- 1Key Laboratory of Special Environment Road Engineering of Hunan Province, Changsha University of Science and Technology, Changsha, China

- 2National Engineering Laboratory of Highway Maintenance Technology, Changsha University of Science and Technology, Changsha, China

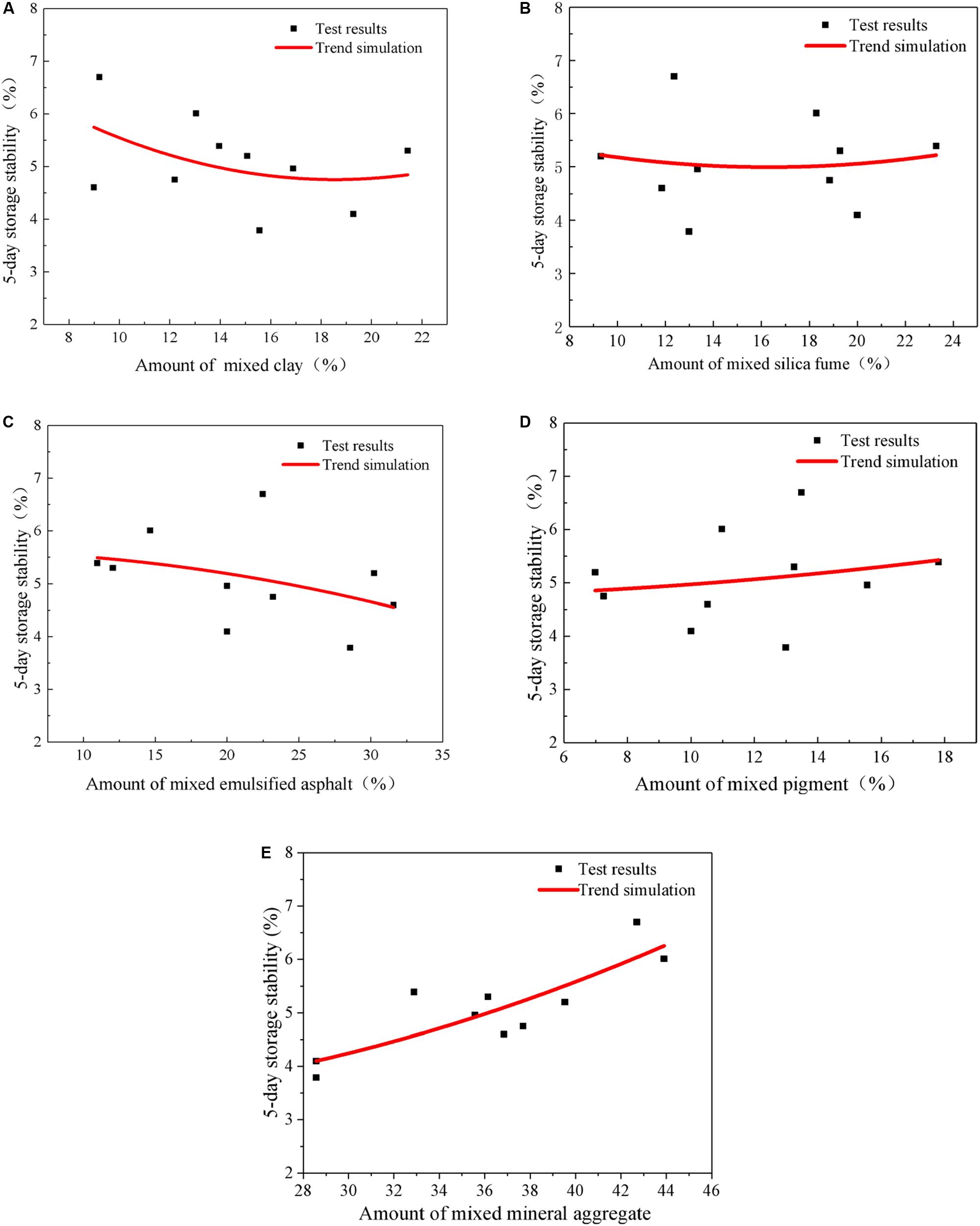

A uniform test design method was used to investigate the storage stability, wear resistance performance, anti-slide performance, and color durability of a colored emulsified asphalt seal mixture (CEASM). The optimal mix proportions of the seal mixture were determined, and the engineering test application and effect evaluation analysis were performed. The results show that the clay, silica fume, pigment, mineral aggregate, and emulsified asphalt contents in the prepared mixture ranged from 15–17, 12–16, 10–14, 28–32, and 25–32%, respectively. In practical engineering applications, CEASM with a molding thickness of 2–3 mm stored in liquid form has a good storage stability and wear resistance, which is suitable for manual scraping pavement or mechanical spraying construction. In addition, it has been shown that colored pavement has the advantages of low cost, safety, environmental protection, convenient construction, good durability, and rapid molding. The CEASM also has great application prospects in color repaving for non-color roads, the early maintenance of colored pavement, and road disease maintenance. The results guide colored pavement designs to improve the storage stability of CEASM and enhance the color durability and crack resistance of colored pavements.

Introduction

Colored pavement has broad application prospects, such as inducing traffic and improving driving safety and transport smoothness (Ando et al., 2011; Xu et al., 2012). Such pavement can provide road divisions, beautify the environment, and contribute to mitigating heat islands (Synnefa et al., 2011). In addition, colored pavement prepared with emulsified asphalt as a binder has several advantages, such as low cost, convenient construction, and a wide raw material availability and application range. However, the effects of the natural environment and driving loads cause color decay and cracks to appear in the initial or recent colored pavement projects (Zhang et al., 2019a,b,c). The disadvantages of colored pavement, such as poor color durability, difficulty of controlling the pavement color, and severe color contamination, limit its promotion and application. In addition, the initial problems of colored pavement have not been effectively solved, such as its poor anti-slide performance and insufficient high-temperature stability. Finally, few materials can be used for colored pavement maintenance. Therefore, the maintenance and repair of colored pavements have gradually become urgent issues that need to be solved.

Several researchers have conducted relevant research on colored pavement due to its increasing application in road construction. Bocci et al. (2012) studied the mechanical and photometric properties of colored pavements and indicated that it has a good wear resistance but poor permanent deformation resistance at high temperatures. Its remarkable photometric properties can improve the lighting design of tunnels, which reduces the costs from lighting equipment and energy use. The shoving, rutting, loose flaking, and poor color durability of colored pavement are still major distress types in long-term use (Lee and Kim, 2007). Tang et al. (2015) mixed aromatic oil with petroleum resin and functional polymers to prepare a colored binder. The colored binder was then mixed with pigment, aggregates, and additives to prepare colored asphalt mixtures. Light-colored synthetic asphalt (LCSA) binders were prepared using aromatic oil, petroleum resin, and various polymer modifiers. The bending beam test (BBR) results show that the binder prepared with SBS, EVA, and SBS + EVA had a better performance under low temperatures with better aging resistance in the seal pavement (Sengoz and Isikyakar, 2008; Tang et al., 2018; Zhou et al., 2020). He (2013) and Jin (2015) indicated that a network structure can be formed by the polymer modifiers in the LCSA binder, which significantly influences the performance at both high and low temperatures. Lin and Luo (2004) found that colored asphalt fading depends on the type and dosage of the dye, as well as the aging spans. The results also demonstrated that red dyes always had better fading resistances than green under ultraviolet light exposure. Gao et al. (2005) found that aged colored asphalt with an increased asphaltene content decreased the colloid contents, aromatic phenol, and saturated phenol, and the original balanced system of asphalt colloids was destroyed, which resulted in deteriorated asphalt performances.

As mentioned, the diseases of colored asphalt pavement and the preparation of a colored asphalt binder have been widely studied. However, the complicated components and various raw materials of colored asphalt have left several problems to be solved for prepared colored asphalts and its mixture, especially regarding its poor color durability and storage stability. Therefore, a uniform design method was adopted here. The emulsified asphalt was modified by adding inorganic materials, such as clay and silica fume. Its mixture proportions and pavement performances were studied in combination with relevant tests to prepare CEASM with a good color durability and high storage stability.

Materials and Tests

Raw Materials

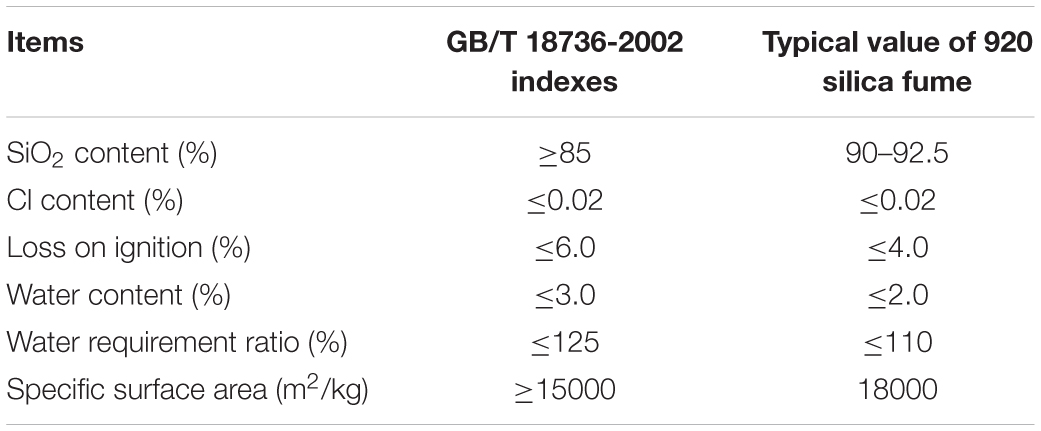

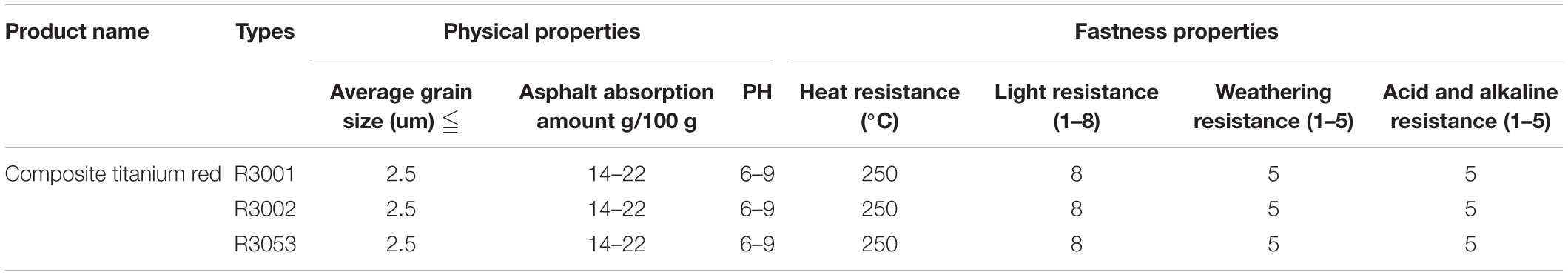

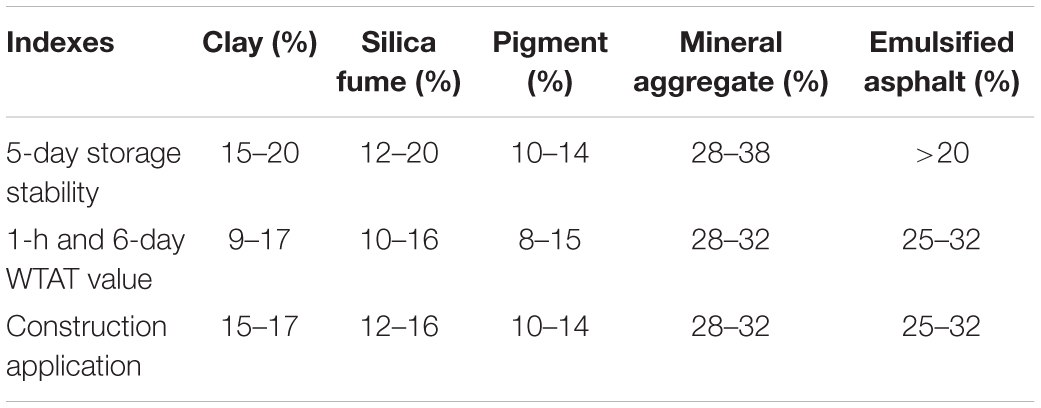

Self-made light-colored emulsified asphalt was used in this study, and its specific technical indexes are shown in Table 1. As suggested by Ouyang et al. (2006) and Sasanipour et al. (2019), 325-mesh clay and D920 semi-encrypted silica fume were selected as the functional fillers. The technical indexes of silica fume are given in Table 2. The composite inorganic pigment of titanium red was selected, and its technical indexes are shown in Table 3. The utilized mineral components and mix proportions are summarized in Table 4.

Table 4. Percent of each component of the mineral aggregate passing through screen aperture and the proportion of each blending.

Preparation Process

The preparation process of CEASM is as follows:

(1) Weigh 1000 g of clay, 1000 g of silica fume, 100 g of pigment, 2000 g of mineral aggregate, and 1500 g of emulsified asphalt for use.

(2) Add tap water to the agitated tank at 11% of the total mass of clay, silica fume, pigments, and mineral aggregate.

(3) Place the agitated tank with water added under the spreader and gradually increase the speed of the debugged spreader to 500–800 rpm.

(4) Weigh the clay, silica fume, and pigment and add them to the agitated tank and stir evenly at 500–800 rpm for 3–4 min.

(5) Weigh the pigment, add it to the agitated tank, and stir evenly at 500–800 rpm for 3–4 min.

(6) Weigh the emulsified asphalt and add it to the agitated tank. Adjust the speed to 1500–1600 rpm (the specific speed is related to the machine power and the size of spreader) and stir for 10–15 min.

(7) Weigh the mineral aggregates and add them to the agitated tank in batches. Adjust the speed to 1500–2500 rpm and stir for 5 min.

(8) Place the produced materials in a marked container for storage.

Test Methods

Considering that CEASM has many components with various content ranges, it is time-consuming and costly to study its pavement performance. Therefore, a uniform test design method proposed by Kaitai and Yuan was used to investigate the effects of dosage for each component, including the clay, silica fume, pigment, mineral aggregate, and emulsified asphalt. This method considers uniformly spaced values over the entire test range, and it is an application of the quasi Monte Carlo method from several theoretical approaches (Fang, 1994; Fang and Wang, 1994). Compared with the “comprehensive trials” and “orthogonal design”, the number of uniform design trials is significantly reduced.

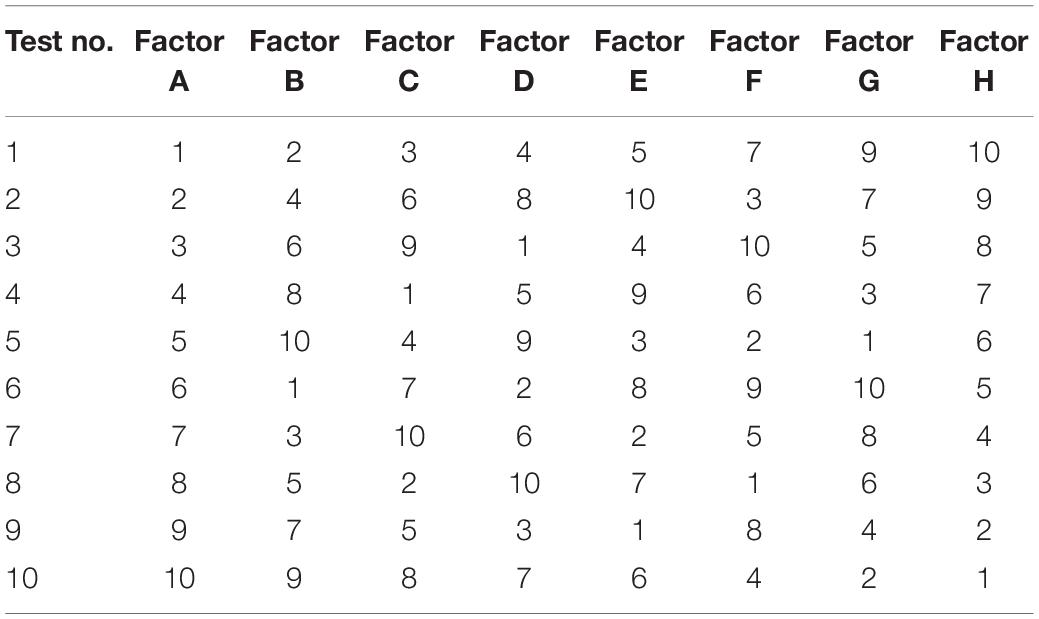

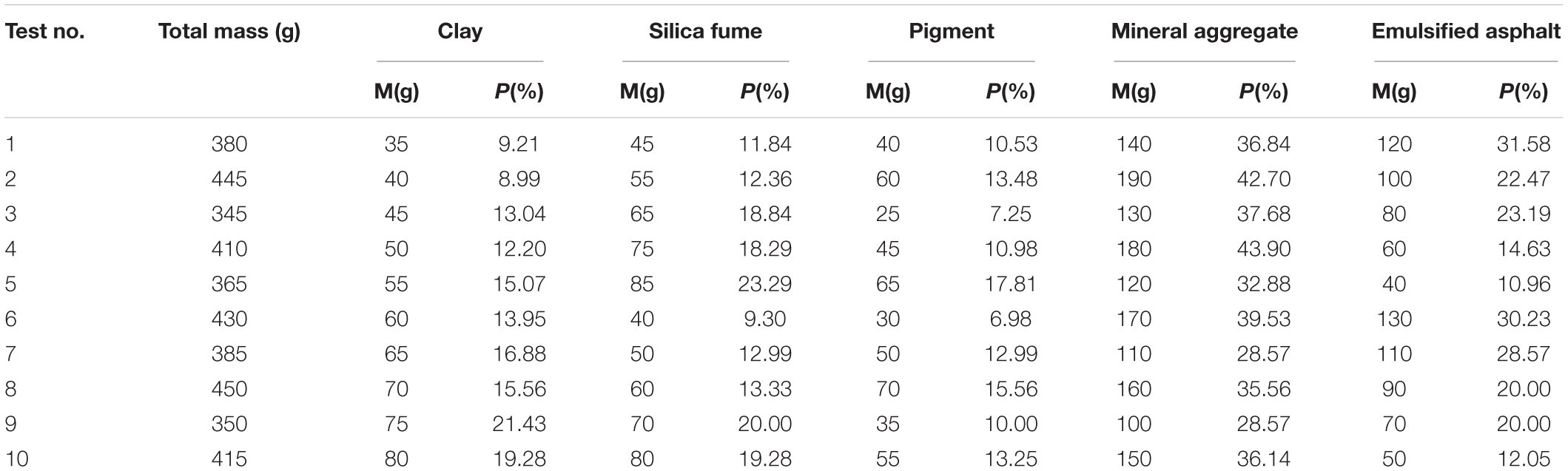

The U∗10(108) table was used for the uniform design (shown in Table 5). According to the rules of the table, the factors were placed in columns 1, 2, 4, 5, and 7. After performing several experiments, it was found that when the clay content was 65 g, the silica fume, pigment, mineral aggregate, and emulsified asphalt contents were 50 g, 50 g, 110 g, and 110 g, respectively. The prepared seal mixture had the advantages of easy storage and stability. Therefore, based on engineering experience, 10 levels for each factor were taken at the upper and lower intervals of these five values. The specific plan is given in Table 6. The amount of each component is expressed as a percent of the total mass. Replicable tests were performed for every test number included in Table 6. If the error for each replicated test result did not exceed ±5%, the test results were adopted as they were deemed reliable.

The storage stability, wear resistance performance, anti-slide performance, and color durability are key indicators that can be used to evaluate the performance of CEASM (Fu et al., 2007; Liang et al., 2015; Yu et al., 2018). Here, laboratory, storage stability, and wear resistance performance tests were performed to study the properties of CEASM. The anti-slide performance and color durability were investigated on a trial road section paved in Guangdong Province.

5-Day Storage Stability Tests

About 300 mL uniform CEASM sample is filtered by a 1.18-mm filter screen into the test tube of stability of asphalt emulsion. It is stored for 5 days at room temperature. Three parallel tests are carried out on each sample to test 5-day storage stability of CEASM.

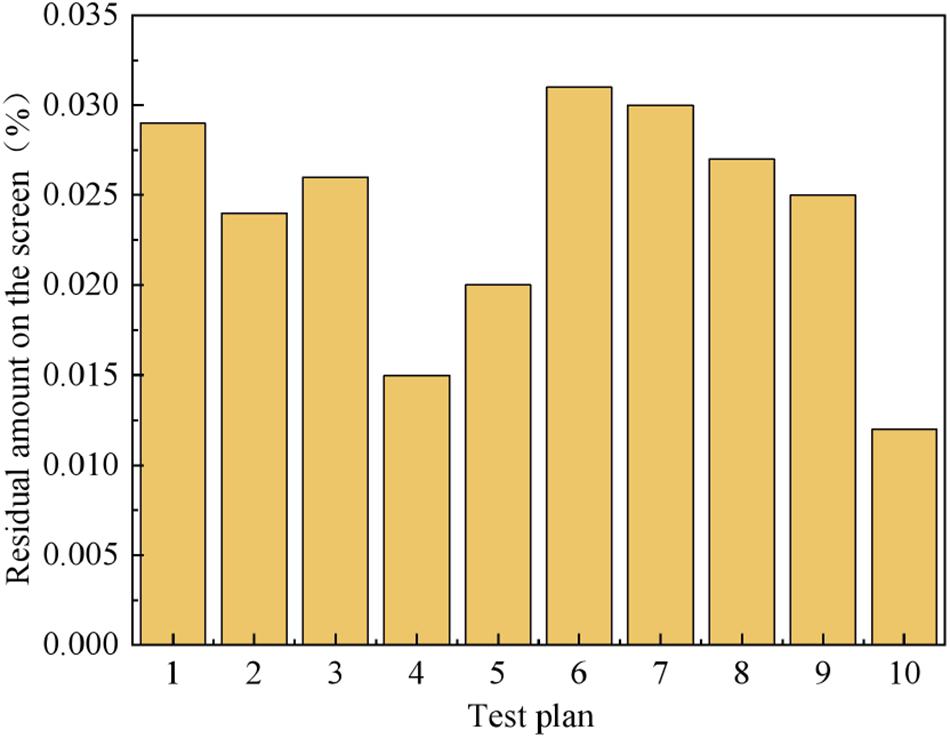

Screen Residue Tests

The CEASM sample is stored for 10 days, and then 500 g uniform CEASM sample is filtered with a 1.18-mm filter screen at the room temperature. The test is used to determine the residue of CEASM on the screen.

Wear Resistance Tests

The wear resistance performance of mixture can be determined by wet track abrasion test (WTAT). The evaluation indexes are 1-h and 6-day WTAT values. The instrument used in this test is wet track abrasion tester.

Anti-slide Tests

The pendulum tester to determine the friction coefficient of pavement is used as the test method of anti-slide performance. It is a field test. The evaluation index is the pendulum friction coefficient value BPN. Each test position needs to be measured in parallel at 3 points, and the average value of measurement results of 3 test points is taken as the test result.

Color Durability Tests

Many factors affect the color attenuation of colored pavement. It is difficult to accurately simulate the color attenuation speed and service condition change of colored pavement in the laboratory. Therefore, through paving the trial section on the Huandao Road in Zhongshan City, Guangdong Province, the color durability is evaluated by observing the color change of pavement after opening to traffic for 6 months.

Results and Discussion

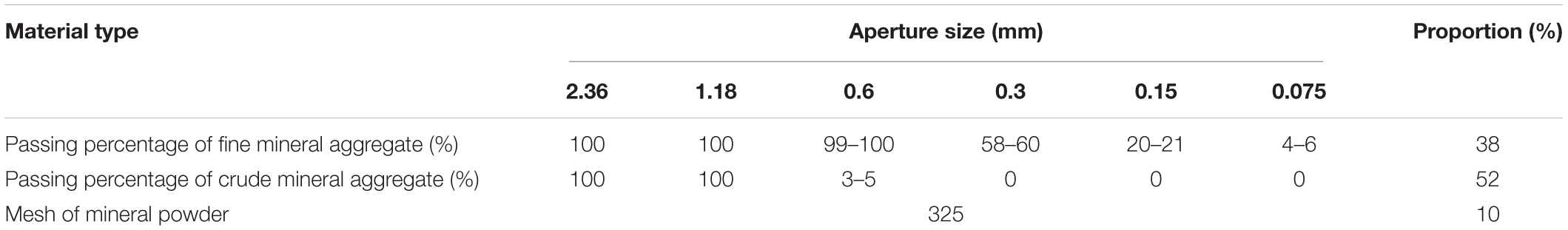

Storage Stability

5-Day Storage Stability

According to the requirements from the Technical Specifications for Construction Highway Asphalt Pavements (JTG F40-2004) in China, the 5-day storage stability index should be no more than 5%. The higher the 5-day storage stability value, the worse the 5-day storage stability. Figure 1 shows the effects of different test factors on the 5-day storage stability of the mixture. It is seen from Figure 1A that with the increased clay content, the 5-day storage stability gradually increased to a stable value, but it had a decreasing tendency when the clay content reached approximately 21%. Therefore, the preferred mixing amount of clay was within 15–20%. As shown in Figure 1B, the silica fume content had little effect on the 5-day storage stability, so a content of 12–20% is suggested. As shown in Figure 1C, additional emulsified asphalt led to a better 5-day storage stability with a preferred mixing amount of over 20%. Figures 1D,E show that with the increasing amount of pigment and mineral aggregate, the 5-day storage stability had a decreasing trend. The pigment content should meet the color requirements after molding with a preferred mixing range from 10–14%. In addition, according to the requirements of the anti-slide performance of pavement after molding, the preferred amount of mixed mineral aggregate ranged from 28 to 38%.

Figure 1. Effect of different test factors on the 5-day storage stability of the mixtures. (A) Amount of mixed clay. (B) Amount of mixed silica fume. (C) Amount of mixed emulsified asphalt. (D) Amount of mixed pigment. (E) Amount of mixed mineral aggregate.

Screen Residue

For CEASM, it is important to ensure that the emulsified asphalt particles are not severely condensated with the functional fillers after long-term storage. Screen residue is a key factor that can evaluate the storage stability of asphalt mixtures.

According to the requirements in the Technical Specifications for Construction Highway Asphalt Pavements (JTG F40-2004), the residual modified emulsified asphalt on the sieve should be no more than 0.1%. As shown in Figure 2, the screen residue in the mixture for each test plan was less than 0.1%, and no agglomerated emulsified asphalt particles were produced. Therefore, the prepared emulsified asphalt mixture has a good storage stability.

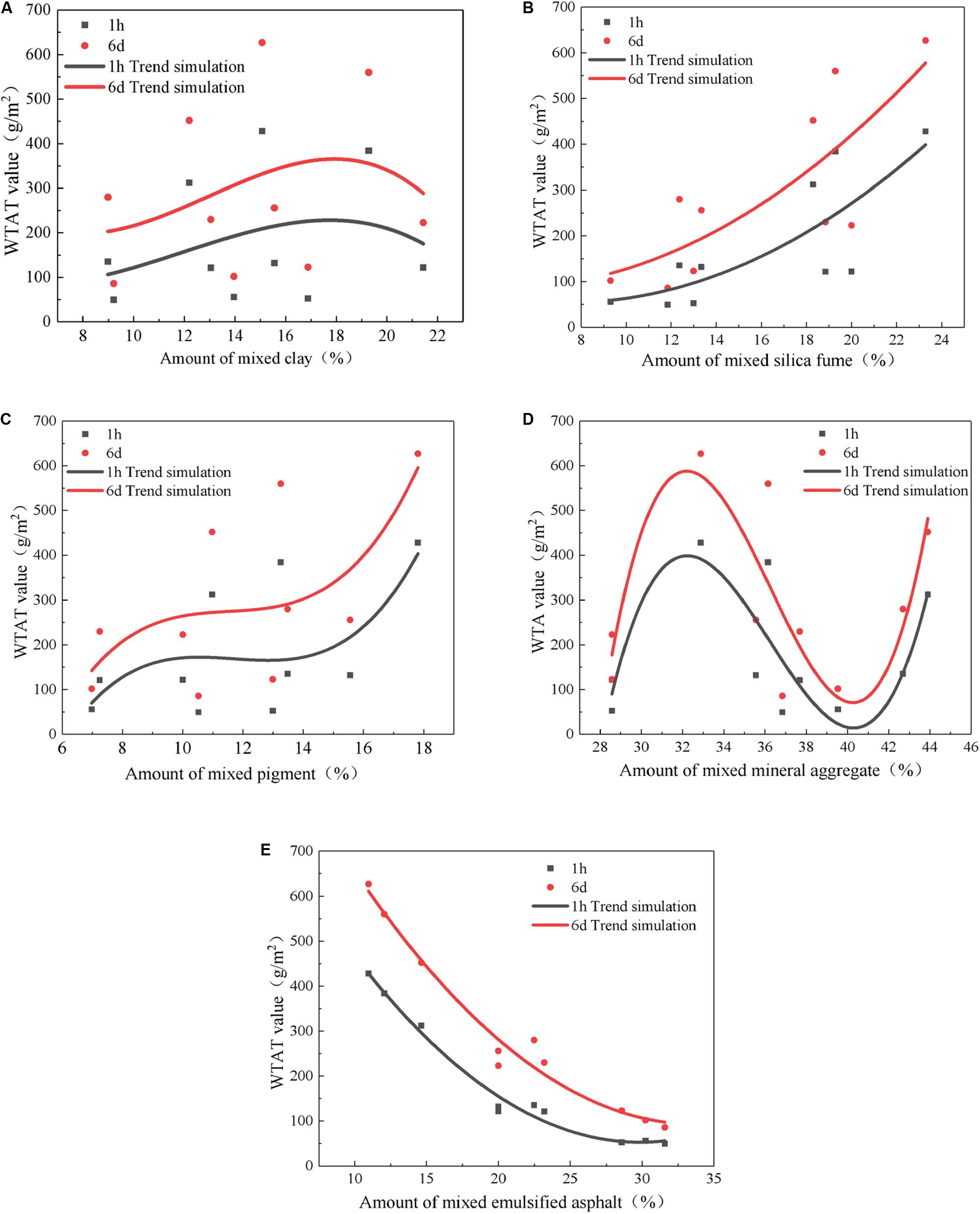

Wear Resistance Performance

Paved CEASM is subjected directly to various loads, so it should have a good wear resistance. Figure 3 shows the effects of different test factors on the WTAT value of the mixtures. As shown in Figure 3A, as the clay increased, the 1-h and 6-day WTAT values did not vary regularly and the test results had a large dispersion. The influence of the clay content on the WTAT values was inconspicuous, indicating that an emulsion with a high viscosity coefficient formed from clay, and the emulsified asphalt had a limited influence on the formed structure of the mixture. Considering the wear resistance performance, the preferred mixing content of clay ranged from 9 to 17%.

Figure 3. Effects of different test factors on the WTAT value of the mixtures. (A) Amount of mixed clay. (B) Amount of mixed silica fume. (C) Amount of mixed pigment. (D) Amount of mixed mineral aggregate. (E) Amount of mixed emulsified asphalt.

It is seen from Figure 3B that there was a good correlation between the amount of mixed silica fume and the WTAT values. With greater silica fume contents, the 1-h and 6-day WTAT values increased, while the wear resistance performance of the mixture decreased significantly. Combined with the requirements of the test indexes, the preferred mixing content for silica fume ranged from 10 to 16%.

Figure 3C indicates that as the pigment increased, the 1-h and 6-day WTAT values increased first and then gradually stabilized. When the amount of mixed pigment was more than 15%, these values rapidly increased. This indicates that the pigment is not only the color source but also increases the compactness of the mixture after molding. In addition, when the pigment content was less than 8%, the color slightly lightened after molding. Combined with the above analysis, the preferred amount of mixed pigment ranged from 8 to 15%.

Figure 3D shows that as the mineral aggregate content increased, the 1-h and 6-day WTAT values varied greatly. The large changes in the WTAT values resulted from the mixed proportions of mineral aggregate and the emulsified asphalt, which reflect the effects of the emulsified asphalt on the moisture damage resistance of the mixture. This also indicates that the quality of the structural system for mineral aggregate could be strongly related to the amount of mixed emulsified asphalt. According to the comprehensive analysis, the preferred amount of mixed mineral aggregate ranged from 28 to 32%.

As shown in Figure 3E, there was a strong effect of emulsified asphalt on the 1-h and 6-day WTAT values. With the increased emulsified asphalt content, the WTAT values were obviously reduced, indicating that emulsified asphalt influenced the moisture damage resistance and wear resistance performance of CEASM. Therefore, the preferred amount of mixed light-colored emulsified asphalt was within 25–32%.

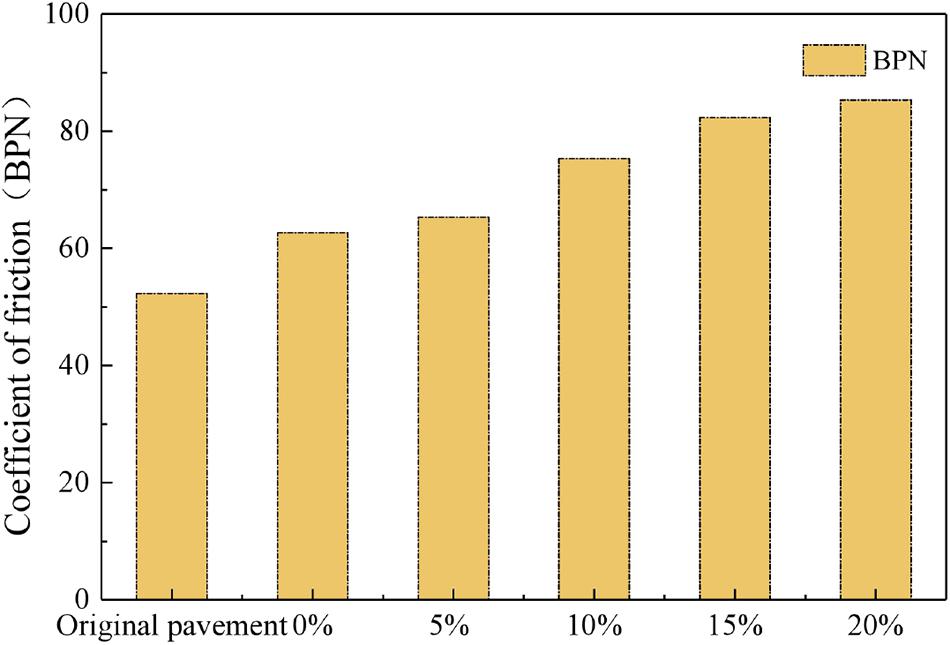

Anti-slide Performance

The CEASM paved on an original road reduces the depth of the pavement structure. To explore the effects of different pavement treatment methods and amounts of mixed aggregate on the frictional pendulum, the No. 7 test plan in the uniform design table was selected, where the contents of all components were within the suggested ranges, and anti-slide performance tests were performed. Basalt rock with a single grain size of 1.18 mm was selected as the aggregate for the asphalt mixture.

As seen in Figure 4, the friction pendulum value of the CEASM was larger than the specification requirement (BPN ≥ 32). It is therefore deduced that the anti-slide performance of the original road can be restored, which is improved by increasing the aggregate content. With the increased aggregate content, the BPN began to increase quickly but slowed when the amount of mixed aggregate was more than 10%. It is therefore proposed that if the trial road section has a strict anti-slide index, the amount of mixed aggregate should be 10%.

Figure 4. Effects of the amount of mixed aggregate on the friction pendulum value of the seal pavement.

Color Durability

The color of pavement decays rapidly after some time. As several complex factors influence color attenuation, such as interactions with sunlight, rain washing, driving, and ground dust, it is difficult to accurately simulate the speed of color attenuation and changes in colored pavement through laboratory tests (Autelitano and Giuliani, 2019).

The pavement study from the trial section of the uniform design plan seven was performed to further explore the color durability of CEASM. Pavement color fading is significant due to the hot weather and abundant rain in Guangdong Province. Therefore, the trial road section in Huandao Road, Zhongshan, China, was selected, as shown in Figure 5. After the trial section was affected by the environment and driving for more than 6 months, there was nearly no color fading on the pavement and the aggregate maintained a good structure and shape, as shown in Figure 6. Thus, the CEASM prepared in this study exhibited a good color durability.

Application Plan

In engineering applications, good construction workability and storage stability are required for CEASM (Zani et al., 2017). Combined with results for the storage stability and wear resistance, the mixture design that satisfies the requirements of engineering applications is shown in Table 7. When the road surface has a strict anti-slide requirement, basalt rock materials with a single grain size from 0.6 to 1.18 mm can be added. A general addition rule is 10%, which was recorded from the mass percentage of CEASM.

Conclusion

The CEASM was prepared by mixing clay, silica fume, pigment, and mineral aggregate. The effects of each component content on the storage stability, wear resistance performance, anti-slide performance, and color durability were studied. The anti-slide performance and color durability for CEASM were tested by applying it to a trial road section in Zhongshan. These results found that there is an optimal mixture design. The main conclusions are summarized as follows.

(1) Considering the storage stability, wear resistance performance, anti-slide performance, and color durability, the clay, silica fume, pigment, mineral aggregate, and emulsified asphalt contents in the prepared mixture are recommended to be in the ranges of 15–17, 12–16, 10–14, 28–32, and 25–32%, respectively.

(2) Considering that CEASM may reduce the structural depth of pavement, the anti-slide performance of the pavement was tested after paving with CEASM. It was found that the friction pendulum value of pavement with CEASM was greater than 32 (above the specification requirements). Therefore, adding aggregates can improve the friction pendulum value of colored seal pavements. In addition, the test of the road performance with CEASM showed that it had a good anti-slide performance and color durability.

(3) When a strict anti-slide requirement was applied to the road surface, basalt rock materials with a single grain size from 0.6 to 1.18 mm are recommended. A general addition of 10% was recorded based on the mass percent of CEASM.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author Contributions

ZS organized the research. ZZ and CW performed all tests. ZS and ZZ wrote the manuscript. ZS, ZZ, and JZ verified the manuscript. All authors contributed to the article and approved the submitted version.

Funding

The authors gratefully acknowledge the financial support offered by the National Natural Science Foundation of China (Nos. 51878078 and 51911530215), the General Project of Education Department of Hunan Province (17C0049), and the Key Project of Open Research Fund of Key Laboratory of Special Environment Road Engineering of Hunan Province (kfj150501).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

Ando, R., Inagaki, T., and Mimura, Y. (2011). Does colored pavement make non-signalized intersections safer? A case study in Japan. Procedia Soc. Behav. Sci. 20, 741–751. doi: 10.1016/j.sbspro.2011.08.082

Autelitano, F., and Giuliani, F. (2019). Daytime and nighttime color appearance of pigmented asphalt surface treatments. Constr. Build. Mater. 207, 98–107. doi: 10.1016/j.conbuildmat.2019.02.100

Bocci, M., Grilli, A., Cardone, F., and Virgili, A. (2012). Clear asphalt mixture for wearing course in tunnels: experimental application in the province of Bolzano. Procedia Soc. Behav. Sci. 53, 115–124. doi: 10.1016/j.sbspro.2012.09.865

Fu, H. Y., Xie, L. D., Dou, D. Y., Li, L. F., Yu, M., and Yao, S. D. (2007). Storage stability and compatibility of asphalt binder modified by SBS graft copolymer. Constr. Build. Mater. 21, 1528–1533. doi: 10.1016/j.conbuildmat.2006.03.008

Gao, M., Xiao, B., Liao, K., and Dai, Y. (2005). Study on the aging behavior of colored paving asphalt. Sci. Tech. Engng. 5, 401–405. (in Chinese) doi: 10.3969/j.issn.1671-1815.2005.07.005

He, X. (2013). Research on the Economical Colored Asphalt Binder and Mixture’s Pavement Performance. Master’s thesis, Chang’an University, Shaanxi. doi: 10.7666/d.D407999.

Jin, N. S. (2015). Study on the pavement performance of colored asphalt and its mixture. Petro. Asphalt. 29, 48–51. (in Chinese),Google Scholar

Lee, H., and Kim, Y. (2007). Laboratory evaluation of color polymer concrete pavement with synthetic resin binder for exclusive bus lanes. Transport. Res. Rec. 1991, 124–132. doi: 10.3141/1991-15

Liang, M., Xin, X., Fan, W., Luo, H., Wang, X., and Xing, B. (2015). Investigation of the rheological properties and storage stability of CR/SBS modified asphalt. Constr. Build. Mater. 74, 235–240. doi: 10.1016/j.conbuildmat.2014.10.022

Lin, D. F., and Luo, H. L. (2004). Fading and color changes in colored asphalt quantified by the image analysis method. Constr. Build. Mater. 18, 255–261. doi: 10.1016/j.conbuildmat.2004.01.004

Ouyang, C. F., Wang, S. F., Zhang, Y., and Zhang, Y. X. (2006). Thermo-rheological properties and storage stability of SEBS/kaolinite clay compound modified asphalts. Eur. Polym. J. 42, 446–457. doi: 10.1016/j.eurpolymj.2005.07.004

Sasanipour, H., Aslani, F., and Taherinezhad, J. (2019). Effect of silica fume on durability of self-compacting concrete made with waste recycled concrete aggregates. Constr. Build. Mater. 227, 116598. doi: 10.1016/j.conbuildmat.2019.07.324

Sengoz, B., and Isikyakar, G. (2008). Evaluation of the properties and microstructure of SBS and EVA polymer modified asphalt. Constr. Build. Mater. 22, 1897–1905. doi: 10.1016/j.conbuildmat.2007.07.013

Synnefa, A., Karlessi, T., Gaitani, N., Santamouris, M., Assimakopoulos, D. N., and Papakatsikas, C. (2011). Experimental testing of cool colored thin layer asphalt and estimation of its potential to improve the urban microclimate. Build. Environ. 46, 38–44. doi: 10.1016/j.buildenv.2010.06.014

Tang, P., Mo, L. T., Pan, C. L., Fang, H., Javilla, B., and Riara, M. (2018). Investigation of rheological properties of light colored synthetic asphalt binders containing different polymer modifiers. Constr. Build. Mater. 161, 175–185. doi: 10.1016/j.conbuildmat.2017.11.098

Tang, X. D., Kong, C., Tian, J., Li, Y., Jin, Z. T., and Bai, H. Y. (2015). Preparation and pavement performance of colored asphalt. Appl. Mech. Mater. 727–728, 362–365. doi: 10.4028/727-728.362

Xu, M., Pan, X., and Deng, Q. (2012). “Setting method of thin-layer antiskid colored pavement in tunnel based on increasing luminance of pavement”. in Proceedings of the The 25th COTA International Conference of Transportation Professionals, Columbus, OH: COTA), 3073–3083. doi: 10.1061/9780784412442.313

Yu, R. E., Zhu, X. J., Zhou, X., Kou, Y. F., Zhang, M. R., and Fang, C. Q. (2018). Rheological properties and storage stability of asphalt modified with nanoscale polyurethane emulsion. Petrol. Sci. Technol. 36, 85–90. doi: 10.1080/10916466.2017.1405028

Zani, L., Giustozzi, F., and Harvey, J. (2017). Effect of storage stability on chemical and rheological properties of polymer-modified asphalt binders for road pavement construction. Constr. Build. Mater. 145, 326–335. doi: 10.1016/j.conbuildmat.2017.04.014

Zhang, J. H., Peng, J. H., Liu, W. Z., and Lu, W. H. (2019a). Predicting resilient modulus of fine-grained subgrade soils considering relative compaction and matric suction. Road Mater. Pavement Des. 1–13. doi: 10.1080/14680629.2019.1651756

Zhang, J. H., Peng, J. H., Zeng, L., Li, J., and Li, F. (2019b). Rapid estimation of resilient modulus of subgrade soils using performance-related soil properties. Int. J. Pavement Eng. 1–8. doi: 10.1080/10298436.2019.1643022

Zhang, J. P., Tan, H. Q., Pei, J. Z., Qu, T., and Liu, W. L. (2019c). Evaluating crack resistance of asphalt mixture based on essential fracture energy and fracture toughness. Int. J. Geomech. 19:06019005. doi: 10.1061/(ASCE)GM.1943-5622.0001390

Keywords: colored pavement, preparation, optimal mix proportions, uniform design method, engineering application

Citation: Sun Z, Zhu Z, Zhang J and Wu C (2020) Composition Optimization and Field Application of Colored Emulsified Asphalt Seal Mixture. Front. Mater. 7:258. doi: 10.3389/fmats.2020.00258

Received: 12 June 2020; Accepted: 14 July 2020;

Published: 11 August 2020.

Edited by:

Dawei Wang, RWTH Aachen University, Aachen, GermanyCopyright © 2020 Sun, Zhu, Zhang and Wu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zhilin Sun, c3VuemhpbGluMTk3OUBjc3VzdC5lZHUuY24=

Zhilin Sun

Zhilin Sun Zhihang Zhu

Zhihang Zhu Junhui Zhang

Junhui Zhang Chao Wu

Chao Wu