- Department of Technologies construction, Vocational School of Technical Sciences, Batman University, Batman, Türkiye

This study explores the influence of varying proportions (5%, 15%, and 25%) of Class F fly ash on the mechanical properties of hybrid steel fiber-reinforced concrete (HSFRC). Concrete mixtures were prepared with fixed total steel fiber content (1% by volume) using micro and macro fibers in specific ratios. Portland cement was partially replaced by fly ash, and slump, compressive, flexural, and splitting tensile strength tests were conducted at 7, 28, and 90 days according to TS EN and ASTM standards. The results showed that while early-age strength decreased due to the slow pozzolanic activity of fly ash, the mixture containing 15% fly ash consistently provided the best mechanical performance at 90 days, reaching a compressive strength of 81 MPa. These findings confirm that 15% fly ash is an optimal replacement level for long-term strength development in HSFRC. The study also emphasizes the economic and environmental benefits of incorporating fly ash in concrete production.

1 Introduction

Concrete is the most commonly used construction material in the construction sector due to its high compressive strength and low cost (Tittelboom and Belie, 2013; Jiao et al., 2017; Arslan and Sarıkaya, 2021; Marvila et al., 2021; Şahan and Ünsal, 2021; Türk et al., 2022a). However, it exhibits low resistance to tensile and bending forces due to its brittle nature (Tittelboom and Belie, 2013; Yavuz et al., 2016; Baduge et al., 2021). For this reason, various fiber materials are added to the concrete mix to improve the tensile strength, crack resistance, abrasion and impact resistance, and toughness of conventional concrete. This enhances the mechanical properties of concrete and increases its overall performance (Çivici, 2006; Ünal and Şimşek, 2022). In steel fiber reinforced concrete, fibers randomly distributed within the cement matrix act as bridges between cracks, resisting the propagation and widening of cracks, thereby reducing brittleness and increasing the ductility of the structure (Topçu and Boğa, 2005; Yalçın et al., 2009).

Hybrid fiber systems combine different fiber types to enhance mechanical properties more effectively than single-fiber systems. They offer significant improvements in compressive strength, tensile strength, and crack resistance (Khan et al., 2017; Afroughsabet et al., 2016). The use of pozzolans, such as fly ash, improves the fiber-matrix interface by enhancing the pore structure (Akeed et al., 2022).

Among mineral admixtures, fly ash is one of the most suitable and economical mineral additives for cement and concrete (Ünal and Şimşek, 2022). Fly ash, a byproduct of coal combustion, is a cost-effective and sustainable material that improves concrete’s workability, flow ability, and late-age strength (Khan et al., 2014; Mark et al., 2019).

Numerous studies have explored the effects of fly ash and fiber combinations on concrete properties. For instance, Almottiri (2011) reported improvements in tensile strength when fly ash was combined with steel fibers, noting that the addition of fly ash enhanced the concrete’s crack resistance. Abdul-Rahman et al. (2018) found that the optimal mechanical performance was achieved with 15% fly ash and 1.25% steel fibers, showing the highest compressive strength at 28 days. This combination also resulted in improved splitting tensile strength and bending resistance. Pal et al. (2020) demonstrated that higher fly ash content led to significant strength gains at later ages, particularly at 90 days, due to the pozzolanic effect, which contributed to enhanced long-term durability. These findings are particularly relevant for hybrid steel fiber-reinforced concrete, where the combination of fly ash and fibers can significantly influence the mechanical properties such as compressive, splitting tensile, and bending strengths, especially over extended curing periods. The effect of fly ash on the late-age strength development is crucial for optimizing the mix design in hybrid fiber-reinforced concrete applications.

Akid et al. (2021) aimed to investigate the combined effect of varying proportions of waste steel fibers and fly ash on the rheological and mechanical performance of fiber-reinforced concrete. Cement was partially replaced with 5%, 10%, and 20% fly ash by weight, and waste steel fibers were included at 1.5% and 3% by volume. The results of the tests showed that fly ash increased workability in all rheological tests, while waste steel fibers reduced workability and increased the density of fresh concrete. The mechanical performance, including compressive strength, splitting tensile, and bending strength, was determined at 7 and 28 days. In the fly ash and waste steel fiber mixes, significant increases were observed in compressive strength, splitting tensile strength, and bending resistance compared to the control. The optimum mechanical performance was found in the mix with 10% fly ash and 3% waste steel fibers.

In the study by Türk et al. (2022a), the engineering and workability properties of steel fiber-reinforced self-compacting concrete mixes were investigated. Three mixes were designed: fiber-free, macro-fiber-only, and hybrid-fiber mixes. Compressive, splitting tensile, and bending strengths were tested at 3, 28, and 90 days. The results showed that fiber-reinforced mixes generally had lower compressive strengths than the control mix due to reduced workability from the fibers. However, compressive strength increased with longer curing times, and the 90-day strength improved due to the pozzolanic effect of fly ash. Hybrid-fiber mixes performed better than single-fiber mixes at both 28 and 90 days. Splitting tensile strength was higher in fiber-reinforced mixes, with hybrid-fiber mixes showing the best results. At 90 days, splitting tensile strength increased by 7%–20% compared to 28 days, again due to fly ash’s pozzolanic effect. Bending tensile strength was also higher in fiber-reinforced mixes, as fibers bridged cracks and delayed their propagation. The improvement in fiber-matrix bonding over time contributes to increased bending tensile strength. However, the addition of micro fibers alone reduced bending strength compared to macro fibers. The pozzolanic effect of fly ash led to a 7.4%–15.3% increase in bending tensile strength at 90 days compared to 28 days.

This study demonstrates that the incorporation of both fly ash and steel fiber reinforcement contributes to improved mechanical properties of concrete. In particular, extended curing periods and the use of hybrid fiber combinations lead to further enhancements in strength development. A review of existing literature reveals a substantial number of studies focused on the addition of steel fibers and fly ash to concrete in order to improve its performance. While many of these studies report consistent findings, some present conflicting results. In light of this, the present study aims to explore the combined effect of fly ash and hybrid steel fiber reinforcement applied in varying proportions on the mechanical properties of concret.

2 Experimental

2.1 Materials

In the experimental study, CEM I 42.5 N Portland cement conforming to TS EN 197-1 (2012), limestone-based aggregates with a particle size distribution of 0–4, 4-8, and 4–16 mm were used. To ensure the homogeneous distribution of fibers within the concrete and improve its mechanical properties, a polycarboxylate ether-based, next-generation superplasticizer was utilized.

Microfibers were produced according to ASTM A820 (2004) and EN 14889-1 (2006) standards, specifically the Micro Fiber Dramix OL 6/16 (6 mm length/0.16 mm diameter), which is a bright, high-carbon wire. The macro fibers used were produced according to ASTM A820 (2004) and EN 14889-1 (2006) standards, identified as Macro Fiber Dramix 3D 45/35 (45 mm thickness/35 mm length), which consists of bright wire glued with water-soluble adhesive. For mineral additives, F-type fly ash compliant with ASTM C 618 (2019) was obtained from the Isken Thermal Power Plant. Figure 1 shows the materials used in the preparation of hybrid steel fiber-reinforced concrete mixtures with fly ash.

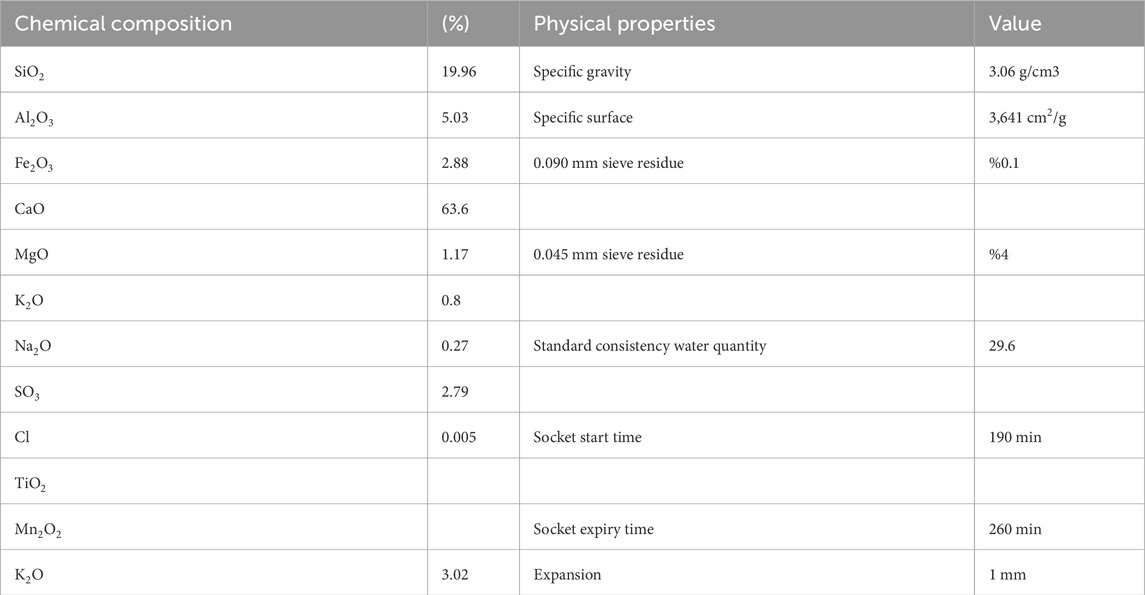

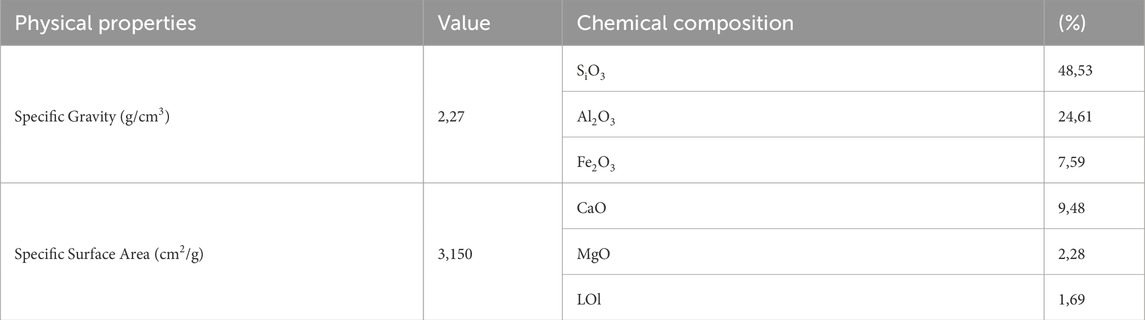

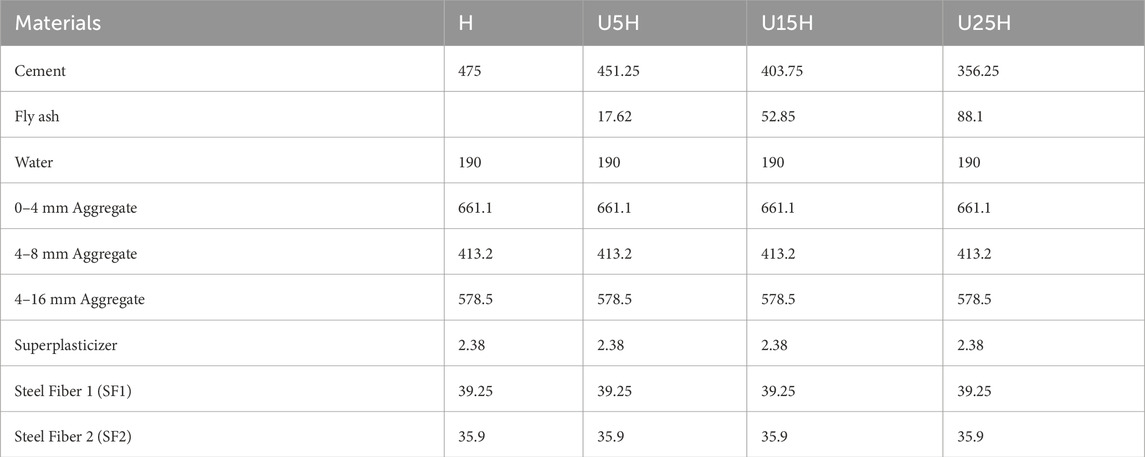

Table 1 presents the chemical and physical properties of the cement used, while Table 2 provides the physical and chemical properties of the fly ash. The water/cement ratio for the produced concretes was set at 0.40, and steel fibers were incorporated into the concrete at a total volumetric rate of 1%. The quantities required for producing 1 m3 of the concrete are provided in Table 3. The sample series were prepared according to the mixture ratios specified in Table 3, following the TS 802 (2016) guidelines for Concrete Mix Calculation Principles for the C40 concrete class. The H series represents the hybrid steel fiber reference sample without fly ash, while U5H, U15H, and U25H represent hybrid series with 5%, 15%, and 25% fly ash, respectively.

A total of 9 specimens were molded for each cure age in each series: 3 for compressive strength, 3 for flexural strength and 3 for tensile strength. Concrete mixtures were prepared in three stages for each series to ensure homogenous mixing of the fresh concrete, adhering to the proportions specified in Table 3. The prepared fresh concrete was then poured into pre-oiled molds in two stages and vibrated on a shaking table for 30 s at each stage. Subsequently, the series were left to rest in the molds for 24 h. Following this period, the hardened series were demolded and subjected to a curing process in a curing pool for a predetermined curing age. Upon completion of the designated curing periods, the specimens were subjected to experiments to determine their mechanical properties.

2.2 Methods

2.2.1 Slump test and fresh concrete unit weight test

The slump test was conducted in accordance with the TS EN 12350-2 (2010) standard to determine the consistency of the fresh concrete mixtures. In the developed concrete designs, a superplasticizer admixture was utilized to maintain the slump values of the concrete consistently within the range of 14 ± 2 cm. Furthermore, the unit weights of the fresh concrete were also determined. The slump test conducted during this study is illustrated in Figure 2.

2.2.2 Concrete compressive strength test

Following the completion of the designated curing periods for the 150 × 150 × 150 mm specimens, compressive strength values were determined in accordance with the TS EN 12390-3 (2019) standard, utilizing a uniaxial concrete compression press as illustrated in Figure 3. For the compressive strength test, specimens were cured for 7, 28, and 90 days under controlled conditions of 20°C ± 2°C and ≥95% relative humidity.

2.2.3 Flexural tensile strength test of beams

For the flexural strength test, specimens were cured for 7, 28 and 90 days under controlled conditions of 20°C ± 2°C and ≥95% relative humidity. Specimens with dimensions of 100 × 100 × 400 mm were subjected to a flexural tensile strength test under two-point loading, adhering to the TS EN 12390-5 (2019) standard. The test was conducted using a Shimadzu testing machine, as depicted in Figure 4. A loading rate of 165 N/s was employed during the test. Flexural tensile strength was calculated using Equation 1, presented below, based on the maximum load recorded on the load indicator:

Where

2.2.4 Splitting tensile strength test

For the splitting tensile strength test, specimens were cured for 7, 28 and 90 days under controlled conditions of 20°C ± 2°C and ≥95% relative humidity. The specimens, measuring 100 mm in diameter and 200 mm in length, were tested upon reaching the designated age in accordance with the TS EN 12390-6 (2002) standard. The testing involved the use of a splitting tensile strength apparatus fitted to a compression press, as illustrated in Figure 5, to measure the splitting tensile strength and was calculated using Equation 2.

Where

3 Results and discussion

3.1 Concrete compressive strength values

In line with previous literature, the study focused primarily on the 28- and 90-day results for flexural and splitting tensile strength, since the pozzolanic effects of fly ash are generally not expected to be significant at early ages, particularly at 7 days.

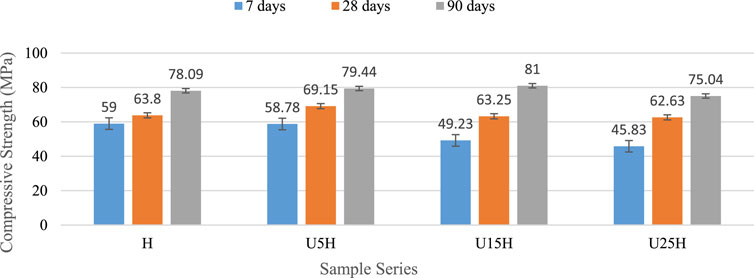

This research investigated the influence of fly ash on the compressive strength values of hybrid steel fiber-reinforced concrete. Figure 6 presents the average compressive strength values obtained at 7, 28, and 90-day periods.

Upon examination of the graph, it is observed that the minimum and maximum compressive strength values at 7 days were 45.83 MPa and 59 MPa, respectively, obtained from the U25H and H series.

At 28 days, the lowest compressive strength value of 62.63 MPa was recorded for the U25H series, while the highest value of 69.15 MPa was obtained from the U5H series.

An increase in compressive strength values is observed at 90 days. The U25H series exhibited a value of 75.04 MPa, and the maximum value of 81 MPa was obtained from the U15H series.

When the percentage change in compressive strength values of hybrid fly ash concretes is examined relative to the hybrid control specimen, a decrease in strength is observed at 7 days: approximately 0.37% for the U5H specimen, 16.56% for the U15H specimen, and 22.32% for the U25H specimen.

At 28 days, an increase in strength of approximately 8.39% is noted for the U5H series, while a decrease is observed for the U15H series approximately 0.86% and the U25H series 1.83%.

At 90 days, an increase in strength is observed for the U5H series approximately 1.73% and the U15H series 3.73% compared to the H series (control), whereas a decrease of 3.91% is observed for the U25H series.

Examining the U15H series, which exhibited the maximum strength at 90 days, reveals an increase in compressive strength of approximately 65.53% compared to its 7-day strength.

Based on the compressive strength results at 7, 28, and 90 days, it is evident that fly ash does not contribute to early-age strength but has a significant influence on strength at later ages. This is attributed to the pozzolanic nature of fly ash, which exhibits minimal contribution to early-age strength but provides positive contributions to strength development at later ages.

The results indicate that the utilization of fly ash negatively affects early-age strength development. This effect is primarily attributed to the slower pozzolanic reaction of fly ash compared to the hydration of cement, leading to delayed strength gain. However, several strategies can be employed to mitigate this issue and enhance the early-age strength of fly ash-incorporated concrete.

One effective approach is reducing the water-to-cement (w/c) ratio while maintaining workability through the use of high-range water-reducing admixtures. Studies have shown that lowering the w/c ratio improves the early-age strength of fly ash-based concretes by enhancing particle packing and reducing porosity (Atiş and Karahan, 2009; Abdul-Rahman et al., 2018). Additionally, the incorporation of silica fume or other highly reactive pozzolanic materials can accelerate early-age strength development by increasing nucleation sites for hydration (Pal et al., 2020).

Another viable strategy is the application of thermal curing methods, such as steam curing or accelerated curing, which enhance the pozzolanic reaction rate of fly ash (Bozkurt et al., 2013). These methods have been reported to significantly improve the early compressive strength of fly ash-based concretes, making them more suitable for applications requiring rapid strength gain. Furthermore, the use of chemical accelerators, including calcium nitrate and calcium chloride, can counteract the slow reaction kinetics of fly ash, facilitating early-age strength development (Akid et al., 2021).

Hybridization of fly ash with other supplementary cementitious materials (SCMs), such as ground granulated blast furnace slag (GGBFS) or metakaolin, is another potential solution. Research suggests that the synergistic effects of these materials can improve both early and long-term mechanical properties (Türk et al., 2022b). Future research should explore optimized combinations of these strategies to achieve a balance between early-age strength and long-term durability.

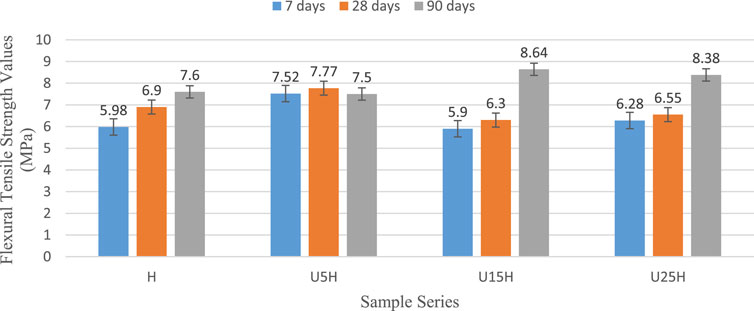

3.2 Flexural tensile strength values of beams

In this research, the influence of varying proportions of fly ash substitution on the flexural tensile strength values of hybrid steel fiber-reinforced concrete was investigated. Figure 7 presents the average flexural tensile strength values obtained at 7, 28 and 90 day periods.

Upon examination of the graph, it is observed that the minimum and maximum strength values at 7 days were 5.9 MPa and 7.52 MPa, respectively, obtained from the U15H and U5H series. The minimum and maximum strength values at 28 days were 6.30 MPa and 7.77 MPa, respectively, obtained from the U15H and U5H series. At 90 days, the minimum and maximum values were 7.5 MPa and 8.64 MPa, respectively, obtained from the U5H and U15H series.

When the percentage change in flexural tensile strength values of hybrid fly ash concretes is examined relative to the hybrid control specimen, an increase in strength is observed at 7 days: approximately 25.75% for the U5H specimen, 5.02% and the U25H series. However, a decrease is noted for the U15H series approximately 1.34%.

When the percentage change in flexural tensile strength values of hybrid fly ash concretes is examined relative to the hybrid control specimen, an increase of 12.61% is observed for the U5H series at 28 days. However, a decrease is noted for the U15H series approximately 8.70% and the U25H series approximately 5.07%.

At 90 days, a decrease of 1.32% is observed for the U5H series. In contrast, increases in flexural tensile strength are observed for the U15H and U25H series, approximately 13.68% and 10.26%, respectively.

The influence of fly ash’s pozzolanic nature is evident in flexural tensile strength, similar to its effect on compressive strength. The positive effects of fly ash utilization on flexural tensile strength are observed at later ages. Comparing the 90-day strength of the U15H series, which exhibited the maximum flexural tensile strength, with its 28-day strength reveals an increase of approximately 37.14% in strength at later ages.

Similar to the compressive strength results, the optimum fly ash content for flexural tensile strength varies with the curing age. For a 28-day curing period, the optimum fly ash content for maximum splitting tensile strength is 5%, while for a 90-day curing period, it is determined to be 15%.

The variation in the optimum fly ash content with curing age is attributed to the time-dependent effects of fly ash’s hydration and pozzolanic reactions, as explained in the compressive strength results. At later ages, the pozzolanic reactions of fly ash and its microstructural densification effects become more pronounced, leading to greater strength enhancement. Consequently, the optimum fly ash content varies with the curing age. Several studies in the literature support these findings (Atiş and Karahan, 2009; Almottiri, 2011; Bozkurt et al., 2013; Abdul-Rahman et al., 2018; Pal et al., 2020; Türk et al., 2022a).

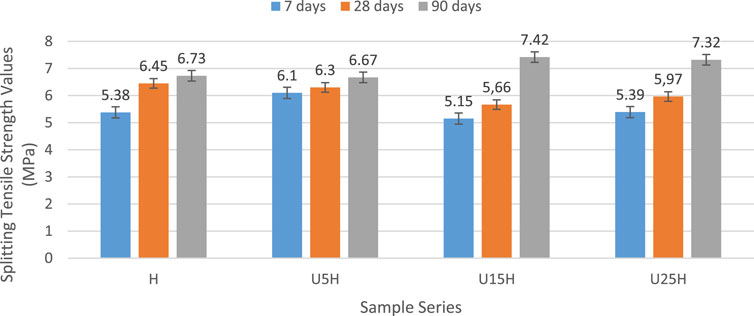

3.3 Splitting tensile strength values

In this study, which investigated the influence of fly ash on the splitting tensile strength values of hybrid steel fiber-reinforced concrete, the average splitting tensile strength values obtained are presented in Figure 8.

Upon examination of the graph, it is observed that the minimum and maximum compressive strength values at 7 days were 5.15 MPa and 6.1 MPa, respectively, obtained from the U15H and U5H series.

Upon examination of the graph, it is observed that the minimum strength value at 28 days was 5.66 MPa, obtained from the U15H series, while the maximum strength value of 6.45 MPa was obtained from the H series (control). The strength value obtained from the U5H series, 6.30 MPa, is noted to be very close to the maximum value obtained from the H series.

At 90 days, the minimum strength value of 6.67 MPa was obtained from the U5H series, while the maximum strength value of 7.42 MPa was obtained from the U15H series.

When the percentage change in Splitting Tensile Strength values of hybrid fly ash concretes is examined relative to the hybrid control specimen, an increase in strength is observed at 7 days: approximately 13.38% for the U5H specimen, 0.19% and the U25H series. However, a decrease is noted for the U15H series approximately 4.28%.

When the percentage change in splitting tensile strength values of hybrid fly ash concretes is examined relative to the hybrid control specimen, a decrease in splitting tensile strength is observed at 28 days: approximately 2.33% for the U5H series, 12.25% for the U15H series, and 7.44% for the U25H series.

At 90 days, compared to the H series (control), a decrease of approximately 0.89% is observed for the U5H series, while increases are noted for the U15H series 10.25% and the U25H series 8.77%. Similar to the trends observed in compressive and flexural tensile strength, the positive effects of fly ash on splitting tensile strength are also evident at later ages. Comparing the 90-day strength of the U15H series, which exhibited the maximum splitting tensile strength, with its 28-day strength reveals an increase of approximately 31.10% in strength at later ages.

The results indicate that the optimum fly ash content for splitting tensile strength, like compressive and flexural tensile strength, varies with the curing age. For a 28-day curing period, the maximum splitting tensile strength is achieved with the series containing no fly ash, while for a 90-day curing period, the optimum fly ash content is determined to be 15%. As observed in the compressive and flexural tensile strength results, the splitting tensile strength results are also influenced by the pozzolanic reactions of fly ash and its microstructural densification effects. The increase in fly ash content at later ages contributes to achieving optimum strength. Several studies in the literature support these findings (Atiş and Karahan, 2009; Almottiri, 2011; Akid et al., 2021; Türk et al., 2022a).

4 Conclusion

This study presented an experimental investigation into the effects of varying proportions of fly ash on the mechanical performance of hybrid steel fiber-reinforced concrete. The findings clearly demonstrate that the utilization of fly ash does not significantly influence the early-age strength of concrete but has a positive impact on strength development at later ages.

The effect of fly ash on compressive, flexural tensile, and splitting tensile strengths varied depending on the curing age. However, for the 90-day curing period, which is crucial for long-term strength development, the optimum fly ash content was found to be 15% for all strength types.

While this study acknowledges the adverse effect of fly ash on early-age strength, it also highlights strategies to mitigate this drawback, thereby enhancing the practical applicability of fly ash-incorporated hybrid steel fiber-reinforced concrete. The reduction of the water-to-cement ratio, incorporation of silica fume, implementation of thermal curing techniques, and the use of chemical accelerators are promising approaches to counteract the delayed strength development associated with fly ash. Moreover, hybridizing fly ash with other SCMs, such as GGBFS or metakaolin, can further optimize concrete performance.

These strategies enhance the feasibility of utilizing fly ash in structural applications requiring both early-age and long-term strength. Future studies should focus on integrating these techniques in real-world construction scenarios to evaluate their effectiveness under practical conditions.

This study holds significant implications for both economy and ecology. Utilizing 15% fly ash in the production of concrete with enhanced mechanical properties resulted in an approximate 10% cost saving, considering the unit prices of 2024. Given the increasing number of construction projects and the associated rise in concrete consumption, it is evident that substantial economic benefits can be achieved. Furthermore, as fly ash is an industrial by-product, its collection and disposal are crucial considerations. Utilizing such waste material in concrete not only reduces disposal costs but also minimizes the ecological problems associated with waste materials, thereby promoting sustainability.

For future studies, it is recommended to reduce the water/cement ratio, increase the fiber content, and adjust the maximum aggregate size within the limits specified by standards to achieve improved compressive, flexural tensile, and splitting tensile strengths.

Future studies should incorporate microstructural analyses such as SEM and XRD to further elucidate the effects of fly ash on hydration reactions and matrix densification. These methods can provide complementary insights into the findings of this study, particularly in understanding the mechanisms underlying the observed mechanical performance.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

NK: Funding acquisition, Writing – original draft, Writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Correction note

A correction has been made to this article. Details can be found at: 10.3389/fmats.2025.1671716.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdul-Rahman, M. B., Ali, A. A., and Younus, A. M. (2018). Effecting of steel fibers and fly ash on the properties of concrete. Tikrit J. Eng. Sci. 25 (4), 30–36. doi:10.25130/tjes.25.4.06

Afroughsabet, V., Biolzi, L., and Ozbakkaloglu, T. (2016). High-performance fiber-reinforced concrete: a review. J. Mater. Sci. 51, 6517–6551. doi:10.1007/s10853-016-9917-4

Akeed, M. H., Qaidi, S., Ahmed, H. U., Faraj, R. H., Mohammed, A. S., Emad, W., et al. (2022). Ultra-high-performance fiber-reinforced concrete. Part II: hydration and microstructure. Case Stud. Constr. Mater. 17, e01289. doi:10.1016/j.cscm.2022.e01289

Akid, A. S., Shah, S. M., Sobuz, M. D., Tam, V. W., and Anik, S. H. (2021). Combined influence of waste steel fibre and fly ash on rheological and mechanical performance of fibre-reinforced concrete. Aust. J. Civ. Eng. 19 (2), 208–224. doi:10.1080/14488353.2020.1857927

Almottiri, F. A. (2011). Physical properties of steel fiber reinforced cement composites made with fly ash. Jordan J. Civ. Eng. 5 (2).

Arslan, E., and Sarıkaya, H. (2021). Farklı boyutlardaki poliamid, poliester ve jüt liflerinin betonun mekanik davranışına etkisi. Uşak Üniversitesi Fen ve Doğa Bilim. Derg. 5 (1), 30–49. doi:10.47137/usufedbid.853757

ASTM C 618 (2019). ISO/ASTM52907-19 additive manufacturing -feedstock materials -methods to characterize metallic powders. West Conshohocken, PA: ASTM International.

Atiş, C. D., and Karahan, O. (2009). Properties of steel fiber reinforced fly ash concrete. Constr. Build. Mater. 23 (1), 392–399. doi:10.1016/j.conbuildmat.2007.11.002

Baduge, S. K., Navaratnam, S., Abu-Zidan, Y., McCormack, T., Nguyen, K., Mendis, P., et al. (2021). Improving performance of additive manufactured (3D printed) concrete: a review on material mix design, processing, interlayer bonding, and reinforcing methods. Structures 29, 1597–1609. doi:10.1016/j.istruc.2020.12.061

Bozkurt, N., Yazıcıoğlu, S., and Gönen, T. (2013). The effect of single and hybrid fibres on fibre reinforced self compacting concrete produced with high level of fly ash usage. SDU Int. Technol. Sci. 5 (5-2), 11–21.

Çivici, F. (2006). Çelik lif donatılı betonun eğilme tokluğu. Pamukkale Üniversitesi Mühendislik Bilim. Derg., 183–188.

EN 14889-1. (2006). Fibres for concrete-Part 1: steel fibres-definitions, specifications and conformity.

Jiao, D., Shi, C., Yuan, Q., An, X., Liu, Y., and Li, H. (2017). Effect of constituents on rheological properties of fresh concrete-A review. Cem. Concr. Compos. 83, 146–159. doi:10.1016/j.cemconcomp.2017.07.016

Khan, M., Abbas, Y., and Fares, G. (2017). Review of high and ultrahigh performance cementitious composites incorporating various combinations of fibers and ultrafines. J. King Saud Univ. - Eng. Sci. 29 (4), 339–347. doi:10.1016/j.jksues.2017.03.006

Khan, S. U., Nuruddin, M. F., Ayub, T., and Shafiq, N. (2014). Effects of different mineral admixtures on the properties of fresh concrete. Sci. World J. 2014 (1), 1–11. doi:10.1155/2014/986567

Mark, O. G., Ede, A. N., Olofinnade, O., Bamigboye, G., Okeke, C., Oyebisi, S. O., et al. (2019). “Influence of some selected supplementary cementitious materials on workability and compressive strength of concrete – a review,”, IOP Conf. Ser. Mater. Sci. Eng. 640. 012071. doi:10.1088/1757-899x/640/1/012071

Marvila, M. T., Azevedo, A. R., Matos, P. R., Monteiro, S. N., and Vieira, C. M. (2021). Materials for production of high and ultra-high performance concrete: review and perspective of possible novel materials. Materials 14 (15), 1–36. doi:10.3390/ma14154304

Pal, S., Shariq, M., Abbas, H., Pandit, A., and Masood, A. (2020). Strength characteristics and microstructure of hooked-end steel fiber reinforced concrete containing fly ash, bottom ash and their combination. Constr. Build. Mater. 247, 118530. doi:10.1016/j.conbuildmat.2020.118530

Şahan, M. F., and Ünsal, İ. (2021). Farklı lif oranına sahip çelik lif takviyeli beton kirişlerde çarpma etkisi. IJIEA., 212–217. doi:10.46460/ijiea.986369

Tittelboom, K. V., and Belie, N. D. (2013). Self-healing in cementitious materials-A review. Materials 6 (6), 2182–2217. doi:10.3390/ma6062182

Topçu, İ. B., and Boğa, A. R. (2005). Uçucu kül ve çelik liflerin beton ve beton borularda kullanımı. Eskişehir osmangazi üniversitesi mühendislik ve mimarlık fakültesi dergisi, 18 (2), 1–14.

TS EN 12390-3. (2019). Concrete hardened concrete tests - Part 3: determination of compressive strength of test specimens.

TS EN 12390-6. (2002). Concrete hardened concrete tests-Part 6: determination of the splitting tensile strength of test samples.

TS EN 197-1. (2012). Cement-Part 1: general cements-composition, properties and conformity criteria.

Türk, K., Çiçek, N., Katlav, M., and Turgut, P. (2022b). Karma çelik lifli kendiliğinden yerleşen betonun elektriksel direnci. Mühendislik Bilim. ve Tasar. Derg. 10 (2), 482–494. doi:10.21923/jesd.960538

Türk, K., Katlav, M., and Turgut, P. (2022a). Karma lif takviyeli KYB karışımlarının i̇şlenebilirlik ve mühendislik özelliklerinin araştırılması. Bitlis Eren Üniversitesi Fen Bilim. Derg. 11 (2), 400–410. doi:10.17798/bitlisfen.984473

Ünal, M. T., and Şimşek, O. (2022). Çimento harçlarında optimum uçucu kül ve PVA lif oranının belirlenmesi. Politeknik Derg. 25 (2), 477–489. doi:10.2339/politeknik.770831

Yalçın, M., Taşdemir, C., and Taşdemir, M. A. (2009). Çelik lif donatılı betonların performans sınıfları. İTÜ Dergisi/d 8 (6), 97–108.

Keywords: fly ash, concrete, steel fiber, hybrid fiber, mechanical properties

Citation: Kaya N (2025) Effect of different fly ash ratios on the mechanical properties of hybrid steel fiber reinforced concrete. Front. Mater. 12:1585291. doi: 10.3389/fmats.2025.1585291

Received: 28 February 2025; Accepted: 30 June 2025;

Published: 10 July 2025; Corrected: 24 September 2025.

Edited by:

Geoffrey Robert Mitchell, Polytechnic Institute of Leiria, PortugalReviewed by:

Amir R. Masoodi, Ferdowsi University of Mashhad, IranViviana Rougier, Universidad Tecnológica Nacional, Argentina

Copyright © 2025 Kaya. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Necim Kaya, bmVjaW0ua2F5YUBiYXRtYW4uZWR1LnRy

Necim Kaya

Necim Kaya