- 1Beijing Water Construction Management Center, Beijing, China

- 2Key Laboratory of Urban Underground Engineering of the Education Ministry, Beijing Jiaotong University, Beijing, China

- 3School of Civil Engineering, Beijing Jiaotong University, Beijing, China

- 4Qingdao Guoxin Development (Group) Co., Ltd., Qingdao, China

- 5CCCC Tunnel Engineering Co. Ltd., Beijing, China

- 6Qingdao Guoxin Second Jiaozhou Bay Subsea Tunnel Co., Ltd., Qingdao, China

During slurry shield tunneling in submarine geological conditions, it is of significance to prepare an appropriate slurry to maintain excellent rheological properties and penetration characteristics. To investigate the effects of seawater intrusion and high-temperature-induced deterioration on the physical properties of different bentonite slurries, four typical commercial sodium bentonites of different origins were selected as raw materials in this study, and mineral composition characterization tests were carried out on the four sodium bentonites, respectively. Additionally, a comprehensive analysis was performed to evaluate the physical properties of the four bentonite slurries, including rheological tests, penetration tests, and microstructure observations. The results indicated that both increased seawater content and elevated temperature had remarkable effects on the rheological properties of the slurries, while the rheological and permeability properties of all four slurries deteriorated to varying degrees. The microstructure and morphology of the slurries mainly appeared as thin sheets with voids between them, and discrete particle accumulation was observed locally. The conclusions presented in this paper could offer guidance for future preparation of slurries used in slurry shield tunneling.

1 Introduction

Recently, a large number of underground projects have been in full swing around the world (Huang et al., 2022; Guo et al., 2025a; Wei et al., 2025; Guo et al., 2023a; Jin et al., 2023). Slurry shield tunneling is a large-scale tunnel boring machine (Guo et al., 2023b; Guo et al., 2023c), which is widely used in tunnel construction (Jin et al., 2022; Jin et al., 2018; Guo et al., 2025b; Geng et al., 2023) due to its high efficiency and safety, especially in the construction of undersea tunnels (Huang et al., 2021; Min et al., 2015; Naghadehi et al., 2019; Guo et al., 2023d). During slurry shield advancement in submarine geological conditions, slurry inevitably encounters seawater due to the presence of seawater in the groundwater of seabed strata (Mao et al., 2020; Min et al., 2019), leading to significant deterioration in the physical properties of the slurry under seawater intrusion (Caenn and Chillingar, 1996; Wan et al., 2011; Collette et al., 1994). Additionally, the friction between the excavation face of the rotating cutterhead and the soils generates significant heat during shield advancement (Haiqing and Bolong, 2019; Wang et al., 2019; Yang et al., 2021), causing changes in the properties of slurries within the excavation chamber under high-temperature conditions. Hence, it is crucial for submarine slurry shield advancement to prepare a suitable bentonite slurry that maintains favorable rheological properties and penetration characteristics (Shao et al., 2023).

The seawater slurry used in slurry shield tunneling mainly consists of two components: raw materials such as bentonite and seawater. Undoubtedly, the raw material significantly affects the physical properties of the seawater slurry. However, bentonite from different production areas or manufacturers varies widely due to differences in geological origins, calcining processes, and additives, resulting in diverse rheological properties of the bentonite slurry. Essentially, the main reason for this phenomenon is the variation in the mineral composition of bentonite. Research on the effect of variations in mineral composition on the physical properties of slurry under seawater intrusion and high temperature has rarely been conducted.

To date, many researchers have conducted rheological tests (Fu et al., 2020; Wu et al., 2015; Yang et al., 2020), penetration tests (Cui et al., 2019; Min et al., 2013; Xu and Bezuijen, 2019), and SEM tests (Wang Q. et al., 2022; Wang et al., 2022b) to evaluate the physical properties of slurry. Wang et al. (2022c) indicated that the addition of polyanionic celluloses (PAC) can remarkably enhance the viscosity of seawater slurry. Wang M. et al. (2021) analyzed the effects of temperature and hydration time on the rheological properties of cement slurry; their results indicated that increasing hydration time increased the shear stress of the slurry, and they established a constitutive equation considering the influences of temperature and hydration time. Min et al. (2018) performed slurry fluid property tests and found that the test slurry exhibited characteristics of the Bingham model at medium to high shear rates, while conforming to the Herschel-Bulkley (H-B) model at low shear rates. Qin et al. (2023) conducted a series of penetration column experiments on two saturated sands of different grain sizes and found that low-permeability filter cake could form on fine sand regardless of the salt content of the seawater slurry. Cui et al. (2020) proposed a novel salt-resistant slurry using xanthan gum as an additive to bentonite slurry for undersea shield tunneling.

In addition, with advances in computational technology, several numerical approaches have been extensively applied to investigate the physical properties of slurry (Yin et al., 2021; Ihmoudah et al., 2023; Zhang and Yin, 2018). Wang et al. (2023) developed an optimized simulation approach for bentonite suspensions by combining the Herschel-Bulkley-Papanastasiou (H-B-P) constitutive model with the finite volume method; the proposed approach could accurately describe the shear-thinning behavior of slurry with no divergence during simulations. Lin et al. (2022) employed a numerical model of penetration column experiments, and their simulations revealed the evolution process of clogging. Zhang et al. (2019) investigated slurry infiltration and filter cake formation through computational fluid dynamics-discrete element method (CFD-DEM) modeling and proposed a model for pressure variation within the filter cake.

As mentioned above, existing research has not focused on the effects of seawater and high temperature on the physical properties of different bentonite slurries. In this study, the deterioration of rheology, permeability, and microstructure of different bentonite slurries induced by seawater intrusion and high temperature was investigated. Four typical commercial sodium bentonites of different origins were selected as raw materials, and mineral composition characterization tests were performed on the four sodium bentonites, respectively. Furthermore, a comprehensive analysis was conducted to evaluate the physical properties of the four bentonite slurries, including rheological tests, penetration tests, and microstructure observations. The conclusions presented in this paper could offer guidance for the preparation of slurry used in submarine slurry shield tunneling.

2 Characterization of the bentonite materials

2.1 Raw materials

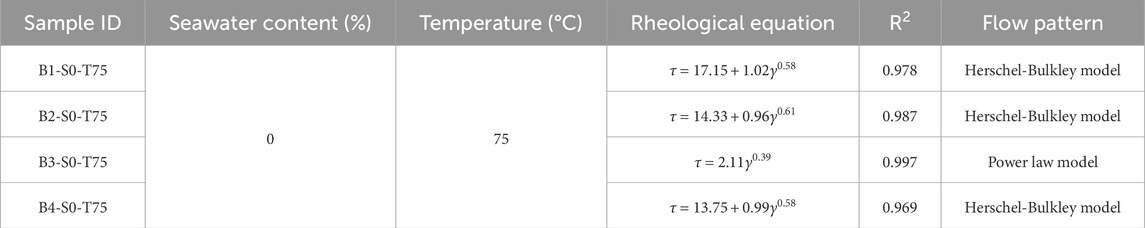

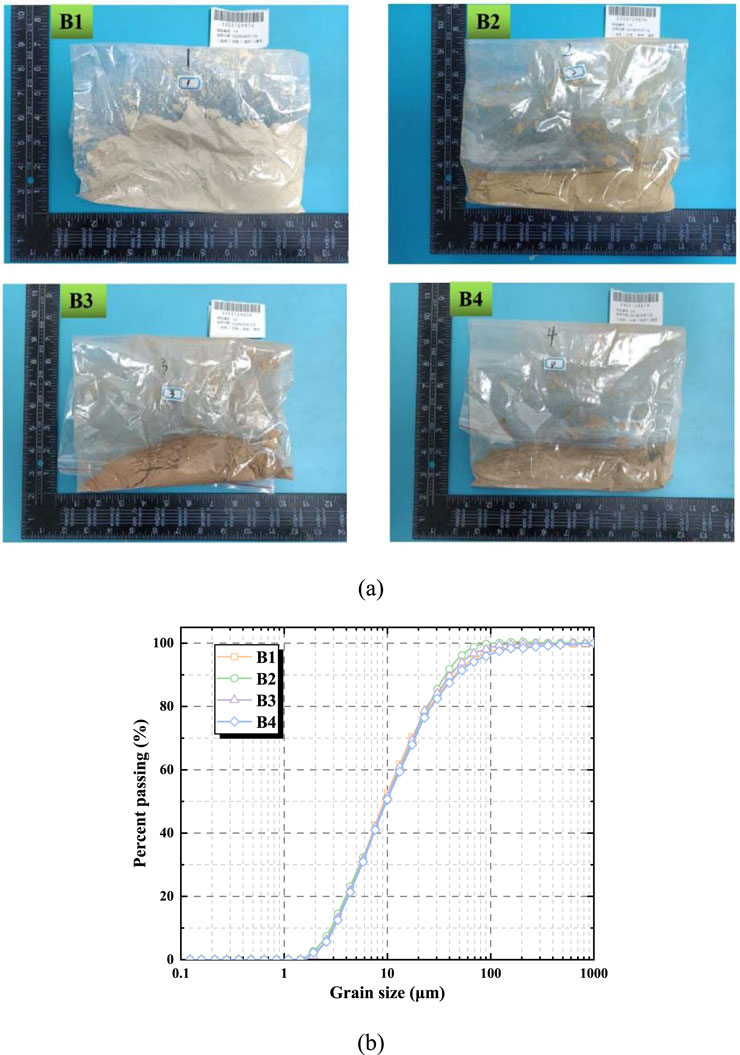

In this paper, four typical commercial sodium bentonites of different origins, identified as B1, B2, B3 and B4 were selected as the raw materials. As depicted in Figure 1a, the four bentonites are in powder form, but there are big differences in color, B1 is light white, B2 is light gray, B3 is brown, and B4 is light brown. The size distributions of four bentonite are described in Figure 1b.

Figure 1. (a) four commercial sodium bentonites of different origins; (b) grain size distributions of four bentonite.

2.2 Characterization tests

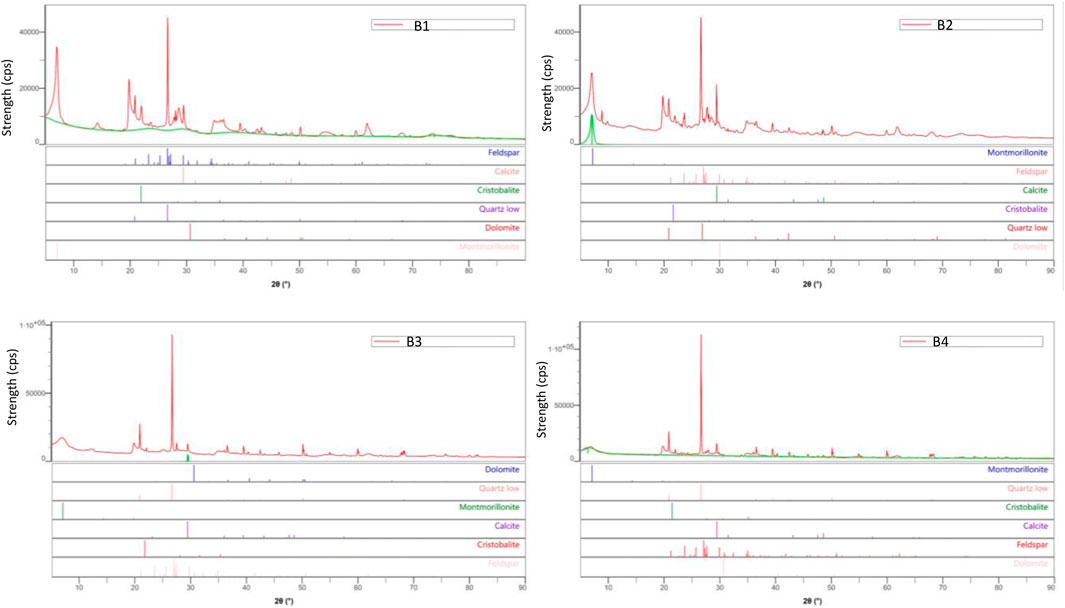

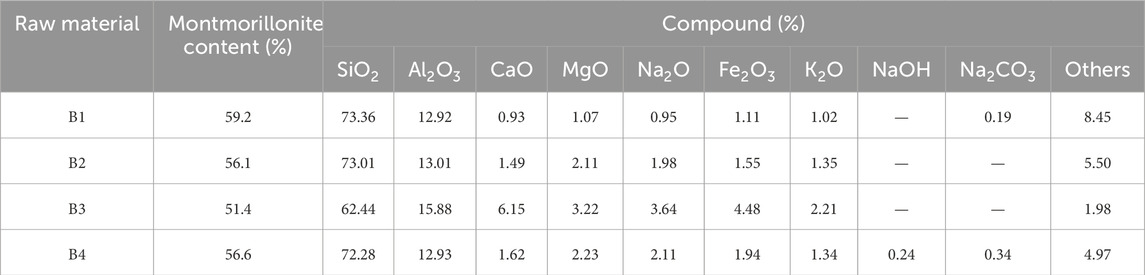

A series of mineral composition characterization tests were carried out on four typical sodium bentonites. Figure 2 shows the results of XRD tests, and the detailed test results are presented in Table 1.

3 Experimental apparatus and testing method

3.1 Rheological test

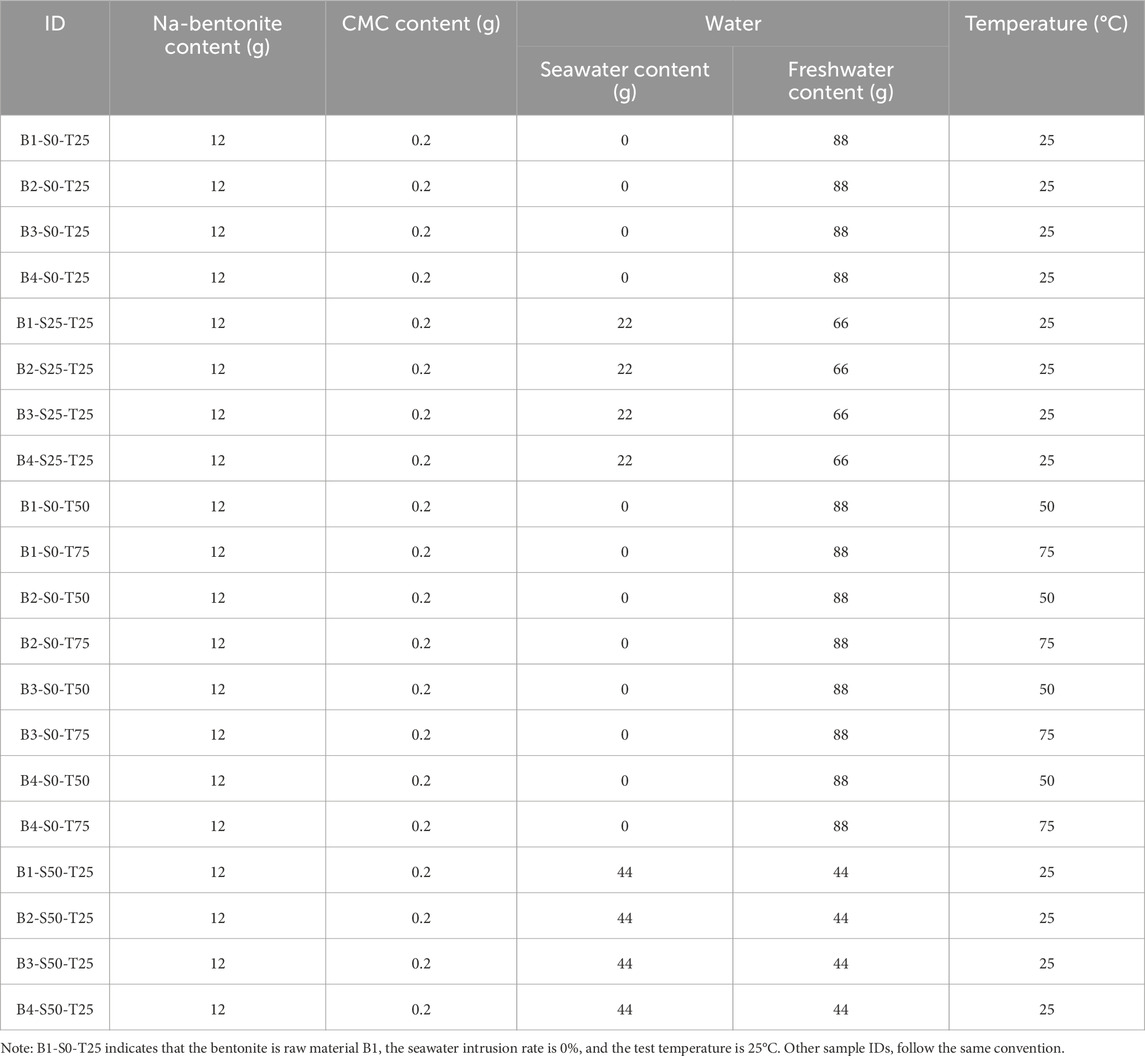

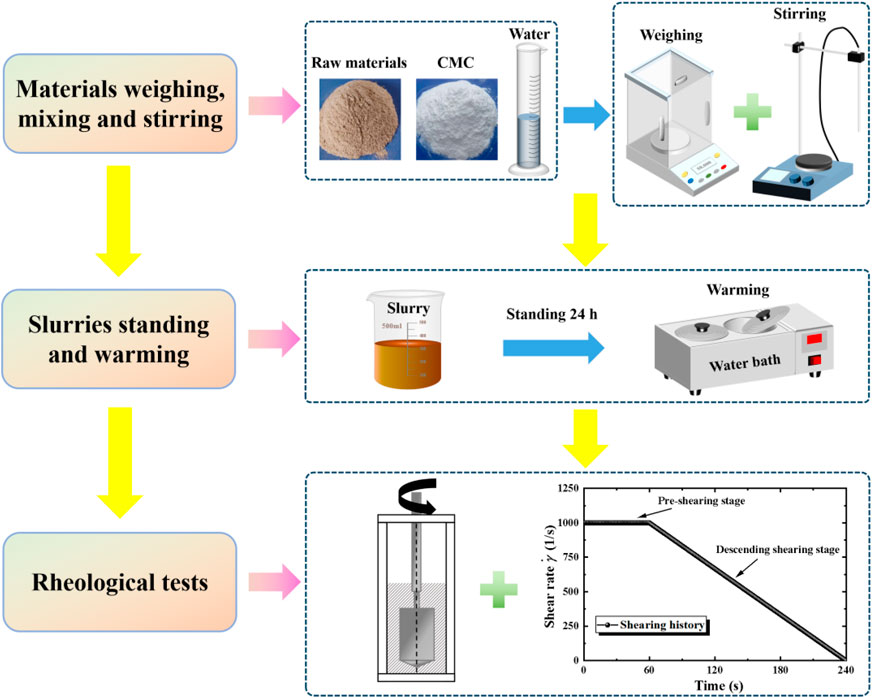

To investigate the rheological properties of slurry under different seawater intrusion rates and high temperatures, a series of rheological tests were conducted in this study. The slurries used in these tests were prepared using Na-bentonite (described in Section 2.1), water (freshwater and seawater), and additives (Carboxymethyl Cellulose, CMC). Deionized water was used as freshwater, and seawater was prepared in the laboratory according to the ASTM D1141 standard (ASTM D1141, 2003). The content of each compound can be found in the study by Guo et al. (2024).

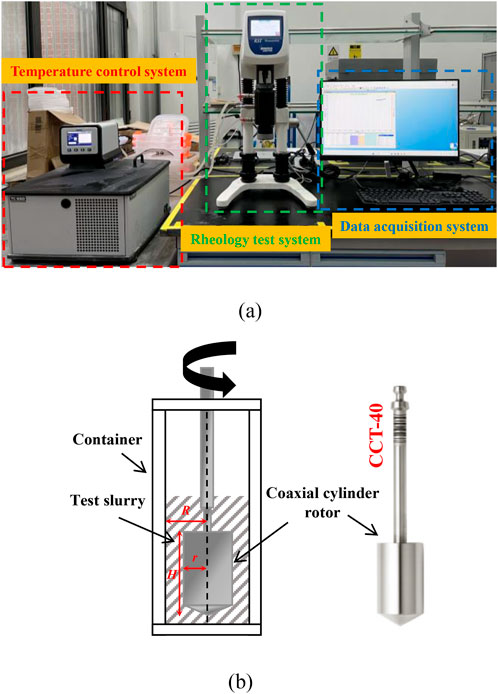

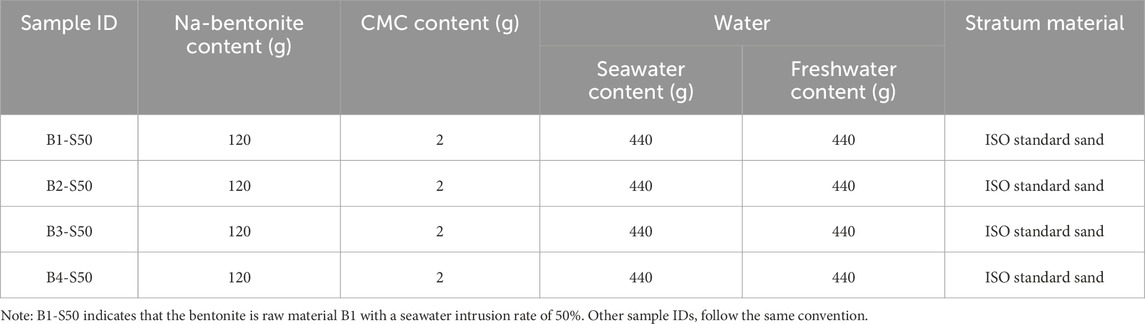

In this paper, the mass ratio of CMC, bentonite, and water was 1:60:400 (Wang T. et al., 2021). Three seawater-to-water ratios (0%, 25%, and 50%) were designated to simulate different seawater intrusion severities, and three constant test temperatures (25°C, 50°C, and 75°C) were selected. The detailed cases of the rheological tests are listed in Table 2.

As shown in Figure 3, an RST-CC Rotational Rheometer was used to measure the rheology of the slurry. During the experiments, the rheometer’s control system regulated the rotor rotation rate. A CCT-40 coaxial cylinder measuring system (height H = 60 mm, outer diameter R = 23 mm, inner diameter r = 20 mm) was employed for rheological measurements. The data acquisition system recorded shear stress changes in real time. Additionally, the temperature control system maintained a stable environment (−20°C–200°C) during each test. Figure 4 illustrates the rheological test schematic, and further details can be found in Guo et al. (Guo et al., 2024). To prevent particle settling, the slurry was homogenized using a mixer at 200 rpm for 1 min prior to testing.

3.2 Penetration test

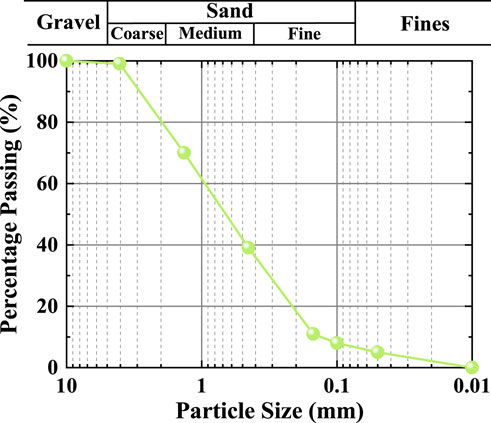

To investigate the effect of bentonite mineral composition on the penetration behavior of slurry under seawater intrusion, a series of penetration tests were conducted in this study. The slurries used in the penetration tests were prepared following the same method described for the rheological tests. ISO standard sand from China was selected as the stratum material for each penetration test. The grain size distribution is shown in Figure 5, and the detailed cases of the penetration tests are listed in Table 3.

Figure 5. Grain size distributions of the ISO standard sand (Jin et al., 2023).

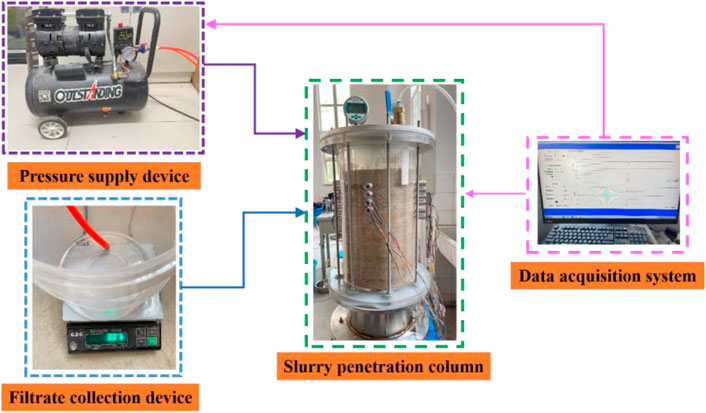

As shown in Figure 6, the penetration test apparatus primarily comprises a slurry penetration column, data acquisition system, filtrate collection device, and pressure supply system. The apparatus enables real-time monitoring of slurry filtration loss. At the end of the test, the slurry penetration distance and filter cake formation can also be observed. The slurry penetration column consists of an acrylic plexiglass cylinder with an inner diameter of 20 cm and a height of 42 cm. To ensure proper sealing, a combination of rubber gaskets and water stoppers was installed between the metal cover plate and the column, secured by eight screws. A barometer (range: 0.6 MPa, accuracy: 1 kPa) mounted on the column monitored internal gas pressure stability. The pressure supply system provided a maximum stable gas pressure of 0.8 MPa. The filtrate collection device included a water collection bucket and an electronic scale (accuracy: 0.1 g) to record filtrate mass in real time. The data acquisition system regulated penetration pressure and logged filtrate mass changes. The specific operating steps of penetration tests are as below:

(a) To ensure complete hydration of the slurry, the slurry must be prepared 24 h prior to the penetration tests, and the detailed preparation process is described in Section 3.1.

(b) Before the penetration test, the test apparatus was connected and assembled, and the air-tightness of the penetration column and the accuracy of the data acquisition system were checked, respectively.

(c) The bottom of the penetration column was filled with a 5 cm high gravel to avoid soil particle loss during the test.

(d) The stratum material was filled in portions (3 cm per filling, until 25 cm filled), and vibrated to be densely packed. When each stratum material was filled, the inlet pipe was connected with the water source to saturate it slowly. Lastly, the stratum was allowed to stand for 24 h to be fully saturated.

(e) When the stratum was fully saturated, the slurry was gently introduced. Next, the air compressor was opened to inject the air to the experiments until the required pressure reached (the slurry penetration pressure was 100 kPa). Noted that the pressure of slurry chamber (the environment for slurry penetratio) is about 50 kPa–300 kPa. Accordingly, the slurry penetration pressure was set to 100 kPa according to the actual slurry pressure.

(f) The drainage valve at the lower part of the penetration column was opened, the penetration time was set to 10 min, which was is based on the experience in the study of Jin et al. (Jin et al., 2024) because the slurry can fully infiltrate to a steady state at this duration, and the change of filtrate quality was recorded every 0.5 s via the data acquisition system during the process of the slurry penetration.

3.3 Microstructure observation tests

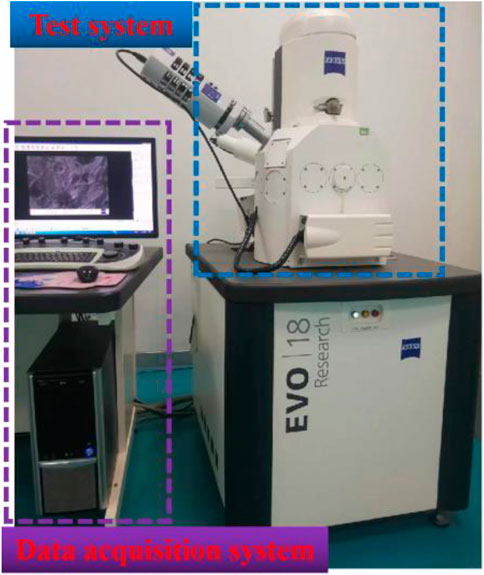

The microstructure of four seawater slurries (50% seawater content) was analyzed using SEM (Figure 7). Prior to testing, samples were dried at 100°C for 24 h and cut into 5 mm × 5 mm × 3 mm pieces.

4 Results and analysis

4.1 Rheological results and analysis

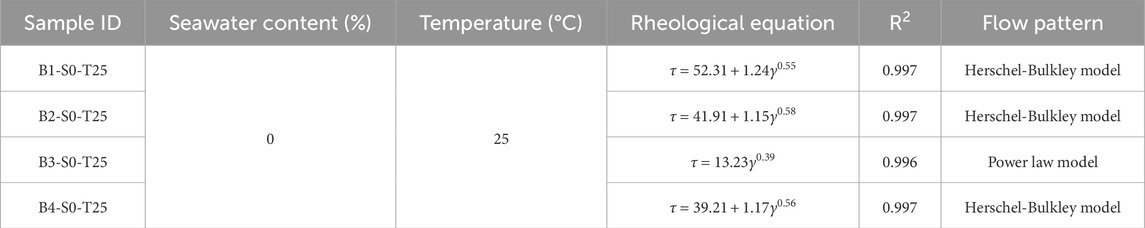

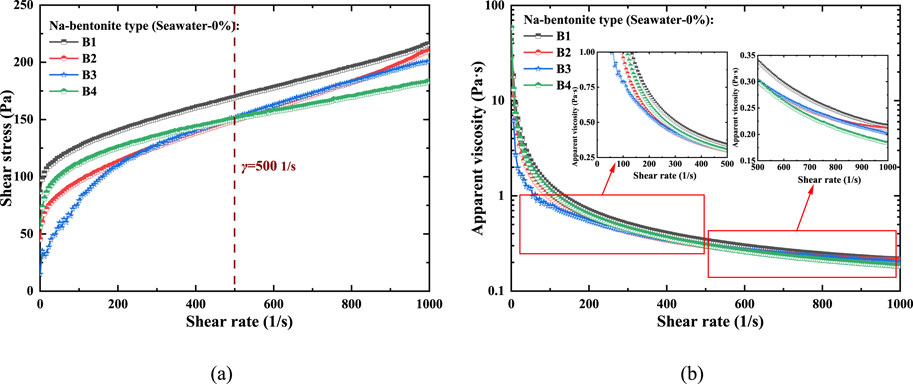

Figure 8 shows the rheological results of four freshwater slurries at a seawater content of 0% and a temperature of 25°C. As described in Figures 8a,b, for freshwater slurries (seawater content of 0%), the B1 slurry exhibits the highest shear stress and apparent viscosity at any given shear rate, and its non-Newtonian behavior is the most pronounced compared to the other slurry types. Additionally, at low shear rates (shear rates below 500 s−1), the shear stress and apparent viscosity of the B4 slurry are slightly higher than those of the B2 and B3 slurries. At high shear rates (shear rates above 500 s−1), the shear stress and apparent viscosity of the B2 slurry are approximately the same as those of the B3 slurry, and both are higher than those of the B4 slurry. All four freshwater slurries exhibit pseudoplastic flow characteristics and shear-thinning behavior; i.e., the viscosity decreases with increasing shear rate. Additionally, it is noted that the yield stress of the B3 slurry is the lowest compared to the other slurries. However, the yield stress of a slurry can represent its viscous strength and is an important parameter to describeits characteristics. Normally, it is appropriate for bentonite slurry used in slurry shield machines to have a certain yield stress. To further investigate the rheological properties of four freshwater slurries, the rheological test results were fitted using different rheological models. Table 4 presents the rheological equations of the four freshwater slurries. As indicated in Table 4, the rheological behaviors of the B1, B2, and B4 slurries are well characterized by the Herschel-Bulkley model, with regression coefficients all being high (0.997). The yield stresses of the B1, B2, and B4 slurries are 52.31 Pa, 41.91 Pa, and 39.21 Pa, respectively, and the B1 slurry exhibits optimal rheological properties. In addition, the B3 slurry is well characterized by the Power-law model due to its negligible yield stress (approximately 0 Pa).

Figure 8. Rheological curves of different slurries (seawater content of 0%): (a) shear stress, (b) apparent viscosity.

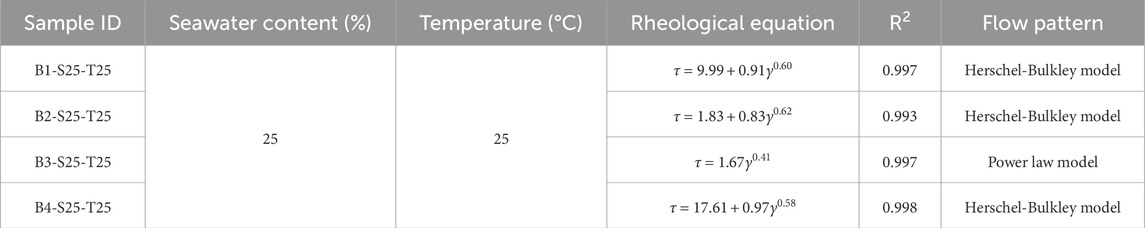

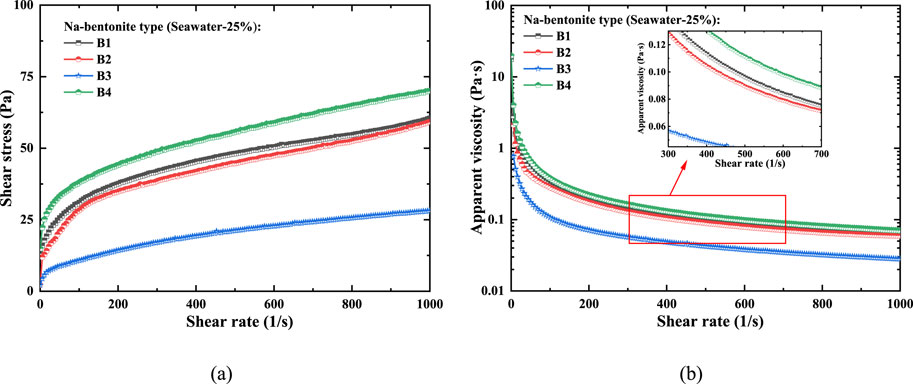

Figure 9 illustrates the rheological results of four seawater slurries at a seawater content of 25% and a temperature of 25°C. As plotted in Figures 9a,b, the shear stress and apparent viscosity of each seawater slurry (25% seawater content) are lower compared to those of the corresponding freshwater slurries at the same shear rate. All four slurries exhibit significant deterioration in rheological properties due to seawater intrusion; however, the B1, B2, and B4 slurries still maintain relatively excellent viscoplastic behavior and conform to the flow pattern of the H-B model, as described in Table 5. Additionally, the B4 slurry shows the least deterioration in rheological properties compared to the other three slurries. In contrast, the rheological properties of the B3 slurry deteriorate the most.

Figure 9. Rheological curves of different slurries (seawater content of 25%): (a) shear stress, (b) apparent viscosity.

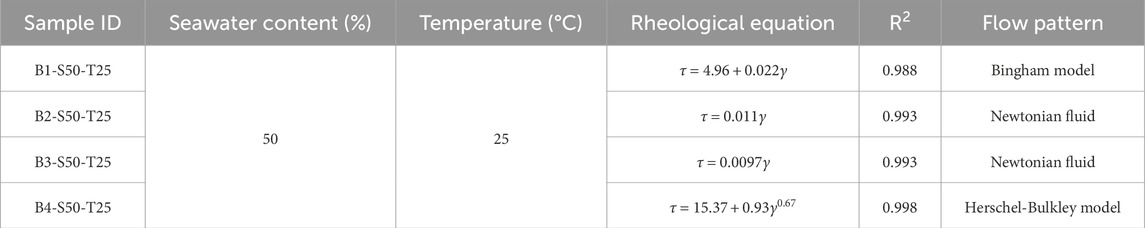

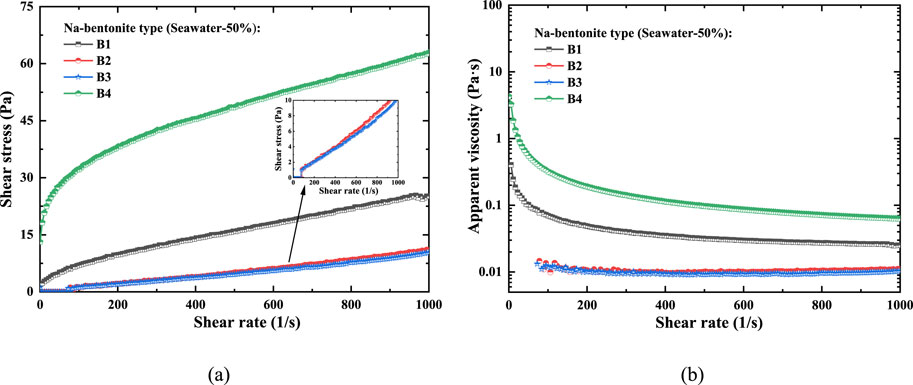

Figure 10 demonstrates the rheological results of four seawater slurries at a seawater content of 50% and a temperature of 25°C. Table 6 presents the rheological equations of the four slurries at a seawater content of 50% and a temperature of 25°C. As shown in Figures 10a,b and Table 6, the B4 slurry maintains relatively excellent viscoplastic behavior and conforms to the flow pattern of the H-B model under a high seawater intrusion rate (50% seawater content), with its rheological properties deteriorating the least compared to the other three slurries. Additionally, the B1 slurry loses its pseudoplastic flow characteristics and transforms into a Bingham fluid with a lower yield stress under a high seawater intrusion rate. In contrast, the rheological properties of the B2 and B3 slurries are severely deteriorated under a high seawater intrusion rate, losing non-Newtonian behavior and approaching the flow characteristics of Newtonian fluids. Accordingly, the B4 bentonite exhibits superior resistance to deterioration and salt corrosion under seawater intrusion, followed by the B1 bentonite. The B2 and B3 bentonites, however, show poor resistance to seawater intrusion, nearly behaving as Newtonian fluids at high seawater intrusion rates.

Figure 10. Rheological curves of different slurries (seawater content of 50%): (a) shear stress, (b) apparent viscosity.

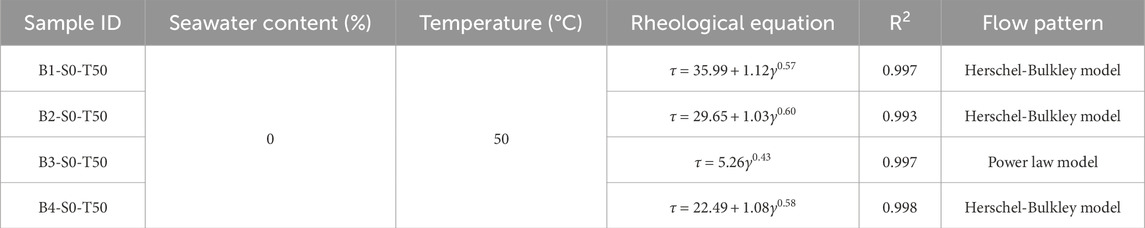

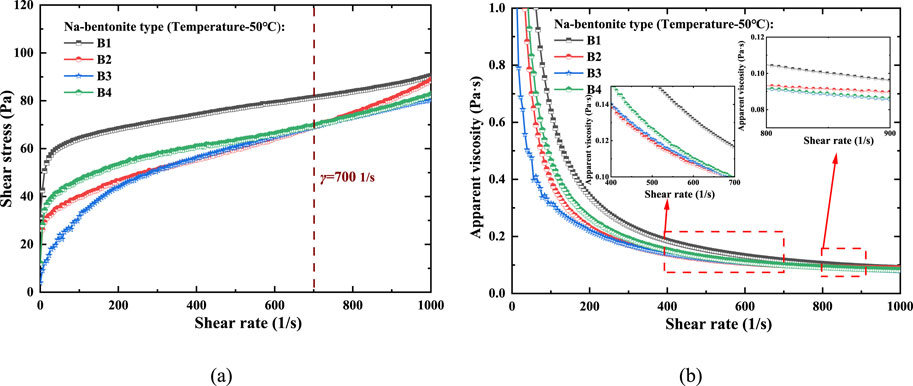

Figure 11 illustrates the rheological results of four freshwater slurries at a high temperature of 50°C. As shown in Figures 11a,b, the shear stress and apparent viscosity of each freshwater slurry are lower compared to those of the corresponding freshwater slurries at room temperature (25°C) under the same shear rate, and all four slurries exhibit deterioration in their rheological properties under high temperature. This demonstrates the high-temperature thinning effect of bentonite slurry. However, the B1, B2, and B4 slurries still maintain relatively excellent viscoplastic behavior and conform to the flow pattern of the H-B model, as described in Table 7. Additionally, the B1 slurry exhibits the highest shear stress at any given shear rate, and its non-Newtonian behavior is the most pronounced compared to the other slurry types. Furthermore, at low shear rates (below 700 s−1), the shear stress of the B4 slurry is slightly higher than those of the B2 and B3 slurries. At high shear rates (above 700 s−1), the shear stress of the B2 slurry is slightly higher than those of the B3 and B4 slurries. Notably, similar to the B3 freshwater slurry at room temperature, the B3 slurry under high temperature (50°C) still conforms to the flow characteristics of the Power-law model.

Figure 11. Rheological curves of different freshwater slurries at a high temperature of 50°C: (a) shear stress, (b) apparent viscosity.

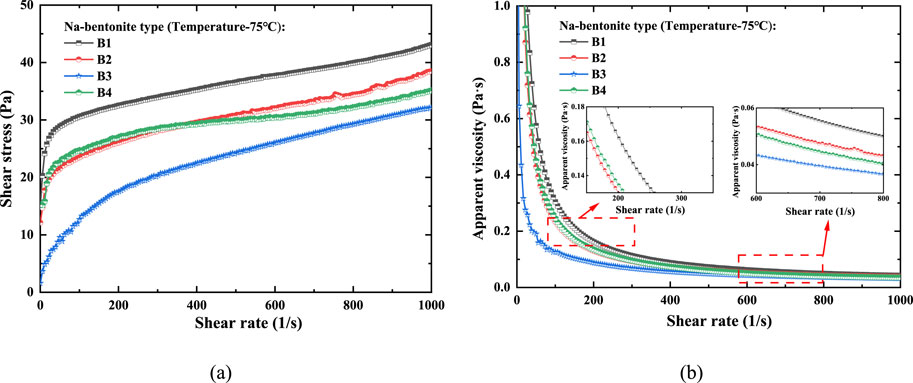

Figure 12 illustrates the rheological results of four freshwater slurries at a high temperature of 75°C. As shown in Figures 12a,b, all four slurries exhibit further deterioration in rheological properties at 75°C compared to those at 50°C. Similar to the 50°C condition, the B1, B2, and B4 slurries conform to the flow pattern of the H-B model, while the B3 slurry follows the Power-law model, as described in Table 8. Furthermore, all four freshwater slurries retain pseudoplastic flow characteristics even at 75°C.

Figure 12. Rheological curves of different freshwater slurries at a high temperature of 75°C: (a) shear stress, (b) apparent viscosity.

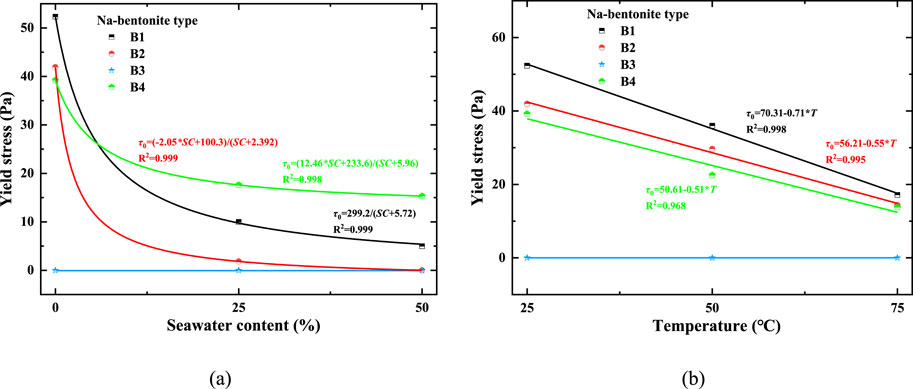

Based on the above analysis of the rheological test results, both seawater content and high temperature significantly affect the rheological properties of the slurries. Figures 13a,b illustrate the relationships between yield stress and seawater content/temperature for slurries made from the four bentonite types, respectively. As shown in Figure 13a, the yield stresses of the B1, B2, and B4 slurries follow an inversely proportional relationship with seawater content, decreasing as seawater content increases. The yield stress of the B4 slurry remains the highest under high seawater intrusion, followed by that of the B1 slurry. As shown in Figure 13b, the yield stresses of the B1, B2, and B4 slurries exhibit a linear relationship with temperature, decreasing linearly as temperature increases. The yield stress of the B1 slurry remains the highest under high temperature, followed by those of the B2 and B4 slurries. Furthermore, since the B3 slurry conforms to the flow patterns of the Power-law model or Newtonian fluids under all conditions, its yield stress is approximately 0 Pa.

Figure 13. (a) Variation of yield stress of slurries with different seawater contents; (b) Variation of yield stress of slurries with different temperature.

4.2 Permeability results and analysis

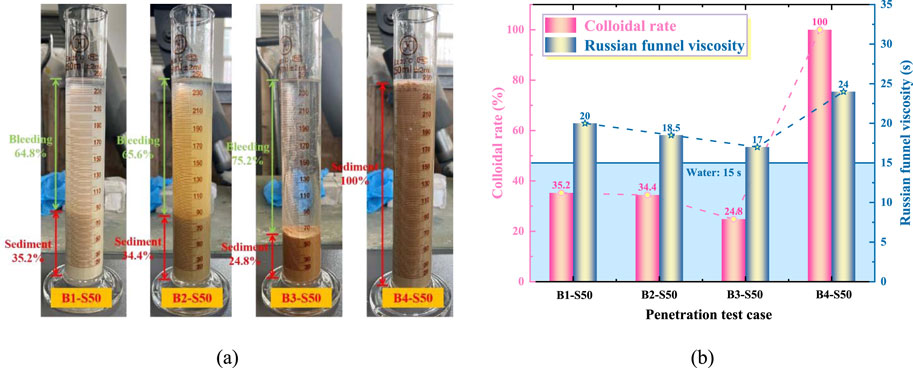

To further investigate the water retention ability and physical stability of the four seawater slurries under their own weight, bleeding tests and Russian funnel viscosity tests were conducted on the slurries used in penetration tests. Figure 14a shows the percentages of bleeding and sediment for each seawater slurry after 24 h, while Figure 14b illustrates the colloidal rate and Russian funnel viscosity for each slurry after 1 day. As clearly seen in Figures 14a,b, the colloidal rate of the B4 slurry is 100% after 1 day, indicating no bleeding phenomenon and excellent water retention and stability. The colloidal rates of the B1 and B2 slurries are 35.2% and 34.4%, respectively, after 24 h. Furthermore, severe segregation occurs in the B3 slurry: its colloidal rate is 24.8% after 24 h, and its Russian funnel viscosity is nearly equivalent to that of water at room temperature.

Figure 14. (a) The bleeding test results after standing 1 d; (b) the colloidal rate and Russian funnel viscosity after standing 1 d.

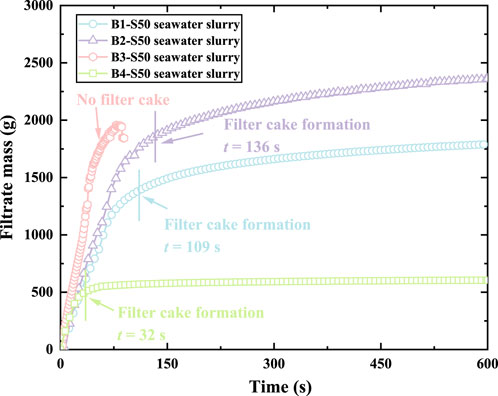

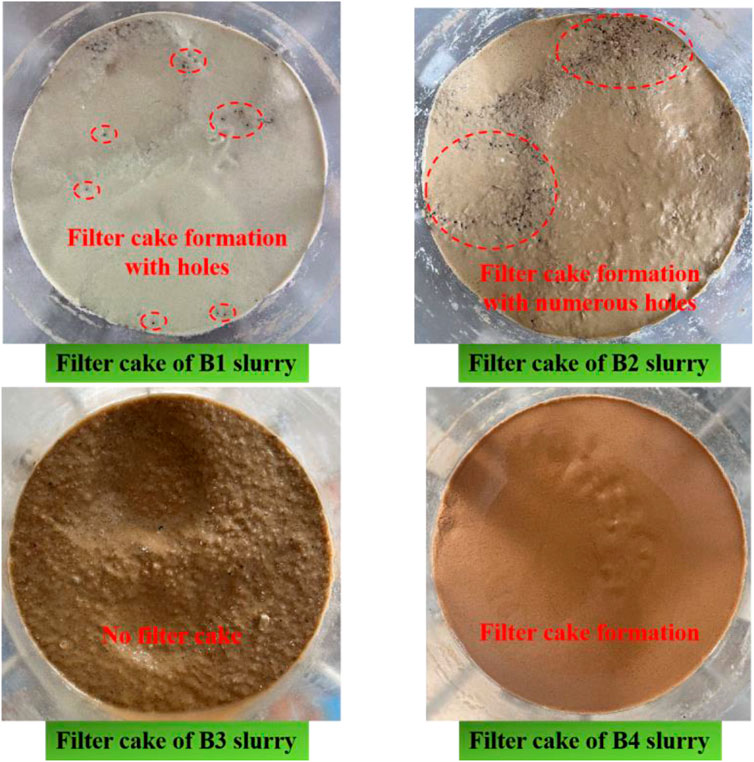

Figure 15 presents the variations of filtrate mass with time for the four seawater slurries. As illustrated in Figure 15, during the penetration test of the B4 slurry, the filtrate mass increases abruptly within a short period of time (about 32 s); this is due to the free water discharge from the pores of the saturated sand layer under the penetration pressure. Subsequently, the filtrate mass remains stable, proving that a dense filter cake has formed with good sealing properties. During the penetration tests of the B1 and B2 slurries, the filtrate discharge process mainly includes three stages: (1) the free water discharge stage in the saturated sand layer, (2) the water discharge stage in the slurry, and (3) the filtrate mass stabilization stage. The B1 and B2 slurries formed filter cakes at 109 s and 136 s, respectively. However, their filtrate masses in the final stabilization stage (1,760 g and 2,260 g) were larger compared to that of the B4 slurry (which stabilized at a lower mass). This confirms that the filter cakes formed by B1 and B2 slurries have poor density and air-tightness properties and cannot effectively maintain the stability of the excavation face in actual engineering applications. During the penetration test of the B3 slurry, the filtrate mass rapidly increases to 2,000 g within 75 s, indicating that free water in the saturated sand layer and B3 slurry escapes under penetration pressure, preventing the formation of a dense filter cake. To further illustrate the morphology of the filter cakes, Figure 16 displays the top view of the filter cakes formed by the four seawater slurries. As visible in Figure 16, the filter cake surface of the B4 slurry is flat and dense, with no obvious holes, resulting in excellent air-tightness and pressure-maintaining performance. In contrast, the filter cakes of the B1 and B2 slurries have some holes, and parts of the sand layer are exposed. Conversely, the upper surface of the sand layer for B3 slurry is completely exposed with only minimal residual slurry and no filter cake formation.

4.3 Microstructure evaluation

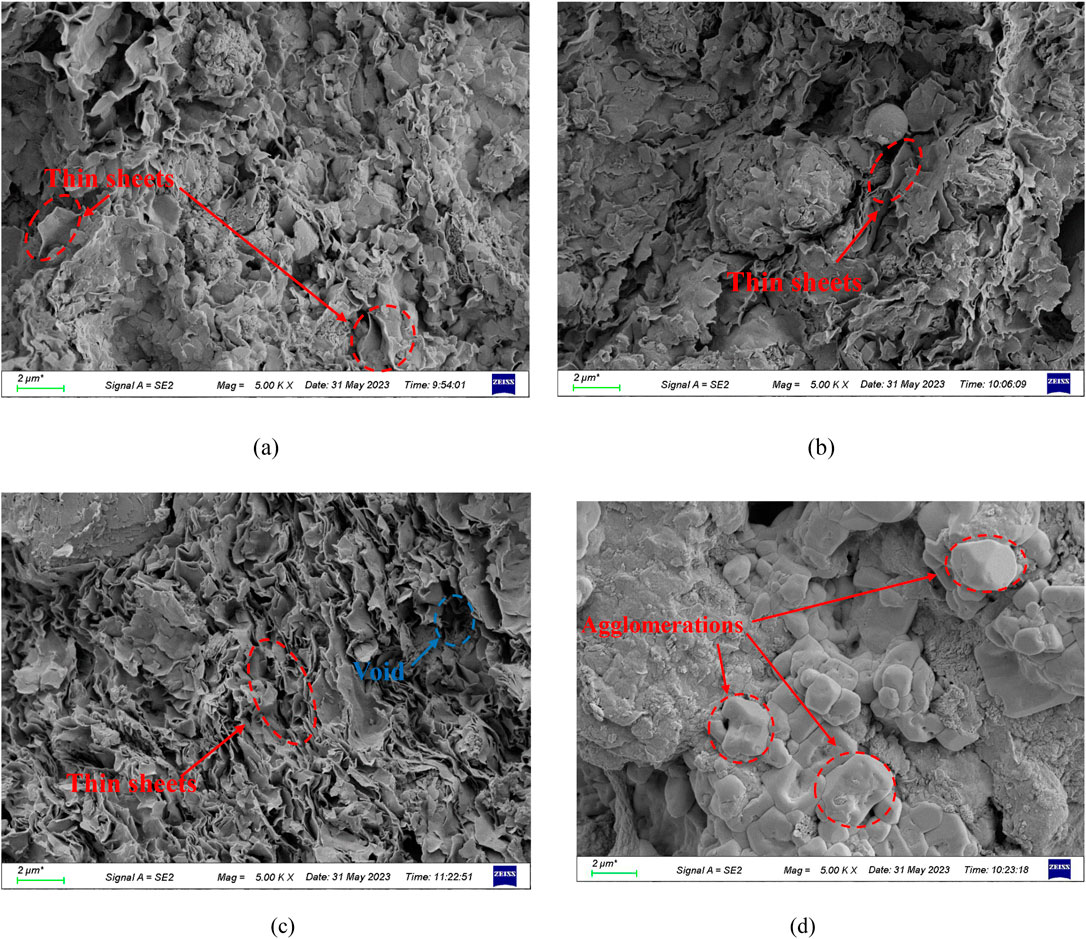

Figure 17 illustrates the microstructure and morphological characteristics of four seawater slurries (50% seawater content) with quantitative microstructural analysis (He et al., 2024; He R. and Lu N. L., 2024; He et al., 2023; He R. and Lu N., 2024). SEM observations at 2 μm scale reveal distinct variations in pore structure and aggregation patterns among the samples. The B4 slurry exhibits densely packed aggregates with an average agglomeration density of 82.3% ± 3.5% (calculated from image analysis), forming a continuous matrix with minimal porosity (<5% void fraction). In contrast, B1 and B2 slurries display lamellar structures consisting of thin sheets (thickness 50–80 nm) separated by interlayer voids measuring 150–300 nm in width. These configurations create localized particle accumulations with porosity values of 18.6% and 22.4% respectively. The B3 slurry presents an expanded porous network featuring sheet-like structures with significantly larger inter-sheet voids (400–650 nm width, porosity 31.8%), creating enhanced hydraulic pathways for free water movement. This microstructural quantification correlates with the observed fluid behavior - the increased pore dimensions and reduced agglomeration density (63.2% ± 4.1% for B3 vs. 78.9% ± 2.8% for B1/B2) directly contribute to the sharp viscosity reduction and decreased colloidal stability under seawater intrusion conditions.

Figure 17. Microsturcture and morphology of seawater slurries (seawater content of 50%): (a) B1 slurry; (b) B2 slurry; (c) B3 slurry; (d) B4 slurry. Scale bar = 2 μm.

5 Discussion

Based on the comprehensive analysis above, the B4 bentonite exhibits superior rheological performance and permeability properties under seawater intrusion. Even at a high seawater intrusion rate (50%), the B4 slurry maintains excellent viscoplastic behavior and conforms to the Herschel-Bulkley (H-B) model. As shown in Table 1, B4 bentonite contains specific additives (0.24% caustic soda and 0.34% soda ash), which are absent in other bentonites. These alkalis chemically react with Ca2+ and Mg2+ in seawater to form inert calcium carbonate, thereby mitigating slurry property deterioration. Therefore, during bentonite processing for submarine slurry shield applications, adding approximately 0.25% soda ash and 0.35% caustic soda is recommended to enhance slurry salt resistance.

Conversely, the physical properties of B3 slurry degrade significantly under high seawater intrusion (50%), transitioning to Newtonian fluid behavior. At elevated temperatures (50°C and 75°C), B3 slurry exhibits the poorest rheology among all tested samples. This is attributed to its low montmorillonite and silica content. Since montmorillonite-rich bentonite (>60% content) improves swelling, dispersion, rheological properties, and water retention, increasing its proportion is advised to enhance slurry stability.

6 Conclusion

In this study, four typical commercial sodium bentonites of different origins were selected as raw materials, and a series of mineral composition characterization tests were conducted on the four sodium bentonites, respectively. Additionally, a comprehensive analysis was performed to evaluate the physical and mechanical properties of the four bentonite slurries, including rheological tests, penetration tests, and microstructure observations. The effects of bentonite mineral composition on the rheology, permeability, and microstructure of slurry under seawater intrusion and high temperature were investigated. The main conclusions are as follows:

(1) Under a seawater intrusion rate of 50%, bentonite slurry containing alkali substances still maintains relatively excellent viscoplastic behavior and conforms to the flow pattern of the H-B model, while the yield stress of the slurry decreases with increasing seawater content. Conversely, the rheological properties of slurries without alkali substances are severely deteriorated, transitioning from the flow patterns of the H-B model/Power-law model to Newtonian fluids.

(2) At a temperature of 75°C, all slurries exhibit deterioration in rheological properties, and the yield stress decreases linearly with temperature increase, revealing the phenomenon of high-temperature thinning in bentonite slurry. However, they retain pseudoplastic flow characteristics and conform to the flow patterns of the H-B model or Power-law model.

(3) The morphology of slurry containing alkali substances appears as dense, continuous agglomerations without obvious voids. In contrast, slurries without alkali substances primarily exhibit thin sheets with inter-sheet voids and localized discrete particle accumulation.

(4) Bentonite with high montmorillonite content (>60%) demonstrates enhanced swelling, dispersion, and water retention, resulting in slurries with improved rheological properties and reduced water loss.

(5) Alkalis in bentonite have a positive effect against the deterioration of the slurry’s physical properties under seawater intrusion, as they chemically react with Ca2+ and Mg2+ to form inert calcium carbonate. Therefore, adding appropriate amounts of soda ash (0.25%) and caustic soda (0.35%) during bentonite processing is recommended to enhance salt resistance for seabed slurry shield applications.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

JR: Writing – review and editing, Data curation, Methodology, Formal analysis, Project administration, Investigation, Resources. YF: Investigation, Writing – original draft, Writing – review and editing, Conceptualization, Data curation, Formal Analysis, Methodology, Visualization, Funding acquisition. YG: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Writing – original draft, Writing – review and editing. LJ: Conceptualization, Investigation, Methodology, Writing – original draft, Writing – review and editing. HL: Investigation, Writing – review and editing. XL: Writing – review and editing, Conceptualization. WQ: Writing – review and editing, Methodology, Project administration, Investigation.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. The authors gratefully acknowledge financial supported by the National Natural Science Foundation of China under Grant No. 52278386.

Conflict of interest

Author LJ was employed by Qingdao Guoxin Development (Group) Co., Ltd. Author HL was employed by CCCC Tunnel Engineering Co. Ltd. Author WQ was employed by Qingdao Guoxin Second Jiaozhou Bay Subsea Tunnel Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

ASTM D1141 (2003). Standard practice for the preparation of substitute ocean water. West Conshohocken, PA, USA: American Society for Testing and Materials.

Caenn, R., and Chillingar, G. V. (1996). Drilling fluids: state of the art. J. petroleum Sci. Eng. 14 (3-4), 221–230. doi:10.1016/0920-4105(95)00051-8

Collette, C., Lafuma, F., Audebert, R., and Brouard, R. (1994). Macromolecular systems in heat-resistant drilling fluids; advantages of gels on linear polymers. J. Appl. Polym. Sci. 53 (6), 755–762. doi:10.1002/app.1994.070530605

Cui, W., Liu, D., Song, H., and Pu, G. J. (2019). Development and experimental study on environmental slurry for slurry shield tunneling. Constr. Build. Mater. 216, 416–423. doi:10.1016/j.conbuildmat.2019.04.265

Cui, W., Liu, D., Song, H., Zhang, S. R., and He, S. W. (2020). Experimental study of salt-resisting slurry for undersea shield tunnelling. Tunn. Undergr. Space Technol. 98, 103322. doi:10.1016/j.tust.2020.103322

Fu, W., Wang, Z., Zhang, J., Cao, Y., and Sun, B. (2020). Investigation of rheological properties of methane hydrate slurry with carboxmethylcellulose. J. Petroleum Sci. Eng. 184, 106504. doi:10.1016/j.petrol.2019.106504

Geng, Z., Jin, D., and Yuan, D. (2023). Face stability analysis of cohesion-frictional soils considering the soil arch effect and the instability failure process. Comput. Geotechnics 153, 105050. doi:10.1016/j.compgeo.2022.105050

Guo, Y., Fang, Y., Li, X., Jin, D., and Liu, H. (2025a). Simulation of screening characterization of double-deck vibrating screen of slurry TBM tunnelling using integrated CFD-DEM-FEM. Tunn. Undergr. Space Technol. 158, 106399. doi:10.1016/j.tust.2025.106399

Guo, Y., Jin, D., Li, X., Cheng, P., Qiao, G., Wang, Q., et al. (2023a). Effect of cutting blind zones on the performance of the rectangular pipe jacking machine with multiple cutterheads: a DEM study. Tunn. Undergr. Space Technol. 134, 104984. doi:10.1016/j.tust.2023.104984

Guo, Y., Li, X., Fang, Y., Jin, D., Yang, Y., and Liu, H. (2024). Investigation into the pregelatinized starch additive alleviated the deterioration in rheological properties of slurries induced by high-temperature environment and seawater intrusion during submarine slurry shield tunneling. Tunn. Undergr. Space Technol. 147, 105693. doi:10.1016/j.tust.2024.105693

Guo, Y., Li, X., Jin, D., Liu, H., and Fang, Y. (2025b). Assessment of slurry chamber clogging alleviation during ultra-large-diameter slurry tunnel boring machine tunneling in hard-rock using computational fluid dynamics-discrete element method: a case study. J. Rock Mech. Geotechnical Eng. doi:10.1016/j.jrmge.2024.09.059

Guo, Y., Li, X., Jin, D., Liu, H., Yang, Y., Fang, Y., et al. (2023d). Assessment on the reverse circulation performance of slurry shield pipeline system assisted with CFD-DEM modeling under sandy cobble stratum. Powder Technol. 425, 118573. doi:10.1016/j.powtec.2023.118573

Guo, Y., Li, X., Jin, D., Yang, Y., Fang, Y., Zhang, Y., et al. (2023b). A new pressure gradient model of slurry shield pipeline system coupling with rheological properties and wall slip behaviour under sandy stratum. Tunn. Undergr. Space Technol. 134, 105024. doi:10.1016/j.tust.2023.105024

Guo, Y., Li, X., Sun, Y., Yang, Y., Fang, Y., and Li, H. (2023c). Investigation into the flow characteristics of slurry shield pipeline system under sandy pebble stratum: model test and CFD-DEM simulation. Powder Technol. 415, 118149. doi:10.1016/j.powtec.2022.118149

Haiqing, Y., and Bolong, L. (2019). Analysis on temperature effects of disc cutters during the rock-cutter interaction. New York: ARMA US Rock Mechanics/Geomechanics Symposium ARMA. ARMA-2019-1728.

He, R., and Lu, N. (2024a). Hydration, fresh, mechanical, and freeze-thaw properties of cement mortar incorporated with polymeric microspheres. Adv. Compos. Hybrid Mater. 7 (3), 92. doi:10.1007/s42114-024-00899-2

He, R., and Lu, N. L. (2024b). Air void system and freezing-thawing resistance of concrete composite with the incorporation of thermo-expansive polymeric microspheres. Constr. Build. Mater. 419, 135535. doi:10.1016/j.conbuildmat.2024.135535

He, R., Nantung, T., and Lu, N. L. (2024). Unraveling microstructural evolution in air-entrained mortar and paste: insights from MIP and micro-CT tomography amid cyclic freezing-thawing damage. J. Build. Eng. 94, 109922. doi:10.1016/j.jobe.2024.109922

He, R., Nantung, T., Olek, J., and Lu, N. (2023). Field study of the dielectric constant of concrete: a parameter less sensitive to environmental variations than electrical resistivity. J. Build. Eng. 74, 106938. doi:10.1016/j.jobe.2023.106938

Huang, K., Sun, Y., Yang, J., Li, Y. J., Jiang, M., and Huang, X. Q. (2022). Three-dimensional displacement characteristics of adjacent pile induced by shield tunneling under influence of multiple factors. J. Central South Univ. 29 (5), 1597–1615. doi:10.1007/s11771-022-5003-z

Huang, K., Sun, Y., Zhou, D., Li, Y. J., Jiang, M., and Huang, X. Q. (2021). Influence of water-rich tunnel by shield tunneling on existing bridge pile foundation in layered soils. J. Central South Univ. 28 (8), 2574–2588. doi:10.1007/s11771-021-4787-6

Ihmoudah, A., Abugharara, A., Rahman, M. A., and Butt, S. (2023). Experimental and numerical analysis of the effect of rheological models on measurements of shear-thinning fluid flow in smooth pipes. Energies 16 (8), 3478. doi:10.3390/en16083478

Jin, D., Cai, B., Li, X., Mou, Z., and Shu, J. (2024). Airtightness failure analysis of filter cake during shield tunneling machine hyperbaric intervention. Acta Geotech. 20, 1089–1102. doi:10.1007/s11440-024-02438-1

Jin, D., Guo, Y., Li, X., Yang, Y., and Fang, Y. (2023). Numerical study on the muck flow behavior in the screw conveyor during EPB shield tunneling. Tunn. Undergr. Space Technol. 134, 105017. doi:10.1016/j.tust.2023.105017

Jin, D., Yuan, D., Li, X., and Zheng, H. (2018). An in-tunnel grouting protection method for excavating twin tunnels beneath an existing tunnel. Tunn. Undergr. Space Technol. 71, 27–35. doi:10.1016/j.tust.2017.08.002

Jin, D., Yuan, D., Ng, Y. C. H., and Pan, Y. (2022). Effect of an undercrossing tunnel excavation on an existing tunnel considering nonlinear soil-tunnel interaction. Tunn. Undergr. Space Technol. 130, 104571. doi:10.1016/j.tust.2022.104571

Lin, Y., Fang, Y., and He, C. (2022). Numerical study on clogging mechanism of slurry infiltration in porous media based on coupled CFD-DEM method. Tunn. Undergr. Space Technol. 128, 104622. doi:10.1016/j.tust.2022.104622

Mao, J., Yuan, D., Jin, D., and Zeng, J. F. (2020). Optimization and application of backfill grouting material for submarine tunnel. Constr. Build. Mater. 265, 120281. doi:10.1016/j.conbuildmat.2020.120281

Min, F., Du, J., Zhang, N., Chen, X., Lv, H., Liu, L., et al. (2019). Experimental study on property change of slurry and filter cake of slurry shield under seawater intrusion. Tunn. Undergr. Space Technol. 88, 290–299. doi:10.1016/j.tust.2019.03.006

Min, F., Song, H., and Zhang, N. (2018). Experimental study on fluid properties of slurry and its influence on slurry infiltration in sand stratum. Appl. Clay Sci. 161, 64–69. doi:10.1016/j.clay.2018.03.028

Min, F., Zhu, W., and Han, X. (2013). Filter cake formation for slurry shield tunneling in highly permeable sand. Tunn. Undergr. Space Technol. 38, 423–430. doi:10.1016/j.tust.2013.07.024

Min, F., Zhu, W., Lin, C., and Guo, X. (2015). Opening the excavation chamber of the large-diameter size slurry shield: a case study in Nanjing Yangtze River Tunnel in China. Tunn. Undergr. Space Technol. 46, 18–27. doi:10.1016/j.tust.2014.10.002

Naghadehi, M. Z., Thewes, M., and Lavasan, A. A. (2019). Face stability analysis of mechanized shield tunneling: an objective systems approach to the problem. Eng. Geol. 262, 105307. doi:10.1016/j.enggeo.2019.105307

Qin, S., Zhou, W. H., and Xu, T. (2023). Effects of seawater on the infiltration behavior of bentonite slurry into sand. Constr. Build. Mater. 371, 130759. doi:10.1016/j.conbuildmat.2023.130759

Shao, W., Zhu, Z., Liu, R., Wang, Z., and Wei, B. (2023). Effects of a polycarboxylate superplasticizer and temperature on the rheological properties of grout blended with seawater. Constr. Build. Mater. 375, 130990. doi:10.1016/j.conbuildmat.2023.130990

Wan, T., Yao, J., Zishun, S., Li, W., and Juan, W. (2011). Solution and drilling fluid properties of water soluble AM–AA–SSS copolymers by inverse microemulsion. J. Petroleum Sci. Eng. 78 (2), 334–337. doi:10.1016/j.petrol.2011.06.027

Wang, F., Luo, F., Huang, Y., Zhu, L., and Hu, H. (2019). Thermal analysis and air temperature prediction in TBM construction tunnels. Appl. Therm. Eng. 158, 113822. doi:10.1016/j.applthermaleng.2019.113822

Wang, M., Zhu, Z., Liu, R., Li, S., Zhang, C., Liu, Y., et al. (2021a). Influence of extreme high-temperature environment and hydration time on the rheology of cement slurry. Constr. Build. Mater. 295, 123684. doi:10.1016/j.conbuildmat.2021.123684

Wang, Q., Xiong, Z., He, J., Lai, M., and Ho, J. (2022a). Effective solution for improving rheological properties of cement paste containing zeolite. Constr. Build. Mater. 351, 128780. doi:10.1016/j.conbuildmat.2022.128780

Wang, T., Yuan, D., Jin, D., and Li, X. (2021b). Experimental study on slurry-induced fracturing during shield tunneling. Front. Struct. Civ. Eng. 15 (2), 333–345. doi:10.1007/s11709-021-0718-8

Wang, Z., Ding, W., Zhu, Z., Liu, R., Wang, C., Yu, W., et al. (2022b). Experimental study on rheological behaviors of Na-bentonite slurries under seawater intrusion. Constr. Build. Mater. 357, 129369. doi:10.1016/j.conbuildmat.2022.129369

Wang, Z., Guo, W., Ding, W., Liu, K., Qin, W., Wang, C., et al. (2023). Numerical study on the hydrodynamic properties of bentonite slurries with Herschel-Bulkley-Papanastasiou rheology model. Powder Technol. 419, 118375. doi:10.1016/j.powtec.2023.118375

Wang, Z., Guo, W., Qin, W., Wang, C., and Ding, W. (2022c). Influences of polyanionic celluloses and temperature on the rheological property of seawater slurries. Constr. Build. Mater. 351, 128964. doi:10.1016/j.conbuildmat.2022.128964

Wei, G., Feng, F., Huang, S., Xu, T., Zhu, J., Wang, X., et al. (2025). Full-scale loading test for shield tunnel segments: load-bearing performance and failure patterns of lining structures. Undergr. Space 20, 197–217. doi:10.1016/j.undsp.2024.05.003

Wu, J. H., Liu, J. Z., Yu, Y. J., Wang, R. K., Zhou, J. H., and Cen, K. F. (2015). Improving slurryability, rheology, and stability of slurry fuel from blending petroleum coke with lignite. Petroleum Sci. 12, 157–169. doi:10.1007/s12182-014-0008-3

Xu, T., and Bezuijen, A. (2019). Experimental study on the mechanisms of bentonite slurry penetration in front of a slurry TBM. Tunn. Undergr. Space Technol. 93, 103052. doi:10.1016/j.tust.2019.103052

Yang, Y., Li, X., Jin, D., Su, W., and Mao, J. (2021). Transient temperature field model for a cutterhead during slurry shield tunneling. Tunn. Undergr. Space Technol. 117, 104128. doi:10.1016/j.tust.2021.104128

Yang, Y., Li, X. G., and Su, W. L. (2020). Experimental investigation on rheological behaviors of bentonite-and cmc-conditioned sands. KSCE J. Civ. Eng. 24 (6), 1914–1923. doi:10.1007/s12205-020-2035-5

Yin, T., Zhang, Z., Huang, X., Shire, T., and Hanley, K. J. (2021). On the morphology and pressure-filtration characteristics of filter cake formation: insight from coupled CFD–DEM simulations. Tunn. Undergr. Space Technol. 111, 103856. doi:10.1016/j.tust.2021.103856

Zhang, Z., and Yin, T. (2018). A coupled CFD–DEM simulation of slurry infiltration and filter cake formation during slurry shield tunneling. Infrastructures 3 (2), 15. doi:10.3390/infrastructures3020015

Keywords: submarine geological conditions, seawater slurry, rheological test, penetration test, high temperature

Citation: Ru J, Fang Y, Guo Y, Jiang L, Liu H, Li X and Qi W (2025) Rheology, permeability and microstructure of seawater-based slurry for slurry shield tunneling: insights from laboratory tests. Front. Mater. 12:1592537. doi: 10.3389/fmats.2025.1592537

Received: 12 March 2025; Accepted: 15 April 2025;

Published: 06 May 2025.

Edited by:

Wenbing Wu, China University of Geosciences Wuhan, ChinaReviewed by:

Chuanqing Fu, Zhejiang University of Technology, ChinaFei Ye, Chang’an University, China

Shuying Wang, Shenzhen University, China

Copyright © 2025 Ru, Fang, Guo, Jiang, Liu, Li and Qi. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Luqing Jiang, amlhbmdsdXFpbmdAcWRneGp0LmNvbQ==

Junqi Ru1

Junqi Ru1 Luqing Jiang

Luqing Jiang