- 1Faculty of Forestry, 2nd Campus in Kuala Bekala, Universitas Sumatera Utara, Medan, Indonesia

- 2Center Excellence for Mangrove (PUI Mangrove), Universitas Sumatera Utara, Medan, Indonesia

- 3Faculty of Engineering, Universitas Sumatera Utara, Medan, Indonesia

- 4Research Center for Biomass and Bioproducts, National Research and Innovation Agency (BRIN), Bogor, Indonesia

- 5Faculty of Agriculture and Forestry, Universitas Satya Terra Bhinneka, Medan, North Sumatra, Indonesia

- 6Faculty of Engineering, Universitas Gadjah Mada, Yogyakarta, Indonesia

- 7Board Chemical Team, Donghwa Enterprise R & D Center, Incheon, Republic of Korea

Introduction: Charcoal briquettes serve as a renewable energy source to reduce dependence on fossil fuels and meet global market demands.

Objective: The aim of this study was to evaluate the characteristics of charcoal briquettes made from the branches of three mangrove species and analyze the influence of the presence of bark and different species of mangrove wood branches on the properties of charcoal briquettes.

Methods: Charcoal briquettes were manufactured from branches of three mangrove species: “bakau hitam” (Rhizophora mucronata), “tancang” (Bruguiera gymnorrhiza), and “mata buaya” (Bruguiera sexangula). The production process began with the conversion of branch wood (with and without bark), followed by carbonization using the pyrolysis method, grinding the charcoal into particle size, mixing with starch adhesive, and making charcoal briquettes with a size of 5 cm × 15 cm in a cylindrical shape.

Results and Discussions: These results indicated that mangrove branch wood is highly suitable as a raw material for charcoal briquettes. The charcoal briquettes met the ISO/TS 17225-8:2016 TW1H standard, with values below 8% for moisture and above 5,016 cal/g for energy content. The results ranged from 0.00% to 6.46% and 6225–7,088 cal/g, respectively. Statistically, there were no significant differences in the properties observed among the charcoal briquettes, either based on the presence of bark (with and no bark) or the species of mangroves. These results demonstrated that mangrove woody branches could meet the industrial standard for making charcoal briquettes and that mangrove forest as the raw material source would be sustainable because only woody branches were utilized as bioenergy source.

1 Introduction

Energy consumption continues to increase with the increasing global population. The primary source of this energy is fossil fuels, which remain the predominant choice to date. Fossil fuels are nonrenewable energy sources with limited reserves that can deplete over time. Additionally, fossil fuels that produce high levels of carbon dioxide emissions adversely affect global warming. Therefore, alternative energy sources have received considerable attention in various countries (Kongprasert et al., 2019). The transition to renewable energy is imperative to reduce fossil fuel consumption. Renewable energy can be generated through technological advances, thus becoming an alternative energy source. One such renewable energy source is biomass-derived bioenergy (Adrian et al., 2023).

Biomass or bioenergy exists in solid, liquid, or gaseous forms. Biomass sources are abundant and originate from living organisms, including plants and animals, and agricultural, livestock, and forestry wastes (Prasetia et al., 2018). However, these biomass sources have not been optimally utilized as energy sources. Therefore, the utilization and development of biomass energy must be pursued as part of energy diversification efforts to reduce the reliance on fossil fuels. Countries in tropical zones, including Indonesia, produce large amounts of biomass throughout the year, including wood, which is a valuable energy source for residents (Tun et al., 2019).

Traditionally, Indonesia uses mangrove forest resources as a supplier of wood biomass as a raw material for energy production by rural coastal communities in many islands in the form of charcoal and firewood (Kusmana and Sukristijiono, 2016). Indonesia possesses the biggest area of mangroves globally, accounting for 21 percent of the total mangrove coverage worldwide (FAO, 2020). Southeast Asia possesses approximately 49,500 km2 of mangrove coverage, constituting nearly one-third of the global total of 147,256 km2. Indonesia possesses 21% of the global mangrove population (Leal and Spalding, 2024).

Research on the biomass of various mangrove species, especially woody branches, has been carried out regarding their basic properties and practical applications; for example, wood briquettes from mangrove branches have been successfully prepared using raw materials from mangrove species such as “mata buaya” (Bruguiera sexangula), “buta-buta” (Excoecaria agallocha), and “bakau minyak” (Rhizophora apiculata) (Tambunan et al., 2023). Recently, wood pellets from mangrove branches and twigs also been investigated using the same species (Kusumahastuti et al., 2025).

In addition to wood briquettes, wood biomass can also be converted into charcoal briquettes using conversion technology. Wood biomass is first converted into solid charcoal through a thermal decomposition process that occurs without oxygen, known as pyrolysis (Ifa et al., 2019). Subsequently, the charcoal is compacted with or without an adhesive, resulting in charcoal briquettes with a high density in specific shapes (Mwampamba et al., 2013). Using charcoal briquettes as fuel have several advantages, including optimal heat production compared to charcoal, nontoxicity, less smoke compared to wood or charcoal, the ability to serve as a substitute for coal at a lower price, and a long burning time. Furthermore, Pari (2012) explained that charcoal briquettes are a modified and innovative form of wood charcoal, resulting in longer burning durability, less residue after burning, minimal smoke production, and a higher calorific value.

In this study, charcoal briquettes were made from the wooden branches of three mangrove species. Producing charcoal briquettes from mangrove wood branches will empower communities living around mangrove forests, as these forests have been mainly utilized for intangible purposes such as environmental services (Onrizal and Kusmana, 2009; Onrizal and Mansor, 2020), ecological functions (Fitri et al., 2018; Karniati et al., 2021), and aesthetic value for ecotourism) (Basyuni et al., 2016; Basyuni et al., 2018a; Basyuni et al., 2018b). The resulting charcoal briquettes can be sold and become a prominent commodity commonly used for cooking, especially for grilling food in Europe, shisha pipe smoking in Middle Eastern countries, cooking in restaurants, and water and space heating in Asia, such as South Korea and Japan (Ministry of Trade of The Republic of Indonesia MarketBrief Charcoal in South Korea, 2015).

Hence, the aim of this study was to evaluate the characteristics of charcoal briquettes made from mangrove wood branches and analyze the influence of the presence of bark and different species of mangrove wood branches on the properties of the resulting charcoal briquettes. Since the charcoal briquettes have had more benefits compare to conventional charcoal or firewood, this study aligns with the United Nations Sustainable Development Goals (SDGs), particularly SDG 7: Affordable and Clean Energy. Furthermore, this initiative contributes to SDG 13: Climate Action, as it represents an effort to combat climate change. The novelty of this study lies in promoting renewable bioenergy sources and reducing dependence on fossil fuels, thereby supporting global efforts to mitigate climate change.

2 Materials and methods

2.1 Materials

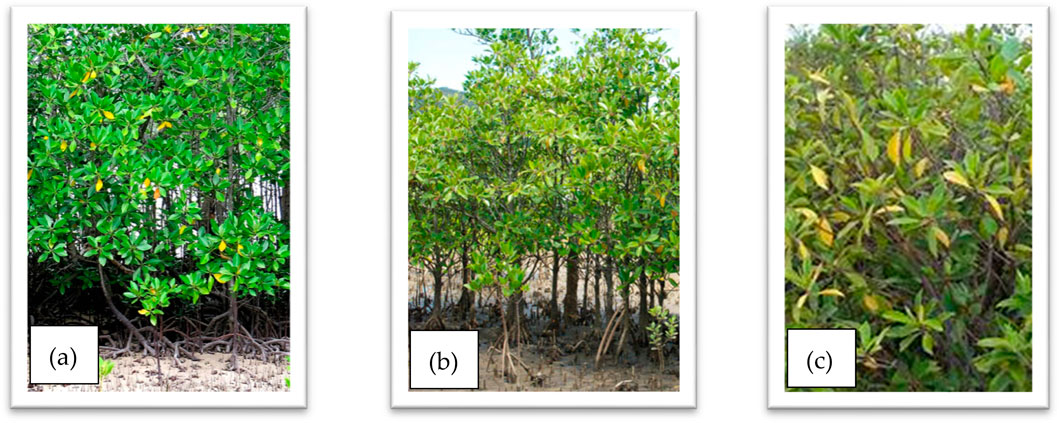

The raw materials were mangrove wood branches from three species, i.e., “bakau hitam” (Rhizophora mucronata), “tancang” (Bruguiera gymnorrhiza), and “mata buaya” (Bruguiera sexangula), obtained from mangrove forests in Lubuk Kertang Village, Brandan Barat District, Langkat Regency, North Sumatra, Indonesia as depicted in Figure 1.

Figure 1. Typical three mangrove species used in this experiment, the branches wood were used as the raw materials, (a) “bakau hitam” (Rhizophora mucronata), (b) “tancang” (Bruguiera gymnorrhiza), and (c) “mata buaya” (Bruguiera sexangula).

2.1.1 Preparation of mangrove wood raw materials

Mangrove branches were pruned at the branch collar to ensure that the main stem remained unharmed. Branch samples were taken 10 cm from the base of the pruned branch to avoid abnormalities (Zhao et al., 2019). The wood branches selected as samples had a diameter of ±2 cm. Three to five branches with the largest diameters were chosen from bottom to top. The obtained wood branches were then dried using sunlight exposure for 3 days to reduce the moisture content. They were then further dried by placing them in a roofed room at room temperature for 2 weeks until ready for conversion into charcoal.

The basic properties of the branches of mangrove wood including the calorific values, were evaluated to understand and compare the properties of the resulting charcoal briquettes with those of the raw materials.

2.2 Testing of physical properties of mangrove wood branches

The physical properties were tested according to the conditions of the existing sample. Mangrove wood branches were tested using samples with an average diameter of ±1.0–2.0 cm with a length of 2 cm. The physical properties included moisture content, density, and specific gravity. Moisture content testing was performed according to the ASTM D 4442-92 (2003) standard (ASTM, 2003a). The moisture content was determined by gravimetric procedure by measuring the initial and final masses of the wood branches after drying in an oven at a temperature of 103 °C ± 2 °C for 24 h. Density and specific gravity testing referred to ASTM D 2395-14 (2003) standard (ASTM, 2014), determined by comparing the mass in the air-dry state and the volume. The measurement of wood branch volume followed the Archimedes principle, resulting in more accurate outcomes owing to the small size of the tested samples. The specific gravity was determined by comparing the obtained density with that of water.

2.3 Testing of mechanical properties of mangrove wood branches

Mechanical testing included determining the modulus of elasticity (MOE) and modulus of rupture (MOR). The test was conducted on solid cylindrical wood branches according to ASTM D143-94 (ASTM, 2000) for small and defect-free (clear) specimens. A universal testing machine/UTM (Tensilon RTF-1350; A&D Company, Tokyo, Japan) was used at a speed of 1.3 mm/min. The MOE and MOR were determined using Equations 1, 2:

where Pe is the elastic load (kgf), Fe is the elastic deflection (cm), P is the maximum load (kgf), L is the supported span (cm), and D is the diameter of the wooden branch (cm).

2.4 The calorific value of mangrove wood branches

Approximately 1 g of mangrove wood branches from each species were prepared, and the calorific value was determined using a Parr Bomb Calorimeter 6400 (Parr Instrument Company, Moline, IL, USA), using the standard calorific value test method based on the ASTM E711-87 standard (ASTM, 2004).

2.5 Conversion of mangrove wood branches into charcoal

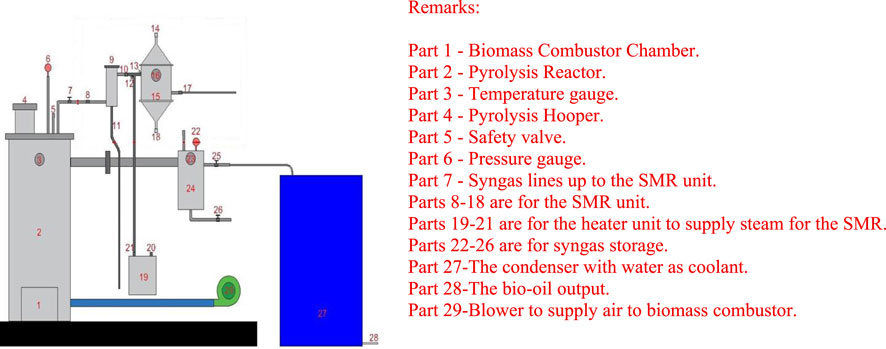

The conversion of mangrove biomass into charcoal was carried out without presence of oxygen gas. The carbonization process used in this study was performed using a batch pyrolysis system with the reactor having a diameter of 50 cm and a height of 100 cm as shown in Figure 2. Parts for SMR or steam methane reformer and WGS or water gas shift reactor (parts 8-18, parts 19-21, and parts 22-26) were closed as the syngas in this experiment was not emphasized.

The carbonization process was carried out using a heating rate of 10 °C per minute until the reactor furnace temperature attains and is maintained at 500 °C and is sustained until the process is complete, as indicated by the end of syngas formation and biooil production, followed by a cooling period lasting up to 16 h. The increase in temperature was recorded for each period to calculate the heating rate. This process typically takes 3 h since the raw material have been exposure. The syngas produced during pyrolysis is channeled through steel pipes into a temporary storage tank before being further directed through copper pipes to an air-cooled condenser, where it is converted into a liquid form, usually referred to as bio-oil. From a single process using this pyrolysis system, approximately 28% biochar, 50% bio-oil, and the rest as syngas that cannot be condensed are obtained.

Carbonization was distinguished based on the presence of bark and wood species. The wooden branches inserted into the reactor furnace were tightly sealed and locked to prevent air from entering. The bottom of the reactor was fed with firewood using a blower to facilitate faster combustion.

2.6 Charcoal briquettes production

The produced charcoal was converted into charcoal powder using a kitchen blender. The charcoal powder was then passed through a 60-mesh sieve (SNI 01-6235-2000, 2000). Charcoal briquettes were manufactured with the aid of tapioca starch at 5% (w/w) of the air-dry weight of the charcoal powder. The water used to prepare the starch-adhesive mixture had a ratio of 5:1 (w/w) to the amount of tapioca used. The water was mixed with tapioca, stirred until evenly distributed, then heated to 70 °C for 5 min until it formed a gel. The charcoal powder was then mixed with the adhesive under continuous stirring until it became homogeneous.

The mixture was then molded into cylindrical shapes (diameter, 5 cm; height, 15 cm) under a pressure of 30 kgf/cm2 for 15 min. The charcoal briquettes were then oven-dried for 2 × 24 h at 60 °C to equalize the moisture content.

2.7 Evaluation of the properties of charcoal briquettes

The quality of the charcoal briquettes was determined by testing their physical (moisture content and density), mechanical (axial and diametral compressive strengths), and chemical properties using pyrolysis-gas chromatography-mass spectrometry (Py-GC-MS) and thermal properties (ash content, volatile matter, fixed carbon, calorific value, and decomposition) using thermogravimetric analysis (TGA). The properties of the charcoal briquettes from the test results were standardized according to ISO/TS 17225-8:2016 (ISO/TS 17225-8, 2016) with a target class of TW1H.

2.8 Testing of physical properties

2.8.1 Moisture content

The charcoal briquettes were weighed and placed in a crucible without a cover, then inserted into an oven at a temperature of 104 °C–110 °C for 1 h. Subsequently, the specimen crucible was removed and quickly covered, placed in a desiccator to cool to room temperature, and weighed as soon as possible. The moisture content was determined according to the ASTM D 5142-02a (ASTM, 2003b) standard, calculated using Equation 3 as follows:

where W is the weight of the charcoal briquette specimen (g), and B is the weight after heating (g).

2.8.2 Density

The charcoal briquettes were weighed, and their dimensions (diameter × height) were measured to determine their volume. The density was determined according to the ASTM D 2395-14 (ASTM, 2014) standard, conducted at a specific moisture content (based on the calculated moisture content according to the ASTM D5142-02a (ASTM, 2003b) standard), using Equation 4 as follows:

where m is the weight of the charcoal briquettes (g), and v is the volume of the charcoal briquettes (cm3).

2.9 Testing of mechanical properties

The ability of the charcoal briquettes to withstand the maximum load until failure was determined through the compressive strength values, both axially and diametrically. The compressive strength of the charcoal briquettes was evaluated using a universal testing machine (Tensilon RTF-1350; A&D Company, Tokyo, Japan) at a speed of 1 mm/min. The axial compressive strength was determined according to the ASTM D 2166-00 (ASTM, 2016) standard and calculated using Equations 5–7:

where ϵ is axial strain, ∆L is the change in length of charcoal briquettes (cm), L0 is the initial length of charcoal briquettes (cm), dan A0 is the initial area of the cross-section of the charcoal briquettes (cm2), A is the cross-sectional area of charcoal briquettes at a given load (cm2), P is given the applied load (kgf), dan σ is axial compressive strength (kgf/cm2).

The diametral compressive strength was determined according to the ASTM D 3967-95a (ASTM, 2001) standard and calculated using Equation 8 as follows:

where σ is diametral compressive strength (kgf/cm2), P is given applied load (kgf), L is the length of charcoal briquettes (cm), dan D is the diameter of charcoal briquettes (cm).

2.10 Testing of chemical properties

2.10.1 Ash content

Charcoal briquette (1 g) was placed into a pre-weighed crucible along with its cover, then inserted into a furnace (Thermolyne Furnace Benchtop Muffle Type 48000; Barnstead Thermolyne, Ramsey, MN, USA) and gradually heated to a temperature of 700 °C–750 °C for 4 h. Subsequently, the crucible was removed, cooled in a desiccator to minimize moisture absorption, and weighed. The ash content was determined as described in ASTM D5142-02a standard (ASTM, 2003b) and calculated using Equation 9 as follows.

where W is the weight of the charcoal briquette specimen (g), F is the weight of the crucible and residue (g), and G is the weight of the empty crucible (g).

2.10.2 Volatile matter

Volatile matter was determined by placing 1 g of a charcoal briquette in a pre-weighed crucible with its cover. Subsequently, the crucible was placed into a furnace (Thermolyne Furnace Benchtop Muffle Type 48000, Barnstead Thermolyne, Ramsey, MN, USA) at a temperature of 950 °C ± 20 °C for 7 min, then cooled in a desiccator until reaching room temperature, and the crucible and its cover were weighed as soon as possible. The volatile matter was determined according to the ASTM D5142-02a (ASTM, 2003b) standard and calculated using Equations 10, 11 as follows:

where W is the weight of the charcoal briquette specimen (g), C is the weight of the charcoal briquette after heating during the volatile-matter test (g), D is the weight loss (%), and M is the moisture content (%).

2.10.3 Fixed carbon

The fixed carbon content was determined according to the ASTM D5142-02a standard (ASTM, 2003b) and calculated using Equation 12:

where M is the moisture content (%), A is the ash content (%), and V is volatile matter (%).

2.10.4 Calorific value

The calorific value was determined by burning the charcoal briquettes in a high-pressure oxygen atmosphere using a Parr Bomb Calorimeter 6400 (Parr Instrument Company, Moline, IL, USA). The calorific value was determined according to the ASTM D5865-10a standard (ASTM, 2010).

2.11 Pyrolysis-gas chromatography-mass spectrometry (Py-GCMS)

The identification test of chemical components presents in the mangrove wood sawdust and its charcoal were identified using Pyrolysis-Gas Chromatography-Mass Spectrometry (Py-GCMS) (Shimadzu GC/MS system QP-2020 NX, Shimadzu, Kyoto, Japan). The Py-GC-MS temperature was programmed as follows: 50 °C for 1 min, 5 °C/min until reaching 280 °C, and 13 min at 280 °C.

2.12 Thermogravimetric analysis (TGA)

TGA was performed on the samples to calculate changes in mass loss due to temperature changes (Olabisi et al., 2023). In this study, TGA (TGA 4000; PerkinElmer, Waltham, MA, USA) was used to determine the decomposition of materials due to temperature changes by preparing mangrove wood branch sawdust and charcoal samples. Approximately 10 mg of each sample was heated from 25 °C to 700 °C at a heating rate of 10 °C/min in a nitrogen gas environment at a flow rate of 20 mL/min.

2.13 Data analysis

The influence of species and its bark on mangrove wood branches on the basic properties of mangrove wood branches and charcoal briquettes was evaluated using a completely randomized nested design consisting of two factors, namely main factor (A) of mangrove wood branch composed of three species, namely “bakau hitam” (R. mucronata), “tancang” (B. gymnorrhiza), and “mata buaya” (B. sexangula), and nested factor (B) of bark presence, namely with bark and no bark, with five replications.

3 Results and discussion

Since this study emphasized on utilization of the wooden branches of mangrove for producing charcoal briquettes, comparison between before and after become the products is necessary. In other words, the basic properties of the wood branches as the raw material and after become charcoal briquettes were compared their properties to show the added values of this effort. Conversion of mangrove wood branches into charcoal briquettes will be beneficial for both forest itself and communities living around mangrove forests, as the forests will be sustainable because only the branches’ part will be harvested and the resulting charcoal briquettes can be sold and become a prominent commodity commonly used for cooking (grilling and smoking) and heating. Further, analyze the influence of the presence of bark and different species of mangrove wood branches on the properties of the resulting charcoal briquettes is important because our previous studies have been directed to bio-energy purposes (Nuryawan et al., 2021; Panggabean et al., 2022; Nuryawan et al., 2023; Tambunan et al., 2023; Simatupang et al., 2024; Kusumahastuti et al., 2025).

3.1 The basic properties of three species of mangrove wood branches

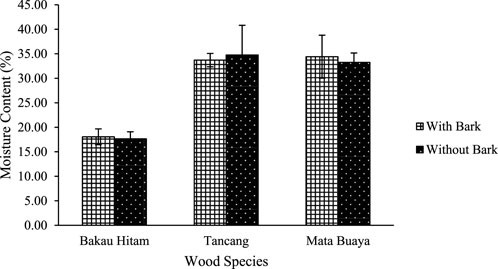

3.1.1 Moisture content

The moisture content of the wood branches in this study ranged from 17.65% to 34.76%, as shown in Figure 3. The lowest moisture content was observed in “bakau hitam” without bark, whereas the highest moisture content was observed in “tancang” with bark. It is crucial to ascertain the moisture content of raw biomass materials as it relates to combustion, both during the conversion process from wood to charcoal and when directly used. The moisture content affects the efficiency of the combustion process, the fuel energy value, and the temperature reached during combustion, especially when converting biomass into charcoal (Pedišius et al., 2021). Wood offers higher combustion efficiency than bark due to its lower ash and moisture content and higher fixed carbon. In contrast, bark contains more minerals and moisture, leading to higher ash production, greater energy loss, and less stable combustion. As a result, wood burns more cleanly and efficiently, making it a more suitable fuel for briquette production.

Statistically, species has a strong and significant effect on moisture content of mangrove wood branches. However, the presence or absence of bark which nested within the species did not have a statistically significant effect as depicted in Supplementary Material S2.

Generally, the moisture content of wood branches with bark was higher than that of branches without bark. This can be explained by the fact that the bark of wood can expand in response to atmospheric humidity variations and to hydration due to variations in soil moisture content (Stahl et al., 2010). Wood bark, particularly its inner layer, contains physiologically active tissues that store water and other compounds, serving as a conduit for radial water transfer from the phloem to the xylem (Ilek et al., 2021).

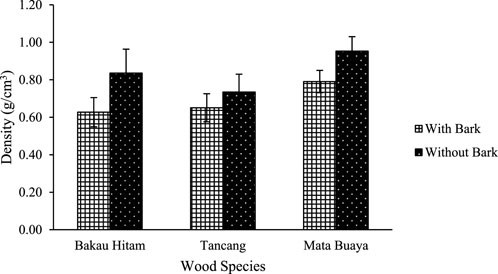

3.1.2 Density

The density of wood branches in this study ranged from 0.63 to 0.95 g/cm3, as presented in Figure 4. The lowest density was found in the “bakau hitam” species with bark, whereas the highest density was found in “mata buaya” without bark. The analysis of variance (in Supplementary Material S2) indicated species does not significantly affect wood density, but the presence or absence of bark (within each species) does. This suggests that bark removal or its presence influences the density of wood, regardless of species.

The density of raw materials can influence the quality of the produced solid biofuel; the higher the density, the higher the energy content, which is related to transport and storage durability (Okot et al., 2018).

The density of wood branches varies and tends to be high. Barkless wood branches have a higher density than wood branches with bark. This finding is consistent with the results of studies conducted by Gryc et al. and Thomas (Gryc et al., 2011; Eberhardt et al., 2017). The bark consists of cells with thin walls closely packed together (Pásztory et al., 2016), and has a higher lignin content than wood. Conversely, wood contains higher cellulose and hemicellulose contents than bark (Chow et al., 2008).

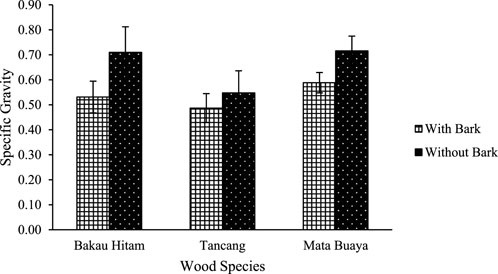

3.1.3 Specific gravity

The specific gravity of wood branches in this study ranged from 0.49 to 0.72, as presented in Figure 5. The lowest specific gravity was found in the “tancang” species with bark, whereas the highest specific gravity was found in the “mata buaya” species without bark. The analysis of variance as depicted in Supplementary Material S2 indicated the species of tree does not significantly affect on the specific gravity of wood branches, whereas the presence or absence of bark does—and this effect is consistent within each species. Bark may influence moisture content, structure, or related wood properties reflected in the specific gravity variable.

The relationship between the density and specific gravity of wood provides information on how dense or heavy a species of wood is. Generally, the higher the wood density, the higher its specific gravity, and vice versa. This can be seen in the mangrove wood species in this study, which exhibited similar trends in density and specific gravity. Specific gravity is influenced by the anatomical properties of wood, such as cell diameter, cell wall thickness, and wood substances (Al-Sagheer and Prasad, 2010). Additionally, the specific gravity of wood species varies based on soil quality and the physical and chemical properties associated with growth, environmental factors, and certain genetic factors (Mahato et al., 2019).

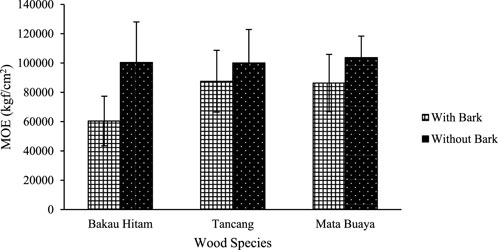

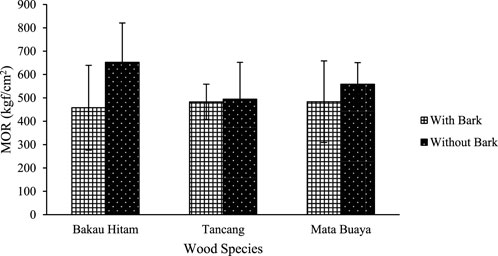

3.1.4 Modulus of elasticity (MOE) and modulus of rupture (MOR)

The mechanical properties (MOE and MOR) of the mangrove wood branches are presented in Figures 6, 7. The MOE and MOR values ranged from 60418.85 to 103708.64 kgf/cm2 and 457.88–652.46 kgf/cm2, respectively. The lowest MOE was observed for the “bakau hitam” species with bark, whereas the highest MOE was observed for the “mata buaya” species without bark. The lowest and highest MOR were observed in “bakau hitam.”

Based on the analysis of variance as attached in SupplementaryMaterial S2, although the species of wood did not significantly affect its MOE, the bark (nested within species) did. However, for MOR, neither species nor the presence/absence of bark within species had a statistically significant effect. Bark which is laid on the surface of wood branches is capable of preventing MOE but not MOR. In other words, the breaking strength of the wood appears to be consistent among species and is unaffected by the presence of bark. This suggests that bark presence affects only the MOE and not the MOR.

Mangrove wood branches with bark exhibited higher MOE/MOR values than branches without bark. In addition, there was a positive linear relationship between the density, specific gravity, and MOE/MOR of the mangrove wood branches. The higher the density and specific gravity, the higher the MOE/MOR. Even though this condition is observed in the present study—characterized by high density and specific gravity values, which correlate with elevated mechanical properties (MOE and MOR)—the material is not yet suitable for application as structural timber. Due to the irregular form of mangrove branch wood, it is more appropriately directed for use as a source of bioenergy.

Mechanical properties are greatly influenced by the density or specific gravity of wood; therefore, factors that affect the density or specific gravity (wood species, age, tree diameter, growth location, position within the stem, humidity, moisture content, and temperature) also affect its mechanical properties (Dwianto et al., 2008). Furthermore, the mechanical properties of wood are determined by the submicroscopic structure of the cell wall. The cell wall comprises several different layers, one of which is the secondary wall with the highest number of cellulose microfibrils. The thickness and orientation relative to the long axis of the cell (known as the microfibril angle/MFA) significantly influence the mechanical properties of wood (Krauss, 2009). Earlier research on the anatomical characteristics of mangrove branch wood also indicated its unsuitability for structural applications and papermaking, due to its underdeveloped vessels, parenchyma, and fibers. As a result, its utilization may be more appropriate for energy wood production (Panggabean et al., 2022).

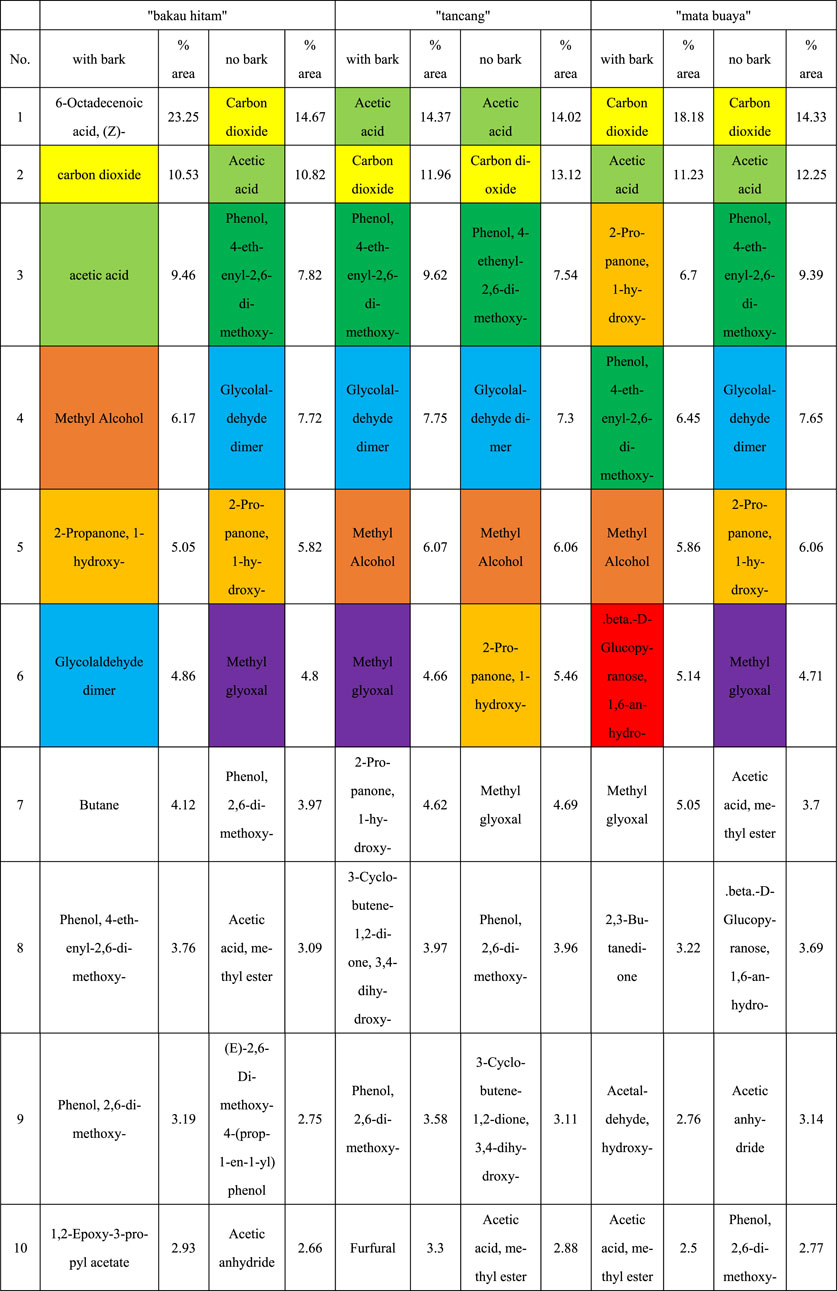

3.1.5 Pyrolysis-gas-chromatography/mass spectrometry (Py-GCMS)

Py-GC-MS analysis was performed to identify the compounds present in the mangrove branches and charcoal. The results of the Py-GC-MS analysis of the wood and the charcoal are presented in Figures 8, 9, respectively. Since the peaks and number were unclear and overlapped in the chromatograms, only the top ten and the top five of the compounds were displayed. For instance, 50 peaks were emerged in the chromatogram of Py-GC-MS of “bakau hitam” wood, therefore the details are attached in the Supplementary Material S1. In general, the compound contents of each species, with and without bark, did not differ. The main compounds with % area identified were 6-octadecenoic acid, (Z)-(23.25%), carbon dioxide (10.53–18.18%), acetic acid (9.46–14.37%), methyl alcohol (5.86–6.17%), 2-propanone, 1-hydroxy- (5.05–6.70%), glycolaldehyde dimer (4.86–7.75%), methyl glyoxal (4.66–4.80%), beta-D-glucopyranose, 1,6-anhydro- (5.14%), and other compounds, including ketones, aldehydes, furans, and phenols.

Figure 8. Summary metrics of Py-GCMS chromatogram of mangrove branch wood: “bakau hitam” with bark and no bark, “tancang” with bark and without bark, “mata buaya” with bark and without bark. Yellow and green colors are carbon dioxide and acetic acid, respectively.

Figure 9. Summary metrics of Py-GCMS chromatogram of mangrove branch charcoal: “bakau hitam” with bark and no bark, “tancang” with bark and without bark, “mata buaya” with bark and without bark. Yellow color is carbon dioxide.

Among these compounds, carbon dioxide and acetic acid were the most abundant in all types of mangrove branch wood. Carbon dioxide is produced by combustion, where oxygen combines with carbon stored in wood (Yadav and Devi, 2019). Acetic acid originates from the acetyl groups of hemicellulose, which are generated by eliminating the acetyl groups initially bound to xylose units (Güllü and Demirbaş, 2001; Harahap, 2020). Additionally, cellulose consists of numerous glucose units linked through β-1,4-glycosidic bonds, and through glucose cleavage, glycolaldehyde is produced (Schandel, 2020). Ketone and aldehyde compounds were the main secondary volatile products, and their small-molecule products originated from the breakdown of single sugar rings. Organic furans are formed through the dehydration of d-xylose monomers (Gao et al., 2013), whereas phenol is produced by the deconstruction of lignin through the breakdown of bonds linking lignin to hemicellulose (Kleinert and Barth, 2008; Mullen and Boateng, 2010).

From Figure 9, it is evident that five peaks are present in the chromatogram. The compounds identified were significantly different from those found in the wood. The dominant compound is carbon dioxide (81.30–98.99%). Carbon dioxide is generally formed in larger quantities in charcoal than in wood because the carbonization process removes most volatile organic compounds and solid residues that are less thermally stable, leaving most of the carbon concentrated in a stable solid carbon form (Asri et al., 2022; Sieradzka et al., 2022). This indicates a positive carbonization process. The higher the fixed carbon content, the more suitable the material is as a fuel. Therefore, the conversion of mangrove wood branches into charcoal is highly effective.

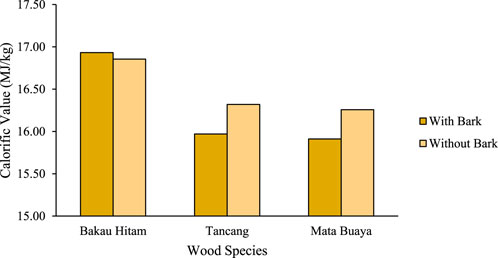

3.1.6 Calorific value

The calorific value of mangrove wood branches in this study ranged from 15.91 MJ/kg to 16.93 MJ/kg, as presented in Figure 10. The lowest calorific value was observed in the bark of “mata buaya,” whereas the highest calorific value was observed in the bark of “bakau hitam.” The calorific values in this study varied, but the mangrove wood branches with bark generally had high calorific values. The differences in calorific values can be attributed to the chemical composition of each wooden branch. In this regard, lignin has the highest calorific value, followed by cellulose and hemicellulose (Günther et al., 2012).

The calorific value of mangrove wood branches is also related to their moisture content. The “bakau hitam” species had the lowest moisture content compared to the other species; thus, they had the highest calorific value. A high moisture content results in a low calorific value. In this context higher heating value or HHV has been compared since the wood branches of the mangrove still contain moisture. This is because the generated heat is primarily used to evaporate the water contained in the wood (Fahrussiam et al., 2023). Calorific value significantly affects the quality of biomass energy, such as charcoal briquettes. Calorific value is a crucial parameter for selecting raw materials for charcoal briquette production. The calorific value of mangrove branch wood in this study is comparable to the HHV of other wood species used for biomass energy, such as gamal (Gliricidia sepium), lamtoro (Leucaena leucocephala), and kaliandra (Calliandra calothyrsus), each of which has a calorific value of 17.94 MJ/kg, 17.22 MJ/kg, and 16.45 MJ/kg, respectively (Tia et al., 2013).

3.1.7 Thermogravimetric analysis (TGA)

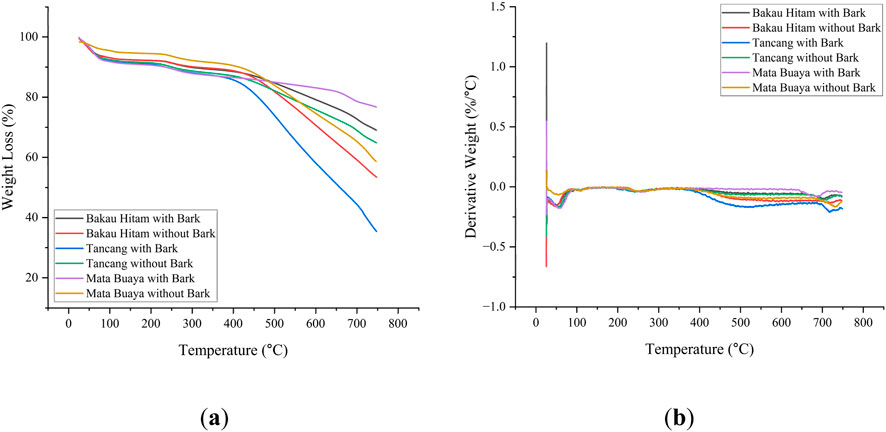

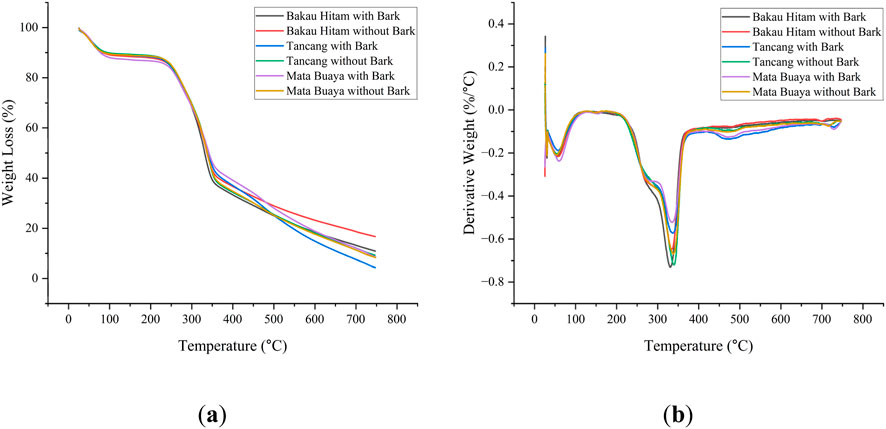

The thermal decomposition behavior of the mangrove branch wood was studied using TGA, as shown in Figure 11. Based on Figure 11, it can be observed that mangrove wood branches have a relatively similar thermal degradation profile consisting of three distinct weight loss stages during thermal degradation: dehydration, active pyrolysis, and passive pyrolysis, with temperatures ranging from 26 °C to 110 °C, 110 °C–361 °C, and 361 °C–748 °C, respectively.

Figure 11. (a) Thermogravimetric (TG) and (b) Derivative Thermogravimetric (DTG) curves of mangrove branch wood.

The recorded temperature reached up to 748 °C even though the setpoint heating was only 700 °C. This indicated that inorganic content therein, such as mineral and ash which were found in the bark as silica. Therefore, this TGA results demonstrated that debarking improved the thermal and combustion quality of biomass for biofuel production. The higher residue in barked samples, suggests greater inorganic content, which may lower biofuel efficiency and cause technical problem in combustion in term as biofuel.

The weight loss of mangrove branch wood in the first stage ranged from 9.46% to 11.83%. The first stage, known as dehydration, is associated with the loss of moisture and light volatile compounds (Wilk et al., 2016). The highest percentage of weight loss occurred in the second stage (42.62–51.83%). The significant weight loss during the second stage was caused by the thermal decomposition of hemicellulose, cellulose, and lignin in the wood.

Mishra and Mohanty (2018) stated that during the second stage, compounds with higher molecular weights undergo fragmentation into smaller molecules under continuous heat application. This stage involves two simultaneous exothermic processes in which hemicellulose, cellulose, and lignin decompose, leading to the formation of higher amounts of volatile substances. Hemicellulose decomposes at lower temperatures (180–340 °C) compared to cellulose (230–450 °C) and lignin (>500 °C). The main peak of DTG is also observed in this stage, particularly in the “bakau hitam” species with bark, which exhibited the highest weight loss of 51.83%, with the maximum weight loss rate at temperatures of 274 °C (0.34%/°C) and 340 °C (0.13%/°C).

In the final stage, the weight loss of the mangrove branch wood ranged from 24.05% to 37.40%. This stage involves a slow and continuous degradation caused by the breakdown of lignin. Compared to the DTG peaks of hemicellulose and cellulose, this peak was flatter. In practice, lignin degradation occurs slowly over wide temperature ranges. This is related to the lignin content, which has many aromatic rings with various branches; its chemical bonding activities cover a wide range, and it is highly stable and resistant to degradation (Yang et al., 2016; Postawa et al., 2022). Finally, at 748 °C, residues ranging from 9.19% to 17.17% were produced, with the lowest and highest yields, respectively, in the “mata buaya” species with bark and “bakau hitam” species without bark species. The differences in degradation temperature, weight loss rate, and final residue are due to the sample composition, species variation, chemical structure, differences in moisture content, and volatile matter (de Luna et al., 2018; Guida et al., 2019).

3.2 Conversion of mangrove wood branches into charcoal

3.2.1 Yield

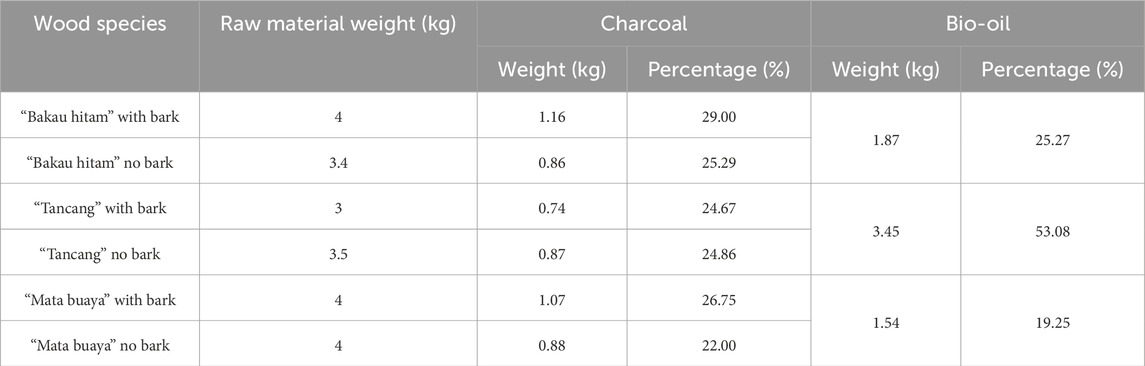

The pyrolysis yields obtained are listed in Table 1. The charcoal production ranged from 22.00% to 29.00%, while the bio-oil production ranged from 19.25% to 53.08%. The highest charcoal production was found in the “bakau hitam” species and the lowest in the “mata buaya” species. The highest bio-oil production was found in the “tancang” species and the lowest in the “mata buaya” species.

One method to enhance the quality of wood into higher-quality fuel is through pyrolysis, which is the thermal decomposition of organic material at high temperatures without oxygen. Wood pyrolysis begins at temperatures around 300 °C. At this temperature, cellulose, which is the main constituent of wood, begins to break down its glycosidic bonds to form smaller, lighter molecules. Hemicellulose and lignin, other main components of wood, begin to degrade at lower temperatures, at 225 °C and 250 °C, respectively. Although lignin begins to decompose at temperatures below 300 °C, it is more stable and less reactive compared to other components (Wretborn, 2016).

The pyrolysis of wood always produces charcoal, liquid, and gas, the amount of which depends on the characteristics of the wood and the pyrolysis conditions. In the pyrolysis process, the composition and yield of the product depend on the type of biomass, pretreatment of the material (particle size and shape), type of reactor, and operating parameters, such as pyrolysis temperature, heating rate, pressure, and residence time (Lu et al., 2009; Varma et al., 2019).

3.3 Characteristics of charcoal briquettes

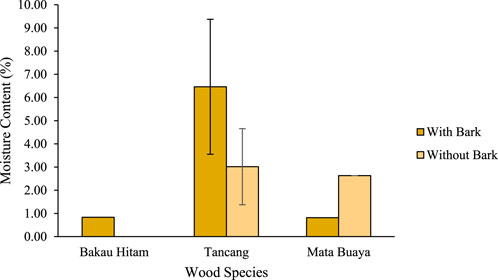

3.3.1 Moisture content

The moisture content of charcoal briquettes in this study ranged from 0.00% to 6.46%, as presented in Figure 12. The lowest moisture content was observed in “bakau hitam” without bark, whereas the highest moisture content was observed in “tancang” with bark. Statistically, moisture content in charcoal briquettes may vary depending on the species of wood used, but the presence or absence of bark nested within each species did not significantly influence moisture levels as depicted in Supplementary Material S2. The moisture content of charcoal briquettes met the ISO/TS 17225-8:2016 class TW1H standard, which required a maximum moisture content of 8%. The drying process after molding played a crucial role in reducing the moisture content of the charcoal briquettes. The moisture content reduces the calorific value and increases the weight. First, it evaporated and affected the overall heating properties of the briquettes. Charcoal briquettes with a lower moisture content are desired because of their higher heating characteristics (Kongprasert et al., 2019).

The combustion characteristics of biomass can be significantly influenced by moisture content. During combustion, the moisture content in the solid fuel absorbs heat from the burning fuel to form steam, thereby significantly reducing the calorific value of the fuel. This can lead to the incomplete combustion of volatile materials and the accumulation of unburned carbon (smoke). A high moisture content can cause ignition (Tamilvanan, 2013).

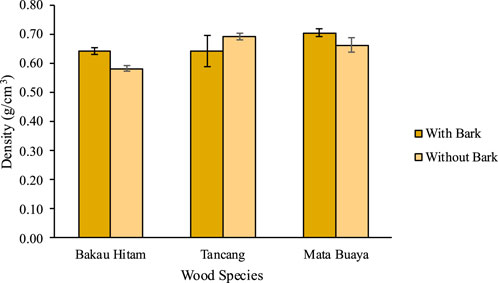

3.3.2 Density

The density of charcoal briquettes in this study ranged from 0.58 to 0.71 g/cm3, as presented in Figure 13. The lowest density was found in the “bakau hitam” species without bark, whereas the highest density was found in the “mata buaya” species with bark. While briquette density did not differ significantly between species, the presence or absence of bark played a significant role in determining the density of the briquettes as depicted in results of statistics analysis within Supplementary Material S2.

Even though bark condition affects how compact or dense the charcoal briquettes are, the density of charcoal briquettes in this study did not meet the ISO/TS 17225-8:2016 class TW1H standard, which required a minimum density of 1.0 g/cm3. The low compression pressure applied by the pressing machine was one of the factors contributing to the failure to meet the charcoal briquette density standard. To improve briquette density, increasing compression pressure during production strengthens particle bonding and minimizes voids, resulting in stronger, more durable briquettes with enhanced combustion efficiency. Additionally, optimizing moisture content and incorporating suitable binders can further increase density and mechanical strength.

Kaliyan and Vance Morey (2009) stated that pressure and temperature are two of the factors affecting the density of solid fuels. The application of high pressure and temperature affects the binding mechanism by forming strong bonds and increasing the contact area between particles; this also reduces the distance between particles, allowing intermolecular attractive forces to participate in the bonding mechanism, thus resulting in solid fuels with high density. Increasing the pressure during compression causes particles to fill empty voids, thereby reducing the porosity and increasing the density (Pambudi et al., 2018).

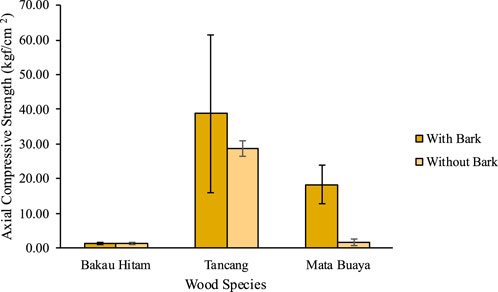

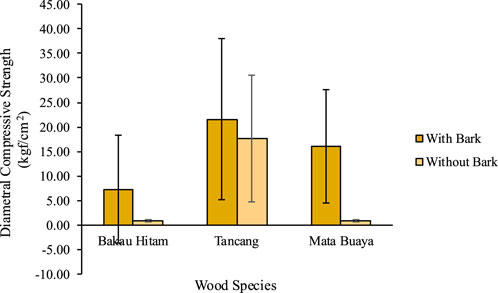

3.3.3 Compressive strength

In this study, charcoal briquettes were axially and diametrically tested for their compressive strengths, and the respective compressive strength values are presented in Figures 14, 15. The axial compressive strength of the charcoal briquettes ranged from 1.28 to 38.70 kgf/cm2 and the value are higher compared to previous study which evaluated briquette wood (Tambunan et al., 2023). The lowest axial compressive strength was observed in “bakau hitam” with bark, whereas the highest was observed in “tancang” with bark. The species of wood used to produce briquettes has a significant effect on their compressive strength—different species produce briquettes with clearly different axial compressive strength properties. However, whether the bark is included or removed within each species does not significantly affect axial strength as depicted in Supplementary Material S2.

The diametric compressive strengths of the charcoal briquettes ranged from 0.86 to 21.60 kgf/cm2 and also the value are higher compared to that of evaluated briquette wood (Tambunan et al., 2023). The lowest diametrical compressive strength was observed in “bakau hitam” without bark, whereas the highest was observed in “tancang” with bark. For diametral compressive strength, neither the species of wood nor the presence or absence of bark has a statistically significant effect as depicted in Supplementary Material S2. The mechanical resistance across species and bark conditions is relatively similar in the diametral direction. ISO/TS 17225-8:2016 does not specify the compressive strength value for charcoal briquettes.

Compressive-strength tests were conducted to measure the ability of the briquettes to withstand specific pressure loads. This is related to the handling process, including packaging, transportation, and storage (Brunerova et al., 2018). The briquette particle size can influence the compressive strength. Smaller particle sizes lead to an increased compressive strength (Pang et al., 2019). The finer particle size distribution in the briquettes resulted in smaller pores owing to stronger intermolecular bonds between the particles, allowing them to interlock and bind together. Hence, briquettes exhibit a high compressive strength (Ajimotokan et al., 2019).

The compressive strength of the charcoal briquettes is also related to their density, indicating that the briquette density correlates well with the compressive strength. Generally, briquettes with high densities exhibited the highest compressive strength values. In this study, charcoal briquettes from the “tancang” and “mata buaya” types had high densities (Figure 13), corresponding to their high compressive strengths. High-density briquettes have few void spaces, resulting in low compressibility, whereas low-density briquettes still have void spaces that tend to cause cracks, making them susceptible to damage when subjected to a load (pressure) (Bello and Onilude, 2020).

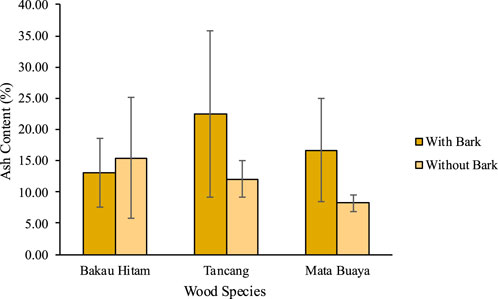

3.3.4 Ash content

The ash content of charcoal briquettes in this study ranged from 8.23% to 22.53%, as presented in Figure 16. The lowest ash content was found in the “mata buaya” species without bark, whereas the highest ash content was found in the “tancang” species with bark. The ash content of charcoal briquettes in this study did not meet the ISO/TS 17225-8:2016 standard, which required a maximum ash content of 5%. Based on the analysis of variance as depicted in Supplementary Material S2, there was no significant difference in the presence of bark or species factors on the ash content. The ash levels were generally stable across all treatments.

The variation in the ash content of charcoal briquettes can be attributed to differences in the chemical characteristics of the species, particularly the high silica content found in mangrove wood branches (Elizondo et al., 2021; Woodu, 2023). The higher the silica content, the higher the ash content (Maulina and Iriansyah, 2018). The ash in the charcoal briquettes is a product of pyrolysis under anoxic conditions, followed by combustion under oxic conditions. Additionally, some elements are likely to volatilize as other minerals form in the ash owing to temperature effects, resulting in varying compositions (Neina et al., 2020). Ash content affects the calorific value of charcoal briquettes; a higher ash content corresponds to a lower calorific value, resulting in low-quality charcoal briquettes (Murni et al., 2021). For practical, to reduce ash content, it is essential to clean the raw materials by minimizing dirt, removing the bark, and washing the feedstock to eliminate silica-rich pollutants, given that the mangrove and its bark possess high silica content. Selecting wood with low silica content is a crucial step to enhance carbonization, resulting in reduced ash and improved briquette quality and combustion efficiency.

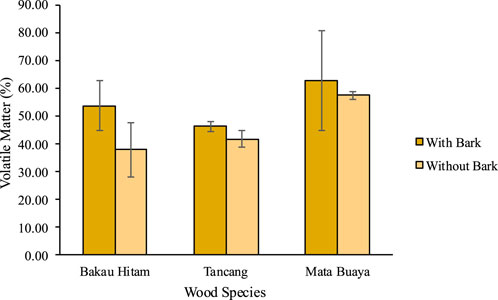

3.3.5 Volatile matter

The volatile matter of charcoal briquettes in this study ranged from 38,00 to 62.73%, as shown in Figure 17. The lowest volatile matter content was found in “bakau hitam” without bark, whereas the highest was found in “mata buaya” with bark. The wood species utilized in the production of charcoal briquettes exhibits a slight impact on volatile matter concentration, indicating that certain species may yield briquettes with higher volatile richness than others; however, the variation is not statistically significant. Simultaneously, bark condition provides no significant influence on volatiles. The results of these analyses were presented in Supplementary Material S2. ISO/TS 17225-8:2016 standard does not specify a specific value for volatile matter. Based on the variance analysis, there was no significant difference in the volatile matter value of charcoal briquettes concerning the presence of bark or species factors. However, the volatile matter of charcoal briquettes in this study was relatively high compared to that of previous studies (Kongprasert et al., 2019; Sotannde et al., 2010) reporting that volatile matter content of charcoal briquettes from branches of Garcinia schomburgkiana and residual wood of Azadirachta indica was 20.30% and 10.75%, respectively.

The pyrolysis process, especially the temperature and duration of mangrove wood branch pyrolysis, affects volatile matter. The higher the temperature and pyrolysis time, the more volatile matter was released, resulting in a lower volatile matter content during testing (Yang et al., 2016). The higher the amount of volatile matter in a fuel, the lower its carbon content, which leads to higher smoke emissions during combustion (Hasfianti et al., 2019). Consequently, the charcoal briquettes become easier to ignite and lighten, resulting in a faster burning rate. A high burning rate will lead to the wasteful use of charcoal briquettes. According to Ivanov et al. (2003), a fuel is classified as smokeless if it contains less than 20% volatile matter.

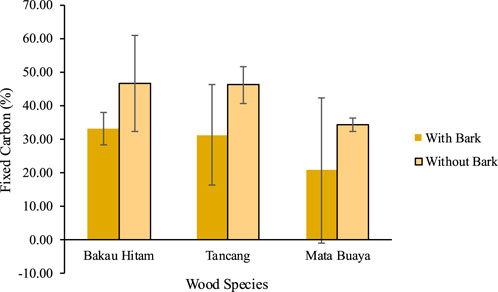

3.3.6 Fixed carbon

The fixed carbon of charcoal briquettes in this study ranged from 20,60 to 46.53%, as shown in Figure 18. The lowest fixed carbon content was found in “mata buaya” with bark, whereas the highest was found in “bakau hitam” without bark. Both species and bark presence have no statistically significant effect on the fixed carbon content of charcoal briquettes as depicted in Supplementary Material S2. The amount of fixed carbon remains relatively stable across all treatments. ISO/TS 17225-8:2016 does not specify the fixed carbon value for charcoal briquettes. Fixed carbon measurements indicate the amount of solid material that can burn after removing volatile matter from solid biofuels.

Fixed carbon is a fuel quality parameter that affects the calorific value. The higher the fixed carbon content, the higher the calorific value, thus improving the fuel quality (Pereira et al., 2021). Additionally, fixed carbon values are influenced by high or low moisture content, ash content, and volatile matter (Hapid et al., 2018). Highly carbon produces charcoal briquettes with smokeless flames and long burning times (Sotannde et al., 2010).

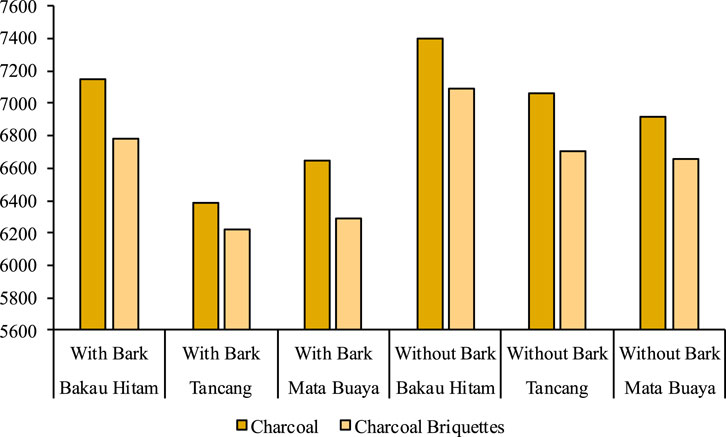

3.3.7 Calorific value

The calorific value is closely related to the quality of the charcoal briquettes, as determined by the moisture, volatile matter, ash, and fixed carbon contents. Calorific value testing was conducted on raw charcoal materials and charcoal briquettes, as shown in Figure 19. The calorific value of charcoal ranged from 6381.75 to 7,399.81 cal/g, while the calorific value of charcoal briquettes ranged from 6225.88 to 7,088.30 cal/g. Both the lowest and highest calorific values were the same, with the lowest values found in the “tancang” species with bark and the highest in the “bakau hitam” species without bark. The calorific value of charcoal briquettes in this study met the ISO/TS 17225-8:2016 class TW1H standard, which required a minimum calorific value of 5,016 cal/g.

As depicted in Figure 19, there is a decrease in the calorific value, where the calorific value of the charcoal raw material is higher than that of the charcoal briquettes. This can be attributed to the type of raw material and proportions used, which affect the calorific value (Njenga et al., 2013). In this case, a starch adhesive containing water was mixed with charcoal during charcoal briquette production. Despite drying, moisture content remained in the charcoal briquette. The moisture content in charcoal briquettes can reduce the combustion efficiency because energy is required to evaporate this moisture (Kongprasert et al., 2019). Further, tapioca starch acts as non-combustible or less-combustible components, thereby decreasing the calorific value of the charcoal briquette. Consequently, this may result in lower calorific values of the charcoal briquette-containing adhesives. Additionally, using tapioca starch adhesive, which has a lower fixed carbon content and calorific value than charcoal (Pari et al., 2014; Jerry et al., 2023), can decrease the overall calorific value of charcoal briquettes.

Pyrolysis increases the calorific value of the solid biomass fuels. In this study, the calorific value of the charcoal briquettes was nearly double that of the raw material from mangrove wood branches. This process removes moisture and increases carbon content and energy density (Hu et al., 2016). Pyrolysis changes the hydrogen-to-carbon (H/C) and oxygen-to-carbon (O/C) ratios of the raw material to charcoal. The H/C and O/C ratios decreased after the pyrolysis. This results in carbon enrichment in the charcoal produced, leading to an increase in calorific value (Rani et al., 2023). High-calorific-value charcoal briquette fuels have a high fixed carbon content, low moisture, and low ash content (Kongprasert et al., 2019).

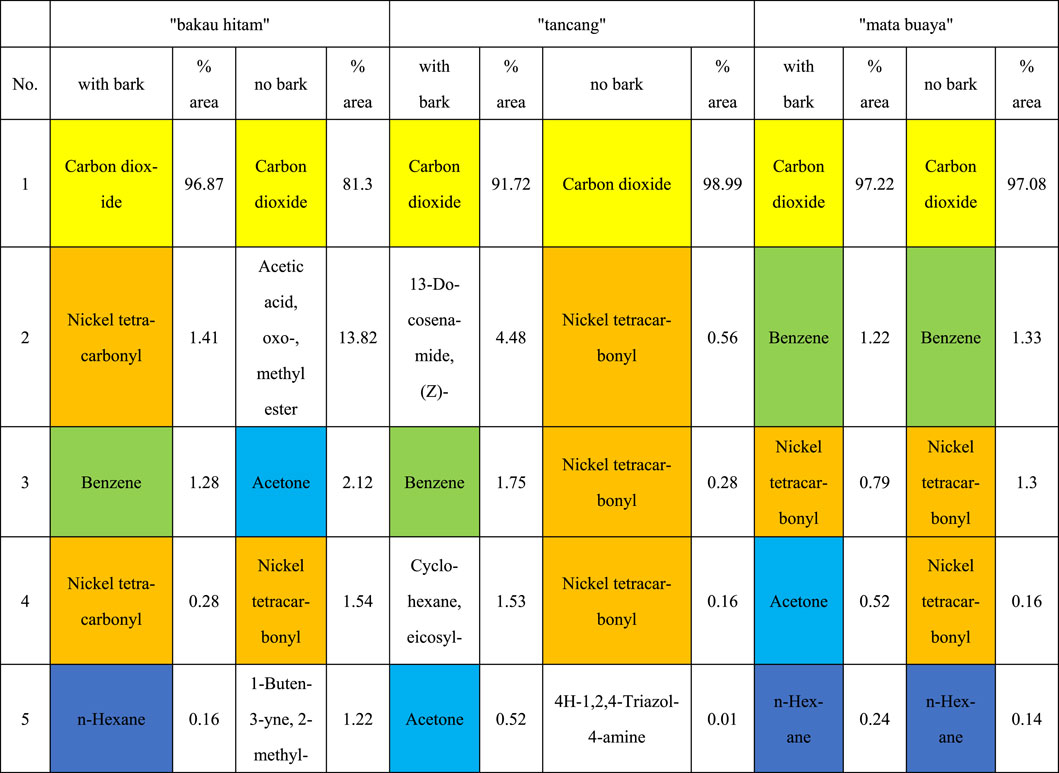

3.3.8 Thermogravimetric analysis (TGA)

Further thermogravimetric analysis was conducted to study the thermal decomposition behavior of charcoal derived from mangrove wood branches, and the thermogravimetric/TG and derivative thermogravimetric/DTG curves of charcoal are presented in Figure 20. Based on Figure 20, it can be observed that charcoal exhibits a different thermal degradation profile compared to mangrove branch sawdust, consisting of two stages, with temperatures ranging from 26 °C to 108 °C and 75 °C–748 °C, respectively.

Similar to mangrove branch wood, the initial stage involved dehydration (water desorption), with the weight loss of mangrove wood branch charcoal ranging from 3.12% to 7.37%. The peak temperature in this stage is 58 °C with a weight loss rate of 0.17%/°C. Subsequently, in the second stage, also known as the charcoal burning stage, there is a slow or stable level of thermal decomposition, yet a cumulative weight loss ranging from 15.50% to 57.12% occurs. At this stage, the slow weight loss with a higher initial degradation temperature was closely associated with the combustion of volatile matter and fixed carbon (Olabisi et al., 2023). At 748 °C, the remaining residue is very high, ranging from 35.84% to 77.14%, with the highest found in the “mata buaya” species with bark and the lowest in the “tancang” species with bark. Therefore, it can be concluded that charcoal from mangrove wood branches is highly thermally stable.

4 Conclusion

The wood branches from the mangrove species in this study are suitable for use as biomass energy feedstock based on their basic properties, especially their calorific value, comparable to several commonly used wood types as energy sources. Charcoal briquettes produced from mangrove wood branches have met the ISO/TS 17225-8:2016 class TW1H standard for moisture content and calorific value. There were no significant differences in the properties of the charcoal briquettes in terms of the presence of bark or species. Mangrove wood-branch charcoal is highly thermally stable, ensuring consistent and efficient combustion. Thus, the charcoal briquettes used in this study are promising biofuel sources because they utilize only branch wood to support sustainable mangroves.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

AN: Conceptualization, Data curation, Investigation, Methodology, Supervision, Validation, Writing – original draft, Writing – review and editing. JS: Data curation, Formal Analysis, Investigation, Software, Validation, Visualization, Writing – original draft. IR: Conceptualization, Supervision, Writing – original draft, Writing – review and editing. TN: Investigation, Methodology, Validation, Writing – original draft. WF: Formal Analysis, Investigation, Writing – original draft. MB: Funding acquisition, Project administration, Resources, Writing – original draft. HT: Software, Validation, Writing – review and editing. SU: Funding acquisition, Resources, Writing – original draft. BJ: Funding acquisition, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by the Equity Project year 2023 based on the Decree of Rector of Universitas Sumatera Utara number 4921/UN5.1. R/SK/PPM/2023.

Acknowledgments

The authors acknowledge the facilities and scientific and technical support provided by the Advanced Characterization Laboratories Cibinong and Serpong–Integrated Laboratory of Bioproduct, National Research and Innovation Agency through E-Layanan Sains, Badan Riset, and Inovasi Nasional via WF.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The editor PA declared past co-authorships with the authors AN and WF at the time of review.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fmats.2025.1611316/full#supplementary-material

References

Adrian, M., Purnomo, E. P., Enrici, A., and Khairunnisa, T. (2023). Energy transition towards renewable energy in Indonesia. HSD 5, 107–118. doi:10.37868/hsd.v5i1.108

Ajimotokan, H. A., Ibitoye, S. E., Odusote, J. K., Adesoye, O. A., and Omoniyi, P. O. (2019). Physico-mechanical properties of composite briquettes from corncob and rice husk. J. Bioresour. Bioprod. 4, 59–165. doi:10.12162/jbb.v4i3.004

Al-Sagheer, N. A., and Prasad, A. D. (2010). Variation in wood specific gravity, density and moisture content of Dipterocarpus indicus (bedd.). among different populations in western ghats of Karnataka, India. Int. J. Appl. Agric. Sci. 5, 583–599. Available online at: https://www.ripublication.com/IJAER/ijaarv5n5_3.pdf.

Asri, W. R., Hasanudin, H., Mara, A., and Desnelli, D. (2022). Pyrolysis of puspa wood sawdust and sugarcane bagasse into biochar. Aceh Int. J. Sci. Technol. 11, 56–69. doi:10.13170/aijst.11.1.25066

ASTM (2000). Standard test methods for small clear specimens of timber. West Conshohocken, PA, USA: ASTM International.

ASTM (2001). D 3967-95a; standard test method for splitting compressive strength of intact rock core specimens. West Conshohocken, PA, USA: ASTM International.

ASTM (2003a). D 4442-92 standard test methods for direct moisture content measurement of wood andWood-Based materials. West Conshohocken, PA, USA: ASTM International.

ASTM (2003b). D 5142-02a; standard test methods for proximate analysis of the analysis sample of coal and coke by instrumental procedures. West Conshohocken, PA, USA: ASTM International.

ASTM (2004). E711-87 standard test method for gross calorific value of refuse-derived fuel by the bomb calorimeter. West Conshohocken, PA, USA: ASTM International.

ASTM (2010). D 5865-10a; standard test method for gross calorific value of coal and coke. West Conshohocken, PA, USA: ASTM International.

ASTM (2014). D 2395-14 standard test methods for density and specific gravity (relative density) of wood and wood-based materials. West Conshohocken, PA, USA: ASTM International.

ASTM (2016). D 2166-00; standard test method for unconfined compressive strength of cohesive soil. West Conshohocken, PA, USA: ASTM International.

Basyuni, M., Bimantara, Y., Slamet, B., and Thoha, A. (2016). Identification of potency and strategy of mangrove ecotourism development at lubuk kertang village, district of west brandan, langkat regency, North Sumatra. Abdimas Talenta 1, 31–38.

Basyuni, M., Bimantara, Y., Siagian, M., Wati, R., Slamet, B., Sulistiyono, N., et al. (2018a). Developing community-based mangrove management through ecotourism in North Sumatra, Indonesia. IOP Conf. Ser. Earth Environ. Sci. 126, 012109. doi:10.1088/1755-1315/126/1/012109

Basyuni, M., Harahap, M. A., Wati, R., Slamet, B., Thoha, A. S., Nuryawan, A., et al. (2018b). Evaluation of mangrove reforestation and the impact to socioeconomic-cultural of community in lubuk kertang village, North Sumatra. IOP Conf. Ser. Earth Environ. Sci. 126, 012113. doi:10.1088/1755-1315/126/1/012113

Bello, R. S., and Onilude, M. A. (2020). Physico-mechanical characteristics of high density briquettes produced from composite sawdust. J. Appl. Sci. Environ. Manag. 24, 779–787. doi:10.4314/jasem.v24i5.8

Brunerova, A., Müller, M., Šleger, V., Ambarita, H., and Valášek, P. (2018). Bio-pellet fuel from oil palm empty fruit bunches (EFB): using European standards for quality testing. Sustainability 10, 4443. doi:10.3390/su10124443

Chow, P., Nakayama, F. S., Blahnik, B., Youngquist, J. A., and Coffelt, T. A. (2008). Chemical constituents and physical properties of guayule wood and bark. Ind. Crops Prod. 28, 303–308. doi:10.1016/j.indcrop.2008.03.006

de Luna, M. Y., Marcelo Rodrigues, P., Torres, A. M. ; G., Antônio Eufrázio, D. C. J., Jackson Queiroz, M., Selma Elaine, M., et al. (2018). A thermogravimetric analysis of biomass wastes from the northeast region of Brazil as fuels for energy recovery. Energy Sources A 41, 1557–1572. doi:10.1080/15567036.2018.1549132

Dwianto, W., Marsoem, S. N., and Hasil-Hasil, T. (2008). Penelitian faktor-faktor alam yang mempengaruhi sifat fisik dan mekanik kayu Indonesia. J. Ilmu Teknol. Kayu Trop. 6, 85–100. Available online at: https://ejournalmapeki.org/index.php/JITKT/article/view/249/222.

Eberhardt, T. L., Dahlen, J., and Schimleck, L. (2017). Species comparison of the physical properties of loblolly and slash pine wood and bark. Can. J. For. Res. 47, 1495–1505. doi:10.1139/cjfr-2017-0091

Elizondo, E. B., Carey, J. C., Al-Haj, A. N., Lugo, A. E., and Fulweiler, R. W. (2021). High productivity makes mangroves potentially important players in the tropical silicon cycle. Front. Mar. Sci. 8, 652615. doi:10.3389/fmars.2021.652615

Fahrussiam, F., Lestari, D., and Ningsih, R. V. (2023). Calorific value of several types of wood through proximate analysis and chemical components approach. J. Biol. Trop. 23, 355–359. doi:10.29303/jbt.v23i1.4416

Fitri, A., Basyuni, M., Wati, R., Sulistiyono, N., Slamet, B., Harahap, Z. A., et al. (2018). Management of mangrove ecosystems for increasing fisheries production in lubuk kertang village, North Sumatra, Indonesia. Aquac. Aquar. Conserv. Legis. 11, 1252–1264. Available online at: https://bioflux.com.ro/docs/2018.1252-1264docx.pdf.

Gao, N., Li, A., Quan, C., Du, L., and Duan, Y. (2013). TG–FTIR and Py–GC/MS analysis on pyrolysis and combustion of pine sawdust. J. Anal. Appl. Pyrol. 100, 26–32. doi:10.1016/j.jaap.2012.11.009

Gryc, V., Horacek, P., Slezingerova, J., and Vavrcik, H. (2011). Basic density of spruce wood, wood with bark, and bark of branches in locations in the Czech Republic. Wood Res. 56, 23–32. Available online at: https://www.woodresearch.sk/wr/201101/03.pdf.

Guida, M. Y., Lanaya, S., Rbihi, Z., and Hannioui, A. (2019). Thermal degradation behaviors of sawdust wood waste: pyrolysis kinetic and mechanism. J. Mater. Environ. Sci. 10, 742–755. Available online at: https://www.jmaterenvironsci.com/Document/vol10/vol10_N8/77-JMES-Guida-2019.pdf.

Güllü, D., and Demirbaş, A. (2001). Biomass to methanol via pyrolysis process. Energy Conv. Manag. 42, 1349–1356. doi:10.1016/S0196-8904(00)00126-6

Günther, B., Gebauer, K., Barkowski, R., Rosenthal, M., and Bues, C. T. (2012). Calorific value of selected wood species and wood products. Eur. J. Wood Prod. 70, 755–757. doi:10.1007/s00107-012-0613-z

Hapid, A., Muthmainnah, M., and Ahmad, A. (2018). The characteristics of briquettes made from a mixture of coconut shells and palaeopi sawdust (heritiera sp.). ForestSains 15, 47–57. Available online at: https://garuda.kemdikbud.go.id/documents/detail/1327146.

Harahap, B. M. (2020). Degradation techniques of hemicellulose fraction from biomass feedstock for optimum xylose production: a review. JKPTB 8, 107–124. doi:10.21776/ub.jkptb.2020.008.02.01

Hasfianti, F. E., Sriningsih, E., and Subhanuddin, D. (2019). Briquettes quality made of left over galam felling waste for alternative energy sources. J. Penelit. Has. Hutan 37, 223–232. doi:10.20886/jphh.2019.37.3.217-224

Hu, Q., Yang, H., Yao, D., Zhu, D., Wang, X., Shao, J., et al. (2016). The densification of bio-char: effect of pyrolysis temperature on the qualities of pellets. Bioresour. Technol. 200, 521–527. doi:10.1016/j.biortech.2015.10.077

Ifa, L., Yani, S., Nurjannah, N., Sabara, Z., Yuliana, Y., Kusuma, H. S., Mahfud, M. M., et al. (2019). Production of bio-briquette from biochar derived from pyrolysis of cashew nut waste. Eco Environ. Cons. 25, 125–131. Available online at: https://repository.umi.ac.id/422/1/4.%20JOURNAL%20EEC-21.pdf.

Ilek, A., Siegert, C. M., and Wade, A. (2021). Hygroscopic contributions to bark water storage and controls exerted by internal bark structure over water vapor absorption. Trees 35, 831–843. doi:10.1007/s00468-021-02084-0

ISO/TS 17225-8 (2016). Solid biofuels—fuel specifications and classes — part 8: graded thermally treated and densified biomass fuels. Geneva, Switzerland: International Organization for Standardization.

Ivanov, I. P., Sudakova, I. G., and Kuznetsov, B. N. (2003). Manufacture of briquetted and granulated fuels from lignite with biobinders and heated die. Chem. Sustain. Dev. 11, 847–852. Available online at: https://sibran.ru/en/journals/issue.php?ID=119843&ARTICLE_ID=124218.

Jerry, P., Febriyanto, P., and Satria, A. W. (2023). Analysis of tapioca industrial solid waste as coal substitution. IOP Conf. Ser. Earth Environ. Sci. 1209, 012012. doi:10.1088/1755-1315/1209/1/012012

Kaliyan, N., and Vance Morey, R. V. (2009). Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 33, 337–359. doi:10.1016/j.biombioe.2008.08.005

Karniati, R., Sulistiyono, N., Amelia, R., Slamet, B., Bimantara, Y., and Basyuni, M. (2021). Mangrove ecosystem in north sumatran (Indonesia) forests serves as a suitable habitat for mud crabs (Scylla serrata and S. olivacea). Biodiversitas 22, 1489–1496. doi:10.13057/biodiv/d220353

Kleinert, M., and Barth, T. (2008). Phenols from lignin. Chem. Eng. Technol. 31, 736–745. doi:10.1002/ceat.200800073

Kongprasert, N., Wangphanich, P., and Jutilarptavorn, A. (2019). Charcoal briquettes from madan wood waste as an alternative energy in Thailand. Procedia Manuf. 30, 128–135. doi:10.1016/j.promfg.2019.02.019

Krauss, A. (2009). On some aspects of a relation between density and mechanical properties of wood in longitudinal direction. Acta Sci. Pol. Silv. Colendar Rat. Ind. Lignar 8, 55–65. Available online at: https://www.forestry.actapol.net/pub/7_1_2009.pdf.

Kusmana, C., and Sukristijiono, S. (2016). Mangrove resource uses by local community in Indonesia. J. Pengelolaan Sumberd. Alam Dan. Lingkung. 6 (2), 217–224. doi:10.19081/jpsl.2016.6.2.217

Kusumahastuti, D. K. A., Cahyanti, M. N., Hartini, S., Trihandaru, S., Nuryawan, A., and Yusran, Y. (2025). Characterisation of branch and twig mangrove bio-pellets as solid energy carriers for coastal communities. Biomass Convers. Biorefnery. doi:10.1007/s13399-025-06873-2

Leal, M., and Spalding, M. D. (2024). The state of the world’s mangroves. Glob. Mangrove Alliance. doi:10.5479/10088/119867

Lu, Q., Li, W. Z., and Zhu, X. F. (2009). Overview of fuel properties of biomass fast pyrolysis oils. Energy Conv. Manag. 50, 1376–1383. doi:10.1016/j.enconman.2009.01.001

Mahato, S., Iqbal, K., Aziem, S., Hussain, A. D., Dasgupta, S., and Todaria, N. P. (2019). Wood specific gravity of temperate forest species of garhwal himalaya, India. Indian For 145, 1035–1038.

Maulina, S., and Iriansyah, M. (2018). Characteristics of activated carbon resulted from pyrolysis of the oil palm fronds powder. IOP Conf. Ser. Mater. Sci. Eng. 309, 012072. doi:10.1088/1757-899X/309/1/012072

Ministry of Trade of The Republic of Indonesia Market Brief Charcoal in South Korea (2015). Ministry of Trade of the Republic of Indonesia: Jakarta, Indonesia.

Mishra, R. K., and Mohanty, K. (2018). Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour. Technol. 251, 63–74. doi:10.1016/j.biortech.2017.12.029

Mullen, C. A., and Boateng, A. A. (2010). Catalytic pyrolysis-GC/MS of lignin from several sources. Fuel Process. Technol. 91, 1446–1458. doi:10.1016/j.fuproc.2010.05.022

Murni, S. W., Setyoningrum, T. M., and Nur, M. M. A. (2021). Production of briquettes from Indonesia agricultural biomass waste by using pyrolysis process and comparing the characteristics. Eksergi 18, 13–17. doi:10.31315/e.v0i0.4572

Mwampamba, T. H., Owen, M., and Pigaht, M. (2013). Opportunities, challenges and way forward for the charcoal briquette industry in Sub-Saharan Africa. Energy sustain. Dev. 17, 158–170. doi:10.1016/j.esd.2012.10.006

Neina, D., Faust, S., and Joergensen, R. G. (2020). Characterization of charcoal and firewood ash for use in African peri-urban agriculture. Chem. Biol. Technol. Agric. 7, 5–10. doi:10.1186/s40538-019-0171-2

Njenga, M., Karanja, N., Jamnadass, R., Kithinji, J., Sundberg, C., and Jirjis, R. (2013). Quality of cooking fuel briquettes produced locally from charcoal dust and sawdust in Kenya. J. Biobased Mater. Bioenergy 7, 315–322. doi:10.1166/jbmb.2013.1355

Nuryawan, A., Syahputra, R. S., Azhar, I., and Risnasari, I. (2021). Basic properties of the mangrove treebranches as a raw material of wood pellets and briquettes. IOP Conf. Ser. Earth Environ. Sci. 891, 012005. doi:10.1088/1755-1315/891/1/012005

Nuryawan, A., Syahputra, R. S., and Risnasari, I. (2023). Physical properties of five species of twigs from mangrove forest. IOP Conf. Ser. Earth Environ. Sci. 1241, 012113. doi:10.1088/1755-1315/1241/1/012113

Okot, D. K., Bilsborrow, P. E., and Phan, A. N. (2018). Effects of operating parameters on maize COB briquette quality. Biomass Bioenergy 112, 61–72. doi:10.1016/j.biombioe.2018.02.015

Olabisi, A. S., Balogun, A. O., Oni, T. O., Fakinle, B. S., Sotoudehnia, F., McDonald, A. G., et al. (2023). Physicochemical characterization of woody lignocellulosic biomass and charcoal for bio-energy heat generation. Sci. Rep. 13, 19242. doi:10.1038/s41598-023-46054-7

Onrizal, O., and Kusmana, C. (2009). Structure and species richness of mangroves plant post-tsunami in Nias Island. Ber. Biol. 9, 359–364.

Onrizal, O., and Mansor, M. (2020). Recovery status of mangroves along western coast of Aceh until 7 years after the 2004 Tsunami. J. Phys. Conf. Ser. 1542, 012060. doi:10.1088/1742-6596/1542/1/012060

Pambudi, F. K., Nuriana, W., Hantarum, H., and Kerapatan, P. T. T. (2018). “Kadar air dan Laju Pembakaran pada biobriket Limbah Kayu Sengon,” in Proceedings of the seminar nasional sains dan teknologi terapan VI (Indonesia: Surabaya).

Pang, L., Yang, Y., Wu, L., Wang, F., and Meng, H. (2019). Effect of particle sizes on the physical and mechanical properties of briquettes. Energies 12, 3618. doi:10.3390/en12193618

Panggabean, L. E., Nuryawan, A., Risnasari, I., and Susilawati, (2022). Anatomical properties of branches and twigs mangrove woods. IOP Conf. Ser. Earth Environ. Sci. 1115, 012066. doi:10.1088/1755-1315/1115/1/012066

Pari, G. (2012). Mahfudin; jajuli. Teknologi pembuatan arang, briket arang dan arang aktif serta pemanfaatannya. Jakarta, Indonesia: Badan Penelitian dan Pengembangan Kehutanan Kementerian Kehutanan.

Pari, G., Darmawan, S., and Prihandoko, B. (2014). Porous carbon spheres from hydrothermal carbonization and KOH activation on cassava and tapioca flour raw material. Procedia Environ. Sci. 20, 342–351. doi:10.1016/j.proenv.2014.03.043

Pásztory, Z., Mohácsiné, I. R., Gorbacheva, G., and Börcsök, Z. (2016). The utilization of tree bark. BioResources 11, 7859–7888. doi:10.15376/biores.11.3.Pasztory

Pedišius, N., Praspaliauskas, M., Pedišius, J., and Dzenajavičienė, E. F. (2021). Analysis of wood chip characteristics for energy production in Lithuania. Energies 14, 3931. doi:10.3390/en14133931

Pereira, A. K. S., Júnior, D. L., da Silva, Á. M., de Souza, E. C., Delatorre, F. M., Rodrigues, B. P., et al. (2021). Understanding the impacts of pyrolysis temperature on the energy performance of Eucalyptus spp. charcoal. Environ. Sci. Proc. 13, 25. doi:10.3390/IECF2021-10794

Postawa, K., Fałtynowicz, H., Szczygieł, J., Beran, E., and Kułażyński, M. (2022). Analyzing the kinetics of waste plant biomass pyrolysis via thermogravimetry modeling and semi-statistical methods. Bioresour. Technol. 344, 126181. doi:10.1016/j.biortech.2021.126181

Prasetia, H., Annisa, N., and Santosa, L. F. (2018). Biomass conversion for renewable alternative energy. ESE Int. J. 1, 6–9.

Rani, I. T., Yoo, J., Park, B. B., Hidayat, W., Wijaya, B. A., Lee, S., et al. (2023). Wood pellet driven-biochar characterization produced at different targeted pyrolysis temperatures. J. Sylva Lestari 11, 558–571. doi:10.23960/jsl.v11i3.796

Schandel, C. B. (2020). Cracking of sugars for production of chemicals. Kongens Lyngby, Denmark: Technical University of Denmark. PhD Thesis.

Sieradzka, M., Kirczuk, C., Kalemba-Rec, I., Mlonka-Mędrala, A., and Magdziarz, A. (2022). Pyrolysis of biomass wastes into carbon materials. Energies 15, 1941. doi:10.3390/en15051941

Simatupang, J., Nuryawan, A., Risnasari, I., Nur, T. B., and Fatriasari, W. (2024). Physical, chemical, and thermal properties of branches mangrove wood of Bruguiera gymnorhiza during conversion into charcoal and charcoal briquette. IOP Conf. Ser. Earth Environ. Sci. 1352, 012038. doi:10.1088/1755-1315/1352/1/012038

Sotannde, O. A., Oluyege, A. O., and Abah, G. B. (2010). Physical and combustion properties of charcoal briquettes from neem wood residues. Int. Agrophys. 24, 189–194.

Stahl, C., Burban, B., Bompy, F., Jolin, Z. B., Sermage, J., and Bonal, D. (2010). Seasonal variation in atmospheric relative humidity contributes to explaining seasonal variation in trunk circumference of tropical rain-forest trees in French Guiana. J. Trop. Ecol. 26, 393–405. doi:10.1017/S0266467410000155

Tambunan, H., Nuryawan, A., Iswanto, A. H., Risnasari, I., Basyuni, M., and Fatriasari, W. (2023). Briquettes made of branches wood of three mangrove species bonded by starch adhesive. Mater. (Basel) 16, 5266. doi:10.3390/ma16155266

Tamilvanan, A. (2013). Preparation of biomass briquettes using various agro-residues and waste papers. J. Biofuels 4, 47–55. doi:10.5958/j.0976-4763.4.2.006

Tia, M., Kayu Sebagai, K. B. J., and Biomassa, B. B. E. (2013). Bachelor’s. Thesis. Bogor, Indonesia: IPB University.

Tun, M. M., Juchelkova, D., Win, M. M., Thu, A. M., and Puchor, T. (2019). Biomass energy: an overview of biomass sources, energy potential, and management in Southeast Asian countries. Resources 1, 81–89. doi:10.3390/resources8020081

Varma, A. K., Thakur, L. S., Shankar, R., and Mondal, P. (2019). Pyrolysis of wood sawdust: effects of process parameters on products yield and characterization of products. Waste Manag. 89, 224–235. doi:10.1016/j.wasman.2019.04.016

Wilk, M., Magdziarz, A., Kalemba, I., and Gara, P. (2016). Carbonisation of wood residue into charcoal during low temperature process. Renew. Energy 85, 507–513. doi:10.1016/j.renene.2015.06.072

Woodu (2023). Mangrove. Available online at: https://www.anyonewood.com/mangrove/ (Accessed March 2, 2024).

Wretborn, T. (2016). Influence of pyrolysis conditions on charcoal yield and charcoal reactivity. Luleå, Sweden: Master’s Thesis. Luleå University of Technology.

Yadav, I. C., and Devi, N. L. (2019). Biomass burning, regional air quality, and climate change. Ency. Environ. Health 2, 386–391. doi:10.1016/B978-0-12-409548-9.11022-X

Yang, H., Huang, L., Liu, S., Sun, K., and Sun, Y. (2016). Pyrolysis process and characteristics of products from sawdust briquettes. BioResources 11, 2438–2456. doi:10.15376/biores.11.1.2438-2456

Keywords: bark of mangrove, bioenergy, branches wood of mangrove, charcoal briquettes, pyrolysis

Citation: Nuryawan A, Simatupang J, Risnasari I, Nur TB, Fatriasari W, Basyuni M, Tambunan H, Utami SS and Jeong B (2025) Physical, chemical, mechanical, and thermal properties of charcoal briquettes produced from mangrove branch wood. Front. Mater. 12:1611316. doi: 10.3389/fmats.2025.1611316

Received: 14 April 2025; Accepted: 11 August 2025;

Published: 02 September 2025.

Edited by:

Petar Antov, University of Forestry, Sofia, BulgariaReviewed by:

Gokulkumar Sivanantham, KPR Institute of Engineering and Technology, Coimbatore, IndiaRia Aniza, Université de Lorraine, France

Copyright © 2025 Nuryawan, Simatupang, Risnasari, Nur, Fatriasari, Basyuni, Tambunan, Utami and Jeong. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Arif Nuryawan, YXJpZjVAdXN1LmFjLmlk

Arif Nuryawan

Arif Nuryawan Jhonny Simatupang

Jhonny Simatupang Iwan Risnasari

Iwan Risnasari Taufiq Bin Nur

Taufiq Bin Nur Widya Fatriasari

Widya Fatriasari Mohammad Basyuni

Mohammad Basyuni Hardiansyah Tambunan

Hardiansyah Tambunan Sentagi Sesotya Utami

Sentagi Sesotya Utami Bora Jeong

Bora Jeong