- School of Mechanical Engineering, Xi’an Jiaotong University, Xi’an, China

Due to the sub-wavelength structural characteristics and excellent wave regulation ability, metamaterials have important application value regulating acoustic and elastic waves. After more than 20 years of continuous development, the achievements of acoustics and elastic metamaterials have become very abundant. Especially in recent years, with the increasingly close integration with engineering application scenarios, metamaterials have shown important application value in many fields, such as aviation, aerospace, ships, rail vehicles, automobiles, home appliances, and architecture. Therefore, in order to promote the development of metamaterials in applications, we have organized three special issues, attracted the attention of many scholars, and received more than 30 submissions. To provide better guidance for the subsequent application research of metamaterials, we will briefly introduce the main breakthroughs in metamaterial applications at present, including sound absorption, sound insulation, vibration absorption, vibration isolation, noise reduction with ventilation, and acoustic detection and communication.

1 Sound absorption

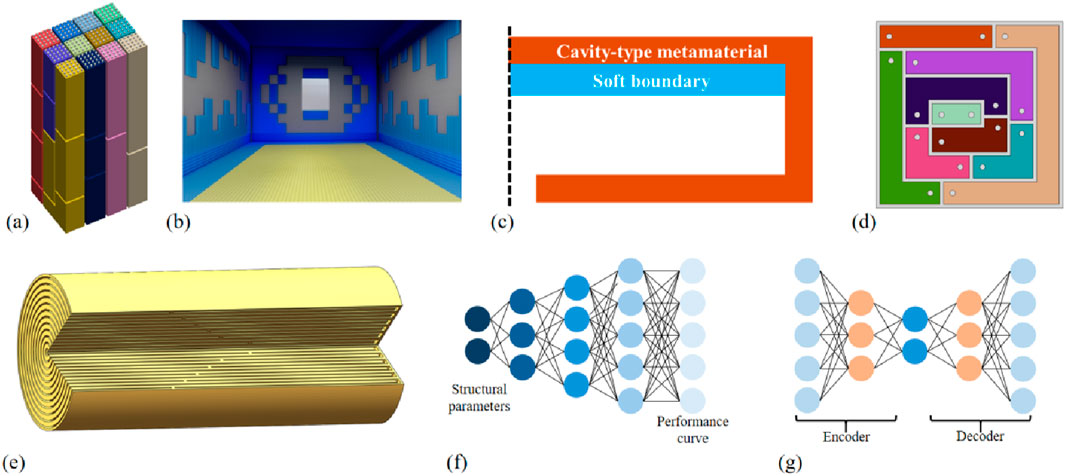

The excellent properties of subwavelength metamaterials make them widely applicable in wave manipulation (Ma et al., 2021; Ma et al., 2022a). Among them, sound-absorbing metamaterials can be divided into three categories according to different structural design methods. The first type is the membrane-type sound-absorbing metamaterials. In 2012, Mei et al. proposed a membrane-type dark acoustic sound absorption metamaterial, which can achieve low-frequency broadband super sound absorption, and the thickness is about three orders of magnitude lower than the operating wavelength (Mei et al., 2012). In 2014, Ma et al. proposed an impedance-matched membrane-type metamaterial, achieving adjustable perfect absorption by tuning the back cavity thickness. The second type is the cavity-type sound-absorbing metamaterials (Ma et al., 2014). In 2014, Cai et al. bent and coiled the sound damping tube with a quarter wavelength so that the sound wave was forced to pass through the gyratory structure, thereby reducing the reflection, and finally achieved more than 90% of the sound absorption effect at 400 Hz (Cai et al., 2014). In 2017, Yang et al. designed a folding broadband sound absorption metamaterial based on the Fabry-Pérot (F-P) cavity, with a thickness of 10.36 cm, which can achieve continuous and perfect sound absorption in the 400–3,000 Hz range. The third type is the porous sound absorption metamaterial (Yang et al., 2017). In 2015, Yang et al. divided porous materials into periodic arrangements with rigid partitions, enhancing low-frequency sound absorption performance (Yang et al., 2015). Although the membrane-type metamaterial achieves good low-frequency sound absorption performance in the size of deep sub-wavelength, its surface tension is difficult to control, which is challenging to meet the actual engineering application. At the same time, the working frequency band of porous sound absorption metamaterial is high, which makes it challenging to solve the contradiction between metamaterial thickness and low-frequency sound absorption. Therefore, we often use cavity-type sound absorption metamaterial in practical engineering applications.

The local resonance mechanism limits the unit’s sound absorption bandwidth for the cavity-type sound-absorbing metamaterials. In 2019, Liu et al. proposed a low-frequency broadband ultra-thin sound absorption metamaterial with multi-order sound absorption characteristics, which can obtain multiple near-perfect absorption peaks at higher frequencies without changing the original absorption peaks and structure size. Its structural thickness is 60 mm, with a continuous near-perfect absorption spectrum in the 450–1,360 Hz (Figure 1a) (Liu et al., 2019). On this basis, by accurately balancing the parameters of each unit, the absorption bandwidth of the subwavelength metamaterial is significantly expanded, which has great engineering application potential. At present, the first anechoic chamber has been constructed based on this study (Figure 1b). In order to further improve the low-frequency broadband sound absorption capacity of cavity-type sound-absorbing metamaterials, in 2021 and 2022, Sheng (Mak et al., 2021) and Ma et al. (2022b) proposed to improve their low-frequency sound absorption capability by opening small holes in the wall and using soft material to build a soft sound boundary, respectively. The method of using soft material to build a soft sound boundary does not need to increase the overall size of the original sound absorption unit. The preparation process is more straightforward and more suitable for rapid preparation. It is expected to improve the low-frequency sound absorption amplitude of cavity-type structures in practical engineering applications (Figure 1c). Simultaneously, the thickness dimension of cavity-type sound-absorbing metamaterials determines the lower limit of sound absorption frequency. It is still difficult to apply if it absorbs low-frequency sound waves in a limited-sized space. For this reason, in 2023, Ma et al. introduced an ultra-thin metasurface design method based on phase-coherent cancellation. Reflection and scattering were suppressed by redistributing the thickness dimension to the planar layer and leveraging phase offsets between weakly absorbing units, thereby enhancing broadband absorption (Ma et al., 2023a). The impedance tube sample test results show that the average sound absorption coefficient in the 600–1,300 Hz frequency band is 0.8, and the thickness is only 23 mm (Figure 1d). A 1.5 m × 1.5 m large-scale sample was fabricated to validate sound absorption under irregular incidence. The reverberation chamber test results show that the sound absorption coefficient in the 600–1,200 Hz range exceeds 0.85, which is conducive to engineering applications.

Figure 1. Research on sound-absorbing metamaterials and application. (a) Low-frequency broadband ultra-thin sound absorption metamaterial. (b) Anechoic chamber based on absorption metamaterial. (c) Soft sound boundary method based on soft material. (d) Ultra-thin metasurface based on phase-coherent cancellation. (e) Ceramic-containing high-temperature resistant large-size ultra-thin shell sound absorption metamaterial. (f) Schematic of a fully connected neural network. (g) Schematic of a autoencoder neural network.

On the other hand, its sound absorption performance can still be maintained under oblique or irregular incidence, indicating that the near-field effect can be ignored. In the same year, in order to make the proposed superstructure easy to realize engineering applications, Ma et al. used a ceramic-containing high-temperature resistant material, and a 3D printing process with a special preheating-preservation-cooling cyclic heat treatment was accordingly developed (Ma et al., 2023b). Through the joint development of materials and processes, the high-precision preparation of large-size and ultra-thin shell structures is realized (Figure 1e). This absorber comprehensively utilizes the advantages of porous material, slit-type absorber, F-P resonant unit, and embedded Helmholtz resonant structure, and the average sound absorption coefficient above 50 Hz reaches 0.8, which has potential application value in engineering fields. In addition, shifting the sound absorption frequency band to a low frequency can be achieved by increasing the volume of the cavity, but this will increase the thickness of the sound absorption structure, which still needs to be weighed in practical engineering applications.

At the same time, in practical engineering applications, sound absorption structures are often harmed by noise and impact energy, which requires them to have good mechanical characteristics to resist external loads and make them ineffective, so the multifunctional materials that integrate noise absorption, high stiffness are increasingly sought after for all-in-one applications. From 2023 to 2025, Li et al. focused on multifunctional metamaterials’ innovative design and performance optimization. They broke through the trade-off limit between acoustic absorption and mechanical properties of traditional materials through decoupling design (Li et al., 2023), bionic design (Li et al., 2024a), and interwoven biphasic design (Li et al., 2025), respectively, providing a design paradigm for lightweight and multifunctional materials for transportation, aerospace, and other fields.

A mature sound-absorbing metamaterial often undergoes multiple iterations of “modeling-simulation-experiment”, which requires a lot of time, computing power and labor costs. Fortunately, the rapid development of machine learning techniques has provided completely new solutions for the on-demand design of sound-absorbing metamaterials. On the one hand, the trained neural network (Figure 1f) can discover the complex and non-intuitive nonlinear relationship between structural geometric parameters and their performance response from the training samples, thus replacing the time-consuming numerical simulation process in the design process of traditional methods. Zheng et al. realized the on-demand design of sound-absorbing metamaterial based on Gauss-Bayesian model in machine learning. Specifically, the complex mapping relationship from structural parameters to sound absorption performance is constructed by training Gauss-Bayesian model instead of time-consuming simulation process. Finally, only 37 evaluations are used to achieve the goal of low frequency sound absorption coefficient ≥0.9 (Zheng et al., 2020). Kumar et al. proposed a feedforward nerual network design method based on machine learning. By adjusting parameters for two different sound absorption metamaterials and adopting artificial neural network (ANN), k-Nearest Neighbor (kNN) and radial basis function neural network (RBFN) respectively achieve fast prediction of model performance, and ANN has the highest prediction accuracy (Kumar et al., 2023). Donda et al. used a two-dimensional CNN network structure to achieve accurate prediction of sound-absorbing metamaterial performance in milliseconds, which was 4 orders of magnitude faster than that of traditional simulation (Donda et al., 2021).

On the other hand, machine learning technology can also be used to achieve a direct mapping from the target performance to structural parameters, which further improves the design efficiency compared with the iterative optimization process. Peng et al. proposed a design method of low-frequency sound absorption metamaterial based on autoencoder-like neural network (ALNN) to solve the control problem of low-frequency noise. The ALNN model is composed of a forward network (decoder part in Figure 1g) and a reverse network (encoder part in Figure 1g), which can realize the accurate prediction of the sound absorption coefficient curve according to the structural parameters and the non-iterative customized design of the structural parameters according to the target sound absorption coefficient curve respectively. Experiments show that the proposed method can design near-perfect sound-absorbing metamaterials in the low frequency range of 50–100 Hz. The sound absorption range of a single cavity is very limited, which is difficult to meet the practical needs of engineering applications (Peng et al., 2025). Furthermore, Liang et al. proposed a 14-cavity coupled sound absorption metamaterial design method based on metaheuristic-enhanced autoencoder network (MEAN) for low-frequency and wideband noise control. A series of methods, such as serialization of structural parameters, staged training and heterogeneous loss functions, optimize the convergence effect of the neural network, and achieve a highly customized design for the sound absorption coefficient in the range of 500–1500 Hz (Liang et al., 2025).

To sum up, the sound-absorbing metamaterial breaks through the thickness limit of a quarter wavelength of traditional porous materials. It achieves near-perfect sound absorption performance at low frequency under ultra-thin conditions, combines with machine learning techniques, the design efficiency can be greatly improved. In order to promote the application of acoustic metamaterials in the field of noise reduction, it is necessary to further develop the advanced manufacturing technology of acoustic metamaterials, solve the problems of large-scale, batch, low-cost, and high-efficiency manufacturing, and strengthen the research on the design methods of multifunctional integrated acoustic metamaterials such as sound absorption, sound insulation, and load bearing, to better meet the everyday needs of the new generation of equipment development for advanced multifunctional material technology.

2 Sound insulation

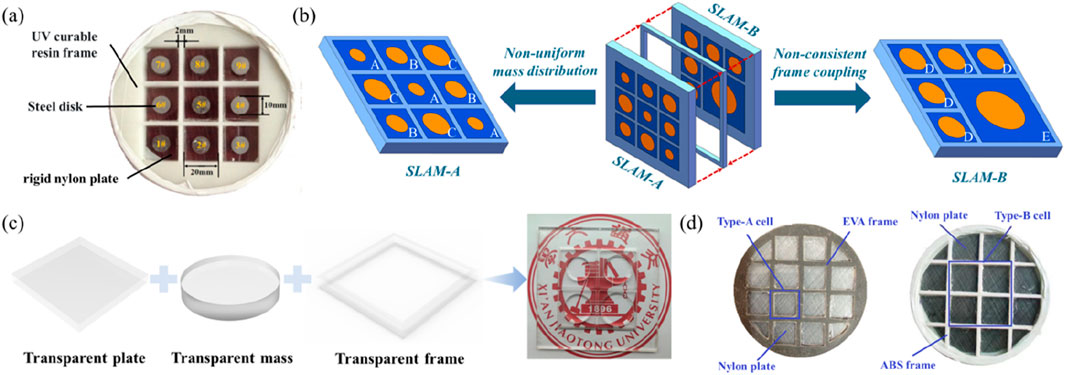

At the beginning of this century, Liu et al. proposed a locally resonant phononic crystal whose lattice constant is smaller than the relevant wavelength by two orders of magnitude yet can exhibit spectral bandgaps, breaking the constraint of the mass law (Liu et al., 2000). Since then, artificially designed acoustic metamaterials for sound insulation have attracted extensive attention in the academic community. Acoustic metamaterials can be classified into two categories based on their structural configurations. One category is the membrane/plate-type acoustic metamaterials composed of frame-membrane/plate-mass structures, and the other is the periodic thin-plate phononic crystals constructed by attaching multiple identical masses to a large thin plate substrate with specific periodicity. The former was initially proposed by Yang et al., in 2008. The specific structural configuration involves attaching a small mass to a membrane with fixed boundaries, which is referred to as membrane-type acoustic metamaterials. It can achieve total reflection of acoustic waves between two intrinsic modes, minimizing sound transmission and breaking the constraint of the mass law (Yang et al., 2008).

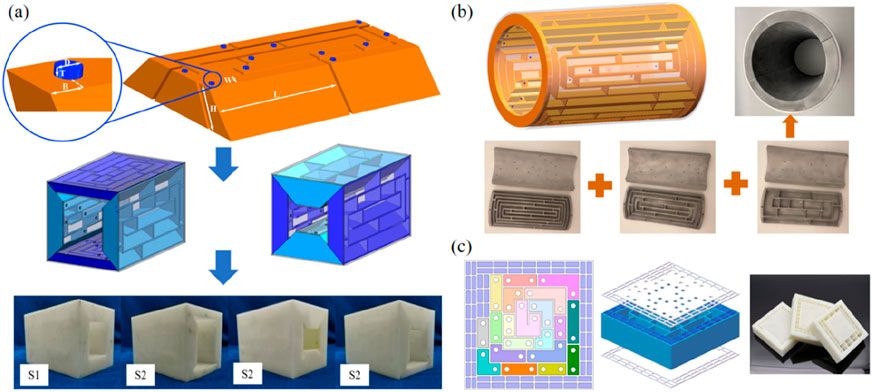

The operating bandwidth can be effectively broadened by employing a parallel coupling design with in-plane gradient parameters (Naify et al., 2011) and a series lamination design in the thickness direction (Yang et al., 2010). In these two design methods, the parallel coupling design with in-plane gradient parameters will attenuate the sound insulation peak to a certain extent. In contrast, the series lamination design in the thickness direction will increase the thickness dimension of the structure. Although membrane-type acoustic metamaterials can achieve noise attenuation effects, their stability and durability are poor since membranes are prone to relaxation and aging, and membranes’ tension is difficult to control precisely. To address this, Ma et al. developed membrane-type acoustic metamaterials into plate-type structures by increasing the thickness of the membrane to reduce dependence on tension, significantly improving their engineering applicability, and achieving low-frequency broadband sound insulation effect through the synergetic coupling effects of multiple units (Figure 2a) (Ma et al., 2017a). Building on this, Li et al. achieved ultra-strong sound insulation across a broadband range with a thickness of 25 mm via the joint utilization of parallel coupling design with in-plane gradient parameters and series lamination design in the thickness direction (Figure 2b) (Li et al., 2024b). Tang et al. achieved broadband sound insulation and vibration reduction while maintaining light transmittance by adopting a parallel coupling design with in-plane gradient parameters and simultaneously compounding multiple pure transparent materials. The structure exhibits a thickness of less than 6 mm and a surface density of less than 6 kg/m2 (Figure 1c) (Ta et al., 2024). Additionally, Ma et al. adopted flexible frames to overcome the issues of excessive structural stiffness and overly high operating frequencies in low-frequency applications for thin-plate structures (Ma et al., 2017b). They transformed the lumped coupling resonance effect’s negative impact into a positive one and achieved an excellent low-frequency broadband sound insulation effect (Figure 2d).

Figure 2. Research on sound insulation metamaterials and application: (a) Synergetic coupling plate-type acoustic metamaterials. (b) Laminated acoustic metamaterials for low-frequency broadband ultra-strong sound insulation. (c) Transparent-sound insulation-vibration reduction multifunctional integrated acoustic metamaterials. (d) Plate-type acoustic metamaterials with positive lumped coupling resonant.

For periodic thin-plate phononic crystals, they can generate a high-amplitude sound insulation peak in the low-frequency range but exhibit poor sound insulation performance in mid-to-high frequency ranges (Xiao et al., 2021). Due to their inherent structural limitations, broadening the operating bandwidth cannot be achieved through parallel coupling of in-plane gradient parameters. To address this, the operating bandwidth can be broadened by series-stacking two or more layers of periodic thin-plate phononic crystals with different structural sizes. However, this method will lead to the problem of enormous thickness dimensions. Additionally, introducing porous materials between two layers of such phononic crystals can effectively improve sound insulation performance in diffuse fields (Wang et al., 2023a).

It is worth mentioning that the introduction of machine learning techniques in the design process of sound insulation acoustic metamaterials can quickly and accurately design the required acoustic metamaterials. For example, Song et al. proposed a deep learning-based inverse design method for the topology and design parameters of laminated plate-type acoustic metamaterials, which can successfully and efficiently design laminated plate-type acoustic metamaterials meeting specific objectives (Song et al., 2024). The development of acoustic metamaterials for sound insulation still focuses on three aspects: lightweight and thin structure, low-frequency broadband performance, and engineering applications. In addition, integrating multiple functions is also a development direction that should be considered in the future, such as integrating sound insulation and load-bearing functions, sound insulation and ventilation functions, sound insulation and vibration reduction functions, etc.

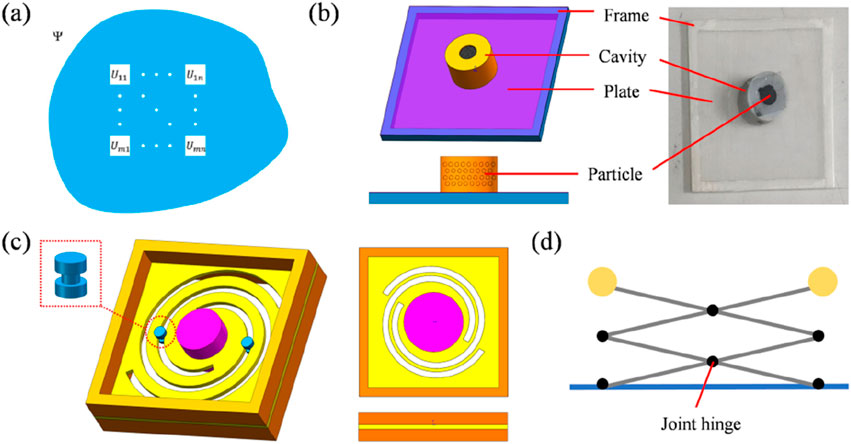

3 Vibration absorption

Based on their working mechanisms, vibration-absorbing metamaterials can be classified into Bragg-type and locally resonant-type. Among them, since the bandgap position and width of local resonance metamaterials are mainly determined by the local resonance characteristics of the scatterers and are independent of the arrangement of the scatterers, it dramatically enhances the potential of such structures for practical engineering applications. From the perspective of typical structural design, current technologies mainly fall into two categories: membrane/plate-type metamaterials and metamaterial inclusions. The earliest studies focused on membrane-type metamaterials, where membranes act as elastic elements to form vibration-absorbing devices. By adding ultra-light thin-membrane local resonance units with a mass of less than 1%, low-frequency vibration absorption of the target object was achieved, which has practical significance for lightweight engineering applications. In 2015, Nouh et al. developed a finite element model to predict various membrane-type metamaterial configurations modal and frequency responses (Nouh et al., 2015). They employed the Floquet-Bloch method to demonstrate metamaterial plates’ excellent low-frequency vibration attenuation performance. Considering that the resonant frequency in such structures is susceptible to membrane tension, Ma et al. increased the membrane thickness and proposed a rigid membrane-type metamaterial to eliminate the dependence on tension, thereby bridging the membrane-type and plate-type metamaterials (Ma et al., 2017b). Building on this concept, they further introduced the multi-unit cooperative weak coupling mechanism (Wang et al., 2023b) and the multi-scale synergistic broadband coupling mechanism (Wang et al., 2024a), which exploit the coupling between units (Figure 3a) and between structures and materials within a unit (Figure 3b), respectively, to achieve low-frequency and broadband vibration attenuation. However, it is important to note that these membrane/plate-type metamaterials generally employ viscoelastic non-metallic materials to ensure elasticity, which limits their suitability under complex engineering conditions. To address this limitation, in 2024, Wang et al. proposed a pure-metal metamaterial, which opens a bending wave bandgap in the low-frequency range by introducing a double-helix slit structure with low stiffness and high compactness into a metallic plate (Wang et al., 2024b). Additionally, they achieved bandgap broadband tunability through a continuous stiffness gradient design (Figure 3c). The second category of locally resonant metamaterials is the inclusion type, where resonant inclusions are embedded in the host structure. These inclusions interact with wave propagation via resonance coupling to generate multiple bandgaps. In 2020, Favier et al. performed numerical and parametric analyses on the homogenized dynamic properties of bi-material and tri-material elastic inclusions (Favier et al., 2020). An analysis of existing research reveals that current vibration-absorbing metamaterials are constrained by the intrinsic properties of the materials used, making them difficult to apply in complex and harsh environments. Furthermore, as structural complexity increases, the design of metamaterials becomes significantly more challenging. To address this issue and improve the efficiency of structural design, researchers have further introduced machine learning into metamaterial design. In 2024, Zhang et al. employed fully connected neural networks and convolutional neural networks to establish a mapping between the geometric parameters of metamaterials and their band structures, enabling the inverse design of high-performance metamaterials (Zhang et al., 2024). However, this approach remains essentially a forward prediction method and struggles to resolve the underdetermined problem where the input parameters number is smaller than that of the output parameters.

Figure 3. Research on vibration insulation metamaterials and application: (a) Multi-unit synergetic coupling vibration absorption; (b) Multi-scale collaborative wideband vibration absorption; (c) Pure metal low-frequency broadband vibration absorption; (d) Inertial amplification of low-frequency vibration absorption.

Notably, the most significant advantage of vibration-absorbing metamaterials in solving engineering problems lies in their unique subwavelength characteristics, which can suppress the vibration capacity of large wavelengths and low frequencies under lightweight conditions. Therefore, the frequency bandwidth and frequency range are important technical indicators. Currently, three primary broadband metamaterial design methods are multi-frequency resonant locally resonant unit design, bandgap mechanism coupling structural design, and active tunable design. Regarding multi-frequency resonant locally resonant unit design, research mainly focuses on the mass components of the metamaterials. The number and width of bandgaps can be increased through multiple combinations of resonators and under strong coupling effects. In 2023, Althamer et al. generated multiple bandgap intervals by constructing a multi-degree-of-freedom local resonant system (Althamer, 2023). The frequency response was accurately simulated based on the finite element calculation method of the Timoshenko beam theory. However, the difficulty of this method lies in the multi-layered structural design, which often results in complex composite structures, thereby increasing the design difficulty and fabrication complexity. Considering that locally resonant bandgaps gradually transform into Bragg bandgaps as they shift to higher frequencies, appropriate adjustment of metamaterial parameters can realize the coexistence or even coupling of the two types of bandgaps, generating ultra-broadband coupled bandgaps. In 2017, Krushynska et al. conducted a theoretical analysis of the coupling effect of two mechanism bandgaps in single-phase elastic metamaterials (Krushynska et al., 2017). The research indicated that when bandgap coupling occurs, the Bragg bandgap coincides with the resonance mode of the metamaterial matrix, which can generate a broad and stable bandgap interval. The third broadband design approach is active tunable design, primarily focusing on using innovative materials, such as piezoelectric materials, electromagnetic materials, dielectric/electrorheological elastomers, shape memory alloys, and optical field tuning. By incorporating multi-field coupled media into the design of metamaterials, it is possible to dynamically adjust the bandgaps of the structures by applying external bias fields that modulate material properties. It enables functionalities such as bandgap switching (Sun and Wang, 2022), tuning (Pierce et al., 2020), and elastic wave manipulation (Li et al., 2019); alternatively, the geometric configuration can be changed through mechanical methods (prestress control or direct load application) to realize mechanically reconfigurable metamaterials. In 2016, Langfeldt et al. controlled the air volume between the membrane and the frame in the double-layer thin-membrane metamaterial to change the membrane’s prestress and geometric stiffness, thereby adjusting the dissipation interval (Langfeldt et al., 2016). In addition, to ensure that the bandgap interval of vibration-absorbing metamaterials is as low as possible, extensive research has been conducted on the Inertial Amplification (IA) mechanism. In 2023, Sun et al. proposed a beam-shaped metamaterial with an X-shaped inertial amplification mechanism (Sun et al., 2023). Meanwhile, the coupling effect of transverse and longitudinal waves exists in the structure, which induces the emergence of a new bandgap interval (Figure 3d). In conclusion, for the design of metamaterials, it is essential to broaden the vibration absorption bandwidth further, and lower the operating frequency range, particularly in achieving complete bandgaps at low frequencies.

4 Vibration isolation

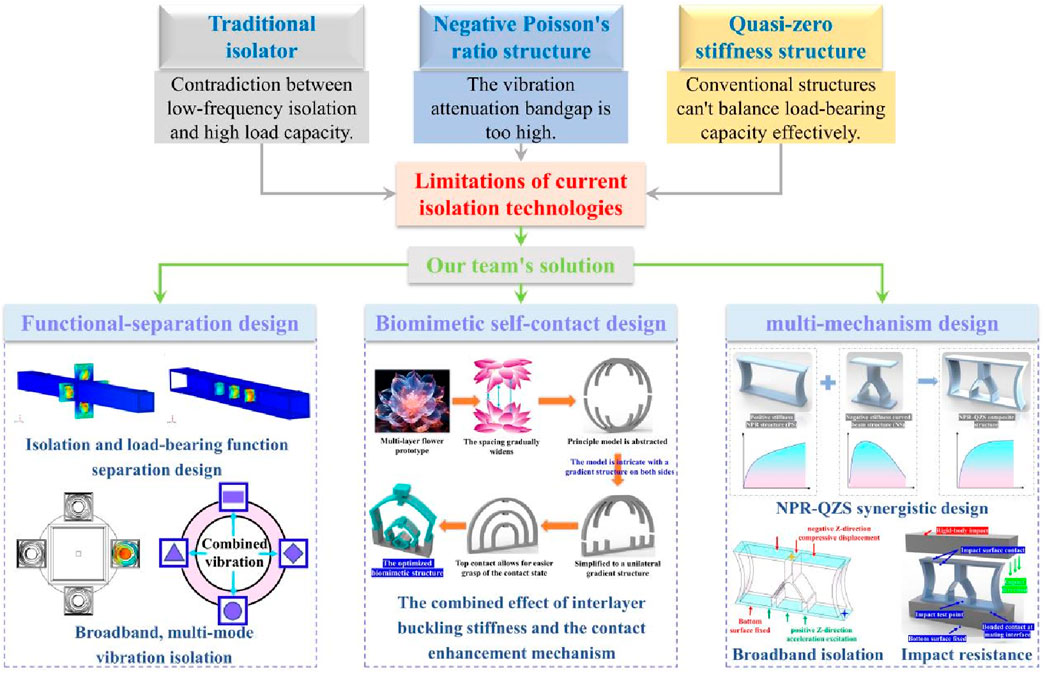

In practical vibration isolation applications for equipment, isolation devices are required not only to suppress vibrations effectively but also to possess sufficient load-bearing capacity to support the weight of the equipment itself. However, existing vibration isolation technologies struggle to integrate load-bearing and isolation capabilities. Figure 4 illustrates the current issues with vibration isolation structures and corresponding solution approaches. First, traditional vibration isolation techniques rely on soft isolators to achieve low-frequency isolation. However, overly compliant structures can not often support heavy loads, limiting their applicability in high-load equipment (Lee, 2007). Second, although vibration isolation metamaterials can enhance isolation performance to some extent, the bandgaps of Negative Poisson’s Ratio (NPR) structures generally fall within the kilohertz to tens-of-kilohertz range, making them ineffective for attenuating low-frequency vibrations (Lakes, 1987; Hu et al., 2019; Yu et al., 2018). In addition, composite Quasi-Zero Stiffness (QZS) structures achieve quasi-zero stiffness by combining positive and negative stiffness elements. However, such configurations are usually bulky, space-consuming, and challenging to manufacture and assemble (Yu et al., 2024; Jing et al., 2022). Existing compliant QZS structures are mostly single-layered and struggle to balance low-frequency isolation and load-bearing capacity (Zhang et al., 2021; Zheng et al., 2023; Chai et al., 2022).

To address the limitations of existing vibration isolation structural design strategies, elastic metamaterials are selected as the research platform, fully utilizing their advantages in elastic wave control and mechanical deformation to improve the shortcomings of current vibration isolation structures in terms of low-frequency isolation performance, vibration attenuation bandwidth, vibration control modes, and load-bearing capacity. First, a function-separated design scheme was proposed for vibration isolation structures based on the “replace isolation with absorption” concept. The vibration isolation and load-bearing functions are decoupled by attaching vibration-absorbing metamaterial units to the supporting steel column, thereby enhancing the system’s overall performance. Periodic vibration-absorbing units, gradient-parameter vibration-absorbing units, and multi-polarization-mode vibration-absorbing units are employed to achieve enhanced vibration attenuation, wide-frequency-band absorption, and multi-polarization mode absorption. Next, a self-contact superposition complementary multi-layer QZS vibration isolation device design was proposed to further improve vibration attenuation efficiency and working bandwidth. By analogizing the special multi-layer structure of plant petals and utilizing the complementary effect of interlayer buckling stiffness and the contact enhancement mechanism, multiple QZS platform regions with distinct gradient differences can be obtained, achieving superior low-frequency isolation performance and higher load-bearing capacity. Furthermore, to address the issues of low load-bearing capacity of existing QZS structures and insufficient low-frequency attenuation capability of NPR structures, an NPR-QZS composite device design was proposed. This device effectively combines NPR structures’ excellent load-bearing and shock resistance capabilities with the low-frequency isolation characteristics of QZS structures, enabling a multifunctional integration of vibration isolation, load-bearing, and shock resistance. Compared with traditional single-vibration isolation structures, the composite structure can meet low-frequency isolation demands and high load-bearing requirements in limited spaces while providing enhanced shock energy absorption capabilities. These research findings provide new solutions for equipment vibration control and high-performance vibration isolation structure design and have significant theoretical and engineering implications for the industrial application of vibration isolation metamaterials.

Looking ahead to the future development of vibration isolation structures, it is difficult for single-mechanism designs to meet the practical demands of compact size, high load-bearing capacity, and strong isolation performance simultaneously. Composite structures based on multi-mechanism integration offer a promising solution by enabling the effective combination of distinct functional characteristics from different mechanisms. Meanwhile, the use of intelligent algorithms such as machine learning can significantly accelerate the design process of metamaterials, enabling optimal parameter selection over a broader design space with faster speed and higher efficiency. This includes, for example, the design of wider QZS platforms and flexible multi-stage platforms. Efficient and customized design driven by machine learning is also one of the key directions for the future development of vibration isolation metamaterials. Additionally, the widespread use of soft materials in current isolation systems significantly limits their durability and environmental adaptability. Future research should focus on exploring the large-deformation behavior of thin-walled metal structures, with the aim of replacing soft materials with metals. This transition must also account for the potential increase in isolation frequency caused by the use of stiffer materials. Ultimately, the goal is to realize a highly reliable, durable, and compact vibration isolation structure that provides low-frequency, broadband isolation along with robust load-bearing capacity—laying the foundation for practical and long-term engineering applications.

5 Noise reduction with ventilation

The traditional ventilation noise reduction technology is limited by the contradiction between ventilation efficiency and noise reduction performance for a long time. However, the emergence of acoustic metamaterials provides a new path to break through this bottleneck. So far, several structures based on acoustic metamaterials have been proposed to address the challenge of sound attenuation while maintaining air channels. In 2019, Wang et al. proposed a perforated constrained plate-shaped sound insulation metamaterial to realize high-efficiency sound insulation under ventilation conditions through the interference between the hole area and the plate area wave field (Wang et al., 2019). In addition, by arranging sound absorption structures around the central ventilation holes, ventilation effects can be achieved while maintaining a specific sound absorption effect. In the same year, Ghaffarivardavagh et al. proposed a meta-open acoustic metamaterial muffler based on Fano-like interference with a central open area and a peripheral spiral structure area and achieving 94% acoustic energy attenuation at 460 Hz with nearly 60% of the open area (Ghaffarivardavagh et al., 2019). In 2020, Kumar et al. designed a ventilation-adjustable acoustic metamaterial by combining a square central ventilation hole and a Helmholtz cavity with two square necks, achieving a sound absorption coefficient of 0.96 and a transmission loss of 18 dB at 1,000 Hz while maintaining a ventilation area of 45% (Kumar et al., 2020). In 2021, Shao et al. constructed a ventilation metamaterial sound absorber by attaching three folded F-P resonators as adhesive components to the airflow channel. Using a parallel design, the sound absorption rate exceeded 90% in the 307–341 Hz frequency band while maintaining good ventilation performance (Shao et al., 2021). Generally speaking, it is possible to parallel multiple basic units with different working frequency bands to achieve broadband ventilation noise reduction. In 2020, Kumar et al. proposed a subwavelength labyrinth acoustic metamaterial by periodically arranging various labyrinth units with different configurations in a hexagonal array, achieving ultra-wideband sound absorption at 400–1,400 Hz and featuring air circulation characteristics (Kumar and Lee, 2020). In 2021, Guan et al. designed a low-frequency open sound insulation barrier with two reverse Helmholtz resonators (Guan et al., 2021). Wideband sound insulation can be achieved through multi-layer structures with a fractional bandwidth of approximately 0.19.

To address the challenges of low-frequency broadband noise reduction and improving ventilation performance under structural size constraints, a breakthrough has been achieved through innovation in spatially folded acoustic metamaterials. In 2024, Liu et al. proposed a metasurface sound absorption coating (Figure 5a). They used spatial folding design, shifted the thickness needed for low-frequency sound absorption to the longitudinal direction of the pipe, and formed a structure that resembles a Helmholtz resonant cavity. It achieved a ventilation rate of 55.5% with a skinny thickness of 10 mm and demonstrated excellent sound absorption performance in the 400–1,200 Hz frequency band (Liu et al., 2024). Under the premise of ensuring ventilation efficiency, this design extends the bandwidth to the range of 200–5,000 Hz by employing gradient thickness cavities. Specifically, shallow cavities enhance high-frequency performance, while deep cavities improve low-frequency characteristics. The peak transmission loss achieved is 54.6 dB. The design’s adaptability to pressure fluctuations was also validated in a liquid-filled pipeline system, providing a critical foundation for optimizing engineering parameters. For instance, increasing the depth of the cavity can strengthen low-frequency performance but may compress the high-frequency bandwidth. Meanwhile, adjusting the aperture size of the perforated plate allows for balancing the sound absorption frequency band with airflow resistance. Based on this, in 2025, Liu et al. continued the design concept and proposed a design scheme for an arc-shaped conformal metasurface underwater sound absorption coating (Figure 5b) (Liu et al., 2025). Through the optimization of elastic wall materials, the design of micro-perforated cover plates, and the integration of multi-stage sound absorption structures, an average transmission loss of 4.2 dB was achieved in the 600–1,040 Hz frequency band. The experimental value is better than the simulation by 3.3 dB. This scheme employs an integrated strategy utilizing multi-stage silencing units. Specifically, wide absorption units are designed to enhance low-frequency performance, whereas narrow units focus on expanding high-frequency capabilities. This approach preserves the integrity of the flow passage section and achieves a 37% extension in noise reduction bandwidth through the gradient combination of unit widths. Consequently, it successfully resolves the inherent contradiction between low-frequency silencing in thin-layer structures and the minimization of the flow passage cross-sectional area. In the same year, Wang et al. introduced an ultrathin spatially shifted metasurface element barrier (Figure 5c) (Wang et al., 2025a). Leveraging the principle of acoustic siphon, this barrier achieved a harmonious integration of low thickness, broadband sound insulation, and high ventilation efficiency. The key to its success lies in an innovative design approach emphasizing sound absorption over traditional isolation methods, thereby revolutionizing the balance between acoustic performance and air permeability. The non-ventilated area of this structure is equipped with a folded labyrinth-type resonant sound absorption unit with a gradient length. By utilizing the Helmholtz resonance principle, the sound absorption unit can absorb the surrounding sound energy and dissipate it through friction. Its absorption radius can cover the ventilated area, effectively solving the problem of sound leakage caused by sound wave diffraction. Large-aperture units can enhance high-frequency sound insulation by optimizing the ratio of aperture to depth in the Helmholtz resonant cavity, whereas small-aperture units compensate for low-frequency performance. Compared to traditional designs, this approach doubles the ventilation area and extends the effective working frequency band by 60%. Its parametric model was verified through COMSOL simulation and 3D printing experiments. Meanwhile, the ventilation performance was measured by the ratio of wind speed to air volume in the experiment. The results show that this structure can maintain efficient ventilation when reducing low-frequency broadband noise. Compared with other ventilation and noise reduction metamaterials, this structure has obvious thickness, ventilation area, and working frequency band advantages. It has broad application prospects in the fields of construction and industry. The research series demonstrates that strategic gradient adjustments of structural parameters (e.g., depth/aperture variations), material-fluid coupling optimizations (e.g., elastic wall impedance matching), and multi-scale unit configurations collectively enable an optimal balance between competing demands for ventilation efficiency and noise reduction bandwidth. This systematic approach facilitates the development of tailored solutions featuring high airflow capacity and broadband acoustic performance across diverse engineering applications. Overall, although ventilation acoustic metamaterials have made continuous progress in low frequency, miniaturization, and flow efficiency, several challenges still need to be overcome urgently. For example, while ensuring structural compactness, further extending effective noise reduction to below 100 Hz still requires the support of a new resonant principle. Furthermore, the current designs are mostly based on laboratory prototypes with limited scalability. Engineering implementation issues such as manufacturing costs and environmental durability remain key obstacles to subsequent development. Meanwhile, how to efficiently integrate multifunctional features such as ventilation, sound insulation, structural strength, and thermal management in a single system will also be a key research direction in the future.

Figure 5. Research on noise reduction with ventilation by acoustic metamaterials. (a) Metasurface sound absorption coating. (b) Arc-shaped conformal metasurface underwater sound absorption coating. (c) Ultrathin spatially shifted metasurface element barrier.

6 Acoustic detection and communication

In sonar detection, underwater sensing and imaging are the core functions that are critical for establishing underwater wireless acoustic communication and exploring and developing marine resources. The space sampling law constrains traditional sonar, and the spatial resolution of acoustic imaging is limited by the number of sensors and the array size. To achieve long-distance and high-precision detection, the system requires higher precision, more sensors, a larger array structure, and more complex processing algorithms. However, this also brings about greater latency, which has restricted the development of traditional sonar systems. The recent research on phononic crystals and sub-wavelength anisotropic acoustic metamaterials has provided new ideas for realizing acoustic detection. The acoustic sources sensing of phononic crystals is achieved based on the defect bandgap design. In 2003, Khelif et al. extracted a part from a perfect crystal and investigated localized defect modes in a complete acoustic bandgap in a two-dimensional lattice of steel cylinders immersed in water, which can enhance the acoustic waves propagating along the defect line within the stopband (Khelif et al., 2003). Based on this phenomenon, in 2018, Jiang et al. designed a phononic crystal resonator device with linear defects capable of generating enhanced directional-sensitive responses and achieving enhanced directional acoustic sensing (Jiang et al., 2018). Although defect bandgap phononic crystals can achieve high signal-to-noise ratio sensing of acoustic signals, their frequencies and directions are relatively limited and unsuitable for identifying and locating multiple acoustic sources over a wide range.

The acoustic detection of anisotropic metamaterials is achieved based on the anisotropic wave modulation of signals in different directions. In 2012, Lemoult et al. designed an anisotropic metamaterial based on resonant unit cells arranged at the deep sub-wavelength scale. They achieved acoustic wave modulation by adjusting the local structure of the unit cells (Lemoult et al., 2013). In 2014, Chen et al. designed an anisotropic metamaterial with a strong wave compression effect, which amplified the pressure field within the structure, thus breaking through the detection limit of traditional acoustic sensing devices and improving the signal-to-noise ratio of the system (Chen et al., 2014). All these studies have demonstrated the possibility of regulating and perceiving sound signals with different characteristics in different directions through the structure’s design.

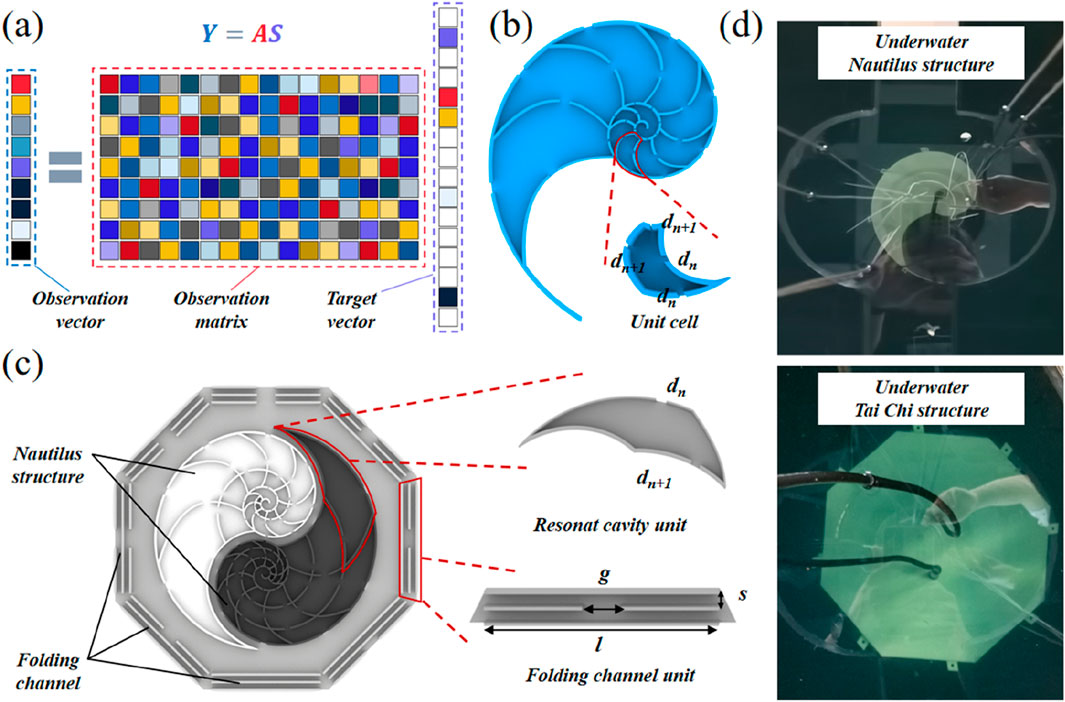

In recent years, the compressive sensing theory has gradually emerged and developed. It breaks through the Nyquist sampling law and can reconstruct high-dimensional signals with low-dimensional data, which is very well adapted to the sound source perception of anisotropic metamaterials. Based on the response results of the structure, the original target signal can be observed and reconstructed by constructing a suitable observation matrix (Figure 6a). Based on this, in 2015, Xie et al. designed a single-sensor multispeaker listening system using a Helmholtz resonator array (Xie et al., 2015). Compressive sensing technology can achieve audio signal multichannel separation through structural encoding and realize high-precision identification of multiple independent sound sources. In 2016, Zhu et al. achieved highly localized Mie resonance on a closed metasurface encapsulating a rigid core (Zhu et al., 2016). They realized sensitive deep sub-wavelength scale directional sensing based on enhancing the pressure field and azimuthal angle dependence. However, both of the above designs have a planar structure, which can only identify and locate sound sources within a single plane of the radial direction.

Figure 6. Research and design of several acoustic perception and detection metamaterials. (a) Compressive sensing algorithm. (b) The Nautilus metamaterial for sound source detection. (c) The Tai Chi metamaterial for sound source perception and localization. (d) Underwater Nautilus and Tai Chi metamaterial.

Subsequently, in 2019, Jiang et al. proposed a space-coiling anisotropic metamaterial with stochastic structural parameters (Jiang et al., 2019). Through the encoding of structural units, they achieved the identification and localization of sound sources on the radial plane. Further, they realized the imaging of sound sources on another target plane by stacking the structure. However, this structure fails to achieve omnidirectional sound source perception and detection, and the space-coiling structure does not possess a gain function. As a result, its resolution for nearby targets and weak sound sources is relatively poor. Meanwhile, considering that the existing acoustic detection systems are mainly used for underwater equipment and the wavelength of sound waves in water is relatively large, this also increases the structural size of the space-wound channels. Further consideration is needed to balance the structural size with the detection effect. Considering the interference of waves and viscous losses, the signal-to-noise ratio of space-wound metamaterials in underwater environments is worrying, and their application will be minimal. In 2020, Sun et al. designed a multi-layer metamaterial spherical shell with spatially disordered distribution and achieved spatial acoustic source perception and detection through compressive sensing (Sun et al., 2020). Integrating multi-layer pores and cavities provides excellent gain amplification, enabling higher resolution in distinguishing nearby targets and weak sound sources. However, the disorderly encoding inevitably leads to a low space utilization rate, and the modulation effect of the structure lacks targetedness. Meanwhile, in the signal processing process, these researchers have not fully utilized the various characteristics of sound signals, which limits the perception accuracy of the system.

Taking these into account, in 2023, Wang et al. proposed a multi-information fusion compressive sensing method (Wang et al., 2023c). Inspired by the structure of the nautilus shell, they designed the structural units in accordance with the equivalent medium theory, thereby constructing the Nautilus metamaterial (Figure 6b). The multi-information fusion compressive sensing method comprehensively analyzed various features such as the phase and amplitude of the sound signal, thereby improving the accuracy of sound source identification and location of the system. The design of the cavity structure unit enhances the response level and achieves higher precision and resolution. The above research only achieved the discrimination of the direction of the sound source, and the use of a single sensor limits the accuracy of sound source perception. In 2025, inspired by the Tai Chi pattern, Wang et al. further designed a Tai Chi acoustic metamaterial (Figure 6c) based on the Nautilus metamaterial (Wang et al., 2025b). Combining two different Nautilus metamaterials and the orthogonal channel structure led to better anisotropy. Using dual sensors further improved the accuracy and resolution of the compressive sensing sound source reconstruction and enabled the detection of the range of the sound source. It is worth mentioning that they further proposed Nautilus and Tai Chi metamaterials suitable for underwater environments by adjusting structural parameters and achieving underwater sound source identification and location (Wang et al., 2025c) (Figure 6d). This further proves the sound source detection ability of anisotropic metamaterials based on compressive sensing to work in underwater space, opening up a path for the design of new low-cost and high-precision sonar systems.

Although anisotropic metamaterials based on compressive sensing can achieve excellent sound source detection, their accuracy still needs to be improved. Firstly, the current detection of anisotropic structures only uses one or two sensors. Increasing the number of detection points appropriately can improve their accuracy without resulting in overly complex systems. Secondly, the accuracy of existing compressive sensing algorithms is limited by the richness of the observation matrix, and the detection range and resolution are also limited by the division of the grid. They have not yet achieved omnidirectional underwater detection. Therefore, it is imperative to balance their complexity and detection performance. Thirdly, the existing acoustic detection metamaterials have not been tested and applied in complex underwater environments. Considerations for underwater waves and static pressure are insufficient, and the selection of structural materials is also relatively limited. Last but not least, the structural forms of existing metamaterials are diverse but lack a systematic design system. The design goals for detection distance, resolution, and accuracy have not established standardized indicators, and the sonar systems and underwater equipment have insufficient correlation. In summary, future research directions and priorities will establish a standardized design scheme, adopt more reasonable structural forms and material compositions, match existing underwater equipment, and consider the actual complex underwater environment.

7 Summary and outlook

From the introduction of different directions mentioned above, it can be seen that the research on acoustics and elastic metamaterials has shifted from basic theoretical research to research driven by application requirements. In basic theoretical research, more attention is paid to the establishment of theoretical models, the revelation of physical and mechanical mechanisms, and the analogy of physical phenomena between different physical fields. In the research of application traction, more emphasis is placed on the implementation of functions and the improvement of performance, focusing on the combination with practical application scenarios. In addition, with the development of artificial intelligence, using artificial intelligence to empower structural design and design more intelligent devices and components has become a very important direction of development. Limited by the fact that this paper is an editorial, it is difficult to provide a detailed introduction to the relevant research progress. The main focus is on providing a brief overview based on the research conducted by the author’s group. For more related developments, readers are advised to pay attention to more professional review papers and textbooks.

Author contributions

FM: Conceptualization, Methodology, Project administration, Supervision, Writing – original draft, Writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author declares that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Althamer, S. (2023). Metamaterial beam with dual-action absorbers for tunable and multi-band vibration absorption. J. Intell. Mater. Syst. Struct. 34, 2257–2267. doi:10.1177/1045389x231164513

Cai, X., Guo, Q., Hu, G., and Yang, J. (2014). Ultrathin low-frequency sound absorbing panels based on coplanar spiral tubes or coplanar Helmholtz resonators. Appl. Phys. Lett. 105, 121901. doi:10.1063/1.4895617

Chai, Y., Jing, X., and Chao, X. (2022). X-shaped mechanism based enhanced tunable QZS property for passive vibration isolation. Int. J. Mech. Sci. 218, 107077. doi:10.1016/j.ijmecsci.2022.107077

Chen, Y., Liu, H., Reilly, M., Bae, H., and Yu, M. (2014). Enhanced acoustic sensing through wave compression and pressure amplification in anisotropic metamaterials. Nat. Commun. 5, 5247. doi:10.1038/ncomms6247

Donda, K., Zhu, Y., Merkel, A., Fan, S.-W., Cao, L., Wan, S., et al. (2021). Ultrathin acoustic absorbing metasurface based on deep learning approach. Smart Mater. Struct. 30, 085003. doi:10.1088/1361-665x/ac0675

Favier, E., Nemati, N., and Perrot, C. (2020). Two-component versus three-component metasolids. J. Acoust. Soc. Am. 148, 3065–3074. doi:10.1121/10.0002424

Ghaffarivardavagh, R., Nikolajczyk, J., Anderson, S., and Zhang, X. (2019). Ultra-open acoustic metamaterial silencer based on Fano-like interference. Phys. Rev. B 99, 024302. doi:10.1103/physrevb.99.024302

Guan, Y., Ge, Y., Sun, H., Yuan, S., and Liu, X. (2021). Low-frequency, open, sound-insulation barrier by two oppositely oriented Helmholtz resonators. Micromachines 12, 1544. doi:10.3390/mi12121544

Hu, L. L., Luo, Z. R., Zhang, Z. Y., Lian, M. K., and Huang, L. S. (2019). Mechanical property of re-entrant anti-trichiral honeycombs under large deformation. Compos. Pt. B-Eng. 163, 107–120. doi:10.1016/j.compositesb.2018.11.010

Jiang, T., He, Q., and Peng, Z.-K. (2018). Enhanced directional acoustic sensing with phononic crystal cavity resonance. Appl. Phys. Lett. 112, 261902. doi:10.1063/1.5024970

Jiang, T., He, Q., and Peng, Z.-K. (2019). Proposal for the realization of a single-detector acoustic camera using a space-coiling anisotropic metamaterial. Phys. Rev. Appl. 11, 034013. doi:10.1103/physrevapplied.11.034013

Jing, X., Chai, Y., Chao, X., and Bian, J. (2022). In-situ adjustable nonlinear passive stiffness using X-shaped mechanisms. Mech. Syst. Signal Proc. 170, 108267. doi:10.1016/j.ymssp.2021.108267

Khelif, A., Choujaa, A., Djafari-Rouhani, B., Wilm, M., Ballandras, S., and Laude, V. (2003). Trapping and guiding of acoustic waves by defect modes in a full-band-gap ultrasonic crystal. Phys. Rev. B 68, 214301. doi:10.1103/physrevb.68.214301

Krushynska, A. O., Miniaci, M., Bosia, F., and Pugno, N. M. (2017). Coupling local resonance with Bragg band gaps in single-phase mechanical metamaterials. Extreme Mech. Lett. 12, 30–36. doi:10.1016/j.eml.2016.10.004

Kumar, S., Jin, H., Lim, K. M., and Lee, H. P. (2023). Comparative analysis of machine learning algorithms on prediction of the sound absorption coefficient for reconfigurable acoustic meta-absorbers. Appl. Acoust. 212, 109603. doi:10.1016/j.apacoust.2023.109603

Kumar, S., and Lee, H. (2020). Labyrinthine acoustic metastructures enabling broadband sound absorption and ventilation. Appl. Phys. Lett. 116, 134103. doi:10.1063/5.0004520

Kumar, S., Xiang, T. B., and Lee, H. P. (2020). Ventilated acoustic metamaterial window panels for simultaneous noise shielding and air circulation. Appl. Acoust. 159, 107088. doi:10.1016/j.apacoust.2019.107088

Lakes, R. (1987). Foam structures with a negative Poisson's ratio. Science. 235, 1038–1040. doi:10.1126/science.235.4792.1038

Langfeldt, F., Riecken, J., Gleine, W., and von Estorff, O. (2016). A membrane-type acoustic metamaterial with adjustable acoustic properties. J. Sound. Vibr. 373, 1–18. doi:10.1016/j.jsv.2016.03.025

Lee, J. (2007). Free vibration analysis of cylindrical helical springs by the pseudospectral method. J. Sound. Vibr. 302, 185–196. doi:10.1016/j.jsv.2006.11.008

Lemoult, F., Kaina, N., Fink, M., and Lerosey, G. (2013). Wave propagation control at the deep subwavelength scale in metamaterials. Nat. Phys. 9, 55–60. doi:10.1038/nphys2480

Li, G., Wang, Y., and Wang, Y. (2019). Active control on switchable waveguide of elastic wave metamaterials with the 3D printing technology. Sci. Rep. 9, 16226. doi:10.1038/s41598-019-52705-5

Li, H., Tang, Z., Zuo, G., and Ma, F. (2024b). Laminated acoustic metamaterials for low-frequency broadband ultra-strong sound insulation. Thin-Walled Struct. 202, 112151. doi:10.1016/j.tws.2024.112151

Li, Z., Li, X., Wang, Z., and Zhai, W. (2023). Multifunctional sound-absorbing and mechanical metamaterials via a decoupled mechanism design approach. Mater. Horiz. 10, 75–87. doi:10.1039/d2mh00977c

Li, Z., Wang, X., Zeng, K., Guo, Z., Li, C., Yu, X., et al. (2024a). Unprecedented mechanical wave energy absorption observed in multifunctional bioinspired architected metamaterials. NPG Asia Mater. 16, 45. doi:10.1038/s41427-024-00565-5

Li, Z., Zeng, K., Guo, Z., Wang, Z., Yu, X., Li, X., et al. (2025). All-in-One: an interwoven dual-phase strategy for acousto-mechanical multifunctionality in microlattice metamaterials. Adv. Funct. Mater. 35, 2420207. doi:10.1002/adfm.202420207

Liang, Z., Liu, C., Liu, Y., Ma, Y., and Ma, F. (2025). Demand-driven inverse design and optimization for ultra-thin broadband sound-absorbing metamaterials based on metaheuristic-enhanced autoencoder network. Compos. Pt. B-Eng. 304, 112643. doi:10.1016/j.compositesb.2025.112643

Liu, C., Wu, J., Xu, C., and Ma, F. (2019). A thin low-frequency broadband metasurface with multi-order sound absorption. J. Phys. D. Appl. Phys. 52, 105302. doi:10.1088/1361-6463/aafaa3

Liu, Y., Cao, G., Liu, C., and Ma, F. (2025). Ultra-thin arc-shaped conformal metasurface coating for broadband noise reduction in underwater pipeline. Appl. Acoust. 228, 110314. doi:10.1016/j.apacoust.2024.110314

Liu, Y., Zhang, W., Cao, G., Zuo, G., Liu, C., and Ma, F. (2024). Ultra-thin ventilated metasurface pipeline coating for broadband noise reduction. Thin-Walled Struct. 200, 111916. doi:10.1016/j.tws.2024.111916

Liu, Z., Zhang, X., Mao, Y., Zhu, Y., Yang, Z., Chan, C., et al. (2000). Locally resonant sonic materials. Science 289, 1734–1736. doi:10.1126/science.289.5485.1734

Ma, F., Huang, M., and Wu, J. H. (2017a). Acoustic metamaterials with synergetic coupling. J. Appl. Phys. 122, 215102. doi:10.1063/1.5003276

Ma, F., Huang, M., and Wu, J. H. (2017b). Ultrathin lightweight plate-type acoustic metamaterials with positive lumped coupling resonant. J. Appl. Phys. 121, 015102. doi:10.1063/1.4972839

Ma, F., Huang, Z., Liu, C., and Wu, J. (2022a). Acoustic focusing and imaging via phononic crystal and acoustic metamaterials. J. Appl. Phys. 131, 011103. doi:10.1063/5.0074503

Ma, F., Liu, C., Li, Y., and Wu, J. (2023b). A thin-walled mesoscopic hybrid slit-resonator metamaterial absorber. Thin Wall. Struct. 193, 111226. doi:10.1016/j.tws.2023.111226

Ma, F., Wang, C., Du, Y., Zhu, Z., and Wu, J. (2022b). Enhancing of broadband sound absorption through soft matter. Mater. Horiz. 9, 653–662. doi:10.1039/d1mh01685g

Ma, F., Wang, C., Liu, C., and Wu, J. (2021). Structural designs, principles and applications of thin-walled membrane and plate type acoustic/elastic metamaterials. J. Appl. Phys. 129, 231103. doi:10.1063/5.0042132

Ma, F., Zhang, H., Wang, X., Liu, C., and Wu, J. (2023a). Ultrathin space-shift phase-coherent cancellation metasurface for broadband sound absorption. Small Meth. 7, 2300569. doi:10.1002/smtd.202300569

Ma, G., Yang, M., Xiao, S., Yang, Z., and Sheng, P. (2014). Acoustic metasurface with hybrid resonances. Nat. Mater. 13, 873–878. doi:10.1038/nmat3994

Mak, H., Zhang, X., Dong, Z., Miura, S., Iwata, T., and Sheng, P. (2021). Going beyond the causal limit in acoustic absorption. Phys. Rev. Appl. 16, 044062. doi:10.1103/physrevapplied.16.044062

Mei, J., Ma, G., Yang, M., Yang, Z., Wen, W., and Sheng, P. (2012). Dark acoustic metamaterials as super absorbers for low-frequency sound. Nat. Commun. 3, 756. doi:10.1038/ncomms1758

Naify, C. J., Chang, C. M., McKnight, G., Scheulen, F., and Nutt, S. (2011). Membrane-type metamaterials: transmission loss of multi-celled arrays. J. Appl. Phys. 109, 104902. doi:10.1063/1.3583656

Nouh, M., Aldraihem, O., and Baz, A. (2015). Wave propagation in metamaterial plates with periodic local resonances. J. Sound. Vibr. 341, 53–73. doi:10.1016/j.jsv.2014.12.030

Peng, X., Xie, X., Yang, W., Chen, M., Wang, Y., and Xu, L. (2025). Low frequency sound absorption metasurface optimization design method based on deep learning. Appl. Acoust. 231, 110446. doi:10.1016/j.apacoust.2024.110446

Pierce, C. D., Willey, C. L., Chen, V. W., Hardin, J. O., Berrigan, J. D., Juhl, A. T., et al. (2020). Adaptive elastic metastructures from magneto-active elastomers. Smart Mater. Struct. 29, 065004. doi:10.1088/1361-665x/ab80e4

Shao, C., Xiong, W., Long, H., Tao, J., Cheng, Y., and Liu, X. (2021). Ultra-sparse metamaterials absorber for broadband low-frequency sound with free ventilation. J. Acoust. Soc. Am. 150, 1044–1056. doi:10.1121/10.0005850

Song, C., Wang, X., Xu, S., Zhao, C., and Huang, Z. (2024). Inverse design of laminated plate-type acoustic metamaterials for sound insulation based on deep learning. Appl. Acoust. 218, 109906. doi:10.1016/j.apacoust.2024.109906

Sun, W., and Wang, Y. (2022). Active control on band gap properties and interface transmission of elastic waves in piezoelectric metamaterial beams. Appl. Math. Mech. 43, 14–25. doi:10.21656/1000-0887.420125

Sun, X., Jia, H., Zhang, Z., Yang, Y., Sun, Z., and Yang, J. (2020). Sound localization and separation in 3D space using a single microphone with a metamaterial enclosure. Adv. Sci. 7, 1902271. doi:10.1002/advs.201902271

Sun, Y., Zheng, H., and Lee, H. P. (2023). Beam-type metastructure with X-shape inertial amplification mechanisms for vibration suppression. Thin-Walled Struct. 189, 110893. doi:10.1016/j.tws.2023.110893

Tang, Z., Wang, X., Li, S., Li, H., Zhu, Z., and Ma, F. (2024). A transparent multifunctional integrated meta-window with excellent sound insulation and vibration reduction performance. Compos. Struct. 353, 118719. doi:10.1016/j.compstruct.2024.118719

Wang, L., Li, W., Huang, Z., Jiang, T., and Ma, F. (2023c). A Nautilus bionic multi-information fusion compressed-sensing acoustic imaging device. Cell Rep. Phys. Sci. 4, 101733. doi:10.1016/j.xcrp.2023.101733

Wang, L., Liu, Y., Du, P., Jiang, T., and Ma, F. (2025b). A Tai Chi acoustic metamaterial for low-dimensional joint compressive sensing and simultaneously azimuth-distance location. Mech. Syst. Signal Process. 224.112228. doi:10.1016/j.ymssp.2024.112228

Wang, L., Liu, Y., Du, P., and Ma, F. (2025c). Underwater far-field multi-directional compressive sensing metamaterial acoustic imaging device. J. Acoust. Soc. Am. 157, 4069–4084. doi:10.1121/10.0036829

Wang, S., Li, H., Liu, Y., Cao, G., Yang, Z., and Ma, F. (2025a). Ultra-thin metasurface meta-barrier for integrated ventilation and sound insulation. Appl. Acoust. 231, 110486. doi:10.1016/j.apacoust.2024.110486

Wang, S., Xiao, Y., Gu, J., Hu, C., Zhang, H., and Wen, J. (2023a). Double-panel metastructure lined with porous material for broadband low-frequency sound insulation. Appl. Acoust. 207, 109332. doi:10.1016/j.apacoust.2023.109332

Wang, X., Luo, X., Yang, B., and Huang, Z. (2019). Ultrathin and durable open metamaterials for simultaneous ventilation and sound reduction. Appl. Phys. Lett. 115, 171902. doi:10.1063/1.5121366

Wang, X., Pang, Y., Wu, J., and Ma, F. (2023b). A broadband metamaterial damper design based on synergetic coupling among multi-cells. Appl. Acoust. 206, 109303. doi:10.1016/j.apacoust.2023.109303

Wang, X., Rui, S., Yang, S., Zhang, W., and Ma, F. (2024b). A low-frequency pure metal metamaterial absorber with continuously tunable stiffness. Appl. Math. Mech.-Engl. Ed. 45, 1209–1224. doi:10.1007/s10483-024-3158-7

Wang, X., Zhang, C., Rui, S., Wu, C., Zhang, W., and Ma, F. (2024a). Multi-scale material/structure integrated elastic metamaterial for broadband vibration absorbing. Mater. Des. 238, 112705. doi:10.1016/j.matdes.2024.112705

Xiao, Y., Cao, J., Wang, S., Guo, J., Wen, J., and Zhang, H. (2021). Sound transmission loss of plate-type metastructures: semi-analytical modeling, elaborate analysis, and experimental validation. Mech. Syst. Signal Proc. 153, 107487. doi:10.1016/j.ymssp.2020.107487

Xie, Y., Tsai, T. H., Konneker, A., Popa, B., Brady, D. J., and Cummer, S. A. (2015). Single-sensor multispeaker listening with acoustic metamaterials. Proc. Natl. Acad. Sci. U. S. A. 112, 10595–10598. doi:10.1073/pnas.1502276112

Yang, J., Lee, J., and Kim, Y. (2015). Metaporous layer to overcome the thickness constraint for broadband sound absorption. J. Appl. Phys. 117, 174903. doi:10.1063/1.4919844

Yang, M., Chen, S., Fu, C., and Sheng, P. (2017). Optimal sound-absorbing structures. Mater. Horiz. 4, 673–680. doi:10.1039/c7mh00129k

Yang, Z., Dai, H. M., Chan, N. H., Ma, G. C., and Sheng, P. (2010). Acoustic metamaterial panels for sound attenuation in the 50–1000 Hz regime. Appl. Phys. Lett. 96, 041906. doi:10.1063/1.3299007

Yang, Z., Mei, J., Yang, M., Chan, N. H., and Sheng, P. (2008). Membrane-type acoustic metamaterial with negative dynamic mass. Phys. Rev. Lett. 101, 204301. doi:10.1103/physrevlett.101.204301

Yu, K., Chen, Y., Yu, C., Li, P., Ren, Z., Zhang, J., et al. (2024). Origami-inspire quasi-zero stiffness structure for flexible low-frequency vibration isolation. Int. J. Mech. Sci. 276, 109377. doi:10.1016/j.ijmecsci.2024.109377

Yu, K., Fang, N. X., Huang, G., and Wang, Q. (2018). Magnetoactive acoustic metamaterials. Adv. Mater. 30, 1706348. doi:10.1002/adma.201706348

Zhang, K., Guo, Y., Liu, X., Hong, F., Hou, X., and Deng, Z. (2024). Deep learning-based inverse design of lattice metamaterials for tuning bandgap. Extreme Mech. Lett. 69, 102165. doi:10.1016/j.eml.2024.102165

Zhang, Q., Guo, D., and Hu, G. (2021). Tailored mechanical metamaterials with programmable quasi-zero-stiffness features for full-band vibration isolation. Adv. Funct. Mater. 31, 2101428. doi:10.1002/adfm.202101428

Zheng, B., Yang, J., Liang, B., and Cheng, J.-C. (2020). Inverse design of acoustic metamaterials based on machine learning using a Gauss–Bayesian model. J. Appl. Phys. 128, 134902. doi:10.1063/5.0012392

Zheng, Y., Shangguan, W. B., Yin, Z., and Liu, X. A. (2023). Design and modeling of a quasi-zero stiffness isolator for different loads. Mech. Syst. Signal Proc. 188, 110017. doi:10.1016/j.ymssp.2022.110017

Keywords: acoustic metamaterials, mechanical metamaterials, sound absorption, sound insulation, vibration absorption, vibration isolation, noise reduction with ventilation, acoustic detection and communication

Citation: Ma F (2025) Acoustic and mechanical metamaterials for various applications – a brief review. Front. Mater. 12:1626945. doi: 10.3389/fmats.2025.1626945

Received: 12 May 2025; Accepted: 25 June 2025;

Published: 10 July 2025.

Edited by:

Xinwei Li, Newcastle University, United KingdomReviewed by:

Zhendong Li, Central South University, ChinaMiao Zhao, University of Electronic Science and Technology of China, China

Copyright © 2025 Ma. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Fuyin Ma, eGptYWZ1eWluQHhqdHUuZWR1LmNu

Fuyin Ma

Fuyin Ma