- Energy Transformation Research Laboratory, Central Research Institute of Electric Power Industry, Yokosuka, Kanagawa, Japan

A series of creep tests, which include those under actual service conditions of ultra-super-critical power plants, have been carried out on long-term serviced Grade 91 steels to investigate the temperature dependence of the remaining creep life of the materials. Linear relationships between the reciprocal of absolute temperature and the logarithms of creep rupture life were observed even under actual service conditions. The temperature dependence of creep rupture data was assessed in detail in terms of the constant C in the Larson-Miller parameter. As far as the results obtained in this work, the experimental values of constant C depend negligibly on stress levels and material strength. The values of constant C are between 18 and 21 for base metals and between 16 and 21 for welded joints of Grade 91 steels. These findings indicate that the impact of temperature-dependent deviations on creep life estimation is not pronounced. An estimation method, which we have proposed for short-term data to predict long-term creep life, was applied to the test data, and it was demonstrated through calculations that the estimation method is valid for Grade 91 steels even under actual service conditions.

1 Introduction

Creep-strength-enhanced ferritic (CSEF) steels such as ASME Grade 91, Grade 92, and Grade 122 possess superior creep strength and have been used as structural materials in high-temperature environments at ultra-super-critical (USC) power plants (Viswanathan and Bakker, 2001; Sklenicka et al., 2003; Bhiograde, 2023). However, a significant number of unforeseen failures have been reported in the piping of CSEF steels at USC plants since the 2000s. For example, cases of steam leakage at welded joints have been reported in Grade 122 piping after approximately 33,000 h of operation, and in Grade 91 piping after approximately 65,000 h of operation (Yoshida et al., 2007). These failures were primarily attributable to a substantial deviation between the long-term creep strength assumed at the time of code and standard formulation and the actual material strength. In response to this issue, re-evaluations of the long-term creep strength of CSEF steels have been carried out with the cooperation of all Japanese organizations which consist of research institutes, plant manufacturers, steel manufacturers, and electric power companies involved in the CSEF steels approximately every 5 years since 2005 for base metals (Kimura, 2005; Kimura, 2006; Kimura and Takahashi, 2012; Kimura and Yaguchi, 2016; Kimura and Yaguchi, 2024) and welded joints (Tabuchi and Takahashi, 2006; Takahashi and Tabuchi, 2006; Yaguchi et al., 2012; Yaguchi et al., 2016; Yaguchi, 2024). With each re-evaluation, the allowable tensile stresses and creep rupture life evaluation equations of CSEF steels have been revised downward in Japan.

Several classical extrapolation methods have been developed for estimating long-term creep life based on a limited test dataset. Representative approaches include the Larson–Miller Parameter (LMP), the Orr–Sherby–Dorn (OSD) parameter, the Manson–Haferd Parameter (MHP), and Wilshire’s method, which incorporates thermodynamic considerations and creep mechanism modeling. These methods are widely used in industry; however, their reliability is often questioned when extrapolated beyond 100,000 h, especially for CSEF steels such as Grade 91 and Grade 92. It is also known that creep mechanisms can vary between short- and long-term regions, potentially affecting extrapolated life predictions. For instance, degradation mechanisms such as Laves phase precipitation and subgrain coarsening may become dominant in the long-term creep regime (Kim et al., 2013; Wilshire and Scharning, 2008). This highlights the importance of direct assessment techniques, such as the miniature specimen method discussed in this paper.

Although the allowable tensile stresses and creep life evaluation equations are proposed on the basis of the conventional methods developed through considerable prior research and operational experiences with high-temperature materials, recent studies have raised concerns that such methods may not be suitable for application to CSEF steels (Maruyama and Yoshimi, 2007). This view is based on analyses indicating that, whereas conventional methods assume that the dependence of creep life on temperature does not vary in the high-temperature range, CSEF steels exhibit the temperature dependence of creep life that is not constant and varies across different time regions or temperature ranges (Maruyama et al., 2015; Maruyama et al., 2016). For example, in Grade 92 base metal, its analysis has revealed that the temperature dependence of creep life varies across time regions and the activation energy associated with the temperature dependence of creep life differs by more than a factor of two between the short- and long-term regions (Maruyama et al., 2021). Accordingly, it has been pointed out that regression analyses performed on the same experimental dataset can yield markedly different evaluations for the long-term creep life of CSEF steels, depending on the treatment of temperature dependence. Therefore, the question of whether the temperature dependence of the creep life of CSEF steels remains constant or varies across different regions within the temperature–time domain relevant to actual service conditions is a critical issue. However, there is still no consensus among researchers regarding this issue, and the likelihood of reaching a consensus at this stage is low. This is primarily due to the absence of experimental data for CSEF steels in the actual operational region, which limits the basis for informed discussion. Given that the creep life under actual service conditions is generally assumed to exceed 100,000 h, the systematic acquisition and organization of experimental data in this region are extremely challenging. However, by utilizing materials that have undergone long-term service at power plants, we may be able to generate relevant data for the actual service condition region through creep testing over several tens of thousands of hours. Accordingly, we have systematically performed a series of creep tests on long-term serviced Grade 91 steel, encompassing conditions representative of the actual service environment. As a result, creep test data in the actual service condition region were obtained for Grade 91 welded joints for the first time. These newly acquired data are particularly relevant given that, in welded joints of Grade 91 steel, long-term creep failure frequently occurs not in the weld metal itself, but in the fine-grained region of the heat-affected zone (HAZ)—a phenomenon commonly referred to as Type IV cracking. This failure mode is characterized by cavity formation along prior austenite grain boundaries and degradation of martensitic microstructures due to recovery and coarsening processes during prolonged exposure to high temperatures. In addition, the weld metal itself may also suffer creep strength degradation due to compositional mismatches or improper post-weld heat treatment (Viswanathan and Bakker, 2001; Abe, 2015). These mechanisms underscore the need for region-specific assessment in creep life evaluation. Furthermore, for the Grade 91 base metal, creep data under service-representative stress levels were acquired, although the temperature was increased by 25°C above the actual service conditions.

In this paper, we report the results of a study on the temperature dependence of Grade 91 steel based on the experimental data obtained. In addition, the applicability and validity of our previously proposed creep life estimation method (Yaguchi and Kanai, 2019; Yaguchi, 2022) are examined through its application to long-term serviced Grade 91 steel under conditions representative of actual service.

2 Experimental procedure and results

2.1 Experimental procedure

The test materials were base metal and welded joints of multiple plate form of Grade 91 steel pipes that had been in long-term service in USC power plants. They were hot reheat steam piping (HRP) with the longest recorded operating time being approximately 148,000 h. The creep test specimens were solid round bars with a gauge diameter of 10 or 6 mm and a gauge length of 50 or 30 mm. In both cases, specimens were extracted from the mid-thickness of the pipe wall, with the specimen axis aligned in the circumferential direction of the pipe. Creep tests were conducted using a lever-type creep testing machine with electric furnace heating.

In this study, iso-stress creep tests were conducted for each material at temperatures ranging from 600°C to 700°C. The applied stress levels ranged from 34 to 80 MPa for welded joints and from 40 to 56 MPa for base metal. For some of the creep tests at 600°C and 650°C, rupture data had already been obtained in our prior studies (Yaguchi and Kanai, 2019), and these data were utilized in the present analysis. In the following sections, we describe the test results obtained thus far within the available range.

2.2 Experimental results

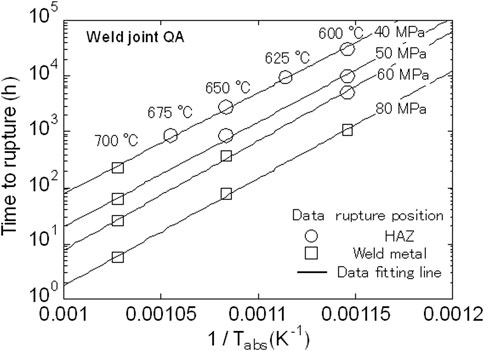

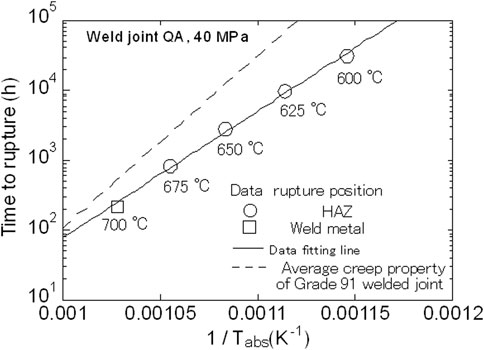

Figure 1 shows the results of iso-stress creep tests conducted on the welded joint of a material (hereafter referred to as QA material) that had been in service for approximately 117,000 h under conditions of 602°C and 38 MPa. In the figure, the horizontal axis represents the inverse of the test temperature (expressed as absolute temperature, Tabs), and the vertical axis indicates the rupture time on a logarithmic scale. For the QA material, rupture data were systematically obtained over wide ranges of stress levels (40–80 MPa) and temperatures (600°C–700°C). Depending on the test conditions, two types of rupture location were observed: rupture in the heat-affected zone (HAZ) and rupture in the weld metal. In Figure 1, circular symbols represent HAZ ruptures, whereas square symbols denote weld metal ruptures. A clear trend was observed: under the same stress level, low temperatures tended to promote HAZ ruptures, and under the same temperature level, low stress levels also led to a shift from a weld metal rupture to a HAZ rupture. However, in the relationship between the inverse of temperature and rupture time, little variation in slope caused by the change in rupture location was observed. Across all stress levels, the rupture data plotted nearly linearly over the temperature range from 600°C to 700°C. Figure 2 shows a comparison of the rupture data at 40 MPa—the stress level corresponding to actual service conditions—with the average creep life evaluation curve for Grade 91 steel welded joints in Japan (Yaguchi, 2024). The rupture data exhibit a clearly lower slope, and the discrepancy between the experimental data and the average creep life evaluation curve becomes more pronounced as the temperature approaches the actual service condition (600°C).

Figure 2. Iso-stress test results of welded joint of material QA and average creep life evaluated using equations for Grade 91 steel welded joint.

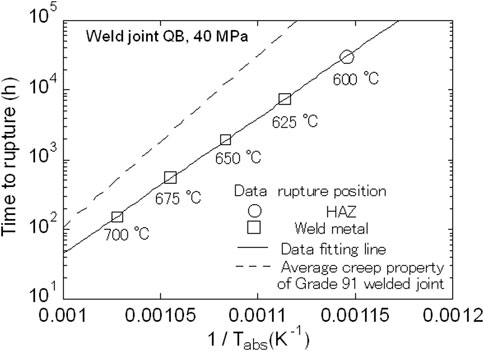

A similar trend was observed in another material (hereafter referred to as QB material) extracted from a different piping system. Figure 3 shows the results of iso-stress creep tests conducted on the welded joint of the QB material, which had been in service for approximately 117,000 h at 602°C and 38 MPa. As with the QA material, a transition in rupture location from the weld metal to the HAZ was observed with decreasing temperature under identical stress levels. Regarding the relationship between the inverse of temperature and rupture time, no significant change in slope caused by the shift in rupture location was observed. The rupture data for all conditions aligned nearly linearly within the temperature range of 600°C–700°C. Furthermore, the slope of the rupture data was clearly smaller than that of the dashed line representing the average creep life evaluation curve for Grade 91 steel welded joints.

Figure 3. Iso-stress test results of welded joint of material QB and average creep life evaluated using equations for Grade 91 steel welded joint.

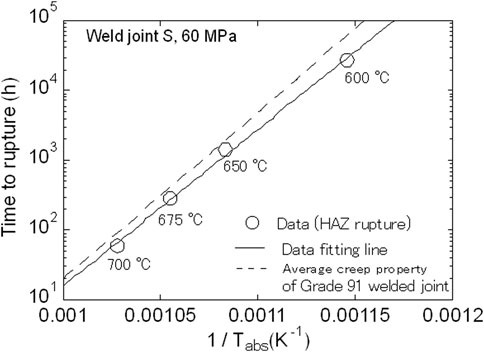

Figure 4 shows the results of iso-stress creep tests conducted on the welded joint of a material (hereafter referred to as S material) that had been in service for approximately 118,000 h at 596°C and 39 MPa. The applied stress for the creep tests was 60 MPa. The rupture data are positioned nearly linearly over the temperature range of 600°C–700°C. When comparing the slope of the rupture data with that of the average creep life evaluation curve for Grade 91 steel welded joints, the difference is minimal in the case of the S material welded joint. It is also noted that, for all test conditions, rupture occurred in the HAZ.

Figure 4. Iso-stress test results of welded joint of material S and average creep life evaluated using equations for Grade 91 steel welded joint.

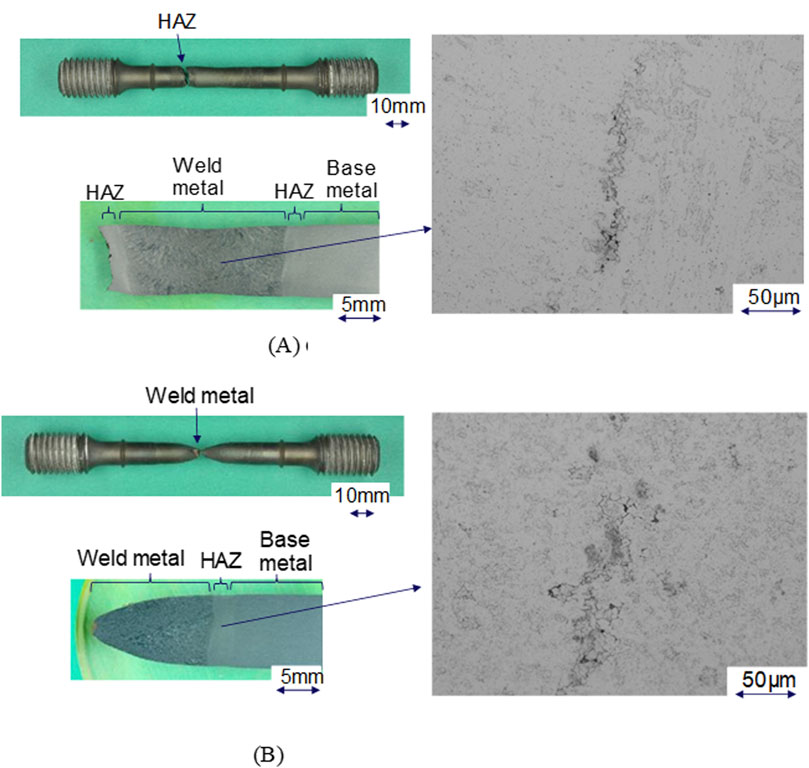

As described above, in the iso-stress creep tests for the QA and QB welded joints, the rupture location varied depending on the test conditions; however, no significant effect of rupture location was observed in the relationship between the inverse of temperature and rupture time. This suggests that there may be no substantial difference in creep life between the HAZ and weld metal in the QA and QB welded joints. To evaluate the validity of this suggestion, the fracture modes of creep-ruptured specimens of QA and QB materials were investigated. As an example, the external appearance and longitudinal cross sections of the QA welded joint specimens are shown in Figure 5. The applied stress was 40 MPa, and all specimens ruptured in the HAZ at a test temperature of 675°C or lower, whereas rupture occurred in the weld metal at 700°C. The observation of the ruptured specimens revealed that, in cases of HAZ rupture, voids and microcracks were present in the weld metal, whereas in cases of weld metal rupture, voids and microcracks were observed in the HAZ. The same tendency was also confirmed under other stress levels for the QA material, as well as for the QB material. Accordingly, it is inferred that there was no significant difference in creep life between the HAZ and weld metal in the QA and QB welded joints. The reason why failure occurred in the HAZ at temperatures ≤675°C but shifted to the weld metal at 700°C remains unclear to the authors. Importantly, in the case of weld metal rupture at 700°C, voids and microcracks were also found in the heat-affected zone, particularly concentrated in the fine-grained heat-affected zone (FGHAZ), which is known to be susceptible to Type IV cracking. These findings suggest that significant creep damage was accumulating in both regions. Additionally, the fracture surfaces in the weld metal were typically located near the center of the weld metal in the width direction, rather than near the fusion line.

Figure 5. Damage states of HAZ and weld metal rupture specimens (Material QA welded joint, 40 MPa) (A) 675°C: HAZ rupture (B) 700°C: weld metal rupture.

The dependence of rupture location on both temperature and stress, as shown in Figure 1, suggests that the failure behavior in welded joints is governed by multiple factors. Specifically, there exists a heat-to-heat scatter in creep rupture life for both the HAZ and the weld metal under the same test conditions. Moreover, the average temperature and stress dependence of rupture life differs between these regions. In welded joints, the creep life is ultimately governed by the region with the shorter life under given conditions. Thus, the observed rupture location is the result of a complex interplay between intrinsic property differences and heat-to-heat variability. Due to this complexity, a simplified approach was adopted in this study, where the creep rupture data from the HAZ and weld metal were analyzed together without separate modeling of each failure mechanism. It should be noted that pronounced necking was observed particularly in specimens that fractured in the weld metal region under constant load conditions. Such local necking can influence the apparent rupture life by accelerating stress concentration and damage accumulation in the necked region. Recent studies, such as the work by Li et al. (2025), have emphasized the significance of accounting for local necking when interpreting creep rupture behavior. Although a detailed inverse analysis was not performed in this study, the potential influence of necking should be taken into consideration when evaluating rupture life data for weld metal specimens.

Furthermore, the observed creep life is ultimately affected by the dominant fracture mode. For example, brittle fracture in the HAZ may occur when the fine-grained region is constrained by adjacent zones—such as the base metal and weld metal—that exhibit higher resistance to deformation than the HAZ itself. Conversely, when the weld metal has lower deformation resistance than the HAZ, ductile fracture tends to occur in the weld metal due to its relatively larger cross-sectional area, which allows greater plastic strain accommodation. These observations indicate that the deformation resistance of the weld metal can vary depending on the material heat and welding conditions—being either higher or lower than that of the HAZ—and this variability influences which region governs the fracture behavior. Therefore, fracture elongation behavior and the governing rupture mode—brittle or ductile—can play a non-negligible role in determining the apparent creep life of welded joints.

Because of space constraints, figures are not provided; however, iso-stress creep tests performed on three other welded joints of long-term serviced Grade 91 steel yielded results consistent with those discussed above.

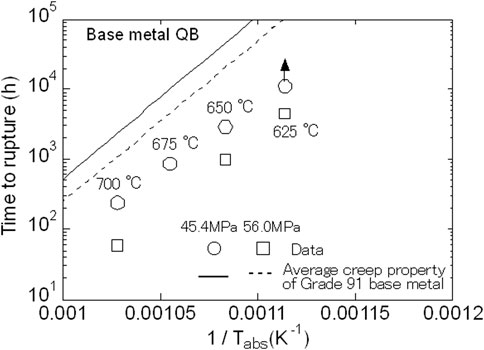

Figure 6 shows the results of iso-stress creep tests on the base metal of the QB material. The applied stress levels were 45.4 and 56.0 MPa. Within the range of data obtained thus far, the rupture data are positioned nearly linearly. When comparing the rupture data with the average life evaluation curve for Grade 91 base metal in plate form (Kimura and Yaguchi, 2016), the regression line at 45.4 MPa exhibits a slightly smaller slope, whereas at 56.0 MPa, the slopes at both stress levels are nearly identical. In addition, iso-stress creep tests were carried out on two other long-term serviced Grade 91 base metals, and the results were consistent with those described above.

Figure 6. Iso-stress test results of base metal of material QB and average creep life evaluated using equations for Grade 91 steel base metal.

The above results can be summarized as follows:

• For long-term serviced Grade 91 welded joints, an approximately linear relationship between the inverse of absolute temperature and the logarithm of rupture time was confirmed over the temperature range from 600°C to 700°C, even at actual service stress levels.

• For long-term serviced Grade 91 base metal, a similar linear relationship may hold over the temperature range from 625°C to 700°C, even under actual service stress levels.

3 Evaluation of temperature dependence of creep life

In this section, the temperature dependence of creep life in long-term serviced Grade 91 steel is evaluated using the iso-stress creep test data shown in the previous section. For the evaluation method, in this study, we employ the C value of the Larson–Miller parameter (LMP) for creep life estimation. LMP provides a formulation for the relationship between temperature and time to rupture (Viswanathan, 1989). In the context of creep life evaluation, the effect of applied stress, σ, can be represented using an arbitrary functional form. If the stress dependence is expressed generally as f(σ), the creep life tr can be estimated using the following expression based on the LMP formulation, as shown in Equation 1.

Accordingly, the relationship between the inverse of Tabs and tr can be expressed by the following equation:

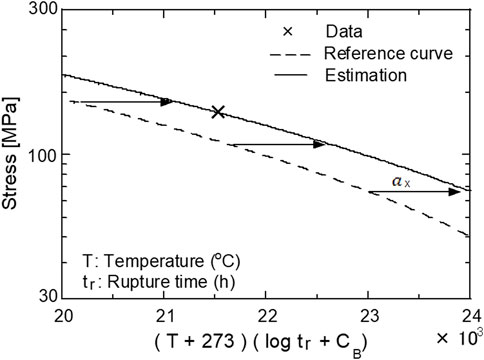

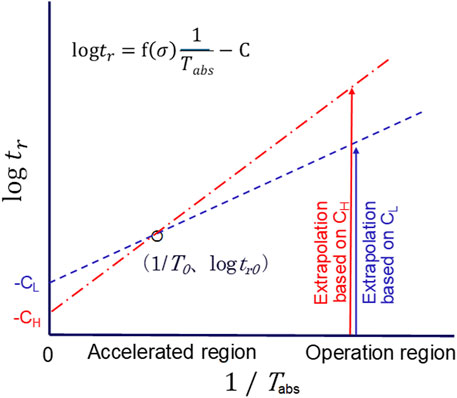

Equation 2 represents a straight line when log tr is plotted on the vertical axis and 1/Tabs on the horizontal axis, with the slope corresponding to f(σ) and the intercept given by–C. If the temperature and rupture time obtained under accelerated conditions are denoted as T0 and tr0, respectively, then the data point (1/T0, logtr0) must satisfy Equation 2. When estimating the creep life in the actual service condition region using accelerated test data, the point (1/T0, logtr0) remains fixed. As illustrated in Figure 7, the evaluated life in the low-temperature (service) region varies depending on the value of C. A smaller value of–C (i.e., a larger absolute value of C) results in a longer evaluated life at low temperatures. Therefore, in creep life estimation based on LMP, it can be concluded that the evaluation of temperature dependence is governed by the value of C.

Figure 7. Schematic of effect of C on extrapolation of creep rupture time using temperature-accelerated creep data in Larson-Miller parameter method.

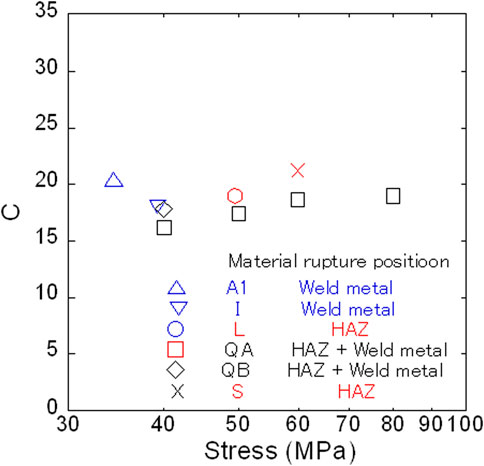

Figure 8 shows the calculated C values derived from each iso-stress creep test dataset for long-term serviced Grade 91 welded joints, plotted as a function of applied stress. Although the data for the QA material alone suggest a slight decreasing trend in C value with decreasing stress, the overall dataset—including other materials—does not exhibit a consistent or systematic dependence of C on stress. For reference, the C value corresponding to the low-stress region in the standard creep life evaluation equation for Grade 91 welded joints is approximately 23 (Yaguchi, 2024). In contrast, the C values obtained in this study range from a maximum of approximately 21 to a minimum of approximately 16.

Figure 8. Relationship between constant C and stress in welded joint of long-term serviced Grade 91 steel.

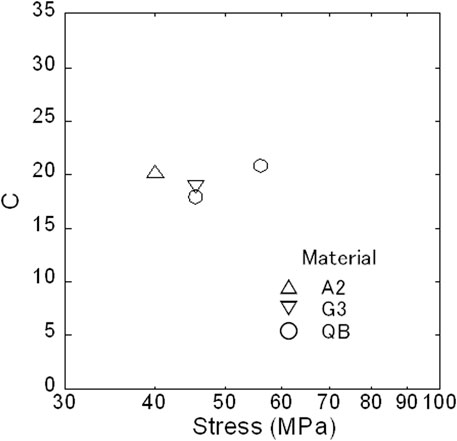

Figure 9 shows the calculated C values derived from each iso-stress creep test dataset for long-term serviced Grade 91 base metal in plate form, organized according to applied stress levels. Although the number of data points is limited, no clear dependence of the C value on stress magnitude is observed at this stage. For reference, the C value on the low-stress side of the standard creep life evaluation equation for Grade 91 base metal in plate form is approximately 21 (Kimura and Yaguchi, 2016), whereas the C values obtained in this study range from a maximum of approximately 21 to a minimum of approximately 18.

Figure 9. Relationship between constant C and stress in base metal of long-term serviced Grade 91 steel.

The above findings can be summarized as follows:

• For long-term serviced Grade 91 steel, no clear differences in the C values of LMP attributable to applied stress were observed.

• Within the range of data obtained in this study, the C values for welded joints approximately ranged from 16 to 21, whereas those for base metal approximately ranged from 18 to 21.

4 Evaluation of validity of previously proposed creep life estimation methods

In this section, we examine the validity of the creep life estimation method on the basis of short-term data, as proposed in a previous study (Yaguchi, 2022), by applying it to creep rupture data corresponding to actual service conditions.

4.1 Outline of creep life estimation method

The following provides an overview of the present creep life estimation method. An analysis of creep rupture data for long-term serviced Grade 91 steel revealed that creep life characteristics can be effectively captured using LMP. Specifically, even when creep rupture times differed by more than one order of magnitude under identical temperature and stress levels, the shape of the master rupture curve described by Equation 2 for each material remained nearly identical, with differences observed only in the horizontal positioning. From this observation, it was inferred that the shape of the master rupture curve for long-term serviced Grade 91 steel is independent of material, and that material-to-material (heat-to-heat) variations of strength can be represented as parallel shifts along the horizontal axis. Consequently, if a single data point is available, it is possible to determine the master rupture curve for the material. A schematic of this estimation method is provided in Figure 10.

On the basis of the above concept, the tr of the material at any given temperature and stress condition can be estimated using Equation 3.

Here, CB, a0, a1, and a2 are material constants, which are determined on the basis of the creep rupture data of a reference material. aX is a parameter that characterizes the strength level of each material and defines the amount of horizontal displacement of the master rupture curve in Figure 10. In the above equation, the only unknown parameter is aX. Therefore, a single rupture data point for the material under evaluation is sufficient to determine the value of aX. In the following, creep life estimations were performed using the material constants previously determined in our earlier study (Yaguchi and Kanai, 2019) based on short-term rupture data (on the order of several hundred hours) for each material.

4.2 Application results of creep life estimation method

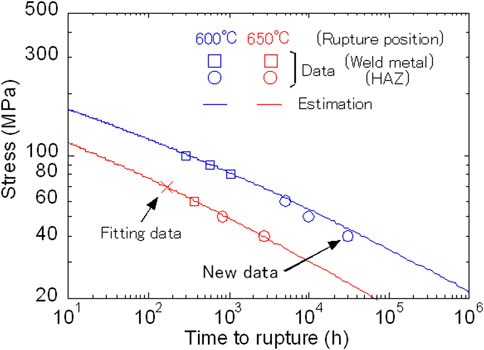

Figure 11 shows the estimated creep life for the QA welded joint. Although both HAZ and weld metal ruptures were observed in the QA welded joint, they were treated collectively in this study for the reasons described in Section 2.2. The proposed method appears to provide a reasonable estimation of creep life, even for the newly obtained rupture data in the actual service condition region (600°C, 40 MPa).

Figure 11. Estimated creep curves and new data in actual service condition region of material QA welded joint.

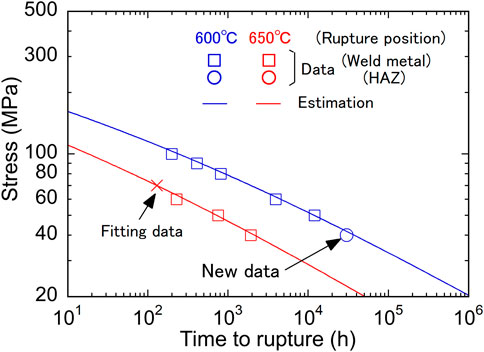

Figure 12 shows the estimated creep life for the QB welded joint. For the QB material as well, the estimated result obtained using the proposed method shows good agreement, within a reasonable accuracy, with the newly obtained rupture data in the actual service condition region (600°C, 40 MPa).

Figure 12. Estimated creep curves and new data in actual service condition region of material QB welded joint.

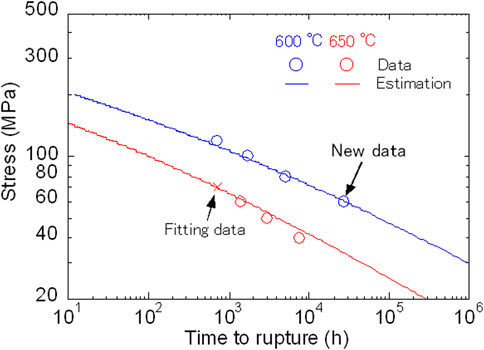

Figure 13 shows the estimated creep life for the S welded joint. The estimated result obtained using the proposed method exhibits good agreement with the newly obtained rupture data in the actual service condition region (600°C, 60 MPa), suggesting a high level of estimation accuracy.

Figure 13. Estimated creep curves and new data in actual service condition region of material S welded joint.

For the newly obtained rupture data from other welded joints and base metals as well, the proposed method could reasonably estimate creep life without any modification to the material constants we previously determined. Although the present evaluation was conducted at 600°C, additional creep tests at 625°C have been initiated for selected heats, and corresponding evaluations at this temperature are underway. Future work will also include evaluations at other temperatures such as 575°C. However, at this stage, systematic datasets for these additional temperatures are not yet available. To facilitate understanding of the proposed model despite the current temperature limitations, we have aimed to describe the role and formulation of its key parameters, including aX, in a transparent and reproducible manner. Due to confidentiality constraints related to the commissioned nature of this study, the precise value of aX is not disclosed.

4.3 Effect of deviations in C value on estimation results

In the previous section, the validity of the proposed method was examined by comparing the estimated results with the newly obtained rupture data in the actual service condition region. However, the number of available test data points in the service region is limited, and it cannot be ruled out that some materials may exhibit temperature dependence different from that observed in this study. Since various materials are used in actual service environments, it is necessary to consider this diversity in advance. Therefore, in this section, the accuracy of the proposed creep life estimation method is discussed with a focus on the variability of the C value in LMP.

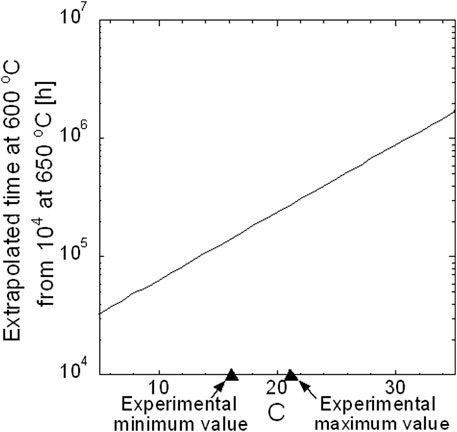

As an illustrative example, Figure 14 shows the estimated rupture time at 600°C obtained by converting a data point at 650°C and 10,000 h using LMP. For reference, the upper and lower bounds of the C values observed in the welded joint experiments shown in Figure 8 are indicated with arrows. When converting ‘650°C, 10,000 h' to 600°C, the estimated rupture time is approximately 60,000 h for C = 10, 240,000 h for C = 20, and 890,000 h for C = 30, indicating that the converted values vary significantly with the C value.

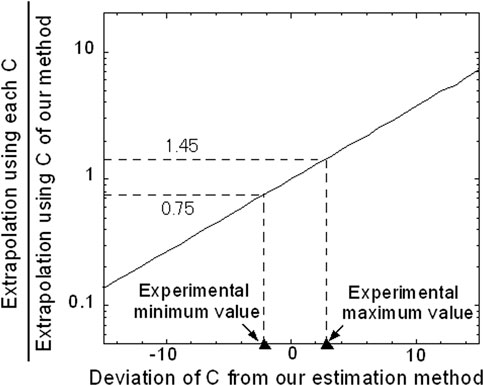

Next, Figure 15 shows the results of a sensitivity analysis in which the horizontal axis represents the deviation from the C value used in the proposed method and the vertical axis represents the ratio of the rupture time at 600°C estimated using the deviated C value to that estimated using the original C value. For the upper and lower bounds of C values confirmed in the welded joint experiments, the corresponding vertical-axis values are 1.45 and 0.75, respectively. This implies that if the temperature dependence varies within the range observed experimentally, the estimation error in creep life using the proposed method could range from approximately 0.75–1.45 times the evaluated value.

Considering the uncertainties associated with the evaluation temperature and applied stress, the variation in creep life estimation within the above range does not appear to constitute a factor with a significant effect. However, this conclusion holds under the condition that the deviation in the C value between the target material and the proposed method remains within ±3. If materials exhibiting deviations beyond this range exist, more substantial discrepancies in the estimated creep life may arise. Therefore, it is desirable to experimentally clarify the temperature dependence of creep life for various Grade 91 steels through systematic investigation. As shown in Figures 1–4, for long-term serviced Grade 91 steel, the relationship between the logarithm of the creep rupture time and 1/T is approximately linear. Accordingly, the example presented in Figure 7 conceptually illustrates how the estimated creep life at lower temperatures is affected by deviations in the C value, under the assumption of linear temperature dependence. It should be noted that this assumption may not apply to virgin Grade 91 steels, for which the relationship is known to be nonlinear. However, because the present study is part of a research project focused on the residual life assessment of long-term serviced materials—not on design evaluations for virgin materials—the assumption of linearity is considered valid in this context.

To obtain creep rupture data under conditions relevant to residual life assessment of long-term serviced materials, it is often necessary to conduct tests under accelerated conditions, either by increasing temperature or stress. In particular, when applying the iso-stress method—as outlined in relevant standards—it is generally required to secure at least three data points with temperature intervals of approximately 25°C. While 700°C may be considered too high for practical use conditions of Grade 91 steel, it often becomes an indispensable test point from a methodological standpoint. Specifically, when the reference temperature is 600°C, acquiring three data points spaced by 25°C mandates testing at 650°C and 700°C. This reflects the practical necessity to derive meaningful results within a constrained testing timeframe, especially in field-oriented residual life evaluations where timely and reliable decision-making is essential.

In the present study, 600°C was selected as the reference temperature based on its relevance to actual service conditions. Although details of individual facilities are not discussed, the authors’ work is conducted within the context of residual life evaluation for components operating in Japanese thermal power plants, where Grade 91 steel is commonly used at around 600°C. Recently, however, some Japanese power plants have adopted life-extension strategies by operating critical components at reduced temperatures, typically by up to approximately 30°C, to mitigate long-term creep damage. This trend underscores the increasing importance of testing at lower temperatures such as 575°C. Accordingly, preparations are underway to obtain such data, and additional tests at 625°C have already been initiated for selected heats, as mentioned before.

To enhance extrapolation accuracy over a wide temperature range—including both accelerated high-temperature tests and emerging lower-temperature conditions—more sophisticated formulations may be beneficial. In this regard, we recognize that the equation proposed by Orr and Burton, (1993) offers a flexible framework to express both stress and temperature dependence and may be particularly useful for long-term predictions requiring high extrapolation fidelity. While a direct comparison with our proposed model was not performed in this study, we intend to explore such comparisons in future work as additional data become available.

4.4 Scope and future direction

Welded joints often exhibit complex rupture behavior compared to base metals, due to factors such as property variations in weld metal depending on specimen orientation, differences in joint geometry, and the relative proportions of weld metal and HAZ. In the present study, the target specimens were limited to welded joints with comparable configurations—specifically, longitudinal welds with narrow-gap groove geometry typical of thick-walled piping in actual thermal power plants. As such, the applicability of the proposed method is limited to joints with similar characteristics.

For other types of welds, such as nozzle welds, the influence of joint geometry, heat input, and the size of the base metal components must be taken into account. Identifying which configuration parameters are critical from an engineering standpoint, and developing simplified parameters that can adequately capture their effects, is considered a key future challenge.

In this context, we are also investigating the integration of the proposed extrapolation-based method with miniature specimen creep testing techniques. This combined approach aims to enable localized and efficient evaluation of creep properties from small material samples extracted from service components. However, such evaluation also requires that the weld configuration be sufficiently similar to the reference cases for which the method has been validated. As such, both standardization of configuration-related parameters and the development of scalable assessment techniques remain important future research directions.

5 Conclusion

The main conclusions obtained in this study are summarized as follows:

1. For long-term serviced Grade 91 welded joints, a clear linear relationship between the inverse of absolute temperature and the logarithm of rupture time was confirmed over the temperature range from 600°C to 700°C, even at actual service stress levels. This indicates that the temperature dependence of creep life remains consistent within the service-relevant range.

2. The creep life estimation method based on short-term data, as proposed previously, demonstrated a high level of accuracy in predicting the creep life of long-term serviced Grade 91 welded joints in the actual condition service region. These results confirm the practical applicability and effectiveness of the method for the service-life assessment of aged components.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

MY: Conceptualization, Supervision, Writing – original draft. MK: Data curation, Investigation, Writing – review and editing. KT: Validation, Writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Bhiograde, D. S. (2023). Ultra Supercritical thermal power plant material Advancements: a review. J. Alloys Metallurgical Syst. 3, 100024. doi:10.1016/j.jalmes.2023.100024

Kim, W. G., Park, J. Y., Jang, J., Choudhary, B. K., Kim, S. J., Kim, Y. W., et al. (2013). “Methodologies for long-term creep life extrapolation of GR. 91 steel,” in Proc. 8th Pacific Rim International Congress on advanced materials and processing, Hawaii, USA, 397–408.

Kimura, K. (2005). “Assessment of long-term creep strength and review of allowable stress of high Cr ferritic creep resistant steels,”. Denver, USA, 237–244. doi:10.1115/pvp2005-71039Proc. PVP2005PVP2005-71039

Kimura, K. (2006). “Creep strength assessment and review of allowable tensile stress of creep strength enhanced ferritic steels in Japan,”. Vancouver, Canada, 359–366. doi:10.1115/pvp2006-icpvt-11-93294Proc. PVP2006-ICPVT-11

Kimura, K., and Takahashi, Y. (2012). “Evaluation of long-term creep strength of ASME Grades 91, 92 and 122 type steels,”. Toronto, Canada, 309–316. PVP2012-78323. doi:10.1115/pvp2012-78323Proc. PVP2012

Kimura, K., and Yaguchi, M. (2016). “Re-Evaluation of long-term creep strength of base metal of ASME Grade 91 type steel,”. Vancouver, Canada, PVP2016–63355.Proc. PVP2016. doi:10.1115/PVP2016-63355

Kimura, K., and Yaguchi, M. (2024). Revision of long-term creep strength of base metal of ASME Grade 91 type steel. Proc. PVP2024, Wash. PVP2024-122999. doi:10.1115/PVP2024-122999

Li, M., Guo, R. Q., Zhou, B., Gong, X. F., Wen, Z. X., Yue, Z. F., et al. (2025). Interpretation of uniaxial creep damage properties and rupture life considering local necking via an inverse approach. Eng. Fract. Mech. 314, 110735. doi:10.1016/j.engfracmech.2024.110735

Maruyama, K., Nakamura, J., and Yoshimi, K. (2015). Prediction of long term creep rupture life of Grade 122 steel by Multiregion analysis. ASME J. Press. Vessel Technol. 137 (2), 021403. doi:10.1115/1.4028203

Maruyama, K., Nakamura, J., and Yoshimi, K. (2016). Assessment of long-term creep rupture strength of T91 steel by Multiregion rupture data analysis. ASME J. Press. Vessel Technol. 138 (3), 031407. doi:10.1115/1.4032647

Maruyama, K., Sekido, N., and Yoshimi, K. (2021). Changes in strengthening mechanisms in creep of 9Cr-1.8W-0.5Mo-VNb steel tested over wide ranges of creep conditions. 5Mo-VNb Steel Test. over Wide Ranges Creep Cond. Int. J. Press. Vessels Pip. 190, 104312. doi:10.1016/j.ijpvp.2021.104312

Maruyama, K., and Yoshimi, K. (2007). Influence of data analysis method and allowable stress Criterion on allowable stress of Gr.122 heat resistant steel. 122 Heat. Resist. Steel, ASME J. Press. Vessel Technol. 129, 449–453. doi:10.1115/1.2748825

Orr, J., and Burton, D. (1993). Experience in data collection and assessment for material standards. Ironmak. and Steelmak. 20, 431–437.

Sklenicka, V., Kucharova, K., Svododa, L., Kloc, L., Bursik, J., and Kroupa, A. (2003). Long-term creep behavior of 9-12%Cr power plant steels. Mater. Charact. 51, 35–48. doi:10.1016/j.matchar.2003.09.012

Tabuchi, M., and Takahashi, Y. (2006). “Evaluation of creep strength Reduction factors for welded joints of modified 9Cr-1Mo steel (P91),”. Vancouver, Canada, 529–534. PVP2006-ICPVT-11-93350. doi:10.1115/pvp2006-icpvt-11-93350Proc. PVP2006-ICPVT-11

Takahashi, Y., and Tabuchi, M. (2006). “Evaluation of creep strength Reduction factors for welded joints of HCM12A (P122),”. Vancouver, Canada, 417–422. doi:10.1115/pvp2006-icpvt-11-93488Proc. PVP2006-ICPVT-11

Viswanathan, R. (1989). Chapter3: creep, damage mechanisms and life assessment of high temperature components, 1989. Novelty, OH: ASM International, Materials Park, 59–110. doi:10.31399/asm.tb.dmlahtc.t60490059

Viswanathan, R., and Bakker, W. (2001). Materials for Ultrasupercritical coal power plants - Boiler materials: Part 1. J. Mater. Eng. Perform. 10, 81–95. doi:10.1361/105994901770345394

Wilshire, B., and Scharning, P. J. (2008). A new methodology for analysis of creep and creep fracture data for 9–12% Chromium steels. Int. Mater. Rev. 53, 91–104. doi:10.1179/174328008x254349

Yaguchi, M. (2022). Remaining creep life prediction method for in-service Boiler pipe Weldment using small Scale specimen. Mater. Perform. Charact. 11 (3), 402–423. doi:10.1520/MPC20210104

Yaguchi, M. (2024). Long-term creep strength evaluation of welded joint of ASME Grade 91 type steel. Proc. PVP2024, Wash. PVP2024-122116. doi:10.1115/PVP2024-122116

Yaguchi, M., and Kanai, M. (2019). “An estimation of creep remaining life of modified 9Cr steel on basis of short-term creep test data,” in Proc. 57th Symposium on strength of materials at high temperatures. Japan: Sendai, 51–55. (in Japanese).

Yaguchi, M., Matsumura, T., and Hoshino, K. (2012). “Evaluation of long-term creep strength of welded joints of ASME Grades 91, 92 and 122 type steels,”. Toronto, Canada, 317–326. PVP2012-78393. doi:10.1115/pvp2012-78393Proc. PVP2012

Yaguchi, M., Nakamura, K., and Nakahashi, S. (2016). “Re-Evaluation of long-term creep strength of welded joint of ASME Grade 91 type steel,”. Vancouver, Canada, PVP2016–63316.Proc. PVP2016. doi:10.1115/PVP2016-63316

Keywords: creep, life evaluation, temperature dependence, Grade 91 steel, welded joint

Citation: Yaguchi M, Kanai M and Tamura K (2025) Temperature dependence of creep rupture life of long-term serviced Grade 91 steel. Front. Mater. 12:1613803. doi: 10.3389/fmats.2025.1613803

Received: 17 April 2025; Accepted: 21 July 2025;

Published: 11 August 2025.

Edited by:

Petr Dymáček, Institute of Physics of Materials (ASCR), CzechiaReviewed by:

Wei Sun, University of Nottingham, United KingdomPetr Kral, Institute of Physics of Materials (ASCR), Czechia

Copyright © 2025 Yaguchi, Kanai and Tamura. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Masatsugu Yaguchi, eWFndWNoaUBjcmllcGkuZGVua2VuLm9yLmpw

Masatsugu Yaguchi

Masatsugu Yaguchi Masayuki Kanai

Masayuki Kanai