- 1National University of Sciences and Technology (NUST), Risalpur Campus, Risalpur, Pakistan

- 2Department of Information Technology, College of Computer and Information Sciences, Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia

- 3Department of Civil Engineering, GIK Institute of Engineering Sciences and Technology, Swabi, Pakistan

- 4Department of Civil Engineering, College of Engineering, King Khalid University, Abha, Saudi Arabia

- 5Department of Civil Engineering, College of Engineering in Al-Kharj, Prince Sattam Bin Abdulaziz University, Al-Kharj, Saudi Arabia

- 6Faculty of Computers and Artificial Intelligence, Benha University, Benha, Egypt

The increasing demand for sustainable concrete has encouraged the use of recycled aggregates (RA), though their limited performance under elevated temperatures remains a key challenge. This study explores the use of supplementary cementitious materials (SCMs) to improve the thermal resistance of recycled aggregate concrete (RAC). Three concrete mixes containing 0%, 25%, and 50% RA were exposed to temperatures up to 600°C. The effects of incorporating 15% silica fume (SF) and 30% fly ash (FA) on residual compressive and tensile strengths were evaluated. Response Surface Methodology (RSM) was employed for experimental design and optimization, while analysis of variance (ANOVA) confirmed the statistical significance of key influencing factors, including temperature and SCM content. Results showed that SCMs improved tensile strength by up to 12% in RAC25 and helped retain strength at elevated temperatures, despite some reduction in compressive strength due to thermal stress. Among all mixes, RAC25 with SCMs showed the most balanced performance. The study highlights the potential of combining SCMs with RSM-based optimization to enhance the fire resistance of RAC. These findings contribute to the development of more durable, eco-efficient concrete materials, particularly for fire-prone or high-temperature environments, and support the advancement of sustainable construction practices.

1 Introduction

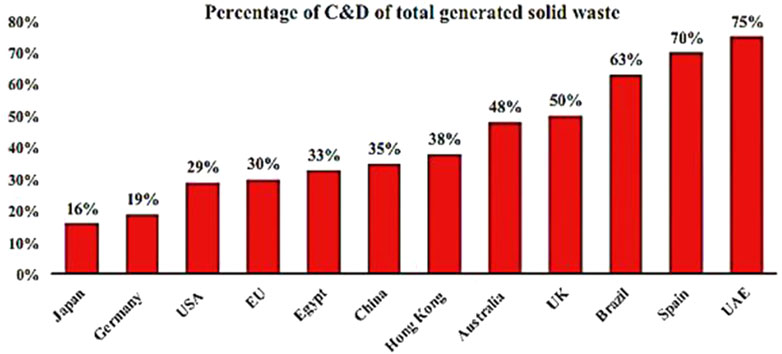

Concrete waste, commonly referred to as construction and demolition (C&D) waste, constitutes a substantial portion of industry-generated waste. Its accumulation poses environmental concerns due to the unsustainable use of construction materials (see Figure 1) (Ashraf et al., 2022). Globally, more than 3 billion tons of C&D waste is generated every year. China, India, and the United States collectively produce over 2 billion tons annually (Sahoo et al., 2024; Agamuthu and Babel, 2023). China consumed 100 years of USA cement usage in just 2 years, resulting in 818 million metric tons of CO2 emissions from concrete alone (China uses as much cement, 2024). Recycling concrete waste as aggregates and reusing it to make new concrete is crucial due to the benefits and potential for resource conservation (Villagrán-Zaccardi et al., 2022). Recycled Aggregate Concrete (RAC) represents a notable innovation in the global construction industry. It involves incorporating recycled aggregates into concrete, thereby reducing the demand for natural resources and promoting the sustainable management of construction and demolition waste. In countries such as Qatar and the United Arab Emirates (UAE), where natural aggregate sources are limited, there is a growing reliance on imported materials or the extraction of mineral aggregates from the seafloor (Torres et al., 2021). Proper waste management could lead to significant energy savings through supplementing aggregates with C&D waste, leading to cost savings (Bao, 2023; Asif et al., 2024a; Asif et al., 2024b). Using recycled aggregates in concrete contributes to sustainability and waste reduction. However, their application is limited due to inferior properties such as higher porosity, greater water absorption, and weak interfacial transition zones (ITZ), which negatively affect strength and durability (Kwa et al., 2012).

Figure 1. Percentage of construction and demolition waste with the total waste generated in different countries (Alsheyab, 2022).

Li and Wong (2024), Fanijo et al. (2023) research has shown that recycled aggregate-based concrete is generally weaker than traditional concrete, but it still meets the necessary strength requirements for construction. RAC has achieved compressive strengths of 25–30 MPa, making it suitable for various structural applications. RAC’s behavior under elevated temperatures is of particular interest due to increasing concerns over fire safety in concrete structures (Kodur, 2000). However, RAC tends to exhibit more pronounced degradation under high-temperature exposure compared to natural aggregate concrete (NAC), primarily due to weak ITZs, residual mortar content, and microcracks (Khan et al., 2025a; Pereiro-Barceló et al., 2024).

Recent research has increasingly focused on the thermal behavior of concrete under elevated temperatures, particularly regarding degradation mechanisms and the residual performance of recycled aggregate concrete (RAC). Exposure to high temperatures leads to strength loss, increased porosity, and microcracking due to dehydration of the cement matrix and decomposition of calcium hydroxide (Cao et al., 2024). RAC, in particular, is more susceptible to these effects due to its weaker interfacial transition zones (ITZs) and the presence of pre-existing microcracks (Ahmed et al., 2022). As per (Ahmed et al., 2022; Dahish et al., 2023), RAC’s thermal performance is similar to that of conventional concrete in terms of its thermal properties. The study concluded that even when exposed to temperatures up to 600°C, RAC was able to retain approximately 60% of its original compressive strength and structural integrity. In a 2023 study, RAC incorporating GGBS retained significantly higher strength compared to control mixes, maintaining 17 MPa after exposure to 600°C, and as low as 7 MPa at 800°C. Furthermore, a study demonstrated that RAC-filled steel-tubular columns performed better under fire compared to traditional NAC columns, showing slower heat penetration and improved fire endurance (Dong et al., 2014). Mineral admixtures like bentonite clay have been found to improve high-temperature resistance and densify the cement matrix, thereby reducing crack propagation and permeability (Khan et al., 2025b).

When normal fineness silica fume (SF) and fly ash (FA) are added to concrete, they may initially reduce its strength. However, in the long term, they provide benefits such as improved strength and durability, enhanced workability, reduced permeability and porosity, and reduced expansion due to alkali-silica reactivity (Ahmad et al., 2023; Asif et al., 2024c). Bentonite clay, silica fume (SF), fly ash, and ground granulated blast furnace slag (GGBS) have been widely utilized as supplementary cementitious materials in Portland cement concrete and blended cements. Among these, metakaolin (MK) and silica fume are particularly effective in enhancing the mechanical strength and durability of concrete due to their high pozzolanic reactivity (Devarangadi et al., 2024; Singh et al., 2023). The use of SF as a partial replacement for regular Portland cement results in a denser matrix, enhancing the strength and durability of concrete and extending the service life of concrete structures. To further understand the thermal behavior of RAC enhanced with SCMs, a multiscale analytical approach is recommended.

Concrete is a heterogeneous composite material whose behavior under thermal and mechanical loads is influenced by interactions occurring at multiple scales. According to Stukhlyak (Stukhlyak et al., 2015), a comprehensive understanding of composite materials such as concrete can be achieved through multiscale analysis at macro-, meso-, and microlevels. In the context of recycled aggregate concrete exposed to elevated temperatures, such an approach is essential to evaluate the complex interactions between the cement matrix, aggregates, and pozzolanic materials. This multiscale framework aids in identifying degradation mechanisms and optimizing concrete formulations for fire resilience. This multiscale perspective is particularly important when optimizing the material composition for durability and performance. Additionally, multi-scale homogenization techniques like those by Pelissou et al. (2009), Gitman et al. (2007) offer numerical and statistical tools for linking microstructural features to the overall mechanical response, allowing for a better theoretical understanding of concrete’s behavior at elevated temperatures.

To validate these properties, Response Surface Methodology (RSM) is utilized, which is a useful statistical tool that can be used to optimize concrete mix designs. RSM enables researchers to model the relationships between different mix components and their impact on the desired properties of the concrete (Abdullah et al., 2024). This approach enables the determination of the best mix proportions while maintaining or enhancing critical performance metrics like compressive strength, flexural strength, and durability (Adamu et al., 2022). In recent years, RSM has been increasingly utilized in the optimization of concrete mixes, demonstrating its effectiveness in improving material performance across a range of applications (DeRousseau et al., 2018; Mandal et al., 2024). Experiments were conducted using Response Surface Methodology to explore the relationship between compressive and tensile strength responses and variables, including mix design, temperature, and pozzolanic component concentration. RSM is widely used in the cement and concrete industries to improve the elements (independent variables) that affect the trial outcomes (dependent variables/responses). Using ANOVA, each factor’s contribution, mutual interaction, and influence on the experiment’s outcomes are carefully evaluated (Reji and Kumar, 2022).

Several studies have shown that incorporating SCMs like fly ash, silica fume, and GGBS into RAC improves strength and durability, but they focus only on normal temperature conditions. Kou and Poon (2009) found significant strength enhancements, while (Gonzalez-Corom et al., 2014) reported improved durability. Nguyen (2024), Rakshvir and Barai (2006) observed similar improvements in compressive strength and elastic modulus. However, these studies did not explore high-temperature performance, which is the focus of this research.

This study aims to fill this gap by focusing on evaluating SCM-based RAC performance at elevated temperatures due to the time-intensive nature of experimental testing for optimization. Therefore, this research investigated the high-temperature performance of SCM-based RAC, using experimental testing and RSM for efficient optimization, contributing to enhanced concrete sustainability and fire resistance.

2 Materials

This section presents the materials used in the research study and its various experimental procedures and methods.

2.1 Binder

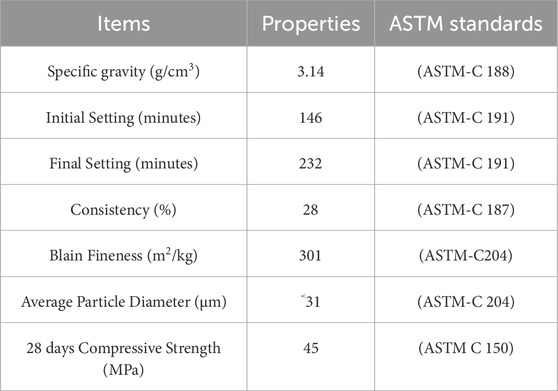

Ordinary Portland Cement (OPC) with a 3140 kg/m3 density was utilized as a binder. The cement conforms to ASTM C150 (C150 standard specification for Portland cement, 2024). The physical properties of the cement are presented in Table 1.

2.2 Aggregates

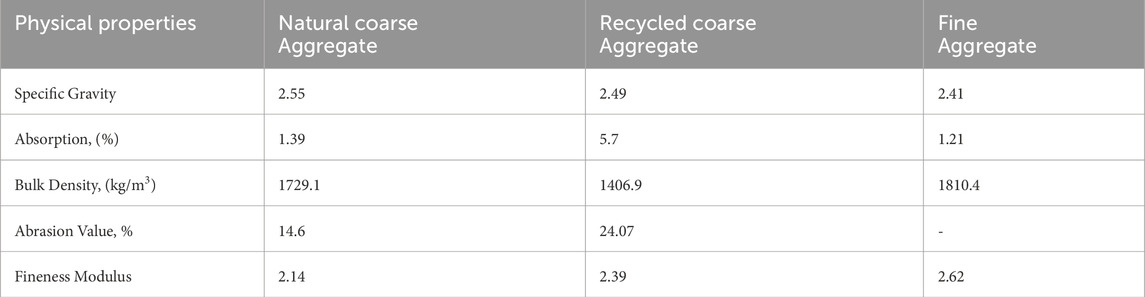

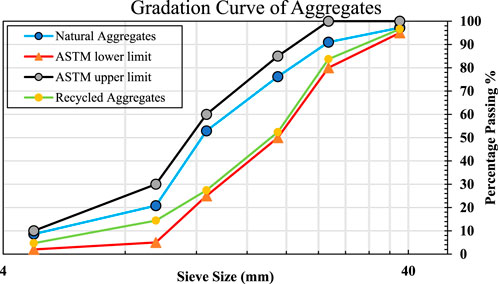

Sand with a fineness modulus of 2.62 from a local source as fine aggregate. Normal-weight crushed minerals were used as coarse aggregate. Recycled aggregates were made by crushing tested concrete cylinders at the National University of Sciences and Technology (NUST) concrete laboratory. The maximum size of both recycled and natural aggregates was 24 mm. We formed two fractions of recycled coarse aggregates. The first fraction had sizes of (5–15) mm, and the other had a particle size of (15–24) mm. They were mixed in a 3:2 ratio. We conducted this with the idea that adding smaller coarse aggregates to high-quality mixes would enhance the concrete’s mechanical strength by reducing the interfacial transition zone. Standard tests were executed to assess the natural aggregates and recycled aggregates’ physical properties. Table 2 shows the results of these tests. Sieve analysis was conducted for both aggregates according to ASTM C33-16 (C33/C33M standard specification for concrete aggregates, 2024). Figure 2 shows the gradation of aggregates.

2.3 Chemical admixture

The concrete mixes were produced using a chemical admixture based on polycarboxylates. This resulted in concrete with enhanced slump retention, reduced water usage, and increased strength development. Due to the elevated water absorption of recycled aggregate, a substantial decrease in water content was required. In this study, Sika® ViscoCrete-3110 was utilized as a superplasticizer to achieve the desired properties in the concrete mixture. Sika® ViscoCrete-3110 meets the requirements of ASTM C494C/494M.

2.4 Fly ash (FA) and silica fume (SF)

FA was incorporated into the concrete mixture as an ingredient. It consists of finely ground and reactive silica, which offers significant benefits such as improved internal cohesion and enhanced fluid retention. It primarily contains alumina silicate pozzolan and resembles a fine grey powder, with a specific gravity of 2.2. Additionally, a compact form of SF with a high bulk density of 660 kg/m3 was utilized in the study. This densified silica fume exhibits a superior microstructure due to its high density and average particle size.

2.5 Methods

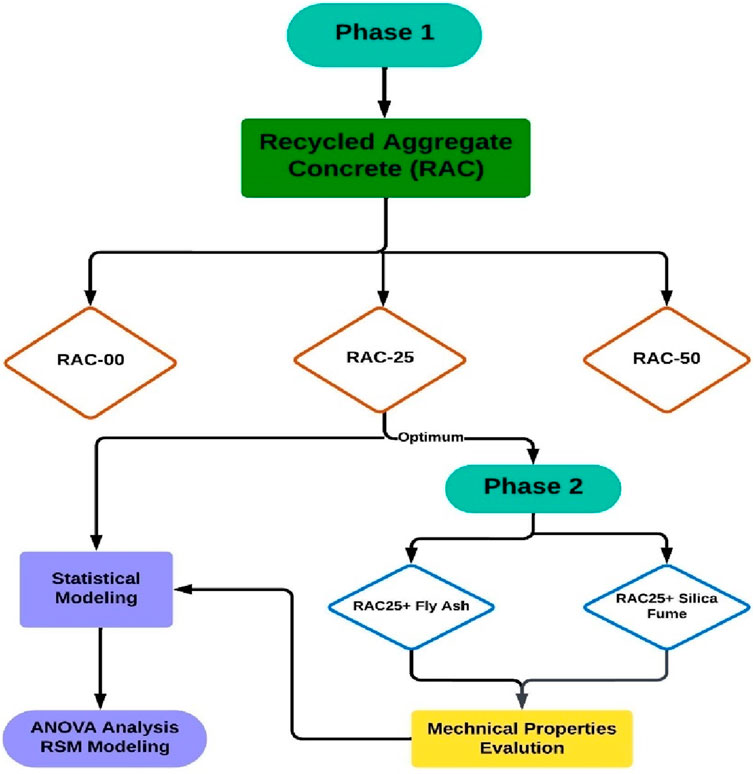

This experimental research examined the behavior of RAC incorporating SCMs under moderate and high temperatures. The study consisted of two phases. In the first phase, the mechanical and physical properties of RAC with 25% and 50% recycled aggregate were examined and compared with NAC in terms of high-temperature behavior. The RAC mixtures were labeled as RAC25 and RAC50, representing the percentage of recycled aggregates used in replacement. In the second phase, a standard concrete mixture with recycled aggregates was used as a baseline, and FA and SF were added to separate batches. The concrete samples were then exposed to 25–600°C.

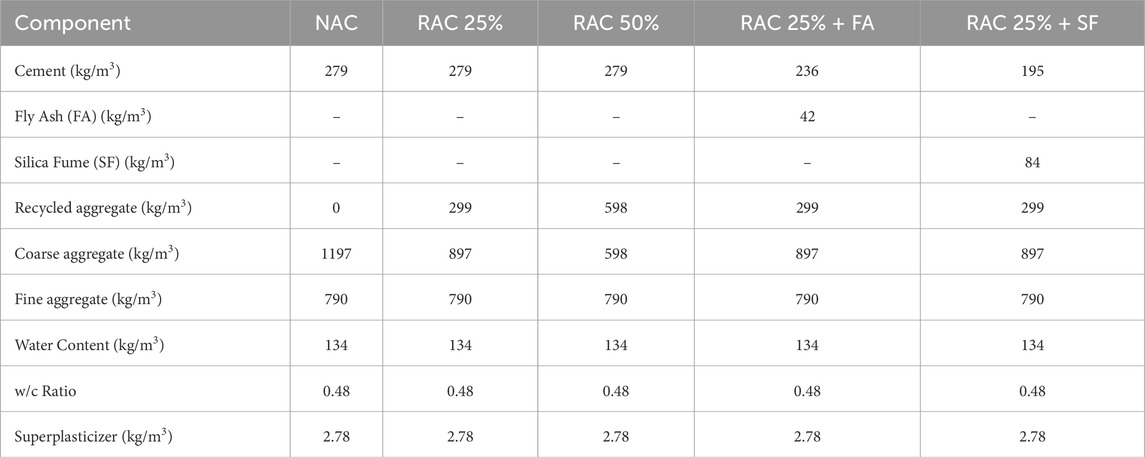

Following the ACI mixture design 211.4, the mixture proportions were determined through laboratory trials. Details of the mixture proportions and laboratory conditions can be found in Table 3. NAC was employed as a control specimen. The research schematic diagram is depicted in Figure 3. The study set out to compare and draw conclusions from these comparative analyses.

2.6 Specimen casting and curing

Recycled aggregates were first oven-dried and then soaked in water for 24 h to account for their high water absorption. The amount of absorbed water was added to the mixing water. A vertical drum mixer was used to combine all the proportioned ingredients. Cylindrical specimens (15 cm in diameter and 30 cm in height) were fabricated to determine compressive strength, tensile strength, and fracture properties of the studied concretes. After pouring, the specimens were left in molds for 24 h before being demolded and water-cured for 28 days at an average temperature of 23°C. Tests were conducted in accordance with ASTM C192/C192M-19. In total, 5 batches of concrete were made for each temperature variation, resulting in a total of 90 concrete cylinders.

2.7 Tests description

Uniaxial compression tests were conducted on all mixtures using a servo-hydraulic universal testing machine with a capacity of 1200 kN, following 28 days of curing at ambient temperature. Additionally, a split cylinder tensile strength test was carried out on mixtures at 28 days to ascertain their tensile capacity. The tests were conducted following the specified standard procedures outlined in ASTM C39/C39M-18.

2.8 Fire loading characteristics

In this study, the furnace’s heating rate was controlled to prevent significant thermal gradients and reduce the risk of high-temperature differentials that could result in spalling. A general guideline of standard procedure by ASTM E119 was followed. A slow, uniform heating rate of 5°C/min was employed to ensure that the temperature rise within the specimens was gradual and that tensile stresses were minimized. Even though the furnace temperature increases at a faster rate than the cylinder’s surface and core temperatures, the slow heating rate allowed for better uniformity between the furnace environment and the samples.

Specifically, two type-K thermocouples were embedded in each specimen—one at the core and one at the surface—to monitor internal and external temperatures during heating, as recommended by ISO 834. This setup allowed for accurate tracking of thermal gradients and ensured uniform temperature exposure throughout the specimens.

Additionally, to ensure that the specimens were subjected to consistent thermal conditions, the cylinders were placed centrally inside the electric furnace. The furnace temperature was allowed to stabilize before each cycle, and the heating process was controlled to allow the core temperature to reach the target temperatures (300°C and 600°C) without significant thermal gradients. A hold time of 2 h was provided once the core reached 300°C, and 3.5 h for the core to reach 600°C. These measures ensured that all specimens experienced controlled and uniform thermal conditions throughout the heating process.

After heating to the target temperature, all specimens were cooled in still air under ambient laboratory conditions (approximately 23°C ± 2°C). This air cooling method was selected to reflect a gradual, realistic post-fire scenario and to avoid inducing thermal shock, which may occur in water quenching. The cooling process continued until specimens reached room temperature before testing was conducted.

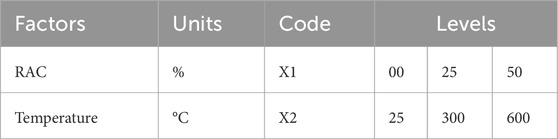

2.9 RSM-based design of experiment

Response Surface Methodology, or RSM, is a statistical method that is frequently applied to the planning, evaluation, improvement, and verification of experimental data. The design of experiments, the creation of statistical models, and the analysis of the relationships between independent variables (causes) and dependent variables (responses) are often used in the concrete. Design Expert 13.0 software was utilized in this study to apply the Optimal Custom Design (OCD) technique for designing trials and identifying analytic components. Optimal Custom Design was selected to minimize the number of runs while ensuring efficient estimation of main effects, interaction terms, and quadratic effects. This method allowed the inclusion of practical constraints on factor levels, ensuring that no unfeasible or overly dense mix proportions were tested. Compressive strength, tensile strength, were the responses taken into account in this experiment, while temperature and RAC quantities influenced factors. The mechanical properties, including compressive and tensile strength, were statistically analyzed using RSM. A polynomial equation of second degree was utilized to anticipate the solutions to the linear and quadratic polynomial equation models that were offered to forecast the strength properties of concrete. The simplified equation for the expected model that was used is shown in Equation 1.

In the equation, X1 and X2 represent the independent variables, which stand for temperature and %RAC, respectively. C is the constant of interception, while A1 through A5 are coefficients. Y represents the response obtained from the experimental data, which includes compressive strength and tensile strength. After selecting components at both low and high levels, a design for 54 experimental runs was created. To ensure the reliability of the experiment’s design and analysis, the key points were replicated five times. The relevant slots in the design expert software were filled using experimental data for compressive and tensile strength. The %RAC and temperature components were then analyzed, modeled, and optimized.

An ANOVA was conducted to assess the model’s performance. The fittingness of the regression models was assessed using the ANOVA’s F-value, p-value, and lack-of-fit metrics. Additionally, the design expert software generates a 3D graphical model to demonstrate how different elements influence the selected response according to the suggested model.

Based on different design factors, the coded equation was developed based on D-optimality criteria to ensure efficient model estimation within the specified factor ranges. Making different variables (like °C and %) comparable and improving the numerical stability of regression models.

Where:

Xi is coded value of the factor (used in regression models)

xi Actual experimental value (e.g., RAC = 25%)

xo Centre point of the factor range (average of low and high levels)

ΔX Step change or half the range of the factor

3 Results and discussions

3.1 Compressive strength

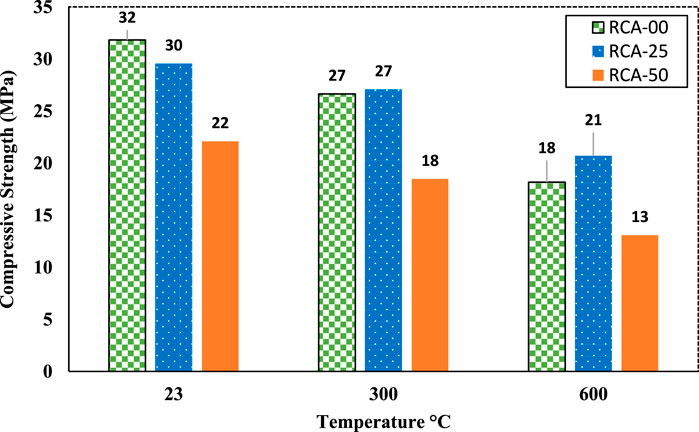

The average compressive strength of all the concrete mixes is depicted in Figure 4. The 28-days strength of NAC achieved at room temperature was approximately 32 MPa. When the samples were heated to 300°C, there was a 16% decrease in strength, which further declined sharply to more than 50% of residual strength at 600°C. Compared to NAC, concrete with 25% and 50% recycled aggregates decreased compressive strength by 10%–30% at 23°C. However, at 300°C, RAC25 showed a significantly lower decline in strength, with only a 1% reduction compared to ambient temperature. Similar findings were observed for RAC50. At 600°C, RAC25 experienced a 28% loss of strength, while RAC50 exhibited a 60% decline. These results indicate that concrete specimens with recycled aggregates were less susceptible to strength loss at high temperatures. Test results for RAC25 were more similar to NAC across all temperature ranges. Consequently, RAC25 was chosen as the new baseline before adding SCMs to the concrete.

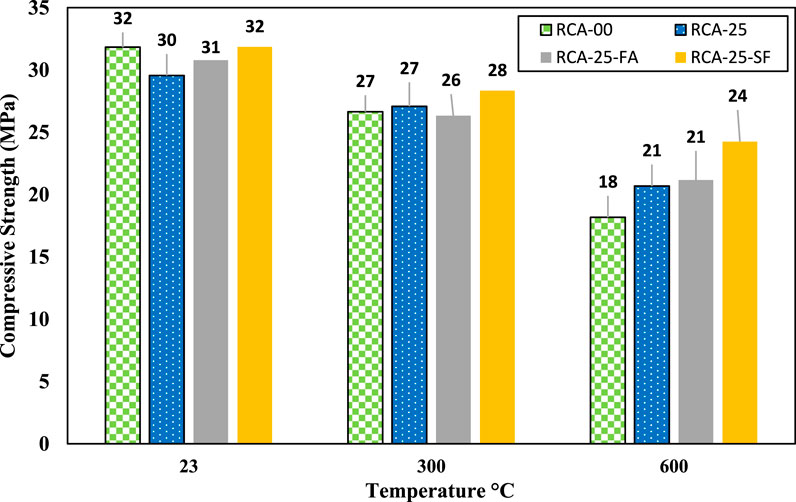

Previous research has demonstrated that adding 30% FA (Amrutha et al., 2011; Khan et al., 2020; Abdelmelek and Lubloy, 2022) and 15% SF (Wang et al., 2020; Nkanpa Moffo et al., 2023) into concrete mixes enhances their properties. These material proportions were utilized to enhance the mechanical characteristics of RAC25 in this study and to explore the feasibility of using pozzolanic materials as a sustainable substitute for conventional cement in recycled aggregate concrete. As shown in Figure 5, when combining RCA25 with 30% FA, the compressive strength at room temperature was 30.78 MPa, surpassing the strength of RCA25 alone by 1.25 MPa. However, at temperatures of 300°C and 600°C, compressive strength decreased to 26.33 MPa and 21.17 MPa, respectively. Similarly, adding the optimal amount of SF into RAC resulted in significant improvements. At room temperature, the compressive strength reached 33.23 MPa, exceeding the strength of RCA25 by 4.14 MPa and NAC by 1.38 MPa. When exposed to temperatures of 300°C and 600°C, the strength was 28.81 MPa and higher than that of RCA25. Recent studies have also highlighted that the incorporation of supplementary materials like FA and SF can enhance the thermal resilience of cementitious composites by refining the pore structure and improving the microstructural integrity of the matrix and ITZ at elevated temperatures (He et al., 2024; He and Lu, 2024a). These findings demonstrate the significant improvement in concrete properties achieved by adding FA and SF at normal and high temperatures.

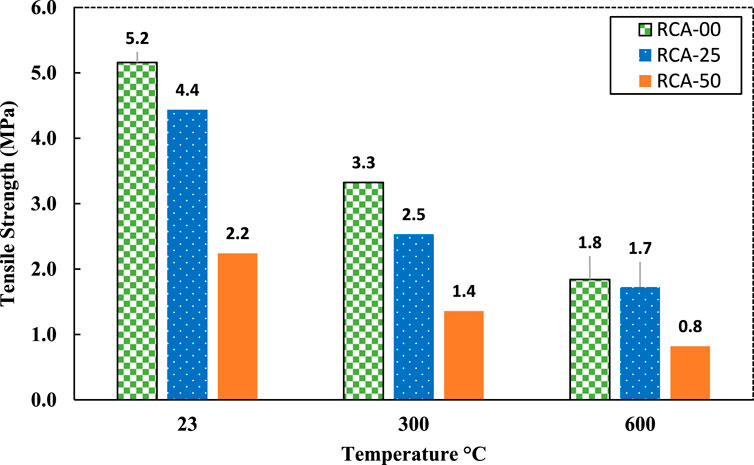

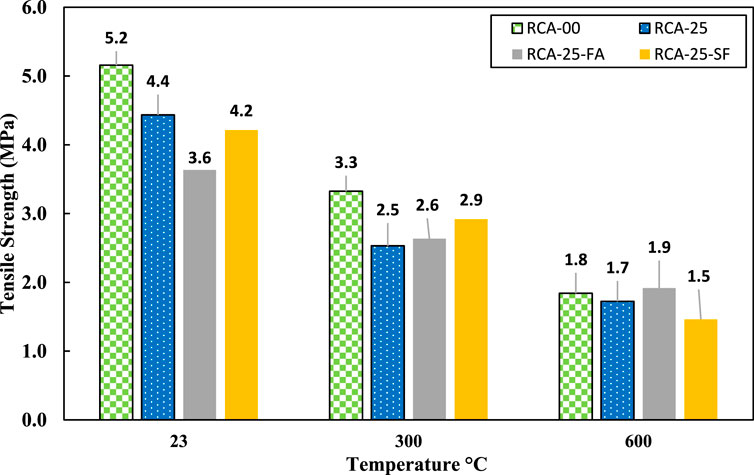

3.2 Tensile strength

The average split tensile strengths are shown in Figure 6. In NAC, the tensile strength decreased by 40% at 300°C, and at 600°C, the NAC samples retained only 35% of their initial tensile strength. Tests on concrete containing 25% and 50% recycled aggregates demonstrated a significant decrease in tensile strength as the temperature increased. Figure 7 indicates that the tensile strength of RAC with the optimal amount of FA is higher than that of RAC25 under normal conditions, with a difference of about 0.48 MPa. Additionally, at temperatures of 300°C and 600°C, the tensile strength of RAC with the optimal FA content exceeds that of RAC25. Furthermore, replacing cement with SF in RAC25 resulted in a higher tensile strength of 4.21 MPa compared to RAC25. Even at elevated temperatures, the tensile strength of RAC25 with SF remained superior to that of RAC25. Techniques such as SEM, TGA, and XRD have confirmed that these materials reduce porosity, densify the ITZ, and refine the pore structure, leading to improved mechanical stability at high temperatures (He et al., 2023; He and Lu, 2024b). In conclusion, the inclusion of SF significantly improved the tensile properties of concrete. These findings indicate that the addition of FA enhances the tensile strength of RAC across all temperature ranges, outperforming RAC25.

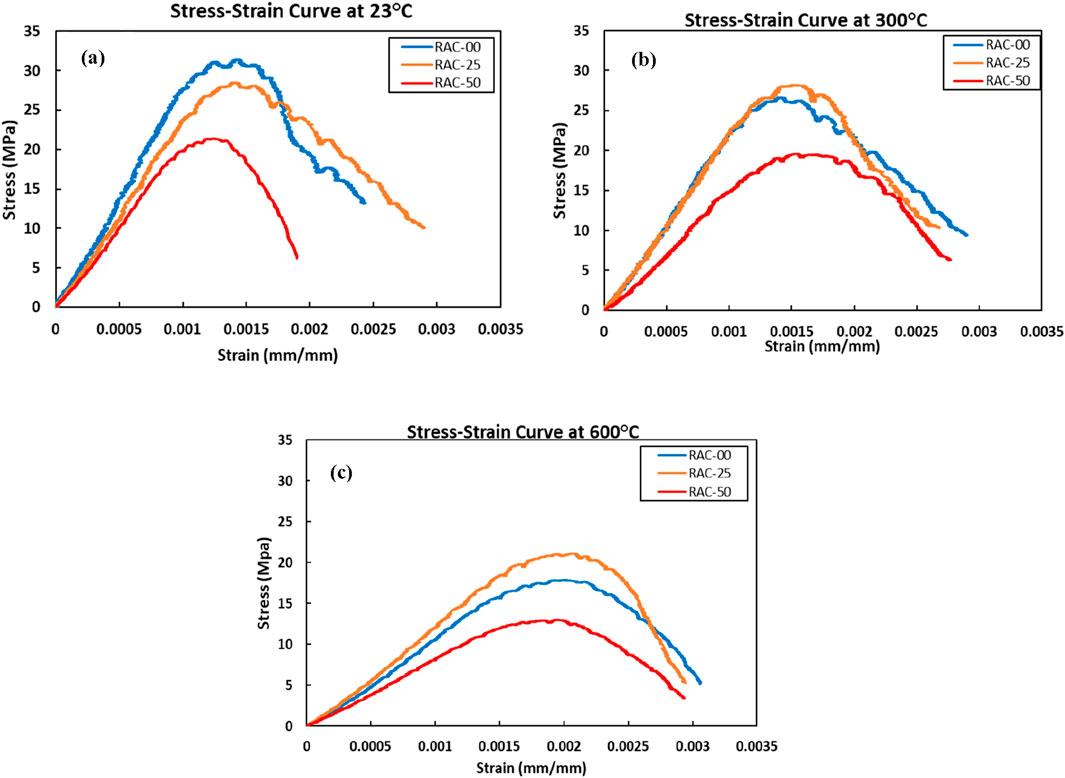

3.3 Stress-strain curve at different temperatures

The stress-strain curves in Figures 8a–c show how temperature affects the mechanical properties of concrete samples. At room temperature, NAC has a higher ultimate strength and is more ductile than RAC25 and RAC50. However, as the temperature rises, RAC25 displays higher residual strength than NAC at 300°C. At 600°C, RAC50 shows a mild slope and lower residual ultimate strength, while the peak strain values for all batches increase to around 0.3%, indicating increased ductility at higher temperatures.

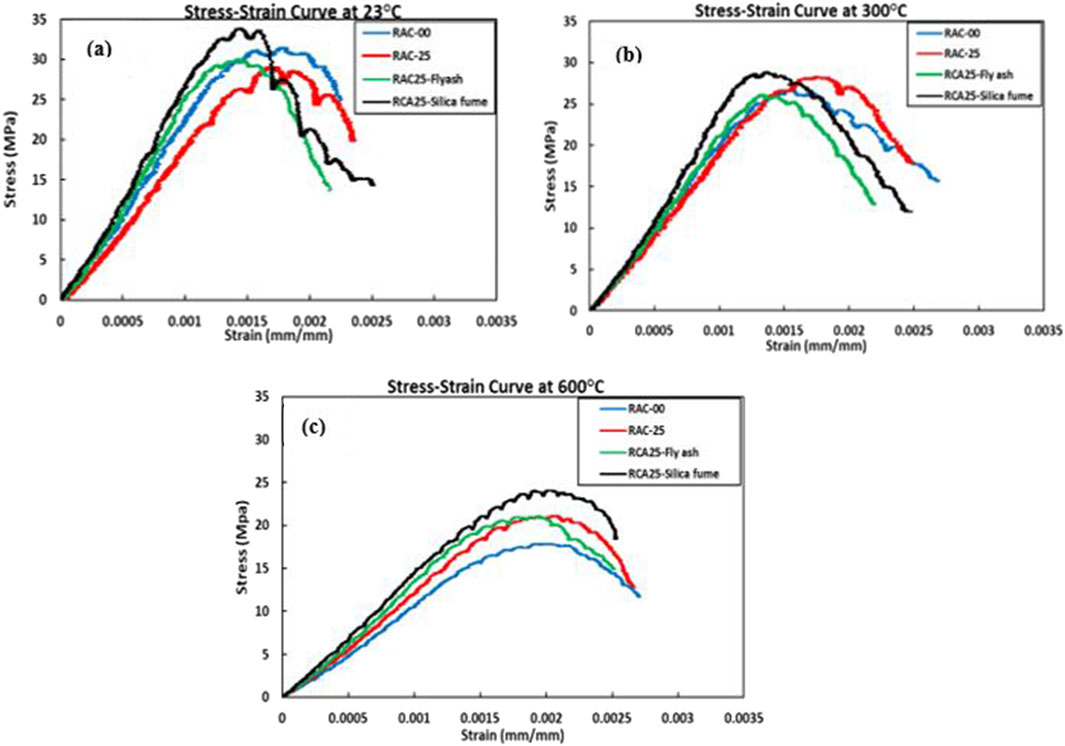

The addition of various mineral admixtures to RAC significantly influences its strength and ductility properties. According to Figures 9a–c, the RAC25+FA concrete mix has the lowest ductility, with a maximum strain limit of only 0.2%. However, adding FA to the RAC25 mix increases its ultimate strength by about 7%. Conversely, introducing SF to the RAC25 mix yields significant improvements in both ultimate strength and ductility properties. The RCA25+SF concrete mix achieves an ultimate strength of 33.86 MPa, representing a 30% increase in strength compared to RAC25 and a 10% improvement over NAC. Moreover, RCA25+SF reaches a peak strain of 0.33%, indicating an enhancement in its ductile properties.

At 300°C, adding FA to RAC25 increases maximum strain from 0.2% to 0.3% due to thermal incompatibility. RAC25+FA also experiences decreased compressive strength but remains above 27.58 MPa, with a peak residual strain increase of 0.1%. At 600°C, RAC with added SF shows the highest compressive strength. The maximum strain limit for RAC with optimal FA and SF is approximately 0.33%, suggesting an increase in ductility for RAC with FA, and a decrease in ductility for RAC with SF.

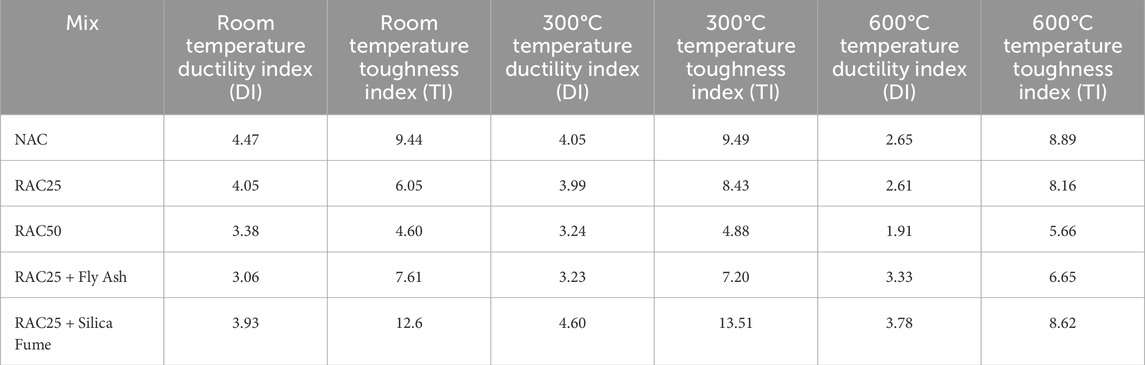

3.4 Ductility and toughness index

The summarized ductility index (DI) and toughness index (TI) values at room temperature, 300°C, and 600°C for different concrete mixes are presented in Table 4. It is evident that the natural aggregate concrete (NAC) exhibits the highest ductility and toughness indices at room temperature, with DI and TI values of 4.47 and 9.44, respectively. These values slightly decrease at elevated temperatures, especially at 600°C, where DI reduces to 2.65, indicating significant loss of ductility due to thermal damage. For recycled aggregate concrete (RAC) mixes, both RAC25 and RAC50 show lower ductility and toughness indices compared to NAC at all tested temperatures, reflecting the inherent microstructural weaknesses introduced by recycled aggregates. RAC25 outperforms RAC50, with DI values of 4.05 (room temperature) and 2.61 (600°C), suggesting better mechanical resilience at elevated temperatures with lower recycled content.

Table 4. Comparative ductility and toughness indices of natural, recycled aggregate, and SCM-Modified concrete mixes exposed to elevated temperature.

The incorporation of pozzolanic materials notably improves the mechanical performance under thermal stress. RAC25 mixes blended with fly ash and silica fume demonstrate improved ductility and toughness indices compared to plain RAC25, particularly at elevated temperatures. For example, RAC25 with fly ash shows DI values of 3.06, 3.23, and 3.33 at room temperature, 300°C, and 600°C, respectively, indicating better maintenance of ductility under heat exposure compared to RAC50 and plain RAC25. Silica fume addition to RAC25 results in the highest toughness indices among all mixes, with values reaching 12.6 at room temperature and increasing slightly to 13.51 at 300°C, highlighting the superior performance of silica fume in enhancing crack resistance and energy absorption capacity under thermal loading. Overall, the results emphasize the detrimental impact of high temperatures on concrete ductility and toughness, more so for recycled aggregate concretes without pozzolanic additives. The use of supplementary cementitious materials such as fly ash and silica fume effectively mitigates the loss in mechanical properties under thermal exposure by refining the microstructure and enhancing matrix densification.

3.5 Physical properties

Visual inspections were conducted on NAC and RAC samples with varying amounts of recycled aggregate (RA) to observe any color, warping, or cracking changes after exposure to high temperatures. At room temperature, the concrete initially exhibited a light gray color, which transitioned to yellowish, gray-brown, and gray-white shades after being exposed to 300°C and 600°C temperatures respectively. The color changes observed at high temperatures are attributed to chemical and physical changes within the concrete. In the case of RAC25 and RAC50, the initial gray color of the concrete changed to a rose-pink color when heated to 300°C, indicating the presence of hydrated iron oxides mainly found in siliceous aggregates. However, upon further heating to 600°C, the red color faded into gray discoloration and eventually pale gray, indicating a significant loss of compressive strength.

The blend of FA and SF samples initially had a dark grey color. However, when heated in the furnace, there were no noticeable visual changes in the concrete specimens. After the specimens were cooled and visually examined, it was observed that at 300°C, discoloration and cracks appeared on the surfaces of the cylinders. At this temperature, the blended colors of the cylinders containing silica fume and fly ash faded to white (light yellowish gray for silica fume and light grey for fly ash). When heated at 600°C, the surface of the FA cylinder darkened with a greyish tint, while the color of the concrete changed to a whitish grey when heated with silica fume at the same temperature. The research studied crack formation and weight loss of different concrete mixtures when exposed to high temperatures. For NAC, increasing temperatures led to wider cracks appearing on the surface, which then grew larger and spread out. RAC showed even more pronounced cracks compared to NAC. The best samples of RAC with fly ash and silica fume did not show significant visible cracks at 300°C, but deeper surface cracks appeared at 600°C. RAC with mineral admixtures experienced less mass loss at elevated temperatures compared to RAC25, indicating that adding pozzolans can reduce moisture release and potentially improve its resistance to thermal stresses and crack formation.

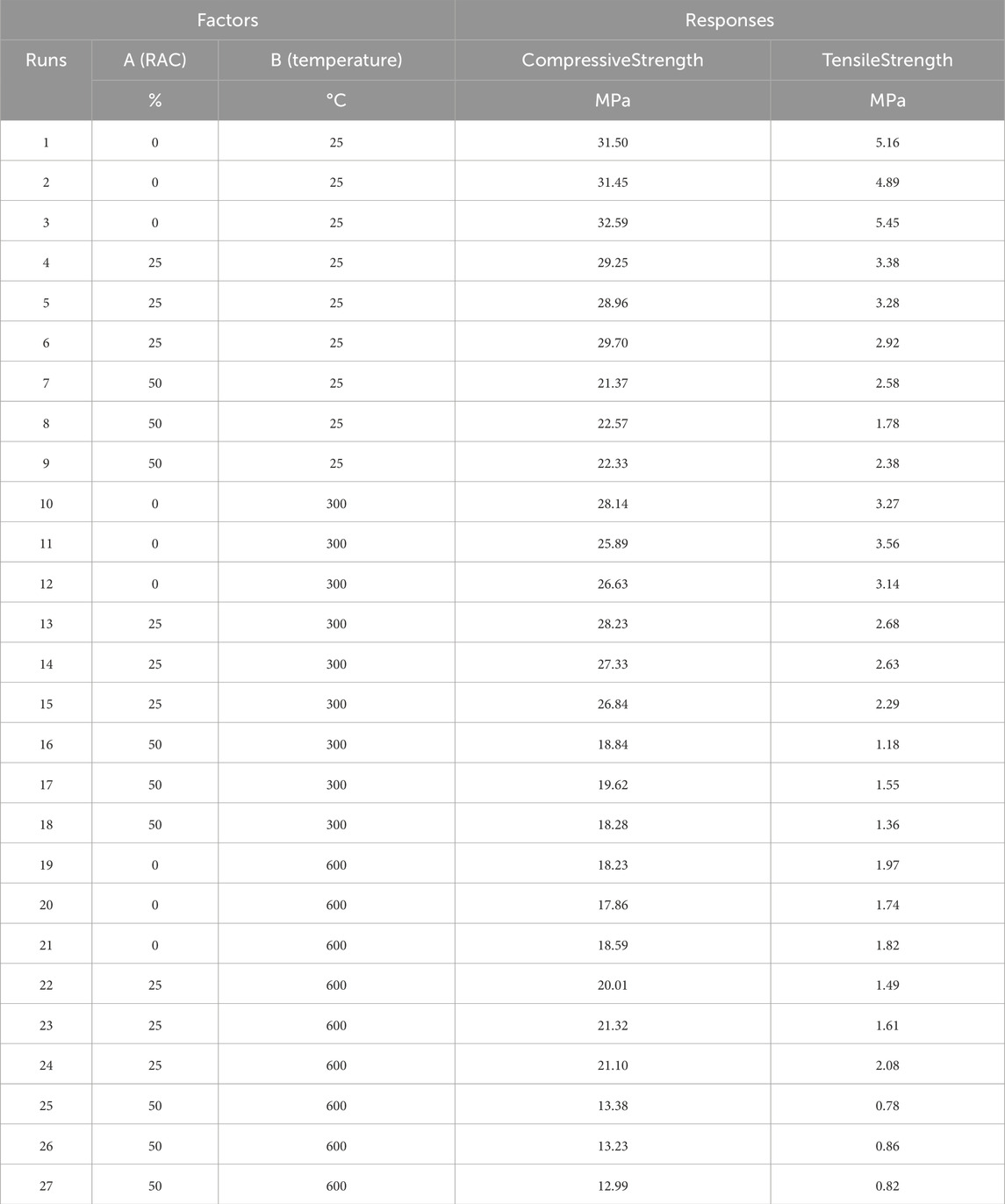

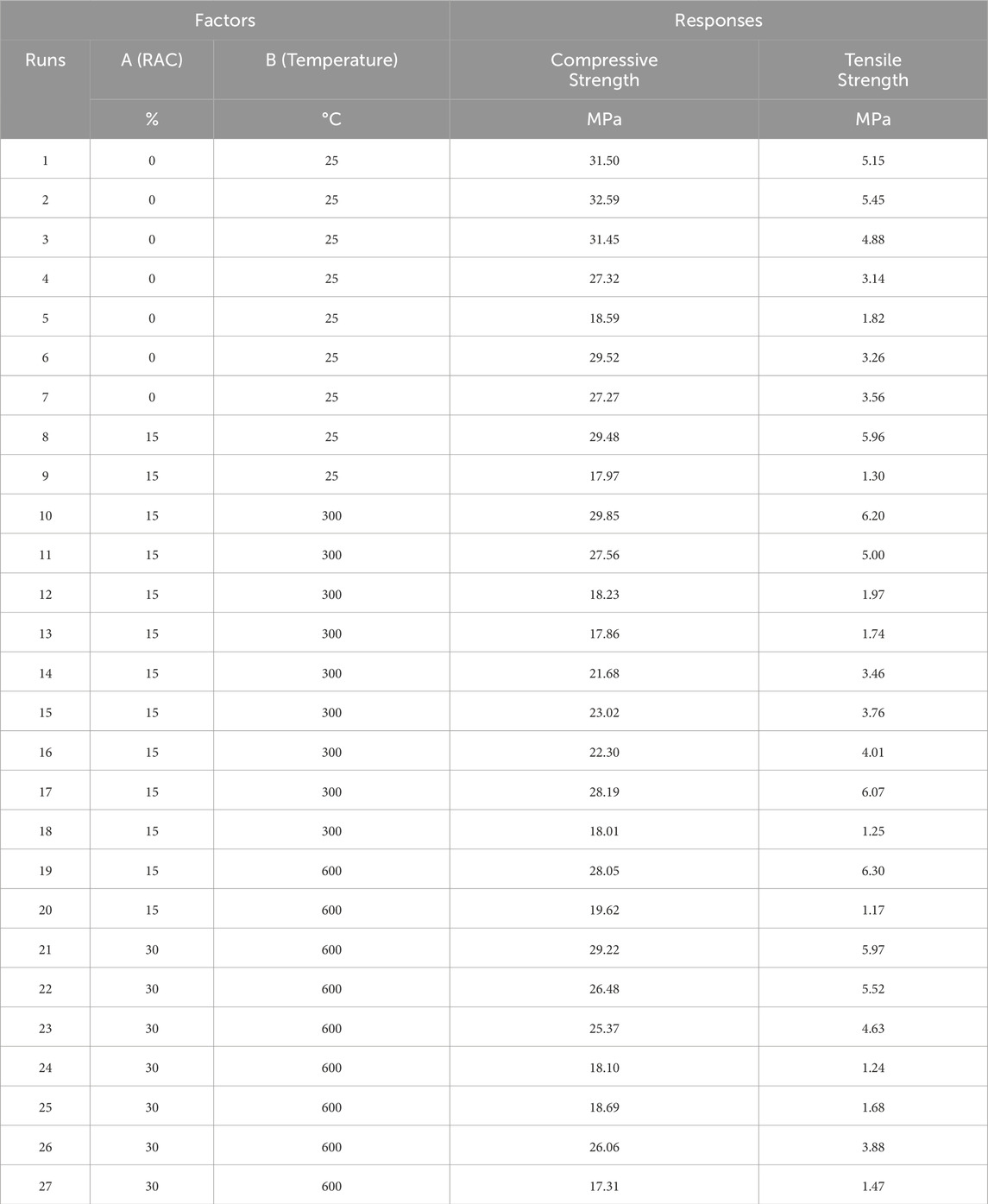

3.6 Selection of models

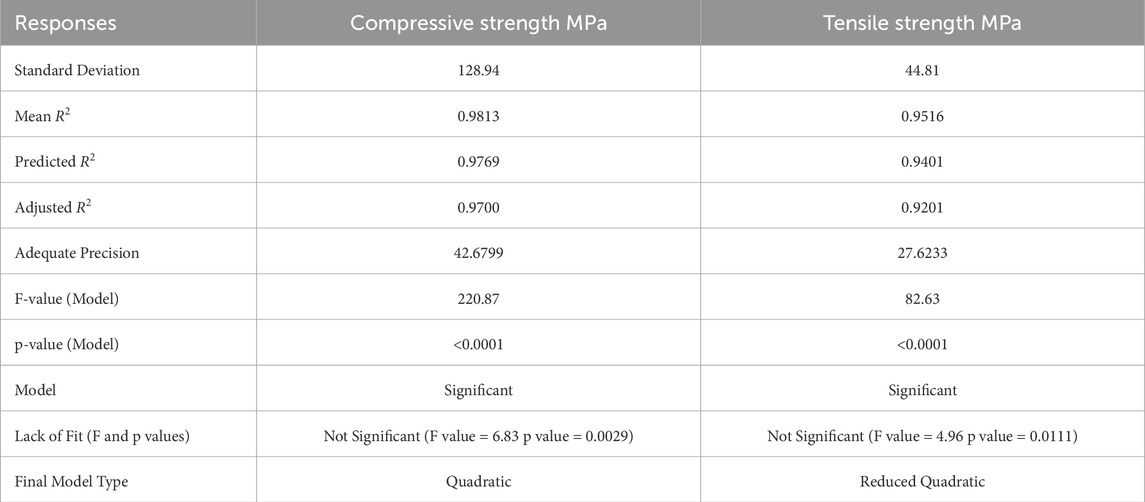

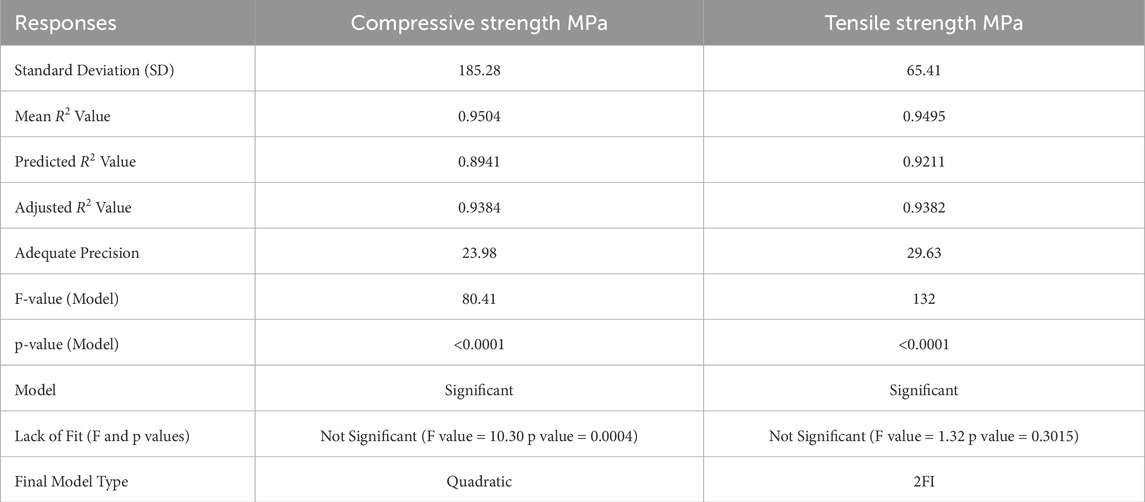

The experimental findings and analyses are presented in Tables 4, 5. Table 4 shows that the compressive strength values ranged from 32.59 MPa to 12.97 MPa, while the tensile strength values varied between 5.45 MPa and 1.24 MPa for runs 3 and 27, respectively. Table 5 provides the findings of the SCM matrix, showing compressive and tensile strength values ranging from 32.59 MPa to 17.31 MPa and 5.45 MPa–1.47 MPa, respectively, with SCMs varying up to 30% and exposed to a maximum temperature of 600°C. The importance of the independent variables and their interactions was evaluated through ANOVA (Table 6). The suitability of the regression models for the responses was assessed using R2, probability (Prob > F), Adjusted R2, and Predicted R2. We used quadratic and reduced quadratic models for response against RAC, and recommended 2FI and quadratic models for SCM models.

3.7 ANOVA analysis of RAC under high temperatures

RSM was employed to analyze, optimize, and validate the strength properties of RAC, along with the optimal RAC incorporating pozzolans. The RSM approach evaluated responses like tensile strength and compressive strength (28 days) while using different percentages of RAC and temperature as variables. Statistical assessment of concrete containing different fractions of recycled aggregates was also conducted.

RSM was used to statistically investigate the mechanical variables, particularly with compressive and tensile strength. An ANOVA analysis was conducted inside RSM to gain a deeper understanding of the performance of the model in terms of strength. Additionally, quadratic polynomial models were proposed to forecast the strength attributes of RAC based on the model’s importance. Equation 2 can be adapted to Equation 3 as shown below.

Y represents the response from experimental results, specifically Compressive and Tensile strengths, while RAC and Temp are the independent constraints. C represents the constant, while A1 through A5 denotes the coefficients in the equation. Table 7 presents the model fit statistics from the ANOVA analysis, which assesses the significance of the developed models. The ANOVA results confirm that the regression models for compressive strength, tensile strength are statistically significant (p < 0.0001), with high F-values indicating a strong effect of the selected variables. The high R2 and predicted R2 values (0.98 for compressive strength, 0.95 for tensile strength suggest excellent model fit and predictive accuracy. The Adequate Precision values, all well above 4, reflect strong signal-to-noise ratios. Notably, the quadratic models capture both main effects and interactions. The coefficient of determination, or R2, is a measure of the quality and degree of fitness of the constructed models. The model is well-fitted, with a substantial amount of agreement between the real and predictable responses, as demonstrated by an R2 value of greater than 0.80.

In addition, the appropriateness of the model and the variability of the data around the fitted model can be evaluated through a lack-of-fit analysis. A lower lack-of-fit F-value and a non-significant p-value (greater than 0.04) suggest that the models fit well. Because of their non-significant lack-of-fit error and lowered F-value, the models that were chosen are highly significant, well-fitting, and helpful in creating a link between factors and responses, as demonstrated by the ANOVA analysis shown in Table 5. The results show that the percentage RAC significantly affects the concrete’s tensile and compressive strengths. Equations 4, 5 are empirical formulas that were created to anticipate the responses following model reduction, based on the real components (RAC and Temperature).

*C.S = Compressive strength

*T.S = Tensile strength

*A = RAC, in %

*B = Temperature in °C

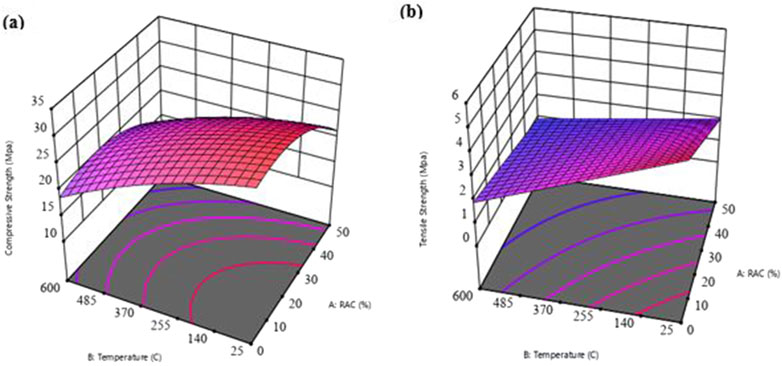

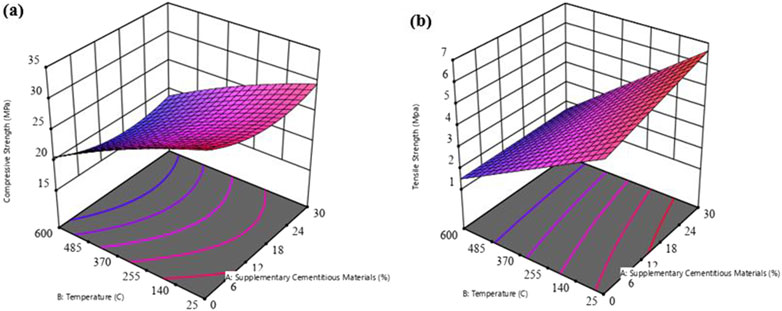

The best way to demonstrate the relationship between the independent factors (RAC and Temp) and the dependent variables (compressive strength, tensile strength) is by using 3-dimensional (3-D) diagrams. Figure 10a displays the three-dimensional response surface for temperature, RAC, and compressive strength, while Figure 10b illustrates the three-dimensional response surface for temperature, RAC, and tensile strength. It's important to note that the strength properties increase as the temperature and RAC concentration increase.

3.7.1 ANOVA analysis of concrete containing RAC and SCMs

The following section covers the effect of adding SCMs on compressive and tensile strength. Table 8 displays the ANOVA results and fit statistics, which evaluate the significance of well-established models. The reputable models demonstrate strong agreement between the variables and answers; their lower p-values and higher F-values indicate their significance. Additionally, the proposed models exhibit more appropriate frequency, better R2 (>0.80), and insignificance of a lack-of-fit, indicating that they are well-fit and significant. Consequently, these models can establish a link between independent factors (temperature and SCMs) and dependent variables (compressive strength and tensile strength). Moreover, Table 6 illustrates the contribution percentages of elements that can be used to assess the impact of each component on the qualities of concrete. The results indicate that temperature and pozzolanic content have a major impact on the strength characteristics of concrete.

ANOVA was utilized to get the coefficients of empirical models, which are based on actual factors (Pozzolans and Temperature) for predicting strengths, as depicted in Equations 6, 7. Furthermore, 3-D visuals were used to effectively illustrate the affiliation amongst the factors and responses, as shown in Figures 11a,b.

Figure 11. Effect of RAC with SCMs and temperature on (a) compressive strength (b) tensile strength.

The ANOVA results indicate that both fly ash (FA) and silica fume (SF) significantly influenced mechanical properties at elevated temperatures. Positive coefficients for SF and FA content reflect their densifying effect on the matrix, improving strength and thermal stability. The negative coefficient for temperature confirms performance degradation with heat. However, significant interaction terms (e.g., Temperature × SF) suggest that SF, due to its high pozzolanic reactivity, mitigates thermal damage more effectively at higher temperatures, an effect similarly noted for FA in synergy with SF.

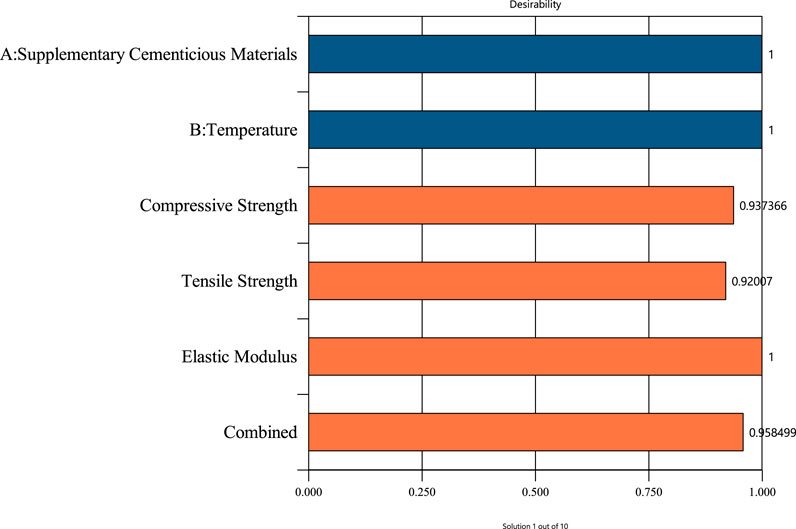

3.8 Multi-objective optimization and validation of mix design

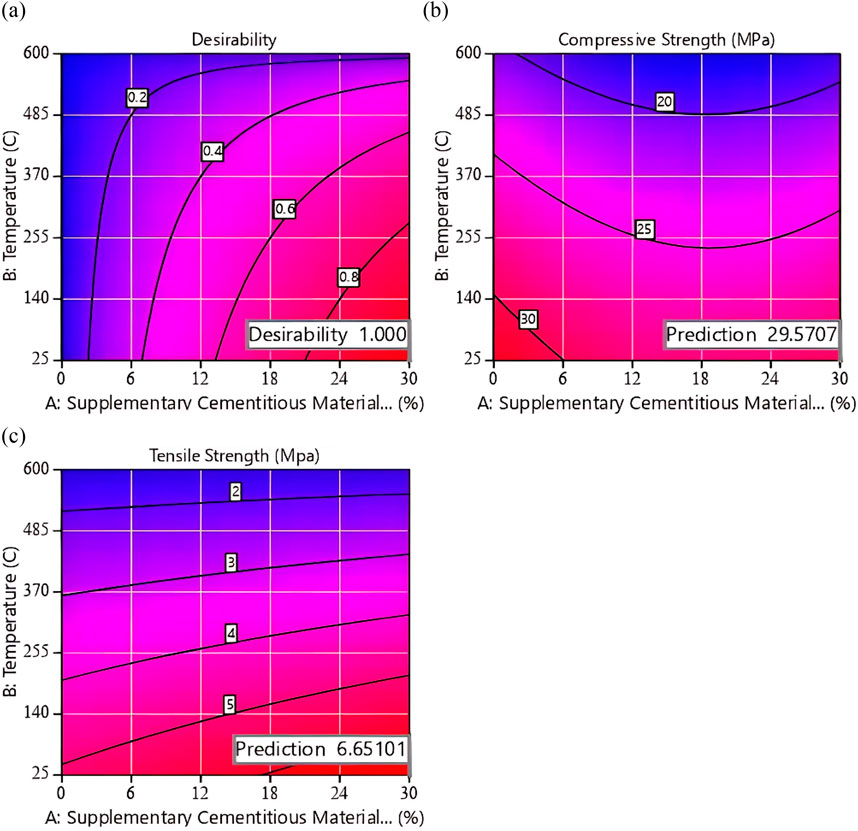

The study aims to develop an RSM model to determine finest values of RAC and SCMs for achieving the best performance. Traditional tests and experiments conducted to determine the optimal SCM content with temperature variations for RAC-SCM mixtures may produce inaccurate results due to the inherent complexity and the involvement of extensive data. Therefore, in this study, multi-objective optimization and statistical evaluation are employed to determine the most effective proportions of SF and FA recycled aggregate concrete, aiming for desirable results. The target responses, such as compressive and tensile strength, were adjusted to their target values (see Table 9). Factors such as SCM quantity and elevated temperatures were also optimized to achieve the highest possible partial replacement.

Table 10 shows the ideal ranges and targeted goals for the research parameters. RSM is used to determine the best values for the optimized variables, reaching a desirability of 95.84% in the mix design. The criteria for variables and responses were established after conducting the ANOVA. It's fascinating to see the effect of using FA-SF blend on the strength of RAC. The optimization results indicate that using 25% RAC and adding SF can considerably improve concrete strength. Further experimentation validates theoretical results and confirms the agreement between predictive model data and observed experimental results. The predicted and experimental results show significant consistency, with an error of less than 5%. Figure 12 illustrates the desired value range and optimal solution for all independent and dependent variables. Mathematical analysis suggests that using 25% SCM and a temperature of 334°C will yield the best performance for the concrete. The optimal mix design was achieved with a high desirability level. For further insight into the interaction influence of each factor on overall response, 2D surface graphs of the responses in the optimal solution were analyzed. Figure 13 shows the surface response to a variation in the content of factors.

Figure 12. 2D surface diagram of (a) Desirability, (b) Compressive Strength, and (c) Tensile Strength of SCMs.

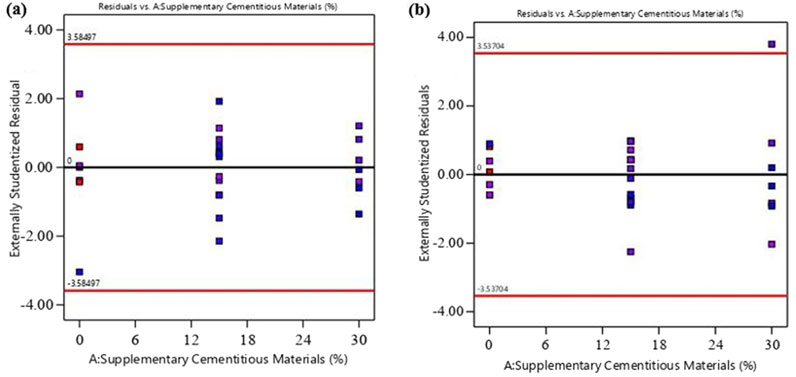

Externally Studentized Residuals vs. Predicted plot for compressive strength and tensile strength are given in Figures 14a,b to address residual analysis and to verify that models are statistically reliable and appropriate for optimization.

Figure 14. Externally studentized residuals versus predicted (a) Compressive strength, (b) Tensile Strength.

These residual plots are employed to evaluate the adequacy of the regression models and to verify the fulfillment of underlying statistical assumptions. The residuals exhibit a random dispersion around the horizontal axis at zero, with no discernible patterns or systematic structure. This behavior indicates that the assumptions of linearity, independence, and homoscedasticity are satisfactorily met. Furthermore, all observations lie within the bounds of ±3.5487, suggesting the absence of influential outliers or leverage points that could disproportionately affect the model estimates. The results affirm the statistical validity and robustness of the predictive models developed for estimating the mechanical properties under consideration.

3.9 Validation of predicted models

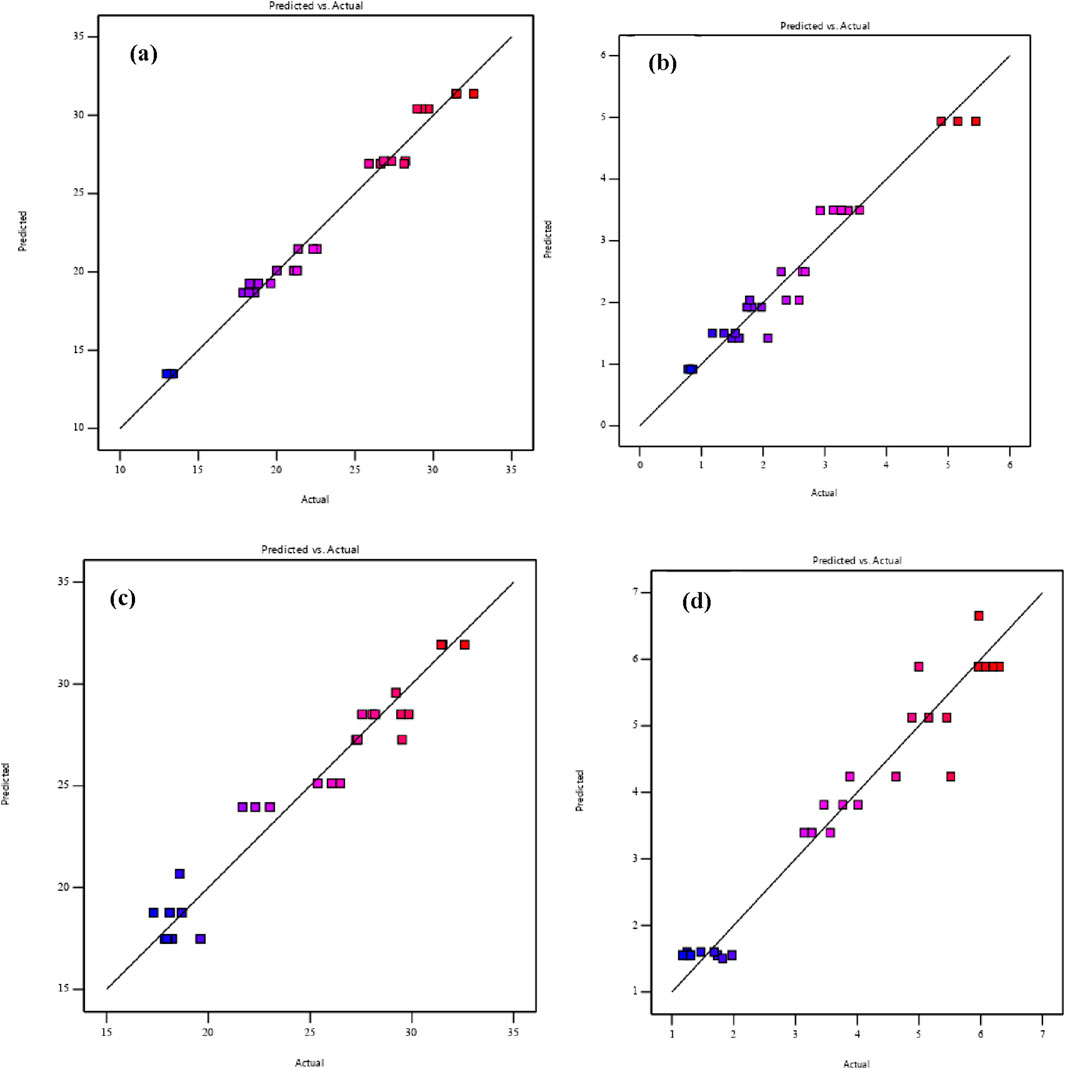

Additional testing was carried out to validate the precision of the improved models by comparing them with the experimental data. Equation 8 is used to calculate the percentage experimental data error which is then employed to assess the consistency between the model and experimental data (Aliyu Yaro et al., 2023).

Figures 15a–d displays the comparison between the actual and predicted results. The error ratio between the RSM model data and experimental responses is found to be lower than 5%, hence validating the functionality of RSM model in accurately predicting response.

Figure 15. Actual vs. Predictive results of RAC (a) compressive strength (fc), (b) Tensile Strength (fy), (c) SCMs-RAC compressive strength, and (d) SCMs-RAC tensile strength.

3.10 Practical implications and applications

The outcomes of this study provide valuable insights for structural engineers and materials scientists aiming to develop sustainable and fire-resilient concrete structures. The observed retention of mechanical properties and enhanced ductility in RAC mixes containing pozzolanic additives such as silica fume and fly ash suggests these materials can be strategically used to improve the fire resistance of recycled aggregate concrete. These findings can inform future revisions to fire design standards by offering evidence-based thresholds for temperature exposure and performance degradation. Moreover, the ductility and toughness data obtained at elevated temperatures serve as a foundation for developing design models for structural elements exposed to fire scenarios. The observed behavior can also guide construction practices in high-risk zones, such as tunnels, industrial plants, and residential buildings in fire-prone areas, where recycled concrete materials are used.

Additionally, the use of Response Surface Methodology (RSM) in this study enables data-driven optimization of mix proportions by analyzing the interactive effects of variables such as SCM content, RAC percentage, and temperature. This statistical approach not only minimizes the need for exhaustive experimental trials but also aids in creating predictive models that can be directly utilized by practitioners for mix design under elevated temperature conditions. RSM-based tools can be integrated into performance-based design frameworks, offering a streamlined path toward the adoption of greener and more durable materials in civil infrastructure.

4 Conclusion

This article investigates the high-temperature performance of SCM-based RAC, using experimental testing and RSM for efficient optimization, contributing to enhanced concrete sustainability and fire resistance. The following conclusions are drawn from the research study.

1. NAC exhibited higher compressive strength at room temperature. However, RAC25 showed superior high-temperature performance, with only a 1% strength loss at 300°C and a 28% loss at 600°C, indicating better thermal resilience compared to NAC.

2. The addition of SF and FA significantly enhanced the mechanical properties of RAC, particularly at elevated temperatures. SF increased compressive strength by 18% at 600°C, while FA improved tensile strength across all temperature ranges.

3. SF particularly improved both tensile strength and ductility. RAC25+SF achieved a 30% increase in compressive strength compared to RAC25, with a peak strain of 0.33%, indicating improved ductility.

4. SCMs in RAC appear to reduce moisture loss and enhance thermal stability, thereby improving resistance to cracking under high-temperature exposure. These improvements, observed through mechanical performance, suggest that RAC25 with SCMs is a promising alternative for elevated-temperature applications.

5. The ANOVA-based statistical models for compressive strength, tensile strength were significant (p < 0.0001), with high R2 and F-values, accurately capturing main and interaction effects and demonstrating strong predictive reliability.

6. Response Surface Methodology (RSM) was employed to optimize the mix design, achieving a high desirability of 95.84%. The optimized mix, RAC25 with silica fume demonstrated significant improvements in mechanical strength. Experimental results closely aligned with model predictions, with errors below 5%, validating the reliability of the predictive models and confirming the enhanced performance of SF-modified RAC.

7. While natural aggregate concrete maintains an advantage at room temperature, recycled aggregate concrete with SCMs presents a promising alternative for applications requiring elevated temperature resistance.

This study introduces a novel application of Response Surface Methodology (RSM) alongside an experimental study to optimize recycled aggregate concrete (RAC) containing pozzolanic materials under elevated temperature exposure. The research fills a critical gap by systematically evaluating how varying levels of recycled aggregate and pozzolanic content influence thermal resistance and mechanical performance—a combination not thoroughly explored in the existing literature. Future research is encouraged to explore the potential of integrating nano-materials, such as nano-silica or graphene oxide, into pozzolanic RAC systems. This could further enhance high-temperature durability, microstructural integrity, and crack resistance in extreme environments, thereby pushing the boundaries of sustainable and thermally stable concrete technology.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding authors.

Author contributions

MS: Writing – review and editing, Methodology, Writing – original draft. AU: Validation, Writing – review and editing. DM: Conceptualization, Funding acquisition, Validation, Methodology, Formal Analysis, Writing – review and editing. MF: Validation, Conceptualization, Resources, Supervision, Methodology, Writing – review and editing, Software, Visualization. MJ: Conceptualization, Writing – review and editing, Resources, Visualization, Project administration, Formal Analysis, Methodology. HA: Resources, Visualization, Conceptualization, Validation, Methodology, Writing – review and editing. DS: Software, Conceptualization, Writing – review and editing, Visualization, Validation.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by Princess Nourah bint Abdulrahman University Researchers Supporting Project number (PNURSP2025R435), Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia.

Acknowledgments

The authors would like to acknowledge the support of Princess Nourah bint Abdulrahman University Researchers Supporting Project number (PNURSP2025R435), Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abbreviations

RAC, Recycled Aggregate Concrete; RA, Recycled Aggregates; SF, Silica Fume; GGBS, Ground Granulated Blast Furnace Slag; C&D, Construction and Demolition; SCM, Supplementary Cementitious Materials; ANOVA, Analysis of Variance; TGA, Thermogravimetric Analysis; ASTM, American Society for Testing and Materials; NAC, Natural Aggregate Concrete; OPC, Ordinary Portland Cement; FA, Fly Ash; MK, Metakaolin; ITZ, Interfacial Transition Zone; RSM, Response Surface Methodology; SEM, Scanning Electron Microscopy; XRD, X-Ray Diffraction; w/c, Water-to-Cement Ratio.

References

Abdelmelek, N., and Lubloy, E. (2022). The impact of metakaolin, silica fume and fly ash on the temperature resistance of high strength cement paste. J. Therm. Anal. Calorim. 147 (4), 2895–2906. doi:10.1007/s10973-021-10700-x

Abdullah, G. M. S., Chohan, I. M., Ali, M., Bheel, N., Ahmad, M., Najeh, T., et al. (2024). Effect of titanium dioxide as nanomaterials on mechanical and durability properties of rubberised concrete by applying RSM modelling and optimizations. Front. Mater 11. doi:10.3389/fmats.2024.1357094

Adamu, M., Marouf, M. L., Ibrahim, Y. E., Ahmed, O. S., Alanazi, H., and Marouf, A. L. (2022). Modeling and optimization of the mechanical properties of date fiber reinforced concrete containing silica fume using response surface methodology. Case Stud. Constr. Mater. 17, e01633. doi:10.1016/j.cscm.2022.e01633

Agamuthu, P., and Babel, S. (2023). Waste management developments in the last five decades: asian perspective. Waste Manag. Res. 41 (12), 1699–1716. doi:10.1177/0734242x231199938

Ahmad, J., Althoey, F., Abuhussain, M. A., Deifalla, A. F., Özklllç, Y. O., and Rahmawati, C. (2023). Durability and microstructure analysis of concrete made with volcanic ash: a review (part II). Sci. Eng. Compos. Mater. 30 (1). doi:10.1515/secm-2022-0211

Ahmed, W., Lim, C. W., and Akbar, A. (2022). Influence of elevated temperatures on the mechanical performance of sustainable-fiber-reinforced recycled aggregate concrete: a review. Buildings 12 (4), 487. doi:10.3390/buildings12040487

Aliyu Yaro, N. S., Sutanto, M. H., Habib, N. Z., Napiah, M., Usman, A., Muhammad, A., et al. (2023). Modeling and optimization of rheological properties and aging resistance of asphalt binder incorporating palm oil mill waste using response surface methodology. J. Infrastructure Intell. Resil. 2 (1), 100026. doi:10.1016/j.iintel.2023.100026

Alsheyab, M. A. T. (2022). Recycling of construction and demolition waste and its impact on climate change and sustainable development. Int. J. Environ. Sci. Technol. 19 (3), 2129–2138. doi:10.1007/s13762-021-03217-1

Amrutha, N. G., Narasimhan, M. C., and Rajeeva, S. V. (2011). High temperature performance of self-compacting high-volume fly ash concrete mixes. J. Struct. Fire Eng. 2 (2), 81–90. doi:10.1260/2040-2317.2.2.81

Ashraf, M., Iqbal, M. F., Rauf, M., Ashraf, M. U., Ulhaq, A., Muhammad, H., et al. (2022). Developing a sustainable concrete incorporating bentonite clay and silica fume: mechanical and durability performance. J. Clean. Prod., 337. doi:10.1016/j.jclepro.2021.130315

Asif, U., Javed, M. F., Abuhussain, M., Ali, M., Khan, W. A., and Mohamed, A. (2024b). Predicting the mechanical properties of plastic concrete: an optimization method by using genetic programming and ensemble learners. Case Stud. Constr. Mater. 20, e03135. doi:10.1016/j.cscm.2024.e03135

Asif, U., Javed, M. F., Alyami, M., and Hammad, A. W. (2024a). Performance evaluation of concrete made with plastic waste using multi-expression programming. Mater Today Commun. 39, 108789. doi:10.1016/j.mtcomm.2024.108789

Asif, U., Memon, S. A., Javed, M. F., Kim, J., and Luísa Velosa, A. (2024c). Predictive modeling and experimental validation for assessing the mechanical properties of cementitious composites made with silica fume and ground granulated blast furnace slag. Buildings 14 (4), 1091. doi:10.3390/buildings14041091

Bao, Z. (2023). Developing circularity of construction waste for a sustainable built environment in emerging economies: new insights from China. Dev. Built Environ. 13, 100107. doi:10.1016/j.dibe.2022.100107

C150 standard specification for Portland cement (2024). C150 standard specification for Portland cement. Available online at: https://www.astm.org/standards/c150

C33/C33M standard specification for concrete aggregates (2024). C33/C33M standard specification for concrete aggregates. Available online at: https://www.astm.org/c0033_c0033m-16.html

Cao, S., Cheng, X., and Ran, H. (2024). Understanding structural changes in recycled aggregate concrete under thermal stress. Buildings 14 (9), 2689. doi:10.3390/buildings14092689

China uses as much cement (2024). China uses as much cement in two years as the US did over the 20th century Available online at: https://www.sustainabilitybynumbers.com/p/china-us-cement

Dahish, H. A., and Almutairi, A. D. (2023). Effect of elevated temperatures on the compressive strength of nano-silica and nano-clay modified concretes using response surface methodology. Case Stud. Constr. Mater. 18, e02032. doi:10.1016/j.cscm.2023.e02032

DeRousseau, M. A., Kasprzyk, J. R., and Srubar, W. V. (2018). Computational design optimization of concrete mixtures: a review. Cem. Concr. Res. 109, 42–53. doi:10.1016/j.cemconres.2018.04.007

Devarangadi, M., Vuppala, S., Shankar, M. U., and Raghunandan, M. E. (2024). Effect of collated fly ash, GGBS and silica fume on index and engineering properties of expansive clays as a sustainable landfill liner. Clean. Mater., 11. doi:10.1016/j.clema.2024.100219

Dong, H., Cao, W., Bian, J., and Zhang, J. (2014). The fire resistance performance of recycled aggregate concrete columns with different concrete compressive strengths. Materials 7 (12), 7843–7860. doi:10.3390/ma7127843

EN 13263-1:2005+A1:2009 - silica fume for concrete - part 1: definitions, requirements and Available online at: https://standards.iteh.ai/catalog/standards/cen/503d9622-7c15-4d83-95c7-c6bbbdfc941a/en-13263-1-2005a1-2009?srsltid=AfmBOopQVPkUIZ2rs35RhtMfrefHeWb6uLzc4fT8Gzym6Ipn55yfit1X

Fanijo, E. O., Kolawole, J. T., Babafemi, A. J., and Liu, J. (2023). A comprehensive review on the use of recycled concrete aggregate for pavement construction: properties, performance, and sustainability. Clean. Mater. 9, 100199. doi:10.1016/j.clema.2023.100199

Gitman, I. M., Askes, H., and Sluys, L. J. (2007). Representative volume: existence and size determination. Eng. Fract. Mech. 74 (16), 2518–2534. doi:10.1016/j.engfracmech.2006.12.021

Gonzalez-Corominas, A., and Etxeberria, M. (2014). Properties of high performance concrete made with recycled fine ceramic and coarse mixed aggregates. Constr. Build. Mater 68, 618–626. doi:10.1016/j.conbuildmat.2014.07.016

He, R., and Lu, N. (2024a). Hydration, fresh, mechanical, and freeze-thaw properties of cement mortar incorporated with polymeric microspheres. Adv. Compos Hybrid. Mater 7 (3), 92–20. doi:10.1007/s42114-024-00899-2

He, R., and Lu, N. (2024b). Air void system and freezing-thawing resistance of concrete composite with the incorporation of thermo-expansive polymeric microspheres. Constr. Build. Mater 419, 135535. doi:10.1016/j.conbuildmat.2024.135535

He, R., Nantung, T., and Lu, N. (2024). Unraveling microstructural evolution in air-entrained mortar and paste: insights from MIP and micro-CT tomography amid cyclic freezing-thawing damage. J. Build. Eng. 94, 109922. doi:10.1016/j.jobe.2024.109922

He, R., Nantung, T., Olek, J., and Lu, N. (2023). Field study of the dielectric constant of concrete: a parameter less sensitive to environmental variations than electrical resistivity. J. Build. Eng. 74, 106938. doi:10.1016/j.jobe.2023.106938

Khan, M. S., Khan, M. I., Choudhry, R. M., Khahro, S. H., and Memon, Z. A. (2025a). Performance analysis of fiber reinforced recycled aggregate concrete at elevated temperatures using response surface methodology. Sci. Rep. 15 (1), 12916–12917. doi:10.1038/s41598-025-94258-w

Khan, M. S., Khan, M. S., Khan, M. I., Al-Nawasir, R., Maureira-Carsalade, N., Avudaiappan, S., et al. (2025b). Enhancing rigid pavement performance: experimental study and design optimization of bentonite clay-blended concrete with a focus on durability. Case Stud. Constr. Mater. 22, e04641. doi:10.1016/j.cscm.2025.e04641

Khan, M. S., Shariq, M., Akhtar, S., and Masood, A. (2020). Performance of high-volume fly ash concrete after exposure to elevated temperature. J. Aust. Ceram. Soc. 56 (2), 781–794. doi:10.1007/s41779-019-00396-6

Kodur, V. K. R. (2000). “Spalling in high strength concrete exposed to fire - concerns, causes, critical parameters and cures,” Struct. Congr., 103. doi:10.1177/1369433218754335

Kou, S. C., and Poon, C. S. (2009). Properties of self-compacting concrete prepared with recycled glass aggregate. Cem. Concr. Compos 31 (2), 107–113. doi:10.1016/j.cemconcomp.2008.12.002

Kwan, W. H., Ramli, M., Kam, K. J., and Sulieman, M. Z. (2012). Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr. Build. Mater 26 (1), 565–573. doi:10.1016/j.conbuildmat.2011.06.059

Mandal, S., Shiuly, A., Sau, D., Mondal, A. K., and Sarkar, K. (2024). Study on the use of different machine learning techniques for prediction of concrete properties from their mixture proportions with their deterministic and robust optimisation. AI Civ. Eng. 3 (1), 7. doi:10.1007/s43503-024-00024-8

Nguyen, H. C. (2024). The influence of recycled coarse aggregate content on the properties of high-fly-ash self-compacting concrete. Civ. Eng. J. 10 (0), 51–61. doi:10.28991/cej-sp2024-010-04

Nkanpa Moffo, N. D., Mwero, J., and Gariy, Z. A. (2023). Performance of silica fume on preventing strength retrogression in hardened cement paste and mortar at elevated temperatures. Buildings 13 (5), 1301. doi:10.3390/buildings13051301

Pelissou, C., Baccou, J., Monerie, Y., and Perales, F. (2009). Determination of the size of the representative volume element for random quasi-brittle composites. Int. J. Solids Struct. 46 (14–15), 2842–2855. doi:10.1016/j.ijsolstr.2009.03.015

Pereiro-Barceló, J., Lenz, E., Torres, B., and Estevan, L. (2024). Mechanical properties of recycled aggregate concrete reinforced with conventional and recycled steel fibers and exposed to high temperatures. Constr. Build. Mater, 452. doi:10.1016/j.conbuildmat.2024.138976

Rakshvir, M., and Barai, S. V. (2006). Studies on recycled aggregates-based concrete. Waste Manag. Res. 24 (3), 225–233. doi:10.1177/0734242x06064820

Reji, M., and Kumar, R. (2022). Response surface methodology (RSM): an overview to analyze multivariate data. Indian J. Microbiol. Res. 9 (4), 241–248. doi:10.18231/j.ijmr.2022.042

Sahoo, A., Dwivedi, A., Madheshiya, P., Kumar, U., Sharma, R. K., and Tiwari, S. (2024). Insights into the management of food waste in developing countries: with special reference to India. Environ. Sci. Pollut. Res. 31 (12), 17887–17913. doi:10.1007/s11356-023-27901-6

Singh, R. P., Vanapalli, K. R., Cheela, V. R. S., Peddireddy, S. R., Sharma, H. B., and Mohanty, B. (2023). Fly ash, GGBS, and silica fume based geopolymer concrete with recycled aggregates: properties and environmental impacts. Constr. Build. Mater 16, 378. doi:10.1016/j.conbuildmat.2023.131168

Stukhlyak, P. D., Buketov, A. V., Panin, S. V., Maruschak, P. O., Moroz, K. M., Poltaranin, M. A., et al. (2015). Structural fracture scales in shock-loaded epoxy composites. Phys. Mesomech. 18 (1), 58–74. doi:10.1134/s1029959915010075

Torres, A., Simoni, M. U., Keiding, J. K., Müller, D. B., zu Ermgassen, SOSE, Liu, J., et al. (2021). Sustainability of the global sand system in the anthropocene. One Earth 4 (5), 639–650. doi:10.1016/j.oneear.2021.04.011

Villagrán-Zaccardi, Y. A., Marsh, A. T. M., Sosa, M. E., Zega, C. J., De Belie, N., and Bernal, S. A. (2022). Complete re-utilization of waste concretes–valorisation pathways and research needs. Resour. Conserv. Recycl, 177. doi:10.1016/j.resconrec.2021.105955

Keywords: Green concrete, residual compressive strength, elevated temperature, SCM-modified concrete, response surface Methodology, ANOVA, recycled concrete (RAC)

Citation: Saqib Khan M, Ulhaq A, Mohammed Alsekait D, Faisal Javed M, Jameel M, Alabduljabbar H and Abdelminaam DS (2025) RSM-based optimization of recycled aggregate concrete with pozzolanic materials under high temperatures. Front. Mater. 12:1601597. doi: 10.3389/fmats.2025.1601597

Received: 28 March 2025; Accepted: 21 July 2025;

Published: 11 August 2025.

Edited by:

Paul Joseph, Victoria University, AustraliaReviewed by:

Lucio Nobile, University of Bologna, ItalyAmir Ali Shahmansouri, Washington State University, United States

Pavlo Maruschak, Ternopil Ivan Pului National Technical University, Ukraine

Copyright © 2025 Saqib Khan, Ulhaq, Mohammed Alsekait, Faisal Javed, Jameel, Alabduljabbar and Abdelminaam. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Muhammad Saqib Khan, bXNraGFuQG1jZS5udXN0LmVkdS5waw==; Aman Ulhaq, YXVoYXFAbWNlLm51c3QuZWR1LnBr; Deema Mohammed Alsekait, ZG1hbHNla2FpdEBwbnUuZWR1LnNh

Muhammad Saqib Khan

Muhammad Saqib Khan Aman Ulhaq

Aman Ulhaq Deema Mohammed Alsekait

Deema Mohammed Alsekait Muhammad Faisal Javed3

Muhammad Faisal Javed3 Mohammed Jameel

Mohammed Jameel Diaa Salama Abdelminaam

Diaa Salama Abdelminaam