- 1Hubei Traffic Investment Beijing Hong Kong Macao Expressway Reconstruction and Expansion Project Management Co., Ltd., Wuhan, Hubei, China

- 2Research Institute of Highway Ministry of Transport, Beijing, China

- 3Beijing Xinqiao Technology Development Co., Ltd., Beijing, China

- 4School of Environmental, Civil, Agricultural and Mechanical Engineering, University of Georgia, Athens, GA, United States

Whether reclaimed asphalt pavement can be reused multiple cycles has become a focal issue in the industry. This paper investigates the macroscopic physical property changes and microscopic four-component alteration mechanisms of multiple recycling asphalt, simulates the multiple recycling processes of asphalt mixtures through laboratory tests, determines the mix proportions of multiple recycling asphalt mixtures through Marshall test, and evaluates the pavement performance of the mixtures using high-temperature wheel tracking test, semi-circular bending test, and freeze-thaw splitting test. The results indicate that after multiple recycling, multiple recycling asphalt exhibits poorer rheological property; high-temperature performance of multiple recycling asphalt mixture is improved, and low-temperature performance of multiple recycling asphalt mixture is significantly degraded. The solubilization of rejuvenator in old asphalt intensifies with increasing rejuvenator dosage but decreases exponentially with the increasing number of recycling cycles. The high-temperature stability of recycled asphalt mixtures gradually increases with the number of recycling cycles, while water stability shows low sensitivity to the number of recycling cycles. After the third recycling, the Marshall volume indicators of the recycled asphalt mixtures can meet the regulatory requirement. After the second recycling, the low-temperature anti-cracking performance of the recycled mixtures deteriorates rapidly. In summary, when asphalt mixtures undergo multiple recycling, special attention should be paid to the restoration of their low-temperature property.

1 Introduction

Due to the increasing scarcity of paving aggregates, the recycling of discarded asphalt pavement aggregates has become an inevitable trend (Fan et al., 2024; Wang J. et al., 2024). Considerable research has been conducted on its recycling mechanism, fraction design, performance evaluation, and construction techniques (Wang Y. et al., 2024; Wu et al., 2024; Rashid et al., 2019; Hou et al., 2007). Asphalt pavement recycling technology, characterized by its excellent performance and stable quality, has been widely applied domestically and internationally, making the recycling of reclaimed asphalt pavement (RAP) a significant development direction in highway transportation (Wang Y. et al., 2024; Wang et al., 2019; Miao et al., 2018).

Similar to that of the ordinary asphalt pavement, the performance of recycled asphalt pavement will also degrade under the combined effects of the traffic load and the environment. Once the recycled asphalt pavement reaches its design life, it also faces major repairs or reconstruction. And the issue of whether the resulting discarded asphalt mixtures can be reused multiple cycles has attracted widespread attention (Zou et al., 2017; Han et al., 2024; Valentová et al., 2016). Currently, research on asphalt recycling primarily rely on traditional physical property indicators (Wang et al., 2017; Yiqiu et al., 2010; Si et al., 2024; Shi et al., 2024; Villegas et al., 2024). Asphalt undergoes aging, resulting in reduced penetration, poorer ductility, increased viscosity, and other physical property changes primarily due to alterations in its chemical composition (Cannone Falchetto et al., 2013; Al-Saffar et al., 2022; Baqersad and Ali, 2019). During the aging and recycling processes of asphalt, changes in the mass fractions of its four chemical components affect the stability of its colloidal structure, leading to differences in physical properties (Gulzar et al., 2023; Abe et al., 2023).

Existing research shows that European and American countries have conducted fruitful research on the rejuvenating results of rejuvenators and evaluation methods for the physical and mechanical properties of recycled asphalt mixtures (Solaimanian and Chen, 2021; AbuQtaish et al., 2018; Guo et al., 2016; Erdem and Blankson, 2014), providing a scientific basis for the practical application of asphalt mixture recycling technology. However, little research has been conducted on the multiple aging and recycling of asphalt (Zou et al., 2019; Zhao et al., 2016). Some researchers have also conducted researches on asphalt recycling technology. Huang et al. (Huang et al., 2001), based on China’s current design methods for base asphalt mixtures and other countries’ design methods for recycled mixtures, proposed targeted mix proportion design method for recycled asphalt and recycled mixtures. Ji et al. (2010) measured the viscosity of recycled asphalt with different blending ratios of new and old asphalt, established and validated the composite viscosity-temperature curve for recycled asphalt and a calculation formula for the heating temperature of new aggregate based on heat conduction, and verified the reliability of the calculation formula through practical engineering projects. Qi et al. (2014) designed a test scheme to simulate the diffusion process of rejuvenators in aged asphalt and conducted regression analysis based on softening point test results, indicating that increases in ambient temperature and diffusion time can significantly improve the diffusion degree of rejuvenators and sufficient diffusion of rejuvenators in aged asphalt is beneficial to improving the strength of recycled asphalt mixtures. Considering only initial recycling while neglecting long-term recycling is detrimental to maximizing economic and social benefits, leading to “lingering concerns” in the application of asphalt pavement recycling technology.

Multiple Recycled Asphalt refers to asphalt subjected to two or more cycles of aging and rejuvenation. Multiple Recycled Asphalt Mixtures are mixtures composed of recycled asphalt that has undergone multiple aging - rejuvenation cycles, along with old aggregates and new aggregates. Previous studies (Fan et al., 2024; Wang J. et al., 2024) mainly focused on the initial recycling of asphalt and asphalt mixtures, neglecting the long-term recycling situation. This study fills this gap by comprehensively investigating the performance changes of multiple recycled asphalt and asphalt mixtures, which is of great significance for promoting the sustainable development of asphalt pavement recycling technology, reducing construction costs, and protecting the environment. In this study, laboratory tests were conducted to simulate the multiple recycling processes of asphalt mixtures, investigate the performance differences of base asphalt undergoing multiple aging and recycling with varying rejuvenator dosages, and reveal the changing patterns of performance indicators for multiple recycled asphalt. Based on the aging and recycling mechanisms of ordinary discarded asphalt pavements, the feasibility of multiple recycling of ordinary discarded asphalt mixtures was explored, and the changing patterns of the performance of multiple recycled asphalt mixtures were studied, aiming to lay a theoretical foundation for the multiple recycling applications of asphalt pavements. This paper investigates a critical gap in sustainable pavement engineering: the long-term feasibility of reusing asphalt through multiple recycling cycles. While existing research focuses on single-cycle recycling, the cumulative effects of repeated aging and rejuvenation remain poorly understood. By evaluating performance degradation across three cycles, this work provides actionable insights for extending pavement service life, reducing resource consumption, and minimizing environmental impacts.

2 Materials and methods

2.1 Materials

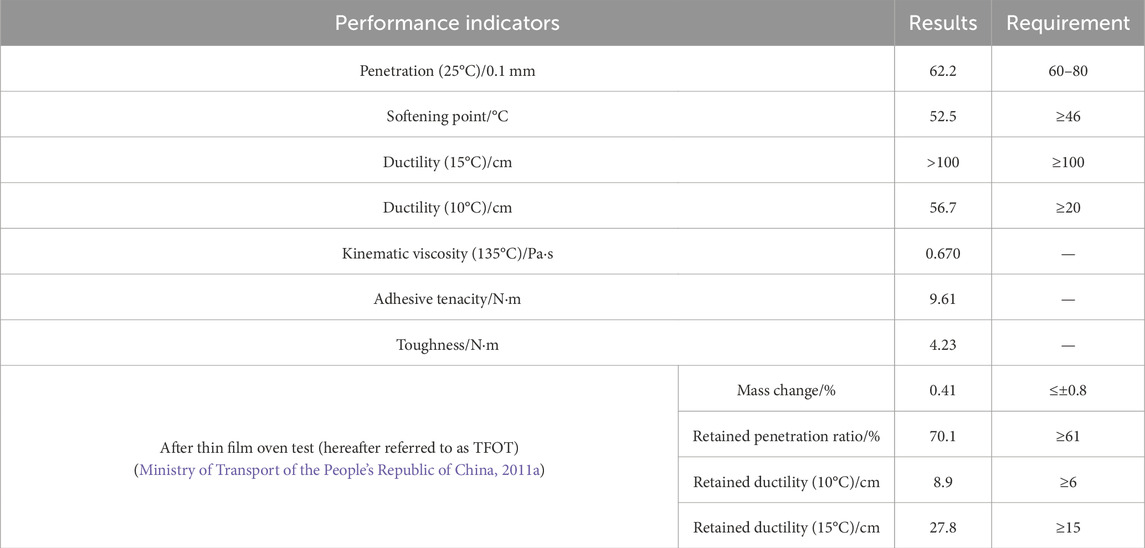

2.1.1 Asphalt

The asphalt used in this study is all Tipco Asphalt 70#. Prior to the experiment, the main performance indicators of the asphalt were tested according to the current “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” (JTG E20-2011) (Ministry of Transport of the People’s Republic of China, 2011a). The test results are shown in Table 1. From Table 1, it can be seen that the main performance indicators of the used 70# asphalt meet the regulatory requirements.

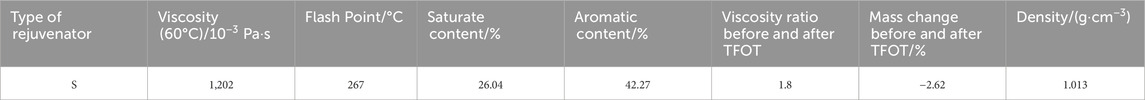

2.1.2 Rejuvenator

The rejuvenator used in this study is denoted as S. Rejuvenator S is selected based on its compatibility with Tipco Asphalt 70# and its widespread use in road rehabilitation projects (Wang et al., 2020). According to ASTM D4552, the main technical indicators of the rejuvenator were tested, as shown in Table 2.

2.2 Simulated aging test scheme

2.2.1 Simulated aging of asphalt

Considering the large amount of asphalt required for this recycling test and the high requirement for asphalt performance stability, it is unreasonable to obtain aged asphalt through extraction. This paper focuses on the study of the basic laws of multiple ageing and recycling. Therefore, the indoor simulated ageing method was adopted to prepare aged asphalt, which is more appropriate for the needs of this study because it is more convenient to operate and can ensure the stability of asphalt properties.

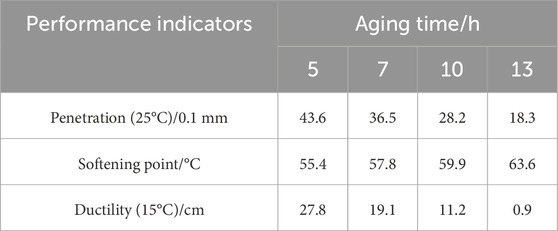

The study uses a Thin-Film Oven Test (TFOT) for indoor aging simulation. Based on the standard TFOT temperature of 163°C, aged asphalt would be obtained by extending the aging time. The test results are shown in Table 3.

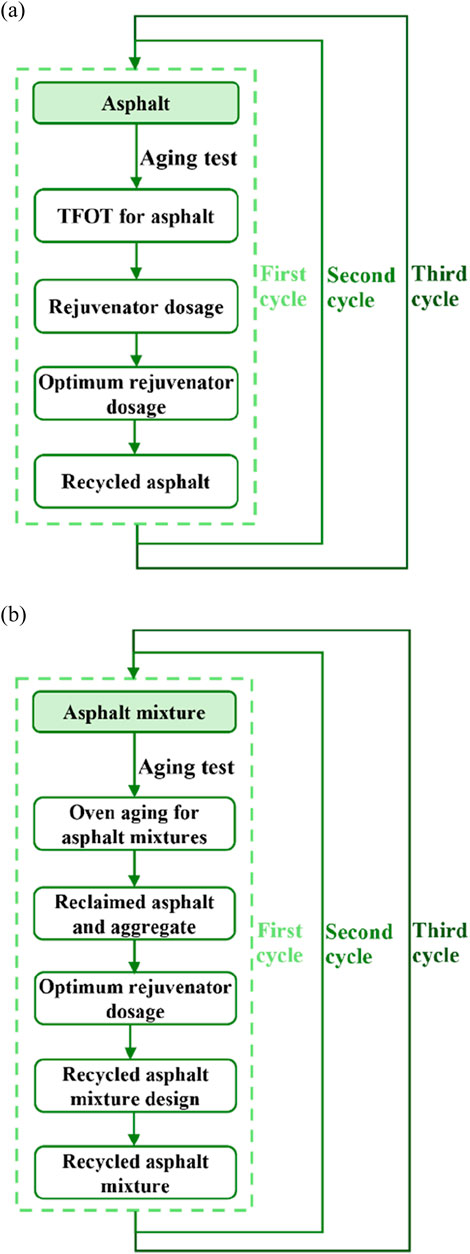

Through investigation of the technical indicators of recycled asphalt in China and in combination with the current “Technical Specifications for Highway Asphalt Pavement Recycling,” it is specified that when heat recycling technology is adopted, the penetration of the original pavement asphalt at 25°C should not be less than 20 (0.1 mm). Therefore, the present study intends to prepare aged asphalt indoors using the TFOT method at 163°C for 10 h. The flowchart of simulated aging and multiple recycling procedures for asphalt can be seen in Figure 1.

Figure 1. Flowchart of simulated aging and multiple recycling procedures for asphalt and asphalt mixtures. (a) Flowchart of simulated aging and multiple recycling procedures for asphalt. (b) Flowchart of simulated aging and multiple recycling procedures for asphalt mixture.

2.2.2 Simulated aging of asphalt mixtures

To analyze the performance changes of asphalt mixtures after multiple recycling, aged asphalt mixtures need to be prepared. The current “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” in China proposes a test method for the long-term aging of asphalt mixtures, which comprises uniformly spreading the mixed asphalt mixture in an enamel tray with an uncompacted layer density of approximately 21–22 kg/m2; placing the mixture in an oven at 135°C ± 3°C under forced ventilation for 4 h ± 5 min, and turning the mixture in the tray with a shovel once an hour; then removing the mixture from the oven and compacting it into a specimen, which is placed on a specimen rack and sent into an oven at 85°C ± 3°C under forced ventilation for continuous heating for 120 ± 0.5 h; then, turning off the oven, opening the oven door, so as to make the specimen cooled naturally to room temperature for no less than 16 h before being taken out. According to the SHRP program research and previous research (Pasetto et al., 2023), the performance of asphalt pavements after 5–7 years of use can be simulated through this method.

Combining a large number of technical conditions of recycled asphalt indicators, through repeated experiments, the proposed aging test method is as follows: uniformly spread the asphalt mixture in an enamel tray with an uncompacted layer density of approximately 21–22 kg/m2, then place the mixture in an oven at 160°C under forced ventilation for 9 h, turn the mixture in the tray with a shovel once an hour, and finally remove the mixture from the oven for the test.

2.2.3 Test scheme for multiple recycling of asphalt

In current engineering applications, most recycled asphalt projects do not exceed three recycling cycles due to concerns about the quality degradation of the recycled material. Therefore, the maximum three recycling cycles were considered.

① Asphalt is aged through the TFOT at 163°C for 10 h to prepare a sufficient number of asphalt specimens. Test the performance indicators of the aged asphalt from both macroscopic and microscopic perspectives. The macroscopic indicators include penetration, softening point, viscosity, adhesive tenacity, and toughness, while the microscopic indicators are the four components of asphalt.

② Add different amounts of rejuvenators to the aged asphalt for recycling, and then test the macroscopic and microscopic performance indicators of the asphalt under different rejuvenator dosages. The mixing temperature of the rejuvenator with the bitumen was 30 min, the mixing speed was 2,200 r/min, and the mixing equipment was an asphalt mixer for indoor testing.

③ Based on the recovery of asphalt performance under different rejuvenator dosages, determine an appropriate rejuvenator dosage to prepare recycled asphalt.

These three steps constitute one cycle, and subsequent tests only need to be repeated to complete the entire process of multiple aging and recycling test scheme. The test process involved in this study consists of three cycles, with the performance indicators of asphalt tested after each aging and recycling.

2.2.4 Test scheme for multiple recycling of asphalt mixtures

① Prepare the asphalt mixture and subject it to indoor aging at 160°C for 9 h according to the aforementioned aging test method to prepare once-aged asphalt mixtures.

② Use centrifugal separation method and Abson distillation method to recover asphalt from the aged mixtures, test the main performance indicators of the recovered asphalt, regenerate the aged asphalt with a rejuvenator, and then determine the appropriate rejuvenator dosage. The dry method of adding 50% RAP and rejuvenator was used in this study.

③ Selecting the aged mixtures preparing indoor for the mix design of recycled asphalt mixtures, using AC-13 as the mixture gradation type and setting the old aggregate content at 50% (mass fraction). Then, conduct performance tests on the recycled mixtures, including high-temperature stability, low-temperature anti-cracking performance, water stability, and dynamic adhesive tenacity. The road performance of asphalt mixture was tested according to “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” (JTG E20-2011) (Ministry of Transport of the People’s Republic of China, 2011a). At the same time, the performance of new aggregates is also tested in comparison with the recycled aggregates.

These three steps constitute one cycle, and subsequent tests only need to be repeated to complete the entire process of multiple aging and recycling test scheme. During the mixture proportioning test process, it is advisable to ensure consistent dosage of mineral aggregate gradation and asphalt content as much as possible. The test process involved in this study consists of three cycles, with the performance indicators of the mixtures tested after each recycling.

2.3 Mix design for multiple recycling asphalt mixtures

The Marshall design method is adopted for the mix design of asphalt mixtures. The new aggregate is divided into four fractions: 10–15, 5–10, 3–5, and 0–3 mm, where the 10–15 and 5–10 mm aggregate are basalt, and the 3–5 mm and 0–3 mm aggregate are limestone. The crushing value of the coarse aggregate is tested according to T 0316-2005 of the “Test Methods of Aggregate for Highway Engineering” (JTG E42-2005) (Ministry of Transport of the People’s Republic of China, 2011b) and the abrasion loss of the aggregate is assessed according to T 0317-2005, and the results are 14.3% and 13.5% respectively.

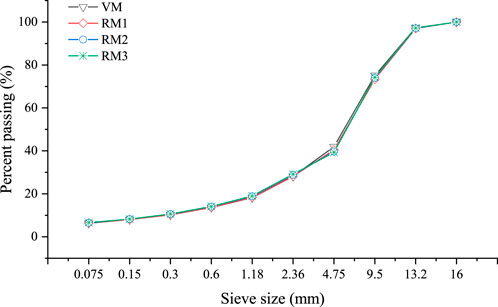

Asphalt Concrete with Nominal Maximum Aggregate Size of 13 mm (AC-13) was selected in this study. And the asphalt mixture was designed according to the Marshall test (Ministry of Transport of the People’s Republic of China, 2019). The gradations of each kind of multiple recycled asphalt mixture are shown in Figure 2. The optimum oil/stone ratio of the mix is 4.8% for virgin and first recycled asphalt mixtures and 4.7% for second and third recycled asphalt mixtures.

Figure 2. Gradation design for multiple recycling asphalt mixtures (Note: VM represents the asphalt mixture with virgin materials; RM1 denotes the first recycling asphalt mixture; RM2 denotes the second recycling asphalt mixture; RM3 denotes the third recycling asphalt mixture).

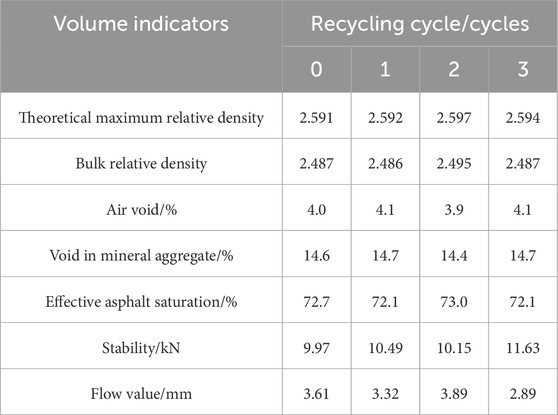

The Marshall volume indicators for multiple recycled asphalt mixtures are shown in Table 4. As shown in Table 4, after multiple recycling, the Marshall volume indicators of the asphalt mixtures, such as air void and asphalt saturation, are basically consistent. Compared to those of once-recycled and twice-recycled mixtures, the stability of the three-cycles-recycled mixtures increases, and the flow value decreases, indicating that the high-temperature performance of the three-cycles-recycled mixtures is enhanced, mainly due to the increased viscosity of asphalt after repeated aging.

3 Performance of multiple recycled asphalt

3.1 Macroscopic performance

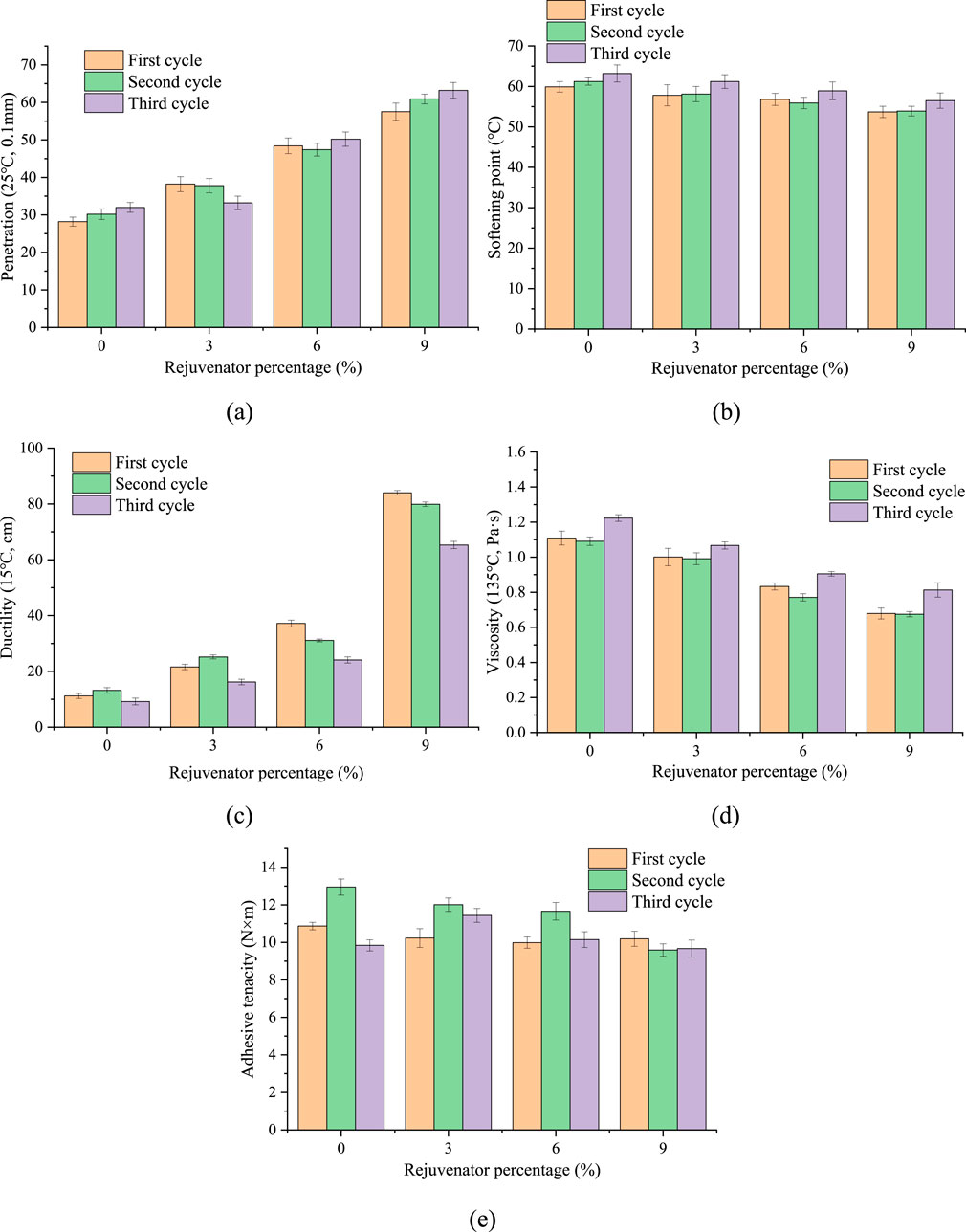

The mass ratios of rejuvenator added to the aged asphalt were 3%, 6% and 9% of the aged asphalt, respectively. Four parallel tests were conducted for each set of tests to ensure the reliability of the results. The recycled asphalt was tested for penetration, softening point, ductility, viscosity, and adhesive tenacity, and the results are shown in Figure 3.

Figure 3. Changes in properties of multiple aged asphalt with rejuvenator dosage. (a) Penetration (b) Softening point. (c) Ductility (d) Viscosity. (e) Adhesive tenacity.

As shown in Figure 3, with increasing aging cycles, the penetration of aged asphalt showed no significant change, while the softening point and viscosity increase, and ductility decrease, albeit with small magnitudes of change. After three aging cycles, adhesive tenacity decrease. That is, after multiple aging cycles, the deformation resistance of asphalt worsens. As the number of recycling cycles increases, there is no significant difference in asphalt penetration. The penetration level of asphalt after three recycling cycles is even higher than that after one recycling cycle, indicating that after multiple aging and recycling cycles, the viscosity of asphalt could recover to the level achieved after one recycling cycle. With increasing recycling cycles, the softening point of asphalt increase, but the magnitude of increase is small, suggesting that after multiple aging and recycling, the high-temperature performance of asphalt is partially improved, albeit not significantly. Comparing the recovery effect of rejuvenators on asphalt ductility, the best effect is observed after one recycling cycle. From the second recycling onwards, the ductility of recycled asphalt gradually decreases. After multiple aging and recycling cycles, the ductility of asphalt fails to reach the level achieved after one recycling, indicating a deterioration in the low-temperature ductility of asphalt. As the number of recycling cycles increases, the overall trend of asphalt viscosity gradually increase, suggesting that after multiple aging and recycling, asphalt becomes thicker and its rheological property worsens.

After multiple recycling, the adhesive tenacity of asphalt generally shows a decreasing trend. This indicates that after multiple aging and recycling, the adhesive tenacity of asphalt could not fully recover to the level achieved after the initial recycling, and its deformation resistance worsens. In summary, after long-term aging and recycling, asphalt properties could still be partially restored. With the same rejuvenator dosage, the softening point and viscosity increase, ductility and toughness decreases, and penetration shows no significant change. This indicates that after multiple recycling, the rheological property of asphalt worsens, high-temperature performance improves slightly, low-temperature performance deteriorates, and its adhesive tenacity could not fully recover to the level achieved after the initial recycling. Considering economic benefits and in order to facilitate the comparison and analysis of multiple recycled asphalt properties, experiments show that when the rejuvenator dosage is 6%, the test results for penetration, softening point, ductility, viscosity, and adhesive tenacity of asphalt after the first, second, and third recycling meet the regulatory requirements.

3.2 Microscopic performance

The asphalt’s four-component test was carried out in accordance with the test method (T0618-1993) in the standard “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” (JTG E20-2011) (Ministry of Transport of the People’s Republic of China, 2011a). The results of the four-component test for multiple recycled asphalt are shown in Figure 4.

Figure 4. Measured and calculated compositions of multiple recycled asphalt. (a) Measured and calculated compositions of asphalt after first recycling. (b) Measured and calculated compositions of asphalt after second recycling. (c) Measured and calculated compositions of asphalt after third recycling.

Assuming that the components of recycled asphalt are merely the sum of the components of the rejuvenator and the old asphalt, the composition can be calculated using the formula:

where Pa is the composition in aged asphalt (%); Pr is the composition in the rejuvenator (%); x is the rejuvenator dosage (%); and y is the composition in recycled asphalt (%).

Equation 1 can be used to calculate the composition of recycled asphalt. The curves of the compositions of the recycled asphalt, which are obtained through multiple calculations and measurements, as they vary with the rejuvenator dosage, are shown in Figure 4.

As shown in Figure 4, with the addition of rejuvenators, the aromatic content increases, the asphaltene and colloid contents decrease, and the saturate content remains basically unchanged, indicating that rejuvenators could recycle old asphalt by adjusting the compositions. The measured aromatic content is higher than the calculated value, while the measured asphaltene, colloid, and saturate contents are basically lower than the calculated values, and this difference increases with increasing rejuvenator dosage.

Research data shows that no chemical reaction occurs between rejuvenators and old asphalt. This indicates that the change in components of recycled asphalt is partly caused by the addition of rejuvenator components and partly due to the rejuvenator’s role in enhancing the compatibility of old asphalt, reducing the solubility parameter difference between asphaltenes and maltenes, and dispersing and dissolving asphaltene molecule groups encapsulated by colloids in old asphalt. Therefore, the change in components of recycled asphalt is not a simple sum of rejuvenator and old asphalt components but rather the result of the combined effects of compatibility and component adjustment.

For Equation 2, the assumption does not hold. The solubility of recycled asphalt is related to the rejuvenator dosage, suggesting the need to modify Equation 2 as follows:

where a and b are compatibility correction coefficients.

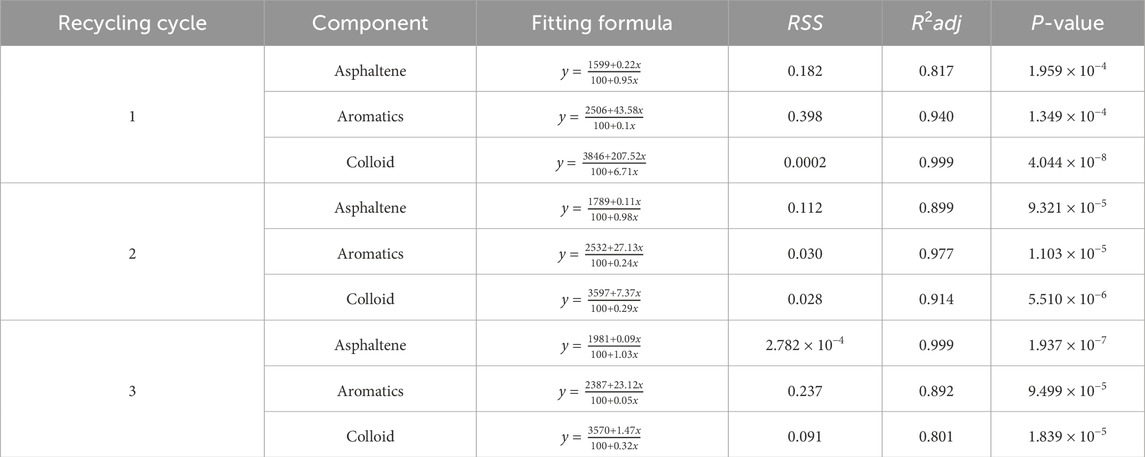

The fitting results for the composition of asphalt after one recycling and rejuvenator dosage are shown in Table 5. In the table, RSS represents the residual sum of squares, R2adj represents the adjusted coefficient of determination, and P is the probability value of the F statistic (using variance to test the significance of the nonlinear model). Since the saturate content remains basically stable, no fitting analysis is conducted for saturates.

As shown in Table 5, this model can well reflect the changes in composition of multiple recycled asphalt with varying rejuvenator dosage. Variance is used to test the significance of the model fitting. The probability P-values of the statistical quantities for each component are much smaller than the confidence level of 0.05, indicating that the curve fitting is statistically significant and the model is consistent with the changes in experimental data, i.e., the experimental data has a good correlation with the regression equation. This suggests that Equation 1 could also accurately reflect the relationship between rejuvenator dosage and composition of asphalt after three cycles of recycling and could be used to calculate the composition of asphalt after three cycles of recycling.

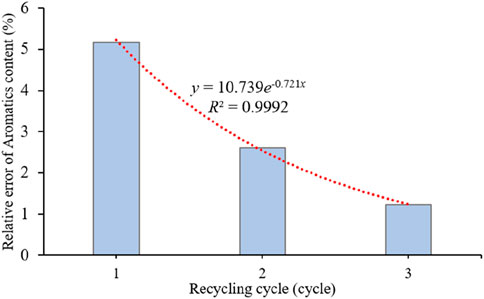

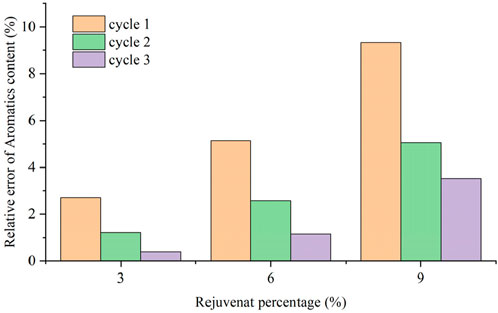

To analyze the differences in compatibility and component adjustment effects of recycled asphalt under multiple recycling conditions, the relative error between the measured and calculated values of the aromatic content of recycled asphalt is used as an evaluation index. The calculation results under different rejuvenator dosages are shown in Figure 5.

Figure 5. Changes in relative error of aromatic content of multiple recycled asphalt with rejuvenator dosage.

As shown in Figure 5, under the condition of multiple recycling, the relative error of the aromatic content of recycled asphalt increases with increasing rejuvenator dosage, indicating that the role of rejuvenators in enhancing the compatibility of old asphalt gradually intensifies, and the intensification rate of the compatibilization accelerates with increasing rejuvenator dosage. Furthermore, with different rejuvenator dosages, the relative errors of aromatic content follow the order: first recycling cycle > second recycling cycles > third recycling cycles, indicating that the compatibilization of rejuvenators is most significant in one-aging-cycle asphalt, and gradually weakens with increasing aging cycles.

To compare the compatibility between asphalt and rejuvenators under different recycling cycles, the rejuvenator dosage is set to 6%, and the relative errors of the aromatic content of recycled asphalt under different recycling cycles are shown in Figure 6.

As shown in Figure 6, the relative error between the measured and calculated values of aromatic content gradually decreases with increasing recycling cycles, indicating that the difference between the calculated and measured values of aromatic content in recycled asphalt becomes smaller, suggesting that the compatibilization of rejuvenators in old asphalt gradually weakens.

During the second recycling, the relative error of aromatic content decreases by 49.6% compared to the first recycling, indicating that the compatibilization significantly weakens after the second cycle of asphalt recycling. After nonlinear analysis, the relative error of aromatic content of recycled asphalt shows a good exponential relationship model with the number of recycling, indicating that the compatibilization of rejuvenators in old asphalt decreases exponentially with increasing recycling cycles. Specifically, the solubilization is strongest during the first recycling, significantly weakens during the second recycling with the largest magnitude of decrease, and gradually stabilizes with further increases in recycling cycles, while the component adjustment effect gradually dominates with increasing recycling cycles.

4 Performance evaluation of multiple recycled asphalt mixtures

Rejuvenators are added to the recycled asphalt at different mass ratios, and tests are conducted on the softening point, penetration, ductility, viscosity, and adhesive tenacity. When the rejuvenator dosage reached 8%, the asphalt penetration basically meets the requirement of a target penetration of 50 (0.1 mm). To compare the performance differences of recycled mixtures after different recycling cycles, it is advisable to maintain a consistent rejuvenator dosage as much as possible. Therefore, a rejuvenator dosage of 8% is proposed.

4.1 High-temperature performance

The high-temperature stability of asphalt pavements refers to the ability of asphalt mixtures to resist permanent deformation under the combined effects of high temperatures and loads. Multiple recycled asphalt mixtures and ordinary asphalt mixtures generally have similar external usage conditions, and their differences in high-temperature performance are mainly reflected in the properties of the mixtures themselves. However, it is difficult to determine the properties of the recycled mixtures composed of repeatedly aged and recycled asphalt mixed with rejuvenators of low viscosity, new asphalt, and new aggregate. To evaluate the high-temperature stability of multiple recycled asphalt mixtures, the present study employs wheel tracking test and uniaxial penetration strength test.

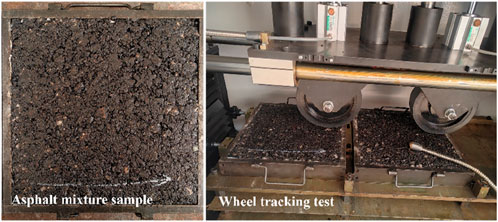

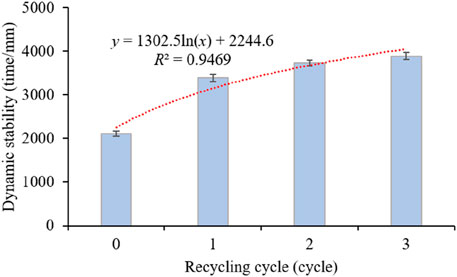

Using the mix design results from Section 2 for multiple recycled asphalt mixtures, calculate the aggregate dosages based on the Marshall specimen density at the optimum asphalt content. The wheel tracking test is performed according to the test procedures (T0719-2011) (Ministry of Transport of the People’s Republic of China, 2011a). The size of the asphalt mixture specimen was 300 mm long, 300 mm wide and 50 mm thick, which is shown in Figure 7. The test temperature was 60°C, the wheel pressure was 0.7 MPa, and the test time was 60 min. Dynamic stability values were obtained from rutting tests. And a comparison of the dynamic stability of recycled asphalt mixtures with that of the virgin asphalt mixtures is shown in Figure 8.

As shown in Figure 8, the dynamic stability of the recycled asphalt mixtures is significantly greater than that of the new aggregate. For example, the dynamic stability of the once-recycled mixture increases by 60.2% compared to the new aggregate, indicating a significant improvement in the high-temperature stability of the recycled mixtures. After multiple aging and recycling, the high-temperature performance of the recycled mixtures further improves, but the increase is smaller. For instance, the dynamic stability of the three-cycles-recycled mixture increases by only 14.8% compared to that of the once-recycled mixture.

Through nonlinear analysis, a good logarithmic relationship is observed between the dynamic stability of the recycled mixtures and the number of recycling cycles. Specifically, during the initial recycling, the dynamic stability of the recycled mixtures increases rapidly, and after repeated aging and recycling, the growth rate of dynamic stability slows down. This is mainly because the recycled mixtures contain old aggregates with asphalt that have undergone long-term aging, resulting in a significant increase in viscosity. Consequently, the high-temperature performance of the recycled mixtures is significantly better than that of the new aggregate. As the number of aging and recycling cycles increases, the growth rate of asphalt viscosity slows down, causing the high-temperature performance of the recycled mixtures to gradually stabilize.

4.2 Low-temperature performance

The Semi-Circular Bend (SCB) test, introduced from rock mechanics, is used to evaluate the cracking performance of asphalt mixtures. The SCB test applies a concentrated load to the mid-span of a simply supported semi-circular specimen of a specified size until the specimen fails. Compared to the beam bending test, the stress state of the SCB specimen is closer to that of the actual pavement structure, offering significant advantages.

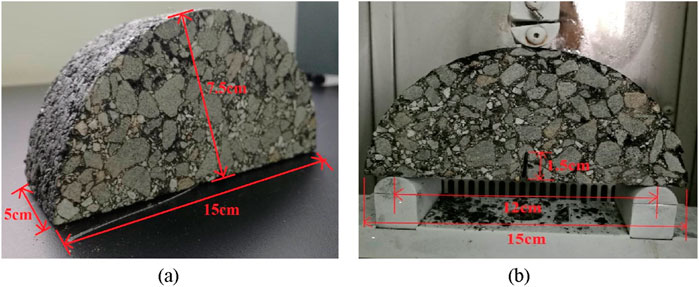

Use a gyratory compactor (SGC) to form SCB specimens, compact the asphalt mixture into cylindrical specimens with a diameter of 150 mm and a height of 105 mm, which are then cut into semi-circular specimens with a diameter of 150 mm and a thickness of 50 mm, with a void ratio controlled at 7% ± 0.5%. Make a pre-cut joint at the mid-span of the bottom of the semi-circular specimen to ensure that cracking of the mixture initiates from the pre-cut joint, with a joint depth of 15 mm, as shown in Figure 9. The test loading rate is 1 mm/min, and the test temperature is −10°C.

It may be difficult to distinguish the superiority of aggregates with different performances solely based on breaking strength or deformability. Studies have shown that it is reasonable to evaluate the anti-cracking performance of asphalt mixtures from an energy perspective by comprehensively considering both stress and deformation factors during asphalt mixture fracture. The larger the strain energy of the asphalt mixture, the greater the energy required for breaking, and thus the better its anti-cracking performance. Therefore, fracture energy (Gf) and tensile strength (R) are selected to evaluate the crack resistance of the recycled mixtures, as shown in Equations 3–5.

where, Gf is the fracture energy (J/m2); D is the specimen diameter (m), a is the joint depth (m); t is the specimen thickness (m); P is the test load (kN); u is the displacement under the load (mm).

4.2.1 Analysis of test results

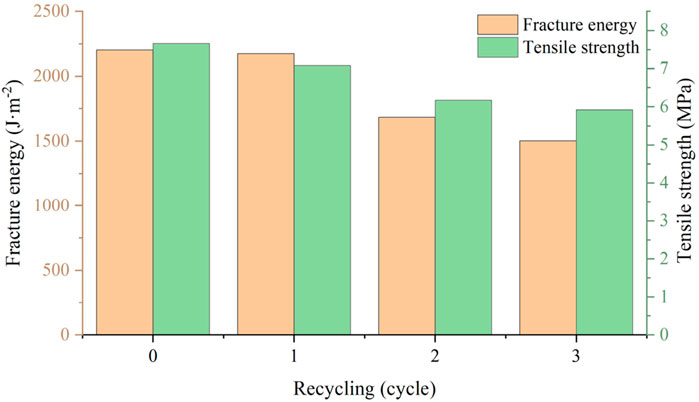

The calculated results for the fracture energy and tensile strength of the multiple recycled asphalt mixtures are presented in Figure 10.

As shown in Figure 10, the addition of old aggregates results in lower low-temperature fracture energy and tensile strength for the mixtures compared to those of the new aggregate, with reductions of 1.4% and 7.6% respectively for the once-recycled mixture. This indicates that old aggregates have a negative impact on the low-temperature performance of asphalt mixtures, but the difference in low-temperature performance between the once-recycled mixture and the new aggregate is relatively small.

After the mixtures undergo two cycles of aging and recycling, both the fracture energy and tensile strength continue to decrease, with a significant increase in the rate of reduction. For instance, the fracture energy and tensile strength of the twice-recycled mixture decreased by 23.6% and 19.5% respectively compared to the new aggregate, indicating that after two cycles of aging and recycling, the low-temperature performance of the mixtures deteriorates rapidly, and the possibility of low-temperature cracking in the pavement increases significantly.

4.2.2 Decay law of low-temperature anti-cracking performance of mixtures under multiple recycling conditions

Based on the previous analysis, after aging, the asphaltene content of asphalt increases, the aromatic content decreases, and the colloidal instability index of asphalt increases, resulting in asphalt with lower temperature sensitivity, i.e., high viscosity, low ductility, and poor low-temperature deformability.

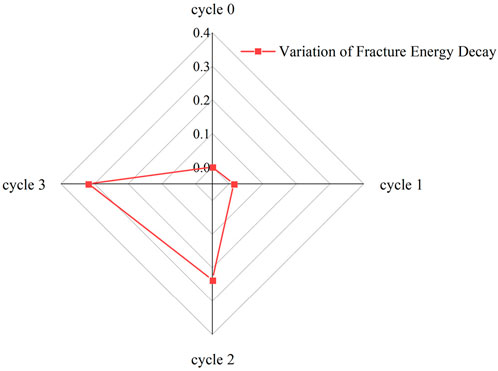

As asphalt continues to undergo multiple aging and recycling, its colloidal properties continue to decay accordingly, which in turn affects the mechanical properties of the mixtures. By studying the change in fracture energy of the mixtures after multiple recycling, the decay law of the low-temperature anti-cracking performance of the recycled mixtures under multiple recycling conditions can be investigated.

Therefore, the decay law of the low-temperature performance of the mixtures can be characterized by measuring the change in fracture energy of the specimens during multiple recycling, calculated using Equation 6.

where, G(n) is the splitting strength after n cycles of recycling; G0 is the fracture energy of the new asphalt mixture.

The variation of fracture energy decay of the recycled mixtures with the number of recycling is shown in Figure 11. As shown in Figure 10, the fracture energy decay of the recycled mixtures gradually increases with the number of recycling cycles. Based on the characteristics of the curve showing the variation of fracture energy decay with the number of recycling, the multiple recycling process of asphalt mixtures can be divided into three stages: (1) Stable decay stage, where the fracture energy of the once-recycled mixture differs slightly from that of the new aggregate; (2) Rapid decay stage, where the fracture energy decay of the twice-recycled mixture increases rapidly. At this point, due to repeated aging, the colloidal instability index of the asphalt increases, causing severe attenuation of the low-temperature deformability of the asphalt, which accelerates the decay of the low-temperature anti-cracking performance of the mixtures; (3) Decay development stage, where the fracture energy decay of the three-cycles-recycled mixture further increases. At this point, after three aging and recycling, the colloidal structure of the asphalt becomes even more unstable, causing further decay of the aggregate properties. Through analysis, it can be concluded that after multiple recycling, the blending ratio of old aggregates should be strictly controlled, or the dosage of rejuvenators or new asphalt should be appropriately increased.

4.3 Water stability performance

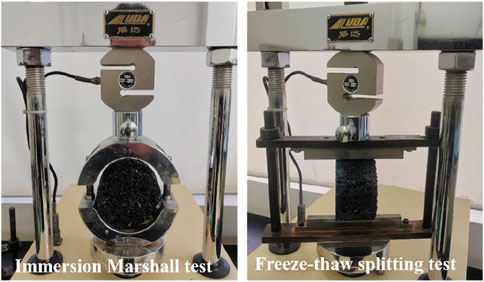

The water stability of asphalt mixtures refers to their ability to resist gradual damage such as asphalt film stripping, particle loss, loosening, and pothole formation due to water erosion (Ma et al., 2022; La Macchia et al., 2024). Water damage is one of the primary issues affecting asphalt pavements. Existing surveys indicate that, with properly designed mixtures, water damage on pavements is associated with inhomogeneity in asphalt mixtures. Recycled asphalt mixtures, containing old aggregate with uneven gradation, are more prone to uneven mixing; the dust on the surface of recycled old aggregate may also impair their adhesion with new aggregate. Additionally, recycled asphalt mixtures contain aged asphalt, which may further diminish their resistance to water damage. Furthermore, asphalt mixtures undergo multiple aging and recycling cycles, resulting in decreased ductility, increased viscosity, and harder, thicker asphalt upon repeated recycling. These changes adversely affect the water stability of multiple recycled asphalt mixtures. Therefore, evaluating the water stability of recycled asphalt mixtures is particularly crucial. This study evaluates the water stability of multiple recycled asphalt mixtures using the immersion Marshall test and freeze-thaw splitting test, which is shown in Figure 12. The tests are carried out according to the “T 0709-2011” and “T 0279-2000” protocols in the specification “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” (JTG E20-2011) (Ministry of Transport of the People’s Republic of China, 2011a).

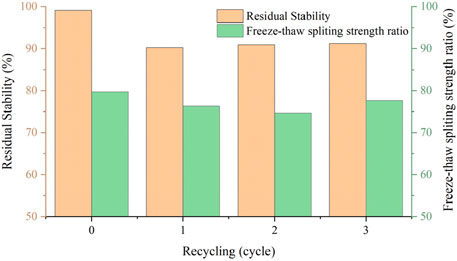

The results of the immersion Marshall test and freeze-thaw splitting test for multiple recycled asphalt mixtures are presented in Figure 13. As can be seen from Figure 13, the addition of old aggregates increases the stability and splitting strength of the mixtures but decreases the retained stability and freeze-thaw splitting strength ratio. Compared to new aggregate, the once-time recycled mixture exhibits a decrease in retained stability and freeze-thaw splitting strength ratio by 8.9% and 4.3%, respectively, but still meets the specifications with a retained stability of no less than 80% and a freeze-thaw splitting strength ratio of no less than 75%. As the number of recycling cycles increases, the stability and splitting strength continue to increase, primarily due to the repeated aging of asphalt, which leads to increased asphalt viscosity. The retained stability and freeze-thaw splitting strength ratio do not exhibit a clear trend with increasing recycling cycles, remaining roughly constant. Compared to new aggregate, the three-cycles recycled mixture shows a decrease in retained stability and freeze-thaw splitting strength ratio by 8.0% and 2.6%, respectively. The retained stability still significantly meets the requirement of no less than 80%, and the freeze-thaw splitting strength ratio meets the requirement of no less than 75%. This indicates that after multiple recycling, the water stability of the recycled mixtures remains roughly equivalent to that after once recycling, suggesting that the water stability of the mixtures is less affected by the recycling cycles.

5 Conclusion

Based on the research on the macro-performance and micro-performance of multiple recycled asphalt, as well as the performance of multiple recycled asphalt mixtures, the main conclusions drawn are as follows:

(1) After multiple aging processes, the base asphalt exhibits significant reductions in penetration and ductility, accompanied by increases in softening point and viscosity. The improvement rates of softening point and viscosity are 30% and 43%, respectively.

(2) Asphalt undergoes deteriorated rheological property after multiple recycling cycles, with enhanced high-temperature performance but notably degraded low-temperature performance.

(3) A nonlinear relationship model between the component content of multiple recycled asphalt and the rejuvenator dosage has been established. Under conditions of multiple recycling, the solubilization of the rejuvenator in aged asphalt intensifies with increasing dosage, yet it decreases exponentially with an increase in the number of recycling cycles. Specifically, the solubilization is strongest during the first recycling, followed by a shift where component adjustment becomes dominant.

(4) After multiple recycling cycles, the Marshall volume indicators of asphalt mixtures can still meet the regulatory requirements. The high-temperature stability increases logarithmically. The low-temperature anti-cracking performance deteriorates rapidly after two recycling cycles, while the water stability shows relatively low sensitivity to the number of recycling cycles.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation. Requests to access these datasets should be directed to c2Qud2FuZ0ByaW9oLmNu.

Author contributions

XY: Formal Analysis, Funding acquisition, Methodology, Resources, Writing – original draft, Writing – review and editing. SW: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Software, Writing – original draft, Writing – review and editing. JW: Conceptualization, Funding acquisition, Investigation, Project administration, Supervision, Validation, Writing – original draft, Writing – review and editing. QC: Data curation, Formal Analysis, Investigation, Methodology, Software, Writing – original draft. DL: Data curation, Formal Analysis, Investigation, Methodology, Validation, Writing – original draft, Writing – review and editing. LW: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Validation, Visualization, Writing – original draft, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. Beijing-Hong Kong-Macao Expressway Hubei Jing E-Yu Border to Junshan Section Reconstruction and Expansion Project Scientific Research Project JGAKY-6 (0223KF06SC1401-03).

Conflict of interest

Authors XY and QC were employed by Hubei Traffic Investment Beijing Hong Kong Macao Expressway Reconstruction and Expansion Project Management Co., Ltd.

Author DL was employed by Beijing Xinqiao Technology Development Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abe, A. A., Rossi, C. O., Eskandarsefat, S., Porto, M., Loise, V., Venturini, L., et al. (2023). Reclaimed asphalt recycling agents: looking into the blueprint of their mechanisms of action. Constr. Build. Mater. 363, 129843. doi:10.1016/j.conbuildmat.2022.129843

AbuQtaish, L., Nazzal, M. D., Kaya, S., Kim, S., Abbas, A., and Abu Hassan, Y. (2018). Afm-based approach to study blending between Rap and virgin asphalt binders. J. Mater. Civ. Eng. 30 (3). doi:10.1061/(ASCE)MT.1943-5533.0002182

Al-Saffar, Z. H., Yaacob, H., Mohd Satar, M. K. I., Putra Jaya, R., Ismael, C. R., Mohamed, A., et al. (2022). Physical, rheological and chemical features of recycled asphalt embraced with a hybrid rejuvenating agent. Int. J. Pavement Eng. 23 (9), 3036–3054. doi:10.1080/10298436.2021.1878517

Baqersad, M., and Ali, H. (2019). Rheological and chemical characteristics of asphalt binders recycled using different recycling agents. Constr. Build. Mater. 228, 116738. doi:10.1016/j.conbuildmat.2019.116738

Cannone Falchetto, A., Montepara, A., Tebaldi, G., and Marasteanu, M. O. (2013). Microstructural characterization of asphalt mixtures containing recycled asphalt materials. J. Mater. Civ. Eng. 25 (1), 45–53. doi:10.1061/(ASCE)MT.1943-5533.0000544

Erdem, S., and Blankson, M. A. (2014). Environmental performance and mechanical analysis of Concrete containing recycled asphalt pavement (Rap) and waste precast Concrete as aggregate. J. Hazard. Mater. 264, 403–410. doi:10.1016/j.jhazmat.2013.11.040

Fan, X., Qiao, Y., Zhang, J., Xiong, Y., Cao, W., Yang, K., et al. (2024). Towards the high Rap dosage obtained by refined processing influence on comprehensive performance of recycled asphalt mixture. Constr. Build. Mater. 452, 138885. doi:10.1016/j.conbuildmat.2024.138885

Gulzar, S., Fried, A., Preciado, J., Castorena, C., Underwood, S., Habbouche, J., et al. (2023). Towards sustainable roads: a state-of-the-art review on the use of recycling agents in recycled asphalt mixtures. J. Clean. Prod. 406, 136994. doi:10.1016/j.jclepro.2023.136994

Guo, M., Motamed, A., Tan, Y., and Bhasin, A. (2016). Investigating the interaction between asphalt binder and fresh and simulated Rap aggregate. Mater. Des. 105, 25–33. doi:10.1016/j.matdes.2016.04.102

Han, H. S., Golestani, B., Park, K., Cho, B., and Nam, B. H. (2024). Utilization of multiple recycled materials in asphalt Concrete: mechanical characterization and cost-benefit analysis. Mater. (Basel) 17 (19), 4742. doi:10.3390/ma17194742

Hou, R., Huang, X., and Li, H. (2007). Influence of recycling technology on hot-recycled asphalt mixture's low temperature anti-cracking performance. J. Highw. Transp. Res. Dev. 24 (3), 30–34. doi:10.1061/jhtrcq.0000190

Huang, X., Zhao, Y., and Jiang, C. (2001). Test and analysis of recycled mixture for old asphalt pavement. Chin. J. Geotechnical Eng. 23 (4), 468–471. doi:10.3321/j.issn:1000-4548.2001.04.018

Ji, X., Zheng, N., Yang, D., and Hou, Y. (2010). Study on mixing temperature of hot recycled asphalt mixtures based on composite viscosity-temperature curve. China J. Highw. Transp. 23 (05), 16–21. doi:10.19721/j.cnki.1001-7372.2010.05.003

La Macchia, J. N., Baglieri, O., Dalmazzo, D., and Santagata, E. (2024). Engineering properties of road paving mixtures with high content of reclaimed asphalt and recycled waste plastics. Materials 17 (23), 5681. doi:10.3390/ma17235681

Ma, X., Wang, J., and Xu, Y. (2022). Investigation on the effects of Rap proportions on the pavement performance of recycled asphalt mixtures. Front. Mater. 8. doi:10.3389/fmats.2021.842809

Miao, Y., Wang, S., Guo, L., Zheng, X., Huang, Y., and Wang, L. (2018). Effect of temperature on deformation properties of unbound granular materials containing fine Rap. Constr. Build. Mater. 169, 443–451. doi:10.1016/j.conbuildmat.2018.02.154

Ministry of Transport of the People's Republic of China (2011a). JTG E20-2011 standard test methods of bitumen and bituminous mixtures for highway engineering. Beijing: China Communication Press.

Ministry of Transport of the People's Republic of China (2011b). JTG E42-2005 test methods of aggregate for highway engineering. Beijing: China Communication Press.

Ministry of Transport of the People's Republic of China (2019). JTG/T 5521-2019 technical specification for highway asphalt pavement recycling. Beijing: China Communication Press.

Pasetto, M., Baliello, A., Giacomello, G., and Pasquini, E. (2023). Laboratory evaluation of the effectiveness of rejuvenation in multiple hot recycling of asphalt mixtures. J. Test. Eval. 51 (4), 2075–2087. doi:10.1520/JTE20220278

Qi, W., Li, L., and Huang, Y. (2014). Study on the evaluation of regenerant diffusion in aged bitumen and its influencing factors. J. Build. Mater. 17 (6), 1020–1024. doi:10.3969/j.issn.1007-9629.2014.06.014

Rashid, F., Hossain, Z., and Bhasin, A. (2019). Nanomechanistic properties of reclaimed asphalt pavement modified asphalt binders using an atomic force microscope. Int. J. Pavement Eng. 20 (3), 357–365. doi:10.1080/10298436.2017.1293268

Shi, Q., Liu, C., Xue, Y., Xue, Y., Zhang, C., Lu, W., et al. (2024). The early performance development of hot in-place recycled asphalt mixture. Coatings (Basel) 14 (2), 175. doi:10.3390/coatings14020175

Si, W., Zhang, B., Zhang, X., Xia, W., Cheng, X., Luo, X., et al. (2024). Maximizing the circularity of asphalt pavements by improving the Rap content in recycled asphalt mixtures. Constr. Build. Mater. 438, 137316. doi:10.1016/j.conbuildmat.2024.137316

Solaimanian, M., and Chen, X. (2021). Investigating degree of blending between reclaimed asphalt pavement and virgin binder using atomic force microscopy and focused ion beam. Transp. Res. Rec. J. Transp. Res. Board 2675 (11), 554–564. doi:10.1177/03611981211018465

Valentová, T., Kotoušová, A., Simnofske, D., Valentin, J., and Mollenhauer, K. (2016). “Properties of asphalt mixtures with multiple recycled asphalt material,” in Fourth Geo-China International Conference. doi:10.1061/9780784480052.001

Villegas, L., Marín, N., Idrogo, C., Suclupe, R., López, A., and Arriola, G. (2024). Use of foamed asphalt and foamed bitumen for recycled asphalt mixtures: a review. Civ. Eng. Archit. 12 (2), 1104–1123. doi:10.13189/cea.2024.120232

Wang, J., Dong, Z., and Zhang, J. (2024). Advances in the research of interfacial properties of reclaimed asphalt mixture: a comprehensive review. J. Clean. Prod. 481, 144154. doi:10.1016/j.jclepro.2024.144154

Wang, J., Qin, Y., Xu, J., Zeng, W., Zhang, Y., Wang, W., et al. (2020). Crack resistance investigation of mixtures with reclaimed SBS modified asphalt pavement using the SCB and DSCT tests. Constr. Build. Mater. 265, 120365. doi:10.1016/j.conbuildmat.2020.120365

Wang, J., Zeng, W., Qin, Y., Huang, S., and Xu, J. (2017). Laboratory evaluation of rejuvenating agent on reclaimed sbs modified asphalt pavement. Appl. Sci. 7 (7), 743. doi:10.3390/app7070743

Wang, J., Zeng, W., Qin, Y., Zhang, Y., Huang, S., and Xu, J. (2019). Properties of mixtures with high percentages of reclaimed Sbs–modified asphalt pavement. J. Mater. Civ. Eng. 31 (1). doi:10.1061/(ASCE)MT.1943-5533.0002532

Wang, Y., Dou, G., Wang, S., and Wang, J. (2024). The effect of refined separation on the properties of reclaimed asphalt pavement materials. Build. (Basel) 14 (6), 1608. doi:10.3390/buildings14061608

Wu, H., Zhan, Y., Song, W., Xu, S., Chen, X., and Liao, H. (2024). Prediction modelling on dynamic modulus of recycled asphalt mixtures based on meso-mechanical analysis. J. Clean. Prod. 469, 143200. doi:10.1016/j.jclepro.2024.143200

Yiqiu, T., Li, Z., Zhang, X., and ZeJiao, D. (2010). Research on high- and low-temperature properties of asphalt-mineral filler mastic. J. Mater. Civ. Eng. 22 (8), 811–819. doi:10.1061/(ASCE)MT.1943-5533.0000015

Zhao, X., Wang, S., Wang, Q., and Yao, H. (2016). Rheological and structural evolution of Sbs modified asphalts under natural Weathering. Fuel Guildf. 184, 242–247. doi:10.1016/j.fuel.2016.07.018

Zou, G., Qin, H., Yan, R., and Sun, J. (2019). Effect evaluation of multiple recycled SBS modified asphalt based on viscoelastic properties. J. South China Univ. Technol. Sci. Ed. 47 (7), 75–82. doi:10.12141/j.issn.1000-565X.180525

Keywords: recycled asphalt, microscopic performance, multiple recycling, reclaimed asphalt pavement mixture, low-temperature performance, water stability

Citation: Yu X, Wang S, Wang J, Cai Q, Li D and Wang L (2025) Research on performance evaluation of multiple recycling asphalt and multiple recycling asphalt mixtures. Front. Mater. 12:1588683. doi: 10.3389/fmats.2025.1588683

Received: 06 March 2025; Accepted: 22 April 2025;

Published: 08 May 2025.

Edited by:

Hui Yao, Beijing University of Technology, ChinaReviewed by:

Silvino Capitão, Instituto Politécnico de Coimbra, PortugalKang Zhao, Liaoning University of Technology, China

Kunpeng Zheng, Hong Kong Polytechnic University, Hong Kong SAR, China

Marco Bruno, University of Bologna, Italy

Copyright © 2025 Yu, Wang, Wang, Cai, Li and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Sudi Wang, c2Qud2FuZ0ByaW9oLmNu; Jie Wang, ai53YW5nQHJpb2guY24=

Xin Yu1

Xin Yu1 Sudi Wang

Sudi Wang