- 1College of Safety and Engineering, Anhui University of Science and Technology, Huainan, China

- 2State Key Laboratory of Coal Mine Disaster Dynamics and Control, Chongqing University, Chongqing, China

- 3State Key Laboratory of Digital Intelligent Technology for Unmanned Coal Mining, Anhui University of Science and Technology, Huainan, China

During the exploitation of deep coal resources, groundwater significantly compromises the stability of the surrounding rock in coal mine roadway. To investigate the effect of seepage fields on the mechanical behaviour and fracture mechanism of coal mine roadway surrounding rock, a series of conventional triaxial compression tests is conducted under various seepage fields. The results indicate that the peak stress of rock decreases linearly under top seepage pressure, with a reduction gradient of 2.20 MPa/MPa. In contrast, the peak stress declines nonlinearly under the condition of bottom seepage pressure, with the rate of reduction decreasing as bottom seepage pressure decreases. Both top and bottom seepage pressures significantly impact rock permeability by influencing pore pressure and seepage pressure differences. During the progressive failure process, the axial strain field transitions from a layered to a concentrated distribution, demonstrating deformation localisation. The primary fracture extends from one edge of the specimen to the opposite edge, suggesting that accumulated bottom seepage pressure induces stress concentration at the end face of specimen. Additionally, secondary cracks adjacent to the primary fracture result from pore pressure effects. A key distinction between unilateral and bilateral seepage pressure is the shift in fracture mode of rock: from a mixed transgranular and intergranular fracture pattern to one dominated by intergranular fracture. The research findings provide a theoretical basis for the design of advanced support systems and the stability analysis of deep coal mine roadways affected by groundwater.

1 Introduction

With the growing energy demand and the depletion of shallow coal resources, coal mining operations are advancing to greater depths underground (Han et al., 2024). The increase in seepage pressure, a characteristic feature of deep earth environment, which can aggravate roadway instability and elevate the risk of water inrush accidents in coal mines (Ding and Tang, 2024; Ping et al., 2024). This issue is especially critical for the safe mining of deep coal mines, where high seepage pressures and complex seepage fields must be considered in the stability analysis of surrounding rock in both coalface and excavation roadways (Luo et al., 2025; Zhu et al., 2022).

The coal mine roadways are excavated within the underground rock mass, which possesses inherent characteristics of inhomogeneity, anisotropy, and discontinuity (Xie et al., 2024). These characteristics make the coal mine roadway surrounding rock highly susceptible to the influence of seepage fields. Groundwater infiltrates surrounding rock through seepage channels formed by pores and cracks, altering the internal stress distribution. In turn, dynamic changes in the stress field also affect the permeability characteristics of surrounding rock (Ma et al., 2022b; Yan et al., 2022; Zan et al., 2024; Zhao et al., 2021). Under seepage–stress coupling, surrounding rock undergoes hydrolysis, dissolution, deformation, and fracture, ultimately leading to instability and failure of coal mine roadways. Therefore, understanding the mechanical behaviour and permeability characteristics of rock under varying seepage field conditions is critical. Investigating this interaction helps to clarify the fracture mechanisms of surrounding rock, offering valuable insights for the design and stability analysis of deep coal mine roadways.

Extensive research has been conducted on the physical and mechanical properties of surrounding rock under seepage–stress coupling, particularly under unilateral seepage pressure (Geng et al., 2023; Li and Zhou, 2023; Zhang et al., 2024). Dong et al. investigated the damage of surrounding rock during roadway blasting excavation and found that the degree of damage was influenced by the internal water flow velocity. Their study revealed a strong coupling effect between failure and seepage pressure, which intensified as both seepage pressure and rock damage increased (Dong et al., 2023). Zhao et al. demonstrated that seepage pressure significantly affects the displacement of surrounding rock and that the use of anchor rods can effectively mitigate deformation (Zhao et al., 2023). Cao et al. performed triaxial seepage tests on split sandstone with varying particle sizes to examine differences in fracture surface morphology and permeability characteristics (Cao et al., 2024). Their findings indicated that sandstone with larger particles exhibited a flatter fracture surface. Ma et al. analysed the permeability and porosity of rock under one-dimensional particle migration, concluding that both parameters increased over time. Their study identified four distinct phases in the infiltration process: rapid increase, slow increase, gradual rise, and stabilisation (Ma et al., 2022a).

In the unilateral seepage pressure condition, one end of the rock specimen is subjected to seepage pressure, while the other end is exposed to the atmosphere as a fluid outlet. To investigate the effects of complex seepage field conditions on the mechanical and permeability characteristics of rock, researchers have applied seepage pressure on both sides of rock specimens while varying the pressure at the top and bottom (Wang et al., 2021a). Wang et al. conducted an experimental study on displacement changes and failure mechanisms of roadway surrounding rock during excavation. Their findings indicate that the stress field of surrounding rock undergoes three distinct phases: stress redistribution, stress adjustment, and stress rebalancing (Wang et al., 2021b). They also observed that the stable loading seepage pressure, pore pressure, and the distance from the measuring point to the roadway edge follow an exponential decay function. Xu et al. employed nuclear magnetic resonance (NMR) technology to analyse permeability characteristics and microscopic pore structure changes in fractured rock masses. Their study revealed that higher fluid velocity results in greater core displacement and a more concentrated fluid flow, leading to the rapid formation of primary seepage channels (Xu et al., 2022). Chen et al. developed a construction strength analysis model for a two-lane shield roadway under anisotropic seepage conditions and conducted numerical simulations to evaluate the stability of roadway surrounding rock in an underwater roadway project (Chen L. H. et al., 2023). These studies contribute valuable insights into the permeability characteristics of surrounding rock and the fracture processes induced by water infiltration.

When the seepage field interacts with surrounding rock, water weakens the mechanical behaviour of the crystal and cementing material through softening, lubrication, and erosion (Burns et al., 2023; Heap et al., 2023; Ji et al., 2024; Yang et al., 2024). Yang et al. investigated the scale effect on damaged rock masses under seepage pressure (Yang et al., 2017). By analysing the progressive failure process and applying fluid-structure coupling theory, they explored the permeability variations in damaged rock masses of different sizes. Wasantha et al. examined crack development patterns in water-saturated specimens, revealing that under low confining pressure, microcrack initiation occurred almost simultaneously with failure stress, resulting in brittle sudden failure (Wasantha and Ranjith, 2014). In contrast, under high confining pressure, microcrack initiation occurred earlier than the failure stress, displaying more quasi-brittle characteristics. Chen et al. investigated the fracture mechanism of rock in deep environment subjected to high seepage pressure and rapid unloading. Their findings indicated that as seepage pressure increased, granite exhibited an earlier onset of nonlinear permeability growth, accompanied by a progressive decline in both compressive strength and energy storage capacity (Chen Z. Q. et al., 2022). Additionally, the permeability, energy hardening, and brittle failure mechanisms of granite were found to be amplified under these conditions.

The conventional triaxial compression tests on surrounding rock in deep coal mine under bilateral seepage pressure were conducted to investigate its fracture mechanism under seepage–stress coupling. The axial stress–strain curves and permeability evolution curves over time were obtained, providing insights into the mechanical behaviour and permeability characteristics of surrounding rock. The failure mode and fracture mechanism were analysed from both macroscopic and microscopic perspectives. The findings offer theoretical support for assessing the stability of surrounding rock and optimising support systems in deep coal mine affected by groundwater.

2 Experimental method

2.1 Sandstone specimen and test system

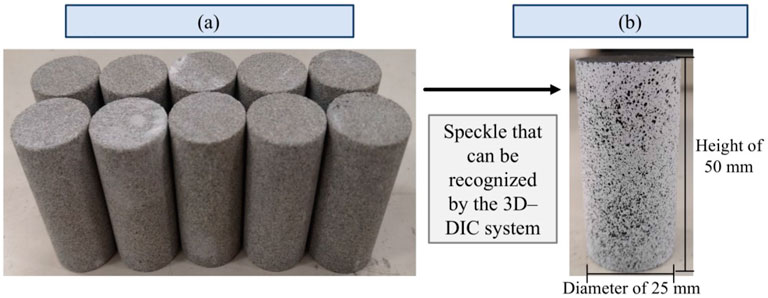

In this study, sandstone, a surrounding rock commonly found in coal mine roadways, is selected for conventional triaxial compression tests under seepage–stress coupling conditions. The sandstone primarily comprises quartz (42.6%), followed by albite (33.6%), potassium feldspar (9.3%), muscovite (7.3%), and chlorite (7.2%). To ensure the reliability of experimental results, the sandstone rock mass is uniformly cut along the same joint direction before fabricating standard cylindrical specimens. The specimens are coated with a black speckle pattern on a white background to enable recognition by a three-dimensional digital image correlation (3D–DIC) system (Chen Y. et al., 2022; 2023c), as shown in Figure 1. Each cylindrical specimen measured 50 mm in height and 25 mm in diameter. Additionally, to minimize end constraints during testing, the flatness of the end face is maintained within 0.05 mm. The prepared sandstone specimen was saturated using the vacuum water saturation method. Once its mass stabilized, the specimen was considered fully saturated. Subsequently, the water-saturated specimen was placed in a transparent pressure chamber for triaxial compression testing.

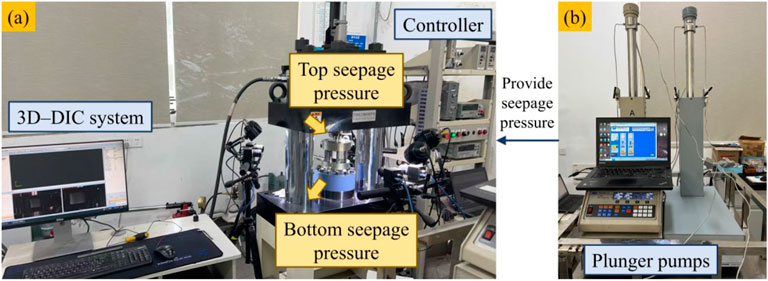

To investigate the mechanical behaviours and permeability characteristics of sandstone, a transparent triaxial compression servo-control test system has been independently developed (Chen et al., 2023b), as shown in Figure 2. A 3D–DIC system is incorporated to track the progressive failure behaviour of specimens under triaxial compression, enabling detailed observation of the spatio–temporal development of the strain fields. Additionally, two plunger pumps are integrated into the system to independently apply seepage pressure to the top and bottom of the specimen, enabling the simulation of seepage–stress coupling conditions.

2.2 Test scheme

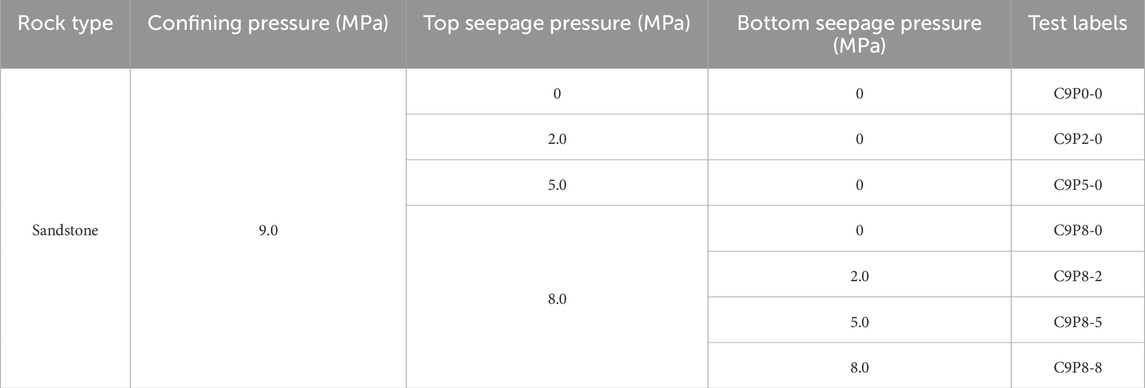

In deep coal mine, groundwater influences the surrounding rock in all directions. Applying seepage pressure to both the upper and lower ends of the sandstone specimen is essential for studying fracture mechanisms under complex seepage fields. Therefore, a conventional triaxial compression test scheme under multiple seepage pressure conditions is designed, as shown in Table 1. In this scheme, the confining pressure is maintained at 9.0 MPa, while the seepage pressures at the upper and lower ends of the specimens are varied. To clearly present the test scheme, a labelling method was developed based on confining and seepage pressure conditions. The test label (CaPb-c) follows a specific format: C denotes confining pressure and P represents seepage pressure. Similarly, a means the value of confining pressure, b means the value of top seepage pressure, and c means the value of bottom seepage pressure.

3 Analysis of experimental results

3.1 Mechanical behaviour

The test system records the mechanical behaviours of the sandstone throughout the triaxial loading procedure, while the radial strain is measured using a virtual extensometer within the 3D–DIC system (Munoz and Taheri, 2017; Munoz et al., 2016). The volumetric strain of the specimen is then calculated based on the axial strain and radial strain, as expressed in Equation 1.

Where,

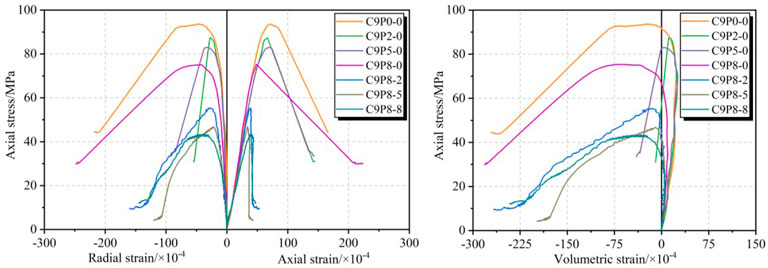

As shown in Figure 3, the axial stress–strain, radial strain, and volumetric strain responses of sandstone are depicted under varying seepage pressure levels. The results indicate that as both top and bottom seepage pressures increase, the peak stress of sandstone decreases. Additionally, changes in the seepage field are positively correlated with strain and failure. With increasing pore pressure, the sandstone exhibits reduced brittleness, demonstrating the softening effect of seepage pressure.

Under seepage–stress coupling, the non-continuous pores within the specimen undergo a sequential process of closure, opening, evolution, and penetration due to external force and seepage pressure. This leads to a gradual loss of bearing capacity of sandstone. The axial stress–axial strain curves reveal that sandstone specimens experience distinct deformation stages: pre-peak pore compaction, elastic deformation, plastic deformation, and residual strength deformation leading to failure. The volumetric strain curves show that specimens transition through volume compaction and volume expansion before complete fracture. Higher seepage pressure results in greater volumetric strain and reduces the stress required for expansion.

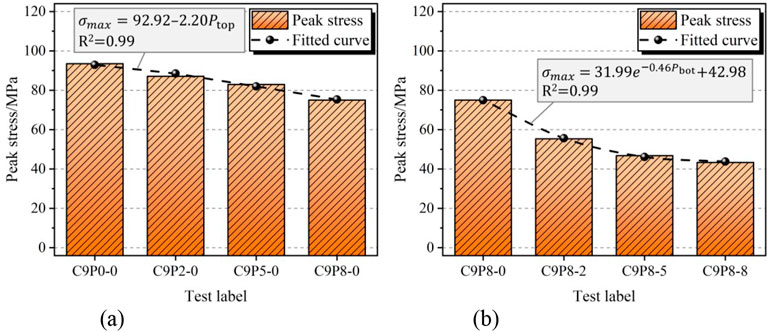

Figures 4a,b present histograms that compare the peak stress of sandstone specimens subjected to different levels of seepage pressure, highlighting the influence of seepage pressure on mechanical behaviours of sandstone. The peak stress of the sandstone specimen decreases with increasing top seepage pressure, following a linear trend. In contrast, as the bottom seepage pressure increases, the peak stress decreases nonlinearly. This behaviour can be attributed to the uniform distribution of top seepage pressure inside the specimen, influenced by gravity, which causes a consistent attenuation of peak stress at approximately 2.20 MPa/MPa. However, the bottom seepage pressure disrupts the internal seepage field flow, leading to a nonlinear increase in pore pressure. This effect partially counteracts the restraining influence of confining pressure, resulting in the observed nonlinear reduction in peak stress.

Figure 4. The histogram of peak stress of sandstone specimen under different seepage pressure conditions (a) Top seepage pressure (b) Bottom seepage pressure.

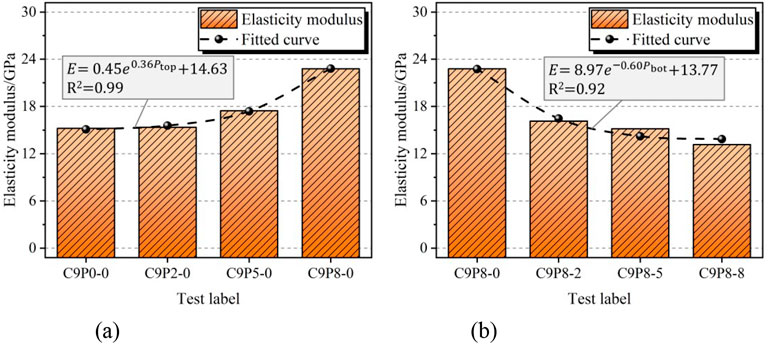

Figures 5a,b present histograms of the elasticity modulus under various seepage pressure conditions. The elasticity modulus of sandstone increases nonlinearly with increasing top seepage pressure and decreasing bottom seepage pressure. A higher elasticity modulus indicates greater brittleness of the sandstone, making it more prone to fracture rather than undergoing significant deformation under triaxial loading. Additionally, the variation in elasticity modulus increases with the hydraulic gradient, highlighting the significant impact of hydraulic gradient on the sandstone’s elastic properties. An exponential function is used to effectively model the nonlinear relationship between elasticity modulus and seepage pressure.

Figure 5. The histogram of elasticity modulus of sandstone specimen under different seepage pressure conditions. (a) Top seepage pressure (b) Bottom seepage pressure.

3.2 Permeability characteristic

In addition to the analysis of the mechanical behaviour of sandstone under seepage–stress coupling, the permeability characteristics also play a crucial role in the deformation and failure of rock during triaxial loading. In the triaxial compression tests of sandstone, the steady-state method is used to measure the permeability of the specimens. Darcy’s Law is applied to calculate the permeability of the specimens over a unit of time, under a stable seepage pressure difference, as shown in Equation 2.

where

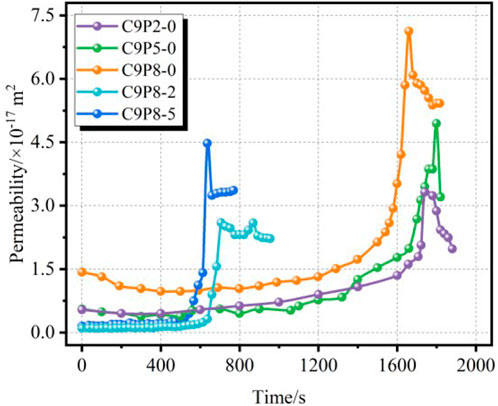

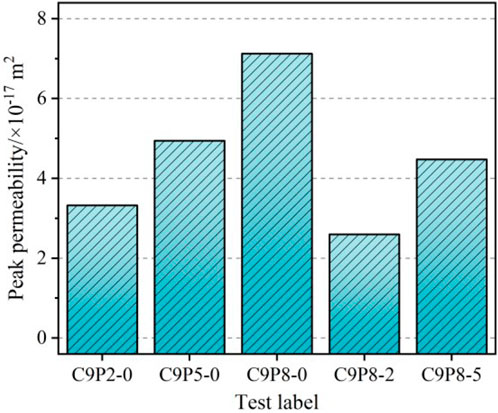

Figure 6 depicts the permeability evolution curves with time of sandstone specimens under various seepage pressure levels, whereas Figure 7 presents corresponding histograms highlighting the differences in permeability across these conditions. Initially, the permeability of sandstone decreases, then increases until reaching peak permeability, after which it stabilizes as the internal seepage channels are fully formed. The application of bottom seepage pressure not only reduces permeability but also accelerates the fracturing of the sandstone, causing the peak permeability to occur earlier.

Figure 6. The curves of permeability of sandstone specimen with time under different seepage pressure.

Figure 7. The histogram of permeability of sandstone specimen under different seepage pressure conditions.

In the initial stage, permeability decreases due to the compression of internal pores, which increases resistance to water flow. As triaxial loading progresses, cracks continuously form within the sandstone, creating new seepage channels and causing a rapid increase in permeability. The subsequent decrease in permeability after peak is attributed to the compression of primary seepage channels, driven by the stress field during the residual strength deformation and failure stages. The occurrence of peak permeability signifies the formation of a continuous seepage channel within the sandstone specimen. This time point can be regarded as the moment of complete structural failure of the specimen. Under the C9P8-5 condition, peak permeability appeared the earliest, indicating that complete failure of the specimen also occurred at the earliest stage among the tested conditions.

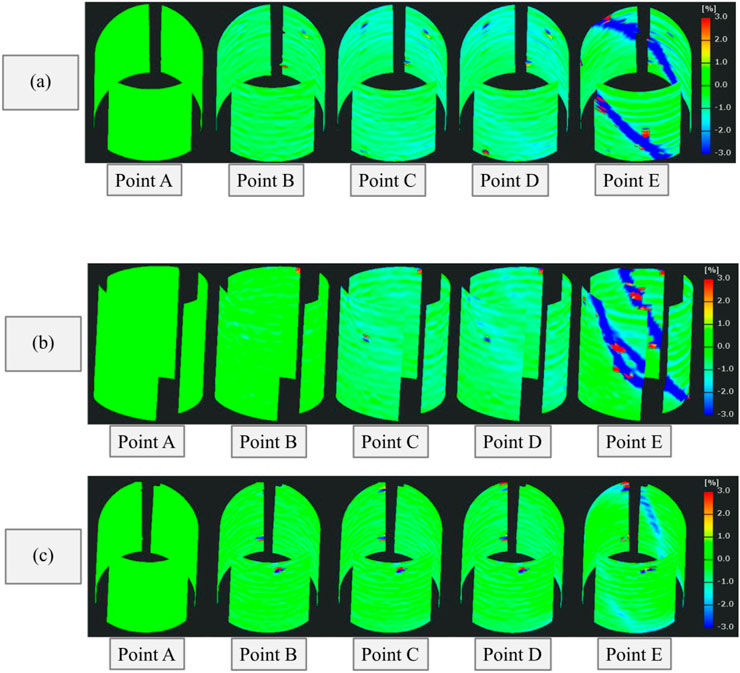

3.3 Surface strain field

The fracture of saturated sandstone under seepage–stress coupling follows a progressive failure process, which is recorded by the 3D–DIC system to calculate the strain field distribution on the surface of specimen (Pu et al., 2024). Figure 8 shows the evolution of the axial strain field on the surface of the sandstone specimen. Point A in the cloud map represents the initial state of the specimen, with no deformation. Point B corresponds to the elastic stage of the sandstone, where a few blue stripes begin to appear in the axial strain field, indicating compression. Point C marks the yield point on the axial stress–axial strain curve, where the blue stripes in the axial strain field deepen, signalling increased axial deformation in the fracture area and further compression. Point D corresponds to the peak stress on the axial stress–axial strain curve, just before failure, and the axial strain field begins to localise. Point E is located in the residual strength stage, after the specimen has fractured, and the fracture region and crack morphology can be clearly observed.

Figure 8. The evolution cloud map of axial strain field of sandstone specimen surface under various seepage pressure conditions. (a) C9P0-0 (b) C9P8-0 (c) C9P8-8.

Under no seepage pressure, the sandstone specimens break cleanly, with linear cracks, and each stage is clearly distinguishable. Under the condition of C9P8-0, the fracture of the sandstone specimen exhibits a complex crack morphology, with numerous secondary fractures. In both of these conditions, the specimen experiences larger axial strain, and the fracture area is clearly visible. For C9P8-8 condition, the strain value in the fracture region is relatively small, yet it still indicates a trend of deformation localisation. Under all test conditions, the fracture surface consistently extended from one end of the sandstone specimen to the other. The phenomenon indicates that stress concentration tends to occur at the edges of the specimen’s end faces, even in the presence of bottom seepage pressure. When localized stress within the sandstone exceeds its fracture strength, stress concentration initiates crack propagation from existing pore tips. These microcracks gradually coalesce, eventually forming through-going fractures. Consequently, vertical fractures extending from the top to the bottom of the specimen were consistently observed.

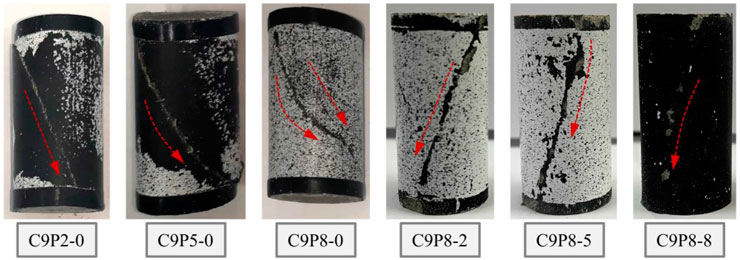

4 Fracture mechanism discussion

During triaxial compression testing, the mechanical behaviours, permeability characteristics, and failure processes of sandstone specimens vary significantly with changes in seepage field conditions. Macroscopic fractures and microscopic crack surface morphologies of the damaged sandstone specimens are analysed to summarize the fracture mechanisms under seepage–stress coupling. Figure 9 presents photos of the macroscopic fractures on the specimen surface. Under triaxial loading with seepage pressure, the sandstone specimen exhibits a single inclined shear fracture, with a primary fracture plane passing through the specimen. However, when the top seepage pressure is 8.0 MPa, small tensile cracks appear beside the primary fracture, indicating a shift from linear to nonlinear fracture morphology with increasing unilateral seepage pressure. The application of bottom seepage pressure increases the pore pressure within the specimen, causing the crack propagation direction to deviate. Vertical tensile cracks emerge at both ends of the specimen, and the specimen exhibits compound failure, resulting from the combined action of tensile and shear fractures. As the internal pore pressure of the sandstone rises, its failure mechanism gradually evolves from predominantly shear failure to a mixed mode of tension–shear failure.

Figure 9. The photos of the macroscopic fracture of sandstone specimen surface under different seepage pressure conditions.

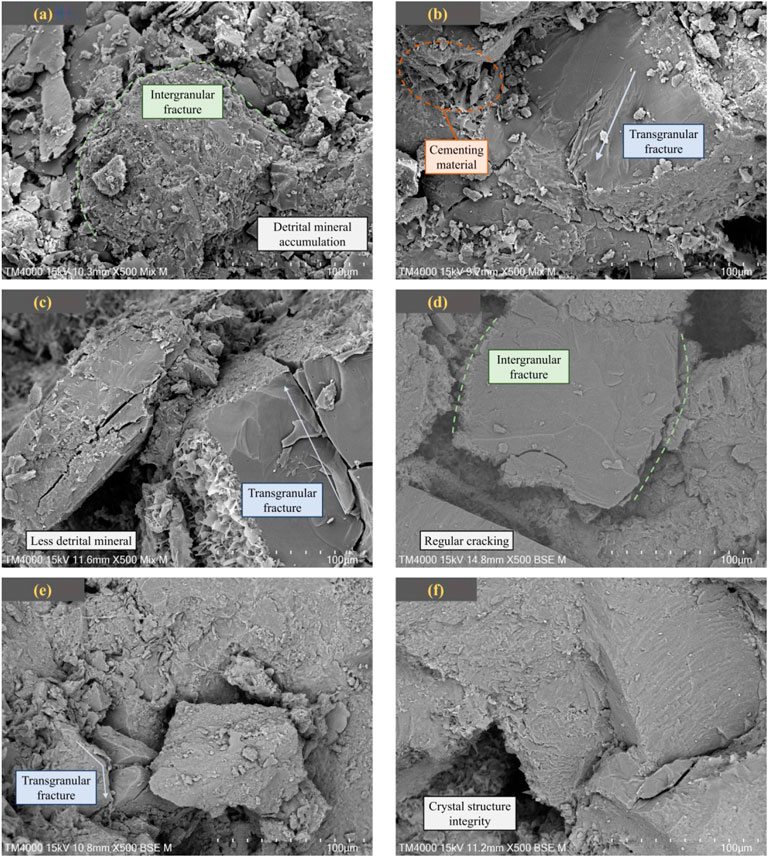

Scanning electron microscope (SEM) analysis is conducted to examine the microscopic morphology of the sandstone fracture surface, as shown in Figure 10. Under low top seepage pressure, the cementing material and crystals in the sandstone are significantly damaged (Zhou et al., 2017). The low seepage pressure is insufficient to wash away the detrital minerals produced during the failure of the sandstone, resulting in a large accumulation of these minerals on the fracture surface. As the top seepage pressure increases, the number of detrital minerals on the fracture surface decreases significantly, and the crystal fracture surfaces become cleaner. A reduction in peak stress results in less crystal damage but a marked increase in the occurrence of intergranular fractures. Under bottom seepage pressure, the bearing capacity of the sandstone continuously decreases, and the cementing material is hydrolysed and destroyed. The low stress levels do not cause complete crystal fracture, resulting in only a small amount of transgranular fractures (Wang et al., 2024). The crystal cracks are orderly, and their structure remains intact. The cementing material in the sandstone is completely destroyed, with no residual material attached to the fracture surface.

Figure 10. The microtopography of fracture surface under different seepage pressure conditions. (a) C9P2-0 (b) C9P5-0 (c) C9P8-0 (c) C9P8-0 (d) C9P8-2 (e) C9P8-5 (f) C9P8-8.

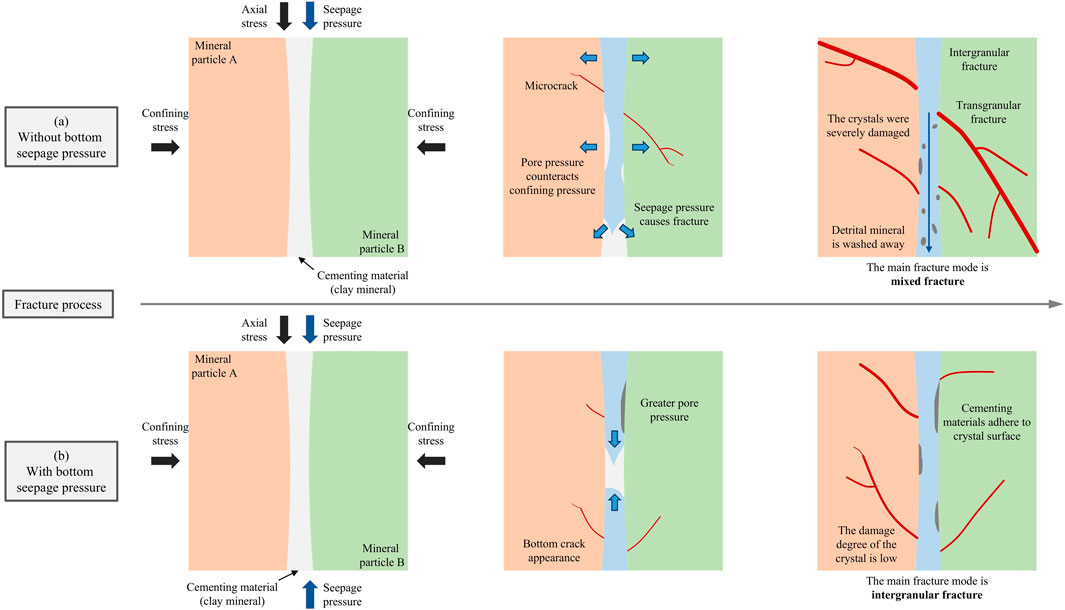

Based on the macroscopic fracture analysis of sandstone and the microscopic morphology of the fracture surface, the fracture mechanism of sandstone under seepage–stress coupling is summarized in Figure 11. From a macroscopic perspective, the fractures on the specimen surface exhibit an obvious nonlinear behaviour under the conditions of C9P5-0 and C9P8-0. The presence of seepage pressure causes the fracture surface to deviate significantly from a planar shape. The primary fracture extends from one edge of the specimen to the other, suggesting that the accumulation of bottom seepage pressure leads to stress concentration at the specimen’s edge.

From a microscopic perspective, the cementing material between crystals is more susceptible to destruction under high top seepage pressure, whereas quartz crystals are less affected by erosion but more influenced by high confining pressure and axial stress, resulting in rapid degradation of the crystal structure (Zhang et al., 2023). Additionally, the high pore pressure inside the sandstone specimen removes detrital minerals from the fracture surface after macro-fracture formation, resulting in a relatively clean fracture surface microtopography. The effect of seepage pressure on the microtopography of the sandstone fracture surface is chiefly reflected in the abundance of detrital minerals and cementing materials resulting from fracture development.

When unilateral seepage pressure is applied to a sandstone specimen, the cementing materials within the sandstone deform and break, with cracks initially forming in the cementing material between mineral particles. This results in an increase in the porosity of the sandstone. The energy required for crack tip propagation reaches a balanced state; as the surface free energy of the mineral particles decreases, the external work required for crack propagation also diminishes (Zhao et al., 2024). Consequently, the axial stress required for the fracture of mineral particles is reduced under high pore pressure. Additionally, the crack tip, influenced by pore pressure, partially offsets the constraining effect of confining pressure, increasing the work done by the fluid on crack tip expansion and accelerating the crack development rate. The primary fracture mode of sandstone under unilateral seepage pressure is a mixed fracture, consisting of both transgranular and intergranular fractures.

When the energy at the crack tip exceeds the energy required for propagation, the crack begins to expand and extend, causing adjacent micro-cracks to nucleate and form cracks in the cementing material. Due to the loose structure of the cementing material, seepage can occur, and cracks within the cementing material can be filled with fluid, generating pore pressure. This pore pressure further reduces the positive pressure on the crack, intensifies stress concentration, and facilitates the continuous development of the crack. Under triaxial loading, the loose mineral particles move and compress the cementing material. Seepage pressure also promotes fluid flow within the sandstone, carrying away part of the cementing material due to water erosion and abrasion, thereby creating space for the movement of mineral particles. At high pore pressures, the sandstone fails more quickly, its bearing capacity is reduced, and the degree of crystal destruction is lower. In this state, the primary failure mode of the sandstone shifts to intergranular fracture.

5 Conclusion

To explore the influence of seepage fields on the mechanical behaviour and fracture mechanisms of surrounding rock in deep coal mine roadways, this study conducted conventional triaxial compression tests on sandstone specimens under seepage–stress coupling conditions. By systematically analysing the stress–strain responses, macroscopic fracture patterns, and microscopic fracture surface morphologies, the evolution and failure characteristics of sandstone under complex hydro-mechanical environments were comprehensively revealed. This research not only deepens the understanding of water–rock interaction in deep mining environments, but also proposes a novel experimental framework for investigating fracture mechanisms under seepage–stress coupling, thereby providing a scientific foundation for the design of more effective support systems and long-term stability assessment of groundwater-bearing surrounding rock in deep coal mine roadways. The specific conclusions are as follows.

(1) Using a transparent triaxial compression servo-control test system, axial stress–strain curves and time-dependent permeability evolution data for sandstone were obtained. The results demonstrate that seepage pressure significantly impacts the mechanical behaviours of sandstone, particularly reducing its bearing capacity. Under unilateral seepage pressure, the peak stress decreases in a linear fashion, with a gradient of 2.20 MPa/MPa. In contrast, the peak stress decreases nonlinearly under bilateral seepage pressure condition, with the reduction diminishing as the bottom seepage pressure decreases. Moreover, increasing the bottom seepage pressure reduces the pressure differential between the ends of the specimen and simultaneously modifies the permeability characteristics of the sandstone.

(2) The spatio–temporal evolution cloud map of the axial strain field during the fracture process of sandstone specimens was recorded using a 3D–DIC system. Initially, the axial strain distribution in the sandstone specimen follows a top-to-bottom gradient under seepage–stress coupling conditions. As deformation progresses, this layered configuration evolves into an inclined shear pattern. Over time, the region of large axial strain transitions from a randomly distributed to a more concentrated pattern, with strain localization becoming apparent on the specimen’s surface. Seepage pressure plays a crucial role in shaping the deformation localisation zone, as evidenced by the development of macroscopic fractures. Consequently, cracks in the sandstone develop and expand nonlinearly.

(3) The fracture mechanism of sandstone is explored through both macroscopic and microscopic perspectives. With the increase of top and bottom seepage pressures, there is a noticeable emergence of secondary cracks due to tensile failure within the specimen. As the seepage pressure difference intensifies, water progressively washes away detrital minerals that form from damaged cementing material and fractured crystals. This process leads to a reduction in the amount of detrital minerals on the fracture surface, resulting in a cleaner crystal surface. A key finding is the transition in fracture mode: under unilateral seepage pressure, the fracture mode consists of a mixed fracture involving both transgranular and intergranular fractures, while under bilateral seepage pressure, the fracture mode shifts to being predominantly intergranular. This transition underscores the significant role of bilateral seepage pressure in influencing the mechanical behaviour and the fracture mode of the sandstone.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

SZ: Funding acquisition, Writing – review and editing, Writing – original draft. YC: Supervision, Writing – review and editing, Funding acquisition. WX: Writing – review and editing. JX: Supervision, Writing – review and editing. XC: Writing – review and editing, Funding acquisition.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was supported and funded by Natural Science Research Project of Anhui Educational Committee (2023AH051223), Scientific Research Foundation for High-level Talents of Anhui University of Science and Technology (2022yjrc113), and National Natural Science Foundation of China (52474090).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Burns, E. F., Rempe, D. M., Parsekian, A. D., Schmidt, L. M., Singha, K., and Barnard, H. R. (2023). Ecohydrologic dynamics of rock moisture in a montane catchment of the Colorado front range water resour. Res. 59, e2022WR034117. doi:10.1029/2022WR034117

Cao, Z. Z., Yang, X. Q., Zhang, P. D., Li, Z. H., Du, F., Wang, W. Q., et al. (2024). Experimental study on the fracture surface morphological characteristics and permeability characteristics of sandstones with different particle sizes. Energy Sci. Eng. 12, 2798–2809. doi:10.1002/ese3.1768

Chen, L. H., Xi, B. P., Dong, Y. S., He, S. X., Shi, Y. X., Gao, Q. B., et al. (2023a). Study on the stability and seepage characteristics of underwater shield tunnels under high water pressure seepage. Sustainability-Basel 15, 15581. doi:10.3390/su152115581

Chen, Y., Xu, J., Cao, Q., Rao, H. K., Cui, M. Q., Zhang, Q. W., et al. (2023b). Experimental study on mechanical and strain localisation behaviour of sandstone under seepage-stress coupling. Rock Mech. Rock Eng. 56, 8457–8470. doi:10.1007/s00603-023-03510-0

Chen, Y., Xu, J., Peng, S. J., Zhang, Q. W., and Chen, C. C. (2022a). Strain localisation and seepage characteristics of rock under triaxial compression by 3D digital image correlation. Int. J. Rock Mech. Min. 152, 105064. doi:10.1016/j.ijrmms.2022.105064

Chen, Y., Xu, J., Peng, S. J., Zhang, Q. W., and Chen, C. C. (2023c). Space-time evolution law of progressive failure area and mechanical behaviour of rock under different seepage conditions. Eng. Geol. 312, 106926. doi:10.1016/j.enggeo.2022.106926

Chen, Z. Q., Ma, C. C., Li, T. B., and He, C. (2022b). Experimental investigation of the failure mechanism of deep granite under high seepage water pressure and strong unloading effect, Acta Geotech., 17, 5009–5030. doi:10.1007/s11440-022-01665-8

Ding, S., and Tang, S. B. (2024). Mechanical behavior evolution and failure characteristics of saturated and dry rocks under different water pressure environments. Int. J. Rock Mech. Min. 178, 105777. doi:10.1016/j.ijrmms.2024.105777

Dong, Q., Liu, X., Gong, H. L., Luo, Y., Li, X. P., and Wang, L. J. (2023). The damage induced by blasting excavation and seepage characteristics of deep rock under high seepage pressure geofluids 2023, 9159098. doi:10.1155/2023/9159098

Geng, J. B., Zeng, G. X., Liu, C. Y., Li, X. S., and Zhang, D. M. (2023). Development and application of triaxial seepage test system for gas-water two-phase in coal rock. Dev. Appl. triaxial seepage test Syst. gas-water two-phase coal rock Energy 277, 127439. doi:10.1016/j.energy.2023.127439

Han, Y. F., Liu, X. R., Wu, X. C., Liang, N. H., and Xu, B. (2024). Large-scale field model testing of the effects of soft rock water content on the bearing performance of tunnel-type anchorages B. Eng. Geol. Environ. 83, 509. doi:10.1007/s10064-024-04015-y

Heap, M. J., Harnett, C., Farquharson, J., Baud, P., Rosas-Carbajal, M., Komorowski, J. C., et al. (2023). The influence of water-saturation on the strength of volcanic rocks and the stability of lava domes J. Volcanol. Geoth. Res. 444, 107962. doi:10.1016/j.jvolgeores.2023.107962

Ji, J. Y., Song, X. Z., Yi, J. L., Song, G. F., and Wang, G. S. (2024). Effects of pore water-rock reaction on heat extraction from the karst geothermal reservoirs: based on the dual media model. Energy 293, 130651. doi:10.1016/j.energy.2024.130651

Li, Z., and Zhou, Z. Q. (2023). Numerical simulation of rock fracture and permeability characteristics under stress-seepage-damage coupling action. Int. J. Geomech. 23, 04022257. doi:10.1061/(Asce)Gm.1943-5622.0002622

Luo, P. K., Li, D. Y., Ma, J. Y., Zhao, J. J., and Jabbar, A. (2025). Experimental study on energy and damage evolution of dry and water-saturated dolomite from a deep mine. Int. J. Damage Mech. 34, 303–325. doi:10.1177/10567895241277948

Ma, D., Duan, H. Y., and Zhang, J. X. (2022a). Solid grain migration on hydraulic properties of fault rocks in underground mining tunnel: radial seepage experiments and verification of permeability prediction Tunn. Undergr. Sp. Tech. 126, 104525. doi:10.1016/j.tust.2022.104525

Ma, D., Duan, H. Y., Zhang, J. X., and Bai, H. B. (2022b). A state-of-the-art review on rock seepage mechanism of water inrush disaster in coal mines Int. J. Coal Sci. Techn. 9, 50. doi:10.1007/s40789-022-00525-w

Munoz, H., and Taheri, A. (2017). Local damage and progressive localisation in porous sandstone during cyclic loading. Rock Mech. Rock Eng. 50, 3253–3259. doi:10.1007/s00603-017-1298-8

Munoz, H., Taheri, A., and Chanda, E. K. (2016). Fracture energy-based brittleness index development and brittleness quantification by pre-peak strength parameters in rock uniaxial compression. Rock Mech. Rock Eng. 49, 4587–4606. doi:10.1007/s00603-016-1071-4

Ping, S. F., Wang, F. G., Wang, D. H., Li, S. W., Wang, Y. H., Yuan, Y. L., et al. (2024). Mechanical damage induced by the water-rock reactions of gypsum-bearing mudstone rock mech. Rock Eng. 57, 6377–6394. doi:10.1007/s00603-024-03855-0

Pu, J. Y., Yu, Q. L., Zhao, Y., Li, Z. F., Cao, Y. S., Le, Z. H., et al. (2024). Deformation analysis of a roadway tunnel in soft swelling rock mass based on 3D mobile laser scanning. Rock Mech. Rock Eng. 57, 5177–5192. doi:10.1007/s00603-024-03772-2

Wang, Y. C., Li, Z. Y., Jing, H. W., Li, Y. B., and Wang, M. T. (2021a). Study on the seepage characteristics of deep buried tunnels under variable high-pressure water heads B. Eng. Geol. Environ. 80, 1477–1487. doi:10.1007/s10064-020-01986-6

Wang, Y. C., Liu, Y., Li, Y. L., Jiang, W., and Wang, Y. M. (2021b). Experimental study on the failure mechanism of tunnel surrounding rock under different groundwater seepage paths. Geofluids 2021, 1–17. doi:10.1155/2021/8856365

Wang, Y. M., Peng, J., Wang, L. F., Xu, C. H., and Dai, B. B. (2024). Micro-macro evolution of mechanical behaviors of thermally damaged rock: a state-of-the-art review. J. Rock Mech. Geotech. 16 (7), 2833–2853. doi:10.1016/j.jrmge.2023.11.012

Wasantha, P. L. P., and Ranjith, P. G. (2014). Water-weakening behavior of Hawkesbury sandstone in brittle regime. Eng. Geol. 178, 91–101. doi:10.1016/j.enggeo.2014.05.015

Xie, H. P., Zhang, R., Zhang, Z. T., Ai, Y. S., Deng, J. H., Chen, Y., et al. (2024). Preliminary research and scheme design of deep underground in situ geo-information detection experiment for Geology in Time Int. J. Min. Sci. Techno. 34, 1–13. doi:10.1016/j.ijmst.2023.12.004

Xu, Y. L., Li, X. L., Wu, X. K., Zheng, W., Zhou, B., and Tong, J. (2022). Experimental study on pore fluid characteristics of fractured sandstone based on nuclear magnetic resonance technology. J. Pet. Sci. Eng. 214, 110408. doi:10.1016/j.petrol.2022.110408

Yan, C. Z., Xie, X., Ren, Y. H., Ke, W. H., and Wang, G. (2022). A FDEM-based 2D coupled thermal-hydro-mechanical model for multiphysical simulation of rock fracturing. Int. J. Rock Mech. Min. 149, 104964. doi:10.1016/j.ijrmms.2021.104964

Yang, T., Liu, H. Y., and Tang, C. A. (2017). Scale effect in macroscopic permeability of jointed rock mass using a coupled stress-damage-flow method. Eng. Geol. 228, 121–136. doi:10.1016/j.enggeo.2017.07.009

Yang, Z. H., Li, S. C., Liu, Y., and Zhang, N. (2024). Experimental study on the influence of water-rock interaction on the time-varying characteristics of coal rock mass. Environ. Geochem. Hlth. 46, 45. doi:10.1007/s10653-023-01832-0

Zan, W. B., Lai, J. X., Zhang, W. J., Yang, Q., Qin, Y. W., and Su, X. L. (2024). Experimental and applied research on similar materials to granular mixtures for solid-liquid coupling model test of an underwater tunnel. Constr. Build. Mat. 416, 135170. doi:10.1016/j.conbuildmat.2024.135170

Zhang, C., Bai, Q. S., and Han, P. H. (2023). A review of water rock interaction in underground coal mining: problems and analysis B. Eng. Geol. Environ. 82, 157. doi:10.1007/s10064-023-03142-2

Zhang, Y. B., Hu, B., Zhang, J., and Yu, P. C. (2024). Dynamic coupled hydromechanical approach for fractured rock mass seepage using two-dimensional discontinuous deformation analysis. Rock Mech. Rock Eng. 57, 3315–3328. doi:10.1007/s00603-023-03731-3

Zhao, J. S., Duan, S. Q., Chen, B. R., Li, L., He, B. G., Li, P. X., et al. (2024). Failure mechanism of rock masses with complex geological conditions in a large underground cavern: a case study. Soil Dyn. Earthq. Eng. 177, 108439. doi:10.1016/j.soildyn.2023.108439

Zhao, Y. L., Liu, Q., Zhang, C. S., Liao, J., Lin, H., and Wang, Y. X. (2021). Coupled seepage-damage effect in fractured rock masses: model development and a case study. Int. J. Rock Mech. Min. 144, 104822. doi:10.1016/j.ijrmms.2021.104822

Zhao, Z. H., Li, C. L., Meng, Z., and Liu, H. (2023). Theoretical analysis of anchorage-seepage coupling effect of the surrounding rock stability in deep buried abandoned chambers Geomech. Geophys. Geo. 9, 150. doi:10.1007/s40948-023-00688-z

Zhou, Z. L., Cai, X., Chen, L., Cao, W. H., Zhao, Y., and Xiong, C. (2017). Influence of cyclic wetting and drying on physical and dynamic compressive properties of sandstone. Eng. Geol. 220, 1–12. doi:10.1016/j.enggeo.2017.01.017

Keywords: deep coal mine, mechanical behaviour, permeability characteristic, microscopic morphology, fracture mechanism

Citation: Zhao S, Chen Y, Xu W, Xu J and Cheng X (2025) Mechanical behaviour and fracture mechanism of coal mine roadway surrounding rock considering seepage field. Front. Mater. 12:1612136. doi: 10.3389/fmats.2025.1612136

Received: 15 April 2025; Accepted: 30 May 2025;

Published: 10 June 2025.

Edited by:

Changtai Zhou, City University of Hong Kong, Hong Kong SAR, ChinaReviewed by:

Cancan Chen, Shenzhen University, ChinaJinhao Wen, Qingdao University of Technology, China

Beichen Yu, China University of Mining and Technology, China

Copyright © 2025 Zhao, Chen, Xu, Xu and Cheng. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yian Chen, eWlhbmNoZW5AYXVzdC5lZHUuY24=

Shujie Zhao

Shujie Zhao Yian Chen

Yian Chen Wensong Xu1

Wensong Xu1