017c), process plant/offshore (Garcia et al., 2017; Ojdrovic and Pridmore, 2017) in piping and vessels; renewable energy and in electronic sensor applications (Nihtianov et al., 2017).

Wider use of CFRC has pushed the global carbon fiber demand. The demand is predicted to reach from ~92,000 ton in year 2018 growing to ~122,000 ton by year 2022 (Das et al., 2016) and the estimated that the value of the CFRC industry is expected to reach USD 37 billion in 2022 (Marketsandmarkets.com, 2017). It's intuitive that research and development within this industry is required to drive down cost and give rise to new and improved CFRCs with properties that are fine-tuned to ever more specialist and technically demanding applications. To draw comparisons; grade 316 stainless steel is a relatively corrosion resistant grade of steel used in maritime and process plant applications which has a tensile strength of 0.53–0.73 GPa, Young's modulus of 200 GPa and density of 8,000 kg/m3 (European Stainless Steel Development Association, 2007). Aluminum alloy 6061 is utilized in aircraft manufacturing and has a tensile strength of 0.31 GPa, Young's modulus of 69 GPa and density of 2,700 kg/m3 (Holt et al., 1996). In comparison to these two metals, a carbon fiber/epoxy composite constructed from 3 layers of Toray T700 12 K fibers [0, 90, and 0°] combined with a Araldite LY5052 resin and HY5052 hardener (bisphenol-A based resin and aromatic diamine hardener) has been shown to possess 1.12 GPa tensile strength, 6.65 GPa Young's modulus and a density of ~2,500 kg/m3 (Rahmani et al., 2014).

CFRC offer mechanical properties similar to a high specification metal alloy at significantly reduced weight; however, it is anisotropic material unlike isotropic metallic alloys. CFRC is shown to have a reduction in flexural strength and modulus (Rahmani et al., 2014). The anisotropic behavior is a result of directional property of the carbon fiber and therefore, the mechanical properties are far better in-plane (i.e., along the carbon fiber) than the out of plane properties. In plane properties are primarily influenced by the carbon fiber whereas the out of plane properties are dependent on the matrix strength and particularly the ability of the matrix to transfer flexural load on to the carbon fiber reinforcement (Lv et al., 2011). Therefore, in order to facilitate an efficient transfer of energy from the polymer to the fiber the interface properties are important. Interfacial properties are influenced by chemical interactions and morphology (Bascom and Drzal, 1987; Drzal et al., 1996; Vautard et al., 2013). Surface properties of both interacting materials largely determines the improved adhesion and therefore, an improvement in mechanical properties.

The epoxy resin is widely used in CFRC and it is a type of polymer characterized often with one or more epoxide functional group with at least one of the epoxide functional group acting as a monomer and terminal unit of the polymer within the structural chain (Lee and Jang, 1998; Miyagawa et al., 2004; Gojny et al., 2014). Epoxy resins are extensively used in the production of lightweight carbon fiber-reinforced composites (CRFP) to deliver desired engineering properties such as high modulus and strength, low creep, superb chemical and thermal stability (Njuguna et al., 2007; Quan et al., 2018). The epoxy/carbon fiber-reinforced composite design, just like any other composite, is heavily dependent on the mechanical and thermal properties of the resulting composites of the manufactured epoxy/carbon fiber-reinforced composite withstanding the conditions set by its application requirements.

Carbon fiber surface is non-polar whereas epoxy resins are polar and therefore does not favor an interaction between fiber and matrix. This issue is further exacerbated for high-modulus carbon fibers used in specialist applications. High-modulus carbon fiber is synthesized from highly aligned PAN precursor and this creates a lower amount of edge defects compared to lower modulus fibers. The reduction in oxygen containing edge defects further reduces the affinity of epoxy to the carbon fiber and can detrimentally affect the interface properties (Bradley et al., 1993; Baral et al., 2008). Carbon fiber has a surface morphology which is generally smooth and hence, it inherently decreases the free surface energy available to favor a good interaction. Resulting poor interface properties can cause CFRCs to delaminate and fail under moderate bending loads. Consequently, a considerable effort has been made in to discovering techniques to promote the fiber/matrix interactions to realize maximum potential of CFRCs.

The objective of this work is to critically review recent advances in carbon fiber, epoxy and graphene composite nanomaterials. The review starts by discussing differences between the graphene derivatives, synthesis techniques and identifying popular methods utilized in CFRC. The main body concentrates on recent discoveries in the fields of carbon fiber surface modification, epoxy polymer modification (covalent and non-covalent), composite processing techniques and nanofiller dispersion in epoxy. The review is generally focused on improvements in mechanical properties and lightly covers thermal and electrical properties only where deemed necessary. Emphasis is paid to molecular interactions throughout discussion because nanoscale relationships ultimately dictate the mechanical, electrical, thermal, rheological and solubility properties of the composite which directly influence industrial processing and consumer application. To the best knowledge of the authors this is the first review which focuses specifically on graphene utilization in CFRC and design rules.

Synthesis Techniques for Graphene and its Derivatives

Nanofiller materials for use in industrial CFRC need to meet certain minimum criteria. Production of nanofiller must be attainable at large scales and produce materials possessing properties which facilitate simple processing techniques. This enables the production of nanofiller/CFRCs with minimal process unit operations and cost efficiently. In order to achieve the capacity required for graphene derived nanofiller a top-down method of synthesis is generally employed. These routes can be wet-chemical or mechanical means. The following subsections discuss common top-down synthesis methods and closes by briefly commenting on bottom-up methods.

Graphene oxide (GO) offers additional flexibility at the nanoscale due to the stability of the macromolecule and the multitude of options for further functionalisation which is extremely appealing for modifying both the carbon fiber and polymer phases of CFRCs. Graphene was first isolated at the University of Manchester in 2004 (Novoselov et al., 2004). Graphene is a two-dimensional carbon allotrope with a honeycomb structure of C6 molecules. The sp2 hybridized carbon atoms are bonded to neighboring atoms by three covalent σ-bonds which leaves the π-electrons delocalized. This contributes to the phenomenal material properties posed by graphene; 130 GPa intrinsic strength, 1.0 Tpa Youngs modulus, 5,000 W/m K thermal conductivity, 200,000 cm2/v s and 97.7% optical transmittance (Lee et al., 2008; Zhu et al., 2010; Pop et al., 2012). The flat structure of graphene gives it an intrinsic surface area of 2,630 m2/g. Such properties make graphene an ideal candidate for inclusion into composite materials. However, there are drawbacks; these are found in the synthesis of pure graphene and the inherent instability of the material. The most common technique for producing anatomically pure graphene is chemical vapor deposition (CVD) (Phiri et al., 2017) however this process involves large quantities of energy and expensive metal catalyst to convert light C1 or C2 gases in to graphene.

Pure graphene is inherently unstable due to the delocalised π electrons. For this reason, graphene is found as graphite in nature because single layer sheets aggregate and fold to increase entropy and increase stability. Fortunately, a derivative of graphene known as “graphene oxide (GO)” which is inherently stable and relatively easy to synthesize using graphite feedstock. The widely accepted Lerf-Klinowski model of GO proposes a sp2 and sp3 C6 skeleton with epoxide and hydroxyl functionalities on the basal plane and carboxylic acid groups on the edges (He et al., 1998; Dreyer et al., 2010). GO is a macro-molecule and non-stoichiometric therefore properties are can be variable depending on degree of oxidation; further observation reported (Feicht et al., 2017) that the in-plane modulus of GO produced by Hummers or Brodie methods varied from ~ 300 to 500 GPa, respectively. Finally, it is now acknowledged that the stronger oxidizing conditions in the former method introduce additional defects on to the surface. GO can be annealed or chemically treated to produce reduced graphene oxide (rGO) which partially reinstates the sp2 carbon on the basal plane and increases electrical and thermal conductivity of the material. GO is stable due to the presence of oxygen functionalities on the basal plane which removes the possibility of π-π folding and aggregation that is observed with pristine graphene. With such surface properties, the GO dissolve in many polar solvents and fully exfoliate in water (Konios et al., 2014). One can resolve that GO is an extremely flexible material which shares many attractive attributes with pure graphene but with the advantage that it is simpler to process. Graphene and derivative materials have been utilized extensively in materials science research to produce novel materials with enhanced properties (Sharma et al., 2014; Wei et al., 2015; Atif et al., 2016; Phiri et al., 2017).

Wet-Chemical Synthesis of Graphene Oxide Precursor and Further Processing

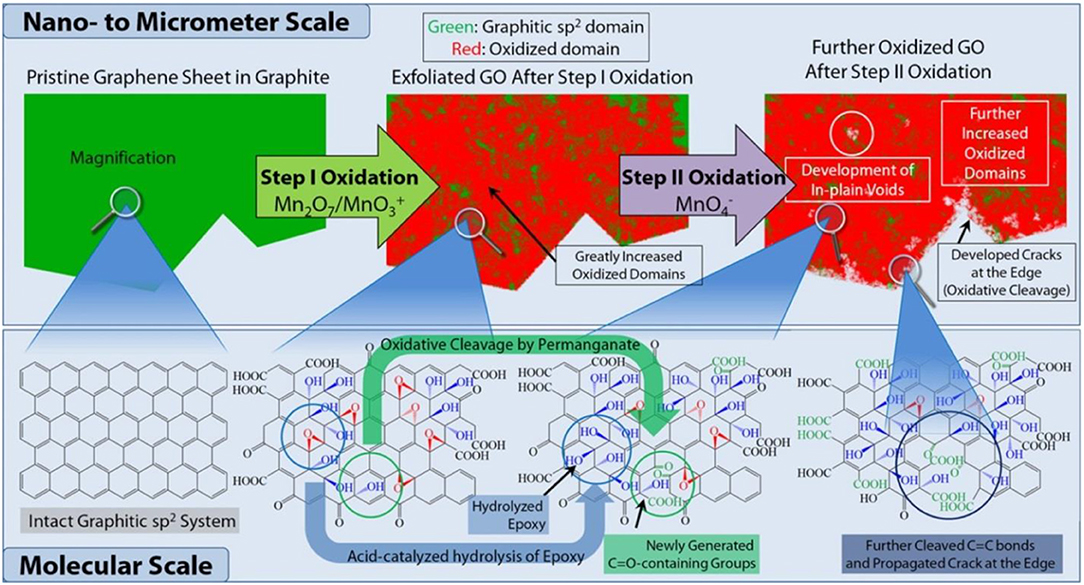

The most common method for producing graphene derived materials for research in to polymer and materials science is the wet-chemical synthesis of graphite oxide from a graphite feed-stock (Romero et al., 2018). This technique is the loosely termed “modified Hummers” method which involves the aggressive oxidation of graphite in a concentrated solution of sulphuric acid (H2SO4) and potassium permanganate (KMnO4). This method was first reported by Hummers and Offeman in 1958 as aforementioned and with the addition of sodium nitrate (NaNO3) (Hummers and Offeman, 1958). The exact reaction mechanism is unknown but the generally accepted pathway (Dreyer et al., 2010; Dimiev and Tour, 2014; Kang et al., 2016) is (1) graphite is mixed with H2SO4 and the disassociated H+ and HSO4− ions of the strong acid penetrate the graphite layers to weaken the attraction and increase layer spacing; (2) side-reactions between H2SO4 and KMnO4 produce the strong oxidiser manganese heptaoxide (Mn2O7) and the permanganyl cation (Mn) and these species percolate the intercalated graphite while progressively oxidizing the basal plane; (3) after water is added a second oxidation occurs due to permanganate ion (Mn). The end-product; graphite (or graphene oxide if in aqueous solution) contains hydroxyl, epoxy and carboxylic acid functional groups joined via sp3 carbon while partially retaining a quantity of sp2 hybridized carbon depending on reaction conditions. Figure 1 illustrates the reaction mechanism.

Figure 1. Proposed reaction pathway for the aggressive oxidation of graphite in concentrated H2SO4 and KMnO4 to produce graphite oxide (modified Hummers reaction). Reproduced from Kang et al. (2016).

Advantages of the modified Hummers reaction are (1) high yield, (2) highly functionalised and therefore flexible product, (3) tuneable reaction variables that can influence product properties, and (4) relatively simple hardware required to perform the reaction. Researchers have achieved a high product yield (in excess of 30 g of GO from 15 g of graphite feedstock) (Zhang et al., 2009; Marcano et al., 2010; Lavin-Lopez et al., 2016). This technique does however have disadvantages, and these are (1) multiple process steps involved in the work-up and (2) single usage of reactants. Work has been done (Lavin-Lopez et al., 2016) to systematically reduce the unit operations from five to three while increasing the reactants to achieve a laboratory scale yield of 34 g/day with no detrimental impact to the product quality. XPS showed a conventional C/O ratio of 0.74; SEM and XRD showed a dry product size of ~10 μm in diameter and 5 layers. Other studies (Ceriotti et al., 2015; Chen et al., 2015) proposed and analyzed several novel work-up methods.

Several techniques reviewed required chemical additives and multiple process steps (Ceriotti et al., 2015). An eloquent filtration step using ceramic paper assisted by a pressurized air driving force to speed-up the process is suitable for up-scalability. Dialysis was proposed (Chen et al., 2015) which proved to be simple and effective however the filtration time of 1 week is not practical for industrial GO production. Green synthesis of GO was demonstrated (Park et al., 2017) using recycled H2SO4 from the first-stage oxidation reaction mixture. The oxidation took place in a Coyette-Taylor reactor and the vortex induced mixing reportedly reduced the reaction time from 24 to 1 h to achieve GO recovery rate and quality comparable to the original Hummers and Offeman control method. The reactor produced a mixture with low viscosity < 200 cp (compared to ~ 10,000 cp for control method) which was easily passed through a 25 μm poly (tetrafluroethylene)(polypropylene) membrane to extract H2SO4. The secondary oxidation step was then performed by adding water to the filtrate. The results showed that high quality GO could be repeatedly produced by recycling the H2SO4; however further analysis of the recycled acid would be beneficial to quantify the purity and fully understand the effects of this step on the second stage oxidation.

GO is a precursor for graphene material and can be further processed to make rGO; the most popular methods are wet-chemical and thermally annealing (Tang et al., 2012; Abdolhosseinzadeh et al., 2015; Romero et al., 2018). Hydrazine hydrate (N2H4·H2O) reducing agent is a popular treatment to remove oxygen functionalities from the basal plane of GO and produces nitrogen gas and water. This partially reinstates the sp2 hybridized carbon network and improves electrical conductivity. There are other wet-chemical methods to produce rGO and GO. For example, a method was demonstrated (Sa et al., 2018) whereby ferrocene (Fe(C10H10)2) and nitric acid (HNO3) was used and produce rGO with an enhanced electrical conductivity of 276 S/m. Thermally annealing GO is highly effective at removing oxygen from the surface (Botas et al., 2013). The annealing process involves heating GO between 300 and 2,000°C depending on the desired final product.

One group of researchers (Tang et al., 2012) thermally annealed GO at 1,150°C and observed electrical resistance decrease from 106 to 10−2 Ω cm. This was accompanied by a reduction in C/O ratio from 2.8 to 6.9 as identified from X-ray photoelectron spectroscopy (XPS). Raman spectral analysis showed a partial reinstatement of the crystalline surface structure which also supports the conclusion that reduction was successful. Thermal annealment at elevated temperatures has been shown to almost fully re-establish the graphitic structure. Therefore, this technique is useful for fine-tuning the required graphitic structure for the application. As a side note; the same work (Tang et al., 2012) also demonstrated a novel and environmentally friendly method to produce ~1 nm GO by heating a 0.5 M solution of glucose in an autoclave at 160°C for 660 min. Although the method did not produce GO on a similar scale to modified Hummers it is appealing due to the omission of expensive solvents or reactants in the process. This work and similar contributes toward achieving more ethical and sustainable sources of graphene for future industrial applications however at present the modified Hummers method is the most practical GO synthesis technique.

Mechanical Exfoliation of Graphite

Graphite has an extremely strong planar structure with each carbon atom forming three covalent bonds with neighboring atoms. This leaves a spare valence electron per atom which becomes delocalised and free to move between the graphite layers. As the electrons move within the complex temporary δ+ and δ− dipoles are setup and hold the graphite layers together by weak van der Waals forces. Therefore, the anisotropic forces within the graphite complex can be exploited to mechanically separate graphite layers in to single or few sheets. External shear forces can be applied to refine graphene nanoparticles (GNP) from the graphite feedstock. Mechanical exfoliation is attractive because:

• it preserves the properties of pristine graphene,

• expensive reactants are not consumed,

• inherently more environmentally friendly; and

• the process is relatively simple.

An ultrafine mortar grinder has been utilized to exfoliate graphite flake and produce GNP (Antisari et al., 2006). The mortar grinder consists of a rotating bowl and pestle pressed on top that imparts a shear force on the particles. This apparatus was preferred over traditional ball milling due to most of the force being applied along the graphite plane rather than randomly throughout the graphite which helps maintain lateral dimensions of the graphite. X-ray diffraction (XRD) and scanning electron microscopy (SEM) results showed that the graphite flakes were exfoliated from an original size ~ 200 diameter and 5.7 m2/g BET surface area to GNP sheets 14 nm thick, ~1–2 μm diameter and 43.3 m2/g BET surface area after 20 hrs of milling. XRD also showed that the surface crystalline structure of the GNP remained relatively defect free as a result of the exfoliation method. Extending the processing time to 60 hrs showed negligible improvement. The technique was performed in water in which graphene is insoluble. Considering the inherent instability of graphene, it is deduced that re-stacking partially contributed toward the observed plateau. Utilizing a solvent with different polarity could improve the degree of exfoliation.

In other work (Al-Sherbini et al., 2017) planetary ball milling of graphite powder of diameter < 20 μm was separately performed in the presence of kerosene and 2-ethyl-hexanol to evaluate the effect that fluid medium viscosity has on the resultant GNP. Solvents with relatively high boiling points (> 150°C) were selected to reduce evaporation during the high energy ball milling process which was performed at 400 rpm for 60 h. Analysis performed using XRD, SEM and Raman spectroscopy qualitatively concluded that the processing in low viscosity kerosene (1.64 cp) produced GNP with fewer layers, more surface defects and smaller sheet size when compared to processing with a more viscous 2-ethyl-hexanol (10.3 cp). The more viscous fluid clearly limited the force imparted to the graphite flakes and directly contributed to the results obtained. Similar research work (Knieke et al., 2010) was able to produce GNP ~3 nm in size and ~1 μm diameter by planetary ball milling 4 μm diameter graphite powder in a solvent solution of water and sodium dodecyl sulfate (SDS). The surfactant SDS acts as a stabilizer and interacts with exfoliated graphene sheets to defer re-aggregation. Process variables were changed, and a plateau processing time of 5 h was identified at 1,500 rpm. The systematic approach of quantitatively modeling stress energy allowed the research team to fine-tune processing conditions. This methodology proved successful in producing few layered GNP and has scope for future use.

The suitably termed “Scotch tape method” was described as a means to isolate graphene from graphite (Novoselov et al., 2004). The group repeatedly applied and pealed adhesive tape to highly orientated pyrolytic graphite to progressively separate layer. This method relies on the adhesive force between the tape and graphite exceeding the van der Waals forces of attraction between the graphene sheets in graphite. The tape is subsequently dissolvent in solvent, e.g., acetone, and graphene transferred to a substrate for further study. The major drawbacks with this method are the time and labor-intensive process for minimal product yield.

In brief, GNP produced by scalable mechanical exfoliation techniques can be performed simply and cheaply and without the use of expensive reactants. However, the product is less flexible than graphene oxide and is generally not single layer thick. That said, GNP production can be efficiently up-scaled and significant research effort has gone in to incorporating this material in to carbon fiber and epoxy composites.

Other Graphene Synthesis Techniques

Anatomically pure graphene is produced by bottom-up CVD synthesis. In a typical process low molecular weight hydrocarbon gas such as methane (CH4) is utilized as carbon source and passed over a transition metal catalyst at elevated temperatures (~1,000°C) in an inert atmosphere (e.g., Argon). The methane molecules are absorbed into the metal surface where they interact with other carbon atoms to form a C6 honeycomb structure. This saturates the metal with carbon material and so the graphene layer is forced to the surface of the catalyst where it is deposited. The graphene/metal catalyst is then further processed; typically, this involves several steps where SiO2 substrate is attached and the metal subsequently chemically etched to remove. This method involved high energy, difficult to handle feedstock (hydrocarbon and inert gas) and multiple work-up steps to produce a very low comparable yield to top-down techniques. However, this method produces superior graphene. Presently within the CFRC research arena graphene produced by CVD is not popular due to the aforementioned reasons and the additional difficulty processing substrate-free anatomically pure graphene (Phiri et al., 2017). The single layer inherent instability causes the material to fold-up which negates the benefits. Nonetheless research in the CVD field is popular due to more specialist graphene applications and this work has driven improvements in the technology which may be transferrable to the CFRC industry.

Bulk graphene film with surface area in the range of ~cm2 has been produced (Reina et al., 2009). The films were constructed of graphene crystals that were 1–12 layers and ~ 20 μm in size. CVD was performed CH4 and H2 over a polycrystalline nickel (Ni) film. The Ni film was premade by electron-beam evaporating on silicon-based substrate and thermally annealing to maximize Ni crystal size; which increases the graphene crystal size. The continuous film production of graphene marked an increase in yield which could appeal to certain graphene applications. In another approach (Wang et al., 2009), 0.05 g of few layer graphene crystals (<1 μm) in size by CVD of CH4 in Argon (Ar) over a powdered magnesium oxide (MgO) supported Cobalt (Co) catalyst of mass 0.5 g. The catalyst was removed by washing with concentrated hydrochloric acid (HCl) and worked-up in a solution of graphene in ethanol (EtOH). This method has potential because yield approaches the gram scale that is required for materials research; however, for industrial purposes the single usage of catalyst is not appealing unless additional processing steps were employed to recycle.

As with other industries, advances have been made within the CVD field to make processes more environmentally sustainable. Several works (Rahman et al., 2014; Seo et al., 2017) have synthesized graphene by CVD using soybean oil and palm oil feedstock, respectively. The reactants were thermally decomposed to methyl and ethyl hydrocarbons and the CVD reaction proceeded in both cases over Ni catalysts. The major advantages with this technique are environmentally sustainable carbon source, relatively cheap reactant and ease of reactant handling (liquid as opposed to gaseous phase).

Electrochemical exfoliation is a top-down method that has shown promising results (Su et al., 2011). Anodes made from graphite were utilized to perform electrolysis in aqueous H2SO4 and in the presence of potassium hydroxide (KOH) to reduce pH and avoid oxidizing the produced graphene. Bi-layer graphene sheets of ~ 30 μm diameter were formed. Raman spectral analysis showed that the graphene produced was of better quality than contemporary methods to synthesize rGO however defects were present which were most likely due to minor oxidation of graphene by H2SO4. The product was dispersed in dimethylformamide (DMF). The presence of defects is not necessarily a detrimental property as this would have contributed to the solubility of graphene in DMF which is important for processing in CFRC applications. Liquid phase exfoliation was performed (Hernandez et al., 2008) which demonstrated the suitability of the solvent N-methylpyrrolidone (NMP) at suspending graphene at 0.01 mg/ml concentration. In this work the solvent was selected based on thermodynamic analysis of the enthalpy of mixing. NMP was selected because it has a surface tension within the range of 40–50 mJ/m2 which is predicted to be compatible with graphite surface energy. Graphite of ~150 μm diameter was sonicated in NMP to produce graphene solution with a yield of 1% w/w. Characterization of product showed that the graphene was 1–2 layer, ~25 μm in diameter and was pristine (i.e., no defects as shown by XPS and Raman spectroscopy).

Although significant advances have been made within CVD and other graphene production techniques the most appealing graphene types for CFRC applications are GNP or GO. The multiple layered structure that GNP exhibits helps stabilize the nanoparticles and reduces aggregation during CFRC preparation.

Types of Graphene Oxide

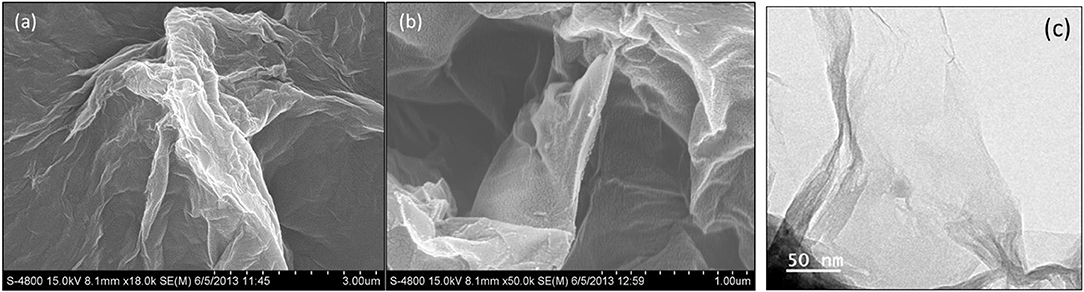

It is important that materials engineers recognize the significant differences between GO and other nanofiller materials such as traditional organic polymers (e.g., starch and cellulose), nanoclays and metallic nanoparticles. Critically, GO is a macromolecule composed of non-stoichiometric amounts of carbon, oxygen and hydrogen. Therefore, there is a wide variance in GO forms and this factor is frequently not given consideration by researchers when constructing nanocomposites. Figure 2 shows typical morphology of GO and experimentation has shown (Muzyka et al., 2017) that there are considerable variations in GO chemistry with different versions of the Hummers method of preparation.

The researchers altered the reaction duration and reactants to explore the effects on chemistry. The XPS analysis showed that the oxygen content in GRO-H1 (1 g Graphite (1 g); 20 ml of H2SO4; 15 ml of HNO3, 3 g of KMnO4) and GRO-H2 (1 g Graphite (1 g); 30 ml of H2SO4; 3 g of NaNO3, 3 g of KMnO4) was significantly higher than GRO-D (1 g Graphite (1 g); 15 ml of H2SO4; 4 g of Na2Cr2O7) ad GRO-H3 (1 g Graphite (1 g); 22.5 ml of H2SO4; 0.5 g of NaNO3, 3 g of KMnO4) which demonstrates favorable reaction parameters to achieve a high degree of oxidation. Additionally, FTIR and XPS showed that GRO-H1 had a higher content of oxygen double bonded to carbon. The elemental analysis results show how the GO product can change significantly depending on reaction parameters. In the materials science context this can greatly affect further opportunities to modify the nanofiller and the performance of the composite. For example, if the materials engineer wishes to further surface functionalise GO then a higher content of reactive oxygen containing species would be desirable. Another interesting observation is that the oxygen content of GRO-H1 and GRO-H2 are comparable which implies similar processability characteristics (i.e., subsequent work-up techniques, handling and flexibility for further chemical functionalisation). However, the reaction times differ from 2 to 24 h for GRO-H2 and GRO-H1, respectively. The lower residence time for GRO-H2 may be favorable from a cost perspective because this yields product at an accelerated rate.

In other work, a modified Hummers method yielded GO from graphite flakes using H2SO4, KMnO4 and H3PO4 as oxidation reactants (Marcano et al., 2010). This produced GO with a higher oxygen content than the control samples. The C1 XPS spectra was deconvoluted and showed the modified method contained 69% oxidized carbon compared to 63% for the traditional Hummers method. The GO produced by this technique contained 31% of carbon with a sp2 structure compared to 40% as produced elsewhere (Muzyka et al., 2017) in sample GRO-H1. Further UV-vis, XRD and TEM analysis by Marcano showed that the modified Hummers method product of GO retained a more crystalline C6 structure compared to the traditionally reported Hummers oxidation.

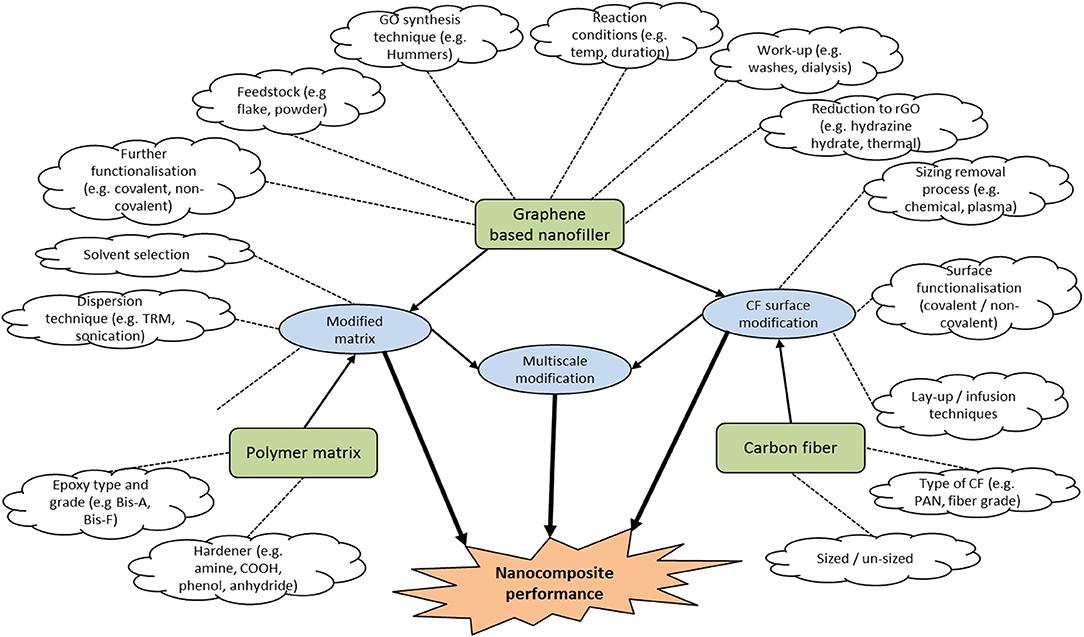

It is natural that changes in reactants and reactant conditions will produce GO with changeable characteristics. Unfortunately, much of the literature assumes that the Hummers oxidation is a simple reaction that lacks in variation and this over simplistic view can miss subtle nuances that the GO type may have on composite performance. There is huge scope for the materials scientist to tailor GO nanofiller to the application. Figure 3 illustrates both the complexity and opportunities for further research by showing the many variables that can affect nanocomposite performance.

Figure 3. Variables that affect nanocomposite performance. Variables are shown in white clouds which can apply to base materials (green boxes) and processes (blue boxes).

At present there is a gap in the literature whereby generally the focus is on constrained to changing a single variable and testing the outcome. Taking a holistic view is important when considering that the purpose of nanocomposite research is to produce viable new materials for use in engineering application; this means that processes need to be as safe, efficient and simple as practically and economically possible. Specific to GO research, materials science has primarily focused on the simple mixing of nanofiller with polymer matrix and constructing a fiber composite which has shown limited and variable results. Figure 2 can be utilized by the materials scientist or engineer as a roadmap to further develop research in to this topic to further expand this field. Having a robust understanding of the GO synthesis methods and the variances in potential GO products is critical to develop further research in to carbon fiber surface and polymer matrix modification with the aim of enhancing CFRC performance.

Surface Modification of Carbon Fiber

Atoms within the body of a uniform three-dimensional solid material such as diamond are bonded together with each carbon atom interacting covalently with four neighboring atoms. However, at the solid material surface there is an interface where the three-dimensional structure ceases to exist. Atoms on the surface are less tightly bound because they are surrounded by less neighboring atoms. These atoms have free valence electrons, and this creates a surface energy density. The fact that surface energy exists is intuitive when considering the paradoxical scenario where the surface was less energetic than the solid body. This would cause solid material to spontaneously form new surfaces as material from the center expelled energy with increasing entropy; but luckily this is not observed. Carbon fiber is effectively a synonym for graphite fiber because the molecular structure is composed of C6 honeycomb sheets that are randomly folded due to Van Der Waals attractive forces to form the fiber. The solid surface of the fiber is composed of sp2 hybridized carbon graphene sheets. The inherent stability of graphene means that the surface energy of untreated and un-sized carbon fiber is relatively low and in the order of ~ 30 mJ/m2 (Paiva et al., 2000). This is an extremely important concept because it influences the wettability of the CFRC interface and directly influences properties.

Liquids display a similar property called surface tension. Cohesive forces are distributed equally within the bulk liquid and this attracts molecules together. Nevertheless, at the surface the attractive forces between the mobile liquid molecules are shared between fewer molecules and create surface tension. Surface tension force is greater than the cohesive force between molecules in the bulk fluid. Epoxy resins DGEBA and tetraglycidyl methylene dianiline (TGMDA) have been shown to have surface tensions of 37 and 41 mJ/m2, respectively (Page et al., 2001).

Wettability is a measure of how a liquid interacts with a solid surface and is a balance between adhesive forces between the solid/liquid interface and cohesive forces between liquid/liquid molecules (Toshev, 2006; Li et al., 2013). Where cohesion between the liquid molecules is high then the liquid will tend to form more spherical shaped droplets on the surface and will have a lower affinity to interact with the solid surface. Similarly, where a solid has a low surface energy there are minimal intermolecular forces to attract the liquid and liquid/liquid cohesive force dominates. This is observed with carbon fiber where attractive force is generated by the presence of delocalised π-electrons producing relatively weak Van Der Waals forces. Conversely; a three dimensional covalent or ionic solid will have a large surface energy density. Thermodynamically the material exists as a solid phase due to strong chemical attractions and it is instinctive that the surface energy will exceed the liquid cohesive energy, therefore allowing for good wettability. Generally the surface energy of the solid should be greater than the surface tension of the liquid in order to achieve favorable wettability. Surface energy is difficult to measure directly therefore contact angle is used to estimate surface energy (Toshev, 2006).

Evidently then CFRC using epoxy resins suffer from problems associated with poor wettability. On the macroscale this can lead to poor penetration of fiber by epoxy resin and can create voids that weaken the composite. At the nanoscale the poor intermolecular attractive forces at the interface create an inherent weak zone that is liable to delaminate when stressed. Fortunately, there are many techniques to improve the surface energy of carbon fiber and improve the molecular interaction between fiber and epoxy at the CFRC interface. The surface energy of a solid can be modified by (1) increasing the surface area or (2) increasing the surface energy by activating with chemicals. When a surface is rough the surface area and therefore contact area between surface and liquid increases. This increases the quantity of molecular interactions between the solid and liquid which is observed by a reduction in contact angle (i.e., increase in surface energy). Surfaces can also be activated by adding polar groups (such as carboxylic acid or hydroxyl). These molecules create permanent δ+ and δ− dipoles between highly electronegative oxygen and hydrogen which effectively increase the surface energy of the solid. The dipoles will interact favorably with other polar molecules (e.g., organic polymers) via hydrogen bonding. This section specifically reviews recent advances in CFRC interface reinforcement using graphene materials.

Covalent Functionalisation of Carbon Fiber

Covalent functionalisation of the carbon surface occurs when the fiber surface reacts chemically with another species and as a result both atoms now share to share an electron pair. This is the strongest type of chemical bond between atoms. The methodology is dependent of carbon fiber modulus and the presence of pre-existing sizing. Lower modulus carbon fiber generally contains more surface defects due to the presence of edges and there are oxygen containing moieties at these sites. For higher grade carbon fiber then the surface may require oxidation to add reactive sites however in order to complete this reaction highly ordered sp2 carbon content is reduced which may reduce the mechanical properties of the base carbon fiber. Thus, there is a compromise between desired interfacial properties and overall tensile strength of the carbon fiber. Table 1 shows recent advances in this area and improvements in properties.

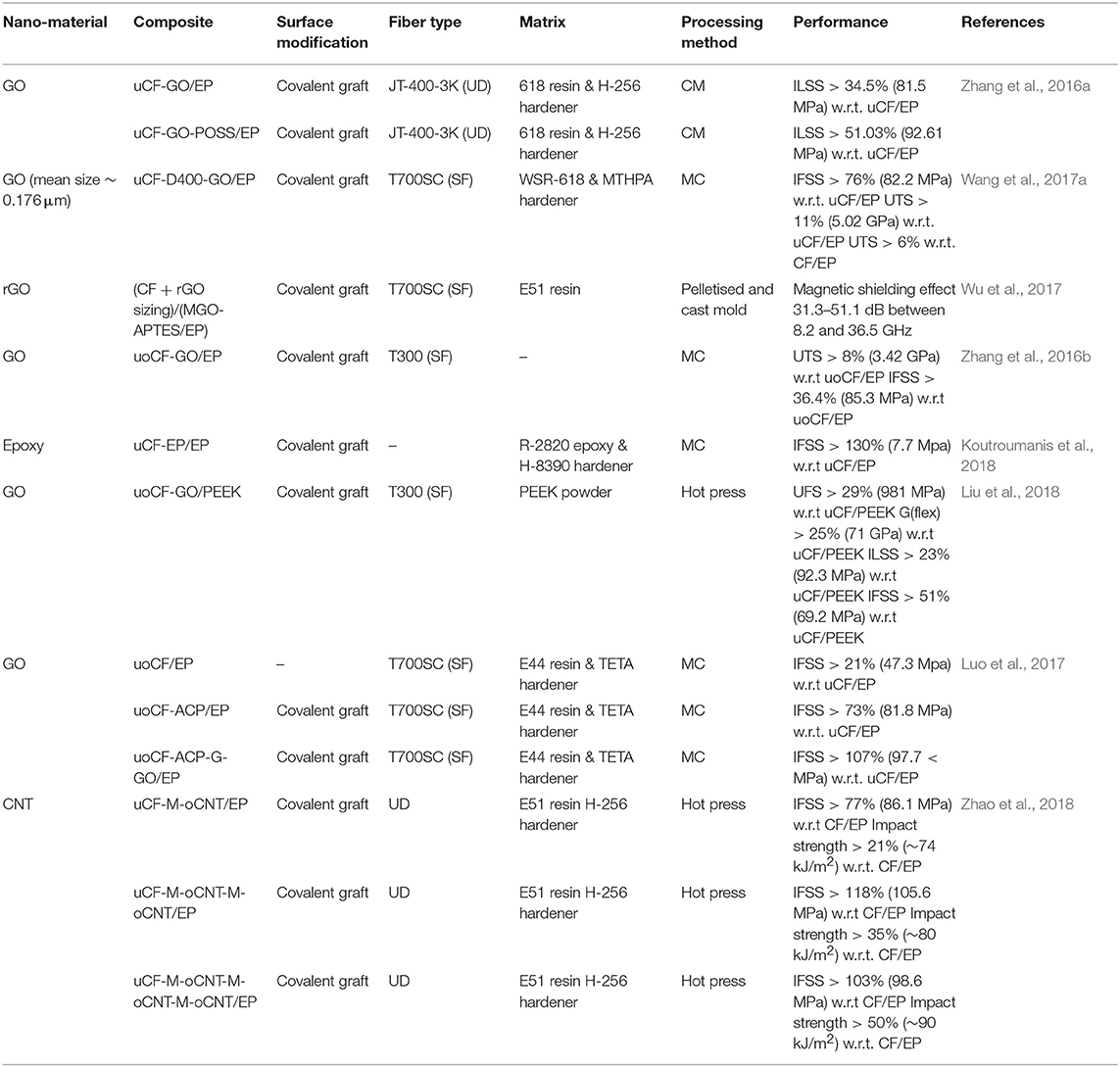

Table 1. A summary of results from literature investigating covalent graft methods to modify the fiber surface properties.

The covalent technique has been reported (Koutroumanis et al., 2018) to achieve 130% improvement in IFSS from 3 to 8 MPa using a laser Raman microscopy characterization method. In this work, low-modulus single de-sized PAN carbon fibers were functionalised with epoxide groups by reacting with 3-chloroperoxybenzoic acid (mCPBA) in dichloromethane solvent. XPS spectra were analyzed and showed an increase in surface oxygen content from 9 to 18% and epoxide species from 9 to 17%. However, increased oxygen content did not damage carbon fiber surface or structure significantly as confirmed by the scanning electron microscopy (SEM) images. The milder epoxidation reaction was found to be less harsh than plasma/gamma radiation or electrochemical treatment. To calculate the interfacial shear strength (IFSS), a single fiber composites were prepared using a “water clear” resin/hardener combination of Fibremax R2820/H8390. A correlation was performed to measure the D and G Raman band shifts while simultaneously straining individual filaments. The correlation between strain and shift is then used to calculate IFSS. The epoxide function groups on the carbon fiber participated in the epoxy curing reaction via covalent bonding with hardener and these strong bonds contributed toward the increase in IFSS. This work suggests potentially promising results for IFSS improvements however for materials science applications the experimentation would need to be performed on a larger scale using carbon fiber fabric. In addition, although SEM showed that there were negligible visual differences between treated and untreated fibers it would have been beneficial to characterize surface energy of the fibers to infer whether IFSS improvement was instigated by morphological and/or chemical changes in the fiber surface.

A more aggressive carbon fiber surface treatment was performed on unidirectional PAN fibers (Zhao et al., 2018). The experimentation involved multiple unit operations but improved IFSS by 118% from 45 to 106 MPa. Fibers were first de-sized in acetone and then treated in a solution of AgNO3 and K2S2O8 to functionalise with carboxylic acid. Separately CNTs were oxidized in a solution of HNO3 and H2SO4 to also add carboxylic acid functionalities. The carbon fibers were further functionalised with melanine in N-[(dimethylamino)-1H-1,2,3-triazolo[4,5,6]-pyridin-1-ylmethylene]-N-methylmethanaminium hexafluoro-phosphate N-oxide (HATU) reagent which created a peptide bond between the carboxylic acid functional group on the fiber and an amide group on the melanine. The CNTs were subsequently attached to the carbon fiber/melanine compound by reacting in HATU to forming a peptide linkage with melanine. This process was repeated up to three times to add progressively stack CNTs on to the surface. Characterization by XPS showed that the ratio of peptide to carboxylic acid reduced with additional reaction cycles which supported the conclusion that peptide bonds were forming in place of carboxylic acid sites. SEM was used to show successful progressive stacking of CNTs as roughness became more visually apparent. Surface energy measurement showed a reducing contact angle with additional functionalisation reactions proving that the surface chemistry and/or morphology had changed and demonstrating that this had improved wettability and therefore interfacial properties.

Composites were made by combining the surface modified carbon fiber with E-52 bisphenol-A based epoxy and cured with 4,4-methylenebis(2-ethylbenzenamine) hardener in a compression mold. Mechanical testing showed that the best performing composite had undergone two cycles of CNT addition which showed an IFSS improvement of 118% compared to 103% for three cycles. The reduction of interface mechanical performance with more than two cycles was attributed to steric hindrance caused by excessive CNTs on the carbon fiber. Impact strength tests showed an improvement of 50% (90 kJ/m2), 35 and 21% for three, two and one cycle(s), respectively. The researchers concluded that this was due to the increased CNT layering acting to deflect impact forces from transmission into the carbon fiber and therefore dampened the forces. The tensile strength of single treated carbon fibers showed a marginal improvement compared to untreated which suggests that this treatment does not adversely affect mechanical properties of the fiber. SEM analysis of the IFSS mechanical tests showed significant residual epoxy on the fiber surface therefore the surface modification had well-reinforced the interface to such an extent that the matrix had become the weak point. Considering that CNTs and carbon fiber are highly conductive then electrical properties of these composites should be characterized in future to show whether there are viable applications. Additionally, this technique may be further developed to assess the suitability of GO as a surface modification. Considering that GO contains edge carboxylic acid groups then this would eliminate the need to perform additional functionalisation on GO. This would potentially reduce unit operations and offer a more efficient process for upscaling.

Another covalent functionalisation technique was demonstrated (Luo et al., 2017) where HNO3 was used to oxidize T700 PAN fibers and add hydroxyl and carboxylic acid functional groups to the fiber surface. The functionalised fibers were then reacted with hexacholorocyclotriphosphazine (HCCP) where hydrogen atoms in the hydroxyl group were substituted with chlorine atoms on HCCP to covalently link fiber and HCCP. The compound was further reacted with 4,4-oxydiphenylamine (ODA) and HCCP in a polycondensation reaction to coat the carbon fiber amine capped polyphosphazene. A primary amine group on ODA reacts with a chlorine molecule on HCCP; the chlorine molecule is substituted to leave a covalent secondary amine linkage between HCCP and ODA. The reaction stoichiometry was designed to leave excess ODA primary amine sites available for further reaction. Separately GO was produced by Hummers method and functionalised in two stages; first HCCP was covalently bonded to the edges of GO at carbonyl sites and then reacted further with glycidol where the chlorine atoms were substituted with the oxygen group on the glycidol. This produced epoxy functionalised GO. XPS and FTIR was used to show the presence of additional epoxy groups present on functionalised GO which inferred covalent functionalisation. XPS also showed the presence of nitrogen and phosphorus to increase after carbon fiber had been functionalised with HCCP and ODA.

The functionalised GO and functionalised carbon fiber were reacted together and covalently linked via peptide bonds. SEM imaging of the product showed GO sheets protruding perpendicularly outwards from the carbon fiber surface. Composites were constructed using functionalised carbon fiber and E44 bisphenol-A based resin, cured with TETA hardener. Mechanical testing of the interface was performed by micro-bond analytical instrument on single fibers. The improvement in mechanical performance would suggest a covalent reinforcement of the interface however without supporting FTIR analysis and discussion it is difficult to draw any firm conclusion. In addition, SEM was performed on functionalised GO only and not on the samples used in mechanical testing, therefore a conclusion cannot be made as to where the weak-point is. The research is and characterization offers a novel method to ensure GO is attached covalently and perpendicular to the carbon fiber. This approach will avoid potential steric effects that would otherwise have been seen had GO wrapped around the carbon fiber. The method the researcher team employed was to functionalise the edges of GO, and the SEM characterization seems to prove that this approach was successful. This technique to orientate GO relative to the carbon fiber is useful for future work as this ought to benefit interfacial properties.

Simpler methods have been employed to covalently functionalise carbon fiber with GO which have also produced marked improvements in mechanical properties. One research group (Wang et al., 2017a) functionalised standard modulus T700 carbon fiber by washing in acetone to remove sizing and then reacting with HNO3 to add carboxylic acid groups to the surface. Polyether amine of circa 400 g/mol molecular weight was reacted with the carbon fiber in the presence of HATU to form a peptide bond. FTIR supported this conclusion with the appearance of new peaks at 3,500 and 940 cm−1 which were attributed to N-H stretch of amino groups, and at 1,450 cm−1 attributed to C-N stretch. XPS supported the FTIR characterization and deconvoluted C1 spectra showed peaks at 285.7 and 287.9 eV indicating C-N and –N-C = O bonds. GO of varying molecular weights was reacted with functionalised carbon fiber in the presence HATU to covalently modify the surface. GO was classified determining on its location within a centrifuged supernatant with low molecular weight (MWt) GO extracted from the surface section and heavier MWt from the lower section. SEM showed average size of 1.108, 0.176, and 0.060 μm2. Interesting the GO C/O ratio was 0.85 in low MWt compared to 0.79 in high MWt. Two conclusions can be made; firstly that the higher oxygen content would improve the stability of the GO(aq) solution therefore it would be expected to find GO of higher oxygen content near the supernatant surface. Secondly, the residue is more likely to contain larger MWt molecules and this could be caused by the presence of (1) physically larger particles and (2) lower oxygen content GO tending to agglomerate together to form larger particles.

Composite samples were created by curing WSR-618 bisphenol-A based epoxy resin with methyltetrahydrophthalic anhydride (MTHPA) anhydrite hardener. The medium MWt GO demonstrated the best mechanical performance with an IFSS improvement of 76% from 47 to 82 MPa and the ultimate tensile strength also improved by 11% to 5 GPa. Contact angle was lowest and surface energy highest for the mid-MWt GO/carbon fiber sample which supports that interfacial mechanical performance was found to be optimum. SEM analysis showed that low and high MWt GO tended to lay flat on the fiber surface and conversely mid-MWt was perpendicular to the surface. It was reasoned that the higher oxygen content in low-MWt GO would have possibly formed amine bonds between functional groups on the GO basal plane and the fiber surface causing it to lay flat. For high MWt-GO the physical size meant that it was likely to lay flat on the fiber surface. SEM analysis of the mechanical samples supported this theory as for mid-MWt GO it appeared to remain on the surface of the fiber and showed evidence of matrix cohesion failure rather than adhesion failure between matrix and fiber. This research work, in a similar way to other reported work (Zhao et al., 2018), demonstrated that there is a limit to what can be achieved through surface modification. A key finding made (Wang et al., 2017a) is that the materials scientist must tailor the GO macro-molecules to the design intent of the experiment; in this work there was an optimal size and C/O ratio of GO. A full understanding of GO synthesis technique and resultant chemical and physical properties is critical to ensure success. This also applies to other macro-molecules utilized in fiber surface modification.

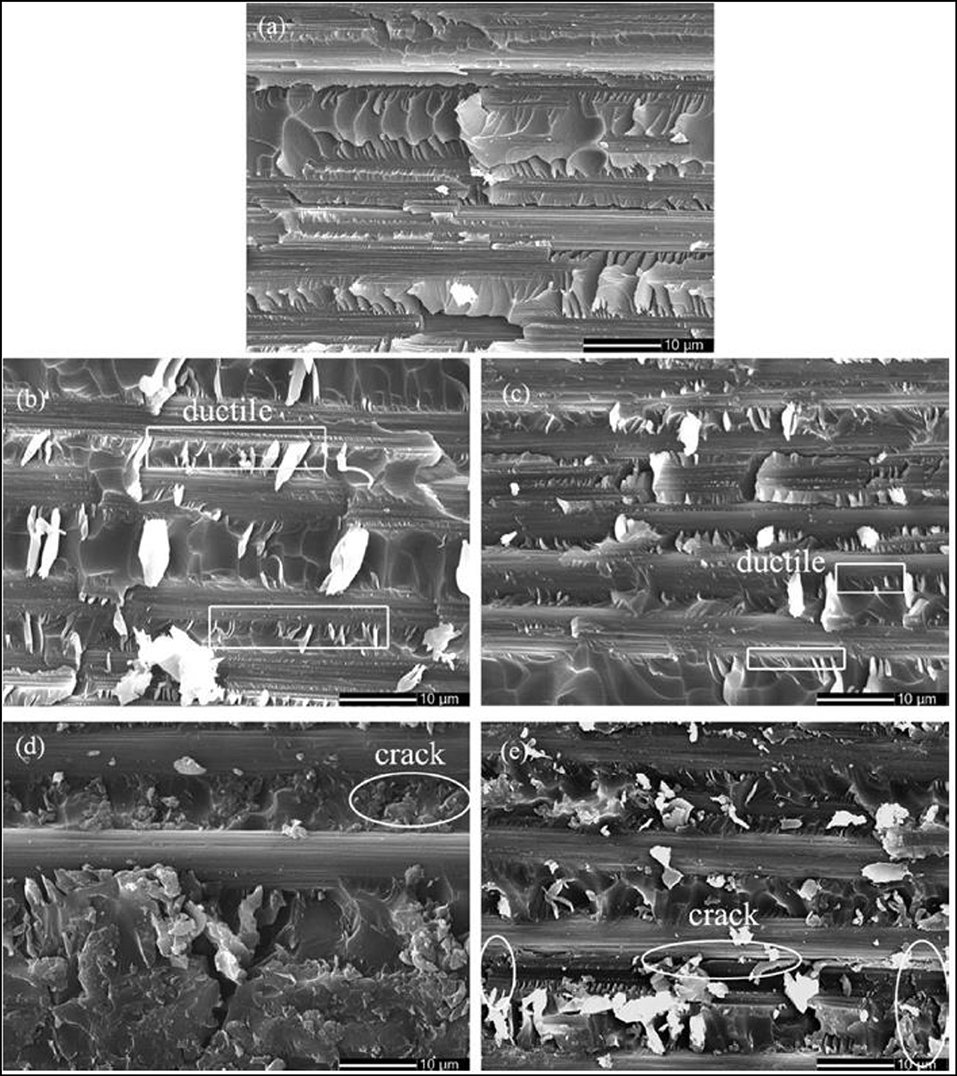

Another simple covalent graft of GO to carbon fiber surface was performed (Zhang et al., 2016b). In their work low modulus carbon fiber was desized in acetone and oxidized in HNO3 to add carboxylic acid functional groups. The fiber was further treated with SOCl2 to make acyl chloride functionalised fiber with functional group –COCl. GO was prepared by a facile modified Hummers method and reacted with ethylenediamine (EDA) to functionalise the edges with primary amine. The modified fiber and GO were then covalently linked via a peptide bond by reacting together in tetrahydrofuran (THF). FTIR, XPS and TGA showed the successful grafting of GO on to the fiber surface and wettability testing showed an improvement after surface modification. Composites were prepared by compression molding using bisphenol-A based epoxy resin and H-256 amine hardener (3,3′-diethyl-4,4′-diaminodiphenylmethane). Mechanical testing showed that IFSS had improved by 36% from 63 to 85 MPa and UTS had improved by 8% from 3.17 to 3.42 GPa. SEM imagery of the fracture surface shows minimal pull-out at the fracture surface in the sample that had carbon fibers modified covalently with GO which shows a strong fiber/matrix interfacial strength. The study provided an example of an up-scalable modification technique on multiple fibers in contrast to much of the research which has focused on single fiber modification and testing.

The research team further improved their work by including polyhedral oligomeric silsequioxane (POSS) in to the surface modification (Zhang et al., 2016a). POSS is a 3-dimensional roughly cubic shaped inorganic molecule. In this work octagylcidyl dimethylsilyl POSS was utilized and the chemical has an epoxy containing chain connected to each corner of the cube structure. The methodology was similar to the earlier work (Zhang et al., 2016b) however an additional reaction was performed to covalently link POSS to the fiber modified with GO-NH2. Composite samples with epoxy resin were prepared and mechanically tested. ILSS showed an improvement of 51% from 61 to 93 MPa, which was an enhancement when compared to the original work. The team concluded that the improved interfacial properties were due to the epoxy functional groups on POSS participating in the epoxy curing reaction.

There are many different techniques which can be utilized to modify the surface of carbon fibers. The challenge for the materials scientist is to find a technique with can be scaled-up for industrial application. Inevitably this will involve a compromise between ease of processabilty and mechanical performance. The challenge is therefore to seek out simpler more facile modification techniques that yield improved mechanical performance.

Electrophoretic Deposition of GO on Carbon Fiber

The electrophoretic deposition technique can be used to deposit nanofiller on to the fiber surface. The procedure typically involves immersing the fiber into a solution containing colloidal particles and passing an electric current through the fiber. The electric field imparts an attractive force on the charged nanoparticles causing them to deposit on the electrode with the opposite charge. For carbon fiber and graphene materials the fiber is setup as the cathode and the negatively charged graphene-based nanoparticles are attracted to the positively charged fiber surface and are deposited. Table 2 shows recent advances in this area and improvements in properties reported in the literature.

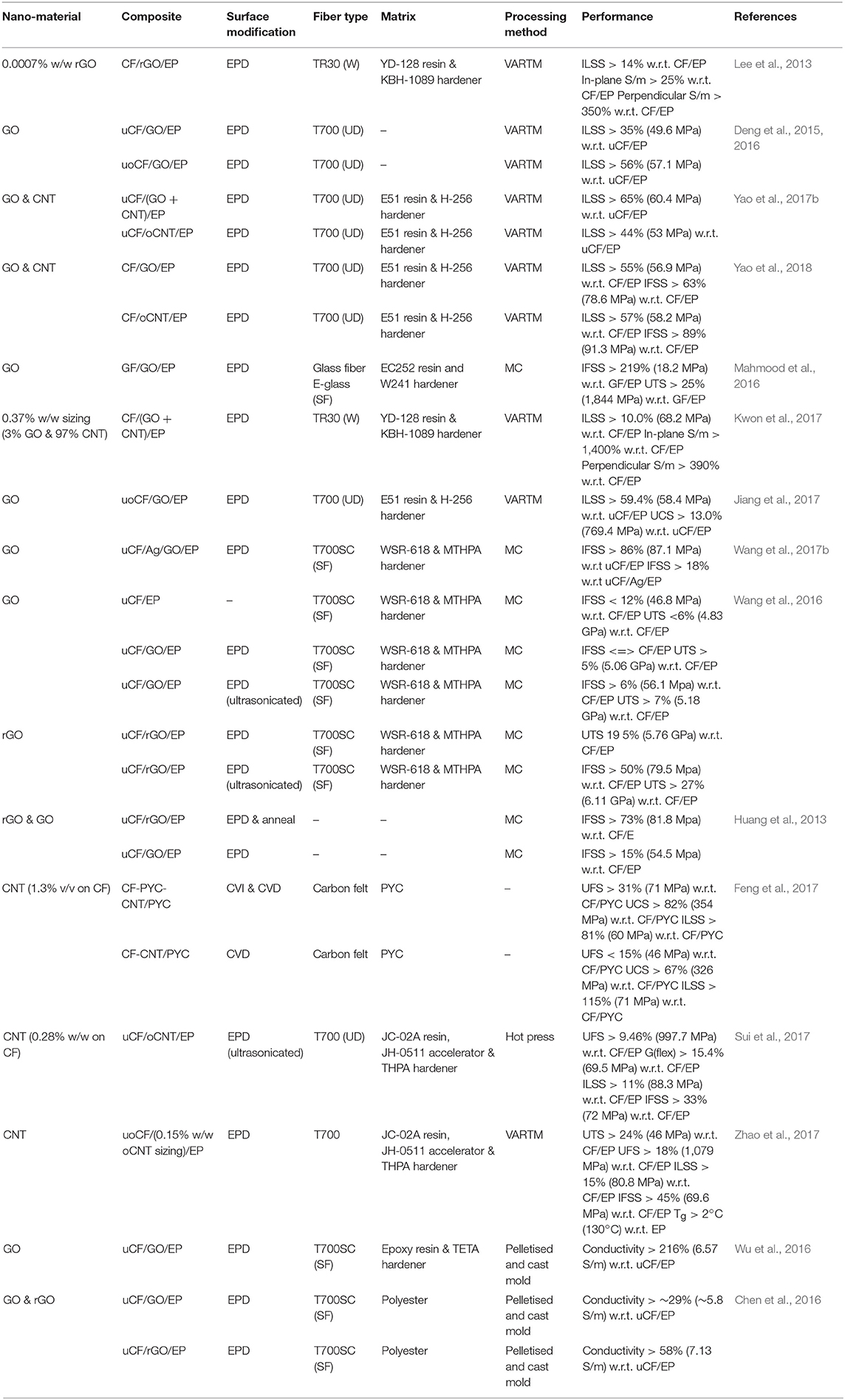

Table 2. A summary of results from literature investigating electrophoretic deposition technique to modify the fiber surface properties.

A series of works (Deng et al., 2015, 2016; Yao et al., 2018) were completed which used electrophoretic deposition (EPD) to modify the carbon fiber surface with GO and CNT sizing; composite samples were made with epoxy and mechanically tested which achieved improvements in IFSS. Compared to the unsized carbon fiber epoxy with IFSS 48 MPa the addition of GO and CNT increased IFSS by 63% to 79 MPa and 89% to 91 Mpa, respectively (Yao et al., 2018). Earlier work by the team (Deng et al., 2015, 2016) proved that oxidizing the carbon fiber in H2O2 and HNO3 added hydroxyl and carboxyl functional groups to the fiber surface and this was concluded from FTIR results and by observing a reduction in contact angle using water and glycol. GO was synthesized by Hummers method and added to the carbon fiber surface by EPD. FTIR, wettability, AFM and SEM showed the presence of GO on the carbon fiber surface and demonstrated that the modification had increase roughness and surface energy; which favorably improved interfacial mechanical properties. Composite single fiber samples were made using E-51 bisphenol-A based resin and H-256 amine hardener and mechanically tested with best results from desized and oxidized carbon fiber with GO deposited on the surface.

Additionally, it was suggested that GO may react covalently during the epoxy curing reaction however no analysis was performed to prove this. Following the same procedure, one study (Yao et al., 2018) compared the performance of CNT to GO with best performance demonstrated by CNT. The work was also up-scaled during the experiments from single fiber to multi-fiber applications showing a potential engineering application. The work concluded that the improvement in CNT performance was due to difference in structure between one dimensional CNT and two-dimensional GO. The CNT increase surface roughness more than GO therefore there is a higher contact area between fiber and matrix which improves mechanical properties. Although GO also increases roughness, it can also act as a steric hindrance due to the flat planar structure which can block contact between the fiber and matrix. These conclusions were supported by moisture absorption tests which were used to qualitatively assess matrix to fiber adhesion and composite porosity. GO modified composites showed the lowest level of moisture absorption compared to CNT and this was due to the layer-by-layer structure compared to the one-dimensional CNT. SEM inspection of the fracture surface showed evidence of a matrix cohesion failure rather than adhesion; proving that both GO and CNT surface modifications were successful.

Novel work (Wang et al., 2017b) modified the carbon fiber by first adding silver nanoparticles through electrophoresis in solution of PVP containing AgNO3. GO was produced by a modified Hummers method and added to the CF-Ag surface by EPD. The surface treatment with Ag and then GO was shown to progressively decrease contact angle and increase surface energy. Composited were made using droplets of bisphenol-A based WSR-618 epoxy resin and H-8390 hardener. Mechanical testing demonstrated that the IFSS had increased by 86% from 47 to 87 MPa. Tensile strength improved by 37% from 4.54 to 6.21 GPa. TEM analysis of CF-Ag showed spherical particles 30–70 nm in diameter on the surface of the fiber and these are said to be silver; supported by FTIR and XPS. After GO was added, Raman, FTIR and XPS showed the change in surface crystalline structure and chemical composition. SEM and TEM showed a rougher surface and concluded that the intermolecular forces of attraction between the carbon fiber and GO macromolecule acted to anchor the Ag nanoparticles in place to create a unique hierarchical structure. The improved performance of the CF/Ag/GO/epoxy composite was concluded to be from silver nanoparticles acting as filler to plug fiber surface defects and reinforce the fiber. This effect was complimented with the addition of GO which acted to reinforce the interface. This technique showed an improvement in mechanical properties when compared to the earlier reported work (Deng et al., 2015, 2016; Yao et al., 2018) performed however for comparison reasons it would have been beneficial for the group (Wang et al., 2017b) to have prepared a control sample of CF/GO/epoxy to quantify the effect that silver omission.

The highest improvement in mechanical performance was achieved with GO modified glass fiber via EPD which achieved an improvement in IFSS of 219% from 6 to 18 MPa (Mahmood et al., 2016). Ultimate tensile strength also increased after fiber surface medication with a 25% improvement from 1.46 to 1.84 GPa. In this work glass fiber was supplied complete with sizing suitable for creating composites with epoxy; and unlike most other work the sizing was not removed. Specific micro tests were performed on the GF/GO interface and found that delamination occurred with at shear force of 0.13 GPa compared to 18 MPa for single fiber fragmentation tests which suggests that the adhesive forces between GO and GF are greater than GO and epoxy. This is an interesting test which would be useful for further characterization of the interface properties of carbon fiber/epoxy composites. Although glass fiber is not the subject of this review, it is important to highlight the potential effect that sizing has, considering that this work (Mahmood et al., 2016) has shown the greatest improvement in IFSS. Carbon fiber sizing is a surface treatment which is often proprietary and commercially sensitive. Performance of the as supplied materials (i.e., sized fiber and epoxy) should also be incorporated in to control experiments in addition to analysis of un-sized fibers and epoxy. This is applicable to all methods of fiber surface modification.

Dipping and Spraying

The dipping and spraying techniques are the most simplistic methods discussed herein and involves either immersing fibers in a solution to nanoparticles or spraying the fibers with the solution. By these means the fiber surface becomes activated with nanoparticles. Table 3 shows recent advances in this area and reported improvements in properties.

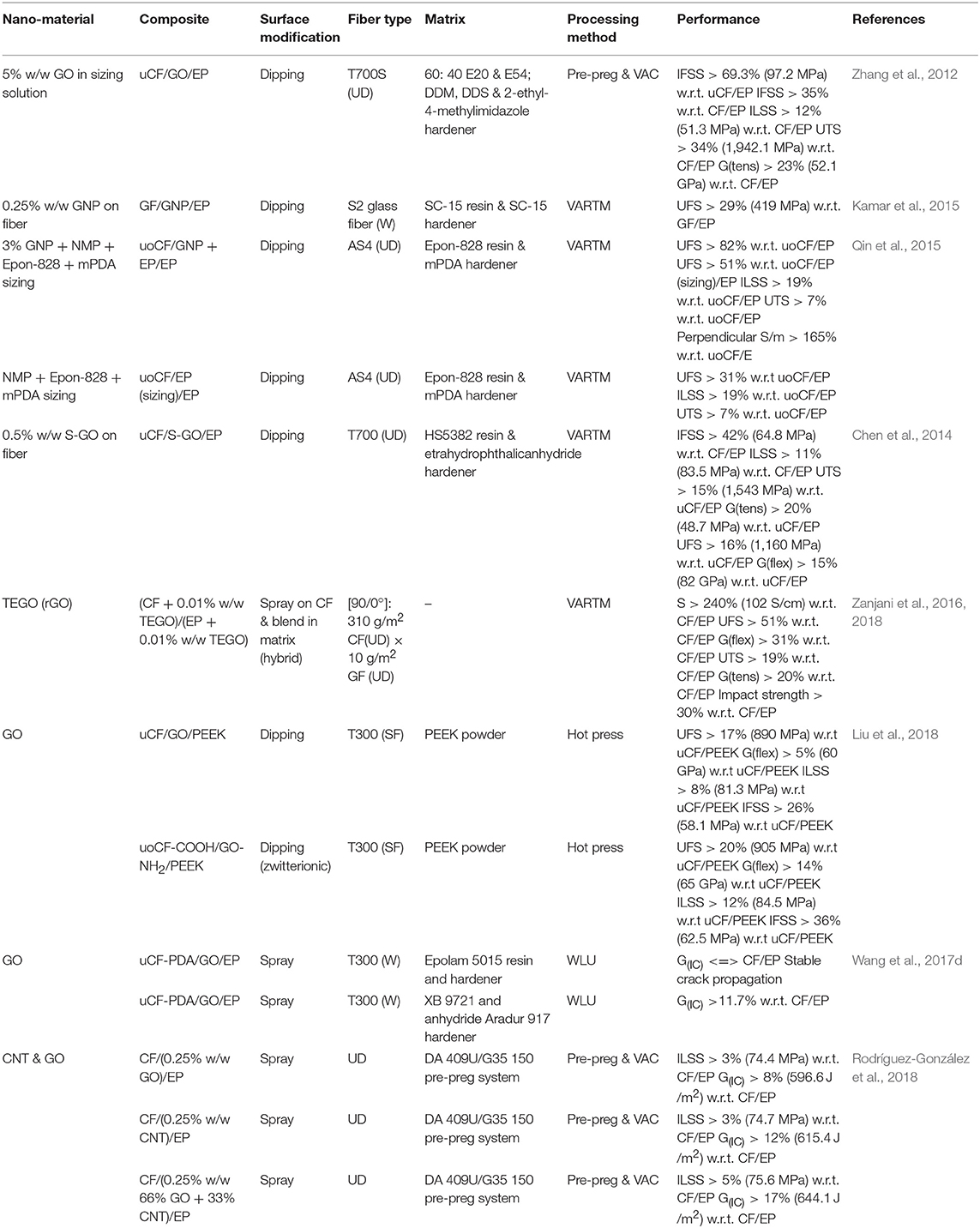

Table 3. A summary of results from literature investigating dipping and spraying methods to modify the fiber surface properties.

A dipping technique was reported (Chen et al., 2014) to modify the surface of carbon with functionalised GO. The Marcano method was employed to synthesize highly oxidized GO which was subsequently reacted with silanol of silane coupling agent KH-550 it was proposed that silanol became covalently linked to GO by reacting with hydroxyl and epoxy groups. Covalent linkages between hydroxide and silanol of silane coupling agent by hydrolysis; and the epoxy groups could form peptide bonds with the amino groups of the coupling agent. This theory was supported with dispersion tests showing that the surface chemistry had changed whereby silanised GO (S-GO) was found to have settled in an aqueous medium unlike GO and furthermore, the solubility in acetone improved. Additional FTIR showed new peaks in S-GO at 2,930 and 2,850 cm−1 from the asymmetric vibration of the -CH2- present in the alkyl chains of t silane moieties. Additional bands at 936, 1,059, and 3,300 cm−1 showed presence of Si-O-C, Si-O-Si groups and N-H vibration. XPS spectra analysis supported these conclusions showing that hydroxyl and epoxy group content of GO had reduced after the reaction and that silicon and nitrogen content had increased.

Carbon fibers were desized in acetone and petroleum ether [95]. GO and S-GO were dispersed in water and acetone, respectively, and carbon fiber was dipped to modify the surface. Composite samples were made with bisphenol-A based HS5832 resin and tetrahydrophthalic anhydride hardener and mechanical testing of sized, un-sized and GO, S-GO modified fibers were performed and achieved IFSS of 65 MPa for 0.5% w/w S-GO compared to 46 and 40 MPa for sized and un-sized carbon fibers. Interestingly fibers functionalised with GO only showed the lowest IFSS of 32 MPa. Similar trends were observed in ILSS, flexural strength and flexural modulus. Tensile strength was observed to improve from 1,340 MPa for base composites to 1,540 MPa for those containing S-GO. Once again, GO modified fiber composites showed a reduction in UTS to 1,150 MPa. Elastic modulus was 34.5, 40.5, and 48.7 GPa for S-GO, base composites and GO, respectively. The researchers proposed that the presence of GO reduced wettability through over aggregation and SEM supports this assessment where the fiber surface appears to be overloaded with GO compared to S-GO. Considering that van der Waals forces of attraction exist between GO and fiber surface then an overloaded fiber surface with GO could weaken the interface. It was suggested that silane in S-GO would have participated in the curing reaction which contributed to the improved mechanical properties. The S-GO chemical properties also allowed for a better dispersion and interaction with the epoxy resin. Further supporting the synergistic effects was analysis of the gradient interphase stiffness that showed a linear transition of stiffness from fiber to epoxy. This allow loading to be uniformly transferred from matrix to fiber with the S-GO dampening the otherwise steep transition that is normally observed to improve interface and mechanical performance. The poor performance of GO was in contradiction to the work that used EPD to deposit GO on fiber surface. This reason for this is unclear; the work (Chen et al., 2014) used 0.5% w/w GO whereas the EPD work did not specify the weight loading. Potentially had GO been loaded at a reduced concentration then improved mechanical performance may have been achievable.

In variant dipping method was employed (Zhang et al., 2012) to size carbon fiber with a solution of epoxy and 5% w/w GO. Treatment of carbon fiber improved IFSS by 35.0% from 72 to 97 MPa in comparison to commercially available sized carbon fibers. Ultimate tensile strength (UTS) improved by 34% from 1.5 to 1.9 GPa and tensile modulus improved by 23% from 42 to 52 GPa. Inspection of the fracture surface by SEM showed that there was minimal fiber pull-out after fibers were treated with GO sizing which shows than the nanofiller acted as a barrier to crack propagation in the interface. This work demonstrated that it is possible to improve interface mechanical properties compared to untreated commercially available products. The researchers cited that improved wettability and better intermolecular interactions at the interface improved mechanical properties (Zhang et al., 2012).

A spraying technique was used (Rodríguez-González et al., 2018) to modify the surface of carbon fiber pre-pregs with CNT and GO was produced by a modified Hummers method. Both GO and multi-walled CNT were separately mixed in ethanol and sprayed between pre-preg layers at a content of 0.25% w/w. FTIR and Ramen showed a change in surface chemistry and crystalline structure depending on which treatment had been performed. An artificial crack was introduced during lay-up by inserting a Teflon film. A hybrid sample of GO and CNT was also prepared at 0.25% w/w made up of 1:2 w/w ratio of GO:CNT. End notched flexural testing was performed to assess crack propagation and the hybrid composite performed best with an improvement of 17% in GIC from 550 to 644 J/m2. ILSS was also best for the hybrid with 5% increase from 72.0 to 75.6 MPa. The researchers concluded that the presence of a three-dimensional CNT and GO surface structure increased the surface roughness between pre-pregs improving interface properties. In addition, they demonstrated that a mixture of hydrophobic (CNT) and hydrophilic (GO) nanofiller can improve compatibility of carbon nanostructures with epoxy as an additional reason for the interface results. The research work shows that there are additional novel methods to incorporate GO and other graphene-based nanomaterials in to composite materials to improve mechanical properties.

A different method introduced thermally exfoliated GO (TEGO) to the fiber surface and matrix to investigate the benefits of multi-scale modification and the multiscale modification demonstrated a good improvement in overall properties (Zanjani et al., 2016, 2018). TEGO was ~23 layers thick with an ~4% oxygen content and therefore relatively graphitic compared to GO produced by Hummers method. TEGO was dispersed in to the composite in three ways; firstly, TEGO was dispersed on to the carbon fiber surface by electro-spraying and secondly TEGO was mixed directly with epoxy hardener and dispersed by sonication. The third method combined the fiber and matrix modifications to create a multi-scale composite (0.01% w/w TEGO on the fiber and mixed in to the hardener). Flexural strength increased by 51% from 730 to 1,104 MPa and flexural modulus increased by 31% to 97 GPa, UTS increased by 19% from to 0.8 GPa and tensile modulus increased by 20% 23 GPa while impact strength improved by 30%. Electrical conductivity was also shown to increase by 240% from 30 to 102 S/cm. The fracture surfaces from flexural testing on unmodified CFRC showed clear indications of delamination. In samples where the fiber only was treated with TEGO there was negligible delamination showing a stronger matrix to fiber interface. For samples where only the matrix was modified delamination was observed however this occurred at a higher flexural load due to the reinforcement of the matrix with TEGO. The hybrid sample failed at a much higher load and showed predominantly matrix cracking fiber failure however their minor fiber pull-out was also observed but not full delamination. This work was performed on fiber fabrics on a demonstrating that multi-scale modification is practically possible in a larger laboratory environment and this technique offers a real improvement in properties. The modification techniques were simple however these techniques can be modified to include covalent modification and tailored to application specific requirements.

A range of surface modification techniques including dipping and covalent bonding was shown (Liu et al., 2018) to improve mechanical properties as illustrated in Figure 3. In all cases low modulus carbon fibers were treated with acetone to de-size. Experiments were setup to test the different intermolecular attractive forces between carbon fiber and GO based surface modification. Composites were made using PEEK and mechanical testing was performed. The first set of experiments tested van der Walls forces by dipping carbon fiber in to a GO(aq) solution. Mechanical testing showed that IFSS and flexural modulus increased by 26% to 58 MPa and 5% to 60 GPa, respectively. The second piece of work tested ionic forces of attraction by first oxidizing carbon fiber in H2SO4 and HNO3 to make CF-COOH. Separately GO was functionalised with primary amine by reacting with APTES to make GO-NH2. CF-COOH and GO-NH2 were then mixed in solution to allow a zwitterionic network to set-up between the constituents (CF-COO−H3N+-GO). Mechanical testing showed that IFSS and flexural modulus had increased by 36% to 63 MPa and 14% to 65 GPa, respectively. The third experiment tested covalent bonding performance whereby CF-COOH was further reacted in SOCl2 to make CF-COCl. This was reacted with GO-NH2 to create a peptide bond between GO and CF. Mechanical testing showed that IFSS and flexural modulus had increased by 51% to 69 MPa and 25% to 71 GPa, respectively. The hierarchical performance was also seen in wettability characterization whereby lowest contact angles and highest surface energies were measured for the covalent bonding of GO to CF. Analysis of fractures by SEM also illustrated this with less fiber full out for the covalent linkage demonstrating a more robust interface. This work is an excellent example of showing how mechanical performance can improve depending on modification technique, however it also validates that for engineering applications a compromise between properties and complexity (i.e., unit operations and processability) may be required.

GO/Epoxy Resin Matrix

The epoxy resin is a type of polymer characterized often with one or more epoxide functional group with at least one of the epoxide functional group acting as a monomer and terminal unit of the polymer within the structural chain. Epoxy resins are extensively used in the production of lightweight carbon fiber-reinforced composites (CRFP) to deliver desired engineering properties such as high modulus and strength, low creep, superb chemical and thermal stability (Pielichowski and Njuguna, 2005; Njuguna, 2016). The epoxy/carbon fiber-reinforced composite design, just like any other composite, is heavily dependent on the mechanical and thermal properties of the resulting composites of the manufactured epoxy/carbon fiber-reinforced composite withstanding the conditions set by its application requirements.

Matrix modification is a viable technique for improving mechanical and/or other properties. Table 4 shows recent advances in this area and reported improvements in properties.

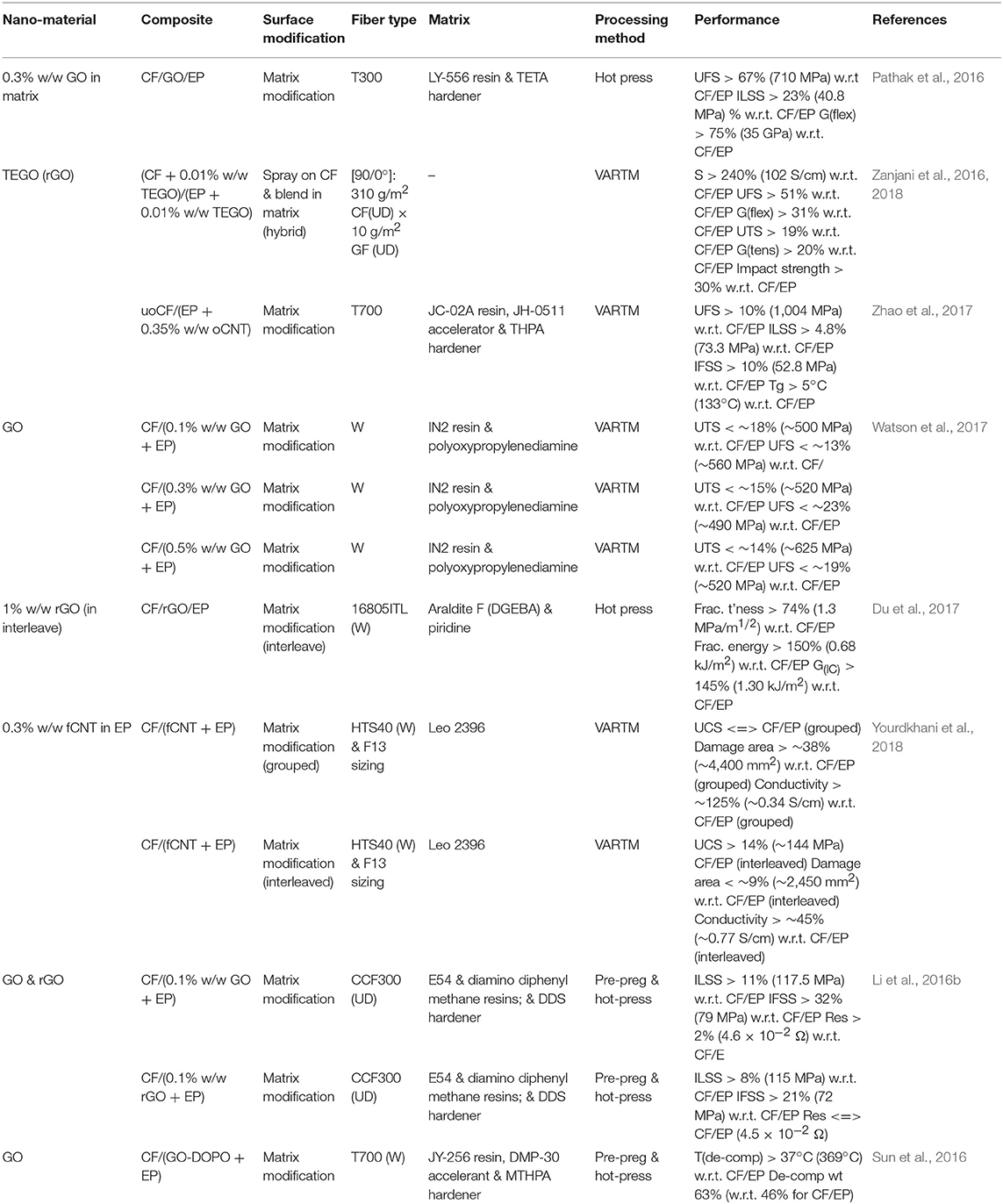

Table 4. A summary of results from literature investigating the impact of resin matrix modifications on the properties of fiber-reinforced composites.

Interactions between filler and matrix can be covalent or via weaker attractive forces such as van der Waals. Epoxy has viscosity that is several orders of magnitude greater than water which has a dynamic viscosity of 1 mPa.s at 20°C. For instance, a typical bisphenol-A based epoxy YD-128 has a dynamic viscosity of 11,500–13,500 MPa.s at 25°C (Kukdo, 2001) whereas the lower viscosity epoxy resins available on the market such as example Eposir-7127 which is a variant of DEGBA epoxy has reported dynamic viscosity of 8,000–10,000 MPa.s at 20°C (SIR Industriale, 2019). The relatively high viscosity of most epoxy resins has a detrimental effect on achieving good dispersion of nanofiller within the uncured resin. For nanofiller to deliver improved properties a homogeneous dispersion is necessary. Hence, desirable matrix modification techniques are those that provide both favorable matrix/nanofiller chemical interactions and that are dispersible at the nanoscale. Most work within this arena of CFRC research has involved purely mixing of graphene based nanofiller with the matrix; exploration of covalent interaction has generally been the reserve of polymer science.

Paredes et al. (2008) and Konios et al. (2014) conducted similar investigations into the dispersion behavior of GO in various organic solvents. In both studies GO was converted to powder form by grinding small flakes of GO with a mortar and pestle. Their studies were both focused on the solubility of GO, and found that NMP, DMF, THF, distilled water and ethylene glycol all showed good solubility characteristics. It is unlikely that the grinding method used in these studies yielded extremely fine GO, thus potentially reducing the solubility of GO in each of the solvents.

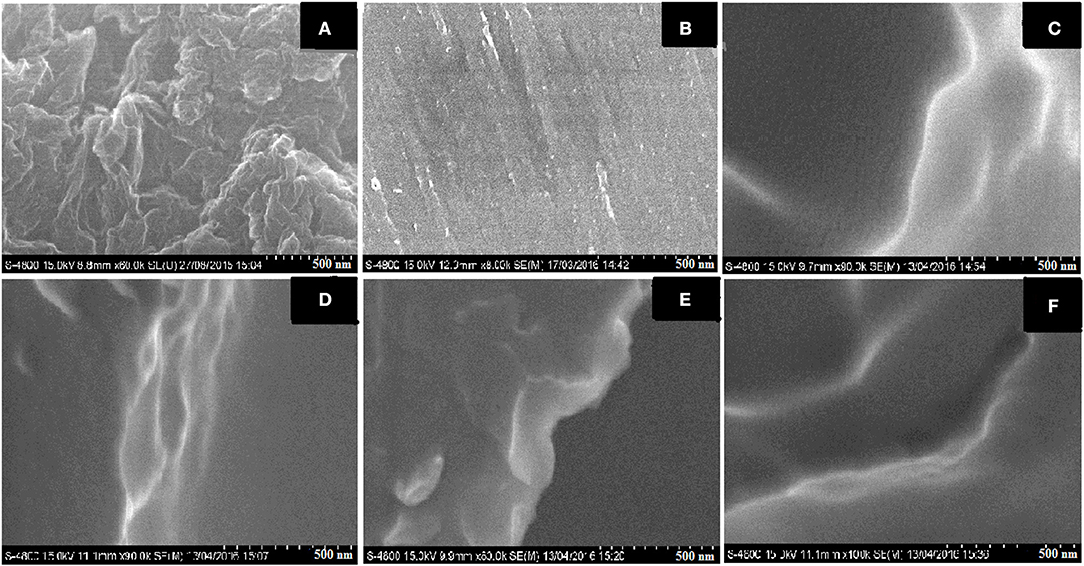

In the literature (Bari et al., 2017) discussed the effects on tensile strengths and elongation of GO/epoxy composites test samples, where the overall tensile strength showed a 30 MPa increase and the elongation of the test specimens showed a 5% decrease in elongations over the span of the various concentrations of GO concentrations studied. The FE-SEM images on Figure 4 show the damage characteristics and failure mechanism. A dynamic mechanical analysis of GO/epoxy composites was carried out by Silva et al. (2015) who reported that the Young's modulus of with GO/epoxy composites showed a 50% increase compared to pristine composites. The results obtained suggest that the presence of isocyanate groups is the key role for achieving good mechanical performance. In particular, the samples prepared with graphene oxide and its reduced form functionalized with isocyanate groups presented better mechanical performance and long-term durability a fact the researchers attributed to the better filler-matrix interactions achieved in theses system.

Figure 4. FE-SEM images of (A) GO, (B) virgin epoxy, (C) 0.2 wt% GO/E, (D) 0.3 wt% GO/E, (E) 0.4 wt% GO/E, and (F) 0.5 wt% GO/E composites.

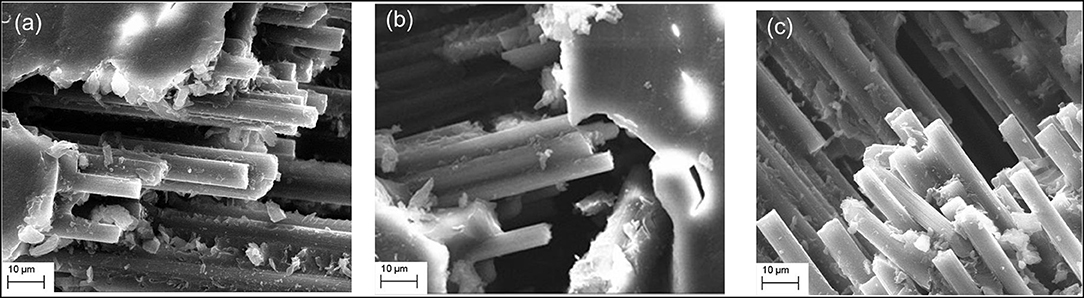

A reported an improvement of 67% in flexural strength from 425 to 710 MPa after mixing 0.3% w/w GO in to the matrix was made (Pathak et al., 2016). FTIR and NMR confirmed successful oxidation with the presence of epoxy, hydroxyl and carboxylic acid functional groups. XRD was used to calculate that the layer spacing had increased from 3.35 to 8.71 Å confirming a physical change in the structure. Raman spectroscopy confirmed changes with the G-band shifting from 1,579.53 to 1,598.83 cm−1 which indicated that oxidation had disturbed the graphite lattice structure by converting sp2 to sp3 carbon. The D-band gives an indication of defects and this shifted from 1,350.96 to 1,351.01 cm−1 as a result of new oxygen surface moieties on the graphitic basal plane. After oxidation the typical high intensity Raman peaks associated with graphite became more distributed which reflects the disordered nature of GO due to oxidation influencing the crystalline structure. Pre-pregs were made with T-300 fibers and then de-aired in a vacuum oven. The manufactured composites demonstrated improved ILSS by 23% to 41 MPa and flexural modulus increased by 75% to 35 GPa.

The test samples were prepared using a range of nanofiller content from 0 0.6% w/w of epoxy and optimal results were observed for 0.3% w/w. The research group concluded that 0.3% w/w represented the percolation threshold whereby the addition of GO up to 0.3% w/w improved crack deflection and reinforced the composite. At higher concentrations GO tended to agglomerate which had a detrimental effect on mechanical properties. SEM analysis of the fracture surface and in all three examples fiber pull-out is evident therefore this technique does not reinforce the interface as robustly as most carbon fiber surface modifications. The GO nanofiller reinforced the matrix whereby crack propagation was retarded and this effect, combined with the increased rigidity of the composites caused failure to occur almost in the single plane. The TEM showed that after sonication in ethanol GO was relatively well-dispersed and had thickness of a few layers although the agglomeration of GO after dispersion in epoxy was also observed.

This evidence highlights the challenge involved in dispersing GO. SEM shows GO sheets dispersed in ethanol and it is observed that sheets are 2–7 μm in size and tend to agglomerate even after dispersion by sonication and the mechanical testing focused purely on interface properties. SEM images showed that GO dispersed in epoxy and further agglomeration was evident. This paper is an excellent example of the challenge that an effective dispersion poses to this technique. It is also telling that flexural mechanical properties only were tested, and no work was performed to characterize tensile properties. Similar work (Watson et al., 2017) using a comparable technique reported that UTS decreased by 15% from 612 to 520 MPa with a 0.3% w/w loading of GO in epoxy.