- 1Guangxi Land and Resources Planning and Design Group Co., Ltd., Nanning, China

- 2Research Center of Road, Research Institute of Highway Ministry of Transport, Beijing, China

- 3Guangxi Xinfazhan Communications Group Co., Ltd., Nanning, China

A new type of trackless emulsified asphalt (TEA) tack coat with a gradient distribution of polyurethane (PU) was prepared via self-migration technology to solve the problems of tracking and poor bonding in common tack coats. The PU distribution in the vertical section of tack coat was characterized by electron microscopy, Fourier transform infrared spectroscopy (FTIR), and contact angle tests. The basic performance of TEA, such as penetration, ductility, softening point, rheological properties, and storage stability, was studied. The pavement performance of TEA tack coat was evaluated by track-free time, tracking resistance, and shearing resistance tests. The results indicate that the gradient distribution of PU (PU content increasing from bottom to apparent) was formed in tack coat. Based on tests on tracking resistance, non-tracking time, and storage stability, an optimal dosage of 3% polyurethane latex modifier was determined. For TEA-3 (with 3% polyurethane latex modifier), the non-tracking time at 35°C was decreased to under 30 min. This substantial reduction significantly enhanced its construction efficiency. Mechanical performance evaluations of TEA-3 demonstrated exceptional temperature resistance, maintaining shear strength exceeding 1 MPa at 60°C while remaining track-free at 70°C. The uniform dispersion of PU within the TEA tack coat matrix contributed to substantial improvements in both track-free characteristics and interfacial shear resistance, even at minimal PU modification levels. The material combines excellent road performance and environmentally friendly preparation process, providing a promising technical solution for the application of tack coat in the field of road engineering.

1 Introduction

Asphalt pavement is a multilayer composite system; its life expectancy can be significantly affected by interlayer bonding (Wang et al., 2017; Zhang, 2017; Hou et al., 2018; Fu et al., 2021). The selection of a suitable tack coat is of utmost importance because it determines the bonding quality of the overlying layer (Al-Qadi et al., 2008; Mohammad et al., 2012). Poor bonding weakens structural strength and results in issues such as cracking, slippage, swelling, and debonding at the asphalt pavement interface that lead to a dramatic deterioration in pavement performance (Hu et al., 2025; Peng et al., 2024). Despite the proper application of tack coats on the existing pavement, a significant issue with conventional tack coats is their propensity to adhere to the tires of construction vehicles. Moreover, the depletion of tack coat in the wheel path not only diminishes the coat’s effectiveness and has the potential to impact interlayer bonding but may also lead to contamination at the construction site (Hou et al., 2018; Seo et al., 2017). Hence, it is extremely important to develop new high-performance trackless tack coat materials to overcome tracking and poor bonding for prolonging road service life.

According to the preparation method, trackless tack coat materials can be divided into emulsified and hot asphalt. Trackless emulsified asphalt (TEA) is more widely used because it is environmentally friendly, saves energy, and sprays conveniently. Yang et al. (2017) achieved the emulsification of 30# hard asphalt by optimizing both the emulsifier type and its dosage. The resultant emulsified asphalt had an average particle size of 2.97 μm and a softening point of 60.8°C. Compared to typical emulsified asphalt, this new product exhibited an increase of 10.6°C in the softening point. Additionally, at 25°C, its track-free time did not exceed 20 min (Yang et al., 2017). Guo et al. (2021) prepared TEA by optimizing the type of emulsifier and then adding a reinforcing agent and elastomer modifier. The softening point of this TEA residue was 94°C as modifier ratio 16%. Fu et al. (2021) developed a special tack coat by adding waterborne epoxy resin (WER). The high temperature heat resistance and adhesion capacity with aggregates of the tack coat was improved by WER. Fu et al. (2021) concluded that WER content should be 20% if it is tightly combined with emulsified asphalt. Li et al. (2019) formulated a trackless asphalt tack coat material with a non-marking time of the non-tracking adhesive coating of less than 1 min at 25°C and seamless at 60°C. Hard asphalt and polymer modifier are beneficial in improving the trackless performance and shear strength of tack coat.

In asphalt pavement construction, the road surface temperature usually reaches 60°C and even 70°C when the pavement is exposed to direct sunlight in summer (Shi et al., 2019). To determine problems of poor adhesion and tracking of tack coat at high temperature, a high dosage of hard asphalt and polymer modifiers (more expensive than asphalt) need to be added to the tack coat material. However, hard asphalt with high dosage entails difficulties in the preparation and spraying of tack coat materials, and excessive hard asphalt may cause the tack coat to embrittle at low temperature (Gingras et al., 2005; Sheng et al., 2018). Moreover, more than 15% polymer modifier is generally needed to achieve a significant improvement in trackless performance at high temperature (60°C) (Fu et al., 2021; Guo et al., 2021; Li et al., 2019). However, the high cost of the material severely limits its practical engineering application.

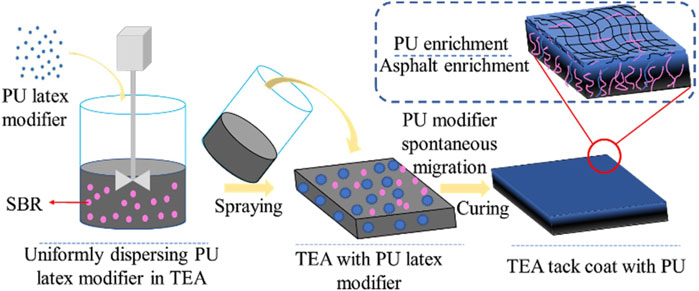

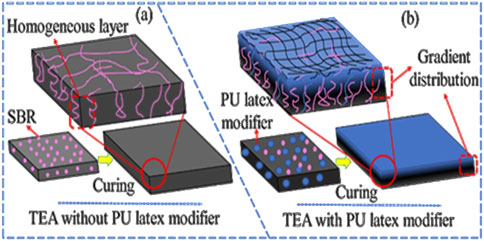

To determine the tracking and poor bonding of tack coat (exceed 60°C) at low cost, we propose a new PU latex modifier based on the concept of gradient materials (Beaugendre et al., 2017; Baghdachi et al., 2015; Hu et al., 2010). Expensive modifier may spontaneously migrate to the apparent emulsified asphalt tack coat during the curing. The hypothetical tack coat is shown in Figure 1. Due to the enrichment of the PU modifier on apparent tack coat, trackless performance and shear strength of tack coat may be significantly improved with a small dose of the PU latex modifier. TEA tack coat where PU is distributed in a gradient manner may become an important cost-effective solution to the problems of poor tracking and bonding, especially above 60°C.

Figure 1. The hypothetical diagram of TEA tack coat. (a) TEA without PU lates modifier (b) TEA with PU lates modifier.

In this study, a new type of TEA tack coat with a gradient distribution of PU was prepared for improving trackless performance and shear strength. The gradient distribution of PU in TEA tack coat was revealed by electron microscopy, FTIR, and contact angle tests. The basic performance of TEA was analyzed, including penetration, ductility, softening point, rheological properties, and storage stability. The composition ratio of TEA with PU latex modifier was optimized by storage stability, track-free time, and tracking resistance tests. We evaluated the road performance of track-free time, trackless performance, and shear strength characteristics. Moreover, we discuss the formation process of TEA tack coat with PU and its tracking behavior in detail. This study holds great significance as it presents a novel approach to enhancing the trackless performance and shear strength of TEA tack coat at a low cost. Because PU has better thermal stability and the polyurethane modifier is enriched on the surface of the adhesive layer, the participation of a small amount of polyurethane can significantly improve the tack coat non-stick wheel effect and shear resistance. The results of this research can improve the quality of asphalt pavement interlayer bonding and play a positive role in improving the life extension and durability of asphalt pavement.

2 Materials and methods

2.1 Materials

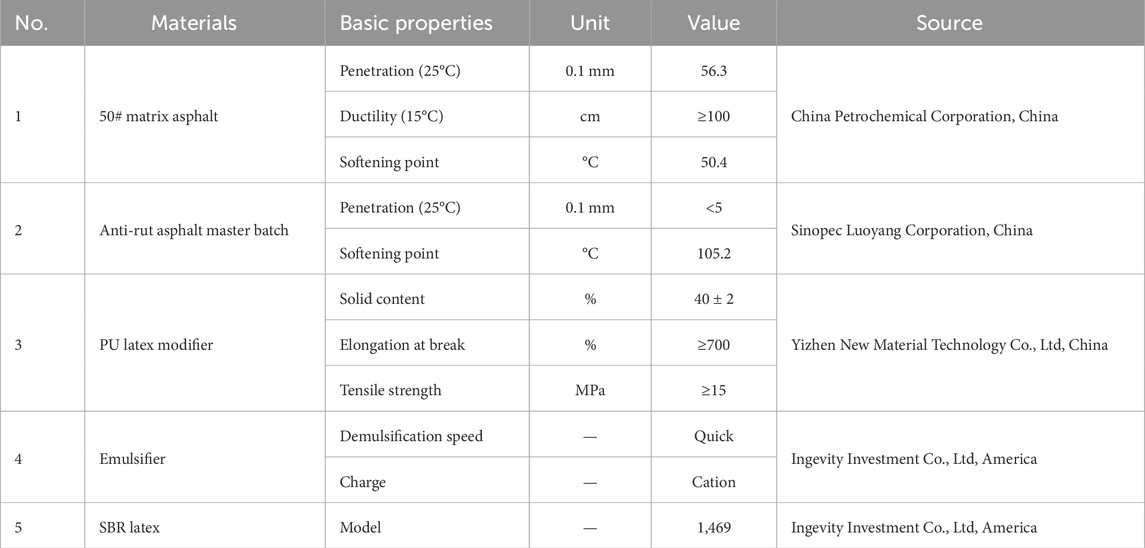

The raw materials for the preparation of TEA tack coat with PU are 50# matrix asphalt, quick-cracking emulsifier, SBR latex, rutting resistance asphalt master batch, and waterborne PU latex modifier. The raw materials’ basic properties are shown in Table 1.

2.2 Sample preparation

The preparation process included the preparation of TEA and TEA tack coat with PU. The asphalt content of TEA was 50%, and the dosage of the emulsifier was 0.8%. The specific steps in the preparation process are presented as follows.

First, to prepare TEA, a predetermined quantity of 50# matrix asphalt was heated to 160°C. The anti-rutting master batch was then introduced into the heated asphalt, and the resulting mixture was blended at 160°C. This blending process continued until the anti-rutting master batch was evenly distributed throughout the asphalt. The calculated amount of soap solution and mixed bitumen were mixed homogeneously and poured slowly into a colloid mill (4,000 rpm), and then the resulting emulsified bitumen was circulated in the colloid mill for 2–3 min to produce the TEA.

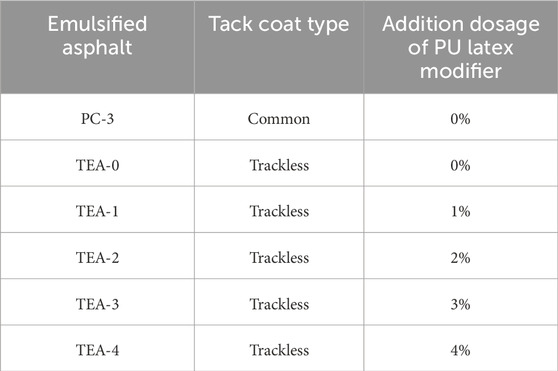

Second, the preparation of TEA tack coat with PU. We mixed triethanolamine and polyurethane latex modifier by stirring at 1,000 rpm until the PU latex modifier was evenly dispersed in the TEA. A TEA tack coat with PU was obtained after the curing process (Figure 2). The sample information of emulsified asphalt (tack coat) in the study is shown in Table 2.

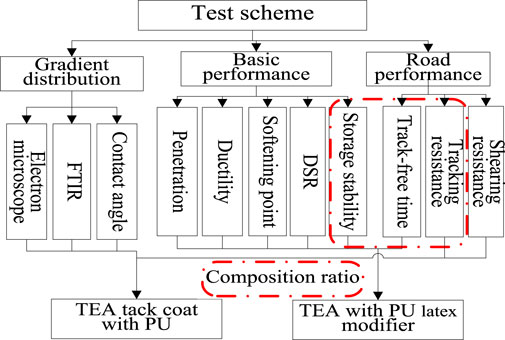

2.3 Characterizations

The test scheme of TEA (tack coat) with PU is shown in Figure 3. The gradient distribution of PU in TEA tack coat was analyzed by electron microscopy, FTIR, and contact angle tests. The penetration, ductility, softening point, DSR, and storage stability tests were performed to evaluate the basic performance. Track-free time, tracking resistance, and shearing resistance tests were used to characterize road performance. Storage stability, track-free time, and tracking resistance tests were also used to determine the optimal composition ratio of TEA with PU latex modifier.

2.3.1 Electron microscope analysis

In order to better observe the vertical section morphology of TEA tack coat, the TEA was poured into a 20 mm × 15 mm × 15 mm cuboid container (depth 10 mm). The container together with the TEA was placed in a 35°C oven until the weight stopped changing. The vertical section morphology of the tack coats was observed by PH100-DB500U (Phenix, China).

2.3.2 FTIR analysis

Nicolet 6700 (Thermo Fisher, America) was used to obtain the chemical composition of tack coat apparent. The wavenumber ranged from 400 cm-1 to 4,000 cm-1.

2.3.3 Contact angle test

The contact angle was tested by a contact angle analyzer (JCY series, Fang Rui instrument, China). The tests results were used to analyze the hydrophilicity properties of the tack coat apparent.

2.3.4 Basic performance test

Tests for penetration, softening point, ductility, and storage stability were conducted by the following respective standard methods: JTG E20 T0604, JTG E20 T0606, JTG E20 T0605, and JTG E20 T0655 (Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering the Ministry of Transport of the People’s Republic of China). To measure the complex modulus (|G*|) and phase angle (δ) of the emulsified asphalt residue, the CVOR-ADS (Malvern, UK) was used, with a frequency varying from 1 to 100 rad/s. A parallel plate with an 8 mm (diameter) and a 1-mm gap was applied in the testing procedure.

2.3.5 Track-free time test

The time required to reach a trackless condition with the minimum curing period is defined as the “track-free time”. Taking reference from the no-pick-up time test of traffic paint as per JT/T 280 (Pavement Marking Paint the Ministry of Transportof the People’s Republic of China), a modified no-pick-up time test was applied to the test. The steel compactor was 35 kg, and the amount of TEA sprayed was 0.5 kg/m2.

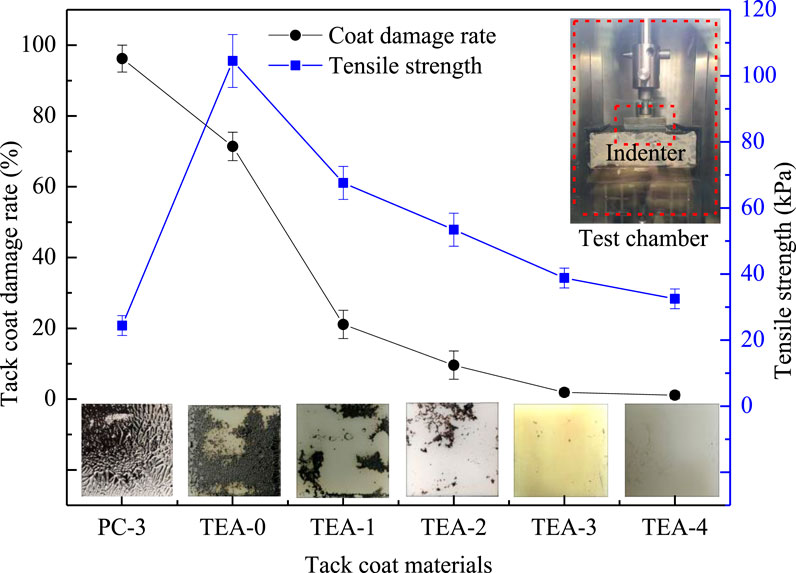

2.3.6 Tracking resistance test

What most distinctly sets TEA apart from typical tack coat is its trackless performance. This characteristic represents the most significant feature of TEA, differentiating it from common tack coats. The test temperature of trackless performance in this study was 70°C (PC-3 at 40°C) (Shi et al., 2019; Li et al., 2025). The indenter was pressed on the tack coat, keeping the displacement unchanged for 5s after the pressure reached 0.8 MPa. Then the indenter was pulled away from the tack coat (10 mm/min). The tack coat damage rate (S) and tensile strength were used to evaluate the trackless performance of the tack coat. S is calculated using Equation 1.

where S is the tack coat damage rate (%), A1 is the adhesive asphalt area of the indenter (mm2), and A0 is the contact area of the indenter with the specimen (mm2).

2.3.7 Shearing resistance test

Shear strength was gauged using a universal testing machine (WHY - 500, sourced from Shanghai Hualong Instrument Equipment in China). The test temperatures were set at 20°C, 40°C, and 60°C. The loading rate was maintained at 10 mm/min, and the quantity of TEA sprayed was 0.8 kg/m2.

3 Result and discussion

3.1 Gradient distribution pattern of PU within TEA tack coat

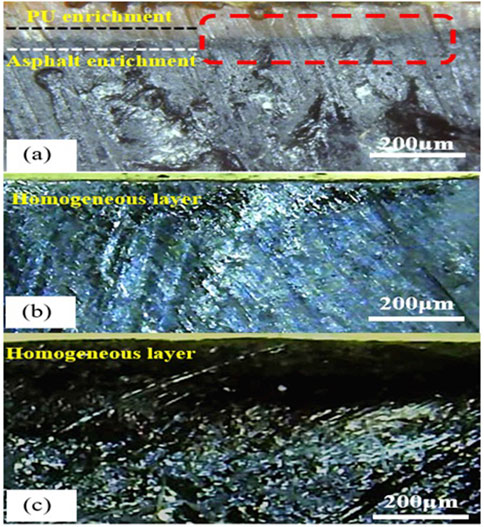

3.1.1 Morphological characteristics of the vertical section morphology of the tack coat

The vertical section images of the special tack coats are shown in Figure 4. As shown in Figure 4a, the TEA tack coat with PU (TEA-3) was divided into upper (brown) and bottom layers (black) on the vertical section, with a transition area between the two layers. Figures 4b and c show the vertical section of tack coat as a homogeneous layer. The uniform TEA-3 was transformed into a “double-layer” tack coat, but TEA-0 and PC-3 (without the PU latex modifier) were transformed into a homogeneous asphalt tack coat during curing. The formation of the “double-layer” structure may be due to the PU spontaneously migrating to the surface of the TEA-3 tack coat during the curing, forming a gradient distribution of PU in the tack coat. Moreover, the spraying quantity of TEA-3 in the electron microscope samples was 12.5 times (depth 10 mm) the common spraying amount (depth 0.8 mm), which made the self-migration effect of the TEA with PU modifier more obvious. The PU modifier may also migrate to form a gradient distribution at the common spraying amount, but the “double-layer” structure is difficult to clearly observe.

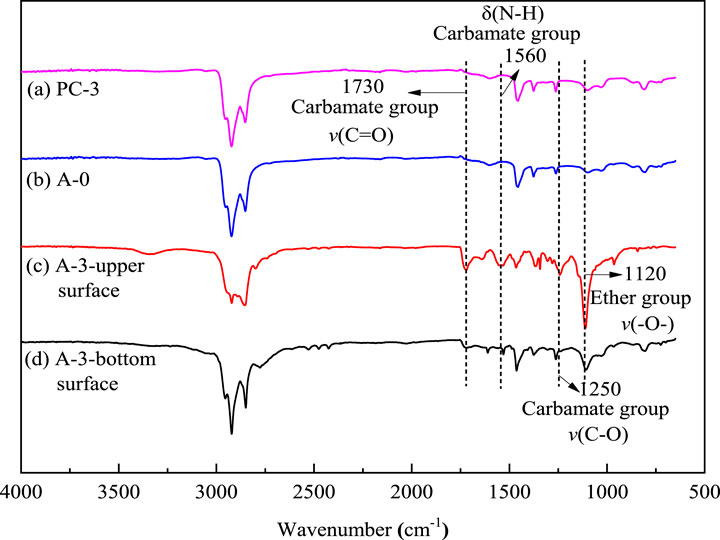

3.1.2 Chemical composition of tack coat

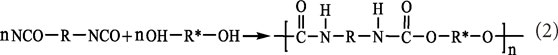

The FTIR spectra of tack coat are shown in Figure 5. Figures 5a–d are the FTIR spectra of the PC-3, TEA-0, and TEA-3 tack coats (upper apparent and bottom apparent), respectively. From Figures 5c, d, the TEA-3 tack coat appears at the carbamate group v (C=O) stretching vibration peak and carbamate group δ(N-H) bending vibration peak at 1,730 cm-1 and 1,560 cm-1, respectively (Zhang et al., 2021). From Figures 5a, b, both vibration peaks do not obviously appear in the PC-3 and TEA-0 tack coat. The v (C=O) of the carbamate group is derived from the reaction of isocyanates with hydroxyls. The corresponding chemical reaction equation is presented as follows (Akindoyo et al., 2016):

Figures 5c, d show an obvious absorption peak at 1,120 cm-1, which is assigned to ether group (-O-) (Cui et al., 2021; Dai et al., 2020). The ether group (-O-) absorption peak is due to the use of polyether polyols in the synthesis of PU latex modifiers. The intensity of the ether group absorption peaks increased with the of PU latex modifier content increasing. Compared with Figure 5c, the absorption peak intensity of infrared spectrum in Figure 5d at 1,120 cm-1 and 1730 cm-1 is obviously weakened. In addition, no obvious absorption peak was found at approximately 1,120 cm-1 and 1730 cm-1 in Figures 5a and b. The FTIR test results indicate that the upper surface of the TEA-3 tack coat had much more PU modifier than the bottom surface. This may be due to the PU modifier spontaneously migrating to the surface of the tack coat during the curing and being concentrated in the apparent.

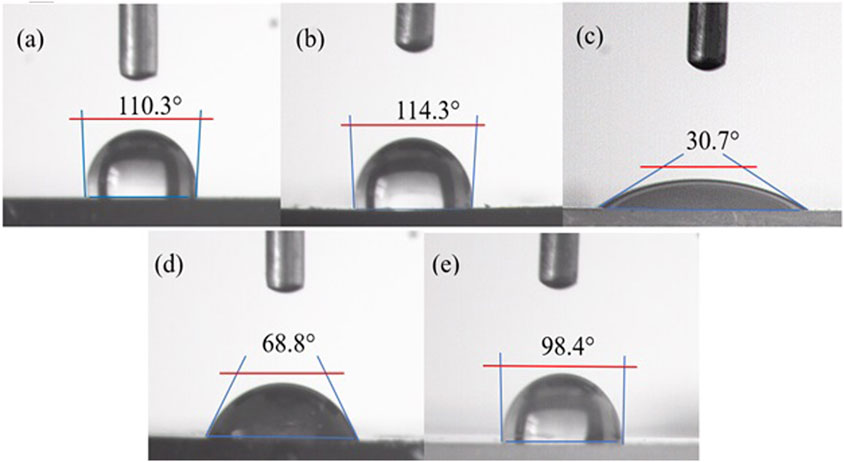

3.1.3 Contact angle of tack coat

The contact angle test results of the tack coat apparent are shown in Figure 6. Here, the contact angle of the PU latex modifier coating (30.7°) is smaller than that of the PC-3 (110.3°) and TEA-0 (114.3°) tack coats. This indicates that the PU modifier material has better hydrophilic properties than asphalt material (Ji et al., 2021; Fihri et al., 2017). Compared with the contact angle between the upper apparent and the bottom apparent of the TEA-3 tack coat, the contact angle of the upper apparent (68.8°) is smaller than that of the bottom apparent (98.4°). The hydrophilicity of the upper apparent is better than that of the bottom apparent, and the hydrophilicity of the upper apparent has obviously improved. The test result indicates that PU modifier (great hydrophilicity) was enriched on the upper apparent of the tack coat (TEA-3). This outcome can potentially be attributed to the fact that the hydrophilic PU modifier spontaneously migrates to the upper apparent of the tack coat during the curing process.

Figure 6. Contact angle of tack coat: (a) PC-3; (b) TEA-0; (c) apparent of PU coating; (d) upper apparent of TEA-3; (e) bottom apparent of TEA-3.

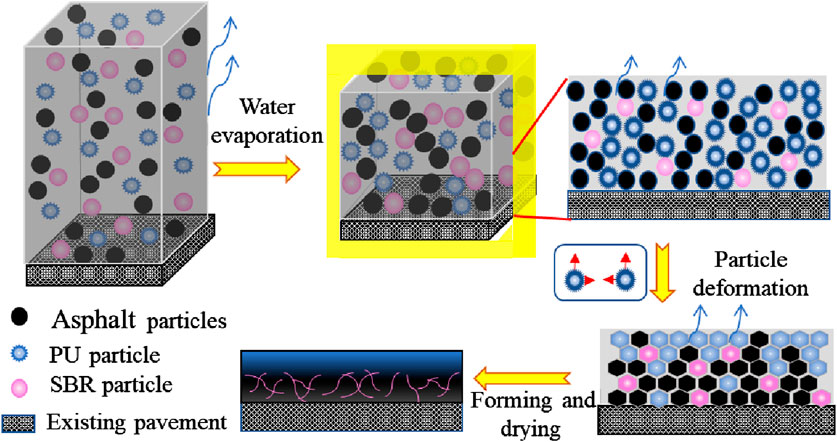

3.1.4 Forming process of TEA tack coat with PU

The forming process of TEA tack coat with PU was proposed according to the electron microscope test result, FTIR, contact angle on the TEA tack coat, and the research results of the polymer emulsion film-forming process (Winnik, 1997; Voogt et al., 2019).

There are two prerequisites for self-migration to form a gradient distribution of PU in the tack coat. First, the multi-components of the polymer have difference apparent tensions. Second, each component must exist stably in the blended system, its separation and migration can only occur during drying and curing, and the migration process is gradual (Huang et al., 2024). As shown in Figure 7, during the first stage with the water evaporation of TEA with PU latex modifier, the concentration of particles increased, and the particles got closer to each other. In the second stage, as the water continued to evaporate, the particles deformed due to the capillary pressure formed by the voids, and the particles began to fuse. The granules underwent a gradual transformation, starting from a spherical shape and evolving into a rhombic dodecahedron. This process continued until the interfaces separating the granules vanished. In the third stage, with the further evaporation of water, TEA with PU modifier underwent phase separation due to the apparent tension difference. The PU modifier gradually migrated to the upper apparent of the tack coat (Hu et al., 2010; Langer et al., 2014). During this phase, a progressive change in PU distribution spontaneously emerged within the TEA tack coat.

3.2 Basic performance of TEA

3.2.1 Penetration, softening point, and ductility (15°C)

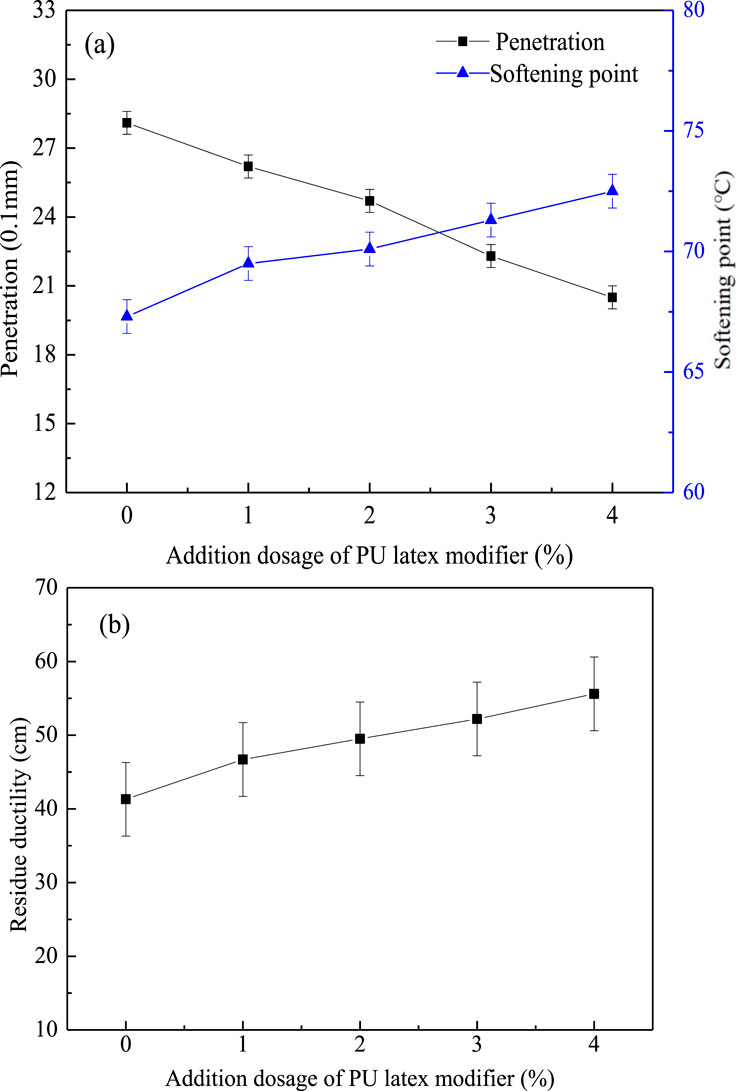

The experimental outcomes are presented in Figure 8. From Figure 8a, the penetration gradually decreases with the addition of polyurethane latex modifiers. The penetration of TEA residue with PU (20∼30 dmm) is smaller than that of common emulsified asphalt residue (40∼70 dmm). This result suggests that the PU latex modifier increased the cohesion of the TEA residue. It may be a factor that PU modifier can improve the trackless performance and shear strength.

Figure 8. Penetration, softening point, and ductility of the TEA residue. (a) Permeability, softening point of triethanolamine residues under different polyurethane latex modifiers. (b) Ductility of triethanolamine residues under different polyurethane latex modifiers.

The softening point serves as a means to depict the high-temperature stability of the residue of emulsified asphalt (Chen et al., 2014). From Figure 8a, the softening point increases slowly as the content of the PU latex modifier increases. Compared with common emulsified asphalt residue (40∼55°C), the softening point of TEA residue with PU (65∼75°C) is much higher. The appropriate increase of the softening point is beneficial for improving the trackless performance and interlayer bonding of TEA tack coat.

Asphalt ductility has a strongly positive correlation with low-temperature flexibility (Wu, 2018). As can be seen from Figure 8b, with the rise in the amount of the PU latex modifier, the ductility of the TEA residue shows a progressive increase. The low-temperature flexibility of the TEA residue gradually improved with the addition of PU latex modifier. However, it should be noted that the emulsified asphalt residue must be stirred and heated to 163°C in the process of penetration, softening point, and ductility sample preparation. The gradient structure of PU in the TEA tack coat was destroyed. The PU latex modifier was only a common asphalt modifier dispersed in the emulsified asphalt tack coat.

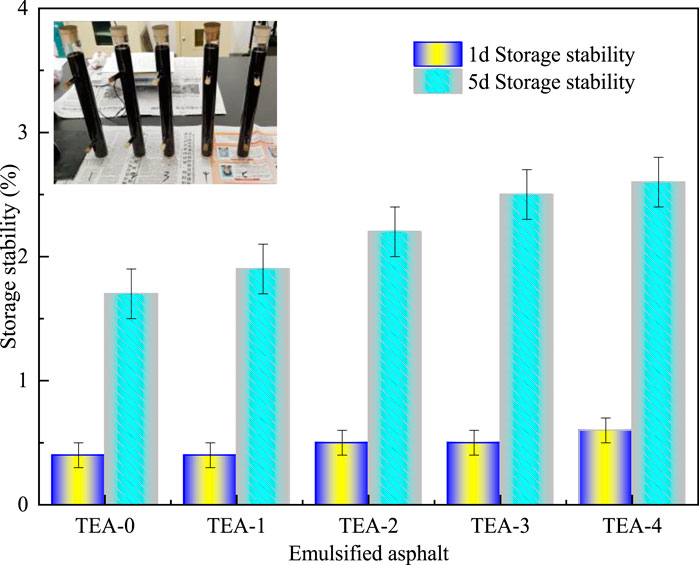

3.2.2 Storage stability

The storage stability of emulsified asphalt is a time-dependent persistent dispersion index which represents the stability and settlement of emulsified asphalt in a period of time (Qiao et al., 2025). As shown in Figure 9, the storage stability of TEA decreases slightly with increasing PU latex modifier addition dosage. The storage stability of TEA with PU latex modifier in 1 day was not greater than 1%, and in 5 days was not greater than 5%. The results show that emulsified asphalt with PU latex modifier has favorable storage stability and meets the requirements of JTG F40.

3.2.3 DSR test S

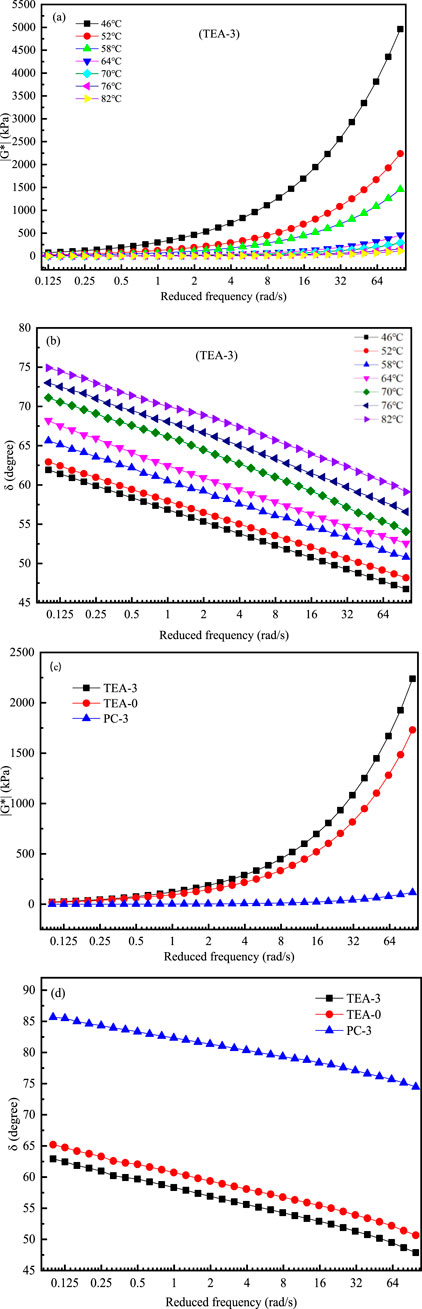

As presented in Figure 10a, there is a direct correlation between the frequency and the complex modulus (|G*|) of the TEA - 3 tack coat at various temperatures. This indicates that tack coat materials possessing a highly complex modulus exhibit greater viscosity; conversely, those with a low complex modulus have lower viscosity. In Figure 10b, the phase angle (δ) of the TEA-3 tack coat increases with increasing temperature, indicating that the elastic recovery ability of the tack coat is reduced. Figure 10c suggests that the complex modulus (|G*|) and the slope of the TEA-3 tack coat curve are greater than those of the TEA-0 and PC-3 tack coats at 52°C. The higher viscosity of the TEA-3 tack coat implies much stronger adhesive and cohesive forces. TEA-3 tack coat may thus have strong adhesion force between layers of asphalt pavement. As shown in Figure 10d, the phase angle (δ) of TEA-3 tack coat is smaller than that of TEA-0 and PC-3 tack coat, suggesting that the former is more viscous than the later and the adhesive force is stronger. The results indicate that TEA-3 tack coat may have better interlayer bonding and shear strength than TEA-0 and PC-3 tack coats.

Figure 10. Rheological properties of TEA tack coat. (a) Effect of temperature on complex modulus (|G*|) of TEA-3 tack coat; (b) effect of temperature on phase angle (δ) of TEA-3 tack coat; (c) complex modulus (|G*|) for tack coat at 52°C; (d) phase angle (δ) for tack coat at 52°C.

3.3 Road performance and tracking behavior

3.3.1 Track-free time analysis

From Figure 11, the area of asphalt adhered on A4 white paper (asphalt adhesion rate) was analyzed by image analysis software (Image-Pro Plus), with the area gradually decreasing with the extension of curing time. The A4 white paper was completely covered with asphalt after track-free time testing at 5-min curing. After 25 min of curing, the TEA-3 tack coat demonstrated an asphalt adhesion rate of 3.8%, exhibiting minimal asphalt residue on the white paper. Comparatively, the TEA-0 and PC-3 tack coats showed significantly higher adhesion rates of 18.2% and 97.8%, respectively. Experimental data revealed that the incorporation of PU latex modifier effectively reduces the track-free time of TEA. Notably, TEA-3 exhibited a track-free time less than 30 min at 35°C, thus substantially decreasing the required curing duration in construction applications.

3.3.2 Tracking resistance test

As shown in Figure 12, the area of asphalt adhered on indenter (rubber) was analyzed by image analysis software (Image-Pro Plus), and the tack coat damage rate gradually decreased with increased PU latex modifier dosage. When heated to 70°C, TEA-3 tack coat exhibited a damage rate of only 1.9%, demonstrating a substantial 97.3% decrease relative to the TEA-0 formulation. The results indicate that the PU latex modifier significantly improved the trackless characteristics of tack coat under elevated temperatures. Furthermore, when the PU latex modifier concentration attained 3%, the damage rate of the coating material reached a plateau. Both TEA-3 and TEA-4 formulations maintained their structural integrity throughout the testing procedure, confirming their superior trackless performance at high-temperature conditions. As shown in Figure 12, the tensile strength of TEA tack coat rapidly decreases with increased PU latex modifier. The tensile strength of TEA-3 tack coat was 37.5 kPa, which was 59.6% lower than that of TEA-0. The results show that the adhesion force between indenter (rubber) and tack coat is reduced by adding PU latex modifier. The results may be due to PU modifier having high cohesion and thermal stability, and PU modifier spontaneously migrating to the tack coat upper apparent. Consequently, the adhesive force between the indenter (rubber) and the tack coat decreased, leading to an improvement in the tack coat’s trackless performance. Based on systematic assessment of three critical performance indicators tracking resistance, track-free period, and storage stability, the investigation concluded that a 3% PU latex modifier content yielded optimal results.

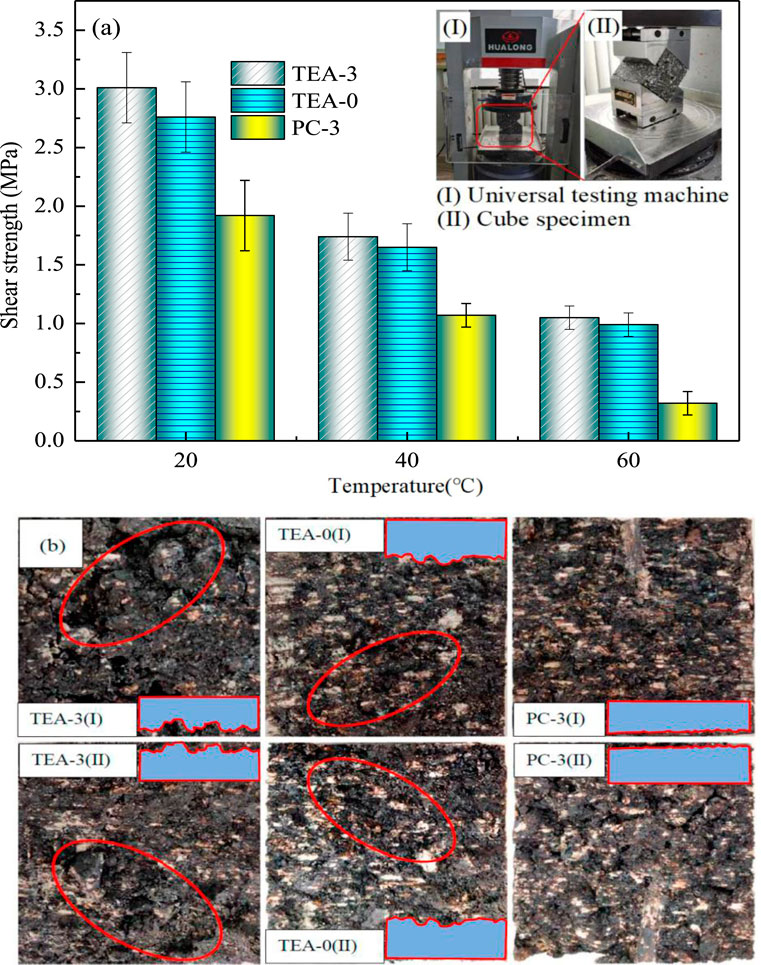

3.3.3 Shearing resistance test

Shear resistance testing was employed to evaluate the interlayer bonding strength of tack coat, with the results shown in Figure 13. As depicted in Figure 13a, within a temperature range of 20°C–60°C, TEA-3 tack coat demonstrated comparable shear strength to TEA-0 while exhibiting superior performance relative to PC-3. At an elevated temperature of 60°C, TEA-3 maintained a shear strength of 1.05 MPa, slightly higher than the 1.01 MPa recorded for TEA-0. Moreover, at 40°C, the shear strength of TEA-3 tack coat rose to 1.6 MPa. The test results show that the TEA tack coat with PU has great shear strength under high temperature. As shown in Figure 13b, the interface of TEA-3 and TEA-0 tack coats after shear failure was irregular, and the asphalt mixture near the tack coat was severely damaged at 40°C. The PC-3 tack coat interface after shear failure was smooth, and the asphalt mixture was basically undamaged. These findings suggest that the TEA tack coat containing PU exhibits substantial shear strength. Compared to TEA-0, the PU latex modifier can marginally enhance shear strength without exerting any adverse impact on the shear strength of TEA tack coat.

Figure 13. Shear strength and interface shear failure of specimens. (a) Shear strength; (b) interface shear failure of specimens.

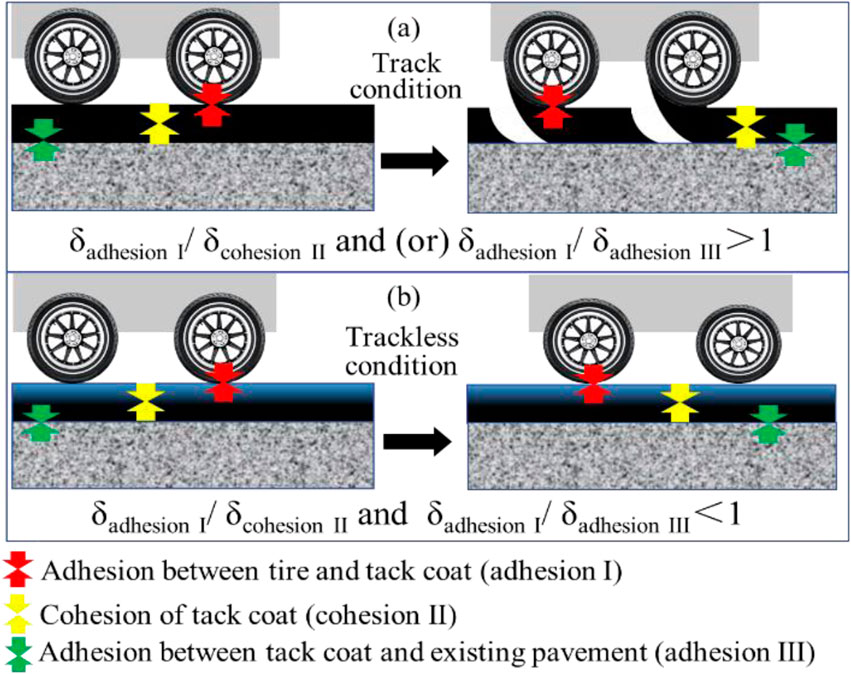

3.3.4 Tracking behavior of tack coat

The effect of construction vehicle tires on tack coat is a complex process which mainly includes the adhesion between tire and tack coat (adhesionⅠ), the cohesion of tack coat (cohesionⅡ), and the adhesive connection between the tack coat and the existing pavement structure (adhesionⅢ). The tack coat is destroyed when adhesionⅠ exceeds cohesionⅡ and/or adhesionⅢ (Seo, 2019; Seo et al., 2016). The tracking behavior of tires on tack coat is shown in Figure 14.

Figure 14. Tracking behavior of tires on tack coat. (a) TEA tack coat without PU modifier; (b) TEA bonding coat containing PU additive.

As shown in Figure 14a, adhesionⅠ of TEA-0 tack coat increases with increased temperature, while cohesionⅡ and adhesionⅢ decrease. The tack coat is damaged when adhesionⅠ exceeds cohesionⅡ and/or adhesion Ⅲ. From Figure 14b, the PU-modified TEA formulation was applied onto the pre-existing pavement surface by spraying, creating a concentration gradient of PU throughout the tack coat layer. The enhanced thermal properties of the PU modifier, particularly its elevated viscous flow temperature and thermal stability, maintained adhesiveⅠ at reduced levels even under high temperatures of 70°C. Additionally, cohesionⅡ and cohesiveⅢ are greatly improved by using anti-rut asphalt master batch and hard asphalt. AdhesionⅠ of TEA with PU latex modifier is also less than that of cohesionⅡ and adhesionⅢ in high temperature (70°C). Therefore, TEA tack coat with PU still has great trackless performance. Tack coat without the PU latex modifier has a great risk of tracking when asphalt pavements are constructed in summer (especially over 60°C).

4 Conclusion

The present research focuses on the development of an innovative TEA adhesive layer by adding PU latex modifier; its gradient distribution, basic performance, and road performance were investigated and discussed in detail. Throughout the curing phase, the PU modifier demonstrated spontaneous surface migration, creating a concentration gradient within the TEA tack coat matrix. Experimental results revealed that the TEA-3 formulation maintained a shear strength exceeding 1.0 MPa at 60°C while exhibiting exceptional trackless characteristics at elevated temperatures up to 70°C. Furthermore, at 35°C, TEA-3 tack coat achieved track-free status within 30 min, significantly enhancing asphalt pavement construction productivity. The comprehensive evaluation of tracking resistance, track-free duration, and storage stability parameters indicated that 3% represents the optimal PU latex modifier concentration. The developed PU-modified TEA tack coat demonstrates substantial potential for highway applications, offering an optimal balance between cost efficiency, superior trackless performance, and enhanced shear strength properties.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material; further inquiries can be directed to the corresponding authors.

Author contributions

XF: investigation, conceptualization, writing – original draft, resources, project administration, and visualization. GZ: methodology, investigation, writing – review and editing, funding acquisition, and data curation. HW: investigation, writing – original draft, data curation, and resources. LL: writing – original draft. ZQ: writing – original draft, formal analysis, and data curation. QM: validation, visualization, and writing – original draft. WL: writing – review and editing. WH: writing – original draft and supervision.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by Development of a High-Precision Intelligent Simulation and Active Prevention Cloud Platform for the Service Performance of Asphalt Pavements on Coastal Hot and Humid Highways. The project number is GuikeAB22080091.

Conflict of interest

Authors XF and HW were employed by Guangxi Land and Resources Planning and Design Group Co., Ltd. Author LL was employed by Guangxi Xinfazhan Communications Group Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Akindoyo, J. O., Beg, M., Ghazali, S., Islam, M., Jeyaratnam, N., and Yuvaraj, AJRA (2016). Polyurethane types, synthesis and applications: a review. RSC Adv. 6 (115), 114453–114482. doi:10.1039/c6ra14525f

Al-Qadi, I. L., Carpenter, S. H., Leng, Z., and Ozer, H. (2008). Tack coat optimization for HMA overlays laboratory testing.

Standard test methods of bitumen and bituminous mixtures for highway engineering the Ministry of Transport of the People’s Republic of China (2024).

Baghdachi, J., Perez, H., Talapatcharoenkit, P., and Wang, B. (2015). Design and development of self-stratifying systems as sustainable coatings. Prog. Org. Coatings 78, 464–473. doi:10.1016/j.porgcoat.2014.06.017

Beaugendre, A., Degoutin, S., Bellayer, S., Pierlot, C., Duquesne, S., Casetta, M., et al. (2017). Self-stratifying coatings: a review. Prog. Org. Coatings 110, 210–241. doi:10.1016/j.porgcoat.2017.03.011

Chen, M., Leng, B., Wu, S., and Sang, Y. (2014). Physical, chemical and rheological properties of waste edible vegetable oil rejuvenated asphalt binders. Constr. Build. Mater. 66, 286–298. doi:10.1016/j.conbuildmat.2014.05.033

Cui, Y., Wang, H., Pan, H., Yan, T., and Zong, C. (2021). The effect of mixed soft segment on the microstructure of thermoplastic polyurethane. J. Appl. Polym. Sci. 138 (45). doi:10.1002/app.51346

Dai, Z., Jiang, P., Lou, W., Zhang, P., Bao, Y., Gao, X., et al. (2020). Preparation of degradable vegetable oil-based waterborne polyurethane with tunable mechanical and thermal properties. Eur. Polym. J. 139, 109994. doi:10.1016/j.eurpolymj.2020.109994

Fihri, A., Bovero, E., Al-Shahrani, A., Al-Ghamdi, A., and Alabedi, G. (2017). Recent progress in superhydrophobic coatings used for steel protection: a review. Colloids Surfaces A Physicochem. Eng. Aspects 520, 378–390. doi:10.1016/j.colsurfa.2016.12.057

Fu, H., Wang, C., Niu, L., Yang, G., and Liu, L. (2021). Composition optimisation and performance evaluation of waterborne epoxy resin emulsified asphalt tack coat binder for pavement. Int. J. Pavement Eng. 23 (11), 4034–4048. doi:10.1080/10298436.2021.1932878

Gingras, J.-P., Tanguy, P. A., Mariotti, S., and Chaverot, P. (2005). Effect of process parameters on bitumen emulsions. Chem. Eng. Process. Process Intensif. 44 (9), 979–986. doi:10.1016/j.cep.2005.01.003

Guo, T., Kai, J., Wenwen, F., and Wen, Z. (2021). Study on Preparation and mechanism of trackless emulsified asphalt. J. China and Foreign Highw. (41), 242–248.

Hou, D., Han, M., Muhammad, Y., Liu, Y., Zhang, F., Yin, Y., et al. (2018). Performance evaluation of modified asphalt based trackless tack coat materials. Constr. Build. Mater. 165, 385–394. doi:10.1016/j.conbuildmat.2017.12.187

Hu, M., Lyu, L., Pahlavan, F., Han, P., Sun, D., and Fini, E. H. (2025). Toward sustainable non-emitting asphalts: understanding diffusion–adsorption mechanisms of hazardous organic compounds. Adv. Sustain. Syst. 9 (3), 2400868. doi:10.1002/adsu.202400868

Hu, Y., Zhang, C., Chen, Y., Liu, X., Lv, M., and Hu, L. (2010). Preparation and structure of fluorinated/non-fluorinated polyacrylate gradient emulsion blend film. Mater. Lett. 64, 2091–2093. doi:10.1016/j.matlet.2010.06.048

Huang, G., Qi, T., Zhang, X., Yang, L., Hao, Y., Zhou, C., et al. (2024). Study on the preparation and modification mechanism of GO/SBR composite modified emulsified asphalt. Road Materials and Pavement Design 26 (6), 1265–1286. doi:10.1080/14680629.2024.2412093

Ji, S., Gui, H., Guan, G., Zhou, M., Guo, Q., and Tan, M. Y. J. (2021). Molecular design and copolymerization to enhance the anti-corrosion performance of waterborne acrylic coatings. Prog. Org. Coatings 153, 106140. doi:10.1016/j.porgcoat.2021.106140

Langer, E., Waśkiewicz, S., Kuczyńska, H., and Kamińska-Bach, G. (2014). Self-stratifying coatings based on Schiff base epoxy resins. J. Coatings Technol. Res. 11 (6), 865–872. doi:10.1007/s11998-014-9603-x

Li, J., Duan, S., Muhammad, Y., Liu, Y., Hou, D., Yang, S., et al. (2019). Synthesis and performance evaluation of modified asphalt-based trackless tack coat material. J. Mater. Civ. Eng. 31 (9). doi:10.1061/(asce)mt.1943-5533.0002812

Li, N., Morozov, I. B., Fu, L. Y., and Deng, W. (2025). Unified nonlinear elasto-visco-plastic rheology for bituminous rocks at variable pressure and temperature. J. Geophys. Res. Solid Earth 130 (3). doi:10.1029/2024jb029295

Mohammad, L. N., Elseifi, M. A., Bae, A., Patel, N., Button, J. W., and Scherocman, R. (2012). Optimization of tack coat for HMA placement. Copyright National Academy of Sciences. Available online at: https://nap.nationalacademies.org/catalog/13652.

Peng, Y., Zhao, T., Miao, J., Kong, L., Li, Z., Liu, M., et al. (2024). Evaluation framework for bitumen-aggregate interfacial adhesion incorporating pull-off test and fluorescence tracing method. Constr. Build. Mater. 451, 138773. doi:10.1016/j.conbuildmat.2024.138773

Qiao, Y., Bian, X., Ke, H., Zhao, Z., Zhang, X., Zhang, X., et al. (2025). Phenolic-based porous composite with embedded short carbon fiber/hollow spheres for mechanical properties and thermostability. Compos. Commun. 55, 102305. doi:10.1016/j.coco.2025.102305

Seo, A. Y. (2019). Quantitative measurement of tackiness and bonding potential of trackless tack coat. Tex. A&M Univ. Available online at: https://hdl.handle.net/1969.1/189179.

Seo, A. Y., Sakhaeifar, M. S., and Wilson, B. T. (2016). Tackiness properties of non-tracking tack coats. Pap. Present. A. T. Int. Conf. Transp. Dev., 740–751. doi:10.1061/9780784479926.068

Seo, A. Y., Sakhaeifar, M. S., and Wilson, B. T. (2017). Evaluating tack properties of trackless tack coats through dynamic shear rheometer. Transp. Res. Rec. 2632, 119–129. doi:10.3141/2632-13

Sheng, X., Wang, M., Xu, T., and Chen, J. (2018). Preparation, properties and modification mechanism of polyurethane modified emulsified asphalt. Constr. Build. Mater. 189, 375–383. doi:10.1016/j.conbuildmat.2018.08.177

Shi, X., Rew, Y., Ivers, E., Shon, C.-S., Stenger, E. M., and Park, P. (2019). Effects of thermally modified asphalt concrete on pavement temperature. Int. J. Pavement Eng. 20 (6), 669–681. doi:10.1080/10298436.2017.1326234

Voogt, B., Huinink, H. P., Erich, S. J. F., Scheerder, J., Venema, P., Keddie, J. L., et al. (2019). Film Formation of high tg latex using hydroplasticization: explanations from NMR relaxometry. Langmuir 35, 12418–12427. doi:10.1021/acs.langmuir.9b01353

Wang, J., Xiao, F., Chen, Z., Li, X., and Amirkhanian, S. (2017). Application of tack coat in pavement engineering. Constr. Build. Mater. 152, 856–871. doi:10.1016/j.conbuildmat.2017.07.056

Winnik, M. A. (1997). Latex film formation. Curr. Opin. Colloid and Interface Sci. 2 (2), 192–199. doi:10.1016/s1359-0294(97)80026-x

Wu, S. (2018). Characterization of ductility of field-aged petroleum asphalt. Petroleum Sci. Technol. 36 (9-10), 696–703. doi:10.1080/10916466.2018.1443125

Yang, C., Zhang, J., and Huang, W. (2017). Preparation of emulsified hard asphalt and its performance evaluation in tack coat, Petroleum Asphalt. Pet. Asph. 31 (01), 64–67. Available online at: https://qikan.cqvip.com/Qikan/Article/Detail?id=671448263 (in Chinese).

Zhang, W. (2017). Effect of tack coat application on interlayer shear strength of asphalt pavement: a state-of-the-art review based on application in the United States. Int. J. Pavement Res. Technol. 10 (5), 434–445. doi:10.1016/j.ijprt.2017.07.003

Keywords: tack coat, emulsified asphalt, polyurethane, self-migration, tracking resistance, shearing resistance

Citation: Feng X, Zhou G, Wang H, Lv L, Qin Z, Ma Q, Li W and Huang W (2025) Synthesis of trackless emulsified asphalt tack coat with gradient distribution of polyurethane via self-migration and its performance evaluation. Front. Mater. 12:1594920. doi: 10.3389/fmats.2025.1594920

Received: 18 March 2025; Accepted: 13 May 2025;

Published: 02 July 2025.

Edited by:

Songtao Lv, Changsha University of Science and Technology, ChinaReviewed by:

Mahmoud Ebrahimi, University of Maragheh, IranYuyao Kuang, University of California, Irvine, United States

Copyright © 2025 Feng, Zhou, Wang, Lv, Qin, Ma, Li and Huang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Gaowei Zhou, emhvdTI5MjU1NTY4MDBAMTYzLmNvbQ==; Qing Ma, Njk0MjE2MTU3QHFxLmNvbQ==

Xuemao Feng1

Xuemao Feng1 Gaowei Zhou

Gaowei Zhou